Page 1

users guide

back

mini

Your Ideal users guide

See reverse for mini installation and servicing guide

C24/C28/C32

S24/S28

When replacing any part of this appliance, use only spare parts that you can be

assured conform to safety and performance specification that we require. Do not use

reconditioned or copy parts that have not been clearly authorised by Ideal Boilers

Page 2

Mini

MiniC24

back

Mini C24 G.C. appliance No. 47 ---348 ---18

Mini C28 G.C. appliance No. 47 ---348 ---19

Mini C32 G.C. appliance No. 47 ---348 ---25A

Mini S24 G.C. appliance No. 41 ---392 ---98

Mini S28 G.C. appliance No. 41 ---392 ---99

Destination countries: GB, IE

INTRODUCTION

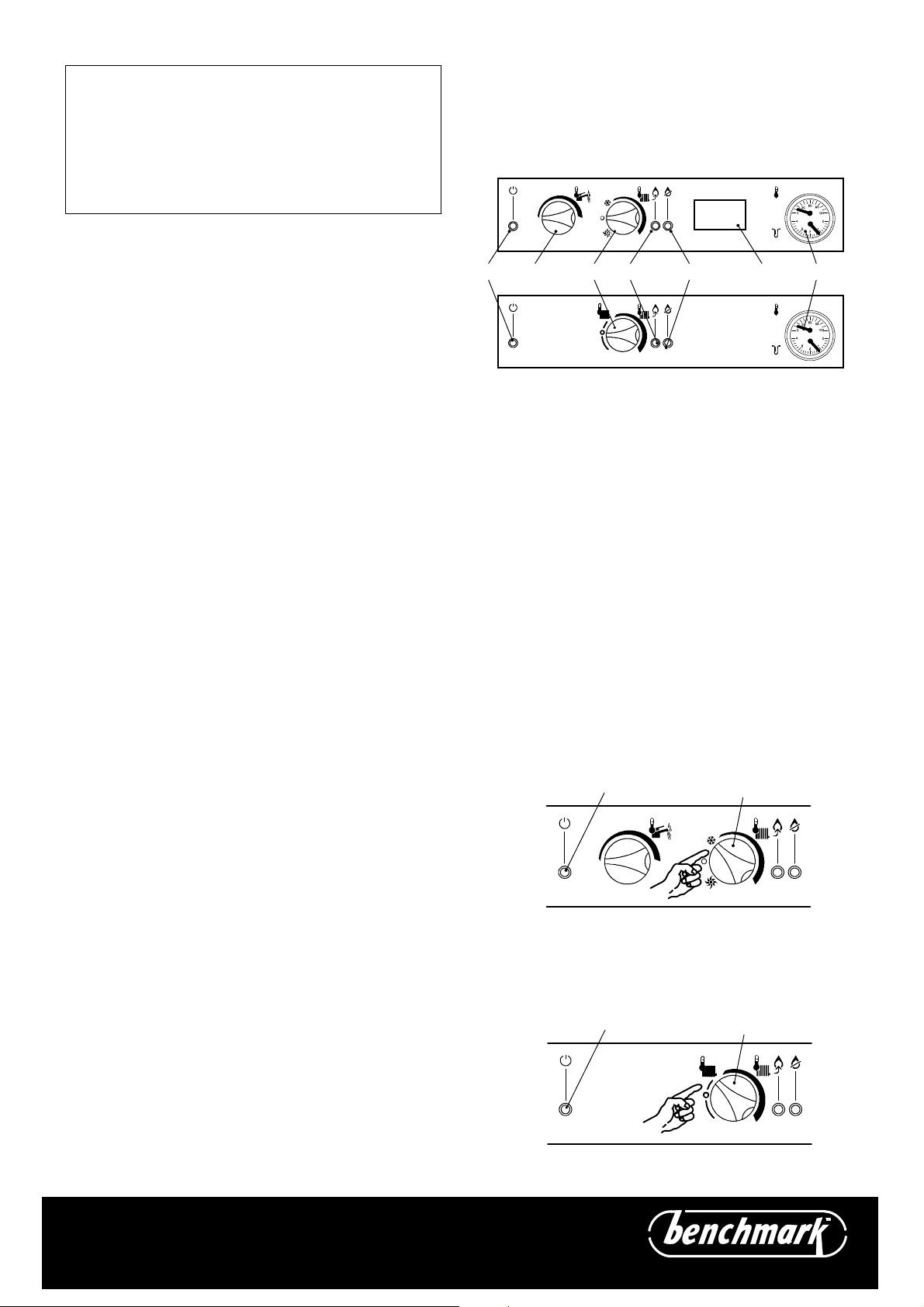

BOILER CONTROLS

Mini C28

Mini C32

Mini are wall mounted, room sealed, non condensing boilers

featuring full sequence automatic spark ignition and fan

assisted combustion.

Mini C24, Mini C28 and Mini C32 are low water content

combination gas boilers.

