Page 1

EU2B Series: 30mm Hazardous Location Switches

EC2B Series: Hazardous Location Control Stations

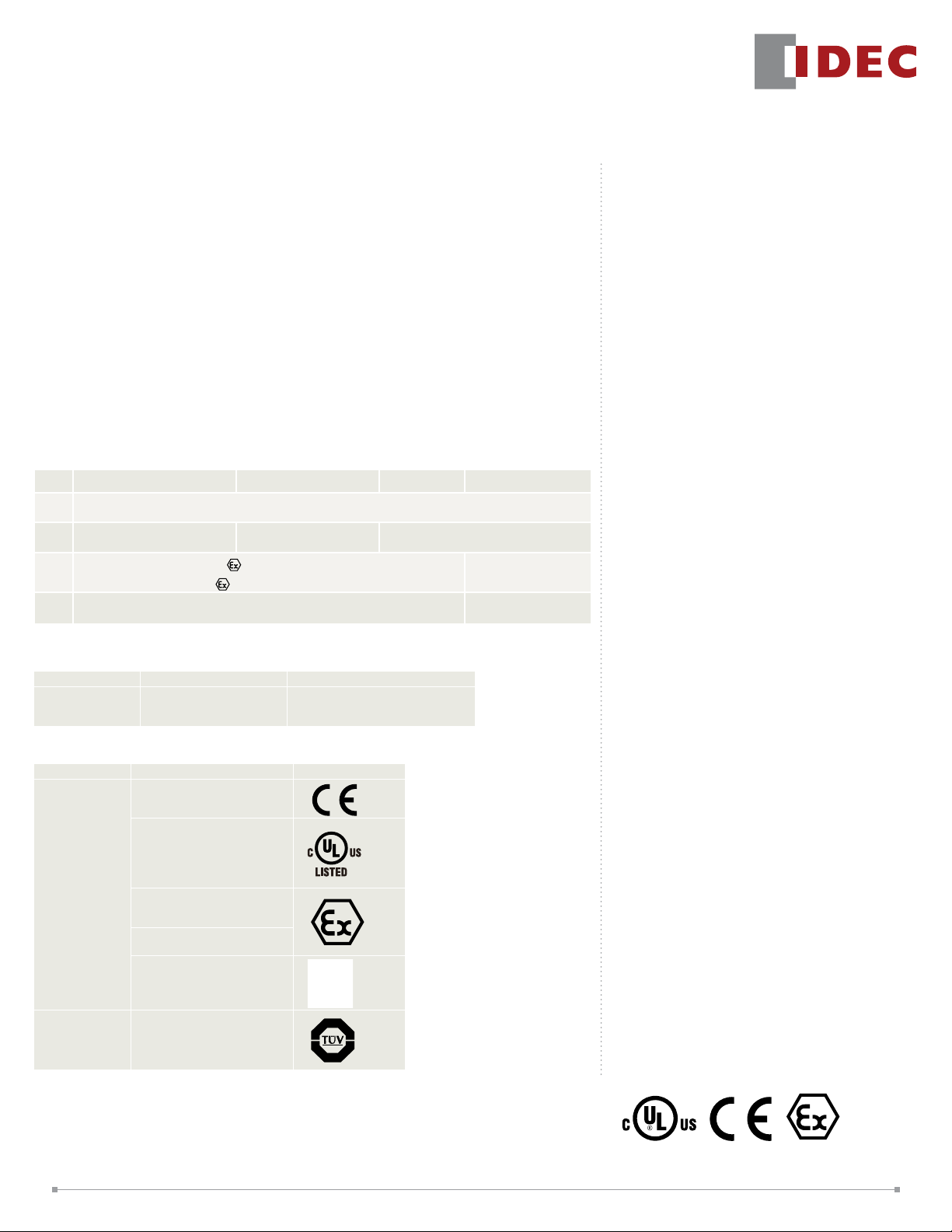

STANDARDS COMPLIANCE

Switches Pilot Lights Meters Control Boxes

UL

Class I, Zone 1, Ex de IIC T6 Gb

c-UL

Class I, Div 2, Groups A, B, C and D

ATE X

IECEx

Class I, Zone 1 AEx d e IIC T6 Gb

Class I Div 2, Groups A, B, C and D

Class I, Zone 1, Ex de IIB T6 Gb

Class I, Div 2, Groups C and D

II2G Ex de IIC Gb

II2D Ex tb IIIC Db IP65

Ex de IIC Gb

Ex tb IIIC Db IP65

Class I, Zone 1, Ex de IIC T6 Gb

Class I, Div 2, Groups A, B, C and D

Ex d e IIC T6 Gb

Ex tb IIIC T80ºC Db (dust)

Ex de IIC T6 Gb

Ex tb IIIC T80ºC Db (dust)

PRODUCT DESCRIPTION

Complying with UL, IECEx, and ATEX

Directives for hazardous environments,

new 30mm EU2B Hazardous Location

Switches and EC2B Hazardous Location

Control Stations provide increased safety

for your applications.

Control Unit Options:

• Pushbuttons

• Pilot Lights

• Selector Switches

• Key Selector Switches

• Emergency Stop Switches

• Meters

Control Station Options:

• Pre-congured stations

• Custom-congured stations

• Open control boxes

• Mounting holes for up to 18 control units

CERTIFICATE NUMBERS

UL/c-UL ATEX IECEx

E347230 PTB 08 ATEX 1053 U

PTB 08 ATEX 1003 U

PTB 08 ATEX 1048

IECEx PTB 15.0006U

IECEx PTB 15.0007U

IECEx PTB 15.0032

APPLICABLE STANDARDS

Control Units Standards Mark

EN60947-5-1

UL60079-0

Pushbuttons

Selector

Switches

Key Selector

Switches

Pilot Lights

Meters

Emergency

Stop Switches

UL 60079 -1

UL60079-7

CAN/CSA C22.2 No. 60079-0

CAN/CSA C22.2 No. 60079-1

CAN/CSA C22.2 No. 60079-7

EN60079-0 EN60079-1

EN60079-7 EN60079-31

IEC60079-0 IEC60079-1

IEC60079-7 IEC60079-31

EN60947-5-5

KEY FE ATURES

• Class I, Zone 1/Division 2

• Applicable in explosive gas atmospheres

(AEx de IIC T6 Gb)

• UL Type 4X rated

• Up to 3 contact blocks

• Selector switches available with lever or

key

• Selector switches available with

overlapping contacts

• Exposed and nger-safe (IP20) screw

terminals available

• Corrosion resistant stainless steel

enclosure (SUS304)

• Melamine coating

• NPT and Metric reducer options

1

Page 2

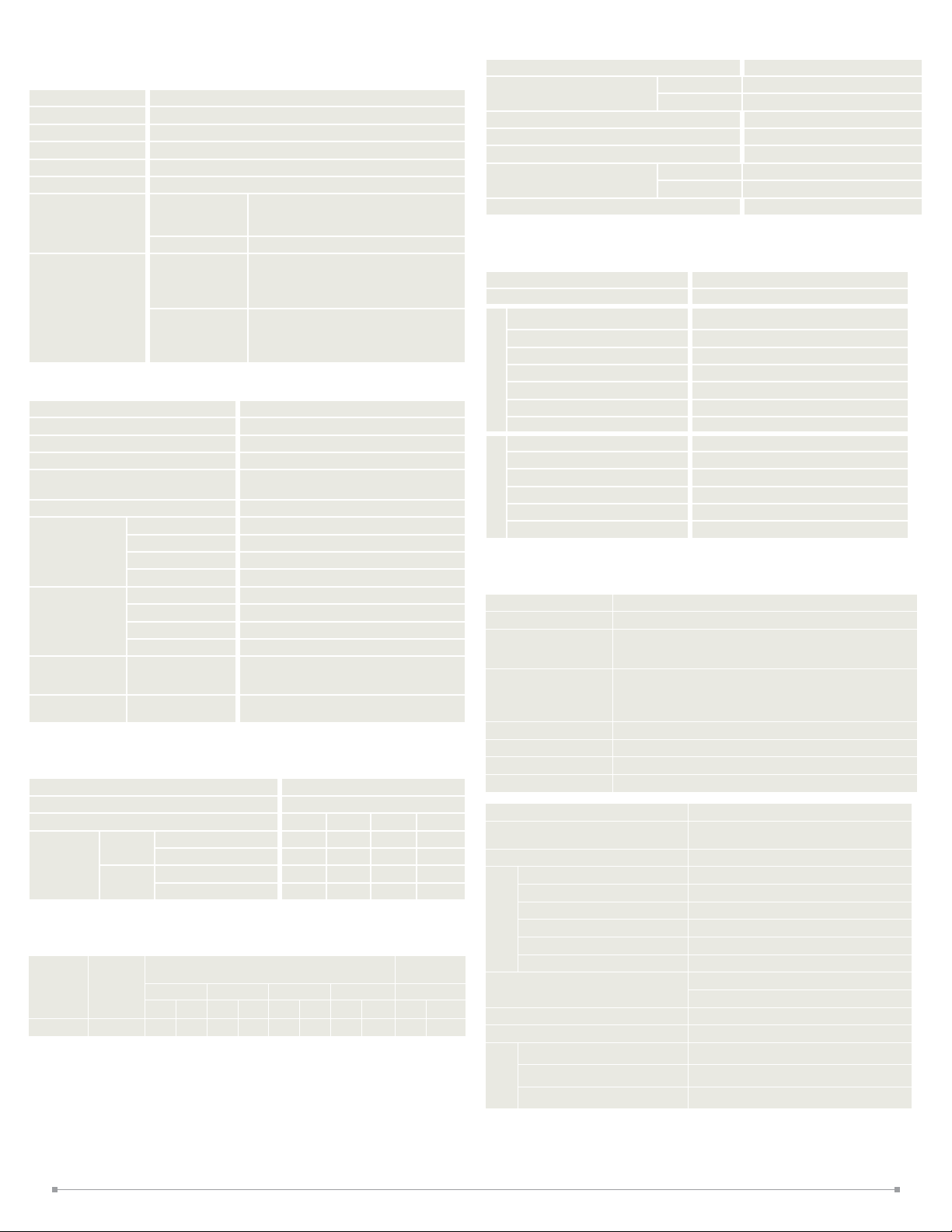

SPECIFICATIONS

General Specications

Degree of Pro tection

Insulation Resistance

Operating Temperature

Operating Humidity

Altitude

Pollution Degree

Shock Resis tance

Vibration Resistance

Switches

Rated Insulation Voltage

Contact Resistance

Impulse Wi thstand Voltage (Uimp)

Insulation Resistance

Short-Circuit Protection

Conditional Short-Circuit Current

Mechanical Life

Electrical Life

Minimum Operator

Stroke Required for

Direct Opening Action

Maximum Operator

Stroke

Note: Contacts will bounce during operation of pushbuttons and selector switches (reference value: 20-

ms). Be sure to take contact bounce time into consideration when designing a control circuit.

Contact Rating (Switches)

Rated Insulation Voltage (Ui)

Rated Thermal Curren t (It h)

Rated Operating Volt age (Ue)

AC

Rated Operating

Current (Ie)

Note: Up to 2 contacts (per control unit): 10A

3 contacts (per control unit): 9A

Minimum applicable load: 3V AC/DC, 5mA

Applicable operating locations may vary according to operating conditions and load types.

