Page 1

2

#61-164

#61-165

Introduction

Utilizing patented technology, the SureTest®circuit analyzers

"look behind walls" to identify wiring problems that can lead to

personal shock hazards, electrical fires, or equipment performance issues. Personal shock

hazards stem from poor grounding, false grounds, and/or no ground fault protection.

Electrical fires are primarily caused from arc faults and high resistance points that lead to

glowing connections in the circuit wiring. And, equipment performance issues arise due to

insufficient voltage available under load, poor ground impedance, and high ground-to-neutral voltage. In fact, it’s estimated that 80% of power quality performance issues are related

to the faulty wiring issues stated above.

Product Features

• True RMS

• Measures voltage drop under 12, 15 and 20-amp loads

• Measures voltage: Line, Ground-to-Neutral, Peak, Frequency

• Measures Hot, Neutral and Ground conductor impedances

• Identifies proper wiring in 3-wire receptacles

• Identifies false (bootleg) grounds

• Tests GFCIs for proper operation

• Tests AFCIs for proper operation (61-165)

• Checks for Shared Neutrals that lead to AFCI nuisance tripping (61-165)

• Verifies dedicated circuits (with 61-176 adapter)

• Includes 1-ft. extension cord and carrying case

General Operation

The SureTest®Circuit Analyzer takes only seconds to test each outlet and circuit under a full

load. This test tool checks for various wiring conditions including: correct wiring, polarity

reversal and no ground per UL-1436. A simple menu gives access to measurements of line

voltage, voltage drop under a full load condition, ground-neutral voltage and line impedances.

The ground fault circuit interrupter (GFCI) test is performed separately in accordance with UL1436 and disrupts the electrical supply if a functional GFCI is present.

The SureTest®w/AFCI, #61-165, also tests arc fault circuit interrupter (AFCI) devices to

ensure that AFCI breakers protecting the circuit have been installed correctly. This test disrupts the electrical supply if a functional AFCI is present. This tool also checks for a shared

neutral condition that leads to AFCI nuisance tripping.

To maintain stated accuracies during repeated use, allow 20 seconds between insertions to

adequately dissipate any heat buildup during the load testing.

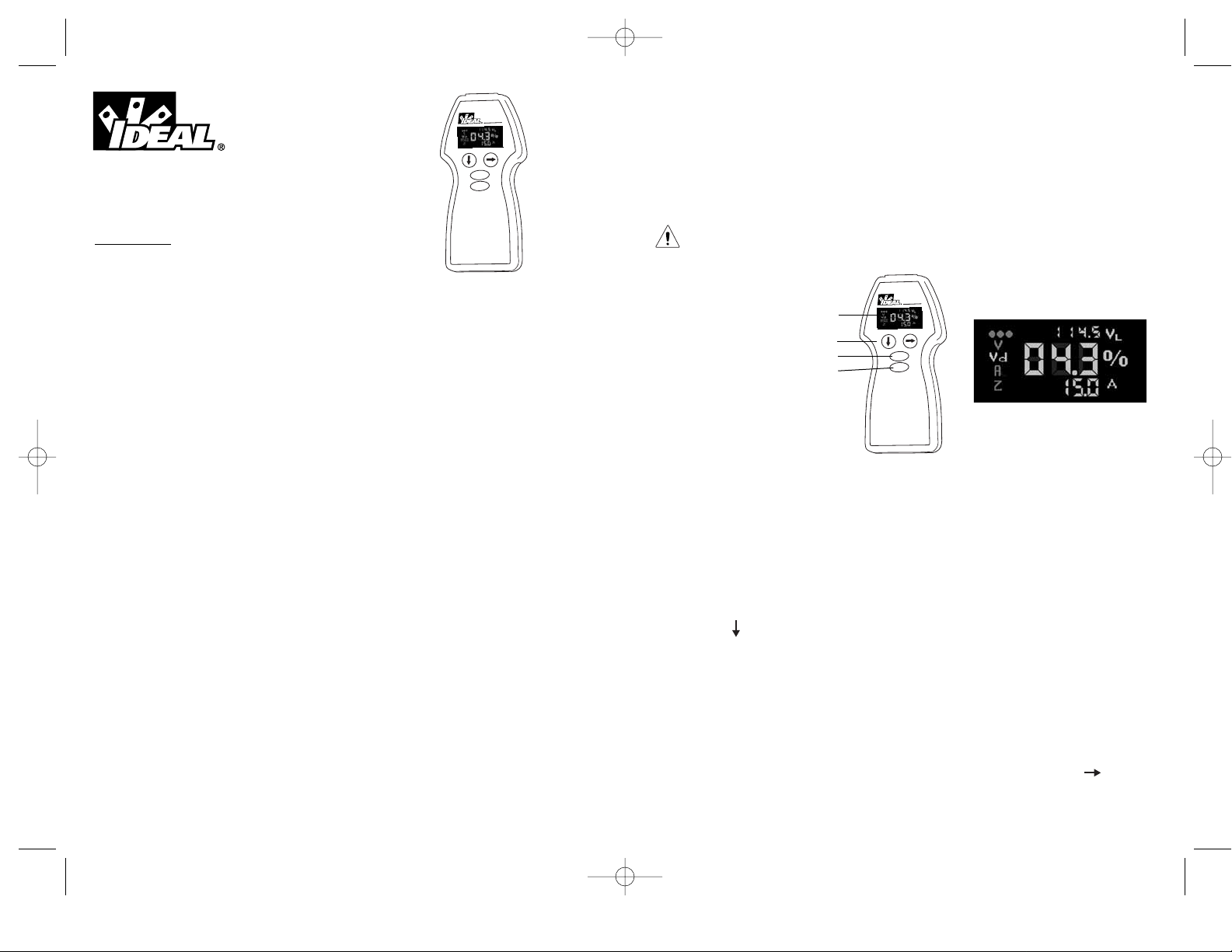

SureTest Circuit Analyzer

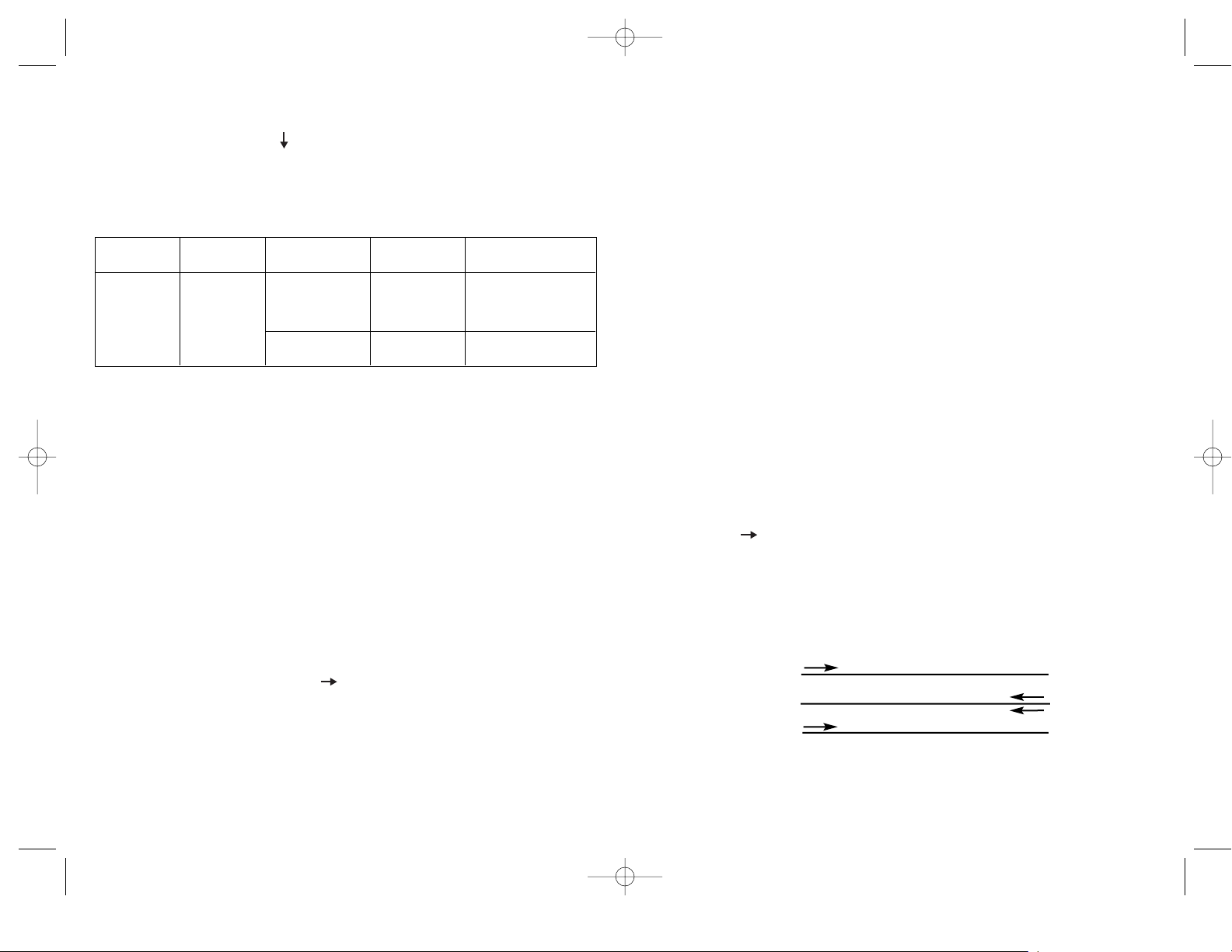

1. Menu Structure

2. Navigation Buttons

3. GFCI Test Button

4. AFCITest Button

Menu Navigation

The microprocessor’s top priorities are to take live measurements and then analyze the data.

