EB3L

Barriers

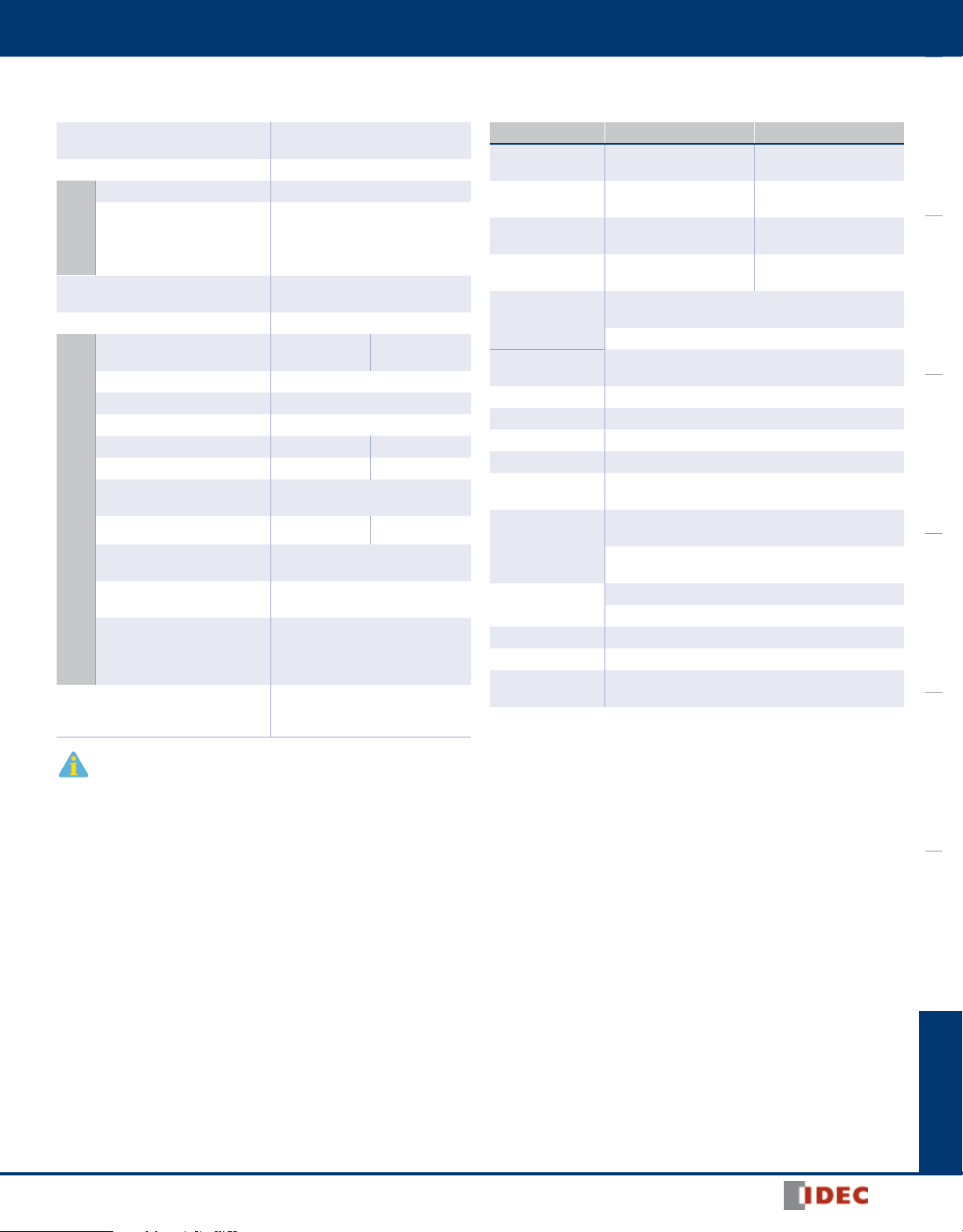

EB3L Discrete Output Barriers

126 types of pilot lights and buzzers can be connected. Illuminated pushbuttons and

illuminated selector switches can be connected by combining with the EB3C discrete

input barrier.Nogrounding required.

Key features:

OI TouchscreensPLCsAutomation SoftwarePower SuppliesSensorsCommunicationBarriers

Explosion protection

Discrete Output Barrier [Exia] II C

Pilot Light (separate wiring) Exia II CT6

Pilot Light (common wiring) Exia II CT4

Illuminated Pushbutton Exia II CT4

Illuminated Selector Switch Exia II CT4

Buzzer (separate wiring) Exia II CT6

• IEC60079 compliant

• Compact and lightweight (46% footprint and 36% weight com pared to IDEC’s

10-circuit IBPL)

• 8- and 16-channel types are available in common wiring types, ideal for connection

to PLCs. 16-circuit types are also available with a connector.

• Universal AC power voltage (100 to 240V AC or 24V DC power

[UL rating: 100 ~ 120V AC])

• No grounding required

• IDEC’s original spring-up terminal minimizes wiring time.

• Installation, 35-mm-wide DIN rail mounting or direct screw mounting

• ø6, ø8, ø10, ø22 and ø30 pilot lights available

• Illuminated pushbuttons and illuminated selector switches can be connected by

combining with the EB3C discrete input barrier.

Illumination colors: Amber, blue, green, red, white, and yellow

(pushlock turn reset type: red only)

• Continuous and intermittent sound types are available for buzz ers (ø30).

• Global usage

USA: UL/FM

Canada: CSA

Europe: CE marking, ATEX

China: CQST

Russia: GOST-R

Japan: TIIS

Korea: KOSHA

• Ship class: NK (Japan), KR (Korea)

Illuminated Pushbutton/Selector Switches

Illuminated pushbutton/selector switches can be used

with the combination of EB3C and EB3L.

234

Common Wiring for PLC Inputs

EB3L Discrete Output Barrier

8- and 16-circuit types are available in common wiring

types, ideal for connection to PLCs (DC voltage only).

Connector Type

MIL connecotr on the non-hazardous side

• Easy connection to PLCs

• Wiring is cut by 90% (compared with IDEC’s 16-circuit EB3C)

• Various 20-pin MIL connectors can be connected.

EB3C Discrete Input Barrier

Spring-up Fingersafe Terminals Reduce

Wiring Time

Finger-safe

www.IDEC.com

Barriers

EB3L

Explosion-Protection and Electrical

Explosion Protection

Degree of Protection IP20 (IEC60529)

Discrete Output Barrier Safe indoor place (non-hazardous area)

Pilot Light, Illuminated Switch,

Location

Buzzer (TIIS approval only)

Installation

Non-intrinsically Safe Circuit

Maximum Voltage (Um)

Operation Input ON, Output ON (1:1)

Wiring Method

Rated Operating Voltage 12V DC

Rated Operating Current 10 mA DC ±10%

Maximum Output Voltage (Uo) 13.2V DC ±10%

Maximum Output Current (lo) 14.2 mA 227.2 mA

Maximum Output Power (Po) 46.9 mW 750 mW

Maximum External

Capacitance (Co)

Maximum External Inductance (Lo)

Allowable Wiring Resistance (Rw)

Intrinsically Safe Circuits (Output)

Maximum Channels per

Common Line

Voltage and Current when

Connecting Control Units

Non-intrinsically Safe Circuits

(Signal Input)