Mini S24 and Mini S28 are low water content system gas

boilers.

SAFETY

Current Gas Safety (Installation & Use)

Regulations or rules in force

In your own interest, and that of safety, it is the law that this

boiler must be installed by CORGI registered installer or in IE

a competent person, in accordance with the above

regulations.

It is essential that the instructions in this booklet are strictly

followed, for safe and economical operation of the boiler.

A Appliance On lamp

B Domestic hot water temperature control

C Main switch and radiator temperature control

D Boiler reset button

E Lock---out signal lamp

F Programmer (optional)

G System pressure and temperature gauge

B C D E F GA

TO LIGHT THE BOILER

ELECTRICITY SUPPLY

The appliance must be efficiently earthed.

Supply 230 V 50 Hz. The fusing should be 3 A.

Connection must be made in a way that allows complete

isolation of the electrical supply, such as a double pole switch,

having a 3 mm (1/8”) contact separation in both poles, or a

plug and socket serving only the boiler and system controls.

The means of isolation must be accessible to the user after

installation.

IMPORTANT NOTES

F This appliance must not be operated without the casing

correctly fitted and forming an adequate seal.

F If the boiler is installed in a compartment then the

compartment MUST NOT be used for storage purposes.

F Under no circumstances should any of the sealed

components on this appliance be used incorrectly or

tampered with.

F If it is known or suspected that a fault exist on the boiler

then it MUST NOT BE USED until the fault has been

corrected by a CORGI registered installer or in IE a

competent person.

MINIMUM CLEARANCES

Clearances of 200 mm (7 7/8“) above and below, 25 mm (1“)

at left, 50 mm (2“) at right and 450 mm (17 3/4“) at the front of

the boiler case must be allowed for servicing.

After installation the following clearances are allowable during

use, providing the encasing parts are removeable for

servicing:

The bottom clearance can be reduced to 20mm (3/4”).

The front clearance can be reduced to 50mm (2”).

All CORGI registered installers carry a CORGI ID card, and have a registration number. Both should be

recorded in your Benchmark Log Book. You can check your installer by calling CORGI direct on 01563 72300

Caradon Ideal Limited is a member of the Benchmark initiative and fully supports the aims of

the programme. Benchmark has been introduced to improve the standards of installation and

commissioning of central heating systems in the UK and to encourage the regular servicing of

all central heating systems to ensure safety and efficiency.

THE LOG BOOK SHOULD BE COMPLETED AFTER EACH SERVICE AND KEPT WITH THESE INSTRUCTIONS

1 Check that the valves located in the lower part of the boiler

are open.

2 Switch the the electricity supply on.

The appliance On lamp A will flash every 4 seconds

(stand--- by condition).

For combination models Mini C24, Mini C28 and Mini C32

3 If the boiler is to be used for CH and DHW position the

main switch as in the following illustration.

The appliance On lamp A will flash every 2 seconds

(operating boiler).

CA

For system models Mini S24 and Mini S28

4 To operate the boiler position the main switch as in the

following illustration.

The appliance On lamp A will flash every 2 seconds

(operating boiler).

CA

Mini S24

Mini S28

Page 3

CONTROL OF CH TEMPERATURE

back

The output temperature of CH water is adjustable from a

minimum of about 38°C to a maximum of about 85°C by

turning the knob C.

Approx CH flow temperatures for the boiler thermostat

settings:

In these cases, however, it is advisable to install a small water

treatment device or softener. With such a device you should

avoid periodic descaling.

Consequently, the DHW heat exchanger will keep its

performance consistent for a longer period of time with

resulting gas savings.

TO SHUT DOWN THE BOILER

Minimum (38 ° C)

C

Maximum (85 ° C)

CONTROL OF DHW TEMPERATURE

(Mini C24, Mini C28 and Mini C32)

The temperature of the DHW leaving the boiler can be varied

from a minimum of about 35°C to a maximum of about 55°C

(within the power limits of the appliance) by turning the

temperature control knob B.

Minimum (35 ° C)

B

Maximum (55 ° C)

For short periods

To turn the boiler off set the function selector C to the O

position.

The appliance On lamp A will flash every 4 seconds.

For long periods

When you do not expect to use the boiler for a long period:

1 Switch the the electricity supply off.

2 Shut off the gas supply cock and the valves for the water

circuits fitted under the boiler.

3 If necessary, empty the water circuits.

FROST PROTECTION

Mini C24, Mini C28 and Mini C32 appliances are provided

with a built in anti--- freeze system that operates the boiler

when the temperature is below 4 ° C

Therefore, when the boiler is not lit and used in cold weather,

with consequent risk of freezing do not isolate the boiler

from the electricity supply or close the gas inlet cock.

ESCAPE OF GAS

Should a gas leak or fault be suspected contact your local

gas supplier without delay.

Do not search for gas leaks with a naked flame.

CLEANING

Adjustment of the DHW temperature is completely separate

from that of the CH circuit.

