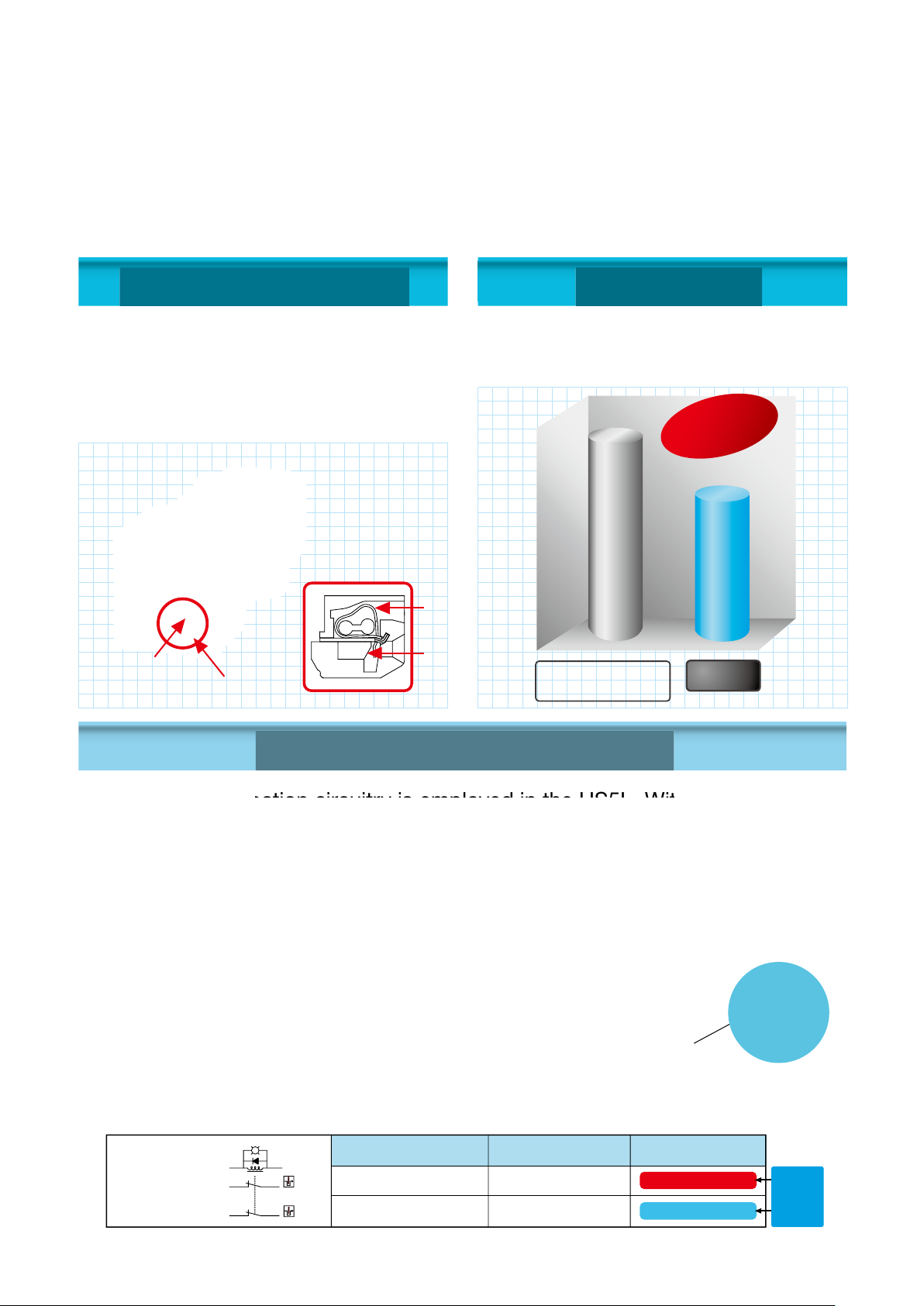

Interlock Switches with Solenoid

HS5L

2-Contact / 4-Contact

SAFETY SWITCH

Protecting workers on-site

Safety Switch

t interlock switches with solenoid.

th the required safety level, while

e features.

Interlock Switch

New 2-contac

2-Contact

Interlock switches usually have more contacts

than needed.

Many interlock switches on the market have 4 or 6 contacts. These

interlock switches are used as they are, even though that many

contacts are not used.

Designed wi

eliminating excessiv

Advantages

Enhance product value and take the lead from

your competitors by introducing a safe machine

that complies with international standards.

Product compliance with international standards are now essential,

as with ISO9000 certication.

2-contact interlock switches with solenoid

with high cost performance are ideal for

with high cost performance are ideal for

with high cost performance are ideal for

with high cost performance are ideal for

customers who want to make use of the

customers who want to make use of the

customers who want to make use of the

customers who want to make use of the

above advantages.

above advantages.

above advantages.

above advantages.

2

switches with solenoid.

fety level, while

.

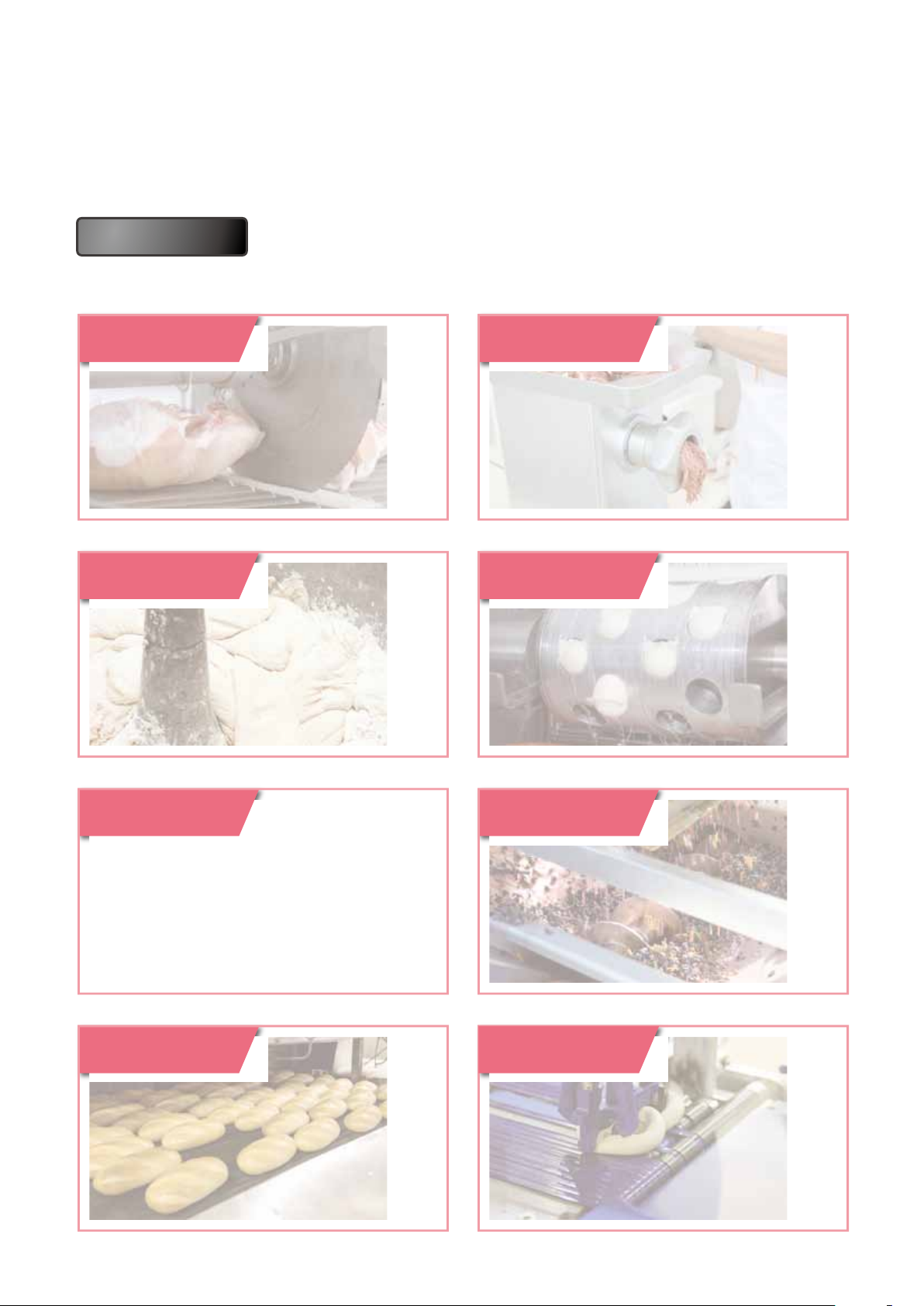

Applications

Ideal as a safety measure for use on machines that do not shut down immediately or

maintain high temperatures.

Cutting Grinding

Mixing Rotating

Packing

Squeezing

Baking Pressing

3

Safety Switch

and performance.

t interlock switches with solenoid.

