Idec MM-SMART-20-HG1B, MM-SMART-20-HG2F-C, MM-SMART10-252, MM-SMART16-452, FC4A-R081 Data Sheet

...Page 1

Programmable Logic Controllers

MicroSmart Pentra Series

The Power to Control.

Anywhere. Anytime.

MicroSmart Pentra Series

OI Touchscreens PLCs Automation Software Power Supplies Sensors Communication Barriers

Power, Performance, Connectivity

Maximize efficiency and cut development time! MicroSmart Pentra PLCs combine advanced networking capabilities with unparalleled power, performance

and connectivity. Designed to meet all your communication requirements, now

and in the future, MicroSmart Pentra PLCs give you the flexibility to expand your

system with as many as fifteen modules! Our new Embedded Ethernet PLC with

built-in Modbus TCP also lets you remotely monitor status in real-time, receive

email alerts and customize your own web page.

The MicroSmart Pentra PLC Family: Everything you need in a controller

Embedded Ethernet Port Email and text notifications

Modbus TCP, RTU and ASCII USB programming port

Seven communication ports NEW Advanced PID control modules

Safety

All MicroSmart Pentra PLCs meet the highest standards for safety including:

cULus listed for Class 1 Division 2 hazardous locations*, CE compliant, as well

as certified for marine use by ABS, DNV, and Lloyd’s Registry*.

*Not applicable for all models. Visit www.IDEC.com/approvals for details.

User web page NEW 4-pt. analog output module

800-262-IDEC (4332) • USA & Canada

59

Page 2

MicroSmart Pentra Series

Embedded Ethernet Port

OI TouchscreensPLCsAutomation SoftwarePower SuppliesSensorsCommunicationBarriers

Programmable Logic Controllers

MicroSmart Pentra Performance

Internet

Remote Access and Control

The new MicroSmart Pentra PLC with an embedded

Ethernet port, you can configure the MicroSmart

Pentra PLC for remote monitoring and control. Using

WindLDR software, you can remotely monitor or

update the PLC programs without having to be near

the PLC.

Web Server Functions

Using standard web browsers like Internet Explorer

or Firefox, you can remotely log-in and access web

pages that are stored directly on the MicroSmart

Pentra PLC. Up to 1 MB of memory is dedicated for

web page storage! Use the built-in web pages or

create your own using an HTML editor.

14 Simultaneous Connections

The new embedded Ethernet Pentra supports up to

14 simultaneous connections through its Ethernet

port. Through the Ethernet port, the embedded

Ethernet Pentra can be configured to communicate

to WindLDR for maintenance communications, to an

Operator Interface touchscreen, and to VFD using

Modbus TCP communications, all simultaneously.

Embedded USB Maintenance Port

60

The new MicroSmart Pentra PLC with an embedded Ethernet PLC port

alsohas an embedded mini-B USB port for maintenance.

You can now easily connect your PC to this PLC using a standard

USBcable.

www.IDEC.com

Page 3

Programmable Logic Controllers

MicroSmart Pentra Series

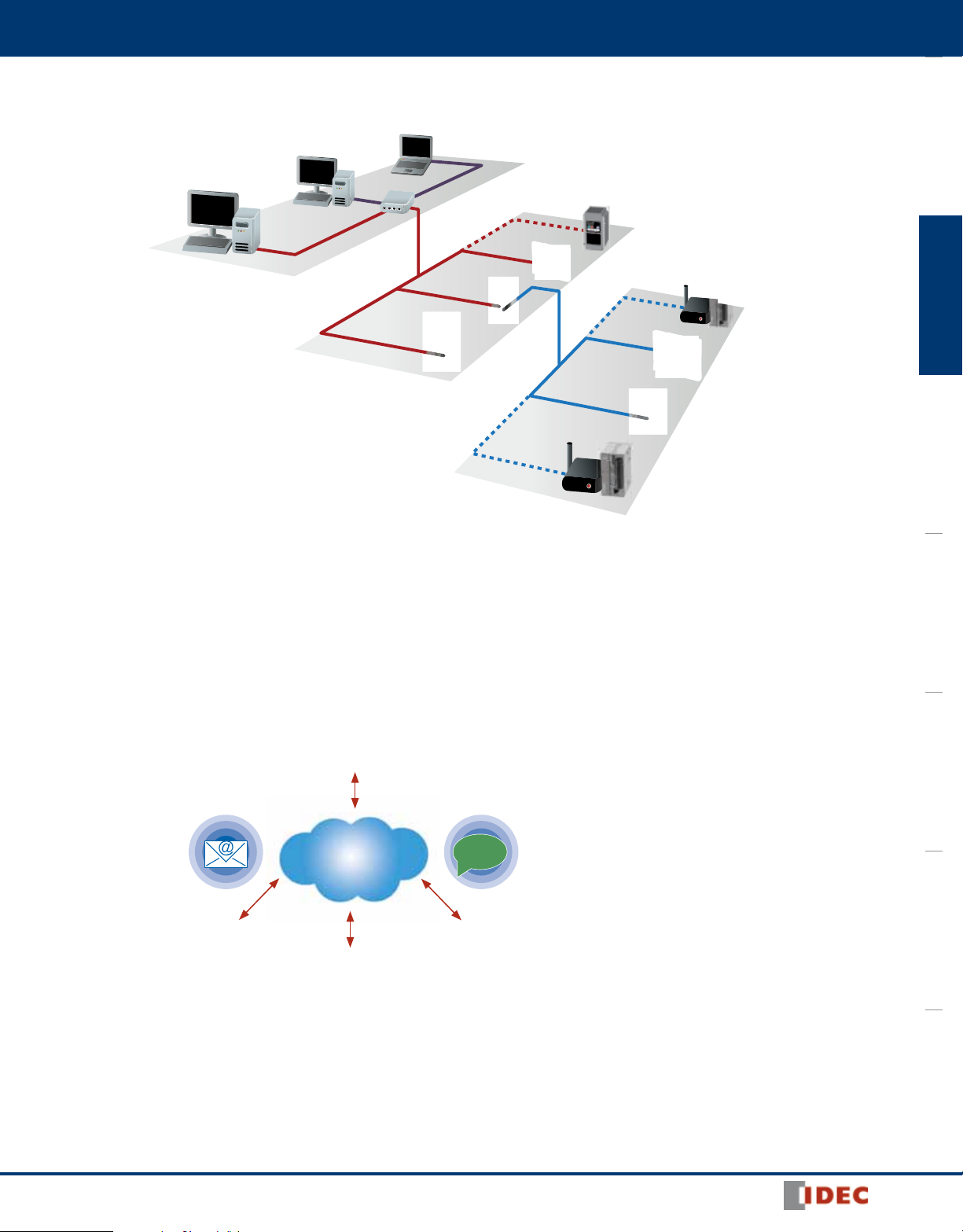

Modbus TCP, RTU and ASCII

SCADA

Supervisory Controls

WindLDR Software

Monitor & Update Program

Modbus TCP

Client

Web Browser - Remote

Monitor & Control

Modbus TCP

Server 1

TCP

Ethernet

Modbus TCP

Server 2

Pentra

Modbus TCP

Server 3

Modbus TCP

Server 255

Pentra

OI

Touchscreen

Modbus RTU/ASCII

RS485

VFD

Pentra with

Radio Modem

Pentra with

Radio Modem

Temperature

Controller

OI

Touchscreen

OI Touchscreens PLCs Automation Software Power Supplies Sensors Communication Barriers

Using intuitive WindLDR software, you can configure the MicroSmart Pentra to be a Master or Slave device on a Modbus network. All MicroSmart Pentra

PLCs support Modbus RTU/ASCII protocols and our CPU with embedded Ethernet port also supports Modbus TCP protocol.

Email and Text Message

Easily configure the MicroSmart

Pentra PLCs to send out system status

and alarms to your email or mobile

Internet

SMS

phone. Data registers values in the

PLC can also be incorporated in the

body of the email. It also supports

email login authentication so third

party email server like Yahoo can be

used. Up to 255 email templates can

be configured with multiple recipients

can be included.

800-262-IDEC (4332) • USA & Canada

61

Page 4

MicroSmart Pentra Series

User Web Pages

OI TouchscreensPLCsAutomation SoftwarePower SuppliesSensorsCommunicationBarriers

Programmable Logic Controllers

With IDEC MicroSmart Pentra, users do not need to know JAVA programming to embed dynamic values and parts on their PLC web pages. Even novice

HTML programmer can take full advantage of the integrated IDEC system library of numerical display/input, horizontal and vertical bar graphs, trend chart,

ON/OFF pilot lights and pushbuttons. Up to 1MB of memory is reserved for user web pages.

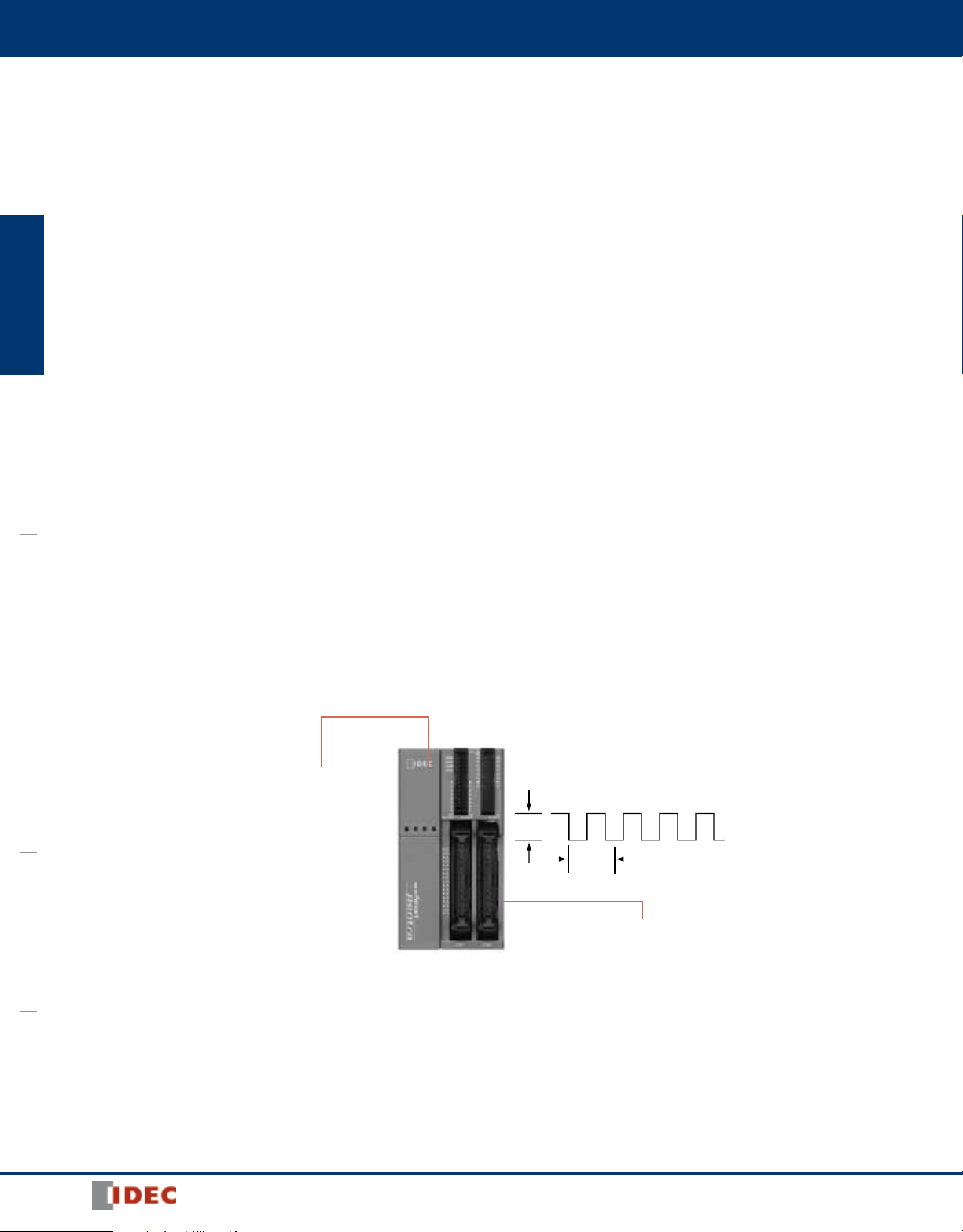

Integrated 100KHz Fast Inputs and Outputs

Configure up to four high-speed inputs from high-speed output devices such as rotary encoders or proximity switches at a maximum frequency of 100KHz, independent of the scan time. Up to three high-speed outputs can be used for simple positioning controls for stepper or servo motors.

HSC1: 930

V out

1 PULSE

62

www.IDEC.com

Page 5

Programmable Logic Controllers

MicroSmart Pentra Series

Maximum 7 Communication Ports

RS232C/RS485

Port 1

RS232C

Port 2

RS232C/RS485

Port 3

RS232C/RS485

Port 4

Port 5

RS232C/RS485

OI Touchscreens PLCs Automation Software Power Supplies Sensors Communication Barriers

Port 6

RS232C/

RS485

With MicroSmart Pentra PLCs, you don’t

have to worry about limited communication

capabilities. It doesn’t matter if you’re just

starting out or a current user expanding your

MicroSmart Pentra PLC, you can rest assured

that these communication modules will

provide reliable and seamless communication. If RS485 modules are used for all six

ports, up to 186 RS485 slave devices can be

connected with as high as a 115K baud rate

available for fast transmission.

Port 7

RS232C/RS485

VFD

Temperature Controller

800-262-IDEC (4332) • USA & Canada

63

Page 6

MicroSmart Pentra Series

Programmable Logic Controllers

Choose a CPU for every application

With three controller types to choose from, MicroSmart Pentra PLCs offer the features you need for your applications. Built to allow you the flexibility to expand when

you need to, MicroSmart Pentra PLCs are the best way to get everything you need in just one controller.

