Page 1

FC9Y-B1283

FC5A

SERIES

PID Module

User’s Manual

Page 2

Warning notices are used to emphasize that improper operation may

cause severe personal injury or death.

Caution notices are used where inattention might cause personal injury

or damage to equipment.

SAFETY PRECAUTIONS

• Read this user’s manual to make sure of correct operation before starting installation, wiring, operation,

maintenance, and inspection of the FC5A series MicroSmart PID modules.

• All MicroSmart modules are manufactured under IDEC’s rigorous quality control system, but users must add a

backup or failsafe provision to the control system using the MicroSmart in applications where heavy damage or

personal injury may be caused in case the MicroSmart should fail.

• In this user’s manual, safety precautions are categorized in order of importance from Warning to Caution.

Warning

• Turn off the power to the MicroSmart before starting installation, removal, wiring, maintenance, and inspection of

the MicroSmart. Failure to turn power off may cause electrical shocks or fire hazard.

• Special expertise is required to install, wire, program, and operate the MicroSmart. People without such expertise

must not use the MicroSmart.

• Emergency stop and interlocking circuits must be configured outside the MicroSmart. If such a circuit is

configured inside the MicroSmart, failure of the MicroSmart may cause a malfunction of the control system,

damage, or accidents.

• Install the MicroSmart according to the instructions described in this user’s manual. Improper installation will

result in disattachment, failure, or malfunction of the MicroSmart.

Caution

• The MicroSmart is designed for installation in a cabinet. Do not install the MicroSmart outside a cabinet.

• Install the MicroSmart in environments described in this user’s manual. If the MicroSmart is used in places where

the MicroSmart is subjected to high-temperature, high-humidity, condensation, corrosive gases, excessive

vibrations, and excessive shocks, then electrical shocks, fire hazard, or malfunction will result.

• The environment for using the MicroSmart is “Pollution degree 2.” Use the MicroSmart in environments of pollution

degree 2 (according to IEC 60664-1).

• Prevent the MicroSmart from being dropped while moving or transporting the MicroSmart, otherwise damage or

malfunction of the MicroSmart will result.

• Prevent metal fragments and pieces of wire from dropping inside the MicroSmart housing. Put a cover on the

MicroSmart modules during installation and wiring. Ingress of such fragments and chips may cause fire hazard,

damage, or malfunction.

• Use a power supply matching the rated value. Use of an incorrect power supply may cause fire hazard.

• Use an IEC 60127-approved fuse on the power line outside the MicroSmart. This is required when equipment

containing the MicroSmart is destined for Europe.

• Use an IEC 60127-approved fuse on the output circuit. This is required when equipment containing the

MicroSmart is destined for Europe.

FC5A MicroSmart PID Module User’s Manual FC9Y-B1283 i

Page 3

• Use an EU-approved circuit breaker. This is required when equipment containing the MicroSmart is destined for

Europe.

• Make sure of safety before starting and stopping the MicroSmart or when operating the MicroSmart to force

outputs on or off. Incorrect operation on the MicroSmart may cause machine damage or accidents.

• If relays or transistors in the MicroSmart output modules should fail, outputs may remain on or off. For output signals

which may cause serious accidents, provide a monitor circuit outside the MicroSmart.

• Do not connect the ground wire directly to the MicroSmart. Connect a protective ground to the cabinet containing

the MicroSmart using an M4 or larger screw. This is required when equipment containing the MicroSmart is

destined for Europe.

• Do not disassemble, repair, or modify the MicroSmart modules.

• When disposing of the

MicroSmart

, do so as an industrial waste.

ii FC5A MicroSmart PID Module User’s Manual FC9Y-B1283

Page 4

NOTICE

1. This publication is not to be, nor any parts of it, photocopied, reprinted, sold, transferred, or rented out without

the specific written permission and consent of IDEC.

2. The contents of this user’s manual are subject to change without notice.

3. Care has been taken to ensure that the contents of this user’s manual are correct, but if there are any doubts,

mistakes or questions, please inquire our sales department.

Category

Modules

MicroSmart

(FC5A Series MicroSmart)

FC5A series MicroSmart pentra

FC5 Series

CPU Modules

All-in-One Type

FC5A-C10R2, FC5A-C10R2C, FC5A-C16R2, FC5A-C16R2C,

FC5A-C24R2, FC5A-C24R2C

Slim Type

FC5A-D16RK1, FC5A-D16RS1, FC5A-D32K3, FC5A-D32S3,

FC5A-D12K1E, FC5A-D12S1E

PID Modules

FC5A-F2MR2, FC5A-F2M2

Expansion Communication Modules

FC5A-SIF2, FC5A-SIF4

Memory Cartridge

FC4A-PM32, FC4A-PM64, FC4A-PM128

Expansion Modules

Expansion I/O module, Function module

Expansion I/O Modules

Input modules, Output modules, Mixed I/O modules

Function Modules

Analog modules, AS-Interface master module, PID module

Communication Expansion Modules

HMI base module, expansion RS232C communication module,

expansion RS485 communication module

Optional Modules

HMI module, Memory cartridge, Clock cartridge, RS232C communication

adapter, RS485 communication adapter

WindLDR

Application software [WindLDR]

IMPORTANT INFORMATION

Under no circumstances shall IDEC Corporation be held liable or responsible for indirect or consequential damages resulting

from the use of or the application of IDEC PLC components, individually or in combination with other equipment.

All persons using these components must be willing to accept responsibility for choosing the correct component to suit their

application and for choosing an application appropriate for the component, individually or in combination with other

equipment.

All diagrams and examples in this user’s manual are for illustrative purposes only. In no way does including these diagrams

and examples in this manual constitute a guarantee as to their suitability for any specific application. To test and approve all

programs, prior to installation, is the responsibility of the end user.

The PID modules is used by connecting to the FC5A series CPU module.

Use this product after thoroughly understanding the specifications of the FC5A

series CPU module.

ABOUT THIS MANUAL

Thank you for purchasing FC5A series MicroSmart PID Module. This user’s manual primarily describes system

configuration, specifications, installation, programming, application examples, and trouble shooting of the PID

module. Read this user’s manual to ensure the correct understanding of the entire functions of the PID module.

MicroSmart Modules

Caution

FC5A MicroSmart PID Module User’s Manual FC9Y-B1283 iii

Page 5

REVISION HISTORY

Date

Manual No.

Description

March, 2011

FC9Y-B1283-0

First print

Revision history of this user’s manual is described here.

iv FC5A MicroSmart PID Module User’s Manual FC9Y-B1283

Page 6

Type No.

Manual Name

Description

FC9Y‐B1283

FC5A Series

PID Module

User's Manual

(this manual)

Describes PID Module specifications and functions.

FC9Y‐B1268

FC5A Series

MicroSmart Pentra

User's Manual

Basic Volume

Describes module specifications, installation instructions, wiring instructions,

basic operation, special function, device addresses, instruction list, basic

instructions, analog modules, user communication, data link communication,

Modbus ASCII/RTU communication, and troubleshooting.

FC9Y‐B1273

FC5A Series

MicroSmart Pentra

User's Manual

Advanced Volume

Describes instruction list, move instructions, data comparison instructions,

binary arithmetic instructions, boolean computation instructions, shift/rotate

instructions, data conversion instructions, week programmer instructions,

interface instructions, program branching instructions, refresh instructions,

interrupt control instructions, coordinate conversion instructions, average

instructions, pulse output instructions, PID instructions, dual/teaching timer

instructions, intelligent module access instructions, trigonometric function

instructions, logarithm/power instructions, file data processing instructions, clock

instructions, computer link communication, modem communication, Modbus

TCP communication, expansion RS232C/RS485 communication modules, and

AS‐Interface master modules.

FC9Y‐B1278

FC5A Series

MicroSmart Pentra

User's Manual

Web Server CPU

Module Volume

Describes FC5A Slim Type Web Server CPU Module specifications and

functions.

RELATED MANUALS

The following manuals related to the FC5A series MicroSmart are available. Refer to them in conjunction with this

manual.

FC5A MicroSmart PID Module User’s Manual FC9Y-B1283 v

Page 7

vi FC5A MicroSmart PID Module User’s Manual FC9Y-B1283

Page 8

TABLE OF CONTENTS

CHAPTER 1: GENERAL INFORMATION ...................................................................................... 1-1

About the PID Modules .................................................................................................................................... 1-1

Quantity of Applicable PID modules ................................................................................................................ 1-1

Applicable CPU and WindLDR version ........................................................................................................... 1-2

Confirming System Program Version .............................................................................................................. 1-2

CHAPTER 2: MODULE SPECIFICATIONS ................................................................................... 2-1

PID Module ...................................................................................................................................................... 2-1

Specifications ................................................................................................................................................... 2-3

Dimensions ...................................................................................................................................................... 2-6

CHAPTER 3: INSTALLATION AND WIRING ................................................................................. 3-1

Mounting Hole Layout for Direct Mounting on Panel Surface ......................................................................... 3-1

Terminal Connection ........................................................................................................................................ 3-3

Terminal Arrangement ..................................................................................................................................... 3-4

Type of Protection ............................................................................................................................................ 3-5

Power Supply for PID Modules ....................................................................................................................... 3-6

CHAPTER 4: PID MODULE MAIN FUNCTIONS .......................................................................... 4-1

Temperature Control Using the PID Module .................................................................................................... 4-1

Fixed Value Control ......................................................................................................................................... 4-3

Auto-Tuning (AT)/Auto-Reset .......................................................................................................................... 4-6

Program Control .............................................................................................................................................. 4-9

Heating/Cooling Control ................................................................................................................................ 4-14

Difference Input Control ................................................................................................................................. 4-14

Cascade Control ............................................................................................................................................ 4-15

CHAPTER 5: DEVICE ALLOCATION OF PID MODULE ................................................................ 5-1

Device Allocation of PID Module ..................................................................................................................... 5-1

Program Size ................................................................................................................................................... 5-2

Valid Devices ................................................................................................................................................... 5-2

Control Register ............................................................................................................................................... 5-2

Control Relay ................................................................................................................................................... 5-3

Data Register Allocation - Block 0 Read Only Parameters ............................................................................. 5-7

Data Register Allocation - Block 1 Write Only Parameters............................................................................ 5-10

Data Register Allocation - Blocks 2, 3 Basic Parameters (SHOT Action) ..................................................... 5-17

Data Register Allocation - Blocks 4, 5 Initial Setting Parameters (SHOT Action) ......................................... 5-19

Data Register Allocation - Blocks 10-19 CH0 Program Parameters (SHOT Action) ..................................... 5-22

Data Register Allocation - Blocks 30-39 CH1 Program Parameters (SHOT Action) ..................................... 5-24

FC5A MicroSmart PID Module User’s Manual FC9Y-B1283 vii

Page 9

CHAPTER 6: CONFIGURING PID MODULE USING WINDLDR .................................................... 6-1

Procedure to configure the PID module .......................................................................................................... 6-1

Expansion Modules Configuration Dialog Box ................................................................................................ 6-6

PID Module Configuration Dialog Box ............................................................................................................. 6-7

PID Module Configuration - Input Parameters List (CH0 and CH1) ................................................................ 6-8

PID Module Configuration - Control Parameters List (CH0 and CH1) .......................................................... 6-13

PID Module Configuration - Output Parameters List (CH0 and CH1) ........................................................... 6-17

PID Module Configuration - Program Parameters List (CH0 and CH1) ........................................................ 6-19

PID Module Configuration - I/O Function Selections ..................................................................................... 6-21

PID Module Configuration - Input Parameters Details .................................................................................. 6-24

PID Module Configuration - Control Parameters Details ............................................................................... 6-34

PID Module Configuration - Output Parameters Details ............................................................................... 6-45

PID Module Configuration - Program Parameters Details ............................................................................ 6-47

Monitoring PID Module .................................................................................................................................. 6-52

CHAPTER 7: APPLICATION EXAMPLES ..................................................................................... 7-1

Application Example 1 ..................................................................................................................................... 7-1

Application Example 2 ..................................................................................................................................... 7-8

Application Example 3 ................................................................................................................................... 7-15

CHAPTER 8: TROUBLESHOOTING ............................................................................................ 8-1

The PID Module Power LED (PWR) is OFF or Flashing. ................................................................................ 8-1

The PID Module output does not operate normally. ........................................................................................ 8-2

Hunting phenomenon is occurring while in ON/OFF control action ................................................................ 8-3

Hunting phenomenon is occurring while in PID, PI, PD, or P control action ................................................... 8-3

The PID Module input does not operate normally. .......................................................................................... 8-4

Loop break alarm turns on even though the actuator operates normally. ....................................................... 8-6

Program control is terminated earlier than the configured time. ..................................................................... 8-6

CHAPTER 9: APPENDIX ........................................................................................................... 9-1

PID Module Function References ................................................................................................................... 9-1

Output Action ................................................................................................................................................... 9-5

Factory Default Settings of the PID Module .................................................................................................... 9-9

viii FC5A MicroSmart PID Module User’s Manual FC9Y-B1283

Page 10

GENERAL INFORMATION

Module Type

I/O Points

I/O Signal

Type No.