Interlock Switch

IDEC ensures reliability

2-Contact

4-Contact

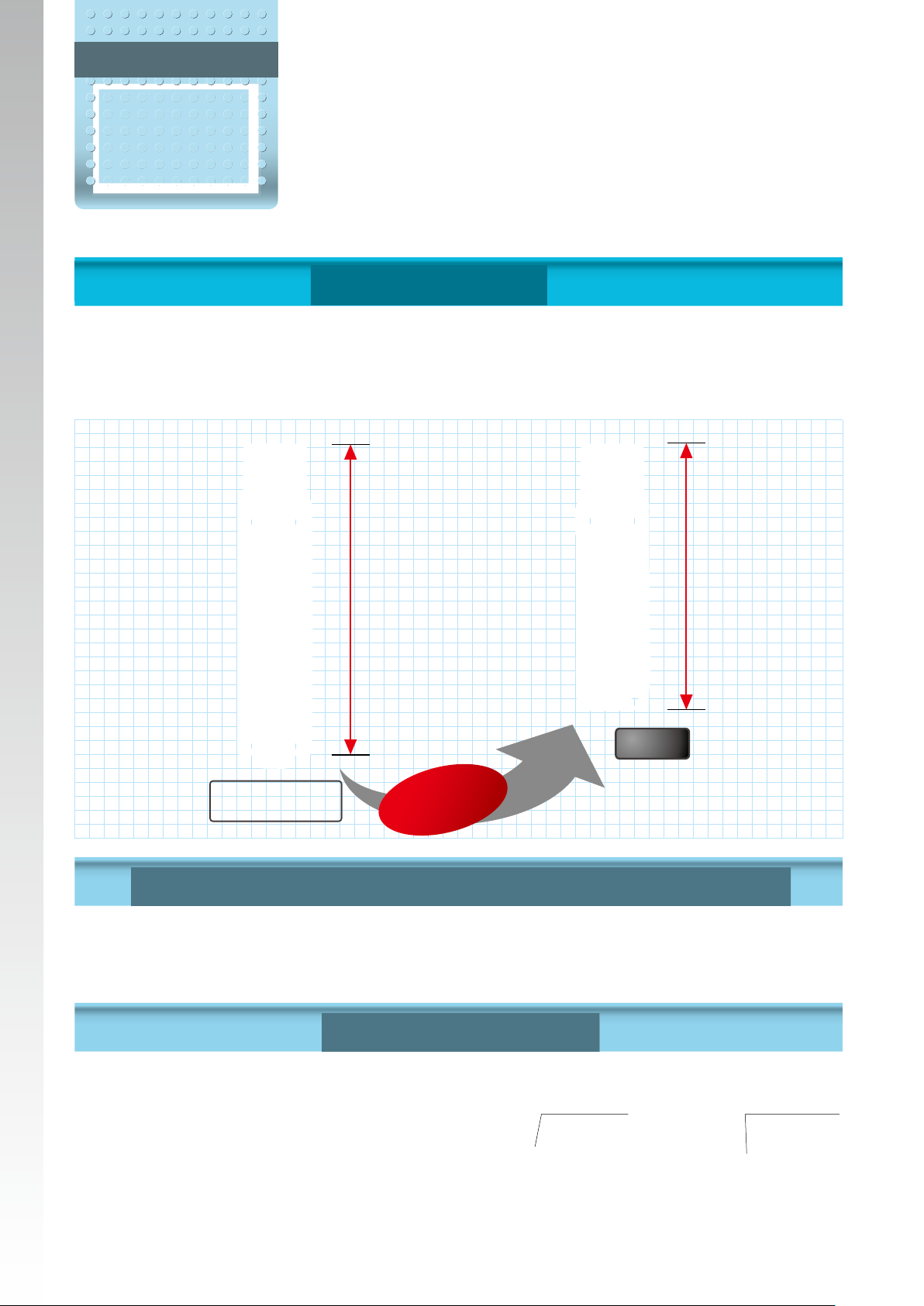

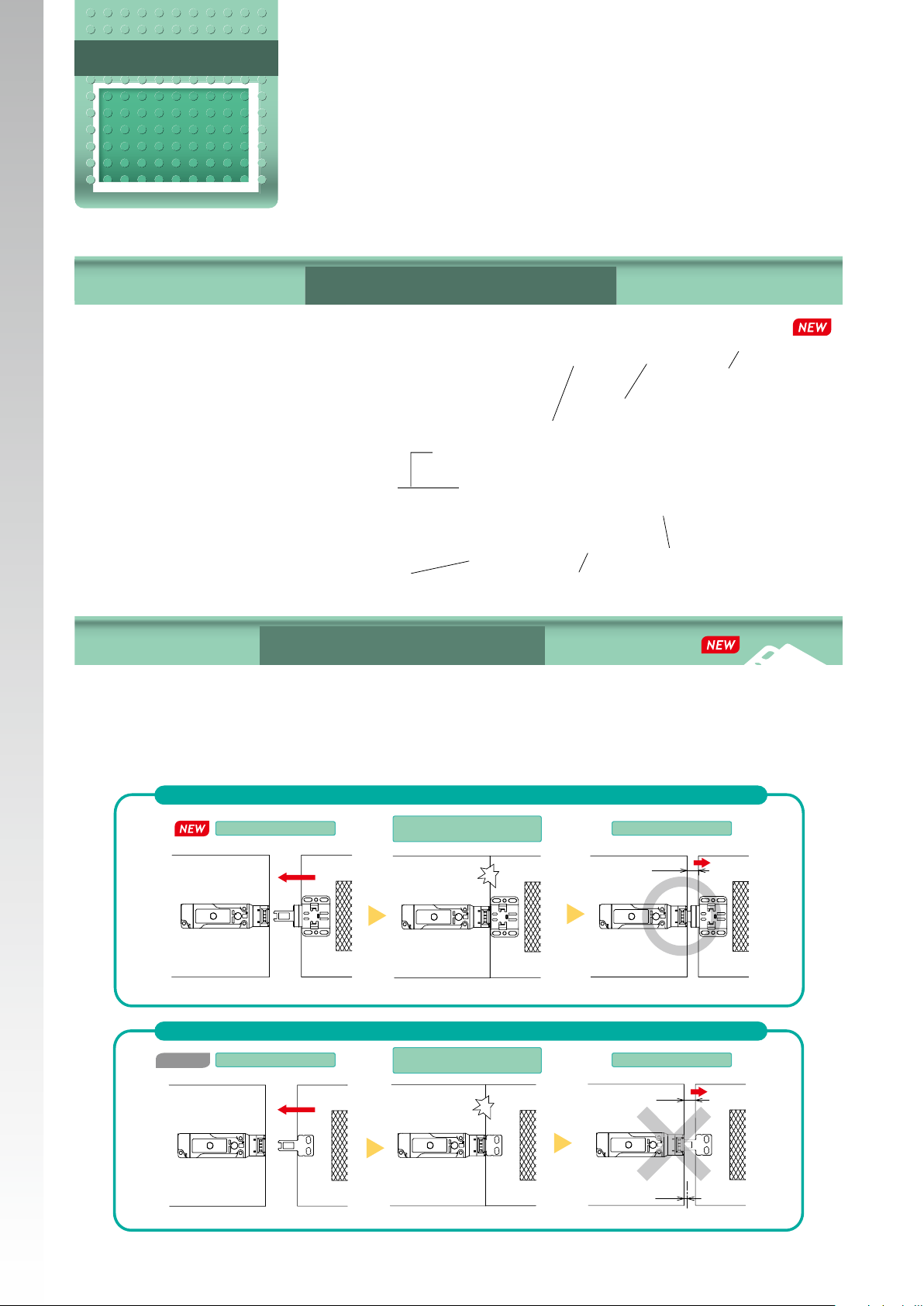

Size is reduced by 13% from conventional models.

Mounts on small doors and aluminum frames of machines.

Compact design with 2- and 4-contacts reduce installation space.

Greater exibility in machine design.

2-contact and 4-contac

Compact and slim!

127

145.7

HS5L

Conventional Model

HS5E

13%

Approx.

(Compared with IDEC products)

shorter

All dimensions in mm.

Compact design with powerful 1400N locking strength

The size is greatly reduced while achieving the same 1400N (Fzh) locking

strength as the conventional HS5E series. (GS-ET-19)

Rear unlocking button

Door lock can be unlocked inside the

barrier by a worker left inside a

hazardous area.

(Complies with escape release

dened in ISO14119 (2013) and

GS-ET-19)

Two types of unlocking buttons to suit

various applications.

4

Rear unlocking

button

Rear lock release

kit for frames

rformance.

th solenoid.

Spring clamp terminals

Spring clamp terminals offer excellent

vibration resistance, preventing wires

from loosening. No need for additional

tightening.

Driver port

Driver port

Wiring port

Wiring port

Energy saving!

Solenoid energy consumption: 200mA

Reduced by 25% from conventional

HS5E series.

266mA

Conventional Model

HS5E

Approx.

(Compared with IDEC products)

200mA

25%

HS5L

reduced

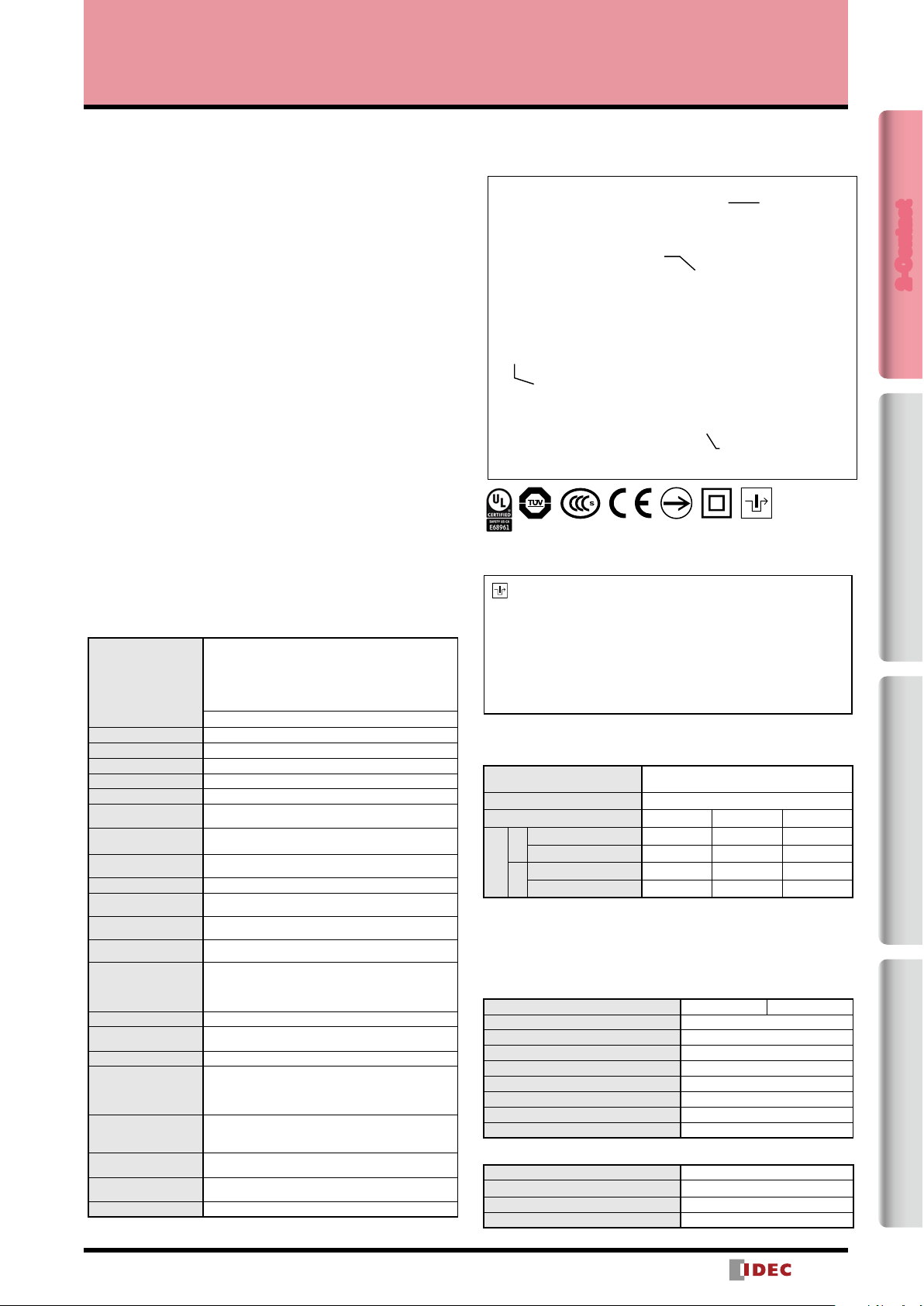

Head Removal Detection Circuitry

Head removal detection circuitry is employed in the HS5L. With this innovative

function, the monitor circuit (41-42) turns off when the head is removed from

the switch, such as when removing the head to change the head direction

(applicable with the HS5L spring lock models). For example, for circuit codes:

VB, VD and DD, which have two or more lock monitor circuits installed,

removing the head results in disparity (41-42: OFF, 51-52: ON).

This disparity is detected by the head removal detection function.

Head removal

detection function

Monitor circuit

(41-42)

● HS5L-VD44M-G (Lock monitor circuit)

(+)(−)

Lock monitor circuit

Lock monitor circuit

A2

41

A1

42

5251

Actuator

unlocked

Actuator unlocked Actuator locked Head removed

OFF ON

OFF ON

Actuator

locked

Head

removed

OFF

Disparity

ON

Note: Head removal detection function is not a direct opening action mechanism.