Contact

Rating Code

Designation

A600 10

50/60Hz

DC

Thermal

Continuous

Tes t

Current

Amperes

IP65 (IEC60529), Type 4X

100 MΩ minimum (500V DC megger)

−20 to +50°C (no freezing)

45 to 85% (no condensation)

2,000m Maximum

3

Operating Extremes

100-m/s²

Emergency Stop Switch:

150-m/s² (without Meter)

Damage Limits

1000-m/s²

5 to 55-Hz, amplitude 0.5 mm

Operating Extremes

Emergency Stop Switch:

5 to 500-Hz, amplitude 0.35-mm, acceleration

50-m/s² (without Meter)

30Hz, amplitude 1.5-mm

Damage Limits

Emergency Stop Switch:

5 to 500-Hz, amplitude 0.35-mm, acceleration

50-m/s²

600V

50mΩ maximum (initial value)

6kV

100MΩ minimum (500V DC megger)

250V/ 10A fu se

(Type aM IEC60269-1/IEC60269-2)

1,000A

Pushbutton

Selector Switch

Key Selector Switch

Emergency Stop Switch

Pushbutton

Selector Switch

Key Selector Switch

Emergency Stop Switch

Emergency Stop Switch

Emergency Stop Switch

1,000,000 operations minimum

500,000 operations minimum

500,000 operations minimum

50,000 operations minimum

250,000 (switching frequency 1800 operations/hr)

250,000 (switching frequency 900 operations/hr)

250,000 (switching frequency 900 operations/hr)

50,000 (switching frequency 900 operations/hr)

7.0mm

9.0mm

600V

10A*

24V 120V 240V 500V

Resisti ve Load (AC12)

Inductive Load ( AC15)

Resisti ve Load (DC12)

Inductive Load (DC13)

Maximum cur rent, Amperes

120 Volt 240 Volt 480 Volt 600 Volt 60 0 Volt

Make Break Make Break Make Break Make Break Make Break

60 6.00 30 3.00 15 1.5 12 1.2 7200 720

10A* 10A* 6A 2.8A

10A* 6A 3A 1.4A

8A 2.2A 1.1A —

4A 1.1A 0.55A —

Volt-Amperes

Maximum

Pilot Lights

Rated Insulation Voltage (Ui)

Rated Operating Volt age (Ue)

Impulse Wi thstand Voltage (Uimp)

Insulation Resistance

Frequency

Power Consumption (approx.)

Lif e (reference value)

Note: Because the built-in LED lamp is a high-brightness version, the lamp may light dimly due to induction

even when power is off.

Voltage

Transformer

Full Voltage

Transformer

500V

6V, 12V, 24V AC/DC

120V, 230V, 240V, 380V, 480V AC

4kV

100 MΩ minimum (500V DC)

50/60Hz

0.3W

1.5W

Approx. 40,000 hours

Meters

Accuracy Class

Insulation Resistance

Rated Insulation Voltage (Ui)

Operation

Impulse Wi thstand Voltage (Uimp)

Power Consumption

Measurement

AC ammeter

Input (CT Ratio)

Extended Memory

Rated Insulation Voltage (Ui)

Operation

Impulse Wi thstand Voltage (Uimp)

Input

DC input met er

Power Consumption (DC ammeter)

Consumption Current (DC voltmeter)

Note: Use a commercially available C T (current transfor mer) for all AC ammeters, and install the CT in a

non-hazardous location.

2.5

100 MΩ minimum (500V DC megger)

300V

Moving core

4kV

1VA

5A, 10A, 30A, 50A, etc

1A, 5A

3 times, etc

150V

Moving coil

2.5kV

0 to10V DC, 4 to 20mA, etc.

0.15 W

1mA

Control Boxes

Degree of protection

Housing Material

Standard Coating

Rated Insulation

Voltage

Insulation Resistance

Operating Temperature

Operating Humidity

Altitude

Agency Approvals

Applicable Enclosure

Mounting Style

Pilot Light

Pushbutton

Emergency Pushbutton

Selector Switch

Control Unit

Key Selector Switch

Meter

Reducer Screw

Degree of Pro tection

Grounding Terminal Screw Material

Stranded W ire (mm2)

Solid Wire (mm2)

Wire

Applicable

Solid/S tranded W ire (AWG)

1: c-UL explosion protection is different when pilot light is inst alled.

IP65 (IEC60529), Type 4X

Stainless steel (SUS304)

Melamine

1-column: Outside coating

2-, 3-column: Inside and outside coating

600V

(with pilot light or ET2A-8PE screw terminal block: 500V)

Meter AC input: 300V

Meter DC input: 150V

100 MΩ minimum (500V DC megger)

−20 to +50°C (no freezing)

45 to 85% (no condensation)

2000m maximum

UL/c-UL, IECEx/ATEX certied

All enclosures except for

6 Control Units x 3 Column

Wall Mount

1

Yes

Yes

Yes

Yes

Yes

Yes

NPT Thread (standard)

Metric Thread

IP65, TYPE4X (UL)

Stainless Steel

1.5 to 2.5

1.2 t o 1.6

16-14

2

Page 3

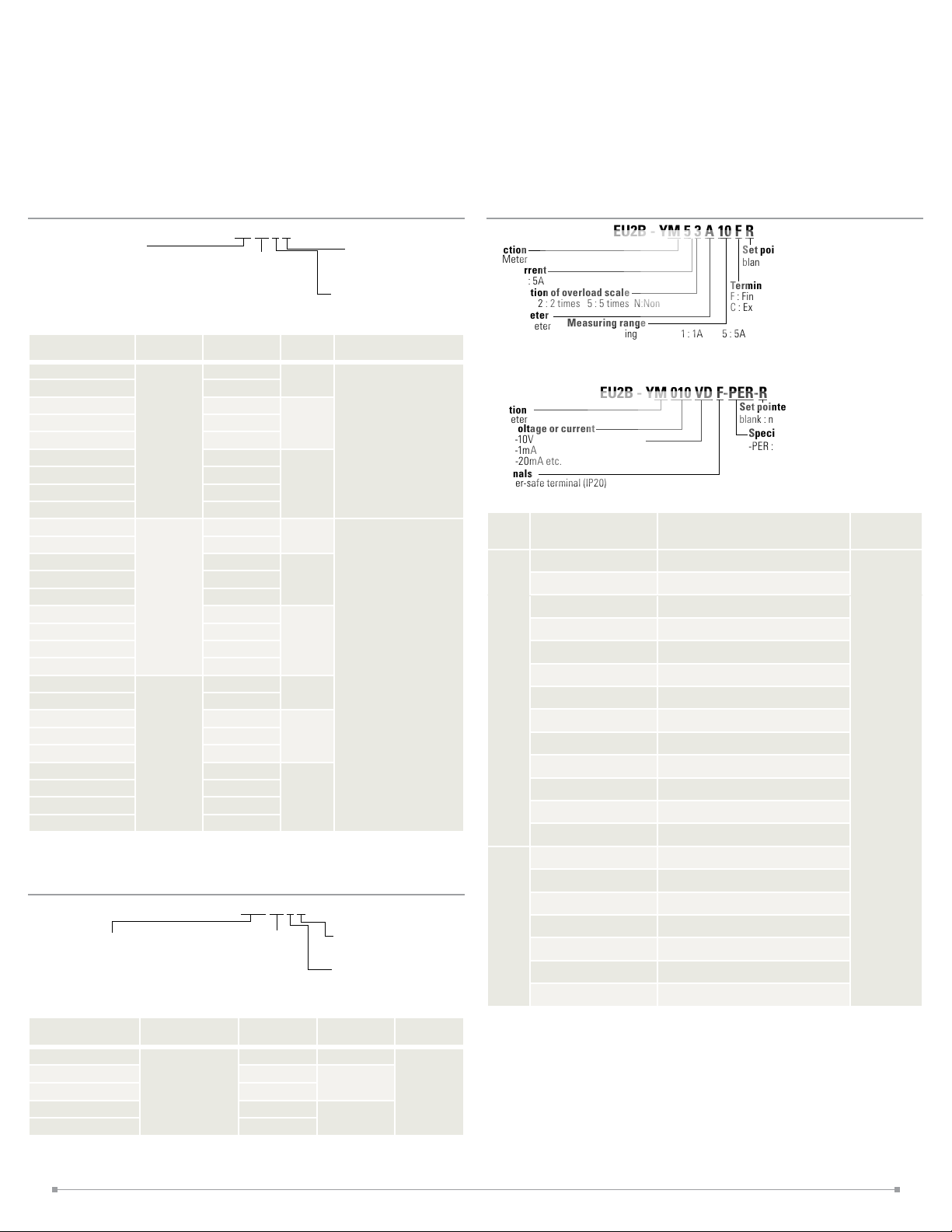

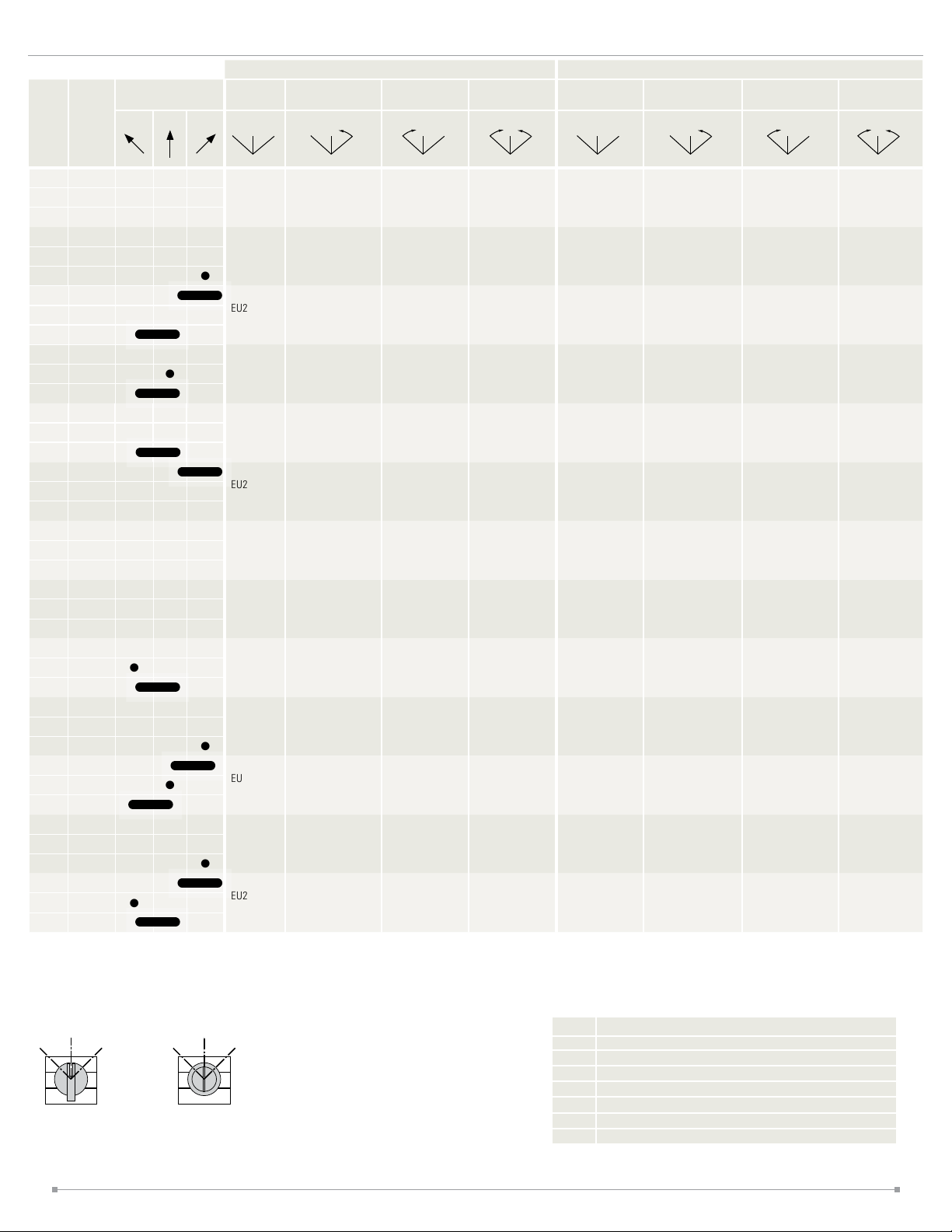

SWITCHES (CONTROL UNITS)

Pushbuttons Emergency Stop Switches Pilot Lights Selector Switches Key Selector Switches Meters

Pushbuttons

Operator (style / function)

B1 :Flush pushbutton / Momentary

B2 : Extended pushbutton / Momentary

B3 : Mushroom pushbutton / Momentary

Part Number

EU 2B-Y B110➃➀ –D

EU2B-YB101➃➀ –D

EU 2B-Y B111➃➀ –D

EU2B-YB120 ➃➀–D

EU2B-YB102➃➀ –D

EU2B-YB121➃➀ –D

EU 2B-Y B112➃➀–D

EU2B-YB130 ➃➀–D

EU2B-YB103➃➀ –D

EU2B-YB 210➃➀ –D

EU2B-YB 201➃➀ –D

EU 2B-Y B211➃➀ –D

EU2B-YB 220➃➀ –D

EU2B-YB 202➃➀–D

EU2B-YB 221➃➀ –D

EU2B-YB 212➃➀ –D

EU2B-YB230➃➀–D

EU2B-YB 203➃➀ –D

EU2B-YB 310➃➀ –D

EU2B-YB 301➃➀ –D

EU 2B-Y B311➃➀ –D

EU2B-YB320➃➀–D

EU2B-YB 302➃➀ –D

EU2B-YB 321➃➀ –D

EU2B-YB 312➃➀ –D

EU2B-YB330➃➀ –D

EU2B-YB303➃➀–D

Note: ➀ Button Color. Specify a contact terminal style in place of ➃ in the part number: F (Finger-safe

terminal), C (Exposed screw terminal)

EU2B - YB1 11 F S - D

Contact arrangement

10 : 1NO

20 : 2NO

30:3NO

11 : 1NO-1NC

21 : 2NO -1NC

St yle and

Function

Flush

Momentary

Extended

Momentary

Mushroom

Momentary

Arrangement

1NO

1NC

1NO-1NC

2NO

2NC

2NO-1NC

1NO-2NC

3NO

3NC

1NO

1NC

1NO-1NC

2NO

2NC

2NO-1NC

1NO-2NC

3NO

3NC

1NO

1NC

1NO-1NC

2NO

2NC

2NO-1NC

1NO-2NC

3NO

3NC

Contact

01 : 1NC

02 : 2NC

03 : 3NC

12 : 1NO -2NC

Weight

(Approx.)

