IDEC EB3C, EB3L, EB3N Catalog

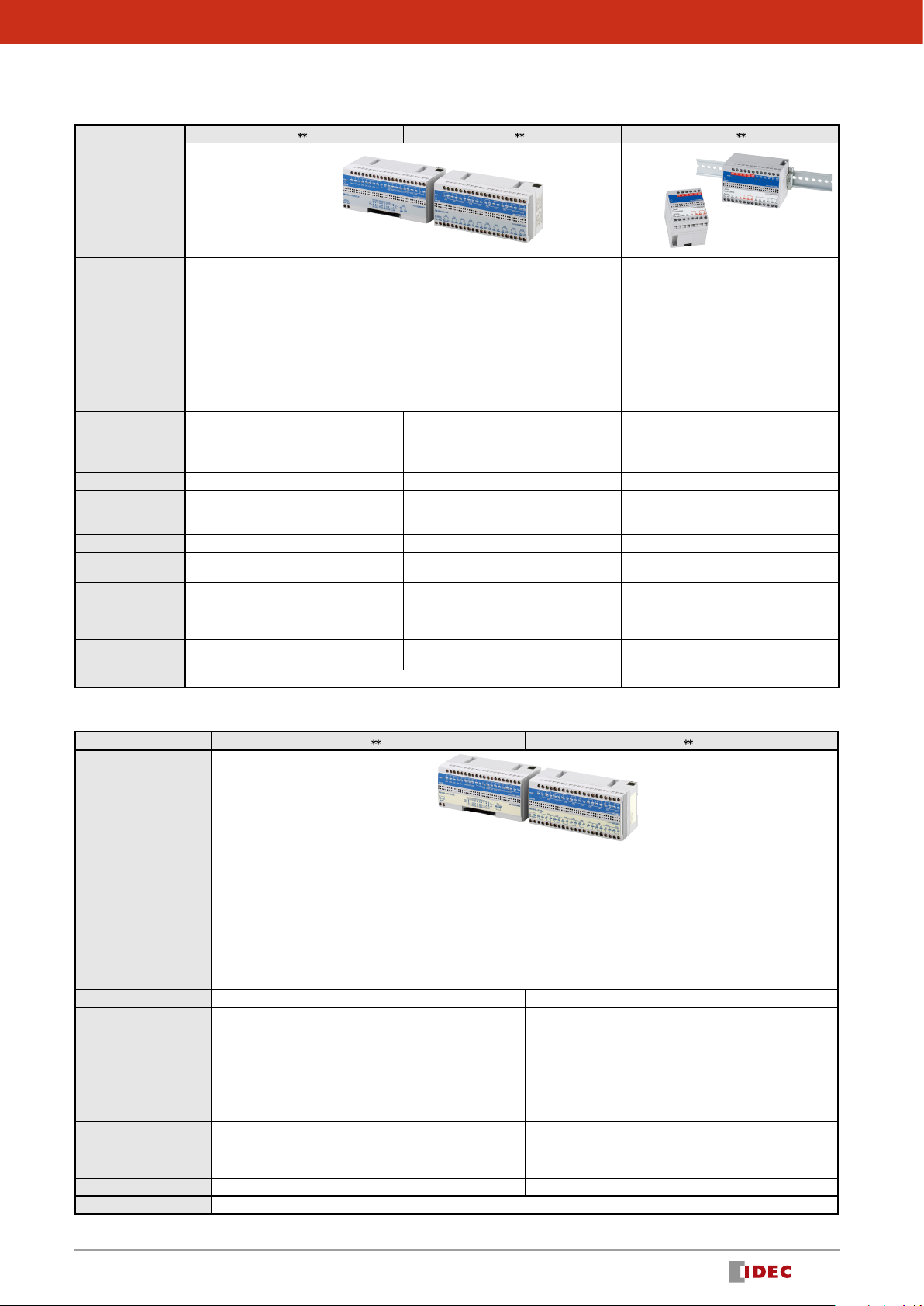

EB3C Relay Barriers

EB3L Lamp Barriers

EB3N Safety Relay Barriers

EB3N

EB3C Relay Barriers

Safety Relay Barriers

EB3L Lamp Barriers

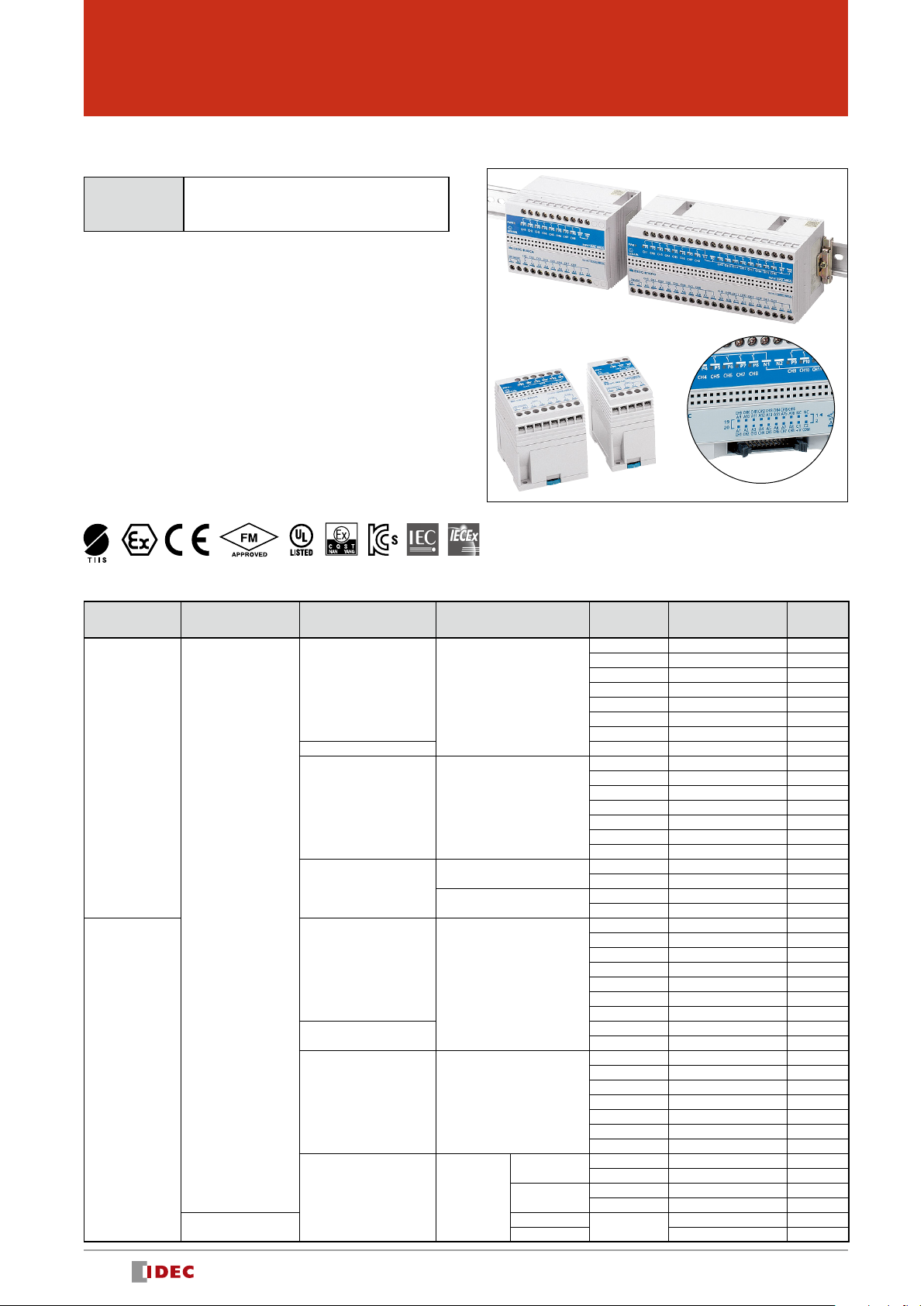

Intrinsically Safe Explosion-proof System

In order to establish an intrinsically safe explosion-proof system, a barrier must be selected depending on the type of device (such as) pushbutton,

pilot light, and proximity switch that are installed in the hazardous area. See the selection chart below.

Zone 0

Zone 1

Separate wiring·

Common wiring

Zone 2

Contacts

need to be

installed.

Safety input

equipment need

to be installed.

Relay barrier

Safety relay barrier

Common

wiring

Wiring conditionWiring conditionWiring condition

Without auxiliary

output

With auxiliary

output

Zone 0

Zone 1

Zone 2

Illuminated

switch needs to

be installed.

Relay barrier

Lamp barrier

Common

wiring

In an hazardous area....

Relay output

1NO

Output

Transistor

output

Auto

reset

Reset

Manual

reset

Relay output

Transistor output

Source input

Input/Output

Sink input

AC

DC

Power SupplyPower SupplyPower Supply

EB3N-A2∗DN

Page 24

EB3N-M2∗DN

Page 24

AC

DC

EB3C-∗∗AN

Relay barrier

Page 4

EB3C-∗∗DN

Relay barrier

Page 4

EB3C∗∗AN

Page 4

EB3L∗∗AN

Page 12

EB3C∗∗DN

Page 4

Pilot light

needs to be

installed.

Buzzer

needs to be

installed.

Lamp barrier

Separate wiring·

Common wiring

Common

wiring

Wiring condition

LED pilot light

Pilot Light

Buzzer (note)