5

Safety Switch

Actuator

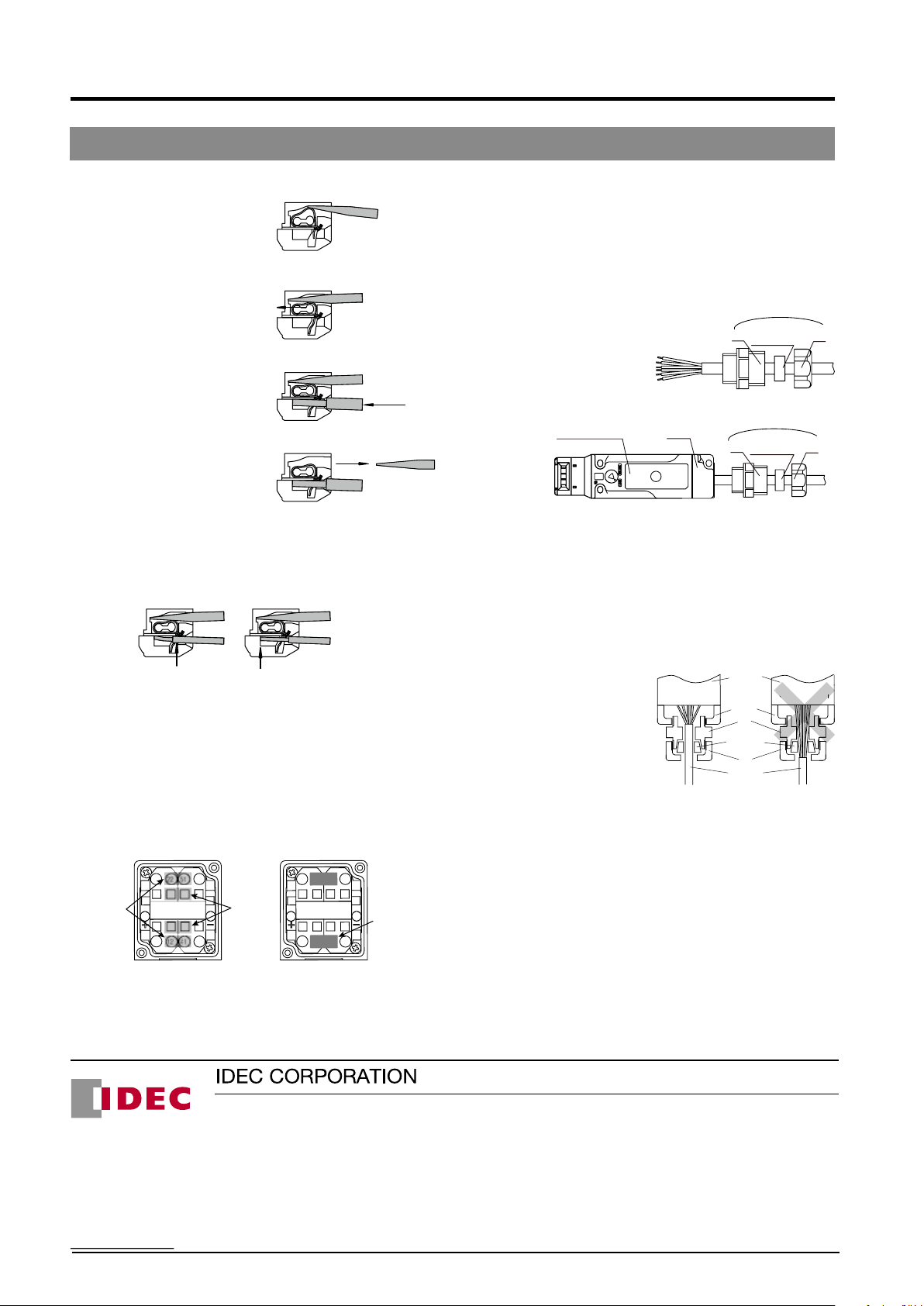

Wide variety of actuators for

interlock switches enhance

HS5 series

Actuators can be selected according to door

shapes and usage.

Actuator with rubber bushing ideal for use

•

on rattling doors.

Plug actuators ideal for use on heavily

•

rattling doors.

Movable actuators ideal for use

•

on hinged doors.

Sliding actuators for easy installation.

•

Actuators ideal for use on bouncing doors

•

also available.

exibility and usability!

Actuators can be selected according to door shapes and usage, and

can be installed exibly according to the installation site.

Wide variety of actuators

Angle Adjustable

(vertical) Actuator

Sliding Actuator

Right-angle Actuator

with rubber bushing

Right-angle Actuator

Straight Actuator

with rubber bushing

Straight Actuator

Spring Loaded

Actuator

Accessory exclusive

∗

for HS5L.

Plug Actuator

Padlock Hasp

Spring loaded actuator

IDEC patented spring loaded actuator locks the door safely when

the door bounces. When the actuator is fully inserted (door closed

completely), the door can tolerate a space of up to 16mm.

∗

HS5L interlock switch and HS9Z-BA5 spring loaded actuator

Conventional

model

(1) Insert

HS5L interlock switch and HS9Z-A51A straight actuator

(1) Insert

(2) Fully inserted

(door completely shut)

(2) Fully inserted

(door completely shut)

The door can bounce open to up to 16mm.

Locking position

of HS9Z-A51A

The door can bounce open to up to 4.6mm.

Locking position

of HS9Z-A51A

(3) Door bounces

16

Lock

(3) Door bounces

16

Patent acquired

Accessory exclusive for HS5L.

4.6

Does not lock

6

HS5L Interlock Switches with Solenoid (2-Contact)

Two-contact solenoid interlock switches ideal for use on applications such as food

machines and injection molding machines.

• Compact body: 35 × 40 × 127mm

• The locking strength is 1400N minimum.

• Spring clamp terminal block prevents loosening of wires due

to vibration.

• Gold-plated contacts suitable for small loads.

• Spring lock models (unlocks when the solenoid is energized)

and solenoid lock models (locks when solenoid is energized)

are available.

• The head orientation can be rotated, allowing 8 different

actuator entries.

• Actuators can be used with other HS5 series interlock

switches. Spring loaded actuator exclusive for HS5L available.

• LED indicator shows solenoid operation.

Spring Lock

• Automatically locks the actuator without power applied to the

solenoid.

• After the machine stops, unlocking is completed by the

solenoid, providing high safety features.

• Manual unlocking is possible in the event of power failure or

maintenance using a manual unlocking key.

• Head removal detection circuitry (spring lock models only).

Solenoid Lock

• The actuator is locked when energized.

• The actuator is unlocked when de-energized.

• Flexible locking function can be achieved, for an application

where locking is not required and sudden stopping of a

machine must be prevented.

Specifications

EN ISO14119

GS-ET-19 (TÜV approval)

EN60947-5-1 (TÜV approval)

Applicable Standards

Type and Coded level Type 2 low level coded interlocking device (ISO14119)

Operating Temperature –25 to + 55°C (no freezing)

Relative Humidity 20 to 95% (no condensation)

Storage Temperature –40 to +80°C (no freezing)

Pollution Degree 3

Impulse Withstand

Voltage

Insulation Resistance

(500V DC megger)

Electric Shock

Protection

Degree of Protection IP67 (IEC60529) Type 4X Indoor Use Only

Shock Resistance

Vibration Resistance

Actuator Operating

Speed

Direct Opening Travel

Direct Opening Force 120N min.

Actuator Retention

Force (Note)

Operating Frequency 900 operations per hour

Mechanical Durability

Electrical Durability

Conditional Shortcircuit Current

Cable

Weight (Approx.) 300g

Note: See page

UL508 (UL Listing)

CSA C22.2 No. 14 (c-UL listed)

GB14048.5 (CCC approval)

IEC60204-1/EN60204-1 (Applicable standards for use)

2.5kV

(between LED, solenoid and grounding: 0.5kV)

Between live and dead metal parts: 100MΩ min.

Between terminals of different poles: 100MΩ min.

Class II (IEC61140)

Operating extremes: 100m/s2 (10G),

Damage limits: 1000m/s2 (100G)

Operating extremes: 10 to 55Hz, amplitude 0.35 min.

Damage limits: 30Hz, amplitude 1.5mm min.

0.05 to 1.0m/s

11.0mm min. (Actuator: HS9Z-A51/A5P)

12.0mm min. (Actuator: HS9Z-A52/A51A/A52A/A53/

55/SH5/SH5L)

24.5mm min. (Actuator: HS9Z-BA5)

Fzh = 1400N min. (GS-ET-19)

However, Fzh=500N min. when HS9Z-A55 is used

2,000,000 times min.

(Operation frequency 900 times/hour, actuator insert/

remove, solenoid operation) 100,000 times min. when

HS9Z-SH5/SH5L (actuator insert/remove)

100,000 times min. (Operating Frequency: 900

operations per hour)

2,000,000 times min. (24V AC/DC, 100mA)

50A (250V) (Use 250V/10A fast-blow fuse for shortcircuit protection.)

0.3mm2 min. and 1.5mm2 max. or AWG22 min. to

AWG16 max. strand wire or single wire

16

regarding actuator retention force.

Straight Actuator

Straight Actuator with

Rubber Bushings

Angle Adjustable

(Vertical) Actuator

Right-angle Actuator

•Korean S Mark approval application pending

Marking for Locking Monitoring

The marking for lock monitoring described in clause 9.2.1

of ISO14119 can be used by satisfying the requirements in

general requirements (5.7.1), locking monitoring (5.7.2.2), and

ISO13849-1 (safety-related parts of control systems). This

marking has been added to the 2013 edition of ISO14119.

However, this marking cannot be applied to solenoid lock

switches according to general requirement (5.7.1).

Ratings

Contact Ratings

Rated Insulation Voltage (Ui)

Rated Current (Ith) 2.5A

Rated Voltage (Ue) *

Resistive Load (AC-12) − 2.5A 1.5A

AC

Inductive Load (AC-15) −

(Ie)*

Resistive Load (DC-12) 2.5A 1.1A 0.55A

DC

Inductive Load (DC-13) 2.3A 0.55A 0.27A

Rated Current

•Minimum applicable load (reference): 3V AC/DC, 5mA

(Applicable range may vary with operating conditions and load types.)

*UL, c-UL rating: Pilot Duty AC 0.75A/250V,

Pilot Duty DC 1.0A/30V

TÜV rating: AC-15 0.75A/250V, DC-13 2.3A/30V

CCC rating: AC-15 0.75A/250V, DC-13 2.3A/30V

Solenoid

Locking Mechanism Spring Lock Solenoid Lock

Rated Voltage 100% duty cycle 24V DC

Rated Current 200mA (initial value)

Coil Resistance 120Ω (at 20°C)

Pickup Voltage Rated voltage × 85% max. (at 20°C)

Dropout Voltage Rated voltage × 10% min. (at 20°C)

Maximum Continuous Applicable Voltage Rated voltage × 110%

Maximum Continuous Applicable Time Continuous

Insulation Class Class F

Indicator

Rated Voltage 24V DC

Rated Current 10mA

Light Source LED

Illumination Color G (Green)

250V

(between LED, solenoid and grounding: 30V)

30V 125V 250V

1.5A

0.75A

2-Contact4-ContactActuatorDimensions / Instructions

7

)

(−)(+)

(−)(+)

(−)(+)

Door Monitor

Lock Monitor

)