68g

92g

116g

70g

94g

118g

76g

101g

125g

Button color

Blank: Red, Green, Black,

and White included

Y : Yellow S : Blue

Terminals

F : Finger-safe terminal (IP20)

C : Exposed screw terminal

➀ Button Color

➀ Blank - supplied with

red, green, black, and white

buttons

For yellow or blue buttons,

specify Y (yellow) or S

(blue).

Specify a button color code

in place of ➀ in the part

number

B : black

G : green

R : red

S : blue

W : white

Y : yellow

Emergency Stop Switches

EU2B - YBV3 11 F R

Operator (style / function)

BV3 : 40mm mushroom/push, pull or

twist release

Part Number Operator

EU2B-YB V301➃R

EU 2B-Y BV311➃ R

EU2B-YB V302➃R

ø40 Mushroom

EU2B-YB V312➃ R

EU2B-YB V303➃R

Specify a terminal st yle in place of ➃ in the part number: F (Finger-safe terminal), C (Exposed screw

terminal)

Contact arrangement

01 : 1NC

11 : 1NO-1NC

02 : 2NC

03 : 3NC

12 : 1NO -2NC

Contact

Arrangement

1NC 96g

1NO-1NC

2NC

1NO-2NC

3NC

Button color

R : Red

Terminals

F : Finger-safe terminal (IP20)

C : Exposed screw terminal

Weight

(Approx.)

120g

Button Color

R : Red

144g

Meters

EU2B - YM 5 3 A 10 F R

Function

M : Meter

Input current

1 : 1A 5 : 5A

Specication of overload scale

3: 3 times 2 : 2 times 5: 5 times N:Non

Type of meter

A : AC ammeter

Measuring range

Direct measuring 1 : 1A 5 : 5A

For current transformers: 10 : 10A 15 : 15A 20 : 20A 30:30A 50:50A

60 : 60A 75 : 75A 100:100A 150:150A

EU2B - YM 010 VD F-PER-R

Function

M : Meter

Input voltage or current

010 : 0-10V

001 : 0-1mA

420 : 4-20mA etc.

Terminals

F : Finger-safe terminal (IP20)

C : Exposed screw terminal

Input Part Number

EU2B-YM53A5➃

EU2B-YM53A10➃

EU2B-YM13A10➃

EU2B-YM53A15➃

EU2B-YM13A15➃

EU2B-YM13A20➃

AC

input

meter

EU2B-YM53A30➃

(ammeter)

EU2B-YM13A30➃

EU2B-YM53A50➃

EU2B-YM53A60➃

EU2B-YM53A75➃

EU2B-YM53A100➃

EU2B-YM53A150➃

EU2B-YM010VD➃-PER

EU2B-YM010VD➃-60HZ

EU2B-YM001MD➃-PER

DC

input

EU2B-YM001MD➃-60HZ

meter

EU2B-YM001MD➃-80HZ

EU2B-YM420MD➃-PER

EU2B-YM420MD➃-60HZ

Specify a terminal style in place of ➃ in the part number: F (Finger-safe terminal), C (Exposed

screw terminal)

Type of meter

VD : DC voltmeter

MD : DC ammeter

Capacity: 5A Expansion scale: x3

Capacity:10/5A Expansion scale: x3

Capacity:10/1A Expansion scale: x3

Capacity:15/5A Expansion scale: x3

Capacity:15/1A Expansion scale: x3

Capacity:20/1A Expansion scale: x3

Capacity:30/5A Expansion scale: x3

Capacity:30/1A Expansion scale: x3

Capacity:50/5A Expansion scale: x3

Capacity:60/5A Expansion scale: x3

Capacity:75/5A Expansion scale: x3

Capacity:100/5A Expansion scale: x3

Capacity:150/5A Expansion scale: x3

0-10V DC Input Scale: 0 to 100%

0-10V DC Input Scale: 0 to 60Hz

0-1mA DC Input Scale: 0 to 100%

0-1mA DC Input Scale: 0 to 60Hz

0-1mA DC Input Scale: 0 to 80Hz

4-20mA DC Input Scale: 0 to 100%

4-20mA DC Input Scale: 0 to 60Hz

Set pointer

blank : non -R : with set pointer

Terminals

F : Finger-safe terminal (IP20)

C : Exposed screw terminal

Set pointer

blank : non -R : with set pointer

Specication of scale

-PER : 0~100%

-60HZ : 0~60Hz

-80HZ : 0~80Hz

Description

Weight

(approx.)

270g

3

Page 4

Pilot Lights

RL RL

Part Number Type

EU 2B-Y L1126 ➃D➀

EU2B-YL1236➃ D➀

EU2B-YL1246➃D➀

Transformer

EU2B-YL138 6➃D➀

EU2B-YL148 6➃D➀

EU2B-YL166 ➃D➀

EU 2B-Y L111➃D➀

Full Voltage

EU2B-YL122➃D➀

Note: ➀ Illumination Color. Specify a contact terminal style in place of ➃ in the part number: F (Finger-safe

terminal), C (Exposed screw terminal)

Operating

Voltage

120V AC

230V AC

240V AC

380V AC

480V AC

6V AC/DC

12V AC/DC

24V AC/DC

Weight

(Approx.)

150g

108g

➀ Illumination

Color Code

R : red

G : green

A : amber

Y : yellow

PW : white

S : blue

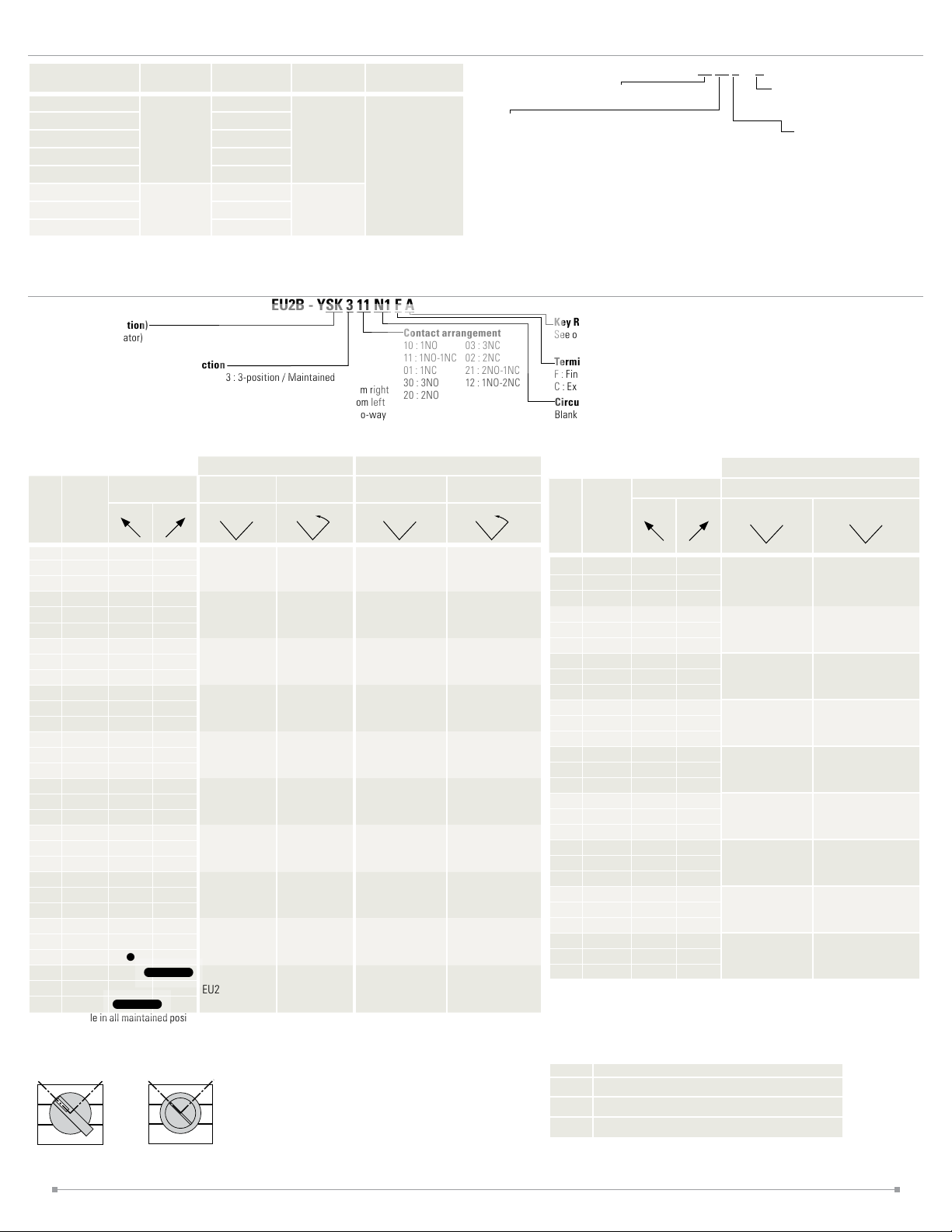

2 Position Selector Switches

EU2B - YSK 3 11 N1 F A

Operator (style / function)

S : Selector (Knob operator)

SK: Key selector (Key operator)

Number of Positions / Spring Return Action

2 : 2-position / Maintained

2R : 2-position / Maintained (Overlap)

2J : 2-position / Maintained (Special function)

21 : 2-position / Spring return from right

3 : 3-position / Maintained

31 : 3-position / Spring return from right

32 : 3-position / Spring return from left

33 : 3-position / Spring return two -way

Contact arrangement

10 : 1NO

11 : 1NO-1NC

01 : 1NC

30:3NO

20 : 2NO

Operating voltage

126 : AC 120V (Transformer t ype)

246 : AC 24 0V (Transformer type)

386 : AC 380V (Transformer type)

486 : AC 480V (Transformer type)

Key Removable Position

03 : 3NC

02 : 2NC

21 : 2NO -1NC

12 : 1NO -2NC

See option codes below

Terminals

F : Finger-safe terminal (IP20)

C : Exposed screw terminal

Circuit Number

Blank : No Designation

N* : See charts

EU2B - YL1 22 F D R

Operator (style / function)

L1 : Pilot Light / dome

66 : AC/DC 6V (Full voltage type)

11: AC/DC 12V (Full voltage type)

22 : AC/DC 24V (Full voltage ty pe)

Lens/LED Colors

R : Red G : Green A : Amber

Y : Yellow PW : White S : Blue

Terminals

F : Finger-safe terminal (IP20)

C : Exposed screw terminal

Con

-

Mount-

tact

NO 1

NC 3

NO 1

NO 3

NC 1

NC 3

NO 1

NC 3

NO 1

NO 2

NO 3

NC 1

NC 2

NC 3

NO 1

NO 2

NC 3

NO 1

NC 2

NC 3

Operator Position Maintained

ing

L

●

●

●

●

●

●

●

●

●

●

Selector Switches Key Selector Switches

R

●

R

L

EU2B-YS210 ➃ EU 2B-Y S2110➃

EU2B-YS201

●

➃ E U2B-YS2101➃

EU2B-YS220➃ EU2B-YS2120➃

●

EU2B-YS202➃ EU2B-YS2102➃

●

EU 2B-Y S211➃ EU2B -YS2111➃

●

●

EU2B-YS230➃ EU2B-YS2130 ➃

●

EU2B-YS203➃ EU2B-YS2103 ➃

●

●

EU2B-YS221➃ EU2B-YS2121➃

●

EU2B-YS212➃ EU2B-YS 2112➃

Spring Return

from Right

R

L

Maintained

L

EU2B-YSK210➃➂ EU2 B-YS K2110➃➂

EU2B-YSK2 01➃➂ EU 2B-YSK2101➃➂

EU2B-YSK2 20➃➂ EU 2B-YSK2120➃➂

EU2B-YSK2 02➃➂ EU 2B-YSK2102➃➂

EU 2B-Y SK2 11➃➂ E U2B -YSK 2111➃➂

EU2B-YSK230➃➂ EU2B-YSK2130➃➂

EU2B-YSK2 03➃➂ EU 2B-YSK2103➃➂

EU2B-YSK2 21➃➂ EU2B-YSK2121➃➂

EU2B-YSK212➃➂ EU2B -YSK 2112➃➂

R

Spring Return from

Right

L

NO 1

EU2B-YS2R11

N/A

➃

EU2B-YSK2R11➃➂

N/A

NC 2

Key is removable in all maintained positions. Specif y key removal position in place of ➂ in the par t number. See table.