1

Intrinsic safety type

(IEC compliant) [Exia] II C

For zone 0, 1, 2 hazardous areas

250V AC 50/60Hz, 250V DC

UL value: 125V AC

1-channel

Separate Wiring

900 (740) nF

1

175 (125) mH 0.68 (0.68) mH

200/(N+1)Ω

(N = number of common channels)

16

Pilot light: 3.5V, 8.5 mA

Miniature pilot light: 2V, 10 mA

Illuminated switch: 3.5V, 8.5 mA

Buzzer: 6.5V, 5.5 mA

Rated voltage: 24V DC

Rated current: 5 mA

(connector type: 4 mA)

Specifications

16-channel

Common Wiring

General

Power Voltage Type AC Power DC Power

Rated Power Voltage

Allowable Voltage

Range

Rated Frequency

Inrush Current

Dielectric Strength

(1 minute, 1 mA)

Operating Temperature

Storage Temperature –20 to +60°C (no freezing)

Operating Humidity 45 to 85% RH (no condensation)

Atmosphere 800 to 1100 hPa

Pollution Degree 2 (IEC60664)

Insulation Resistance

Vibration Resistance

(damage limits)

Shock Resistance

(damage limits)

Terminal Style M3 screw terminal

Mounting 35-mm-wide DIN rail or panel mounting (M4 screw)

Power Consumption

(approx.)

100 to 240V AC

(UL rating: 100 ~ 120V AC)

85 to 264V AC

(UL rating: 85 ~ 125V AC)

50/60 Hz (allowable range: 47

to 63 Hz)

10A (100V AC)

20A (200V AC)

Between intrinsically safe circuit and non-intrinsically safe

circuit: 1500V AC

Between AC power and signal input: 1500V AC

–20 to +60°C (no freezing)

10 MΩ minimum (500V DC megger, between the same poles

as the dielectric strength)

Panel mounting: 10 to 55 Hz, amplitude 0.75 mm

(2 hours each on X, Y, Z)

DIN rail mounting: 10 to 55 Hz, amplitude 0.35 mm

(2 hours each on X, Y, Z)

Panel mounting: 500 m/s

DIN rail mounting: 300 m/s2 (3 times each on X, Y, Z)

8.8 VA (EB3L-S10SA at 200V AC)

5.2 W (EB3L-S16CSD at 24V DC)

24V DC

21.6 to 26.4V DC

10A

2

(3 times each on X, Y, Z)

OI Touchscreens PLCs Automation Software Power Supplies Sensors Communication Barriers

—

1. Values in ( ) are those approved by TIIS (Technology Institution of Industrial Safety, Japan).

800-262-IDEC (4332) • USA & Canada

235

EB3L

Barriers

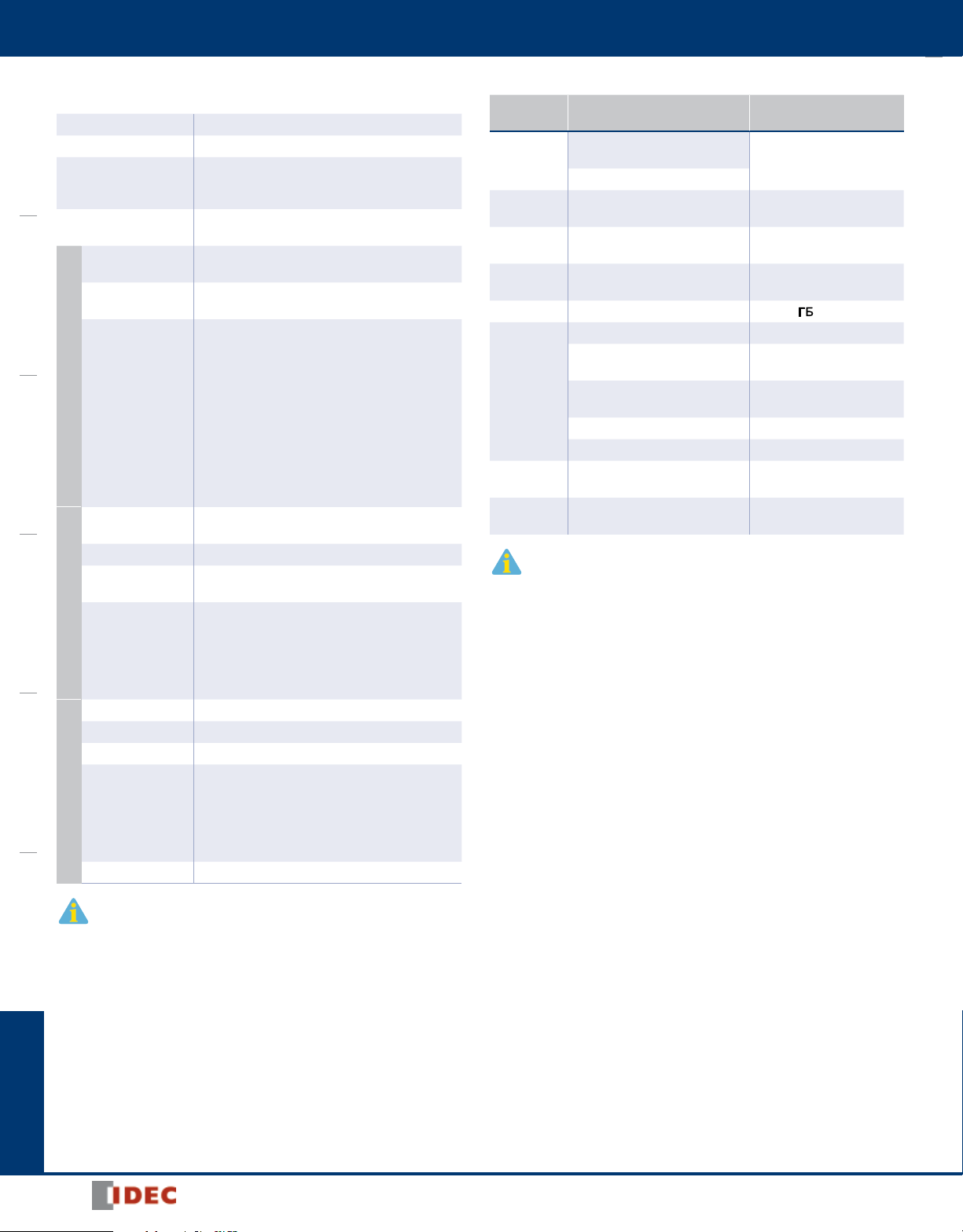

General Specifications of Pilot Light, Illuminated Pushbutton,

Illuminated Selector Switch, and Buzzer

Operating Temperature –20 to +60°C (no freezing)

Operating Humidity 45 to 85% RH (no condensation)

OI TouchscreensPLCsAutomation SoftwarePower SuppliesSensorsCommunicationBarriers

Dielectric Strength

(1 mA, 1 minute)

Insulation Resistance

Degree of Protection

Lens/Illumination

Color

Intrinsic Safety

Ratings and

Parameters

Pilot Light and Miniature Pilot Light

Degree of Protection

Illumination Color Amber, blue, green, red, white, yellow

Contact

Voltage/Current

Intrinsic Safety

Illuminated Switch

Ratings and

Parameters

Degree of Protection IP20 (IEC60529) (except for terminals)

Sound Volume 75 dB minimum (at 1 m)

