IDEC HS5D-11, HS5D-02, HS5D-12, HS5D-03 Instruction Sheet

B-19 02-1(0)

INSTRUCTION SHEET - HS5D Series Safety Switch

( 1 / 5 )

2016.08

1

Type

HS5D-11ZRNM

Contact configration

11 : 1NO-1NC

02 : 2NC

12 : 1NO-2NC

03 : 3NC

Gland Port Size

Blank : G1 /2

M : M20

P : PG13.5

Material of Head

Blank : Plastic

Z : Metal

Ratings approved by safety agencies

(1) TÜV rating / CCC rating / KOSHA rating

AC-15 250V, 3A

DC-13 30V, 4A

(2)UL, c-UL rating

A300 3A, 250V ac, Pilot Duty

4A, 30V dc

EN ISO / ISO14119

IEC60947-5-1, EN60947-5-1, GS-ET-15

UL508, CSA C22.2 No.14, GB14048.5

IEC60204-1, EN60204-1

Low Voltage Directive, Machinery Directive

10A

900 operations / hour

0.05 to 1.0 m/s

10 mm minimum (HS9Z-A51)

50 N minimum (HS9Z-A51)

50mΩ maximum (Initial value)

IP67 (IEC60529)

250V AC, 10A fast acting type fuse

30V

10A

10A

8A

4A

125V

10A

5A

2.2A

1.1A

250V

6A

3A

1.1A

0.6A

Resistive load (AC12)

Induc ive load (AC15)

Resistive load (DC12)

Induc ive load (DC13)

Applicable Standards

Standards for Use

Applicable Directives

Thermal Current ‹Ith›

Contact Ra ings

‹Ue, Ie›

Operating Frequency

Operating Speed

Direct Opening Travel

Direct Opening Force

Contact Resistance

Degree of Protection

Short-Circuit Protective Device

AC

DC

Operating Condition

Operating Temperature

Operating Humidity

Pullution Degree

-30 to +70°C (no freezing)

45 to 85%RH (no condensation)

3 (Inside 2)

Al itude

2000m maximum

Impulse with voltage ‹Uimp›

4kV

Rated Insula ion voltage ‹Ui›

300V

Mechanical Durability

1,000,000 operations minimum (GS-ET-15)

B10d

Electrical Durability

Conditional short circuit current

2,000,000 (EN ISO 13849-1 Annex C Table C.1)

100A(250V)

100,000 operations min. (AC-12 250V•6A)

1,000,000 operations min. (AC/DC 24V 100mA)

(900 operations / hour)

