Operator Interfaces

Operator Interface Touchscreen Family

Smart design to fi t your needs

From the large 12.1” TFT LCD Screen, to the compact

4.6” STN LCD, our screens support either monochrome or 256 colors with high pixel resolution to

give you sharp images and excellent visibility. In

keeping with IDEC’s attention to detail, our slimbody design adapts to applications where space is

limited. With up to 8MB of memory and a 200MHz

32-bit RISC CPU, IDEC Touchscreens put control,

power and speed at your fi ngertips.

Versatile, High functionality

IDEC Touchscreens can function as either a stand

alone controller or communicate with IDEC PLCs

and a wide array of major manufacturers’ PLCs.

Touchscreens interface with any of your equipment

to provide graphical data presentations in vivid color

and to display bar graphs and meters to represent

analog data. Illuminated pushbuttons can replace

physical mechanical switches; pilot lamps can display on/off states and show almost any production

information you need to monitor.

OI Touchscreen Family

PLCs Operator Interfaces Automation Software Power Supplies Sensors

12.1” HG4F

Programming power made easy

IDEC’s powerful WindO/I-NV2 software lets you create colorful graphical interfaces for easier production supervision and control. A built-in library of over

5000 bitmap images helps you easily display almost

every manufacturing activity you want to control.

Our programming software is intuitive and userfriendly. With re-sizeable pop-up screens, Windows

compatible fonts, and multilingual text capabilities,

you enjoy the utmost fl exibility in designing and

programming.

5.7” HG2F

10.4” HG3F

4.6” HG1F

Communication & Networking

USA: 800-262-IDEC Canada: 888-317-IDEC

71

OI Touchscreen Family

Operator Interfaces

Features

The OI Touchscreen Family is ideally matched to today’s sophisticated technology.

Using a wide range of graphical options, you can represent specifi c equipment, make

production information immediately apparent and instantly display safety problems.

PLCsOperator InterfacesAutomation SoftwarePower SuppliesSensors

Consolidating controls on an IDEC touchscreen eliminates costly investments in wiring and installation of multiple pushbutton indicators on a traditional control panel.

Just think how you can benefi t with touchscreens.

Expansion I/O

An expansion digital I/O module gives you the

option of expanding your system with 16 DC

inputs and 16 transistor outputs for basic PLC

control (excluding 4.6” HG1F touchscreen).

Basic Data Representation

A built-in software library of over 5000 bitmapped images lets you graphically represent almost any plant activity or equipment that you want to monitor or control. In addition

to representing meters, bar graphs and switches, you can also incorporate keypads

to facilitate changing values. Our user-friendly programming software lets you

design each screen by simply selecting objects from a pull-down menu or from a row of object icons and dropping it onto the screen work area. All bitmap images are

available in 256 colors and are easily re-confi gurable.

Ethernet Support

Remote

Network

Local Area

Network

Ethernet

The built-in 10BaseT Ethernet port found on the 10.4” and 12.1” touchscreens allow communications with PLCs using Ethernet/IP, Modbus TCP/IP or IDEC networking

protocol. The touchscreens also allow you to remotely monitor machine-operating status via the Internet or your Local Area Network using any web browser. Regardless of your location, you can use your PC’s browser (Netscape or Internet Explorer) to collect data about any touchscreen project. You can effi ciently monitor and

manage production activity from your offi ce without the time or expense of travel.

Recipe, Alarm and Trend Logging

Compact Flash Card

The Recipe function allows you to conveniently set operational parameters,

which can be individually defi ned for different processes. The Alarm function stores historical events with a date and time stamp compliant to the ISA

(Instrument Society of America) Standards, adding additional options to display

and manage alarm messages. Trend Logging expresses data in graphical form

according to the time period you defi ne. Using these functions, you can quickly

view production information and collect and manage data.

Communication & Networking

72

OI Touchscreens (excluding 4.6” HG1F) support Compact Flash (CF) Cards with

up to 512 MB of memory. In addition to storing recipe, alarm and trending data,

the CF Card can also store screen captures in a BMP format for documentation

purposes. The CF Card can hold one or more projects and you can easily transfer

a project directly to another touchscreen by simply inserting the card into the

second touchscreen and downloading what you need.

www.idec.com

Operator Interfaces

OI Touchscreen Family

Features, con’t

To meet your application needs, IDEC

offers 12.1” and 10.4” TFT LCD screens,

and 4.6” and 5.7” STN LCD screens that

come with 256 colors or in monochrome

to provide you with either multicolored or

gray scale graphics. All screens have high

pixel resolution and super bright LCD

screens with 400 cd/m2 for the 12.1”, 450

cd/m2 for the 10.4” screen, 250 cd/m2 for

the 5.7” and 500 cd/m2 for the 4.6” screen

to provide sharp quality images, with

RS-232 / RS-485 / RS-422 communica-

tion. In addition, all IDEC

Touchscreens communicate with IDEC as well as many other

industry leading PLC manufacturers.

Their slim body style of: 35.3mm depth for the 4.6” HG1F,

50mm depth for the 5.7” HG2F, 49.6mm depth for the 10.4”

HG3F, and 52.1mm depth for the 12.1” HG4F, provide an

advantage in space in a panel.

OI Link Communication

Support of Leading Manufacturer’s PLCs

IDEC Touchscreen communications capabilities expand well beyond IDEC brand

PLCs. Other major PLC manufacturers supported are: Allen Bradley, Mitsubishi,

Omron, Automation Direct (Koyo), Keyence, GE, Modicon, Siemens, Sharp,

Hitachi, Schneider, Yaskawa, Fanuc, Matsushita Electric Works (Panasonic) and

Yokogawa.

The 10.4” and 12.1” IDEC Touchscreens can remotely communicate with multiple

devices or PLCs over an Ethernet network, using Ethernet/IP, Modbus TCP/IP, or

IDEC 1:N drivers. Only one centrally located IDEC touchscreen is necessary to communicate with up to 16 PLCs that are located in different locations. The Ethernet/IP

driver supports the following Allen Bradley Series PLCs: Micrologix, SLC500, PLC5

and ControlLogix.

Approvals and International Ratings

The OI Touchscreen Family is UL listed for use in hazardous locations (Class I Div.

2). In addition the 4.6” and 5.7” screens are IP65 and Nema Type 13 rated, while

the 10.4” and 12.1” screens are IP66, Nema Type 4, 4X, 13 rated so they can be

used in the most demanding industrial applications.

Printer Function

PLCs Operator Interfaces Automation Software Power Supplies Sensors

This permits a single PLC to communicate with multiple IDEC touchscreens,

where one touchscreen serves as the master and up to 15 as slaves. An OI Link

will accommodate communications over a maximum distance of 200 meters. The

OI Link should be used whenever you are using more than one touchscreen in a

location to monitor and control a single PLC.

1:N PLC Communication

This mode allows a single IDEC touchscreen to communicate with multiple PLCs.

It is used when you need only one centrally located touchscreen to monitor and

control PLCs in different locations. Depending on the PLC type, a maximum of 31

PLCs can be connected to one touchscreen. PLC manufacturers supported for 1:N

communication are: IDEC OpenNet Controller and MicroSmart family, Automation Direct (Koyo): DirectLogic-DL205/405 and Modicon: Modbus RTU.

Pass Thru Function

This function lets you download a PLC program from a PC through the touchscreen without interrupting operations. Only one cable is needed to program

both units. The Pass Thru communications function is applicable to the following

PLCs: IDEC OpenNet Controller and MicroSmart family, and Mitsubishi MELSECFX, FX3UC and Q.

Use this capability to print alarm data so a hard-copy record of specifi c events

can be maintained. Copies of screens can also be printed when needed for documentation. Serial printers are supported on all OI Touchscreens, while Parallel

Printers are supported on 10.4” and 12.1” models.

Barcode Reader Support

IDEC Touchscreens provide a serial port

that you can confi gure for use by special

communication devices such as barcode

readers. A barcode reader can send data

directly to the touchscreen, where it can

be used for quick viewing before being

transferred to the PLC for further data

manipulation.

Debugging Functions

Two modes are available for either monitoring data or troubleshooting. Once

you download the project you created in WindO/I-NV2 to the touchscreen, you

can use the Debugging Mode to communicate directly with the touchscreen and

switch between screens or view and modify batch data from the controls of your

PC. In Simulation Mode, you can use simple On/Off control without connecting

to the PLC.

Communication & Networking

USA: 800-262-IDEC Canada: 888-317-IDEC

73

OI Touchscreen Family

Easy Programming: Intuitive Drag & Drop Functionality

The WindO/I-NV2 software for all OI Touchscreens is the programming

PLCsOperator InterfacesAutomation SoftwarePower SuppliesSensors

tool that lets you create colorful graphical interfaces to visualize operating

conditions. The software is very intuitive with drag and drop functionality.