Sound Source Piezoelectric oscillator (continuous or intermittent)

Intrinsic Safety

Buzzer

Ratings and

Parameters

Weight 100g

EB3P: 1000V AC

IPL1: 500V AC

(between intrinsically safe circuit and dead parts)

10 MΩ minimum (500V DC megger, between the same

poles as the dielectric strength)

IP65 (IEC60529) (except for terminals)

EB3P-LU/IPL1: IP40

Pilot light: Amber, blue, green, red, white, yellow

Miniature pilot light: Amber, green, red, white, yellow

1-channel Separate Wiring

Maximum input voltage (Ui): 13.2V

Maximum input current (Ii): 14.2 mA

Maximum input power (Pi): 46.9 mW

Internal capacitance (Ci): ≤ 2 nF

Internal inductance (Li): ≤ 5 µH

16-channel Common Wiring

Maximum input voltage (Ui): 13.2V

Maximum input current (Ii): 227.2 mA

Maximum input power (Pi): 750 mW

Internal capacitance (Ci): ≤ 32 nF

Internal inductance (Li): ≤ 80 µH

IP65 (IEC60529) (except for terminals)

EB3P-LSAW**: IP54

12V DC ±10%, 10 mA ±20%

(when connecting to the EB3C)

16-channel Common Wiring

Maximum input voltage (Ui): 13.2V

Maximum input current (Ii): 227.2 mA

Maximum input power (Pi): 750 mW

Internal capacitance (Ci): ≤ 32 nF

Internal inductance (Li): ≤ 80 µH

1-channel Separate Wiring

Maximum input voltage (Ui): 13.2V

Maximum input current (Ii): 14.2 mA

Maximum input power (Pi): 46.9 mW

Internal capacitance (Ci): ≤ 260 nF

Internal inductance (Li): ≤ 100 mH

Certification Number

Certification

Organization

FM

CSA

NEMKO

CQST

GOST-R [Exia] II C POCC JP.

TIIS

NK

KOSHA

Note: Illuminated switches, pilot lights, and miniature pilot lights are certified by TIIS and NK

only. Other certification organizations, such as UL, regard these units as simple apparatus,

and require no certification.

Explosion Protection Certification No.

Class I, II, III Div. 1

Group A, B, C, D, E, F, G

Class I, Zone 0 AEx [ia] II C

Class I Div. 1

Group A, B, C, D

Discrete output barrier: [Exia] II C

Buzzer: Exia II CT6

Discrete output barrier: [Exia] II C

Buzzer: Exia II CT6

Discrete output barrier: [Exia] II C TC16355

Pilot light/miniature pilot light:

(separate wiring): Exia II CT6

Pilot light/miniature pilot light:

(common wiring): Exia II CT4

Illuminated switch: Exia II CT4 TC16362

Buzzer: Exia II CT6 TC16363

Discrete output barrier: [Exia] II C

Buzzer: Exia II CT6

Discrete output barrier: [Exia] II C

Buzzer: Exia II CT6

3015417

LR 21451

Nemko 02ATEX279

Nemko 03ATEX1628X

CNEX 10.2445

TC16361

TC16360

Type Test No. 02T606

Type Test No. 04T605

KOB17821-EL001

KOB17821-EL002

05.B03253

Note: Connect buzzers in separate wiring. Buzzers cannot be used in com mon wiring.

236

www.IDEC.com

Barriers

EB3L

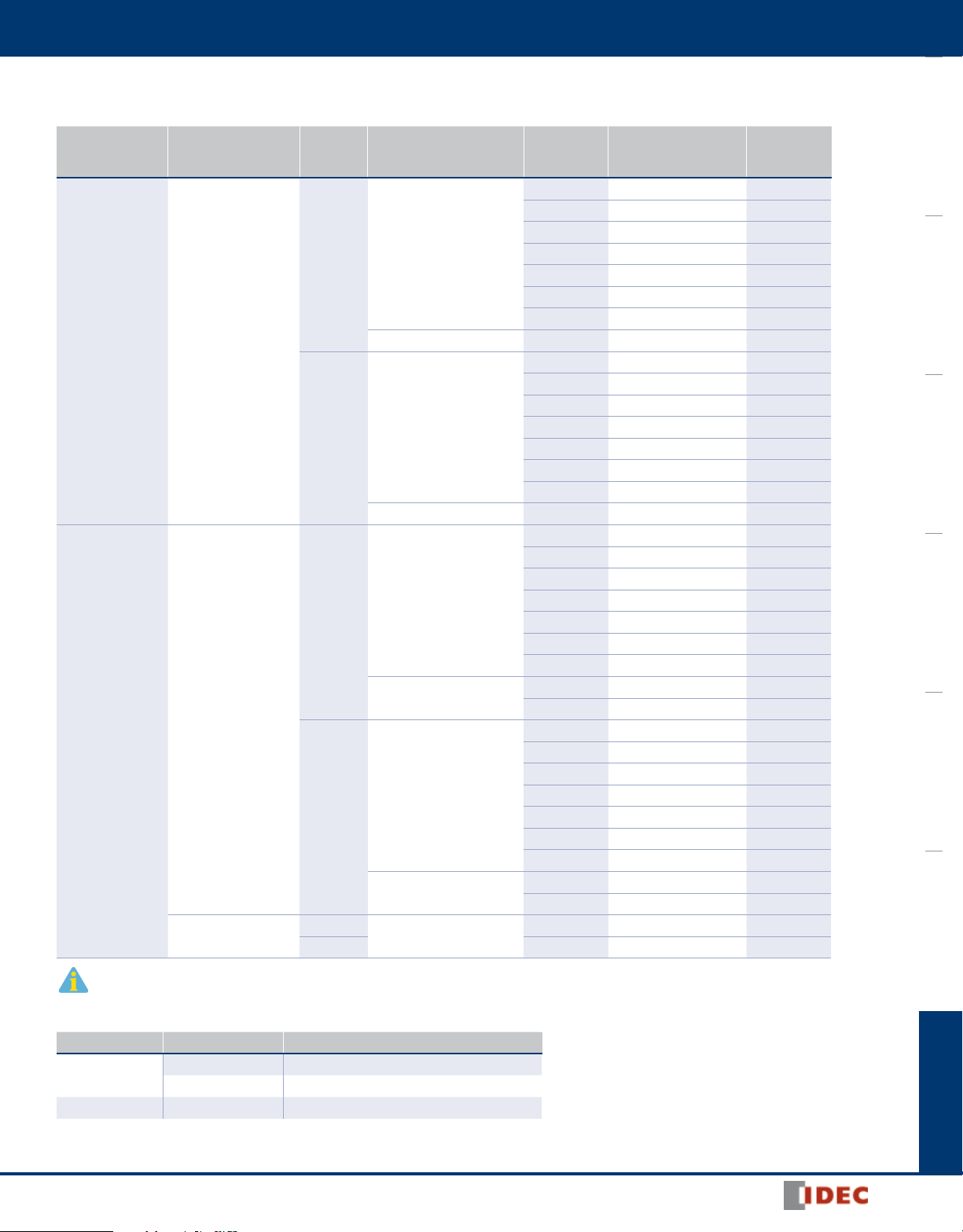

Discrete Output Barriers

Power Voltage

100 to 240V AC

(UL rating: 100 ~

120V AC)