Relay Output

2 inputs

Thermocouple [K, J, R, S, B, E, T, N, PL- II, C (W/Re5-26)]

Resistance thermometer (Pt100, JPt100)

Voltage (0 to 1V DC, 0 to 5V DC, 1 to 5V DC, 0 to 10V DC)

Current (0 to 20mA DC, 4 to 20mA DC)

FC5A-F2MR2

2 outputs

Relay contact

Non-Contact Voltage

(for SSR drive)/

Current Output

2 inputs

Thermocouple [K, J, R, S, B, E, T, N, PL- II, C (W/Re5-26)]

Resistance thermometer (Pt100, JPt100)

Voltage (0 to 1V DC, 0 to 5V DC, 1 to 5V DC, 0 to 10V DC)

Current (0 to 20mA DC, 4 to 20mA DC)

FC5A-F2M2

2 outputs

Non-contact voltage(for SSR drive)/Current

Type

All-in-One Type

Slim Type

FC5A MicroSmart CPU

FC5A-C10R2

FC5A-C10R2C

FC5A-C10R2D

FC5A-C16R2

FC5A-C16R2C

FC5A-C16R2D

FC5A-C24R2D

FC5A-C24R2

FC5A-C24R2C

FC5A-D16RK1

FC5A-D16RS1

FC5A-D32K3

FC5A-D32S3

FC5A-D12K1E

FC5A-D12S1E

Number of PID Modules

4

7

1: GENERAL INFORMATION

This chapter describes general information and specifications of the FC5A series PID modules. Make effective

use of the PID modules after reading and understanding thoroughly functions and characteristics.

About the PID Modules

The PID module performs control actions to eliminate the deviation between the set point (SP) and process

variable (PV). The PID module, which is an expansion module, is required to connect to the FC5A series CPU

for use. Depending on the difference of output specifications, the PID modules are categorized into two types,

and can be used by connecting to a FC5A slim type CPU, or 24-I/O all-in-one type CPU (except 12V DC CPU).

The input channel can accept voltage, current, thermocouple or resistance thermometer signals. The output

channel generates relay output, non-contact voltage (for SSR drive), or current signals.

To configure the PID modules, the Expansion Modules Configuration dialog box in WindLDR is used.

The following table shows the PID module type numbers.

PID Module Type Numbers

Quantity of Applicable PID modules

The maximum number of PID modules that can be connected to the MicroSmart CPU differs depending on the

CPU type. The following table shows the maximum number of the PID modules.

FC5A MicroSmart PID Module User’s Manual FC9Y-B1283 1-1

Page 11

GENERAL INFORMATION

Type

All-in-One Type

Slim Type

FC5A MicroSmart CPU

FC5A-C10R2

FC5A-C10R2C

FC5A-C10R2D

FC5A-C16R2

FC5A-C16R2C

FC5A-C16R2D

FC5A-C24R2D

FC5A-C24R2

FC5A-C24R2C

FC5A-D16RK1

FC5A-D16RS1

FC5A-D32K3

FC5A-D32S3

FC5A-D12K1E

FC5A-D12S1E

CPU System Program Version

230 or higher *1

WindLDR Version

6.40 or higher

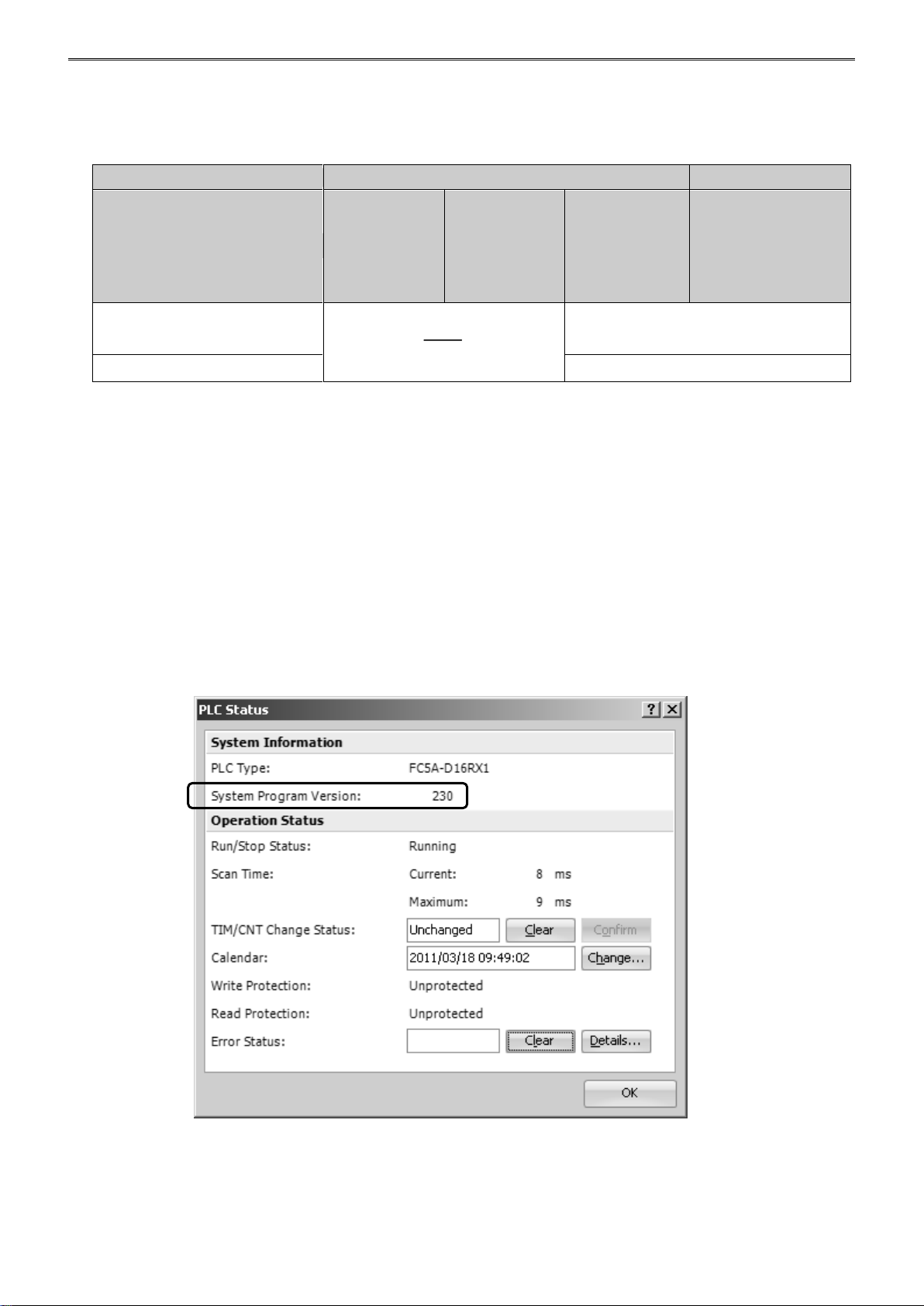

Applicable CPU and WindLDR version

PID modules can be used with the following FC5A CPU module system program version and WindLDR version

as listed below.

*1: The PID module can be used with FC5A-D12K1E/-S1E with the system program version 100 or higher.

Confirming System Program Version

The system program version can be confirmed using WindLDR.

1. Connect a PC to port 1 or 2 of the FC5A CPU using serial computer link cable I/F (FC2A-KC4C) or USB

cable HG9Z-XCM2A for FC5A-D12x1E CPU.

2. From the WindLDR menu bar, select Online > Monitor.

3. From the WindLDR menu bar, select PLC > Status. The PLC Status dialog box appears and system

program version is shown.

1-2 FC5A MicroSmart PID Module User’s Manual FC9Y-B1283

Page 12

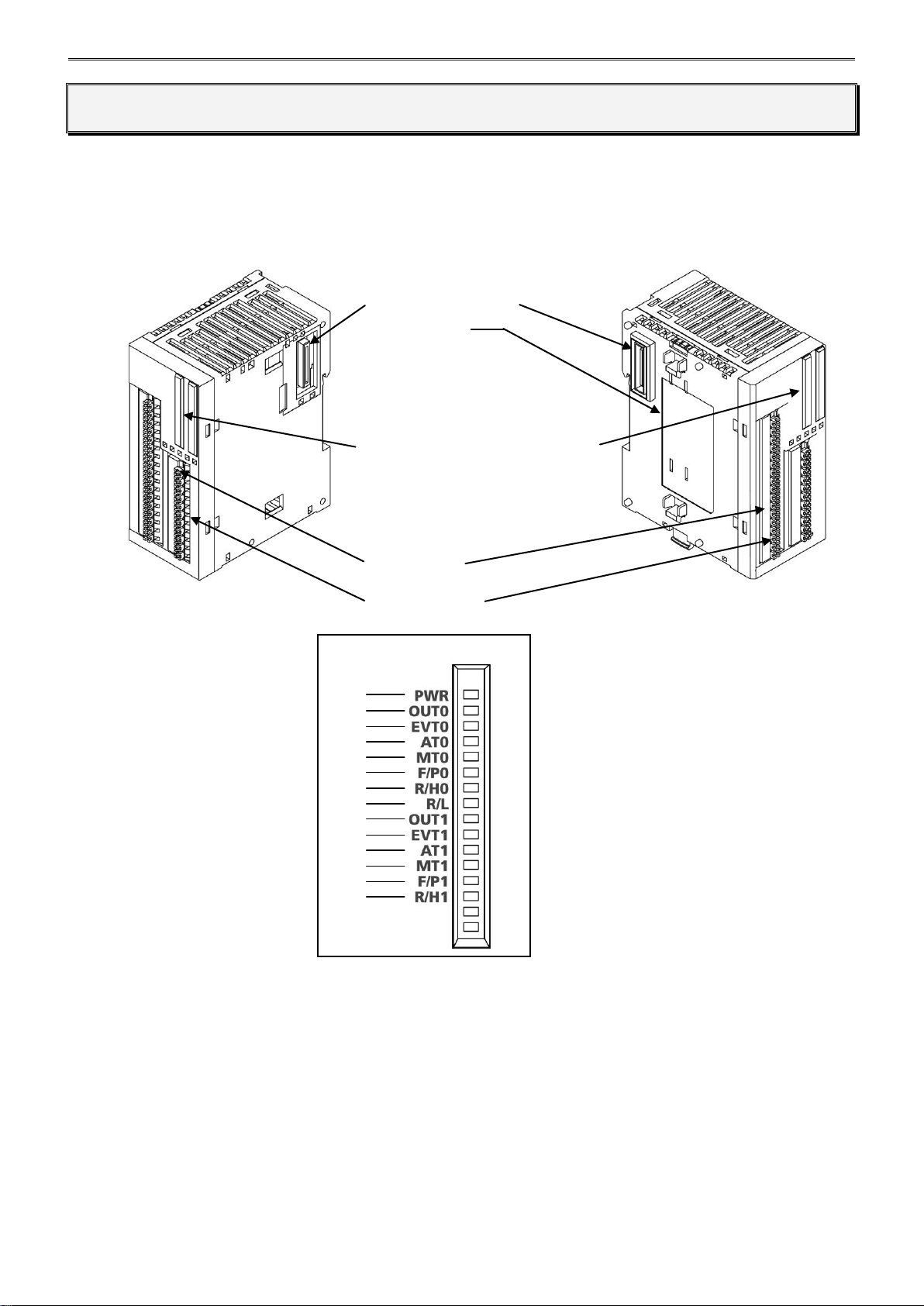

MODULE SPECIFICATIONS

(12) Expansion Connector

(1) Module Label

(2) Power LED (PWR)

(3) Control Output LED (OUT0, OUT1)

(4) Event Output LED (EVT0, EVT1)

(5) Auto-tuning (AT)/Auto-reset LED (AT0, AT1)

(6) Manual Mode LED (MT0, MT1)

(7) Fixed Value Control Mode/Program

Control Mode LED (F/P0, F/P1)

(8) Program Control RUN/HOLD LED

(R/H0, R/H1)

(9) External SP Enable/Disable LED (R/L)

(10) Terminal No.

