Page 1

OI Touchscreen

Basic Tutorial

This Tutorial describes the basic procedures for

programming a screen using WindO/I-NV2 software.

It is intended for users who are trying IDEC OI

Touchscreens for the first time and for those who

wish to master the fundamentals of WindO/I-NV2

software.

Chapter 1

Introduction

Chapter 2

Installation

Chapter 3

Screen Creation

Chapter 4

Download

IDEC Touchscreen Family

Chapter 5

Operation Check

Chapter 6

Appendix

www.IDEC.com/usa

Page 2

Contents

Chapter 1 - Introduction

Chapter 2 - Installation

Chapter 3 - Screen Creation

1. Operator Interface Features ................................................3

Features .....................................................................3

Operator Interface Advantages ..................................4

2. WindO/I-NV2 Overview .......................................................5

Preparations ............................................................... 5

Operation Flow ...........................................................6

1. Software Installation ............................................................7

1. Sample Program ................................................................10

Part Names ..............................................................10

Available Devices and Parts Operation ....................11

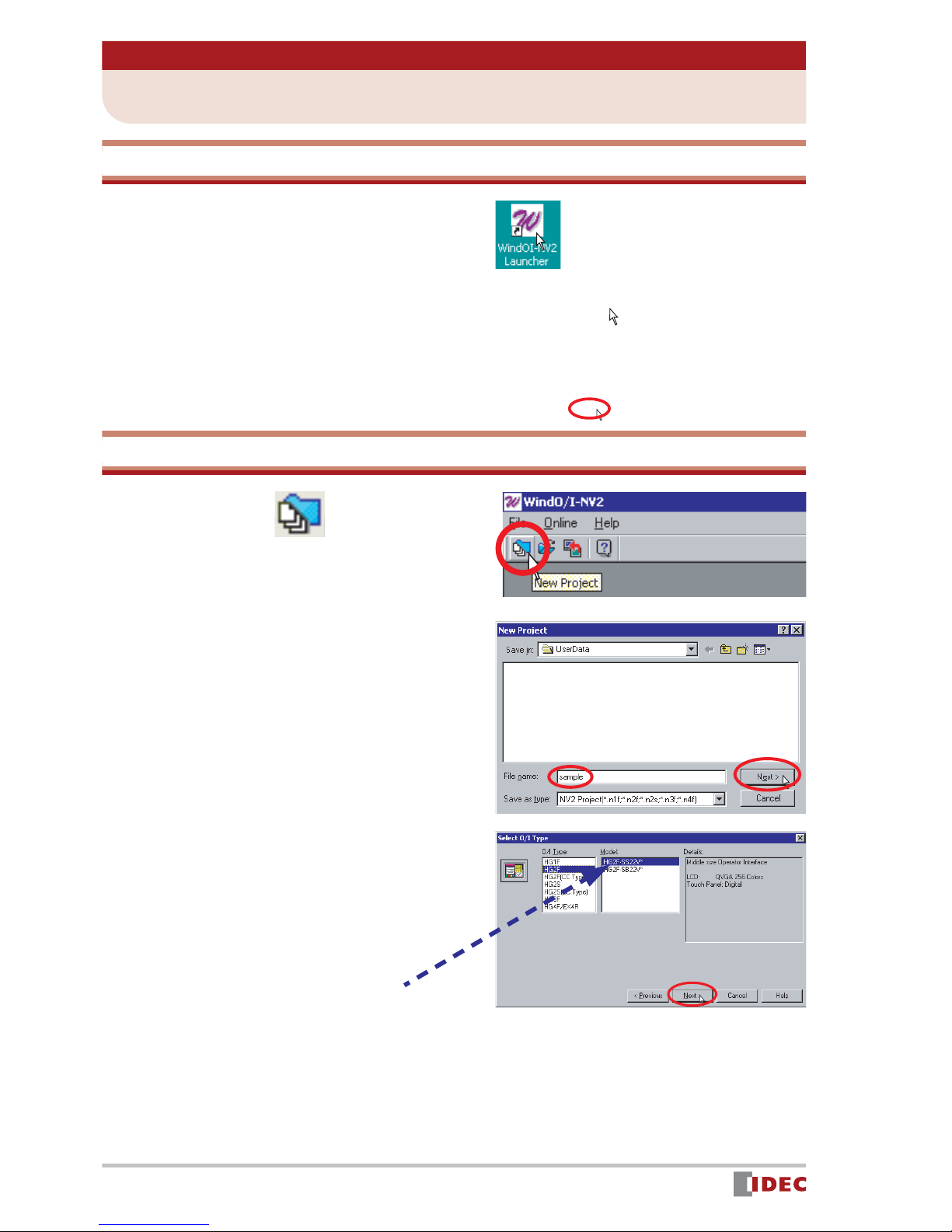

2. Launching WindO/I-NV2 & Creating New Projects ............12

Starting WindO/I-NV2 ...............................................12

Creating a New Project ............................................12

3. Creating Screens ...............................................................14

[Operating Screen] ...................................................14

[Numerical Target Setting Screen] ...........................28

Saving ......................................................................33

Chapter 4 - Download

1. Downloading the Project ....................................................34

Chapter 5 - Verify Operation

1. Simulation Mode ................................................................36

Starting Simulation Mode .........................................36

Simulating .................................................................37

2. Debug Mode ......................................................................38

Start Debug Mode ....................................................38

Verify Operation with the Screen Monitor .................39

End Debugging Mode ...............................................41

Chapter 6 - Appendix

1. Tools and Functions ..........................................................42

Shortcut Keys ...........................................................42

Object List ................................................................42

Project List ................................................................43

System Requirements ..............................................44

Operator Interface Models ........................................44

2

www.IDEC.com/usa

Page 3

n

Chapter 1 Introduction

1 Operator Interface Features

Features

Design Tool Compatible With All IDEC OI Touchscreens

- Users can easily create screens and setup operations by using the design tool,

WindO/I-NV2 software.

Supports Multiple Languages

- The Operator Interface supports multiple languages, such as Japanese, Chinese (simplified and traditional Chinese characters), Korean, and European languages.

- Up to 16 types of display languages can be switched to during operation.

1

Bright, Legible Display

- Brignt LCD

- Wide view angle

Connects to Peripheral Equipment

- RS232C/RS-485/RS-422

- Ethernet port

- CF card slot

*1

Conforms to International Standards

- Conforming to UL/c-UL standards, EN standards, and EU directives.

Inroductio

*1: The type of interface available for the OI varies depending on the model.

(Refer to "Operator Interface Models" on page 44)

www.iIDEC.com/usa

3

Page 4

Chapter 1 Introduction

Operator Interface Advantages

Conventional Control Panel

- Large size

- Complicated wiring

- Many components

- Adding and modifing

components is difficult

Operator Interface

- Small size

- Cable wiring is reduced

- Applicable to multiple items

(Easy to add and modify

components)

- Multifunction, flexibility in

expansion

Operate screens by touching

directly with a finger.

Enter data with a

numeric keypad.

Parts can be

placed anywhere.

Easily switch between

displayed screens.

4

www.IDEC.com/software

Page 5

n

Chapter 1 Introduction

2 WindO/I-NV2 Overview

Preparations

Before creating a screen for the OITouchscreen using WindO/I-NV2 software, you will need

the following:

(1) WindO/I-NV2 Software

Part Number: HG9Y-ZSS2W

1

(2) PC

(3)

(4) Operator Interface

If the OI Touchscreen will be configured to communicate with a host (ie. PLC), then you will

also need the following:

*1

To use a PC that does not have a COM

port, use a commercially available

USB-RS232C converter.

Part Number: FC4A-USB

Programming Cable for the

OI Touchscreen

Part Number: HG9Z-XCM1A

or FC2A-KC4C

*2

Example Part Number:

HG2F-SS22VCF

*1: For PC system requirements, refer to page 44 (back cover).

*2: To supply power to the Operator Interface, a 24 V DC power supply is required.

Inroductio

(5) Programmable Controller

(PLC)

Example: MicroSmart

(6) Communication Cable

(between the MicroSmart & OI)

Example: FC4A-KC2CA

www.IDEC.com/software

5

Page 6

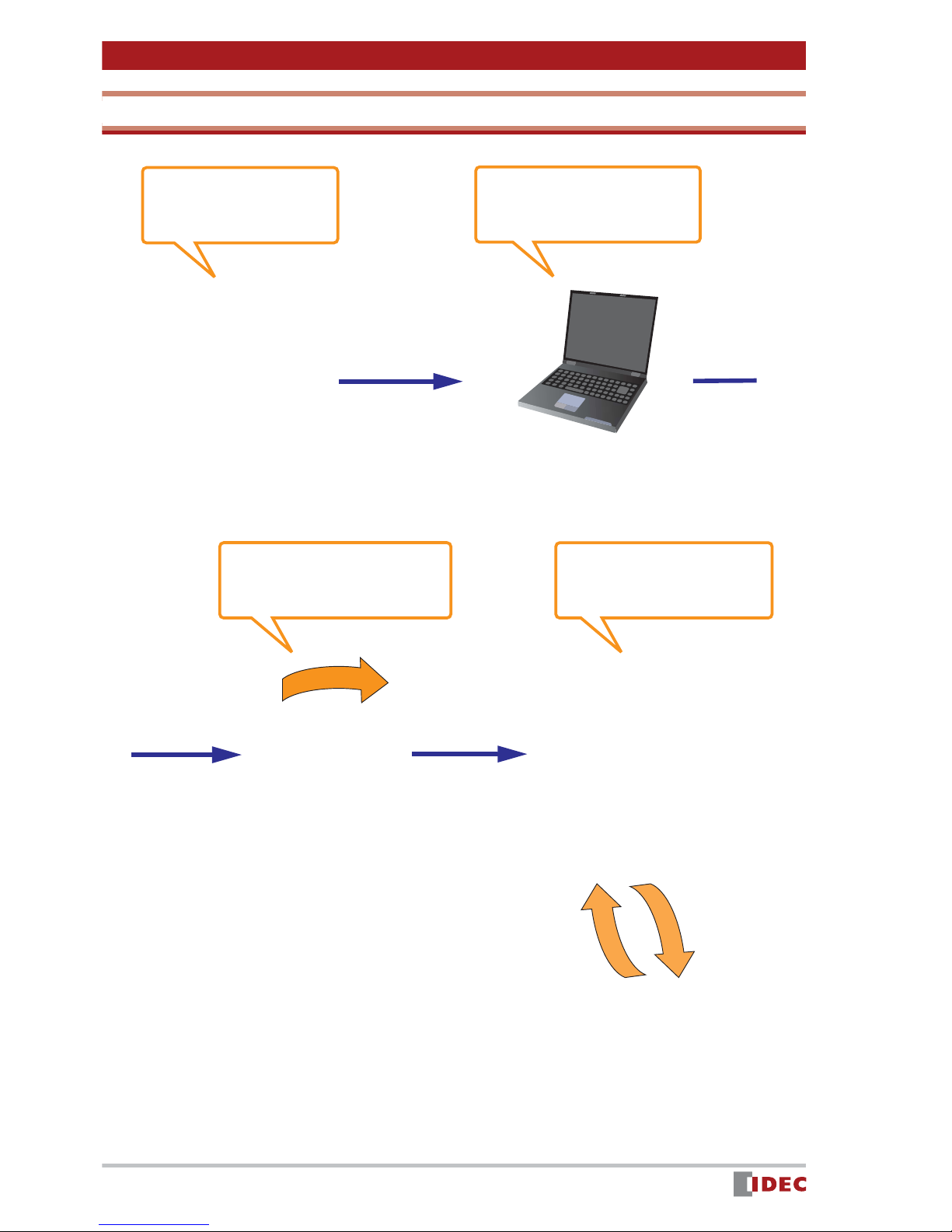

Chapter 1 Introduction

Operation Flow

(1) Software

installation

Refer to Chapter 2 on page 7

Software

WindO/I-NV2

(3)Downloading the project

to the OI

Refer to Chapter 4 on page 34 Refer to Chapter 5 on page 36

(2)Creating a screen

on the PC

Refer to Chapter 3 on page 10

PC

(4)Simulation (operation

verification)

