Page 1

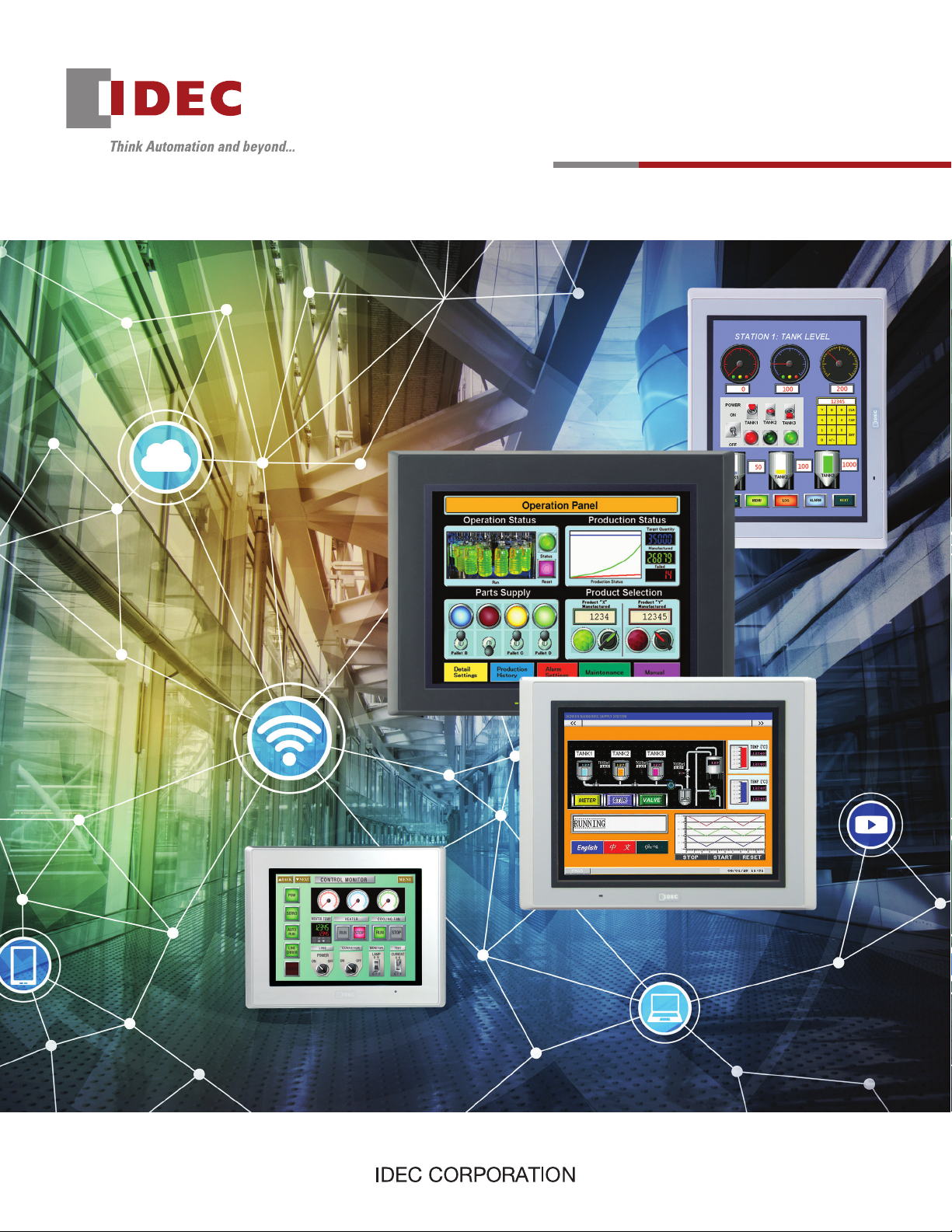

OI Touchscreens

High-Performance Series

Page 2

IDEC High-Performance OI Touchscreens

The next generation in exceptional performance and cutting-edge features

The High-Performance Series brings performance

to a whole new level with advanced features and

intuitive software. The best value in the market,

these high-quality touchscreens offer flexible

solutions and remote access and control for your

HMI applications. Features include:

Multiple Levels of Service

When you buy an IDEC OI Touchscreen, you

get more than just a great product; you get

the entire IDEC team of resources at your

fingertips. We feel it’s important to provide

you with innovative technology and quality

products, as well as world-class service,

something no other company offers.

FREE software upgrades

FREE technical support

FREE training with Training Kit

(www.Training.IDEC.com)

• Vivid Display

• Superior Design

• Adaptable Hardware

• Comprehensive Control

• User-friendly Programming

2 3

3

Page 3

Vivid Display

Groundbreaking OI Touchscreens

are the brightest on the market!

