Page 1

EB3N

EB3N Discrete Input Barrier with Redundant Output

Build a safety system in an explosive atmosphere.

Key features:

Safety Performance Performance level e Category 4

OI TouchscreensPLCsAutomation SoftwarePower SuppliesSensorsCommunicationBarriers

• [Exia] II C

• Ensures safety and machine safety in an explosive atmosphere

• Machine safety system can be built in compliance with ISO13849-1 Category 4,

Performance level e.

• Safety input devices applicable in any explosive gas and hazardous areas are

available.

• Available with auxiliary inputs (5 points) used to monitor the operating status of

safety input devices

• Global usage

USA (UL),

Global IEC-Ex,

Europe (ATEX),

Japan (TIIS),

China (CQST)

Machine safety: TÜV Rheinland

• No grounding required

Barriers

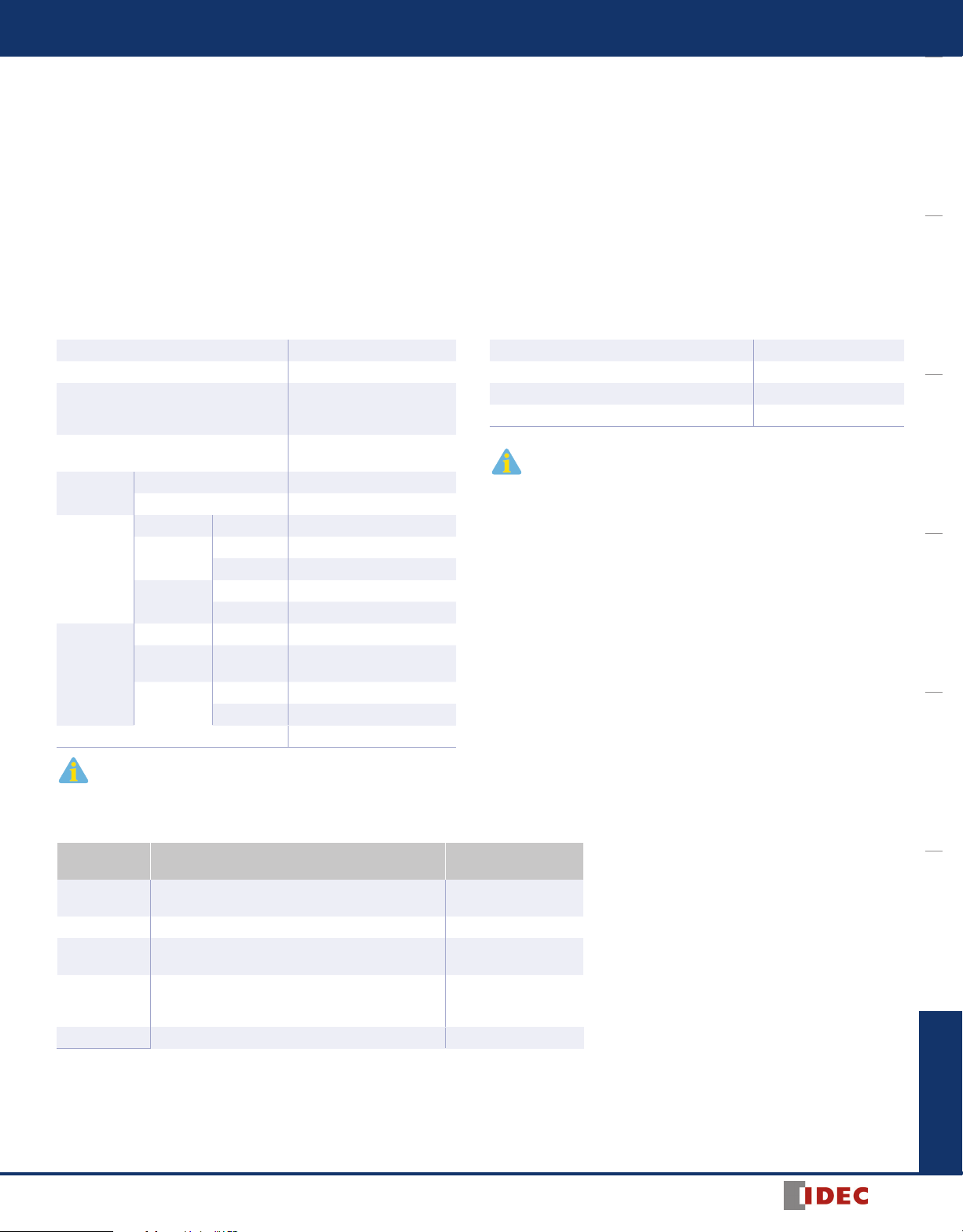

Entity Barrier Parameters

Ta= 60°C, Um= 250V, (Um=125V UL only), Uo=13.2V, Io= 14.2mA, Po= 46.9mW at each channel

Pn-Nn Io=227.2mA, Po= 750mW at max 16 channels Pn-Nn

Io(mA) 14.2 28.4 42.6 56.8 71.0 85.2 99.4 113.6 127.8 142.0 156.2 170.4 184.6 198.8 213.0 227.2

Po(mW) 46.9 93.8 140.6 187.5 234.3 281.2 328.1 375.9 421.8 468.7 515.5 562.4 609.2 656.1 702.9 750

0.67 0.65 0.63 0.61 0.59 0.57 0.55 0.53 0.51 0.49 0.47 0.44 0.42 0.39 - - 1.0 Uo 13.2V 13.2V

0.79 0.77 0.76 0.75 0.73 0.72 0.70 0.69 0.67 0.66 0.64 0.62 0.61 0.59 0.57 0.55 0.5 Io 14.2mA 227.2mA

Co(μF)

0.94 0.94 0.94 0.94 0.94 0.94 0.94 0.93 0.92 0.91 0.90 0.88 0.87 0.86 0.85 0.84 0.2 Po 46.9mW 750mW

0.94 0.94 0.94 0.94 0.94 0.94 0.94 0.94 0.94 0.94 0.94 0.94 0.94 0.94 0.94 0.94 0.1 Co 0.47μF 0.28μF

Note 1 Added to above table, the next values combined Lo and Co are allowable; Lo 87.5mH 0.56mH

