IDEC HR2S Sales Brochure

HR2S

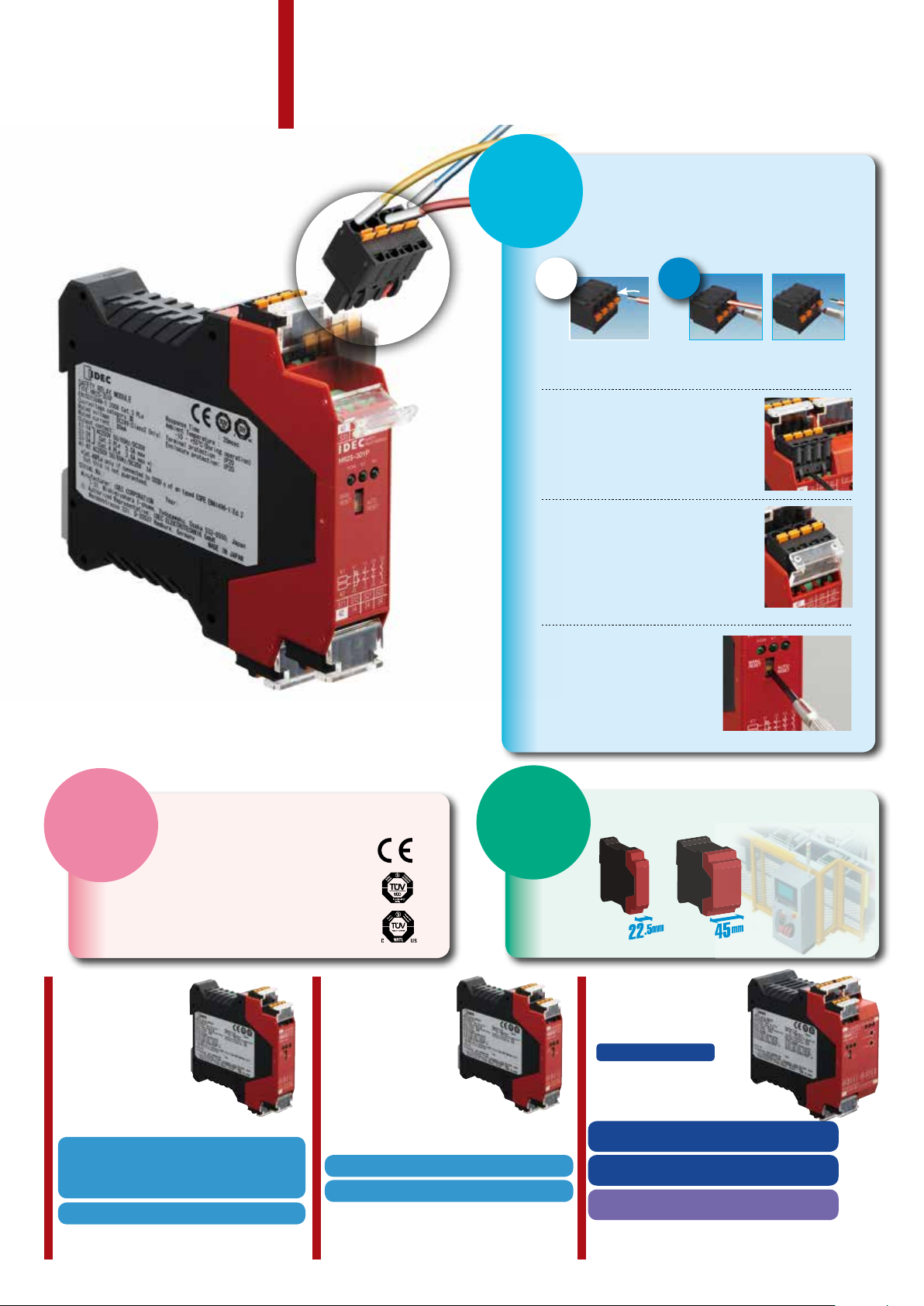

Safety Relay Modules

Compact Design and Maintenance Improvements for

Compact Design and Maintenance Improvements for

Outstanding Usability!

Outstanding Usability!

HR2S-301P

Compliant with

Performance level (PL) e

Category 4

EN ISO 13849-1

HR2S-301N

TÜV SÜD

European and North American (NRTL)

HR2S-332NT075/T15/T30

With time-delay output

SIMPLE

COMPACT

SAFETY

Slim safety relay module with spring

HR2S

Safety Relay Modules

terminals enables easy wiring!

SIMPLE

1

1

Removable terminal block

enables easy replacement

The terminals can be attached and

removed easily with a at screwdriver

allowing easy replacement of the

module.

The terminal cover detects

improper connection

The terminal cover does not close if

the terminal is not fully inserted into

the module.

Simple wiring procedure

No complex work required. Just insert a

ferrule into the terminal. The wire is locked

into the spring terminal so a screwdriver is not

required when inserting the wire.

Insert

No tools needed.

Directly insert a

ferrule into the terminal.

The wire is locked.

Removal

1

1

Insert a at

screwdriver

into the terminal

entrance.