OI TouchscreensPLCsAutomation SoftwarePower SuppliesSensorsCommunicationBarriers

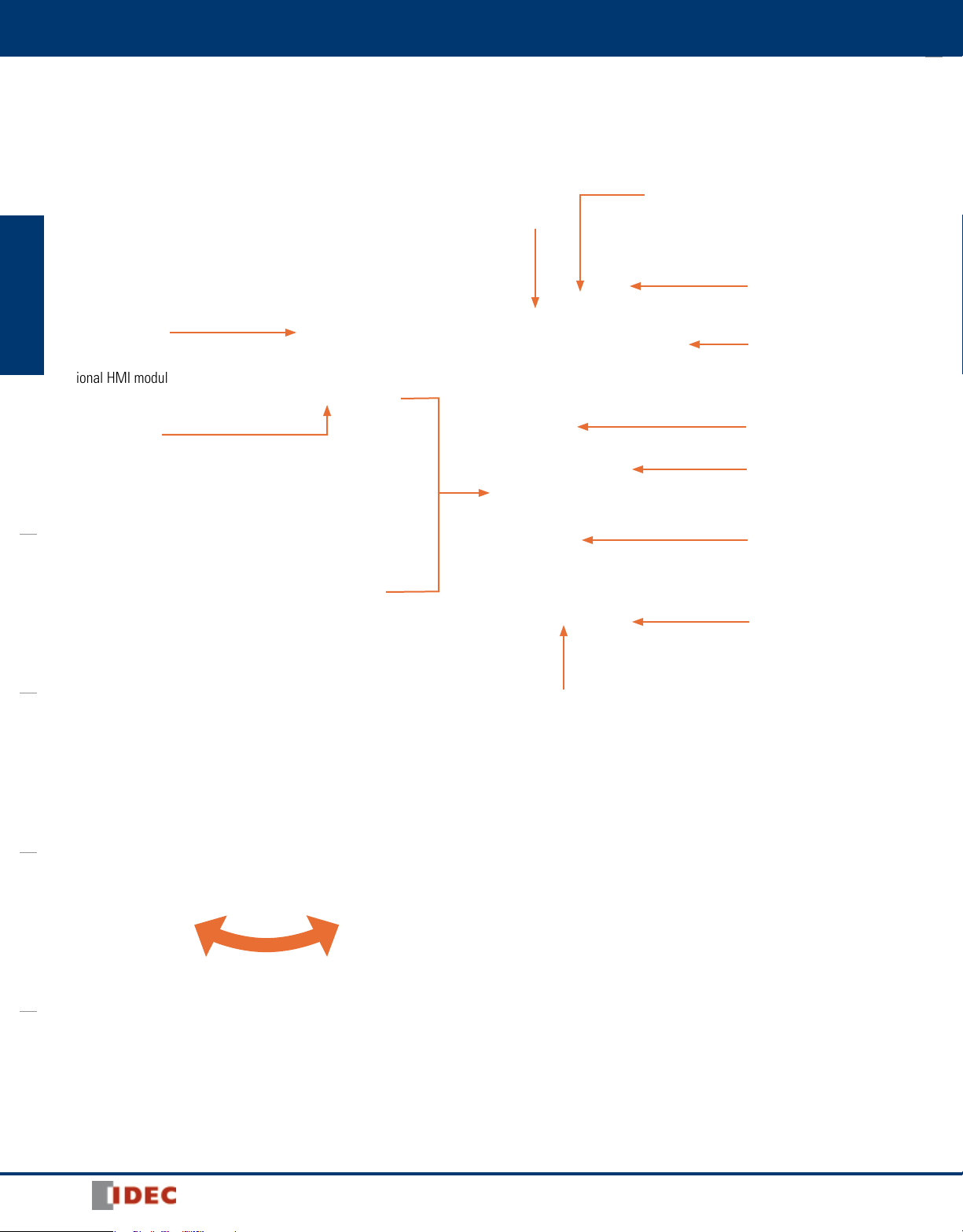

Potentiometer 0-10V DC Analog Input

(8-bit resolution)

Power, Status, I/O

LED Indicators

Removable Terminal

Optional HMI module

Block

Optional Clock

Cartridge

• Optional RS232C adaptor

(8-pin mini DIN connector)

• Optional RS485 adaptor

(8-pin mini DIN or screw

terminal connector)

Optional HMI base module

• Optional RS232C module

• Optional RS485 module

(mini-DIN or screw terminal type)

USB mini-B

Programming Port

Optional EEPROM

cartridge (up to 128KB)

RJ-45 Ethernet Port

Power Terminal

Slim CPU with Ethernet Port

The perfect design when you need Ethernet capability, this slim CPU with embedded

Ethernet port is available with 24V DC power and equipped with eight DC inputs and

four transistor outputs (sink or source). Up to seven functional modules, including

analog and communication modules can be mounted on the right-hand expansion

bus. Using an expansion interface module, an additional eight discrete expansion

modules can be mounted.

Modules snap together easily without the need for additional tools.

64

www.IDEC.com

Page 7

Programmable Logic Controllers

MicroSmart Pentra Series

OI Touchscreens PLCs Automation Software Power Supplies Sensors Communication Barriers

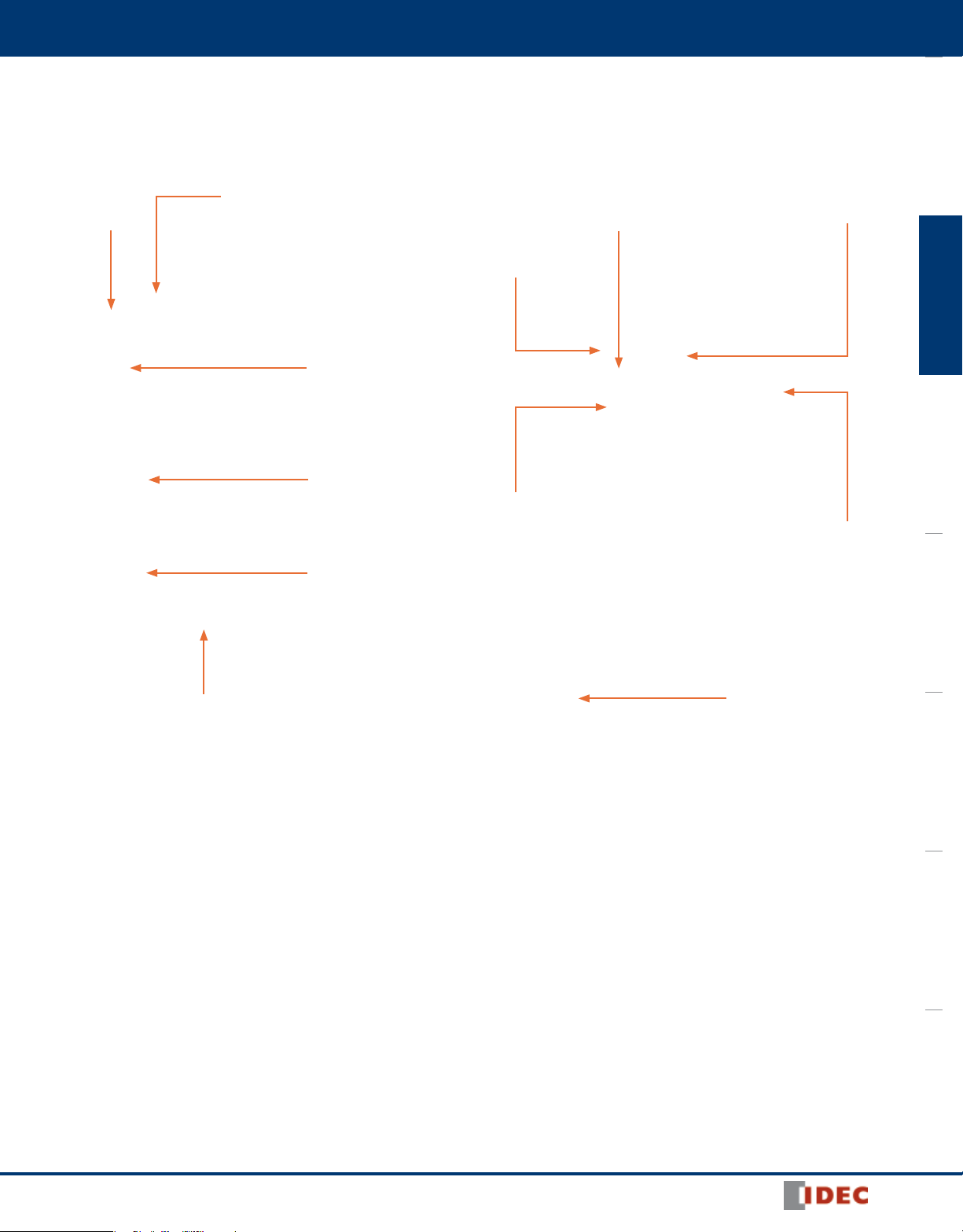

Potentiometer

0-10V DC Analog Input

(8-bit resolution)

RS232C port

Optional Clock

Cartridge

Optional EEPROM

cartridge

RS232C port

Potentiometer (x2)

•OptionalRS232Cadaptor

(8-pin mini DIN connector)

•OptionalRS485adaptor

(8-pin mini DIN or screw

terminal connector)

Optional HMI module

Power, Status, I/O

LED Indicators

Screw Terminal or MIL

connector termination

Slim CPU

If you don’t need Ethernet, but still want a high-performance CPU, the MicroSmart Pentra slim CPU is your best choice! Available with 24V DC power,

this controller has all the functionalities you need in 16 and 32 I/O configurations. Each 16 I/O CPU is equipped with eight DC inputs, two transistor outputs

(sink or source) and six relay outputs, while the 32 I/O CPU is equipped with 16

DC inputs and 16 transistor outputs (sink or source).

•OptionalEEPROMcartridge

•OptionalClockCartridge

All-in-One CPU

Available with 12V DC, 24V DC and 100-240V AC power, you can choose from

10, 16 and 24 I/O configurations. The 10 I/O CPU is equipped with six DC inputs

and four relay outputs, while the 16 I/O CPU is equipped with nine DC inputs and

seven relay outputs. The 24 I/O CPU is equipped with 14 DC inputs and ten relay

outputs. The 24 I/O CPU (24V DC and 100-240V AC models) can also be expanded

with a maximum of four functional or discreet expansion modules.