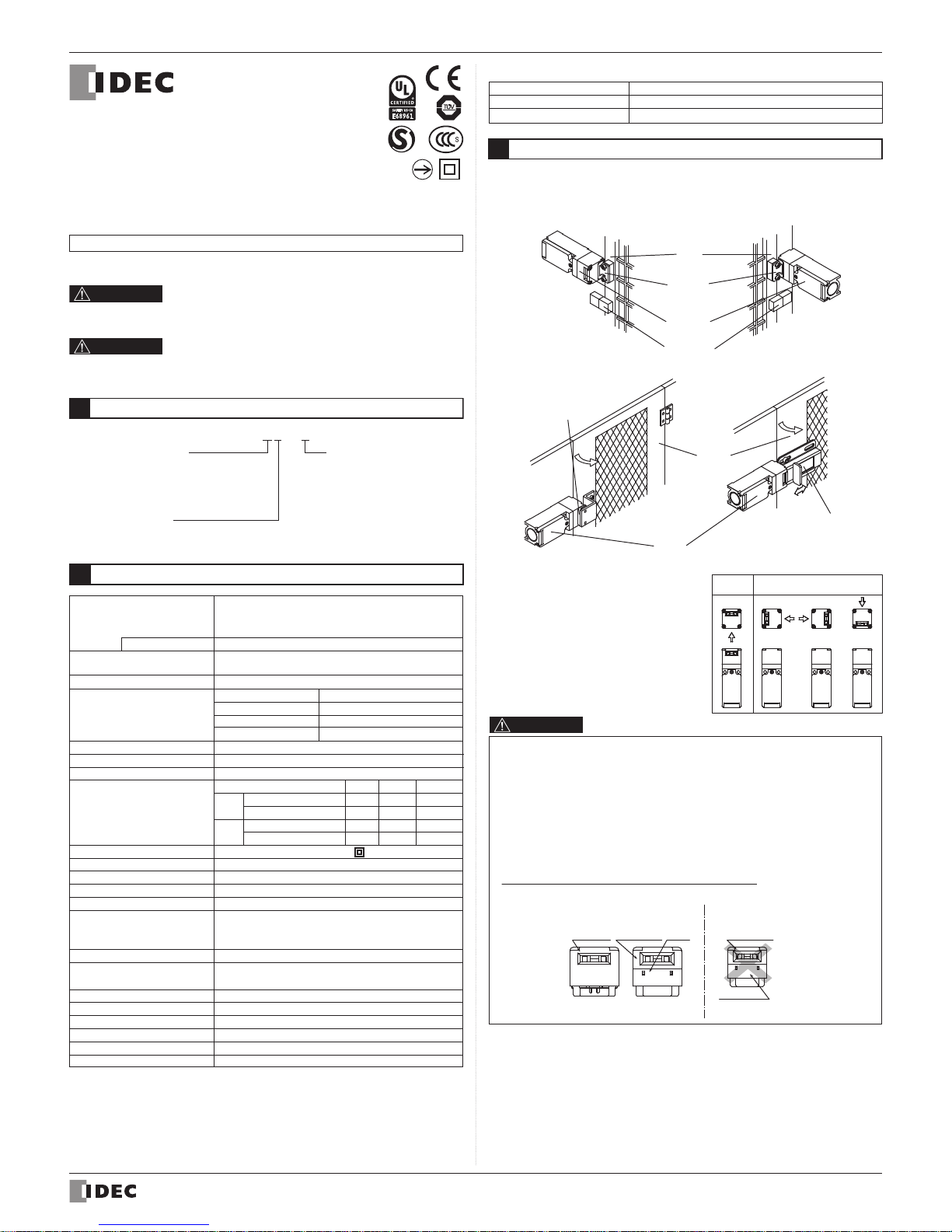

HS5D

Safety Switch

HS9Z-SH5

Actuator

Hinged

Door

HS9Z-A52

Actuator

Door Stop

HS5D

Safety Switch

Door

HS9Z-A51

Actuator

(Examples of Mounting on Sliding Doors)

(Examples of Mounting on Hinged Doors)

2

Specifications and Ratings

3

Mounting Examples

Class of Protection

Class II (IEC61140)

Confirm that the delivered product is what you have ordered.

Read his instruction sheet to make sure of correct operation.

In this operation instruction sheet, safety precautions are categorized in order of

importance to Warning and Caution :

Warning notices are used to emphasize that improper operation may cause severe

personal injury or death.

Caution notices are used where inattention might cause personal injury or damage to

equipment.

INSTRUCTION SHEET

Original Instructions

Safety Switch

HS5D Series

SAFETY PRECAUTIONS

CAUTION

WARNING

* In order to verify if the product

you are interested in is certified

with the S mark, please check

the following section on our

website: "List of type numbers

certified with the S mark"

※

• Install the interlock switch on the immovable machine or guard, and install the

actuator on the movable door. Do not install both interlock switch and actuator on

themovable door, otherwise the angle of insertion of the actuator to the safety switch

may become inappropriate, and failure will occur.

Changing the Mounting Directions of

the HS5D Head

• The head of HS5D can be mounted in four

directions by removing the four screws on

the corners of the HS5D head.

WARNING

Mounting Directions of the HS5D Head

• When replacing the HS5D head, make sure that no foreign object enters into the

safety switch.

• Tighten the screws tightly, o herwise he safety switch may malfunction.

• Don't remove the screws of head expect when the mouting directions of head is

changed.

• When tightening the screw in the head section with an electric screwdriver or

similar tool, temporarily tighten the first part of the screw by hand first, and then

tighten with the electric screwdriver.

Mounting the HS5D Head

• Do not use the metal head for the HS5L with lock type. Be sure to use the plastic

head or metal head for the HS5D. Be sure to use the correct head.

When

Shipped

Alternative Moun ing

Directions

Color:

Red

HS5D

Metal HeadPlastic Head Metal Head

HS5L

Metal,

Color:Silver

Metal,

Color:Silver

Plastic,

Color Red

Color:Black

Shock Resistance

Vibration Resistance

Damage Limits: 1000m/s

2

Operating Extremes:10 to 55 Hz, half amplitude 0.5mm

Damage Limits: 30 Hz, half amplitude 1.5mm

10 operations min.

100MΩ(Initial value)

1,000V 1minute(Initial value)

Mechanical durability

Insulation resistance

Dielectric strength

HS5D Head Removal Detection Function (Screw Terminal No.11-12)

Interlocking device Type

/ the level of coded

Type 2 Interlocking device

/ low level coded actuator (EN ISO / ISO14119)

B-19 02-1(0)

INSTRUCTION SHEET - HS5D Series Safety Switch

( 2 / 5 )

2016.08

When the center of the hinged door is

on the extension line of

the actuator mounting surfade.

When the center of the hinged door is

on the extension line of the contact

surface of actuator and safety switch.