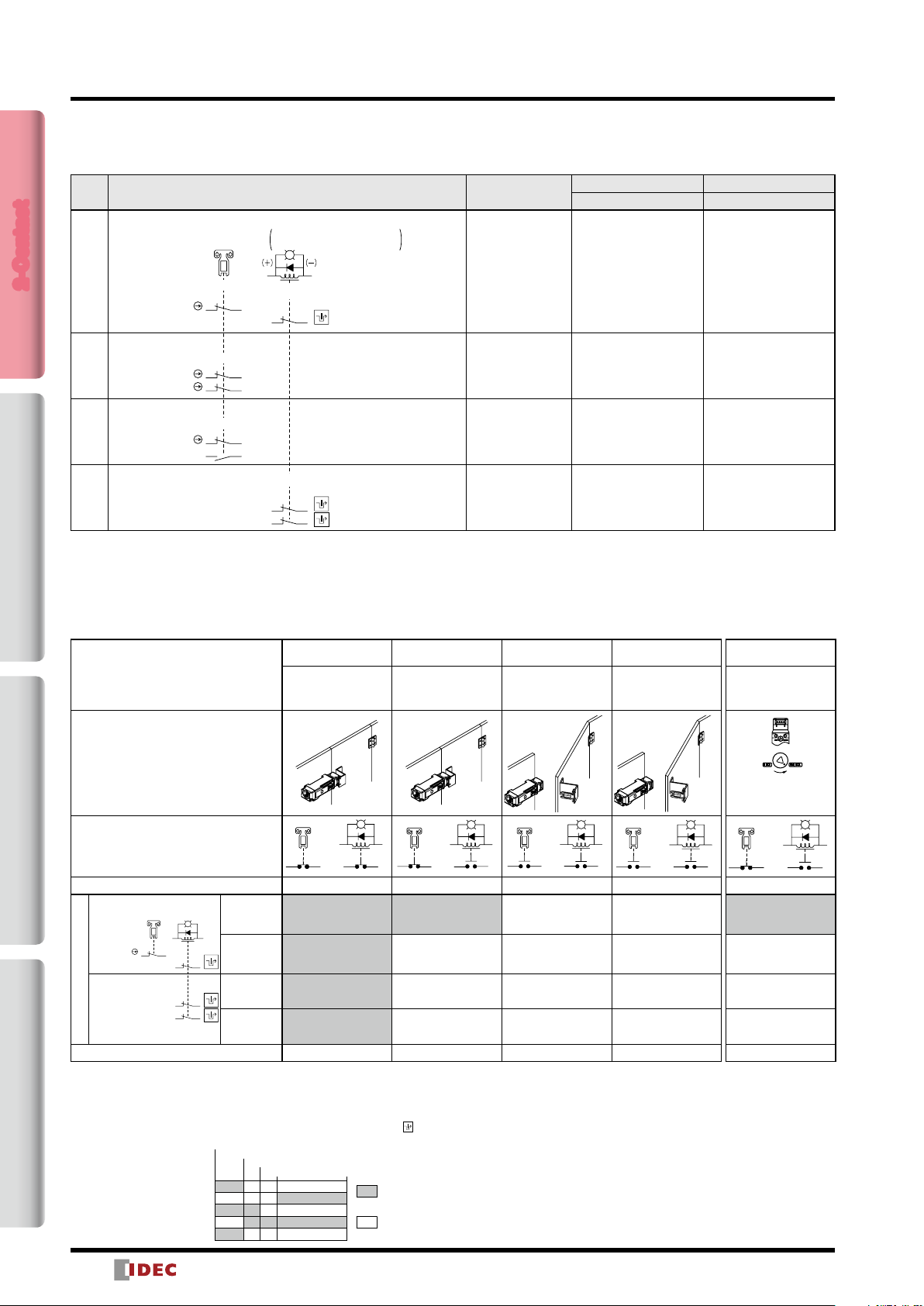

HS5L Interlock Switches with Solenoid (2-Contact)

0

(Actuator Mounting Reference Position)

HS5L Interlock Switches with Solenoid (2-Contact)

2-Contact Package Quantity: 1

Circuit

Code

Door Monitor

(Actuator inserted)

XD

2-Contact4-ContactActuatorDimensions / Instructions

Door Monitor Circuit: 1NC

Monitor Circuit:

Monitor Circuit:

Door Monitor Circuit: 2NC

XF M20 — HS5L-XF7Y4M-G

Monitor Circuit:

Monitor Circuit:

Door Monitor Circuit: 1NC,1NO

XG M20 — HS5L-XG7Y4M-G

Monitor Circuit:

Monitor Circuit:

XH

Monitor Circuit:

Monitor Circuit:

Contact Conguration Gland Port Size

Lock Monitor

Spring lock→Solenoid OFF

Solenoid lock→Solenoid ON

A2 A1

Lock Monitor Circuit: 1NC

1211

(Note)

4241

1211

21 22

1211

2423

Lock Monitor Circuit: 2NC

(Note)

4241

5251

(Note)

M20

M20

Note: This marking cannot be applied to solenoid locks according to general requirement (5.7.1) in ISO14119.

• The contact conguration shows the status when the actuator is inserted and the switch is locked.

• Actuators are not supplied with the interlock switch and must be ordered separately.

Spring lock Solenoid

Part No. Part No.

HS5L-XD44M-G HS5L-XD7Y4M-G

HS5L-XH44M-G HS5L-XH7Y4M-G

Circuit Diagrams and Operating Characteristics

Spring Lock

Status 1 Status 2 Status 3 Status 4

Interlock Switch Status

Door Closed

Machine ready to

operate

Solenoid de-energized

Door Status

(+)

Circuit Example: HS5L-XD4

A2

11 12 4241

Door Closed (locked) Closed (unlocked) Open Open

(Actuator inserted)

HS5L-XD4

Monitor Circuit:

Monitor Circuit:

(Solenoid OFF)

A2 A1

1211

HS5L-XH4

Monitor Circuit:

Monitor Circuit:

Part No. Circuit Diagram

Solenoid Power A1-A2 (common to all types) OFF (de-energized) ON (energized) ON (energized) OFF (de-energized)

(−)(+)

4241

4241

5251

Monitor Circuit

(door closed)

11-12

Monitor Circuit

(locked)

41-42

Monitor Circuit

(locked)

41-42

Monitor Circuit

(locked)

51-52

• The contact conguration shows the status when the actuator is inserted and the

switch is locked.

• Monitor Circuit: Sends monitoring signals of protective door open/closed status

(door monitor) or protective door lock/unlock status (lock monitor).

• For safety circuit input, connect to the monitor circuit with marking.

Approx. 3.3 (Locked position)

Main Circuit

Door Monitor Circuit (door open, NO)

Door Monitor Circuit (door closed, NC)

Lock Monitor Circuit (unlocked, NO)

Lock Monitor Circuit (locked, NC)

Approx. 5.3

Approx. 6.9

Approx. 26.4

Door Closed

Machine cannot be

operated

Solenoid energized

(−

A1

11 12 4241

(Stroke: mm)

: Contacts ON

(closed)

: Contacts OFF

(open)

Door open

Machine cannot be

operated

Solenoid energized

A2

A1

A2

A1

424111 12

Note: Actuator can be unlocked manually for

conrming the door movement before wiring

and energizing, and also for emergency

situation such as power failure.

• The operation characteristics shown in the chart are for HS9Z-A51.

For other actuators, add 1.3mm.

• See page 21 for HS9Z-BA5.

• The operation characteristics show the contact status when the

actuator enters the entry port of an interlock switch.

Door open

Machine cannot be

operated

Solenoid de-energized

A2

424111 12

When unlocking

manually

Door Closed

Machine cannot be

operated

Solenoid de-energized

Turn the manual

unlock key

(Note)

A1

(+)

11 12 4241

Closed (unlocked)

OFF (de-energized)

A2

(−

A1

8

HS5L Interlock Switches with Solenoid (2-Contact)

)

)

)

)

)

Circuit Diagrams and Operating Characteristics

Solenoid Lock

Status 1 Status 2 Status 3 Status 4

Interlock Switch Status

Door Closed

Machine ready to

operate

Solenoid energized

Door Closed

Machine cannot be

operated

Solenoid de-energized

Door open

Machine cannot be

operated

Solenoid de-energized

Door open

Machine cannot be

operated

Solenoid energized

Unlocking using

Manual Unlock Key

Door Closed

Machine cannot be operated

Solenoid de-energized

energized

➝

Door Status

(−

Circuit Example: HS5L-XD7Y

(+)

A2

11 12 4241

(−

A1

11 12 4241

(+)

A2

(−

A1

(+)

A2

(+)

A1

424111 12

A2

424111 12

Door Closed (locked) Closed (unlocked) Open Open

4241

4241

5251

Monitor Circuit

(door closed)

11-12

Monitor Circuit

(locked)

41-42

Monitor Circuit

(door closed)

11-12

Monitor Circuit

(door closed)

21-22

Monitor Circuit

(door closed)

11-12

Monitor Circuit

(door open)

23-24

Monitor Circuit

(locked)

41-42

Monitor Circuit

(locked)

51-52

ON (energized)

(Note 2)

Door Monitor

HS5L-XD7Y

Monitor Circuit:

Monitor Circuit:

(Actuator

inserted)

Lock Monitor

(Solenoid ON)

A2 A1

1211

HS5L-XF7Y (Note 3)

Monitor Circuit:

Monitor Circuit:

21 22

1211

HS5L-XG7Y (Note 3)

Monitor Circuit:

Monitor Circuit:

1211

2423

Part No. and Circuit Diagram

HS5L-XH7Y

Monitor Circuit:

Monitor Circuit:

Solenoid Power A1-A2 (all models) OFF (energized) OFF (de-energized) OFF (de-energized)

Note 1: Do not unlock manually while the solenoid is energized.

Note 2: Do not energize the solenoid for a long period of time while the door is open or while the door is unlocked

manually.

Note 3: Circuit codes XF and XG do not have signals to notify whether the switch is locked or unlocked. A different

method should be used to check the lock status.

• The contact conguration shows the status when the actuator is inserted and the switch is locked.

• Monitor Circuit: Sends monitoring signals of protective door open/closed status (door monitor) or protective door

lock/unlock status (lock monitor).

(−

A1

11 12 4241

Closed (unlocked)

(Note 1) (Note 2)

OFF (de-energized)

ON (energized)

➝

UNLOCKLOCK

When unlocking

manually

(+)

A2

(−

A1

2-Contact4-ContactActuatorDimensions / Instructions

Operation Characteristics (Reference)

0

(Actuator Mounting Reference Position)

Approx. 3.3 (Locked position)

Approx. 5.3

Approx. 6.9

Main Circuit

Door Monitor Circuit (door open, NO)

Door Monitor Circuit (door closed, NC)

Lock Monitor Circuit (unlocked, NO)

Lock Monitor Circuit (locked, NC)

• The operation characteristics shown in the chart above are for HS9Z-A51. For other actuators, add 1.3mm.

• See page 21 for HS9Z-BA5.

• The operation characteristics show the contact status when the actuator enters the entry port of an interlock switch.

Approx. 26.4

(Stroke: mm)

: Contacts ON

(closed)

: Contacts OFF

(open)

9

HS5L Interlock Switch with Solenoid (4-Contact)

Four-contact solenoid interlock switches ideal for use on limited mounting spaces

such as small doors.

• Compact body: 35 × 40 × 127mm

• The locking strength is 1400N.

• Spring clamp terminal block prevents loosening of wires due

to vibration.

• A variety of circuits. Dual safety circuit and four-circuit

independent outputs available.

2-Contact4-ContactActuatorDimensions / Instructions

• Gold-plated contacts suitable for small loads.

• Spring lock models (unlocks when the solenoid is energized)

and solenoid lock models (locks when solenoid is energized)

are available.

• The head orientation can be rotated, allowing 8 different

actuator entries.

• Actuators can be used with other HS5 series interlock

switches. Spring loaded actuator exclusive for HS5L available.

• LED indicator shows solenoid operation.

Spring Lock

• Automatically locks the actuator without power applied to the

solenoid.

• After the machine stops, unlocking is completed by the

solenoid, providing high safety features.

• Manual unlocking is possible in the event of power failure or

maintenance using a manual unlocking key.

• Head removal detection circuitry (spring lock models only).

Solenoid Lock

• The actuator is locked when energized.

• The actuator is unlocked when de-energized.

• Flexible locking function can be achieved, for an application

where locking is not required and sudden stopping of a

machine must be prevented.

Specifications

EN ISO14119, GS-ET-19 (TÜV approval),

Applicable Standards

Type and Coded Level Type 2 low level coded interlocking device (ISO14119)

Operating Temperature –25 to + 55°C (no freezing)

Relative Humidity 20 to 95% (no condensation)

Storage Temperature –40 to +80°C (no freezing)

Pollution Degree 3

Impulse Withstand

Insulation Resistance

(500V DC megger)

Electric Shock Protection Class II (IEC61140)

Degree of Protection IP67 (IEC60529) Type 4X Indoor Use Only

Shock Resistance

Vibration Resistance

Actuator Operating Speed 0.05

Direct Opening Travel

Direct Opening Force 120N min.

Actuator Retention Force

(Note)

Operating Frequency 900 operations per hour

Rear Unlocking Button

Mechanical Durability

Mechanical Durability

Electrical Durability

Conditional Short-circuit

Current

Cable

Weight (Approx.) 300g

Note: See page 16 regarding actuator retention force.

EN60947-5-1 (TÜV approval), UL508 (UL Listing

CSA C22.2 No.14 (c-UL listed), GB14048.5

IEC60204-1/EN60204-1 (Applicable standards for use)

Voltage

2.5kV (between LED, solenoid and grounding: 0.5kV)

Between live and dead metal parts: 100MΩ min.