Hence, the microchip occasionally will not recognize the keypad buttons being rapidly

depressed, while it’s executing these routines. To avoid this issue, hold down the keypad

button each time until the menu changes.

The measurements taken by the SureTest are broken into five main menus positioned down

the left side of the display: Wiring Configuration (•••), Voltage (V), Voltage Drop (VD),

Amperage (A), and Impedance (Z). To navigate to each of the main menus, use the down

arrow button ( ).

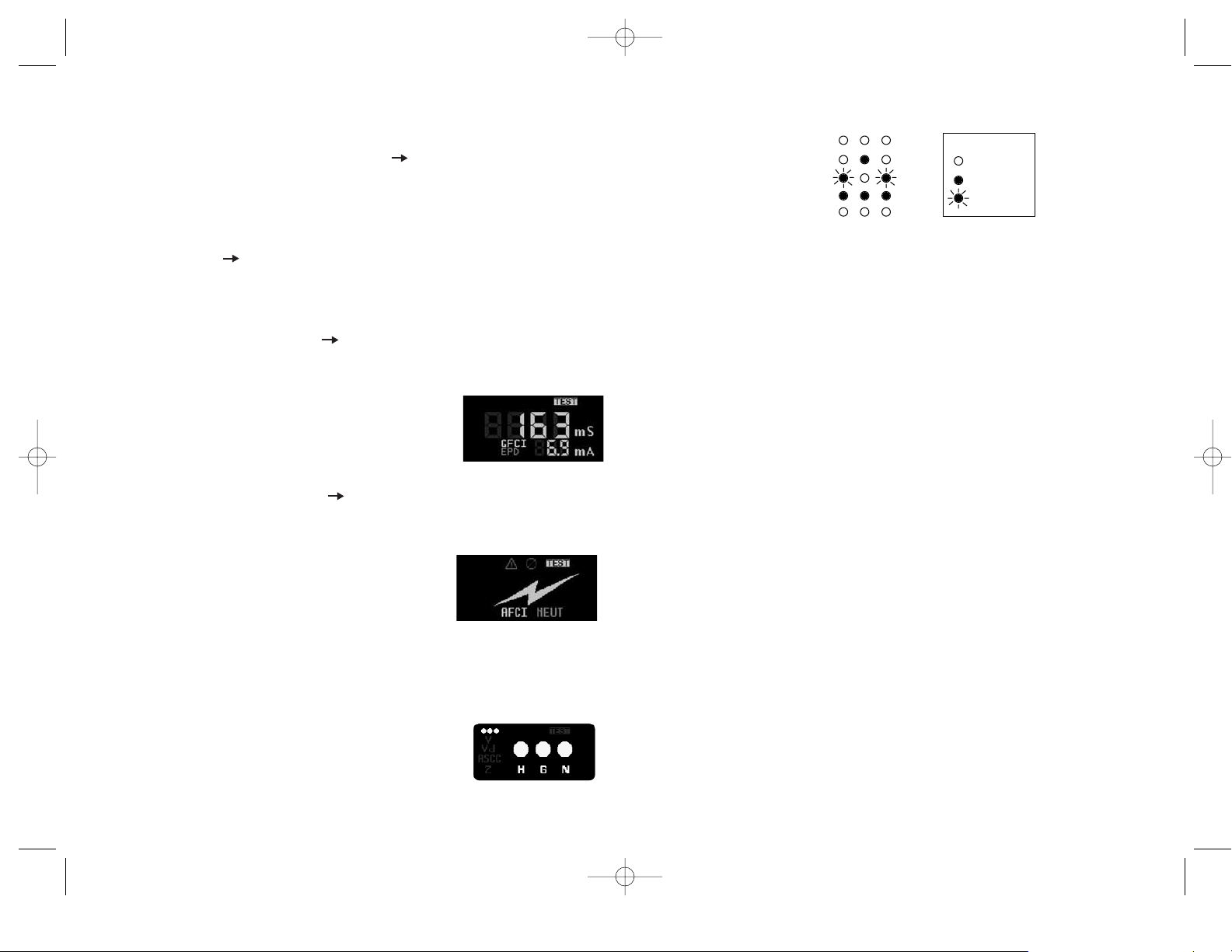

The Wiring Configuration (•••) screen indicates correct wiring, reverse polarity, hot/

ground reversal and no ground conditions by sequencing the three balls. The label on the

back of the product explains the wiring sequence indications.

The Voltage (V) menu displays the True RMS line voltage in real-time. This main menu has

a sub-menu positioned horizontally at the bottom of the screen that displays the line voltage (RMS HN), ground-to-neutral voltage (RMS GN), Peak voltage (Peak), and

Frequency (Hz). To navigate through the submenu, use the side arrow button ( ).

#61-165

GFCI

AFCI

RM

S

True

S

u

r

e

e

T

s

t

SureTest®

Circuit Analyzer

WARNING: Do not use on outputs from UPS systems, light dimmers or square

wave generating equipment as damage to the analyzer will occur.

SureTest®Circuit Analyzer

Instruction Manual

#61-165

GFCI

AFCI

RMS

True

S

u

r

e

e

T

s

t

SureTest®

Circuit Analyzer

2

3

4

1

ND 5481-6 61-164 165 Ins 8/28/08 1:55 PM Page 1

Page 2

4

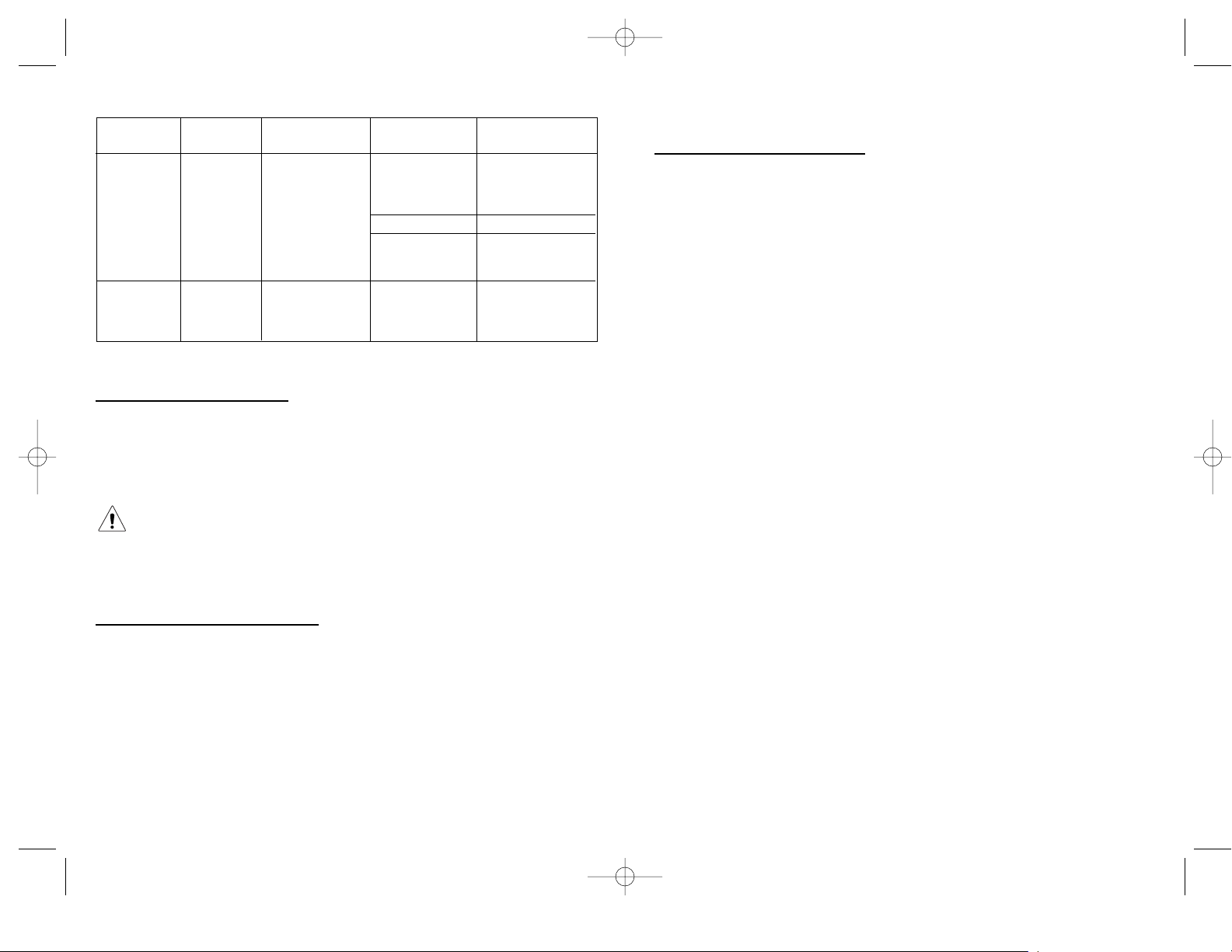

Wiring Condition Display Indication

HGN

Correct Wiring

No Ground

Polarity Reversal

Open/Hot Neutral

False Ground

If the wiring condition is other than normal, the SureTest is limited on its

measurements that can be performed. If a no ground condition exists, only the

line voltage and voltage drop measurements are available. In a hot/ground reversal, open neutral or open hot condition, the unit will not have any power so the

display will be blank.

Notes:

1) Will not detect two hot wires in a circuit.

2) Will not detect a combination of defects.

3) Will not detect reversal of grounded and grounding conductors.

