IDEAL Networks FiberTEK III User Manual

FiberTEK III

FiberTEK III Document 164802 Iss 4

User Manual Page 1

COPYRIGHT NOTICE

The information contained in this document is the property of IDEAL INDUSTRIES Ltd. and is

supplied without liability for errors and omissions. No part of this document may be

reproduced or used except as authorized by contract or other written permission from

IDEAL INDUSTRIES Ltd. The copyright and all restrictions on reproduction and use apply to

all media in which this information may be placed.

IDEAL INDUSTRIES Ltd. pursues a policy of continual product improvement and reserves the

right to alter without notice the specification, design, price or conditions of supply of any

product or service.

© IDEAL INDUSTRIES LTD. 2016

All rights reserved

Publication ref: 164802

Issue 4 - 02/2016

(Applies to LanTEK III software revision 3.067 onwards)

IDEAL INDUSTRIES LTD.

Stokenchurch House

Oxford Road

Stokenchurch

High Wycombe

Buckinghamshire

HP14 3SX UK

www.idealnetworks.net

FiberTEK III Document 164802 Iss 4

User Manual Page 2

Safety Precautions

WARNING!

NEVER look directly into the port of measuring adapter, at connector surface, open fiber ends or

into couplers. There is a risk of light emerging from the fiber that is not visible, which could

permanently damage your eyes.

If you are not sure whether the device is switched on or whether the fiber transmits light, for safety

reasons always assume that the device is active.

Handle bare fibers properly; there is a risk of injury from fiber splinters.

Protect your eyes when working with bare fibers; fiber splinters could permanently damage your

eyes.

Never let fiber scraps lie openly and never dispose of them loosely in normal waste containers;

there is a risk of injury from fiber splinters.

CAUTION!

When connecting the measuring adapter to a light-conducting line, the maximum measuring range

must be observed (see specifications of individual modules). Exceeding it could result in damages

to FiberTEK™ III modules.

NOTE:

Before connecting cable adapter to FiberTEK™ III adapter, ensure that the plugs of cable

connectors are clean.

Clean ferrules of measuring adapter only with dry, lint-free, non-abrasive materials.

The plugs can be cleaned with suitable fiber cleaning cloths or cleaning pens. IDEAL

recommends cleaning set #1219-00-1621025205 (2.5 mm) and 025204 (1.25 mm) to care

for the modules and patch cord.

Disclaimer

IDEAL INDUSTRIES, LTD. does not assume any liability for death, injury or damage to

equipment or property resulting from improper use of the battery packs.

IDEAL INDUSTRIES, LTD. will not be liable for consequential damages that may result from

tampering with the battery packs or charger or their use thereafter.

Subject to technical changes.

Environmental Protection

If you have any questions concerning these precautions, the operating instructions, or any

other concerns about the safe use and disposal of the battery packs used in LanTEK

®

III,

please contact a representative of IDEAL INDUSTRIES, LTD.

FiberTEK III Document 164802 Iss 4

User Manual Page 3

Information on the use of this Instruction Manual

The following symbols used in this manual indicate that the user should exercise particular

caution in order to prevent personal injury or damage to the FiberTEK™ III or the system

under test.

WARNING!

This symbol indicates potentially lethal voltages or dangerous situations. The life and/or

health of the person performing the activity or anybody in the vicinity is at risk.

CAUTION!

This symbol indicates that the relative activity could possibly harm the environment or

damage technical equipment.

NOTE:

Here you will find general notes, additional information, or support.

Typographical Conventions

• Boldface Refers to a button on LanTEK III Cable Certifier.

• Italics Refers to a menu option in this Operating Manual.

• Quotation marks " " identify a "Screen Message".

FiberTEK III Document 164802 Iss 4

User Manual Page 4

CONTENTS

Chapter 1.