Io(mA) 14.2 28.4 227.2

Lo(mH) 175* 87.5 30.0 2.5 0.55 0.25 43.5* 21.5 20.0 3.5 0.43 0.25 0.68* 0.34 0.68 0.6 0.22 0.13

0.90* 0.45 0.33 0.54 0.77 0.90 0.90* 0.45 0.30 0.48 0.80 0.90 0.90* 0.45 0.45 0.49 0.80 0.90

Co(µF)

Note 2 The intrinsic safe apparatus and wirings shall be accordance to following formulas; for example: Ui ≥ Uo Ii ≥ Io Pi ≥ Po Ci+Cc ≤ Co Li+Lc ≤ Lo

*: Therefore, the values are allowable only at Li ≤ 1%Lo and Ci ≤ 1%Co of the intrinsic safe apparatus. (In the case of 50% of Co and Lo parameters are applicable,the maximum

capacitance allowed shall not be more than Co = 1 µF for IIB and Co= 600 nF for IIC.)

Discrete Input Barrier with Redundant Output

2 2NO Without Without

2 2NO 5 (1 common) 5NO (1 common)

1. A maximum of ve monitor contacts from safety input devices can be connected to the auxiliary input terminals. In addition, non-safety input devices can also be connected to the auxiliary input

terminals.

2. On auto reset (auto start) models, when the safety condition is met (two safety inputs are both on), safety outputs are turned on automatically.

Connect the reset (start) input terminals Y1 and Y2 together except for the following cases:

When connecting a contactor or force guided relay to the safety output of the EB3N, connect the NC contacts of the contactor or force guided relay to the reset (start) input terminals Y1 and Y2 of the

EB3N for use as a backcheck input signal.

3. On manual reset (manual start) models, while the safety condition is met (two safety inputs are both on), safety outputs are turned on at the falling edge of the reset switch (start switch) signal

(OFF

ON OFF) (start off check).

