Page 1

#33-931

FiberMASTER

TM

Fiber Optic Testing Kit

Instruction Manual

Introduction

The IDEAL FiberMASTERTM ber optic testing kit allows

the user to measure absolute power and calculate the

loss of ber optic links at several wavelengths. Absolute

power measurements are helpful when trouble shooting

equipment that may not be operating properly. The dB

calibration feature allows the operator to set a reference

level to the light source and directly read the loss of ber

optic links without needing to manually calculate the values. The unique form

factor allows the light source to be docked neatly within the power meter. This

makes the kit compact for easy storage while still allowing full operation of both

the source and meter.

Product Features

• 850, 1300/1310, 1490 and 1550 wavelength measurement capability

on power meter

• 850/1300/1310/1550nm laser light source (33-931 kit)

• Power measurement in dBm and µW, loss display in dB

• Power meter auto power off

• Operates on standard AAA batteries, three in each unit

• Includes universal adapter for power meter and ST, SC and FC adapters

for light source

• Includes rugged carrying pouch, multimode and single mode SC jumpers

and calibration coupler

1

Page 2

ADVICE AND PRECAUTIONS

Laser Warning:

• Do not look inside the optical ber port when the FiberMASTER is

operating. The emissions can be dangerous and cause permanent

damage to your vision.

• To prevent damage to the lens, do not insert items other than optical

connectors into the port of the FiberMASTER.

• Do not look into the ber if it is connected to an active device. The

wavelength of the light transmitted by the equipment is invisible to

the human eye and may cause permanent vision damage.

• Always assume that a ber optic cable is connected to an active

device that is emitting dangerous, invisible light.

General Operation

FiberMASTER operates in two basic modes; absolute power measurement

and relative power measurement.

Absolute power measurement is the measure of the strength of the light

energy coming into the power meter. This mode is indicated by the dBm

(decibel milliwatt) or µW (microwatt) annunciators in the LCD display. This

mode is helpful when measuring the output of an optical device to determine

if it is operating within its specications. For example, most ber optic

network devices specify their typical output power in dBm. By connecting the

FiberMASTER power meter to the output of a network device the direct power

can be instantly measured to isolate a faulty transmitter.

Relative power measurements are used to calculate the difference in power

between two measurements. This mode is indicated by the dB annunciator

in the LCD panel. This mode is used mostly by installers when measuring

ber optic cabling from end-to-end to determine the link loss of the system.

To use this mode, the power meter must rst be connected to a stable light

source then that power level in stored in the meter’s memory. Then future

measurements are compared to the stored reference value and the difference

is calculated and displayed as dB.

2

Page 3

Power Meter Display and Functions

1. Wavelength measurement annunciator.

2. Numeric display for power and loss measurements.

Also displays “null” when power is below detection

level.

3. Decibel toggle button. Press to change between power

measurement mode (dBm) and loss calculation mode

(dB). Changing to dB mode automatically stores the

current input level as the reference for loss calculations.

4. Power button.

5. Unit of measure annunciator, displays either dBm, dB or µW.

6. Wavelength select and dB/µW toggle button. Press and release to

change wavelength between 850/1300/1310/1490/1550nm. Press and

hold for 2 seconds then release to toggle between dBm and µW modes.