Specifications ............................................................................................................ 5

Chapter 2. Product Description .................................................................................................. 8

2.1 Test Modules .................................................................................................................................................... 8

2.1.1 Controls, Ports, Indicators and Connectors .............................................................................. 8

2.2 Fiber Adapters ......................................................................................................................................... 10

2.3 Encircled Flux ........................................................................................................................................... 10

Chapter 3. Calibration ................................................................................................................. 11

3.1 Field Calibration ............................................................................................................................................ 11

3.2 Performing Field Calibration ............................................................................................................... 11

Chapter 4. Testing using FiberTEK™ III .................................................................................... 14

4.1 Test Setup According to Reference Method with Three Test Cords .................................... 14

4.2 Test Setup According to Reference Method with One Test Cord ..................................... 14

4.3 Set Autotest Pref..................................................................................................................................... 15

4.3.1 Selection of Fiber Test Standard ................................................................................................ 15

4.3.2 Selection of Refractive Index ........................................................................................................ 16

4.3.3 Selection of Fiber size and Wavelength .................................................................................. 16

4.3.4 Determine Loss Budget ................................................................................................................... 17

4.4 Evaluation of Autotest Results for Fibers (LWL) ...................................................................... 18

4.4.1 Passed/Failed Rating ....................................................................................................................... 18

4.4.2 Saving Current Autotest Results ................................................................................................. 18

4.4.3 Manual Saving of Autotest Results (Autosave off) ............................................................. 19

4.4.4 Working with Jobs ....................................................................................................................... 19

4.4.5 Display of Result Details ................................................................................................................. 19

Chapter 5. FiberTEK™ III Analyse Mode .................................................................................. 20

5.1.1 Continuous Run ................................................................................................................................. 20

5.1.2 Power Meter Mode ............................................................................................................................ 21

FiberTEK III Document 164802 Iss 4

User Manual Page 5

Chapter 1. Specifications

Operational Conditions

(unless specified

otherwise)

1. At 23 ±1 ºC unless otherwise specified.

2. After ten-minute warm-up time.

Testing speed

Autotest 8 seconds for each fiber / fiber pair (i.e. twice this for a BiDirectional test)

Input (Meter) connectors Universal with adaptors for FC, ST, SC and LC

Output (Source)

connectors

Universal with adaptors for FC, ST, SC and LC

Fiber type

9/125 µm, 50/125 μm and 62.5/125 μm

Source type and nominal

wavelength

MM LED: 850 nm LED and 1300 nm LED

SM Laser: 1310 nm and 1550 nm FP laser

Source wavelengths

MM: 850 ±20 nm

1300 nm -35 to +30 nm

SM: 1310 ±20 nm

1550 nm ±30 nm

Source spectral width

MM LED: Source spectral width (Full-Width Half-Maximum -

FWHM):

35 nm at 850 nm typical

80 nm at 1300 nm typical

Source power in light

source mode

MM 850 nm LED: -20 to -23 dBm nominal

With EF mode conditioner: -23 to -26 dBm nominal

MM 1300 nm LED: -15 to -20 dBm

With EF mode conditioner: -18 to -23 dBm

SM Laser: > -7 dBm

Source power stability

850, 1300 nm LED: ±0.25 dBm over 8 hours

1310, 1550 nm Lasers: ±0.25 dBm over 8 hours

Encircled Flux Compliance

Using optional external mode conditioner, complies withTIA-526-14B and IEC 61280-1-4 at the end of the cable

Length measurement

MM LED: 0 – 7,500 m of 50/125 or 62.5/125 µm fiber

SM Laser: : 0 - 20,000 m 9/125 µm fiber

Length measurement

accuracy

±1.5 m ±2% of length, 2 m minimum

Power meter type InGaAs detector

Power meter calibrated

wavelengths

MM: 850 nm, 1300nm

SM: 1310 nm, 1550 nm

Power measurement

range

0 to -55 dBm (850 nm)

0 to –60 dBm (1300/1310 nm and 1550 nm)

Power measurement

uncertainty (accuracy)