HS9Z-A52

HS9Z-A52A

Mounting centers:12mm

Mounting centers:20mm

HS9Z-A55

R1

230 mm

230 mm

310 mm

70 mm

(Horizontal Swing)

R2

260 mm

260 mm

70 mm

(Vertical Swing)

R3

170 mm

120 mm

170 mm

50 mm

(Horizontal Swing)

R4

190 mm

140 mm

50 mm

(Vertical Swing)

Minimum Radius

(Actuator deviation)

+

(Door movement)

≤ 1.7 mm

≤ 3.0 mm

≤ 2.5 mm

HS9Z-A51

HS9Z-A52

HS9Z-A51A

HS9Z-A52A

HS9Z-A55

Minimum Radius of Hinged Door

• When using the safety switch for a hinged door, the minimum radius of the applicable door is shown in the following figures.

Actuator Mounting Tolerance

• Mounting tolerance of the actuator is 1.0mm in the four lateral directions.

• Make sure he actuator can be inserted into the entry slot without any issue.

• When closing the door, the actuator is inserted within a certain distance from the

reference position. The contact operation is not affected by the actuator movement.

The above example are based on the condi ion that the actuator enters and exits

the actuator entry slot smoothly when the door is closed or opened.

Since there may be deviation or dislocation of the hinged door, make sure of

correct operation in the actual application before installation.