1

2

5

3

6

4

3

Page 4

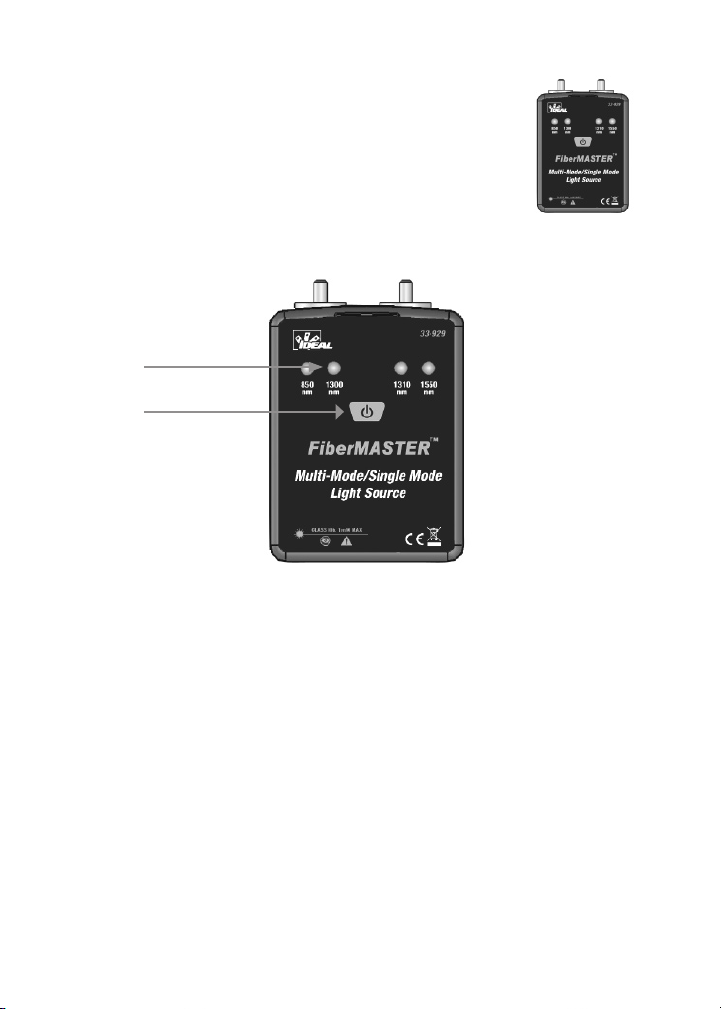

Light Source Indicators and Functions

1. Wavelength LEDs. Lights green to indicate active

source. Blinks red when battery is low. At 3.6V unit will

power off after 10 minutes. At 3.3V unit will power off

after 5 seconds.

2. Power button. Press the toggle wavelength, hold to

power off.

1

2

The power output of the light source will vary slightly during the rst ve

minutes of operation as it warms to operating temperature. To ensure best

measurement accuracy, allow the light source to operate for ve minutes

before calibrating the meter or making measurements.

4

Page 5

Basic Operation

dBm

nm

dBm

nm

-

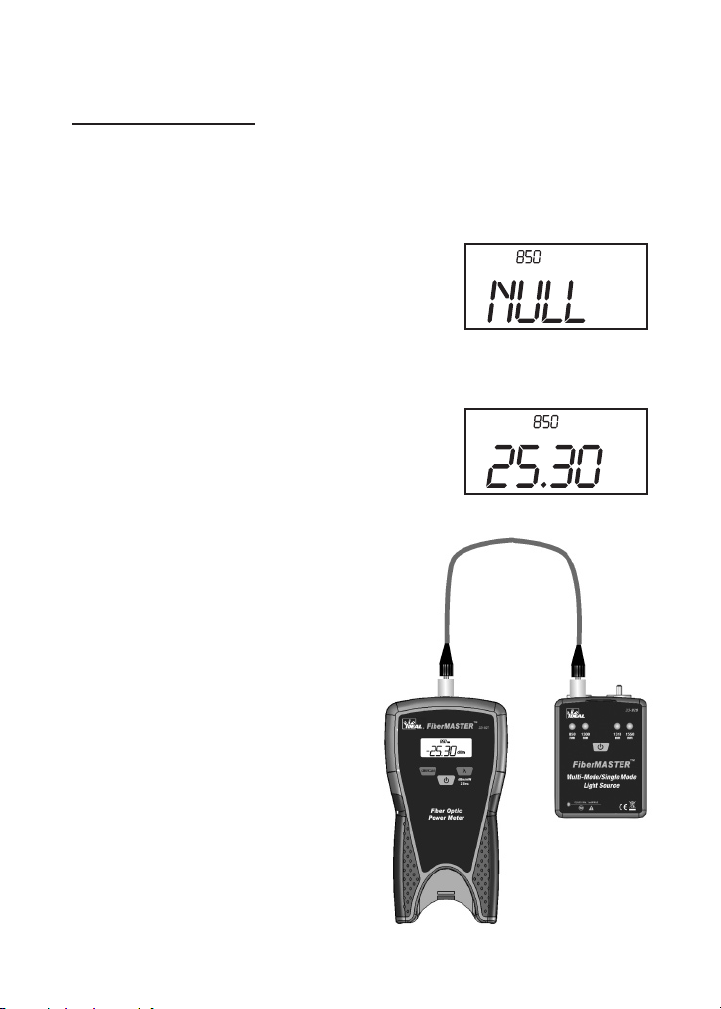

Measuring Optical Power

Important: When the power meter is rst turned on it self-calibrates to a “no light” condition which is necessary for accurate

