Page 1

DS2 series Instruction manual

INDEX

1. GENERAL INFORMATION..................................................................................................................... 1

1.1. General description of the AREAscan

TM

light grid............................................................................ 1

1.2. Selecting the device ......................................................................................................................... 2

1.3. Typical applications .......................................................................................................................... 3

2 INSTALLATION MODES ........................................................................................................................4

2.1. Precautions to be observed for the choice and installation of the device........................................ 4

2.2. General information on device positioning.......................................................................................4

2.2.1. Minimum installation distance ................................................................................................ 4

2.2.2. Minimum distance from reflecting surfaces ........................................................................... 5

2.2.3. Installation of several adjacent light grids .............................................................................. 6

3. MECHANICAL MOUNTING .................................................................................................................... 7

4. ELECTRICAL CONNECTIONS...............................................................................................................8

4.1. Notes on connections....................................................................................................................... 9

5. FUNCTIONING MODES........................................................................................................................ 10

5.1. Detection mode ..............................................................................................................................10

5.2. Measurement mode ....................................................................................................................... 10

5.3. Transition detection (number of transitions)................................................................................... 11

5.4. Notes on functioning mode ............................................................................................................11

5.5. RS485 serial output setting ............................................................................................................ 12

6. FUNCTION AND PROGRAMMING SELECTION................................................................................. 12

6.1. Local programming.........................................................................................................................13

6.1.1. Teach-in with detection ........................................................................................................ 14

6.1.2. Absolute detection mode ..................................................................................................... 15

6.1.3. Relative detection mode ...................................................................................................... 16

6.2. Remote programming..................................................................................................................... 17

6.2.1. DS2 user interface – General information ........................................................................... 18

6.2.2. Program installation .............................................................................................................19

6.2.3. Graphic user interface..........................................................................................................20

6.2.4. Connection with AREAscanTM DS2 series........................................................................... 20

6.2.5. Configuration of the AREAscanTM DS2 series ..................................................................... 24

6.2.6. File saving of the configuration options ............................................................................... 29

6.2.7. File loading of the configuration options ..............................................................................29

7. AREASCANTM DS2 SERIES – COMMUNICATION PROTOCOL........................................................30

7.1. Packet description .......................................................................................................................... 30

7.1.1 Binary data packet structure ................................................................................................30

7.1.2. Short protocol binary data packet structure ......................................................................... 30

7.1.3. ASCII data packet structure ................................................................................................. 30

7.2 Operating mode: DS2 (master) Host Interface (slave) .............................................................. 31

7.2.1. Packet description................................................................................................................31

7.3. Configuration mode: DS2 (slave) Host (master) ....................................................................... 34

7.3.1 Host appropriation procedure of the bus ............................................................................. 34

7.3.2 Command packet description: .............................................................................................35

8. DIAGNOSTIC FUNCTIONS AND LED INTERFACE ERROR SIGNALLING ...................................... 41

8.1. Device status visualisation .............................................................................................................41

9. CHECKS AND PERIODICAL MAINTENANCE.................................................................................... 42

10. TECHNICAL DATA ............................................................................................................................... 43

10.1. Response time ......................................................................................................................... 43

11. LIST OF AVAILABLE MODELS ........................................................................................................... 44

12. OVERALL DIMENSIONS ...................................................................................................................... 44

Page 2

Instruction manual DS2 series

1. GENERAL INFORMATION

1.1. General description of the AREAscan

TM

light grid

The AREAscanTM light grids are multibeam optoelectronic devices that can be used to detect objects,

including small and transparent targets as well as for measurement detection.

The variety of functions implemented make the DS2 a particularly flexible device that suits many

different applications.

The AREAscan

TM

light grids of the DS2 series are manufactured in accordance with the international

Standards in force and in particular:

CEI EN 60947-5-2: low voltage proximity devices

CEI EN 50319: proximity switches: requirements for proximity switches with analogue

output

The device, consisting of emitter and receiver units housed inside sturdy aluminium profiles, generates

infrared beams that detect any object positioned in the light grid’s detection field.

The command and control functions are inside the two units; the connections are made through M12

connectors located in the lower side of the profiles.

The synchronisation between the emitter and the receiver takes place via cable through direct

connection between the two units.

The control and management of the emitted and received beams are guaranteed by microprocessors.

The operator obtains information relative to the light grid status and error conditions through LEDs

located on the device and/or through the control interface of a remote PC.

Some parts or paragraphs of this manual, containing important information for the operator, are

proceeded by a note:

Notes and detailed descriptions about particular characteristics of the AREAscan

been added to better explain functioning.

DATASENSOR Technical Support is available for questions related to the functioning and installation

of the DS2 series light grids and for any information and/or suggestions necessary for a correct

installation (see section 9 “Checks and periodical maintenance”).

AREAscan

TM

ARE NOT safety devices; the use of the device for safety purposes and operator

safeguarding is not conform and dangerous.

TM

devices have

1

Page 3

DS2 series Instruction manual

1.2. Selecting the device

The selection of the correct device version is linked to the detection area needed, which is considered

as the sensitive area height of the device as well as to the maximum operating distance, considered

as the distance between the emitter unit (TX) and receiver unit (RX) and optics interaxis.

Versions are available:

DS2-05-07-015-JV

DS2-05-07-030-JV

DS2-05-07-045-JV

DS2-05-07-060-JV

DS2-05-07-075-JV

DS2-05-07-090-JV

DS2-05-07-105-JV

DS2-05-07-120-JV

DS2-05-07-135-JV

DS2-05-07-150-JV

DS2-05-07-165-JV

Operating distance Detection field

5m

5m

5m

5m

5m

5m

5m

5m

5m

5m

5m

21 beams; h=150mm 6.75mm

42 beams; h=300mm

63 beams; h=450mm

84 beams; h=600mm

105 beams; h=750mm

126 beams; h=900mm

147 beams; h=1050mm

168 beams; h=1200mm

189 beams; h=1350mm

210 beams; h=1500mm

231 beams; h=1650mm

interaxis

6.75mm

6.75mm

6.75mm

6.75mm

6.75mm

6.75mm

6.75mm

6.75mm

6.75mm

6.75mm

DS2-05-25-045-JV

DS2-05-25-060-JV

DS2-05-25-075-JV

DS2-05-25-090-JV

10m 18 beams; h=450mm 25mm

10m

10m

10m

24 beams; h=600mm 25mm

30 beams; h=750mm 25mm

36 beams; h=900mm 25mm

The functions characterising the DS2 AREAscan

TM

light grids are available on all the versions that

consequently have the same operating modes.

The specific technical characteristics (e.g. resolution, sensitivity etc) remain the same for all the

versions, until differently indicated.

For food industry applications, please verify with DATASENSOR Technical Support the compatibility of

the materials of the light grid shell with the eventual chemical agents that are used in the production

process.

2

Page 4

Instruction manual DS2 series

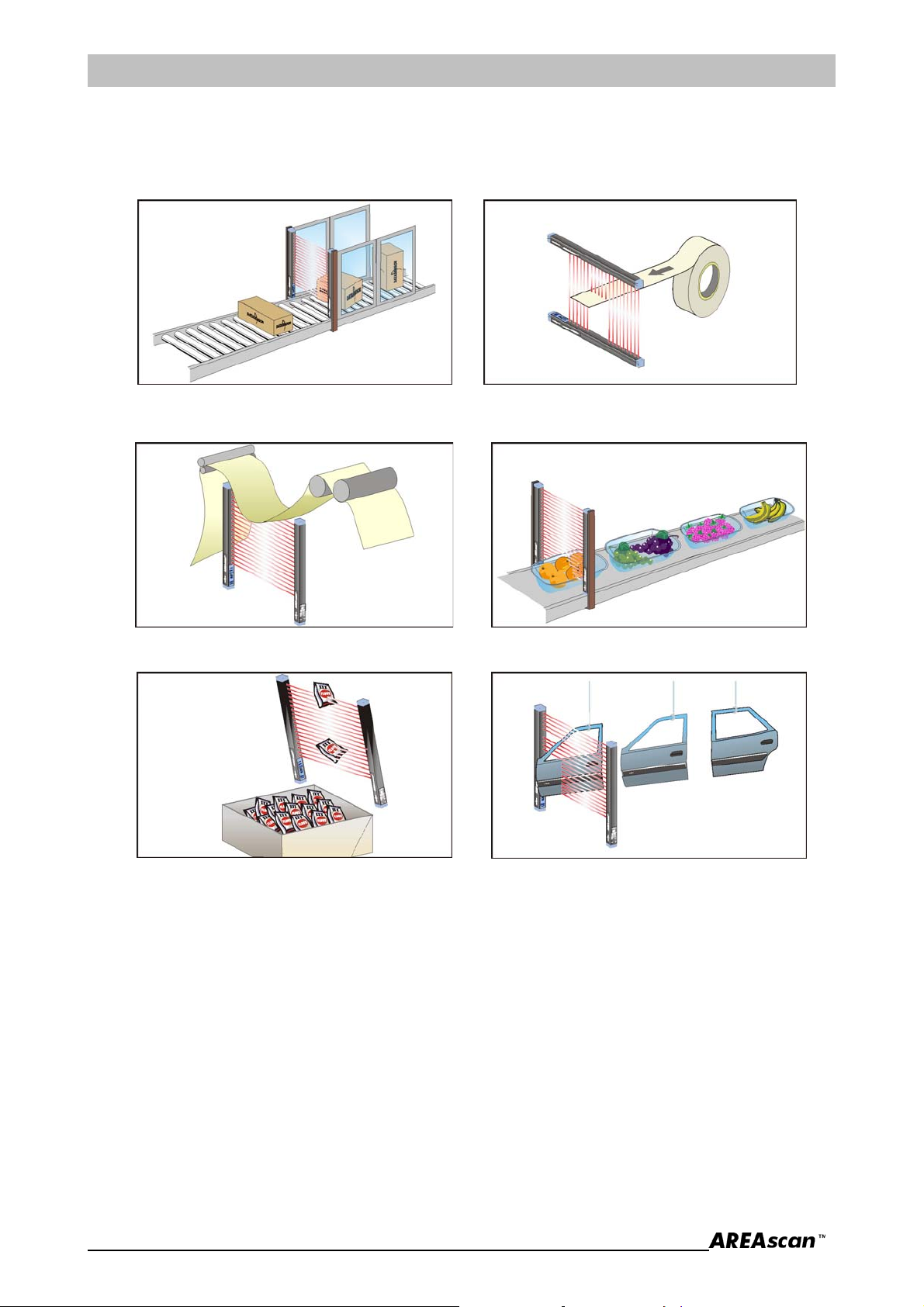

1.3. Typical applications

The following images supply an overview on some main applications.

