Page 1

FC4A SERIES

MICROSmart

Web Server Unit

Instruction Manual

FC9Y-B919

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 2

PRECAUTIONS

● Read this user’s manual to make sure of correct operation before starting installation, wiring, operation,

maintenance, and inspection of the MicroSmart modules.

● All MicroSmart modules are manufactured under IDEC’s

rigorous quality control system, but users must

add a backup or failsafe provision to the control system using the MicroSmart in applications where

heavy damage or personal injury may be caused in case the MicroSmart should fail.

● In this user’s manual, safety precautions are cate g orized in order of im

portance to Warning and Caution.

Precautions on hazards that could result in death or serious injury if equipment is handled

incorrectly.

Precautions on ha

zards that could result in injury or equipment damage if equipment is handled

incorrectly.

● Turn off the po

wer to the MicroSmart before starting in

stallation, remo

val, wiring, maintenance, and

inspection of the MicroSmart. Failure to turn power off may cause electrical shocks or fire hazard.

● Special expertise is required to install, wire, program, and operate the MicroSmart. People without such

expertise must not use the

MicroSmart.

● Emergency stop and interlocking circuits must be configured outside the Mi

croSmart. If such a circuit is

configured inside the MicroSmart, failure of the MicroSmart may cause disorder of the control system,

damage, or accidents.

● Install the MicroSmart according to the instructions described in this

user’s manual. Improper installation

will r

esult in falling, failure, or malfunction of the MicroSmart.

● The MicroSmart is designed for installation in a cabinet

. Do not install the MicroSmart outside a cabinet.

● Install the MicroSmart in environments described in this user’s manual

. If the MicroSmart is used in places

where the MicroSmart is subjected to high-temperature, high-humidity, condensation, corrosive gases,

excessive vibrations, and excessi ve shocks, then electrical shocks, fire hazard, or malfunction will result.

● The environment for using the MicroSmart is “Pol

lution de

gree 2”. Use the MicroSmart in environments

of pollution degree 2 (according to IEC 60664-1).

● Prevent the MicroSmart from falling while moving or transporting

it, otherwise damage or malfunction of

the MicroSmart will result.

● Prevent metal fragments and pieces of wire from dropping inside the MicroSm

art housing. Put a cover on

the MicroSmart modules during installation and wiring. Ingress of such fragments and chips may cause

fire hazard, damage, or malfunction.

● Use a power supply of the rated value. Use of a

wrong power su

pply may cause fire hazard.

● Use an IEC 60127-approved fuse on the power line outside the MicroSmart. This is required when

equipment containing the MicroSm

art is destined for Europe.

● Use an IEC 60127-approved fuse on the output circuit. This is required when equipment containing the

MicroSmart

is destined for Europe.

● Use an EU-approved circuit breaker. This is required when equipment containing the MicroSma

rt is

destined for Europe.

● Make sure of safety before starting and stopping the MicroSmart or when operating the MicroSmart to

force

outputs on or off. Incorrect operation on the MicroSmart may cause machine damage or accidents.

● Do not connect the ground wire directly to the MicroSmart. Connect a protective ground to the cabinet

containing the MicroSmart using an M4 or la

rger screw. This is required when equipment containing the

MicroSmart is destined for Europe.

● Do not disassemble, repair, or modify the MicroSmart modules.

● Dispose of the battery in the MicroSmart module

s when the battery is dead in accordance with perta

ining

regulations. When storing or disposing of the battery, use a proper container prepared for this purpose.

This is required when equipment containing the MicroSmart is destined for Europe.

● When disposing of the MicroSmart, do s

o as an industrial waste.

WARNING

!

CAUTION

!

WARNING

!

CAUTION

!

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 3

INTRODUCTION

Thank you for your purchase of the IDEC Izumi Web Server Unit.

This manual contains the specifications of the Web Server Unit (Mic

roSmart communication module), and

describes how to use the unit.

Before using the unit, read this manual to thoroughly familiarize yourself with t

his product's functions and

performance, and to ensure correct operation.

• WindLDR is a registered trademark of IDEC Izu

mi Corporation.

• Microsoft

®

Windows® and Microsoft® Internet Explorer are registered trademarks or trademarks of

Microsoft Corporation (US) in the US and other countries.

• Java and all the trademarks and logos related to Java are registered trademarks or trademarks of Sun

Microsystems, Inc. (US)

in the US and other countries.

• Netscape, Netscape Navigator and Netscape’s N logo are registered trademarks of Netscape

Communicati

ons Corporation in the US and other countries. Netscape’s logo, Netscape Communicator

and other product/service names are trademarks (or registered trademarks in some countries) of Netscape

Communications Corporation. Copyrights of Netscape Navigator are reserved by Netscape

Communications Corporation.

• Ethernet is a trademark of X

erox Corpor

ation USA.

• Other company names and product names shown in this manual are trademarks or registered tradem

arks

of each company.

Important

1. Unauthorized reproduction, reprinting, sale, transfer or lending of this manual in whole or part is strictly

prohibited.

2. The contents of this manual are subject to change without prior notice.

3. Every effort has been taken to ensure the accuracy of the information contained in this manual.

However, if you do discover an error or omission, report it to your place of purchase or nearest IDEC

Izumi sales office or branch.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 4

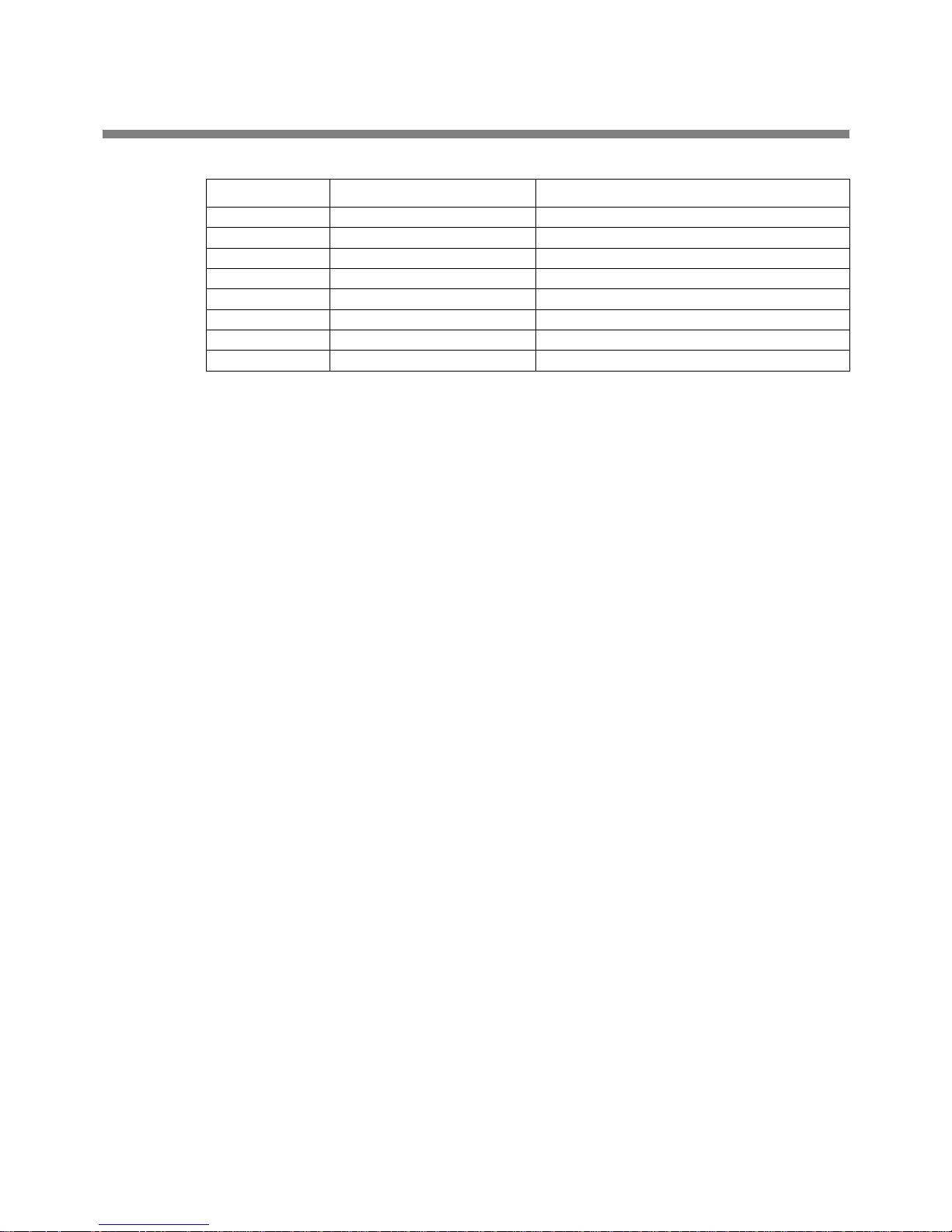

REVISION HISTORY

The revision history of this manual (FC9Y-B919) is shown below.

Date of revision Documentation control No. Description

June 2005 B919-(0) First edition

This manual’s documentation control No. is printed at the back cover.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 5