800-262-IDEC (4332) • USA & Canada

65

Page 8

MicroSmart Pentra Series

Programmable Logic Controllers

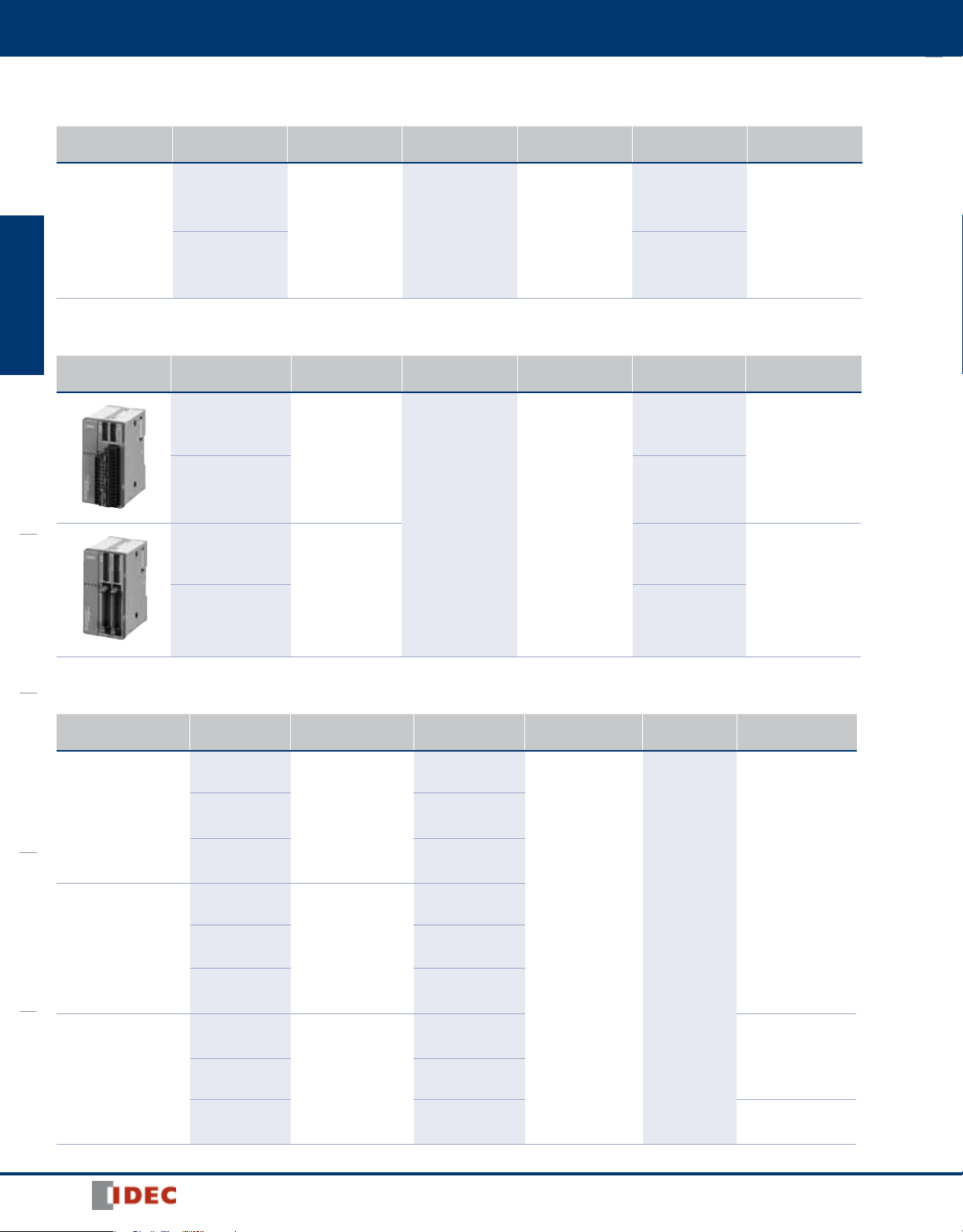

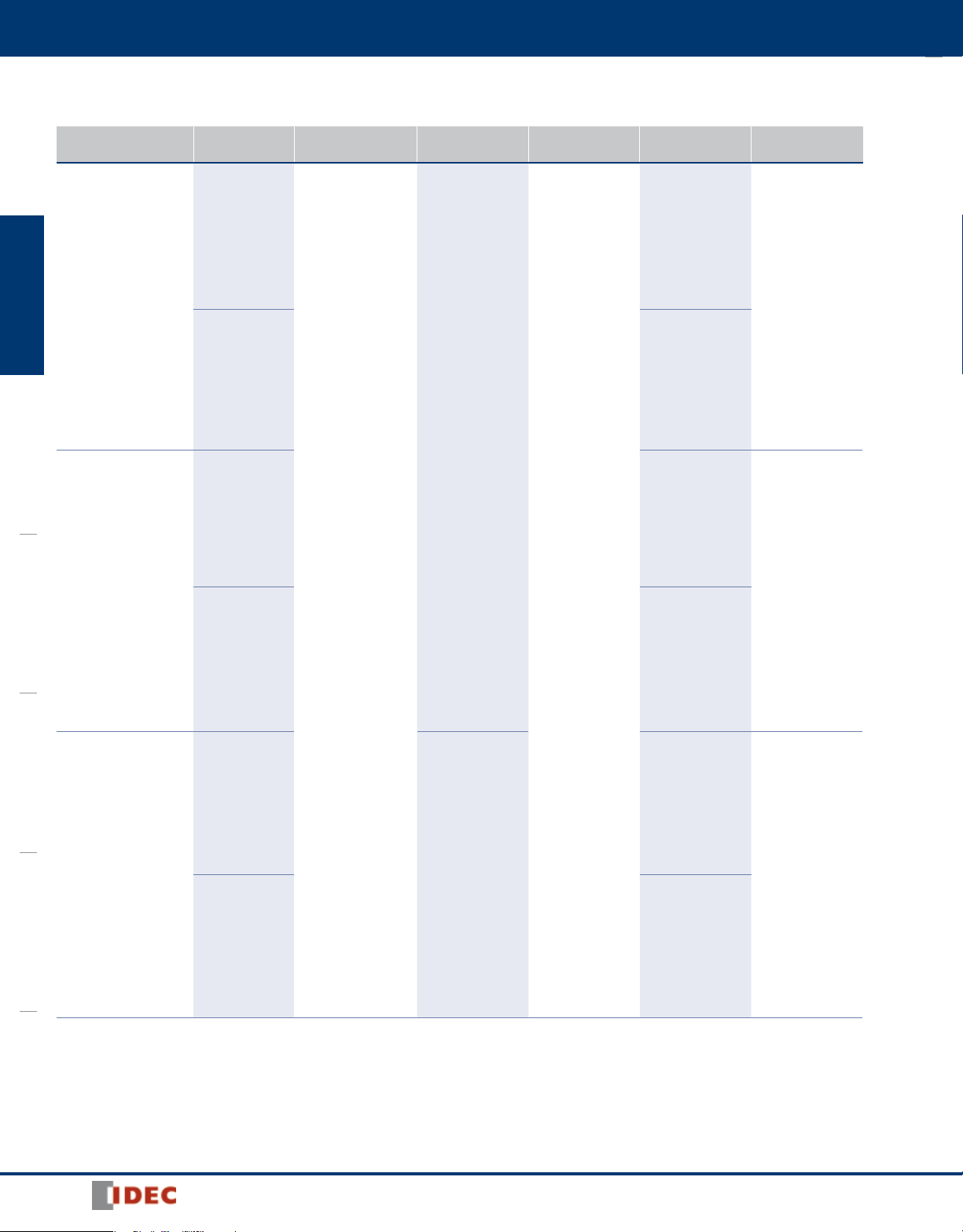

MicroSmart Pentra CPU Part Numbers

Slim Base Module with Embedded Ethernet

Style Part Number Embedded I/Os Operating Voltage

OI TouchscreensPLCsAutomation SoftwarePower SuppliesSensorsCommunicationBarriers

FC5A-D12K1E

12 (8in/4out) 24V DC Yes

FC5A-D12S1E Transistor Source

Slim Base Module

Style Part Number Operating Voltage Ethernet & USB Port Output

Ethernet & USB

Port

Output

Transistor Sink

Maximum No. of

Expansion Modules

15 (Maximum 492

digitalI/Os)

Maximum No. of

Expansion Modules

FC5A-D16RK1

16 (8in/8out)

FC5A-D16RS1

24V DC —

FC5A-D32K3

32 (16in/16out)

FC5A-D32S3 Transistor Source

6 Relays, 2 Trans.

Sink

6 Relays, 2 Trans.

Source

Transistor Sink

All-in-One Base Module

Style Part Number Operating Voltage Ethernet & USB Port Output

FC5A-C10R2

FC5A-C10R2C 24V DC

FC5A-C10R2D 12V DC

FC5A-C16R2

10 (6in/4out)

120-240V AC

120-240V AC

15 (Maximum 496

digital I/Os)

15 (Maximum 512

digital I/Os)

Maximum No. of

Expansion Modules

—

66

FC5A-C16R2C 24V DC

FC5A-C16R2D 12V DC

FC5A-C24R2

FC5A-C24R2C 24V DC

FC5A-C24R2D 12V DC —

16 (9in/7out)

120-240V AC

24 (14in/10out)

— Relay

4 (Maximum 88

digitalI/Os)

www.IDEC.com

Page 9

Programmable Logic Controllers

MicroSmart Series

MicroSmart Series

MicroSmart Performance

Key features:

• Available in 10, 16, 20, 24, and 40 I/O CPUs.

• PID Controls

-Program up to 14 PID loops

• High Speed I/O

-Built-in 4 high speed inputs

-Single or Dual Phase

-Max. 20KHz frequency

• Built-in 2 High speed outputs (Slim model only)

• Configure up to 264 I/O Points

• Data link up to 32 MicroSmart and Pentra CPUs

• Using RS485 communication module/port, you can create a network

of up to 32 CPUs.

• Worldwide Approvals

-cULus listed, CE marked

-Class 1 Div. 2 for hazardous locations

-Lloyds Registered and ABS approved for shipping industry

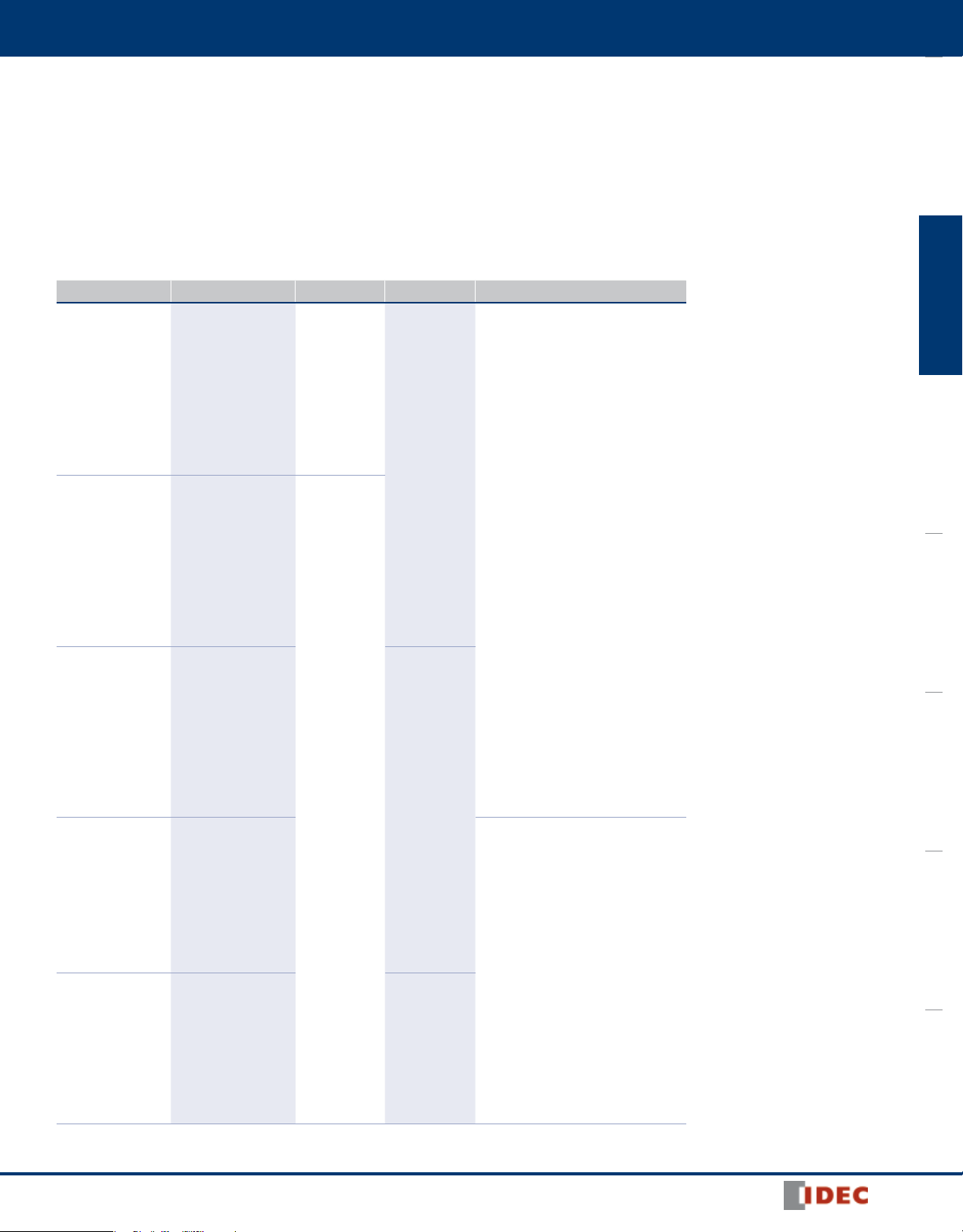

MicroSmart CPU Part Numbers

All-in-One

Style Part Number Power I/O Points Input Output

OI Touchscreens PLCs Automation Software Power Supplies Sensors Communication Barriers

Maximum No.

of Expansion

Modules

FC4A-C10R2C 24V DC

FC4A-C10R2 100-240V AC

FC4A-C16R2C 24V DC

FC4A-C16R2 100-240V AC

FC4A-C24R2C 24V DC

FC4A-C24R2 100-240V AC

10 (6 in/ 4 out)

16 (9 in/ 7 out)

24 (14 in/ 10 out)

—

24V DC (Sink/Source) Relay

4 (Maximum 88

digital I/Os)

800-262-IDEC (4332) • USA & Canada

67

Page 10

MicroSmart Series

Programmable Logic Controllers

MicroSmart CPU Part Numbers

Slim

Style Part Number Power I/O Points Input Output

OI TouchscreensPLCsAutomation SoftwarePower SuppliesSensorsCommunicationBarriers

Maximum No. of

Expansion Modules

FC4A-D20RK1

FC4A-D20RS1

20 (12 in/8 out)

FC4A-D20K3 Transistor Sink

24V DC

FC4A-D20S3 Transistor Source

24V DC (Sink/Source)

6 Relays, 2 Transistor

Sink

6 Relays, 2 Transistor

Source

7 (Maximum 244

digital I/Os)

7 (Maximum 148

digital I/Os)

FC4A-D40K3

FC4A-D40S3 Transistor Source

68

40 (24 in/16 out)

www.IDEC.com

Transistor Sink

7 (Maximum 264

digital I/Os)

Page 11

Programmable Logic Controllers

MicroSmart Family

MicroSmart Family

Digital I/O Expansion Modules

Key features:

• 15 modules to choose from

• Available with Screw or MIL connectors

• Easy snap-on

• Available 8, 16 or 32 point modules

• Up to 512 I/O can be configured in the Pentra and 264 I/O in the

MicroSmart system

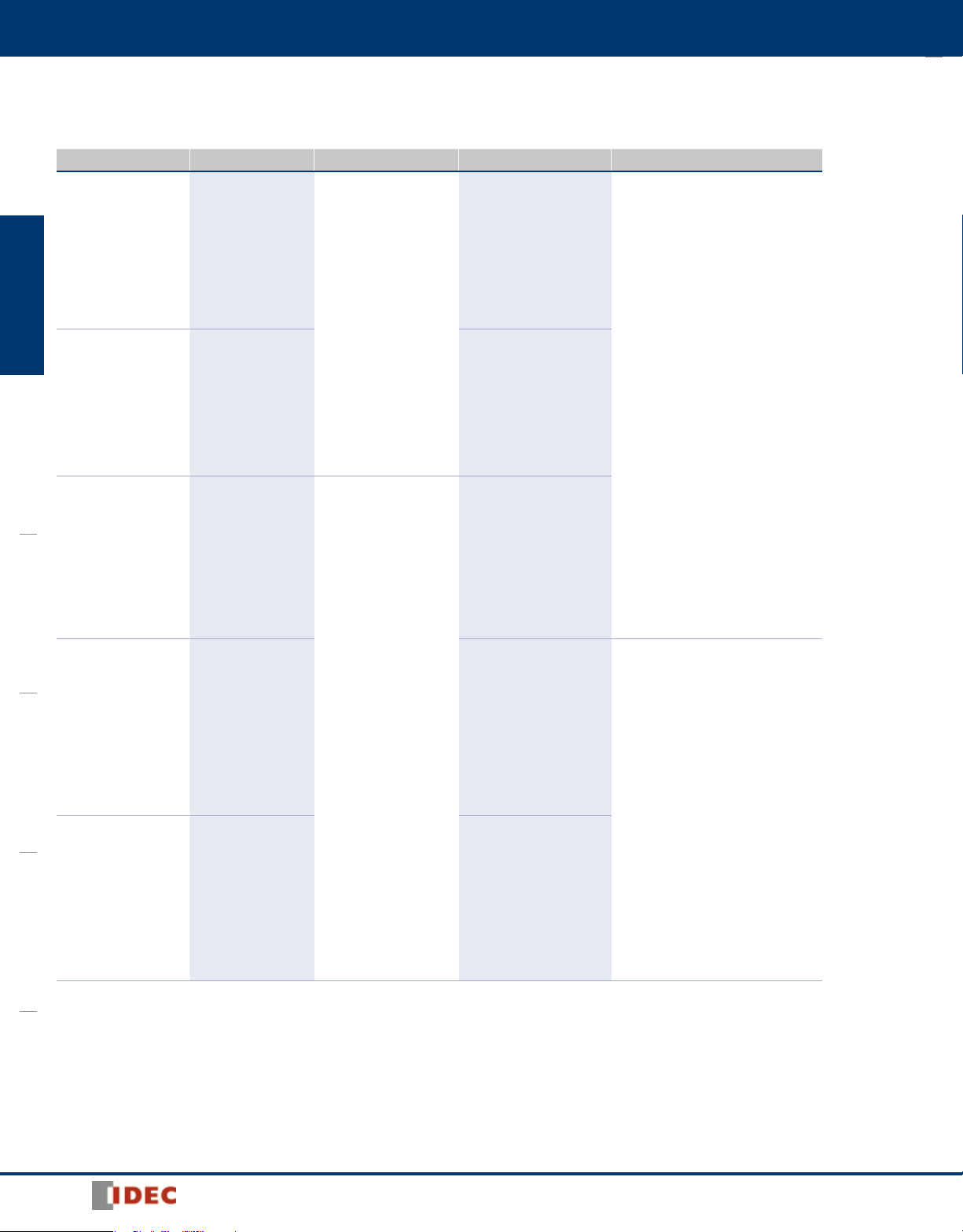

Input Modules

Style Part Number Input Input Points Terminal

FC4A-N08A11 100-120V AC

8

OI Touchscreens PLCs Automation Software Power Supplies Sensors Communication Barriers

FC4A-N08B1

FC4A-N16B1

FC4A-N16B3

24V DC

Removable Screw Terminals

16

MIL Connector (ribbon cable)