The Help menus are a great source of information and a built-in library

of bitmaps provides over 5000 images to help expand your creativity. The

software also includes a debug function where you can go online with the

touchscreen for monitoring and changing data.

Flexible Screen Display for Effi cient Editing

With WindO/I-NV2 software, screens can be easily arranged. A total

of 3000 base screens can be created (as allowed by the memory size).

Sub-screens known as pop-up menus can be resized, made (showing

backgrounds) using the superimpose function, and can be made to appear

anywhere inside the base screen.

Easy to manage Projects and Screens

Screens and Project Settings List:

Operator Interfaces

WindO/I-NV2

Programming Software

•

Screens can be duplicated and their properties can be changed easily.

•

Project settings can be edited.

•

Devices, text, and images can be imported or exported.

Screen Preview List:

•

Screens can easily be selected using the preview image function.

Object List:

•

Each object displays its properties such as; type of device used, conditions and operations.

Buttons:

•

A button selected from an object list is shown on the editing screen.

Extensive Image Library

A built-in symbol library provides over 5000 symbols to help you create

cutting-edge graphical screens. Image data from BMP, JPG, DXF, WMF, and

ICO fi les can also be imported.

Communication & Networking

74

www.idec.com

Operator Interfaces

OI Touchscreen Family

WindO/I-NV2 Software, con’t

Compatible with Standard WindowsTM Fonts

Fonts used in WindowsTM can be used on the OI Touchscreens, making it possible

to choose from a variety of text styles.

Easy Programming of Operating Conditions

Multilingual Capabilities for Worldwide Applications

•

The OI Touchscreen family can support other languages. With the text group

function you can create a text database in different languages. Once the

touchscreen is in a different country (e.g. China or Mexico) the customer can

easily switch all text messages from English to Chinese or Spanish by a touch

of a button.

•

Windows 2000, Vista and XP make it possible to input Japanese, Simplifi ed Chinese, Traditional Chinese, and Korean languages, Western European

languages (English, German, French, Italian, Spanish, Dutch, Norwegian, Danish, Finnish, Swedish, etc.) Central European languages (Czech, Hungarian,

Romanian, Croatian, Slovene, Polish, and Slavic), Baltic languages, Cyrillic

languages (Russian, Ukranian, Bulgarian, Macedonian).

PLCs Operator Interfaces Automation Software Power Supplies Sensors

Operating conditions for objects such as switches, lamps, bit/word write,

•

screen switching, and many more are easy to use. Step by step wizards guide

the user through the set-up process.

Create Recipes to set parameters for different processes

•

Upload or download parameters to and from the PLC

•

1,024 available channels; store up to 8,000 parameters per channel

Set up Alarm Log function for messages and alerts

•

Monitors alarm conditions from a PLC and stores historical events with a date

and time stamp

•

Meets ISA standards for visual alarm management

•

Select size and contrast of alarm message and status

•

Scroll a list of alarm messages

Create Trend Graphs to monitor critical data points

•

Quickly view production information

Script function

Users with programming knowledge in C can combine conditional statements,

•

mathematical operations and other functions to create simple and complex

processes.

Greatly reduce the programming required in the PLC.

•

A syntax check function is also available to provide easy program trouble-

•

shooting.

Security function

Provides different levels of security and restrictions for multiple users on edit-

•

ing projects or displaying screens and objects.