±0.25 dB at – 20 dBm, calibration performed with an FC adaptor

Measurement linearity

• 850 nm: target ±0.2 dB between 0 and -45 dBm, ± 0.25 dB below

-45 dBm

• 1300/1310 nm and 1550 nm: target ±0.2 dB between 0 and -55

dBm, ± 0.2 dB below -55 dBm

Display resolution

Power/attenuation: 0.01dB or dBm

Power W: 3 digits

1.00 to 9.99 nW

10.0 to 99.9 nW

100 to 999 nW

1.00 to 9.99 uW

10.0 to 99.9 uW

100 to 999 uW

Length: 0.1m / 0.5ft

Display update rate Approximately 2 updates per second on power meter function

FiberTEK III Document 164802 Iss 4

User Manual Page 6

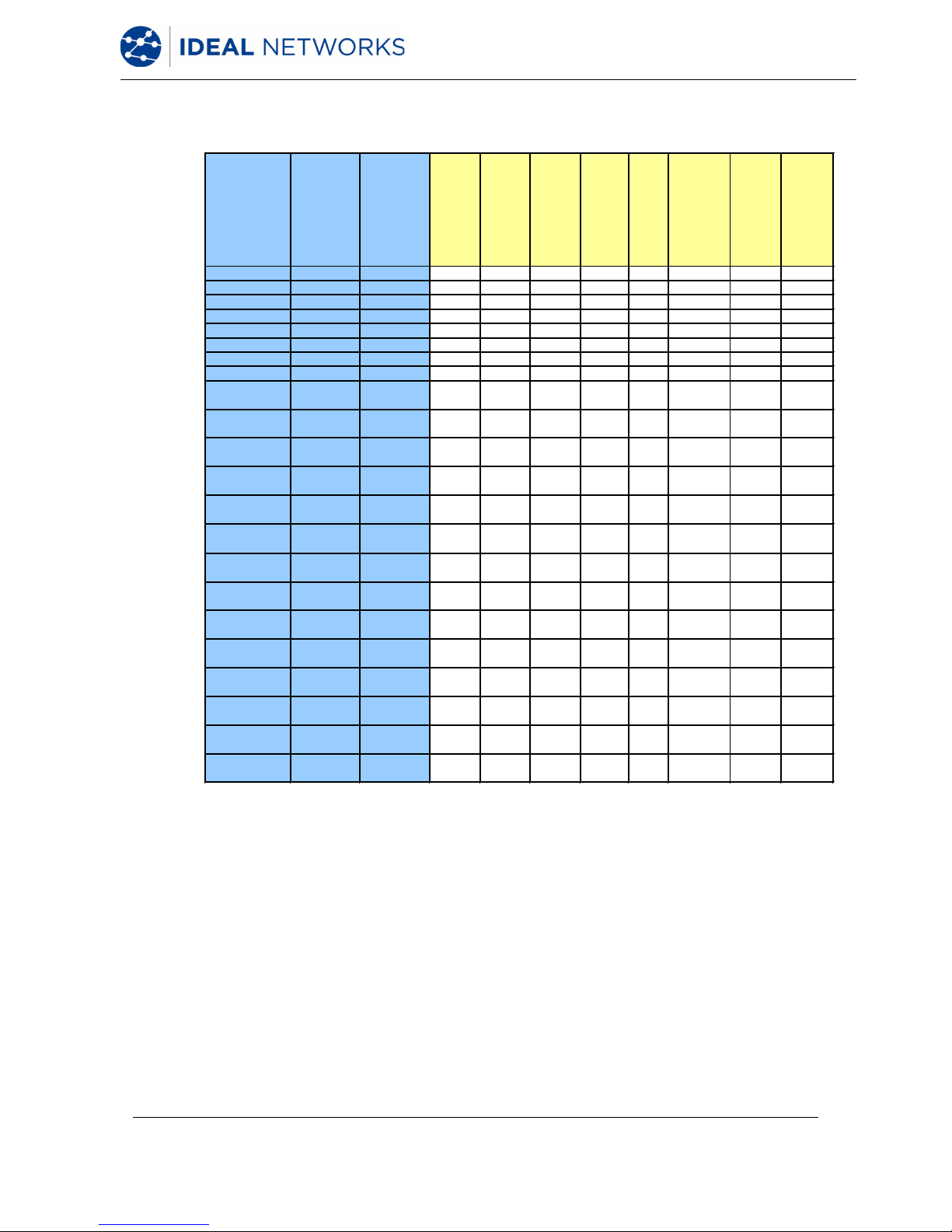

Standards

Organization

Classification or

Application

Fiber Type

Core size (um) /

wavelength (nm)