Object detection and measurement on conveyor belt

Loop control and positioning (also transparent material)

Control of the correct material positioning (opaque and transparent)

during functioning (plastic, metal, paper etc)

Detection of objects with different shapes in the food industry

Detection of objects in different positions (parallel beams)

Detection of slots and holes in different positions

3

Page 5

DS2 series Instruction manual

2 INSTALLATION MODES

2.1. Precautions to be observed for the choice and installation of the device

• The dimension of the smallest object to be detected should not to be lower than the resolution level of

the device.

• The DS2 should be installed in a place compatible with the technical characteristics (see section 10

“Technical Data”) of the AREAscan

TM

light grids.

Other considerations:

- avoid installation near very intense and/or flashing light sources, in particular near the receiver

unit.

- strong electromagnetic interference can compromise the correct functioning of the device. Please

contact DATASENSOR Technical Service when this problem occurs.

- the operating distance of the device can be reduced in the presence of smog, fog or airborne

dust.

- a sudden change in environment temperature, with very low minimum peaks, can generate a

small condensation layer on the lenses and jeopardise functioning.

- relevant variations of the power supply can reduce the operating distance of the device.

2.2. General information on device positioning

• Place the device near the detection area.

• Align the receiver (RX) and emitter (TX) units in order that they are the most parallel possible.

Verify that the green receiver LED is on (stability condition), otherwise slight adjustments of both

units have to be made in order to reach the stability position.

• Fix the receiver and emitter units on rigid supports not conditioned by strong vibrations using

specific fixing brackets (see section 3 “Mechanical mounting”)

• Check that the distance between the receiver and emitter units is within the device operating

distance (see section 10 “Technical data”)

2.2.1. Minimum installation distance

The minimum installation distance corresponds to the minimum operating distance = 0.3 m.

4

Page 6

Instruction manual DS2 series

2.2.2. Minimum distance from reflecting surfaces

Reflecting surfaces placed near light beams of the AREAscanTM device (over, under or laterally)

may cause passive reflections that can compromise the detection of an object inside the controlled

area (see Fig.1).

Fig. 1

However, the object may not be detected if the receiver detects a secondary beam (reflected by the

side-reflecting surface), even if the entering object interrupts the main beam.

It is thus important to position the units at the correct distance from any reflecting surface:

The minimum distance depends on:

- device operating distance

- reflecting surface nature

- position of the object inside the sensitive area

It is necessary to evaluate this distance on the field according to the operating conditions; however

a minimum distance from the reflecting surface of about 0.5 m is suggested.

5

Page 7

DS2 series Instruction manual

2.2.3. Installation of several adjacent light grids

When several devices must be installed in adjacent areas, it is necessary to prevent the

interference between the emitter of one device and the receiver of another.

Fig.2 provides an installation example of possible interference between different devices and two

possible solutions.

NO

SI

SI

Fig. 2

6

Page 8

Instruction manual DS2 series

3. MECHANICAL MOUNTING

The emitter and receiver units have to be mounted with the relevant sensitive

surfaces facing each other. The connectors must be positioned on the same

side and with the operating distance of the model used (see section 10

“Technical data”).

The two units must be aligned and parallel as much as possible.

To mount the device, insert the threaded pins supplied (see Fig.3) in the slots

present on the two units.

Depending on the particular application and/or type of support, the operator

can use the fixing pins or the rigid fixing brackets supplied to mount the two

units (see Fig.4).

Fig. 3

Fig. 4

Rigid fixing brackets can be used where no big mechanical corrections are required during the

alignment operation.

Rotating supports for the correction of the unit inclination of ±1° on the medial transversal axis and of

±5° on the longitudinal axis, are available on request.

In applications with particularly strong vibrations, the use of anti-vibration shock absorbers able to

reduce the impact of vibrations together with threaded pins, rigid brackets and/or rotating supports are

recommended.

7

Page 9

DS2 series Instruction manual

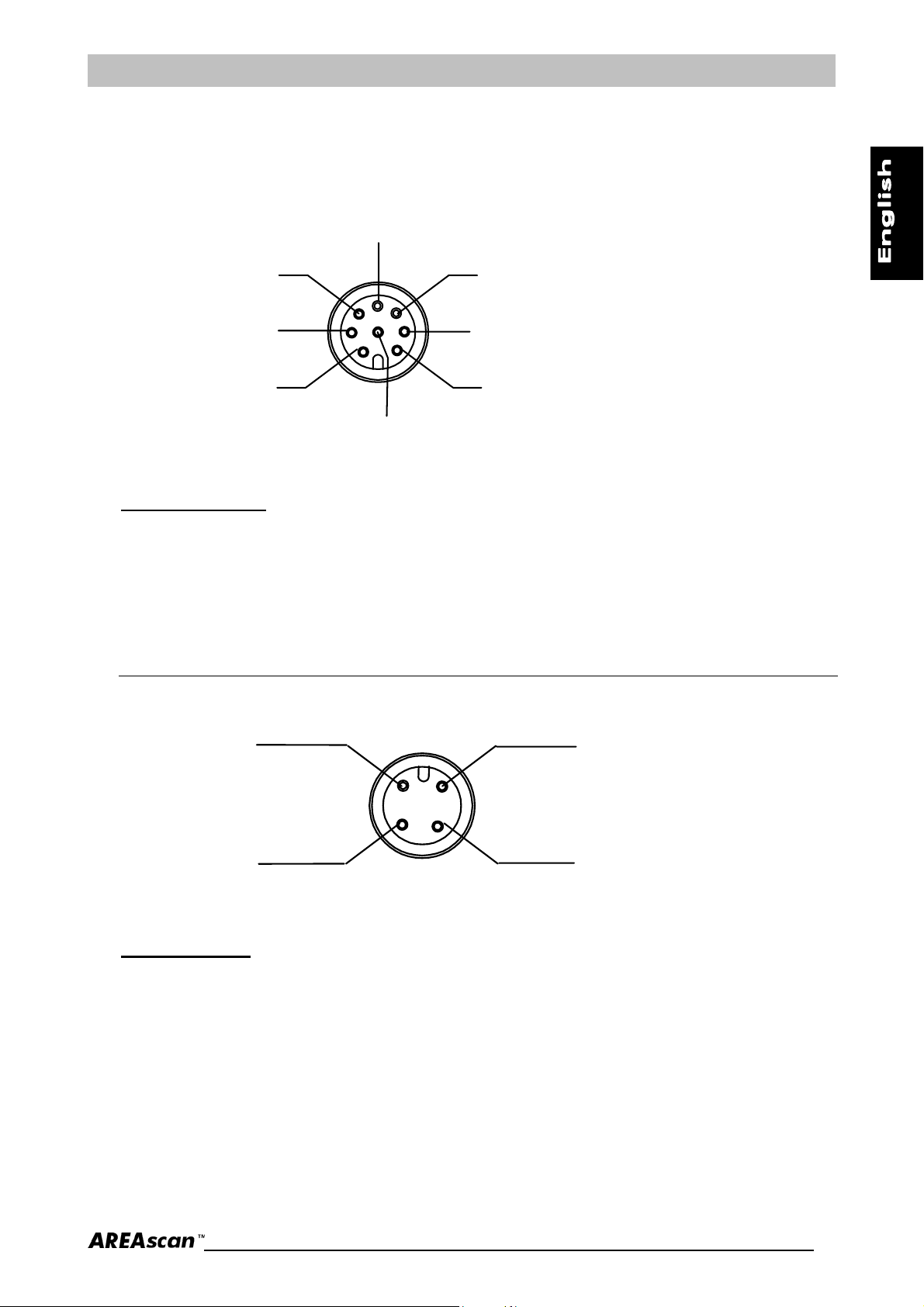

4. ELECTRICAL CONNECTIONS

The electrical connection between the emitting and receiving units is made through a male M12

connector located in the lower part of the light grid.

TEACH-IN /

(OUTPUT HOLD) / (SERIAL OUTPUT ENABLE)

RECEIVER (RX):

RX/TX +

GND

RX/TX -

NOT USED

5

6

7

1

4

3

2

8

SYNC

1 = white = RX/TX 2 = brown = +VDC

3 = green = ANALOGUE OUT

4 = yellow = SWITCHING OUTPUT

5 = grey = TEACH-IN / (OUT HOLD) / (SERIAL OUT ENABLE)

6 = pink = RX/TX +

7 = blue = GND

8 = red = SYNC

SWITCHING OUTPUT

ANALOGUE OUTPUT

+ VDC

+VDC

2

1

EMITTER (TX):

GND

3

4

SYNC

8

1 = brown = +VDC

2 = white = NOT USED

3 = blue = GND

4 = black = SYNC

Page 10

Instruction manual DS2 series

4.1. Notes on connections

The following precautions regarding electrical connections have to be respected for the correct

functioning of the AREAscan

TM

light grid.

• Shielded cables are not foreseen in the standard connection.

However, if necessary, these cables can be used in presence of ground connection of both the unit

and cable, as shown in Fig.5.

Fig. 5

• In any case, these cables must not be placed in contact with or near any high voltage cables (e.g.

motor power supplies, inverters, etc) that, generating strong electromagnetic fields, can

compromise the correct functioning of the device.