False Ground Indication

The SureTest indicates when a false ground condition exists from an improper bond

via a bootleg (ground jumper wire at the outlet device) or inadvertent contact of the

ground wire to the neutral connection. Note that if the SureTest is within 15-20 feet

of the main panel, the unit will indicate a false ground condition on a properly wired

circuit due to its close proximity to the proper ground-neutral bond in the main

panel.

Voltage Measurements

The line voltage measurement should be 120VAC +/-10% fluctuation at 60 Hz. The peak voltage should be 1.414 times the rms line voltage reading for a clean sine waveform. Ground-toneutral voltage should be less than 2 VAC. In a single-phase circuit, a higher ground-neutral

voltage indicates excessive current leakage between the neutral and ground conductors. In a 3phase circuit with a shared neutral, a high ground-neutral voltage could indicate an unbalanced

load between the three phases or harmonic distortion on the shared neutral. Excessive groundneutral voltage may result in inconsistent or intermittent equipment performance.

Legend

On

Off

Flashing

F

The Voltage Drop (VD) screen dual displays percent voltage drop with a 15 amp load along

with the resultant loaded voltage (VL). This main menu has a submenu, which also displays the percent voltage drop and loaded voltage with 20 amp and 12 amp loads. To navigate through the submenu, use the side arrow button ( ).

The Amperage (A) menu displays the Estimated Load on Line (ELL) in real-time and holds

the maximum amperage in the upper right of the display. The main menu has a submenu

positioned horizontally which displays (ASCC1), Available Short-Circuit Current from H-N

and (ASCC2) Available Short Circuit Current H-N-G. To navigate through the submenu, use

the side arrow button. ( )

The Impedance (Z) main menu displays the impedance in ohms (Ω) of the hot conductor.

This main menu has a sub-menu positioned horizontally at the bottom of the screen that

also displays the neutral (N) and ground (G) conductor impedances. To navigate through

the submenu, use the side arrow button ( ). Note that testing the ground impedance will

trip a GFCI protected circuit.

GFCI Test Button

Depressing this button displays the GFCI main menu. Two tests can

be performed in this menu: GFCI and EPD. The GFCI tests Ground

Fault Circuit Interrupting devices by faulting 6-9mA from hot-toground per UL-1436. The EPD tests those breakers, which have an

Equipment Protective Device feature that trips the breaker if a ground fault of greater than 30mA

is detected. Pressing the side arrow button ( ) navigates between these two tests. Once the

desired test is highlighted, depress the GFCI test button on the keypad to activate the test.

AFCI Test Button

Depressing this button displays the AFCI main menu. Two tests

can be performed in this menu: AFCI and NEUT. The AFCI

tests Arc Fault Circuit Interrupting devices by creating a 106-141

amp short-duration arc between the hot and neutral conductors

per UL1436. The NEUT tests for a Shared Neutral or falsely grounded neutral conductor,

which causes AFCI breakers to nuisance trip with normal loads. This test applies 300mA

between hot and neutral to ensure that the AFCI breaker does not trip.

Testing Procedure

Wiring Verification

Immediately after being inserted into a receptacle, the

SureTest displays the IDEAL logo while it performs a batter y

of tests. The first test result displayed is the wiring condition.

The SureTest checks for the following conditions and indicates

the test result on the display.

3

ND 5481-6 61-164 165 Ins 8/28/08 1:55 PM Page 3

Page 3

5

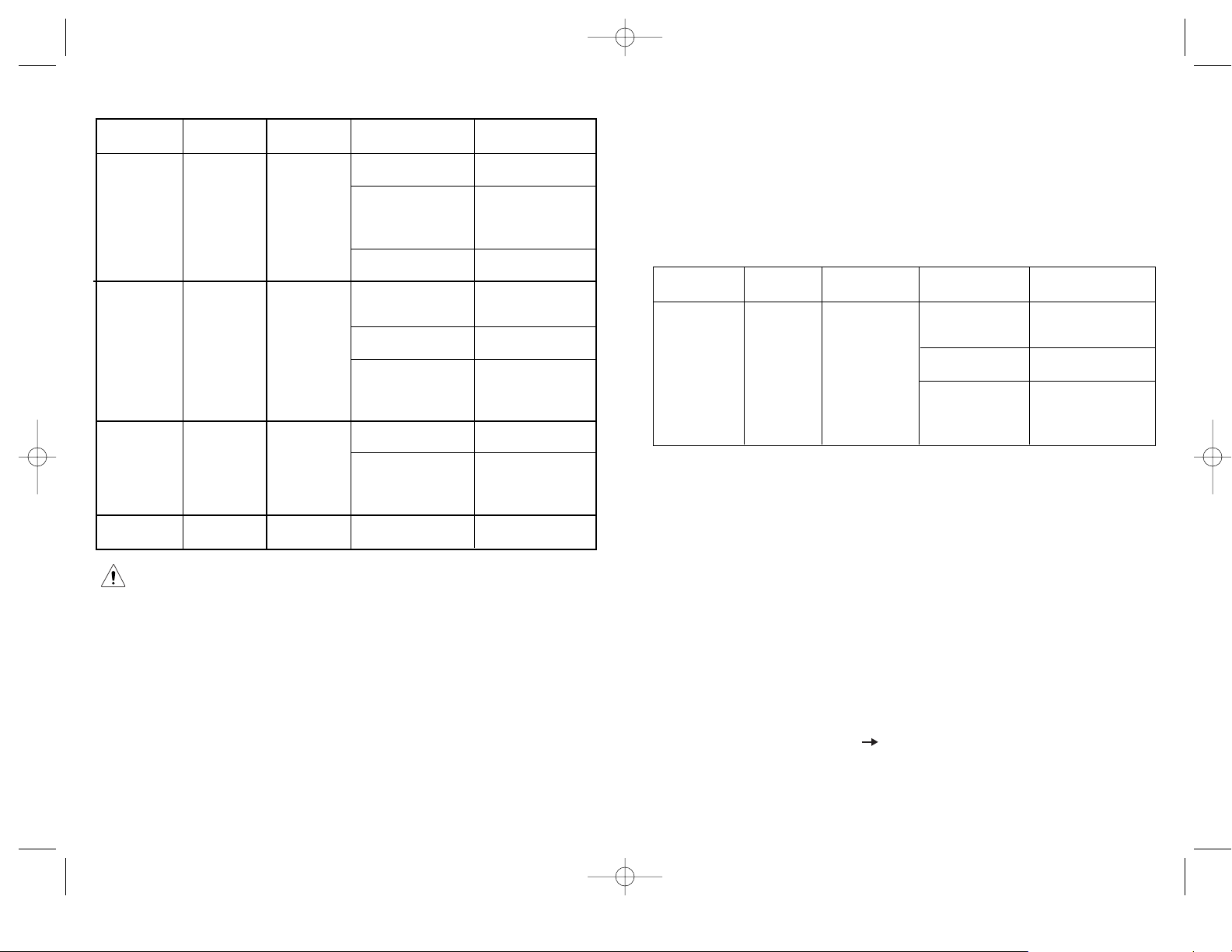

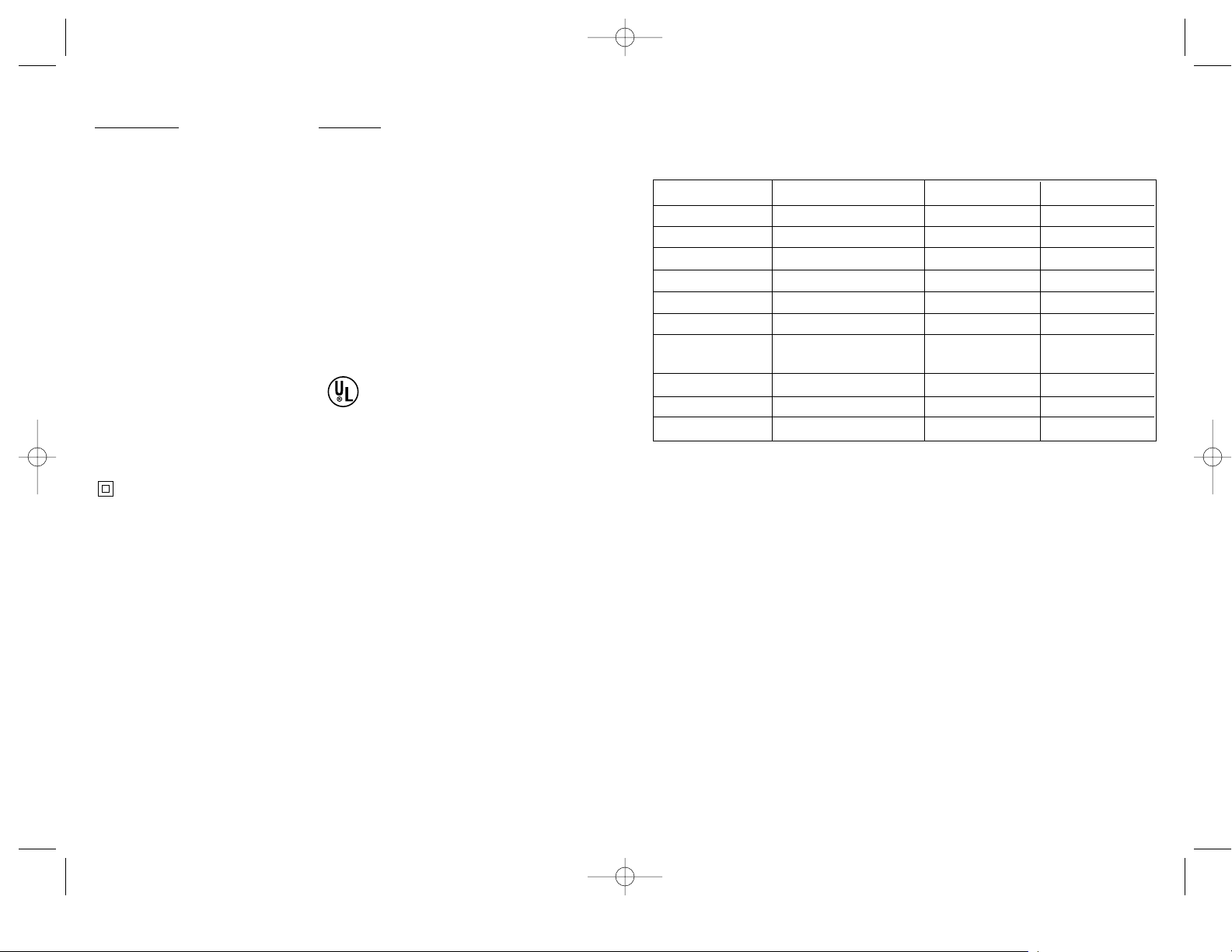

Troubleshooting Tips for Voltage Issues

Measurement Expected Problem Possible Possible

Result Causes Solutions

Too much load on Redistribute loads

the load on circuit. on the circuit.