Specify a terminal st yle in place of ➃ in the part number: F (Finger-safe terminal), C (Exposed screw terminal).

2-position, 2-position/inverse cam

Selector Switch Key Selector Switch

j

k

l

Contact

Block

Position

j

k

l

Contact

Block

Position

Operator Position Maintained Maintained

-

Mount-

R

Con

tact

ing

NO 1

R

L

●

EU2B-YS2J10➃

EU2B-YS2J01

NC 3

NO 1

●

●

EU2B-YS2J20➃

NO 3

NC 1

●

●

EU2B-YS2J02➃

NC 3

NO 1

●

●

EU 2B-Y S2J11➃

NC 3

NO 1

NO 2

NO 3

NC 1

NC 2

NC 3

NO 1

NO 2

NC 3

NO 1

NC 2

NC 3

●

●

●

●

●

●

●

●

●

●

●

●

●

EU2B-YS2J30➃

EU2B-YS2J03➃

EU2B-YS2J 21➃

EU2B-YS2J12➃

➂ Key Removable Option Codes (2-position)

Code Description

A Key removable in any position

B Key removable in left position

C Key removable in right position

Selector Switches Key Selector Switches

R

L

R

L

EU2B-YSK2 J10➃➂

EU2B-YSK2J01➃➂

➃

EU2B-YSK2 J20➃➂

EU2B-YSK2J02➃➂

EU 2B-Y SK2 J11➃➂

EU2B-YSK2J30➃➂

EU2B-YSK2J03➃➂

EU2B-YSK2 J21➃➂

EU2B-YSK2 J12➃➂

4

Page 5

3 Position Selector Switches

C

C

Operator Position Maintained

Mount

Con

tact

-

-

ing

C

L

R

L C R

Selector Switches Key Selector Switches

Spring Return from

Right

L C R L C R

Spring Return

from Left

Spring Return Two

Way

L C R

Maintained

L C R

Spring Return from

Right

L C R L C R

Spring Return from

Left

Spring Return Two

Way

L C R

NO 1

NO 3

NO 2

NO 3

NC 1

NC 3

NC 2

NC 3

NO 1

NC 3

NC 1

NO 3

NO 1

NC 2

NC 2

NO 3

●

● ●

●

●

●

●

●

●

●

●

●

EU2BYS320➃

EU2BYS320N1➃

EU2BYS302➃

EU2BYS302N1➃

EU2BYS 311➃

EU2BYS 311N1➃

EU2BYS 311N2➃

EU2BYS 311N3 ➃

EU2B-YS3120 ➃ EU2B-YS3220➃ EU2B-YS3320➃ EU2B-YSK320➃➂ EU2 B-YSK3120➃➂ EU2B-YSK3220➃➂

EU2B-YS3120N1➃

EU2B-YS302➃ EU2B-YS3202➃ EU2B-YS3302➃ EU2B -YSK3 02➃➂ EU 2B-YSK3 02➃➂ EU2B-YSK3202➃➂

EU2BYS3102N1➃➂

EU 2B-Y S311➃ EU 2B-Y S32 11➃ EU2B-YS3311➃ EU 2B-Y SK311➃➂ E U2B -YSK 311➃➂ E U2B -YSK 3211➃➂

EU 2B-Y S3111N1➃

EU 2B-Y S3111N 2➃

EU 2B-Y S3111N 3➀

EU2BYS3220N1➃

EU2BYS3202N1➃➂

EU2BYS 3211N1➃

EU2BYS 3211N 2➃

EU2BYS 3211N 3➀

EU2BYS3320N1➃

EU2BYS3302N1➃

EU2BYS 3311N1➃

EU2BYS 3311N 2➃

EU2BYS 3311N 3➀

EU2BYSK320N1➃➂

EU2BYSK302N1➃➂

EU2BYSK3 11N1➃➂

EU2BYSK3 11N2➃➂

EU2BYSK3 11N3➃➂

EU2BYSK 3120N1➃➂

EU2BYSK3102N1➃➂

EU2BYSK3 111N1➃➂

EU2BYSK3 111N2➃➂

EU2BYSK3 111N3➃➂

EU2BYSK3220N1➃➂

EU2BYSK3202N1➃➂

EU2BYSK3 211N1➃➂

EU2BYSK3 211N2 ➃➂

EU2BYSK3 211N3 ➃➂

EU2BYSK3320➃➂

EU2BYSK3320N1➃➂

EU2BYSK3302➃➂

EU2BYSK3302N1➃➂

EU2BYSK3 311➃➂

EU2BYSK3 311N1➃➂

EU2BYSK3 311N2 ➃➂

EU2BYSK3 311N3 ➃➂

NO 2

● ●

EU2BYS 311N4 ➃

EU 2B-Y S3111N 4➃

EU2BYS 3211N 4➃

EU2BYS 3311N 4➃

NC 3

NO 1

NO 2

NO 3

NC 1

NC 2

●

● ●

●

EU2BYS330➃

EU2B-YS3130➃ EU2B-YS3230➃ EU2B-YS3330➃ EU2B-YSK330➃➂ EU 2B-YSK3130➃➂ EU2B-YSK3230➃➂

●

EU2BYS303➃

EU2B-YS3103➃ EU2B-YS3203➃ EU2B-YS3303➃ E U2B-Y SK30 3➃➂ EU2B-YSK 3103➃➂ EU2B-YSK3203➃➂

NC 3

NO 1

NC 2

NO 3

NC 1

NO 2

●

●

● ●

●

EU2B-YS3

21N1➃

EU2B-YS3

12N1➃

EU2B-YS3121N1➃

EU 2B-Y S3112 N1➃

EU2BYS3221N1➃

EU2BYS3212N1➃

EU2BYS33 21N1➃

EU2BYS3312N1➃

NC 3

Specify a terminal style in place of ➃ in the part number: F (Finger-safe terminal), C (Exposed screw terminal).

3-position, 3-position/inverse cam

Selector Switch Key Selector Switch

L R

j

k

l

Contact

Block

Position

L R

j

k

l

Contact

Block

Position

EU2BYSK3 11N4➃➂

EU2BYSK321N1➃➂

EU2BYSK 312N1➃➂

EU2BYSK3 111N4➃➂

EU2BYSK312 1N1➃➂

EU2BYSK3 112N1➃➂

EU2BYSK3 211N4 ➃➂

EU2BYSK3221N1➃➂

EU2BYSK 3212N1➃➂

EU2BYSK3 311N4 ➃➂

EU2BYSK3330➃➂

EU2BYSK3303➃➂

EU2BYSK3321N1➃➂

EU2BYSK 3312N1➃➂

Key is removable in all maintained positions. Specify key removal position in

place of ➂ in the part number. See table.

➂ Key Removable Option Codes (3-Position)

Code Description

A Key removable in any position

B Key removable in left and center positions

C Key removable in center and right positions

D Key removable in center position

E Key removable in left and right positions

G Key removable in left position

H Key removable in right position)

5

Page 6

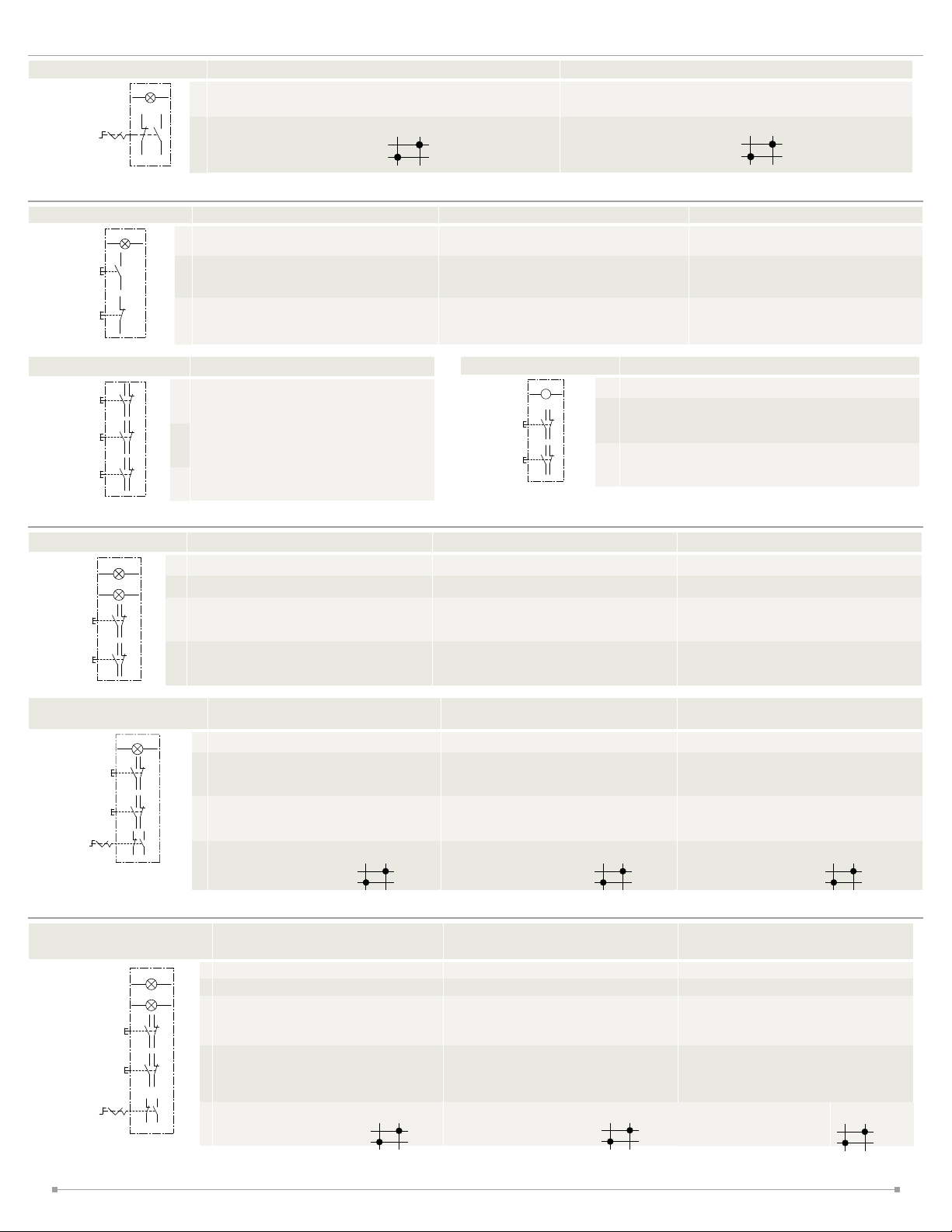

CONTROL BOXES

OFF ON

OFF ON

1 control unit 2 control units 3 control units 4 control units 5 control units

EC2BB21B011N2➀-U

1 column

6 control units 9 control units 12 control units 15 control units 18 control units

EC2BB33B063N2➀-U

3 columns

EC2BB21B021N2➀-U

EC2BB33B093N2➀ -U

EC2BB31B031N2➀-U

EC2BB53B12 3N3➀ -U

EC2BB51B 041N3 ➀-U

EC2BB53B153N3➀-U

STANDARD CONTROL STATIONS

1 Control Unit × 1 Column

1 pushbutton

3 1

j

4 2

EC2B-1102BN2N1-U EC2B-1102BN2N2-U EC2B-1102BN2N3-U EC2B-1102BN2N4-U

Flush momentary

1NO contact

➀

Nameplate ON

Button color: black, green, red, and white

1NO-1NC contact

Flush momentary

1NC contact

Nameplate OFF

Button color: black, green, red, and white

EC2BB51B051N3➀ -U

EC2BB63B18 3N3➀ -U

4 control units 6 control units 8 control units 10 control units

EC2BB32B042N2➀-U

2 columns

Thread Size

Code Description Code Description

M1 M16 blank no terminal block

M2 M20 C Exposed screw terminals

M3 M25 F Finger-safe terminals

M4 M32

M5 M40

N1 NPT1/2

N2 NPT3/4

N3 NPT1

N4 NPT1 1/4

Flush momentary

1NO-1NC contact

Nameplate ON

Button color: black, green, red, and white

EC2BB32B062N2➀-U

➀ Terminal Block Style

Other thread size options available. To specify different

thread sizes, use table at left to select a code to use in

place of N2 or N3 in the part number.

