IDEC TW Series Instruction Sheet

Oiltight Switches & Pilot Devices

ø22mm - TW Series

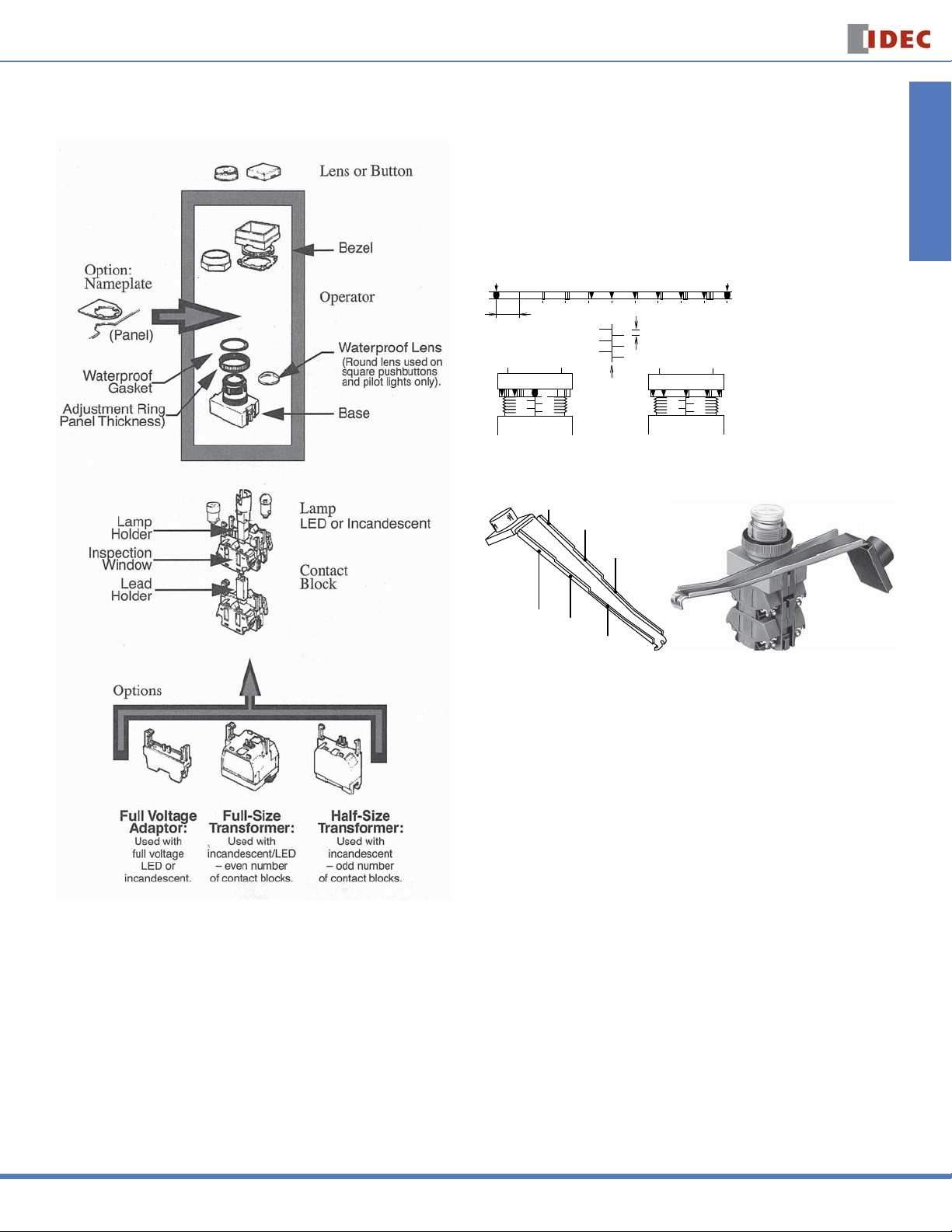

Component Construction and General Instructions — TW Series

Instructions for Switches and Pilot Devices

TW Series: Adjustment for Panel Thickness

The panel thickness ring provides adjustment from 0.04” to 0.24” (1 to 6mm)

in 0.004” (0.1mm) increments. Rotate the ring until the markings around the

periphery are aligned for the desired thickness, as shown below.

Scale on Adjustment (in 0.1 mm)

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 0

0.1 mm

2

3

4

5

66

Ex. Panel thickness 2 mm

An adjustment for panel thicknesses shown below can be made quickly by using

the contact block remover tool.

1.6 mm

2.3 mm

1

2

3

4

5

6

A

Panel Thickness Scale

1 mm

(in 1 mm on the operator)

3

4

5

Ex. Panel thickness 2.6 mm

Switches & Pilot Lights Display Lights Relays & Sockets Timers Terminal Blocks

Note: When a nameplate

or an anti-rotation ring

is used, add 0.03”

(0.8mm) to the panel

thickness dimension.

Tool TW-KC1

1 mm

2 mm

3.5 mm

3.2 mm

USA: 800-262-IDEC Canada: 888-317-IDEC

Circuit Breakers

599

ø22mm - TW Series

Oiltight Switches & Pilot Devices

Instructions continued

Pilot Lights and Pushbuttons

IMPORTANT: Install the body of the TW control unit with the panel thickness scale facing up.

Octagonal and Round Bezels

Octagonal and round bezels screw into the operator. Use a locking ring wrench (optional) for secure tightening and easy removal. Round fl ush and extended buttons

Switches & Pilot LightsDisplay LightsRelays & SocketsTimersTerminal Blocks

snap onto the operator base. Mushroom buttons screw onto the operator base.

Every round lens can be used with or without legend markings. Engraving can be done on a white translucent plate which is placed in the lens, or clear mylar can be

printed and placed in the lens.

Round

Marking

Unit

Insert marking

plate under lens

Press in

Square Bezels

Square bezels are installed in a 3-step procedure. First install the base plate from the front. Then install the lock nut using the nut locking wrench (optional). Finally,

install the square bezel, which snap-fi ts onto the base plate. Square buttons also snap onto the operator base.

Marking

Plate

Lens

Press in round fl ush and

extended lens.

Screw in mushroom lens

Every square lens can be used with or without legend markings. Engraving can be done on a white translucent plate which is placed in the lens, or clear mylar can be

printed and placed in the lens. Square units include a round waterproof lens which screws into the operator. The square outer lens snaps on.

Square

Marking

Pilot Light

Illuminated Pushbutton

Units

Press in

Insert marking

plate under lens

Insert

Square Lens

Marking Plate

Insert marking

plate under lens

Square Lens

To remove square lens from operator, place a screwdriver under the indentation on the side of the lens. To remove the marking plate, place a screwdriver under the

indentation and lift out the plate. The lens retainer can be removed by pressing a 3/16” screwdriver into one of the recesses.

Marking Plate

Lens Retainer

Waterproof Lens

Marking Plate Engraving Area

Shape Engraving Area Used With Part Number

Round

Mushroom Ø 0.55” (14mm) Illuminated mushroom ALW3B

Circuit Breakers

Square

Square

Ø 0.55” (14mm) Illuminated pushbuttons ALW2B

Ø 0.55” (14mm) Pilot lights APW2B

q 0.83” (21mm)

q 0.83” (21mm)

Square pilot lights APQW1B

Square illuminated pushbuttons ALQW2B

600

www.idec.com

Loading...

Loading...