High resistance Locate high resistance

connection within connection/device and

the circuit or at repair/replace.

the panel.

Supply voltage Consult power

too high/low. company.

Current leaking Identify source of leakage:

from neutral to multiple bonding points,

ground. equipment or devices.

Unbalanced 3- Check load balance

phase system. and redistribute load.

Triplen harmonics Oversize neutral to

returning on impedance. Reduce

neutral in 3-phase harmonic effect via

system. filter or other methods.

Supply voltage Consult power

too high/low. company.

High Peak Loads Evaluate number of

on line caused by electronic devices on

electronic equipment circuit and redistribute

on line. if necessary.

Supply frequency Consult power

too high/low. company.

Voltage Drop (VD) Measurements

The SureTest measures the line voltage, applies a load on the circuit, measures the loaded

voltage, then calculates the voltage drop. Results are displayed for 12A, 15A, and 20A

loads. The National Electrical Code recommends 5% as the maximum voltage drop for

branch circuits for reasonable efficiency (NEC article 210-19. FPN 4). And, the voltage

under load (VL) should not drop below 108VAC for reliable equipment operation.

A good branch circuit should start out with less than 5% voltage drop at the furthest receptacle from the panel at the end of the cable run. Then, each receptacle tested in sequence

towards the panel should show a steady decrease in voltage drop. If the voltage drop is

above 5% and does not noticeably decrease as you get closer to the first device on the circuit, then the problem is between the first device and the panel. Visually check the terminations at the first device, the wiring between the device and the panel, and the circuit breaker

connections. High resistance points can usually be identified as hot spots using an infrared

thermometer or by measuring the voltage across the breaker. If the voltage drop exceeds

5% but noticeably decreases as you nearer the panel, the circuit may have undersized wire,

too long of a cable run, or too much current on the circuit. Check the wire to ensure that it

is sized per code and measure the current on the branch circuit. If a voltage drop reading

changes significantly from one receptacle to the next, then the problem is a high impedance

point at or between two receptacles. It is usually located at a termination point, such as a

bad splice or loose wire connection, but it might also be a bad receptacle.

Troubleshooting Tips for Voltage Drop

Measurement Expected Problem Possible Possible

Result Causes Solutions

Too much Redistribute the

load on load on

the circuit. the circuit.

Undersized wire for Check code requirements

length of run. and re-wire if necessary.

High resistance Locate high

connection within resistance connection/

the circuit or at device and

the panel. repair/replace.

Estimated Load on Line (ELL) Measurement

The SureTest now estimates the load on a branch circuit to provide an indication of how

much capacity in the circuit remains or to quickly check if the circuit is dedicated. This

function is a rough estimate (no stated accuracy), as accurately measuring circuit current

has to be done with a clamp meter at the electrical panel. The proprietary way in which

these calculations are made allows the user to plug the unit into an outlet and quickly determine the current load on that branch circuit.

Both the distance of the SureTest from the load and branch circuit impedance will affect

accuracy. Best accuracy is obtained by positioning the SureTest in the same outlet as the

largest load on line; otherwise, try to position the SureTest between the load(s) and the

electrical panel. The maximum amperage reported by the tester is 15A.

ASCC Measurement

The SureTest calculates the Available Short-Circuit Current (ASCC) that the branch circuit

can deliver through the breaker during a bolted fault (dead-short) condition.

The ASCC is calculated by dividing the line voltage by the circuit’s line impedance (hot +

neutral). Depressing the side arrow ( ) displays the worst-case scenario where all three

conductors (hot, neutral, ground) are shorted together -- the neutral and ground provide a

lower impedance via a parallel return path. Note that this second test will trip a GFCI. See

the following equations for clarification.

Voltage Drop <5%

High Voltage

Drop

6

Line Voltage

120VAC

220VAC

Neutral-Ground

Voltage

Peak Voltage

120VAC

220VAC

Frequency

108-132VAC

198-242VAC

<2VAC

Voltage

153-185VAC

280-342VAC

60HZ

High/low

High G-N

>2VAC

High/low

peak voltage

High/low

frequency

WARNING: Do not exceed the unit’s maximum voltage rating of 250VAC.

ND 5481-6 61-164 165 Ins 8/28/08 1:55 PM Page 5

Page 4

8

GFCI Testing

To test the GFCI device, the SureTest®creates an imbalance between the hot and neutral conductors by leaking a small amount of current from hot to ground using a fixed value resistor.

The test current applied by the SureTest®should not be less than 6mA or greater than 9mA

per UL-1436. A functional GFCI should sense the imbalance and disconnect the power. The

SureTest displays the actual test current in milliamps and trip time in milliseconds.

To conduct a GFCI test, press the GFCI button to enter the GFCI main menu. The GFCI

symbol in the display should be highlighted as the default test. If EPD is lit, then use the

side arrow ( ) to highlight the GFCI symbol. Then, press the GFCI button to activate the

test. The actual current being leaked to ground is displayed. The TEST icon and hourglass

symbol appear on the display to let the user know that the GFCI test is being performed.

The GFCI device should trip within the UL established guideline causing the display to

blank out with the loss of power. When the GFCI device is reset, the unit displays the actual

trip time that the GFCI took to respond to the current imbalance and open the circuit.

Pressing the down arrow button ( ) returns it to the wiring verification mode. If the GFCI

fails to trip, the SureTest terminates the test after 6.5 seconds. Further inspection should

determine whether the GFCI circuitry is faulty, the GFCI is installed incorrectly, or if the circuit is protected by a GFCI device.

UL Guideline

for trip time:

Notes:

1) In order to test a GFCI in a 2-wire system (no ground), the #61-175 ground continuity

adapter must be used. Connect the alligator clip on the adapter to a ground source,

such as to a metal, water or gas pipe.

2) All appliances or equipment on the ground circuit being tested should be unplugged

to help avoid erroneous readings.

In addition to performing a GFCI test for evaluating personal protection from shock hazards,

the SureTest can also conduct testing to ensure equipment protection from ground faults

exceeding 30mA. The method of operation is the same as the GFCI test noted in the first

paragraph above but uses a different resistor to create a 30mA leakage current from hot-toground. To conduct an EPD test on an Equipment Protective Device, press the GFCI button

to enter the GFCI main menu. The GFCI symbol in the display should be highlighted as the

default test. Press the side arrow ( ) button to highlight the EPD symbol. Then, press

the GFCI button to activate the test. The actual current being leaked to ground is displayed.

The TEST icon and hourglass symbol appear on the display to let the user know that the

EPD test is being performed. The EPD should trip causing the display to blank out with the

Where: T = seconds (s)

I = milliamps (mA)

I

T

=(

20)1.43

7

ASCC1= Line Voltage (VHN)/ (Hot Ω + Neu Ω)

ASCC2= Line Voltage (VHN)/ (Hot Ω + 1/(1/Neu Ω+ 1/ Grd Ω)

Impedance (Z) Measurements

If the voltage drop measurement exceeds 5%, analyze the hot and neutral impedances. If

one is significantly higher than the other, the problem is with the conductor with the much

higher impedance. Then, check all connections on that conductor back to the panel. If

both impedances appear high, the source can be undersized wire for the length of run, a

bad device, or poor connections at the pigtails, devices, or panel.

The ground impedance measured should be less than 1 ohm as a rule of thumb to ensure

that fault current has a sufficient path back to the panel. IEEE states the ground impedance

should be less than 0.25 ohms to ensure the ground conductor can safely return any fault

current which could damage equipment on the circuit. Surge suppression systems require

a good ground to adequately protect equipment from transient overvoltages. Note that a

small amount of current is applied to the ground conductor to accurately measure its

impedance. By the inherent nature of this test, a GFCI protected circuit will trip unless the

device is temporarily removed from the circuit.

Troubleshooting Tips - Impedances

Measurement Expected Problem Possible Possible

Result Causes Solutions

<0.0048Ω/foot Too much load Redistribute the load

of 14 AWG wire on branch circuit. on the circuit.

<0.003Ω/ foot Undersized wire Check code requirements

of 12 AWG wire for length of run. and rewire if necessary.

<0.001Ω/ foot High resistance Locate high resistance

or 10 AWG wire connection within connection/device

the circuit or at and repair/replace.

the panel.

< 1 Ω to

protect people

High resistance Locate high resistance

connection within connection/device

the circuit or at and repair/replace.

the panel.

Hot and Neutral

Impedance

Ground

Impedance

<0.25Ω to

protect

equipment

Undersized wire

for length of run.

Check code requirements

and re-wire if necessary.