Manual reset (manual start) models have a monitoring function of reset switch contacts (detection of welded contacts). Use NO contacts of a momentary switch for the reset (start) input.

When connecting a contactor or force guided relay to the safety output of the EB3N, connect the NC contacts of the contactor or force guided relay to the reset (start) input terminals Y1 and Y2 of the

EB3N for use as a backcheck input signal.

Combined

Lo(mH)

Auto reset (Auto start) EB3N-A2ND

Manual reset (Manual start) EB3N-M2ND

Auto reset (Auto start) EB3N-A2R5D

Manual reset (Manual start) EB3N-M2R5D

TIISI only

Ta=60°C, Um=250V

1 ch

Seperate

5 ch

Common

254

1705151127

Page 2

Barriers

EB3N

Selection Guide

1. Selecting the reset (start) function

Auto reset (auto start): Select this model when connecting safety control devices, such as safety relay modules or safety controllers, to the EB3N safety

outputs to set up a safety system, using the reset (start) function of the safety control device.

Select this model when connecting contactors or force guided relays to the EB3N safety outputs to set up a safety system, and a

risk assessment on the entire system has not found any safety problem in using auto reset (auto start).

Manual reset (manual start): Select this model when connecting contactors or force guided relays to the EB3N safety outputs to set up a safety system, and a

risk assessment on the entire system has found that manual reset (manual start) is necessary.

2. Selecting the auxiliary outputs

Without auxiliary outputs: Select this model when the operating status of safety input devices are not monitored.

With auxiliary outputs: Select this model when the operating status of safety input devices are monitored or when non-safety input devices are also con-

nected.

Specications

EB3N General Specications

Rated Power Voltage 24V DC

Power Voltage Range 20.4 to 26.4V DC

Operating Temperature

Operating Humidity

Power

Consumption

Safety

Output

Auxiliary

Output

Mounting DIN rail or panel mounting

*: Channel Numbers: 1 to 5

Without auxiliary output 5.5W maximum

With auxiliary output 7.0W maximum

Contacts 13-14, 23-24 2NO

Rated Load

Response

(rated voltage)

Contacts A* - C1 5NO/1 common

Rated Load Resistive

Response

(rated voltage)

Resistive 30V DC, 1A

Inductive DC-13, 24V, 1A

Turn on 100 ms maximum

Turn off 20 ms maximum

Turn on 15 ms maximum

Turn off 10 ms maximum

–20 to +60°C (no freezing)

UL: –20 to +40°C

(no freezing)

45 to 85% RH

(no condensation)

24V DC, 3A,

common terminal 5A max.

EB3N Safety Specications

Category 4

Performance Level (PL) e

Mean Time to Dangerous Failure (MTTFd) 100 years

Diagnostic Range 99% minimum

Calculation conditions for MTTFd

t

: Mean operation cycle = 1 hour

cycle

: Mean operation hours per day = 24 hours

h

op

d

: Mean operation days per year = 365 days

op

Note: When t

is shorter than 1 hour, MTTFd will decrease

cycle

OI Touchscreens PLCs Automation Software Power Supplies Sensors Communication Barriers

EB3N Certications

Certication

Organization

UL

PTB (IEC-Ex) [Exia] II C, [Exia D] IEC Ex PTB 10.0015

PTB (ATEX)

TIIS

CQST [Exia] IIC CNEx11.0038

1705151127

Ratings Certication Number

Class I, Zone 0, [AExia] II C

Class I, II, III, Div. 1, Groups A, B, C, D, E, F and G

II (1) G [Exia] II C

II (1) D [Exia D]

Discrete Input Barriers with Redundant Output [Exia] II C

Switch (EB9Z-A) Exia II CT6

Switch (EB9Z-A1) Exia II BT6

E234997

PTB 09 ATEX 2046

TC18753

TC15758

TC15961

255

Page 3

EB3N

65.0

75.0

110.5

77.5

75.0

2-M4 tapped or

2-ø4.5 drilled holes

1:1 connection with a safety input device, compliant with Category

Connection with multiple safety input devices, capable of monitoring up to 5 contact operations, compliant with Category

For monitoring operating statuses of safety input devices located in a non-hazardous area