EB3L∗∗DN

Page 12

AC

DC

EB3L-S∗AN

Lamp barrier

Page 12

EB3L-S∗DN

Lamp barrier

Page 12

2

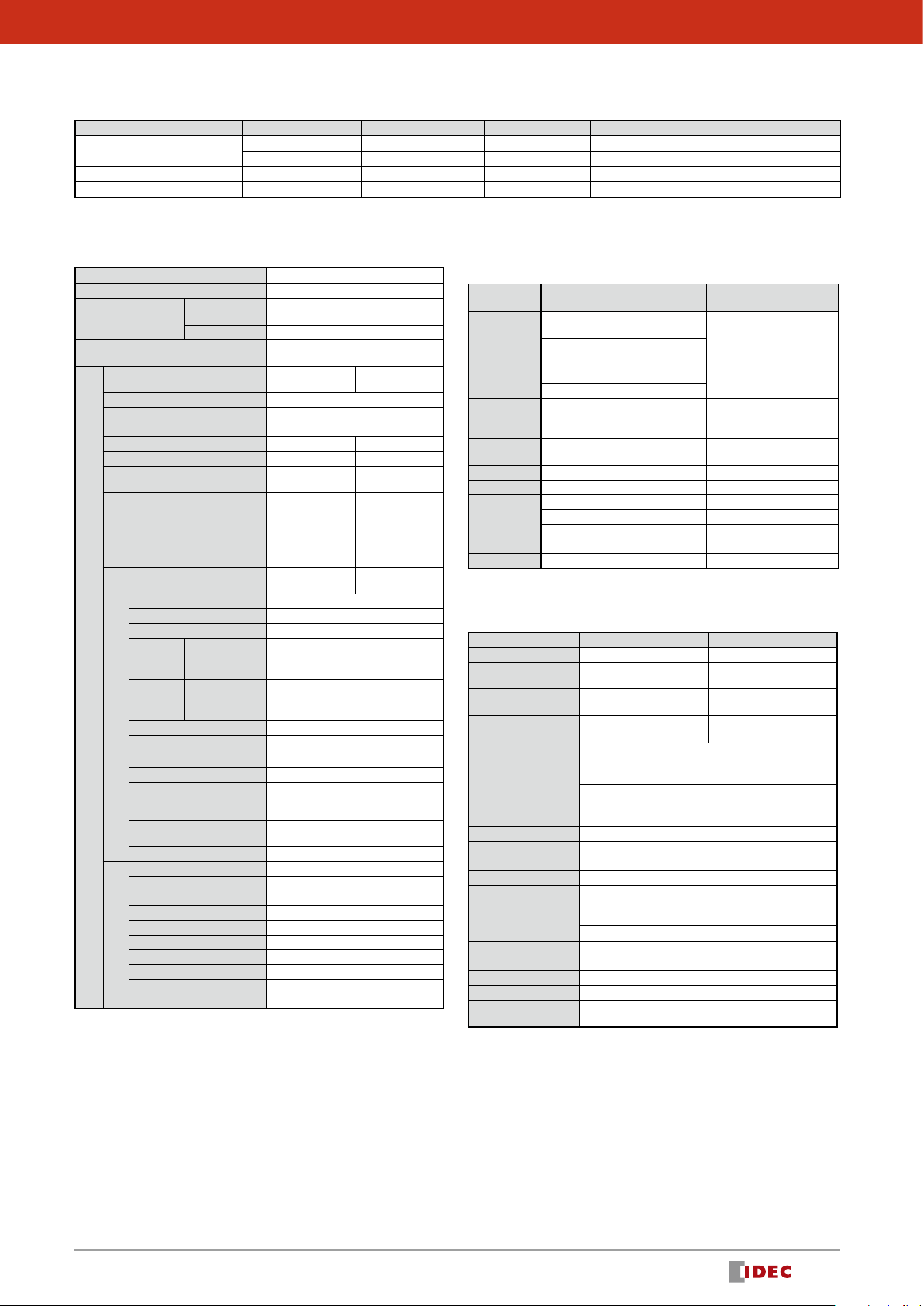

Relay Barrier

Model

Shape

Relay Barrier / Lamp Barrier Selection

EB3C- AN EB3C- DN EB3N- D

FM: Class I, II, III Div1 / Group A, B, C, D, E, F, G

UL: Class I, II, III Div1 / Group A, B, C, D, E, F, G

Class I, Zone 0 / AEx [ia] II C

Explosion Protection

Degree of Protection IP20 IP20 IP20

No. of Channels 1, 2, 3, 5, 6, 8, 10, 16 1, 2, 3, 5, 6, 8, 10, 16

Power Voltage 100 to 240V AC 24V DC 24V DC

Output

Connection Screw Terminal Screw Terminal, Connector Screw Terminal

Mounting

Size

(excluding projections)

Weight (approx.) 0.38kg (EB3C-R10AN) 0.39kg (EB3C-R16CDN)

Page 4 24

PTB (ATEX, IECEx): [Exia] II C, Exia] III C

CQST: [Exia Ga] II C

TIIS: [Exia] II C

KCS: [Exia] II C

NK: [Exia] II C

KR: [Exia] II C

Relay

Transistor

(Sink/Source)

35-mm-wide DIN rail

Panel mounting

42W×75H×77.5D (1 channel)

65W×75H×77.5D (2, 3 channels)

110.5W×75H×77.5D (5, 6, 8 channels (common))

171.5W×75H×77.5D (8, 10, 16 channels (common))

Class I, Zone 0 / AEx [ia] II C

Relay

Transistor

(Sink/Source)

35-mm-wide DIN rail

Panel mounting

42W×75H×77.5D (1 channel)

65W×75H×77.5D (2, 3 channels)

110.5W×75H×77.5D (5, 6, 8 channels (common))

171.5W×75H×77.5D (8, 10, 16 channels (common))

Relay Barrier: [Exia] II C

EB3N-£2ND: 2 safety circuits

EB3N-£2R5D: 2 safety circuits,

5 auxiliary circuits

Relay

35-mm-wide DIN rail / Panel mounting

65.0W×75.0H×77.5D

(EB3N-£2ND)

110.5W×75.0H×77.5D

(EB3N-£2R5D)

220g (EB3N-£2ND)

300g (EB3N-£2R5D)

Lamp Barrier

Model

EB3L- AN EB3L- DN

Shape

FM: Class I, II, III Div1 / Group A, B, C, D, E, F, G

UL: Class I, II, III Div1 / Group A, B, C, D, E, F, G

Class I, Zone 0 / [AEx ia] II C

Explosion Protection

Degree of Protection IP20 IP20

No. of Channels 1, 2, 3, 5, 6, 8, 10 1, 2, 3, 5, 6, 8, 10, 16

Power Voltage 100 to 240V AC 24V DC

Input/Output

Connection Screw Terminal Screw Terminal, Connector

Mounting

Size

(excluding projections)

Weight (approx.) 0.36kg (EB3L-S10SAN) 0.36kg (EB3L-S16CSDN)

Page

PTB (ATEX, IECEx): [Exia] II C, Exia] III C

CQST: [Exia Ga] II C

TIIS: [Exia] II C

KCS: [Exia] II C

NK: [Exia] II C

KR: [Exia] II C

Transistor input (sink)

Transistor input (source)

35-mm-wide DIN rail

Panel mounting

42W×75H×77.5D (1 channel)

65W×75H×77.5D (2, 3 channels)

110.5W×75H×77.5D (5, 6, 8 channels (common))

171.5W×75H×77.5D (8, 10 channels)

Class I, Zone 0 / AEx [ia] II C

Transistor input (sink)

Transistor input (source)

35-mm-wide DIN rail

Panel mounting

42W×75H×77.5D (1 channel)

65W×75H×77.5D (1 channel)

110.5W×75H×77.5D (5, 6, 8 channels (common))

171.5W×75H×77.5D (8, 10, 16 channels (common))