• Ground connection of the two units is not necessary. However, if required, the connection is

possible tightening the specific screw supplied instead of one of the 8 screws that lock the heads of

each unit (see Fig.6).

• Follow the connection illustrated in Fig.5 when ground connection of the entire system is used.

Fig. 6

9

Page 11

DS2 series Instruction manual

5. FUNCTIONING MODES

The DS2 light grids detect and measure objects placed inside the detection area. Hence, beam

interruptions can cause output switching, analogue output signal variation and serial output updating.

Small objects (up to 12 mm) detection and geometrical measurements determined with approximately 6

mm resolution can be obtained by setting the device according to the different functioning modes.

Beam scanning is sequential and the update of all the outputs is made at each scanning, within a period

equal to the device response time.

5.1. Detection mode

The detection mode is activated whenever at least one beam is interrupted inside the detection area.

The activation causes the digital output switching (signalled by the powering of the yellow LED). The

DS2 presents many different functions, listed below, that condition the switching output:

• Switching Output Mode: indicates if electrical current passes through switching output; the output

can be normally closed (N.C.) or normally open (N.O.).

• Switching Output Delay: delays the re-setting of the switching output after detection. The delay

time can be selected.

• Acquisition and detection (Teach-in): allows a conditioned detection of the object inside the

detection area: if the object corresponds (without resolution) to the object detected during the Teachin phase, the output switches. On the contrary nothing happens. The following modes can be set:

- absolute Teach-in detection: the output switches only if the previously set object is re-detected

in the same position.

- relative Teach-in detection: the output switches only if the previously set object (without

resolution) is re-detected, independently from the position in the sensing area.

5.2. Measurement mode

The measurement mode depends on the number of interrupted beams and causes the switching of

the analogue output and of the serial output (and also of the digital output).

The DS2 presents many different measurement functions, listed here below:

• Absolute measurements: measurement is obtained considering the first photoelement (1) as the

reference beam beginning from the connector side. The DS2 light grid has in particular the following

functions:

1. top beam: provides the measurement between the reference beam and the obscured beam

furthest away from the reference

2. bottom beam: provides the measurement from the reference beam and the obscured beam

closest to the reference

3. middle beam: provides the measurement of the beam corresponding to the medium point

between the obscured beam furthest away from the reference and the obscured beam closest to

the reference

• Relative measurements: measurement is obtained not considering absolute references. The

measurement depends on the number of obscured beams. The DS2 light grid has in particular the

following functions:

4. total beams: supplies the measurement corresponding to the total number of obscured beams

5. total contiguous beams: supplies the measurement corresponding to the maximum number of

contiguous beams obscured

10

Page 12

Instruction manual DS2 series

5.3. Transition detection (number of transitions)

The transition detection counts the number of transitions in the detection area. The number of

transition increases each time that an object is detected inside the detection area and decreases each

time the objects remain outside (transition light->dark).

5.4. Notes on functioning mode

• The DS2 light grids can configure the beam reference status, specifically selecting it from the user

interface. The default selection is “dark beam”, but the operator can select the complementary

situation i.e. “light beam”.

• Not all the functions can be selected using dip-switches. Please refer to the following tables to

discover the local programmability of the device.

• The 0-10 V analogue output, supplies limited information if compared to the information that can be

obtained from the serial output; some functions are significant only if obtained in a serial ambient.

The analogue voltage value is supplied, in these cases, without direct correspondence, as

indicated in the tables found in page 12, 24 and 26.

The formula to determine the voltage is obtained with the following syntax:

V

OUT

=V

RES

* N

[xxx ; yyy]

BEAM

Where V

V

= voltage value of the analogue output

OUT

= 10V/total n° of beams of the device = Voltage value corresponding to the

RES

minimum resolution (obtained obscuring only one beam)

N

[xxx ; yyy] = Number of beams belonging to the group [XY]

BEAM

(i.e. between “xxx” beam and “yyy” beam)

Please note that the longer DS2 is, the less conditioning is V

In the worst case V

RES.

= 43 mV !

RES

(using the DS2 165 model)

The first reference beam to select, by using only dip-switches, can be the one closest beam

(default reference) or the one furthest away from the connector, located at the opposite side of the

unit where the analogue voltage is at the minimum level (positive ramp 0-10 V) or maximum

(negative ramp 10-0V) in correspondence of the obscuring of the default reference beam.

Fig. 10 can be used as an example, considering a device with 10 beams, where the obscuring of

one beam corresponds to the V

variation of 1V (V

OUT

= 1V). At last beam obscuring, the V

RES

OUT

reaches 10 V full scale.

If the first beam is selected as the reference, the V

selected as the reference, the V

in the example is = 7 V (B).

OUT

in the example is = 6 V. If the last beam is

OUT

Analogue output Output level Switching output

A Reference = 1° beam 6 V

B Reference = last beam 7 V

ON

Fig. 10

The information can be obtained from the serial output, setting the top beam and bottom beam

measurement modes.

11

Page 13

DS2 series Instruction manual

5.5. RS485 serial output setting

Serial output data updating is usually made at the end of each scanning cycle. This conditions

enormously the response time, as it is depends on the serial baud-rate, data structure and information

detail that has to be transmitted on the serial output for the application. Some serial configuration

commands have been added to make the device flexible to different applications. The remote user

interface completely controls these commands.

• Baud-rate: allows the change of the serial switching speed. The 485 standard guarantees

excellent disturbance immunity and thus the increase of the transmission speed may compromise

the system. The speed has to be evaluated according to the application, plant and cabling.

• Transmission standard selection: the ASCII or Binary data structure transmitted by the serial

output can be selected; in applications where time is important, the binary structure is preferred.

For details concerning data transmission please see section 7 “Communication protocol”.

• Data partition selection: allows a partial serial data transmission. In particular, the transmission of

the complete beam status array or partial beam status array is distinguished: The two conditions

exclude each other (one or the other). If the partial transmission is selected, one of the

aforementioned measurement modes has to be chosen. Partial transmission is preferred for

applications where time factors are important. Further partial transmission is short protocol which

transmission is purely binary and extremely fast. Fuction is enable for single measure only.

For data transmission details please see section 7 “Communication protocol”.

• Data sending mode selection: function allows the operator to choose when to send the data from

the serial output. The sending can also be inhibited by a specific selection (via “software”, using the

specific command, via “hardware” programming the serial output enable input – pin 5 RX

connector – using the user interface). The sending mode selection can be reached only via remote

control. Four options can be selected: data sending at each machine cycle which is the default

setting, data sending at each output status change, data sending at analogue output value

change, user sending request, using the interface command button. This last condition can be

requested also by an external command previously programming the device (per details please see

section 7 “Communication protocol”).

6. FUNCTION AND PROGRAMMING SELECTION

The functions implemented in the AREAscanTM DS2 light grids can be selected

using the dip-switches present on the device receiving unit or via remote.

The default configurations are given below:

• Default configuration for receiver unit

The device is supplied with the standard configuration shown in the figure:

• Default configuration for emitter unit

The device is supplied with the maximum emission adjustment setting (minimum sensitivity)

• Sensitivity adjustment

Sensitivity adjustment is made using the trimmer located inside the

emitter unit lid. This function allows the operator to change the

emitter intensity.

ON

ON

1 2 3 4

ON

1 2 3 4

12

Page 14

Instruction manual DS2 series

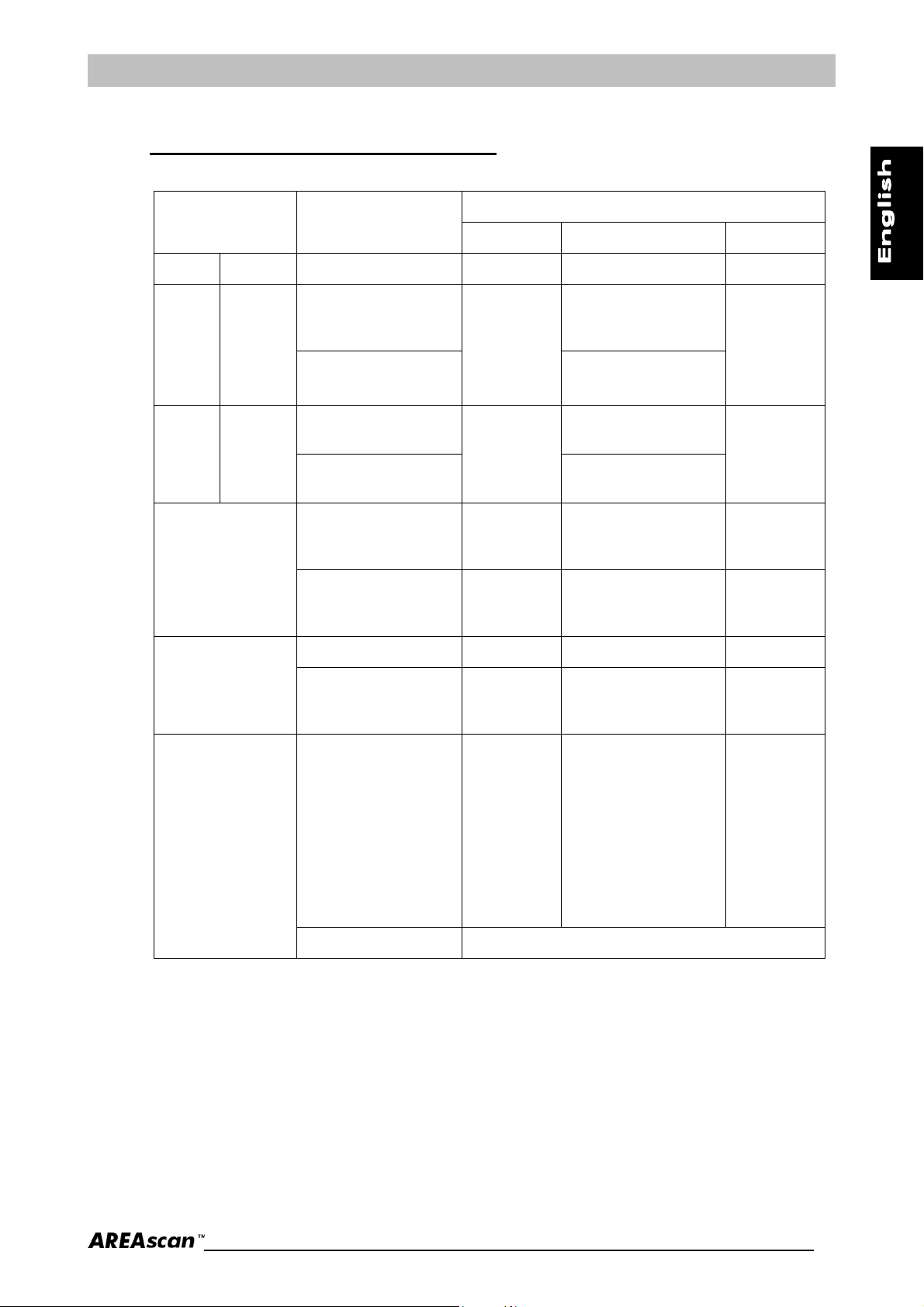

6.1. Local programming

ON

1A 2A 3A 4A

ON

1B 2B 3B 4B

Dip

N.

