Page 1

IDEAL INDUSTRIES, INC.

TECHNICAL MANUAL

MODEL: 61-340

MODEL: 61-342

Multimeter Service Information

The Service Information provides the following information:

• Precautions and safety information

• Specifications

• Basic maintenance (cleaning, replacing the battery and fuses)

• Performance test procedures

• Calibration and calibration adjustment procedures

Form Number: TM61340-2

Revision: 2. Date: November 2007

Form Number 2 TM61340-2 Rev November 2007

Page 2

TABLE OF CONTENTS Page

Introduction 1

Precautions and Safety Information 1

Symbols 1

Safety 2

Specifications 3

General Specifications 3

Measurement Characteristics 4

Voltage Specifications 4

Current Specifications 4/5

Resistance, Diode, Continuity, Capacitance Specifications 6

Frequency, Temperature Specifications 7

Auto Power Off, Data Hold/Backlight, SELECT, RANGE, REL, Hz/DUTY, MAX/MIN 7/8

Physical and Environment Characteristics 9

Certifications and Compliances 9

Required Equipment 10

Basic Maintenance 11

Opening the Meter Case 11

Replacing the Battery 11

Replacing Fuses 12

Fuse Replacement 12

Cleaning 12

Performance Tests 13

Testing the Display 13

Testing the Voltage Function 14/15

Testing the DC Current Functions 15/16

Testing the AC Current Functions 16/17

Testing the Resistance Function 18

Testing the Capacitance, Diode, Continuity Functions 18/19

Testing the Frequency Function 20

Testing the DUTY CYCLE Function 20

Testing the Temperature Function 21

Calibration 22

Calibration Adjustment, DCV, ACV DCA and Temperature Functions 22/23

Form Number 2 TM61340-2 Rev November 2007

Page 3

Page 1

Introduction

Warning

To avoid shock or injury, do not perform the verification tests or calibration procedures described in

the manual unless you are qualified to do so.

The information provided in this document is for the use of qualified personnel only.

Caution

The 61-340 serials contain parts that can be damaged by static discharge.

Follow the standard practices for handling static sensitive devices.

For additional information about IDEAL INDUSTRIES, INC. and its products, and services, visit IDEAL

INDUSTRIES, INC. web site at:

www.idealindustries.com

Precautions and Safety Information

Use the meter only as described in the Service Manual. If you do not do so, the protection provided by the

meter may be impaired. Read the “Safety Information” page before servicing this product.

In this manual, a Warning identifies conditions and actions that pose hazard (s) to the user; a Caution

identifies conditions and actions that may damage the meter or the test instruments.

The Symbols

The symbols used on the meter and in this manual are explained in Table A.

Table A. The Symbols

Risk of electric shock

See instruction card (Caution information)

DC measurement

Equipment protected by double or reinforced

insulation

Low Battery indicator

Earth

AC measurement

Conforms to EU directives

Form Number 2 TM61340-2 Rev November 2007

Page 4

Page 2

SAFETY

Review the following safety precautions to avoid injury and prevent damage to this product or any

products connected to it. To avoid potential hazards, use the product only as specified.

For operating instructions, see the 61-340 / 61-342 Digital Multimeter Instruction Manual.

CAUTION: These statements identify conditions or practices that could result in damage to the

equipment or other property.

WARNING: These statements identify conditions or practices that could result in personal injury or

loss of life.

Use proper Fuse. To avoid fire hazard, use only the fuse type and rating specified for this product.

Do not operate without covers. To avoid personal injury, do not apply any voltage or current to the

product without covers in place.

Do Not Exceed the maximum rated input limits, as marked on the meter.

Electric overload. Never apply a voltage to a connector on the product that is outside the range

specified for that connector.

Avoid electric shock. To avoid injury or loss of life, do not connect or disconnect probes or test leads

while they are connected to a voltage source.

Do not operate in wet/damp conditions. To avoid electric shock, do not operate this product in wet or

damp conditions.

Use great care when you are required to make measurements on live circuits that exceed 50V.

Form Number 2 TM61340-2 Rev November 2007

Page 5

SPECIFICATIONS

All specifications are warranted unless noted typical and apply to the 61-340 & 61-342

Stated accuracies are at 23°C±5°C at less than 75% relative humidity and without the battery indicator

displayed.