FC4A-N32B3 32

800-262-IDEC (4332) • USA & Canada

69

Page 12

MicroSmart Family

Programmable Logic Controllers

Digital I/O Expansion Modules

Output Modules

Style Part Number Output Output Points Terminal

OI TouchscreensPLCsAutomation SoftwarePower SuppliesSensorsCommunicationBarriers

FC4A-R081

Relay

FC4A-R161 16

FC4A-T08K1

8

Removable Screw Terminals

8

FC4A-T16K3 16

FC4A-T32K3 32

Transistor Sink

MIL Connector (ribbon cable)

70

www.IDEC.com

Page 13

Programmable Logic Controllers

MicroSmart Family

Digital I/O Expansion Modules

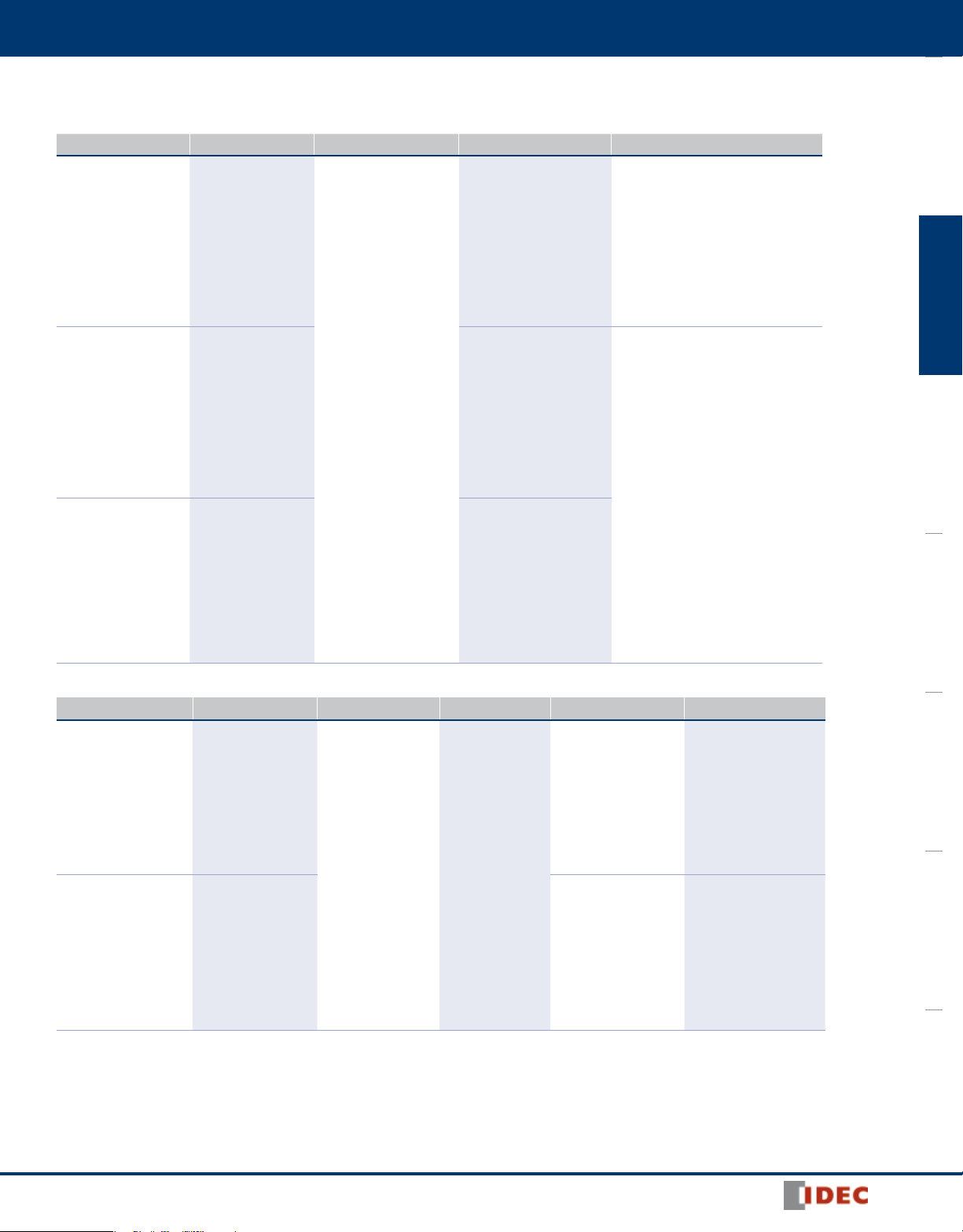

Output Modules (cont.)

Style Part Number Output Output Points Terminal

FC4A-T08S1

FC4A-T16S3 16

Transistor Source

8 Removable Screw Terminals

OI Touchscreens PLCs Automation Software Power Supplies Sensors Communication Barriers

MIL Connector (ribbon cable)

FC4A-T32S3 32

Combination I/O Modules

Style Part Number Input Output I/O Points Terminal

FC4A-M08BR1

24V DC (Sink/Source) Relay

FC4A-M24BR2 24 (16 in/ 8 out) Wire Spring Clamp

8 (4 in/4 out) Removable Screw Terminals

800-262-IDEC (4332) • USA & Canada

71

Page 14

MicroSmart Family

Programmable Logic Controllers

Analog I/O Expansion Modules

Key features:

• 9 different modules to choose from

• 0-10V, 4-20mA, RTD, Thermocouple, Thermistor inputs, 0-10V DC or

OI TouchscreensPLCsAutomation SoftwarePower SuppliesSensorsCommunicationBarriers

Modules

Style Part Number I/O Points Input Output Resolution Terminal

-10V DC to 10V DC output

• 12 or 16-bit resolution

• Fast conversion time

• Maximum of 56 I/O can be configured in the MicroSmart Pentra

system

• Easy to configure using a Macro instruction in WindLDR

FC4A-J8C1 8 (8 inputs)

FC4A-L03A1 3 (2 inputs, 1 output) 0-10V DC, 4-20mA

FC4A-J2A1 2 (2 inputs) –

FC4A-J4CN1 4 (4 inputs)

0-10V DC, 4-20mA

0-10V DC, 4-20mA, RTD,

Thermocouple

– 16-bit (0-50000)

– 16-bit (0-50000)

12-bit (0-4095)

Removable Screw

Terminals

72

FC4A-L03AP1 3 (2 inputs, 1 output) RTD, Thermocouple 0-10V DC, 4-20mA 12-bit (0-4095)

www.IDEC.com

Page 15

Programmable Logic Controllers

MicroSmart Family

Analog I/O Expansion Modules

Modules (cont.)

Style Part Number I/O Points Input Output Resolution Terminal

FC4A-J8AT1 8 (8 inputs) Thermistor (NTC/PTC) – 12-bit (0-4000)

FC4A-K2C1 2 (2 outputs) – -10 to 10V DC, 4-20mA 16-bit (0-50000)

FC4A-K1A1 1 (1 output)

Removable Screw

Terminals

OI Touchscreens PLCs Automation Software Power Supplies Sensors Communication Barriers

– 0-10V DC, 4-20mA 12-bit (0-4095)

FC41-K4A1 4 (4 outputs)

Communication Modules

Web Server Module

Features:

• Easy to configure

• Comes with interface cable and Quick Start Guide

Part Numbers

Style Part Number Description Style Part Number Description

FC4A-ENET

Web Server Module

(includes cable and Quick

Start Guide)

Quick Start Guide

Web Server Module for MicroSmart PLC

FC9Y-QS100-0 Quick Start Guide

800-262-IDEC (4332) • USA & Canada

73

Page 16

MicroSmart Family

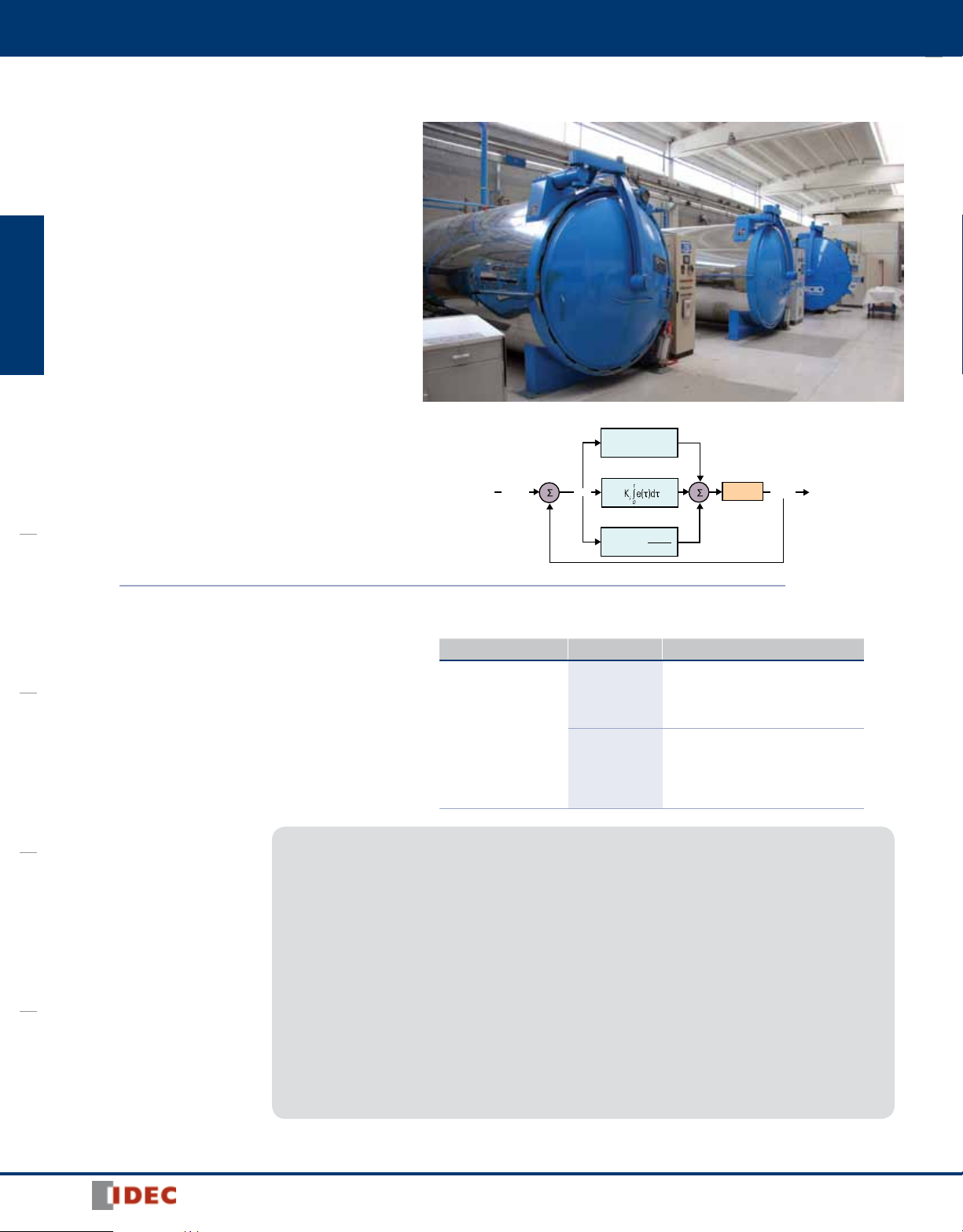

Advanced PID for precision control

PID (Proportional Integral Derivative) is the most commonly used

feedback control loop in industrial control systems. PID calculates

an error value as the difference between a measured process vari-

OI TouchscreensPLCsAutomation SoftwarePower SuppliesSensorsCommunicationBarriers

able and a desired set point. The controller then attempts to minimize the error by adjusting the process control. With MicroSmart

Pentra PLCs, PID implementation can be deployed in two ways:

integrated PID controls or a dedicated Process Control module,

which can be mounted on the MicroSmart Pentra expansion bus.

Programmable Logic Controllers

K e(t)

P

p

Advanced PID Control Module

A dedicated PID Control module is available for extreme stability and complex applications. This particular module has more

functionalities than you will find in any other controller on the

market. Independent of CPU scan time, the PID Control module

does the work, reducing PLC scan time without taking up PLC

memory space.

PID Control Module Highlights:

• Precise, stable and accurate PID

control with less than a 0.2% error

• Available in two models:

– Built-in 2 analog inputs, 2 x 4-20mA/

non-contact voltage for SSR drive

– Built-in 2 analog inputs, 2 x relay outputs

• Each input individually configured to accept different

signal types

• Up to seven modules can be mounted on the MicroSmart

Pentra

• Maximum 14 PID loops with auto-tuning

+

Setpoint

Error

I

–

de(t)

K

D

d

dt

Advanced PID Control Module Part Numbers

Style Part Number Description

PID Control Module with 2x analog

FC5A-F2M2

FC5A-F2MR2

• 14-bit resolution

• ARW (anti-reset windup)

• Accepts many different input types including:

– Type K, J, R, S, B, E, T, C, PL-II and N thermocouples

– RTD

– 0-20 mA and 4-20 mA

– 0-1V, 0-5V, 1-5V, and 0-10V DC

• Numerous control methods including:

– Cascade

– External set point

– Heating and cooling control action

– Difference input control

inputs and 2x 4-20mA/non-contact

voltage for SSR drive

PID Controls Module with 2x analog

inputs and 2x Relay Outputs

Process

Output

74

www.IDEC.com

Page 17

Programmable Logic Controllers

MicroSmart Family

Communication Modules

AS-Interface Module

AS-Interface Master Module

Style Part Number Description

OI Touchscreens PLCs Automation Software Power Supplies Sensors Communication Barriers

FC4A-AS62M MicroSmart AS-Interface Master Module

The Actuator Sensor-interface (AS-Interface) is the simplest and most costeffective of the PLC-based , industrial-networking protocols. AS-Interface is a

truly open, low-cost electromechanical connection system designed to operate

over a two-wire cable carrying data and power over a distance of up to 100m. It

is especially suitable for lower levels of plant automation where simple - often

binary (On/Off) - field devices such as switches, sensors, and actuators need to

interoperate in a local area automation network controlled by a PLC. IDEC supports this open technology.

Master-Slave Principle

The AS-Interface master controls and monitors the status of slave devices connected to the AS-Interface bus. Normally, the AS-Interface master is connected

to a PLC (sometimes called ‘host’) or a gateway.