Between terminals of different poles: 100MΩ min.

Operating extremes: 100m/s

2

(100G)

1000m/s

Operating extremes: 10 to 55Hz, amplitude 0.35 min.

Damage limits: 30Hz, amplitude 1.5mm min.

to

1.0m/s

11.0mm min. (Actuator: HS9Z-A51/A5P)

12.0mm min. (Actuator: HS9Z-A52/A51A/A52A/A53/

A55/SH5/SH5L)

24.5mm min. (Actuator: HS9Z-BA5)

Fzh = 1400N min. (GS-ET-19)

However, Fzh=500N min. when HS9Z-A55 is used

3,000 times min. (HS5L-L)

2,000,000 times min.

(Operation frequency 900 times/hour, actuator insert/

remove, solenoid operation) 100,000 times min. when

HS9Z-SH5/SH5L (actuator insert/remove)

100,000 times min.

(Operating Frequency: 900 operations per hour)

2,000,000 times min. (24V AC/DC, 100mA)

50A (250V) (Use 250V/10A fast-blow fuse for shortcircuit protection.)

2

min. and 1.5mm2 max. or AWG22 min. to

0.3mm

AWG16 max. strand wire or single wire

),

(CCC approval)

2

(10G), Damage limits:

Straight Actuator with

Rubber Bushings

Marking for Locking Monitoring

The marking for lock monitoring described in clause 9.2.1

of ISO14119 can be used by satisfying the requirements in

general requirements (5.7.1), locking monitoring (5.7.2.2), and

ISO13849-1 (safety-related parts of control systems). This

marking has been added to the 2013 edition of ISO14119.

However, this marking cannot be applied to solenoid lock

switches according to general requirement (5.7.1).

Ratings

Contact Ratings

Rated Insulation Voltage (Ui)

Rated Current (Ith) 2.5A

Rated Voltage (Ue)*

AC

(Ie)*

DC

Rated Current

•Minimum applicable load (reference): 3V AC/DC, 5mA

(Applicable range may vary with operating conditions and load types.)

*

UL, c-UL rating: Pilot Duty AC 0.75A/250V,

Pilot Duty DC 1.0A/30V

TÜV rating: AC-15 0.75A/250V, DC-13 2.3A/30V

CCC rating: AC-15 0.75A/250V, DC-13 2.3A/30V

Solenoid

Locking Mechanism Spring Lock Solenoid Lock

Rated Voltage 100% duty cycle 24V DC

Rated Current 200mA (initial value)

Coil Resistance 120Ω (at 20°C)

Pickup Voltage Rated voltage × 85% max. (at 20°C)

Dropout Voltage Rated voltage × 10% min. (at 20°C)

Maximum Continuous Applicable Voltage Rated voltage × 110%

Maximum Continuous Applicable Time Continuous

Insulation Class Class F

Indicator

Rated Voltage 24V DC

Rated Current 10mA

Light Source LED

Illumination Color G (Green)

Straight Actuator

Right-angle

Actuator

•Korean S Mark approval application pending

250V

(between LED, solenoid and grounding: 30V)

30V 125V 250V

Resistive Load (AC-12)

Inductive Load (AC-15) − 1.5A 0.75A

Resistive Load (DC-12)

Inductive Load (DC-13) 2.3A 0.55A 0.27A

− 2.5A 1.5A

2.5A 1.1A 0.55A

Adjustable actuator

(Bounce tolerant type)

10

3433

Monitor Circuit:

Lock Monitor

HS5L Interlock Switch with Solenoid (4-Contact)

HS5L Interlock Switches with Solenoid (4-Contact)

4-Contact (Spring Lock / Solenoid Lock) Package Quantity: 1

Circuit

Code

Contact Conguration Gland Port Size

Spring lock Solenoid

Part No. Part No.

VA

Door Monitor: 1NC,1NO

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Door Monitor: NC,1NO

Monitor Circuit:

VB

Monitor Circuit:

Monitor Circuit:

Door Monitor: 2NC

Monitor Circuit:

VC

Monitor Circuit:

Monitor Circuit:

Door Monitor: 2NC

Monitor Circuit:

VD

Monitor Circuit:

Monitor Circuit:

Door Monitor: 3NC

Monitor Circuit:

VF

Monitor Circuit:

Monitor Circuit:

Door Monitor

(Actuator inserted)

12

231124

1211

23 24

12

211122

11 12

2221

1211

2221

31 32

Spring lock→Solenoid OFF

Solenoid lock→Solenoid ON

A2 A1

Lock Monitor Circuit: 1NC,1NO

41 42

53 54

Lock Monitor Circuit: 2NC

41

Lock Monitor Circuit: 1NC,1NO

41 42

53 54

Lock Monitor Circuit: 2NC

Lock Monitor Circuit: 1NC

41 42

(Note)

42

(Note)

(Note)

5251

(Note)

4241

(Note)

5251

(Note)

(Note)

M20

M20 HS5L-VB44M-G HS5L-VB7Y4M-G

M20 HS5L-VC44M-G HS5L-VC7Y4M-G

M20 HS5L-VD44M-G HS5L-VD7Y4M-G

M20 HS5L-VF44M-G HS5L-VF7Y4M-G

HS5L-VA44M-G HS5L-VA7Y4M-G

2-Contact4-ContactActuatorDimensions / Instructions

Door Monitor: 2NC, 1NO

Monitor Circuit:

Monitor Circuit:

VG

11 12

2221

Lock Monitor Circuit: 1NC

4241

(Note)

M20

HS5L-VG44M-G HS5L-VG7Y4M-G

Note: This marking cannot be applied to solenoid locks interlock switches according to general requirement (5.7.1) in ISO14119.

• The contact conguration shows the status when the actuator is inserted and the switch is locked.

• Actuators are not supplied with the interlock switch and must be ordered separately.

• For safety circuit input, connect to the monitor circuit with marking.

11

Door Monitor

Lock Monitor

HS5L Interlock Switch with Solenoid (4-Contact)

4-Contact / Rear Unlocking Button (Spring Lock) Package Quantity: 1

Circuit

Code

Contact Conguration Gland Port Size

Spring lock

Part No.

(Actuator inserted)

VA

Door Monitor Circuit: 1NC,1NO Lock Monitor Circuit: 1NC,1NO

Monitor Circuit:

2-Contact4-ContactActuatorDimensions / Instructions

Door Monitor Circuit: 1NC,1NO Lock Monitor Circuit: 2NC

VB

Door Monitor Circuit: 2NC Lock Monitor Circuit: 1NC,1NO

VC

Door Monitor Circuit: 2NC Lock Monitor Circuit: 2NC

VD

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

231124

1211

23 24

211122

11 12

2221

(Solenoid OFF)

A2 A1

41 4212

53 54

42

41

5251

41 4212

53 54

4241

5251

M20

M20 HS5L-VB44LM-G

M20 HS5L-VC44LM-G

M20

HS5L-VA44LM-G

HS5L-VD44LM-G

• The contact conguration shows the status when the actuator is inserted and the switch is locked.

• Actuators are not supplied with the interlock switch and must be ordered separately.

4-Contact / Dual Safety Circuit (Spring Lock) Package Quantity: 1

Circuit

Code

Contact Conguration Gland Port Size

Door Monitor

(Actuator inserted)

Lock Monitor

(Solenoid OFF)

Spring lock

Part No.

DD

Main Circuit: 1NC+1NC

1NC+1NC

Main Circuit:

Main Circuit:

11 12 4241

21

A1A2

525122

M20 HS5L-DD44M-G

• The contact conguration shows the status when the actuator is inserted and the switch is locked.

• Actuators are not supplied with the interlock switch and must be ordered separately.

4-Contact / Dual Safety Circuit / Rear Unlocking Button (Spring Lock) Package Quantity: 1

Circuit

Code

DD

Main Circuit: 1NC+1NC

1NC+1NC

Main Circuit:

Main Circuit:

Contact Conguration Gland Port Size

Door Monitor

(Actuator inserted)

11 12 4241

21

Lock Monitor

(Solenoid OFF)

A1A2

525122

M20 HS5L-DD44LM-G

• The contact conguration shows the status when the actuator is inserted and the switch is locked.

• Actuators are not supplied with the interlock switch and must be ordered separately.

Spring lock

Part No.

12

HS5L Interlock Switch with Solenoid (4-Contact)

(−)

0

(Actuator Mounting Reference Position)

(−)

(−)

(−)

(−)

Circuit Diagrams and Operating Characteristics

4-Contact / Rear Unlocking Button (Spring Lock)

Status 1 Status 2 Status 3 Status 4

Interlock Switch Status

Door Closed

Machine ready to

operate

Solenoid de-energized

Door Closed

Machine cannot be

operated

Solenoid energized

Door open

Machine cannot be

operated

Solenoid energized

Door open

Machine cannot be

operated

Solenoid de-energized

When unlocking

manually

Door Closed

Machine cannot be

operated

Solenoid de-energized

Press

Door Status

11

23

12

24

(+)

A2

(+)

A2

A1

Circuit Example: HS5L-VA4

Door Closed (locked) Closed (unlocked) Open Open

HS5L-VA4

Door Monitor

(Actuator

inserted)

Lock Monitor

(Solenoid OFF)

A2

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

41

24

53

HS5L-VB4

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

122311

24

HS5L-VC4

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

122111

22

41 42

53 54

HS5L-VD4

Monitor Circuit:

11 12

Monitor Circuit:

Part No. and Circuit Diagram

Monitor Circuit:

2221

HS5L-VF4

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

31 32

1211

2221

41 42

HS5L-VG4

Monitor Circuit:

11 12

Monitor Circuit:

Monitor Circuit:

2221

3433

42122311

54

4241

5251

4241

5251

4241

A1

Monitor Circuit

(door closed)

Monitor Circuit

(door open)

Monitor Circuit

Monitor Circuit

(unlocked)

Monitor Circuit

(door closed)

Monitor Circuit

(door open)

Monitor Circuit

Monitor Circuit

Monitor Circuit

(door closed)

Monitor Circuit

(door closed)

Monitor Circuit

Monitor Circuit

(unlocked)

Monitor Circuit

(door closed)

Monitor Circuit

(door closed)

Monitor Circuit

Monitor Circuit

Monitor Circuit

(door closed)

Monitor Circuit

(door closed)

Monitor Circuit

(door closed)

Monitor Circuit

Monitor Circuit

(door closed)

Monitor Circuit

(door closed)

Monitor Circuit

(door open)

Monitor Circuit

(door locked)

11−12

23−24

(locked)

41−42

53−54

11−12

23−24

(locked)

41−42

(locked)

51−52

11−12

21−22

(locked)

41−42

53−54

11−12

21−22

(locked)

41−42

(locked)

51−52

11−12

21-22

31-32

(locked)

41-42

11−12

21-22

33-34

41-42

11

23

122441

53

42

54

11

23

12

24

(+)

A2

41

53

42

54

A1

11

23

(+)

A2

122441

53

A1

42

54

Solenoid Power A1-A2 (all models) OFF (de-energized) ON (energized) ON (energized) OFF (de-energized)

•The contact conguration shows the status when the actuator is inserted and the switch is locked.

•Monitor Circuit: Sends monitoring signals of protective door open/closed status (door monitor)

or protective door lock/unlock status (lock monitor).

•For safety circuit input, connect to the monitor circuit with

Operation Characterics

(Reference)

Main Circuit

Door Monitor Circuit (door open, NO)

Door Monitor Circuit (door closed, NC)

Lock Monitor Circuit (unlocked, NO)

Lock Monitor Circuit (locked, NC)

Approx. 3.3 (Locked position)

Approx. 5.3

Approx. 6.9

Approx. 26.4

marking.

(Stroke: mm)

: Contacts ON

(closed)

: Contacts OFF

(open)

•The operation characteristics shown in the chart above are for HS9Z-A51.

For other actuators, add 1.3mm.