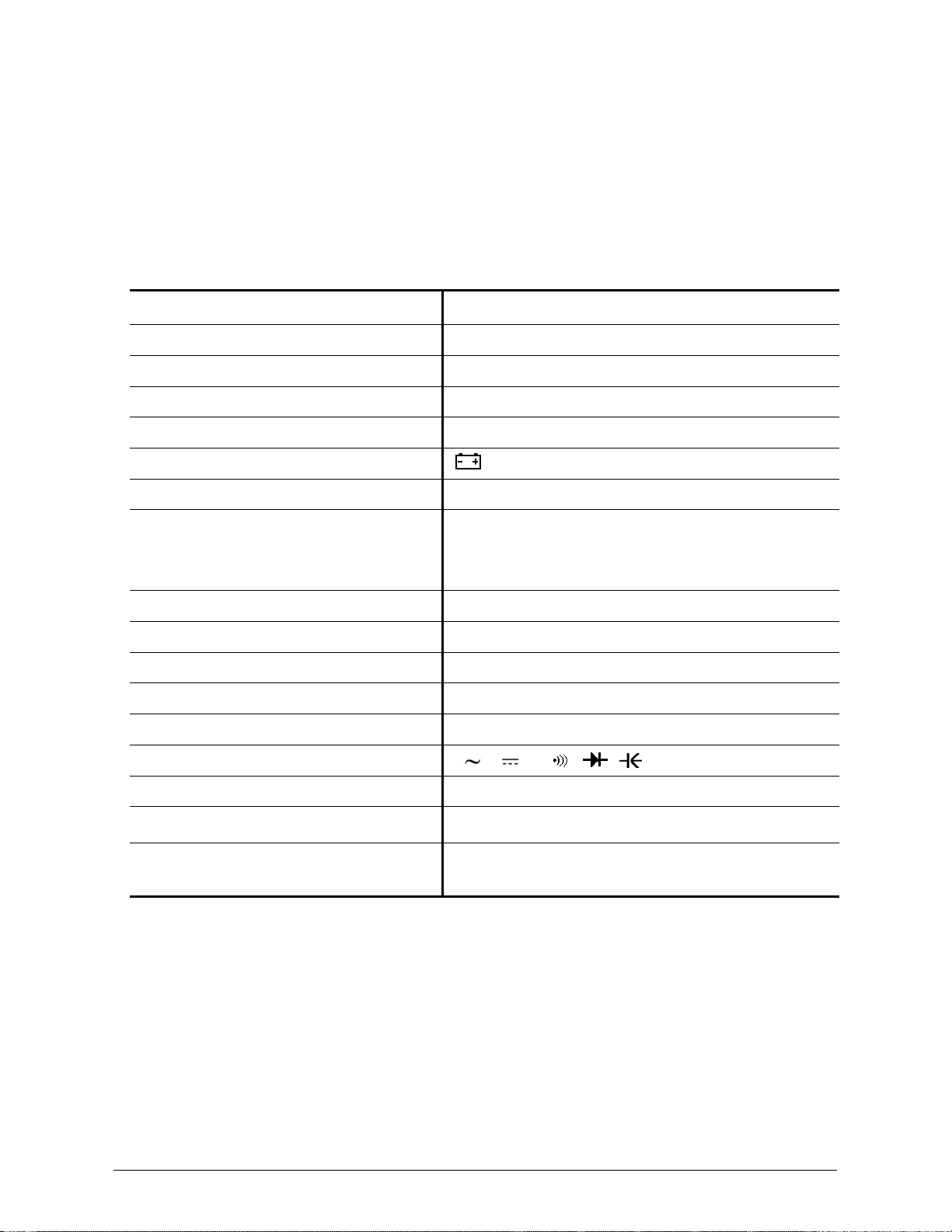

General specifications

Characteristics Description

Display count 3 3/4 digit liquid crystal display, max count 4000

Numeric update rate 2.5 times / sec

Polarity display Automatic

Over range display “OL” is displayed

Low battery indicator is indicated

Automatic power-off time Automatic power off ≈ 10minutes

Page 3

Power source

*Maximum input voltage 1000Vrms CAT III between V and COM

*Maximum floating voltage

Maximum input current 400mA between µA /mA and COM

Overload protection mA connector 500mA (250V) fast blow fuse.

Overload protection 10A connector 10A (250V) fast blow fuse.

V connector V , V , Ω, , , , Hz

µA /mA connector µA, mA, Temp

Temperature Coefficient 0.1×(Spec. Accuracy) per °C, <18°C or >28°C

Battery Life

9.0V battery: types- NEDA 1604, JIS006P, IEC6F22

for both 61-340 and 61-342

1000Vrms CAT III between any terminal and earth ground

Alkaline 9V, ≈ 200 hours for 61-340

Alkaline 9V, ≈ 150 hours for 61-342

Form Number 2 TM61340-2 Rev November 2007

Page 6

Page 4

Measurement Characteristics

Accuracy is ±(% reading + number of digits) at 23°C ± 5°C, less than 75% R.H.

(1) DC Volts(for 61-340 / 61-342)

Range Resolution Accuracy

Over voltage

protection

400.0mV 0.1mV ±(0.8% reading + 3 digits)

4.000V 1mV

40.00V 10mV

±(0.8% reading + 1 digits)

1000VDC or 750VAC

400.0V 100mV

1000V 1V ±(1.0% reading + 3 digits)

Input Impedance: 10MΩ

(2) AC Volts (61-340/61-342)

Range Resolution Accuracy

400.0mV 0.1mV

±(1.2%+8)

Over voltage

protection

4.000V 1mV

40.00V 10mV

1.0% + 5

1000VDC or 750VAC

400.0V 100mV

750V

1V

±(1.2%+5)

Input Impedance: 10MΩ

AC Conversion Type: 61-340: Average sensing rms indication calibrated to the sine wave input.

61-342: AC conversion is True RMS responding, calibrated to a sinusoidal

waveform

Crest Factor: C.F. = Peak/RMS

For non-sinusoidal waveform, C.F. > 2 add ±1% to accuracy,

Frequency response: 40~400Hz

(3a) DC micro-amp and milli-amps (for 61-340 / 61-342)

Range Resolution Accuracy Input Protection

400.0µA 0.1μA

±(0.8% reading + 2 digits)*

4000µA 1μA

40.00mA 10μA

±(0.8% reading + 3 digits)*

400.0mA 0.1mA

Overload Protection: mA Input: 500mA, 250V Fast Blow fuse. (61-340 / 61-342)

Form Number 2 TM61340-2 Rev November 2007

500mA, 250V Fast

Blow Fuse

Page 7

(3b) DC Current (61-340 / 61-342)

Range Resolution Accuracy Input Protection

Page 5

4.000A 0.001A

±(1.5% reading + 5 digits)

10.00A* 0.01A

10A, 250V Fast Blow

Fuse

Overload Protection: A Input: 10A, 250V Fast Blow fuse. (61-340 / 61-342)

*Caution

followed by a 15 minute cool down period. Exceeding 15 seconds may cause da mage to the meter and/or the test

leads.