(11) Cable Terminal

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(3)

(4)

(5)

(6)

(7)

(8)

2: MODULE SPECIFICATIONS

This chapter describes parts names, functions, specifications, and dimensions of the PID modules.

PID Module

Parts Description

(1) Module Label Indicates the PID module type No. and specifications.

(2) Power LED (PWR) ON : Power is normally supplied.

Flashes : External power supply (24V DC) error.

OFF : Power is not supplied.

LED Details

FC5A MicroSmart PID Module User’s Manual FC9Y-B1283 2-1

Page 13

MODULE SPECIFICATIONS

(3) Control Output LED (OUT0, OUT1)

ON : Control output is turned on.

OFF : Control output is turned off.

Flashes : When current output is used, the LED flashes in a cycle of 125 ms

according to the duty ratio of the output manipulated variable (MV).

When output manipulated variable (MV) is 20%, the LED turns on for

25 ms and off for 100 ms continuously.

(4) Event Output LED (EVT0, EVT1)

ON : Any alarm out of alarm 1 to alarm 8, loop break alarm is triggered.

OFF : None of the alarms is triggered.

(5) Auto-tuning (AT)/Auto-reset LED (AT0, AT1)

Flashes : Auto-tuning (AT) or auto-reset is performing.

OFF : Auto-tuning (AT) or auto-reset is stopped.

(6) Manual Mode LED (MT0, MT1)

ON : Manual mode

OFF : Auto mode

(7) Fixed Value Control Mode/Program Control Mode LED (F/P0, F/P1)

ON : Program control mode

OFF : Fixed value control mode

(8) Program Control RUN/HOLD LED (R/H0, R/H1)

ON : Program control is performing, or while in fixed value control enabled.

Flashes : Program control is held, or power is restored.

OFF : Program control is stopped, or while in fixed value control disabled.

(9) External SP Enable/Disable LED (R/L)

ON : External SP input is enabled.

OFF : External SP input is disabled.

(10) Terminal No. Indicates terminal numbers.

(11) Cable Terminal Spring clamp type terminal for connecting a cable.

(12) Expansion Connector Connects to the CPU module and other expansion modules.

2-2 FC5A MicroSmart PID Module User’s Manual FC9Y-B1283

Page 14

Type No.

FC5A-F2MR2

FC5A-F2M2

Rated Scale

Thermocouple

Type

Measurement Range

Input Value

of LSB

K

-200 to 1370°C

-328 to 2498°F

1°C (°F)

K (with decimal point)

-200.0 to 400.0°C

-328.0 to 752.0°F

0.1°C (°F)

J

-200 to 1000°C

-328 to 1832°F

1°C (°F)

R

0 to 1760°C

32 to 3200°F

1°C (°F)

S

0 to 1760°C

32 to 3200°F

1°C (°F)

B

0 to 1820°C

32 to 3308°F

1°C (°F)

E

-200 to 800°C

-328 to 1472°F

1°C (°F)

T

-200.0 to 400.0°C

-328.0 to 752.0°F

0.1°C (°F)

N

-200 to 1300°C

-328 to 2372°F

1°C (°F)

PL-II

0 to 1390°C

32 to 2534°F

1°C (°F)

C(W/Re5-26)

0 to 2315°C

32 to 4199°F

1°C (°F)

Resistance Thermometer

Type

Measurement Range

Input Value

of LSB

Pt100

-200 to 850°C

-328 to 1562°F

1°C (°F)

Pt100 (with decimal point)

-200.0 to 850.0°C

-328.0 to 1562.0°F

0.1°C (°F)

JPt100

-200 to 500°C

-328 to 932°F

1°C (°F)

JPt100(with decimal point)

-200.0 to 500.0°C

-328.0 to 932.0°F

0.1°C (°F)

Current/Voltage

Type

Measurement Range

Input Value

of LSB

4 to 20mA DC

-2000 to 10000 (12000 increments) *1

1.333μ

0 to 20mA C

-2000 to 10000 (12000 increments) *1

1.666μA

0 to 1V DC

-2000 to 10000 (12000 increments) *1

0.083mA

0 to 5V DC

-2000to 10000 (12000 increments) *1

0.416mA

1 to 5V DC

-2000 to 1000 (12000increments)

*1

0.333mA

0 to 10V DC

-2000 to 10000 (12000 increments) *1

0.833mA

*1: Linear conversion possible

Input

Input type

Thermocouple

K, J, R, S, B, E, T, N, PL-II, C (W/Re5-26)

External resistance: 100Ω maximum

However, B input, External resistance: 40Ω

maximum

Resistance

Thermometer

Pt100, JPt100, 3-wire type

Allowable conductor resistance (per wire):

10Ω maximum

Sensor (detection) current: 0.2A

Current

0 to 20mA DC, 4 to 20mA DC

Input impedance: 50Ω

Maximum permanent allowed overload (No

damage): 50mA maximum

Voltage

0 to 1V DC

Input impedance: 1MΩ minimum

Maximum permanent allowed overload (No

damage): 5V DC maximum

Allowable output impedance: 2kΩ maximum

0 to 5V DC, 1 to 5V DC, 0 to 10V DC

Input impedance: 100kΩ minimum

Maximum permanent allowed overload (No

damage): 15V DC maximum

Allowable output impedance: 100Ω maximum

Power Supply Voltage

24V DC (External power), 5V DC (Internal power)

Allowable Voltage Range

20.4 to 28.8V DC

Specifications

PID Module Specifications

Rating

MODULE SPECIFICATIONS

FC5A MicroSmart PID Module User’s Manual FC9Y-B1283 2-3

Page 15

MODULE SPECIFICATIONS

Type No.

FC5A-F2MR2

FC5A-F2M2

Connector

Connector on

MotherBoard

Input : F6018-17P (Fujicon)

Output : F6018-11P (Fujicon)

Connector

Insertion/Removal

Durability

Type No.

FC5A-F2MR2

FC5A-F2M2

Maximum Error at 25°C

Thermocouple

±0.2% of full scale or ±2°C (4°F),

whichever is greater

However, R, S inputs, 0 to 200°C (0 to 400°F):

±6°C (12°F)

B input, 0 to 300°C (0 to 600°F): Accuracy is

not guaranteed.

K, J, E, T, N inputs, Less than 0°C (32°F):

±0.4% of full scale

Resistance

Thermometer

±0.1% of full scale or ±1°C (2°F), whichever is

greater

Voltage, Current

±0.2% of full scale

Input Accuracy (at 0 to 55°C)

Thermocouple

±0.7% of full scale

However, R, S input, 0 to 200°C (0 to 400°F):

±6°C (12°F)

B input, 0 to 300°C (0 to 600°F): Accuracy is

not guaranteed.

K, J, E, T, N inputs, Less than 0°C (32°F):

±0.9% of full scale

Resistance

Thermometer

±0.6% of full scale

Voltage, Current

±0.7% of full scale

Data Accuracy

Maximum error at 25°C±Minimum digital resolution of each input range

Cold Junction Temperature

Compensation Accuracy

±1°C at 0 to 55°C

Sampling Period

125 ms

Type No.

FC5A-F2MR2

FC5A-F2M2

Control Output

Relay output 1a

Rated load:

5A 250V AC (resistive load)

5A 30V DC (resistive load)

3A 250V AC (inductive load

cosφ=0.4)

Non-contact voltage (for SSR drive)

12V DC±15%

Current :

4 to 20mA DC

Type No.

FC5A-F2MR2

FC5A-F2M2

Time Setting Accuracy

±0.5% of setting time

Progressing Time Error

After Power is Restored

Maximum 6 minutes

Non-volatile Memory

Write Limit

1,000,000 times

General Specifications

Input Specifications

Output Specifications

Program Control Specifications

2-4 FC5A MicroSmart PID Module User’s Manual FC9Y-B1283

Page 16

Type No.

FC5A-F2MR2

FC5A-F2M2

Isolation

Photocoupler-isolated between input and internal circuit

Photocoupler-isolated between input and power circuit

Photocoupler-isolated between input and internal circuit

Photocoupler-isolated between output and internal circuit

Dielectric Strength

Output terminal - External power:

1500kV AC 5mA for 1 minute

Output terminal - Internal power:

1500kV AC 5mA for 1 minute

Input power - Output power:

1500kV AC 5mA for 1 minute

FG - External power:

548V AC 5mA for 1 minute

Input terminal - External power:

548V AC 5mA for 1 minute

Input terminal - Internal power

548V AC 5mA for 1 minute

Output terminal - External power:

2500V AC 5mA for 1 minute

Output terminal - Internal power

2500V AC 5mA for 1 minute

External power -Internal power

548V AC 5mA for 1 minute

Input terminal - Output terminal

548V AC 5mA for 1 minute

FG - External power:

548V AC 5mA for 1 minute

I/O terminal - External power:

548V AC 5mA for 1 minute

I/O terminal - Internal power:

548V AC 5mA for 1 minute

External power - Internal power:

548V AC 5mA for 1 minute

Input terminal - Output terminal:

548V AC 5mA for 1 minute

Type No.

FC5A-F2MR2

FC5A-F2M2

Power Consumption

Approx. 3.5W maximum

Module Power

Consumption

(Interior)

5V DC

65mA

24V DC

0mA

Ambient Temperature

0 to 55°C (No icing)

Ambient Humidity

10 to 95%RH (Non-condensing)

Weight

Approx. 140g

Environmental

Specifications

Conforms to RoHS directive.