Various types of slave devices can be connected to the AS-Interface bus, including sensors, actuators, and remote I/O devices. Analog slaves can also be connected to process analog data. Slaves are available in standard slaves and A/B

slaves. Standard slaves have an address of 1 through 31 in the standard address

Controller

IDEC offers a plug-in AS-Interface master module (as well as other AS-Interface

devices, please see AS-Interface Communication section) that is easy to configure; it can also connect up to 62 slaves. With this technology, you’ll reduce the

amount of engineering needed, simplify wiring and enhance your operations;

requiring less maintenance. With an average cost of savings of 15 to 40%

compared with traditional cabling methods, using an IDEC AS-Interface module

is the easy choice.

range. A/B slaves have an address of 1A through 31A in the standard address

range or 1B through 31B in the expanded address range. Among the A/B slaves,

slaves with an address of

1A through 31A are called A slaves, and slaves with an address of 1B through

31B are called B slaves. (see AS-Interface Communication section for more

details)

Master

Master call A-Slaves

Slave 1A

Slave 1A Slave 2A Slave 31A

Slave 2A

Slave answer A-Slaves

Slave 31A

800-262-IDEC (4332) • USA & Canada

Master call B-Slaves

Slave 1B

Slave 1B

Slave answer B-Slaves

Slave 2B

Slave 2B

75

Page 18

MicroSmart Family

Programmable Logic Controllers

Communication Module

Style Part Number Description

RS485 Communication

FC5A-SIF4

OI TouchscreensPLCsAutomation SoftwarePower SuppliesSensorsCommunicationBarriers

FC5A-SIF2

Module for MicroSmart

Pentra configure as port

3 to 7

RS232 Communication

Module for MicroSmart

Pentra configure as port

3 to 7

Communicate with up to seven different serial devices

Only IDEC offers communication modules that enable you to configure up to seven serial devices! Now you can connect your operator interface, PC, barcode reader,

RFID equipment, printer and more. Just imagine the possibilities.

Using the MicroSmart Pentra slim CPU,you can configure up to seven communication ports. Using the All-in-one MicroSmart Pentra you can communicate with up

to five serial devices.

76

www.IDEC.com

Page 19

Programmable Logic Controllers

MicroSmart Family

Optional Modules

Style Part Number Description Usage

FC4A-HPH1 HMI Base Module

FC4A-PH1 HMI Module For displaying and changing operands

FC4A-PM32

FC4A-PM64

EEPROM memory

cartridge

EEPROM memory

cartridge

For mounting HMI module and communication ports with slim model CPU module

OI Touchscreens PLCs Automation Software Power Supplies Sensors Communication Barriers

(HMI module is not included)

32KB EEPROM memory cartridge

64KB EEPROM memory cartridge

FC4A-PM128

FC4A-PT1 Clock cartridge Real-time clock cartridge

EEPROM memory

cartridge

Communication Ports

Style Part Number Description Terminal

FC4A-PC1 RS232C Mini DIN

FC4A-PC2 RS485 Mini DIN

128KB EEPROM memory cartridge

FC4A-PC3 RS485 Screw Terminal

800-262-IDEC (4332) • USA & Canada

77

Page 20

MicroSmart Family

Programmable Logic Controllers

Communication Module — for Slim CPU

Style Part Number Description Terminal

OI TouchscreensPLCsAutomation SoftwarePower SuppliesSensorsCommunicationBarriers

FC4A-HPC1 RS232C Mini DIN

FC4A-HPC2 RS485 Mini DIN

FC4A-HPC3 RS485 Screw Terminal

Expansion Power Supply Module

Style Part Number Description

FC5A-EXM1M

FC5A-EXM1S

FC5A-EXM2

Master Expansion

Power Supply For

MicroSmart Pentra

Slave Expansion

Power Supply For

MicroSmart Pentra

Expansion Power

Supply For

MicroSmart Pentra

Expansion Power Supply System Configuration

FC5A-EXM2 (Expansion Interface Module)

Slim CPU Module FC5A-EXM2

FC5A-EXM1M and FC5A-EXM1S (Expansion Interface Master & Salve Modules)

Slim CPU Module

FC5A-KX1C (Expansion Interface Cable)

1m

FC5A-EXM1S

FC5A-EXM1M

78

www.IDEC.com

Page 21

Programmable Logic Controllers

MicroSmart Family

Communication Cables

Appearance

Part

Number

FC4A-KC4CA 5ft. (1.53m)

FC4A-USB 6ft. (1.83m)

FC4A-KC3C

Length

0.33ft.

(100mm)

Expanded

Description

Programming cable

(Maintenance/User

Communication

Mode selectable)

USB to Serial

Converter

Web Server Module

interface cable

Cables

Appearance

Part

Number

FC2A-KM1C

FC2A-KP1C

FC5A-KX1C

Length

9.84 Ft. (3m)

9.84 Ft. (3m)

3.28 Ft. (1m)

OI Touchscreens PLCs Automation Software Power Supplies Sensors Communication Barriers

Expanded

Description

Modem cable. Used

to connect a modem

to the MicroSmart

RS232C port.

User communica-

tion cable. Used

to connect RS232C

equipment to the

MicroSmart RS232C

port.

MicroSmart Pentra

expansion power

supply interface

cable. Used to

connect expansion

interface master

and expansion slave

modules.

HG9Z-XCM2A 6ft. (1.83m)

USB programming

cable for embedded

Ethernet CPU

MIL Connector Cables (use with Breakout Modules)

Use with Part Number Model Length Use with Part Number Model Length

CPU Module

(26-wire)

BX1D-S26A,

BX1D-T26A

FC9Z-H050B26

FC9Z-H100B26 3.28ft. (1m) FC9Z-H100B20 3.28ft. (1m)

FC9Z-H200B26 6.56ft (2m) FC9Z-H200B20 6.56ft (2m)

FC9Z-H300B26 9.85ft. (3m) FC9Z-H300B20 9.85ft. (3m)

FC9Z-H050A26

FC9Z-H100A26 3.28ft. (1m) FC9Z-H100A20 3.28ft. (1m)

FC9Z-H200A26 6.56ft (2m) FC9Z-H200A20 6.56ft (2m)

FC9Z-H300A26 9.85ft. (3m) FC9Z-H300A20 9.85ft. (3m)

FC9Z-H100C26A

Non-shielded

Shielded

Shielded Single

Connectors

1.64ft. (0.5m)

1.64ft. (0.5m) FC9Z-H050A20

5ft. (1.5m) FC9Z-H100C20A

I/O Expansion

Modules (20-wire)

BX1D-S20A,

BX1D-T20A

FC9Z-H050B20

Non-shielded

Shielded

Shielded Single

Connectors

1.64ft. (0.5m)

1.64ft. (0.5m)

5ft. (1.5m)

Breakout Modules

Use with Part Number Descrption

26-wire MIL connector

cable

BX1D-S26A 26-terminal breakout module

20-wire MIL connector

cable

BX1D-T26A

BX1D-S20A 20-terminal breakout module

BX1D-T20A

26-terminal touch-down terminal breakout

module

20-terminal touch-down terminal breakout

module

800-262-IDEC (4332) • USA & Canada

79

Page 22

MicroSmart Family

Programmable Logic Controllers

Accessories

Part Number Use with Description

FC4A-PMT13

FC5A-PMT13 13-position left-side terminal block for FC5A-D16RK1/-D16RS1 CPU

OI TouchscreensPLCsAutomation SoftwarePower SuppliesSensorsCommunicationBarriers

FC4A-PMTS16 16-position right-side terminal block for FC4A-D20RS1 and FC5A-D16RS1 CPU

FC4A-PMTK16 16-position right-side terminal block for FC4A-D20RK1 and FC5A-D16RK1 CPU

FC4A-PMT11

FC4A-PMT10 10-position terminal block for 16-pt I/O expansion modules

FC4A-PMC20 20-position connector socket for MIL connector I/O expansion modules

FC4A-PMC26 26-position connector socket for MIL connector CPU modules

FC4A-PSP1 Direct mounting strips for mounting on a panel

FC4A-PMAC2 Analog voltage input cable for slim CPU

FC4A-DS824-SW14 14-pt input simulator switch for 24 I/O CPU

FC4A-DS824-SW9 9-pt input simulator switch for 16 I/O CPU

FC4A-DS824-SW6 6-pt input simulator switch for 10 I/O CPU

FC9Y-B812-0A MicroSmart user manual

FC9Y-B1138-0 MicroSmart Pentra user manual

SW1A-WIC Automation Organizer Software Suite

CPU module

I/O expansion modules

RV8H Series 6mm Interface Relays

Key FeaturesRV8H

• Space-saving 6mm width

• Only 70mm in height from DIN rail

• Gold-plated contacts

• Pre-assembled relay and DIN mount socket

• Universal screw terminals (flat and Phillips)

• Universal AC/DC socket with built-in surge suppression and green LED

• Lever for easy locking and removal of relay

• Wide input voltage range: 6 to 240V

• High dielectric strength and impulse withstand voltages

• Sensitive coil 170mW

• Reverse Polarity protected

• 400V AC maximum switching voltage

• 1500VA maximum switching power

• RoHS compliant

13-position left-side terminal block for FC4A-D20RK1/-D20RS1 CPU

11-position terminal block for 8-pt I/O expansion modules

(when using combination of

RV1H relay and SV1H socket)

Part Numbers

Coil Voltage Part Number

6V RV8H-L-D6

9V RV8H-L-D9

DC

AC/DC

Standard stock models in bold.

12V RV8H-L-D12

18V RV8H-L-D18

24V RV8H-L-D24

12V RV8H-L-AD12

18V RV8H-L-AD18

24V RV8H-L-AD24

48V RV8H-L-AD48

60V RV8H-L-AD60

110V - 125V RV8H-L-AD110

220V - 240V RV8H-L-AD220

80

Accessories

Item Color Part Number

Black SV9Z-J20B

Jumper (20 combs) 1

Spacer (circuit separator)

Marking plate (10 pcs)

1. Jumper combs come with 20 points, if shorter lengths are needed simply cut off the excess points.

2. Width of spacer: 2mm

Note: When using a cut jumper, please use a spacer on the cut side. For additional information see instruction sheet.

2

Gray SV9Z-J20W

Blue SV9Z-J20S

- SV9Z-SAW

- SV9Z-PW10

www.IDEC.com

Page 23

Programmable Logic Controllers

MicroSmart Family

Starter Kits and Solution Packages

MicroSmart Starter Kits

Item Part Numbers Controller Power Supply Software (Prog. Cables Included)

MM-SMART-10 10 I/O FC4A-C10R2 CPU –

MM-SMART-16 16 I/O FC4A-C16R2 CPU –

MM-SMART-20 20 I/O FC4A-D20RK1 CPU 15W

MicroSmart

Pentra

MicroSmart

MicroSmart Solution Packages

MM-SMART-24 24 I/O FC4A-C24R2 CPU –

MM-SMART-40 40 I/O FC4A-D40K3 Slim CPU 15W

MM-PENTRA-16 16 I/Os FC5A-D16RS1 CPU 30W

MM-PENTRA-24 24 I/Os FC5A-C24R2 CPU –

MM-PENTRA-12 12 I/Os FC5A-D12S1E Embedded Ethernet 30W

KIT-PENTRA-12-HG3G-AHP shown

Automation Organizer Software Suite

OI Touchscreens PLCs Automation Software Power Supplies Sensors Communication Barriers

Part Numbers Operator Interface Controller Power Supply Software (Prog. Cables Included)

KIT-PENTRA-24-HG1F 4.6" HG1F Mono 24 I/O FC5A-C24R2C CPU 60W

KIT-PENTRA-12-HG1F 4.6" HG1F Mono 12 I/O FC5A-D12S1E Embedded Ethernet CPU 60W

KIT-PENTRA-24-HG2G-M 5.7" HG2G Color TFT LCD 24 I/O FC5A-C24R2C CPU 60W

KIT-PENTRA-12-HG2G-M 5.7" HG2G Color TFT LCD 12 I/O FC5A-D12S1E Embedded Ethernet CPU 60W

KIT-PENTRA-24-HG2G-TE 5.7" HG2G Color TFT LCD 24 I/O FC5A-C24R2C CPU 60W

KIT-PENTRA-12-HG2G-TE 5.7" HG2G Color TFT LCD 12 I/O FC5A-D12S1E Embedded Ethernet CPU 60W

KIT-PENTRA-24-HG2G-HP 5.7" HG2G Color TFT LCD 24 I/O FC5A-C24R2C CPU 60W

KIT-PENTRA-16-HG2G-HP 5.7" HG2G Color TFT LCD 16 I/O FC5A-D16RS1 CPU 60W

KIT-PENTRA-12-HG2G-HP 5.7" HG2G Color TFT LCD 12 I/O FC5A-D12S1E Embedded Ethernet CPU 60W

KIT-PENTRA-16-HG3G-8HP 8.4" HG3G Color TFT LCD 16 I/O FC5A-D16RS1 CPU 60W

KIT-PENTRA-12-HG3G-8HP 8.4" HG3G Color TFT LCD 12 I/O FC5A-D12S1E Embedded Ethernet CPU 60W

KIT-PENTRA-16-HG3G-AHP 10.4" HG3G Color TFT LCD 16 I/O FC5A-D16RS1 CPU 60W

KIT-PENTRA-12-HG3G-AHP 10.4" HG3G Color TFT LCD 12 I/O FC5A-D12S1E Embedded Ethernet CPU 60W

KIT-PENTRA-16-HG4G-HP 12.1" HG4G Color TFT LCD 16 I/O FC5A-D16RS1 CPU 60W

KIT-PENTRA-12-HG4G-HP 12.1" HG4G Color TFT LCD 12 I/O FC5A-D12S1E Embedded Ethernet CPU 60W

OI Touchscreens have black bezels. All packages come with Automation Organizer software suite and communication cables.

Automation Organizer Software Suite

800-262-IDEC (4332) • USA & Canada

81

Page 24

MicroSmart Family

OI TouchscreensPLCsAutomation SoftwarePower SuppliesSensorsCommunicationBarriers

Programmable Logic Controllers

Automation Organizer Suite

Programming Software

Automation Organizer (AO) is a powerful software suite containing PLC programming software (WindLDR), OI touchscreen configuration software (WindO/I-NV2) and

system configuration software (WindCFG). AO boasts a completely new graphic user interface and redesigned menu icons. AO is a one-stop automation software

package for IDEC MicroSmart Pentra PLCs and IDEC OI touchscreens, and is compatible with Windows XP, Vista (32 bit) and Windows 7 (32 and 64-bit).

All IDEC MicroSmart Pentra PLCs are programmable with WindLDR ladder

logic software. This icon-driven programming tool combines logic and intuition

with an incredibly easy-to-use interface to allow you to take advantage of

MicroSmart features. Even without ladder program experience, you can use the

built-in editors, shortcuts and debuggers to configure programs. WindLDR is an

excellent, long-term investment for your control solutions.

Simulation Mode

WindLDR allows you to simulate ladder programs with built-in Simulation mode.

You can easily test and verify functionality of your ladder program without actual

hardware.

Online Editing

Shutting down your PLC for minor changes can be a major hassle, so WindLDR

allows you to edit and download programs without interrupting PLC operation.