Specify terminal block style in place of

(standard versions do not cont ain a terminal block).

EC2BB52B082N3➀-U

Flush momentary

1NO-1NC contact

Nameplate OFF

Button color: black, green, red, and white

EC2BB52B102N3➀-U

➀ in part number

1 pilot light

X1 X2

1 selector switch

OFF

1 3

ON

2 4

EC 2B-1101B N211-U E C2B -1101BN2 12-U EC2B -1101BN2 3-U EC2B -1101BN213- U EC 2B-1101B N214 -U EC2 B-1101BN 26-U

j

120V AC

➀

Illumination color: red

EC2B-1106BN2N1-U

Knob selector

2-position maintained

j

➀

1NO-1NC contact

Name plate

OFF-ON

2 Control Units × 1 Column

2 ush pushbuttons

3

4

1

2

1 pilot light/1 pushbutton

X1 X2

3 1

4 2

EC2B-2102BN2N1-U

Flush momentary

j

1NO contact, Nameplate ON

➀

Button color (black, green, red, and white buttons)

k

Flush momentary

1NC contact, Nameplate OFF

➁

Button color (black, green, red, and white buttons)

j

k

240V AC

Illumination color: red

1 key selector switch

EC 2B-2110B N2N5-U EC 2B-2110B N2N6-U EC 2B-2110B N2N 3-U

120V AC

➀

Illumination color: red

Flush momentary

1NO-1NC contact

➁

Name plate STOP

Button color (black, green, red, and white buttons)

24V AC/DC

Illumination color: red

1 3

ON

OFF

j

2 4

EC2B-1106BN2N4-U

Key selector

2-position maintained

(removable at all

➀

positions)

1NO-1NC contact

Nameplate OFF-ON

120V AC

Illumination color: green

2 Mushroom Pushbuttons

3 1

4 2

3 1

4 2

240V AC

Illumination color: red

Flush momentary

1NO-1NC contact

Name plate STOP

Button color (black, green, red, and white buttons)

j

k

240V AC

Illumination color: green

1 e-stop switch

EC2B-2102BN2N4-U

Mushroom momentary

➀

1NO-1NC contact, Nameplate ON

Button color (black)

Mushroom momentary

1NO-1NC contact, Nameplate OFF

Button color (red)

24V AC/DC

Illumination color: red

Flush momentary

1NO-1NC contact

Name plate STOP

Button color (black, green, red, and white buttons)

24V AC/DC

Illumination color: green

EC2B-1102BN2N7-U

121

Emergency stop switch

2NC contact

Nameplate EMER-

➀

j

GENCY STOP

2

Button color (red)

Specify terminal st yle code in place of in part no. C (standard screw terminal), F (nger-safe screw terminal)

6

Page 7

2 Control Units × 1 Column

OFF ON

OFF ON

HAND AUTO

HAND AUTO

HAND AUTO

HAND AUT

O

HAND AUT

O

HAND AUTO

1 pilot light / 1 selector switch

X1 X2

j

1 3

ON

OFF

2 4

➀

k

➁

3 Control Units × 1 Column

1 pilot light / 2 pushbuttons

X1 X2

j

4

3

2

1

➀

k

➁

l

➂

EC2B-2117BN2N3-U EC2B-2117BN2N4-U

120V AC

Illumination color: red

Knob, 2-position,

1NO-1NC contact

Maintained, Name plate OFF-ON

240V AC

Illumination color: red

Knob, 2-position,

1NO-1NC contact

Maintained, Name plate OFF-ON

EC 2B- 3110B N2N 5-U EC 2B- 3110B N2N 6-U EC 2B- 3110B N2N 3-U

120V AC

Illumination color: red

Flush momentary

1NO contact, Nameplate ON

Button color (black, green, red, and white buttons)

Flush momentary

1NC contact, Nameplate OFF

Button color (black, green, red, and white buttons)

240V AC

Illumination color: red

Flush momentary

1NO contact, Nameplate ON

Button color (black, green, red, and white buttons)

Flush momentary

1NC contact, Nameplate OFF

Button color (black, green, red, and white buttons)

24V AC/DC

Illumination color: red

Flush momentary

1NO contact, Nameplate ON

Button color (black, green, red, and white buttons)

Flush momentary

1NC contact, Nameplate OFF

Button color (black, green, red, and white buttons)

3 pushbuttons

3 1

4 2

3 1

4 2

3 1

4 2

EC2B-3102BN2N1-U

➀

j

Flush momentary

1NO-1NC contact,

k

➁

Blank nameplate

Button color (black, green, red, and white buttons)

l

➂

4 Control Units × 1 Column

2 pilot lights / 2 pushbuttons

X1 X2

X1 X2

3 1

4 2

3 1

4 2

1 pilot light / 2 pushbuttons /

1selectorswitch

X1 X2

3 1

4 2

3 1

4 2

AUTO

HAND

31

EC 2B- 4110B N3N 5-U EC 2B- 4110B N3N 6-U EC 2B- 4110B N3N 3-U

➀

120V AC, Illumination color: red 240V AC, Illumination color: red 24V AC/DC, Illumination color: red

j

➁

120V AC, Illumination color: green 240V AC, Illumination color: green 24V AC/DC, Illumination color: green

k

Flush momentary

➂

1NO-1NC contact, Nameplate ON

l

Button color (black, green, red, and white buttons)

Flush momentary

m

➃

1NO-1NC contact, Nameplate OFF

Button color (black, green, red, and white buttons)

➀

j

k

➁

l

➂

m

➃

1 meter / 2 pushbuttons

j

3A1

k

4 2

3 1

l

4 2

Specify the meter's capacity and scale in place of in the part number

Flush momentary

1NO-1NC contact, Nameplate ON

Button color (black, green, red, and white buttons)

Flush momentary

1NO-1NC contact, Nameplate OFF

Button color (black, green, red, and white buttons)

EC2B-3152BN2N1-U

➀

Specify input, capacity, and scale

Flush momentary

➁

1NO-1NC contact, Nameplate ON

Button color (black, green, red, and white buttons)

Flush momentary

➂

1NO-1NC contact, Nameplate OFF

Button color (black, green, red, and white buttons)

Flush momentary

1NO-1NC contact, Nameplate ON

Button color (black, green, red, and white buttons)

Flush momentary

1NO-1NC contact, Nameplate OFF

Button color (black, green, red, and white buttons)

EC 2B- 4113B N3N 5-U EC 2B- 4113B N3N 6-U EC 2B- 4113B N3N 3-U

120V AC, Illumination color: red 240V AC, Illumination color: red 24V AC/DC, Illumination color: red

Flush momentary

1NO-1NC contact, Nameplate ON

Button color (black, green, red, and white buttons)

Flush momentary

1NO-1NC contact, Nameplate OFF

Button color (black, green, red, and white buttons)

Knob, 2-position, maintained

1NO-1NC contact

Nameplate HAND-AUTO

Flush momentary

1NO-1NC contact, Nameplate ON

Button color (black, green, red, and white buttons)

Flush momentary

1NO-1NC contact, Nameplate OFF

Button color (black, green, red, and white buttons)

Knob, 2-position, maintained

1NO-1NC contact

Nameplate HAND-AUTO

Flush momentary

1NO-1NC contact, Nameplate ON

Button color (black, green, red, and white buttons)

Flush momentary

1NO-1NC contact, Nameplate OFF

Button color (black, green, red, and white buttons)

Knob, 2-position, maintained

1NO-1NC contact

Nameplate HAND-AUTO

5 Control Units × 1 Column

2 pilot lights / 2 pushbuttons /

1selectorswitch

X1 X2

X1 X2

3 1

4 2

3 1

4 2

2 4

ON

OFF

1 3

Specify terminal st yle code in place of in part no. C (standard screw terminal), F (nger-safe screw terminal)

EC 2B- 5113BN3 N5-U EC2 B-5113BN3N 6-U EC2B -5113BN3N3-U

➀

120V AC, Illumination color: red 240V AC, Illumination color: red 24V AC/DC, Illumination color: red

j

➁

120V AC, Illumination color: green 240V AC, Illumination color: green 24V AC/DC, Illumination color: green

k

Flush momentary

➂

1NO-1NC contact, Nameplate ON

l

Button color (black, green, red, and white buttons)

Flush momentary

m

➃

1NO-1NC contact, Nameplate OFF

Button color (black, green, red, and white buttons)

n

Knob, 2-position, Maintained,

➄

1NO-1NC contact,

Name plate HAND-AUTO

Flush momentary

1NO-1NC contact, Nameplate ON

Button color (black, green, red, and white buttons)

Flush momentary

1NO-1NC contact, Nameplate OFF

Button color (black, green, red, and white buttons)

Knob, 2-position, Maintained,

1NO-1NC contact

Name plate HAND-AUTO

7

Flush momentary

1NO-1NC contact, Nameplate ON

Button color (black, green, red, and white buttons)

Flush momentary

1NO-1NC contact, Nameplate OFF

Button color black, green, red, and white buttons)