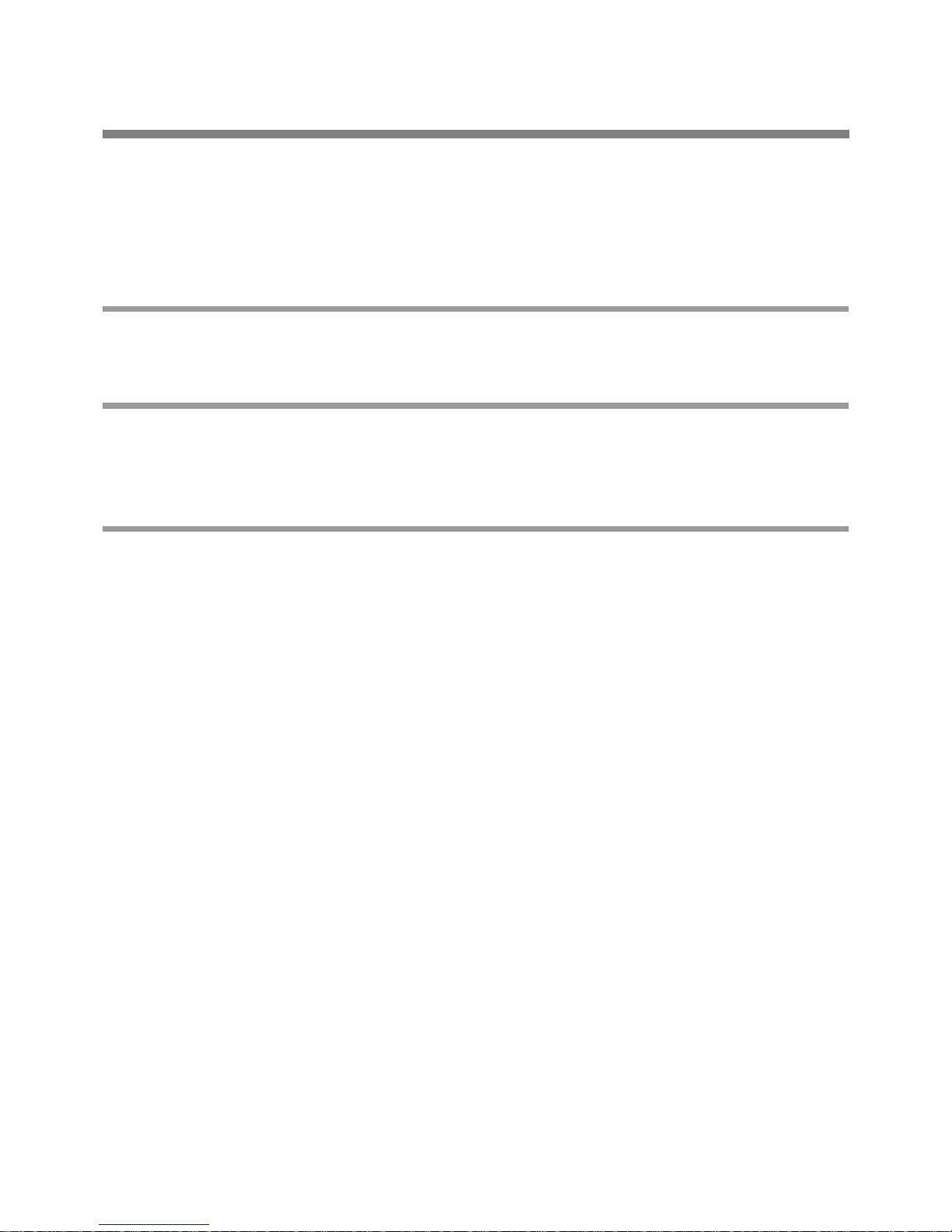

TABLE OF CONTENTS

Precautions

Introduction

Revision History

Table of Contents

CHAPTER 1: Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1 Web Server Unit Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

CHAPTER 2: Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1 Names and Specifications of Module Components . . . . . . . . . . . . . . . 2-2

2 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

CHAPTER 3: Module Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1 Web Server Unit Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

2 Remote Maintenance Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3 Web Server Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

4 Ethernet User Communication Function. . . . . . . . . . . . . . . . . . . . . . . 3-21

5 Mail Sending Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Connection Diagram

Troubleshooting

Glossary

Index

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 6

1-1

CHAPTER 1 OVERVIEW

This chapter provides an overview of the Web Server Unit.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 7

1-2

This section provides an overview of the Web Server Unit.

■ Applications

The We b Server Unit has following four major functions.

Remote Maintenance Function The remote maintenance function using MicroSmart.

Web Server Function The remote monitoring function using Web bro

wser.

Ethernet User Communication Function The communication function between MicroSmart modules.

Mail Se

nding Function The mail sending function from MicroSmart.

■ Functions

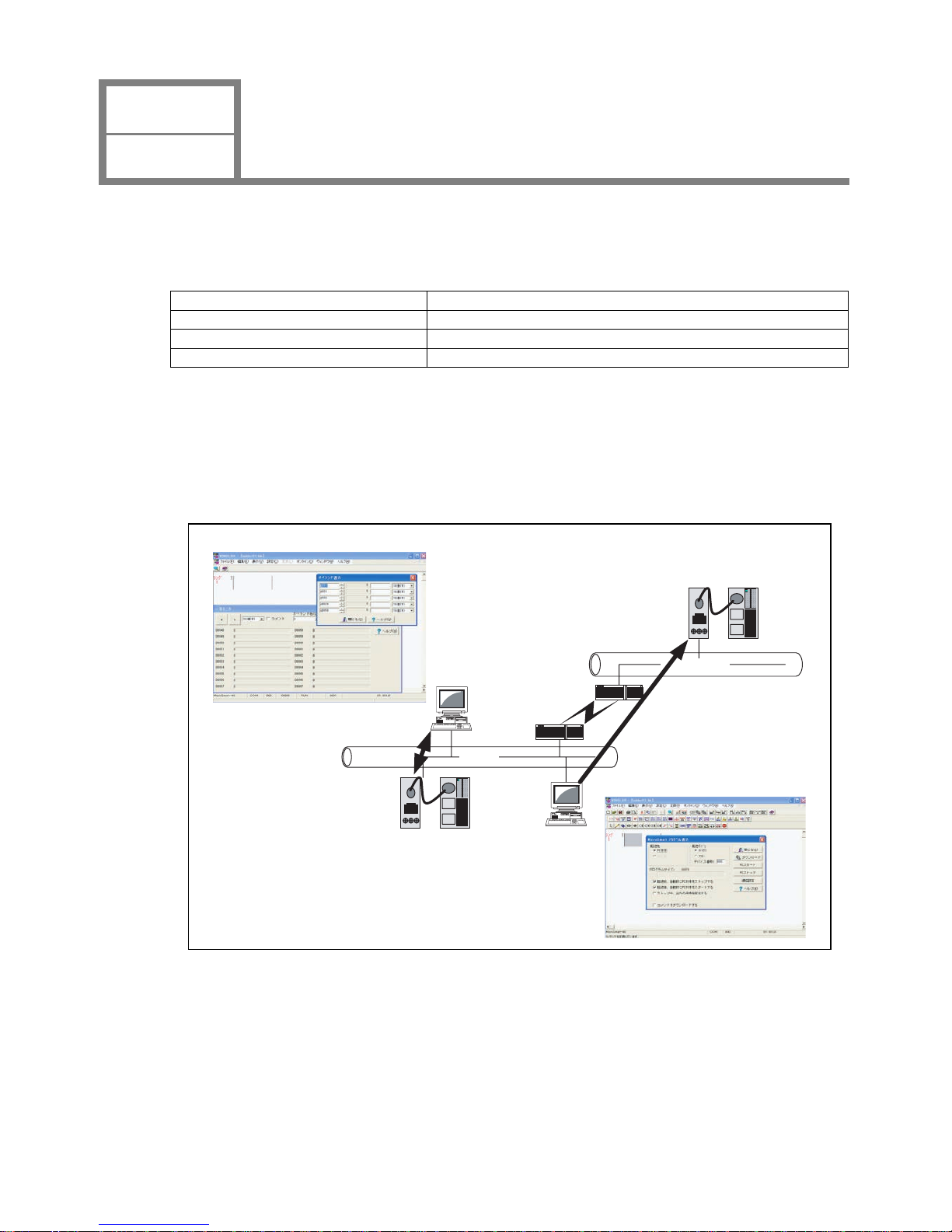

● Remote Maintenance Function

Using the Web Server Unit and WindLDR version 4.70 (or a later version) enables Ethernet-based MicroSmart

ladder progr

am reading/writing and operand read/write operations.

1_1_1_Remote_Control_Over view_E

Block diagram of remote maintenance (WindLDR)

Ethernet

Ethernet

User program download

Rout er

Router

Web Server Unit + MicroSmart

Web Server Unit + MicroSmart

Monitor Dialog

Download di alog

Read / Write of the operand

CHAPTER 1

OVERVIEW

Web Server Unit Overview

1

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 8

1-3

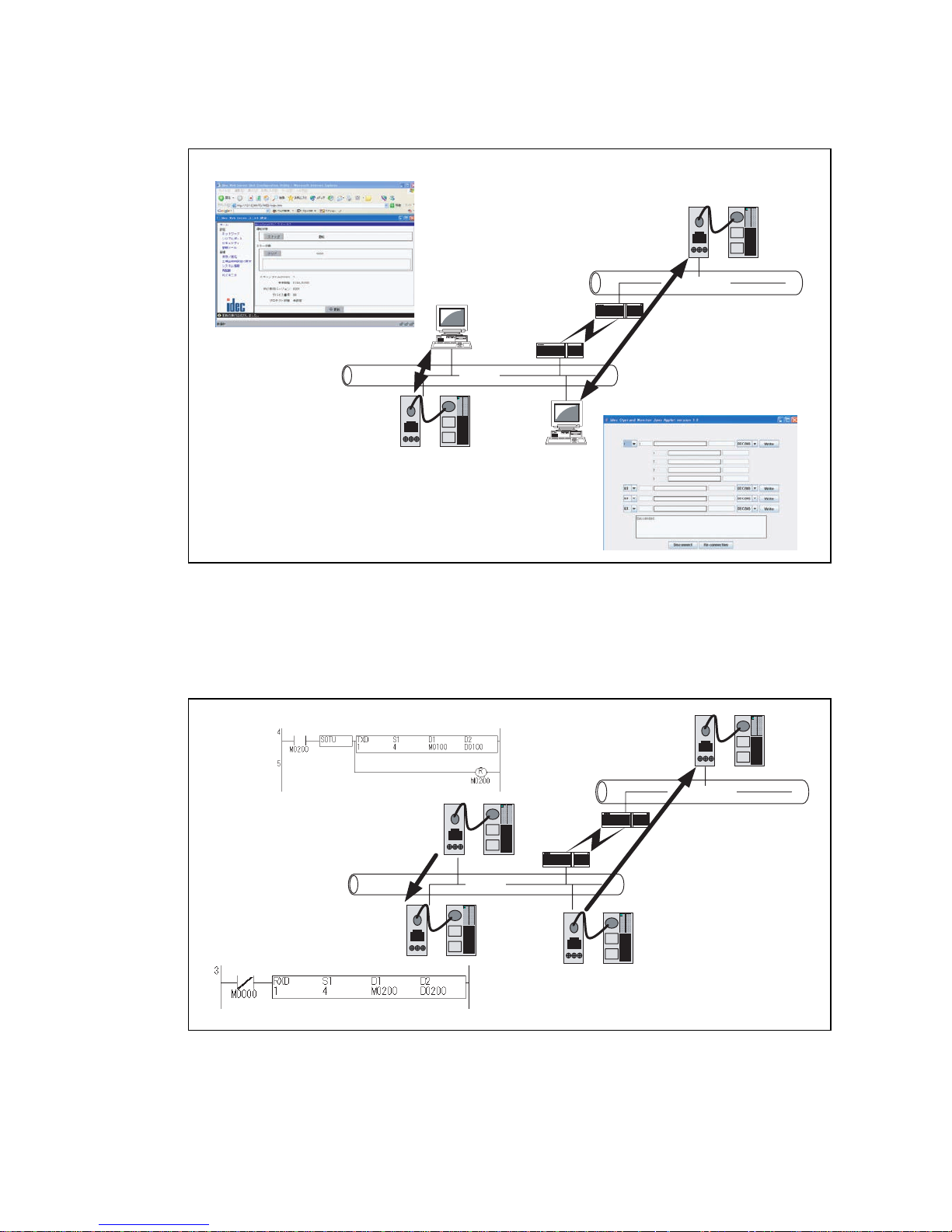

● Web Server Function

The Web server’s sample screens or user creation screens enable MicroSmart operand read/write op

erations from a

Web browser.

1_1_2_Remote_Control_Over view_E

Block diagram of remote monitoring (Web browser)

Ethernet

Ethernet

Rout er

Router

Web Server Unit +MicroSmart

Web Server Unit + MicroSmart

Simple Monitor / Web Browser

Operand Monitor / Web Browser

Read/Write of the operand

Read/Write of the operand

● Ethernet User Communication Function

The Web Server Unit function and MicroSmart user communication commands enable Ethernet-based 1:1

communication between Micro

Smart modules.