Cable

6

Operator Interface

MicroSmart

www.IDEC.com/software

Page 7

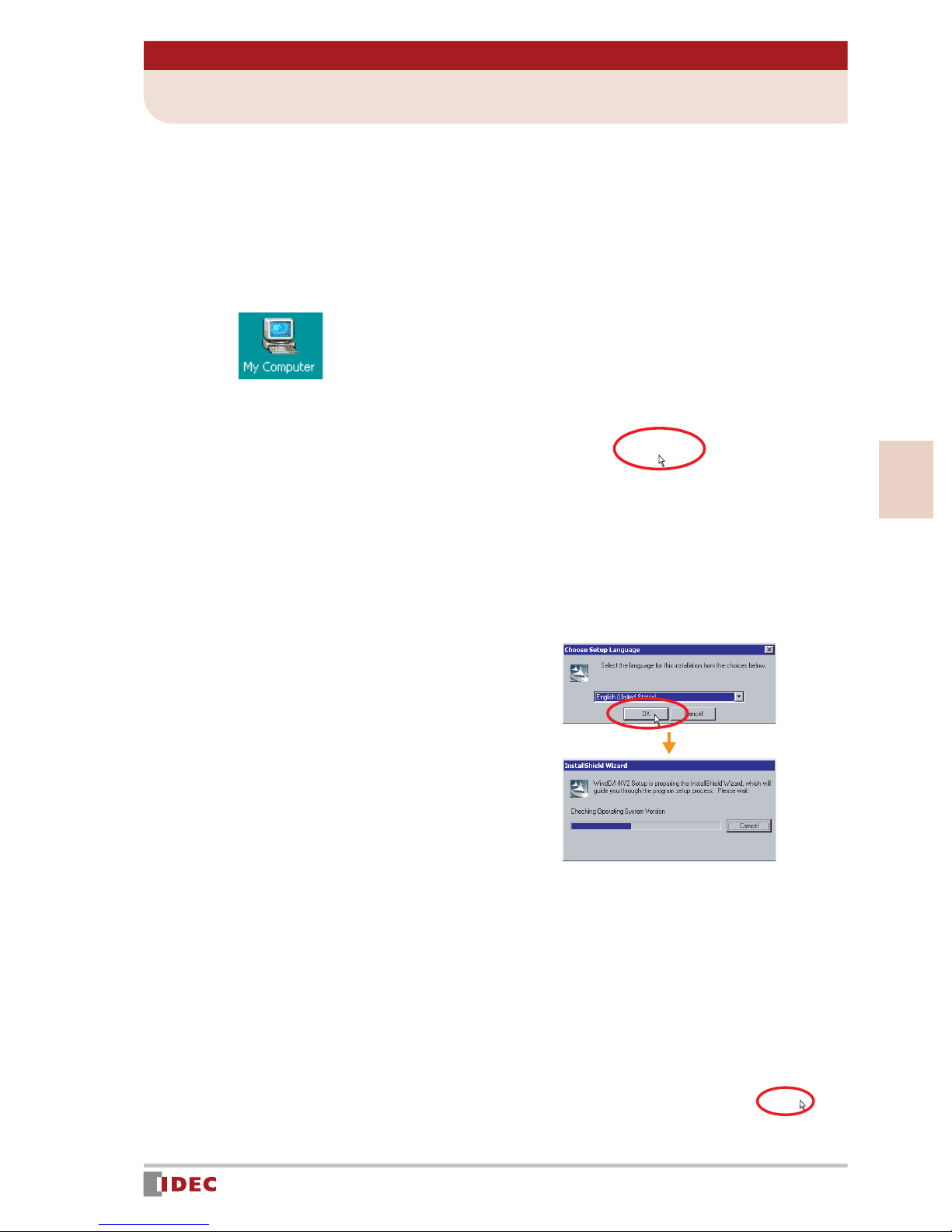

Chapter 2 Installation

1 Software Installation

This section describes the procedure for installing WindO/I-NV2 software.

1.

2.

3.

Insert the WindO/I-NV2 CD-ROM into the CD-ROM drive of the PC.

The WindO/I-NV2 setup program will automatically start.

If the setup program does not start:

1. Double-click the My Computer icon on the desktop.

2. Double-click NV2lande.exe in the CD drive.

Click the [WindO/I-NV2 Install] button.

2

4.

5.

Installation

Make sure that English is selected,

and click [OK].

InstallShield Wizard will start.

Click [Next].

www.IDEC.com/software

7

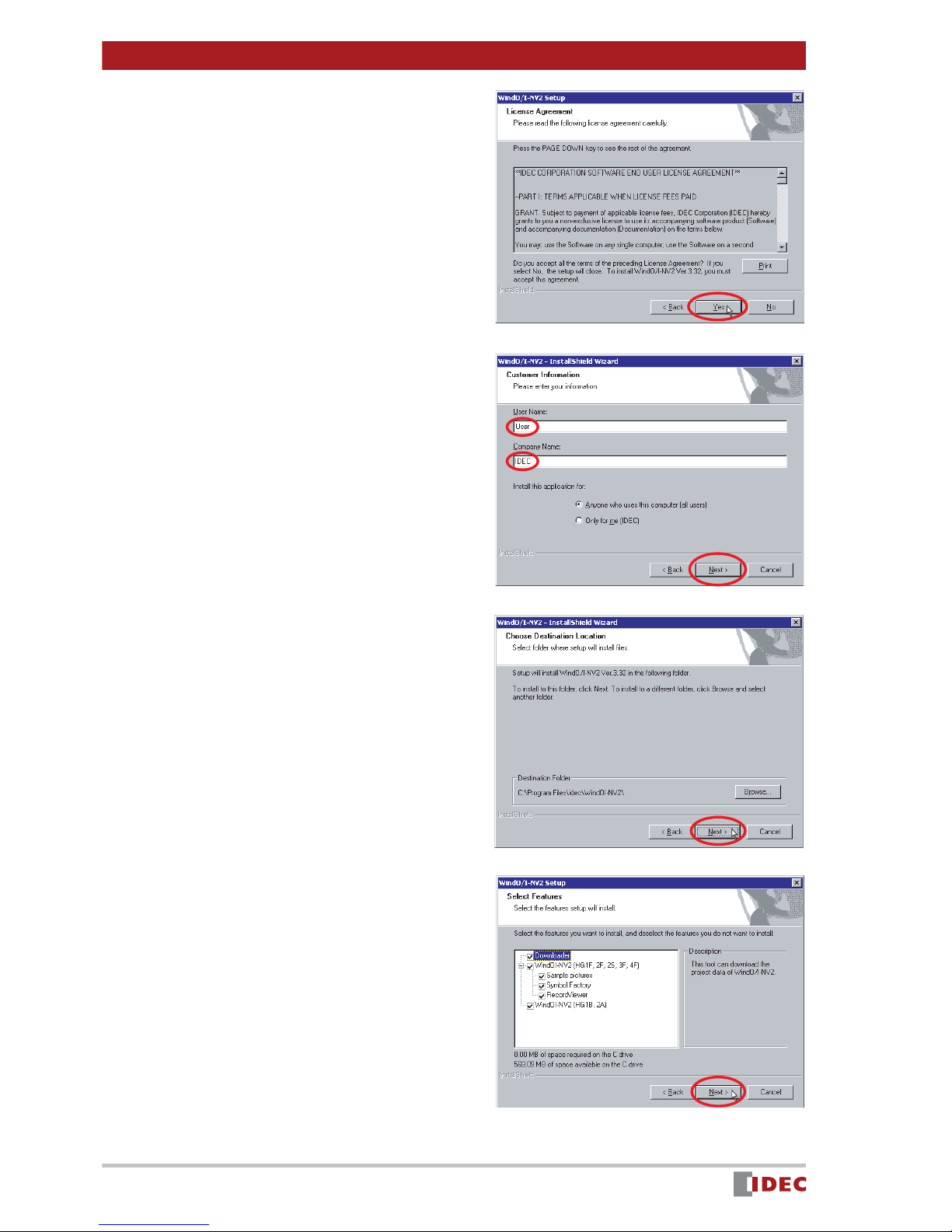

Page 8

Chapter 2 Installation

6.

7.

Review the contents of the license

agreement. If you accept the terms

of the agreement, click [Yes].

Enter User Name and Company

Name , and click [Next].

In this example, User and IDEC are

entered in User Name and Company

Name , respectively.

8.

9.

Click [Next].

Click [Next].

8

www.IDEC.com/software

Page 9

Chapter 2 Installation

10.

11.

Click [Next].

Review the settings and click

[Next].

2

12.

13.

Installation

Installation will start.

Click [Yes].

After installation is completed,

click [Finish].

www.IDEC.com/software

9

Page 10

Chapter 3 Screen Creation

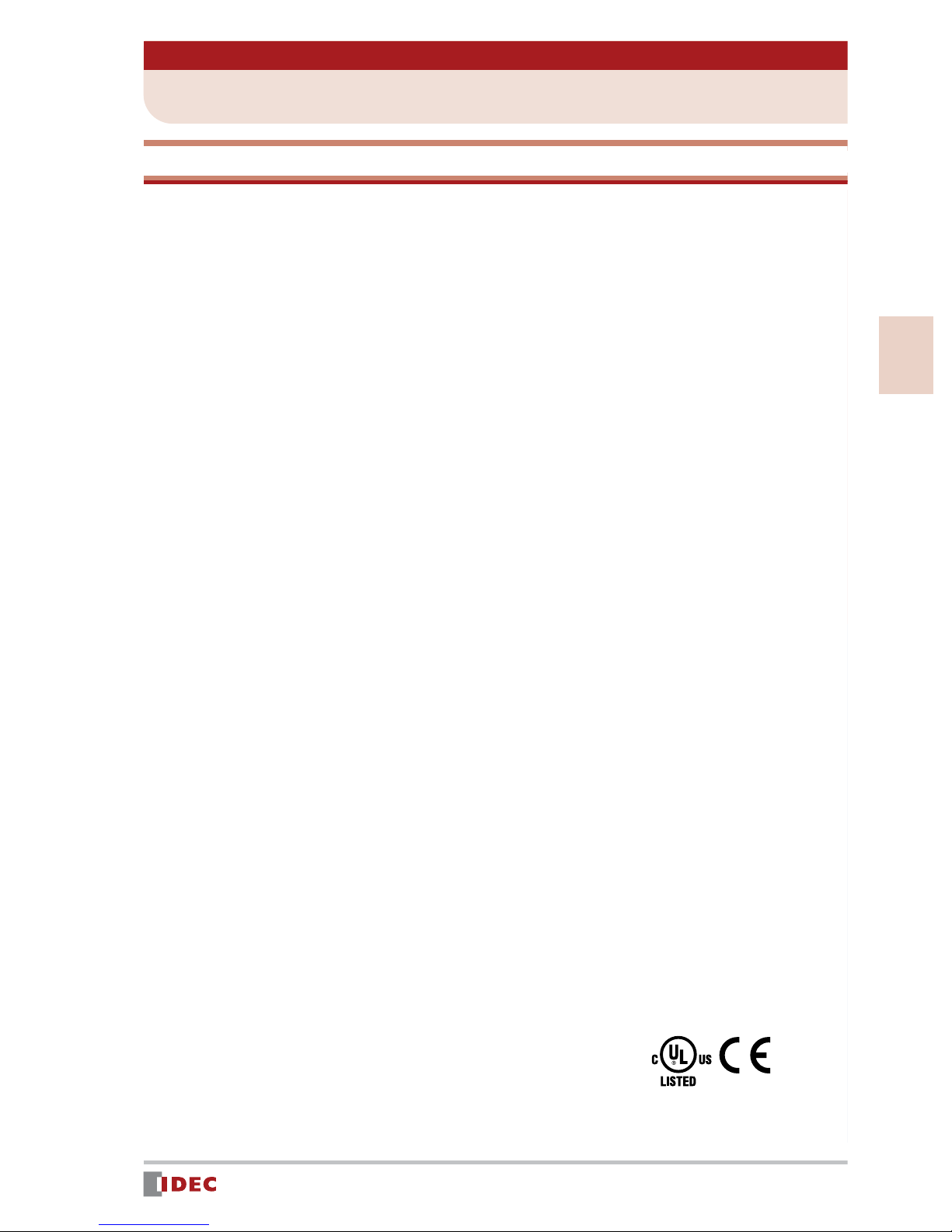

1 Sample Program

Using WindO/I-NV2 installed in Chapter 2, even beginners can easily create the following

screen:

Create a project to control & monitor a product ion line

Using a production line as the application, create a screen that functions as follows:

(1) Starting and stopping the production line using the [START] and [STOP]

buttons

(2) Indicate operation status of the production line with a Pilot Lamp

(3) Entering a target production quantity in Numerical Target , and display-

ing the target quantity in Target

(4) Pressing the [SET the results] button increments the value displayed in

Results by one.