: Do not make high current measurements on the 10A scale for longer that 15 seconds. This should be

(4a) AC micro-amp and milli-amps Current (61-340 / 61-342)

Range Resolution Accuracy Input Protection

1

400.0µA 0.1μA

±(1.5% reading + 5 digits) *

4000µA 1μA

40.00mA 10μA

±(2.0% reading + 5 digits) *

400.0mA 0.1mA

40Hz

40Hz

~ 400Hz

~ 400Hz

500mA, 250V Fast

1

Blow Fuse

Overload Protection: μA / mA Input: 500mA,250V Fast Blow fuse. (61-340 / 61-342)

(4b) AC Current (61-340 / 61-342)

Range Resolution Accuracy Input Protection

4.000A 0.001mA

±(2.5% reading + 5 digits) *

10.00A* 0.01mA

40Hz

~ 400Hz

1

10A, 250V Fast Blow

Fuse.

Overload Protection: A Input: 10A (250V) fast blow fuse.

AC Conversion Type: AC conversions are True RMS responding, calibrated to the sine wave input.

1

*

The specified accuracy is for sine wave at full scale and non-sine wave at half scale with crest factor

up to 2.

*Caution:

followed by a 15 minute cool down period. Exceeding 15 seconds may cause da mage to the meter and/or the test

leads.

Do not make high current measurements on the 10A scale for longer that 15 seconds. This should be

Form Number 2 TM61340-2 Rev November 2007

Page 8

Page 6

(5) Resistance (for 61-340 / 61-342)

Range Resolution Accuracy

400.0Ω *1 0.1Ω ±(1.2% reading + 5 digits)

4.000KΩ 1Ω

40.00KΩ 10Ω

400.0KΩ 100Ω

4.000MΩ 1KΩ ±(1.2% reading + 2 digits)

40.00MΩ *2 10KΩ ±(2.0% reading + 5 digits)

Open circuit Voltage: 0.44V approx.

1

*

< 5 digit of reading rolling.

2

*

< 2% of reading rolling.

(6) Diode Check and Continuity (for 61-340 / 61-342)

Over voltage

protection

±(1.0% reading + 2 digits)

600Vrms

Range Resolution Accuracy

Max. Test

Current

Max. Open

Circuit Voltage

1mV Not specified * <1mA, approx. 2.5V, approx.

Overload Protection: Not specified

Continuity: Built-in buzzer sounds when resistance is less than approximately 120 Ω with a response

time of approximately 100 msec.

(7) Capacitance (for 61-340 / 61-342)

Range Resolution Accuracy

40.00nF 10pF

REL:±(3% reading + 10 digits)

Over voltage

Protection

400.0nF 100pF

4.000μF 1nF

±(3% reading + 5 digits)

40.00μF 10nF

400.0μF 100nF

±(20% reading + 5 digits) *

2

4000μF *1 10μF

*1 In this range the reading maybe rolling within specification.

2

*

Specify reading < half full scale of range.

Note: The meter selects the proper range automatically. Each measurement takes about one

second per range, Readings >40.00μF will take ≈ 8 seconds or greater

Form Number 2 TM61340-2 Rev November 2007

Page 9

(8) Frequency (for 61-340 / 61-342)

Page 7

Range Resolution Sensitivity Accuracy

10.00Hz 0.01Hz

100.0Hz 0.1Hz

1.000KHz 1Hz

10.00KHz 10Hz

0.7V rms *

Frequency:

(± 0.1% + 3 digit)

100.0KHz 100Hz

1.000MHz 10KHz

4.000MHz 10KHz 3.0V rms

(9) Temperature: Type K thermocouple (for 61-340 / 61-342)

Range Resolution Accuracy

1

-50 to 750 ºC

-58 to1382 ºF

ºC ±3.0% ± 3 ºC

1

ºF ±3.0% ± 5 ºF

protection

Not Specified

(10) Auto Power Off (APO)

If the meter idles for more than ≈ 10 minutes, the meter automatically turns the power off.

(11) Data Hold/Backlight

Overload

protection

600V rms

Overload

Press this button less than 2 seconds the meter enter data hold mode and “ HOLD ” symbol appear

on LCD, and the momentary value while pressing the button display on LCD. Press it again to exit this mode

and “ HOLD ” symbol disappear on display. As data hold function, this button do not effect on diode

and continuity test function. The secondary function of this button is backlight enable and disable. If you

press it more than 2 seconds, the backlight will be turn on and press it more than 2 seconds again will make

the backlight off.

(12) SELECT

There are several functions at one rotary switch position, press SELECT button to select

function you want, It allowable to select AC or DC voltage, AC or DC current, Resistance ,Diode , Audible

continuity or capacitance, ℃ or ℉ temperature measurement.

(13) RANGE

When power on, meter at auto range mode, press RANGE button you can select measurement range

you want. Range is run up with times of pressing RANGE button until its max, then return the min range.