measurements. THE DUST COVER MUST REMAIN ON THE

POWER METER PORT WHEN IT IS FIRST TURNED ON.

1. With the dust cap on the power meter, press

the power button. The meter will display ‘null’,

indicating that it is ready to measure and

is currently receiving no power. Press the

wavelength ‘λ’ button to change to the desired

wavelength.

2. Remove the dust cap and connect the meter

to a cable to begin taking measurements. The

default measurement mode is dBm and can

be changed to uW by holding the ‘λ’ button

for 2 seconds then releasing.

In addition to using a separate light source,

the power meter can measure the output

from any optical switch, media converter

or other device as long as its wavelength

is within one of the operating windows of

the 33-927 power meter.

5

Page 6

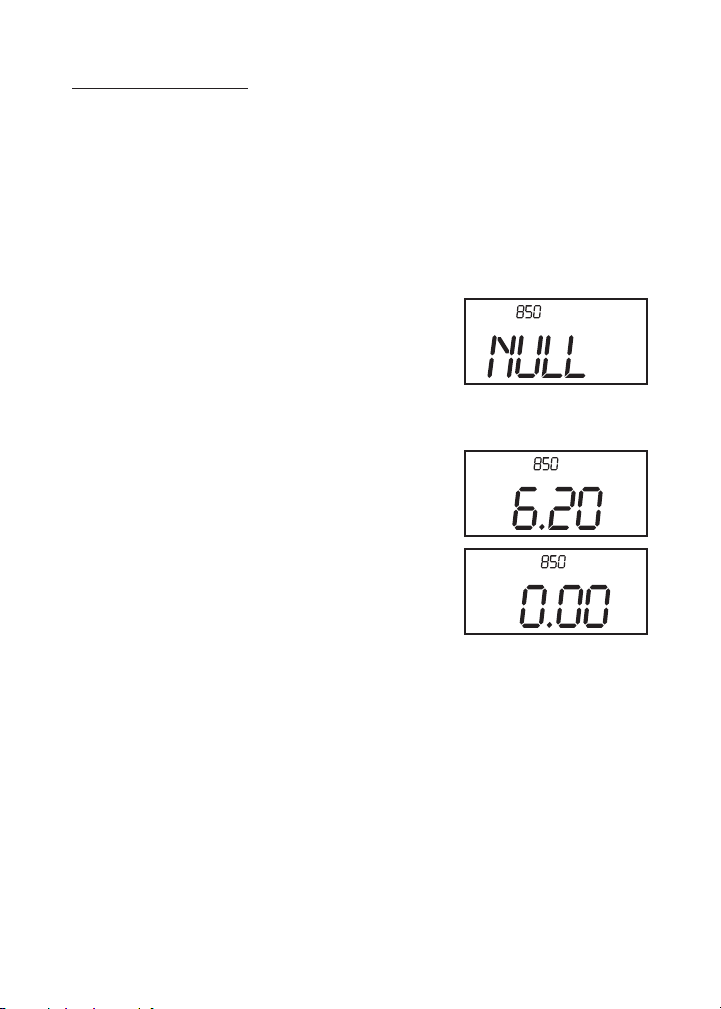

Measuring Cabling Loss

dBm

nm

-

dBmnmdB

nm

-

Loss measurements are performed to certify a cabling link meets certain

criteria for attenuation. Loss (dB) can be manually calculated by subtracting

the power (dBm) through the cabling under test from the power (dBm) of the

light source when connected directly to the meter. To make this process easier

FiberMASTER includes a calibration function that stores the light source power

level and compares it to future readings and directly displays loss in dB on the

LCD panel.