You can write new values to counters, timers and registers at any time without

switching between editor mode (for programming) and monitor mode.

Firmware Download

With WindLDR version 6.4 or later, you have the option to upgrade or downgrade

your CPU system program. It’s as simple as clicking on the checkbox in the

Download dialog box. Now you can easily update your PLC system firmware

with the click of a button.

WindO/I-NV2 software is the programming tool available for all IDEC OI touchscreens. It is used to create projects or programs that can display information

from a PLC, process status, or can be used to input data with virtual switches or

keypads to make changes to a process. The objects are extremely easy to configure with the help of step- by-step navigation. It lets you quickly create colorful

graphical screens in no time using drop-down menus and intuitive drag and drop

functionality for the objects. A workspace is available to help you organize and

manage projects, objects and screens.

WindCFG is a system layout and configuration tool for IDEC PLCs and OI touchscreens. Using WindCFG, you can create a visual layout of the system design

and basic configuration of your PLC and OI touchscreens.

FREE Upgrades

The Automation Organizer suite comes with free lifetime upgrades. Once you

make the initial purchase, upgrades are absolutely free.

Part Number

Part Number Description

SW1A-W1C Automation Organizer software suite

For more information,

see page 121.

82

www.IDEC.com

Page 25

Programmable Logic Controllers

MicroSmart Family

Specifications

Slim Type

Model

FC5A-D12K1E

FC5A-D12S1E

Rated Power Voltage 24V DC

Allowable Voltage Range 20.4 to 26.4V DC (including ripple)

Maximum Input Current 700 mA (26.4V DC)

Maximum Power Consumption 19W (26.4V DC)

Allowable Momentary

Power Interruption

Dielectric Strength

Insulation Resistance

Noise Resistance

Inrush Current 50A maximum (24V DC)

Power Supply Wire UL1015, AWG22, UL1007 AWG18

Operating Temperature 0 to 55°C

Storage Temperature –25 to +70°C (no freezing)

Relative Humidity Level RH1 (IEC61131-2), 10 to 95% (no condensation)

Altitude Operation: 0 to 2,000m, Transport: 0 to 3,000m

Pollution Degree 2 (IEC60664-1)

Corrosion Immunity Free from corrosive gases

Degree of Protection IP20 (IEC60529)

Grounding Wire UL1015, AWG22, UL1007, AWG18

Vibration Resistance

Shock Resistance 147 m/s2 (15G), 11 ms duration, 3 shocks per axis on three mutually perpendicular axes (IEC61131-2)

Weight 200g 230g 190g 140g 185g 180g

1. CPU module + 7 I/O modules

FC5A-D16RK1

FC5A-D16RS1

2 hours per axis on each of three mutually perpendicular axes (IEC61131-2)

FC5A-D32K3

FC5A-D32S3

1

1

FC4A-D20K3

FC4A-D20S3

560 mA (26.4V DC)

14W (26.4V DC)

FC4A-D20RK1

FC4A-D20RS1

1

1

10 ms (at 24V DC)

Between power and

Between I/O and

terminals: 500V AC, 1 minute

terminals: 500V AC, 1 minute

Between power and terminals: 10 MΩ minimum (500V DC megger)

Between I/O and terminals: 10 MΩ minimum (500V DC megger)

DC power terminals: 1.0 kV, 50 ns to 1 µs

I/O terminals (coupling clamp): 1.5 kV, 50 ns to 1 µs

5 to 8.4 Hz amplitude 3.5 mm, 8.4 to 150 Hz acceleration 9.8 m/s

When mounted on a DIN rail or panel surface:

2

(1G),

700 mA (26.4V DC)

17W (26.4V DC)

OI Touchscreens PLCs Automation Software Power Supplies Sensors Communication Barriers

FC4A-D40K3

FC4A-D40S3

1

1

800-262-IDEC (4332) • USA & Canada

83

Page 26

MicroSmart Family

Programmable Logic Controllers

All-in-One Type

Model

FC5A-C10R2C

FC5A-C10R2D

Rated Power Voltage AC power type: 100 to 240V AC, DC power type: 24V DC, 12V DC

FC5A-C10R2

OI TouchscreensPLCsAutomation SoftwarePower SuppliesSensorsCommunicationBarriers

Allowable Voltage Range AC power type: 85 to 264V AC, 24V DC power type: 20.4 to 28.8V DC (including ripple), 12V DC type: 10.2 to 18.0V DC

Rated Power Frequency AC power type: 50/60 Hz (47 to 63 Hz)

Maximum Input Current

250 mA (85V AC)

160 mA (24V DC)

FC5A-C10R2/FC4A-C10R2: 30VA (264V AC), 20VA (100V AC)3

Maximum

Power

Consumption

AC Power

DC Power

FC5A-C16R2/FC4A-C16R2: 31VA (264 V AC), 22VA (100V AC )3

FC5A-C24R2/FC4A-C24R2: 40VA (264V AC), 33VA (100V AC)

FC5A-C10R2C/FC4A-C10R2C: 3.9W (24V DC) *5 FC5A-C10R2D: 2.8W (12V DC)

FC5A-C16R2C/FC4A-C16R2C: 4.6W (24V DC) *5 FC5A-C16R2D: 3.4W (12V DC)4

FC5A-C24R2C/FC4A-C24R2C: 8.7W (24V DC) *3 FC5A-C24R2D: 4.2W (12V DC)4

Allowable Momentary

Power Interruption

Dielectric Strength

Insulation Resistance

Noise Resistance

FC5A-C10R2/FC5A-C10R2C/FC5A-C16R2/

Inrush Current

FC5A-C16R2C: 35A

FC5A-C10R2D/FC5A-C16R2D: 20A

Power Supply Wire UL1015 AWG22, UL1007 AWG18

Operating Temperature 0 to 55°C

Storage Temperature –25 to +70°C (no freezing)

Relative Humidity Level RH1 (IEC61131-2), 10 to 95% (no condensation)

Altitude Operation: 0 to 2,000m, Transport: 0 to 3,000m

Pollution Degree 2 (IEC60664-1)

Corrosion Immunity Free from corrosive gases

Degree of Protection IP20 (IEC60529)

Ground Ground resistance 100Ω (max.)

Grounding Wire UL1007, AWG16

Vibration Resistance

Shock Resistance 147 m/s2 (15G), 11 ms duration, 3 shocks per axis on three mutually perpendicular axes (IEC61131-2)

Weight

1. CPU module (including 250 mA sensor power) + 4 I/O modules

2. CPU module + 4 I/O modules

3. CPU module (including 250 mA sensor power)

4. CPU module

AC type: 230g

DC type: 240g

FC5A-C16R2

FC5A-C16R2C

FC5A-C16R2D

300 mA (85V AC)

190 mA (24V DC)

FC5A-C24R2

FC5A-C24R2C

FC5A-C24R2D

450 mA (85V AC)1

360 mA (24V DC)

1

FC4A-C10R2

FC4A-C10R2C

250 mA (85V AC)

2

160 mA (24V DC)

4

10 ms (rated power voltage)

Between power and

or terminals: 1,500V AC, 1 minute

Between I/O and or terminals: 1,500V AC, 1 minute

Between power and

or terminals: 10 MΩ minimum (500V DC megger)

Between I/O and or terminals: 10 MΩ minimum (500V DC megger)

AC power terminals: 1.5 kV, 50 ns to 1 µs

DC power terminals: 1.0 kV, 50 ns to 1 µs

I/O terminals (coupling clamp): 1.5 kV, 50 ns to 1 µs

FC5A-C24R2/

FC5A-C24R2C: 40A

FC5A-C24R2D: 20A

When mounted on a DIN rail or panel surface:

5 to 8.4 Hz amplitude 3.5 mm, 8.4 to 150 Hz acceleration 9.8 m/s

2 hours per axis on each of three mutually perpendicular axes (IEC61131-2)

AC type: 250g

DC type: 260g

AC type: 305g

DC type: 310g

AC type: 230g

DC type: 240g

FC4A-C16R2

FC4A-C16R2C

300 mA (85V AC)

190 mA (24V DC)

35A 40A

2

(1G),

AC type: 250g

DC type: 260g

FC4A-C24R2

FC4A-C24R2C

450 mA (85V AC)1

360 mA (24V DC)

AC type: 305g

DC type: 310g

2

84

www.IDEC.com

Page 27

Programmable Logic Controllers

MicroSmart Family

Slim Type Function Specifications

Model

Control System Stored program system

Instruction Words

Program Capacity

User Program Storage

Processing

Time

Expandable I/O Modules

I/O

Points

Internal Relay 2,048 points 1,024 points

Shift Register 256 points 128 points

Data Register 42,000 points 42,000 points

Expansion Data Register 6,000 points — 6,000 points

Counter 256 points 100 points

Timer (1-sec, 100-ms, 10-ms, 1-ms) 256 points 100 points

RAM Backup

Self-diagnostic Function

Input Filter Without filter, 3 to 15 ms (selectable in increments of 1 ms)

Catch Input/Interrupt Input

Counter

High-speed

Analog

Potentiometer

Analog

Voltage

Input

Pulse

Output

Note: The maximum number of relay outputs that can be turned on simultaneously is 54 including those on the CPU module. Modem communication not possible on FC5A-D12K1E/D12S1E modules.

1. 1 step equals 6 bytes.

2. Expandable up to 62.4 KB when a memory cartridge is used.

3. Not including expansion I/O service time, clock function processing time, data link processing time, and interrupt processing time.

4. Extra data registers D10000 through D49999 are enabled using WindLDR Function Area Settings, then run-time program download cannot be used.

5. Maintenance communication (change monitor device values, upload/download user programs, download system program)

6. Maintenance communication, user communication, modem communication, data link, Modbus ASCII/RTU master/slave communication (FC5A only).

1

Basic Instruction 83 µs (1,000 steps) 1.65 ms (1,000 steps)

END Processing

Input 8

Output 4 8 16 8 8 16

Backup Data Internal relay, shift register, counter, data register, expansion data register

Backup Duration Approx. 30 days (typical) at 25°C after backup battery fully charged

Battery Lithium secondary battery

Charging Time Approx. 15 hours for charging from 0% to 90% of full charge

Battery Life 5 years in cycles of 9-hour charging and 15-hour discharging

Replaceability Not possible to replace battery

Maximum Counting

Frequency and High-speed

Counter Points

Counting Range 0 to 4,294,967,295 (32 bits) 0 to 65,535 (16 bits)

Operation Mode Rotary encoder mode and adding counter mode

Quantity 1 point

Data Range 0 to 255

Quantity 1 point

Input Voltage Range 0 to 10V DC

Input Impedance Approx. 100 kΩ

Data Range 0 to 255 (8 bits)

Quantity 3 points 2 points 3 points 2 points

Maximum Frequency 100 kHz 20 kHz

FC5A-D12K1E

FC5A-D12S1E

152 advanced 126 advanced 130 advanced 53 advanced 72 advanced

127.8 KB

(21,300 steps)

Flash ROM (10,000

times rewritable)

3

7 modules + additional 8 modules using the expansion interface

Expansion: 224

Additional: 256

Power failure, watchdog timer, data link connection, user program ROM sum check, timer/counter preset value sum check, user program RAM

sum check, keep data, user program syntax, user program writing, CPU module, clock IC, I/O bus initialize, user program execution

Four inputs

(I2 and I5) Minimum turn on pulse width: 40 µs maximum

Minimum turn off pulse width: 150 µs maximum

(I3 and I4) Minimum turn on pulse width: 5 µs maximum

Minimum turn off pulse width: 5 µs maximum

Total 4 points Single/two-phase selectable: 100 kHz (2 points)

Single-phase: 100 kHz (2 points)

FC5A-D16RK1

FC5A-D16RS1

42 basic 35 basic

62.4 KB (10,400 steps)

0.35 ms 0.64 ms

module

8

Expansion: 224

Additional: 256

FC5A-D32K3

FC5A-D32S3

16

Expansion: 224

Additional: 256

4

1,300 points

FC4A-D20K3

FC4A-D20S3

27 KB

(4,500 steps)

EEPROM (10,000 times rewritable)

12

Expansion: 128

Four inputs

(I2 through I5)

Minimum turn on pulse width: 40 µs maximum

Minimum turn off pulse width: 150 µs maximum

Total 4 points Single/two-phase selectable: 20 kHz (2 points)

Single-phase: 5 kHz (2 points)

FC4A-D20RK1

FC4A-D20RS1

31.2 KB (5,200 steps) 2

7 modules

12

Expansion: 224

FC4A-D40K3

FC4A-D40S3

24

OI Touchscreens PLCs Automation Software Power Supplies Sensors Communication Barriers

Expansion: 224

800-262-IDEC (4332) • USA & Canada

85

Page 28

MicroSmart Family

Programmable Logic Controllers

Slim Type Function Specifications (con’t)

Model

OI TouchscreensPLCsAutomation SoftwarePower SuppliesSensorsCommunicationBarriers

Ethernet

Port

Port 1

Port 2 Communication Adapter/

Module (option)

Clock Cartridge (option) Possible

Memory Cartridge (option) Possible

HMI Module (option) Possible

Ethernet Specifications

Ethernet Interface RJ45

User Web Page Area 1 MB

Compliant Browser Internet Explorer 7 and 8, Firefox 3

Protocol

Function (see table

next page)

6

Note: The maximum number of relay outputs that can be turned on simultaneously is 54 including those on the CPU module. Modem communication not possible on FC5A-D12K1E/D12S1E modules.

1. 1 step equals 6 bytes.

2. Expandable up to 62.4 KB when a memory cartridge is used.

3. Not including expansion I/O service time, clock function processing time, data link processing time, and interrupt processing time.

4. Extra data registers D10000 through D49999 are enabled using WindLDR Function Area Settings, then run-time program download cannot be used.

5. Maintenance communication (change monitor device values, upload/download user programs, download system program)

6. Maintenance communication, user communication, modem communication, data link, Modbus ASCII/RTU master/slave communication (FC5A only).