Max Link Channel

Loss (dB)

Max Connector

Insertion Loss (dB)

Max Splice

Insertion Loss (dB)

Min Connector

Return Loss (dB)

Maximum Distance

(m)

Min Operating

Distance (m)

(

50um/62.5um)

Max Fiber

Attenuation

(d

B/km)

Min Fiber

Bandwidth (MHz-

km

)

TIA 568-B.3 Horizontal link Multimode 62.5/850

n/s

0.75 0.3

>20 90 n/s 3.5 160

Horizontal link Multimode 50/850

n/s

0.75 0.3

>20 90 n/s 3.5 500

Horizontal link Multimode 62.

5/1300

n/s

0.75 0.3

>20 90 n/s 1.5 500

Horizontal link Multimode 50/1300

n/s

0.75 0.3

>20 90 n/s 1.5 500

Backbone Multimode 62.5/850

n/s

0.75 0.3

>20 2km n/s 3.5 160

Backbone Multimode 50/850

n/s

0.75 0.3

>20 2km n/s 3.5 500

Backbone Multimode 62.5/1300

n/s

0.75 0.3

>20 2km n/s 1.5 500

Backbone Multimode 50/1300

n/s

0.75 0.3

>20 2km n/s 1.5 500

Horizontal link Single mode 9/1310

n/s

0.75 0.3

>26 90 n/s 1.0 n/a

Horizontal link Single mode 9/

1550

n/s

0.75 0.3

>26 90 n/s 1.0 n/a

Backbone (ISP) Single mode 9/1310

n/s

0.75 0.3

>26 3km n/s 1.0 n/a

Backbone (ISP) Single mode 9/

1550

n/s

0.75 0.3

>26 3km n/s 1.0 n/a

Backbone (OSP)

Single mode 9/1310

n/s

0.75 0.3

>26 3km n/s 0.5 n/a

Backbone (OSP)