1. With the dust cap on the power meter, press

the power button. The meter will display ‘null’,

indicating that it is ready to measure and

is currently receiving no power. Press the

wavelength ‘λ’ button to change to the desired

wavelength.

2. Set the light source to the desired wavelength.

3. Remove the dust cap and connect the

reference jumpers between the power meter

and light source. The meter will display the

current power dBm from the light source.

4. Press the ‘dB/Cal’ button on the power meter

to store the current value into memory. The

display will now indicate 0.00dB.

5. Remove the coupler from the two reference

jumpers, connect to the cabling under test and

begin making measurements. The display will

indicate the attenuation (dB) compared to the

initial calibration power (dBm).

See diagrams on the following page.

Do not disconnect the reference jumper from the

light source after calibrating the test set. Doing so

will cause inaccuracies and requires recalibration.

6

Page 7

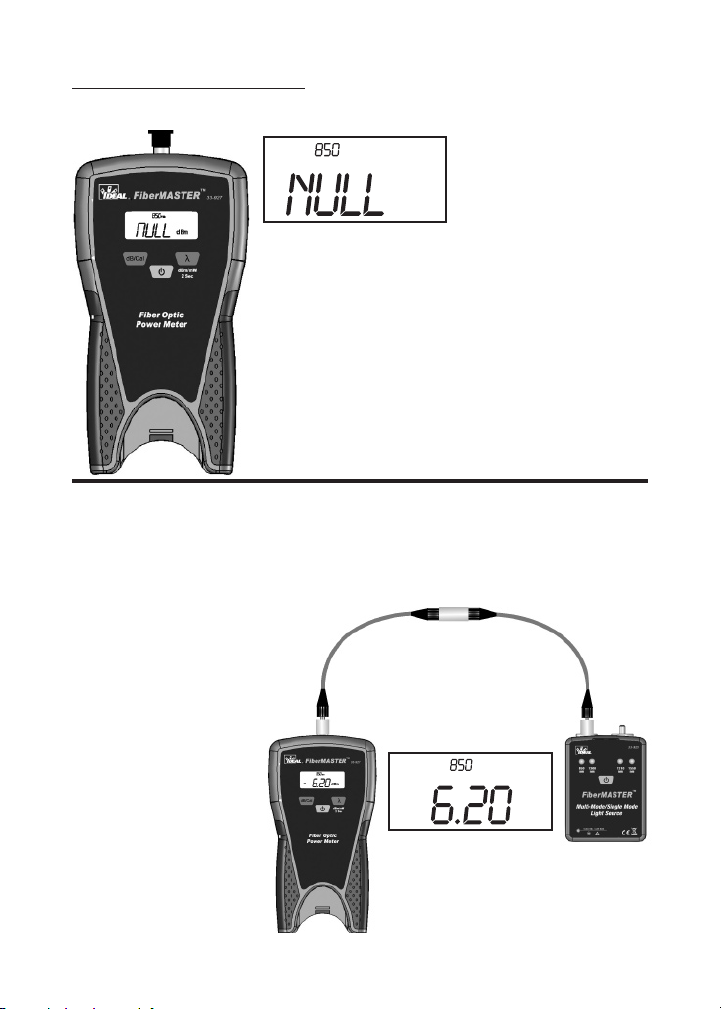

Calibration Procedure Diagrams

dBm

nm

dBm

nm

-

The following diagrams supplement steps 1–4 on the previous page.

Afx the black dust cap

to the input of the power

meter. Clear dust caps

allow ambient light to

pass and cannot be used. Turn on the power meter

and wait for ‘null’ to be displayed on the LCD. The

meter is now ready to use.

Connect known good reference jumpers between the light source and power

meter. In this example two jumpers are used in conjunction with a coupler.

This conguration allows the jumpers to be connected directly to a patch panel

when making measurements. A single jumper can also be used as long as it

is not disconnected from the light source after the calibration process.

The LCD will display the

current power level at the

power meter input. Typical

values for the 33-929

light sources are -6 to

-7dBm. Levels lower than

this (ex -15dBm) indicate

excessive loss in the

reference jumpers.