12

3

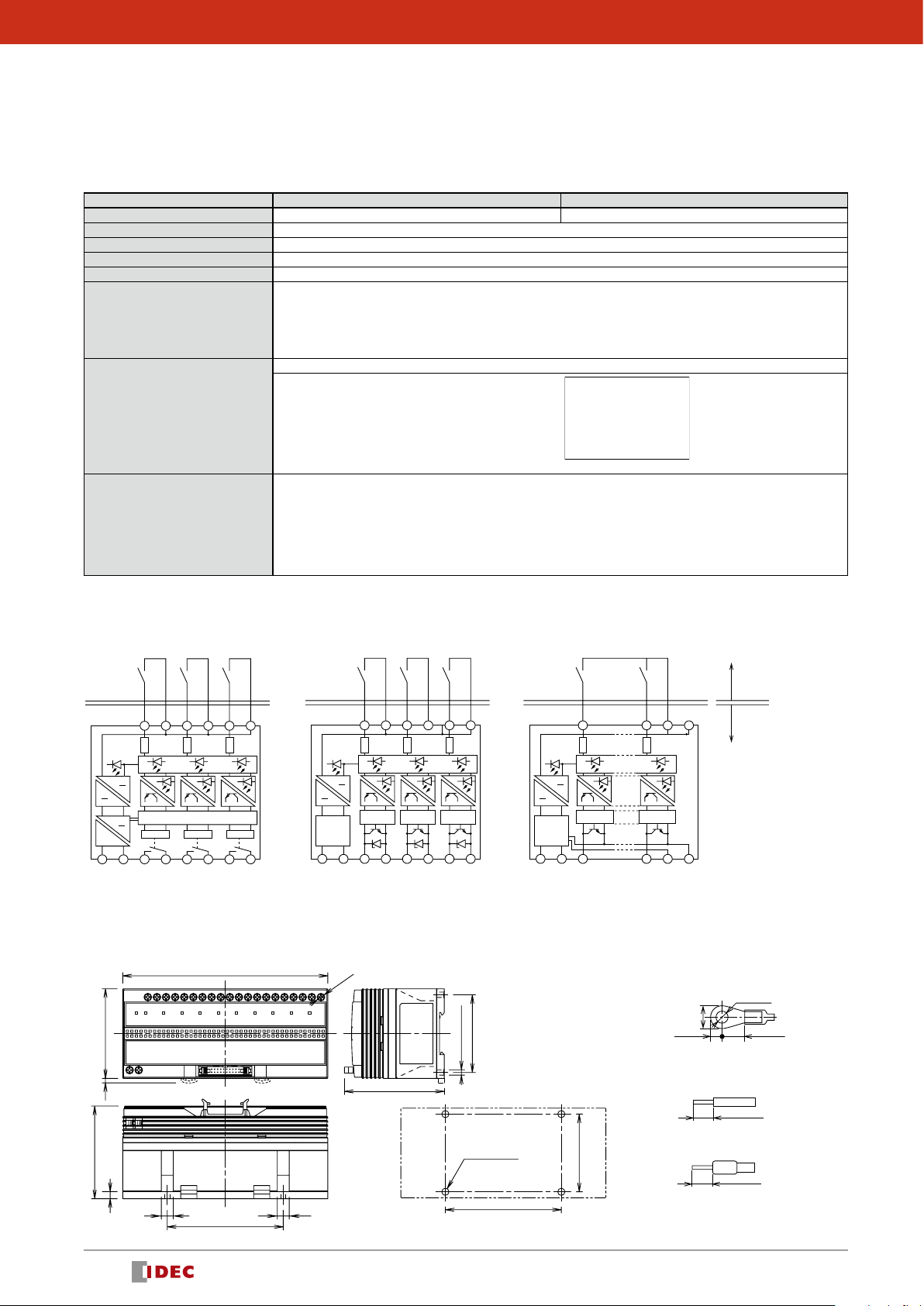

EB3C Relay Barriers

EB3C Relay Barriers

Input contacts can be used in any explosive gas and Zone 0/Class I Div. 1 areas.

Explosion

protection

Relay Barrier: [Exia] II C

Switch (EB9Z-A): Exia II CT6

Switch (EB9Z-A1): Exia II BT6

• IEC60079 compliant.

• Wide variety of models ranging from 1-circuit to 16 circuit models.

• 8- and 16-channel are available in common wiring, ideal for connection to

PLCs. 16-circuit also available with a connector.

• No grounding required.

• IDEC’s original spring-up terminal minimizes wiring time.

• 35-mm-wide DIN rail mounting or direct screw mounting.

• Global usage

IECEx

USA: FM, UL Europe: CE marking, ATEX

China: CQST Korea: KCS

Taiwan TS

Japan: TIIS

• Ship class: NK (Japan), KR (Korea)

Relay Barriers

Power

Voltage

100 to 240V AC

24V DC

Connection to

Non-intrinsically

Safe Circuit

Screw Terminal

Connector

Input Wiring Method Output

Separate/Common

Wiring Compatible

Common Wiring Only 8

Separate/Common

Wiring Compatible

Common Wiring Only

Separate/Common

Wiring Compatible

Common Wiring Only

Separate/Common

Wiring Compatible

Common Wiring Only Transistor

Relay

Transistor (Sink/Source)

Transistor (Sink)

Transistor (Source)

Relay

Transistor (Sink/Source)

Sink

Source

Sink

Source

Number of

Channels

1

2

3

5

6

8

10

1

2

3

5

6

8

10

8

16

8

16

1

2

3

5

6

8

10

8

16

1

2

3

5

6

8

10

8

16

8

16

16

Connector Model

Part No. Weight (g)

EB3C-R01AN

EB3C-R02AN

EB3C-R03AN

EB3C-R05AN

EB3C-R06AN

EB3C-R08AN

EB3C-R10AN

EB3C-R08CAN

EB3C-T01AN

EB3C-T02AN

EB3C-T03AN

EB3C-T05AN

EB3C-T06AN

EB3C-T08AN

EB3C-T10AN

EB3C-T08CKAN

EB3C-T16CKAN

EB3C-T08CSAN

EB3C-T16CSAN

EB3C-R01DN

EB3C-R02DN

EB3C-R03DN

EB3C-R05DN

EB3C-R06DN

EB3C-R08DN

EB3C-R10DN

EB3C-R08CDN

EB3C-R16CDN

EB3C-T01DN

EB3C-T02DN

EB3C-T03DN

EB3C-T05DN

EB3C-T06DN

EB3C-T08DN

EB3C-T10DN

EB3C-T08CKDN

EB3C-T16CKDN

EB3C-T08CSDN

EB3C-T16CSDN

EB3C-T16CKD-CN

EB3C-T16CSD-CN

150

180

190

260

270

300

380

280

140

170

180

250

260

320

340

260

260

260

260

130

170

180

250

260

260

360

270

390

120

160

170

240

250

250

320

250

350

250

350

330

330

4

EB3C Relay Barrriers

Accessories

Name Part No. Ordering No. Package Quantity Description

DIN Rail

End Clip BNL6 BNL6PN10 10 For fastening EB3C units on the DIN rail.