Barriers

Dimensions (mm)

EB3N-A2ND

EB3N-M2ND

OI TouchscreensPLCsAutomation SoftwarePower SuppliesSensorsCommunicationBarriers

Mounting Hole Layout

EB3N-A2ND

EB3N-M2ND

65

51

EB3N System Conguration Examples

Hazardous Area Non-hazardous Area

Safety Input Device

Safety Input Device

EB3N-A2R5D

EB3N-M2R5D

EB3N-A2R5D

EB3N-M2R5D

2-M4 tapped or

2-ø4.5 drilled holes

97

EB3N-A2ND Safety Control Device

EB3N-M2ND Safety Contactor

Barrier Safety Output

Barrier Safety Output

Backcheck Input

Reset (Start) Input

65

Reset (Start) Input

Terminal Functions

24V DC Power

Y1-Y2 Reset input (Start input)

11-12 Safety input 1

21-22 Safety input 2

N1, N2 Signal ground

P*-N3 Auxiliary input

13-14 Safety output 1

23-24 Safety output 2

A*-C1 Auxiliary output

*: 1 to 5

4

Safety Output

Backcheck Input

Safety Contactor

• A safety relay module or safety controller is

used to set up a safety circuit, using the reset

(start) function of the safety relay module or

safety controller.

• The reset (start) function is used to set up a

safety circuit, without using a safety relay

module or safety controller.

3

Hazardous Area Non-hazardous Area

Safety Input Devices

Connected in Series

…

Monitor

Safety Input Devices

Connected in Series

…

Monitor

EB3N-A2R5D

EB3N-M2R5D

Barrier Safety Output

Auxiliary Output

(Monitor Output)

Barrier Safety Output

Backcheck Input

Reset (Start) Input

Auxiliary Output

(Monitor Output)

Safety Control Device

PLC

Safety Contactor

PLC

Safety Output

Backcheck Input

Reset (Start) Input

Safety Contactor

• A safety relay module or safety controller is

used to set up a safety circuit, using the reset

(start) function of the safety relay module or

safety controller.

• The manual reset (manual start) function of

the EB3N is used to set up a safety circuit,

without using a safety control device.

256

1705151127

Page 4

Barriers

Installing a reset switch in a hazardous area, using auxiliary input and output

EB3N

Hazardous Area Non-hazardous Area

Safety Input Devices

…

Reset (Start) Switch

Other Input Device

Safety Input Devices

Reset (Start) Switch

Other Input Device

EB3N-A2R5D

EB3N-M2R5D

Barrier Safety Output

Reset (Start) Output

Other Output

Barrier Safety Output

Backcheck Input

Reset (Start) Input

Other Output

Safety Control Device

Safety Contactor

Safety Input Devices Connectable to Safety Input Terminals (Examples)

Emergency stop switch: (Non-illuminated) XW1E-BV402M-R, XN4E-BL412MRH

Safety switch: HS6B-02B05, HS1B-02R

Notes for Operation

1. Do not disassemble, repair, or modify the EB3N discrete input barrier with

redundant output, otherwise the safety characteristics may be impaired.

2. Use the EB3N within its specication values.

3. The EB3N can be mounted in any direction.

4. Mount the EB3N on a 35-mm-wide DIN rail or directly on a panel surface using screws. When mounting on a DIN rail, push in the clamp and use end clips

to secure the EB3N. When mounting on a panel surface, tighten the screws

rmly.

5. Excessive noise may cause malfunction or damage to the EB3N. When the

internal voltage limiting circuit (thyristor) has shut down the power due to

noise, remove the cause of the noise before powering up again.

6. The internal power circuit contains an electronic fuse to suppress overcurrents. When the electronic fuse has tripped, shut down the power, remove the

cause of the overcurrent before powering up again.

7. Use crimping terminals with insulation sheath for wiring. Tighten the terminal

screws, including unused terminal screws, to a recommended tightening

torque of 0.6 to N·m using a screwdriver of ø5.5 mm in diameter.