[Operating Screen]

Text: Text to be displayed on

the screen

Rectangle

Pilot Lamp

- When the [START]

button is pressed,

the lamp is ON.

-When the [STOP]

button is pressed,

the lamp is OFF

[START] button

[STOP] button

[Numerical Target Setting Screen]

[SET UP] button:

switches the screen to [Numerical Target

Setting Screen].

Pressing this button

Target: A value entered in the numerical

input field is displayed.

Results: An actual result count is dis-

played.

[SET the results] button:

Pressing this button increments the

value displayed in [Results] by one.

10

www.IDEC.com/software

Numerical input: Pressing this field

displays a numeric input keypad.

[Back to the Operating Screen]

button:

the screen to [Operating Screen].

Pressing this button switches

Page 11

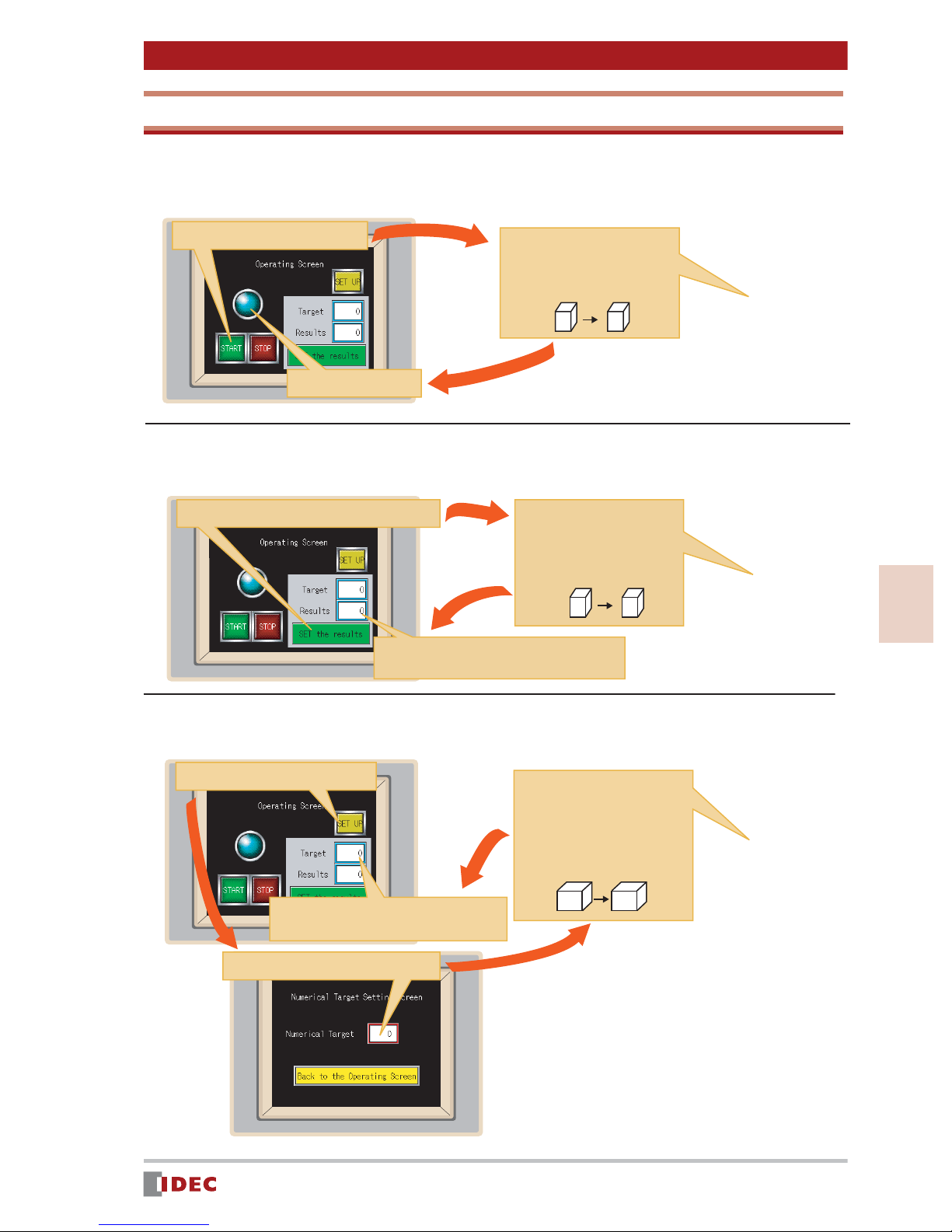

Chapter 3 Screen Creation

0

10

Available Devices and Parts Operation

Each part will be operated with the following devices:

[Q 0]: [START (or [STOP]) button and pilot lamp operation

1. Press the [START] button.

3. Pilot Lamp lights up.

2. Bit 1 is written in device

[Q 0].

Device

[Q 0]

Device

[Q 0]

0 1

[D 10]: [INC the results] button and [Results] display

1. Press the [SET the results] button.

3. The value of device [D 10] is displayed.

2. The value of device [D 10]

is incremented by one.

Device

[D 10]

0 1

Device

[D 10]

3

[D 20]: Numerical input field and [Target] display

1. Press the [SET UP] button.

3. The entered

value is written in

device [D 20].

Device

[D 20]

4. The value of device [D 20] is displayed.

2. Enter a numerical value.

www.IDEC.com/software

Screen Creation

Device

[D 20]

11

Page 12

Chapter 3 Screen Creation

2 Launching WindO/I-NV2 & Creating a New Project

Starting WindO/I-NV2

1. Double-click the WindO/I-NV2

Launcher icon on the desktop.

2. Select HG1F/2F/2S/3F/4F .

3. Click [Yes]. WindO/I-NV2 will start.

Creating a New Project

4. Click the (New Project) icon.

5. Enter the file name of a project,

and click [Next].

Enter sample for File name .

6. Select the type and model of the

Operator Interface being used, and

click [Next].

Select HG2F for O/I Type , and select

HG2F-SS22V for Model .

HG2F-SS22VF

12

www.IDEC.com/software

Page 13

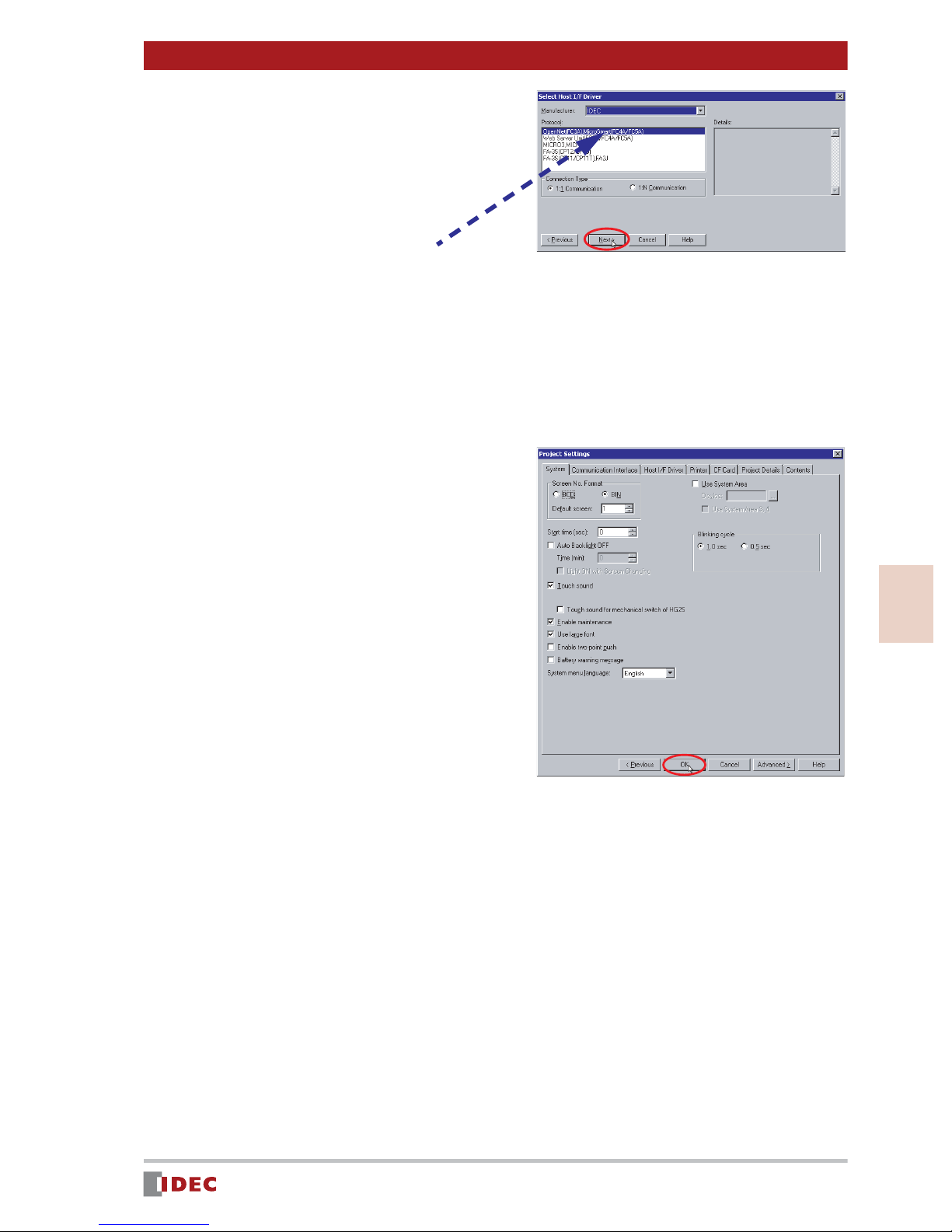

7. Set the items in Select Host I/F

Driver , and click [Next].

Select IDEC for Manufacturer , and

OpenNet (FC3A), MicroSmart (FC4A/

FC5A) for Protocol .

MicroSmart

The Project Settings window will be displayed.

8. Click [OK].

The Project Settings window enables

common settings for all screens of a

project. However, you may keep the

same settings as shown in this window.

Chapter 3 Screen Creation

If you wish to change the settings later,

select [Set up] > [Project Settings]

menu.

Creation of a new project is complete.

The Screen Properties window will be

displayed, and you can proceed to create a screen.