Static Electricity Caution Plate EB9Z-N1 EB9Z-N1PN10 10 Polyester 20 (W) x 6 (H) mm

Explosion-Protection and Electrical

Specifications

Explosion Protection Intrinsic safety type

Degree of Protection IP20 (IEC60529)

Installation Location

Non-intrinsically Safe Circuit

Maximum Voltage (Um)

Wiring Method

Rated Operating Voltage 12V DC ±10%

Rated Operating Current 10 mA DC ±20%

Maximum Output Voltage (Uo) 13.2V DC

Maximum Output Current (lo) 14.2 mA 227.2 mA

Maximum Output Power (Po) 46.9 mW 750 mW

Maximum External

Capacitance (Co) (Note 1)

Maximum External Inductance (Lo)

(Note 2)

Intrinsically Safe Circuits

Allowable Wiring Resistance (Rw) 300Ω

Maximum Channels per

Common Line

Contact Conguration 1NO

Rated Insulation Voltage (Ui) 250V AC, 125V DC

Thermal Current (lth) 3A (common terminal: 8A)

Contact

Allowable

Power

Rated

Load

Minimum Applicable Load 0.1V DC, 0.1 mA (reference value)

Contact Resistance

Relay Output

Turn ON Time 12 ms maximum (rated voltage)

Turn OFF Time 10 ms maximum (rated voltage)

Mechanical Life

Electrical Life

Short-circuit Protection None

Non-intrinsically Safe Circuits

Rated Voltage 24V DC

Maximum Voltage 30V DC

Maximum Current 100 mA (connector model: 15 mA)

Leakage Current 0.1 mA maximum

Voltage Drop 1.5 V maximum

Clamping Voltage 33V (1W)

Inrush Current 0.5A maximum (1 sec)

Transistor Output

Turn ON Time 0.1 ms maximum (resistive load)

Turn OFF Time 0.4 ms (typical) (resistive load)

Short-circuit Protection None

Note: Values in ( ) are those approved by TIIS (Technology Institution of Industrial Safety,

Japan).

Relay Barrier

Switch For zone 0, 1, 2 hazardous areas

Resistive Load AC: 750 VA, DC: 72W

Inductive Load

Resistive Load 250V AC 3A, 24V DC 3A

Inductive Load

BAA1000 BAA1000PN10 10 Aluminum (1m long)

BAP1000 BAP1000PN10 10 Steel (1m long)

Certification No.

Safe indoor place

(safe area: non-hazardous area)

250V AC

1-channel

Separate Wiring

470 nF (470 nF) 490 nF (365 nF)

87.5 mH (87.5 mH) 0.6 mH (0.425 mH)

– 16

16-channel

Common Wiring

600/(N+1)Ω

(N = number of

common

channels)

Certication

Organization

FM

UL

PTB (ATEX)

PTB (IECEx)

CQST [Exia Ga] II C CNEx14.0047

KCS [Exia] II C 14-AV4B0-0373

TIIS

NK [Exia] II C Type Test No. 13T606

KR [Exia] II C TYK17821-EL003

Note: For details about switches, see “Switch Explosion-Protection Specica tions” on page

6 and “3. Switches in the Hazardous Area” on page 10.

Explosion Protection Certication No.

Class I, II, III Div. 1

Group A, B, C, D, E, F, G

Class I, Zone 0 AEx [ia] II C

Class I, II, III, Div. 1

Group A, B, C, D, E, F, G

Class I, Zone 0 AEx [ia] II C

[Exia] II C: Gas, Vapour

[Exia] III C: Dust PTB09 ATEX2046

[Exia] II C: Gas, Vapour

[Exia] III C: Dust

Relay barrier: [Exia] II C TC20539

Switch (EB9Z-A): Exia II CT6 TC15758

Switch (EB9Z-A1): Exia II BT6 TC15961

General Specifications

Power Voltage AC Power DC Power

AC: 750 VA (cos ø = 0.3 to 0.4)

DC: 48W (L/R = 7 ms)

250V AC 3A (cos ø = 0.3 to 0.4)

24V DC 2A (L/R = 7 ms)

50 mΩ maximum (initial value)

20,000,000 operations minimum

(at 18,000 operations/hour, without load)

100,000 operations minimum

(at 1,800 operations/hour, rated load)

Rated Power Voltage 100 to 240V AC 24V DC

Allowable Voltage Range –15 to +10% ±10%

Rated Frequency

Inrush Current

Dielectric Strength

(1 minute, 1 mA)

Operating Temperature –20 to +60°C (no freezing)

Storage Temperature –20 to +60°C (no freezing)

Operating Humidity 45 to 85% RH (no condensation)

Atmosphere 800 to 1100 hPa

Pollution Degree 2 (IEC60664)

Insulation Resistance

Vibration Resistance

(damage limits)

Shock Resistance

(damage limits)

Terminal Style M3 screw terminal

Mounting 35-mm-wide DIN rail or panel mounting (M4 screw)

Power Consumption

(approx.)

50/60 Hz (allowable range: 47

to 63 Hz)

10A (100V AC)

20A (200V AC)

Between intrinsically safe circuit and non-intrinsically safe

circuit: 1526.4V AC

Between AC power and output terminal: 1500V AC

Between DC power and transistor output terminal:

1000V AC (screw terminal model only)

10 MΩ minimum (500V DC megger, between the same poles

as the dielectric strength)

Panel mounting: 10 to 55 Hz, amplitude 0.75 mm

DIN rail mounting: 10 to 55 Hz, amplitude 0.35 mm

Panel mounting: 500 m/s

DIN rail mounting: 300 m/s

9.6 VA (EB3C-R10AN at 200V AC)

4.8W (EB3C-R16CDN at 24V DC)

3047250

E234997

IECEx PTB10.0015

—

10A

2

(3 times each on X, Y, Z)

2

(3 times each on X, Y, Z)

5

Caution Label Example

A1NLC1A2C2A3C3

A1 C1 A2 C2 A3 C3–+

A1–+ A16 C1 C2

Area)

M3

77.5

Mounting Hole Layout

Applicable Crimping Terminal

EB3C Relay Barrriers

Switch Explosion-Protection Specifications (Japan only)

Simple apparatuses in accordance with relevant standards of each country can be installed in the hazardous area and connected to the EB3C located in the safe area.

In Japan, any switches, though regarded as simple apparatuses, must be certied for explosion-proof devices. EB9Z-A and EB9Z-A1 are IDEC’s generic Part No. of

any single apparatuses certied by TIIS for use with the EB3C, therefore simple appa ratuses with specications shown below can be used as those approved by the

Japanese explosion-proof certication.

Switch Part No. EB9Z-A EB9Z-A1

Explosion Proof (Note 1) Exia II CT6 Exia II BT6

Operating Temperature –20 to +60°C (no freezing)

Operating Humidity 45 to 85% RH (no condensation)

Degree of Protection IP20

Dielectric Strength 500V AC, 1 mA

Intrinsic Safety Ratings and Parameters

Enclosure Material

Switch Ratings (Note 2)

Note 1: See “Precautions for Operation” on page 10.