Knob, 2-position, Maintained,

1NO-1NC contact

Name plate HAND-AUTO

Page 8

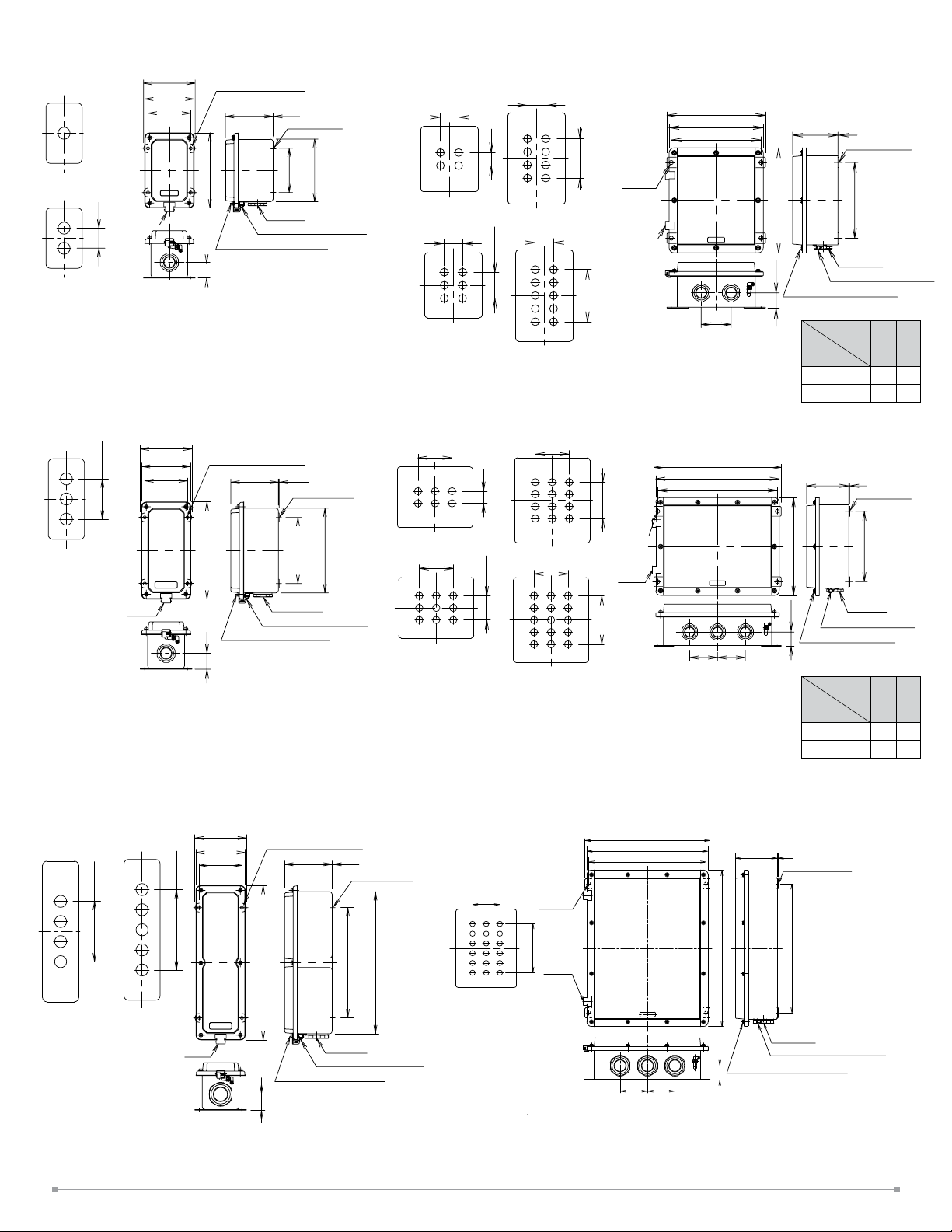

DIMENSIONS

Flush

ø40

39.0

67.7

All dimensions in mm

Control Units

Pushbuttons

Shown with finger-safe contacts

32.2

ø 40.0

13.3

Emergency Stop Switches

Shown with finger-safe contacts

32.2

47.4

ø 40.0

13.3

1.0 to 4.5 (panel thickness)

Mushroom

33.0

ø40

48.0

1.0 to 4.5 (panel thickness)

35.0 67.7

67.7

24.5

Extended

ø 24.0

Pilot Lights

Shown with finger-safe contacts

61.4

19.3

Meters

Shown with finger-safe contacts

38.4

32.5

32.0

ø 40.0

1.0 to 4.5 (panel thickness)

20.3

ø 40.0

67.7

62.0

67.720.3

8.0

1.0 to 4.5 (Panel thickness)

ø 28.0

Selector Switches

Shown with finger-safe contacts

32.2

47.4

Key Selector Switch

Shown with finger-safe contacts

32.2

47.4

ø 40.0

37.3 67.7

ø 40.0

27.3

1.0 to 4.5 (panel thickness)

1.0 to 4.5 (panel thickness)

67.7

38.4

ø 64.0

33.5 62.1

38.4

Mounting Hole Dimensions

+0.2

4.8

ø

30.5

+0.5

0

0

50 min (*note)

0

+0.5

33

70 min

Panel thickness: 1.0 to 4.5 mm.

*Note: The meter can be mounted on the top mounting holes of a standard 50mm mounting cen-

ters. The meter can be mounted on any mounting hole with a 70mm or larger mounting center.

8

Page 9

1, 2 control units x 1 column

weight: 1.2kg/1.4kg

Hinge

115

110

95

(mounting

hole)

1 control unit

2 control units

50

3 control units x 1 column

weight: 1.8kg

3 control units

2×50P

115

110

95

(mounting

hole)

4-ø7 (mounting hole)

10 6

170

Reducer

M4 grounding terminal

M5 lid mounting screw

36

4-ø7 (mounting hole)

106 1.5

220

1.5

Mounting tab

hole )

142

100

(mountin g

Mounting tab

hole)

150

(mounting

192

2, 3, 4, 5 control units x 2 columns

weight: 3.8/4.2/4.6/5.0 kg

4 control units

2 control units

70

3 control units

70

50

5 control units

2×50P

70

70

2, 3, 4, 5 control units x 3 columns

weight: 4.8/5.2/6.5/7.1 kg

50

2×50P

4 control units

140

5 control units

140

2 control units

140

3 control units

140

3×50P

4×50P

3×50P

(mounting hole)

4-ø10

(mounting

hole)

Hinge

10

4-ø

Hinge

230

220

210

2106

Mounting tab

A

R

(mounting

hole)

Reducer

36.5

70

M4 grounding terminal

M5 lid mounting screw

Dimensions

No. of

Control Units

A R

2 or 3 250 180

4 or 5 350 280

320

310

300

106

2

Mounting tab

A

R

(mounting

hole)

Hinge

4, 5 control units x 1 column

weight: 2.4kg

4 control units

5 control units

3x50P

4x40P

Hinge

36

115

110

95

(mounting

hole)

Reducer

M4 grounding terminal

M5 lid mounting screw

4-ø7 (mounting hole)

350

M5 lid mounting screw

36

1.5106

Mounting tab

322

250

hole)

(mounting

Reducer

M4 grounding terminal

6 control units x 3 columns

weight: 8.1kg

Control Unit

Mounting Holes

140

4-ø10

(mounting

5×50P

Hinge

hole)

4×50P

36.5

7070

Reducer

M4 grounding terminal

M5 lid mounting screw

Dimensions

No. of

Control Units

A R

2 or 3 250 180

4 or 5 350 280

320

310

300

70

70

106

2

Mounting tab

400

Reducer

36.5

M4 grounding terminal

M5 lid mounting screw

hole)

330

(mounting

9

Page 10

Terminal Blocks

Marking Plate

40

(6.5)

Insert

➀

Terminal blocks are not supplied with the standard control boxes (without wiring). When wiring

inside the control box is required, specify the wiring circuit. The terminal block type used on the

control boxes with wiring depends on the terminal style of the control unit.

C terminal style

exposed screw terminal

ET2A-8PE

polyamide

IECEx TUR 15.0043U,

TÜV 15 ATE X 7799U

34

22

101

123

F terminal style

nger-safe screw terminal

IP20 clamp terminal: 264-238 (WAGO)

polyamide

IECEx PTB 04.0003U, PTB 98 ATEX

3129 U

The number of terminal blocks, poles, and the installation direction that can be installed on the

control box are as follows:

1-column 1, 2 units

(1 terminal block

1-column 3 units

(1 terminal block

/8 poles)

/ 8 poles)

32

22

1-column 4, 5 units

(1 terminal block

/ 8 poles)

84

96

2-column 2, 3 units

(2 terminal blocks

/16 poles)

Fittings and Reducers

Reducers installed at the bottom of the control box are as follows: 1 column: 1 reducer, 2 columns: 2 reducers, 3 columns: 3 reducers. Material is nickel-plated brass. Use cable lead-in ttings

that are commercially available. See the following table for optional reducers

Control Box St yle Par t No. Thread Size Symbol UL c-UL

EC9E-H3M16E-UL M16 M1

1 column

(1 to 3 control units)

2, 3 columns

(2, 3 control units)

1, 2, 3 columns

(4, 5 control units)

3 columns

(6 control units)

: Standard reducer

EC9E-H3M20E-UL M20 M2

EC9E-H3M25E

EC9E-H3M32E

EC9E-H3NPT1E

EC9E-H3NPT2E

EC9E-H3NPT3E

EC9E-H4M25E

EC9E-H4M32E

EC9E-H4M40E

EC9E-H4NPT2E

EC9E-H4NPT3E

EC9E-H4NPT4E

: non-standard reducer

-UL M25 M3

-UL M32 M4

-UL NP T 1/2 N1

-UL NPT 3/4 N2

-UL NPT 1 N3

-UL M25 M3

-UL M32 M4

-UL M40 M5

-UL NPT 3/4 N2

-UL NPT 1 N3

-UL NPT 1 1/4 N4

The reducers in the table above are for replacement use only. All EC2B boxes are supplied with

a reducer that has been secured to the housing per UL regulations. If it is necessary to replace a

reducer, the user should follow appropriate UL standards for securing to EC2B housing.

.

2-column 4,5 units

(4 terminal blocks/ 32

poles)

3-column 2, 3 units

(3 terminal blocks/ 24

poles)

3-column 4, 5, 6 units

(6 terminal blocks/ 8

poles)

ACCESSORIES

All dimensions in mm

Nameplates

Used for pilot light, pushbutton, selector switch, and key selector switch.

Appearance Part Number Dimensions

(35)

EU9Z-NM

ø40

Nameplate Inserts

Appearance Legend Part Number

Blank EU9Z-NP0

ON EU9Z-NP1

4.5

OFF EU9Z-NP2

START EU9Z-NP3

28.5

STOP EU9Z-NP4

OFF-ON EU9Z-NP31

HAND-AUTO EU9Z-NP35

1.5

HAND-OFF-AUTO EU9Z-NP53

Material: Aluminum

Inst alling the Insert to the Nameplate Removing the Inser t from the Nameplate

➁

Flat screwdriver

Insert

Nameplate

To remove the Insert, insert a at screwdriver between the Insert and Nameplate.

10

Page 11

Rubber Boots

ø58

ø40.5

32.1

Base

(panel thickness)

23.2

Appearance Description/Usage Part Number

For Flush Pushbuttons

Not for use with name plate EU9Z-DB1

Emergency Stop Switch Padlock Cover

Used with EU2B-YBV emergency stop switch to maintain the switch in the latched status.

Appearance Part Number Dimensions

For Flush Pushbuttons

For use with name plate EU9Z-DB1N

For Extended Pushbuttons

Not for use with name plate EU9Z-DB2

For Extended Pushbuttons

For use with name plate EU9Z-DB2N

Emergency Stop Switch Nameplate Stickers

Appearance Legend Part Number Dimensions

Blank EU9Z-NVS0

ø58

ø40.5

EU9Z-PCE

50

55.4

Coating: yellow Material: Stainless Steel

Mounting Hole Plug

Used to plug unused mounting holes (ø30.5) on the mounting panel.

Appearance Part Number Dimensions / Usage

EU9Z-BP

13.3

ø40

1.0 to 10.5

Buttons

Appearance Style Part Number Button Color Code

Flush

HW1A-B1➀

46

8

32.2

Emergency

Stop

Material: yellow synthetic paper Legend: black

EU9Z-NVS27

Padlock Cover

EU2B-YB2 extended pushbutton: to maintain latched status

EU2B-YB1 flush pushbutton/EU2B-YSK key selector switch: to prevent operation

Appearance

Note: mounted to outside of enclosure with screws, not provided by IDEC

Material: Stainless Steel

Part

Number

EU9Z-PC

Dimensions

8

44

Specify a color code in place of ➀

in the Ordering Number.

ø58

ø40.5

Material: Polyacetal

Extended

ø40 Mushroom

HW1A-B2➀

HW1A-B4➀

R : red

G : green

B : black

Y : yellow

W : white

S : blue

Lenses

Appearance Lens Color Part Number

Red EU9Z-LR

Green EU9Z-LG

Amber EU9Z-LA

46

24.5

Material: AS resin (gasket supplied)

Yellow EU9Z-LY

White EU9Z-LW

Blue EU9Z-LS

11

Page 12

LED Lamps

Control Box Shade

Operating

Voltage

6V AC/

DC±10%

12V AC/

DC±10%

24V AC/

DC±10%

Current Draw

AC DC

7mA

(A, R, W)

8mA

5.5mA

(G, PW, S)

11mA 10mA

11mA 10mA

Part

Number

LSTD-6➀

LSTD-1➀

LSTD-2➀

Illumination Color Code Base

Specify a color code in place

of ➀ in the part number

R : red

G : green

A : amber

PW : white

S : blue

Use a white (PW) LED with

yellow (Y) lens.

BA9S/13

OPERATING INSTRUCTIONS

Installation Area

Do not install the EC2B control box in an environment where more than IP65 protection degree

(more than Type 4X in North America) is required.

Use the EC2B control box under ambient temperature of –20 to +50°C. If the control box is

exposed to direct sunlight and the surface temperature may rise above 50°C, provide a shade to

keep the surface temperature below 50°C.