Recommended Cable

Twisted pair cable

Insulation, Dielectric Strength

Insulation, Dielectric Strength

MODULE SPECIFICATIONS

Other

FC5A MicroSmart PID Module User’s Manual FC9Y-B1283 2-5

Page 17

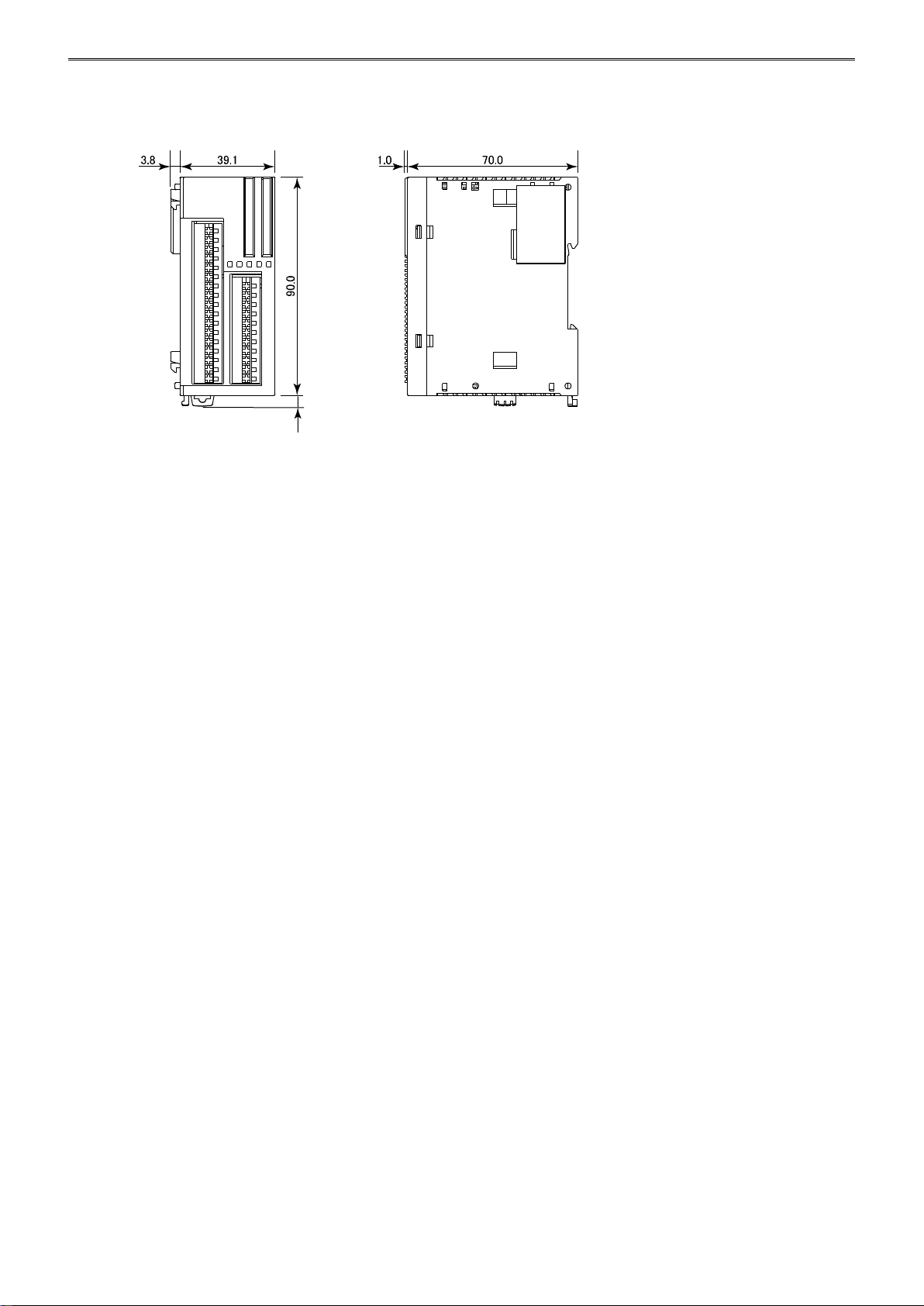

MODULE SPECIFICATIONS

4.5

*

Dimensions

(All dimensions in mm)

* 8.5mm when the clamp is pulled out

2-6 FC5A MicroSmart PID Module User’s Manual FC9Y-B1283

Page 18

INSTALLATION AND WIRING

Caution • Assemble the CPU module and PID modules before installing them on a DIN rail.

Otherwise, they may break.

• Do not lay out or wire the modules while power is supplied to them. Otherwise, they

may be damaged.

• When installing modules, follow the instructions described in the FC5A MicroSmart

user’s manual. If there are flaws in the installation, it may cause disattachment,

failure or malfunction.

Direct mounting strip

FC4A-PSP1P

3: INSTALLATION AND WIRING

This chapter describes how to install and wire the PID modules. For general methods and precautions for

installation and wiring of the PID modules, see chapter 3 in the FC5A MicroSmart user’s manual (FC9Y-B1268).

Be sure to use the PID modules properly after understanding installation and wiring thoroughly.

Mounting Hole Layout for Direct Mounting on Panel Surface

To mount the PID module on a panel surface,

use the direct mounting strip and two M4 screws

(6 or 8 mm long).

For details about the direct mounting strip, see the

FC5A MicroSmart user’s manual (FC9Y-B1268).

(All dimensions in mm)

FC5A MicroSmart PID Module User’s Manual FC9Y-B1283 3-1

Page 19

INSTALLATION AND WIRING

Example: Mounting hole layout for FC5A-C24R2 and four PID modules

(All dimensions in mm)

3-2 FC5A MicroSmart PID Module User’s Manual FC9Y-B1283

Page 20

Caution • Make sure that the operating conditions and environments are within the specified

values.

• Be sure to connect the grounding wire to a proper ground, otherwise electrical

shocks may be caused.

• Do not touch live terminals, otherwise electrical shocks may be caused.

• Do not touch terminals immediately after power is turned off, otherwise electrical

shocks may be caused.

• When using ferrules, insert a wire to the bottom of the ferrule and crimp the ferrule.

• When connecting a stranded wire or two solid wires to single-pole terminal block, be

sure to use a ferrule. Otherwise the wire may slip off the terminal block.

Phoenix Type

Cable Size

AI 1-8 RD

UL1007AWG18

AI 0.5-8 WH

UL1015AWG22

Phoenix Type

Cable Size

AI-TWIN2x0.75-8 GY

UL1007AWG18

AI-TWIN2x0.5-8 WH

UL1015AWG22

Ferrule for

Terminal block

Terminal Connection

To cramp the following ferrules, use the specified crimping tool (CRIMPFOX ZA 3).

For 1-cable connection For 2-cable connection

For 1-cable connection

INSTALLATION AND WIRING

Note: The above ferrules, crimping tool, and screwdriver are made by Phoenix Contact and are available from Phoenix

For 2-cable connection

Contact.

FC5A MicroSmart PID Module User’s Manual FC9Y-B1283 3-3

Page 21

INSTALLATION AND WIRING

Caution • Connect an IEC 60127-approved fuse appropriate for the applied voltage and

current draw, at the position shown in the diagram. (This is required when

equipment containing the MicroSmart is destined for Europe.)

• Do not connect a thermocouple to hazardous voltage (60V DC, 42.4V DC peak or

higher).

• Be sure to check the wiring before the power is turned on. Faulty wiring may result in

damage to the PID module.

• Applicable electric cables are listed below.

Cable size AWG16: Single-cable

Cable size AWG18, AWG22: Single-cable/Twisted cable

+

-

NC

+

NC

-

+

-

NC

-

NC -

NC NC NC -

L

L

+

FG

NC

B

-

+

-

TC

A

B

B

RTD

+

-

+

-

+

-

+

-

TC

A

B

B

RTD

+

-

+

-

+

-

-

-

NC

NC

+

”

+

’

+

-

NC

-

B

’

A

B

+

”

+

’

+

-B

’

A

DC DC DC

DC DC DC

24V DC

IN0

IN1

OUT1

OUT0

Channel

Terminal

No.

Terminal

No.

Channel

L

0 to 5V

4 to 20mA

1 to 5V

0 to 10V

0 to 20mA

0 to 1V

0 to 5V

4 to 20mA

1 to 5V

0 to 10V

0 to 20mA

0 to 1V

Fuse (50V-1.2A)

*1

*1

DC : Voltage/Current

RTD : Resistance thermometer

TC : Thermocouple

: Load

: Analog current input instrument

: Fuse

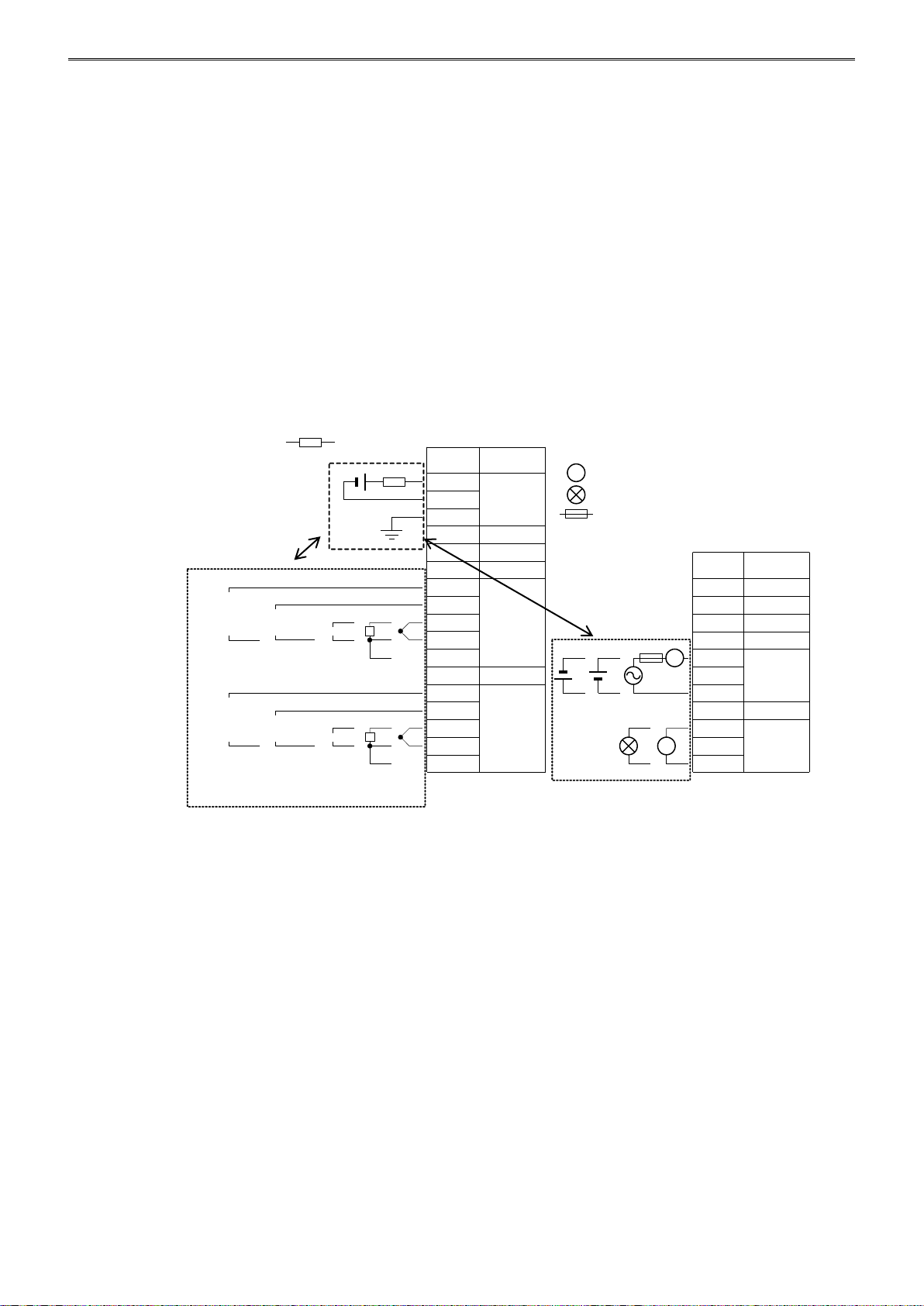

Terminal Arrangement

*1: OUT0 is a connection example of relay output.