1_1_3_Microsmart_communication_overview_E

Block diagram of communication between MicroSmart modules

Ethernet

Ethernet

Rout er

Rout er

Web Server Un it + MicroSmart

Transmit data

with TXD command

Receive data

with RXD command

Transmit data

with TXD command

Receive data

with RXD command

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 9

1-4

● Message Sending Function

The W eb Server Unit function and MicroSmart user communication commands enable message (mail) sending to a

PC

or mobile phone.

1_1_4_Massagesend_Overview_E

The Internet

E-mail

To: AAA@BBB

Subject: ERROR

Transmit the t rigger signal

of sen ding alarm mail

E-mail

From: CCC@DDD

Subject: ERROR

Mail server

Mail server

Block diagram of mail transmission

■ Network Cautions

● Caution when connecting

The Web Server Unit has to be used on the local network. When accessi

ng the PLC via network using the Web

Server Unit function, it takes time to transfer the data in some communication environments. Be sure to set the

timeout value in the PLC communication settings.

As regards the network connection, please co

nsult with the n

etwork administrator.

● Security Caution

The W eb Server Unit’s user name and password authentication function will

not completely prevent unauthorized

access.

● Limitation on User Screen Creation

User screen sample pages are provided, but kno

wledge of Java applets is needed to modify sample screens to create

original pages. See the Sun Microsystems Inc. web site for more information on Java applets.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 10

2-1

CHAPTER 2 SPECIFICATIONS

This chapter contains information on the Web Server Unit’s specifications. Familiarize

yourself with the information in this chapter to ensure effective use of the Web Server

Unit.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 11

2-2

This section provides the names and specifications of Web Server Unit components.

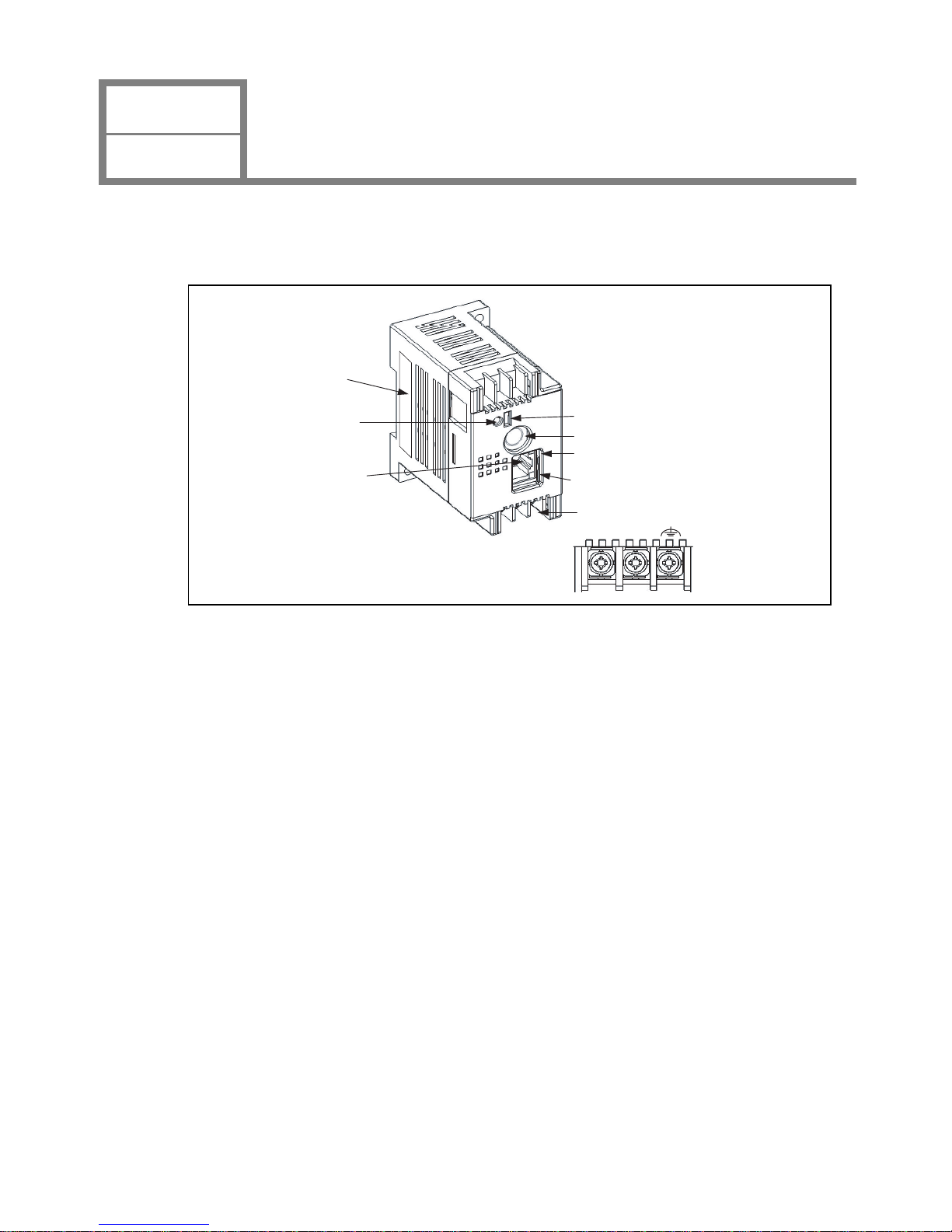

■ Names

2_1_1_System_Configration_E

System configuration diagram

(1)Format label

(2)Power display

LED (PWR)

(4) Function selector switch

(5) MicroSmart connection port

(6) LINK LED

(7) Network LED

(8) Terminal Name

+

-

(3)Ethernet port

1) Format label

Indicates the Web Server Unit model No./type.

2) Power display LED ; Green (PWR)

Lights when power is being supplied to the Web Server Unit.

3) Ethernet port

The port into which the ends (RJ-45) of the Ethernet cable is inserted.

4) Functio

n selector switch

Used to switch the Web Server Unit’s function.

When using the remote maintenance function and the Web server functi

on, set the switch to “REMOTE”.

When using the Ethernet user communication function and the mail sending functio

n, set the switch to “USER”.

*The default setting is “REMOTE”.

5) MicroSmart connection port

Serial communication port connecting the W

eb Server Unit and MicroSmart.

6) LINK LED

Lights when the cable is connected to the Web Server Unit.

7) Net

work LED

Flashes when the Web Server Unit is sending/receiving data.

8) Termin

al name

Indicates the terminal name.

CHAPTER 2

SPECIFICATIONS

Names and Specifications of Module Components

1

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 12

CHAPTER 2

SPECIFICASIONS

Performance Specifications

2

2-3

This section provides the Web Serv er Unit’s performance specifications.

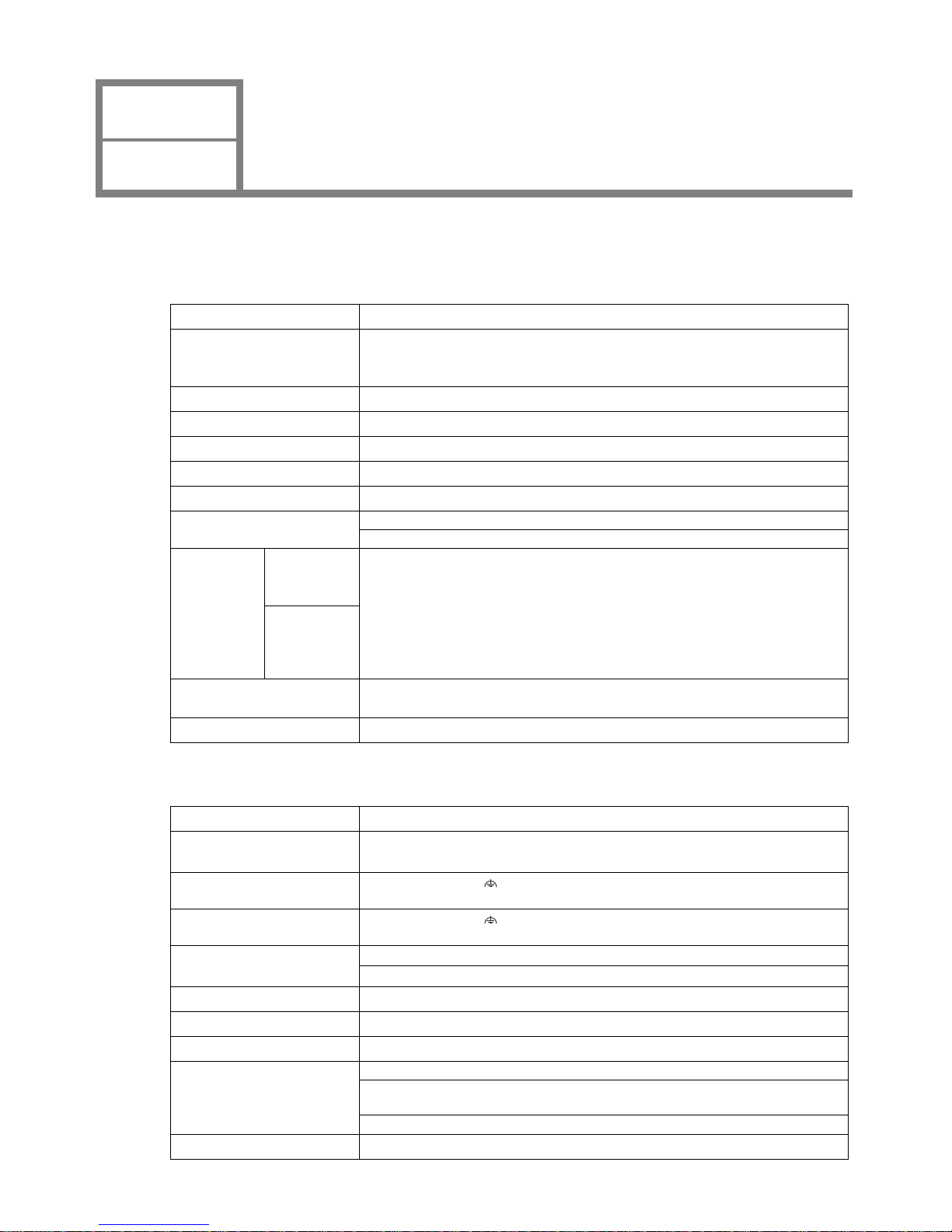

■ General Specifications

● Normal Operating Conditions

Model type FC4A-SX5ES1E

Operating Temperature

(Operating ambient

tem

perature)

0 to 55°C

Storage Te m perature

−25 to +70°C (non-freezing)

Relative Humidity 10 to 95% (non-condensing)

Pollution Degree 2 (IEC60664-1)

Degree of Protection IP20 (IEC60529)

Corrosion Immunity Free from corrosive gases

Altitude

Operation: 0 to 2,000m (0 to 6,565 feet)

T

ransport: 0 to 3,000m (0 to 9,840 feet)

Vibration

Resistance

When

mounted on a

DIN rail:

5 to 9Hz amplit

ude 3.5mm,

9 to 150Hz acceleration 9.8m/s

ec

2

2 hours per axis on each of three mutually perpendicular axes (IEC61131-2)

When

mounted on a

pane

l

surface:

Shock Resistance

147m/sec2 (15G) 11msec duration, on three mutually perpendicular axes

(IEC61131-2)

Antistatic discharger Contact: ±6kV, Aerial: ±8kV (IEC61

000-4-2)

● Power Supply

Rated Power Voltage 24V DC

Allowable Momentary Power

Interruption

Greater than or equal to 10msec (at 24V DC)

Dielectric strength

Between power and

terminal

500V AC 1 minutes

Insulation resistance

Between power and

terminal

Greater than or equal to 10MΩ (500V DC megger)

Noise Resistance

DC power terminals

1.0kV, 50nsec to 1

µsec (Direct connecting)

Ethernet cable

0.5kV, 50nsec to 1

µsec (Coupling clamp)

Grounding

100Ω

Grounding wire UL1007 AWG16

Power Supply Wire UL1015 AWG22, UL1007 AWG18

Effect of Improper Power

Supply Connection

Rever s e po l arity No operation, no damage

Improper voltage or

frequency

Permanent damage may be caused

Improper lead connection Permanent damage may be caused

Weight 120g

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 13

2-4

● Communication Functions

Serial

Standards Compatible with the EIA RS232C standard

Baud Rate 9,600bps (Default) to 115,200bps

Synchro system Asynchronous communication method

Transmission method Full duplex

Ethernet

Standards Compatible with the IEEE802.3 standa

rd

Transmission rate

10BASE-T

100BASE-TX (Out of

the standard coverage)

*1.Depending on the noise environments, Web Server Unit cannot communicate on the 100BASE-TX in

some cases.

*1

Communication protocol

IP/ICMP/ARP/TCP

*2.The number of unit to be connected at the same moment is one unit.

*2

/SMTP/HTTP/Telnet

● Functions

Web Server

Supported Web Browser

Internet Explorer 6.0 or later

Netscape Navigator 7.2 or later

Java VM Versions 1.42 or later

Alarms

Alarm contents Alarm contents have to be registered in the Web Server Unit in advance.

The number of alarm types 32 types

Alarm character strings Within 63 characters (1 byte character)

The number of destination

ad

dresses

2 addresses (The sum of two address characters is up to 64 characters)

● Connectable Unit

*1.The PLC requires the connecting cable type, FC4A-KC3

C, to connect to the Web Server Unit.

PLC

*1

FC2A series

*2.Except for Micro3 in FC2A series.

*2

, FC3A series, FC4A series

Programmable Display

*3,*4

*3.The programmable display requires the connecting cable type, HG9Z-3C125, to connect to the Web

Server Unit.

*4.The programmable display requires the firmware versions 1.

8 or later.

*5.Please contact IDEC for more detail.

HG2F

*5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 14

3-1

CHAPTER 3 MODULE OPERATION

This chapter provides an overview of the operation method, and contains information

on parameters and sample programs. Familiarize yourself with the information in this

chapter to ensure effective use of the Web Server Unit.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 15

3-2

This section describes how to set the Web Server Unit.

■ Setting Procedure

The following settings are needed to connect the Web Server Unit to Ethernet and operate its functions.

System Configuration

System Setting Screen

Network Address Setting Procedure

Serial Communication Setting Procedure

Other Function Settings

1) Security

2) Mail Sending

3) Administration

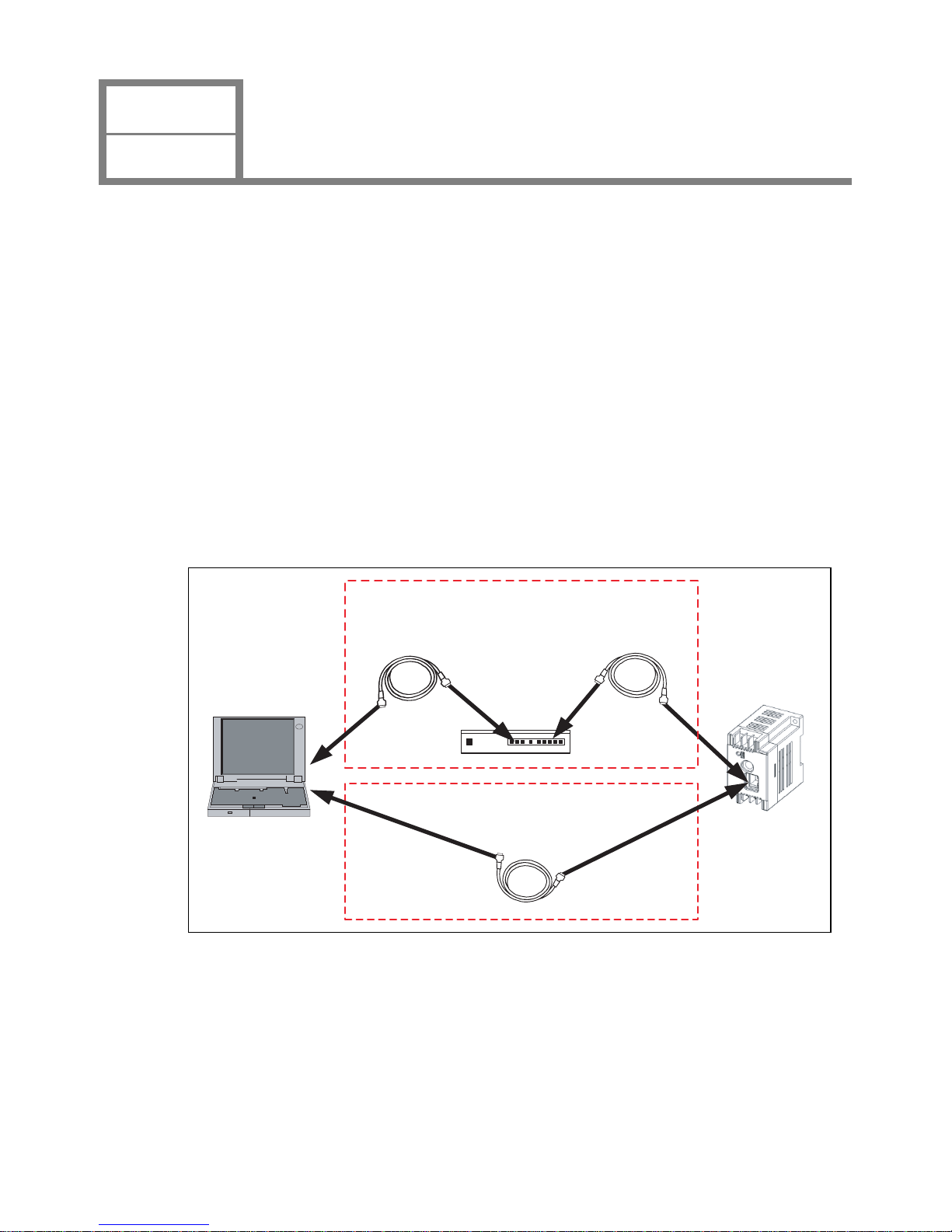

● System Configuration

Use the following either methods to connect the Web Server Unit to a PC* with WindLDR version 4.70 (or a later

v

ersion) installed.

(1

) The connection using a Hub and Ethernet straight cables

(2) The connection using an Ethernet cross cable

Connection methods

3_1_1_Crosscable_Connection_E

Web Server UnitPersonal computer

Ethernet cross cable

Ethernet straight cable

Ethernet straight cable

Hub

(1) The connection using a Hub

and Ethernet straight cables

(2) The connection using a Ethernet cross cable

* Make sure an IP address is set for the PC. To initialize Web Server Unit from the factory default state, it is

necessary to connect the personal computer and the Web Server Unit by the same network setting. Because the

factory default IP address for the Web Server Unit is [192.168.1.5], the IP address of Personal Computer have to

be [192.168.1.1] for instance.

* The PC must be able to run a Web browser (such as Inte

rnet Explorer). Enable JavaScript and

Java applets.

* When connecting to a network such as a company LAN, consult the network administrator before conn

ecting

the W eb Server Unit.

CHAPTER 3

MODULE OPERATION

Web Server Unit Settings

1

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 16

3-3

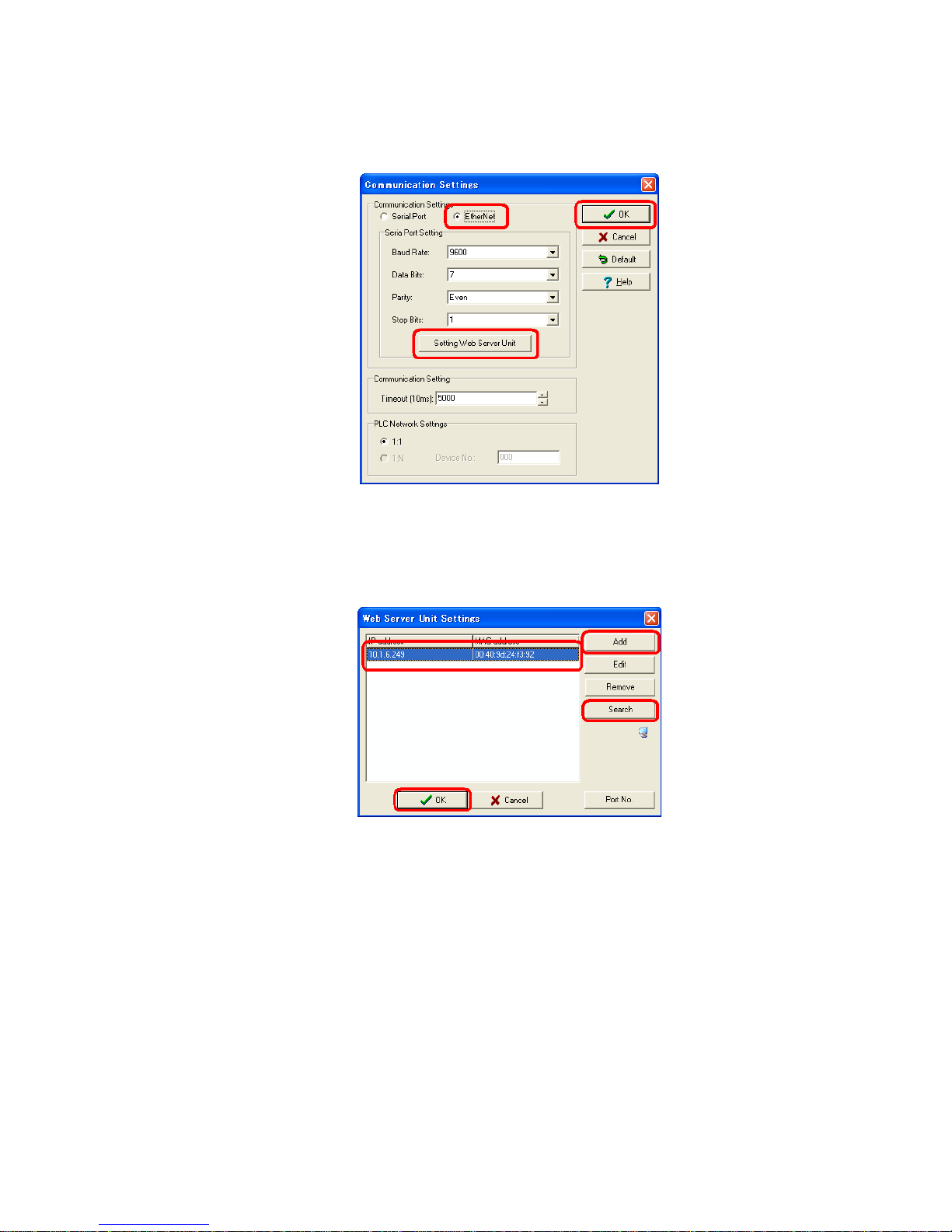

● System Setting Screen

1. Select [Configure]→[Communication Settings]→[Ethernet] from the WindLDR menu and press [OK]. Then

select [Setting Web Server Unit]. *This time, the correct PLC have to be selected on the [Configure]→[PLC

Selection].