Communication & Networking

•

Collect and manage data

•

Up to 16 channels in a graph

USA: 800-262-IDEC Canada: 888-317-IDEC

75

OI Touchscreen Family

Operator Interfaces

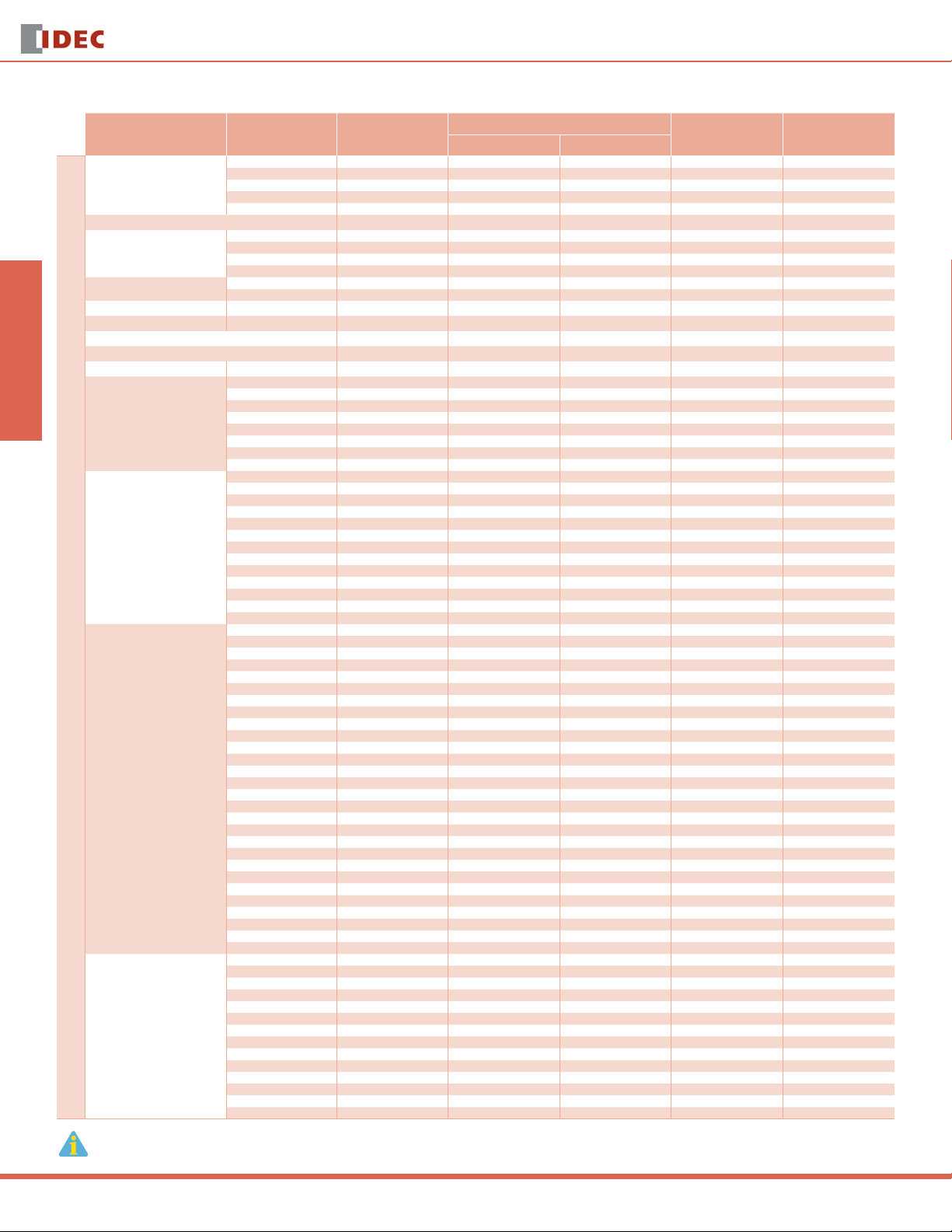

Available Functions

Category Item HG1F

PLCsOperator InterfacesAutomation SoftwarePower SuppliesSensors

Communication

User Memory

Interface

Display Color

Brightness

Resolution

Touch Switch

CC Switch

Expansion Unit

Features

Functions

Available Functions

Parts

WindO/I-NV2 Functions

Communication & Networking

*2MB used for OS

**four tactile push regions (40 x 70 pixels)

HG2F

Standard CC Switch Option

PLC link communication √√√√√

DM link communication √√√√√

OI link communication √√√√√

Ethernet — — — √ √

No host √√√√√

RS232C/RS485 (422) √√√√√

Ethernet — — — √ √

CF card slot — √ √ √ √

Parallel — — — √ √

256 colors — √ √ √ √

Monochrome √ √ √ — —

(cd/m2) 500 250 250 450 400

(pixels) 300 x 100 320 x 240 320 x 160** 640 x 480 800 x 600

Digital I/O unit — √ √ √ √

System program download √ √ √ √ √

Font download √ √ √ √ √

Download via Ethernet — — — √ √

Download via OI link √ √ √ √ √

Project transfer via CF card — √ √ √ √

Printer output √ √ √ √ √

Backlight replacement √ √ √ √ √

Environment resistance √ √ √ √ √

Simulation √ √ √ √ √

Pass through √ √ √ √ √

Device monitor √ √ √ √ √

Web server function — — — √ √

Overlapped screens √ √ √ √ √

Sub-screen superimpose √ √ √ √ √

Text group switching √ √ √ √ √

Script √ √ √ √ √

Part operating condition setting √ √ √ √ √

Alarm log √ √ √ √ √

Logging √ √ √ √ √

Recipe √√√√√

Password setting √ √ √ √ √

Bit button √ √ √ √ √

Word button √√√√√

Goto screen button √ √ √ √ √

Print button √ √ √ √ √

Key button √ √ √ √ √

Keypad √ √ √ √ √

Selector switch √ √ √ √ √

Potentiometer √ √ √ √ √

Numerical input √ √ √ √ √

Character input √ √ √ √ √

Pilot lamp √ √ √ √ √

Picture display √ √ √ √ √

Message display √ √ √ √ √

Message switching display √ √ √ √ √

Alarm list display √ √ √ √ √

Alarm log display √ √ √ √ √

Numerical display √ √ √ √ √

Bar graph √ √ √ √ √

Trend chart √ √ √ √ √

Pie chart √ √ √ √ √

Meter √ √ √ √ √

Calendar √ √ √ √ √

Bit write command √ √ √ √ √

Word write command √ √ √ √ √

Goto screen command √ √ √ √ √

Timer √√√√√

Print command √ √ √ √ √

Screen print command √ √ √ √ √

Debugging √ √ √ √ √

Log data upload tool √ √ √ √ √

Graphic library tool √ √ √ √ √

Screen import √ √ √ √ √

Text browser √√√√√

Device browser √ √ √ √ √

Script browser √ √ √ √ √

Picture browser √ √ √ √ √

Basic/advanced mode √ √ √ √ √

Preview √√√√√

Windows font √ √ √ √ √

Library function √ √ √ √ √

Global replace √ √ √ √ √

Work space √√√√√

1 MB 2 MB 2 MB 8 MB* 8 MB*

— 16 x 12 16 x 8 32 x 24 40 x 30

— — 4 x 1 row (bottom) — —

HG3F HG4F

76

www.idec.com

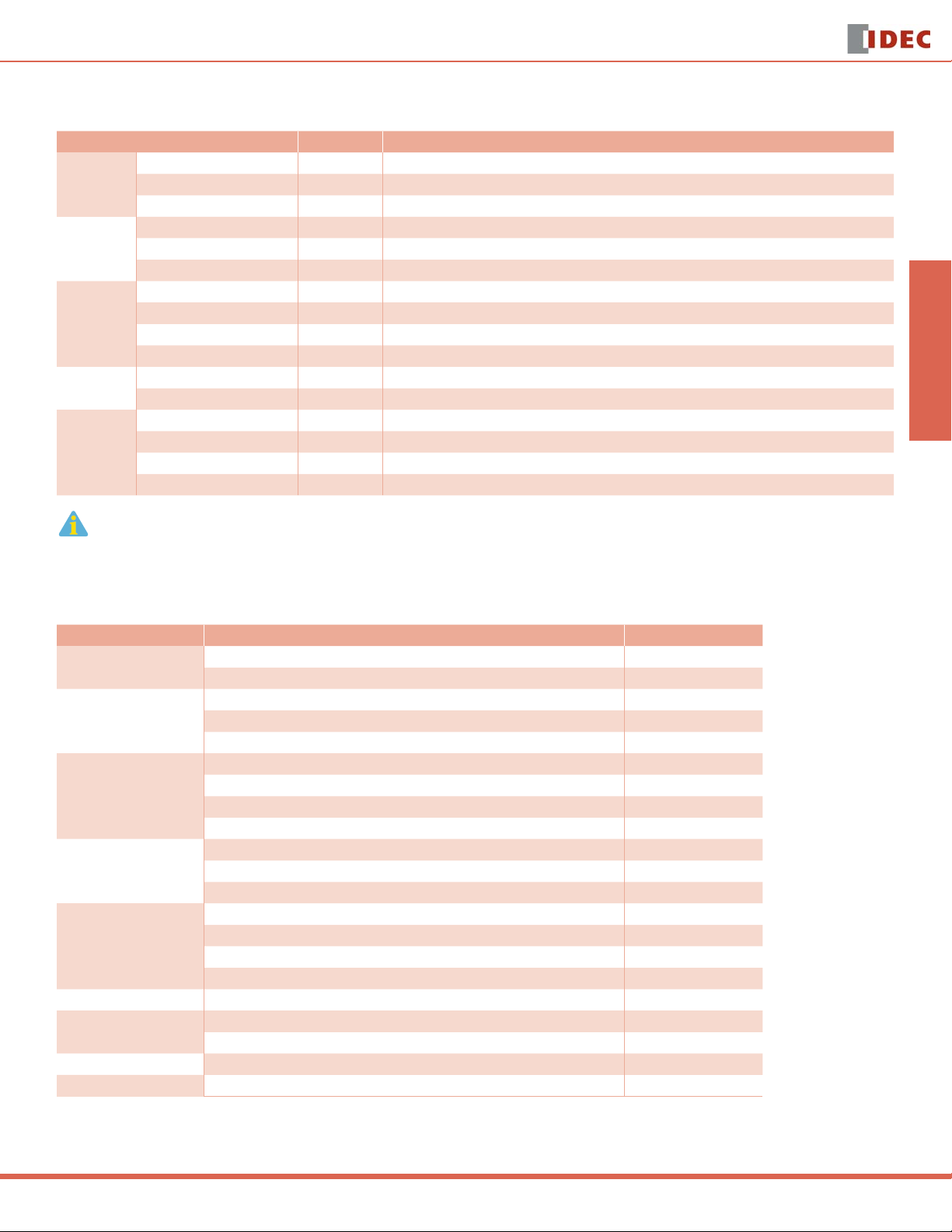

Operator Interfaces

OI Touchscreen

Part Numbers Bezel Color Description

HG4F-JT22TFW Light Gray Color TFT LCD Touchscreen

12.1”

10.4”

5.7”*

5.7” with

CC Click

4.6”

*Black bezel models available upon request.

HG4F-JT22TFB Black* Color TFT LCD Touchscreen

HG4F-JT22TFW-DH485-500 Light Gray Color TFT LCD Touchscreen with DF1 / DH485 converter/cable package for SLC 500 (w/RJ45 connector)

HG3F-FT22TFW Light Gray Color TFT LCD Touchscreen

HG3F-FT22TFB Black* Color TFT LCD Touchscreen

HG3F-FT22TFW-DH485-500 Light Gray Color TFT LCD Touchscreen with DF1/DH485 converter/cable package for SLC 500 (w/RJ45 connector)

HG2F-SS22VCF Light Gray Color STN LCD Touchscreen

HG2F-SB22VCF Light Gray Monochrome STN LCD Touchscreen

HG2F-SS22VCF-DH485-500 Light Gray Color STN LCD Display with DF1 / DH485 converter/ cable package for SLC500 (w/RJ45 connector)

HG2F-SB22VCF-DH485-500 Light Gray Monochrome STN LCD Display with DF1 / DH485 converter / cable package for SLC500 (w/RJ45 connector)

HG2F-SS52VCF Light Gray Color STN LCD Touchscreen w/ CC Click Tactile Touchbutton Technology

HG2F-SB52VCF Light Gray Monochrome STN LCD Touchscreen w/ CC Click Tactile Touchbutton Technology

HG1F-SB22BF-W Light Gray Monochrome STN LCD Touchscreen, RS-232 comm.

HG1F-SB22BF-B Black Monochrome STN LCD Touchscreen, RS-232 comm.

HG1F-SB22YF-W Light Gray Monochrome STN LCD Touchscreen, RS-485/RS-422 comm.

HG1F-SB22YF-B Black Monochrome STN LCD Touchscreen, RS-485/RS-422 comm.

OI Touchscreen Family

Part Numbers

PLCs Operator Interfaces Automation Software Power Supplies Sensors

Accessories

Accessories

Accessory Description Part Number

Programming Tools

Converters

Protective Sheet

Mounting Clips

Replacement Backlight

OI Link Unit For all OI touchscreens HG9Z-2G1

32 Point Digital I/O

Compact Flash Card 128MB CF Card for 5.7” HG2F, 10.4” HG3F, 12.1” HG4F HG9Z-MF128

Replacement Battery Lithium Battery for 4.6” HG1F HG9Z-XR1

WindO/I-NV2 Programming software for all IDEC Touchscreen Series HG9Y-ZSS2W

Cable connecting PC to Touchscreen via RS-232 Serial Port HG9Z-XCM1A

USB to RS-232 Convertor for PCs without Serial Ports FC4A-USB

AB SLC500 (w/RJ45 connector) DF1 / DH485 Communication Package for HG2F/3F/4F HG9Z-GWDF1DH485-3

AB SLC500 (w/RJ45 connector) DF1 / DH485 Communication Package for 4.6” HG1F HG9Z-GWDF1DH485-4