2

2

Remove the

wire by releasing

the lock with a

screwdriver.

HR2S-301P

SAFETY

Complies with international standards

• Safety Category 4, Performance

Level e according to

EN ISO 13849-1: 2008

• TÜV SÜD

European and North American (NRTL)

HR2S-301P HR2S-301N

Operation modes can be

changed with a single

action

The switch on the front panel

allows switching between Auto

and Manual modes.

COMPACT

Compact design enables

installation in a narrow space

HR2S-301P

HR2S-301N

HR2S-332NT

HR2S-332NT075/15/30

Time-delay output

Not fully inserted

•Compliant with categories 2 and 3 when

used with a safety switch.

•Compliant with categories 2 (type 2) and

4 (type 4) when used with a safety light curtain.

3NO and 1NC output contacts

Auxiliary output (NC) can be used for monitoring.

2

Compliant with Category 4

3NO and 1NC output contacts

Auxiliary output (NC) can be used for monitoring.

3NO (safety output) and

3NO (time-delay safety output)

Time-delay output

compliant with category 4

Time setting can be selected from

31 different time ranges

· HR2S-332N-T075=0.5/1/1.5/2/2.5/3/3.5/4/4.5/5/5.5/6/6.5/7/7.5s

· HR2S-332N-T15=1/2/3/4/5/6/7/8/9/10/11/12/13/14/15s

· HR2S-332N-T30=2/4/6/8/10/12/14/16/18/20/22/24/26/28/30s

HR2S-301P/HR2S-301N Safety Relay Modules

Production

monitored

Safety

tested

Functional

Safety

HR2S-301P/HR2S301N

Contact Conguration

Safety Output Auxiliary Contact

3NO 1NC

Dimensions

13 23 3341

S34

A2A1

S33

SAFETY

RELAY MODULE

HR2S-301P

K1 K2

POW

MANU

RESET

AUTO

RESET

SEAL

All dimensions in mm

111.2

33

131441

23

K1

34

K2

24

42

S11

S12

S21S22

14 24 34

42

22.5

Terminal position (76.7)

Terminal position (95.7)

111

Package Quantity: 1

Input Supply Voltage Part No.

Positive 24V DC –15% to +10% HR2S-301P

Negative 24V DC –15% to +10% HR2S-301N

Specifications

EN ISO 13849-1: 2008

EN 954-1: 1996

Applicable Standards

Applicable Standards for Use EN 60204-1: 2006

Performance level (PL) e (EN ISO 13849-1)

Safety Category (Note 2) 3 or 4 (EN ISO 13849-1)

Stop Category 0 (IEC/EN 60204-1)

Operating Temperature –10 to +55°C (no freezing)

Relative Humidity 30 to 85% (no condensation)

Altitude 0 to 2000m (operating)

Insulation Resistance

Dielectric Strength

Shock Resistance

Bump

Vibration Resistance

Degree of Protection Terminals: IP20 Housing: IP40

Rated Voltage 24V DC –15% +10%

Power Consumption 2.2W (26.4V DC)

Overcurrent Protection Built-in, electronic (approx. 0.9A)

Contact Resistance

Turn-On Time 50 ms maximum (Note 4)

Minimum Applicable Load 24V DC / 5 mA (Reference value)

Response Time 20 ms maximum (Note 4) (Note 5)

Overvoltage Category III (IEC60664-1)

Pollution Degree 2 (IEC60664-1)

EN 50178: 1997

EN 55011/A2: 2007

EN 61000-6-2: 2005

UL508/R2005-07 (Note 1)

CAN/CSA C22.2 No.14: 2005 (Note 1)

100Ω minimum

(500V DC megger, same measurement

positions as dielectric strength)

Between outside housing and internal

circuit:

3,750V AC,1 minute

Between outputs of different poles:

2,500V AC, 1 minute

Between input and output terminals:

2,500V AC, 1 minute

Between power supply and output terminals:

2

, pulse width 11m sec, 3 shocks

300 m/s

in each of 3 axes

2

, pulse width 16m sec, 1000

100 m/s

times in each of 3 axes

2,500V AC ,1 minute

10 to 55 Hz, 1 octave/minute,

0.7 mmp-p in each of 3 axes, 20 sweeps,

5 to 55 Hz, 30 m/s

of 3 axes

2

, for 2 hours in each

200 mΩ maximum (Note 3)

Rated Insulation Voltage

(output contact)

Terminals

13-14

23-24

33-34

Rated Load

(Note 6) (Note 7)

Safety

Circuit

250V (IEC60664-1)

250V AC / 30V DC (resistive load) (Note 8)

Category 3 or lower: 5.0A maximum

Category 4 or lower: 3.6A maximum

AC15 240V AC / 2A cosø=0.3

DC13 24V DC / 1A L/R=48 ms

No. of Outputs 3 (NO contact output)

Rated Load

(Note 7)

Terminals

41-42

Output Contact Ratings

Safety

Circuit

250V AC / 30V DC (resistive load)

Category 3 or lower: 5.0A maximum

Category 4 or lower: 3.6A maximum

AC15 240V AC / 2A cosø=0.3

DC13 24V DC / 1A L/R=48 ms

No. of Outputs 1 (NC contact output)

Mechanical Durability 5,000,000 operations minimum

Electrical Durability 100,000 operations minimum

2

Wire Size 0.2 mm

to 1.5 mm2 (24 to 16 AWG)

Weight (approx.) 200g

Note 1: UL and CSA are approved by TÜV SÜD America Inc., an accredited

NRTL.