2. By pressing the [Search] button, the list of the Web Server Unit information appears in the WindLDR screen. Or

otherwise, using the [Add] button enter the IP address and add the item for the list. Then select the

communication target from the list and press [OK].

WindLDR dialog

3_1_2_WindLDR_Dialog_E

WindLDR dialog

3_1_3_WindLDR_Dialog_E

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 17

3-4

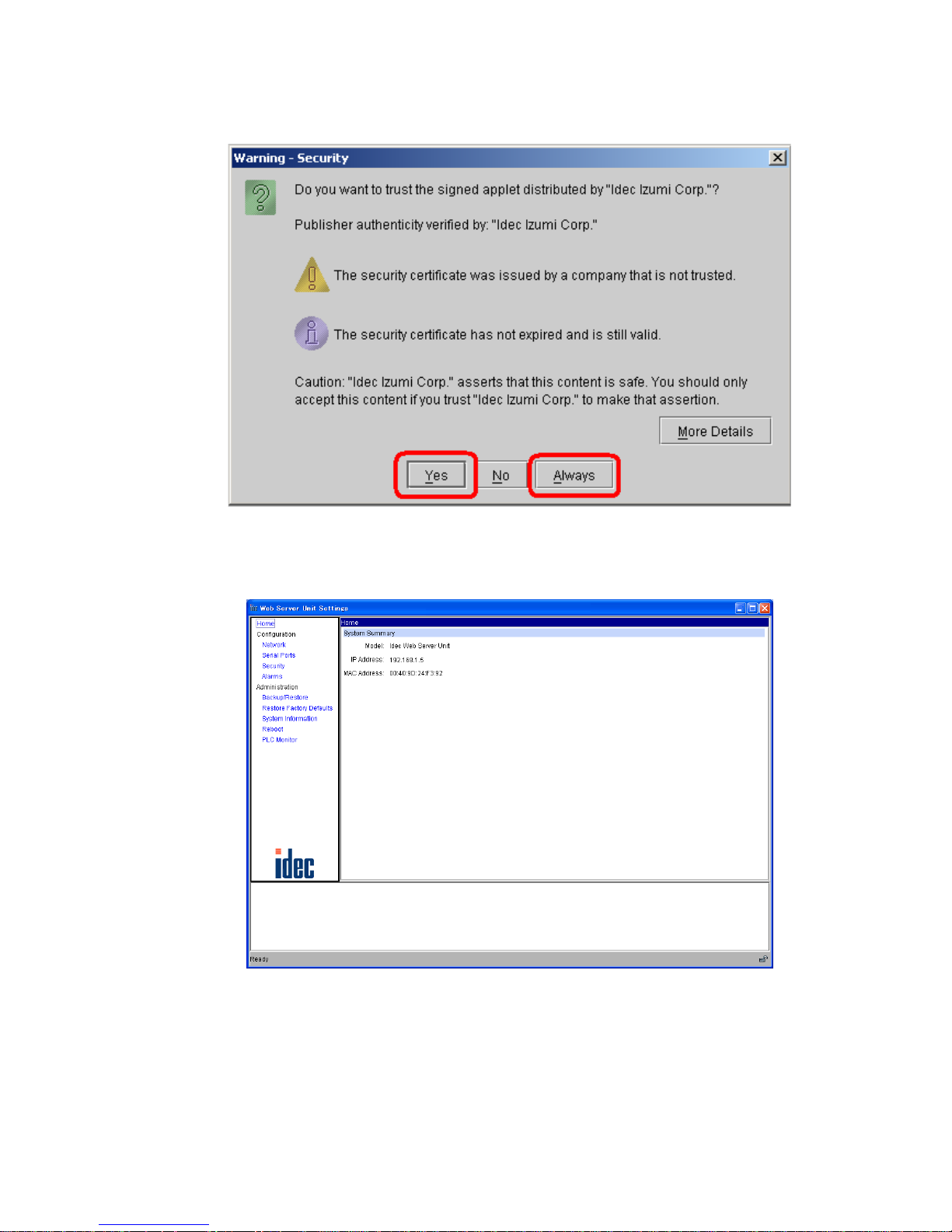

3. A warning dialog appears asking whether to start the applet. Select [Yes] or [Always]. When you select

[Always], the dialog does not appear the next time you start the Web browser.

Java applet is loaded.

4. The System Setting Screen below appears. Use it to make the settings.

3_1_4_Applet_Bootup_Warning_E

Warning dialog during Ja va applet startup

3_1_5_System_Setting_Screen_E

System Setting Screen

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 18

Menu Description

HOME

Initial screen when the system startups. Model, IP address and MAC

address are displa

yed.

Configuration

Network Network settings

Serial Ports Serial port settings

Security Password settings

Alarms Message settings

Administration

Backup/Restore Saves and backups the set values.

Restore Factory

De

faults

Rev

erts to the default values.

System Information Displays the system information.

Reboot Restarts the system.

PLC Monitor Displays the PLC status when a PLC is connected.

3-5

The following settings are available in the System Setting Scr

een.

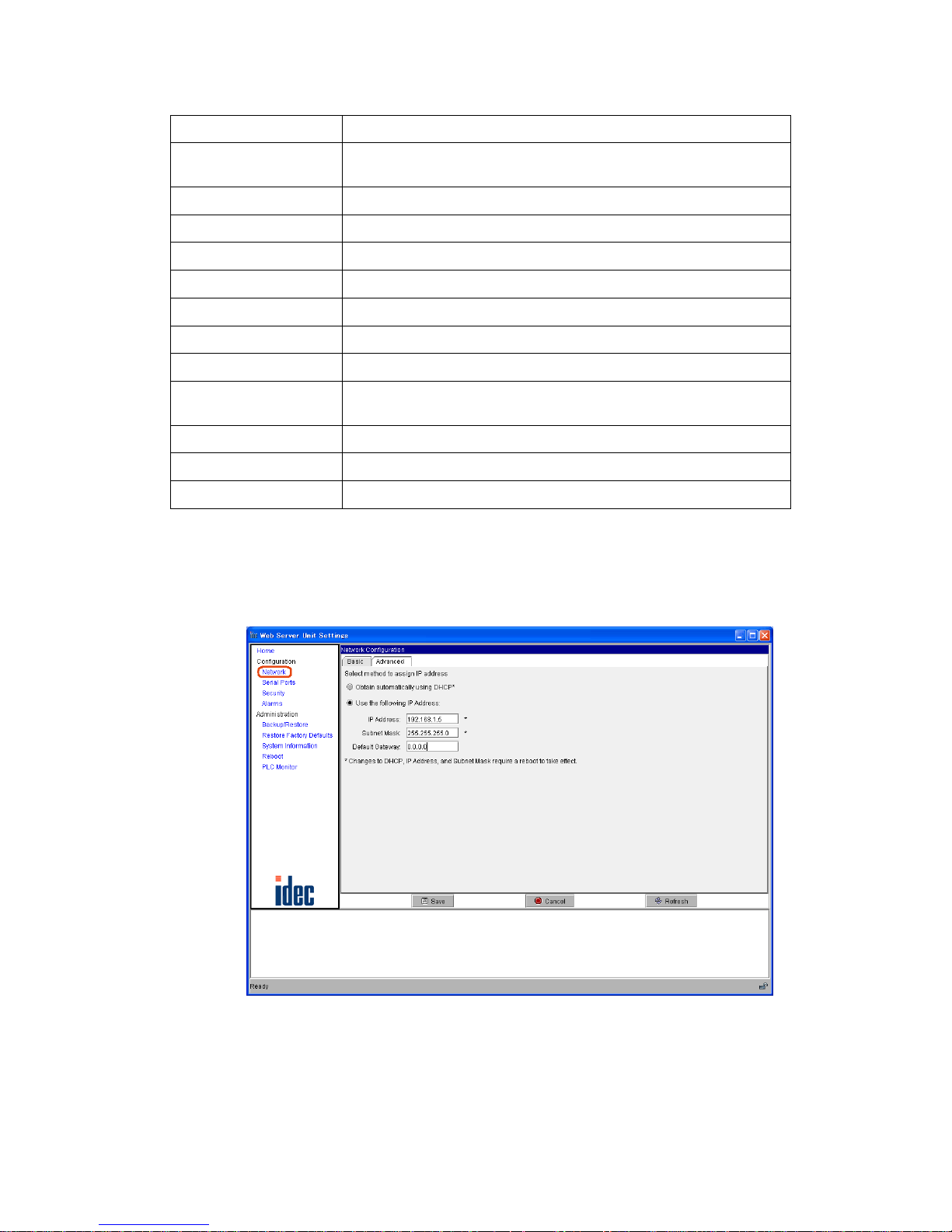

● Network Address Setting Procedure

To connect the Web Server Unit to Ethernet, the IP address (the network address), subnet mask and def

ault gateway

need to be set. T o set the Web Server Unit’ s network address, open the abov e-mentioned System Setting Screen, then

select [Network] on the left menu to display the screen below. You can use either of the following methods to make

the network settings.

3_1_6_Network_Setting_E

Network settings screen

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 19

3-6

1) Acquiring network address from DHCP server*

This method acquires the Web Server Unit’s network address from

the DHCP serv

er. In the network settings

screen, select [Obtain automatically using DHCP], and click the [Save] button. The setting is applied when you

connect to the network and then restart the Web Server Unit.

2) Fixed network address allocation

Sets a fixed user-specif i ed network address. Make sure that e

very IP address set in the same

network is unique.

In the network settings screen, select [Use the following IP Address :], and enter the desired IP address, subnet

mask and default gateway address. Click the [Save] button. The setting is applied when yo u connect to the

network and then restart the Web Server Unit.

* If there is no DHCP server in the same network used b

y the Web Server

Unit, the network address can’t be

acquired, so use method (2) to set the network address.

3_1_7_DHCPserver_network_E

When using DHCP server or not

Ethernet

Ethernet

Personal

computer

Router

DHCP server

The DHCP server allocates the

network address.

When the DHCP server and the Web Server Unit

are in the same network.

It operates on the network address

allocated by the DHCP server.

When the DHCP server and the Web Server Unit

are not in the same network.