High conductor

impedance

High ground

impedance

ND 5481-6 61-164 165 Ins 8/28/08 1:55 PM Page 7

Page 5

9

loss of power. When the EPD is reset and power is restored, the unit displays the actual

trip time that the EPD took to respond to the current imbalance and open the circuit.

Pressing the down arrow button ( ) returns it to the wiring verification mode. If the EPD

fails to trip, the SureTest terminates the test after 6.5 seconds. Further inspection should

determine whether the EPD circuitry is faulty, the EPD is installed incorrectly, or if the circuit is protected by an EPD.

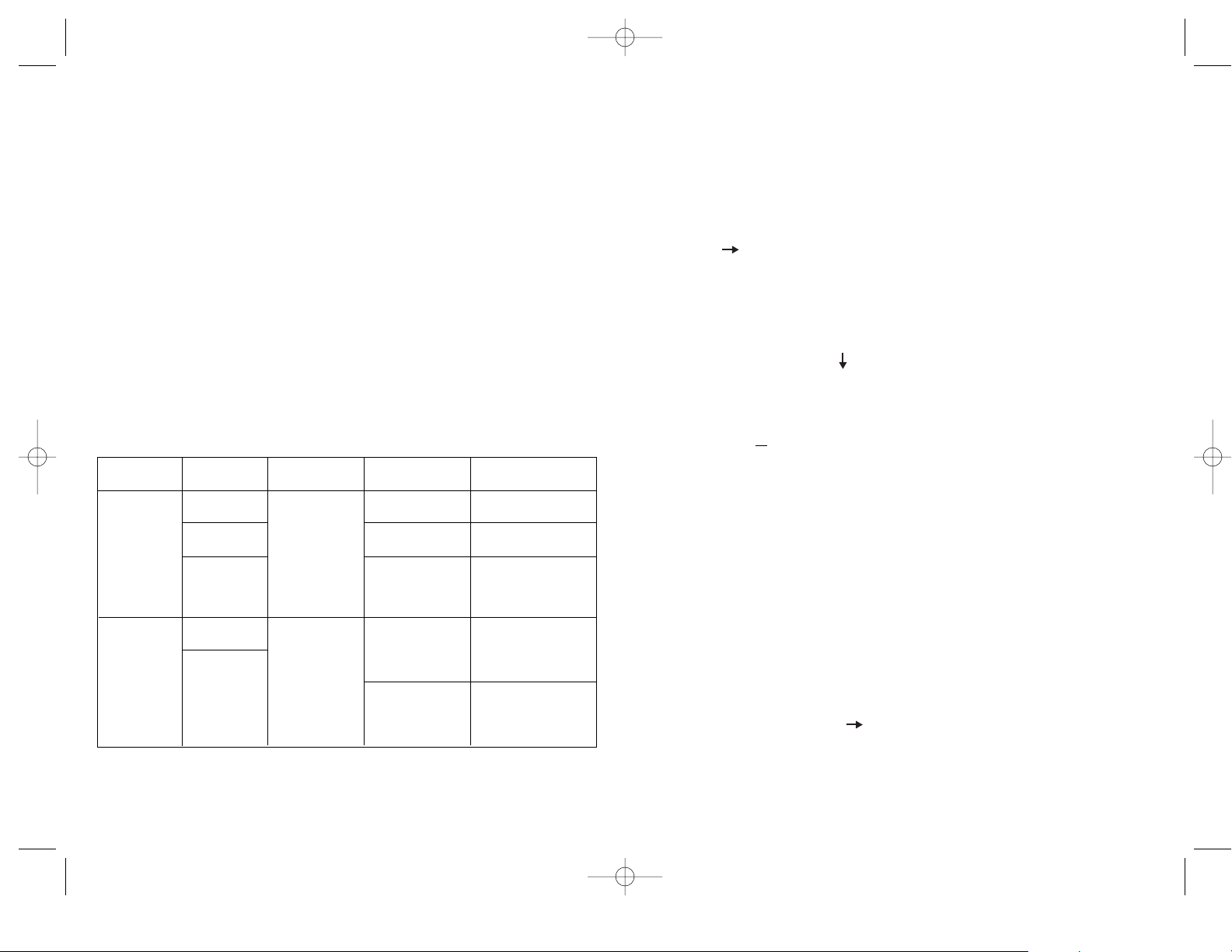

Troubleshooting Tips

Measurement Expected Problem Possible Possible

Result Causes Solutions

Check wiring for proper

installation in accordance

with manufacturer’s

instructions and NEC.

GFCI doesn’t trip.

GFCI may be Check wiring and ground.

defective. Replace GFCI if necessary.

AFCI Testing (#61-165 only)

The SureTest®w/AFCI applies 8-12 current pulses in less than a half second across hot-toneutral with each pulse no longer than 8.3ms in duration, and having an amplitude of 106141 amps in accordance with UL1436. A functional AFCI breaker should recognize these

current pulses as a dangerous arc and disconnect the power to the circuit. To restore

power, reset the breaker at the panel.

To properly test the AFCI, execute the following steps:

1) Consult the AFCI manufacturer's installation instructions to determine that the AFCI is

installed in accordance with the manufacturer's specifications.

2) Plug in the SureTest and check for correct wiring of receptacle and all remotely connected receptacles on the branch circuit. Then, go to the panel and operate the test button on the AFCI installed in the circuit. The AFCI must trip. If it does not, do not use the

circuit - consult an electrician. If the AFCI does trip, reset the AFCI.

3) Return to the tester and press the AFCI button on the tester to enter the AFCI main

menu. The AFCI symbol in the display should be highlighted as the default test. If

NEUT is lit, then use the side arrow ( ) to highlight the AFCI symbol. Then, press

the AFCI button to activate the test. The TEST icon and lightning bolt symbol light

brightly on the display to let the user know that the AFCI test is being performed. The

AFCI device should trip causing the display to blank out with the loss of power. If the

AFCI fails to trip, the SureTest®will not lose power and the display shows a dimly lit

GFCI Test

GFCI trips

within trip time

GFCI doesn’t

trip within proper

trip time.

GFCI maybe

installed

improperly.

10

lightning bolt. This non-trip condition would suggest:

a) A wiring problem with a totally operable AFCI, or

b) Proper wiring with a faulty AFCI.

Consult with an electrician to check the condition of the wiring and AFCI.

4) CAUTION: AFCIs recognize characteristics unique to arcing, and AFCI testers produce

characteristics that mimic some forms of arcing. Because of this, the tester may give a

false indication that the AFCI is not functioning properly. If this occurs, recheck the

operation of the AFCI using the test and reset buttons. The AFCI’s test button function

should demonstrate proper operation.

Note: The AFCI circuitry is protected by a thermal sensor to assure long life. If a

thermometer icon appears in the display during repeated AFCI testing, the sensor

delays further testing until the circuitry cools. At that point, the testing will automatically

continue.

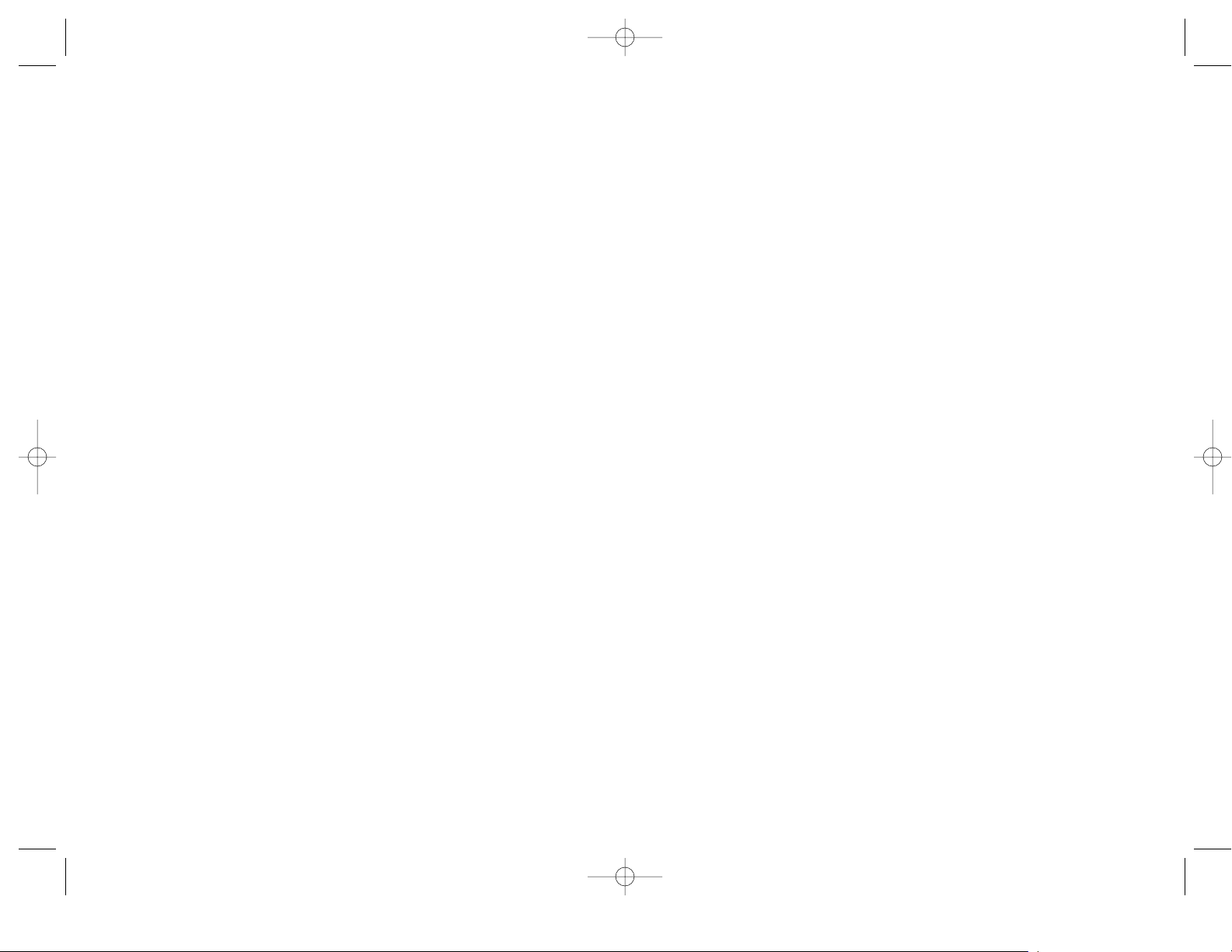

Shared Neutral Test (#61-165 only)

AFCI breakers are prone to nuisance tripping when wired with a shared neutral or when the

neutral conductor is accidentally grounded before the panel. The AFCI tripping occurs

because it senses an imbalance between the current going out on the hot and the current

returning on the neutral. A shared neutral between two hot conductors creates this imbalance. See the illustration below to see how this imbalance can occur.