3

Screen Creation

www.IDEC.com/software

13

Page 14

Chapter 3 Screen Creation

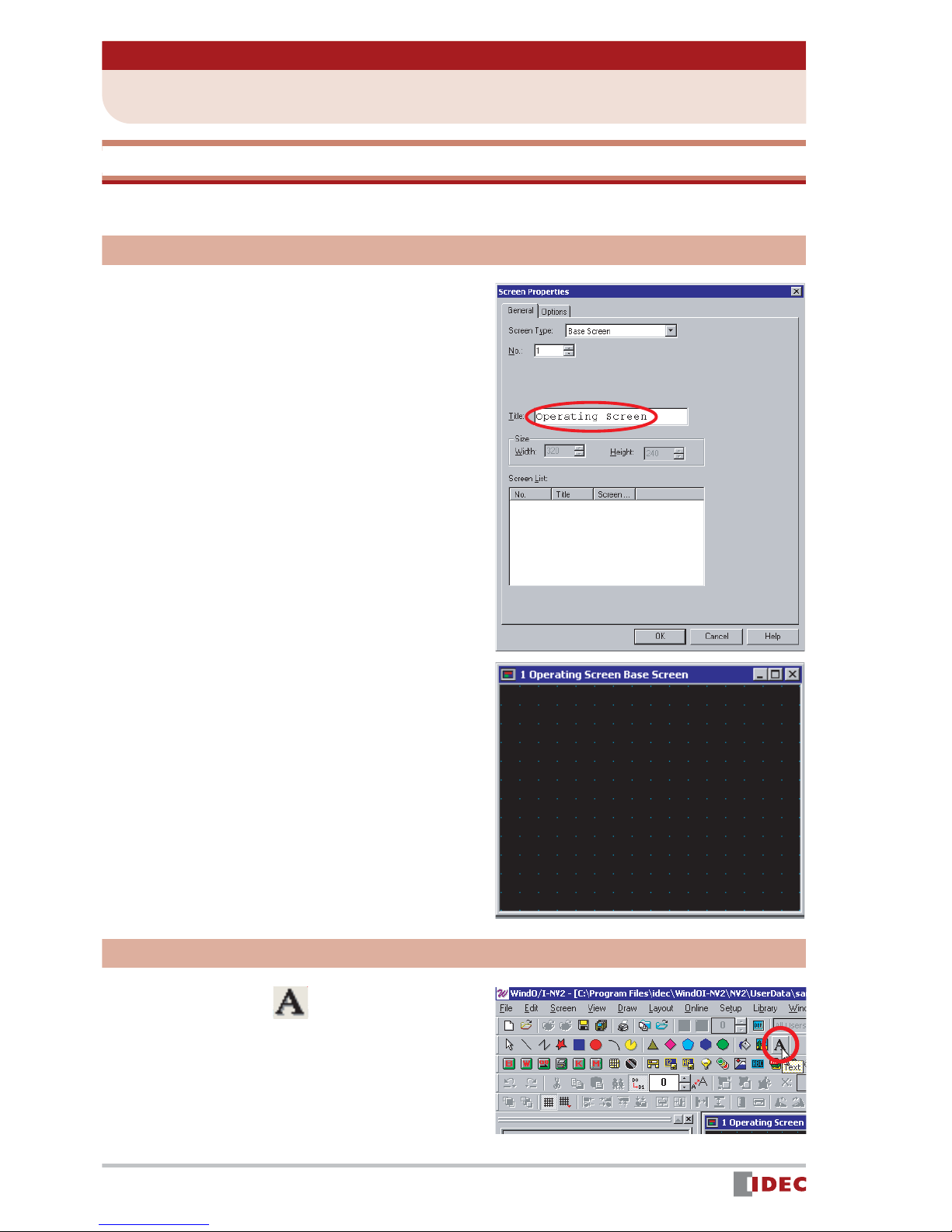

3 Creating Screens

[Operating Screen]

Set Up

1. Enter [Title]. (optional)

In this example, select Base Screen for

[Screen Type], and enter 1 in [No.].

If you wish to change the above settings,

double-click the screen to display the

Screen Properties window.

2. Click [OK].

The [Operating Screen] setup is complete, and 1 Operating Screen Base

Screen is displayed.

Creating screen text

1. Click the (T ext) icon, and then

click on the screen where you

want the text to be.

The Properties of Text window is displayed.

14

www.IDEC.com/software

Page 15

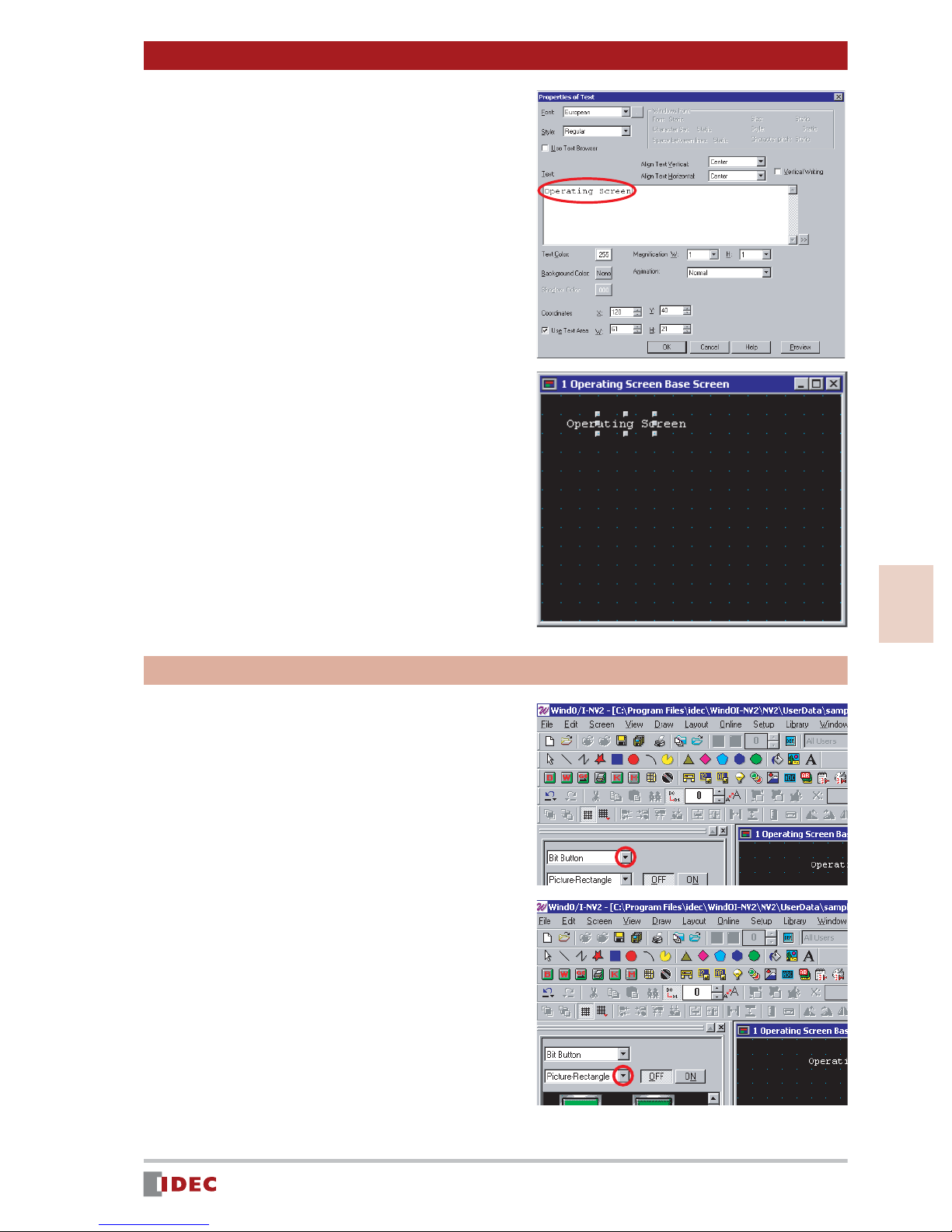

2. Enter Operating Screen in the

text box.

3. Click [OK].

The text will be displayed on the screen.

Chapter 3 Screen Creation

To move the text, use the Drag & Drop

function.

[START] and [STOP] buttons

Create a [START] button and [STOP] button to

turn a Pilot Lamp on/off.

1. To create the [START] and [STOP]

buttons, select Part tab on workspace.

Click [ ] for the parts list and select

2. Click [ ] for shape, and select

Bit Button .

Picture - Rectangle .

3

Screen Creation

www.IDEC.com/software

15

Page 16

Chapter 3 Screen Creation

3. Select the desired part, and place

the part on 1 Operating Screen

Base Screen using drag & drop

operations.

In this example, select Bit Button

sq03_g .

4. Double-click the part placed on the

screen.

The Properties of Bit Button window

is displayed.

5. Click [ ] for Action Mode , and

select Set .

If Set is selected for Action Mode ,

1 will be written in the specified

device when this button is pressed.

6. Enter Q 0 in [Destination

Device].

Insert a space between the letter Q

and the number 0 .

In this example, 1 will be written in

PLC device Q 0 .

7. Select the Registration Text tab,

and enter the text that will appear

on the button.

Q

In this example, enter START .

16

www.IDEC.com/software

Page 17

8. Click the [Color] selection button

to change the text color.

In this example, select 255 (white).

Chapter 3 Screen Creation

9. Click [OK].

The [START] button will appear on the

screen.

10. Create a [STOP] button by follow-

ing the previous steps 1 to 8 as

shown below.

- In Step 1, place Bit Button sq03_r on

the screen.

- In Step 5, select Reset .

(If Reset is selected for Action

Mode , 0 will be written in a specified

device when this button is pressed.)

- In Step 6, enter Q 0.

- In Step 7, enter STOP .

3

Screen Creation

The [STOP] button will appear on the

screen.

www.IDEC.com/software

17

Page 18

Chapter 3 Screen Creation

Pilot Lamp

Create a pilot lamp that will turn on when the [START] button is pressed, and turn off when

the [STOP] button is pressed.

1. T o create a pilot lamp, select Pilot

Lamp .

Click [ ] for the parts list, and select

2. Click [ ] for shape, and select

Pilot Lamp .

Picture - Circle .

3. Click the (Snap to Grid) icon.

The icon is reset (shown as

and the Snap to Grid setting is

disabled.

Disabling Snap to Grid allows you to

place the object/part anywhere on the

screen.

),

4. Select the desired part, and place

the part on 1 Operating Screen

Base Screen using drag & drop

operations.

In this example, select Pilot Lamp

dm13_s .

5. Click the (Snap to Grid) icon.

The Snap to Grid (shown as ),

setting becomes active.

Enabling Snap to Grid allows you to set

the push buttons on a grid so they function properly.

18

www.IDEC.com/software

Page 19

6. Double-click the part placed on the

screen.

The Properties of Pilot Lamp window is

displayed.

7. Select the Trigger Condition tab,

and click [ ] for [Trigger Type].

Select While ON .

If While ON is selected for [Trigger

Type], the lamp will remain lit when the

specified device is ON.

Chapter 3 Screen Creation

8. Enter Q 0 in [Device].

Insert a space between Q and 0 .

In this example, the lamp will be

switched ON/OFF by the PLC device

Q 0 .

9. Click [OK].

Q

3

Screen Creation

www.IDEC.com/software

19

Page 20

Chapter 3 Screen Creation

[SET UP] button

Create a [SET UP] button that will change from [Operating Screen] to [Numerical Target

Setting Screen] when pressed.

1. T o create a [SET UP] button, select

the Goto Screen Button .

Click [ ] for the parts list, and select

2. Click [ ] for shape, and select

Goto Screen Button .

Picture - Rectangle .

3. Select the desired part, and place

the part on 1 Operating Screen

Base Screen using the drag &

drop function.

In this example, select the Goto Screen

Button sq81_y .

4. Double-click the part placed on the

screen.

The Properties of Goto Screen Button

window will be displayed.

20

www.IDEC.com/software

Page 21

Chapter 3 Screen Creation

5. Click [ ] for Action Mode to

select Switch Base Screen .

6. In Goto Screen set Screen No.

to 2 .

The screen No. is set to 2 .

7. Select the Registration Text tab,

and specify the text to be shown

on the button.

In this example, enter SET UP in the

text box.

8. Click the [Color] selection button

to change the text color.

In this example, select 000 (black).

9. Click [OK].

The [Set Up] button will appear on the

screen.