For 12.1” HG4F (minimum order quantity is 2 pcs.) HG9Z-4DAP

For 10.4” HG3F (minimum order quantity is 2 pcs.) HG9Z-3DAP

For 5.7”HG2F (minimum order quantity is 5 pcs.) HG9Z-2D2

For 4.6” HG1F (minimum order quantity is 5 pcs.) HG9Z-1D

For 10.4” HG3F & 12.1” HG4F (minimum order quantity is 10 pcs.) HG9Z-4K1

For 5.7” HG2F (minimum order quantity is 4 pcs.) HG9Z-2K1

For 4.6” HG1F (minimum order quantity is 10 pcs.) SLD-K02

For 12.1” HG4F HG9Z-4FB

For 10.4” HG3F HG9Z-3FB2

For 5.7” HG2F HG9Z-2B1

For 4.6” HG1F HG9Z-1FB

For 10.4” HG3F & 12.1” HG4F (16 Inputs & 16 Outputs) HG9Z-3P102

For 5.7” HG2F (16 Inputs & 16 Outputs) HG9Z-2P101

Communication & Networking

USA: 800-262-IDEC Canada: 888-317-IDEC

77

Cables

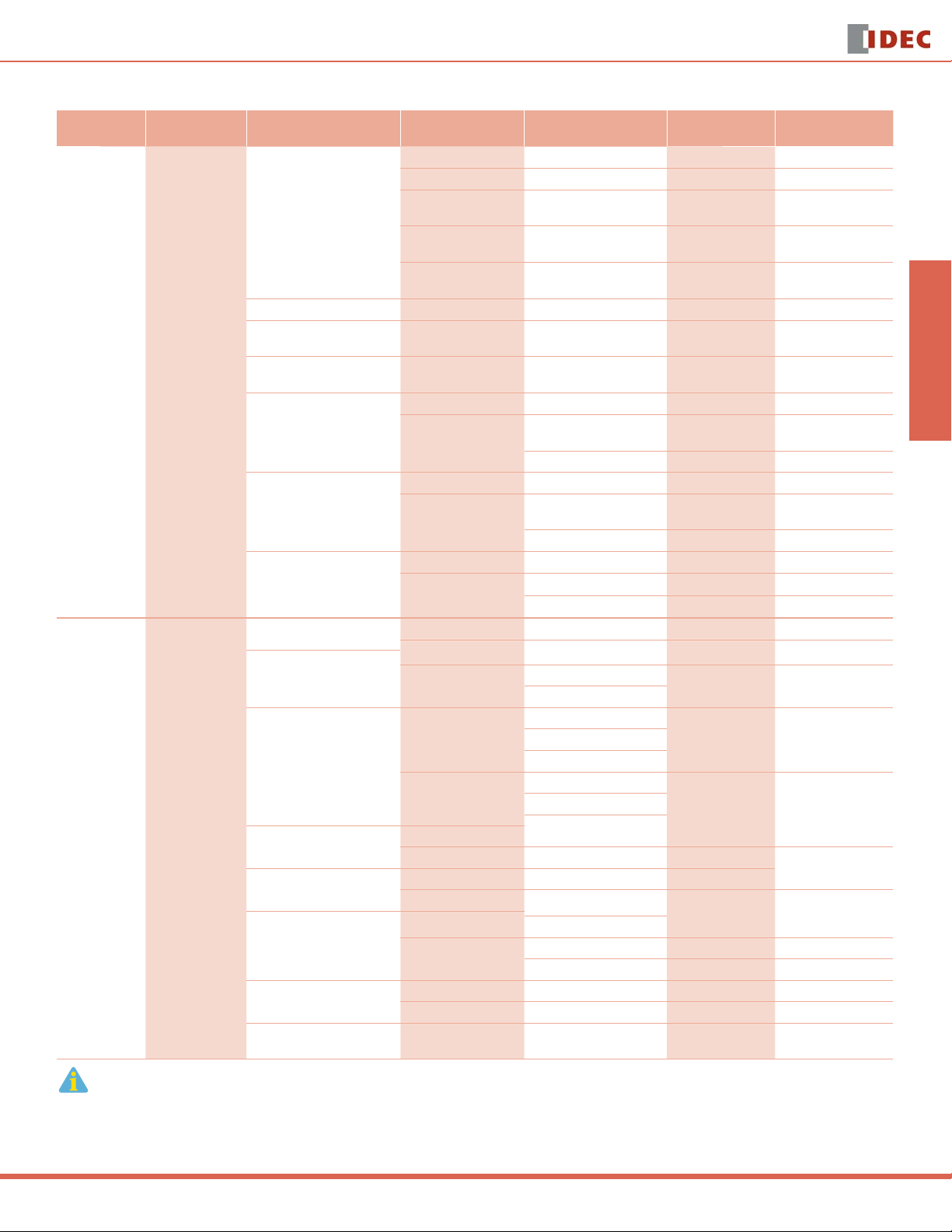

OI Touchscreen Family

Operator Interfaces

Manufacturer Series Applicable CPU

PLCsOperator InterfacesAutomation SoftwarePower SuppliesSensors

FA-3S

FA-2J PF2J

Micro3 FC2A RS485 Built-in Port HG9Z-1C121A HG9Z-3C115A

Micro3C FC2A-%C

IDEC

OpenNet FC3A

MicroSmart/Pentra

MicroSmart

PLC-5 1785

PLC-5E 1785 Ethernet Built-in Port Not Supported

SLC-5/03, SLC5/04, SLC5/05

Allen Bradley

SLC5/05 1747-L55 Ethernet Buit-in Port Not Supported

MicroLogix 1000,

1100, 1200, 1500

MicroLogix 1100 1763 Ethernet Built-in Port Not Supported

ControlLogix 1756

CompactLogix 1768, 1769

FlexLogix 1794-L33, 1794-L34 RS232 Built-in Port Contact IDEC* Contact IDEC*

1. * Consult IDEC for wiring schematic and cable.

2. Visit www.idec.com/oi for the most up-to-date list of cables.

PF3S-CP12/CP13

PF3S-CP11/CP11T

FC4A, FC5A

1747-L53, 1747-L54, 1747-L55

1761, 1762, 1763, 1764

Communication & Networking

Communication

Type

RS232

RS485 PF3S-SIF4

RS232 PF2-CLA

RS232 Built-in Port HG9Z-XC183 HG9Z-3C125A

RS485 Built-in Port HG9Z-1C131A HG9Z-2C145A

RS232 Built-in Port HG9Z-XC183 HG9Z-3C125A

RS485 Built-in Port HG9Z-1C131A HG9Z-2C145A

Ethernet FC4A-SX5ES1E Not Supported

RS232

RS485

Ethernet FC4A-SX5ES1E Not Supported

RS232

RS422

Ethernet 1785-ENET Not Supported

RS232 Built-in Port HG9Z-XC100 HG9Z-2C125A

DH485 Built-in Port

Ethernet 1761-NET-ENI Not Supported

RS232 Built-in Port HG9Z-XC500 HG9Z-2C135A

Ethernet 1761-NET-ENI Not Supported

RS232 Built-in Port Contact IDEC* Contact IDEC*

Ethernet 1756-ENBT Not Supported

RS232 Built-in Port Contact IDEC* Contact IDEC*

Ethernet Buit-in Port Not Supported

Communication Module

Required

PF2-CLA

PF3S-SIF2

Built-in Port FC4A-KC1CA

FC4A-PC1/HPC1

FC4A-PC2/HPC2 HG9Z-1C121A HG9Z-3C115A

FC4A-PC3/HPC3 HG9Z-1C131A HG9Z-2C145A

Built-in Port

1770-KF2

Built-in Port

1770-KF2

HG1F Comm.

Cable P/N

Contact IDEC* Contact IDEC*

HG9Z-XC183 or

FC4A-KC1CA

Contact IDEC* Contact IDEC*

please purchase

IDEC converter:

HG9ZGWDF1DH485-4

(DF1-DH485 converter)

HG2F/3F/4F Comm.

Cable P/N

CAT 5 Ethernet

Crossover cable

FC4A-KC2CA

CAT 5 Ethernet

Crossover cable

CAT 5 Ethernet

Crossover cable

CAT 5 Ethernet

Crossover cable

please purchase

IDEC converter:

HG9Z-GWDF1DH485-3

(DF1-DH485 converter)

CAT 5 Ethernet

Crossover cable

CAT 5 Ethernet

Crossover cable

CAT 5 Ethernet

Crossover cable

CAT 5 Ethernet

Crossover cable

CAT 5 Ethernet

Crossover cable

CAT 5 Ethernet

Crossover cable

78

www.idec.com

Operator Interfaces

Cables

OI Touchscreen Family

Manufacturer Series Applicable CPU

Direct Logc 05 DL05 Ethernet D0-ECOM/DO-ECOM100 Not Supported

Direct Logc 06 DL06 Ethernet D0-ECOM/D0-ECOM100 Not Supported

D2-240 RS232 Built-in Port HG9Z-XC400 Contact IDEC*

Automation

Direct (Koyo)

Siemens

Schneider

(Telemecanique,

SquareD)

Direct Logic 205

Direct Logic 405

S7-200

S7-300

S7-400 CPU 412, 414, 416, 416F-2, 417

Twido

D2-240, D2-250, D2-250-1,

D2-260

D4-430, D4-440

D4-430, D4-440,D4-450 Ethernet

CPU 212, 214, 215, 216, 221,

222, 224, 224XP, 226, 226XM

CPU 313, 314, 315,

315-2DP, 316, 318

TWDLCA10DRF RS485 Built-in Port HG9Z-1C121A HG9Z-3C115A

TWDLCA*DRF

( *16,24,40 CPUs)

TWDLMDA*DTK/DUK/DRT

(* 20 & 40 CPUs)

Momentum 171CCC96020 RJ-45 Ethernet Port Built-in RJ-45 Port Not Supported

Others Others

Panasonic

(Aromat)

1. * Consult IDEC for wiring schematic and cable.