Note 2: For details, see “3. Switches in the Hazardous Area” on page 10.

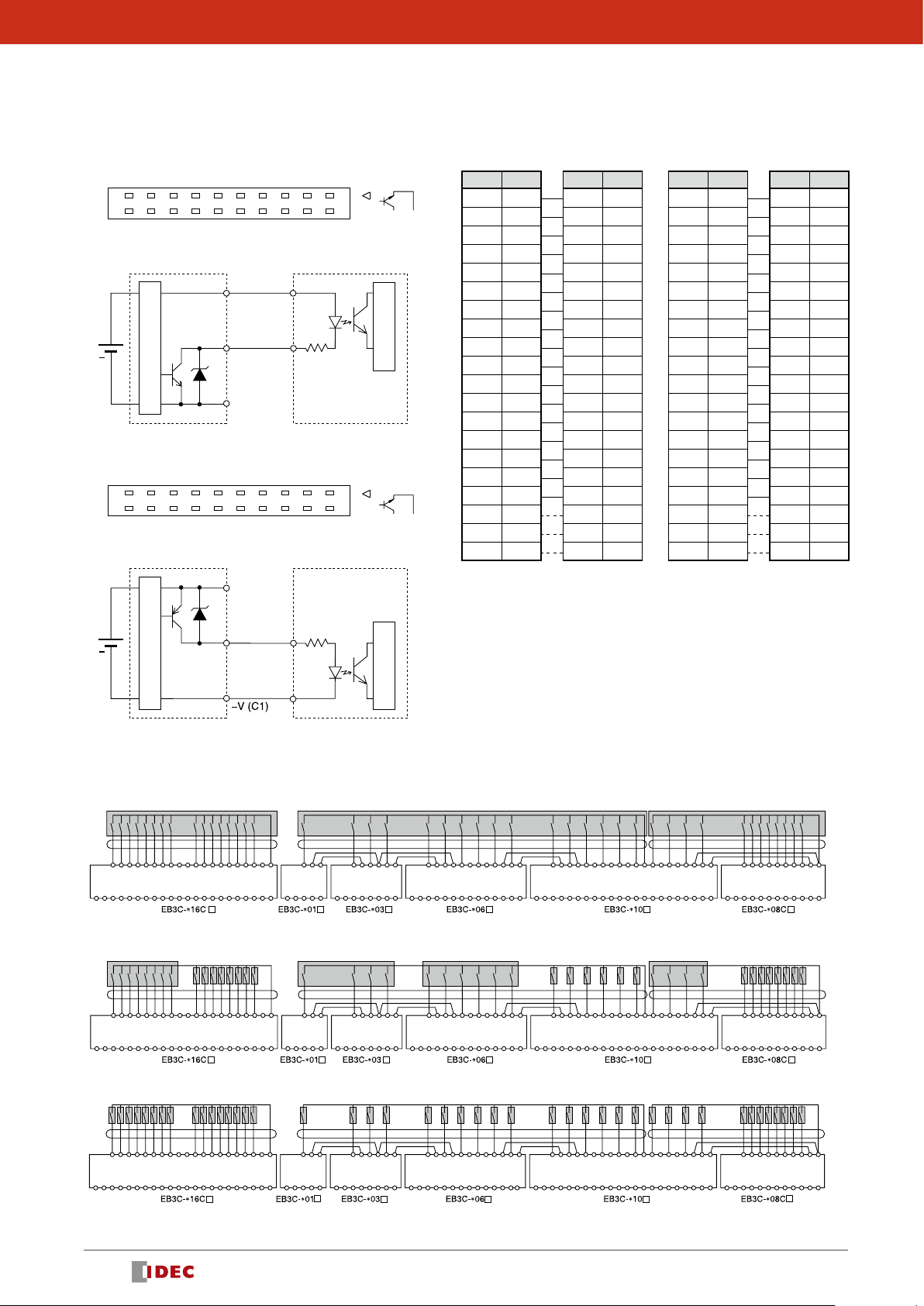

Internal Circuit Block Diagram

AC Power, Relay Output DC Power, Transistor Output Connector Wiring, Sink Output

1-channel Separate Wiring

Maximum input voltage (Ui): 13.2V

Maximum input current (Ii): 14.2 mA

Maximum input power (Pi): 46.9 mW

Internal capacitance (Ci): ≤ 2 nF

Internal inductance (Li): ≤ 5 µH

Metallic: Magnesium content must be 7.5% or less (steel and aluminum are acceptable)

Plastic: Switch operator exposed area

IIC: 20 cm2 maximum

IIB: 100 cm2 maximum

When the switch has a wider exposed area, attach a caution label as

shown at right.

Contact rating: Ui, Ii minimum

Contact resistance: 0.5Ω maximum

Cross sectional area of wire: 0.000962 mm2 minimum

Printed circuit board: Thickness 0.5 mm minimum

Copper foil width 0.15 mm minimum

Thickness 18 µm minimum one/both side(s)

A resistor to prevent contact welding and an LED can be connected to 1-channel separate wiring circuits.

Consult IDEC for details.

16-channel Common Wiring

Maximum input voltage (Ui): 13.2V

Maximum input current (Ii): 227.2 mA

Maximum input power (Pi): 750 mW

Internal capacitance (Ci): ≤ 32 nF

Internal inductance (Li): ≤ 80 µH

Caution

To prevent electrostatic

charges, do not rub the

switch surface during

operation. Use a soft cloth

dipped with water for

cleaning.