•See page 21 for HS9Z-BA5.

•The operation characteristics show the contact status when the actuator

enters the entry port of an interlock switch.

Note 1: Actuator can be unlocked manually for conrming

the door movement before wiring and energizing,

and also for emergency situation such as power

failure.

Note 2: When the operator is conned in a hazardous zone,

the actuator can be unlocked manually by pressing

the rear unlocking button.

41

53

·Turn the

manual

unlock key

(Note 1)

A1

11

42

23

54

Closed (unlocked)

OFF (de-energized)

·Press the

unlocking

(+)

A2

122441

53

rear

button

(Note 2)

42

54

2-Contact4-ContactActuatorDimensions / Instructions

A1

13

HS5L Interlock Switch with Solenoid (4-Contact)

(−)

(−)

(−)

(−)

Door Monitor

Lock Monitor

(−)

Circuit Diagrams and Operating Characteristics

4-Contact (Solenoid Lock)

Status 1 Status 2 Status 3 Status 4

Interlock Switch Status

2-Contact4-ContactActuatorDimensions / Instructions

Door Status

Door Closed

Machine ready to

operate

Solenoid energized

Door Closed

Machine cannot be

operated

Solenoid de-energized

Door open

Machine cannot be

operated

Solenoid de-energized

Door open

Machine cannot be

operated

Solenoid energized

Unlocking using

Manual Unlock Key

Door Closed

Machine cannot be operated

Solenoid de-energized

energized

When unlocking

manually

➝

UNLOCKLOCK

Circuit Example: HS5L-VA7Y

Door

HS5L-VA7Y

(Actuator inserted)

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

HS5L-VB7Y

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

HS5L-VC7Y

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

HS5L-VD7Y

Monitor Circuit:

Monitor Circuit:

Part No. and Circuit Diagram

Monitor Circuit:

HS5L-VF7Y

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

HS5L-VG7Y

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

231124

12

231124

12

211122

11 12

2221

1211

2221

31 32

11 12

2221

3433

(Solenoid OFF)

(−)(+)

A2

41

4212

53

54

4241

5251

41 42

53 54

4241

5251

41 42

4241

A1

Monitor Circuit

(door closed)

11−12

Monitor Circuit

(door open)

23−24

Monitor Circuit

(locked)

41−42

Monitor Circuit

(unlocked)

53−54

Monitor Circuit

(door closed)

11−12

Monitor Circuit

(door open)

23−24

Monitor Circuit

(locked)

41−42

Monitor Circuit

(locked)

51−52

Monitor Circuit

(door closed)

11−12

Monitor Circuit

(door closed)

21−22

Monitor Circuit

(locked)

41−42

Monitor Circuit

(unlocked)

53−54

Monitor Circuit

(door closed)

11−12

Monitor Circuit

(door closed)

21−22

Monitor Circuit

(locked)

41−42

Monitor Circuit

(locked)

51−52

Monitor Circuit

(door closed)

11−12

Monitor Circuit

(door closed)

21-22

Monitor Circuit

(door closed)

31-32

Monitor Circuit

(locked)

41-42

Monitor Circuit

(door closed)

11−12

Monitor Circuit

(door closed)

21-22

Monitor Circuit

(door open)

33-34

Monitor Circuit

(locked)

41-42

(+)

A2

A1

11

122441

23

Closed (locked) Closed (unlocked) Open Open

53

42

54

11

23

12

24

(+)

A2

41

53

A1

42

54

Solenoid Power A1-A2 (all models) ON (energized) OFF (de-energized) OFF (de-energized)

•The contact conguration shows the status when the actuator is inserted and the switch is locked.

•Main Circuit: Connected to the control circuit of machine drive part, sending interlock signals of the protective door.

•Monitor Circuit: Sends monitoring signals of protective door open/closed status (door monitor) or protective door

lock/unlock status (lock monitor).

Operation Characterics

(Reference)

Main Circuit

Door Monitor Circuit (door open, NO)

Door Monitor Circuit (door closed, NC)

Lock Monitor Circuit (unlocked, NO)

Lock Monitor Circuit (locked, NC)

0

(Actuator Mounting Reference Position)

Approx. 3.3 (Locked position)

Approx. 5.3

Approx. 6.9

Approx. 26.4

(Stroke: mm)

: Contacts ON

(closed)

: Contacts OFF

(open)

•The operation characteristics shown in the chart above are for HS9Z-A51.

For other actuators, add 1.3mm.

•See page 21 for HS9Z-BA5.

•The operation characteristics show the contact status when the actuator

enters the entry port of an interlock switch.

14

11

23

(+)

A2

122441

53

A1

42

54

(+)

A1

A2

41

12

11

53

24

23

ON (energized)

(Note 2)

Note 1: Do not attempt manual unlocking

whenthe solenoid is energized.

Note 2: Do not energize the solenoid for a long

time while the door is open or when the

door is unlocked manually.

11

42

23

54

Closed (unlocked)

OFF (de-energized)

ON (energized)

(+)

A2

122441

53

(Note 1) (Note 2)

42

54

➝

A1

HS5L Interlock Switch with Solenoid (4-Contact)

)

)

)

)

)

Circuit Diagrams and Operating Characteristics

4-Contact / Dual Safety Circuit, 4-Contact / Dual Safety Circuit / Rear Unlocking Button (Spring Lock)

Status 1 Status 2 Status 3 Status 4

Interlock Switch Status

Door Closed

Machine ready to

operate

Solenoid de-energized

Door Closed

Machine cannot be

operated

Solenoid energized

Door open

Machine cannot be

operated

Solenoid energized

Door open

Machine cannot be

operated

Solenoid de-energized

Door Status

(−

Circuit Example: HS5L-DD4

Door

HS5L-DD44

Door Monitor

(Actuator inserted)

Main Circuit:

Main Circuit:

11 12 4241

21

Lock Monitor

(Solenoid OFF)

A1A2

525122

HS5L-DD44L

Main Circuit:

Main Circuit:

Part No. and Circuit Diagram

11 12 4241

21

525122

Solenoid Power A1-A2 (all model)

(+)

A2

A1

11 42

12 41

5122

Closed (locked) Closed (unlocked) Open Open

Main

Circuit

11−42

Main

Circuit

21−52

Main

Circuit

11−42

Main

Circuit

21−52

OFF (de-energized) ON (energized) ON (energized) OFF (de-energized)

11 12 4241

5221

(+)

A2

(−

A1

11 42

12 41

52512221

(+)

A2

(−

A1

5221

5122

(+)

A2

11 42

12 41

5122

Note 1: Actuator can be unlocked manually for conrming the door movement before wiring and energizing, and also for emergency

situation such as power failure.

Note 2: When the operator is conned in a hazardous zone, the actuator can be unlocked manually by pressing the rear unlocking button.

(Only for the type with rear unlocking button)

• The contact conguration shows the status when the actuator is inserted and the switch is locked.

• Main Circuit: Connected to the control circuit of machine drive part, sending interlock signals of the protective door.

• For safety circuit input, connect to the monitor circuit.

Unlocking using

Manual Unlock Key

Door Closed

Machine cannot be

operated

Solenoid de-energized

·Turn the

manual

unlock key

(Note 1)

(−

A1

11 42

5221

Closed (unlocked)

OFF (de-energized)

·Press the

unlocking

(Note 2)

(+)

A2

12 41

5122

Press

rear

button

(−

5221

2-Contact4-ContactActuatorDimensions / Instructions

A1

Operating Characteristics (Reference)

(Actuator insertion position)

0

Approx. 3.3 (Locked position)

Approx. 5.3

Approx. 6.9

Main Circuit

• The operation characteristics shown in the chart above are of the HS9Z-A51. For other actuators, add 1.3mm.

• See page 21 for HS9Z-BA5.

• The operation characteristics show the contact status when the actuator enters the entry slot of an interlock switch.

Approx. 26.4

(Stroke: mm)

: Contacts ON

(closed)

: Contacts OFF

(open)

15

30

7.1

9

2.1

30

Actuators for HS5 Series Interlock Switches

Actuator

Description Part No. Package Quantity Remarks

Straight HS9Z-A51 1

Straight with Rubber Bushings HS9Z-A51A 1

Right-angle HS9Z-A52 1

Right-angle with Rubber Bushings HS9Z-A52A 1

Angle Adjustable (vertical) HS9Z-A53 1

Angle Adjustable (vertical/horizontal) HS9Z-A55 1

2-Contact4-ContactActuatorDimensions / Instructions

Accessories

Description Ordering No. Part No. Package Quantity Remarks

Sliding Actuator (Note 1) (Note 2) HS9Z-SH5 HS9Z-SH5 1

Spring Loaded Actuator (Note 2) (Note 3) HS9Z-BA5 HS9Z-BA5 1 Weight: 70g

Plug Actuator HS9Z-A5P HS9Z-A5P 1

Padlock Hasp HS9Z-PH5 HS9Z-PH5 1

Jumper (Note 4) HS9Z-JP5L HS9Z-JP5LPN02 2

Note 1: For specication on sliding actuators, see separate catalog.

Note 2: Actuator retention force is Fzh=1400N.

Note 3: HS9Z-BA5 can only be used for HS5L interlock switches. Also, HS9Z-BA5 can be used only on slide doors. Do not use on hinge doors.

Note 4: HS9Z-BA5 can only be used for HS5L interlock switches.

Actuator Dimensions and Mounting Hole Layouts All dimensions in mm.

Straight (HS9Z-A51)

6.2

28

20

2.24-R

Note: Actuator Stop

(supplied with the actuator)

10

32.4

6.4

(6)

0.85.2

15

26

Actuator Mounting Hole Layout

(Straight, Right-angle)

2-M4 Screw

2

20

Straight with Rubber Bushings (HS9Z-A51A)

7. 3 43.8

2-ø4.3

12

(20)

Washer (supplied)

0.8

Rubber Bushing

When

mounted (5)

Actuator retention force is Fzh=1400N.

Actuator retention force is Fz=500N. When a retention force of

500N or more is required, use HS9Z-A53.

∗

15.3

2-ø10

2-ø9

0.8

Note: Actuator Stop

(supplied with

the actuator)

2

The mounting center distance is set to

12 mm at the factory. When a 20mm

distance is required, adjust the

distance by moving the rubber

bushing sideways.

∗

The actuator has exibility to the

15

direction indicated by the arrows.

Actuator Mounting Hole Layout

(Straight with Rubber Bushings)

(Right-angle with Rubber Bushings)

2-M4 Screw

Ver tical

Swing

∗

Mounting centers can be widened to

20mm by moving the Rubber

Bushings.

12

Right-angle (HS9Z-A52) Right-angle with Rubber Bushings (HS9Z-A52A)

When mounted (39.7)

33

2 7.27.2

28

0.84.5

Note: Actuator Stop

(supplied with the actuator)

Actuator Cover

15

2-ø4.4

2

20

1.6

Jumper (HS9Z-JP5L)

2

16

5

5.4

When

mounted

(11.2)

30

Rubber Bushing

When

mounted

(5)

15.8

8.5

2-ø9

0.8

Horizontal

15

Washer (supplied)

0.8

2

2-ø10

Note: Actuator Stop

(supplied with the actuator)

Swing

Vertical

Swing

12

(20)

2-ø4.3

∗ When the mounting center

distance is set to 12mm at the

factory, the actuator has exibility

both vertically and horizontally.

∗ When the mounting center

distance is set to 20mm, the

actuator swings vertically.

Adjust the distance by moving the

rubber bushings.

Orienting Insert

Interlock Switch

Actuators for HS5 Series Interlock Switches

Actuator Mounting Hole Layout

Note: Actuator Stop Film

49

Actuator Dimensions and Mounting Hole Layouts All dimensions in mm.

Angle Adjustable (vertical) (HS9Z-A53)

R3.2

18

Door Hinge

Side

20°

44

72

58

2-M6 Screw

(Angle Adjustable (vertical))

58

(supplied with the actuator)

5

20

29

Angle Adjustment

(M3 hexagon socket head bolt)

33 max.