24V DC

*Note: These models are NOT Listed by UL

Non-intrinsically

Screw Terminal

Screw Terminal

Connector

Connection to

Safe Circuit

Part Numbers

Input Input Wiring Method

Separate/Common

Source

Sink

Source

Sink

Source

Sink 16 EB3L-S16CKD-C* 350

Wiring Compatible

Common Wiring Only 8 EB3L-S08CSA 260

Separate/Common

Wiring Compatible

Common Wiring Only 8 EB3L-S08CKA 260

Separate/Common

Wiring Compatible

Common Wiring Only

Separate/Common

Wiring Compatible

Common Wiring Only

Common Wiring Only

Number of

Channels

1 EB3L-S01SA 150

2 EB3L-S02SA 180

3 EB3L-S03SA 190

5 EB3L-S05SA 250

6 EB3L-S06SA 260

8 EB3L-S08SA 330

10 EB3L-S10SA 360

1 EB3L-S01KA 150

2 EB3L-S02KA 180

3 EB3L-S03KA 190

5 EB3L-S05KA 250

6 EB3L-S06KA 260

8 EB3L-S08KA 330

10 EB3L-S10KA 360

1 EB3L-S01SD 130

2 EB3L-S02SD 160

3 EB3L-S03SD 170

5 EB3L-S05SD 240

6 EB3L-S06SD 250

8 EB3L-S08SD 310

10 EB3L-S10SD 250

8 EB3L-S08CSD 340

16 EB3L-S16CSD 350

1 EB3L-S01KD 130

2 EB3L-S02KD 160

3 EB3L-S03KD 170

5 EB3L-S05KD 240

6 EB3L-S06KD 250

8 EB3L-S08KD 310

10 EB3L-S10KD 340

8 EB3L-S08CKD* 250

16 EB3L-S16CKD* 350

16 EB3L-S16CSD-C 350

Part Number Weight (g)

OI Touchscreens PLCs Automation Software Power Supplies Sensors Communication Barriers

Accessories

Name Part Number Description

DIN Rail

End Clip BNL6 Medium DIN rail end clip

BNDN1000 Aluminum (1m long, 10.5mm high)

BAP1000 Steel (1m long, 7.5mm high)

800-262-IDEC (4332) • USA & Canada

237

EB3L

Barriers

Pilot Lights, Illuminated Pushbuttons, Illuminated Selector Switches, and Buzzers

TW

HW

LW

UP

1

Dome — — EB3P-LAN1-*

Square — — EB3P-LUN3B-*

Rectangular

w/Metal Bezel

Dome w/Diecast Sleeve — — EB3P-LAD1-*

Flush — — EB3P-LAW1-*

Flush

(Marking Type)

Dome — — EB3P-LAW2-*

Square Flush (Marking Type) — — EB3P-LUW1B-*

Round Flush — — EB3P-LHW1-*

Dome — — EB3P-LHW2-*

Square Flush — — EB3P-LHW4-*

Round — — EB3P-LLW1-*

Square — — EB3P-LLW2-*

Extended — — IPL1-18-*

Dome — — IPL1-19-*

Flush — — IPL1-87-*

Extended — — IPL1-88-*

Dome — — IPL1-89-*

Flush — — IPL1-67-*

Extended — — IPL1-68-*

Dome — — IPL1-69-*

Shape Operation Mode Contact Ordering Number

— — EB3P-LUN4-*

— — EB3P-LAW1B-*

Unit Size Series

OI TouchscreensPLCsAutomation SoftwarePower SuppliesSensorsCommunicationBarriers

Pilot Light

Miniature Pilot Light

ø30 N

ø22

ø10

ø8

ø6

1. Codes N, TW, HW, LW, and UP are the series names of IDEC’s control units.

2. Specify a color code in place of *.

3. Illuminated selector switches have a knob operator.

4. Above parts are recommended for EB3L barriers. However, none of these parts are UL recognized.

Lens Color/

Illumination

Color Code*

A: Amber

G: Green

R: Red

S: Blue

W: White

Y: Yellow

A: Amber

G: Green

R: Red

W: White

Y: Yellow

Operation

—

—

238

www.IDEC.com

Barriers

EB3L

Pilot Lights, Illuminated Pushbuttons, Illuminated Selector Switches, and Buzzers, con’t

Unit Size Series

ø30 N

Illuminated Pushbutton

ø22

ø30 N Round

3

ø22

Illuminated Selector Switch

ø30 — —

Buzzer

1. Codes N, TW, HW, LW, and UP are the series names of IDEC’s control units.

2. Specify a color code in place of *.

3. Illuminated selector switches have a knob operator.

4. Above parts are recommended for EB3L barriers. However, none of these parts are UL recognized.

1

Extended

Mushroom Pushlock Turn Reset 1NO-1NC EB3P-LBAVN311-R Red only

TW

HW Round

LW

TW Round

HW Round

LW Round 2-position DPDT EB3P-LSL1W2C2-* Maintained

Extended

Mushroom Pushlock Turn Reset 1NO-1NC EB3P-LBAVW411-R Red only

Round

Square

Shape Operation Mode Contact Ordering Number

Momentary 1NO-1NC EB3P-LBAN211-*

Maintained 1NO-1NC EB3P-LBAON211-*

Momentary 1NO-1NC EB3P-LBAW211-*

Maintained 1NO-1NC EB3P-LBAOW211-*

Momentary 1NO EB3P-LBH1W110-*

Maintained 1NO EB3P-LBHA1W110-*

Momentary DPDT EB3P-LBL1W1C2-*

Maintained DPDT EB3P-LBLA1W1C2-*

Momentary DPDT EB3P-LBL2W1C2-*

Maintained DPDT EB3P-LBLA2W1C2-*

2-position 1NO-1NC EB3P-LSAN211-* Maintained

3-position 2NO EB3P-LSAN320-* Maintained

2-position 1NO-1NC EB3P-LSAW211-* Maintained

2-position, return from right 1NO-1NC EB3P-LSAW2111-* Spring return from right

3-position 2NO EB3P-LSAW320-* Maintained

3-position,

return from right

3-position,

return from left

3-position,

2-way return

2-position 1NO-1NC EB3P-LSHW211-* Maintained

3-position 2NO EB3P-LSHW320-* Maintained

Continuous sound — EB3P-ZUN12C —

Intermittent sound — EB3P-ZUN12F —

2NO EB3P-LSAW3120-* Spring return from right

2NO EB3P-LSAW3220-* Spring return from left

2NO EB3P-LSAW3320-* 2-way spring return

2

Lens Color/

Illumination

Color Code*

A: Amber

G: Green

R: Red

S: Blue

W: White

Y: Yellow

A: Amber

G: Green

R: Red

S: Blue

W: White

Y: Yellow

A: Amber

G: Green

R: Red

S: Blue

W: White

Y: Yellow

OI Touchscreens PLCs Automation Software Power Supplies Sensors Communication Barriers

Operation

—

Accessory

Name Ordering Number Package Quantity Remarks

LED Lamp EB9Z-LDS1-* 1 Specify a color code in place of * in the Ordering No. A: amber, G: green, R: red, S: blue, W: white, Y: yellow

Above part is recommended for EB3L barriers. However, this part is not UL recognized.