3

Screen Creation

www.IDEC.com/software

21

Page 22

Chapter 3 Screen Creation

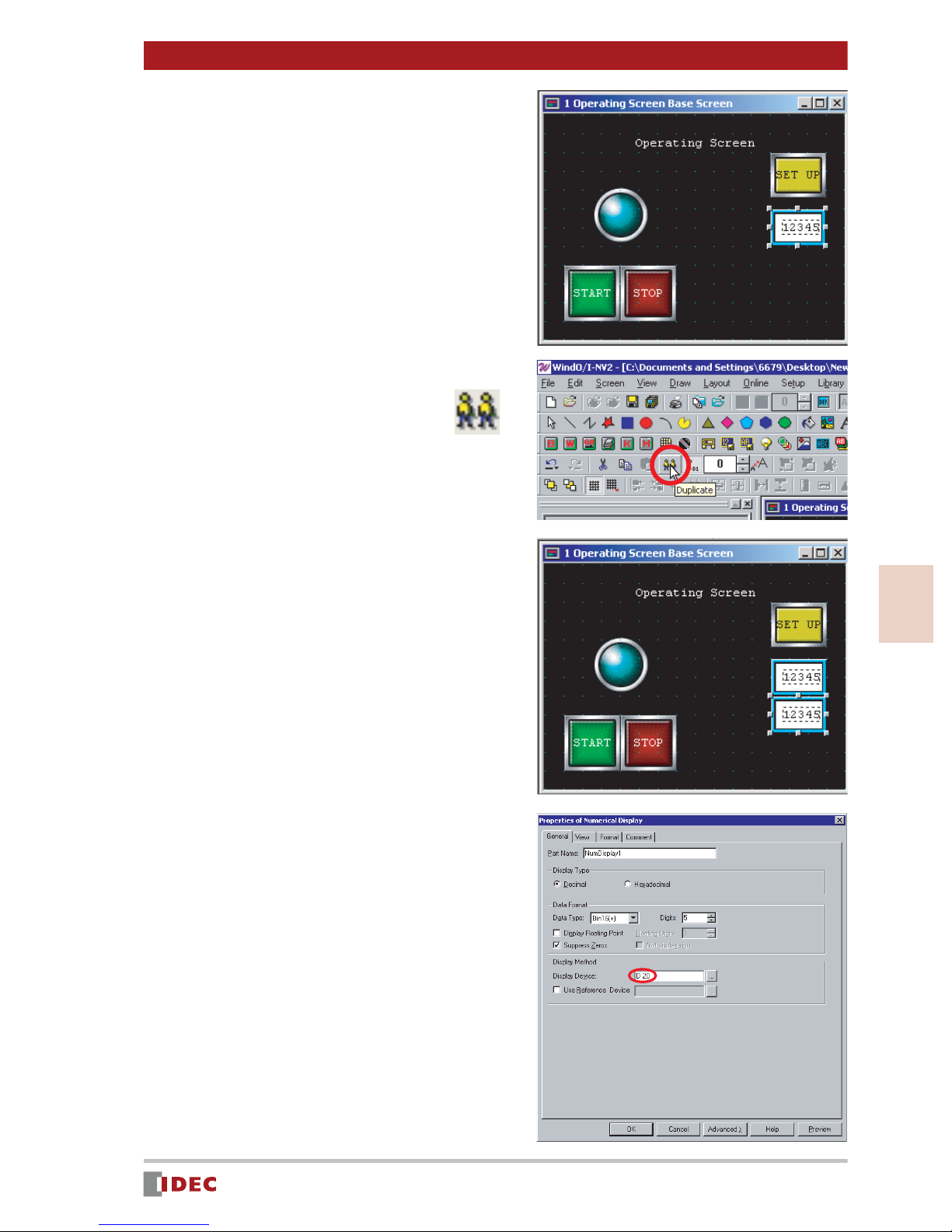

[Target] & [Results] Displays

Create a [Target] display to show the value entered in the Numerical Target (numerical

input field). Create a [Results] display that will increment the displayed value by one, every

time the [SET the results] button is pressed.

1. To create the [Target] display,

select Numerical Display .

Click [ ] for the parts list, and select

Numerical Display .

2. Select the desired part, and place

it on 1 Operating Screen Base

Screen using the drag & drop

function.

In this example, select Numerical Display

F0004 .

3. Double-click the part placed on the

screen.

The Properties of Numerical Display

window will be displayed.

4. Enter D 10 in [Display Device].

Insert a space between D and 10 .

In this example, the value of the PLC

device D 10 will be read and displayed

in the [Target].

22

www.IDEC.com/software

Page 23

5. Click [OK].

6. Select the numerical display for

the [Target], and click the

(Duplicate) icon.

The numerical display will be copied.

Chapter 3 Screen Creation

7. Drag and drop the copied numeri-

cal display below the [Target]

numerical display.

8. Double-click the duplicated

numerical display, and change the

setting of the Display Device to

D 20 .

Insert a space between D and 20 .

In this example, the value of the PLC

device D 20 will be read and displayed

in [Results].

3

Screen Creation

www.IDEC.com/software

23

Page 24

Chapter 3 Screen Creation

9. Click [OK].

Objects

1. Click the (Rectangle) icon.

2. Click the (Snap to Grid) icon.

The icon is reset (shown as

and the Snap to Grid setting is

disabled.

Disabling Snap to Grid allows you to

place the object/part anywhere on the

screen.

),

3. Click on the screen to start draw-

ing a rectangle.

4. Use the click & drag function to

resize the rectangle if necessary.

24

www.IDEC.com/software

Page 25

5. Double-click the rectangle.

The Properties of Rectangle window

will be displayed.

6. Click the [Fg. Color] selection but-

ton to change the foreground

color.

In this example, select 012 (gray).

Chapter 3 Screen Creation

7. Click the [Palette] selection but-

ton to change the Pattern Palette.

In this example, select Fore 100% .

8. Click [OK].

The completed (rectangle) will appear on

the screen.

3

Screen Creation

9. Place text ( Target and Results )

on the object, following the procedure for Creating text to be displayed on the screen on page 14.

For the text color, select 000 (black).

www.IDEC.com/software

25

Page 26

Chapter 3 Screen Creation

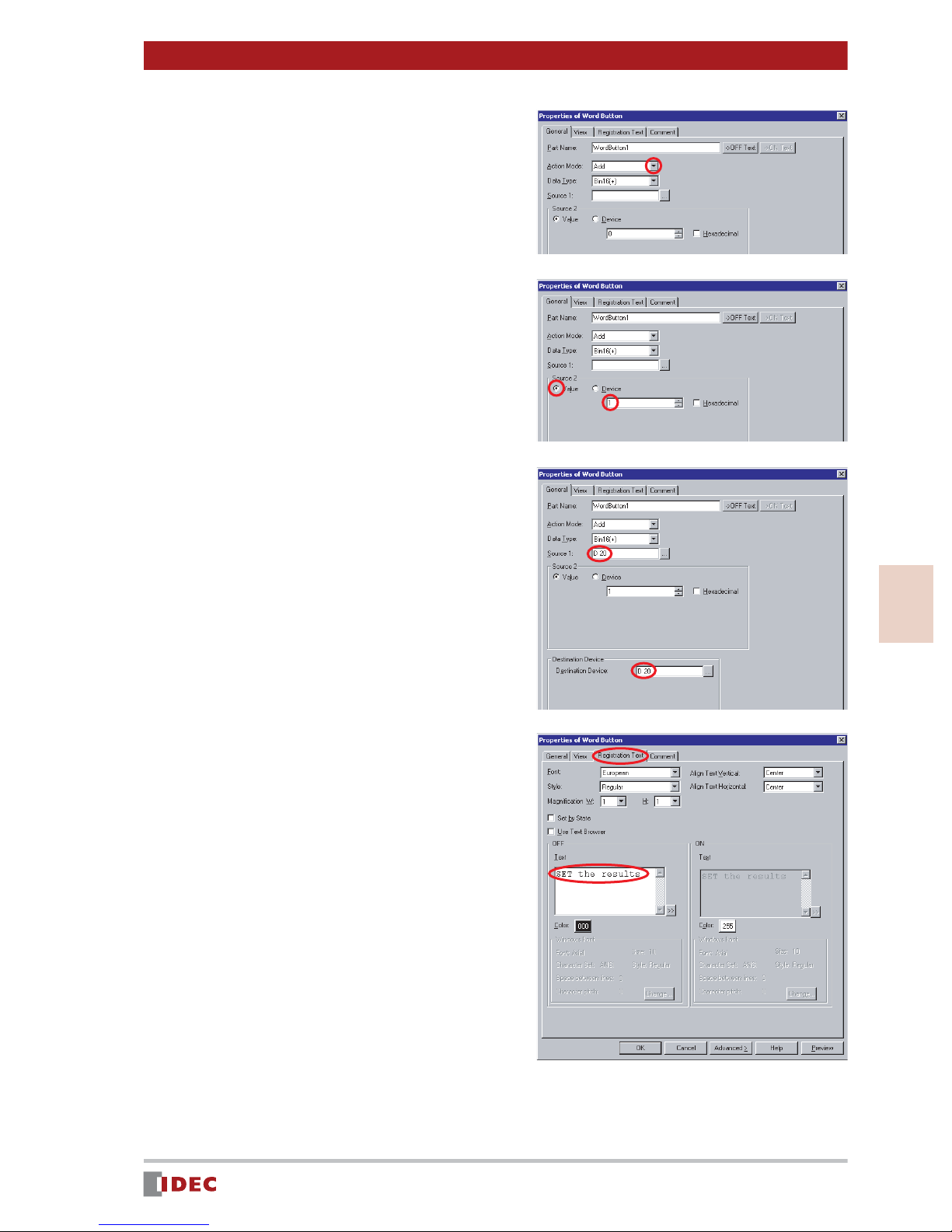

[SET the results] Button

Create a [SET the results] button that will increment the value displayed in [Results] by one,

every time the button is pressed.

1. To create the [SET the results] but-

ton, select Word Button .

Click [ ] for the parts list, and select

Word Button .

2. Click [ ] for shape, and select

Rectangle .

3. Select the desired part, and place

it on 1 Operating Screen Base

Screen using the drag & drop

function.

In this example, select Word Button

B0001 .

4. Change the size of the part using

the drag & drop function.

5. Double-click the part placed on the

screen.

The Properties of Word Button window

will be displayed.

26

www.IDEC.com/software

Page 27

Chapter 3 Screen Creation

6. Click [ ] for Action Mode , and

select Add .

In this example, select Add , so that the

displayed value will increment.

7. Enter 1 for Value in [Source 2].

In this example, enter 1 for Value so

that the displayed value will increment

by one.

8. Enter D 20 for both [Source 1]

and [Destination Device].

Insert a space between D and 20 .

In this example, the value of the PLC

device D 20 , which is used for the

[Results] display setting, will be read.

The read value will be inceased by one,

and written in D 20 .

3

9. Select the Registration Text tab,

and specify the text to be shown

on the button.

In this example, enter SET the results

in [OFF] - [Text] box.

www.IDEC.com/software

Screen Creation

27

Page 28

Chapter 3 Screen Creation

10. Click [OK].

The [SET the results] button will appear

on the screen

11. Click the (Snap to Grid) icon.

The icon is set (shown as

and the Snap to Grid setting becomes

active.