The SureTest can test for these conditions by applying a small load of 300mA between hot

and neutral to simulate a normal load and ensure that the AFCI breaker does not trip. To

conduct a shared neutral test, press the AFCI button to enter the AFCI main menu. Press

the side arrow ( ) to highlight the NEUT symbol. Then, press the AFCI button to activate

the test. The TEST icon will light brightly while the test is being conducted. The AFCI

breaker should not trip. If the breaker does trip, a shared neutral is the probable cause.

Illustration:

SureTest Shared Neutral Test w/300mA load

3A H1

3.3A N

300mA H2

)

)

)

)

Lights

Outlet

Circuit #1: Breaker

Circuit #2: Breaker

ND 5481-6 61-164 165 Ins 8/28/08 1:55 PM Page 9

Page 6

This adapter can also be used to test GFCI receptacles on 2-wire circuits. Connect the alligator

clip on the adapter to a ground, such as a metal water or gas pipe prior to testing the GFCI.

#61-176 Isolated Ground Adapter

This adapter allows the operator to verify that a receptacle is completely isolated from the

system ground that is bonded to other devices on the branch circuit. Test the ground

impedance of the receptacle and record the ohms value. (See the section on Line

Impedance Testing for details on obtaining the ground impedance value). Remove the

SureTest and plug it into the isolated ground adapter. Attach the alligator clip to the center

receptacle screw or metal junction box, and re-insert the SureTest into the receptacle and

record the ohms value.

The isolated ground adapter creates a parallel pathway to ground, which results in a lower

ground impedance reading with the adapter versus with the receptacle with the isolated

ground. If the two readings are the same, then the receptacle does not have an isolated

ground. If the reading taken with the isolated ground adapter is lower, then the receptacle

has an isolated ground.

Maintenance

Clean case with a damp cloth and mild detergent. Do not use abrasives or solvents.

Service and Replacement Parts:

This unit has no user-serviceable parts. To inquiry about ser vice information, call Technical

Support at 877 201-9005 or visit our website at www.testersandmeters.com.

Repair address is:

IDEAL INDUSTRIES, INC.

Attention: Repair Dept.

1000 Park Ave.

Sycamore, IL 60178

12

Troubleshooting Tips

Measurement Expected Problem Possible Possible

Result Causes Solutions

Check wiring and re-

wire device according

to manufacturer’s

instructions.

AFCI defective. Replace AFCI.

High source of Check for

line impedance high voltage

or resistance. drop.

Re-wire circuit

per AFCI

manufacturer’s

Instructions.

Optional Accessories

#61-183 Alligator Clip Adapter

This adapter allows the SureTest to analyze non-outlet based circuits for branch circuit

safety and performance. Simply plug the alligator clip adapter into the IEC connection on

the front of the SureTest. Then, properly connect the hot (black), neutral (white) and ground

(green) alligator clips onto the circuit. Correct test results are dependent on making good

connections with the alligator clips onto the circuit.

WARNING: The SureTest is designed for 120/240VAC circuits only. Do not

exceed the rating of the SureTest with this adapter.

This adapter also allows the operator to use the SureTest (#61-165 only) to verify AFCI

protection on non-outlet based circuits in bedrooms, such as on circuits used for lighting,

ceiling fans, and smoke detectors.

#61-175 Ground Continuity Adapter

This adapter allows the operator to verify that a cabinet or equipment chassis has been

properly bonded to the system ground. Plugging the SureTest into the ground continuity

adapter isolates the SureTest from the electrical ground. If the equipment is properly

grounded, then connecting the alligator clip from the ground continuity adapter to the cabinet or equipment chassis should provide a pathway to ground, and consequently a normal

wiring condition on the SureTest.

After the ground continuity adapter has been connected, the SureTest can be used to measure the ground impedance of the cabinet or equipment chassis back to the panel. See the

section on Line Impedance Measurements for test instructions for ground impedance.

AFCI Test

AFCI installed

incorrectly.

Shared neutral

exists.

Shared Neutral

Test

AFCI does

not trip

AFCI does

trip.

AFCI trips

AFCI does

not trip.

11

ND 5481-6 61-164 165 Ins 8/28/08 1:55 PM Page 11

Page 7

1413

General Specifications

Characteristics Description

Display 128 x 64 OLED with backlight

Display update for Volt Less than 2.5 times Second.

Over-range Indication on all functions Display "OL"

Operating Environment,

Relative Humidity 32°F to 122°F (0°C to 50°C) at <80%RH

Storage Environment: 32°F to 122°F (0°C to 50°C) at <80% RH

Case Construction: ABS UL 94V/0/5VA rated

Altitude: 6561.7 ft (2000m)

Dimensions: 6.4" (L) x 3" (W) x 1.4" (D)

162mm (L) x 76mm (W) x 36mm (D)

Weight: 9.4 oz (267g)

Safety: UL61010B-1, Cat III-300V

UL-1436 for AFCI, GFCI & Outlet

Accessories: Includes 1’ plug adapter, carr ying case,

instruction manual. Optional alligator clip

adapter available.

Double Insulation

Instrument has been evaluated and complies with insulation category III (overvoltage category III). Pollution degree 2 in accordance with IEC-644. Indoor use.

Measurement Specifications:

All specifications are at 23°C ± 5°C at less than 80% relative humidity.

Accuracy is state as ± ([% of range] + [counts]).

AC converter is true rms sensing.

Measurement Ranges Resolution Accuracy

Line Voltage 85.0 - 250.0 VAC 0.1V 1.0% ± .2V

Peak Line Voltage 121.0 - 354.0 VAC 0.1V 1.0% ± .2V

Frequency 45.0 - 65.0 Hz 0.1Hz 1.0% ± .2Hz

% Voltage Drop 0.1% - 99.9% 0.1% 2.5% ±.2%

Voltage Loaded 10.0 - 250.0 VAC 0.1V 2.5% ± .2V

Neutral-Ground V 0.0 - 10.0 VAC 0.1V 2.5% ± .2V

Impedance - Hot 0.00 Ω - 3.00 Ω 0.01Ω 2.5% ± .02Ω

Neutral, & Ground > 3 Ω Unspecified.

GFCI Trip Time 1mS to 6.500S counter. 1 mS 1.0% ± 2mS

GFCI Trip Current 6.0 - 9.0 mA 0.1 mA 1.0% ± .2mA

EPD Trip Current 30.0 - 37.0 mA 0.1 mA 1.0% ± .2mA

ND 5481-6 61-164 165 Ins 8/28/08 1:55 PM Page 13

CUS

Page 8

1615

Limited Warranty

This meter is warranted to the original purchaser against defects in material or workmanship for two years from the date of purchase. During this warranty period, IDEAL INDUSTRIES, INC. will, at its option, replace or repair the defective unit, subject to verification of

the defect or malfunction. This warranty does not apply to defects resulting from abuse,

neglect, accident, unauthorized repair, alteration, or unreasonable use of the instrument.

Any implied warranties arising out of the sale of an IDEAL product, including but not limited

to implied warranties of merchantability and fitness for a particular purpose, are limited to

the above. The manufacturer shall not be liable for loss of use of the instrument or other

incidental or consequential damages, expenses, or economic loss, or for any claim or

claims for such damage, expenses or economic loss.

State laws vary, so the above limitations or exclusions may not apply to you. This warranty

gives you specific legal rights, and you may also have other rights, which vary from state to

state.

Warranty limited solely to repair or replacement; no warranty of merchantability, fitness for a

particular purpose or consequential damages.

ND 5481-6 61-164 165 Ins 8/28/08 1:55 PM Page 15

Page 9

18

Operación en general

El analizador de circuitos SureTest®demora sólo segundos en probar cada tomacorriente y

circuito bajo plena carga. Esta herramienta de prueba comprueba diversas condiciones del

cableado, que incluyen: corrección del cableado, inversión de polaridad y falta de tierra según

norma UL-1436. Un sencillo menú permite acceder a las mediciones de tensión de línea,

caída de tensión en condiciones de plena carga, tensión tierra-neutro e impedancias de línea.

La prueba de disyuntores diferenciales por falla de tierra (GFCI) se realiza por separado de

acuerdo con la norma UL-1436 e interrumpe el suministro eléctrico si está presente un GFCI

en funcionamiento.