1A

2A

3A

reference beam

4A

Function

Programming

mode

Serial output

analysis mode

Measurement

Measurement

analysis beam

The function programming and selection is made

using dip-switches located inside the receiver unit

lid.

The following table indicates the type of function and

relative position of the dip-switches.

Active Pos

Run

Time

Start-up

Start-up

Start-up

Setting Output

Mode Analogue Switching Serial

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Local

Remote

- - -

See remote setting

Complete - -

Partial - -

Reference = First

(closest to connector)

Beam

Reference = Last

Beam

Top or Bottom

(Absolute Measure)

Total

(Relative Measure)

V=V

Res*NBEAM

Incr. Ramp(0-10V)

V=10-V

Decr. Ramp(10-0V)

V=V

[Top; ref]

Res*NBEAM

[Top; ref]

- -

Res*NBEAM

[dark]

Complete

Beam Status

Array

Partial

ASCII

-

Partial

Top Beam

Partial

Bottom Beam

-

Partial

Total Beam

Inactive Teach-in

1B

analysis mode

2B

3B

4B

Teach-in

detection

Teach-in

Mode

Switching

Output

Mode

Switching

Output

Delay

ON

OFF

Start-up

ON

Start-up

OFF

ON

Start-up

OFF

ON

OFF

Start-up

(Normal mode)

Active Teach-in -

Absolute pos.

detection

Relative pos.

detection

Normally

Open

Normally

Closed

No

Delay

100ms -

- Presence detection -

Conditional

presence detection

-

from Teach-in

Positional detection

-

of Teach-in ref.

-

object

-

Detection of Teach-

in reference object

-

Voltage on

-

switching device

-

during detection

No voltage on

-

switching device

-

during detection

- - -

Restore from

detection

-

delay = 100ms

( - ) Shows that the state of considered dip-switch does not influence kind of output correlated; ouptut is old setting by state of

function of the others dip-switches.

The functions, with the exception of the programming mode, cannot be activated during device

functioning. The functions are activated at device powering.

13

Page 15

DS2 series Instruction manual

6.1.1. Teach-in with detection

The Teach-in mode can be selected using dip-switches and using remote user interface.

For local programming of the Teach-in mode, the Teach-in wire should be connected to a pushbutton normally open on the 24 V line and proceed as follows:

• Select the Teach-in enable mode (dip switch 1B OFF).

• Switching output deactivated

• Place object inside the detection area at the desired position

• Press the push-button.

• Release the push-button only after switching output deactivation

(yellow receiver LED on)

The object detection will be signalled by the switching on of the yellow LED in presence of the

object.

The detected object (in the detection position) is stored in a non-volatile memory until a

successive detection.

The data is memorised also after device turning off and re-powering.

Fig. 12

14

Page 16

Instruction manual DS2 series

6.1.2. Absolute detection mode

The digital output switches only if the object, whose dimensions have been previously memorised,

passes in the exact position where it has been previously detected (see Fig.13).

The analogue output is always active in this configuration and supplies a voltage value according to

the measurement setting.

Analogue output, absolute

measurement (top beam)

= 6 V ON = 3 V (1,2,3 beams) OFF

Switching

Output

Analogue output, relative

measurement (total beam)

= 5 V (4,5,6,7,8 channels) OFF

Analogue output, relative

measurement (total beam)

Switching

Output

Switching

Output

Fig. 13

15

Page 17

DS2 series Instruction manual

6.1.3. Relative detection mode

The digital PNP output switches each time the sample object passes through the sensitive area,

independently from its position (see Fig.14).

The analogue output is always active in this configuration and supplies a voltage value according to the

measurement setting.

Analogue output, absolute

measurement (top beam)

= 6 V ON = 3 V (1,2,3 beams) ON

Switching

Output

Analogue output, relative

measurement (total beam)

= 5 V (4,5,6,7,8 channels) OFF

Analogue output, relative

measurement (total beam)

Switching

Output

Switching

Output

Fig. 14

16

Page 18

Instruction manual DS2 series

6.2. Remote programming

The function programming and selection is made using an user interface on a remote host, which

communicates with DS2 using the standard RS232 serial interface.

The interface can be found in the CD supplied with the device packet.

The remote programming function selection is activated only by dip-switches (dip-switch

1Aoff)

N.B.:

DS2 device fix in memory the last setting configuration from remote user interface. At the

first interface startup, DS2 set it self following the factory configuration which is

eventually restoring by appropriate push-buton “RESTORE”.

Fig. 15 - DS2 Graphic user interface

17

Page 19

DS2 series Instruction manual

6.2.1. DS2 user interface – General information

The DS2 user interface is a Windows program, compatible with 9x/SE/Me/NT/2000/XP versions,

that controls the scanning trend and the digital output status of the DS2 AREAscan

TM

light grids.

Thanks to the easy and intuitive user interface, the different configuration parameters of the light

grid, stored in the non-volatile device memory, can be visualised and modified.

The number and type of measurements transmitted depend on the local or remote programming.

In local programming, a fixed measurement is transmitted for each operating mode.

Whereas in remote programming, one or more measurements can be selected amongst those listed

in section 5.2 “Measurement mode”.

Please acknowledge that the same measurements cannot be selected twice.

This data can be transmitted either in binary or in ASCII code.

The communication protocol can be developed according to the Master Slave mode.

The information exchange can be made in the request-reply mode: the master sends a data packet

to the slave and the slave replies sending another data packet to the master.

The communication line is a half duplex (RS485) type and can be used by only one unit a time.

The master always begins the exchange.

18

Page 20

Instruction manual DS2 series

6.2.2. Program installation

Insert the CD of the DS2 Host Interface software in the PC reader.

The installation program will begin automatically. Simply follow the indications provided.

Fig. 16

19

Page 21

DS2 series Instruction manual

6.2.3. Graphic user interface

The following window will be visualised at program initialisation:

Fig. 17

Two important areas are distinguished: the data control area on the left (graph representing light

grid with scanning area, Teach-in status indicated on a measurement bar, a panel with luminous

indicators and dip-switch status, various digital indicators for measurement visualisation and a

communication status bar). The function selection area is on the right side.

6.2.4. Connection with AREAscan

TM

DS2 series

As mentioned, the DS2 light grid has a RS485 serial communication line (half duplex).

As far as the PC is concerned, a RS232/RS485 serial adapter is necessary in order to communicate

with the light grid receiver. The program controls the receipt/transmission on the RS485 line using

the RTS line present on the RS232 connector. The adapter has to support this characteristic.

Fig. 18

20

Page 22

Instruction manual DS2 series

The following figures show the typical diagram of a RS232/RS485 converter.

2

3

4

7

DB25

TXD

RXD

RTS

GND

TX

RX

TX+

TX-

RX+

RX-

A

B

Host PC

(DB9)

Converter

(RS232-DB25 side)

Converter

(RS485 side)

DS2

TXD (3) TXD (2) A D+ (6)

RXD (2) RXD (3) B D- (1)

RTS (7) RTS (4)

GND (5) GND (7)

Host PC

(DB25)

Converter

(RS232-DB25 side)

Converter

(RS485 side)

DS2

TXD (2) TXD (2) A D+ (6)

RXD (3) RXD (3) B D- (1)

RTS (4) RTS (4)

GND (7) GND (7)

The program is ready to function after connecting the PC to the RS485 serial line and powering the

DS2. Select the COM1, COM2, COM3 or COM4 serial communication port and press Connect. A

small window visualises a “Wait please…” message. The program will effect scanning on the serial

line testing separately each transmission speed until reaching the set DS2 speed (please consider

that this operation requires a few seconds). Once connected, the program will memorise the

transmission speed reached on the disk in order to optimise successive connections. This will

reduce the connection time, eliminating the initial scanning testing time.

The following window will appear if the connection fails:

In this case check the electrical connection and device powering.

21

Page 23

DS2 series Instruction manual

Fig.19

After connection (see Fig. 19) and according to the local or remote programming, the graphic on the

left side of the user interface’s main window will visualise the following:

• the beams and object shape

• the Teach-in memorised in the receiver unit

• the indicators of the two measurements according to the programming mode selected

• local and remote configuration status

The bars that represent the light grid are automatically re-sized according the DS2 model

connected. The Configure button is activated and the Connect button becomes Disconnect.

Passing the cursor over the scanning area, the digital indicator below lights up showing the position

of the beam selected. The same happens in the Teach-in bar.

The current programming mode selected is visualised under the virtual panel. The programming

mode can be changed only using the dip-switch located on the DS2 light grid, also during device

powering. The dip-switch, corresponding to the programming mode, is the only one decoded in real

time. All the other switches require device turning off and re-powering. Misalignments can thus

occur between the real dip-switches and the virtual ones of the interface.