~

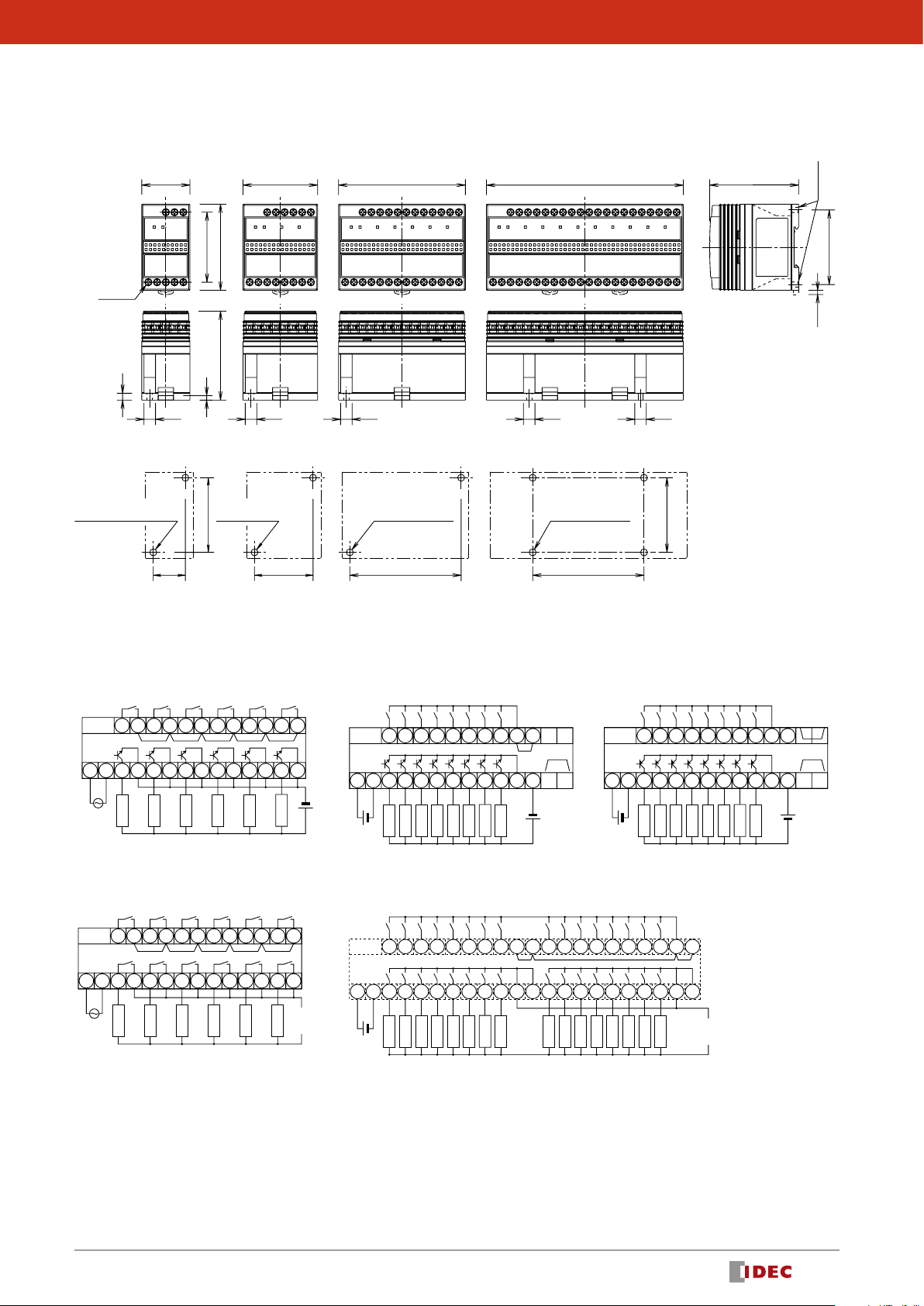

Dimensions

Connector Model

EB3C-T16C-CN

75

(4)

P1 N1 P2 N2 P3 N3

YellowYellowYellow

Green

6

10

171.5

97

••••••••

P1 N1 P2 N2 P3 N3

YellowYellowYellow

Green

~

~

~

ø6

65

4-ø4.4 hole

83.5

4-M4

or

4-4.5 holes

10

97

••••

P1 P16 N1 N2

YellowYellow

Green

~

~

~

••••

65

6 max.

Stripping the Wire End

Solid Wire

Stranded Wire (Ferrule)

Hazardous Area

Safe Area

(Non-hazardous

ø3.2 min.

5.4 min.3 max.

6 to 8 mm

6 to 8 mm

All dimensions in mm.

6

Screw Terminal

EB3C-∗01N

EB3C-∗10NEB3C-∗06NEB3C-∗03N

r

Load Power

Relay Output

(Ex.: EB3C-R06AN)

ø22 TW Series Switches & Pilot Lights

EB3C Relay Barrriers

EB3C-∗02N EB3C-∗05N EB3C-∗08N

EB3C-∗16CNEB3C-∗08CN

42

110.565 77.5

171.5

ø4.4

75

61

M3

ø6 hole

77.5

6

4

10

Mounting Hole Layout (Screw Mounting)

2-M4 tapped or

2-ø4.5 mounting holes

2-ø4.5 mounting holes

65

28 51 97 97

External Wiring Examples

Transistor Output

(Ex.: EB3C-T06AN)

2-M4 tapped or2-M4 tapped or

2-ø4.5 mounting holes

Transistor Sink Output

(Ex.: EB3C-T08CKDN)

4-M4 tapped or

4-ø4.5 mounting holes

Transistor Source Output

(Ex.: EB3C-T08CSDN)

65

(4)

10101010

65

240V AC

Note: On the sink/source transistor output model, ter minals

L N A1 C1 A2 C2 A3 C3 A4 C4 A5 C5 A6 C6

100 to

240V AC

P1 N1 P2 N2 P3 N3 P4 N4 P5 N5 P6 N6

L N A1 C1 A2 C2 A3 C3 A4 C4 A5 C5 A6 C6

100 to

Load

Load

Load

Load

Load

Load

A can be used as a positive common line.