El instrumento SureTest®con AFCI, Nº 61-165, prueba también dispositivos disyuntores

por falla de arco (AFCI) para asegurar que dichos dispositivos de protección de circuitos

hayan sido instalados correctamente. Esta prueba interrumpe el suministro eléctrico si hay

presente un AFCI en funcionamiento. La herramienta comprueba también las condiciones

de neutro compartido que originan disparos de AFCI injustificados.

Para mantener las precisiones indicadas durante el uso repetido, espere 20 segundos entre

inserciones para disipar adecuadamente cualquier acumulación de calor producida durante

la prueba bajo carga.

Analizador de circuitos

SureT est

®

1. Estructura de menús

2. Botones de navegación

3. Botón de prueba de GFCI

4. Botón de prueba de AFCI

17

Introducción

Gracias a su tecnología patentada, los analizadores de circuitos

SureTest®"ven a través de las paredes" para identificar problemas

de cableado que pueden causar riesgos de descarga eléctrica a las

personas, incendios o problemas en el funcionamiento de los

equipos. Los riesgos personales de descarga eléctrica se originan en conexiones a tierra

incorrectas, tierras falsas y/o ausencia de protección contra fallas de tierra. Los incendios

eléctricos se producen como consecuencias de fallas de arco y puntos de alta resistencia

que crean fuego en las conexiones del cableado del circuito. Finalmente, los problemas de

funcionamiento de los equipos surgen debido a la insuficiencia de la tensión disponible en

carga, una impedancia a tierra deficiente y una alta tensión de tierra a neutro. Como dato,

se estima que el 80% de los problemas de la calidad del suministro eléctrico se relacionan

con las fallas del cableado arriba indicadas.

Características del producto

• Valor eficaz verdadero

• Medición de caídas de tensión bajo cargas de 12, 15 y 20 A

• Medición de tensión: de línea, de tierra a neutro, valor pico y frecuencia

• Medición de impedancias de conductores vivos, neutros y de tierra

• Identificación del cableado correcto en receptáculos para tres conductores

• Identificación de tierras falsas

• Prueba de funcionamiento correcto de disyuntores diferenciales por falla de tierra (GFCI)

• Prueba de funcionamiento correcto de disyuntores por falla de arco (AFCI) (61-165)

• Verificaciones de neutros compartidos que producen disparos de AFCI injustificados

(61-165)

• Verificación de circuitos dedicados (con adaptador 61-176)

• Cordón de extensión de 1 pie (30 cm) y estuche de transporte incluidos

#61-165

GFCI

AFCI

RM

S

True

S

u

r

e

e

T

s

t

SureTest®

Circuit Analyzer

Analizador de circuitos SureTest

®

Manual de Instrucciones

#61-164

#61-165

ADVERTENCIA: No use este instrumento en salidas de sistemas UPS, atenu-

adores de luz o equipos generadores de onda cuadrada, puesto que puede dañarse el

analizador.

#61-165

GFCI

AFCI

RMS

True

S

u

r

e

e

T

s

t

SureTest®

Circuit Analyzer

2

3

4

1

ND 5481-6 61-164 165 Ins 8/28/08 1:55 PM Page 17

Page 10

20

Botón de prueba de GFCI

Al oprimir este botón se muestra el menú principal de GFCI. Es posible realizar dos pruebas en este menú: GFCI y EPD. La prueba de

GFCI verifica los dispositivos disyuntores diferenciales por falla de

tierra enviando del vivo a tierra 6-9 mA según norma UL-1436. La

prueba EPD es para probar los disyuntores que tienen una características de dispositivo protector

de equipos (EPD) que dispara el disyuntor si se detecta una falla de tierra superior a 30 mA.

Oprimiendo el botón de flecha lateral ( ) se navega entre estas dos pruebas. Una vez resaltada

la prueba deseada, oprima el botón de prueba de GFCI del teclado para activar la prueba.

Botón de prueba de AFCI

Al oprimir este botón se muestra el menú principal de GFCI. Es

posible realizar dos pruebas en este menú: AFCI y NEUT. La

prueba de AFCI comprueba los dispositivos disyuntores por falla

de arco creando un arco de corta duración de 106-141 A entre los

conductores vivo y neutro según norma UL1436. La prueba NEUT comprueba si existe un

conductor neutro compartido o falsamente puesto a tierra, lo que causa que los disyuntores

AFCI produzcan disparos injustificados con cargas normales. En esta prueba se aplican

300 mA entre el vivo y el neutro para asegurar que el disyuntor AFCI no se dispare.

Procedimiento de las pruebas

Verificación del cableado

Inmediatamente después de ser insertado en un receptáculo el

instrumento SureTest muestra el logotipo de IDEAL mientras

realiza una batería de pruebas. El primer resultado de prueba

mostrado es el estado del cableado. SureTest comprueba las

siguientes condiciones e indica los resultados de la prueba en la pantalla.

Condición del Indicación de pantalla

cableado H G N

Cableado correcto

Falta de tierra

Inversión de polaridad

Vivo/neutro abierto

Tierra falsa

Símbolos

Encendido

Apagado

Destellando

F

19

Navegación por los menús

Las máximas prioridades del microprocesador son tomar mediciones en vivo y luego

analizar los datos. Por lo tanto, ocasionalmente el microchip no reconoce los botones del

teclado que se pulsan rápidamente, mientras está ejecutando estas rutinas. Para evitar este

problema, mantenga oprimido el botón del teclado cada vez, hasta que cambie el menú.

Las mediciones tomadas por el SureTest se dividen en cinco menús principales que se ubican en el costado izquierdo de la pantalla: Configuración de cableado (•••), Tensión (V),

Caída de tensión (VD), Corriente (A) e Impedancia (Z). Para navegar a cualquiera de los

menús principales, use el botón de flecha abajo ( ).

La pantalla de configuración del cableado (•••) indica la corrección del cableado y las

condiciones de inversión de polaridad, inversión de vivo/neutro y falta de tierra, efectuando

una secuencia con los tres círculos. El rótulo del dorso del producto explica las indicaciones de la secuencia del cableado.

El menú de tensión (V) muestra el valor eficaz (RMS) de la tensión de línea en tiempo real.

Este menú principal tiene un submenú ubicado horizontalmente al pie de la pantalla, que

muestra la tensión de línea (RMS HN), la tensión de tierra a neutro (RMS GN), la tensión

pico (Peak) y la frecuencia (Hz). Para navegar por el submenú, use el botón de flecha lateral ( ).

La pantalla dual de caída de tensión (VD) muestra la caída de tensión porcentual con una

carga de 15 A, junto con la tensión en carga resultante VL). Este menú principal tiene un

submenú, que muestra también la caída de tensión porcentual y la tensión en carga con

cargas de 20 y 12 A. Para navegar por el submenú, use el botón de flecha lateral ( ).

El menú Corriente (A) muestra la carga estimada en línea (ELL) en tiempo real y retiene la corriente máxima en la parte superior derecha de la pantalla. El menú principal tiene un submenú

posicionado horizontalmente que muestra (ASCC1), la corriente de cortocircuito disponible

entre vivo y neutro (H-N) y (ASCC2), la corriente de cortocircuito disponible en vivo, neutro y

tierra (H-N-G). Para navegar por el submenú, use el botón de flecha lateral ( ).

El menú principal de impedancia (Z) muestra la impedancia en ohmios (Ω) del conductor

vivo. Este menú principal tiene un submenú ubicado horizontalmente al pie de la pantalla,

que muestra también las impedancias de los conductores neutro (N) y de tierra (G). Para

navegar por el submenú, use el botón de flecha lateral ( ). Tenga en cuenta que la prueba

de impedancia a tierra hará disparar un circuito protegido por un GFCI.

ND 5481-6 61-164 165 Ins 8/28/08 1:55 PM Page 19

Page 11

22

Medición Resultado Problema Causas Soluciones

esperado posibles posibles

Exceso de carga en Redistribuya las

el circuito. cargas del circuito.

Mediciones de caída de tensión (VD)

El instrumento SureTest mide la tensión de línea, aplica una carga al circuito, mide la tensión en carga y calcula la caída de tensión. Se muestran los resultados para cargas de 12,

15 y 20 A. El Código Eléctrico Nacional de EE.UU. recomienda un 5% como máxima caída

de tensión en circuitos de ramales para lograr un rendimiento razonable (NEC, artículo 210-

19. FPN 4). Asimismo, para que la operación de los equipos sea confiable, la tensión en

carga (VL) no debe caer por debajo de 108 VCA.

21

Si el estado del cableado no es normal, se limitan las mediciones que se pueden efectuar con SureTest. Si existe una condición de falta de tierra, sólo están disponibles

las mediciones de tensión de línea y caída de tensión. En una condición de inversión

de vivo y neutro, neutro abierto o vivo abierto, la unidad no tiene alimentación, de

modo que la pantalla queda en blanco.

Notas:

1) No se detectan dos cables vivos en un circuito.

2) No se detecta una combinación de defectos.

3) No se detecta la inversión de los conductores puesto a tierra y de conexión a tierra.

Indicación de tierra falsa

El instrumento SureTest indica cuando existe una condición de tierra falsa debido a la

interconexión incorrecta mediante una tierra falsa (un puente de alambre en el dispositivo de tomacorriente) o el contacto inadvertido del cable de tierra con la conexión del

neutro. Tenga en cuenta que si SureTest está dentro de los 4.5 a 6 m (15-20 pies) del

tablero principal, la unidad indicará una condición de tierra falsa en un circuito correctamente cableado debido a su proximidad con respecto a la interconexión tierra-neutro

correcta del tablero principal.