Single mode 9/1550

n/

s

0.75 0.3

>26 3km n/s 0.5 n/a

OF-300 OM1

50 or

62.5/1300

1.95

0.75 ea/

1.5 total

0.3

>20 n/

s 300 1.5 500

OF-300 OM2

50 or

62.5/850

2.55

0.75 ea/

1.5 total

0.3

>20 n/

s 300 3.5 500

OF-300 OM2

50 or

62.5/1300

1.95

0.75 ea/

1.5 total

0.3

>20 n/

s 300 1.5 500

OF-300 OM3 50/850

2.55

0.75 ea/

1.5 total

0.3

>20 n/

s 300 3.5 1500

OF-300 OM3 50/

1300

1.95

0.75 ea/

1.5 total

0.3

>20 n/

s 300 1.5 500

OF-300 OS1

9/1310 or

1550

1.80

0.75 ea/

1.5 total

0.3

>35 n/

s 300 1.0 n/s

OF-500 OM1

50 or

62.5/850

3.25

0.75 ea/

1.5 total

0.3

>20 n/

s 500 3.5 200

OF-500 OM1

50 or

62.5/1300

2.25

0.75 ea/

1.5 total

0.3

>20 n/

s 500 1.5 500

Summary of Fiber Optic Cabling Standards & Application Requirements

ISO 11801

Generic

C

abling

ISO 11801

Generic

C

abling

Generic

Cabling

FiberTEK III Document 164802 Iss 4

User Manual Page 7

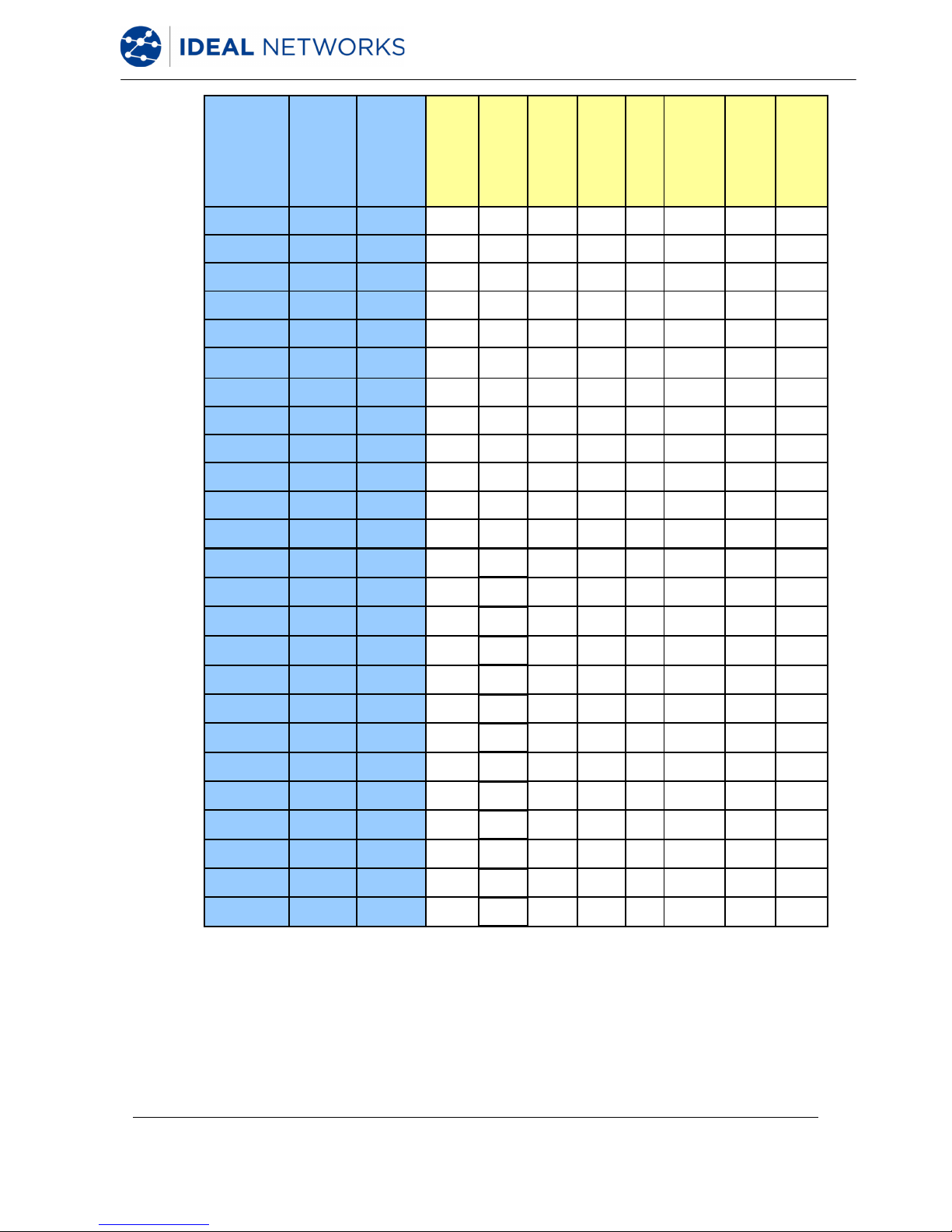

Standards

Organization

Classification or

Application

Fiber Type

Core size (um) /

wavelength (nm)

Max Link Channel

Loss (dB)

Max Connector

Insertion Loss (dB)

Max Splice

Insertion Loss (dB)

Min Connector

Return Loss (dB)

Maximum Distance

(m)

Min Operating

Distance (m)