OUT1 is a connection example of non-contact voltage/current output. The PID module having both outputs

is non-existent.

3-4 FC5A MicroSmart PID Module User’s Manual FC9Y-B1283

Page 22

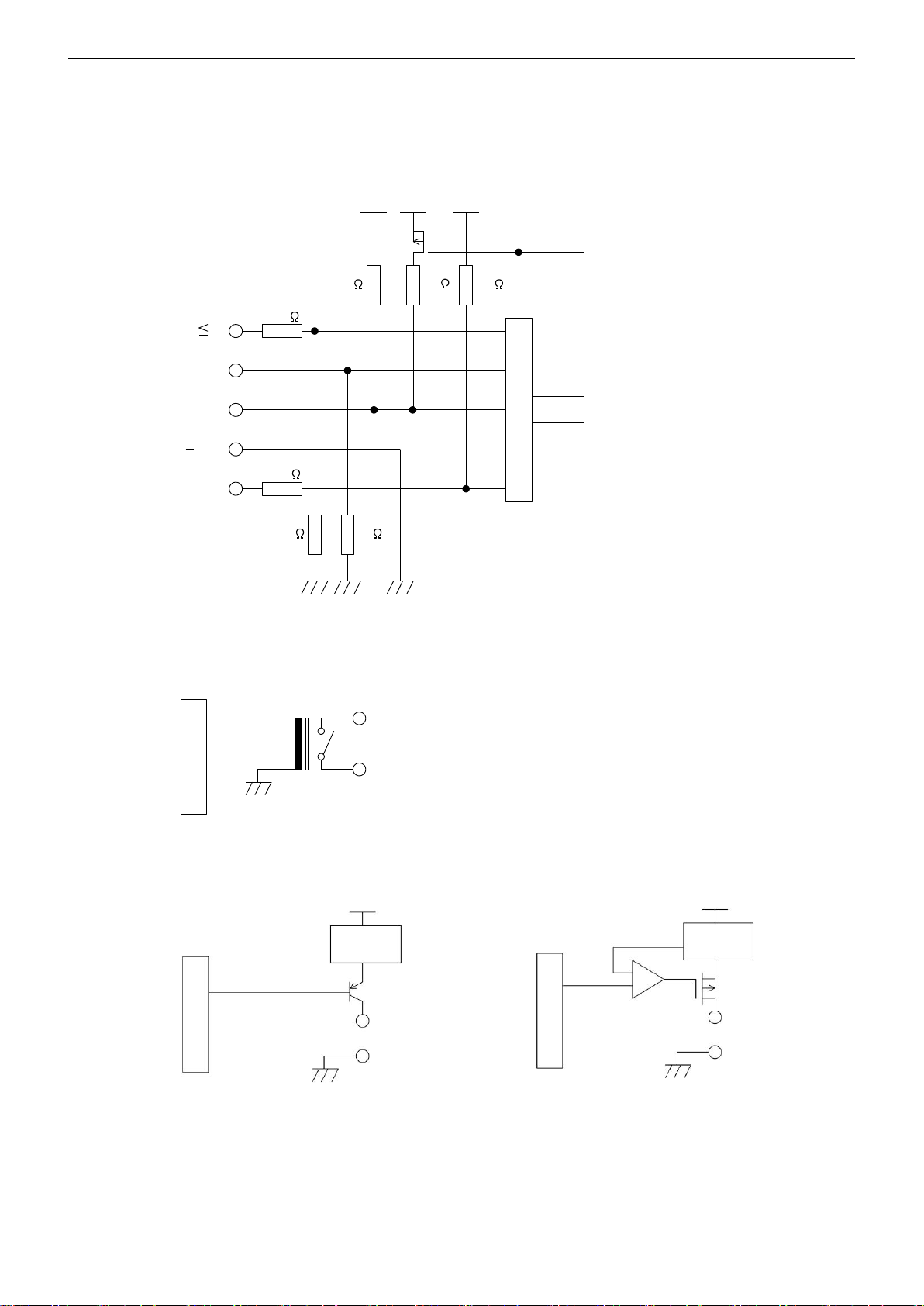

Output Circuit

(A)

(B)

(B)

+

mA

5V

160k

Multiplexer

Input Selection Signal

Input

20M 15k 15k

5040k

100

Output Circuit

Current

Detection

+

-

Output Circuit

Short Circuit

Protected

+

-

Type of Protection

Input Circuits

FC5A-F2MR2、FC5A-F2M2

INSTALLATION AND WIRING

Output Circuits

FC5A-F2MR2

FC5A-F2M2 [Non-contact Voltage Output (for SSR drive)] FC5A-F2M2 (Current Output)

FC5A MicroSmart PID Module User’s Manual FC9Y-B1283 3-5

Page 23

INSTALLATION AND WIRING

Separate the I/O lines

from the power line

as much as possible.

DC : Voltage/Current

RTD : Resistance thermometer

TC : Thermocouple

: Load

: Analog current input instrument

: Fuse

+

-

NC

+

NC

-

+

-

NC

-

NC -

NC NC NC -

L

L

+

FG

NC

B

-

+

-

TC

A

B

B

RTD

+

-

+

-

+

-

+

-

TC

A

B

B

RTD

+

-

+

-

+

-

-

-

NC

NC

+

”

+

’

+

-

NC

-

B

’

A

B

+

”

+

’

+

-B

’

A

DC DC DC

DC DC DC

24V DC

IN0

IN1

OUT1

OUT0

Channel

Terminal

No.

Terminal

No.

Channel

L

0 to 5V

4 to 20mA

1 to 5V

0 to 10V

0 to 20mA

0 to 1V

0 to 5V

4 to 20mA

1 to 5V

0 to 10V

0 to 20mA

0 to 1V

Fuse (50V-1.2A)

Power Supply for PID Modules

When supplying power to the PID modules, take the following into consideration.

Using the same power supply for the MicroSmart CPU and the PID module is recommended to suppress the

influence of noise. If the same power source is used for the PID module and MicroSmart CPU module, after the

MicroSmart CPU is started to run, the PID module performs initialization for a maximum of 5 seconds. During

this period, each parameter has an indefinite value. Design the user program to make sure that each parameter

is referred in the CPU module after the PID module operating status is changed to 0001h (Normal operation).

Wiring of Power Line and I/O Lines for the PID Module

Separate the I/O lines, particularly resistance thermometers, from the power line as much as possible to

suppress the influence of noise.

3-6 FC5A MicroSmart PID Module User’s Manual FC9Y-B1283

Page 24

PID MODULE MAIN FUNCTIONS

B. PID Module

A. Thermocouple

Control Target, such

as Electric Furnace

or Constant

Temperature Oven.

Heater

C. Actuator

200V AC

Temperature

Set point (SP)

Time

Temperature

Set point (SP) B

Time

Set point (SP) A

4: PID MODULE MAIN FUNCTIONS

This chapter describes the temperature control, fixed value control, auto-tuning (AT), program control,

heating/cooling control, difference input control, and cascade control of the PID module.

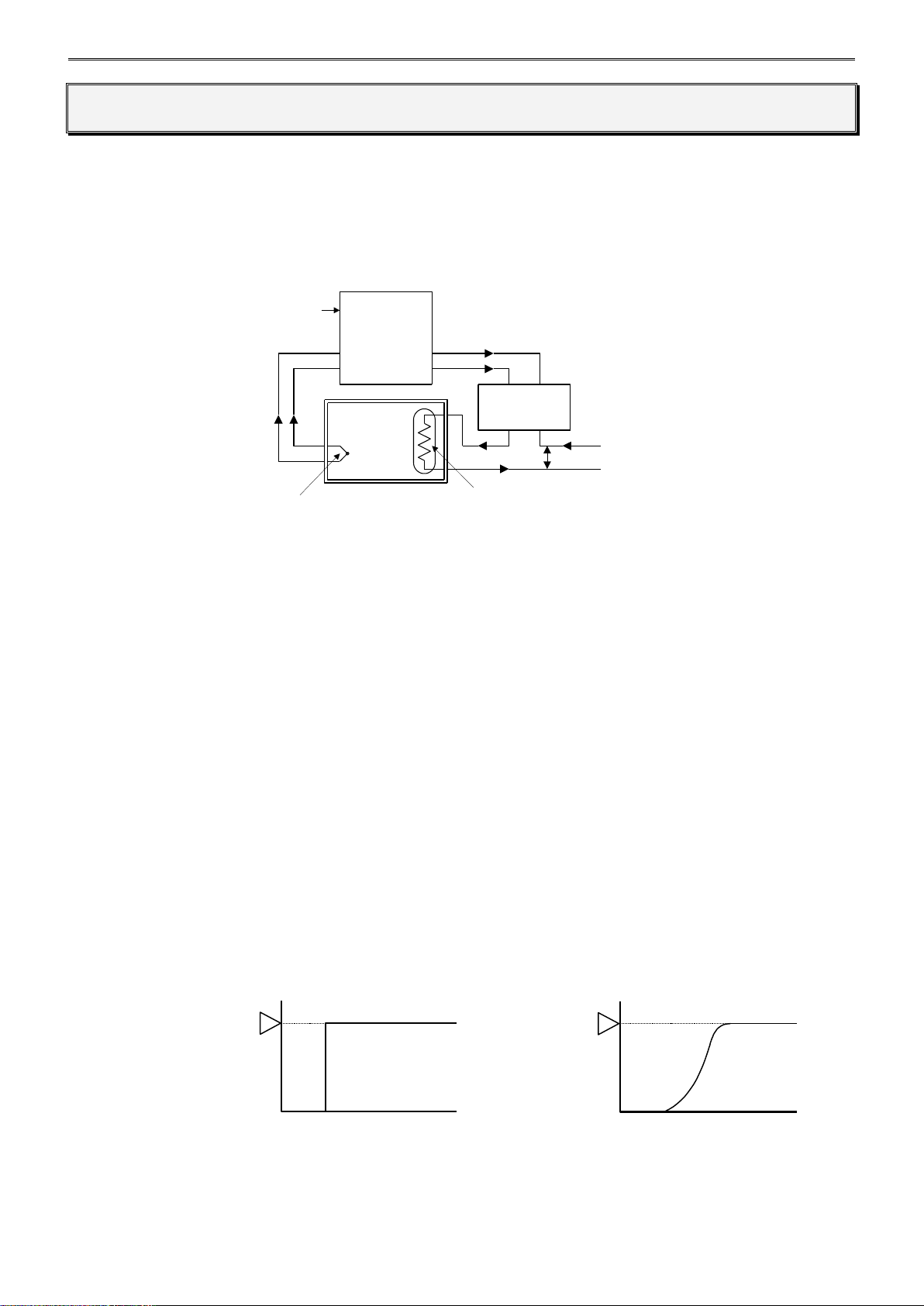

Temperature Control Using the PID Module

Temperature Control Configuration Example Using the PID Module

A. Sensor

Measures temperature of the control target. Thermocouple, resistance thermometer, voltage input,

or current input can be used as the sensor.

B. PID module

Receives the temperature measured by the sensor as the process variable (PV), and calculates the

output manipulated variable (MV) so that temperature difference (deviation) between the process

variable (PV) and the set point (SP) can be eliminated. The output manipulated variable (MV) is

outputted to the actuator as a control signal. Relay output, non-contact voltage output, or current

output can be used as the control signal.

C. Actuator

Receives a control signal from the PID module and turns on the load power supply to the heater.

Electromagnetic switches, SSR, or power controllers can be used as the actuator.

Optimal Temperature Control

The ideal temperature control, as shown in Figure 1, is to control the temperature to correspond with the

set point (SP) regardless of any disturbances. There should be no overshoot or response delay of time

until the temperature reaches the set point (SP).