800-262-IDEC (4332) • USA & Canada

239

EB3L

–

P1 N1 P2 N2 P3 N3

S1NLC1S2C2S3C3

–

–

~

Green

YellowYellowYellow

–+–+–+

–+–+–

+

–

P1 P16 N1 N2

S1 S16 C1 C2

–

Green

YellowYellow

–+

~

~

~

–

P1 N1 P2 N2 P3 N3

S1 C1 S2 C2 S3 C3

–

Green

YellowYellowYellow

–+

~

~

~

Safe Area

(Non-hazardous Area)

Hazardous Area

65

10101010

65

28 51 97 97

65

10

6

77.5

75

61

42

171.5

110.565 77.5

4

(4)

EB3L–S02

EB3L–S03

EB3L–S06

EB3L–S05

EB3L–S08C

EB3L–S16C

EB3L–S10

EB3L–S08

EB3L–S01

2-M4 tapped or

2-ø4.5 mounting holes

4-M4 tapped or

4-ø4.5 mounting holes

2-M4 tapped or

2-ø4.5 mounting holes

2-M4 tapped or

2-ø4.5 mounting

holes

ø6 hole

ø4.4

Intrinsic Safety Side:

Light Blue

Non-Intrinsic Safety Side:

Yellow

Mounting Hole Layout (Screw Mounting)

Terminal

83.5

ø6

6

(4)

4- ø4.5 holes

77.5

75

97

171.5

10

10

65

97

65

4-M4 or 4-ø4.5 holes

Mounting Hole Layout

EB3C–T16C -C

Connector

5.4 min.3 max.

6 max.

ø3.2 min.

6 to 8 mm

Solid Wire

Stripping the Wire End

Applicable Crimping Terminal

Barriers

Internal Circuit Block Diagram

AC Power

Source Input

OI TouchscreensPLCsAutomation SoftwarePower SuppliesSensorsCommunicationBarriers

DC Power

Sink Input

Connector Wiring

Source Input

Dimensions (mm)

240

www.IDEC.com

Barriers

ø35

21.5

36

40

23.5

Panel Thickness 0.8 to 7.5

M3 Terminal

Screw

M3 Terminal

Screw

40

36

34×40

52.2

44

29.5

10.5

Panel Thickness 0.8 to 4.5

ø24.8

9

29.8

ø35

40

21.4

ø40

Panel Thickness 0.8 to 7.5

M3.5 Terminal

Screw

M3 Terminal

Screw

40

36

34

Panel Thickness 0.8 to 5.5

23

20

52.2

44

28.5 13

Panel Thickness 1 to 6

30

ø2937ø24

17

34.3

M3.5

Terminal

Screw

Terminal Cover (supplied)

APS-PVL

28.5 13

25

30

ø23.6

ø29

37

M3.5

Terminal

Screw

34.3

Panel Thickness 1 to 6

Terminal Cover (supplied)

APS-PVL

Marking Plate: 22

28.5 13 30

37

16

25

30

M3.5

Terminal

Screw

34.3

Panel Thickness 1 to 6

Terminal Cover (supplied)

APS-PVL

M3.5 Terminal Screw

Gasket

Locking Ring

Flush

X2

X1

Panel Thickness 0.8 to 6

0.5

743.3

Dome Round/Dome

17.5

ø29

Square

29.6

7.2

4.5

Gasket

Locking Ring

Panel Thickness 0.8 to 6

SquareRound

+ Terminal

M10

P1.0

Panel Thickness 0.6 to 4

7

ø12

13.8

9

12

20

5.5

+ Terminal

M10

P1.0

Panel Thickness 0.6 to 4

7

ø12

13.8

9

12.8

20.8

ø9.9

5

+ Terminal

M8

P0.75

Panel Thickness 0.6 to 4

6.1

9

13.8

3

21.8

ø10

11.5

+ Terminal

M8

P0.75

Panel Thickness 0.6 to 4

6.1

ø10

11.5

9

11.5

19.5

4.5

+ Terminal

M8

P0.75

Panel Thickness 0.6 to 4

6.1

ø10

11.5

ø8.1

5

9

11.8

19.8

+ Terminal

M6

P0.75

9.2

ø7.5

2.5

20.3

11.8

7

Panel Thickness 0.6 to 4

4.6

+ Terminal

M6

P0.75

9.2

ø7.5

7

Panel Thickness 0.6 to 4

4.6

10

3.5

18.5

+ Terminal

M6

P0.75

9.2

ø7.5

7

Panel Thickness 0.6 to 4

4.6

11.3

3

ø6

19.8

M3 Terminal Screw

M3.5 Terminal Screw

63

9

23.5

Panel Thickness 0.8 to 7.5

5.5

23

ø35

ø24

ø40

40

M3 Terminal Screw

M3.5 Terminal Screw

63

23.5

Panel Thickness 0.8 to 7.5

5.5

23

ø40

36

40

EB3L

Pilot Lights

EB3P-LAN1

Terminal Cover: APN-PVL

(sold separately)

ø22 EB3P-LAW1

ø22 EB3P-LHW1/EB3P-LHW2/EB3P-LHW4

Terminal cover attached.

ø30 EB3P-LUN4

Terminal Cover: APN-PVL

(sold separately)

ø30 EB3P-LAD

Terminal Cover: APD-PVL

(sold separately)

ø22 EB3P-LAW1B ø22 EB3P-LAW2

ø22 EB3P-LLW1/EB3P-LLW2/EB3P-LLW3

Terminal cover attached.

OI Touchscreens PLCs Automation Software Power Supplies Sensors Communication Barriers

ø30 EB3P-LUN3B

Terminal Cover: APN-PVL

(sold separately)

ø22 EB3P-LUW1B

Miniature Pilot Lights (Terminal cover not available)

ø10 IPL1-18

ø8 IPL1-89

ø10 IPL1-19

ø8 IPL1-67

Illuminated Pushbuttons

ø30 EB3P-LBAN211/LBAON211

Terminal cover: N-VL4 (2 pcs.) (sold separately)

ø10 IPL1-87

ø8 IPL1-68

ø30 EB3P-LBAVN311-R

Terminal cover: N-VL4 (2 pcs.) (sold separately)

ø10 IPL1-88

ø8 IPL1-69

800-262-IDEC (4332) • USA & Canada

241

EB3L

13

19.5

Panel Thickness

1 to 6

37

30

ø29

ø24

ø24

Adjustment

Ring

M3.5 Terminal

Screw

69.4

37

30

13

22.5

ø40

Reset 75°

69.4

Panel Thickness

1 to 6

Adjustment

Ring

M3.5 Terminal

Screw

49.4

25

Panel Thickness 0.8 to 6

ø29

41.4

29.4

13

LOCK

Locking Ring

Lever Stop

M3.5 Terminal

Screw

9

11.7

R18

25.4

23.2

8.5

53.5

Panel Thickness 0.8 to 6

ø25.8

LOCK

M3 Terminal

Screw

9

11.7

R18

25.4

23.2

8.5

53.5

25.8

LOCK

Panel Thickness 0.8 to 6

M3 Terminal

Screw

Panel Thickness 0.8 to 7.5

63 28

9

ø35

ø25

5.5

23

M3.5 Terminal

Screw

M3 Terminal

Screw

ø40

40

9

69.4

13

25

ø

ø29

30

37

Panel Thickness 1 to

6

M3

.5 Terminal

w

M3.5 Terminal

Screw

LOCK

69.4

29.4

41.4

25

ø29

7

21

Panel Thickness

0.8 to 6

ø25.8

9

17.5

11.7

R18

25.4

23.2

8.5

53.5

Panel Thickness

0.8 to 6

LOCK

M3 Terminal

Screw

M3.5 Terminal Screw

41

Panel Thickness

0.8 to 3.5

ø50

35.5

10.6

20.4

Illumination Color

Intrinsic Safety Identification: Light Blue

IDEC Exi

Barriers

ø22 EB3P-LBAW211/LBAOW211

Terminal cover attached.