Press RANGE button more than 2 seconds , the meter return to auto range. This button do not effect on

frequency, duty cycle, capacitance, diode & continuity test and temperature measurement.

Form Number 2 TM61340-2 Rev November 2007

Page 10

Page 8

(14) REL

Press this button the meter enter relative measuring state and “Δ” symbol appear on LCD.

The result of the relative measurement is the difference between measuring value and

reference value. The reference value is produced same as momentary reading value when

pressing this button, press it again to exit this state and “Δ” symbol disappear on display, and

this button do not effect on frequency, diode and continuity test function. Press this button less

than 2 seconds the meter enter relative measuring state and “Δ” symbol appear on LCD.

(15) Hz/DUTY

When you make frequency, AC voltage or AC current measurement, press this button to switch Hz or

duty cycle test mode.

(16) MAX/MIN

Press MAX/MIN button the meter enter Maximum value / Minimum value record mode and “ MAX ” / ”

MIN ” symbol appear on LCD, the LCD will display the maximum value or minimum value science pressing

the button always. Press MAX/MIN more than 2 seconds button again to exit this mode and “ MAX ” / ” MIN ”

symbol disappear on display. This button do not effect on diode and continuity test function, capacitance

measurement, frequency measurement.

Form Number 2 TM61340-2 Rev November 2007

Page 11

Physical and Environmental Characteristics

Characteristics Description

Page 9

Dimensions (H×W×D)

Weight (with battery& holster) 0.379Kg (13.4 oz.)

Environmental characteristics Description

Temperature operating 0 to +40°C

Non-Operating -20 to +60°C <75% R.H.

Humidity (operating) <70% R.H.

Altitude 6561.7 Ft. (2000m)

Indoor Use Indoor Use

Certifications and compliances

Safety

Input Safety Rating

Complies with UL 61010B-1

V / Ω: , UL 61010B-1, UL 61010-B-2-031, EU 61010-1

EN61010-2-031, Cat IV 600Volts, Cat III 1000V

180mm(H) ×91mm (W) ×43mm(D) (with holster)

7.1” (H) x 3.6”(W) x1.7”(D)

CAT IV: Service drop to service entrance,

CAT III: Distribution level mains, fixed installation.

CAT II: Local level mains, appliances, portable equipment

CAT I: Signal level, special equipment or parts of equipment,

telecommunication, electronics.

Pollution Degree 2

EC Declaration

of Conformity

Do not operate in environments where conductive

Pollutants may be present.

Meets the intent of Directive 89/336/EEC for Electromagnetic

Compatibility and Low Voltage Directive 73/23/EEC for product

safety. Compliance was demonstrated to the following specifica-

tions as listed in the official Journal of the European Communities:

En 55011 Class A: Radiated and Conducted

Emissions.

En 50082-1 Immunity: IEC 801-2 Electrostatic Discharge

IEC 801-3 RF Radiated

En 61010-1 Safety requirements for electrical equipment for

measurement, control, and laboratory use.