(50um/62.5um)

Max Fiber

Attenuation

(dB/km)

Min Fiber

Bandwidth (MHz-

km)

OF-500 OM2

50 or

62.5/850

3.25

0.75 ea/

1.5 total

0.3

>20 n/s 500 3.5 500

OF-500 OM2

50 or

62.5/1300

2.25

0.75 ea/

1.5 total

0.3

>20 n/s 500 3.5 500

OF-500 OM3 50/850

3.25

0.75 ea/

1.5 total

0.3

>20 n/s 500 3.5 1500

OF-500 OM3 50/130

2.25

0.75 ea/

1.5 total

0.3

>20 n/s 500 1.5 500

OF-500 OS1

9/1310 or

1550

2.00

0.75 ea/

1.5 total

0.3

>35 n/s 500 1.0 n/a

OF-2000 OM1

50 or

62.5/850

8.50

0.75 ea/

1.5 total

0.3

>20 n/s 2km 3.5 200

OF-2000 OM1

50 or

62.5/1300

4.50

0.75 ea/

1.5 total

0.3

>20 n/s 2km 1.5 500

OF-2000 OM2

50 or

62.5/850

8.50

0.75 ea/

1.5 total

0.3

>20 n/s 2km 3.5 500

OF-2000 OM2

50 or

62.5/1300

4.50

0.75 ea/

1.5 total

0.3

>20 n/s 2km 1.5 500

OF-2000 OM3 50/850

8.50

0.75 ea/

1.5 total

0.3

>20 n/s 2km 3.5 1500

OF-2000 OM3 50/130

4.50

0.75 ea/

1.5 total

0.3

>20 n/s 2km 1.5 500

OF-2000 OS1

9/1310 or

1550

3.50

0.75 ea/

1.5 total

0.3

>35 n/s 2km 1.0 n/a

IEEE 802.3 10Base-FL

Multimode/

OM1-OM2

62.5/850

12.50

0.75 ea/

1.5 total

n/s

>20 2km 0 3.75 160

10Base-FL

Multimode/

OM1-OM3

50/850

12.50

0.75 ea/

1.5 total

n/s

>20 1.5km 0 3.75 160

100Base-FX

Multimode/

OM1-OM3

62.5 or

50/1300

11.00

0.75 ea/

1.5 total

n/s

n/s 2km 0 3.75 500

1000Base-SX

Multimode/

OM1-OM2

62.5/850

2.33

0.75 ea/

1.5 total

n/s

>20 n/s 220 3.75 160

1000Base-SX

Multimode/

OM2-OM3

62.5/850

2.53

0.75 ea/

1.5 total

n/s

>20 n/s 275 3.75 200

1000Base-SX

Multimode/

OM1-OM3

50/850

3.25

0.75 ea/

1.5 total

n/s

>20 n/s 500 3.5 400

1000Base-SX

Multimode/

OM2-OM3

50/850

3.43

0.75 ea/

1.5 total

n/s

>20 n/s 550 3.5 500

1000Base-LX

Multimode/

OM1-OM2

62.5/1300

2.32

0.75 ea/

1.5 total

n/s

>20 n/s 550 1.5 500

1000Base-LX

Multimode/

OM1-OM2

50/1300

2.32

0.75 ea/

1.5 total

n/s

>20 n/s 550 1.5 400/500

1000Base-LX

Singlemode/

OS1

9/1310

4.50

0.75 ea/

1.5 total

n/s

>26 n/s 5km 0.5 n/a

10GBase-SR

MultimodeOM1

62.5/850

2.60

0.75 ea/

1.5 total

n/s

>20 n/s 26 3.5 160

10GBase-SR

MultimodeOM1

62.5/805

2.50

0.75 ea/

1.5 total

n/s

>20 n/s 33 3.5 200

10GBase-SR

Multimode/

OM2-OM3

50/850

2.20

0.75 ea/

1.5 total

n/s

>20 n/s 66 3.5 400

ISO 11801

Generic

Cabling

Loading...

Loading...