High-Definition Quality TFT LCD displays

Brightest on the market

With an LED backlight shining up to 800 cd/m², OI Touchscreens create a very powerful

visual presentation. Immediately after the touchscreen is turned on, the screen lights up and

lasts much longer than a CCFL (Cold Cathode Florescent Lamp) with a lifespan of 100,000

hours or greater. A 48-level adjustment also provides flexibility, allowing you to determine

the brightness.

Our high-performance OI Touchscreens are so vivid

thanks to cutting-edge color conversion technology,

SVGA resolution

The High Definition Quality TFT LCD Screens with SVGA resolution (8.4”, 10.4” and 12.1”

OI Touchscreens) provide sharp images and superior visibility. The high resolution also

gives you more space to create additional images and parts for your project, while enjoying

exceptional clarity.

65,536 Colors

With so many colors, screen views are realistic and crisp, providing true-to-life images and

making it easy to view precise readings of data and images. Distinctly different from 8-bit,

256 color screens, the High-Performance Series offers an intense depth-of-color perfect for

graphical displays.

A visible

difference

256 Colors 65,536 Colors

Touch Panel

A front panel power LED indicator makes it easy to check your status or to troubleshoot,

while the analog resistive touch panel itself was designed to be intuitive, making it simple

to place any size object anywhere on the screen. Plus the IDEC logo is easily removable, so

you can customize the touchscreen with your own logo or image.

the same technology used in LCD TVs. These screens

deliver a superior experience with intense screens.

4 5

4 5

Page 4

Superior Design

Fast. Flexible. Environmentally-friendly!

Switch Screens

in a Flash!

Portrait

Landscape

Mounting Flexibility

All High-Performance Series can be mounted

with the screen orientation set to portrait

or landscape mode depending on space

requirements. This allows you the flexibility

of mounting the touchscreen according

to your specific application needs. Plus OI

Touchscreens are designed with a slim body

style, providing a big advantage in situations

where panel space is at a premium.

High-speed CPU

The fastest in its class, a 400MHz RISC

processor means that these touchscreens

have quick operation and response times,

as well as exceptional performance. Not to

mention, start-up is 3 seconds from power

on, so you can start working without delay.

Low Energy Consumption

Designed with an energy-saving design and LED

backlight, these touchscreens use 50% less energy

compared with conventional models. While all OI

Touchscreens in the High-Performance Series consume

a maximum of 27 watts of power (depending on model

size), if a USB host and expansion I/O are not used,

less wattage is used. For instance, the 8.4” and 10.4”

consume a maximum of 15 watts when not using these

devices. Similarly, having full control of how and when

the LED backlight dims or goes to sleep mode allows

you to save more energy.

Long LED Life

With a best-in-class LED backlight life of

up to 100,000 hours, you also get the added

value of your screen lasting twice as long

as the competition.

Approvals

We are dedicated to ensuring the safety of life and

property at sea. To that end, IDEC OI Touchscreens are

trusted and approved by leading maritime classification

agencies, such as the American Bureau of Shipping (ABS

Type Approval), Lloyd’s Register and NK. This means

our touchscreens meet technical and safety needs that

allow them to be used in marine, offshore structures and

shore-based installations. All high-performance models

are also CE-marked and c-UL-us listed.

6 7

6 7

Page 5

Adaptable Hardware

Expand your control

With a wide range of connectivity options, our high-performance OI Touchscreens

offer a communication solution for every application. Store programming or log data

with up to 12MB of user memory, communicate with multiple controllers and devices

and even remotely monitor and control. If extra storage is needed, an SD card or USB

flash drive can easily be used.

The connectivity you want,

the flexibility you need

SD Card

• Supports up to a 32GB SD card for storage

• Store IDEC MicroSmart ladder and touchscreen programs, pictures, log

data, alarm logs, screen hard copies, recipe data, operation logs, audio

and video files

USB Port A (USB 2.0)

• Connect a USB flash drive

– Store IDEC MicroSmart ladder and touchscreen programs,

log data and screen capture (if transferred from SD card)

• Connect barcode readers

USB Port mini B

• Connect PC directly to OI Touchscreen for high

speed transfer of program upload, download,

or monitoring

• Connect to a USB printer

Expansion Module

Depending on your application and OI Touchscreen size, up to

4 MicroSmart expansion digital I/O modules can be connected.

They easily snap on the back of any High-Performance Series OI

touchscreen to offer simple I/O control with the option to perform

independently of the touchscreen scan time using Cyclic Script.