22

Page 24

Instruction manual DS2 series

Figure 20 shows the windows on the right side of the interface, which is initially deactivated:

• Remote prog.: this page visualises the different parameter settings and thus allows their

modification in the remote mode.

• Local prog.: visualises only the status of the dip-switches present on DS2.

• Teach-in: edits the object shape using the Teach-in mode.

Fig.20

23

Page 25

DS2 series Instruction manual

6.2.5. Configuration of the AREAscanTM DS2 series

The configuration session can be accessed selecting the Configure button.

Fig.21

The access in the configuration mode suspends the scanning during the entire session. A small

window visualises a “Wait please…” message.

If the command is accepted, the Configure button changes and becomes End, and the Download

and Update buttons are activated. The data entry fields and the selection buttons are also active.

Three different sections are distinguished in the Remote prog. page:

• Serial transmission: allows to set the transmission baud-rate, type of data (binary or ASCII) to

send periodically at the end of each scanning in case of digital output switching or user request.

In the latter, the Request button becomes active if the DS is functioning in remote mode, when

exiting from the configuration session. The serial transmission can be completely deactivated. It

remains active only for communication with host.

Short Protocol is a data transmission mode very simple and it is used for one measure only

“Restore” push-button recall default factory configuration.

24

Page 26

Instruction manual DS2 series

Remote configuration from host user interface

: synoptic table showing the output variation with

respect to the serial output configuration

Function Mode

Enable - - Comm. Enable

Disable - - Comm. Disable

pin5 RX connector

on 24Vdc

pin5 RX connector

Serial

Communication

Enable

SW

HW

floating

Analog Switching Serial

- - Comm. Enable

- - Comm. Disable

Outputs

ASCII - - Type ASCII Serial Transmission

Type

Binary - - Type Binary

9600 - - -

Baud Rate

19200 - - 38400 - - 57600 - - -

Cyclical - -

Send every

cycle

Send when

PNP/NPN

output changes

state

Send when

Analogue

output changes

Data Sending Type

Output changes state - -

Analogue output changes

state

- -

state

On request - -

Short Protocol Binary only - -

Send by host

request

Send with

short protocol

Short Protocol enables the transmission of one single char in binary code related to one single

measure. This protocol is available in remote configuration mode only, binary transmission.

• Detection analysis and output mode: allows to set the object detection mode (normal or Teach-in),

the normally open or normally closed switching output and any delay after detection. In the latter a

delay time ranging from 0 to 200 milliseconds can be selected.

25

Page 27

DS2 series Instruction manual

Remote configuration from host user interface

: synoptic table showing the output variation with

respect to the detection analysis mode configuration

Outputs

Function Mode

Analog Switching Serial

Normal - Presence detection -

Switching

Output Mode

Switching

Output Delay

Output Hold

TEACH-

IN

TEACHIN Mode

Get TEACH-IN

from DS2

-

Set TEACH-IN from

User Interface

Absolute Positioning

Detection

-

Relative Positioning

Detection

Conditional presence

detection from

TEACH-IN

Conditional presence

detection from

TEACH-IN

Positional detection of

TEACH-IN ref. object

Detection of TEACH-

IN reference object

-

-

Current on switching

Normally Opened -

device during

-

detection

No current on

Normally Closed -

switching device

-

during detection

No Delay - - -

Restore from

0 < T

< 200ms -

DELAY

Enable

It holds

analogue and

serial output

to the higher

detected

value during

enable of

“output

HOLD” input

(pin5 RX

connector on

24Vdc)

detection delay =

T

DELAY

-

-

It holds

analogue and

serial output

to the higher

detected

value during

enable of

“output

HOLD” input

(pin5 RX

connector on

24Vdc)

Disable Normal operation

26

Page 28

Instruction manual DS2 series

The local teach-in mode can be emulated through

serial interface selecting a group of contiguous beams.

Select the first and last photoelements of the segment

that have to be added and then press Add. The shape

is immediately drawn in the Teach-in bar (see Fig.22).

This operation can be repeated to set different objects

with the most varied shapes.

The entire shape can be changed or inverted selecting

repetitively the Cancel and Invert buttons. The object

presence is characterised by a dark colour and the

object absence by a light colour.

Fig. 22

• Measurement analysis: maximum two measurement

transmissions can be set in the remote mode according to the Serial transmission section.

Different options are available:

- None

- Beam Status Array

- Top Beam (dark or light)

- Bottom Beam (dark or light)

- Middle Beam (dark or light)

- Total Beam (dark or light)

- Total Contiguous Beam (dark or light)

- Transition number (dark or light)

27

Page 29

DS2 series Instruction manual

Remote configuration from host user interface: synoptic table showing the output variation with

respect to the detection analysis mode configuration

Function Mode

Complete

Beam

Status

V=V

Array

Top

Beam

Bottom

Beam

Middle

Beam

Dark (default)

Light

Dark (default)

Light

Dark (default)

Light

Dark (default) V=V

Total Beam

Light V=V

Total

Contiguous

Beam

Dark (default) V=V

Light V=V

Light Dark

(default)

Total Beam

Dark Light V=V

Analogue Switching Serial

RES*NBEAM

V=V

RES*NBEAM

reference]

V=V

RES*NBEAM

[Top light;

reference]

V=V

RES*NBEAM

[Bottom;

reference]

V=V

RES*NBEAM

light; reference]

V=V

RES*NBEAM

[0.5*(Top-

Bottom); reference]

V=V

RES*NBEAM

[0.5*(Top

light-Bottom light);

reference]

RES*NBEAM

RES*NBEAM

RES*NBEAM

RES*NBEAM

V=V

RES*NBEAM

RES*NBEAM

[dark]

[Top;

[Bottom

[dark] Total Beam

[dark]

[dark]

[dark]

[dark]

[dark]

Outputs

Top Beam

Top Beam

(light)

Bottom

Beam

Bottom

Beam (light)

Middle

Beam

Middle

Beam (light)

Total Beam

(light)

Total

Contiguous

Beam

Total

Contiguous

Beam (light)

Transitions

LightDark

Transitions

DarkLight

Binary

N.

N.

ASCII

ASCII

Binary

ASCII

Binary

ASCII

Binary

ASCII

Binary

ASCII

Binary

ASCII

Binary

ASCII

Binary

ASCII

Binary

ASCII

Binary

ASCII

Binary

ASCII

Binary

ASCII

Binary

Some sections exclude each other (one or the other), i.e. if the Beam Status

Array has been chosen as measurement 1, all the items of measurement 2

are deactivated. Another example: if Top Beam Dark has been chosen as

the first measurement, the operator can choose any other measurement

excluding the same type as the first and Beams Status Array. The items not

admitted become grey.

The settings will be memorised in the DS2 non-volatile memory pressing

the Update button.

The graphic will be restored with the last shape stored in the DS2 memory

by selecting the Download button.

Press End to quit configuration session. The system will request the exit confirmation.

28

Page 30

Instruction manual DS2 series

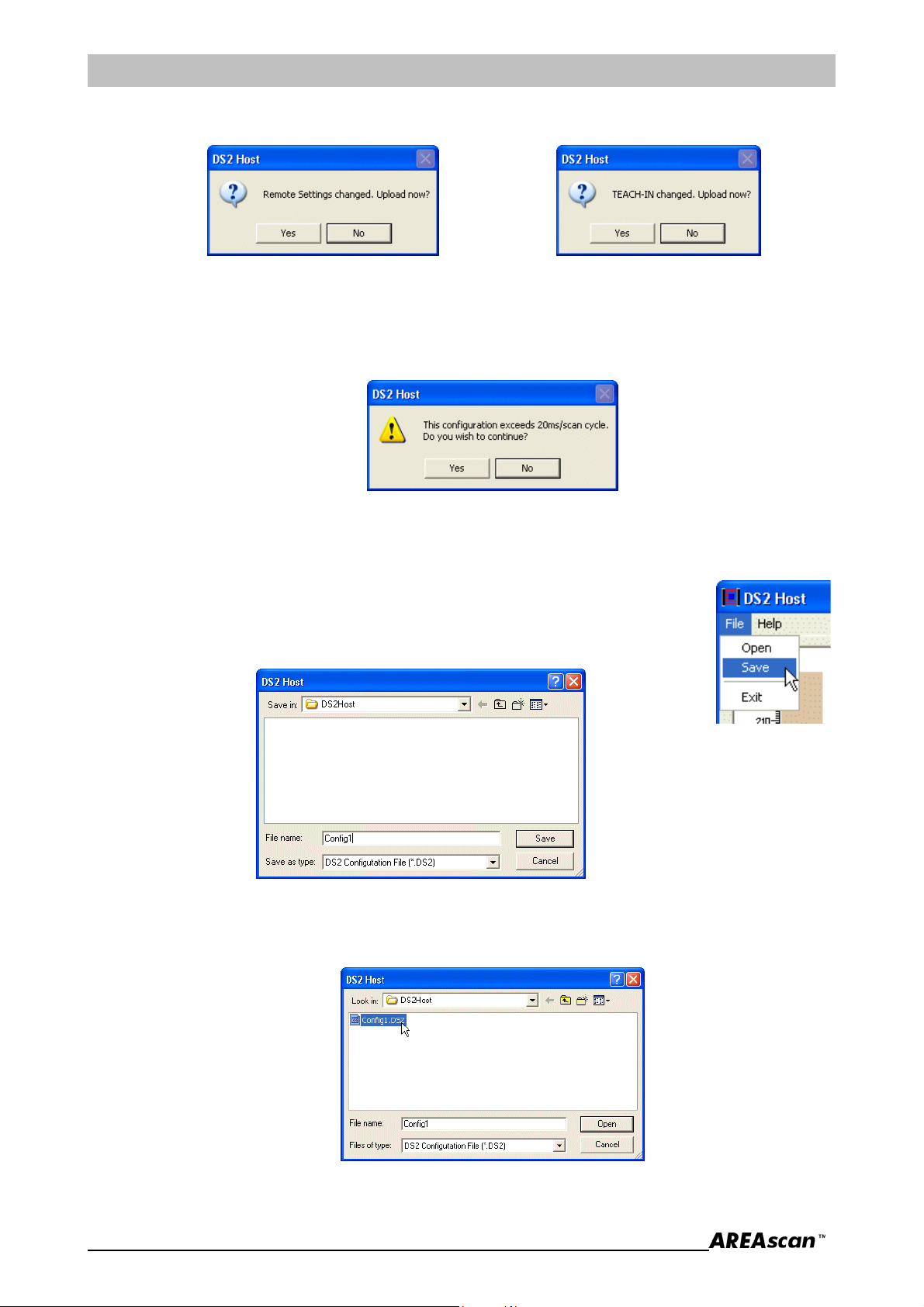

The following windows can appear successively:

If one or both windows appear, some data have been changed or the operator has forgotten to

update DS2 with the changes.