FC5A-D12K1E

FC5A-D12S1E

Electrical Characteristics:

Complies with IEEE802.3

Transmission Speed:

10BASE-T/100BASE-TX

Data Link Layer: IP, ARP

Network Layer: UDP, TCP, ICMP

Application Layer: SMTP, DHCP, HTTP, NBNS,

DNS, SNTP

Web server, Send email, PING, Maintenance

commnunication server, Modbus TCP server/

client, User communication server/client,

SNTP

USB mini-B (CDC class)

Maintenance Communication

5

FC5A-D16RK1

FC5A-D16RS1

FC5A-D32K3

FC5A-D32S3

RS232C – maintenance communication, user communications,

Modbus slave ASCII/RTU communication (FC5A only)

Possible

FC4A-D20K3

FC4A-D20S3

—

FC4A-D20RK1

FC4A-D20RS1

FC4A-D40K3

FC4A-D40S3

86

www.IDEC.com

Page 29

Programmable Logic Controllers

MicroSmart Family

All-in-One Type Function Specifications

Model

FC5A-C10R2C

FC5A-C10R2D

Control System Stored program system

FC5A-C10R2

Instruction Words

Program Capacity

1

103 advanced 103 advanced 115 advanced 38 advanced 40 advanced 48 advanced

13.8 KB (2,300 steps) 27 KB (4,500 steps) 54 KB (9,000 steps) 4.8 KB (800 steps) 15 KB (2,500 steps) 27 KB (4,500 steps)

User Program Storage EEPROM (10,000 times rewritable)

Processing

Time

Basic Instruction 1.16 ms (1,000 steps) 1.65 ms (1,000 steps)

END Processing

2

Expandable I/O Module — 4 modules — 4 modules

I/O Points

Input 6 9 14

Output 4 7 10 4 7 10

Internal Relay 2,048 points 256 points 1,024 points

Shift Register 128 points 64 points 128 points

Data Register 2,000 points 400 points 1,300 points

Expansion Data Register — —

Counter 256 points 32 points 100 points

Timer (1-sec, 100-ms, 10-ms, 1-ms) 256 points 32 points 100 points

Backup Data Internal relay, shift register, counter, data register

Backup Duration Approx. 30 days (typical) at 25°C after backup battery fully charged

Battery Lithium secondary battery

Charging Time Approx. 15 hours for charging from 0% to 90% of full charge

RAM Backup

Battery Life 5 years in cycles of 9-hours charging and 15-hours discharging

Replaceability Not possible to replace battery

Power failure, watchdog timer, data link connection, user program EPPROM sum check, timer/counter preset value sum check, user

Self-diagnostic Function

program RAM sum check, keep data, user program syntax, user program writing, CPU module, clock IC, I/O bus initialize, user program

Input Filter Without filter, 3 to 15 ms (selectable in increments of 1 ms)

Catch Input/Interrupt Input

Maximum Counting

Frequency and High-speed Counter

Points

Counter

Counting Range 0 to 65,535 (16 bits)

High-speed

Operation Mode Rotary encoder mode and adding counter mode

Analog

Potentiometer

Analog

Voltage

Input

Pulse

Output

Sensor Power

Supply

(AC Power Type

Only)

Quantity 1 point 2 points 1 point 2 points

Data Range 0 to 255

Quantity

Input Voltage Range

Input Impedance

Data Range

Quantity

Max. Frequency

Output Voltage/Current 24V DC (+10% to –15%), 250 mA

Overload

Detection

Isolation Isolated from the internal circuit

Total 4 points

Single/two-phase selectable: 50 kHz (1 point)

Single-phase: 5 kHz (3 points)

Not available

Port 1 RS232C – maintenance communication, user communications, Modbus ASCII/RTU slave communication (FC5A only)

4

Port 2 Communication Adapter (option)

Possible Possible Possible — Possible Possible

Clock Cartridge (option) Possible Possible Possible Possible Possible Possible

Memory Cartridge (option) Possible Possible Possible Possible Possible Possible

HMI Module (option) Possible Possible Possible Possible Possible Possible

1. 1 step equals 6 bytes.

2. Not including expansion I/O service time, clock function processing time, data link processing time, and interrupt processing time.

3. Expansion modules cannot be connected to FC5A-C24R2D.

4. Maintenance communication, user communication, Modem communication, data link, Modbus ASCII/RTU master/slave communication (FC5A only).

Note: The maximum number of relay outputs that can be turned on simulatneously is 33 including those on the CPU module.

FC5A-C16R2

FC5A-C16R2C

FC5A-C16R2D

FC5A-C24R2

FC5A-C24R2C

FC5A-C24R2D

FC4A-C10R2

FC4A-C10R2C

FC4A-C16R2

FC4A-C16R2C

42 basic 35 basic

0.64 ms 0.64 ms

Expansion:

64

6 9 14

3

execution

Four inputs (I2 through I5)

Minimum turn on pulse width: 40 µs maximum

Minimum turn off pulse width: 150 µs maximum

Total 4 points

Single/two-phase selectable: 20 kHz (1 point)

Single-phase: 5 kHz (3 points)

—

—

FC4A-C24R2

FC4A-C24R2C

OI Touchscreens PLCs Automation Software Power Supplies Sensors Communication Barriers

Expansion: 64

800-262-IDEC (4332) • USA & Canada

87

Page 30

MicroSmart Family

Programmable Logic Controllers

Communication Port (Port 1) Specifications

CPU Module FC5A-D12K1E/D12S1E Slim CPU All-in-One CPU

Standards USB 2.0 EIA RS232C

Maximum Baud Rate USB 2.0

OI TouchscreensPLCsAutomation SoftwarePower SuppliesSensorsCommunicationBarriers

Cable HG9Z-XCM2A FC2A-KC4C, FC2A-KP1C, FC4A-KC1C, FC4A-KC2C

Isolation between Internal Circuit and

Communication Port

Not isolated Not isolated

FC5A: 57,600 bps (maintenance communication)

FC4A: 19,200 bps (maintenance communication)

Slim Type Input Specifications

Model

Input Points

Rated Input Voltage 24V DC sink/source input signal

Input Voltage Range 20.4 to 26.4V DC

Rated Input Current

Input Impedance

Turn ON Time

Turn OFF Time

Connector

Isolation

Input Type Type 1 (IEC61131-2)

External Load for I/O

Interconnection

Single Determination Method Static

Effect of Improper Input

Connection

Cable Length 3m in compliance with electromagnetic immunity

On Mother Board

Insertion Durability 100 times minimum

FC5A-D12K1E

FC5A-D12S1E

8

(8/1 common)

FC5A I0, I1, I3, I4, I6, I7: 4.5 mA/point (24V DC)

I2, I5, I10 to I17: 7 mA/point (24V DC)

FC4A I0, I1, I6, I7: 5 mA/point (24V DC)

I2 to I5, I10 to I27: 7 mA/point (24V DC)

FC5A I0, I1, I3, I4, I6, I7: 4.9 kΩ

I2, I5, I10 to I17: 3.4 kΩ

FC4A I0, I1, I6, I7: 5.7 kΩ

I2 to I5, I10 to I27: 3.4 kΩ

FC5A I0, I1, I3, I4, I6, I7: 5 µs + filter value

I2 and I5: 35 µs + filter value

I10 to I17: 40 µs + filter value

FC4A I0, I1, I6, I7: 35 µs + filter value

I2 to I5: 35 µs + filter value

I10 to I27: 40 µs + filter value

FC5A I0, I1, I3, I4, I6, I7: 5 µs + filter value

I2 and I5: 150 µs + filter value

I10 to I17: 150 µs + filter value

FC4A I0, I1, I6, I7: 45 µs + filter value

I2 to I5: 150 µs + filter value

I10 to I27: 150 µs + filter value

MC1.5/16-G-

3.81BK

(Phoenix Contact)

Both sinking and sourcing input signals can be connected, therefore reverse connection does not cause permanent damage.

If any input exceeding the rated value is applied, permanent damage may be caused.

FC4A-D20K3

FC4A-D20S3

12

(12/1 common)

FL26A2MA

(Oki Electric Cable)

FC5A-D16RK1

FC5A-D16RS1

8

(8/1 common)

MC1.5/13-G-3.81BK

(Phoenix Contact)

Between input terminals: Optocoupler isolated

Internal circuit: Not isolated

FC4A-D20RK1

FC4A-D20RS1

12

(12/1 common)

Not needed

FC5A-D32K3

FC5A-D32S3

16

(8/1 common)

FL26A2MA

(Oki Electric Cable)

FC4A-D40K3

FC4A-D40S3

24

(12/1 common)

88

www.IDEC.com

Page 31

Programmable Logic Controllers

MicroSmart Family

All-in-One Type Input Specifications

FC5A-C10R2

Model

Input Points

Rated Input Voltage 24V DC sink/source input signal 12V DC sink/source input signal

Input Voltage Range 20.4 to 28.8V DC 10.2 to 18.0V DC

Rated Input Current

Input Impedance

Turn ON Time

Turn OFF Time

Isolation

Input Type Type 1 (IEC61131-2)

External Load for I/O

Interconnection

Single Determination Method Static —

Effect of Improper Input

Connection

Cable Length 3m in compliance with electromagnetic immunity

FC5A-C10R2C

FC4A-C10R2

FC4A-C10R2C

6

(6/1 common)

FC5A I0 and I1: 6.4 mA/point

I2 to I7, I10 to I15: 7 mA/point (24V DC)

FC4A I0 and I1: 11 mA

I2 to I7, I10 to I15: 7 mA/point (24V DC)

FC5A I0 and I1: 3.7 kΩ

I2 to I7, I10 to I15: 3.4 kΩ

FC4A I0 and I1: 2.1 kΩ

I2 to I7, I10 to I15: 3.4 kΩ

FC5A I0 and I1: 2 µs + filter value

I2 to I5: 35 µs + filter value

I6, I7, I10 to I15: 40 µs + filter value

FC4A I0 and I1: 35 µs + filter value

I2 to I5: 35 µs + filter value

I6, I7, I10 to I15: 40 µs + filter value

FC5A I0 and I1: 16 µs + filter value

I2 to I5: 150 µs + filter value

I6, I7, I10 to I15: 150 µs + filter value

FC4A I0 and I1: 45 µs + filter value

I2 to I5: 150 µs + filter value

I6, I7, I10 to I15: 150 µs + filter value

Both sinking and sourcing input signals can be connected, therefore reverse connection does not cause permanent damage.

If any input exceeding the rated value is applied, permanent damage may be caused.

FC5A-C16R2

FC5A-C16R2C

FC4A-C16R2

FC4A-C16R2C

9

(9/1 common)

FC5A-C24R2

FC5A-C24R2C

FC4A-C24R2

FC4A-C24R2C

14

(14/1 common)

Between input terminals: Optocoupler isolated

Internal circuit: Not isolated

FC5A-C10R2D FC5A-C16R2D FC5A-C24R2D

— — —

6

(6/1 common)

I0 and I1: 6 mA

I2 to I7, I10 to I15: 6 mA

I0 and I1: 1.8 kΩ

I2 to I7, I10 to I15: 2.0 kΩ

I0 and I1: 2 µs + filter value

I2 to I5: 35 µs + filter value

I6, I7, I10 to I15: 40 µs + filter value

I0 and I1: 16 µs + filter value

I2 to I5: 150 µs + filter value

I6, I7, I10 to I15: 150 µs + filter value

Not needed

9

(9/1 common)

OI Touchscreens PLCs Automation Software Power Supplies Sensors Communication Barriers

14

(14/1 common)

800-262-IDEC (4332) • USA & Canada

89

Page 32

MicroSmart Family

Programmable Logic Controllers

Transistor Sink and Source Output Specifications

FC5A-D12K1E

Model

OI TouchscreensPLCsAutomation SoftwarePower SuppliesSensorsCommunicationBarriers

Transistor Output Points 4 (4/1 common) 2 (2/1 common) 2 (2/1 common) 16 (8/1 common)

Output

Type

Rated Load Voltage 24V DC

Operating Load Voltage Range 20.4 to 28.8V DC

Rated Load Current 0.3A per output point

Maximum Load Current 1A per common

Voltage Drop (ON Voltage) 1V maximum (voltage between COM and output terminals when output is on)

Inrush Current 1A

Leakage Current 0.1 mA maximum

Clamping Voltage 39V±1V

Maximum Lamp Load 8W

Inductive Load L/R = 10 ms (28.8V DC, 1 Hz)

External Current Draw

Isolation

Connector on Mother Board

Connector Insertion/

Removal Durability

Output

Delay

Transistor Sink

Transistor Source

Turn ON Time

Turn OFF Time

FC5A-D12S1E

—

Sink output: 100 mA maximum, 24V DC (power voltage at the +V terminal)

Source output: 100 mA maximum, 24V DC (power voltage at the –V terminal)

Between output terminal and Internal circuit: Photocoupler isolated

Between output terminals: Not isolated

MC1.5/16-G-3.81BK

(Phoenix Contact)

FC5A Q0 to Q2: 5 µs max.

Q3 to Q7, Q10 to Q17: 300 µs max.

FC4A Q0, Q1: 5 µs max.

Q2 to Q7, Q10 to Q17: 300 µs max.

FC5A Q0 to Q2: 5 µs max.

Q3 to Q7, Q10 to Q17: 300 µs max.

FC4A Q0, Q1: 5 µs max.

Q2 to Q7, Q10 to Q17: 300 µs max.

FC4A-D20RK1

FC4A-D20RS1

FL26A2MA

(Oki Electric Cable)

—

FC5A-D12K1E/D16RK1/D32K3

FC4A-D20K3/D20RK1/D40K3

FC5A-D12S1E/D16RS1/D32S3

FC4A-D20S3/D20RS1/D40S3

100 times minimum

FC5A-D16RK1

FC5A-D16RS1

—

MC1.5/16-G-3.81BK

(Phoenix Contact)

FC5A-D32K3

FC5A-D32S3

FC4A-D40K3

FC4A-D40S3

FL26A2MA

(Oki Electric Cable)

90

www.IDEC.com

Page 33

Programmable Logic Controllers

MicroSmart Family

Relay Output Specifications

FC5A-C10R2

FC5A-C10R2C

Model

Relay Output Points 4 7 10 6

COM0 3 4 4 —

Output Points per

Common Line

Output Type 1NO

Maximum Load Current

Minimum Switching Load 1 mA/ 5V DC (reference value)

Initial Contact Resistance 30 mΩ maximum

Electrical Life 100,000 operations minimum (rated load 1,800 operations/hour)

Mechanical Life 20,000,000 operations minimum (no load 18,000 operations/hour)

Rated Load

Dielectric Strength

Connector on Mother Board — *

Connector Insertion/

Removal Durability

1. MC1.5/16-G-3.81BK (Phoenix Contact)

COM1 1 2 4 3

COM2 — 1 1 2

COM3 — — 1 1

FC5A-C10R2D

FC4A-C10R2

FC4A-C10R2C

Between output and

Between output terminal and internal circuit: 1,500V AC, 1 minute

Between output terminals (COMs): 1,500V AC, 1 minute

FC5A-C16R2

FC5A-C16R2C

FC5A-C16R2D

FC4A-C16R2

FC4A-C16R2C

8A per common line

240V AC/2A (resistive load, inductive load cos ø = 0.4)

30V DC/2A (resistive load, inductive load L/R =7 ms)

terminals: 1,500V AC, 1 minute

— 100 times minimum

FC5A-C24R2

FC5A-C24R2C

FC5A-C24R2D

FC4A-C24R2

FC4A-C24R2C

2A per point

FC5A-D16RK1

FC5A-D16RS1

FC4A-D20RK1

FC4A-D20RS1

1

OI Touchscreens PLCs Automation Software Power Supplies Sensors Communication Barriers

800-262-IDEC (4332) • USA & Canada

91

Page 34

MicroSmart Family

e

FC5A: I0, I1, I3, I4, I6, I7

3.3 kΩ (FC5A)

I0, I1

FC5A: I2, I5, I10 to I17

+V

Input Usage Limits

Slim CPU

FC5A-D16RK1/D16RS1

FC5A-D12K1E/D12S1E

OI TouchscreensPLCsAutomation SoftwarePower SuppliesSensorsCommunicationBarriers

26.4

24.0

All-in-One CPU

FC5A-C10R2

FC5A-C10R2C

FC4A-C10R2

FC4A-C10R2C

0 50 100 0 50 100 0 50 100 0 50 100

I/O Simultaneous ON Ratio (%)

Ambient Temperature

40ºC

Ambient

Temperature

55ºC

FC5A-D32K3/D32S3

FC4A-D40K3/D40S3

Input Voltage (V DC)Input Voltage (V DC)

26.4

24.0

I/O Simultaneous ON Ratio (%)

FC5A-C16R2

FC5A-C16R2C

FC4A-C16R2

FC4A-C16R2C

Ambient Temperature

40ºC

Ambient

Temperature

55ºC

Programmable Logic Controllers

FC4A-D20K3/D20S3 FC4A-D20RK1/D20RS1

Input Voltage (V DC)

26.4

24.0

I/O Simultaneous ON Ratio (%) I/O Simultaneous ON Ratio (%)

Ambient Temperature

40ºC

Ambient

Temperature

55ºC

FC5A-C24R2

FC5A-C24R2C

FC4A-C24R2

FC4A-C24R2C

Input Voltage (V DC)

26.4

24.0

CAUTION: When using at an operating ambient

temperature above 40°C, reduce the input

voltage or the quantity of I/O points that turn

on simultaneously.