2 Serial Ports

RS232 and RS485 (422)

• Host – Communicate with a PLC/device using 1:1 or 1:N PLC

communication

• Sub Host – Communicate with an IDEC MicroSmart PLC or

Modbus RTU device

• O/I Link – Various PLCs including the IDEC MicroSmart PLC

can network with multiple OI Touchscreens, where one is a

master and up to 15 slaves are connected

• User – Communicate using transmit or receive instructions

to build your own protocol

Audio Out Port:

• Connects to speakers to playback pre-saved .WAV audio

files for custom alarms or alerts

Audio In Port

• Connects to a microphone to listen and monitor audio

sounds

Ethernet Port

• 10BaseT or 100Base-TX connection

• Remote communication with the PLC and download, upload or monitor

PLC and OI Touchscreen projects

• Allows remote access for monitor and control

8 9

Video In Port

• Connects to a video camera to display video images on

the touchscreen

Page 6

Comprehensive Control

Real-time video monitoring

Remote access,

monitoring and control

Play movie files and audio on your touchscreen

The High-Performance Series (8.4”, 10.4” and 12.1” OI Touchscreens)

features a built-in video interface (Video In) and audio interface (Audio

In/Out). That means a video camera, microphone and speaker can be

connected to the OI Touchscreen and used in the following ways:

• Display video images on the touchscreen display

• Play movie files on the touchscreen display (MP4 supported)

• Play audio files on the touchscreen display

• Record video for viewing on the touchscreen display

Using the video and audio interfaces, you can monitor and record

machine faults or conditions on the plant floor simply by using a video

camera and microphone, and setting it to display on the OI Touchscreen. You can also play your operation manual as a movie or play

movie files to give information or instructions to a user or customer.

This makes it easy to explain detailed information and makes it a useful feature for troubleshooting.

Email and Text Notification

Dynamic PLC/HMI values can be

incorporated to the email body.

Screenshot, Alarm Log file, Data Log

file and Operation Log file can be

attached in the email as well. Up to

255 email templates can be configured

to multiple recipients.

Connect anytime, anywhere using your

PC, PDA or Smart Phone

Distance isn’t an issue with our high-performance line of OI Touchscreens. When

you need access to your machine or equipment, but can’t get to the factory

floor or even to the office, all you need is a computer, tablet or smart phone and

you can remotely access, monitor and control your touchscreen through a web

browser. It’s that simple!

Monitor current values or processes, click pushbuttons to control operation, print,

switch screens or even change program values just as if you were in front of your

touchscreen on site. You can also troubleshoot, test and do maintenance.

• No additional software tools or modules needed to use the Remote Monitor

and Control function

• Up to 5 clients can remotely monitor and control simultaneously

• Simple configuration to enable remote access

10

10 11

11

Page 7

Instant Communications

Multiple Protocols

The High Performance Series supports

multiple protocols—up to four PLC protocols

simultaneously. The HMI acts as a communication

gateway, allowing data to pass between multiple

devices. IDEC supports over 100 serial and

networking drivers, including Modbus RTU Master/

Slave and Modbus TCP/IP.

1:N PLC Communication

Connect a single HMI to multiple PLCs for

centralized control. One touchscreen can

monitor and control each system with PLCs in

several different locations.

Note: The maximum number of connected PLCs depends

on the PLC brand. See WindO/I-NV2 manual for supported

manufacturers.

Barcode Reader

PLC

FTP Communication

FTP functions allow users to transfer projects,

data logs, pictures, and sound and movie files

between the HMI and a PC without loading IDEC

software on the PC. This simplifies program

updates as there is no need to have IDEC

software installed on multiple PCs throughout a

facility or company.

User Communication

Set the HMI communication protocol to the one

required by your serial devices. This function

uses transmit and receive instructions to build

your own protocol.

Drive

Sub Host Communication

Communicate with two different PLC/devices

at the same time. A serial or ethernet port

can be configured from our list of supported

PLC manufacturers as a host, and the other

serial port can be configured as a sub host

communication with supported protocols

including IDEC MicroSmart and Modbus RTU.

Master

Slave 1

IDEC

MicroSmart

Modbus

Slave 2

Pass-Through Communication

Conveniently download a PLC program from a

PC using your OI Touchscreen. Only one cable is

needed to program both units. The Pass-through

function applies to IDEC (MicroSmart and

OpenNet controllers) and Mitsubishi (MELSECFX, and Q) PLCs.