12 (21)

1

Note: The actuator stop lm and actuator stop are supplied with the

actuator and used when adjusting the actuator position. Remove

after the actuator position is determined.

Angle Adjustable (vertical/horizontal) (HS9Z-A55)

(Horizontal Swing)

(Vertical Swing)

Orienting

Insert

15 7

Orienting

Insert

3

Note: Actuator Stop Film

(supplied with the actuator)

Angle Adjustment

(M3 hexagon socket head bolt)

Note: Actuator Stop Film

(supplied with the actuator)

20゚

18.5 29

0.8

Angle Adjustment

(M3 hexagon socket head bolt)

2

20゚

Actuator Mounting Hole Layout

(Angle Adjustable (vertical/horizontal))

2-M4 Screw

23

R2.1

(M4 Hole)

1

3.6

26

38

38

2-Contact4-ContactActuatorDimensions / Instructions

Horizontal / Vertical Actuator Orientation

Accessory Dimensions and Mounting Hole Layouts All dimensions in mm.

Spring Loaded Actuator (HS9Z-BA5)

3

Horizontal Swing Vertical Swing

Actuator Stop

HS9Z-A51

Actuator

2.5

7

±0.75

Mounting

Actuator (SUS)

tolerance range

Thickness: 2.5

11.3

0.8mm line

31

15

35.1

3.3mm line

Lock limit line

41

The orientation of actuator swing (horizontal/vertical) can be changed using the orienting insert (white

plastic) installed on the back of the actuator. Attach the orienting insert if necessary. (See left diagram)

Do not lose the orienting insert, otherwise the actuator will not operate properly.

Actuator Mounting Reference Position

Interlock Switch

Actuator Stop

As shown in the gure on the right, the mounting reference

position of the actuator when inserted in the interlock switch

is the position where the actuator stop placed on the actuator

lightly touches the side surface of the interlock switch.

Actuator Cover

HS9Z-A52

Actuator

Note: After mounting the actuator, remove the actuator stop from the

actuator.

Mounting Hole Layout

10 to 15

6-M5

Screw

range: ±1.0

Mounting tolerance

Fasten at least four parts (either

A or C, and B in the drawing on

the right) with mounting screws.

Always fasten B to prevent

movement during use.

10 to 15

47

HS5L Interlock Switch with Actuator

A

57

0.8

B

C

47

+2.5

0

86.5

20 to 22

∗ When the actuator is installed on the same plane

as the HS5L interlock switch, because the height

of the actuator will be 5mm lower than the

interlock switch, adjustment is required by the

customer.

36.2

(Mounting tolerance range: 0.8 )

5

Body (SUS)

23

15

7

40

Door Stop

Door Stop

7

58

47

∗5±0.5

(Height adjustment)

17

HS5L Interlock Switches with Solenoid

61.6

61.6

Interlock Switch Dimensions and Mounting Hole Layouts

HS5L-

4

When using Horizontal Mounting / Straight Actuator (HS9Z-A51)

5.2 6.2

2-Contact4-ContactActuatorDimensions / Instructions

42.2

R2.2

Manual Unlock

LED

(with Indicator)

-G (with Indicator)

30

29.2

11

10

1

20

35

3

HS5L-

When using Horizontal Mounting / Straight Actuator (HS9Z-A51)

11

5

36.2

9

44.5

127

86.5

40

34

20

Manual Unlocking Key (supplied)

3-M4 Screw

20 to 22

10 to 11

Mounting Hole Layout

3

915

(24)

18 6.5

(24.5)

42.2

86.5

Manual Unlock

LED

(with Indicator)

4

5.2 6.2

29.2

R2.2

-G (with Indicator)

30

11

36.2

9

44.5

127

86.5

10

1

20

35

3

40

34

20

Rear Unlocking Button (supplied)

All dimensions in mm.

11

5

Manual Unlocking Key (supplied)

3-M4 Screw

7.7

27

Mounting Hole Layout

(24)

ø14

10 to 11

3

915

18

(24.5)

20 to 22

9

86.5

6.5

Accessories

Description Part No. Package Quantity Remarks

HS9Z-FL53 1

Rear Unlocking Button Kit (Note)

HS9Z-FL55 1

Note: See table below when selecting rear unlocking button kit.

Part No.

HS9Z-FL53

HS9Z-FL54

HS9Z-FL55

HS5L

Interlock Switch

(sold separately)

HS5L Interlock Switch Rear Unlocking Button Kit

Panel Thickness * (X)

(When mounting HS5L-L directly)

ø10.4

< X ≤ 33

23

< X ≤ 43

33

< X ≤ 53

43

Hinge + Plate

(SUS)

Pin (SUS)

Button (PA66)

ø40

Button pressed

(unlocked)

Button released

Panel Thickness * (X) HS9Z-FL54 1

M5 Screw

40

3325.5

73

31.5

16

30

33

25.5

60.5

ø22 to 30

Rear Unlocking

Button Hole (Note)

Rear Unlocking Button Kit

Mounting Hole Layout

60.5

16 to 30

Panel Thickness (X): 23 to 53

Link Rod

(SUS)

Screw (Iron)

All dimensions in mm.

Note: With the mounting hole dimension, the rear unlocking button rod does not touch the hole even when the interlock switch moves sideways.

18

Safety Precautions

HS5L Interlock Switches with Solenoid

• In order to avoid electric shock or re, turn power off before

installation, removal, wiring, maintenance, or inspection of the

interlock switch.

• If relays are used in the circuit between the interlock switch

and the load, use only safety relays, since welded or sticking

contacts of standard relays may invalidate the functions of the

interlock switch. Perform a risk assessment and make a safety

circuit which satises the requirements of the safety category.

• Do not place a PLC in the circuit between the interlock switch

and the load. Safety security can be endangered in the event of

a malfunction of the PLC.

• Do not disassemble or modify the interlock switch, otherwise a

malfunction or an accident may occur.

• Do not install the actuator in a location where a human body may

come into contact. Otherwise injury may occur.

• Solenoid lock is locked when energized, and unlocked when

de-energized. When energization is interrupted due to wire

disconnection or other failures, the interlock switch may be

unlocked causing possible danger to the operators. Solenoid

lock must not be used in applications where locking is strictly

required for safety. Perform a risk assessment and determine

whether solenoid lock is appropriate.

• When changing the head orientation, disconnect the cable and

turn the manual unlock to the UNLOCK position in advance. If

Instructions

• Do not use the interlock switch as a door stop. Install a

mechanical door stop at the end of the door to protect the

interlock switch against excessive force.

• Do not apply excessive shock to the interlock switch when

opening or closing the door. A shock to the interlock switch

exceeding 1,000m/s

switch.

• Prevent foreign objects such as dust and liquids from

entering the interlock switch while connecting a conduit or

wiring.

• Plug the unused actuator entry slot using the slot plug

supplied with the interlock switch.

• Do not store the interlock switches in a dusty, humid, or

organic-gas atmosphere, or in an area subjected to direct

sunlight.

• Use proprietary actuators only. When other actuators are

used, the interlock switch may be damaged.

• The locking strength is rated at 1400N. Do not apply a load

higher than the rated value. When a higher load is expected,

provide an additional system consisting of another interlock

switch without lock (such as the HS5D interlock switch) or a

sensor to detect door opening and stop the machine.

• Regardless of door types, do not use the interlock switch

as a door lock. Install a separate lock using a latch or other

measures.

• While the solenoid is energized, the switch temperature

rises approximately 40°C above the ambient temperature (to

approximately 95°C while the ambient temperature is 55°C).

Do not touch to prevent burns. If cables come into contact

with the switch, use heat-resistant cables.

• Although the HS9Z-A51A/A52A actuators alleviate shock

when the actuator enters a slot in the interlock switch, make

sure that excessive shock is not applied. If the Rubber

Bushings become deformed or cracked, replace with new

ones.

2

may cause damage to the interlock

the head orientation is changed when the cable is connected

and the manual unlock is in the LOCK position, machines may

start to operate, causing danger to the operators.

• HS5L interlock switches are Type 2 low level coded

interlocking devices (ISO14119). According to ISO14119, the

following is required to minimize defeat when installing and

constructing systems:

1. Prevent dismantling or de-positioning of the elements of

the interlocking device by use of non-detachable xing (e.g.

welding, gluing, one-way screws, riveting). However, use of

non-detachable xing can be an inappropriate solution in

cases where a failure of the interlocking device during lifetime

of the machinery can be expected and a fast change is

necessary. In this case measures mentioned below, should be

used to provide the required level of risk reduction.

2. Apply at least one out of the four measures below.

➀ Mounting out of reach.

➁ Physical obstruction or shielding.

➂ Mounting in hidden position.

➃ Integration of defeat monitoring by means of status

monitoring/cyclic testing.

Mounting Examples

Refer to the following drawing for the installation. Mount the

interlock switch to a xed machine or guard, and actuator

on the hinged door. Do not mount both interlock switch and

actuator on the hinged doors. This may result in the actuator

being inserted at a wrong angle to the interlock switch,

resulting in malfunction.

Application of Sliding Doors

Door

HS9Z-A51

Actuator

HS5L

Interlock

Switch

Latch

Door Stop

Application of Hinged Doors

HS9Z-A52

Actuator

Interlock Switch

Door

HS5L

Latch

HS9Z-A51

Actuator

2-Contact4-ContactActuatorDimensions / Instructions

19

HS5L Interlock Switches with Solenoid

m

Instructions

Minimum Radius of Hinged Door

When using the interlock switch for a hinged door, refer to the

minimum radius of doors shown below. Especially for doors with

a small turning radius, use vertical/horizontal movable actuators

(HS9Z-A53/A55).

Note: Because deviation or dislocation of a hinged door may occur in actual

applications, make sure of the correct operation by installing the

2-Contact4-ContactActuatorDimensions / Instructions

actual machine rst before use.

HS9Z-A52 Actuator

When the center of the hinged door is used as the reference for

the interlock switch contact surface:

Minimum Radius

(35)

Interlock Switch

Mounting Hole

Minimum Radius

170mm

Door Hinge

190mm

Door Hinge

(36.2)

When the center of the hinged door is used as the reference for

the actuator mounting surface:

Minimum Radius

(40.3)

Interlock Switch

Mounting Hole

Minimum Radius

230mm

Door Hinge

260mm

Door Hinge

(41.5)

HS9Z-A52A Actuator (with Rubber Bushings)

When the center of the hinged door is used as the reference for

the interlock switch contact surface:

Centers 12mm: 120mm

Centers 20mm: 170mm

Minimum Radius

Door Hinge Door Hinge

(36.2)

When the center of the hinged door is used as the reference for

the actuator mounting surface:

Minimum Radius

140mm

(35)

Interlock Switch

Mounting Hole

(161)

(231)

(111)

When using the HS9Z-A53 Angle Adjustable (vertical)

Actuator

• When the center of the hinged door is used as the reference for

the interlock switch contact surface: 50mm

• When the center of the hinged door is used as the reference for

the actuator mounting surface: 80mm

• Angle adjustment screw recommeded tightening torque: 0.8N·m.

Minimum Radius

50mm

Door

Hinge

(36.2)

Interlock

Switch

Mounting

Hole

(38)

Minimum Radius

80mm

Door

Hinge

(56.5)

Interlock

Switch

Mounting

Hole

(68)

When using the HS9Z-A55 Angle Adjustable (vertical/

horizontal) Actuator

• When the center of the hinged door is used as the reference for

the interlock switch contact surface: 50mm

• When the center of the hinged door is used as the reference for

the actuator mounting surface: 70mm

• When the center of the hinged door is used as the reference for

the interlock switch contact surface:

Horizontal Swing

Minimum Radius

50mm

Door

Hinge

(36.2)

When the center of the hinged door is used as the reference for

the actuator mounting surface:

Minimum Radius

70mm

Door Hinge

(55.5)

Vertical Swing

Minimum

Radius

50mm

Minimum Radius

70mm

Door

Hinge

(36.2)

Interlock

Switch

Mounting

Hole

(38)

Vertical SwingHorizontal Swing

Door Hinge

(55.5)

Interlock

Switch

Mounting

Hole

(58)

Centers 12mm: 230mm

Centers 20mm: 310m

Minimum Radius

Door Hinge

(48.2)

Minimum Radius

260mm

Door Hinge

(47)

Interlock Switch

Mounting Hole

(231)

Actuator Angle Adjustment (vertical/horizontal)

• Using the angle adjustment screw, the actuator angle can

be adjusted (refer to the dimensional drawing on page 16).