Press Yes to confirm, or No to ignore changes.

Lastly, depending on the options selected, a window like this could appear:

This window warns the operator that the scanning time exceeds the value set in milliseconds per

cycle.

6.2.6. File saving of the configuration options

The current device configuration can be memorised during the configuration

session. Select File and then Save.

The system will request the operator to assign a name to the file with the

configuration options.

6.2.7. File loading of the configuration options

A previously stored device configuration can be loaded from file during the configuration session.

Select File and then Open. Select the desired file.

The Remote prog. page and the Teach-in bar are updated with the values contained in the file.

To update the DS2 memory, press Update.

29

Page 31

DS2 series Instruction manual

7. AREAscanTM DS2 SERIES – COMMUNICATION PROTOCOL

7.1. Packet description

As mentioned, the communication protocol requires a master unit and a slave unit. The

communication type is half duplex (RS485).

The exchange of information is made in the request-reply mode: the master sends a data packet to

the slave that replies sending another data packet to the master.

7.1.1 Binary data packet structure

A binary data packet is composed of a group of bytes placed in a well-defined sequence, that

identifies it univocally. It presents a heading, body and an end.

The heading and the end have a fixed length while the body has a variable length.

Packet start Length Type Data Packet end Checksum

Heading Body End

• Packet beginning: 1 byte, STX ASCII code (‘0x02’)

• Length: 1 byte, length in bytes of the Type field plus the Data field

• Type: 1 byte, code identifying the packet type ( ‘A’, ‘B’, ‘C’ ASCII code, etc.)

• Data: variable number of bytes (from 0 to 254) that form the packet information

• Packet end: 1 byte, ETX ASCII code(‘0x03’)

• Checksum: 1 byte, complement to one of the Length, Type and

Data field bytes sum.

7.1.2. Short protocol binary data packet structure

There is a binary data packet with reduced protocol composed by one byte. This format is reserved

to trasmission of numeric type value only (for example one measure).

Data

Data: 1 byte with binary data packet

7.1.3. ASCII data packet structure

An ASCII data packet is composed of:

Packet start Type Data Packet end

• Packet beginning: 1 byte, ‘*’ ASCII code (0x2A)

Heading Body End

Body

• Type: 1 byte, code identifying the packet type ( ‘A’, ‘B’, ‘C’ ASCII code, etc.)

• Data: variable number of ‘0’-‘9’ ‘A’-‘Z’ ASCII codes (from 0 to 254) that form the

packet information

• Packet end: 1 byte, CR ASCII code (0x0D)

30

Page 32

Instruction manual DS2 series

7.2 Operating mode: DS2 (master) Host Interface (slave)

At powering the DS2 becomes the master and transmits periodically, as previously explained, a

packet at each scanning of the measurement information according to the configuration. The host,

which is the slave, receives the packet and elaborates the data. This is the only case where a

response packet is not necessary.

7.2.1. Packet description

a. Complete binary

scanning result (Complete beam status array) - 0x41 (‘A’ ASCII)

Sends to host the pattern with the binary information relative to each beam.

DS2 sends:

0x02 n

0x41

aaa bbb ccc ….. zzz s 0x03 x

where:

n = 0x0E (600 mm model), 0x14 (900 mm model), 0x1A (1200 mm model), 0x23 (1650 mm

model)

aaa = 3 bytes with information concerning the 01-21 photoelements

bbb = 3 bytes with information concerning the 22-42 photoelements

ccc = 3 bytes with information concerning the 42-63 photoelements

zzz = 3 bytes with information concerning the last 21 photoelements

s = 1 byte indicating scanning status:

bit 0 = Power LED (0 OFF, 1 ON)

bit 1 = Failure LED (0 OFF, 1 ON)

bit 2 = Output LED (0 OFF, 1 ON)

bit 3 = PNP/NPN output (0 deactivated, 1 active)

bit 4 = Short-circuit output (0 no, 1 yes)

bit 5 = Misaligned photoelements or stability (0 no, 1 si)

bit 6 = N/A.

bit 7 = Programming mode (0 local, 1 remote)

x = checksum (complement to one of the Length, Type and Data field bytes sum)

Example:

Supposing to have the following data range:

0x01 0x02 0x03 0x04 0x05 0x06

the length will be 0x07 (one byte of the Type field plus six bytes of the Data field).

If the packet is a 0x41 type (‘A’ ASCII), then the checksum will be:

checksum = (0x07 + 0x41 + 0x01 + 0x02 + 0x03 + 0x04 + 0x05 + 0x06) XOR 0xFF = 0xA2

The correspondence between the photoelements (21) and the bits of a bytes tern is given below:

Photoelement 21 20 19 18 17 16 15 14 13 12 11 10 09 08 07 06 05 04 03 02 01

Bytes tern D7 D6 D5 D4 D3 D2 D1 D0 D7 D6 D5 D4 D3 D2 D1 D0 D7 D6 D5 D4 D3 D2 D1 D0

first byte second byte third byte

The position of one beam can be identified by the weight of the single bits, and the status from its

value from zero or one.

A bit at zero, indicates a non-obscured beam, and a bit at one indicates an obscured beam.

31

Page 33

DS2 series Instruction manual

b. Complete ASCII scanning result (Complete beam status array) - 0x41 (‘A’ ASCII)

Sends to host the pattern with the ASCII information relative to each beam.

DS2 sends:

0x2A

0x41

aaaaaa bbbbbb cccccc ….. zzzzzz ss 0x0D

where:

aaaaaa = 6 ASCII codes (3 bytes) with information concerning the 01-21 photoelements

bbbbbb = 6 ASCII codes (3 bytes) with information concerning the 22-42 photoelements

cccccc = 6 ASCII codes (3 bytes) with information concerning the 42-63 photoelements

zzzzzz = 6 ASCII codes (3 bytes) with information concerning the last 21 photoelements

ss = 2 ASCII codes (1 byte) indicating scanning status (see above)

c. Partial Binary

scanning result (Measurements) - 0x42 (‘B’ ASCII)

Sends to host one or due numeric measurements.

DS2 sends (only one measurement

):

0x02 0x04

0x42

m a s 0x03 x

where:

m = ASCII char linked to kind of measure (ASCII code linked to kind of measure get as sum of

char “A” and numeric value of kind of measure .

a = 1 byte with the (0 – 231)

x = checksum (complement to one of the Length, Type and Data field bytes sum)

s = 1 byte with scan state:

bit 0 = Power Led (0 OFF, 1 ON)

bit 1 = Failure Led (0 OFF, 1 ON)

bit 2 = Output Led (0 OFF, 1 ON)

bit 3 = Uscita PNP/NPN (0 disable, 1 enable)

bit 4 = short-circuit switching output (0 none, 1 yes)

bit 5 = stability (0 none, 1 yes)

bit 6 = n. a.

bit 7 = Programming Mode (0 local, 1 remote)

DS2 sends (two measurements

):

0x02 0x06

0x42

m a n b s 0x03 x

where:

m = ASCII char linked to kind of measure (ASCII code linked to kind of measure get as sum of

char “A” and numeric value of kind of measure .

a = 1 byte with #1 measurement (0 – 231)

n = 1 ASCII code with #2 measurement (‘A’ + numerical value of the measurement type)

b = 1 byte with #2 measurement (0 – 231)

x = checksum (complement to one of the Length, Type and Data field bytes sum)

s = 1 byte with scan state:

bit 0 = Power Led (0 OFF, 1 ON)

bit 1 = Failure Led (0 OFF, 1 ON)

bit 2 = Output Led (0 OFF, 1 ON)

bit 3 = Uscita PNP/NPN (0 disable, 1 enable)

bit 4 = short-circuit switching output (0 none, 1 yes)

bit 5 = stability (0 none, 1 yes)

bit 6 = n. a.

bit 7 = Programming Mode (0 local, 1 remote)

32

Page 34

Instruction manual DS2 series

d. Partial Binary

scanning result (Measurements) – Short protocoll

Send to host one measure only with reduced binary format (one byte).

DS2 sends (one measurement only

):

a

where:

a = 1 byte with measure (0 – 231)

e. Partial ASCII scanning result (Measurements) - 0x42 (‘B’ ASCII)

Sends to host one or due numeric measurements in ASCII (see above).