OVER 100 SERIAL AND NETWORKING DRIVERS ARE SUPPORTED

O/I Link Communications

Create an OI Touchscreen network where multiple

HMIs in different locations connect to the same

PLC for convenient monitoring and control.

One HMI can serve as a master, while up to 15

additional touchscreens can be slaves in the O/I

Link, with a total maximum distance of 200 meters.

12 13

Maximum

15 slaves

For a complete listing of supported drivers, please refer to WindOI-NV4 Communication Manual.

Page 8

Automation Organizer

User-friendly Programming

A one-stop automation software package

for all IDEC PLC and OI Touchscreens

Automation Organizer (AO), combines the latest versions of our PLC

programming software (WindLDR) SmartAxis Touch software (WindOI-NV3)

and our HMI programming software (WindOI NV4). AO gives you a powerful

and easy-to-use tool to design, debug, and document control systems,

saving valuable time and money.

WindO/I-NV4 software is the simplest programming tool for all IDEC OI

Touchscreens Series from 4.3” to 12.1” except the HG1F 4.6”. The WindOINV4 software has great features, such as support of multiple protocols, FTP

and Email functions. It is used to create projects that can display information

from a PLC, process status, or can be used to input data with virtual switches

or keypads to make changes to a process. The objects are extremely easy to

configure with the help of step-by-step navigation. It lets you quickly create

colorful graphical screens in no time using drop-down menus and intuitive

drag and drop functionality for the objects. A workspace is available to help

you organize and manage projects, objects and screens.

Easy-to-manage Projects and Screens

It’s as easy as 1, 2, 3!

Create

1

Creating a project is simple! Just name a project file and select your

parameters (OI type and model, protocol type, and optional settings).

Configure

2

Select a functional part and assign a device address. The other tabs allow you to change image, color,

or add more parameters.

With our software, up to 7,000 base screens can be created (as allowed

by the memory size). Sub-screens or pop-up menus can be resized, created

(showing backgrounds) using the superimpose function, and made to appear

anywhere around the base screen. In addition:

• Edit project settings

• Import or export addresses, text and images

• Change or duplicate screens and properties

Drag and Drop

Screen Design

Easy step-by-step

configuration

Download

3

Once your project is ready to be downloaded to the touchscreen, select “Online” and then

“Download.” You can now debug or monitor your program as needed. It’s as simple as that!

14 15

Page 9

User-friendly Programming

Extensive Image Library

A built-in symbol library provides over 7,000 bitmaps

to help you create cutting-edge graphical screens.

Image data from BMP and JPG files can also be

imported.

Tag Database

You can create a database of device addresses, including Tag Names, which

help you label each address to best match your information or documentation.

By creating a Tag database, you can choose addresses used to read data

from the PLC or Host device, or write data to the PLC or device. Even more

convenient, if you have a list of IDEC PLC addresses already made in WindLDR,

you can easily import it to the Tag Database.

Supports Standard Windows Fonts

These OI Touchscreens support all fonts used in

Windows, including Stroke and 7 Segment Display

fonts, making it possible to choose from a variety of

text styles to create the look and feel you want to

achieve.

Multilingual Capabilities

The IDEC Touchscreen family supports many different languages.

Using the Text Group function you can create a text database in

Japanese, Chinese, Korean, Taiwanese, as well as Baltic, Cyrillic

and other European languages. Plus, you can easily switch text

messages from English to Japanese or any other supported

language with the touch of a button.

Allen Bradley Logix Native Tag Import

Project Conversion

The High-Performance models support “Allen Bradley Logix Native Tag Import,”

which means you can easily import any tag database file (L5K or CSV file)

created with Allen Bradley PLC software. Once registered in the Tag Editor, you

simply select the Tag name for your part.

16 17

A Zooming Conversion function makes it easy to convert

existing program images and functional parts, created

for a small display, to a larger display or vice versa. Don’t

waste time recreating projects for a different display

when you can save time and energy by using this easy-touse tool!

Page 10

User-friendly Programming

Security Function

When you have multiple users editing projects or displaying

screens and parts, it may be necessary to have different levels

of security and restrictions. With the Security Function, you can

password protect programs, screens and parts from other users.

Operation and Alarm Log Functions

The operating log helps investigate, analyze and solve problems and

system errors by checking who, when, what and where operations were

performed. Plus, once you setup up the Alarm Log function for messages

and alerts, it can monitor alarm conditions from a PLC and store historical

events with a date and time stamp on a memory card (in CSV format).

The High-Performance Series also meets ISA standards for visual alarm

management.