2. Visit www.idec.com/oi for the most up-to-date list of cables.

FP

Any PLCs that support MODBUS/TCP protocol

FP0 RS232 Built-in-Port HG9Z-XC300 HG9Z-2C165A

FP1

Communication

Type

Ethernet

RS232

RS422 Built-in Port

RS485 Built-in Port Contact IDEC* HG9Z-2C155A

RS232

RS232

RS485 Built-in Port HG9Z-1C121A HG9Z-3C115A

RS232 TWD NAC 232D HG9Z-XC183 HG9Z-3C125A

RS485 TWDNAC485D HG9Z-1C121A HG9Z-3C115A

RS485 TWDNAC485T HG9Z-1C131A HG9Z-2C145A

Communication Module

Required

D2-ECOM

D2-ECOM-F

D2-ECOM100

Built-in Port

D4-ECOM

D4-ECOM-F

D4-ECOM100

CP-340-RS232C or

CP-341-RS232C

CP-340-RS 422/485 or

CP-341-RS 422/485

CP-440-RS 422/485 or

CP-441-RS 422/485

CP-440-RS232C or

CP-441-RS232C

HG1F Comm.

Cable P/N

Not Supported

Contact IDEC* Contact IDEC*D4-DCM

Not Supported

Contact IDEC* Contact IDEC*RS485

HG2F/3F/4F Comm.

Cable P/N

CAT 5 Ethernet

Crossover cable

CAT 5 Ethernet

Crossover cable

CAT 5 Ethernet

Crossover cable

CAT 5 Ethernet

Crossover cable

RS485 Built-in Port HG9Z-1C121A HG9Z-3C115A

RS232 TWDNOZ232D HG9Z-XC183 HG9Z-3C125A

RS485 TWDNOZ485D HG9Z-1C121A HG9Z-3C115A

RS485

RS485

RS232

RJ-45 Ethernet Port Built-in RJ-45 Port Not Supported

RS232

RS422 Built-in-Port

TWDNOZ485T or TWDXCPODM+ TWDNAC485T

TWDXCPODM + TWDNAC485D

TWDXCPODM + TWDNAC232D

Built-in-Port

HG9Z-1C131A HG9Z-2C145A

HG9Z-XC183 HG9Z-3C125A

HG9Z-1C121A HG9Z-3C115A

CAT 5 Ethernet

Crossover cable

CAT 5 Ethernet

Crossover cable

Contact IDEC* Contact IDEC*AFP8550

PLCs Operator Interfaces Automation Software Power Supplies Sensors

Communication & Networking

USA: 800-262-IDEC Canada: 888-317-IDEC

79

Cables

OI Touchscreen Family

Operator Interfaces

Manufacturer Series Applicable CPU

PLCsOperator InterfacesAutomation SoftwarePower SuppliesSensors

Panasonic

(Aromat) con’t

Mitsubishi

Communication & Networking

1. * Consult IDEC for wiring schematic and cable.

2. Visit www.idec.com/oi for the most up-to-date list of cables.

FP

MELSEC-A

MELSEC-Q

MELSEC-QnA

FP Sigma

FP10, FP10SH

FP2, FP2SH

A1N, A2N, A3N

A1SH

A2CCPUC24 RS232 Built-in-Port HG9Z-XC203

A0J2, A0J2H

A2A, A3A, A2U, A3U, A4U

A2US, A2USH-S1

A2N

A1SJH, A1SH, A2SH, A2C,

A0J2H

A2A, A3A, A2US, A2USH

A2U, A2USH-S1

Q00CPU, Q01CPU

Q02CPU-A

Q02CPU, Q02HCPU, Q06HCPU,

Q12PHCPU, Q25HCPU

Q00JCPU,Q00CPU,Q01CPU,Q02

CPU,Q02HCPU,Q06HCPU,Q12H

CPU,Q25HCPU

Q4ACPU, Q4ARCPU, Q3ACPU,

Q2ACPU-S1, Q2ACPU

Communication

Type

RS232

RS485 FPG-COM3 (AFPG803)

RS232

RS232

RS485

RS485

RS232

RS232 A0J2-C214-S1 HG9Z-XC145 HG9Z-3C135A

RS485 A0J2-C214-S1

RS485

RS232

RS232

RS485

RS422 Built-in-Port HG9Z-XC255 HG9Z-3C165A

RS232 Built-in-Port HG9Z-XC265 Contact IDEC*Q02CPU

RS232

RS485

Ethernet

RS232 AJ71QC24N-R2 HG9Z-XC145 HG9Z-3C135A

RS485

Ethernet AJ71QE71N3-T Not Supported

Ethernet AJ71QE71N-B2 Not Supported

Ethernet AJ71QE71N-B5 Not Supported

Communication Module

Required

Built-in-Port

FPG-COM1 (AFPG801)

FPG-COM2 (AFPG802)

Built-in-Port

AFP3462

Built-in-Port

AFP3462

AJ71C24-S3/S6/S8 or

AJ71UC24

AJ71C24-S3/S6/S8 or

AJ71UC24

A1SJ71C24-R2/R4 or

A1SJ71UC24-R2/R4

A1SJ71C24-R2/R4 or

A1SJ71UC24-R2/R4

AJ71C24-S6/S8 or

AJ71UC24

AJ71C24-S6/S8 or

AJ71UC24

A1SJ71C24-R2/R4 or

A1SJ71UC24-R2/R4

A1SJ71C24-R2/R4 or

A1SJ71UC24-R2/R4

QJ71C24, QJ71C24N

QJ71C24N-R2

QJ71C24 , QJ71C24N

QJ71C24N-R2

QJ71E71-100

QJ71E71-B5

QJ71E71-B2”

AJ71QC24N,

AJ71QC24N-R4

HG1F Comm.

Cable P/N

Contact IDEC*

HG9Z-XC145 HG9Z-3C135A

Contact IDEC* Contact IDEC*

HG9Z-XC203 HG9Z-3C145A

Contact IDEC* Contact IDEC*

HG9Z-XC145 HG9Z-3C135A

HG9Z-XC203 HG9Z-3C145A

Contact IDEC* Contact IDEC*

HG9Z-XC203 HG9Z-3C145A

Contact IDEC* Contact IDEC*

Not Supported

Contact IDEC* Contact IDEC*

HG2F/3F/4F Comm.

Cable P/N

HG9Z-2C165A

Contact IDEC*

CAT 5 Ethernet

Crossover cable

CAT 5 Ethernet Crossover cable

CAT 5 Ethernet Crossover cable

CAT 5 Ethernet Crossover cable

80

www.idec.com

Operator Interfaces

Cables

OI Touchscreen Family

Manufacturer Series Applicable CPU

Q2ASH CPU-S1, Q2ASHCPU,

Q2ASCPU-S1, Q2ASCPU

FX1,FX2,FX2C RS422 Built-in Port HG9Z-XC255 HG9Z-3C165A

FX0,FX0N,FX2N,FX2NC,FX3U

C,FX3U

Mitsubishi,

continued

Omron SYSMAC-C

1. * Consult IDEC for wiring schematic and cable.