8. Before inspecting or replacing the EB3N, turn off the power.

OI Touchscreens PLCs Automation Software Power Supplies Sensors Communication Barriers

Safety Output

Backcheck Input

PLC

PLC

Safety Contactor

Instructions

Notes for Machine Safety

1. Operate the safety input device to check the EB3N functionality everyday.

2. For safety input devices, such as safety switches or emergency stop switches,

connected to the EB3N, use safety standard-compliant devices with direct

opening action and 2NC contacts.

3. Do not use the auxiliary input as a safety input.

4. For safety control devices connected with the EB3N, use machine safety

standard-compliant devices with a disparity detection function.

5. Use safety inputs and safety outputs in a circuit conguration compliant with

safety requirements.

6. To calculate the safety distance, take into consideration the response time

of all devices comprising the system, such as the EB3N and safety devices

connected to the EB3N.

7. Separate the input and output wiring from power lines and motor lines.

8. When using multiple EB3N discrete input barriers with redundant output, do

not connect one switch to more than one EB3N. Use separate switches for

each EB3N.

9. To ensure EMC, use shielded cables for safety inputs and auxiliary inputs.

Connect the shield to the FG of the control panel on which the EB3N is

mounted.

10. For protection against overcurrents, connect an IEC60127-2-compliant 2A

fast-blow fuse (5 × 20 mm).

11. Evaluate the ISO 13849-1 category and performance level in consideration of

the entire system.

1705151127

257

Page 5

EB3N

Barriers

Safety Notes

1. Install the EB3N in an enclosure capable of protecting against mechanical

shocks at a hazardous location in accordance with intrinsic safety ratings and

parameters.

2. Install and wire the EB3N so that the EB3N is not subject to electromagnetic

OI TouchscreensPLCsAutomation SoftwarePower SuppliesSensorsCommunicationBarriers

and electrostatic induction and does not contact with other circuits.

For example, keep a minimum spacing of 50 mm between intrinsically safe

and non-intrinsically safe circuits, or provide a metallic separating board

between the intrinsically safe circuit and non-intrinsically safe circuit. When

providing a metallic separating board, make sure that the board ts closely to

the enclosure (top, bottom, and both sides). Allowable clearance between the

board and the enclosure is 1.5 mm at the maximum.

When a motor circuit or high-voltage circuit is installed nearby, keep a wider

spacing than 50 mm between intrinsically safe and non-intrinsically safe

circuits.

3. Keep a minimum spacing of 3 mm between the terminal or relay terminal

block of the intrinsically safe circuit and the grounded metal parts of the

metal enclosure.

4. Connect the terminals so that IP20 is ensured.

5. To prevent disengaged wires from contacting with other intrinsically safe

circuits, bind together the end of wires.

6. Make sure that the voltage of the power supply for the devices connected to

the non-intrinsically safe circuit or the internal voltage of such devices does

not exceed 250V AC/DC 50/60 Hz (UL rating: 125V AC 50/60 Hz) or 250V DC

(UL rating: 200V DC) under any normal and abnormal conditions.

7. Make sure that the wiring of intrinsically safe circuits does not contact with

other circuits or is not subject to electromagnetic and electrostatic inductions,

otherwise protection from hazards is not ensured.

8. When identifying intrinsically safe circuits by color, use light blue terminal

blocks and cables.

9. When wiring the intrinsically safe circuit, determine the distance to satisfy

the wiring parameters shown below.

a) Wiring capacitance Cw ≤ Co – Ci

Co: Intrinsically safe circuit allowable capacitance

Ci: Internal capacitance of switches

b) Wiring inductance Lw ≤ Lo – Li

Lo: Intrinsically safe circuit allowable inductance

Li: Internal inductance of switches

c) Wiring resistance ≤ Rw

Rw: Allowable wiring resistance

Switches in the Hazardous Area

1. A switch contains the switch contact, enclosure, and internal wiring. A switch

contact refers to an ordinary switching device which consists of contacts only.

2. When the switch has internal wiring or lead wire, make sure that the values

of internal capacitance (Ci) and inductance (Li) are within the certied values.

3. Enclose the bare live part of the switch contact in an enclosure of IP20 or

higher protection.

258

1705151127

Loading...

Loading...