CAUTION

Door Hinge Door Hinge Door Hinge Door Hinge

Minimum Radius

Minimum Radius

Minimum Radius

Minimum Radius

R1

R2

R4

R3

Actuator Stop

Safety Switch

Door Stop

HS9Z-A51

Actuator

Actuator Stop

Safety Switch

Door Stop

Safety Switch

HS9Z-A52

Actuator

HS9Z-A55

Actuator

Actuator Cover

Actuator Stop

Center

Safety Switch

1.7mm

3.0mm

±1.0mm

±1.0mm

HS9Z-A51 HS9Z-A52

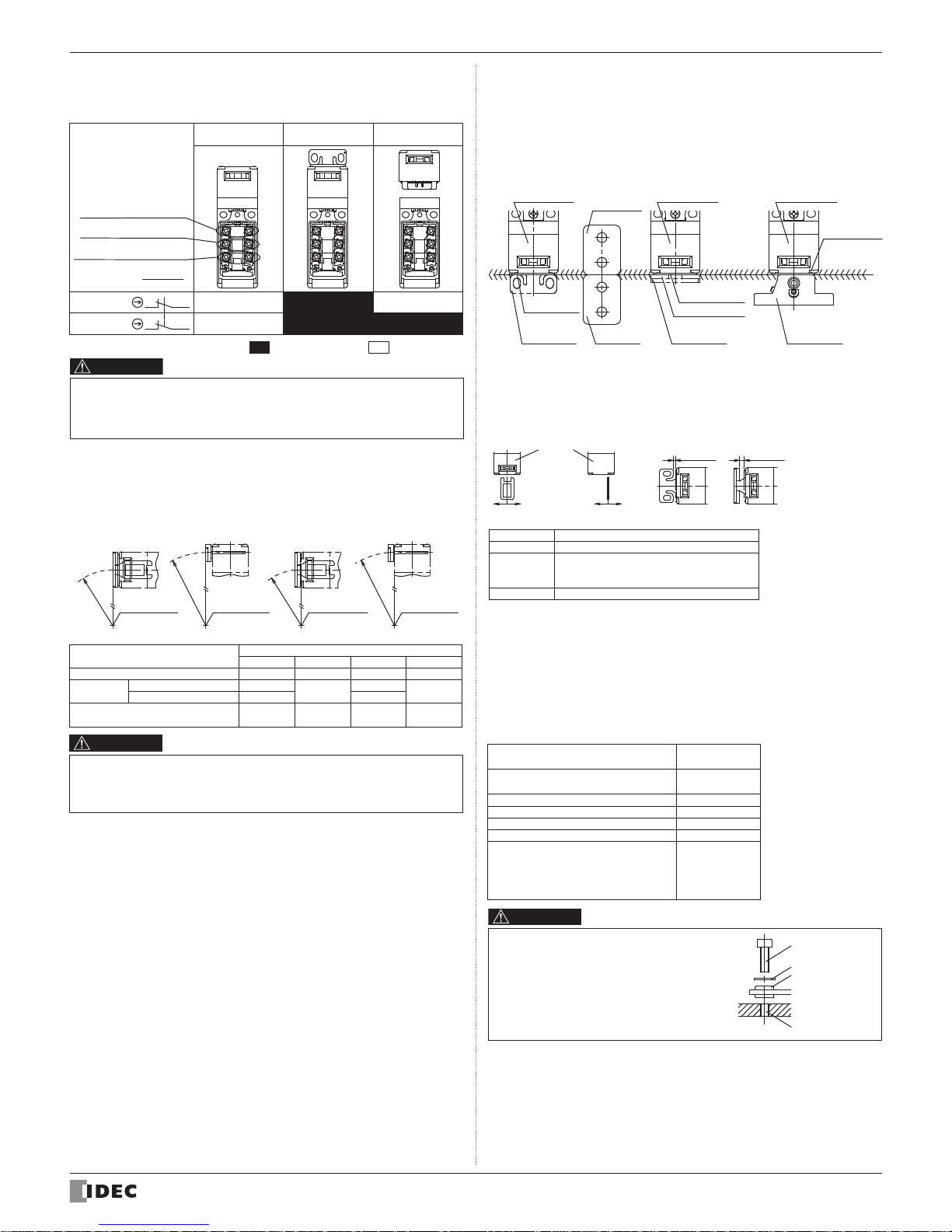

HS5D Head Removal Detection Function

• The the NC contacts of the two main circuits (11-12, 21-22) are operated similarly by

the actuator. But, when the HS5D head is removed, the NC contact of the main

circuit (11-12) is opened, and other NC contact (21-22) remains closed.

:

Contact Closed

:

Contact Open

Main Circuit:

1211

21 22

Main Circuit:

Main Circuit

(

11-12

)

Main Circuit

(

21-22

)

Monitor Circuit

(

33-34

)

Actuator inserted

When the HS5D

head is removed

Actuator pulled

(

31-32

)

• When the HS5D head is removed, the NC contact of the main circuit (11-12) is

opened, and other NC contact(s) remain closed. Use the NC contact of the main

circuit (11-12) for the safety circuit.

• Turn off he power when using this function.

CAUTION

HS9Z-A51A/HS9Z-A52A

• When there is a displacement of safety switch and actuateor, the actuator may hit the

entry slot of safety switch hardly, thus damaging the entry slot and acutuator. The

rubber cushions on the HS9Z actuator prevent the actuator from damaging the entry

slit by absorbing the shock with movement flexibility. Do not, however, exert excessive shocks, otherwise the failure of safety switch may be caused.

• The rubber cushions may deteriorate depending on the operating enviroment and

conditions. Immediately replace the deformed or cracked rubber cushions with new

ones.

*1 When the torque is not enough to recommended

screw tightening torque, make sure hat the

screw do not become loose by using adhesive

sealants etc. to keep right operation and

mounting positioning.

*2 In the case of HS9Z-A51A and HS9Z-A52A,

using two M4 screws and two attached washers,

fasten the actuator securely on the door.

CAUTION

Recommended Screw Tightening Torque

Screw Tightening

Torque

1.8 to 2.2N・m

0.2 to 0.4 N・m

0.6 to 0.8 N・m

2.7 to 3.3 N・m

0.9 to 1.1 N・m

For moun ing the safety switch

(M4 screw) *1

1.8 to 2.2 N・m

0.8 to 1.2 N・m

1.0 to 1.5 N・m

For moun ing the actuator

(HS9Z-A51: M4 screw) *1

(HS9Z-A52: M4 Phillips screw)

*1, 2

(HS9Z-A51A/A52A/A55: two M4 screws)

For moun ing the HS5D lid (M3)

Terminal screw (M3)

Cable gland

For moun ing the HS5D head (M3)

Name or Use

M4 Screw

Washer

Rubber Cushion

Door

M4 mounting hole

Adjusting the Angle Adjustable (vertical/horizontal) Actuator

(Type HS9Z-A53/A55)

• Using the angle adjustment screw (M3 hexagon socket set screw), the actuator angle

can be adjusted up to 20°(refer to dimensions).

• The larger the actuator angle, the smaller the applicable radius of the door swing.

After installing the actuator, open the door. Then adjust the actuator angle so that the

actuator enters the entry slot of the safety switch properly.

• After adjusting the actuator angle, apply loctite or the like on the adjustment screw to

prevent loosening.

(Type HS9Z-A53)

Tightening torque of angle adjustment screw : 0.8 N•m.

(Type HS9Z-A55)

Use screw locking agent that is compatible with the base material.

Base : PA66 (66 nylon) of glass reinforced grade

Angle adjustment screws : stainless steel

Actuator Mounting Reference Position

As shown below, the mounting reference position of the actuator inserted into the

safety switch is:

(Type HS9Z-A53)

The actuator stop film placed on the actuator touches the safety switch lightly.

(Except Type HS9Z-A53)

The actuator and actuator cover touches the actuator stop placed on the safety

switch lightly.

(After mounting the actuator, remove the actuator stop from the safety switch.)

Loading...

Loading...