OI TouchscreensPLCsAutomation SoftwarePower SuppliesSensorsCommunicationBarriers

ø22 EB3P-LBL1W1C2/LBLA1W1C2

Terminal cover: LW-VL2M (sold separately)

Illuminated Selector Switches

ø30 EB3P-LSAN211/EB3P-LSAN320

Terminal cover: N-VL4 (2 pcs.) (sold separately)

ø22 EB3P-LBAVW411-R

Terminal cover attached.

ø22 EB3P-LBL2W1C2/LBLA2W1C2

Terminal cover: LW-VL2M (sold separately)

ø22 EB3P-LSAW***

Terminal cover attached

ø22 EB3P-LBH1W110/LBHA1W110

Terminal cover attached.

All dimensions in mm.

ø22 EB3P-LSHW211/EB3P-LSHW320

Terminal cover attached

Buzzer

ø30 EB3P-ZUN12C/ZUN12F

Terminal cover: AZ-VL5 (sold separately)

ø22 EB3P-LSL1W2C2/EB3P-LSL3W3C2

Terminal cover: LW-VL2M (sold separately)

ø30 EB9Z-LDS1

Illumination color is marked on the terminal.

242

www.IDEC.com

Barriers

Pin Terminals

Positive Terminal

Negative Terminal

Light Blue Marking

Pilot Light

1 kΩ

12V DC

C6

N

6

P6

S5C4S4

S2C1S1

P3N3

P5N5

100 to

240V AC

C2

P8P6P5

P3

S1S2S3S6S7

24V DC

C6

N

6

P6

S5C4S4

S2C1S1

P3N3

P5N5

100 to

240V AC

C2

P

9P8P6P5P3

S1S2S4

S5S6S8C1S

S12

P1

3

S15

P15

S16

P1

6

C4

N

3

24V DC

9

P6

S1

S4

S5

C1

SPS12

S13

S14

S15

P

S16

6

C4

EB3L

Polarity Identification

Pilot Lights/Illuminated Pushbuttons/Illuminated Selector Switches

Positive terminal: X1

Negative terminal: X2

Miniature Pilot Lights

Positive terminal: Long pin terminal

Negative terminal: Short pin terminal

A light blue marking is

indicated on the negative

terminal side to identify

intrinsically safe usage.

Buzzer

Positive terminal: +

Negative terminal: –

LED Lamp

Positive

Negative

Panel Cut-out

Pilot Lights/Illuminated Pushbuttons/Illuminated

Selector Switches/Buzzers

ø30 ø30

Miniature Pilot Lights

ø10 ø8 ø6

* The 4.8 or 3.2 recess is needed only when using an anti-rotation ring or a nameplate with an anti-

rotation projec tion.

EB3P-LHW does not have an anti-rotation groove.

All dimensions in mm.

OI Touchscreens PLCs Automation Software Power Supplies Sensors Communication Barriers

Lamp Test

When checking the lamp lighting without using the EB3L discrete output barrier,

first make sure that the atmosphere is free from explosive gases. Connect a 12V

DC power supply and a pro tection resistor of 1 kΩ in series to turn on the pilot

light.

Non-intrinsically Safe External Input Wiring Examples

6-channel Source

(Ex.: EB3L-S06SA)

16-channel Common Wiring, Source

(Ex.: EB3L-S16CSD)

8-channel Common Wiring, Source

(Ex.: EB3L-S08CSD)

16-channel Common Wiring, Sink

(Ex.: EB3L-S16CKD)

P2

P5P3 P4

6-channel Sink

(Ex. EB3L-S06KA)

P7 P8

N2 P

P12

P13

15

P1

N3 N4

S2 S3

24V DC

800-262-IDEC (4332) • USA & Canada

S6 S7 S8

C2

243

EB3L

Connector Wiring Terminal Arrangement

EB3L-S16CSD-C

19

20

OI TouchscreensPLCsAutomation SoftwarePower SuppliesSensorsCommunicationBarriers

EB3L-S16CKD-C

19

20

CH10 CH11 CH12 CH13 CH14 CH15 CH16

CH9

S9 S10 S11 S12 S13 S14 S15 S16 NC NC

S2 S3 S4 S5 S6 S7 S8 C1 C2

S1

CH2 CH3 CH4 CH5 CH6 CH7 CH8 COM +V

CH1

EB3L

+V (C2)

+

Internal Circuit

CH10 CH11 CH12 CH13 CH14 CH15 CH16

CH9

S9 S10 S11 S12 S13 S14 S15 S16 NC NC

S2 S3 S4 S5 S6 S7 S8 C1 C2

S1

CH2 CH3 CH4 CH5 CH6 CH7 CH8 COM -V

CH1

EB3L PLC

+

Internal Circuit

S1-S16

COM (C1)

COM (C1)

S1-S16

Output

Q0-Q15

COM

COM

Output

Q0-Q15

PLC

CHn

1

Sn

2

+

Internal Circuit

CHn

1

Sn

2

–

Internal Circuit

COM

COM

Barriers

FC4A-T16K3 EB3L-S16CSD-C

Terminal Output Input Terminal

–

20 Q0 S1 20

19 Q10 S9 19

18 Q1 S2 18

17 Q11 S10 17

16 Q2 S3 16

15 Q12 S11 15

14 Q3 S4 14

13 Q13 S12 13

12 Q4 S5 12

11 Q14 S13 11

10 Q5 S6 10

+

9 Q15 S14 9

8 Q6 S7 8

7 Q16 S15 7

6 Q7 S8 6

5 Q17 S16 5

4 COM COM 4

3 COM NC 3

2 +V +V 2

1 +V NC 1

Note: The wiring in dashed line does not affect the operation of the EB3L.

Applicable connector is IDEC’s JE1S-201.

Output power for PLC outputs is supplied by the EB3L, therefore the PLC output does not need an

external power supply.

FC4A-T16S3 EB3L-S16CKD-C

Terminal Output Input Terminal

20 Q0 S1 20

19 Q10 S9 19

18 Q1 S2 18

17 Q11 S10 17

16 Q2 S3 16

15 Q12 S11 15

14 Q3 S4 14

13 Q13 S12 13

12 Q4 S5 12

11 Q14 S13 11

10 Q5 S6 10

9 Q15 S14 9

8 Q6 S7 8

7 Q16 S15 7

6 Q7 S8 6

5 Q17 S16 5

4 COM COM 4

3 COM NC 3

2 –V –V 2

1 –V NC 1

244

www.IDEC.com

Barriers

1. Common Wiring (Maximum 16 circuits) (Buzzers cannot be wired in a common line.)*

2. Separate Wiring

3. Wiring Illuminated Pushbuttons and Illuminated Selector Switches

(+) ( –)

(A maximum of 16 channels of EB3L and EB3C can be wired to a common line.)