Ambient Temperature

55ºC

Input Voltage (V DC) Input Voltage (V DC) Input Voltage (V DC)

28.8

26.4

0 50 100 0 50 100 0 50 100

I/O Simultaneous ON Ratio (%) I/O Simultaneous ON Ratio (%) I/O Simultaneous ON Ratio (%)

Ambient Temperature

55ºC

28.8

26.4

Ambient Temperature

45ºC

Ambient

Temperature

55ºC

28.8

26.4

Ambient Temperature

45ºC

Ambient

Temperatur

55ºC

Input Internal Circuit

Slim CPU All-in-One CPU FC5A All-in-One CPU 12V DC Type

FC4A: I0, I1, I6, I7

Input

COM

FC4A: I2 to I5, I10 to I27

Input

COM

4.7 kΩ

3.3 kΩ

Internal Circuit

Internal Circuit

I0, I1

Input

COM

I2 to I15

Input

COM

1.8 kΩ (FC4A)

Internal Circuit

3.3 kΩ

Internal Circuit

Input

COM

I2 to I15

Input

COM

1.8 kΩ

2.0 kΩ

Internal Circuit

Internal Circuit

Output Internal Circuit

Slim CPU

Sink Output

Internal

Circuit

92

Source Output

COM (+)

Output

COM (–)

Internal

Circuit

Output

–V

www.IDEC.com

Page 35

Programmable Logic Controllers

MicroSmart Family

Communication Adapter/Module Specifications

Model

FC4A-PC1

FC4A-HPC1

Standards EIA RS232C EIA RS485 EIA RS485

FC5A: 57,600 bps

Maximum Baud Rate

Maintenance

Communication

FC4A: 19,200 bps

Possible Possible Possible

User Communication Possible Possible

Data Link Communi-

— Possible Possible

cation

Half-duplex Com-

— Possible Possible

munication

Maximum Cable

Special cable

Length

Quantity of Slave

Stations

— 31

Isolation between

Internal Circuit and

Not isolated

Communication Port

Cable

Conductor

RS485 Cable

Resistance

Shield Resis-

tance

1. Maximum speed is 115,200 bps for FC5A-D12*1E.

2. Maximum speed when data link is used.

3. FC5A (all types), FC4A-D20RK1, FC4A-D20RS1, FC4A-D40K3, FC4A-D40S3

4. FC2A-KC4C, FC2A-KM1C, FC4A-KC1C, FC4A-KC2C, FC2A-KP1C

5. FC2A-KP1C

1

4

—

FC4A-PC2

FC4A-HPC2

FC5A: 57,600 bps1

FC4A: 19,200 bps

3

Special cable

5

FC4A-PC3

FC4A-HPC3

FC5A: 57,600 bps1

FC4A: 19,200 bps

(38,400 bps2)

Possible

200m

31

Twisted-pair

shielded cable

with a minimum

core wire of 0.3

2

mm

85 Ω/km maximum

20 Ω/km maximum

HMI Module Specifications

OI Touchscreens PLCs Automation Software Power Supplies Sensors Communication Barriers

Model FC4A-PH1

Power Voltage 5V DC (supplied from the CPU module)

Weight 20g

Memory Cartridge Specifications

Model FC4A-PM32 FC4A-PM646 FC4A-PM1286

Memory Type EEPROM

3

Accessible

Memory Capacity

Hardware for

Storing Data

Software for

Storing Data

Quantity of Stored

Programs

6. Even when using a large-capacity memory cartridge, the program capacity of the

CPU module takes effect, except when using FC4A-D20RK1, FC4A-D20RS1, FC4AD40K3, and FC4A-D40S3 CPU modules, the program capacity expands to 64KB.

32 KB 64 KB 128 KB

CPU Module

WindLDR

One user program can be stored on one memory cartridge

Clock Cartridge Specifications

Model FC4A-PT1

Accuracy ±30 sec/month (typical) at 25°C

Backup Duration Approx. 30 days (typical) at 25°C after backup battery fully charged

Battery Lithium secondary battery

Charging Time Approx. 10 hours for charging from 0% to 90% of full charge

Replaceability Not possible to replace battery

800-262-IDEC (4332) • USA & Canada

93

Page 36

MicroSmart Family

Expansion Serial Communication Module

General Specifications

(Expansion RS232C Communication Module)

Model FC5A-SIF2

No. of Port 1

OI TouchscreensPLCsAutomation SoftwarePower SuppliesSensorsCommunicationBarriers

Synchronization Synchronization Start-stop synchronization

Electrical Characteristics Electrical Characteristics EIA RS232C compliant

Maximum Delay in One Scan Approx. 4 ms

Operating Temperature 0 to 55°C

Relative Humidity 10 to 95% (no condensation)

Recommended Cable

Specifications

Recommended Cable

Connector on Mother Board

Connector Insertion/Removal

Durability

Isolation from Internal Circuit Transformer isolated

Quantity of Applicable

Expansion RS232C

Communication Modules

Internal Current Draw 40 mA (5V/24V DC)

Weight 100g

Note: FC5A-SIF2 cannot be connected to FC4A CPU modules.

1. FC5A All-in-One 24-I/O CPU module cannot use the FC5A-SIF2/SIF4 module in combination

with the function modules listed in the table on the left. When using these modules in

combination with the FC5A-SIF2/SIF4 module, use the slim type CPU module.

Function Modules Type No.

Analog Modules

AS-Interface Master Module FC4A-AS62M

5. 85 mA (5V DC), 0 mA (24V DC) when the communication module version is lower than V200.

Shielded multi-core cable: 24AWG x 6

Dielectric strength: 2,000V AC/min

Insulation resistance: 100 MΩ/km

KIDU-SB 24 AWG×6C

(Nihon Electric Wire & Cable)

MC1.5/10-G-3.81BK (Phoenix Contact)

Applicable terminal block: FC4A-PMT10P

100 times minimum

All-in-One 24-I/O type CPU module: 3 maximum

Slim type CPU module: 5 maximum

5

FC4A-L03A1, FC4A-L03AP1, FC4A-J2A1,

FC4A-K1A1, FC4A-J4CN1, FC4A-J8C1,

FC4A-J8AT1, FC4A-K2C1, FC4A-K4A1

Programmable Logic Controllers

(Expansion RS485 Communication Module)

Model FC5A-SIF4

No. of Port 1

Synchronization Synchronization Start-stop synchronization

Electrical Characteristics Electrical Characteristics EIA RS485 compliant

Maximum Baud Rate 115,200 bps

Operating Temperature 0 to 55°C

Relative Humidity 10 to 95% (no condensation)

Recommended Cable

Specifications

Connector on Mother

Board

Connector Insertion/

Removal Durability

Isolation from Internal

Circuit

1

Quantity of Applicable

Expansion RS485C

Communication Modules

Internal Current Draw 40 mA (5V/24V DC)

Weight 100g

Note: FC5A-SIF4 cannot be connected to FC4A CPU modules.

Communication Specifications

Model FC5A-SIF2 FC5A-SIF4

Maximum Baud Rate 1,200/2,400/4,800/9,600/19,200/38,400/57,600

Maintenance

Communication

Modbus

Communication

Data Link - 0

Max Cable Length 10m 1,200m

Quantity of

Slave Stations

2. Run-time program download is not possible.

3. Data Link can be used only on one of the communication ports.

4. Can be used when the communication module is version V200 or higher.

Shielded twisted pair cable:

22 AWG (0.3 mm2 x 2P)

Conductor Resistance:

67 MΩ/km maximum (at 20°C)

MC1.5/10-G-3.81BK (Phoenix Contact)

Applicable terminal block: FC4A-PMT10P

100 times minimum

Transformer isolated

All-in-One 24-I/O type CPU module: 3 maximum

Slim type CPU module: 5 maximum

Modbus ASCII master

Modbus ASCII slave

Modbus RTU master

1 31

2

Possible

Modbus RTU slave

1

4

/115,200

3

4

94

www.IDEC.com

Page 37

Programmable Logic Controllers

MicroSmart Family

Specifications (I/O Modules)

Input Module Specifications

Model FC4A-N08B1 FC4A-N16B1 FC4A-N16B3 FC4A-N32B3 FC4A-N08A11

Input Points 8 (8/1 common) 16 (16/1 common) 32 (16/1 common) 8 (4/1 common)

Rated Input Voltage 24V DC sink/source input signal 100 to 120V AC (50/60 Hz)

Input Voltage Range 20.4 to 28.8V DC 85 to 132V AC

Rated Input Current 7 mA/point (24V DC) 5 mA/point (24V DC) 17 mA/point (120V AC, 60 Hz)

Input Impedance 3.4 kΩ 4.4 kΩ 0.8 kΩ (60 Hz)

ON Voltage 15V minimum 79V minimum

OFF Voltage 5V maximum 20V maximum

ON Current 4.2 mA minimum (at 15V DC) 3.2 mA minimum (at 15V DC) —

OFF Current 1.2 mA maximum 0.9 mA maximum —

Turn ON Time 4 ms 25 ms

Turn OFF Time 4 ms 30 ms

Isolation

External Load for I/O

Interconnection

Single Determination

Method

Effect of Improper Input

Connection

Cable Length 3m in compliance with electromagnetic immunity —

Connector on Mother Board MC1.5/10-G-3.81BK (Phoenix Contact) FL20A2MA (Oki Electric Cable) MC1.5/11-G-3.81BK (Phoenix Contact)

Connector Insertion/

Removal Durability

Applicable Ferrule

Internal

Current

Draw

Internal Power

Consumption (at 24V DC

while all inputs ON)

Weight 85g 100g 65g 100g 80g

All Inputs

ON

All Inputs

OFF

Both sink and source input signals can be connected. If any input exceeding the

1-wire: AI 0.5-8 WH (Phoenix Contact)

2-wire: AI-TWIN 2×0.5-8 WH (Phoenix

Contact)

25 mA (5V DC) 40 mA (5V DC) 35 mA (5V DC) 65 mA (5V DC) 60 mA (5V DC), 0 mA (24V DC)

5 mA (5V DC) 5 mA (5V DC) 5 mA (5V DC) 10 mA (5V DC) 30 mA (5V DC), 0 mA (24V DC)

0.17W 0.27W 0.24W 0.44W —

Between input terminals: Not isolated

Internal circuit: Photocoupler isolated

Not needed Not needed

Static Static

rated value is applied, permanent damage may be caused.

100 times minimum

— —

Between input terminals in the same common: Not isolated

Between input terminals in different commons: Isolated

Between input terminals and internal circuits: Photocoupler isolated

If any input exceeding the rated value is applied, permanent damage

may be caused.

OI Touchscreens PLCs Automation Software Power Supplies Sensors Communication Barriers

800-262-IDEC (4332) • USA & Canada

95

Page 38

MicroSmart Family

Programmable Logic Controllers

Transistor Output Module Specifications

Model

Output Points 8 (8/1 common) 16 (16/1 common) 32 (16/1 common)

OI TouchscreensPLCsAutomation SoftwarePower SuppliesSensorsCommunicationBarriers

Output Type

Rated Load Voltage 24V DC

Operating Load

Voltage Range

Maximum Load Current

Voltage Drop

(ON Voltage)

Inrush Current 1A maximum

Clamping Voltage 39V±1V

Maximum Lamp Load 8W

Inductive Load L/R = 10 ms (28.8V DC, 1 Hz)

External Current Draw

Isolation

Connector on

Mother Board

Connector Insertion/

Removal Durability

Applicable Ferrule

Internal

Current

Draw

Internal Power Consumption

(at 24V DC while all

outputs ON)

Output

Delay

Weight 85g 70g 105g

All outputs ON10 mA (5V DC)

All outputs

OFF

Turn ON

Time

Turn OFF

Time

FC4A-T08K1

FC4A-T08S1

FC4A-T0K0: Transistor sink output

FC4A-T0S0: Transistor source output

0.3A per point 0.1A per point

3A per common 1A per common

1V maximum (voltage between COM and output terminals

24V DC (power voltage at the +V terminal)

24V DC (power voltage at the –V terminal)

Between output terminal and internal circuit:

Between output terminals: Not isolated

MC1.5/10-G-3.81BK

(Phoenix Contact)

1-wire: AI 0.5-8 WH

(Phoenix Contact)

2-wire: AI-TWIN

2×0.5-8 WH (Phoenix Contact)

20 mA (24V DC)

5 mA (5V DC)

0 mA (24V DC)

0.55W 1.03W 1.82W

FC4A-T16K3

FC4A-T16S3

20.4 to 28.8V DC

when output is on)

FC4A-T0K0: 100 mA maximum,

FC4A-T0S0: 100 mA maximum,

Photocoupler isolated

FL20A2MA (Oki Electric Cable)

100 times minimum

10 mA (5V DC)