Form Number 2 TM61340-2 Rev November 2007

Page 12

Page 10

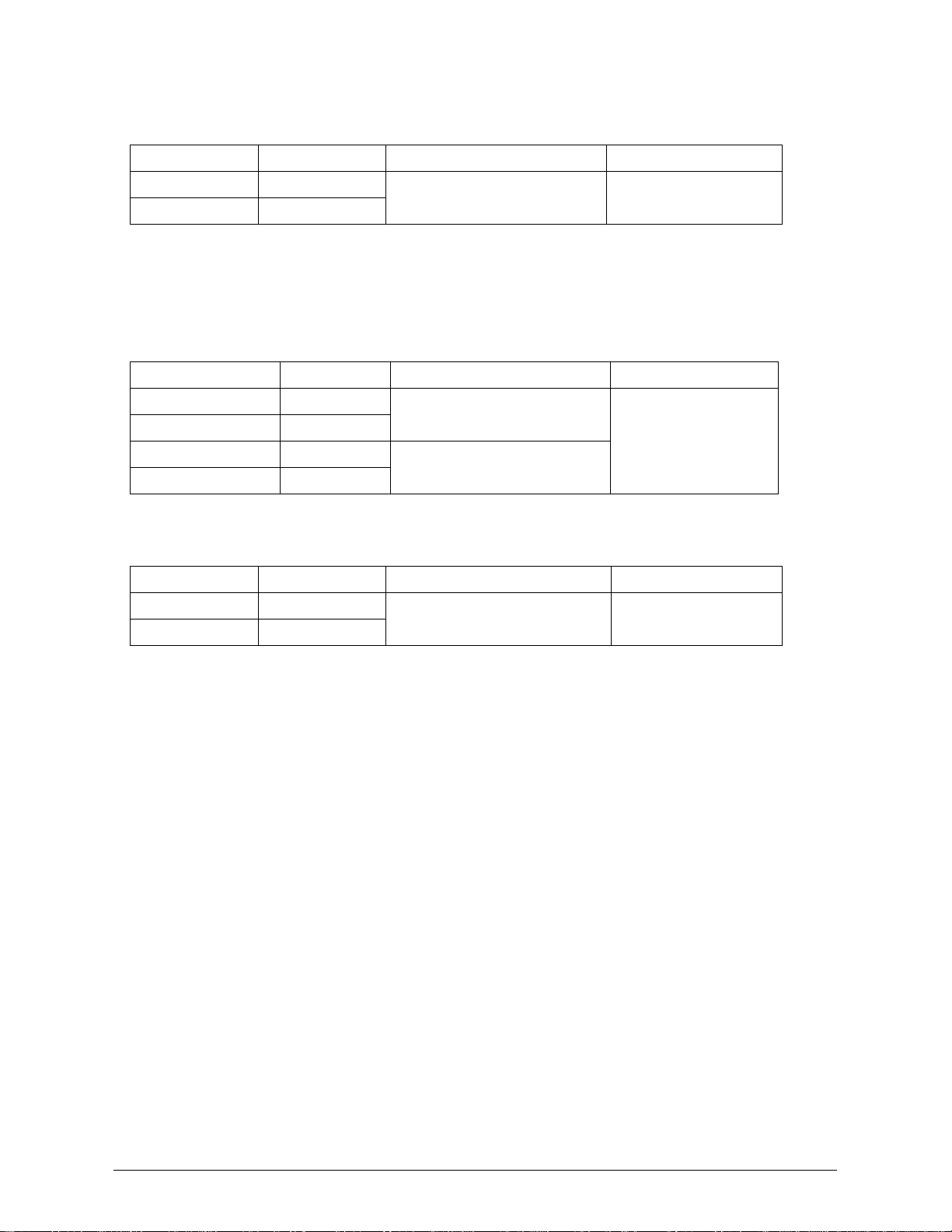

Required Equipment

Required equipment is listed in Table B. If the recommended models are not available, equipment with

equivalent specifications may be used.

Repairs or servicing should be performed only by qualified personnel.

Table B. Required Equipment

Equipment Required Characteristics Recommended Model

Calibrator

AC Voltage Range: 0

Accuracy: ±0.07% (Basic)

Frequency Range: 40

Accuracy: ±2%

DC Voltage Range: 0

Accuracy: ±0.006% (Basic)

Current Range: 0

Accuracy: AC (40Hz to 1KHz): ±0.08% (Basic)

DC: ±0.02% (Basic)

Frequency Source: 1.00Hz

Accuracy: ±0.001%

Amplitude: 0.5V p-p

Accuracy: ±5%

Resistance Range: 1Ω

Accuracy: ±0.03% (Basic)

Capacitance Range: 1pF

Accuracy: ±0.10% (Basic)

~ 750V AC

~ 1KHz

~ 1000V DC

~ 10A

~ 10MHz

~ 5.0V p-p (square wave)

~ 100MΩ

~ 10mF

Fluke 5500 or Wavetek

9100 Calibrator or

equipment

Form Number 2 TM61340-2 Rev November 2007

Page 13

Basic Maintenance

Warning

To avoid shock, remove the test leads and any input signals before opening the case or replacing the

battery or fuses.

Opening the Meter Case

Caution

To avoid unintentional shock circuit, always place the uncovered meter assembly on a protective surface.

When the case of the meter is open, circuit connections are exposed.

1. Disconnect test leads from any live source, turn the rotary switch to OFF, and remove the test leads

from front terminals.

2. For battery replacement, follow instructions under Replacing the Battery section

3. For fuse replacement, follow instructions under Fuse Replacement section.

Replacing the Battery

The 61-340/61-342 meter are both powered by 9V, types are, NEDA 1604, JIS006P, IEC 6F22

1. Remove the rubber holster

2. Remove the screw on the battery cover and open the battery cover

3. Remove the old battery and install the new battery

4. Return the battery cover and reinstall the battery cover screw.

5. Replace the rubber boot.

Battery and Fuse Replacement

Page 11

Form Number 2 TM61340-2 Rev November 2007

Figure 1

Page 14

Page 12

Replacing Fuses

Warning

To avoid electrical shock, remove the test leads and any input signals before replacing the battery

or fuses. To prevent damage or injury, INSTALL ONLY quick acting fuses with the following

Volt/Amp current interrupt rating:

F340: 500mA, 250V Fast Blow Fuse

F342: 10A, 250V Fast Blow Fuse

Fuse Replacement

The 61-340 and 61-342 are fused in both the μA /mA input and 10 amperes input ports.

μA /mA input port is fused by a F340: 500mA, 250V FAST BLOW fuse, 10 A input port is fused by

F342: 10A, 250V FAST BLOW fuse

1. Remove the rubber holster

2. Remove the screw on the battery cover and open the battery cover.

3. Remove the two screws at the bottom of back cover and a screw under the support stand.

4. Take out the old battery, and remove the back case cover.

5. * Replace the defective fuse with the standard rated fuse for this meter

6. Return the back case cover, reinsert the case screws.

a. It is recommended you replace the old battery with new battery.

7. Return the battery cover and reinstall the battery cover screw.

8. Replace the rubber boot.

Use only a fuse with the amperage, interrupt voltage, and speed rating specified.

Cleaning

Warning

To avoid electrical shock or damage to the meter, never allow water inside the case. To avoid

damaging the meter’s housing, never apply solvents to the meter.

Form Number 2 TM61340-2 Rev November 2007

Page 15

Performance Tests

The following performance tests verify the complete operability of the meter and check the accuracy of

each meter function against the meter’s specifications.

For operating instructions, see the 61-340 / 61-342 Digital Multimeter Instruction Manual.

Accuracy specifications are valid for a period of one year after calibration, when measured at an

operating temperature of 18°C to 28°C and a maximum of 75% relative humidity.