The adjustment system integrated within the boiler

automatically controls the flow of gas to the burner in order to

keep the temperature of DHW delivered constant, between

the limits of maximum and minimum output.

Where the demand is at a low level or with the temperature

set to the minimum, it is normal to see a cycle of lighting and

extinguishing of the burner when running.

Adjustment

It is advisable to adjust the DHW temperature to a level

commensurate with the demand, minimising the need to mix

with cold water. In this way, the automatic control facilities will

be fully exploited.

Moreover, where the amount of limescale present in the water

may be particularly great, not exceeding the position as

shown in the following illustration (about 50 ° C) minimises

annoying incidences of scale deposits and clogging.

B

For normal cleaning simply dust with a dry cloth.

To remove stubborn marks and stains use a damp cloth and

mild detergent.

Do not use abrasive cleaning materials.

MAINTENANCE

The appliance should be serviced at least once a year by a

CORGI registered installer.

FAULTS

No heating or hot water

Check that gas and electricity are available at the boiler and

that all switches are on.

Check that the system water water pressure gauge G reads at

least 0,5 bar.

Check the lock--- out signal lamp E. If it is illuminated press the

boiler reset button D to restart the ignition sequence.

Hot water but no heating

Check that the programmer and room thermostat (if fitted) are

both calling for heat.

Heating but no hot water

Check that cold water flows out of the taps at a minimum rate

of 3.5 litres per minute (or 1 pint in 10 seconds or less). If not,

look for stop valves not fully open.

If these simple checks fail to solve the problem, or the

problem recurs, consult your service engineer.

Page 4

Points for Boiler User

back

Note. In line with our current warranty policy we would ask that you check through the following guide to

identify any problems external to the boiler prior to requesting a service engineers visit. Should the

problem be found to be other than with the appliance we reserve the right to levy a charge for the visit, or

for any pre-arranged visit where access is not gained by the engineer.

Troubleshooting – Typical Non Product Faults

Problem Solution

• Is there power to the boiler i.e. is the left hand side green LED (A) alight and

flashing every 4 seconds. If not this is not a boiler fault – contact the installer

• Check pressure gauge on boiler shows a minimum of 1 bar

Boiler is not working for

central heating or hot water

Boiler goes through ignition

sequence but will not fire for

either central heating or hot

water and then goes to

ignition lockout

If not re-pressurise via the filling loop to 1 bar (if unsure contact your

installer), turn off the tap on the filling loop and press the reset button (D) to

reset the boiler. If unable to do so or if the pressure continues to drop after

filling then contact your installer

• Is the lockout signal lamp (E) alight – Press boiler reset button (D) – If boiler

still does not fire contact the installer

• Check gas supply (try another gas appliance cooker/fire etc) If no gas

supply then this is not a boiler fault – Contact the gas supplier

Fan & pump run

continuously but there is no

attempt at ignition

Mini C Only

Operating for hot water but

will not operate for central

heating

The nature of all combination boilers is to heat up water directly from the incoming mains water supply directly

through the boiler to supply domestic hot water at the stated flow rates, (as shown in the boiler installation

instructions), to achieve a 35°C temperature rise. As the ambient temperature of the cold main varies during the

summer and winter months it is likely in the colder winter months that the flow rate will need to be reduced at the

outlet taps to achieve the same temperatures achieved in the warmer summer months. This is not a fault with the

appliance but is relevant to the varying temperature of the incoming cold mains water supply.

Mini S Only

Operating for hot water but

will not operate for central

heating

Operating for central heating

but will not operate for hot

water

• Check that the air pressure switch test caps, on top of the boiler, are fitted

correctly.

• Check that integral programmer is set to an ‘on’ period and the function

switch is set to ‘auto’ – If it still does not operate contact your installer

• If fitted with an external programmer check that the central heating channel

is set at an ‘on’ period – If it still does not operate contact your installer.

• Check the room thermostat is set at the required temperature – Test the

room thermostat by turning fully up – If this does not respond contact your

installer

• Check the radiator temperature control (C) is set at the winter setting for

central heating.

• If fitted with an external programmer check that the central heating channel

is set at an ‘on’ period – If it still does not operate contact your installer.

• Check the room thermostat is set at the required temperature – Test the

room thermostat by turning fully up – If this does not respond contact your

installer

• If fitted with an external programmer check that the domestic hot water

channel is set at an ‘on’ period – If it still does not operate contact your

installer.

• Check the cylinder thermostat is set at the required temperature – Test the

cylinder thermostat by turning fully up – If this does not respond contact

your installer

Ideal Consumer Helpline

Tel: 01482 498660

www.idealboilers.com

Caradon Ideal Limited pursues a policy of continuing improvement in the design and

performance of its products. The right is therefore reserved to vary specification without notice.

Ideal Boilers, P.O. Box 103, National Ave, Kingston Upon Hull, HU5 4JN. Tel.

01482 492251 Fax. 01482 448858. Registration No. London 322 137.

Loading...

Loading...