Switches, Pilot Lamps, and Meters

Hundreds of colorful pushbuttons, switches and meter images can give your display a

realistic appearance mimicking a real panel. Pushbuttons and switches are used to set

a bit, move data, switch screens or print screen images, while pilot lamps or multi-state

lamps read and display statuses from single or multiple bits on the PLC or device.

Bar Graphs and Trend Charts

Use the Bar graphs and numerical displays to show range or flow for analog values from

your PLC or device, or create Trend Charts to closely monitor critical data points. Display

historical data (based on a fixed time period or event) with the option to show date and

time on the x-axis or store it (in csv format) on the memory card or internal memory for

easy viewing and data manipulation on your PC.

Recipe

A Recipe function allows you to conveniently set operational parameters, which can be

individually defined for different processes. There are 1,024 available channels, which

can store up to 8,192 parameters per channel. Plus you can easily upload or download

parameters to and from your PLC.

Script Function

Users with basic programming knowledge in “C” can use a Script

function to combine conditional statements, mathematical operations

and other functions to create simple and complex processes, reducing

the programming required in the PLC. A Syntax Check function is also

available providing easy program troubleshooting.

18 19

Animation

Want to give your screen a “WOW” factor? It’s simple to display animation by

using the Picture Display function and configuration is a breeze. Simply import

a series of images when using the Picture Display Function. Those images will

then be displayed depending on the device value or constant time period.

Page 11

Part Numbers / Specifications

Touchscreen Part Numbers

5.7" 8.4" 10.4" 12.1"

Base Color

Light gray HG2G-5FT22TF-W HG3G-8JT22MF-W HG3G-AJT22MF-W –

Black HG2G-5FT22TF-B HG3G-8JT22MF-B HG3G-AJT22MF-B HG4G-CJT22MF-B

Silver HG2G-5FT22TF-S – – –

Display Specifications

5.7" 8.4" 10.4" 12.1"

Model HG2G-5FT22TF HG3G-8JT22MF HG3G-AJT22MF HG4G-CJT22MF

Display Type Color TFT LCD Color TFT LCD Color TFT LCD Color TFT LCD

Color Depth 65,536 65,536 65,536 65,536

Portrait or Landscape

Mounting

User Memory 12MB 12MB 12MB 12MB

Display Resolution 640W × 480H pixels 800W × 600H pixels 800W × 600H pixels 800W × 600H pixels

Backlight LED LED LED LED

Backlight Life *1 100,000 hours min. 100,000 hours min. 100,000 hours min. 100,000 hours min.

Brightness *2 800cd/m

Brightness Adjustment 48 scales 48 scales 48 scales 48 scales

SD Card Slot

MicroSmart Digital

I/O Cards Supported

Ehternet Port 1 RJ-45 1 RJ-45 1 RJ-45 1 RJ-45

USB Port

Serial Ports

Video In –

Audio In/Out –

Remote Monitor

and Control

*1 The backlight life refers to the time until the surface brightness reduces by half after continuous use at 25°C.

*2 Brightness of the LCD only.

2

2 4 4 4

1 Type A and 1

mini-B

2 (RS-232, RS-485,

RS-422 configurable)

1 Type A and 1

2 (RS-232, RS-485,

RS-422 configurable)

Composite Video

RCA connector (NTSC

3.5mm audio mini-

600cd/m

mini-B

or PAL)

jack (Stereo)

2

1 Type A and 1

2 (RS-232, RS-485,

RS-422 configurable)

Composite Video

RCA connector (NTSC

3.5mm audio mini-

700cd/m

mini-B

or PAL)

jack (Stereo)

2

550cd/m

1 Type A and 1

mini-B

2 (RS-232, RS-485,

RS-422 configurable)

Composite Video

RCA connector (NTSC

or PAL)

3.5mm audio mini-

jack (Stereo)

General Specifications

5.7" 8.4" 10.4" 12.1"

Model HG2G-5FT22TF HG3G-8JT22MF HG3G-AJT22MF HG4G-CJT22MF

Rated Power Voltage

Power Voltage

Range

Power Consumption

Allowable

Momentary

Power Interruption

Inrush Current

Dielectric Strength

Insulation

Resistance

Operating

Temperature

Operating Humidity

Storage Temperature

Storage Humidity

Pollution Degree

Vibration Resistance

2

Shock Resistance

Noise Immunity

Electrostatic

Discharge

Corrosion Immunity

Degree of

Protection *1

Switching Element

Operating Force

Mechanical Life

Sound

Acknowledgement

Dimensions

Weight (approx.)

Approvals

Do not use the touchscreen in an environment subject to strong ultraviolet rays, otherwise the LCD quality will deteriorate.