),

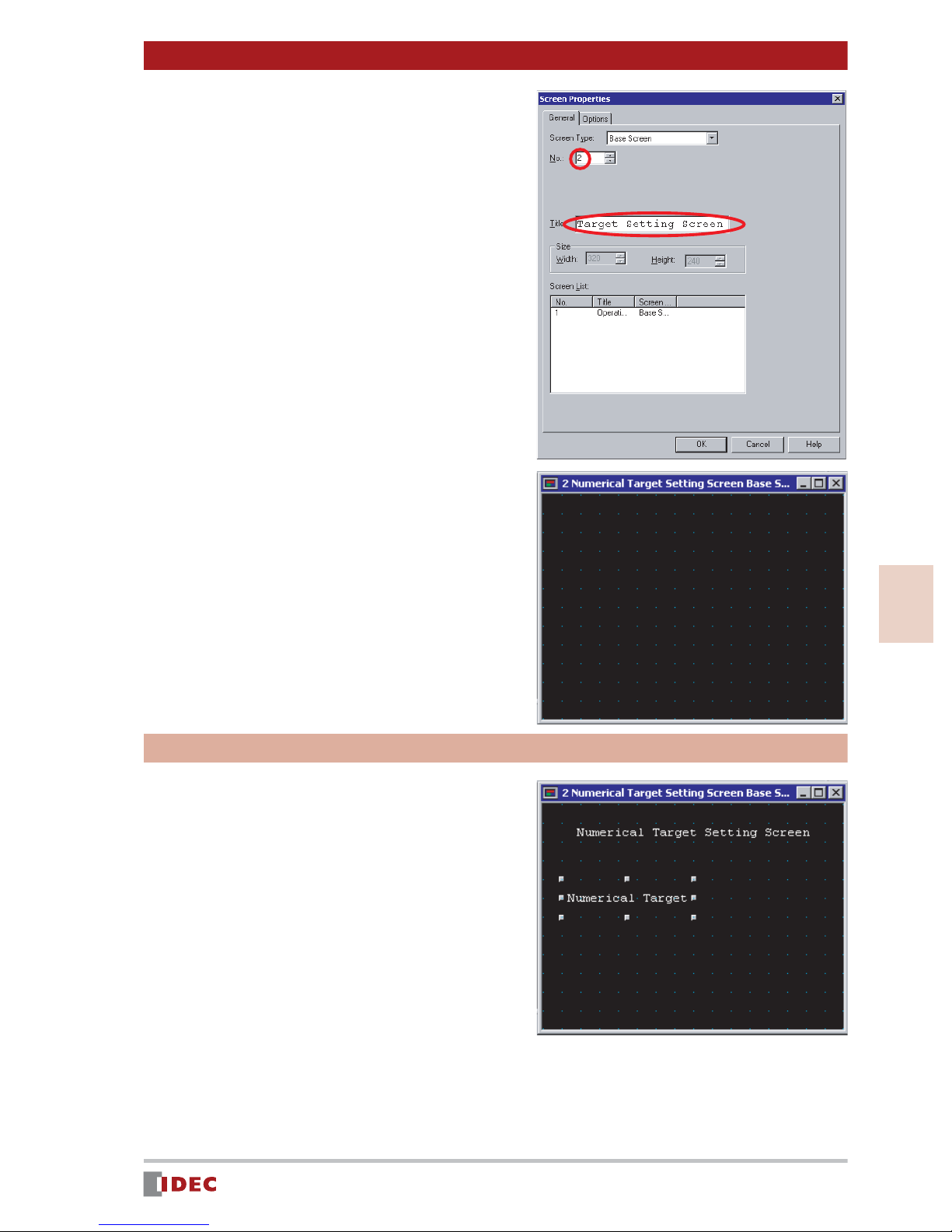

[Numerical Target Setting Screen]

Create a [Numerical Target Setting Screen] to display a screen when the [SET UP] button

is pressed.

Set Up

1. Click the (New Screen) icon.

The Screen Properties window will be

displayed.

28

www.IDEC.com/software

Page 29

2. Enter 2 in [No.], and enter

Numerical T arget Setting Screen

in [Title].

3. Click [OK].

Chapter 3 Screen Creation

[Numerical Target Setting Screen] set up

is complete, and 2 Numerical Target

Setting Screen Base Screen will be displayed.

Creating screen text

1. Create text for ( Numerical Target

Setting Screen , and Numerical

Target ), according to the procedure for Creating screen text as

described on page 14.

For the text color, select 255 (white).

3

Screen Creation

www.IDEC.com/software

29

Page 30

Chapter 3 Screen Creation

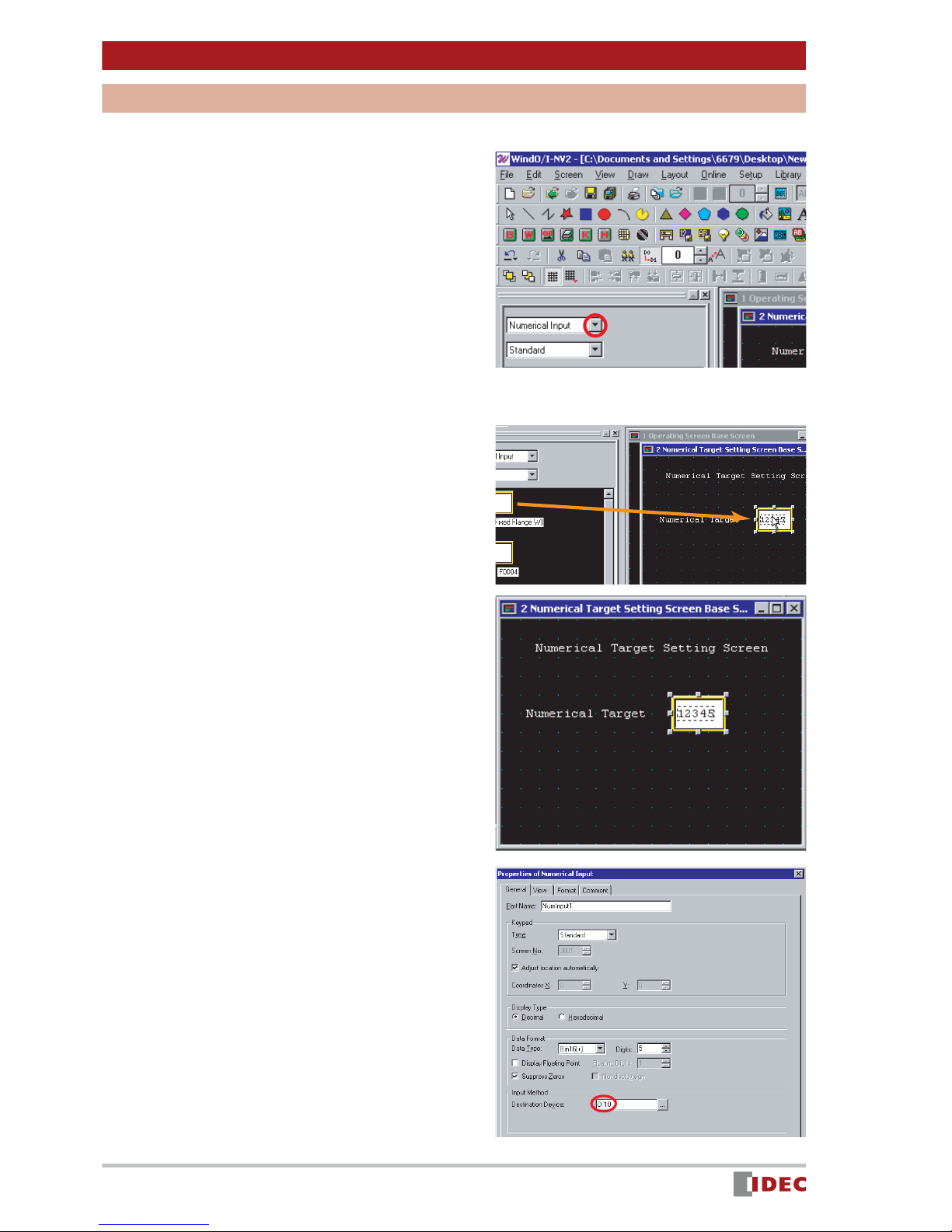

Numerical Target input field

Create a numerical input field to enter and display a target value.

1. To create the Numerical Target

input, select Numerical Input .

Click [ ] for the parts list, and select

Numerical Input .

2. Select the desired part, and place

it on 2 Numerical Target Setting

Screen Base Screen using the

drag & drop function.

In this example, select Numerical Input

F0006 .

3. Double-click the part placed on the

screen.

The Properties of Numerical Input window will be displayed.

4. Enter D 10 in [Destination

Device].

Insert a space between D and 10 .

In this example, the entered value will be

written in PLC device D 10 .

30

www.IDEC.com/software

Page 31

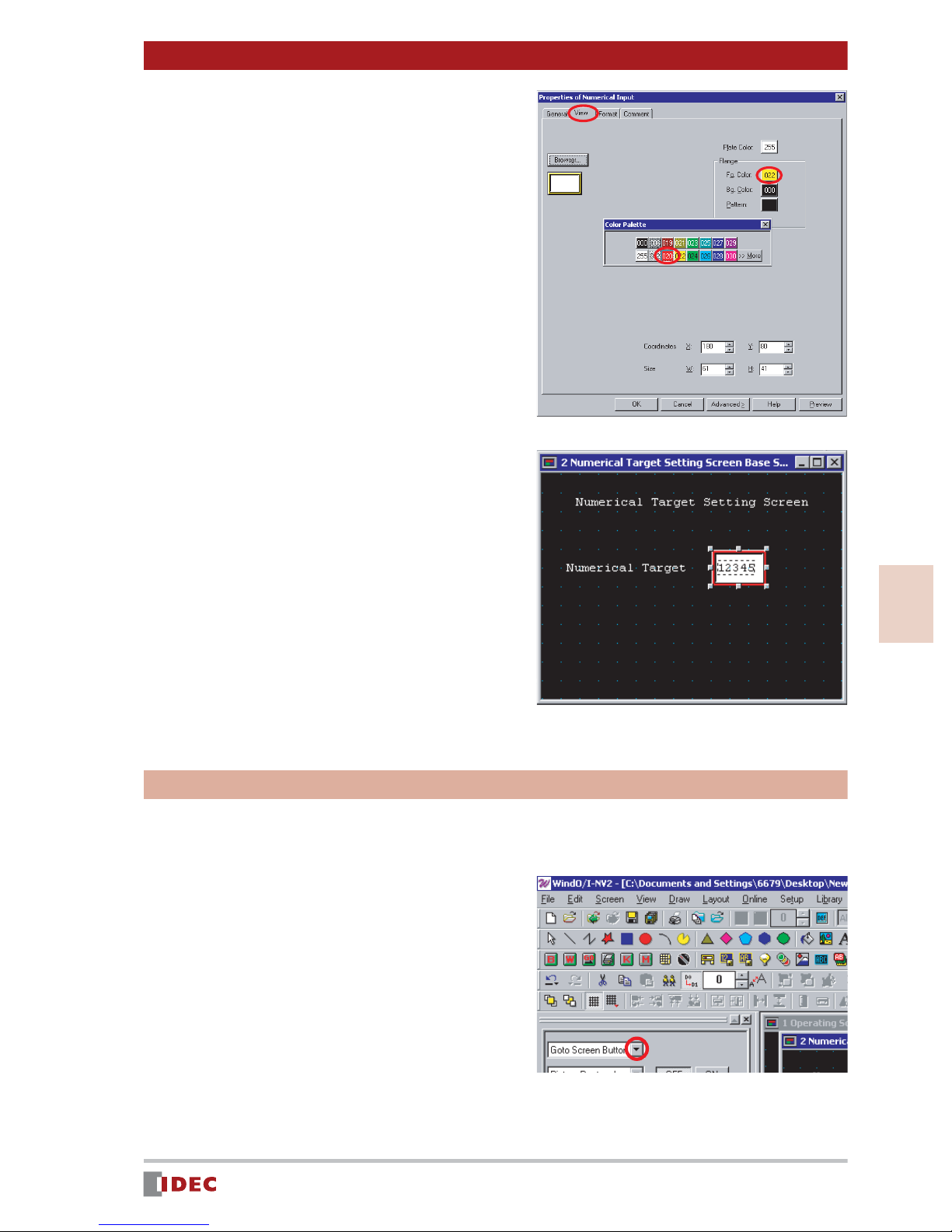

5. Select the [View] tab, and click the

[Fg. Color] selection button in

[Flange] to change the foreground

color.

In this example, select 020 (red) for

[Fg. Color].

Chapter 3 Screen Creation

6. Click [OK].

The numerical input field for the Numerical Target will be displayed on the

screen.

[Back to the Operating Screen] button

Create a [Back to the Operating Screen] button that will switch from the [Numerical Target

Setting Screen] to the [Operating Screen] when pressed.