Adjustable angle: 0 to 20°

• The larger the adjusted angle of the actuator, the smaller the

applicable radius of the door opening. After installing the

actuator, open the door. Then adjust the actuator so that its

edge can be inserted properly into the actuator entry slot of the

interlock switch.

• After adjusting the actuator angle, apply Loctite to the

adjustment screw so that the screw will not move.

20

Installing the Head

Do not use plastic and metallic heads of HS5D interlock switches

on the HS5L. Be sure to use HS5L metallic heads.

* The metal heads of the HS5D and HS5L look similar. When using

these interlock switches adjacently, ensure that the heads are

not interchanged.

HS5LHS5D

Metallic HeadMetallic HeadPlastic Head

Metal

Plastic

Color: Red

* The metal head can be distinguished easily by the color of the

plastic.

Color: Silver

Color:

Red∗

Color:

Black∗

A

Instructions

HS5L Interlock Switches with Solenoid

Rotating the Head

The head can be rotated by removing the four screws from the

corners of the head and reinstalling the head in the desired

orientation. However, when changing the mounting direction of the

head after wiring, turn the manual lock release to the “UNLOCK”

position using the enclosed manual lock release key rst. When

reinstalling the head, make sure that no foreign object enters

the interlock switch. Tighten the screws tightly, without leaving a

space between the head and body, otherwise the interlock switch

may malfunction.

(Recommended tightening torque: 0.9 to 1.1 N·m)

Factory SettingHead can be rotated

Head Removal Detection Function

• Solenoid locks interlock switches are not equipped with the head

removal detection function.

• The head removal detection function is available only on spring

lock interlock switches with circuits VB, VD, and DD having two

or more lock monitor circuits. Removing the head will result in

disparity (41-42: OFF, 51-52: ON). Note that this function cannot

be detected with other models.

• Only the lock monitor circuit 41-42 turns off (open) when the

head is removed, such as when the head is rotated. The other

monitor circuit 51-52 turns ON (close). Be sure to connect the

lock monitor circuit (41-42) to a safety circuit.

Spring Loaded Actuator

• When using the actuator, be careful of protruding ends.

• Regardless of door types, do not use the HS9Z-BA5 actuator as

a door lock or a door stop.

• When an operator enters the hazardous zone, take safety

measures such as using a HS9Z-PH5 padlock hasp so that the

operator is not trapped inside and the machine cannot start by

mistake.

• Use the actuator only on sliding

doors. Do not use on hinged doors.

• As shown in the gure on the right,

do not insert the sliding actuator from

below. The actuator may fall out due

to shocks.

• The HS9Z-BA5 actuator can only be

used for HS5L interlock switches. Do

not use the HS9Z-BA5 actuator for

other products.

• Do not modify or disassemble the

actuator.

Installation (when installation reference is 0.8mm)

• The actuator protrudes out when the actuator is not inserted

(door is open) as shown in 1. in the drawing.

• The mounting reference position can be set to 0.8mm when the

actuator is fully inserted and the actuator protrudes up to the

0.8mm line.

1. Removed

2. When fully inserted

(the door is completely shut)

A

3. Bounce (door gap)

Bounce tolerance

(Within the

lockable range)

· Drawing of interlock switch and HS9Z-BA5

when the actuator is fully inserted

(when the door is completely shut)

Mounting

reference

0.8mm

Interlock

switch

16mm

Detail view of A

Actuator

0.8mm line

Interlock switch

Align with the

0.8mm line

Interlock switch

Lock limit line

HS9Z-BA5

0.8mm line

Adjustment

Adjustment Procedure

1. Make a hole at A or C.

2. Fasten temporarily with screws, and check the actuator

position.

3. Make a hole at B and x the actuator using a screw or a rivet.

• 3.3mm line

The mounting reference position is where the door is fully closed,

and there is a 0.8mm space between the safety switch and

HS9Z-BA5, but can be adjusted up to the 3.3mm line.

The actuator is most securely locked when the mounting

reference position is at the 0.8mm line. However, adjust between

0.8 to 3.3mm if the safety switch is mounted on a door where the

space might become smaller.

• Lock limit line

When a door opens by bouncing, if the

lock limit line is outside of the edge of the

3.3mm line

0.8mm

line

interlock switch, the force of the bounce

may be too large so that the door may not

lock.

Safety Precautions

Lock limit

line

• The maximum gap of the door that can be locked is 16mm.

(When mounting reference is a the 0.8mm line)

• If the safety distance and minimum gap does not satisfy the

requirements of ISO13857, make the gap smaller by overlapping

the doors or by providing sufcient distance from the hazardous

source.

• The operating characteristics may change when the actuator is

used with the HS5L. Check the operating characteristics before

use.

Characteristic Diagram (Reference)

When the mounting reference is at the 0.8mm line:

Normal door

closing position

0

∗ Bounce can be tolerated to approximately 16mm.

Door close contact ON/

Door open contact OFF

Locking position

Approx. 10.1mm

Lockable range

Maximum gap 16mm

40.2mm

Insert

Approx. 20.4mm Door open contact ON

Approx. 18.4mm Door close contact OFF

Approx.16mm Locking position

Pull out

B

2-Contact4-ContactActuatorDimensions / Instructions

C

21

HS5L Interlock Switches with Solenoid

Screw

Instructions

[Reference] When using HS9Z-A51A with HS5L interlock switch:

Approx. 4.6mm Locking position

Approx. 6.6mm Door open contact ON

Approx. 8.2mm Door close contact OFF

0

Lockable range

Maximum gap

Approx. 4.6mm

2-Contact4-ContactActuatorDimensions / Instructions

∗ Approx. 4.6mm for HS9Z-A51A.

Approx. 8.2mm Door open contact ON

Approx. 6.6mm Door close contact OFF

Approx. 4.6mm Locking position

23.1mm

Insert

Pull out

Manual Unlocking

Spring lock

The spring lock interlock switch allows manual unlocking of the

actuator to precheck proper door movement before wiring or

turning power on, as well as for emergency use such as a power

failure.

Solenoid lock

The solenoid interlock switch does not unlock even when the

solenoid is de-energized. However, the interlock switch can be

unlocked manually in emergency cases.

UNLOCKLOCKUNLOCKLOCK

UNLOCK

LOCK

Normal Position

Manual Unlocking

Position

When locking or unlocking the interlock switch manually, turn the

key fully using the manual unlock key supplied with the interlock

switch. Using the interlock switch with the key not fully turned

(less than 90°) may cause damage to the interlock switch or

operation failures (when manually unlocked, the interlock switch

will keep the main circuit disconnected and the door unlocked).

Do not apply excessive force to the manual unlock, otherwise the

manual unlock will become damaged. Do not leave the manual

unlock key attached to the interlock switch during operation.

This is dangerous because the interlock switch can always be

unlocked while the machine is in operation.

Safety Precautions

Before manually unlocking the interlock switch, make sure that the

machine has come to a complete stop. Manual unlocking during

operation may unlock the interlock switch before the machine

stops, and the function of interlock switch with solenoid is lost.

Installing the Rear Unlocking Button

(HS5L-L)

After installing the interlock switch on the

panel, place the rear unlocking button

(supplied with the switch) on the push

rod on the back of the interlock switch,

and fasten the button using M3 sems

screw (supplied with the switch).

Push Rod

Rear Unlocking

Button

Mounting

Screw

(M3 sems)

HS5L-L

When installing on a mounting frame

thicker than 6mm, use the rear unlocking button kit HS9Z-FL5

(sold separately).

Safety Precautions

After installing the rear unlocking button, apply Loctite to the

screw so that the screw does not become loose. The rod is made

of SUS, the button is made of glass-reinforced PA66 (66 nylon)

and the screw is made of iron. Take the compatibility of the plastic

material and Loctite into consideration.

Installing the Rear

Push Rod

Unlocking Button Kit

1. Install the connecting rod onto the

push rod on the HS5L-L rear

unlocking button interlock switch.

2. A pin is attached to the connecting

rod. Insert the pin into the hole in

the push rod, using pliers.

Connecting

Rod

Panel

HS5L-L

Pin

Interlock Switch

3. Pull the connecting rod from the hole in the mounting frame,

and turn the button operating pin to the horizontal position.

Connecting

Rod

Pull

Connecting Rod Orientation

Correct

Incorrect

Safety Precautions

• Ensure that the connecting rod is pulled out completely and it is

horizontal to the interlock switch, otherwise the unlocking button

cannot be installed.

Note: Frame must be supplied by the user.

For the mounting hole layout of interlock switches, see

dimensions on page 18.

4. Install the unlocking button on the connecting rod by tting the

pin to the grooves on the back of the button, and fasten the

base plate on the mounting frame using the screws.

Button

Groove

(1) Pull up once

Unlocking

Button

Button

Operating

A

Pin

B

(2)

5. After fastening the screws, check if locking and unlocking

operations can be performed.

Safety Precautions

• Install the rear unlocking button

kit in the correct direction as

shown below. Do not install

the kit in incorrect directions,

otherwise malfunction may

occur.

• Do not apply strong force

Correct

orientation

Incorrect orientation

exceeding 100m/s2 to the

interlock switch while the rear unlocking button is not pressed,

otherwise malfunction may occur.

Unlocking the Manual Lock Using the

Rear Unlocking Button

Use the rear unlocking button when a worker is locked inside

a safety fence (hazard area). (Compliant with escape release

described in ISO14119 (2003) and GS-ET-19)

Unlock

Rear Unlocking Button

Procedure

• When the rear unlocking button is pressed, the interlock switch

is unlocked and the door can be opened.

• To lock the interlock switch, pull back the button.

• When the button remains pressed, the interlock switch cannot

be locked even if the door is closed, and the main circuit remains

open.

Safety Precautions

• Install the rear unlocking button in the place where only the

operator inside the hazardous area can use it. Do not install the

button in a place where an operator outside the hazardous area

can use it, otherwise the interlock switch can be unlocked during

usual machine operation, causing danger.

Unlock

Rear Unlocking

Button Kit

22

Instructions

Terminal wiring diagram

M4 Screw

8 to 9mm

ø2.5

HS5L Interlock Switches with Solenoid

• Operate the rear unlocking button by hand only. Do not operate

using a tool or with excessive force. Do not apply force to

the button from the direction other than the proper direction,

otherwise the button will be damaged.

Recommended Tightening Torque

• HS5L interlock switch: 1.8 to 2.2 N·m (four M4 screws)*

• Lid mounting screw: 0.5 to 0.7 N·m (M3 screw)

• Rear unlocking button: 0.5 to 0.7 N·m (M3 screw)

• Rear unlocking button kit: 4.8 to 5.2 N·m (M5 screw)

• Actuators

HS9Z-A51: 1.8 to 2.2 N·m (two M4 screws)*

HS9Z-A52: 0.8 to 1.2 N·m (two M4 flat head screws)

HS9Z-A51A/A52A: 1.0 to 1.5 N·m (two M4 screws)*

HS9Z-A53: 4.5 to 5.5 N·m (two M6 screws)*

HS9Z-A55: 1.0 to 1.5 N·m (two M4 screws)*

HS9Z-BA5: 4.5 to 5.5 N·m (two M5 screws/four)*

* If the mounting screw recommended tightening torque values

above is not satised, check loosening after installation

throughly.

• Mounting screws need to be prepared by the customer.