*1 Protection degree of the front surface after mounting. Operation not guaranteed in certain environments.

10W maximum when not using USB inter-

face (USB2) or expansion module interface

1 minute between power and FG terminals

10MΩ minimum between power and

FG terminals (500V DC megger)

10 to 90% RH (no condensation) 10 to 90% RH (no condensation) 10 to 90% RH (no condensation)

10 to 90% RH (no condensation) 10 to 90% RH (no condensation) 10 to 90% RH (no condensation)

5 to 8.4Hz amplitude 3.5mm,

8.4 to 150Hz, acceleration 9.8m/s

10 cycles (100 minutes) on each of three

mutually perpendicular axes

5 shocks on each of three mutually

Power terminals: ±1kV, Communication line:

±0.5 kV (IEC/EN61131-2: 2007)

ESD-3 (RH-1), Level 3 (Contact ±6kV, air

IP66 (IEC 60529) (front part when mounted)

167.2W × 134.7H × 54.4D mm 231W × 176H × 54.4D mm 270W × 212H × 52.7D mm 314W × 240H × 54.1D mm

Safety Standards: UL508, CSA C22.2

No.142, Class 1 Div 2, Hazardous Location

Ship Classification Standards: ABS, LR, NK

24V DC 24V DC 24V DC

20.4 to 28.8V DC 20.4 to 28.8V DC 20.4 to 28.8V DC

19W maximum

15W maximum when not using USB interface

(EXT)

10ms maximum 10ms maximum 10ms maximum

30A maximum 30A maximum 30A maximum

1,000V AC, 10 mA,

0 to +50°C (no freezing) 0 to +50°C (no freezing) 0 to +50°C (no freezing)

−20 to +60°C (no freezing) −20 to 60°C (no freezing) −20 to +60°C (no freezing)

2 2 2

2

147m/s2, 11ms

perpendicular axes

Fast transient/burst test,

±8kV)

(IEC/EN61131-2: 2007)

Free from corrosive gases Free from corrosive gases Free from corrosive gases

Type 4X, 13

Analog resistive membrane Analog resistive membrane Analog resistive membrane

3N maximum 0.55 to 2.3N 0.55 to 2.3N 3N maximum

1,000,000 operations 1,000,000 operations 1,000,000 operations

Electronic buzzer Electronic buzzer or speaker output Electronic buzzer or speaker output

0.65kg 1.25kg 1.65kg 2.1kg

(USB2) or expansion module interface (EXT)

1 minute between power and FG terminals

10MΩ minimum between power and

10 cycles (100 minutes) on each of three

Power terminals: ±2kV, Communication line:

ESD-3 (RH-1), Contact ±6kV, air ±8kV

IP66 (IEC 60529) (front part when mounted)

Safety Standards: UL508, CSA C22.2 No.142,

Ship Classification Standards: ABS, LR, NK

25W maximum

1,000V AC, 10 mA,

FG terminals (500V DC megger)

5 to 8.4Hz amplitude 3.5mm,

8.4 to 150Hz, acceleration 9.8m/s

mutually perpendicular axes

2

147m/s

5 shocks on each of three mutually

Fast transient/burst test,

±1kV (IEC 61131-2: 2007)

(IEC 61131-2: 2007)

Class 1 Div 2, Hazardous Location

, 11ms

perpendicular axes

TYPE 4X, Type 13

18W maximum when not using USB interface (USB2)

or expansion module interface (EXT)

1 minute between power and FG terminals

10MΩ minimum between power and

2

10 cycles (100 minutes) on each of three

Power terminals: ±2kV, Communication line:

ESD-3 (RH-1), Level 3 (Contact ±6kV, air ±8kV)

IP66 (IEC 60529) (front part when mounted)

Safety Standards: UL508, CSA C22.2 No.142, Class 1

Ship Classification Standards: ABS, LR, NK

27W maximum

1,000V AC, 10 mA,

FG terminals (500V DC megger)

5 to 8.4Hz amplitude 3.5mm,

8.4 to 150Hz, acceleration 9.8m/s

mutually perpendicular axes

2

147m/s

5 shocks on each of three mutually

Fast transient/burst test,

±1kV (IEC/EN61131-2: 2007)

(IEC/EN61131-2: 2007)

Div 2, Hazardous Location

, 11ms

perpendicular axes

Type 4X, 13

2

20 21

Page 12

Part Numbers

Communication Cables

5.7”