To perform the following tests, it is not necessary to open the case, no adjustments are

necessary, merely make the required connections, apply the designated inputs, and

determine if the reading on the meter display falls within the acceptable range indicated.

If the meter fails any of these tests, it needs calibration adjustment or repair.

Testing the Display

Turning the meter on from the “OFF” position, the meter will full display all segment and symbols.

Compare the display with the example in Figure 2.

LCD Graphics 61-340 / 61-342

Page 13

Figure 2 Display Test

Form Number 2 TM61340-2 Rev November 2007

Page 16

Page 14

Testing the Voltage Function (for 61-340 / 61-342)

To verify accuracy in the AC and DC voltage ranges, do the following:

1. Turn the rotary switch to “

2. Connect the calibrator to the

” position.

and COM inputs on the meter.

3. Set the calibrator for the voltage from step 1 to 7 in Table 1.

4. Compare the reading on the meter display with the display reading shown in Table 1.

5. If the display reading falls outside of the range shown in Table 1, the meter does not meet

specification.

Table 1 DC Voltage Test:

Step

1

2

3

4

5

6

7

Range

400mV

400mV

400mV

4V

40V

400V

1000V

Input Reading

-300.0mV -297.3 to -302.7

4.0mV 3.6 to 4.4

300.0mV 297.3 to 302.7

3.000V 2.975 to 3.025

30.00V

300.0V

1000V

29.75 to 30.25

297.5 to 302.5

987 to 1013

1. Turn the rotary switch to position. “

”

2. Set the calibration for the voltage and frequency from step 1 to 10 in Table 2.

3. Compare the reading on the meter display with the display reading shown in Table 2.

4. If the display reading falls outside of the range shown in Table 2, the meter does not meet

specification.

Form Number 2 TM61340-2 Rev November 2007

Page 17

Table 2 AC Voltage Test:

Step Range Input Frequency Reading 61-340 Reading 61-342

1 400mV 300mV 60 295.6 to304.4 295.6 to304.4

2 400mV 300mV 400 295.6 to304.4 295.6 to304.4

Page 15

3

4

5

6

7

8

9

10

4V

4V

40V

40V

400V

400V

750V

750V

3.000V 60Hz 2.965 to 3.035 2.965 to 3.035

3.000V 400Hz 2.965 to 3.035 2.965 to 3.035

30.00V 60Hz 29.65 to 30.35 29.65 to 30.35

30.00V 400Hz 29.65 to 30.35 29.65 to 30.35

300.0V 60Hz 296.5 to 303.5 296.5 to 303.5

300.0V 400Hz 296.5 to 303.5 296.5 to 303.5

750V 60Hz 736 to 764 736 to 764

750V 400Hz 736 to 764 736 to 764

Testing the DC microamperes Function (for 61-340 and 61-342)

To verify the accuracy of AC and DC current measurement functions, do the following:

1. Connect the calibrator to the

2. Turn the rotary switch to

and COM inputs on the meter.

a. Press the SELECT button to select the DC function

3. Apply the inputs for steps 1-3 in Table 3a.

4. For each input, compare the reading on the meter display to the reading for your meter in Table 3a

5. If the display reading falls outside of the range shown in Table 3a, the meter does not meet

specification.

Table 3a DC microamperes Test:

Step

1

2

3

Range

400µA

400µA

4000µA

Source Reading

4.0µA 3.5 to 4.5

300.0µA 297.4 to 302.6

3000µA 2974 to 3026

Testing the DC milli amperes Function (for 61-340 and 61-342)

1. Connect the calibrator to the

2. Turn the rotary switch to

.

and COM inputs on the meter.

a. Press the SEL button to select the DC function

3. Apply the inputs for steps 1-4 in Table 3b.

4. For each input, compare the reading on the meter display to the reading for your meter in Table 3b

5. If the display reading falls outside of the range shown in Table 3b, the meter does not meet

specification.

Form Number 2 TM61340-2 Rev November 2007

Page 18

Page 16

Table 3b DC mA Test:

Step

1

2

Range

40mA

400mA

Source Reading

30.00mA 29.73 to 30.27

300.0mA 297.3 to 302.7

Testing the DC ampere Function (for 61-340 and 61-342)

1. Connect the calibrator to the 10A and COM inputs on the meter.

2. Turn the rotary switch to

.

a. Press the SELECT button to select the DC function

3. Apply the inputs for steps 1-2 in Table 3c.

4. For each input, compare the reading on the meter display to the reading for your meter in Table 3c

5. If the display reading falls outside of the range shown in Table 3c, the meter does not meet

specification.

Table 3c DCA Test:

Step

1

2

Range

4

10

Source Reading

3.000A 2.950 to 3.050

10.00A 9.80 to 10.20

Testing the AC microampere Function (for 61-340 and 61-342)

To verify the accuracy of AC and DC current measurement functions, do the following:

1. Connect the calibrator to the

2. Turn the rotary switch to

and COM inputs on the meter.

a. Press the SELECT button to select the AC function

b. Press the REL button to make the display is zero

3. Apply the inputs for steps 1-6 in Table 4a.

4. For each input, compare the reading on the meter display to the reading for your meter in Table 4a

5. If the display reading falls outside of the range shown in Table 4a, the meter does not meet

specification.