Figure 1. Ideal Temperature Control Figure 2. Optimal Temperature Control

FC5A MicroSmart PID Module User’s Manual FC9Y-B1283 4-1

Page 25

PID MODULE MAIN FUNCTIONS

Temperature

Set point (SP)

Time

Time

Temperature

Set point (SP)

Characteristics of Control Target

Thermal Capacity

Static

Characteristic

Disturbance

Dynamic

Characteristic

In reality, the ideal temperature control shown in Figure 1 on the previous page is almost impossible to

achieve due to a number of complicated factors such as thermal capacity, static characteristics, dynamic

characteristics and disturbances.

Figure 2 is regarded as an optimal temperature control result. Depending on the usage and objective, for

some temperature control applications, suppression of overshoot is required even if the temperature

rises very slowly as shown in Figure 3. For some temperature control applications, it is necessary to

stabilize the temperature as quickly as possible by raising the temperature rapidly even if overshoot is

generated as shown in Figure 4. In general, however, Figure 2 is regarded as an optimal temperature

control. The PID module is designed to raise the process variable (PV) to the set point (SP) as quickly as

possible in order to stabilize the process variable (PV) at the set point (SP) so as to perform the optimal

temperature control. If the temperature fluctuates due to sudden disturbances, the PID module responds

to the fluctuation with speedy response in the shortest possible time and performs quick control to

stabilize the temperature.

Figure 3. Stable but slow temperature rise control

Figure 4. The temperature rises rapidly; however, the control stabilizes after overshoot and undershoot.

Characteristics of the Control Target

To perform optimal temperature control, it is necessary to have a good knowledge of the thermal

characteristics of the PID module, sensors, actuators as well as control targets. For example, the PID

module controls a constant temperature oven and its temperature can rise up to 100°C. Even if the set

point (SP) of the PID modules is configured as 200°C, the temperature of the constant temperature oven

rise only up to 100 °C due to its static characteristic.

The characteristic of the control target is determined by the combination of the following 4 factors.

1. Thermal capacity:

This represents how the target is easily heated, and has a relation with the volume size of the control

target.

2. Static characteristic:

This represents the capability of heating, and is determined by the size of the heater capacity.

3. Dynamic characteristic:

This represents the rising characteristic (transitional response) during initial heating. This is a

complicated process involving heater capacity, furnace capacity size and sensor location.

4. Disturbance:

Any change in control temperature causes disturbance. For example, the change of ambient

temperature or supply voltage can cause disturbance.

4-2 FC5A MicroSmart PID Module User’s Manual FC9Y-B1283

Page 26

PID MODULE MAIN FUNCTIONS

Set Point (SP)

Temperature

Time

Control Output

ON

OFF

Undershoot

Overshoot

Hunting

Set Point (SP)

Temperature

Time

Proportional Band

Offset

Point A

Fixed Value Control

The PID module provides 2 control modes, one is the fixed value control and the other is the program control.

The fixed value control is a standard temperature control which performs to eliminate the deviation between

the single set point (SP) and process variable (PV). The program control allows you to define the set point

(SP) that changes as the time progresses so that the process variable (PV) can be controlled to match the set

point (SP) changing as the time progresses. For detail about the program control, see 4-9.

Control actions that can be used for fixed value control and program control are described below.

ON/OFF Control Action

In the ON/OFF control action, when the process variable (PV) is lower than the set point (SP), the control

output is turned on, and when the process variable (PV) exceeds the set point (SP), the control output is

turned off. Overshoot, undershoot, and hunting are generated. ON/OFF control is suitable for processes

which do not require accuracy.

If the proportional band or proportional gain of the PID module parameter is set to 0, the control action

becomes ON/OFF control.

Overshoot, Undershoot

As the temperature of the control target

rises as shown in the figure on the right,

the process variable (PV) sometimes

exceeds the set point (SP) greatly.

This is called overshoot. If the process

variable (PV) drops below the set point

(SP), this is called undershoot.

Hunting

The control result oscillates as shown

in the figure on the right. This is the

the hunting.

P Control Action (Proportional Action)

P control action outputs the manipulated variable (MV) in proportion to the deviation between the process

variable (PV) and the set point (SP) within the proportional band. The control output is ON until the

process variable (PV) reaches the point A that is determined by the proportional band. If the process

variable (PV) exceeds the point A (enters the proportional band), the control output starts turn on/off

according to the control period and the manipulated variable (MV). If the process variable (PV) exceeds

the set point (SP), the control output is completely turned off. While the process variable (PV) rises from

the point A to the set point (SP), the control output ON time decreases and the control output OFF time

increases. Compared to ON/OFF control action, there is no overshoot in P control action, and hunting

becomes less frequent; however, the offset is generated. The P control action is suitable for processes

such as gas pressure control or level control, in which there is no dead time.

If the integral time and derivative time of the PID module parameter are set to 0, the control action

becomes the P control action.

FC5A MicroSmart PID Module User’s Manual FC9Y-B1283 4-3

Page 27

PID MODULE MAIN FUNCTIONS

Output Manipulated

Variable

100

50

0

Proportional Band

Set Point (SP)

A

B

C

Proportional band area that

can be configured with reset

function.

Offset can be corrected within

±proportional band from the

set point (SP).

Output Manipulated Variable

A: 100%

B: 50%

C: 0%

Set Point (SP)

Temperature

Time

Proportional Band

Disturbance

• If the proportional band is narrowed (Proportional gain is made larger)

Because the control output starts turning on/off at around the set point (SP), the time until the process

variable (PV) reaches the set point (SP) is shortened, and the offset is small; however, hunting is

frequent. If the proportional band is greatly narrowed, the control action becomes similar to the ON/OFF

control action.

• If the proportional band is broadened (Proportional gain is made smaller)

Because the control output starts turning on/off at the significantly low temperature from the set point

(SP), overshoot or hunting is reduced; however, it takes time for the process variable (PV) to reach to

the set point (SP), and the offset between the process variable (PV) and the set point (SP) becomes

broadened.

The offset caused by the P control action can be corrected by configuring the reset value. If the reset

value is configured, the proportional band range can be shifted as shown in the figure below. The reset

value can be automatically calculated by the auto-reset function.

PI Control Action (Proportional + Integral Action)

I (Integral) action automatically corrects the offset caused by P control action, and temperature control is

performed at the set point (SP). However, it takes time for the process variable (PV) to be stable if the

process variable (PV) is changed rapidly due to disturbance. PI control action is suitable for the

processes in which the temperature slowly changes.

If the derivative time of the PID module parameter is set to 0, the control action becomes the PI control

action.

• If the integral time is shortened too much, the integral action becomes strong. The offset can be

corrected in a shorter time; however, hunting with a long cycle may be caused.

• If the integral time is extended too much, the integral action becomes weak and it takes time to correct

the offset.

4-4 FC5A MicroSmart PID Module User’s Manual FC9Y-B1283

Page 28

Set Point (SP)

Temperature

Time

Proportional Band

Disturbance

Set Point (SP)

Temperature

Time

Disturbance

PD Control Action (Proportional + Derivative Action)

Compared with P action, the response to rapid temperature change due to disturbance is faster, the

temperature control can be stabilized in a shorter time, and transitional response characteristic can be

improved in PD control action. PD control action is suitable for the processes in which the temperature

rapidly changes.

If the integral time of the PID module parameter is set to 0, the control action becomes the PD control

action.

• If the derivative time is shortened, the derivative action becomes weak. The response to the rapid

temperature change becomes slower. Because the action to suppress the rapid temperature rises

becomes weaker, the time for the process variable (PV) to reach the set point (SP) is shortened;

however, overshoot can occur.

• If the derivative time is extended, the derivative action becomes strong. The response to the rapid

temperature change becomes faster. Because the action to suppress the rapid temperature rises

becomes strong, the time for the process variable (PV) to reach the set point (SP) is extended; however,

overshoot can be decreased.

The offset caused by the PD control action can be corrected by configuring the reset value. The reset

value can be automatically calculated by the auto-reset function.

PID Control Action (Proportional + Integral + Derivative Action)

P action suppresses the overshoot and the hunting, I action corrects the offset, and D action corrects

rapid temperature change due to disturbance in shorter time. Thus, using PID control action, optimal

temperature control can be performed. The proportional band, integral time, derivative time, and ARW

can be automatically calculated by the auto-tuning (AT).

PID MODULE MAIN FUNCTIONS

FC5A MicroSmart PID Module User’s Manual FC9Y-B1283 4-5

Page 29

PID MODULE MAIN FUNCTIONS

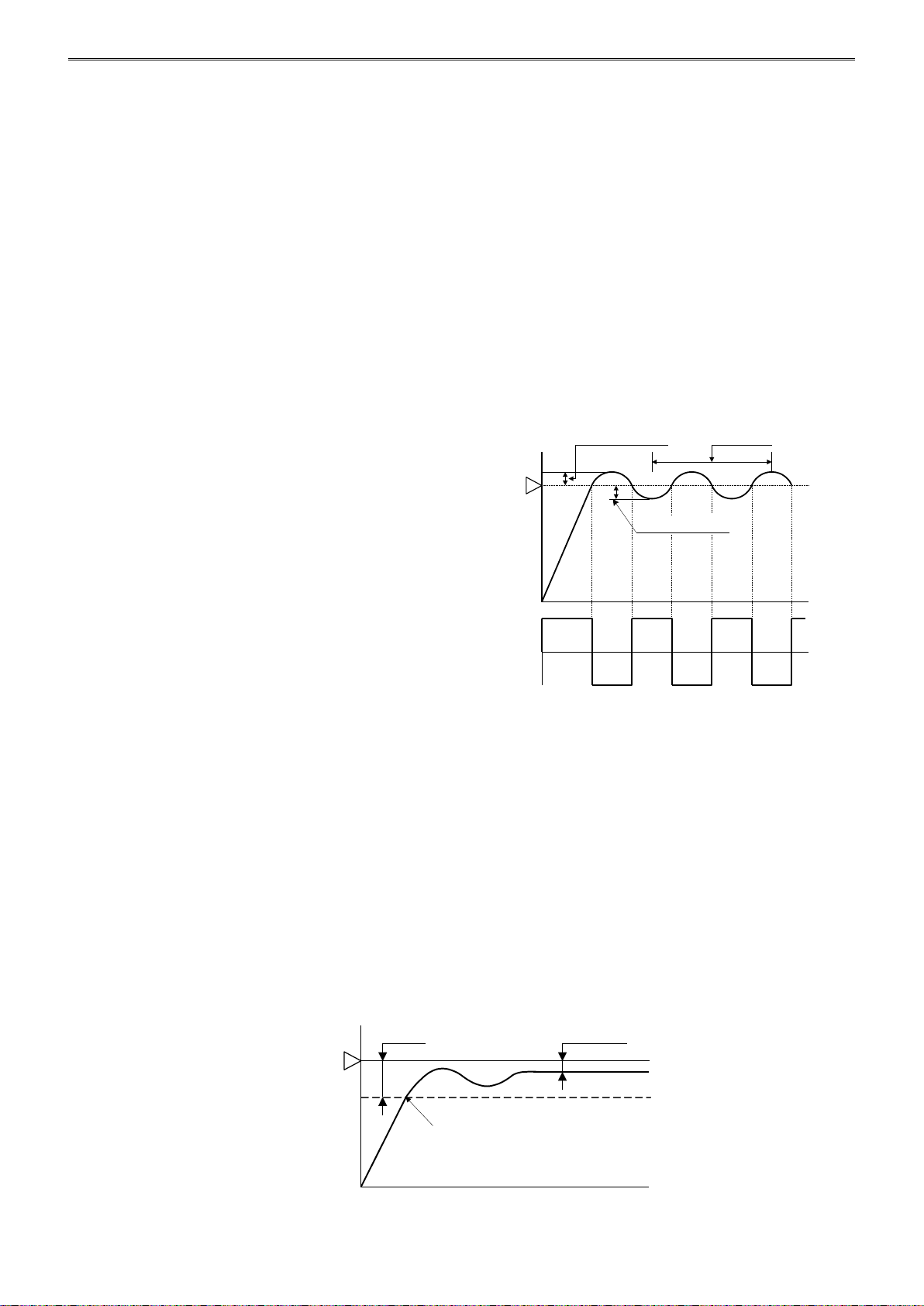

(1) (2) (3)

SP

AT

SP+20

(4)

(4)

Time

Temperature

C

SP-20

C

SP-20

SP

AT

(1) (2) (3)

(4)

Temperature

Time

C

Caution • Perform auto-tuning (AT)/auto-reset during the trial run.