New jumpers should

be used.

7

Page 8

Press the ‘dB/Cal’ button

dB

nm

-

dB

nm

-

to store the reference

value. The LCD will

display ‘0.00dB’.

The meter is now measuring

loss.

Repeated pressing of the

‘dB/Cal’ button again will

change between the dBm

power measurement mode

and dB loss measurement

mode. Each time the meter

enters the dB mode it stores the current power level as a new reference level.

Once the calibration value is set, do not toggle out of the dB mode. Otherwise

it will be necessary to perform the calibration step again.

The meter does not store a separate reference value for each wavelength.

When changing wavelengths repeat the jumper reference procedure.

Disconnect the two

reference jumpers and

connect to the cabling

under test. The meter will

display the total loss of all

components between the

two reference jumpers.

8

Page 9

Reference Information

dB vs. Power Table

dB Loss % of Power Remaining % of Power Lost

1 79.00% 21.00%

2 63.00% 37.00%

3 50.00% 50.00%

4 40.00% 60.00%

5 32.00% 68.00%

6 25.00% 75.00%

7 20.00% 80.00%

8 16.00% 84.00%

9 12.00% 88.00%

10 10.00% 90.00%

11 8.00% 92.00%

12 6.30% 93.70%

13 5.00% 95.00%

14 4.00% 96.00%

15 3.20% 96.80%

16 2.50% 97.50%

17 2.00% 98.00%

18 1.60% 98.40%

19 1.30% 98.70%

20 1.00% 99.00%

25 0.30% 99.70%

30 0.10% 99.90%

40 0.01% 99.99%

50 0.001% 99.90%

Maintenance

Clean the case with a damp cloth, do not use detergents. Clean the optical

ports with lint free tissues and swabs designed for ber optic components

and use 99% pure isopropyl alcohol and de-ionized water. Do not blow into

the optical ports.

Service and replacement parts

This unit has no user serviceable parts. To obtain service call Technical

Support at 800-854-2708 or 858-627-0100.

9

Page 10

Power Meter Specications

Wavelength 850, 1300, 1310, 1490, 1550nm

Detector InGaAs

Measurement Range -60 to +3dBm

Accuracy ±5%

Display Resolution .01

Connector Universal 2.5mm w/ FC adapter

Power Supply AAA Alkaline Battery x 3

Operating Time 360 hours

Operating Temp -10 to +60°C

Storage Temp -25 to +70°C

Light Source Specications

Wavelength 850/1300/1310/1550nm laser diode

Output Power -6 to -7 dBm Typical

Stability .05dB after 15min, 0.1dB over 8 hrs

Connector 2.5mm w/ ST, SC, FC adapters

Power Supply AAA Alkaline Battery x 3

Operating Time 40 hours

Operating Temp -10 to +60°C

Storage Temp -25 to +70°C

Limited Warranty

This instrument is warranted to the original purchaser against defects in material or workmanship for one year from the date of purchase. During this warranty period, IDEAL INDUSTRIES,

INC. will, at its option, replace or repair the defective unit, subject to the verication of the

defect or malfunction. This warranty does not apply to malfunctions resulting from abuse,

neglect, accident, unauthorized repair, alteration or unreasonable use of the instrument.

Any implied warranties arising out of the sale of an IDEAL product, including but not limited

to implied warranties of merchantability and tness for a particular purpose, are limited to the

above. The manufacturer shall not be liable for loss of use of the instrument or other incidental or consequential damages, expenses or economic loss, or for any claim or claims for such

damage, expenses or economic loss.

State laws vary, so the above limitations or exclusions may not apply to you. This warranty

gives you specic legal rights, and you may also have other rights, which may vary from

state to state.

Warranty limited solely to repair or replacement; no warranty or merchantability, tness for

a particular purpose or consequential damages.

10

Page 11

IDEAL INDUSTRIES, INC.

Sycamore, IL 60178, U.S.A.

800-435-0705 Customer Assistance, 800-854-2708 Technical Support

www.idealindustries.com

6510-92-0001 Rev C Made in China / Fabriqué aux China / Fabricado en China

11

Loading...

Loading...