Table 4a AC microampere Test:

Step

1

2

3

4

Range

400µA

400µA

400µA

400µA

Source

40µA

40µA

300.0µA

300.0µA

Frequency

60

400

400

400

Reading

38.9 to 41.1

38.9 to 41.1

295.0 to 305.0

295.0 to 305.0

5

6

4000µA

4000µA

3000µA

3000µA

Form Number 2 TM61340-2 Rev November 2007

60

400

2950 to 3050

2950 to 3050

Page 19

Testing the AC milliampere function: (for 61-340and 61-342)

Page 17

1. Connect the calibrator to the

2. Turn the rotary switch to

.

and COM inputs on the meter.

a. Press the SELECT button to select the AC function

b. Press the REL button to make the display is zero

3. Apply the inputs for steps 1-4 in Table 4b.

4. For each input, compare the reading on the meter display to the reading for your meter in Table 4b

5. If the display reading falls outside of the range shown in Table 4b, the meter does not meet

specification.

Table 4b ACmA Test:

Step

1

2

3

4

Range

40 mA

40 mA

400 mA

400 mA

Source Frequency Reading

30.00mA 60Hz 29.35 to 30.65

30.00mA 400Hz 29.35 to 30.65

300.0mA 60Hz 293.5 to 306.5

300.0mA 400Hz 293.5 to 306.5

Testing the AC A function (for 61-340 / 61-342)

1. Connect the calibrator to the 10A and COM inputs on the meter.

2. Turn the rotary switch to

.

a. Press the SELECT button to select the AC function

b. Press the REL button to make the display is zero

3. Apply the inputs for steps 1-4 in Table 4c.

4. For each input, compare the reading on the meter display to the reading for your meter in Table 4c

5. If the display reading falls outside of the range shown in Table 4c, the meter does not meet

specification.

Table 4c AC A Test:

Step

1

2

3

4

4A

4A

10A

10A

Source Frequency Reading

3.000A 60Hz 2.920 to 3.080

3.000A 400Hz 2.920 to 3.080

10A 60Hz 9.70 to 10.30

10A 400Hz 9.70 to 10.30

Form Number 2 TM61340-2 Rev November 2007

Page 20

Page 18

Testing the Resistance Function (for 61-340 / 61-342)

To verify the accuracy of the resistance function, do the following:

1. Connect the calibrator to

2. Turn the rotary switch to

and COM on the meter.

.

a. Press the SELECT button to select the Ω function

3. Apply the inputs for step 1-7 in Table 5.

4. Compare the meter display readings to the display readings in Table 5.

5. If the display reading falls outside of the range shown in Table 5, the meter does not meet

specification.

Table 5 Ω Resistance Test:

Step

1

2

3

4

5

6

Range

400Ω*

400Ω*

4kΩ

40kΩ

400kΩ

4MΩ

Source Reading

4.0Ω 3.5 to 4.5

300.0Ω 295.9 to 304.1

3.000KΩ 2.968 to 3.032

30.00KΩ 29.68 to 30.32

300.0KΩ 296.8 to 303.2

3.000MΩ 2.968 to 3.032

7

40MΩ

30.00MΩ 29.35 to 30.65

*Lead resistance on the 400Ω range is not included in error.

Testing the Capacitance Function (for 61-340 / 61-342)

The meter measures capacitance by charging the capacitor with a known direct current, measuring the

resultant voltage, and calculating the capacitance. If the same capacitance is measured on an

impedance bridge, a different reading may result. This variance is likely to be greater at higher

frequencies.

To verify the accuracy of the capacitance measuring function, do the Following:

1. Apply the capacitor to the

2. Turn the rotary switch to

a. Press the SELECT button to select the

and COM inputs on the meter. For steps 1 through 7 in Table 6.

.

function

b. Press the REL button to make the display is zero

3. Compare the reading on the meter display to the reading in Table 6.

4. Note : The meter selects the proper range automatically. Each measurement takes about one

second per range, readings >40.00μF will take ≥ 5 to 30 seconds

5. If the display reading falls outside of the range shown in Table 6, the meter does not meet

specification.

Form Number 2

TM61340-2 Rev November 2007

Page 21

Table 6 Capacitance Test:

Page 19

Step

1

2

3

Range

40nF

40nF

400nF

Source Reading

10.000nF 9.60 to 10.40

30.00nF 29.00 to 31.00

300.0nF 290.5 to 309.5

4 4µF 3.000µF 2.905 to 3.095

5 40.00µF 30.00µF 29.05 to 30.95

6 100.0µF 100.0µF 79.5 to 120.5

7 1000µF 1000µF 795 to 1205

Checking the Diode Test Function (for 61-340 / 61-342)

To check the diode test function, do the following:

1. Connect the DVM (Digital Voltage Meter) to the

2. Turn the meter’s rotary switch to

.

Press the SELECT button to select the function

The DVM display should display OL

3. Insert a Si diode with correct polarity “+” and “-“

The meter display should read within 0.5~0.7Vdc

4. Reverse polarity on the Si diode

The meter display should read OL

.

Checking the Continuity Function (for 61-340 / 61-342)

To check the diode test function, do the following:

and COM inputs on the meter.

1. Connect the DVM (Digital Voltage Meter) to the

2. Turn the meter’s rotary switch to

.

a) Press the SELECT button to select the

and COM inputs on the meter.

function

b) The DVM display should display OL

3. Insert a 50Ω resistor

a) The meter inner beeper will sound

Form Number 2 TM61340-2 Rev November 2007

Page 22

Page 20

Testing the Frequency Function (for 61-340 / 61-342)

To verify the accuracy of the meter’s frequency function, do the following:

1. Connect the calibrator to the

and COM inputs on the meter.