Installation

Use four M6 bolts for 1-column, four M8 bolts for 2- and 3-column, or other methods with

equivalent strength to install the control box. Mounting tab thickness is 1.5mm for 1 column and

2mm for 2, 3, and 4 columns.

• If bolts become may loose due to vibration, use spring washers.

• If bolt corrosion is anticipated, use anti-corrosion bolts or other countermeasures.

Notes on Emergency Stop Switches

When using the emergency stop switches on safety-related parts of the control system, observe

safety standards and regulations of the relevant country or region. Also be sure to perform a risk

assessment before operation.

Opening/Closing the Lid

Use a Philips screwdriver to loosen lid mounting screws. While holding the unhinged side, open

the lid slowly without exerting excessive force on the hinge.

Before closing the lid, make sure of the following:

• No foreign substances are on the packing or joint surfaces.

• No displacement of the waterproof packing.

• Wires are not caught between the joint surfaces.

• Next, close the lid slowly and tighten the screws to a proper torque of 1.6 to 2.4 N·m.

Limitation of the Operating Current

Major heat sources comes from the wiring which is connected to the control box. Therefore,

not only the operating current but wiring conditions (size, no. of wires, no. of wire bundles) may

cause temperature rise. When wiring, observe the following conditions.

Stranded wire: 1.5 to 2.5 mm2 (UL-c-UL certified) / Solid wire: ø1.2 to ø1.6 mm (16 to 14 AWG)

• Maximum no. of wires per bundle: 16

• Maximum operating current: 10A

When using the control box under an operating environment of 40°C minimum, use a heat

resistant cable of 70°C minimum.

Shape Part No.

D

H

Material: stainless steel

Thickness: 1mm

Photo: Part No. EC9Z-F2A52

Protects control units from direct sunlight and rain. The sur face of the control box shade is uncoated.

Can be installed by tightening to the mounting tabs on the control box.

W

EC9Z-F2A21M

EC9Z-F2A31M EC2B-31*B 230 160 160

EC9Z-F2A51

EC9Z-F2A32

EC9Z-F2A52

EC9Z-F2A33

EC9Z-F2A53

EC9Z-F2A63 EC2B-63*B 410 510 160

Applicable

Control Box

EC 2B-11*B

EC2B -21*B

EC2B -41*B

EC2B -51*B

EC2B-22*B

EC2B-32*B

EC2B-42*B

EC2B-52*B

EC2B-23*B

EC2B-33*B

EC2B-43*B

EC2B-53*B

Determine the operating current so that the total heat value of 1 wire bundle is below 300 [A

Also, when calculating the heat value, take the current fluctuation (10%) into consider-

wires].

ation.

[calculation example: EC2B-41**B (8 circuit)]

➀ Apply 10A to 1 circuit, 1A to the remaining 7 circuits:

Dimensions (mm)

H W D

180 160 160

360 160 160

260 420 160

360 420 160

260 510 160

360 510 160

2

×

{(10A × 1.1)2 × 2 wires} + {(1A ×1.1)2 × 14 wires} ≈ 259 (can be used because < 300)

➁ Apply 10A to 1 circuit, 2A to the remaining 7 circuits:

{(10A × 1.1)2 × 2 wires} + {(2A × 1.1)2× 14 wires} ≈ 310 (cannot be used because > 300)

See the table below for the allowable operating current when applying current evenly to each

control box.

Allowable Operating Current

Control

Box

Part No.

EC 2B-11 3 16 (16×1) 8 (8×1) 7A

EC2B-21 6 16 (16×1) 8 (8×1) 5A

EC2B-31 9 16 (16×1) 8 (8×1) 4A

EC2B-41 12 16 (16×1) 16 (16×1) 3A

EC2B-51 15 16 (16×1) 16 (16×1) 3A

EC2B-22 12 32 (16×2) 16 (8×2) 5A

EC2B-32 18 32 (16 ×2) 16 (8×2) 4A

EC2B-42 24 32 (16×2) 32 (16×2) 3A

EC2B-52 30 32 (16×2) 32 (16× 2) 3A

EC2B-23 18 48 (16× 3) 24 (8×3) 5A

EC2B-33 27 48 (16×3) 24 (8×3) 4A

EC2B-43 36 48 (16× 3) 48 (16×3) 3A

EC2B-53 45 48 (16×3) 48 (16× 3) 3A

EC2B-63 54 48 (16x3) 4 8 (16x3) 3A

*1: Make sure that the number of wires per bundle is a maximum of 16 by reducing the wiring or by jumper

wiring. The maximum number of wires per bundle may need to be further reduced depending on the

wire size, lead-in tting, or conduit size.

*2: The allowable current value (reference) when applying current evenly to all circuits of the maximum

number of circuits.

Max.

No. of

Circuits

Max No. of Wires per Bundle (*1)

[wires] ([wires]×[bundle])

Without terminalblocks

With terminal

blocks

Allowable Operating

Current

(reference) (*2)

12

Page 13

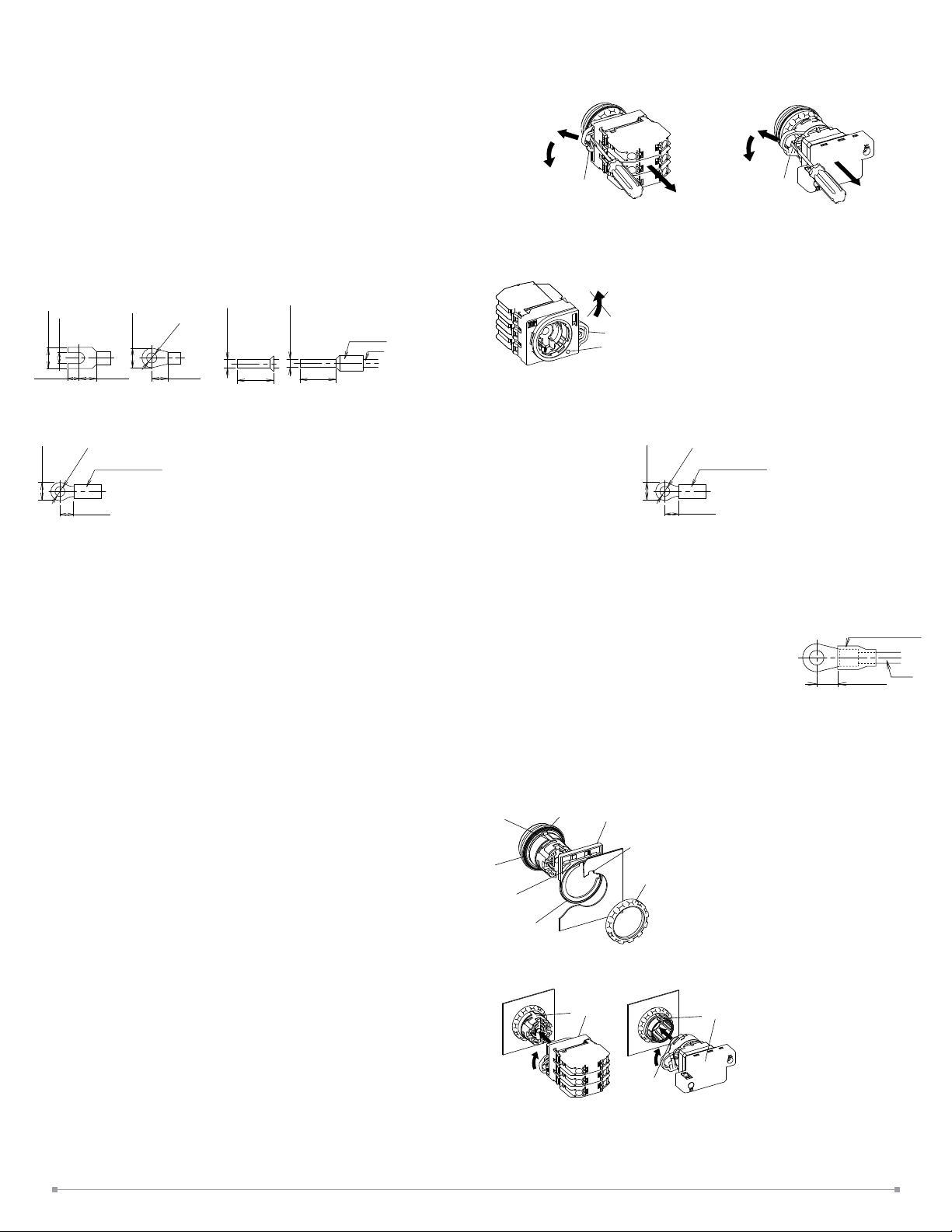

Wiring

Insulation Sheath

All dimensions in mm.

Wiring Construction

Observe the laws and regulations in each country concerning wiring construction.Use cable

wiring or metal conduit wiring for installation in hazardous locations. If foreign objects or water

may enter the box, install a sealing fitting near the cable entry of the box and seal the control box

using a compound. Standard type control boxes do not contain a terminal block. Wire the control

units directly.

Applicable Wires

Stranded wire: 1.25 to 2.5 mm2, solid wire: ø1.2 to ø1.6 mm (AWG16 to 14). Do not connect more

than 2 wires to the same terminal.

Applicable crimping terminal

Ring and spade terminals cannot be used for EU2B control units with IP20 finger-safe terminals.

Ring and spade terminals cannot be used for IP20 clamp type terminal blocks. When connecting

two ferrules to an EU2B control unit, use ferrules without insulating sheath.

(Spade terminal) (Ring terminal) (Ferrule)

6.9 max.

3.6 min

3.4 max. 5.5 min.

6.9 max.

ø3.6min.

5.5 min.

For screw terminal ET2A-8PE For IP20 clamp terminal

(WAGO: 264-238)

(Ring terminal)

Without

insulating

sheath

∗£1.8 max.

8.0 max.

With

insulating

sheath

∗£1.8 max.

∗ Dimensions after crimping

8.0 max.

Insulation

sheath

Wire

Removing and Installing the Contact Unit / Lamp Unit

To remove the contact unit or the lamp unit from the operator, pull the protruding yellow part of

the locking lever outwards as shown in the figure below using a screwdriver, and turn it to the

left. The contact unit or lamp unit can be removed.

➁

(Turn)

locking lever

(Lift)

➀

TOP

➂

(Pull)

EU2B-YB/ YBV

EU2B-YS/ YSK

(Turn)

➁

➀

(Lift)

locking lever

EU2B-YL

➂

(Pull)

When the contact unit is removed from the emergency stop switch operator, the NO contact

closes and the NC contact opens.

Do not turn the locking lever when the contact unit is removed from the operator (the red indicator protruding out, see the figure below) or the switch can be damaged.

locking lever

indicator (red)

Panel mounting for the operator, lens unit and meter

Remove the locking ring from the operator and check that the rubber gasket is in place. Insert the

operator from the panel front into the panel hole. Place the projection on the operator with TOP

(Ring terminal)

Insulation sheath

ø4.2 min.

8.5 max.

5 to 6.6

Recommended crimping terminal (WAGO) Ferrule with insulating sheath: 216-204

Ferrule without insulating sheath: 216-104 Crimping plier: 206-204

Recommended Tightening Torque

EU2B control units (M3.5) and ET2A-8PE terminal block (M4): 1.0 to 1.3 N·m

Warning

Incorrect wiring may cause fire hazard. Observe the following conditions.

Be sure to install an insulating sheath on the crimping terminal or the crimping terminal with

insulation.

When connecting solid wires or stranded wires directly, strip the insulation as mentioned below,

and insert the wire all the way in.

EU2B Control units: 8.6 mm maximum

IP20 crimping terminal: 8 to 9 mm

When using stranded wires, make sure that there are no wire whiskers.

Make sure that the spade crimping terminals and ferrules are inserted all the way in.

Use insulated ring terminals for the ET2A-8PE terminal block. Use only applicable crimping

terminals and do not directly connect stranded wires or solid wires.

Insulation sheath

ø4.2 min.

8.5 max.

5 to 6.6

marking upward and the recess on the mounting panel in the same direction. Meters have no

projection.

Tighten the locking ring using ring wrench XN9Z-T1 to a torque of 2.5 Nm. When using a nameplate or padlocking cover, install it between the operator and panel. Make sure that the groove

of the namplate or padlocking cover and the projection on the TOP marking of the operator are in

the same direction.

Note: The locking ring for emergency stop switches and meter

is metallic. The meter can’t mount the nameplate or podlocking

cover.