Communication

Module

Built-in Port HG9Z-AC102 HG9Z-AC501

FC4A-PC1/HPC1 HG9Z-AC102 HG9Z-AC501

FC5A-SIF2 HG9Z-AC312 N/A

FC4A-PC2/HPC2 HG9Z-AC172 N/A

FC4A-PC3/HPC3 Use Shielded Pair HG9Z-AC502

FC5A-SIF4 Use Shielded Pair HG9Z-AC502

FC4A-SX5ES1E Use CAT 5 Ethernet cable CAT 5 Ethernet cable

Built-in CAT 5 Ethernet cable CAT 5 Ethernet cable

Built-in(SLC-5/05),

1761-NET-ENI

D2-EC0M,-EC0MF,-

ECOM100

D4-ECOM, -ECOM-F,

ECOM100

IC693CMM311 N/A HG9Z-AC510

AJ71C24/-S3/-S6/-S8,

AJ71UC24, AOJ2C214-S1, AJY1C24S6/-S8, AJ71UC24,

AJ71QC24N-R2,

AJ71QC24N

QJ71C24N-R2, QJ71C24,

QJ71C24N

Accessories

Part Number Description

Programming Software SW1A-W1C Automation Organizer

USB Maintenance Cable HG9Z-XCM2A USB Programming Cable USB-miniB

Mounting Clip

Host Communication Plug

SLD-K02 Replacement clips

HG9Z-4K2 Replacement clips

HG9Z-XT09V Replacement terminal block plug.

(min. 10 pieces) (4 pieces are supplied with HMI)

(min. 10 pieces) (4 pieces are supplied with HMI)

HG9Z-XT09 Replacement terminal block plug.

Replacement Battery HG9Z-XR1 Lithium battery CR2032

(one battery is supplied with HMI)

USB Cable Lock Pin HG9Z-XU1 Used to lock USB cable

USB panel-mount extension

cable

HG9Z-XCE11 For USB-A port

HG9Z-XCE21 For USB-mini B port

(1m)

Memory Card HG9Z-XMS2 SD Memory Card

Protective Cover HG9Z-2E2 Use with 5.7” HMI. Covers entire front of HMI.

HG9Z-2D5 Use with 5.7" HMI. Sheet lays over LCD area.

Protective Sheet *1

HG9Z-3D8 Use with 8.4” HMI. Sheet lays over LCD area.

HG9Z-3DA2 Use with 10.4” HMI. Sheet lays over LCD area.

HG9Z-4DC Use with 12.1” HMI. Sheet lays over LCD area.

HG9Z-XJ3 Short type for installing expansion I/O modules

Expansion Module Clamp *2

HG9Z-XJ4 Long type for installing expansion I/O modules

HG9Z-XJ5 Extra-Long type for installing expansion I/O modules

L-shaped Terminal Block

Connector for I/O Module

Panel Mount Adaptor

*1 The protective sheet is UV resistant, however, resistance against direct sunlight in outdoor usage is not guaranteed.

*2 Use the expansion module clamp when using expansion modules.

Order the module clamp by referring to the width of the module shown in the dimensions of each module.

Note: When connecting more than 3 expansion modules to the HG3G/4G, note the limits shown below (for more information see module manual).

-Current flow rate at 5V: 130mA max. total width: 92.3mm max.

-Current flow rate at 24V: 150mA max.

HG9Z-PMT10L For 10-pole MicroSmart I/O Module

HG9Z-PMT11L For 11-pole MicroSmart I/O Module

HG9Z-2A1 Adaptor for mounting HG2G to the panel cut-out of HG2F.

HG9Z-2A2 Adaptor for mounting HG2G to 156 x 123.5mm panel cut-out

(2m)

(1 is supplied with HMI)

(1 is supplied with HMI)

(for USB2)

.

(1m)

(2GB)

(1 piece)

(1 piece)

(1 piece)

(1 piece)

(1 piece)

(total width 17.6 to 41.1mm)

(total width 47 to 68.8mm)

(total width 70.1 to 93.9mm)

(min. 2 pieces)

(min. 2 pieces)

(other manufacturer)

Applicable Model

5.7" 8.4"/10.4" 12.1"

-

-

- -

- -

-

-

- -

- -

- -

.