DS2 sends (one measurement

):

0x2A

0x42

m aaa ss 0x0D

dove:

m = ASCII char linked to kind of measure (ASCII code linked to kind of measure get as sum of

char “A” and numeric value of kind of measure .

aaa = 3 ASCII codes with measurement (“000” – “231”)

ss = 2 ASCII char (1 byte) with scan state:

bit 0 = Power Led (0 OFF, 1 ON)

bit 1 = Failure Led (0 OFF, 1 ON)

bit 2 = Output Led (0 OFF, 1 ON)

bit 3 = Uscita PNP/NPN (0 disable, 1 enable)

bit 4 = short-circuit switching output (0 none, 1 yes)

bit 5 = stability (0 none, 1 yes)

bit 6 = n. a.

bit 7 = Programming Mode (0 local, 1 remote)

DS2 sends (two measurements

):

0x2A

0x42

m aaa n bbb ss 0x0D

where:

m = ASCII char linked to kind of measure (ASCII code linked to kind of measure get as sum of

char “A” and numeric value of kind of measure .

aaa = 3 ASCII codes with #1 measurement (“000” – “231”)

n = 1 ASCII code with #2 measurement (‘A’ + numerical value of the measurement type)

bbb = 3 ASCII codes with #2 measurement (“000” – “231”)

ss = 2 ASCII char (1 byte) with scan state:

bit 0 = Power Led (0 OFF, 1 ON)

bit 1 = Failure Led (0 OFF, 1 ON)

bit 2 = Output Led (0 OFF, 1 ON)

bit 3 = Uscita PNP/NPN (0 disable, 1 enable)

bit 4 = short-circuit switching output (0 none, 1 yes)

bit 5 = stability (0 none, 1 yes)

bit 6 = n. a.

bit 7 = Programming Mode (0 local, 1 remote)

ASCII code linked to kind of measure get as sum of char “A” and numeric value of kind of measure.

‘A’ = Measure disabled (n. a.)

‘B’ = Complete beams status array (n. a.)

‘C’ = Top beam dark

‘D’ = Top beam light

‘E’ = Bottom beam dark

‘F’ = Bottom beam light

‘G’ = Middle beam dark

‘H’ = Middle beam light

‘I’ = Total beam dark

‘J’ = Total beam light

‘K’ = Total contiguous beam dark

‘L’ = Total contiguous beam light

‘M’ = N. of transitions dark

‘N’ = N. of transitions light

33

Page 35

DS2 series Instruction manual

7.3. Configuration mode: DS2 (slave) Host (master)

7.3.1 Host appropriation procedure of the bus

To access the configuration mode, the DS2 has to receive a special command that momentary

suspends scanning and the control is passed to the host. The host thus becomes the master and

the DS2 the slave. All the outputs are deactivated.

The device remains in this mode until it receives the configuration quit command.

The host controls the bus and becomes the master sending a particular string denominated

synchronism code (ASCII SYN ‘0x16’).

The DS2 light grid is normally the master and is set to discharge control only after the following

conditions:

Between one scanning and the other, the DS2 is in the receiving mode for a short period (few

milliseconds). To discard the control, the DS2 has to receive, 3 synchronism codes within 2.5

seconds from the receipt of the first code, the device will then suspend the data transmission and

leaves a larger receiving window open (about 250 milliseconds) where the host can send the

command.

If the command is not decoded or exceeds the time available, the DS2 will re-assume the line

control and the operation has to be repeated. This technique has to be used before sending any

command if the DS2 light grid is the master. The transmission of the synchronism codes is not

necessary if DS2 is already the slave.

The following figure represents an example of data exchange on the serial communication line

using the SYNCHRONISM command.

The transmitted packets are highlighted in black (TXD) by the DS2 at the end of each scanning.

When effecting a command, the host begins to send the SYN codes (0x16) in the temporal windows

left between the two consecutive scannings (see points 1, 4 and 5). If the host transmits

contemporarily the SYN codes to the DS2, the SYN codes will be lost (see points 2 and 3).

The codes have to be continuously sent until the DS2 ends the packet transmission (see point 6).

The Host can now include the 0x43 synchronism command and the DS2 replies with the respond

packet (see point 7 and 8). The DS2 effects the scanning immediately after (see point 9).

command 0x43

answer 0x63

34

Page 36

Instruction manual DS2 series

7.3.2 Command packet description:

a. Synchronism command - 0x43 (‘C’ ASCII)

The host can use this command when connected to DS2 to obtain the local/remote configuration

parameters. If the serial transmission speed is missing, all known baud-rates can be tested until the

connection is established.

Host sends:

0x02 0x01

0x43

0x03 0xBB

DS2 replies:

0x02 0x0A

0x63

n l rrrrrrr 0x03 x

N = 1 byte with photoelement number (84, 126, 168 or 231)

L = 1 byte with the local configuration status (Dip-switch)

bit 0 = OutDelay 4B - Output Delay (No Delay/100ms Delay)

bit 1 = OutMode 3B - Output Mode (NO/NC)

bit 2 = TeachMode 2B - Teach-in Mode (Absolute/Relative)

bit 3 = TeachAcc 1B - Teach-in active (Inactive/Active)

bit 4 = MeasAna 4A - Measurement Analysis Mode (BotTop/Total)

bit 5 = MeasRef 3A - Measurement Reference Beam (Bottom/Top)

bit 6 = SerMode 2A - Serial Output Mode (Binary/ASCII)

bit 7 = ProgMode 1A - Programming Mode (Local/Remote)

rrrrrrr = 7 bytes with the remote configuration status

byte 1 = SerComm Serial Communication (1 = Active, 0 = Inactive)

Short Protocol (bit 7 = 1 Enable, bit 7 = 0 Disable)

byte 2 = BaudRate Baud-rate (range 0 = 9600, 1 = 19200, 3 = 38400 4 = 57600)

byte 3 = MeasAna1 Measurement Analysis Mode 1 (see below)

byte 4 = MeasAna2 Measurement Analysis Mode 1 (see below)

byte 5 = SendType Data Sending Type (0 = Cyclical, 1 = On Change or 2 = On Request)

byte 6 = DipSw Remote setting by virtual dip-switches (only partially applicable)

byte 7 = OutputDelay Output Delay 0-200ms

x = checksum (complement to one of the Length, Type and Data field bytes sum)

Numeric value associated to measurement type:

0 = Measure disabled

1 = Complete beams status array

2 = Top beam dark

3 = Top beam light

4 = Bottom beam dark

5 = Bottom beam light

6 = Middle beam dark

7 = Middle beam light

8 = Total beam dark

9 = Total beam light

10 = Total contiguous beam dark

11 = Total contiguous beam light

12 = N. of transitions dark

13 = N. of transitions light

Remote configuration state (Virtual Dip Switch)

bit 0 = OutDelay 4B - Output Delay (No Delay/Delay)

bit 1 = OutMode 3B - Output Mode (NO/NC)

bit 2 = TeachMode 2B - Teach-In Mode (Absolute/Relative)

bit 3 = TeachEna 1B - Teach-In Enable (Disable/Enable)

bit 4 = MeasAna 4A - n. a.

bit 5 = MeasRef 3A - n. a.

bit 6 = SerMode 2A - Serial Output Mode (Binary/ASCII)

bit 7 = ProgMode 1A - n. a.

35

Page 37

DS2 series Instruction manual

b. Scanning suspension command - 0x44 (‘D’ ASCII)

Momentary suspends the scanning and passes the control to the host.

Host sends:

0x02 0x01

0x44

0x03 0xBA

DS2 responds:

0x02 0x01

0x64

0x03 0x9A

The following figure is similar to the previous one with the difference that the scanning now does not

re-start automatically after receiving the command (see point 9).

answer 0x64

command 0x44

c. Scanning re-start command - 0x45 (ASCII ‘E’ )

Informs DS2 to re-start the normal scanning mode and the host looses the line control.

Host sends:

0x02 0x01

0x45

0x03 0xB9

DS2 replies:

0x02 0x01

0x65

0x03 0x99

In this case the SYN codes do not have to be sent as the scanning is suspended.

The command is accepted immediately. After the exchange of the packets (see points 1 and 2),

DS2 re-starts the scanning (see point 3).

answer 0x65

command 0x45

36

Page 38

Instruction manual DS2 series

d. Scanning command on request (Data sending on request ) - 0x46 (ASCII ‘F’ )

When DS2 is programmed in Remote Mode – Data Sending On Request, the host sends this

special command to request the information packet relative to each single beam or partial scanning

information in the form of one or two numeric measurements of the following type:

- Top Beam (dark or light)

- Bottom Beam (dark or light)

- Middle Beam (dark or light)

- Total Beam (dark or light)

- Total Contiguous Beam (dark or light)

- Transition number (dark or light)

Host sends:

0x1B

0x46

DS2 replies:

The DS2 replies with one of the following packets according to the selected programming mode:

- Complete Binary Scanning (Beam Status Array) - 0x41 (‘A’ ASCII)

- Complete ASCII Scanning (Beam Status Array) - 0x41 (‘A’ ASCII)

- Partial Binary Scanning (Measurements) - 0x42 (‘B’ ASCII)

- Partial ASCII Scanning (Measurements) - 0x42 (‘B’ ASCII)

For the description of these packets, see section “Scanning modes”.

e. Remote configuration reading command - 0x47 (‘G’ ASCII)

Reads the binary information relative to the remote configuration.

Host sends:

0x02 0x01

0x47

0x03 0xB7

DS2 replies:

0x02 0x08

0x67

rrrrrrr 0x03 x

where:

rrrrrrr = 7 bytes with the remote configuration status (see Synchronism packet)

x = checksum (complement to one of the Length, Type and Data field bytes sum)

37

Page 39

DS2 series Instruction manual

f Remote configuration writing - 0x48 (‘H’ ASCII)

Saves in the DS2 non-volatile memory the binary information of the remote configuration.

Host sends:

0x02 0x08

0x48

rrrrrrr 0x03 x

DS2 replies:

0x02 0x01

0x68

0x03 0x96

where:

rrrrrrr = 7 bytes with the remote configuration status (see Synchronism packet)

x = checksum (complement to one of the Length, Type and Data field bytes sum)

g. Teach-in 0x49 reading command (‘I’ ASCII)

Reads the pattern with the binary information relative to the shape of the object used in the Teachin mode.

Host sends:

0x02 0x01

0x49

0x03 0xB5

DS2 replies:

0x02 0x22

0x69

aaa bbb ccc ….. zzz 0x03 x

where:

aaa = 3 bytes with Teach-in of the 01-21 photoelements

bbb = 3 bytes with Teach-in of the 22-42 photoelements

ccc = 3 bytes with Teach-in of the 42-63 photoelements

zzz = 3 bytes with Teach-in of the 211-231 photoelements

x = checksum (complement to one of the Length, Type and Data field bytes sum)

The correspondence between the photoelements (21) and the bits of a bytes tern is similar to the

Scanning Result packet.

h. Writing command 0x4A Teach-in (‘J’ ASCII)

Saves in the DS2 non-volatile memory the new pattern with the binary information relative to the

shape of the object to use in the Teach-in mode.