Installing the contact unit and lamp unit

5.5 to 6.0

Wire

To install the contact unit, place the TOP marking on the operator

and the TOP marking on the contact block adapter in the same

direction, and then attach the contact unit to the operator. Then turn the locking lever to the right.

Follow the same procedure when installing the lamp unit.

When installing the lamp unit, check that the inner lens is not loose.

The contact block adapters for emergency stop switches cannot be used for pushbuttons, selec-

tor, or key selector switches.

TOP marking

Rubber

gasket

Recess on the

Nameplate

Nameplate

gasket

Projection

Nameplate or

Padlocking cover

Recess on the panel

Locking ring

TOP marking

EU2B-YL

TOP marking

➀

➁

TOP

inner lens

EU2B-YB

EU2B-YS

➀

➁

13

Page 14

Removing the Contact Block

To remove the contact block, insert a flat screwdriver under the latch of the contact block adaptor

and disengage the latch as shown in the figure below.

Installing EU9Z-PC Padlock Cover

(Flush/extended pushbtton/key selector switch)

EU9Z-PC can be installed in the following two ways.

Remove the cover in the reverse step of installing the cover. Do not install or remove the cover

forcefully, or it will cause failure.

[Installation A]

Flat Screwdriver

Installing the Contact block

When installing the contact block after maintenance or wiring, make sure that the contact

configuration is correct. Installing the contact block in the incorrect position or incomplete installation may cause malfunction of the switch.

Remove the contact block from the operator before installing the contact block to the contact

block adaptor. Also make sure that the contact block is correctly installed to the contact block

adaptor before attaching the operator. Do not install the contact block adaptor with the operator

attached. Otherwise, malfunction may result.

Protective Grounding

Protective grounding must be performed according to the installation environment and rating

requirements. Observe laws and regulations set by each country.

• Connect the M4 grounding terminal of the EC2B control box to a proper ground (grounding

resistance 10Ω maximum). When operating the EC2B control box by connecting to circuits

of 300V or below, the grounding resistance must be 100Ω maximum.

• When using cables, connect one of the cable cores to the grounding terminal in the

enclosure.

• If the grounding terminal in the enclosure cannot be used, use the M4 grounding terminal

on the outside of the enclosure.

Recommended tightening torque:

M4: 1.0 to 1.3 Nm

M6: 3.9 to 5.4 Nm

• For grounding, use appropriate wires (size, material, insulation) that can tolerate the ex-

pected maximum grounding current. Be sure to protect the grounding wire with protection,

such as metal conduit, from external damage.

Accessories

Padlock Cover

The following padlocks and hasps can be used.

(Padlock Size) a b c

Flush/extended pushbutton/key selector

switch

Emergency Stop Switch

ø3.5 to

7.0 mm

ø5.5 to

7.0 mm

15 mm min. 70 mm max.

— —

Recommended Hasp

Manufacturer Part No.

Panduit PSL-1, PSL-1A, PSL-1.5, PSL-1.5A, PSL-HD1

Master Lock 420, 421

Padlock and hasp are available in various shapes and sizes. Make sure that they do not interfere

with the control units. Note: Not supplied by IDEC.

Keep the total weight of padlock and hasp under 1500g max, otherwise the switch may malfunction or result in failure. No vibration should be applied when padlock or hasp are installed. When

padlock or hasp are disfigured, stop usage immediately.

Ensure that no shock or electric sparks are generated.

When using the plate lock padlock cover with the extended pushbutton, the switch contact may

turn on/off when the cover is being installed. Ensure to provide functional safety measure to

prevent unexpected startup.

When using the padlock cover on the safety-related part of the control system, observe safety

standards and regulations of the relevant country or region. Also be sure to perform risk assessment before operation.

Cover

[Installation B]

This method is effective when the neighboring control unit interferes when installing in method

A.

Cover

Installing EU9Z-DB Rubber Boots

To install the rubber boot on flush and extended pushbuttons, place the rubber boot on the cap

and push the rubber boot holder straight. The notches around the rubber boot must show evenly.

Rubber boot holder

Rubber boot

Cap

Push the rubber boot holder further around on the two notches on the holder so that the holder

fits the button completely

Make sure that the rubber boot and rubber boot holder are installed straight.

On Nameplate Types, the EU2B and the rubber boot holder must be aligned so that when in-

stalled, the anti-rotation projection on the EU2B comes to the center of the groove on the holder.

Make sure that the rubber boot is installed completely, otherwise water droplets might enter the

rubber boot, but no water will enter the control box.

Align

To remove the rubber boot from the flush and extended pushbuttons, gently insert the slotted screwdriver (0.5t x 4w or below)

inside a notch on the rubber boot holder and tilt to the direction

shown by the arrow ➀. To prevent damage, do not apply excessive

force to the EU2B when removing the rubber boot.

Notches

Notches for

screwdriver

Push-in position

14

Page 15

Maintenance and Inspection

EU2B switches should be installed in an appropriate control box.

Maintenance and Inspection Method

Perform daily or periodical maintenance and inspection for items such as damage and temperature rise of the EU2B switches listed in the Maintenance and Inspection table below.

Observe laws and regulations set by each country. Do not open the lid when inspecting the EC2B

while it is energized. Never disassemble the control box. Do not use tools that cause sparks during maintenance and inspection. When using measuring devices, use explosion-protected types.

When the EC2B needs to be disassembled or assembled for maintenance or repair, contact IDEC.

Maintenance and Inspection

Inspection Items Inspection Method Inspections Measures

Enclosure base Visual

Tightening bolt,

screws

Packings Visual

Connecting parts Visual, tactile

Temperature rise Thermometer, tactile

Visual, tactile

No rusting

No damages

No loosening

No rusting

No cracks

No apparent deformation

No loosening of screws

No dirt on insulation

materials

Surface temperature

80ºC max.

Cleaning

Rust-resistant treatment

Tightening

Cleaning

Replacement

Tightening

Cleaning

Investigate the cause

Disposal

Observe laws and regulations set by each country concerning refuse disposal.

Safety Precautions

EU2B Control Units

Use EU2B switches that are applicable for use in hazardous areas (potentially explosive atmosphere where explosive gas or vapor may exist), otherwise explosion or fire hazard may result.

• EU2B switches can be installed only in zones 1 and 2. Do not use in zone 0.

• Turn power off to the EU2B switches before installation, removal, wiring, or maintenance,

otherwise explosion, fire hazard, or electric shock may result.

• Do not disassemble, repair, or modify, otherwise damage or accident may result.

• Do not use damaged EU2B switches, otherwise damage or accident may result.

• When connecting external devices, make sure that each cable is connected to the correct

terminal, otherwise electric shock, fire hazard, or explosion may result.

• Use wires of a proper size to meet voltage and current requirements. Incorrect wiring may

cause abnormal temperature rise and lead to fire hazard and explosion.

• Connect the grounding terminal to a proper ground, otherwise electric shock, fire hazard,

or explosion may result.

• Operate the EU2B switches at the rated current and voltage specified in this catalog,

otherwise short-circuiting, fire hazard, or explosion may result.

• Stop operation immediately if abnormal operation occurs. Otherwise, a secondary ac-

cident may occur.

• Use explosion-proof electrical equipment that are applicable for use in hazardous areas

(potentially explosive atmosphere where explosive gas or vapor may exist), otherwise

explosion or fire hazard may result.

EC2B Control Boxes

• EC2B control boxes can be installed only in zones 1 and 2. Do not use in zone 0. In North

America, the EC2B can be installed in Division 2 areas, but cannot be installed in Division

1 areas.

• Turn power off to the EC2B control box before installation, removal, wiring, or maintenance, otherwise explosion, fire hazard, or electric shock may result.

• Special skills and knowledge of explosion protection, electric system installation, and relevant laws/regulations are required to transport, install, wire, operate, repair, and inspect

the EC2B control box. People without such expertise must not use the EC2B control box,

otherwise damage or accident may result.

• Do not modify the EC2B, otherwise damage or accident may result.

• Do not use a damaged EC2B control box, otherwise damage or accident may result.

• When connecting external devices, make sure that each cable is connected to the correct

terminal, otherwise electric shock, fire hazard, or explosion may result.

• Use wires of a proper size to meet voltage and current requirements. Incorrect wiring may

cause abnormal temperature rise and lead to fire hazard and explosion.

• Connect the grounding terminal to a proper ground, otherwise electric shock, fire hazard,

or explosion may result.

• Do not sit on or hang from the EC2B control box, otherwise damage, personal injury, or

accident may result.

• Do not open the lid of the EC2B control box when it is energized, otherwise electric shock,

fire hazard, or explosion may result.

• Operate the EC2B control box at the rated current and voltage specified in this catalog,

otherwise short-circuiting, fire hazard, or explosion may result.

• When measuring the insulation resistance of the EC2B control box, make sure that

potentially explosive atmosphere of explosive gas or vapor does not exist in the vicinity,

otherwise explosion may result. Also, do not touch the terminals without paying attention,

otherwise electric shock will result.

• Do not place any obstacles in front of the nameplate.

• Do not remove the nameplate.

• When opening the lid for wiring, maintenance or inspection, make sure that substances

such as dust, concrete powder, or metal powder do not enter inside the box, otherwise

contact failure or insulation failure may result.

• Do not drop the EC2B control box during transportation.

• Be sure to open the carton the right way up, otherwise damage or personal injury may

result.

• Check that the product is what you have ordered. Using an incorrect model might result in

malfunction or accident.

• Stop operation immediately if abnormal operation occurs. Otherwise, a secondary accident may occur.

• The surface temperature of the EC2B control box may become extremely hot during operation. Before maintenance or inspection of the EC2B, be sure to wear gloves to prevent

burning your hand.

15

Page 16

TO: IDEC Corporation

Company:

EC2B

TEL:

1-column Control Box Specication Sheet

No. of Control Box

Contact Person:

Select the required specifications by checking the checkboxes, and specify the details.

Control box size

£ EC2B-110 £ EC2B-210 £ EC2B-310 £ EC2B-410 £ EC2B-510

Nameplate

NP

1

Nameplate (NP)

No

£ £

nameplate

E1

Material: Acrylic (53 mm × 12 mm, plate thickness 2 mm)

Legend color: black letter, white background

Maximum no. of letters: 19 letters per line (up to 2 lines)

1 line £ 2 lines

NP

1

2

E1

Control Units

Position

1

2

3

4

5

Control Unit Part No. Control Unit Nameplate

£ ON £ OFF £ START £ STOP £ EMERGENCY STOP

£ OFF ON £ HAND AUTO £ HAND OFF AUTO £ Blank

£ No nameplate £ Specify letters ( )

£ ON £ OFF £ START £ STOP £ EMERGENCY STOP

£ OFF ON £ HAND AUTO £ HAND OFF AUTO £ Blank

£ No nameplate £ Specify letters ( )

£ ON £ OFF £ START £ STOP £ EMERGENCY STOP

£ OFF ON £ HAND AUTO £ HAND OFF AUTO £ Blank

£ No nameplate £ Specify letters ( )

£ ON £ OFF £ START £ STOP £ EMERGENCY STOP

£ OFF ON £ HAND AUTO £ HAND OFF AUTO £ Blank

£ No nameplate £ Specify letters ( )

£ ON £ OFF £ START £ STOP £ EMERGENCY STOP

£ OFF ON £ HAND AUTO £ HAND OFF AUTO £ Blank

£ No nameplate £ Specify letters ( )

FAX:

NP

NP

1

2

3

E1

1st line

2nd line

1

2

3

4

E2 E2

NP

1

2

3

4

5

Lead-in Fitting (E1/E2)

Without specification

(standard reducer)

With specification

• Specify wiring diagram when wiring is required. • Specify when other accessories are required.

•

EC2B-110, 210, 310 EC2B-410, 510

M16

M20

M25

M32

NPT 1/2

NPT 3/4

NPT 1

1703140803

16

NPT 3/4

Code

E2

Cable lead-in method

UL/c-UL, IECEx/ATEX certied

EC2B-110, 210, 310 EC2B-410, 510

Code

Cable lead-in method

Check Specification

£

£

E1

Reducer

£

£

£

£

£

©2017 IDEC Corporation. All Rights Reserved. EU9Y-DS200-0

Reducer

NPT 1

Check Specification

£

£

£

£

£

£

M25

M32

M40

NPT 3/4

NPT 1

NPT 1 1/4

Loading...

Loading...