EB3P consisting of one

enclosure

One int r insically sa fe circuit

Note:

When using t wo or more EB3L's

to set up one intrinsically sa fe circuit

in the common wiring configu ration,

interconnect two neut ral terminals

(N1 through N10) on each EB3L

between adjacent EB3L's in pa rallel .

L

N

(+) ( –)

L

N

(+) ( –)

L

N

(+) ( –)

L

N

(+) ( –)

L

N

(+) ( –)

L

N

S1S2S3S4S5S6S7S8C1C2S9

S10

S11

S12

S13

S14

S15

S16C3C4

S1S2S3S4S5S6S7S8C1C2S9

S10

S11

S12

S13

S14

S15

S16C3C4

P1P2P3P4P5P6P7

P8

N1

N2

P9

P10

P11

P12

P13

P14

P15

P16

N3

N4

P1P2P3P4P5P6P7

P8

N1

N2

P9

P10

P11

P12

P13

P14

P15

P16

N3

N4

S1

C1

P1N1P2N2P3

N3

P1N1P2N2P3

N3

P4N4P5N5P6

N6

P1N1P2N2P3

N3

P4N4P5

N5P6N6

P7

N7

P8N8P9

N9

P10

N10

S4C4S5C5S6

C6

S2C2S3

C3

(+) ( –)

L

N

S1

C1

P1N1P2N2P3

N3

S2C2S3

C3

(+) ( –)

L

N

S1

C1

P1N1P2N2P3

N3

S2C2S3

C3

S1

C1

S2C2S3

C3

(+) ( –)

L

N

P1N1P2N2P3

N3

P4N4P5N5P6

N6

S4C4S5C5S6

C6

S1

C1

S2C2S3

C3

(+) ( –)

L

N

P1N1P2N2P3

N3

P4N4P5N5P6

N6

S4C4S5C5S6

C6

S1

C1

S2C2S3

C3

S4C4S5C5S6

C6

S1

C1

S2C2S3

C3

S8C8S9

C9

S10

C10

S7

C7

(+) ( –)

L

N

P1N1P2N2P3

N3

P4N4P5

N5P6N6

P7

N7

P8N8P9

N9

P10

N10

S4C4S5C5S6

C6

S1

C1

S2C2S3

C3

S8C8S9

C9

S10

C10

S7

C7

(+) ( –)

L

N

P1N1P2N2P3

N3

P4N4P5

N5P6N6

P7

N7

P8N8P9

N9

P10

N10

S4C4S5C5S6

C6

S1

C1

S2C2S3

C3

S8C8S9

C9

S10

C10

S7

C7

LS3LS2LS1LB3LB2LB1LS3LS2LS1LB3LB2LB1

(+) ( –)

L

N

P1N1P2N2P3

N3

P4N4P5N5P6

N6

S4C4S5C5S6

C6

S1

C1

S2C2S3

C3

(+) ( –)

L

N

P1N1P2N2P3

N3

P4N4P5

N5P6N6

P7

N7

P8N8P9

N9

P10

N10

A4C4A5C5A6

C6

A1

C1

A2C2A3

C3

A8C8A9

C9

A10

C10

A7

C7

S1S2S3

S4

S7

S8

C1

C2

S5

S6

P1P2P3

P4

P7

P8

N1

N2

P5

P6

(+) ( –)

L

N

S1S2S3

S4

S7

S8

C1

C2

S5

S6

P1P2P3

P4

P7

P8

N1

N2

P5

P6

(+) ( –)

L

N

S1

C1

C2

P1

N1

N2

(+) ( –)

L

N

S1

C1

C2

P1

N1

N2

(+) ( –)

L

N

S1

C1

C2

P1

N1

N2

Diagram Symbols

One intrinsically safe circuit is a connection consisting

of one or more illuminated units connected to a common

line.

All output lines are wired to a common line inside the intrinsically safe equipment (one common line per intrinsically safe circuit) - DC input models only.

Each output line of the EB3L makes up one independent intrinsically safe circuit of a pilot light or buzzer.

The following example illustrates the wiring for a total of 10 contacts used by three illuminated

pushbuttons (LB1 to LB3) and three illuminated selector switches (LS1 to LS3).

All input lines are wired to a common line outside the intrinsically safe equipment (one common line per intrinsically safe circuit).

100

350

Connector B

Connector A

EB3L

Wiring Example of Intrinsically Safe External Outputs

OI Touchscreens PLCs Automation Software Power Supplies Sensors Communication Barriers

*This is permitted under TIIS approvals

Recommended Connector Cable for Connector Types

Description No. of Poles Length (m) Part Number Shape Applicable Type

0.5 FC9Z-H050A20

With Shield

Without Shield

20

I/O

Terminal

Cable

Cable with Crimping Terminal

40-pin Cable for PLC

1 FC9Z-H100A20

2 FC9Z-H200A20

3 FC9Z-H300A20

0.5 FC9Z-H050B20

1 FC9Z-H100B20

2 FC9Z-H200B20

3 FC9Z-H300B20

1 BX9Z-H100E4

3 BX9Z-H300E4

1 BX9Z-H100B

2 BX9Z-H200B

3 BX9Z-H300B

800-262-IDEC (4332) • USA & Canada

IDEC MicroSmart

I/O Module

IDEC MicroSmart

I/O Module

Screw Terminal2 BX9Z-H200E4

Mitsubishi A Series

Output Module (sink)

EB3L-S16CSD-C

245

EB3L

JE1S-201

IDEC Connector

JE1S-201

IDEC Connector

1 1

2 2

3 3

4 4

5 5

6 6

7 7

8 8

9 9

10 10

11 11

12 12

13 13

14 14

15 15

16 16

17 17

18 18

19 19

20 20

2 1

4 3

6 5

8 7

10 9

12 11

14 13

16 15

18 17

20 19

2 1

4 3

6 5

8 7

10 9

12 11

14 13

16 15

18 17

20 19

Fujitsu Connector

FCN-367J040-AU/F

BA

Connector A

IDEC

JE1S-201

Connector B

IDEC

JE1S-201

IDEC Connector

Y-shaped Compression Terminal

(Marking Tube No,)

JE1S-201

Intrinsically Safe Circuit

Barriers

OI TouchscreensPLCsAutomation SoftwarePower SuppliesSensorsCommunicationBarriers

246

FC9Z-H£££A, FC9Z-H£££B

BX9Z-H£££B Internal Connection

Internal Connection

IDEC Connector

JE1S-201

19

20

17

18

15

16

13

14

11

12

9

10

7

8

5

6

3

4

1

2

(Connection Side) (Connection Side)

IDEC Connector

JE1S-201

19 20

17 18

15 16

13 14

11 12

910

78

56

34

12

FC9Z-H£££ E4

Internal Connection

IDEC Connector

JE1S-201

1

2

5346

7

8

9

10

12

11

13

14

15

16

18

17

20

19

(Connection Side)

Y-shaped Compresion Terminal

(Marking Tube Number)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Precautions for Operation

Installation of EB3L Discrete Output Barriers

1. The EB3L can be installed in any direction.

2. Install the EB3L discrete output barrier in a safe area (non-hazard ous area) in

accordance with intrinsic safety ratings and parameters. To avoid mechanical

shocks, install the EB3L in an enclosure which suppresses shocks.

3. When installing or wiring the EB3L, prevent electromag netic and electrostatic

inductions in the intrinsically safe circuit. Also prevent the intrinsically safe

circuits from contacting with another intrinsically safe circuit and any other

circuits.