• If the auto-tuning (AT) is performed near the ambient temperature, sufficient

fluctuations cannot be given to the process, and auto-tuning (AT) may fail. In

such case, configure the P, I, D, and ARW values manually.

• Perform auto-reset when the process variable (PV) is stabilized within the

proportional band.

• Once auto-tuning (AT)/auto-reset is performed, it is unnecessary to perform

auto-tuning (AT)/auto-reset again as long as the process is unchanged.

• When voltage or current input is selected and the auto-tuning (AT) is performed,

fluctuations are given to the process at the set point (SP) regardless of AT bias.

• During program control, fluctuations are given to the process as soon as

auto-tuning (AT) is started.

Auto-Tuning (AT)/Auto-Reset

The optimal temperature control parameters differ depending on the characteristics of the process to control.

For PID control action, the proportional band, integral time, derivative time, and ARW are automatically

configured by performing auto-tuning (AT). For P control or PD control action, the reset value is automatically

configured by performing auto-reset.

Auto-tuning (AT)

In order to configure P (proportional band), I (integral time), D (derivative time), and ARW (Anti-Reset

Windup) automatically with optimal values, the auto-tuning (AT) can be performed. The auto-tuning (AT)

gives temperature fluctuation to the process to calculate those parameters. To perform an optimal

auto-tuning (AT), temperature fluctuation is given to the process when the process variable (PV) reaches

near the set point (SP). By setting the AT bias, the temperature to start giving fluctuation can be configured.

The relation between the set point (SP), AT bias, auto-tuning (AT) starting point, and fluctuation starting point

are shown below.

[Process variable (PV) ≤ Set point (SP) - AT bias value]

When AT bias is set to 20°C, the PID module starts giving the temperature fluctuation to the process at the

temperature 20°C lower from the set point (SP).

(1) Fluctuation period. PID parameters are

measured.

(2) PID parameters are calculated and auto

tuning (AT) is finished.

(3) Temperature is controlled with the PID

parameters configured with auto-tuning (AT).

(4) AT bias value (20°C)

▲ AT: Auto-tuning (AT) perform bit is turned on

[Set point (SP) - AT bias value < Process variable (PV) < Set point (SP) + AT bias value]

The PID module starts giving the temperature fluctuation to the process when the process variable (PV)

reaches the set point (SP).

(1) Fluctuation period. PID parameters are

measured.

(2) PID parameters are calculated and auto

tuning (AT) is finished.

(3) Temperature is controlled with the PID

parameters configured with auto-tuning (AT).

(4) AT bias value (20°C)

▲ AT: Auto-tuning (AT) perform bit is turned on

4-6 FC5A MicroSmart PID Module User’s Manual FC9Y-B1283

Page 30

SP+20

SP

AT

Temperature

(4)

Time

(1) (2) (3)

C

SP

Time

Temperature

Offset Span

Offset is Corrected.

Auto-reset is Performed.

PID MODULE MAIN FUNCTIONS

[Process variable (PV) ≥ Set point (SP) + AT bias value]

When AT bias is set to 20°C, the PID module starts giving the temperature fluctuation to the process at

the temperature 20°C higher from the set point (SP).

(1) Fluctuation period. PID parameters are

measured.

(2) PID parameters are calculated and auto

tuning (AT) is finished.

(3) Temperature is controlled with the PID

parameters configured with auto-tuning (AT).

(4) AT bias value (20°C)

▲ AT: Auto-tuning (AT) perform bit is turned on

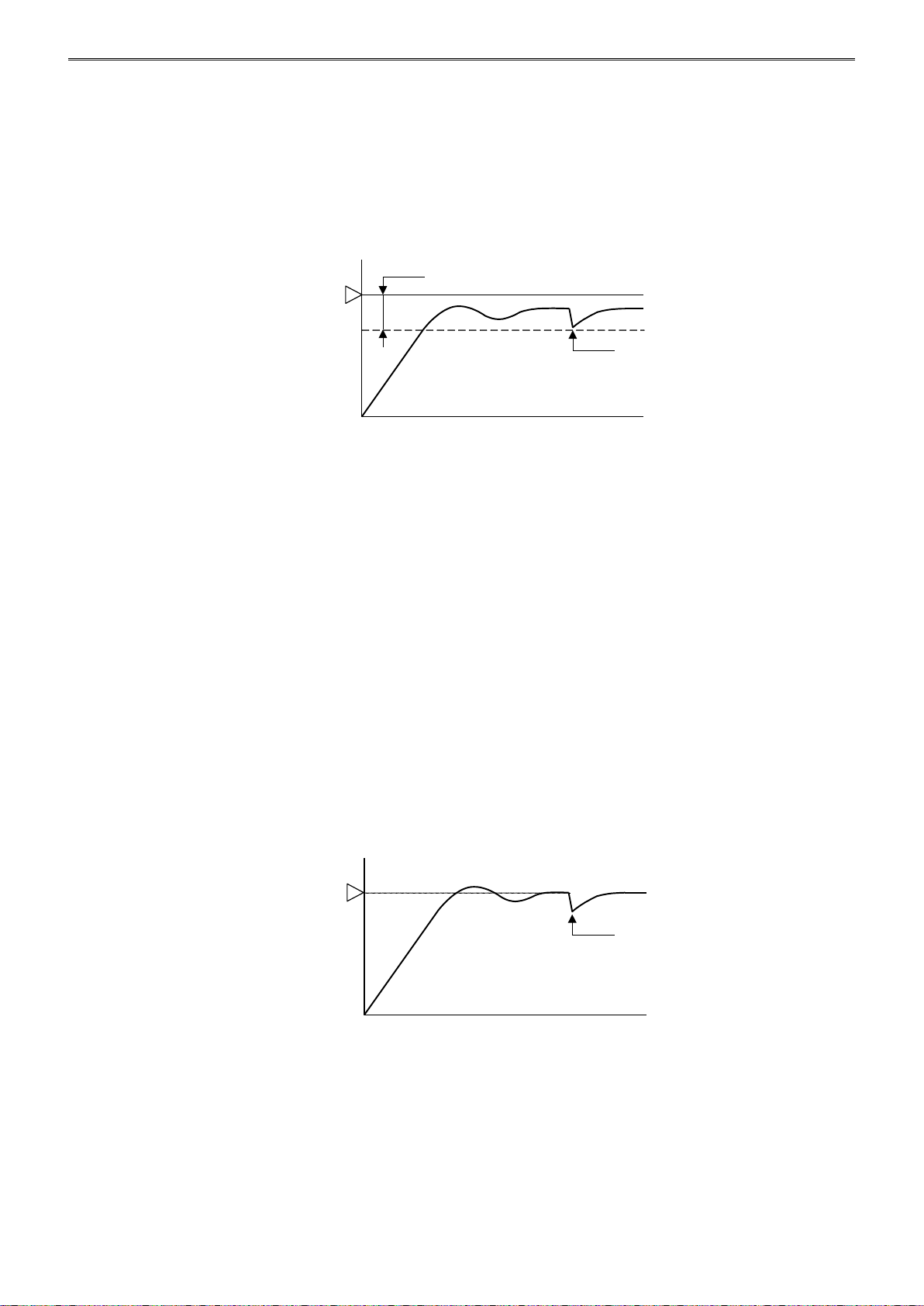

Auto-reset

During the P control or PD control action, the deviation (offset) between the process variable (PV) and the

set point (SP) is generated when the process variable (PV) is stabilized. By performing auto-reset, the reset

value can automatically be calculated to correct the offset. It is required to perform auto-reset when the

process variable (PV) is stabilized within the proportional band. When the auto-reset is completed, the CPU

module automatically reads all parameters including the calculated reset value from the PID module and

stores those parameters in the data registers. It is unnecessary to perform the auto-reset again as long as

the process is unchanged.

When the proportional band (P) is set to 0 or 0.0, the reset value is cleared.

Auto-tuning (AT)/Auto-reset Perform/Cancel

The Auto-tuning (AT)/Auto-reset function can be performed or cancelled by turning on/off the operation

parameter bits allocated to each channel. For the operation parameter bits, see page 5-10.

Perform Auto-tuning (AT)

To perform auto-tuning (AT), turn on the control enable/disable bit (Bit0) and auto-tuning (AT)/auto-reset

bit (Bit1) of the operation parameter. P, I, D and ARW values will automatically be configured.

When auto-tuning (AT) is performed during the program control, P, I, D and ARW values of the current

step are configured. While auto-tuning (AT) is performed, the Auto-tuning (AT)/Auto-reset LED (AT0/AT1)

flashes.

When auto-tuning (AT) is completed, the operation parameter Bit1 is automatically turned off, and the

CPU module reads all parameters of the AT performed channel from the PID module and store those

parameters in the data registers. If any parameters in the data registers of the CPU module have been

changed but have not been written to the PID module, those parameters will be overwritten with the

parameters read from the PID module when auto-turning (AT) is finished.

FC5A MicroSmart PID Module User’s Manual FC9Y-B1283 4-7

Page 31

PID MODULE MAIN FUNCTIONS

When external input I0 is turned on, CH0

operation parameter Bit1 is set, and

Auto-tuning (AT)/Auto-reset will be started.

When external input I1 is turned on, CH0

operation parameter Bit1 is reset, and

Auto-tuning (AT) will be cancelled.

Control Enable/Disable Bit

D1022.0

Auto-tuning (AT)/Auto-reset

Perform/Cancel Bit

D1022.1

Auto-tuning (AT)/Auto-reset

Perform/Cancel Bit (Monitor)

D1009.1

Auto-tuning is started when Auto-tuning

(AT)/Auto-reset Perform/Cancel bit

(D1022.1) is turned off to on.

Auto-tuning (AT)

cannot perform

while Control is

disable.

If auto-tuning (AT) is cancelled while

it is performed, the P, I, D and ARW

values will be reverted to the original

values at the time that auto-tuning

(AT) was started.

When auto-tuning (AT) is completed:

•The P, I, D, and ARW values

will be updated.

•Auto-tuning (AT)/Auto-reset

Perform/Cancel bit (D1022.1) will

be automatically turned off.

ON

OFF

ON

OFF

ON

OFF

Cancel Auto-tuning (AT)

To cancel auto-tuning (AT) while it is performed, turn off Auto-tuning (AT)/Auto-reset bit (Bit1) of the

operation parameter. When the operation parameter Bit1 is turned off, auto-tuning (AT) is canceled, and

the Auto-tuning (AT)/Auto-reset LED (AT0/AT1) will go off. When auto-tuning (AT) is cancelled, P, I, D and

ARW values are reverted to the original values at the time that auto-tuning (AT) was started.

Perform Auto-reset

To perform auto-reset, turn on Auto-tuning (AT)/Auto-reset bit (Bit1) of the operation parameter. The reset

value will automatically be configured and the offset is corrected. During auto-reset is performed, the

Auto-tuning (AT)/Auto-reset LED (AT0/AT1) flashes.

Auto-reset cannot be cancelled.