Host sends:

0x02 0x22

0x4A

aaa bbb ccc ….. zzz 0x03 x

DS2 replies:

0x02 0x01

0x6A

0x03 0x94

where:

aaa = 3 bytes with Teach-in of the 01-21 photoelements

bbb = 3 bytes with Teach-in of the 22-42 photoelements

ccc = 3 bytes with Teach-in of the 42-63 photoelements

zzz = 3 bytes with Teach-in of the 211-231 photoelements

x = checksum (complement to one of the Length, Type and Data field bytes sum)

The correspondence between the photoelements (21) and the bits of a bytes tern is similar to the

Scanning Result packet.

38

Page 40

Instruction manual DS2 series

i. Firmware release reading command - 0x4B (ASCII ‘K’)

Reads the firmware release.

Host sends:

0x02 0x01

0x4B

0x03 0xB3

DS2 replies:

0x02 0x0B

0x6B

vvvvvvvvvv 0x03 x

where:

vvvvvvvvvv = 10 ASCII codes with the firmware version

x = checksum (complement to one of the Length, Type and Data field bytes sum)

j. Dip-switch reading command - 0x4C (ASCII ‘L’ )

Reads the dip-switch status.

Host sends:

0x02 0x01

0x4C

0x03 0xB2

DS2 replies:

0x02 0x02

0x6C

l 0x03 x

L = 1 byte with the local configuration status (Dip-switch)

bit 0 = OutDelay 4B - Output Delay (No Delay/100ms Delay)

bit 1 = OutMode 3B - Output Mode (NO/NC)

bit 2 = TeachMode 2B - Teach-in Mode (Absolute/Relative)

bit 3 = TeachEna 1B - Teach-in Active (Inactive/Active)

bit 4 = MeasAna 4A - Measurement Analysis Mode (BotTop/Total)

bit 5 = MeasRef 3A - Measurement Reference Beam (Bottom/Top)

bit 6 = SerMode 2A - Serial Output Mode (Binary/ASCII)

bit 7 = ProgMode 1A - Programming Mode (Local/Remote)

x = checksum (complement to one of the Length, Type and Data field bytes sum)

k. LEDs piloting command - 0x4D (‘M’ ASCII)

Turns on and/or turns off the panel LEDs.

Host sends:

0x02 0x04

0x4D

p f o 0x03 x

DS2 replies:

0x02 0x01

0x6D

0x03 0x91

where:

p = 1 byte with the Power LED status (0 off, 1 on)

f = 1 byte with the Failure LED status (0 off, 1 on)

o = 1 byte with Output LED status (0 off, 1 on)

x = checksum (complement to one of the Length, Type and Data field bytes sum)

39

Page 41

DS2 series Instruction manual

l. PNP/NPN output piloting command - 0x4E (‘N’ ASCII)

Turns on and/or turns off the PNP/NPN output.

Host sends:

0x02 0x02

0x4E

o 0x03 x

DS2 replies:

0x02 0x01

0x6E

0x03 0x90

where:

o = 1 byte with the PNP/NPN output status (0 off, 1 on)

x = checksum (complement to one of the Length, Type and Data field bytes sum)

m. Analogue output piloting command - 0x4F (‘O’ ASCII)

Sets the analogue output level.

Host sends:

0x02 0x02

0x4F

p 0x03 x

DS2 replies:

0x02 0x01

0x6F

0x03 0x8F

where:

p = 1 byte with the analogue output percentage (0 = 0V, 100 = 10V)

x = checksum (complement to one of the Length, Type and Data field bytes sum)

n. A/D Photoelement Conversion Reading Command - 0x50 (‘P’ ASCII)

Reads the result of the A/D conversion for an expansion of 21 photoelements.

Host sends:

0x02 0x02

0x50

e 0x03 x

DS2 replies:

0x02 0x16

0x70

a ….. n 0x03 x

where:

e = 1 byte with the expansion number to read (1 to 21)

a = 1 byte with the result in bit of the conversion for the photoelement 1

n = 1 byte with the result in bit of the conversion for the photoelement 21

x = checksum (complement to one of the Length, Type and Data field bytes sum)

The result of a conversion can be interpreted as follows:

V

Photoelement

[ mV ] = Bit

Photoelement

* 5000 / 255

Note: the 3 less important bits of a conversion [2-0] have to be zeroed before the calculation.

The scanning times vary and depend on different factors such as the number of photoelements, the

serial transmission speed, the measurement type selected and the binary or ASCII data format. The

values can vary from a minimum of 8 reaching a maximum of 90 milliseconds.

The serial transmission parameters are:

Baud-rate Equity Data bits Stop bits

9600

19200

38400

None 8 1

57600

40

Page 42

Instruction manual DS2 series

8. DIAGNOSTIC FUNCTIONS AND LED INTERFACE ERROR SIGNALLING

8.1. Device status visualisation

The operator can verify the device functioning status using the three LEDs present the receiver unit and

the one present on the emitter unit.

The meaning of the LEDs present of the receiver unit (RX) depends on the light grid operating mode.

Signalling Status

RECEIVING UNIT (RX)

- No power supply.

- Microprocessor in the reset condition.

- Normal RX functioning

- Presence of object inside sensitive area or units misaligned.

- Short-circuit signalling on switching output

- Generic anomaly on RX unit

- Critical alignment of the TX and RX units or weak received signal.

EMITTER UNIT (TX)

Signalling Status Signalling Status

- No power supply.

- Microprocessor in the

reset condition.

- Generic anomaly of

the TX unit

Normal TX functioning

- No synchronism

between RX and TX

units

41

Page 43

DS2 series Instruction manual

9. CHECKS AND PERIODICAL MAINTENANCE

The following is a list of recommended check and maintenance operations that should be periodically

carried out by qualified personnel.

Check that:

• The operating distance and the alignment of the two units conforms to the indications given in section 2

“Installation mode” and section 10 “Technical data”.

• The DS2 device and external electrical connections are not damaged.

The frequency of the checks depends on the particular application and operating conditions of the light

grid.

The AREAscan

of the cleaning of the protective surfaces of the optics.

Use a cotton cloth dampened with water for cleaning.

Do not use under any circumstances:

• alcohol or solvents

• wool cloths of synthetic fabric

Disturbances that generate power supply shifts or lacks can open temporarily the outputs but do not

compromise the functioning of the light grid.

All appliances are under a 18 month guarantee from the manufacturing date. Datasensor will not be

liable for any damages to persons and things caused by the non-observance of the correct installation

modes and device use.

The warranty will not cover damages caused by incorrect installation, incorrect use and accidental

causes such as bumps or falls.

In presence of problems, please contact the DATASENSOR S.p.A. Technical Support:

Technical Support

Tel.: +39 051 6765611

Fax.: +39 051 6759324

email: service@datasensor.com

TM

devices of the DS2 series do not require particular maintenance, with the exception

42

Page 44

Instruction manual DS2 series

10. TECHNICAL DATA

DS2-05-07-xxx-JV DS2-05-25-xxx-JV

Power supply:

Consumption of emitter unit:

Outputs:

Output current on switching output: 100 mA; short-circuit protection

Output voltage on switching output:

Response time: See table “Response time” below

Emission type: Infrared (880 nm)

Resolution: 12 mm 35 mm

Relative measurement precision:

Absolute measurement precision: 6 mm 22.5 mm

Dimensional difference between objects

equally detected in asbolute Teach-in:

Dimensional difference between objects

equally detected in relative Teach-in

Operating distance: 0.3 ÷ 5 m 0.3 ÷ 10 m

Available functions: See previous sections

Operating temperature: 0 …+ 50 °C

Storage temperature: - 25…+ 55 °C

Electrical protection: Class I

Mechanical protection: IP 65 (EN 60529)

Vibrations:

Shock resistance: 11 ms (30 G) 6 shock for each axis (EN 60068-2-27)

Housing material: Painted aluminium (RAL9005 shiny black)

Lens material: PMMA

Connections:

Weight: Min. 1.9 kg – Max. 4.6 kg

1 switching output; load max 10 kΩ

load min 100 Ω

1 analogue output ; 0-10 V (∆V

-1.5 Vmax of the power supply

± 6 mm ± 22.5 mm

± 6 mm ± 22.5 mm

∆ = 12 mm ∆ = 45 mm

0. 5 mm width, 10 … 55 Hz frequency,

24 Vdc ± 20%

250 mA max without load

2%)

max.

at T=25°C

(EN 60068-2-6)

M12 4-pole connector for TX

M12 8-pole connector for RX

10.1. Response time

Model

DS2-05-07-015-JV 5.5 12.5 5.5 13 5.5 15 6.5 10

DS2-05-07-030-JV 7 14 7 14.5 7 18 8.5 21

DS2-05-07-045-JV 8.5 15.5 8.5 16 8.5 21 10 24

DS2-05-07-060-JV 10 17 10 18 10 26 12 38

DS2-05-07-075-JV 11.5 18.5 11.5 19 11.5 31 15 44

DS2-05-07-090-JV 13 20 13 20 13 36 17 54

DS2-05-07-105-JV 14.5 21.5 14.5 22 14.5 40 19 62

DS2-05-07-120-JV 17 24 17 24 17 44 21 70

DS2-05-07-135-JV 18.5 25 19 26 19 48 23 80

DS2-05-07-150-JV 20 26.5 21 28 21 53 25 84

DS2-05-07-165-JV 22 28 23 30 23 56 28 91

DS2-05-25-045-JV 5 11 5 11 5 13 6 18

DS2-05-25-060-JV 5.5 12 5.5 12.5 5.5 14.5 6.5 19.5

DS2-05-25-075-JV 6 13 6 13.5 6 16 7 21