2. Visit www.idec.com/oi for the most up-to-date list of cables.

MELSEC-FX

FX0,FX0N,FX2N,FX2NC,FX3U

C,FX3U

FX2N

FX1N

FX3UC, FX3U

CPM1, CPM1A

CPM2A

C500, C500F, C1000H, C2000,

C2000H

C1000HF

C200HS

C200HE, C200HG, C200HX

C120, C120F

CQM1H, C200HSCPU21/23/31/33

Communication

Type

RS232 A1SJ71QC24N-R2 HG9Z-XC203 HG9Z-3C145

RS485 A1SJ71QC24N Contact IDEC* Contact IDEC*

Ethernet A1SJ71QE71N3-T Not Supported

Ethernet A1SJ71QE71N-B2 Not Supported

Ethernet A1SJ71QE71N-B5 Not Supported

RS422

RS422 Built-in Port HG9Z-XC245 Contact IDEC*

RS232 FX2N-232-BD Contact IDEC* Contact IDEC*

RS422

RS232 FX1N-232-BD Contact IDEC* Contact IDEC*

RS422

RS422 Built-in Port HG9Z-XC255 HG9Z-3C165A

RS232

RS232 CPM1-CIF01 HG9Z-XC213 HG9Z-3C155A

RS422 CPM1-CIF11 Contact IDEC* Contact IDEC*

RS232

RS232

RS422

RS422

RS232 C500-LK203 HG9Z-XC155

RS232 C200H-LK201 HG9Z-XC155

RS422

RS422

RS232

RS232 C120-LK201-V1 HG9Z-XC155 HG9Z-3C135A

RS422 C120-LK202-V1 Contact IDEC* Contact IDEC*

RS232 Built-in-Port HG9Z-XC213 HG9Z-3C155A

Communication Module

Required

Built-in Port w/ cable FX20P-CADP

FX2N-422-BD and FX-20PCADP

FX2N-422-BD HG9Z-XC245 Contact IDEC*

FX1N-422-BD and FX-20PCADP

FX1N-422-BD HG9Z-XC245 Contact IDEC*

FX3U-232ADP Contact IDEC* Contact IDEC*

FX3U-232-BD Contact IDEC* Contact IDEC*

Built-in-Port

CPM1-CIF01

C120-LK201-V1

C500-LK203

C120-LK202-V1

C500-LK201-V1

C500-LK203

C200H-LK202

C200HW-COM03/06

C200H-LK201 HG9Z-XC155 HG9Z-3C135A

C200HW-COM02/040/5/06 HG9Z-XC213 HG9Z-3C155A

HG1F Comm.

Cable P/N

HG9Z-XC255 HG9Z-3C165A

HG9Z-XC255 HG9Z-3C165A

HG9Z-XC255 HG9Z-3C165A

HG9Z-XC213 HG9Z-3C155A

HG9Z-XC155 HG9Z-3C135AC500-LK201-V1

Contact IDEC* Contact IDEC*

Contact IDEC* Contact IDEC*

HG2F/3F/4F Comm.

Cable P/N

CAT 5 Ethernet Crossover cable

CAT 5 Ethernet Crossover cable

CAT 5 Ethernet Crossover cable

HG9Z-3C135A

PLCs Operator Interfaces Automation Software Power Supplies Sensors

Communication & Networking

USA: 800-262-IDEC Canada: 888-317-IDEC

81

Cables

OI Touchscreen Family

Operator Interfaces

Manufacturer Series Applicable CPU

PLCsOperator InterfacesAutomation SoftwarePower SuppliesSensors

SYSMAC-C

Omron con’t

Keyence

GE Fanuc

SHARP New Satellite JW

Hitachi

JTEKT(TOYODA)

Toshiba Machine

Works

YASKAWA

ELECTRIC

CORPORATION

FANUC Power Mate

1. * Consult IDEC for wiring schematic and cable.

2. Visit www.idec.com/oi for the most up-to-date list of cables.

CS1 CS1G, CS1H

CJ1 CJ1M, CJ1H, CJ1G RS232 Built-in-Port HG9Z-XC213 HG9Z-3C155A

Conventional KV KV 10, 16, 24, 40, 80

Visual KV KV-10,16,24,40

KV-700/1000 KV-700, KV-1000

VersaMax

Nano/Micro

Series 90-30

S10mini S10mini

S10V LQP510

TOYOPUC-PC2J PC2J RS485 Buit-in Port

TOYOPUC-PC3J

TC200 TC3-13B1 RS232 Buit-in Port

TCmini TC03-01, TC03-02 RS232 Buit-in Port

Machine Controller MP920, MP930, MP2300

C200HE-CPU42, C200HGCPU43/63, C200HX-CPU44/64

10 I/Os, 14 I/Os

23 I/Os, 28 I/Os

CPU 311, 313, 323, 331, 341,

350, 351, 352, 360, 363, 364,

374

CPU 331, 341, 350, 351, 352,

360, 363, 364, 374

JW-21CU, JW-22CU, JW31CUH/H1, JW-32CUH/H1,

JW-33CUH/H1/H2/H3

JW-50CU/CUH, JW-70CU/

CUH, JW-100CU/CUH

JW-22CU, JW-70CU/CUH,

JW-100CU/CUH

JW-32CUH/H1, JW-33CUH/

H1/H2/H3

PC3J RS485 Buit-in Port

PC3JD, PC3JG RS485 Buit-in Port

Power Mate-MODEL D RS422 Buit-in Port

16i, 160i RS232 Buit-in Port

Communication

Type

RS232 Built-in-Port

RS232

RS422 CS1W-SCB41 (port2) Contact IDEC* Contact IDEC*

RS232 Built-in-Port

RS232/485/422 KV-L-20R

RS232 Built-in-Port

RS485 Built-in-Port HG9Z-XC273A

RS485 Built-in-Port

RS232

RS485

RS485 JW-21CM

RS485 JW-10CM

RS232 Built-in Port

RS232

RS485

RS485 Buit-in Port

RS232 LQE160

RS485 LQE165

RS232 LQE560

RS485 LQE565

RS232

RS485

RS232 LQE560

RS485 LQE565

RS232 Buit-in Port

RS232 217IF

Communication Module

Required

Built-in-Port

CS1W-SCB41 (port1)

IC693CMM311

Built-in Port

Buit-in Port

HG1F Comm.

Cable P/N

HG9Z-XC213 HG9Z-3C155A

Contact IDEC*

Contact IDEC*

HG2F/3F/4F Comm.

Cable P/N

Contact IDEC*

Communication & Networking

82

www.idec.com

Operator Interfaces

Cables

OI Touchscreen Family

Manufacturer Series Applicable CPU

FA-M3(F3SP05, F3SP20,

F3SP21, F3SP25, F3SP30,

F3SP35, F3SP38, F3SP53,

YOKOGAWA FA-M3

FLEX-PC

FUJI

MICREX-F

PROSEC T Series

Toshiba

V Series

LS Industrial

Systems

1. * Consult IDEC for wiring schematic and cable.

2. Visit www.idec.com/oi for the most up-to-date list of cables.

MASTER-K

F3SP58, F3FP36, F3BP20,

F3BP30)

FA-M3(F3SP05, F3SP21,

F3SP25, F3SP28, F3SP35,

F3SP38, F3SP53, F3SP58)

NB1, NB2, NB3, NJ-CPU-E4,

NJ-CPU-A8, NJ-CPU-B16, NS

F55 RS232 NV1L-RS2

F70

F80H, F120H, F120S, F140S,

F150S

F30, F50, F50H, F55, F60, F70,

F70S, F80H, F81, F120H, F120S,

F140S, F150S, F250

T1:

T1-16,T1-28,T1-40

T1S:

T1-40S

T2: PU224 RS485 Buit-in Port

T2E:

PU234E

T2N:

PU215N,PU235N, PU245N

T3/T3H: PU315, PU325,

PU325H, PU326H

S2I/ S2E/L1/S2/S3:

PU672T, PU662T, PU612E,

L1PU11H,L1PU12H, S2PU82,

S2PU72, S2PU32, S2PU22,

S3PU65, S3PU55, S3PU45,

S3PU21

K10S1 RS232 Buit-in Port

K80S, K120S, K200S RS232 Buit-in Port

K80S

K200S

K300S RS232 G4L-CUEA

Communication

Type

RS232 F3LC11-1N

RS485 F3LC11-2N

RS232 Buit-in Port

RS232

RS485

RS232

RS485

RS232 NJ-RS2

RS485 NJ-RS4

RS232

RS485

RS232 NC1L-RS2

RS485 NC1L-RS4

RS232

RS485

RS232

RS485

RS232 Buit-in Port

RS485 CU111

RS232

RS485

RS485 CU111

RS232 Buit-in Port

RS485 CM231E

RS232 CM232E

RS232

RS485

RS485 Buit-in Port

RS485 Buit-in Port

RS232 G7L-CUEB

RS232 G7L-CUEC

RS232 G6L-CUEB

RS232 G6L-CUEC

Communication Module

Buit-in Port

NB-RS1-AC/DC

NS-RS1

FFU120B

FFK120A-C10

Buit-in Port

Buit-in Port

Required

HG1F Comm.

Cable P/N

Contact IDEC* Contact IDEC*

HG2F/3F/4F Comm.