P1 N1 P2 N2 P3 N3 P4 N4 P5 N5 P6 N6

Load

Load

Load

Load

Load

Load

Load

Power

AC/DC

P1 P2 P3 P4 P5 P6 P7 P8 N1 N2

+–

A1 A2 A3 A4 A5 A6 A7 A8 C1 C2

Load

Power

24V DC

24V DC

Load

Load

Relay Output Common Wiring

(Ex.: EB3C-R16CDN)

P1 P2 P3 P4 P5 P6 P7 P8 N1 N2

–

+

A1 A2 A3 A4 A5 A6 A7 A8 C1 C2P9A9

Load

24V DC

Load

Load

Load

Load

Load

P1 P2 P3 P4 P5 P6 P7 P8 N1 N2

+ – A1 A2 A3 A4 A5 A6 A7 A8 C1 C2

Load Powe

Load

Load

Load

24V DC

Load

24V DC

Load

Load

Load

Load

Load

Load

Load

Load

24V DC

P10

P11

P12

P13

P14

P15

P16

A10

A11

A12

A13

A14

A15

A16N3C3N4C4

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Power

AC/DC

7

+

–

COM

An

CHn

–

+

COM

An

CHn

COM

An

CHn

COM

An

CHn

EB3C PLC

+

EB3C PLC

+

EB3C Relay Barrriers

Connector Model Output Wiring Diagram

EB3C-T16CKD-CN (Sink)

CH10 CH11 CH12 CH13 CH14 CH15 CH16

CH9

A9 A10 A11 A12 A13 A14 A15 A16 NC NC

19

20

A2 A3 A4 A5 A6 A7 A8 C1 C2

A1

CH2 CH3 CH4 CH5 CH6 CH7 CH8 +V COM

CH1

+V (C1)

A1-A16

Internal Circuit

COM (C2)

EB3C-T16CSD-CN (Source)

CH10 CH11 CH12 CH13 CH14 CH15 CH16

CH9

A9 A10 A11 A12 A13 A14 A15 A16 NC NC

19

20

A2 A3 A4 A5 A6 A7 A8 C1 C2

A1

CH2 CH3 CH4 CH5 CH6 CH7 CH8 –V COM

CH1

COM (C2)

A1-A16

COM

Input

I0-I15

Input

I0-I15

1

2

1

2

–

+

Internal Circuit

+

–

Wiring Example with IDEC’s MicroSmart PLC Input Modules

EB3C-T16CKD-CN

Terminal Output

20 A1

19 A9

18 A2

17 A10

16 A3

15 A11

14 A4

13 A12

12 A5

11 A13

10 A6

9 A14

8 A7

7 A15

6 A8

5 A16

4 +V

3 NC

2 COM

1 NC

Note: The wiring in dashed line does not affect the operation of the EB3C.

Applicable connector is IDEC’s JE1S-201.

Input power for PLC inputs is supplied by the EB3C, therefore the PLC input does not

need an external power supply.

FC4A-N16B3

Input Terminal

I0 20

I10 19

I1 18

I11 17

I2 16

I12 15

I3 14

I13 13

I4 12

I14 11

I5 10

I15 9

I6 8

I16 7

I7 6

I17 5

COM 4

COM 3

NC 2

NC 1

EB3C-T16CSD-CN

Terminal Output

20 A1

19 A9

18 A2

17 A10

16 A3

15 A11

14 A4

13 A12

12 A5

11 A13

10 A6

9 A14

8 A7

7 A15

6 A8

5 A16

4 –V

3 NC

2 COM

1 NC

FC4A-N16B3

Input Terminal

I0 20

I10 19

I1 18

I11 17

I2 16

I12 15

I3 14

I13 13

I4 12

I14 11

I5 10

I15 9

I6 8

I16 7

I7 6

I17 5

COM 4

COM 3

NC 2

NC 1

Internal Circuit

COM

Internal Circuit

Wiring Example of Intrinsically Safe External Inputs

e wired to a common line inside the intrinsically safe switch (one common line per intrinsically safe circuit).

P1P2P3P4P5P6P7

L

NA1A2A3A4A5A6A7A8C1C2A9A10

P1P2P3P4P5P6P7

LNA1A2A3A4A5A6A7A8C1C2A9

P8

N1

N2

P8

N1

N2

e wired to a common line outside the intrinsically safe switch (one common line per intrinsically safe circuit).

P9

P10

P11

P12

P13

P14

P15

P16

A11

A12

A13

A14

A15

A16C3C4

N3

N4

P1

LNA1C1C2

NNNN

P9

P10

P11

P12

P13

P14

P15

A10

P16

A11

A12

A13

A14

A15

A16C3C4

N3

N4

P1

LNA1C1C2

N

N1

N1

N2

N2

N

P1N1P2

LNA1C1A2

P1N1P2

LNA1C1A2

P1N1P2

C2 N2

A3 P3

C3 N3LNA1C1

while others are outside switches

P1N1P2

C2 N2

A3 P3

C3 N3LNA1C1

NN N

P1N1P2

A2

C2 N2

A3 P3

C3 N3

A4 P4

C4 N4

A5 P5

C5 N5

A6 P6

C6 N6LNA1C1

A2

C2 N2

A3 P3

C3 N3

A4 P4

C4 N4

A5 P5

C5 N5

A6 P6

C6 N6

A7 P7

C7 N7

A8 P8

C8 N8

A9 P9

C9 N9

N

P1N1P2

A2

C2 N2

A3 P3

C3 N3

A4 P4

C4 N4

A5 P5

C5 N5

A6 P6

C6 N6LNA1C1

A2

C2 N2

A3 P3

C3 N3

A4 P4

C4 N4

A5 P5

C5 N5

A6 P6

C6 N6

A7 P7

C7 N7

A8 P8

C8 N8

A9 P9

C9 N9

A10 P10

C10 N10LNA1A2

A10 P10

C10 N10LNA1A2

P1P2P3

P1P2P3

A3

A4 P4

A5 P5

A6 P6

A7 P7

A8 P8

C1 N1

C2 N2

N

A3

A4 P4

A5 P5

A6 P6

A7 P7

A8 P8

C1 N1

C2 N2

N

P1P2P3P4P5P6P7

LNA1A2A3A4A5A6A7A8C1C2A9

8

P8

P9

N1

N2

P10

P11

P12

P13

P14

P15

A10

P16

A11

A12

A13

A14

A15

A16C3C4

N

N3

N4

P1

N1

LNA1C1C2

N2

N

P1N1P2

LNA1C1A2

C2 N2

A3 P3

C3 N3LNA1C1

P1N1P2

A2

C2 N2

A3 P3

C3 N3

A4 P4

C4 N4

A5 P5

C5 N5

A6 P6

C6 N6LNA1C1

P1N1P2

A2

C2 N2

A3 P3

C3 N3

A4 P4

C4 N4

A5 P5

NN NN

P1P2P3

C5 N5

A6 P6

C6 N6

A7 P7

C7 N7

A8 P8

C8 N8

A9 P9

C9 N9

A10 P10

C10 N10LNA1A2

A3

A4 P4

A5 P5

A6 P6

A7 P7

A8 P8

C1 N1

C2 N2

Loading...

Loading...