- -

- -

Manufacturer Series Applicable CPU Comm. Type

RS232

MicroSmart/

Pentra MicroSmart

(FC4A/FC5A)

IDEC

MicroSmart FC6A FC6A

SLC 500

Allen Bradley

Automation

Direct (Koyo)

-

MicroLogix

ControlLogix 5550, 5555

CompactLogix 1768, 1769

FlexLogix 1794-L33, 1794-L34 RS232 Built-in Port HG9Z-AC142 HG9Z-AC503

Direct Logic 05/06 DL05 , DL06 Ethernet D0-ECOM, D0-ECOM100 CAT 5 Ethernet cable CAT 5 Ethernet cable

Direct Logic

Direct Logic 205 D2-240 RS232 Built-in Port N/A HG9Z-AC508

Direct Logic 405

-

GE Fanuc Series 90-30

MELSEC A

Mitsubishi

Siemens S7-300 CPU 313-2PtP RS485 Built-in Port N/A HG9Z-AC510

Note: For a complete list of Supported PLC/Host Manufacturers, please check our Com. Manual.

N/A: Communication cable not available.

MELSEC-QnA

MELSEC Q

MELSEC-FX

FC4A, FC5A

SLC-5/03, SLC-5/04,

SLC-5/05

1000, 1200, 1500

1500 RS232 Built-in Port (9 Pin Dsub) HG9Z-AC132 HG9Z-AC505

1100, 1400 RS232 Built-in Port HG9Z-AC152 HG9Z-AC518

1100 Ethernet Built-in Port CAT 5 Ethernet cable CAT 5 Ethernet cable

D2-240,-250,-250-1,

-260

D4-430, D4-440

D4-430,-440,450

CPU331, 341, 350,

351, 352, 360, 363

A1N, A2N, A3N,

A0J2, A0J2H, A2A,

A3A, A2U, A3U, A4U

Q4A, Q4AR, Q3A,

Q2ACPU-S1, Q2ACPU

Q02CPU, Q02HCPU,

Q06HCPU, Q12PHCPU,

Q25HCPU

FX0, FX0N, FX1N,

FX0S, FX1S

RS485

Ethernet

RS232 Built-in Port FC6A-KC1C FC6A-KC2C

RS485 Built-in Port FC6A-KC1C N/A

Ethernet Built-in Port CAT 5 Ethernet cable CAT 5 Ethernet cable

RS232 Built-in Port HG9Z-AC112 HG9Z-AC504

DH485 Built-in Port HG9Z-GWDF1DH485-5 N/A

Ethernet

RS232 Built-in Port HG9Z-AC122 HG9Z-AC511

Ethernet 1761-NET-ENI CAT 5 Ethernet cable CAT 5 Ethernet Crossover cable

RS232 Built-in Port HG9Z-AC142 HG9Z-AC503

Ethernet 1756-ENBT CAT 5 Ethernet cable CAT 5 Ethernet cable

RS232 Built-in Port HG9Z-AC142 HG9Z-AC503

Ethernet Built-in Port CAT 5 Ethernet cable CAT 5 Ethernet cable

Ethernet

RS232 Built-in Port N/A HG9Z-AC506

RS422 Built-in Port N/A HG9Z-AC507

RS232 D4-DCM N/A HG9Z-AC506

Ethernet

RS232

RS485

RS232

RS232

RS485(422) Built-in Port HG9Z-AC182 N/A

22 23

(HG2G-5T, HG2G-5FT), 8.4” & 10.4” (HG3G-8JT/-AJT) , 12.1” (HG4G-CJT22MF)

Terminal Block Type 9-Pin Dsub

CAT 5 Ethernet cable CAT 5 Ethernet cable

CAT 5 Ethernet cable CAT 5 Ethernet cable

CAT 5 Ethernet cable CAT 5 Ethernet cable

HG9Z-AC192 N/A

N/A N/A

Page 13

Touchscreen Family Series

Compact Series

4.3” HMIs

(HG1G) (HG2G-5T) (HG2G-5F, HG3G, HG4G)

These super-bright and compact TFT color LCD

displays also list a long backlight life.

• Sunlight-readable brightness of 800 nits

• Support most of the features of a large screen

• A wide range of operating temperatures

• Priced to fit in a tight budget

Enhanced Series

5.7” HMIs

The cost-effective Enhanced HMI series offers

quality features at an affordable price.

• 65K color display with brightness of 500 nits

• 16-shade monochrome display with brightness

of 1100 nits

• Best-in-class LED backlight life of 100K hours

• A wide range of operating temperatures

High Performance Series

5.7” to 12.1” HMIs

The High-performance HMI Series brings

efficiency to a new level with a high-speed CPU

processor.

• 5.7”,8.4”, 10.4”, 12.1” HMIs

• Fast operation and response times

• Up to four expansion digital I/O modules can

be added

• Built-in Video/Audio interface

(8.4”- 12.1”screens only)

• Best-in-class LED backlight life of 100K hours

Loading...

Loading...