Cable P/N

PLCs Operator Interfaces Automation Software Power Supplies Sensors

Communication & Networking

USA: 800-262-IDEC Canada: 888-317-IDEC

83

OI Touchscreen Family

Operator Interfaces

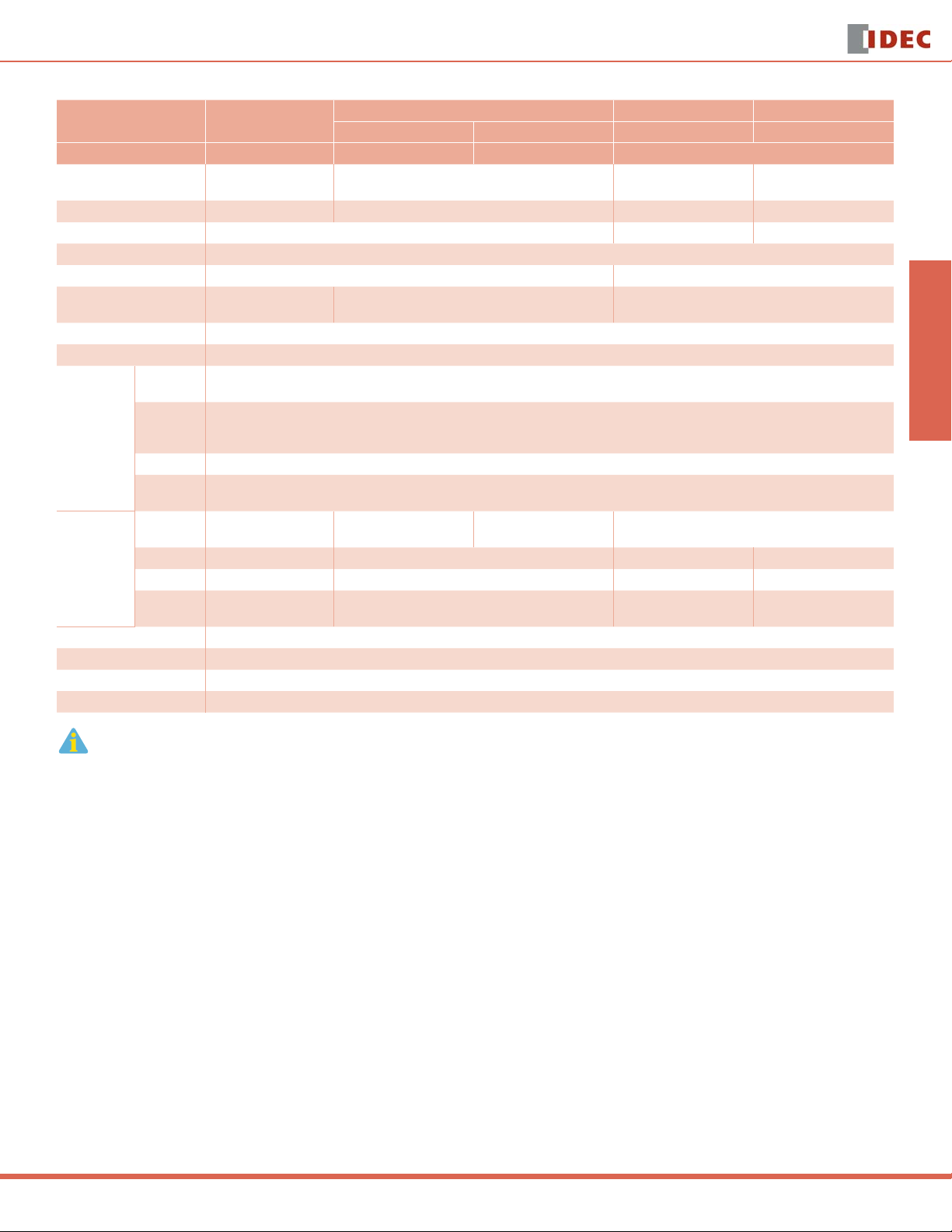

Specifi cations

General Specifi cations

Model HG1F HG2F HG3F HG4F

Voltage 24V DC

Voltage Range 20.4 to 28.8V DC 19.2 to 28.8V DC

PLCsOperator InterfacesAutomation SoftwarePower SuppliesSensors

Power Consumption 10W maximum 25W maximum

Inrush Current 20A maximum 15A maximum (cold start)

Allowable Momentary Power Interruption 10 ms minimum

Dielectric Strength 1,000V AC, 10 mA, 1 minute between power and FG terminals 1,500V AC, 10 mA, 1 minute between power and FG terminals

Insulation Resistance

Backup Battery

Operating Temperature 0 to 50°C (no freezing) 0 to 45°C (no freezing)

Operating Humidity 10 to 90% RH (no condensation) 10 to 95% RH (no condensation) 20 to 85% RH (no condensation)

Storage Temperature –20 to +60°C (no freezing)

Storage Humidity 10 to 90% RH (no condensation) 10 to 95% RH (no condensation) 20 to 85% RH (no condensation)

Pollution Degree 2 (IEC 60664-1)

Corrosion Immunity Atmosphere free from corrosive gases

Vibration Resistance (damage limits) 10 to 20Hz amplitude 0.625 mm, 20 to 55Hz acceleration 9.8 m/s

Shock Resistance (damage limits) 147 m/s2 (15G), 11 ms, 5 shocks on each of three mutually perpendicular axes

Noise Immunity Fast transient/burst test, common mode: Level 3, power terminals: ±2 kV, communication line: ±1 kV (IEC/EN 61000-4-4)

Electrostatic Discharge ESD-3 (RH-1), Level 3, (contact ±6 kV, aerial ±8 kV) (IEC/EN 61000-4-2)

Mounting Panel mounting

Degree of Protection IP65 NEMA TYPE 13 IP66 NEMA TYPE 4, 4X, 13

Dimensions (mm) 147W x 47H x 39.3D 172W x 136H x 56D 324W x 240H x 56D 348W x 270H x 58D

Weight (approx.) 280g 800g 2800g 3400g

50 MΩ minimum between power and FG terminals

(500V DC megger)

CR2032 lithium batteryy

Life approx. 4 years (25ºC)

2

(1G), 2 hours per axis on each of three mutually perpendicular axes

Operation Specifi cations

Model HG1F

Switching Element Resistive membrane

Touch Region Resolution 1 x 1 16 x 12 16 x 8 32 x 24 40 x 30

CC Switch Quantity — 4 x 1 row (bottom only) — —

Operating Force 0.2 to 0.8N 2.5 to 5.0N 0.2 to 0.8N 0.2 to 0.8N

Mechanical Life 1,000,000 operations

Acknowledge Sound Electronic buzzer

Screen Types Base screen, popup screen, system screen

Number of Screens

User Memory 1MB (including expansion fonts) 2MB 8MB*

Parts

Calendar Year, Month, Day, Hour, Min., Sec., Day of Week

Print Function (support)

Power Failure Backup Backup data: Calendar, log data, keep internal relay, keep internal register

Backup Duration 1 month (at 25°C) after full charging for two days

Battery Life 4 years (at 25ºC) —

*2MB for OS

Base screen: 3000 max.,

popup screen: 3015 max.

Bit Button, Word Button, Goto Screen Button, Print Button, Key Button, Keypad, Selector Switch, Potentiometer, Numerical Input, Character Input, Pilot

Lamp, Multi-state Lamp, Picture Display, Message Display, Message Switching Display, Alarm List Display, Alarm Log Display, Numerical Display, Bar

Graph, Trend Chart, Pie Chart, Meter, Calendar, Bit Write Command, Word Write Command, Goto Screen Command, Timer, Print Command, Screen Script

Command

ESC/P, PC-PR: Epson VP-700

Standard CC Switch Option

SII: DPU414

Communication & Networking

HG2F

Base screen: 3000 max., popup screen: 3000 max.

10 MΩ minimum between power and FG terminals

(500V DC megger)

—

HG3F HG4F

ESC/P, PC-PR, PCL, EPSON LP2500/VP-700/PX-V600/

Stylus C83, C84, C87, C88, D88, HP Deskjet 3820

84

www.idec.com

Operator Interfaces

OI Touchscreen Family

Display Specifi cations

Model HG1F

LCD Monochrome STN Color STN Monochrome STN Color TFT

Effective Display Area

(mm)

Display Resolution 300W x 100H 320W x 240H pixels 640W x 480H pixels 800W x 600H pixels

LCD Life 50,000 hours minimum 100,000 hours minimum 60,000 hours minimum

Contrast Adjustment Possible in steps using the front touch screen

Backlight Cold-cathode tube Cold-cathode tube (2 tubes)

Backlight Life

Backlight Control Automatic OFF

Backlight Replacement Possible

1/4 size

Display

Character

Size

Quantity of

Characters

Character Magnifi cation 0.5, 1, 2, 3, 4, and 8 vertically and horizontally

Character Attribute Blink (1 or 0.5 sec period), reverse, bold, shadowed

Graphics Type Straight line, polyline, polygon, rectangle, circle, ellipse, arc, pie, equilateral polygons (3, 4, 5, 6, 8), paint, bitmap image

Window Display 3 popup screens + 1 system screen

Note: The backlight life refers to the time until the surface brightness reduces to a half after using continuously at room temperatures.