2. Note: The accuracy of the calibrator’s frequency function must be appropriate for the specified

accuracy of the meter.

3. Set the rotary switch to

.

4. Set the calibrator or function generator for the square wave voltage and frequency for steps 1-6 of

Table 7a.

5. Compare the reading on the meter display with the display reading shown in Table 7a.

6. If the display reading falls outside of the range shown in Table 7a, the meter does not meet

specification.

Table 7a Frequency Test:

Step

1

2

3

4

5

Range

100Hz

100Hz

1kHz

10kHz

100kHz

Source Level Reading

9.0Hz 3V rms 8.987 to 9.013

90Hz

900Hz

9kHz

90kHz

3V rms

3V rms

3V rms

3V rms

89.87 to 90.13

898.7 to 901.3

8.987 to 9.013

89.87 to 90.13

6

1MHz

900kHZ

3V rms

898.7to 901.3

Testing the Duty Cycle Function (for 61-340 / 61-342)

To verify the accuracy of the meter’s frequency function, do the following:

1. Connect the calibrator to the

and COM inputs on the meter.

2. Note: The accuracy of the calibrator’s frequency function must be appropriate for the specified

accuracy of the meter.

3. Set the rotary switch to

.

a. Press the Hz/DUTY button to select the DUTY CYCLE function

4. Set the calibrator or function generator for the square wave voltage and frequency as Table 7b.

5. Compare the reading on the meter display with the display reading shown in Table 7b.

6. If the display reading falls outside of the range shown in Table 7b, the meter does not meet

specification.

Table 7b Duty Cycle Test:

Step

1

Range

1kHz

Source Level Reading

1kHz

3V rms

48.3% to 51.7%

Form Number 2 TM61340-2 Rev November 2007

Page 23

Testing the Temperature Function (for 61-340 / 61-342)

To verify the accuracy of the meter’s temperature function, do the following:

Page 21

1. Connect the calibrator to the

2. Set the rotary switch to the

3. Set the calibrators temperature output to the source values in Table 8, for steps 1-7.

4. Compare the reading on the meter display with the display reading shown in Table 8.

5. If the display reading falls outside of the range shown in Table 8, the meter does not meet

specification.

Table 8 Temperature Test:

Step

1

2

3

4

5

6

7

Range

ºF / ºC as instructed in Table 8.

ºC

ºC

ºC

ºC

ºF

ºF

ºF

and COM inputs on the meter.

Source Reading

ºC -3 to 3

0

ºC -23 to –17

-20

ºC 288 to 312

300

ºC 725 to 775

750

ºF -9 to 1

-4

ºF 27 to 37

32

ºF 1338 to 1426

1382

Form Number 2 TM61340-2 Rev November 2007

Page 24

Page 22

Calibration Procedure

Recalibrate your meter:

It is recommended that the multimeter be calibrated once each year.

1. Perform calibration at an ambient temperature of 23°C±2°C and a relative humidity of <70%

Disconnect the test leads and turn the meter off. Remove the test leads from the front terminals.

2. Position the meter face down. Remove the battery cover screw and the 2 bottom case cover screws.

3. Lift the end of the bottom case cover until it gently unsnaps from the case top at the end nearest the

LCD.

(A) DC V Calibration (Adjust VR1)

1. Set the rotary switch to position “

2. Set the output of DC calibrator for 300.0mV and connect to

” for the DC Volts function.

and COM input terminals on

meter.

3. Using a small flat-tipped screwdriver, adjust VR1 until the display reads 299.5 to 300.5mV

4. Disconnect the DC calibrator from the meter.

(B) AC V Calibration (Adjust VR2)

Model 61-340:

1. Set the rotary switch to position. “

2. Set the output of the calibrator for 3.000V at 60Hz and connect to

” for the AC Volts function.

and COM input

terminals on meter.

3. Using a small flat-tipped screwdriver, adjust VR2 until the display reads 2.995 to 3.005Volts

4. Disconnect the AC calibrator from the meter.

Model 61-342:

1. Set the rotary switch to position. “

” and press SELECT button to select AC A function,

then press RANGE button to select 10A range .

2. Using a small flat-tipped screwdriver, adjust VR4 until the display reads 0 to 3 digits.

3. Press RANGE button to select 4A range and adjust VR5 until the display reads same as the

digits at AC 10A range ( 0 to 3 digits)

4. Set the rotary switch to position. “

5. Set the output of the calibrator for 3.000V at 60Hz. and connect to

” for the AC Volts Function.

and COM input

terminals on meter.

Form Number 2 TM61340-2 Rev November 2007

Page 25

6. Using a small flat-tipped screwdriver, adjust VRtr until the display reads 2.995 to 3.005Volts

7. Disconnect the AC calibrator from the meter.

(C) TEMP Calibration (Adjust VR3)

1. Set the rotary switch to the "

ºF/ ºC " position.

2. Set the output of the calibrator to 300 ºC

Page 23

3. Connect the calibrator temperature output to the

and COM input terminals

4. Using a small flat-tipped screwdriver to adjust VR3 for a 300 ºC +/- 1 ºC (299 to 301) display

Form Number 2 TM61340-2 Rev November 2007

Loading...

Loading...