It operates on the network address

that is set by the user.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 20

3-7

● Serial Communication Setting Procedure

The W eb Server Unit and PLC are connected by serial communication. Settings

such as the baud rate, data length,

stop bit, parity bit and flow control are needed. To set Web Server Unit serial communication, open the System

Setting Screen, and select [Serial Ports] on the left menu to display the screen below.

The MicroSmart serial com

munication def

aults are shown below. Normally, there is no need to change the initial

values of these items.

3_1_8 Serial_Port_Setting_E

Serial port communication settings

Baud Rate: 9600 bps

Data Bits: 7 bits

Parity: Even

Stop Bits: Bit 1

Flow Control:None

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 21

3-8

● Other Function Settings

The other Web Server Unit settings are described below.

1) Security

Sets the user name and password. The setting is enabled to open the system screen or to use WindLDR for

communication. The settings are applied after bei

ng saved.

3_1_9_Password_Setting_E

Password setting

Checking the [Enable password authentication] check box allows you to input the user name and password.

2) Mail Sending

Used to send messages from external devices as specified by the startup conditions. See Sec

tion 3-5, “Mail

Sending Function”.

3) Administration

Backup/Restore: Used to save or restore the current Web Server Unit settings.

Restore Factory Def

aults: Restores the Web Server Unit to the settings i

t had at the time of factory shipment.

System Information: Displays the Web Server Unit’s system information.

Reboot: Restarts the Web Server Unit.

PLC Monitor: Displays the connected PLC’

s status information.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 22

3_1_10_PLC_Monitor_E

PLC monitor

3-9

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 23

CHAPTER 3

MODULE OPERATION

Remote Maintenance Function

2

3-10

This section describes the Web Server Unit’s remote maintenance function. Use this function to perform

remote PLC maintenance from WindLDR via the Web Server Unit.

■ System Configuration Example

Use Ethernet to connect the Web Server Unit to a PC with WindLDR version 4.70 (or a later version) installed.

Make the network settings before han d to enable a LAN or cross-cable connection.

3_2_1_LAN_Connection_Image_E

Illustration of LAN connection

Ethernet

Ethernet

User program download

Rout er

Rout er

Web Server Unit + MicroSmart

Web Server Unit + MicroSmart

Monitor Dialog

Download di alog

Read/Write of the operand

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 24

3-11

■ WindLDR Settings

● Communication Setting Dialog

Select [Configure]→[Communication S

ettings]→[Ethernet], and press [OK]. A dialog for selecting the Web Server

Unit is displayed the next time you start communication. Set the communication target to start.

3_2_2_Communication_setting_E

Communication setting (Selecting Ethernet)

The screen below appears when communication starts. By pressing the [Search] button, the list of the Web Server

Unit information appears in the W indLDR screen. Or otherwis e, using the [Add ] b utton enter the IP address and add

the item for the list. Then select the communication target from the list and press [OK].

3_2_3_Communication_Target_Setting_E

Communication setting (Selecting the target IP address)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 25

3-12

■ Web Server Unit Settings

To perform remote maintenance, the Web Server Unit’s network settings must enable connection, as shown below.

● Network Services Settings

TCP/IP port 2101 ON (default). You can access [Network Services

] from [Configuration] → [Serial Ports] →

[Network Services].

3_2_4_TCP_IP_Setting_E

TCP/IP settings

● Serial Settings

Leave at the default settings. You can access from [Configuration] → [Ser

ial Ports] → [Basic].

3_2_5_Serial_Setting_E

Serial settings

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 26

3-13

■ Remote Maintenance From WindLDR

You can perform PLC remote maintenance from WindLDR via the Web Server Unit. Among the online functions

supported by the serial port, the functions below can be used on the network.

• Online Monitor

• Communication Error

• Upload Program

• Verify Program

• Download Program

• Partial Program Download

In some communication environments, it takes time to transfer the data. Set the timeout

v

alue in the WindLDR c

ommunication settings and PLC communication settings as

needed.

If the communication time-out occurs at ti me of do wnload b y w a y of W eb Server Unit , set

th

e time-out v

alue - [Configure]→[Communication Settings]→[Timeout] - longer than the

current value. For reference, if the program size is 32 KB, the time-out value is greater

than or equal to 2,400×10m sec, though this value is somewhat different depending on

the network situations.

When user name/password authentication is s

et in the Web

Server Unit, you will be

prompted for authentication during WindLDR communication access. Enter the user

name and password. Communication starts when authentication has been performed.

■ SCADA Software/OPC Server

Using the Web Server Unit with an OPC server or SCADA that supports Ethernet enables Ethernet-based

MicroSmart data reading/writing. This feature enables graphical operation monitoring, and servicing/maintenance

with an outstanding GUI.

Confirmed software

WindSRV, IDEC Corporation

For more detail, please contact IDEC.

NOTE

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 27

CHAPTER 3

MODULE OPERATION

Web Server Function

3

3-14

The Web Server Unit’s Web server function enables operations such as PLC monitoring using a Web

browser with Java applets.

■ PLC Operand Monitor

A PLC operand monitor is provided as a sample program. The PLC operand monitor is not installed in the Web

Server Unit with the initial settings at time of factory shipment. You must upload the sample PLC operand monitor

from the CD-ROM provided.

● System Configuration Example

First make the network settings, then connect the Web server to a PC with a Web browser usi

ng a LAN or cross

cable. When monitoring, MicroSmart should be connected to the Web Server Unit and activated.

3_3_1_LAN_Connection_Image_E

Illustration of LAN connection

Ethernet

Ethernet

Rout er

Router

Web Server Unit + MicroSmart

Web Server Unit + MicroSmart

Simple Monitor / Web Browser

Operand Monitor / Web Browser

Read/Write of the operand

Read/Write of the oper and

The PC must be able to run a Web browser (such as Internet Explorer), and JavaScript and Java applets must be

enabled.

● Web Browsers

Confirmed Web browsers:

Internet Explorer 6.0, Netscape 7.1

* The Java VM running environment is required.

● Uploading PLC Monitor Sample Scr

een

How to

upload the PLC monitor screen is described below. At time of factory shipment, the PLC monitor screen is

not installe

d in the Web Server Unit. (Use the Java Applet Monitor from the CD-ROM.)

Due to restrictions on server file volume capacity, the System Setting Screen and Java applet monitor can’t coexist.

How to upload the sample program (Java applet) is described bel

ow, u

sing Internet Explorer 6.0 as an example.

1. Start Internet Explorer.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 28

3-15

2. In the address bar, enter the Web Server Unit’s IP address and the file name, as shown below (example: when

the IP address is 192.168.1.101). The settings screen for management appears.

http://192.168.1.101/home.htm

The screen below appears.

3_3_2_Master_Setting_E

Settings screen for management

3. Open the [File Management] screen and delete the files currently in the server. Select [File Management] from

the menu on the left. The screen below appears.

3_3_3_File_Management_E

File Management screen

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 29

3-16

4. Check all files under [Manage Files], and click [Delete]. The files are deleted and the screen below appears.

5. You are now ready to upload the files. Upload the two files below. The sample program consists of the applet

that generates the monitor screen and the HTML file that runs the applet.

3_3_4_Delete_Files_E

Screen after the files are deleted

3_3_5_1_File_Folder_E

Instruction

Manual

Setting Files

Sample

Program

-

index.htm

operandapp.jar

CD

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 30

3-17

6. Click the [Browse...] button, and select the desired file by clicking on it. Click the [Upload] button. Repeat this

process to upload the two files. When uploading has finished, the screen below appears.

7. Click [Home] on the left menu. To mak e the screen the initial screen, click [Set as Default] in the screen below.

The next time you open the Web browser, the default screen displayed when this server is accessed will be the

PLC operand monitor. (Restart the Internet Explorer.)

3_3_5_Upload_Files_E

Screen after uploading the file is completed

Set as Default screen

3_3_6_Set_As_Default_E

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 31

3-18

8. To restore the original system setting screen, repeat Steps 1 to 4 to delete all the files, then upload all the files

below by the method of Step 6. Next, click 'Set as Default' as in Step 7 to make the system setting screen the

default screen.

● PLC Operand Monitor

An operation example using the sample program (Ja

va applet) is give

n below. This example is for Internet Explorer

6.0.

1. Enter the Web Server Unit’s IP address in the address bar as shown below (exam

ple: when the IP address is

192.168.1.101).

http://192.168.1.101/

2. The initial screen starts the sample program (PLC operand monitor). Program downloading starts, and a

warning dialog appears asking whether to start the applet. Select [Yes] or [Always]. If you select [Always], this

dialog will not appear the next time the sample program starts.

3_3_5_1_File_Folder_E

Instruction

Manual

-

inde x.htm

comm on.jar

CD

Setting

Files

Sample

Program

configapp.jar

config.ini

3_3_7_Warning_Dialog_E

Warning dialog

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 32

3-19

3. IDEC operand monito r starts. If you have set the user name and password in the Web Server Unit in advance,

you are prompted to enter them.

4. You can no w perform operand monitoring and writing. Select the operand type and enter the address. Addresses

are 4 digits. Five consecutive addresses can be written or monitored at the top part. Enter the values in the input

field and press the [Write] button to write the values.

Operand types

I/X Input (word) i/x Input (bit)

Q/Y Output (word) q/y Output (bit)

M Internal relay (word) m Internal relay (bit)

R Shift register (word) r Shift register (bit)

T Timer (set value)

t Timer (count value)

C Counter (set value)

c Counter (count value)

D Data register

Display formats

DEC(W) Decimal (unsigned) DEC(I) Decimal (signed)

DEC(D) Decimal (unsigned), 2 words DEC(L) Decimal (signed), 2 words

HEX(W) Hexadecimal HEX(D) Hexadecimal, 2 words

BIT Bit

• The PLC operand monitor screen is stored in the Web Server Unit, but executed by the

PC.

• The Java applet performs communication between the PC it runs on and the Web

Server Unit.

• The W

eb Server Unit relays commands receiv ed on Ethernet (TCP/IP) to the PLC, and

returns the PLC's reply on Et

hernet (TCP/IP).

NOTE

3_3_8_Operand_Monitor_E

Operand Monitor Java Applet

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 33

3-20

■ User Screen Creation

The original PLC monitor screens can be made and built into the Web Server Unit. Also the sample page can be

referred to this programming. To make these screens, the knowledge for Java Applet is required. For more

information, see the Sun Microsystems Inc. web site.

● Sample Program Creation Environment

The sample program PLC operand monitor was created on

Java 2 SDK Standard Edition version 1.4.2, and Ant 1.6.

● Creating/Uploading

The sample program source code is included in the CD-ROM provided. The CD-R

OM also includes referential

materials such as the Java.doc file.

To upload a created HTML file or Ja

va appl

et, see the previous section of “Uploading PLC Monitor Sample

Screen”.

• Security precautions and other adaptations should be made when running them on the network.

CAUTION

!

• Sample programs are provided as is, and their operation is not always guaranteed.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 34

CHAPTER 3

MODULE OPERATION

Ethernet User Communication Function

4

3-21

This section describes Ethernet user communication for the Web Server Unit.

MicroSmart user communication can support Ethernet via the Web Server Unit.