1/2 size

Full size 16 x 16 pixels (Japanese JIS fi rst and second level characters, simplifi ed Chinese, traditional Chinese, Korean)

Double

size

1/4 size 37 characters x 12 lines

1/2 size 37 characters x 6 lines 40 characters x 15 lines (40 x 10, cc click type) 80 characters x 30 lines 100 characters x 37 lines

Full size 18 characters x 6 lines 20 characters x 15 lines (20 x 10, cc click type) 40 characters x 30 lines 50 characters x 37 lines

Double

size

115W x 39W 118.2W x 89.4H 211.2W x 158.4H 246W x 184.5H

50,000 hours nominal

(Note)

8 x 8 pixels (Western European language: ISO 8859-1, Central European language: ANSI 1250,

8 x 16 pixels (Western European language ISO 8859-1, Central European language: ANSI 1250,

9 characters x 3 lines 10 characters x 7 lines (10 x 5, cc click type) 20 characters x 15 lines 25 characters x 18 lines

Color Monochrome Color Color

40,000 hours nominal (Note) 50,000 hours nominal (Note)

16 x 32 pixels, 24 x 48 pixels, 32 x 64 pixels (Western European language: ISO 8859-1)

32 x 32 pixels (Japanese JIS fi rst level characters, Mincho font)

40 characters x 30 lines

(40 x 20, cc click type)

HG2F HG3F HG4F

Japanese katakana and symbols: JIS 8-bit code)

Japanese katakana and symbols: JIS 8-bit code)

80 characters x 60 lines 100 characters x 75 lines

PLCs Operator Interfaces Automation Software Power Supplies Sensors

USA: 800-262-IDEC Canada: 888-317-IDEC

Communication & Networking

85

OI Touchscreen Family

Operator Interfaces

Interface Specifi cations

CF Card Interface Specifi cations Parallel Interface Specifi cations (HG3F/4F) Ethernet Specifi cations (HG3F/4F)

Interface Specifi cations Compact Flash Type I standard compliant* — IEEE 802.3 standard compliant, 10Base-T

Electrical Characteristics — Centronics interface compliant —

Connector 50-pin compact fl ash card connector D-sub 25-pin female connector —

PLCsOperator InterfacesAutomation SoftwarePower SuppliesSensors

*Memory size supports up to 512MB.

Interface Specifi cations

RS232C

Electrical Characteristics EIA RS232C compliant

Transmission Speed

Synchronization Asynchronous

Communication Method Half or full duplex

Control System Hardware control or none

Connector D-sub 25-pin female connector

Electrical Characteristics EIA RS485 (422) compliant

Transmission Speed

Synchronization Asynchronous

Communication Method Half or full duplex

Control System Hardware control or none

Connector D-sub 25-pin female connector

1200, 2400, 4800, 9600, 19200, 38400,

57600, 115200 bps

RS485 (422)

1200, 2400, 4800, 9600, 19200, 38400,

57600, 115200 bps

Electrical Characteristics EIA RS232C compliant

Transmission Speed 9600, 19200, 38400, 57600, 115200 bps

Synchronization Asynchronous

Communication Method Half duplex, proprietary protocol

Connector Mini DIN 8-pin connector

Electrical Characteristics EIA RS485 compliant

Transmission Speed 38400, 57600, 115200 bps

Synchronization Asynchronous

Communication Method Half duplex, proprietary protocol

Connector Special connector

Maintenance Communication

OI Link Communication

Expansion Unit (Digital I/O Unit)

Applicable Quantity 1

Mounting Style Mounted on the rear of the HG unit

Input Points 16

Voltage 12 to 24V DC (allowable range 10 to 28V DC)

Input

Isolation Method Photocoupler

Output Points 16

Load Voltage 12 to 24V DC (allowable range 10 to 28V DC)

Isolation Method Photocoupler

Output Signal NPN open collector

Output

Output ON Voltage 1.6V maximum

Output Current 30 mA max. per point, 200 mA total

Connector

24-pin connector (Fujitsu FCN-365P024-AG)

2 connectors for inputs and outputs

Communication & Networking

86

www.idec.com

Operator Interfaces

Mounting Clip

Mounting Clip

HG2F

Panel

162.5

+0.5

0

126.5

+0.5

0

Panel thickness: 1.6 to 5mm

OI Touchscreen Family

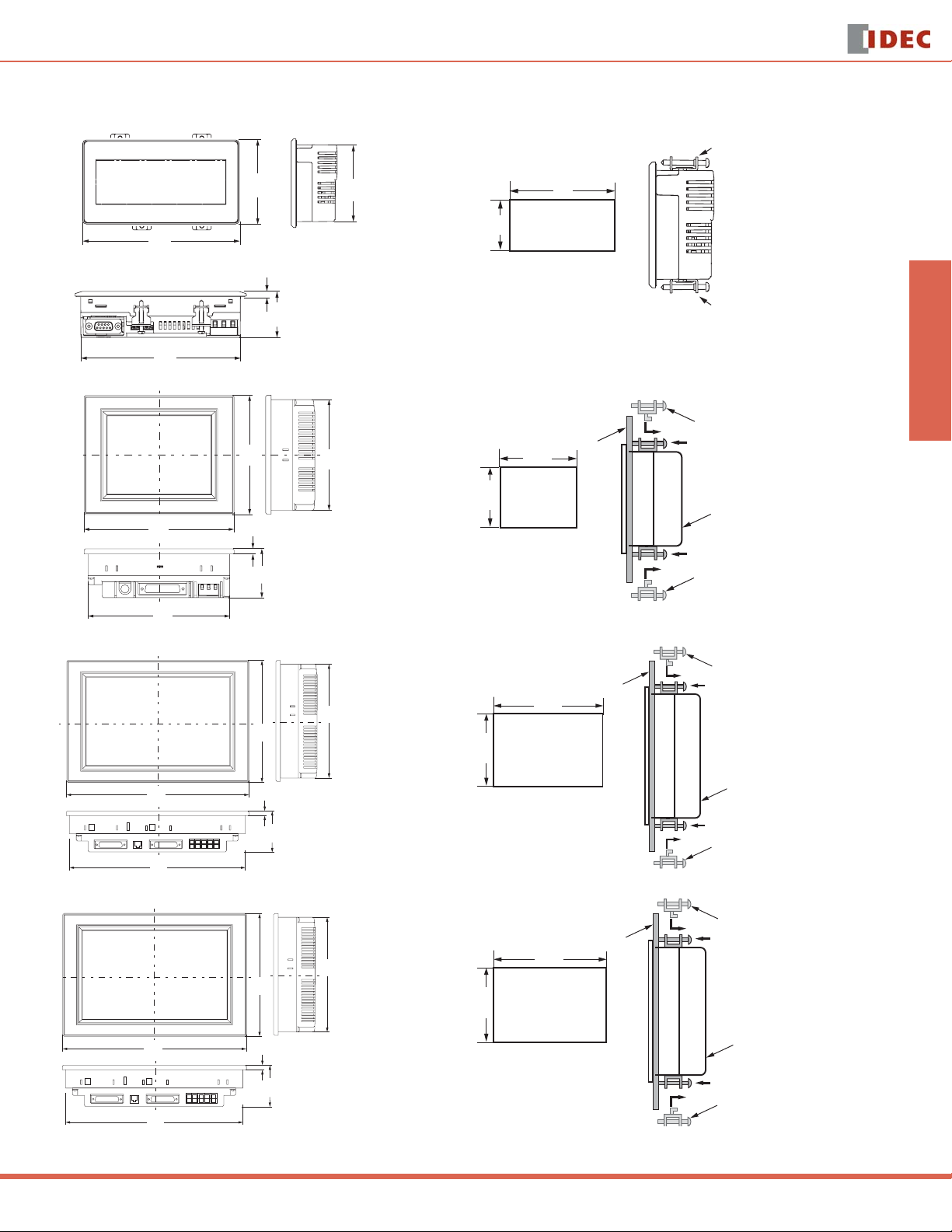

Dimensions & Panel Cutouts

HG1F Dimensions HG1F Installation Panel Layout

+1.5

137

0

147mm

76mm

65.8mm

+1

0

66

Mounting Clip

PLCs Operator Interfaces Automation Software Power Supplies Sensors

136.8mm

4mm

Panel thickness: 1.6 to 5m

39.3mm

m

HG2F Dimensions HG2F Installation Panel Layout

172mm

162mm

136mm

6mm

56mm

126mm

HG3F Dimensions HG3F Installation Panel Layout

Panel

+0.5

302

0

301mm

240mm

+0.5

0

228

Mounting Clip

Mounting Clip

324mm

301mm

6mm

55.8mm

Panel thickness: 2 to 5mm

HG4F Dimensions HG4F Installation Panel Layout

+1

332

0

331mm

All dimensions in mm.

348mm

331mm

270mm

6mm

58mm

+1

0

258

Panel thickness: 2 to 5mm

USA: 800-262-IDEC Canada: 888-317-IDEC

HG3F

Mounting Clip

Mounting Clip

Panel

Communication & Networking

HG4F

Mounting Clip

87

Loading...

Loading...