\

1. To create the [Back to the Operat-

ing Screen] button, select Goto

Screen Button .

3

Screen Creation

Click [ ] for the parts list, and select

Goto Screen Button .

www.IDEC.com/software

31

Page 32

Chapter 3 Screen Creation

2. Click [ ] for shape, and select

Rectangle .

3. Select the desired part, and place

it on 2 Numerical Target Setting

Screen Base Screen using the

drag & drop function.

In this example, select Goto Screen Button B0055 (Fixed Flange W) .

4. Change the size of the part using

the click & drag function.

5. Double-click the part placed on the

screen.

The Properties of Goto Screen Button

window will be displayed.

6. Click [ ] for Action Mode , and

select Switch Base Screen .

7. In [Goto Screen] set [Screen No.]

to 1 .

In this example, set the screen No. to 1

because the [Opeating Screen] No. or

the screen to be switched to, is 1 .

32

www.IDEC.com/software

Page 33

8. Select the [View] tab, and click the

[Fg. Color] selection button in

[OFF] to change the foreground

color.

In this example, select 022 (yellow) for

[OFF] - [Fg. Color].

9. Select the Registration Text tab

and enter the text to be shown on

the button.

In this example, enter Back to the Operating Screen .

Chapter 3 Screen Creation

10. Click [OK].

[Back to the Operating Screen] button is

will be displayed.

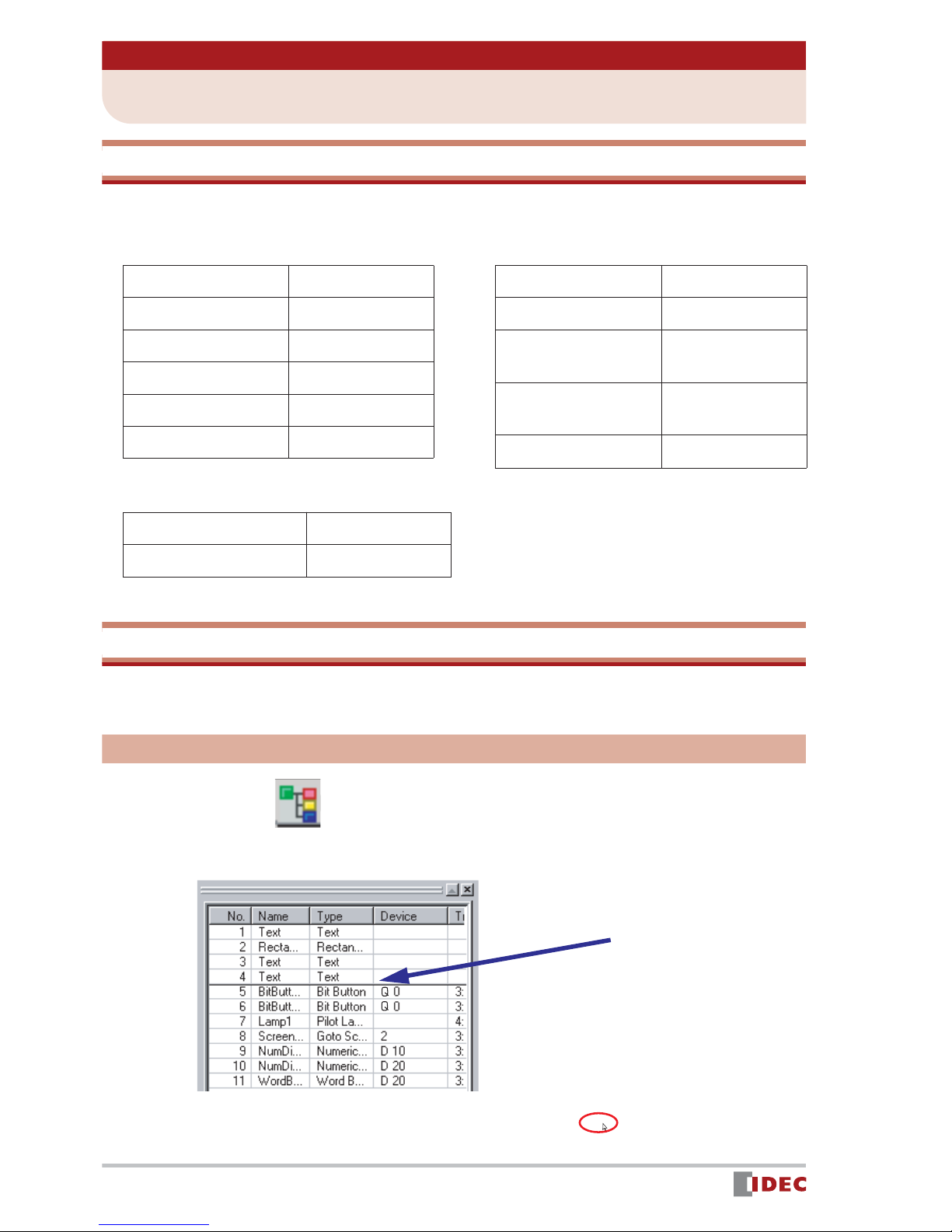

Saving

Click the (Save Project) icon.

3

Screen Creation

www.IDEC.com/software

33

Page 34

Chapter 4 Download

1 Downloading the Project

If you download the project data created in Chapter 3 to an Operator Interface, the project

will be displayed and can be operated on the OI screen.

1. Connect the Operator Interface to

a PC with a cable.

Cable for connecting PC to Operator Interface

(HG9Z-XCM1A or FC2A-KC4C)

2. Click the (Download Project) icon.

3. Click [Download].

The Operator Interface starts downloading the project.

Connect the cable to the maintenance

communication interface.

Connect the cable to the RS232C port.

4. After the download confirmation

message appears, click [Yes].

34

www.IDEC.com/software

Page 35

5. After download is complete, click

[OK].

6. Click [Close].

Chapter 4 Download

If download cannot be completed, check the following:

- Check the power supply to the Operator Interface.

- Check the cable connection between the Operator Interface and the PC.

- Check the COM port of the PC connected to the Operator Interface.

* If the COM port is being used by another application, then the port is not available for

download.

Host Communication Error

Once a project is downloaded to the Operator Interface, the Operator Interface may display

a Host Communication Err message after approx. 10 seconds.

This error is caused by improper connection

between the Operator Interface and the PLC that

the Operator Interface is to communicate with.

Even if the Host Communication Err message is

displayed, the Operator Interface can execute offline operation checks using the simulation function. (Refer to Simulation Mode on page 36.)

HostCommunicationerr

4

Download

www.IDEC.com/software

35

Page 36

Chapter 5 Verify Operation

1 Simulation Mode

Running Simulation Mode will verify whether the downloaded project data is displayed correctly and if it will function properly on the Operator Interface.

Starting Simulation Mode

The IDEC OI Touchscreens have a simulation mode that enables the Operator Interface to

check the functionality of the project without being connected to a PLC.

1. Simultaneously press the top right

and top left corners on the screen

for 3 seconds.

The Maintenance screen appears.

HostCommunicationerr

2. Press the [System Mode] button.

The Main Menu screen appears.

3. Press the [Debug] button.

The Debug screen appears.

4. Press the [Simulat n] button.

0DLQWHQDQFH

6\VWHP0RGH

'HYLFH0RQLWRU

$GMXVW&RPWUDVW

0DLQ0HQX

,QLWLDO

6HWWLQJ

6HOI

'LDJQRVLV

6\VWHP

,QIRUPDWLRQ

Fri4/04/200812:00:01

0DLQ0HQX 'HEXJ

6LPXODWQ

(1*-31

&ORFN6HW

'HEXJ

5XQ6WDUW

5. Press the [Start] button.

The project [Operating Screen] is displayed, and simulation is enabled.

( Simulation Mode will blink at the bottom left of the screen.)

36

www.IDEC.com/software

0DLQ0HQX 'HEXJ

<RXFDQGHEXJXVLQJRQO\2,

ZLWKRXW3/&

6WDUW

6LPXODWQ

Page 37

Simulating

1. Press the [START] button.

The pilot lamp turns on.

2. Press the [STOP] button.

The pilot lamp turns off.

3. Press the [SET UP] button.

The [Numerical Target Setting Screen]

appears.

Chapter 5 Verify Operation

4. Press the Numerical input.

The numeric keypad appears.

5. Enter 100 , and press the [ENT]

key.

100 is set in [Numerical Target].

6. Press the [Back to the Operating

Screen] button.

The [Operating Screen] appears, and

100 is displayed in [Target].

7. Press the [SET the results] button.

5

Every time this button is pressed, the

value displayed in [Results] increments

by one.

www.IDEC.com/software

Verify Operation

37

Page 38

Chapter 5 Verify Operation

2 Debug Mode

If the Operator Interface does not operate normally when connected to a PLC, you can

check and correct the settings, while monitoring operations with WindO/I-NV2.

Start Debug Mode

The process for detecting and correcting errors in project data is called Debug .

WindO/I-NV2 software provides a debug function (debugger).

Cable for connecting PC to Operator Interface

(HG9Z-XCM1A or FC2A-KC4C)

Connect the cable to the maintenance

1. Connect the Operator Interface to

a PC with a cable.

communication interface.

Connect the cable to the RS232C port.

2. Click the [Online] menu.

3. Click the [Start Debug] menu.

The Operator Interface displays the

screen monitor window and the debug

tool bar, and starts debugging.

In this step, the monitor window displays

information on the [Operating Screen].

38

www.IDEC.com/software

Page 39

Chapter 5 Verify Operation

Verify Operation with the Screen Monitor

The screen monitor allows you to verify actual screen operation and automatically display

all devices being used for the target screen. You can also view the data values or change

the data value of each device used.

If the screen monitor is not displayed, click the (Screen

Monitor) icon.

Checking pilot lamp operation on [Operating Screen]

1. Double-click Value for device

address Q 0 .

Up and down buttons are displayed.

2. Click [ ] to set the value to 1 ,

and press [Enter].

The pilot lamp on the Operator Interface

will turn on.

If the pilot lamp does not turn on,

check the device for the lamp.

(Refer to "Pilot Lamp" on page 18.)

Q

Q

5

www.IDEC.com/software

Verify Operation

39

Page 40

Chapter 5 Verify Operation

Verifying [Target] and [Results] Values on [Operating Screen]

1. Double-click the Value cell for

device address D 10 .

Up and down buttons are displayed.

Q

2. Click [ ] to set the value and

press [Enter].

In this example, the value is set to 5 .

The value will be displayed in the [Tar-

get] numerical display on the Operator

Interface.

3. Repeat Steps 1 and 2 to check

device address D 20 .

The value will be displayed in the

[Results] display on the Operator Interface.

If the value is not shown in each numerical display, check the device for

the numerical display [Target] or [Results] .

(Refer to "[Target] & [Results] Displays" on page 22.)

Q

Q

Verifying [Numerical Target] on [Numerical Target Setting Screen]

1. Click (Next Screen) button.

[Screen Monitor - 2 Numerical Target

Setting Screen Base Screen] appears.

The [Numerical Target Setting Screen] is

displayed on the Operator Interface.

40

Q

www.IDEC.com/software

Page 41

2. Double-click the Value cell for

device address D 10 .

Up and down buttons are displayed.

Chapter 5 Verify Operation

3. Click [ ] to set the value and

press [Enter].

In this example, the value is 5 .

The value will be displayed in the

[Numerical Target] numerical input field

on the Operator Interface.

If the value does not display in the numerical input field, check the

devices for the [Numerical Target] numerical input field.

(Refer to " Numerical Target input field" on page 30.)

End Debugging Mode

Once debugging is complete, exit debug mode.

Click the (Stop Debugging) icon.

www.IDEC.com/software

5

Verify Operation

41

Page 42

Chapter 6 Appendix

1 Tools and Functions

Shortcut Keys

Using keyboard shortcuts, you can execute frequently used operations.