■ System Configuration Example

Ethernet user communication enables the Web Server Unit to communicate between MicroSmart modules or

communicate with another device (with an IP address set).

3_4_1_Ethernet_User_Communication_E

Example of a system configuration f or Ethernet user communication

Ethernet

Ethernet

Rout er

Rout er

Web Server Unit + MicroSmart

Transmit data

with TXD command

Receive data

with RXD command

Transmit data with

TXD command

Receive data

with RXD command

.

Conditions for Ethernet user communication

1) Remote comm unication device

The Ethernet user communication feature enables user communication using the TCP

protoco

l client function. A device with a TCP protocol server function must be selected as

the remote communication device.

2) Number of remote communication devices

Ethernet user communication can only be performed wi

th the registered IP address po

rt No.

In other words, there can only be one remote communication device.

3_4_2_User_Communication_E

Conditions for Ethernet user communication

Ethernet

Data transmissio n

Data reception

Only one communication

target is avail able.

NOTE

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 35

3-22

■ Web Server Unit Settings

Follow the procedure below to make the Web Server Unit settings.

● Switching Web Server Unit Mode

Turn the Web Server Unit’s mode selection switch to “USER”.

* The default setting of the Web Server Unit’s mode selection switch is “REMOTE”.

3_4_3_Toggle_Switch_E

Function selector switch

USER

Make the switch the “USER”!

REMOTE

Performing Ethernet user communication between MicroSmart modules

T o p erform Et hernet u ser commun ication between Micro Smar t modul es, the onl y operat io n needed

for the Web Server Uni

t on the TCP protocol server is to set the mode selection switch to “USER”.

The rest of the setting procedure is giv en i n the descri ption of t he TCP prot ocol client sett ings.

● Opening Web Server Unit System Setting

Screen

Open the W eb Server U

nit’s settings screen.

There are two ways to open this screen:

1) Opening settings screen from WindLDR (see “System Setting Screen” in Section 1 of Chapter 3 for more inf

ormation)

1. Select [Setting Web Server Unit] in WindLDR.

2. The previously

set IP address appears in the WindLDR screen.

3. Doub le-click the IP address of the Web Server Unit performing Ethernet user communication. The Web

browser starts, and the System Setting Screen as below appears.

2) Opening setting s screen directly from Web browser

1. Start the Web browser.

2. In the Web browser’s address bar, enter the IP address of the Web Server Unit performing Ethernet user

communication, and press the Web browser’s [Refresh] button or the keyboard’s Enter key.

3. The System Setting Screen appears.

NOTE

3_4_5_System_Setting_E

System Setting Screen

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 36

3-23

● Setting TCP Client Mode

1. Specify [Serial Ports] in the left menu of the system setting screen, and select the [Port Services] tab.

2. Check the [TCP Client]- [Enable TCP client service] check box.

3_4_6_System_Setting_Screen_Alarms_E

Port Services

3_4_7_Alarm_IP_Address_E

Enable TCP client service

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 37

Difference betwe en [Always] and [When data present on serial line]

[Always] and [When data present on serial line] each specify a dif

ferent timing for sending the

request to establish the communication path to the remote communication device.

Item Timing for sending request to establish communication path

Always When power is turned ON

When data present on serial line When register ed data is received from serial line

When [When data present on serial line] is selected

The registered character string used to star

t Ethernet user communication is the trigger for sending

a communication path establishment request to the remote communication device. It is also data

sent to the remote communication device. In other words, the registered character string is sent to

the remote communication device. If this registered character string is not needed by the remote

communication device, it must be deleted by the remote communication device’s settings or

receiving program.

3-24

3.

Select [Always] or [When

data present on serial line].

4. When selecting [When data present on serial line], enter the character string used for starting Et

hernet user

communication in the [initial match string] field.

You can enter up to 31 characters (only single-byte alphanumeric characters).

NOTE

NOTE

3_4_8_Portservice_TCP_Cliant_E

TCP client connecting conditions

3_4_9_Initial_Match_String_E

Enlarged character string input screen

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 38

3-25

5. Click the [Save] button, and the [Reboot] button on the left menu to complete the setting procedure.

3_4_10_Portservice_reboot_E

Reboot screen

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 39

3-26

■ MicroSmart Settings

MicroSmart user communication commands are used to perform Ethernet user communication.

● User Communication Command Settings

For more information on user communication, see Chapter 17, “User Communication

Ins

truct

ions” in the MicroSmart instruction manual.

1. Set the MicroSmart port for performing Ethernet user communication (1st or 2nd port).

In WindLDR, select [Configuration] → [Function Area S

ettings] → [Communication] tab.

Select the port to use for Ethernet user communication under [User Protocol].

3_4_11_Usercom_Port_Setting_E

User protocol selection

2. Enter the user communication command in the ladder program.

Enter the TXD command or RXD command in the ladder program.

3_4_12_TXD_RXD_Command_E

TXD and RXD commands in a ladder program

3. Download the ladder program.

In WindLDR, select [Online] → [Downloa

d Program...] → [Download].

When [When data present on serial line] is set in the Web Server Unit settings

When [When data present on serial line] is set for the Web Server Unit’s TCP client mode, be sure

to make the character s

tring registered in the W eb Serv er Unit the same as the character string data

used by the TXD command. Ethernet user communication is only possible when the strings are

the same.

NOTE

NOTE

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 40

3-27

■ Ethernet User Communication Sample Program

● Communication Between MicroSmart Modules

System configuration

3_4_15_Between_Microsmart_E

Communication between MicroSmart modules

Ethernet

Web Server Unit B

IP address: 192.168.1.5

TCP protocol server mode

IP address: 192.168.1.5

(1) Data transmission

(2) Data rece ption

(3) Data transm ission

(4) Data rece ption

The setting of Web Server Unit A

IP address: 192.168.1.2

TCP protocol client mode: "Always"

Target IP address: 192.168.1.5

Service: RAW

Connected Port No.: 2101

MicroSmart A

MicroSmart B

Web Server Unit A: TCP protocol (Client mode)

Web Server Unit B: TCP protocol (Server mode)

MicroSmart A

MicroSmart B

1) MicroSmar t A transmits data with the TXD command, and becomes

ready to receive data with the

RXD

command. Web Server Unit A transmits the data sent from MicroSmart A to Web Server Unit B (to which the

target IP address, the service and the target port number are registered).

2) Web Server Unit B receives the data addressed to it, and transmits data to MicroSmart B. MicroSmart B

receives the data with the RXD

command.

3) MicroSmar t B transm its data wi th the TXD command. Web Server Unit B transmits the data sent from

MicroSmart B to Web Serv

er Unit A.

4) Web Server Unit A receives the data addressed to it and transmits data to MicroSmart A. MicroSmart

A receives

data with the RXD command.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 41

3-28

● Sample Ladder Program

MicroSmart on Web Server Unit A side

3_4_16_Between_Microsmart_Sample_E

If the start input M0000 is turned on, MicroSmart transmits 4-byte data from port 2, and becomes ready to receive

data.

MicroSmart on Web Server Unit B side

3_4_17_Between_Microsmart_Sample_E

When it finishes receiving 4-byte data from port 1, and then transmits 4-byte data from port 1.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 42

CHAPTER 3

MODULE OPERATION

Mail Sending Function

5

3-29

This section describes the Web Server Unit’s mail sending function.

You can use MicroSmart’s user communication functions to send messages to devices that can receive

mail from PCs or similar devices.

■ System Configuration Example

3_5_1_Message_Sending_System_E

Configuration example of mail transmission system

The Internet

E-mail

To: AAA@BBB

Subject: ERROR

Transmit the t rigger signal

of sen ding alarm mail

E-mail

From: CCC@DDD

Subject: ERROR

Mail server

Mail server

Conditions for using mail sending functi on

1) Mail server

A mail server IP address is needed to send messages. Ask your network admini

strator for

your mail server IP address.

NOTE

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 43

2) Messages

• The character strings registered in the Web Server Unit (up to 63 sing

le-byte

alphanumeric characters) can be sent as messages utilizing the subject column of the Email.

• The message body is fixed to “Data Pattern Alarm”.

• You can specify up to 32 dif

ferent messages (subjects), with 2 recipient mail addres

ses

for each.

• You can set recipient mail addresses of up to

64 single-byte alphanumeric characters.

• Mail sending timing: Messages are sent only when the character string registered in the

Web Server Unit is receiv

ed from the serial line.

3_5_2_Message_Sending_Condition_E

Illustration of mail transmission

12:00

26 May 13:15

Sub: Temp. High

Data Pattern Alarm

From: WebAlart@idec

To: abcdefg1234@idec;

hijkim5678@idec

From: WebAlart@idec

Subject: Temp. High

Data Pattern Alarm

3-30

■ Web Server Unit Settings

Follow the procedure below to make the Web Server Unit settings.

● Switching Web Server Unit Mode

Set the Web Server Unit’s mo de selection switch to “USER”.

* The default set

ting of the Web Server Unit’s mode selection switch is “REMOTE”.

3_5_3_Toggle_Switch_E

Function selector switch

USER

Make the switch the “USER”!

REMOTE

● Opening Web Server Unit System Setting Screen

Open the W eb Server Unit’s setting screen.

There are two ways to open this screen:

1) Opening setting s screen from WindLDR (see “System Setting Screen” in Section 1

of Chapter 3 for more

information).

1. Select [Setting Web Server Unit] in WindLDR.

2. The previously set IP address app

ears in the WindLDR screen.

3. Doub le-click the IP address of the Web Server Unit performing Ethernet user communication. The Web

browser starts, and the System Setting Screen as below appears.

2) Opening setting s screen directly from Web browser

1. Start the Web browser.

2.

In the Web brow

ser’s address bar, enter the IP address of the Web Serv er Unit performing Ethernet user

communication, and press the Web browser’s refresh button or the keyboard’s Enter key.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 44

3_5_5_System_Setting_E

System Setting Screen

3-31

3. The System Setting Screen appears.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 45

3-32

● Alarms

1. Specify [Alarms] on the left menu of the system setting screen, and check the [Enable sending alarms] check

bo

x.

2. Enter the mail server’s IP address in the [SMTP server address] field, and the Web Server Unit’s mail address*

in the [From] field.

* Ask your network administrator for the mail address.

Mail server settings

3_5_7_Alarm_IP_Address_E

3_5_6_System_Setting_Screen_Alarms_E

Alarms

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 46

3-33

3. Check the [Enable alarm] check box and enter the recipient mail address in the [To1:] field (and [To2:] field

when sending to two addresses).

4. Enter the message text in the [Subject] field.

NOTE

Recipient mail addresses

The total character number of target addresses, [To1:] plus [To2:], ha ve to be within 64 characters.

NOTE

Messages ([Subject] field)

The total message length for a single message is up to 63 characters.

3_5_8_Alarm_Sending_Address_E

Target address

3_5_9_Alarms_Subject_E

Subject

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 47

Mail send timing character strings

The W eb Server Unit can register up to 32 dif ferent messages. The send timing char

acter string for

each message must be unique.