Note 2: HR2S-301N is recommended for use in category 4 safety

applications. The requirements of the safety category must be

determined according to the safety equipment. We recommend that

you consult a third party organization.

Categories may change depending on the combination of the safety

equipment. Categories may also change depending on the output

contact ratings.

Note 3: Measured using 5 or 6V DC, 1A voltage drop method.

Note 4: When measured at the rated voltage (at 20°C), excluding contact

bounce time.

Note 5: The time from when the safety input turns OFF to when the safety

output turns OFF.

Note 6: Leave 5 mm of space between the sides of the module when more

than 3A is continuously applied to the relay contact.

Note 7: The module is not suitable for use with a load less than the

minimum applicable load. Once a large load is applied, contacts

may not operate with a small load.

Note 8: The maximum current of the safety output contact is specied by

the approved standard.

Category 4 HR2S-301N, HR2S-301P + Type 4 OSSD’s 3.6A

Category 3 HR2S-301P 5.0A

•To prevent the safety output contact from overcurrent, use a fuse. To satisfy

Category 4, use a fuse with a maximum current of 3.6A. This fuse is not

required if the short circuit current is less than 5A.

3

HR2S-301P/HR2S-301N Safety Relay Modules

41 13 23 33

S34S33

Y2Y1

HR2S-301P

SAFETY

RELAY MODULE

K2

K1

POW

MANU

RESET

AUTO

RESET

42 14 24 34

S22S21S12S11

K2

K1

41 13 23 33

42 14 24 34

1

2

3

4

7

8

6

5

13 23 3341

S34

S33

A2A1

AUTO

RESET

MANU

RESET

POW

K1 K2

SAFETY

RELAY MODULE

HR2S-301P

42 14 24 34

S22S21S12S11

K2

K1

41 13 23 33

42 14 24 34

0V

24V DC

C

(1) Use a 3.6A maximum fuse for output

Terminal Arrangement

3

1

13 23 3341

S34

S33

8

7

6

5

HR2S-301P

POW

MANU

RESET

SAFETY

RELAY MODULE

K1 K2

AUTO

RESET

Part Description

Part No. Part Names and Functions

CN1: Power supply input,

1

start/off-check input

2 CN2: Safety input (dual channel)

A2A1

3 CN3: Safety output contact

4 CN4: Safety output contact

Switch: Select AUTO or MANU

5

mode

6 POW: Power LED

7 K1: ON-LED for safety output

8 K2: ON-LED for safety output

33

131441

23

K1

K2

34

24

42

S22

S21

S11

S12

14 24 34

42

2

4

HR2S-301P Wiring Diagram

Safety Category 4 Circuit Example (using a safety light curtain)

Terminal Arrangement

Terminal Markings I/O Signals Notes

A1

CN1

A2

S33

S34

S11

S12 Function

CN2

S21

S22 Function

41–42

CN3

CN4

13–14

23–24

33–34

Note: 5.0A max. Category 3 or lower HR2S-301P

3.6A max . Categ ory 4 HR2S-301N, HR2S-301P + Type 4 OSSD’s

Power supply

+24V DC input

Power supply 0V

input

Start/off-check

input

Safety

Common

input 1

Safety

Common

input 2

Monitor contact

for safety output

(NC)

Safety output

contact (NO)

Use a dry contact.

For HR2S-301N, use

a dry contact.

When connecting

TYPE 4 safety light

curtain to HR2S301P, use only S12

(S22).

Rated load

250V AC / 30V DC, 1A

(Resistive load)

Rated load

250V AC / 30V DC

(Note) (Resistive load)

*EDM function disabled

SE4B Light Curtain (TYPE4, PNP Output)

Safety category is achieved by the entire

control system. Take the connected

safety equipment and wiring into

consideration.

Emitter

24V DC

(Blue)

0V

(Brown)

24V DC

(Blue)

0V

(Brown)

24V DC

(White)

TEST/START

External Device

A1

A2

The SE4B light curtains are used in the above system.

Receiver

Turn on DIP switch #3 on the receiver.

(Yellow)

EDM

(Pink)

OSSD2

2

K2

ESC: External Start Condition

F1 to 3: Protective fuse for the output of safety relay module

K1 to 2: Safety Contactor

S2: Start Switch

S33-S34: Feedback loop

F1 F2 F3

(1) (1) (1)

13 23 33

K1

K2

14 24 34

N.C. (No Connect)

33

34 42

line protection.

41

to PL

(Gray)

OSSD1

ESC

S2

S34

S12S22S21S11

1

b

a

K1

S33

Off Check

Relay

a

ON

b

Sub

Control

Circuit

AUTO: Short

MANU: Open

K1

K2

(1)

13

23

K1

K2

14 24

Stop Category 0

4

Loading...

Loading...