Edit

Undo Ctrl + Z

Redo Ctrl + Y

Cut Ctrl + X

Copy Ctrl + C

Paste Ctrl + V

Duplicate Ctrl + D

Screen

New Screen Ctrl + N

Open Screen Ctrl + O

Open Previous

Screen

Open Next

Screen

Save Screen Ctrl + S

Ctrl + R

Ctrl + E

Others

Snap to Grid F8

Download F9

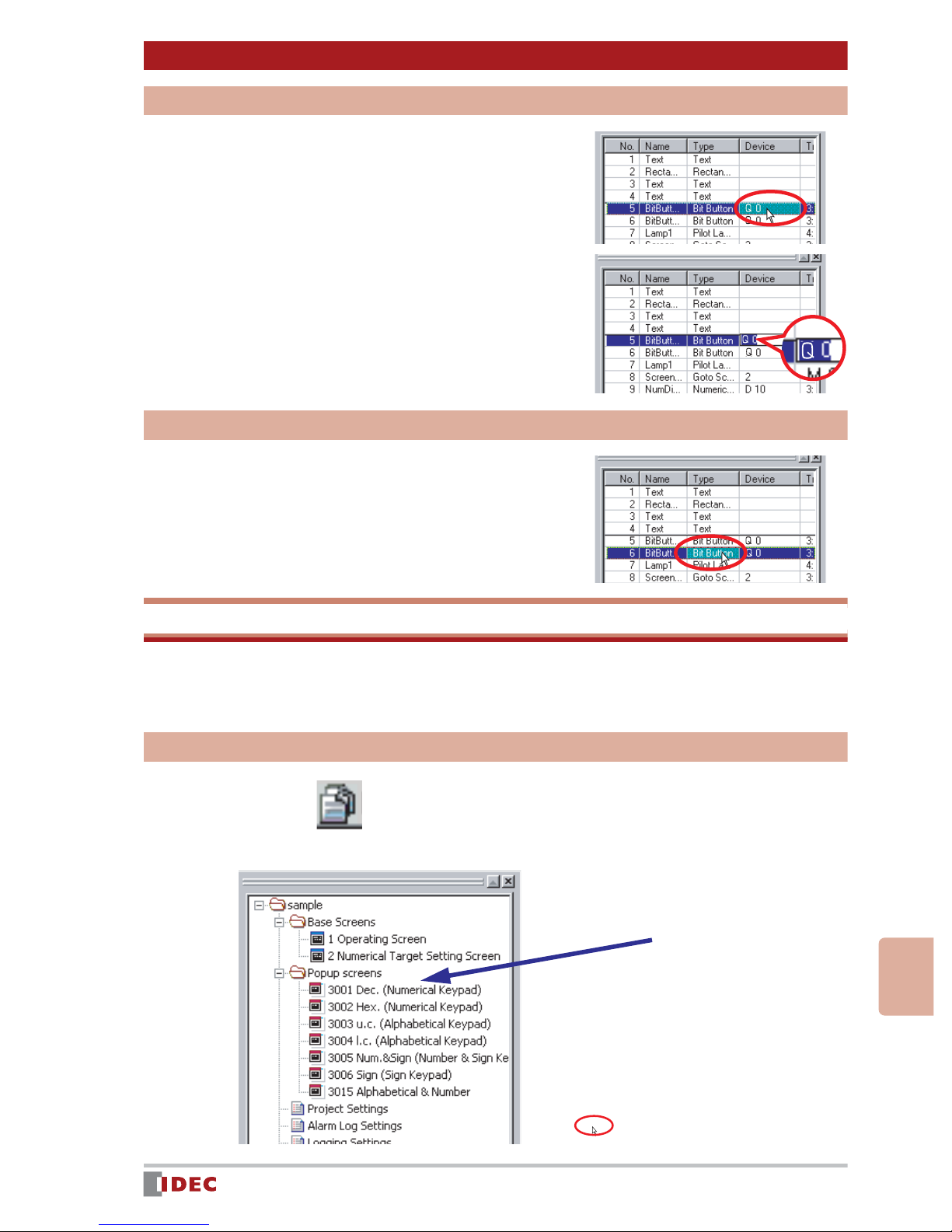

Object List

The Object List displays a list of parts and objects that have been placed on a screen. You

can easily change the properties of the listed parts.

Displaying an object list

Click the (Object ) button at the bottom of the workspace.

42

www.IDEC.com/software

Page 43

Changing objects in the workspace

Click the cell you want to change and

press [F2] or [F3] on the keyboard.

You can change a destination device through

direct input on the keyboard.

Changing properties

Double-click the No. , Name or Type

cell.

Chapter 6Appendix

The Properties window appears.

Project List

The Project List enables overall project management. It displays a list of screens and

related settings that have been saved for a particular project allowing you to easily change

their properties.

Displaying a project list

Click the (Project) button at the

bottom of the workspace.

www.IDEC.com/software

6

Appendix

43

Page 44

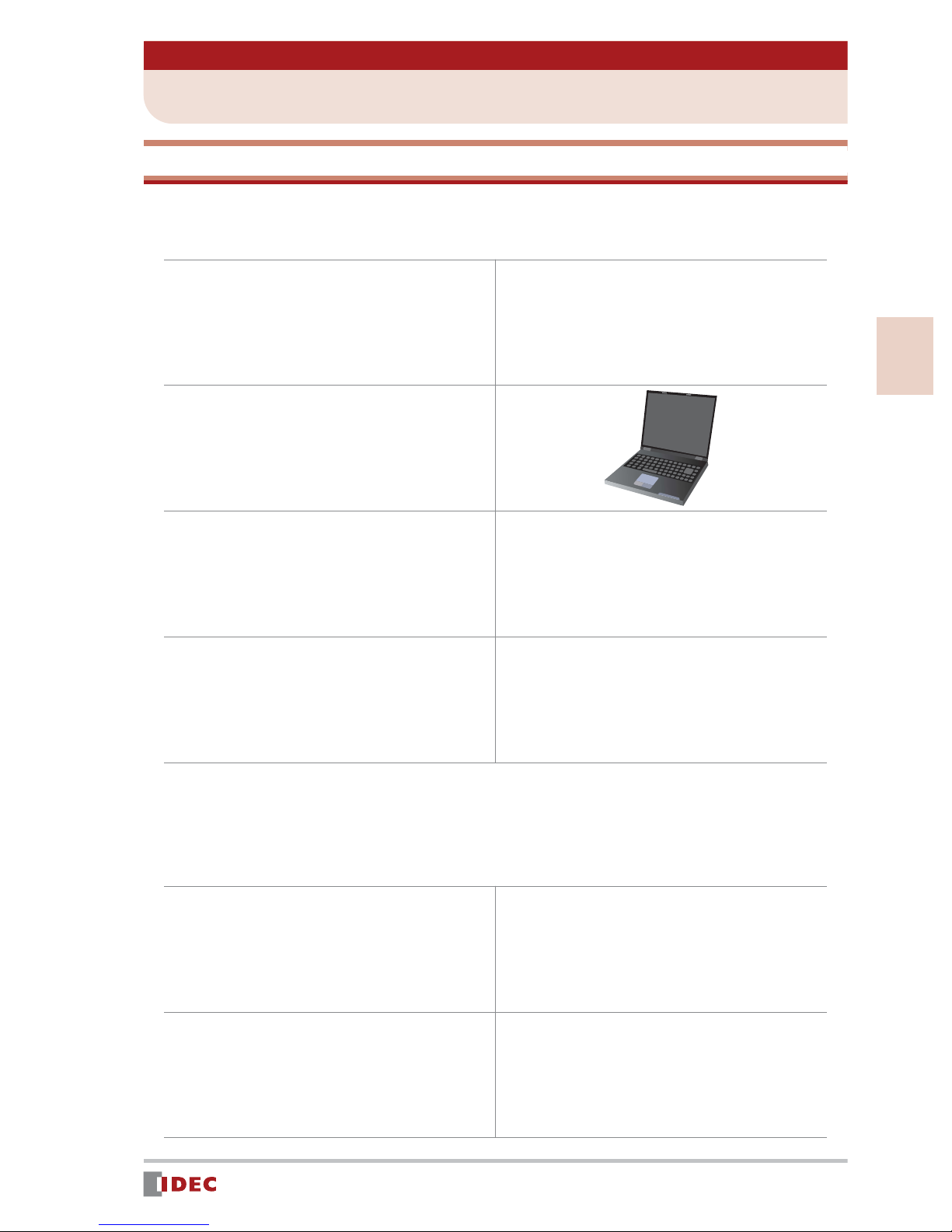

System Requirements

Compatible PC PC-AT compatible model

Compatible OS

Windows 95 (OSR2 or later version)/98/Me/NT4.0/2000/XP/Vista

(Incompatible with 64-bit version)

CPU CPU that normally runs Windows (Pentium, 200 MHz or higher)

RAM 64MB minimum

Hard Disk Empty area: 150MB minimum (including manual)

Graphic SVGA (800 x 600) or higher resolution

User

User authorized as administrator (for use of Windows NT4.0/2000/

XP/Vista)

Others Mouse, CD-ROM drive, COM port

Operator Interface Models

Model

Type HG4F HG3F

Screen Size 12.1 inches 10.4 inches 5.7 inches 5.7 inches

Appearance

Large Medium Small CC Pendant

HG2F

(Color)

HG2F

(Monochrome)

HG1F

(Monochrome)

HG2S

(Color)

(Monochrome)

4.6 inches 5.7 inches 5.7 inches

HG2S

LCD

Pixels

Display Color

User Memory Size

Memory Card (CF)

Ethernet Port

O/I Link

USB

RS232C

RS485/422

UL

CSA (c-UL)

CE

USA

IDEC Corporation

Tel (408) 747-0550

opencontact@idec.com

Canada

IDEC Canada Ltd.

Tel (905) 890-8561

sales@ca.idec.com

Australia

IDEC Australia Pty . Ltd.

Tel +61-3-9763-3244

sales@au.idec.com

TFT

800 × 600

256 colors

6 MB

Yes

Yes

Yes

—

Yes

Yes

Yes

Yes

Yes

TFT

640 × 480

256 colors

6 MB

Yes

Yes

Yes

—

Yes

Yes

Yes

Yes

Yes

Japan

IDEC Corporation

Tel +81-6-6398-2571

products@idec.co.jp

United Kingdom

IDEC Electronics Ltd.

Tel +44 (0) 1256-321000

sales@uk.idec.com

Specifications and other descriptions in this catalog are subject to change without notice.

STN

320 × 240

256 colors

2 MB

Yes

—

Yes

Yes

Yes

Yes

Yes

Yes

Yes

STN

320 × 240

Monochrome

2 MB

Yes

—

Yes

Yes

Yes

Yes

Yes

Yes

Yes

2VN-I/OdniWDesign T ool

www.idec.com

Germany

IDEC Elektrotechnik GmbH

Tel: +49-40-253054-0

service@idec.de

Hong Kong

IDEC (H.K.) Co., Ltd.

Tel +852-2803-8989

info@hk.idec.com

©2007 IDEC Corporation. All Rights Reserved

www.idec.com

STN

300 × 100

Monochrome

1 MB

—

—

Yes

—

Yes

Yes

Yes

Yes

Yes

China/Beijing

IDEC (Shanghai) Corporation

Tel +86-10-6581-6131

idec@cn.idec.com

China/Shanghai

IDEC IZUMI (Shanghai) Co., Ltd.

Tel: +86-21-5353-1000

idec@cn.idec.com

STN

320 × 240

256 colors

2 MB

—

—

Yes

—

Yes

Yes

Yes

Yes

Yes

China/Shenzhen

IDEC (Shenzhen) Corproation

Tel: +86-755-8356-2977

Singapore

IDEC Asia Pte. Ltd.

Tel +65-6746-1155

info@sg.idec.com

Taiwan

IDEC Taiwan Corporation

Tel: +886-2-2698-3929

service@idectwn.com.tw

STN

320 × 240

Monochrome

2 MB

—

—

Yes

—

Yes

Yes

Yes

Yes

Yes

WindO/I-NV2 Ver.3.3 07-391-082

Loading...

Loading...