Auto-tuning (AT)/Auto-reset Program Example

The ladder program and the timing chart below describe an example of performing and canceling

auto-tuning (AT)/auto-reset of CH0. In this example, D1000 is allocated to the control register and M1000

is allocated to control relay.

Ladder Program

Timing Chart

Notes

• Auto-tuning (AT)/Auto-reset bit is automatically turned off when Auto-tuning (AT)/Auto-reset is completed.

• If Auto-tuning (AT)/Auto-reset bit is kept on, Auto-tuning (AT)/Auto-reset will be performed continuously. Use

SOTU and SET instructions to turn on Auto-tuning (AT)/Auto-reset bit so that auto-tuning (AT)/auto-reset is

performed only once.

• If auto-tuning (AT) is cancelled while it is performed, P, I, D, and ARW values will be reverted to the original values

at the time that auto-tuning (AT) was started.

• Auto-reset cannot be cancelled.

4-8 FC5A MicroSmart PID Module User’s Manual FC9Y-B1283

Page 32

PID MODULE MAIN FUNCTIONS

Step

Temperature

Time

Program Control

The program control allows you to define the set point (SP) that changes as the time progresses so that the

process variable (PV) can be controlled to match the set point (SP) changing as the time progresses. The set

point (SP) and time can be configured for each step. A maximum of 10 steps can be configured and performed.

The set point (SP) can be configured as shown in the following diagram.

The program control is suitable for applications, such as electric furnaces for ceramic industries or food

machineries.

Main functions of the program control are described as follows:

Program Pattern and Steps

1 program pattern consisting of 10 steps can be performed per channel.

Program Hold Function

Suspends the progression of the program control while the program control is running and performs the fixed

value control with the set point (SP) at the time that the program control is held.

Advance Next Function

Terminates the current step while the program control is running and proceeds to the start of the next step.

Advance Previous Function

Moves back the progression of the program control while the program control is running.

Wait Function

When a step ends during program control, if the deviation between the process variable (PV) and set point

(SP) is bigger than the wait value, the program control does not move to the next step. The program control

proceeds to the next step once the deviation between the process variable (PV) and set point (SP) becomes

smaller than the wait value.

Repeat Function

When the all steps are executed and the program control is terminated, the program control can be repeated

from Step 0 as many times as the repeat number configured.

FC5A MicroSmart PID Module User’s Manual FC9Y-B1283 4-9

Page 33

PID MODULE MAIN FUNCTIONS

Program Control Operation Bits and Status Monitoring

By turning on/off the operation parameter bit, program control progression can be operated. By

monitoring program run status, the current status of program control can be monitored.

For the allocation of operation parameter, program run status, operating status, see pages 5-7 to 5-10.

Program Control Start (Start the program control)

Turn on the program control bit (Bit3) of the operation parameter. Program control starts.

Program Control Stop (Terminate the program control)

Turn off the program control bit (Bit3) of the operation parameter. Program control stops and enters

standby status.

Program Hold (Suspend the program control)

Turn on the program hold bit (Bit4) of the operation parameter. Program control is held (Suspended).

While the program control is held, time progression is suspended, and fixed value control is performed

with the set point (SP) at the time that the program control is held.

While program is held, the Program Control RUN/HOLD LED (R/H0 or R/H1) of the PID module flashes.

To resume the program control, turn off the program hold bit (Bit4).

Advance Next Function (Proceed to the next step)

Turn off to on the advance next step (Bit6) of the operation parameter. The current step is terminated and

the program control is proceeded to the start of the next step. The advance next function is also effective

while the program control is in wait action.

Advance Previous Function (Move back the program control)

Turn off to on the advance previous step (Bit7) of the operation parameter. The progression of the current

step is stopped and the program control is moved back. If the elapsed time in the current step is less than

1 minute, the program control goes back to the start of the previous step. If the elapsed time in the

current step is longer than 1 minute, the program control goes back to the start of the current step.

Even when the advance previous function is executed at Step 0, the program control does not move back

to Step 9 regardless of the program end action.

Current Step Remaining Time

The remaining time of the current step is stored in the “Current Step Remaining Time” of Block 0. The

remaining time is stored in seconds or minutes according to the “Step time unit” setting.

Current Step Number

The current step number (0 to 9) is stored in the “Current Step Number” of Block 0.

Program Wait (Perform program wait)

While the program wait is functioning, the program wait bit (Bit5) of the operating status is turned on. If

the condition below is satisfied, the wait function is cancelled, the program control proceeds to the next

step, and the program wait bit (Bit5) is turned off.

Set point (SP) - Wait value ≤ Process variable (PV) ≤ Set point (SP) + Wait value

If the advance next function (Bit6) is turned from off to on or if the program control bit (Bit3) is turned off,

the wait function is canceled.

Program End Output (Program Termination)

When the program control is finished, the program end output bit (Bit6) of the operating status is turned

on. If the program control bit (Bit3) of the operation parameter is turned off, the program end output bit

(Bit6) is turned off. To start program control again, turn off to on the program control bit (Bit3) of the

operation parameter.

4-10 FC5A MicroSmart PID Module User’s Manual FC9Y-B1283

Page 34

PID MODULE MAIN FUNCTIONS

Time

Set Point (SP)

100°C

60 minutes

Starts program control

Set point (SP) when program

control starts

Time

Set Point (SP)

100°C

25°C

60 minutes

45 minutes

When program control is started, the

control starts from the PV starting

point (25°C of the process variable).

PV Starting Point

Action when Program Control Starts

The program control mode start type can be selected from 3 types: PV start, PVR start, and SP start.

When SP start is selected, the program control starts from the set point (SP) configured with “Set point

(SP) when program control starts.” When PV start or PVR start is selected, and the program control starts,

the step time is advanced until the set point (SP) matches to the process variable (PV), and then the

program control starts. For details about the program control mode start type, see page 6-41.

In the following example, the set point (SP) is 100°C, the step time is 60 minutes, and the process

variable (PV) when program control starts is 25°C.

[SP Start] [PV/PVR Start]

Program End Action

Program end action can be selected from 3 types: Terminate program control, Continue program control

(Repeat), and Hold program control. When the all steps from 0 to 9 are executed and completed, the

program control is finished. When “Terminate program control” is selected, the PID module will enter

standby status after the program control is finished. While in standby status, no control is performed and

the control output is in OFF status. If “Continue program control (Repeat)” is selected, the program

control is repeated from step 0 as many times as the repeat number configured. When “Hold program

control” is selected, the program control is held (suspended) after the program control is finished, and the

fixed value control is performed with the set point (SP) of Step 9. For details about the program end

action, see page 6-43.

FC5A MicroSmart PID Module User’s Manual FC9Y-B1283 4-11

Page 35

PID MODULE MAIN FUNCTIONS

Program End

Action

PID Module Status before the Power Failure

Standby

Status (*1)

Program

Control is

Performing.

Program Control is

suspended (Hold)

Program Control is

Terminated.

Terminate

Program Control

Standby

status is

maintained.

The program

control is

continued.

*2, *3

The program hold is

canceled, and the

program control is

continued. *2, *3

The program control is

started from the Step 0.

Continue

Program Control

(Repeat)

Hold Program

Control

The program hold is

maintained. Fixed value

control is performed with

the set point (SP) at the

time that the power is

turned off.

Step Number

Step Time

Program

Control Status

Saved Point

Elapsed Time

from Program

Control Start 0 1

2

3

10 min

3 min

(2)

(1)

(3)

4

15 min

6 min

10 min

24 min

28 min

6 min

12 min

25 min

30 min

34 min

18 min

0 min

Action after Power Is Restored

When the power is restored, every bit of the operation parameter excluding the program hold bit stored in

the data register is maintained. If the power is failed and restored while the PID module performs the

program control, the PID module starts its operation in accordance with the original PID module status

before the power failure as shown in the table below.

*1: The PID module is in standby status when the control enable bit is on but the program control bit is off. While in

standby status, the PID module performs no control.

*2: While the program control is running, the PID module saves the program control status every 6 minutes after the

program control is started (after the program control bit is turned on). The program control status is also saved at

the start of each step. If the power to the PID module is turned off while the program control is running, the PID

module resumes the program control from the latest saved point.

For example, if the power to the PID module is turned off in 7 minutes after the program control is started at step

0, the PID module resumes the program control at the status (1) when the power is restored. If the power to the

PID module is turned off in 4 minutes after the program control enters step 1, the PID module resumes the

program control at the status (2) when the power is restored. If the power to the PID module is turned off in 2

minutes after the program control enters step 2, the PID module resumes the program control at the status (3),

which is the start of step 2, when the power is restored.

*3: To restart the program control from the start of step 0, turn off and on the program control bit (operation

parameter Bit3).

4-12 FC5A MicroSmart PID Module User’s Manual FC9Y-B1283

Page 36

Program Pattern

100 100 800 800

0

500

1000

60 60 300 30

10 0 10 0

0 1 2 3

10 10 10 10

200 200 200 200

50 50 50 50

50 50 50 50

0 0 0 0

0 10 0 10

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

100 100 100 100

0 0 0 0

1.0 1.0 1.0 1.0

0.0 0.0 0.0 0.0

Step No.

Set Point (SP)

Set Point

Wait Value

Proportional Term

Integral Time

ARW

Output MV Rate-of-Change

Alarm 1 Value

Output MV Upper Limit

Output MV Lower Limit

Cooling Proportional Band

Overlap/Dead Band

Time (Minutes)

C

Derivative Time

( )

Alarm 2 Value

Alarm 3 Value

Alarm 4 Value

Alarm 5 Value

Alarm 6 Value

Alarm 7 Value

Alarm 8 Value

(SP)

Program Pattern Example

The set point (SP) configured for each step is handled as the set point (SP) at the end of the step. The

time configured for each step is the process time of each step.

PID MODULE MAIN FUNCTIONS

When the program pattern is configured as shown in the above table, the following control is

performed at each step:

[Step 0]: The set point (SP) is gradually risen to 100°C in 60 minutes.

When the step 0 ends, the wait function works so that the program control does not

proceed to the step 1 until the process variable (PV) reaches 90°C.

[Step 1]: The fixed value control is performed at 100°C of the set point (SP) for 60 minutes.

[Step 2]: The set point (SP) is gradually risen to 800°C in 5 hours.

[Step 3]: The fixed value control is performed at 800°C of the set point (SP) for 30 minutes.

When the step ends, the wait function works so that the program control does not proceed

to the step 3 until the process variable (PV) reaches 790°C.

FC5A MicroSmart PID Module User’s Manual FC9Y-B1283 4-13

Page 37

PID MODULE MAIN FUNCTIONS

Cooling

Control

Target

PID

Module

Heating

PID

Module

Cabinet

Input CH1

Input CH0

Output CH0

Fan

Interior

Temperature

External

Temperature

PID

Module

Tank A

Input CH1

Input CH0

Tank B

Heating/Cooling Control

When it is difficult to control the target process with heating control only, cooling control can be added to

perform the heating/cooling control. Control results derived from the set point (SP) and process variable (PV)

are outputted to 2 outputs, heating output (CH0) and cooling output (CH1). If the process variable (PV) is

higher than the set point (SP), cooling output will be turned on. If the process variable (PV) is lower than the

set point (SP), heating output will be turned on. The area in which both heating and cooling outputs are turned

on can be configured as overlap. The area in which neither heating output nor cooling output is output can be

configured as dead band.

Example: Heating/Cooling control uses both heating and cooling outputs and is suitable for the heat producing

processes such as extruders or for temperature control at near ambient temperature such as

environment testers.

Difference Input Control

Difference input control is the control to keep the input difference between input CH0 and input CH1 at the

same level. When the difference input control is selected, input CH0 and input CH1 are independently

measured, and the difference between those inputs is used as process variable (PV). PID module controls

output so that the difference between those inputs is matched to the set point (SP).