Maintain at least 50 mm clearance, or provide a metallic separating board

between the intrinsically safe circuit and non-intrinsically safety circuit. When

providing a metallic separating board, make sure that the board fits closely to

the enclosure (top, bottom, and both sides). Allowable clearance between the

enclosure and board is 1.5 mm at the maximum.

The clearance of 50 mm between the intrinsically safe circuit and non-intrin-

sically safe circuit may not be suffi cient when a motor circuit or high-voltage

circuit is installed nearby. In this case, provide a wider clearance between the

circuits referring to 6. (3) “Minimum Parallel Distance between the Intrinsically Safe Circuit and Other Circuits.”

www.IDEC.com

4. In order to prevent contact between intrinsically safe cir cuits and non-intrinsically safe circuits, mount EB3L units with terminals arranged in the same

direction.

Non-intrinsically

Safe Circuit

EB3L

EB3L

EB3L

EB3L

EB3L

Intrinsically Safe Circuit

5. Maintain at least 6 mm (or 3 mm according to IEC60079-11: 1999) clearance

between the terminal of intrinsically safe circuit and the grounded metal part

of a metal enclosure, and between the relay terminal block of an intrinsically

safe circuit and the grounded metal part of a metal enclosure.

6. For installing the EB3L, mount on a 35-mm-wide DIN rail or directly on a

panel using screws. The EB3L can be installed in any direction. Make sure to

install securely to withstand vibration. When mounting on a DIN rail, push in

the clamp completely. Use the BNL6 end clips on both sides of the EB3L to

prevent from moving sideways.

7. Excessive extraneous noise may cause malfunction and damage to the EB3L.

When extraneous noise activates the voltage limiting circuit (thyristor),

remove the noise source and restore the power.

Barriers

EB3L

Terminal Wiring

1. Using a ø5.5 mm or smaller screw driver, tighten the ter minal screws (including unused terminal screws) to a torque of 0.6 to 1.0 N·m (recommended

value).

2. Make sure that IP20 is achieved when wiring. Use insu lation tubes on bare

crimping terminals.

3. To prevent disengaged wires from contacting with other intrinsically safe

circuits, bind together the wires of one intrinsically safe circuit.

4. When the adjacent terminal is connected to another intrinsically safe circuit,

provide an insulation distance of at least 6 mm.

Signal Input

1. Connect the EB3L to the switches or output equipment which have a low leakage current (0.1 mA maximum).

2. The EB3L is equipped with power supply. Do not apply external power to the

EB3L.

3. When connecting the EB3L’s of connector type in paral lel, make sure that the

same power supply is used. When using C1 and C2 terminals to supply power

to out side equipment, maintain the current at 50 mA maxi mum.

Power Voltage

1. Do not apply an excessive power voltage, otherwise the EB3L may be damaged.

2. The EB3L of AC power type may operate at a low volt age (approx. 20V).

Pilot Lights and Buzzers in the Hazardous Area

1. EB3P and IPL1 units shown on page 238 can be used with the EB3L. Buzzers

cannot be connected in common wiring.

2. Install the EB3P and IPL1 units on enclosures of IP20 or higher protection.

Use a metallic enclosure with magne sium content of 7.5% or less (steel and

aluminum are acceptable).

3. When wiring, make sure of correct polarities of the EB3P and IPL1.

4. Certification mark is supplied with the units. Attach it on the visible area of

the EB3P or IPL1 (for Japan applica tion).

5. EB3P (except for buzzers) and IPL1 illuminated units, which are simple apparatuses in accordance with rele vant standards of each country, can be installed

in the hazardous area and connected to the EB3L located in the safe area.

6. When connecting illuminated switches to the EB3L discrete output barrier and

the EB3C discrete input barrier, a maximum of 16 channels can be connected

in common wiring.

Wiring for Intrinsic Safety

1. The voltage applied on the general circuit connected to the non-intrinsically

safe circuit terminals of the EB3L discrete output barrier must be 250V AC,

50/60Hz (ULrating: 125V AC 50/60Hz), or 250V DC (UL rating: 125V DC) at the

maximum under any conditions, including the voltage of the power line and

the internal circuit.

Safety Precautions

2. When wiring, take into consideration the prevention of electromagnetic and

electrostatic charges on intrinsically safe circuits. Also, prevent intrinsically

safe circuits from contacting with other circuits.

3. The intrinsically safe circuits must be separated from non-intrinsically safe circuits. Contain intrinsically safe circuits in a metallic tube or duct, or separate

the intrinsi cally safe circuits referring to the table at right.

Note: Cables with a magnetic shield, such as a metallic sheath, prevent elec tromagnetic induction and

electrostatic induction, however, a non-mag netic shield prevents electrostatic induction only. For

non-magnetic shields, take a preventive measure against electromagnetic induction.

Finely twisted pair cables prevent electromagnetic induc tion. Adding shields

to the twisted pair cables provides protection against electrostatic induction.

Voltage and Current

of Other Circuits

Over 440V 2000 2000 2000 2000

440V or less 2000 600 600 600

220V or less 2000 600 600 500

110V or less 2000 600 500 300

60V or less 2000 500 300 150

Note: Above chart is applicable under TIIS standards only.

Over 100A 100A or less 50A or less 10A or less

Minimum Parallel Distance between the Intrinsically Safe Circuit and Other Circuits (mm)

1. When identifying intrinsically safe circuits by color, use light blue terminal

blocks and cables.

2. When using two or more EB3L’s to set up one intrinsi cally safe circuit in the

common wiring configuration, interconnect two neutral terminals (N1 through

N10) on each EB3L between adjacent EB3L’s in parallel.

3. Make sure that the power of the EB3L, pilot lights, and other connected units

are turned off before starting inspection or replacement.

4. When wiring the intrinsically safe circuit, determine the dis tance to satisfy the

wiring parameters shown below. Note that parameters are different between

separate wiring and common wiring and depend on the connected units, such

as pilot lights, illuminated pushbuttons, and buzzers.

a) Wiring capacitance Cw ≤ Co – Ci

Co: Maximum external capacitance of the EB3L

Ci: Internal capacitance of the connected unit

b) Wiring inductance Lw ≤ Lo – Li

Lo: Maximum external inductance of the EB3L

Li: Internal inductance of the connected unit

c) Wiring resistance ≤ Rw

Rw: Allowable wiring resistance

d) Allowable wiring distance D (km) is the smallest value of those

calculated from the capacitance, inductance, and resistance.

D ≤ Cw/C C (nF/km): Capacitance of cable per km

D ≤ Lw/L L (mH/km): Inductance of cable per km

D ≤ Rw/2R R (Ω/km): Resistance of cable per km

Note: For the details of wiring the intrinsically safe circuits, refer to a rel evant test guideline for

explosion-proof electric equipment in each country.

OI Touchscreens PLCs Automation Software Power Supplies Sensors Communication Barriers

Do not use the EB3C Discrete Input Barrier and EB3L Discrete Output Barrier for other than explosion protection purposes.

Read the user’s manual to make sure of correct operation before starting installation, wiring, operation, maintenance, and inspection of the EB3C Discrete Input

Barrier and EB3L Discrete Output Barrier.

800-262-IDEC (4332) • USA & Canada

247

Loading...

Loading...