3-34

5. Select [pattern_match], and enter the message send timing character string.

6. Click the [Save] button, and the [Reboot] button on the left menu to complete the setting procedure.

NOTE

3_5_10_Alarms_Pattern_Match_E

Mail send timing character string

3_5_11_Alarms_Reboot_E

Reboot screen

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 48

3-35

■ MicroSmart Settings

MicroSmart user communication commands are used to send messages.

● User Communication Command Settings

For more information on user communication,

see Chapter 17, “User Communication

I

nstructions” in the MicroSmart instruction manual.

1. Set the MicroSmart port for performing Ethernet user communication (1st or 2nd port).

In WindLDR, select [Configuration] → [Function Area S

ettings] → [Communication] tab.

Select the port to use for Ethernet user communication under [User Protocol].

3_5_12_Usercom_Port_Setting_E

User protocol selection

2. Enter the user communication command in the ladder program.

Enter the TXD command in the ladder program.

NOTE

3_5_13_TXD_Command_E

Example of communication command in a ladder program

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 49

3-36

3. Download the ladder program.

In WindLDR, select [Online] → [D

ownloa

d Program...] → [Download].

Web Server Unit settings and user communication command settings

Be sure to make the Web Server Unit’s send timing character string (Pattern) th

e same as the

MicroSmart TXD command data.

3_5_14_Same_String_Setting_E

Example of character string for sending timing

NOTE

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 50

3-37

■ Sample Program for sending messages

● System Configuration

3_5_15_Sample_System_Configration_E

Example of sending a sample mail (System config u ration)

EthernetEthernet

The setting of Web Server Unit

IP address: 192.168.1.2

SMTP server: 192.168.1.5

From: AAA@BBB

To1: CCC@BBB

Message text strings: ERROR

Pattern: temp

SMTP (mail) Server A

IP address: 192.168.1.5

Mail server B

From: AAA@BBB

To: CCC@BBB

Subject: ERROR

Data Pattern Alarm

(1) TXD command: Data transmission (temp)

(2) Transmi t the alarm mail data

to the SMTP Server

(3) Receive the alarm mail data

from the Mail Server B

(4)Personal Computer

MicroSmart:

1) MicroSmart transmits data (the alphanumeric characters: temp) with the TXD command.

Web Server Uni

t:

2) Web Server Unit compares data transmitted from MicroSmart with th

e pattern that is registered. If data are

corresponding with it, W eb Server Unit transmits the alarm mail data that is registered to the SMTP server.

Mail server:

3) Mail server transmits the alarm mail data sent from Web Server Unit to the targeted mail address.

Personal Computer:

4) The personal computer receives the mail in w

hich the subject is used as

a message character string. This string

is registered to the Web Server Unit in advance.

● Sample Ladder Program

3_5_16_Sample_Ladder_Program_E

If the start input M0200 is turned on, MicroSmart transmit the character string of “temp” from its port 1.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 51

3-38

CONNECTION DIAGRAM

■ PLC connecting cable (Model No.: FC4A-KC3C, Cable Length : 10cm)

● The external of cable

4_1_1_Connection_Diagram_E

MicroSmart Side Web Server Unit Side

● The pin layout of connectors

4_1_2_Connection_Diagram_E

8

7

6

3

2

1

45

● The connection diagram of cable

4_1_3_Circuit_Diagram_CabÇåe3_E

1DSR

2CTS

3SD

4RD

5RTS

6 NC

7GND

8DTR

Cover Shield

Web Server Unit Side

Pin Number

Name

Pin Number

Port 1 Port 2

1 NCRS

2 NCER

3SD

4RD

5 NCDR

6CMSW SG

7SGSG

8 NC NC

Cover Shield

MicroSmart Side

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 52

3-39

TROUBLESHOOTING

■ The following troubles and solutions could be considered

● When power display LED (PWR) does not go on

5_1_1_Trouble_Shooting_E

The PWR LED does not go on.

Is the power supplied?

Is the PWR LED on?

Supply power.

Is the power voltage

correct?

Apply the rated voltage, 24V DC.

Is the PWR LED on?

Call IDEC for assistance. END

YES

NO

NO

NO

NO

YES

YES

YES

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 53

3-40

● It is not possible to communicate with WindLDR

5_1_2_Trouble_Shooting_E.eps

It is not possible to

communicate with WindLDR.

Is the Ethernet cable

connected?

Connect the Ethernet

cable.

Is the PLC connection

cable connected?

Connect the PLC

connection cable.

Extend the communication

timeout value of the WindLDR!

Make the function

selector switch to the

"REMOTE".

YES

NO

Is the network address of the

Web Server Unit correct?

Set the network address

of the Web Server Unit.

(Refer to Chapter 3-1.)

Is the position of the function

selector switch the “REMOTE”?

Is the serial communications

setting of the Web Server Unit the

same as the setting of the PLC?

Set as well as the serial

communication setting of

the PLC.

Is the port of the PLC the

maintenance mode?

Make the port of the PLC

to the maintenance mode.

Extend the reception timeout

value of the PLC!

[Configure][Communication

Settings]-[Timeout]

Can you communicate with

WindLDR?

Select [Configure]-[Function Area

Settings]-[Communication][Maintenance Protocol][Configure]-[Receive Timeout] and

set the timeout value. Then

connect the PLC to the WindLDR

by the serial connection and

download the program.

Can you communicate with

WindLDR?

Call IDEC for assistance.

END

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

YES

YES

NO

NO

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 54

3-41

● Ethernet user communication does not operate normally

5_1_3_Trouble_Shooting_E

Ethernet user communication

does not operate normally.

Is the Ethernet cable

connected?

Connect the Ethernet

cable.

Is the PLC connection

cable surely connected?

Connect the PLC

connection cable.

Make the function

selector switch to the

"USER".

YES

NO

Is the address of the transmit/

receive target correct?

Set the network address

of the Web Server Unit.

(Refer to Chapter 3-4.)

Is the position of the function

selector switch the "USER”?

Is the serial communication

setting of the Web Server Unit the

same as the setting of the PLC?

Set as well as the serial

communication setting of

the PLC.

Is the port of the PLC the user

communication mode?

Make the port of the PLC

to the user

communication mode.

Extend the reception timeout

value of the PLC!

Select [Configure]-[Function Area

Settings]-[Communication]-[User

Communication]-[Configure]-[Receive

Timeout] and set the time-out value.

Then connect the PLC to the WindLDR

by the serial connection and download

the program.

Can you communicate with

the communication target?

Call IDEC for assistance.

END

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

YES

NO

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 55

3-42

● When the alarm mail is not transmitted

5_1_4_Trouble_Shooting_E

The alarm mail is not transmitted.

Is the Ethernet cable

connected?

Connect the Ethernet

cable.

Is the PLC connection

cable connected

Connect the PLC

connection cable.

Make the function

selector switch to the

“USER”.

YES

NO

Is the mail sending function

setting of the Web Server Unit

correct?

Set the mail sending

function of the Web

Server Unit (Refer to

Chapter 3-5.)

Is the position of the function

selector switch the “USER”?

Is the serial communication

setting of the Web Server Unit the

same as the setting of PLC?

Set as well as the serial

communications setting

of the PLC.

Is the port of the PLC the user

communication mode?

Make the port of the PLC

to the user

communication mode.

Is the alarm mail

transmitted?

Call IDEC for assistance. END

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

YES

NO

Are the pattern of the

transmission condition and the

transmission data with the TXD

command the same?

Make the pattern of

the transmission

condition the same as

the transmission data

with the TXD

command!

NO

YES

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 56

A-1

GLOSSARY

ICMP (Internet Control Message Protoc ol)

An IP-layer protocol used to transfer error messages and control messages. Used for mutual

status confi

rmation between computers or network devices connected by TCP/IP.

DHCP (Dynamic Host Configuration Protocol)

A method of dynamically assigning IP addresses to network devices on a LAN. The DHCP

server dynamically assi

gns a single preset IP address to each network device when the device

starts.

IP (Internet Protocol) address

The 32-bit address information us

ed to identify each device on a TCP/IP network.

IP addresses

are unique numbers assigned to devices that use IP to communicate. They are used to specify the

recipient device when exchanging data.

Subnet mask

The mask value used when requesting a subnet network address from an IP address. The IP

address and subnet mask are combined by

an AND operation to obtain the subnet address.

The IP address is divided into a network address No. and host address No., and the network

address is further divide

d into the subnet.

Port No.

An auxiliary address created at a lower level than the IP address, used to connect multiple

recipients at the same time during TCP/IP comm

unication. Numbers from 0 to 65535 are used to

specify ports. Data is sent/received using the combination of IP address and port No.

TCP (Transmission Control Protocol)

The standard protocol used on the Internet. Corresponds to the OSI (Open Systems

I

ntercon

nection) reference model transport laye r. Bridges the network-layer IP and protocols

above the session layer (such as HTTP, FTP, SMTP and POP).

HTTP (Hypertext Transfer Protocol)

The protocol used between the Web browser and Web server to send and receive data such as

HTML

files.

SMTP (Simple Mail Transfer Protocol)

The protocol used to send email on a TCP/IP network.

Java

An object-oriented interpreter language developed by Sun Microsystems, Inc.

JavaScript

A script language developed by Netscape Communicati

ons Corporation. Based on Net

scape’s

LiveScript. Incorporates some Java features.

Java VM

An environment for interpreting/executing programs using intermediate codes generated by a

Java compiler.

J

ava applets

Java programs downloaded from the network by the Web browser, and embedded in and

executed by

browser windows.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 57

A-2

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 58

INDEX

A

Alarms

Sending alarms .........................................3-32

B

Backup .............................................................3-8

C

Communication between MicroSmart modules 3-27

Communication settings

WindLDR ................................................3-11

Connection port ...............................................2-2

Cross-cable ......................................................3-2

D

DHCP server ....................................................3-6

E

Ethernet user communication ........................3-21

F

Function selector switch ..................................2-2

J

Java applets ....................................................3-14

L

LINK LED .......................................................2-2

M

Mail send timing ............................................3-34

Mail sending function ....................................3-29

Mail server .....................................................3-29

Messages .............................................. 3-30, 3-33

N

Network address ..............................................3-2

Network address setting ...................................3-5

Network LED ...................................................2-2

O

OPC server .....................................................3-13

Other function ..................................................3-2

P

PLC Monitor ....................................................3-8

PLC operand monitor ....................................3-18

Power display LED ..........................................2-2

R

Reboot ..............................................................3-8

Recipient mail addresses ................................3-33

Remote maintenance ............................ 3-10, 3-13

Restore .............................................................3-8

Restore Factory Defaults ..................................3-8

S

SCADA ..........................................................3-13

Security ............................................................3-8

Java applet ..................................................3-4

Password ..................................................3-13

Serial communication ......................................3-2

Serial communication setting ...........................3-7

System configuration .......................................3-2

System Information ..........................................3-8

System Setting Screen

Web browser ............................................3-22

WindLDR ......................................... 3-3, 3-22

T

TCP client mode ............................................3-23

Always .....................................................3-24

When data present on serial line ..............3-24

Timeout ..........................................................3-13

U

User communication

Sending messages ....................................3-35

User communication command .....................3-26

User screen .....................................................3-20

W

Web server function .......................................3-14

WindLDR .......................................................3-11

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Loading...

Loading...