Mediciones de tensión

La medición de tensión de línea debe ser 120 VCA +/-10% de fluctuación a 60 Hz. La tensión

pico debe ser 1.414 veces la tensión eficaz de línea en el caso de una onda senoidal limpia. La

tensión de tierra a neutro debe ser inferior a 2 VCA. En un circuito monofásico, una tensión

tierra-neutro superior indica una corriente de fuga excesiva entre los conductores neutro y de

tierra. En un circuito trifásico con neutro compartido, una tensión tierra-neutro elevada podría

indicar una carga desequilibrada entre las tres fases o distorsión armónica en el neutro comparti

do. Una tensión tierra-neutro excesiva puede ocasionar un funcionamiento inconsistente o

intermitente de los equipos. Consejos para la resolución de problemas relacionados con

tensiones

ADVERTENCIA: No exceda la clasificación de tensión máxima de 250 VCA de

la unidad.

Tensión de línea

120 VCA

220 VCA

Tensión entre

neutro y tierra

Tensión pico

120 VCA

220 VCA

Frecuencia

108-132 VCA

198-242 VCA

Tensión

<2VCA

153-185 VCA

280-342 VCA

60 HZ

Frecuencia

Conexión de alta

resistencia dentro del

circuito o en eltablero.

Localice la conexión/

dispositivo de alta resistencia

y repárelo/reemplácelo

Tensión del suministro

eléctrico demasiado alta/baja

Consulte a la compañía de

electricidad

Identifique el origen de la fuga:

múltiples puntos, equipos o

dispositivos de conexión a

tierra.

Sistema trifásico

desequilibrado

Verifique el equilibrio de

carga y redistribúyala.

Tensión del suministro

eléctrico demasiado alta/baja

Consulte a la compañía de

electricidad.

Frecuencia del suministro

eléctrico demasiado alta o baja

Consulte a la compañía de

electricidad.

Las armónicas de orden

múltiplo de 3 retornan por

el neutro en un sistema

trifásico

Aumente la impedancia de

neutro a tierra Reduzca el efecto de la armónica mediante fil-

tros u otros métodos.

Cargas pico elevadas en la

línea causada por los equipos

electrónicos conectados

Evalúe el número de dispositivos electrónicos conectados

al circuito y redistribúyalos de

ser necesario.

T-N alta

>2VCA

Frecuencia demasi-

ado alta o baja

Tensión pico

demasiado alta o

baja

Fuga de corriente del

neutro a tierra

ND 5481-6 61-164 165 Ins 8/28/08 1:55 PM Page 21

Page 12

24

Medición de ASCC

SureTest calcula la corriente de cortocircuito disponible (ADCC) que el circuito del ramal

puede entregar a través del disyuntor durante una condición de falla de cortocircuito por

conexión mecánica entre fases (cortocircuito con resistencia cero).

La ASCC se calcula dividiendo la tensión de línea por la impedancia de línea del circuito

(vivo + neutro). Oprimiendo la flecha lateral ( ) se muestra el escenario del peor caso,

donde los tres conductores (vivo, neutro y de tierra) están cortocircuitados entre sí -el neutro y la tierra proporcionan una menor impedancia mediante una ruta de retorno en paralelo. Tenga en cuenta que esta segunda prueba hará disparar un GFCI. Para clarificar el

tema, vea las siguientes ecuaciones.

ASCC1= Tensión de línea (VHN)/ (Hot Ω + NeuΩ)

ASCC2= Tensión de línea (VHN)/ (Hot Ω + 1/(1/Neu Ω + 1/ Grd Ω)

Mediciones de impedancia (Z)

Si la caída de tensión excede el 5%, analice las impedancias del vivo y el neutro. Si una es

significativamente mayor que la otra, el problema radica en el conductor de mayor impedancia. Por lo tanto, verifique todas las conexiones de ese conductor hasta el tablero. Si

ambas impedancias son altas, el origen del problema puede ser el tamaño insuficiente del

cable para la longitud del tendido, un dispositivo defectuoso o conexiones deficientes en

los cables flexibles, los dispositivos o el tablero.

Como regla aproximada, la impedancia a tierra medida debe ser inferior a 1 ohmio para asegurar que la corriente de falla tenga un camino suficiente de regreso el tablero. El IEEE indica

que la impedancia a tierra debe ser inferior a 0.25 ohmios para asegurar que el conductor de

tierra puede retornar con seguridad cualquier corriente de falla que pueda dañar los equipos

conectados al circuito. Los sistemas supresores de sobretensiones transitorias requieren una

buena tierra para proteger adecuadamente a los equipos contra dichas sobretensiones. Tenga

en cuenta que se aplica al conductor de tierra una pequeña corriente para medir su impedancia con precisión. Por la naturaleza inherente de esta prueba, un circuito protegido por un

GFCI se disparará a menos que este dispositivo se retire temporalmente del circuito.

23

Un buen circuito de ramal debe comenzar con una caída de tensión inferior al 5% en el

receptáculo más alejado del tablero, en el extremo del tendido de cables. De esta forma,

cada receptáculo probado en secuencia hacia el tablero debería presentar una disminución

constante en la caída de tensión. SI la caída de tensión es superior al 5% y no disminuye en

forma perceptible a medida que uno se acerca al primer dispositivo del circuito, significa

que el problema está entre el primer dispositivo y el tablero. Verifique visualmente las terminaciones del primer dispositivo, el cableado entre el dispositivo y el tablero, y las conexiones del disyuntor. Los puntos de alta resistencia se pueden identificar normalmente como

puntos calientes usando un termómetro infrarrojo o midiendo la tensión entre los terminales

del disyuntor. Si la caída de tensión excede el 5% pero disminuye en forma perceptible al

acercarse al tablero, el problema puede deberse a que los cables del circuito son de tamaño

insuficiente, el tendido es demasiado largo o el circuito tiene demasiada corriente. Verifique

el cable para asegurarse de que el tamaño sea correcto según el código y mida la corriente

del circuito. Si la lectura de caída de tensión varía significativamente desde un receptáculo

al siguiente, el problema es un punto de alta impedancia en o entre dos receptáculos.

Normalmente se encuentra en un punto de terminación, tal como un empalme incorrecto o

una conexión floja, pero puede deberse también a un receptáculo en mal estado.

Consejos para la resolución de problemas relacionados con caídas de tensión

Medición Resultados Problema Causas Soluciones

esperados posibles posibles

Medición de la carga estimada en línea (ELL)

El SureTest estima ahora la carga en un ramal de circuito para proporcionar una indicación

de la magnitud de la capacidad remanente del circuito o verificar rápidamente si dicho circuito está dedicado. Esta función es una estimación gruesa (sin exactitud garantizada),

puesto que la medición exacta de la corriente del circuito se debe realizar con una pinza

amperométrica en el tablero de electricidad. La forma propietaria en que se realizan estos

cálculos permite al usuario enchufar la unidad a un tomacorriente y determinar rápidamente

la carga de corriente en ese ramal del circuito.

Tanto la distancia del SureTest a la carga como la impedancia del ramal de circuito afectan a

la exactitud. La mejor exactitud se obtiene colocando el instrumento en el mismo tomacorriente que la mayor carga de la línea. De lo contrario, trate de posicionar el SureTest entre la

carga y el tablero de electricidad. La máxima corriente que mide el instrumento es 15 A.

Caída de

tensión

<5%

Caída de tensión

elevada

Exceso de carga en

el circuito

Cable de tamaño

insuficiente para la l

ongitud del tendido

Conexión de alta

resistencia dentro del

circuito o en el tablero

Caída de tensión

elevada

Verifique los requisitos

del código y recablee

si fuera necesario.

Localice la conexión/dis-

positivo de alta resistencia

y repárelo/reemplácelo

ND 5481-6 61-164 165 Ins 8/28/08 1:55 PM Page 23

Page 13

26

prueba después de 6.5 segundos. Una inspección ulterior debería determinar si el circuito

del GFCI tiene una falla, si este dispositivo está instalado correctamente o si el circuito está

protegido por un GFCI.

Pauta de tiempo

de disparo de UL:

Notas:

1) A fin de probar un GFCI en un sistema bifilar (sin tierra), se debe usar el adaptador de

continuidad de tierra Nº 61-175. Conecte la pinza cocodrilo del adaptador a una fuente

de tierra, tal como una tubería metálica de agua o de gas.

2) Se deben desenchufar todos los artefactos o equipos conectados al circuito de tierra

para evitar lecturas incorrectas

Además de realizar una prueba de GFCI para evaluar la protección personal contra riesgos

de descarga eléctrica, SureTest puede realizar también pruebas para asegurar la protección

de los equipos contra fallas de tierra superiores a 30 mA. El método de operación es similar a la prueba de GFCI explicada en el primer párrafo precedente, pero se usa un resistor

diferente para crear la corriente de fuga de 30 mA del vivo a tierra. Para realizar la prueba

de EPD en un equipo protector de equipos, oprima el botón GFCI para entrar al menú principal de GFCI. El símbolo GFCI de la pantalla debe estar resaltado como prueba por defecto. Oprima el botón de flecha lateral ( ) para resaltar el símbolo de EPD. Luego, oprima

el botón GFCI para activar la prueba. Se muestra la corriente real que se fuga a tierra. El

icono TEST y el símbolo del reloj de arena aparecen en la pantalla para hacer saber al

usuario que se está realizando la prueba de EPD. El EPD debe dispararse, haciendo que la

pantalla quede en blanco debido a la pérdida de la alimentación eléctrica. Cuando se

restablece el EPD, la unidad muestra el tiempo de disparo real que demoró el EPD para

responder al desequilibrio de corriente y abrir el circuito. Al oprimir el botón de flecha

abajo ( ) el instrumento vuelve al modo de verificación de cableado. Si el EPD no se dispara, SureTest termina la prueba después de 6.5 segundos. Una inspección ulterior debería

determinar si el circuito del EPD tiene una falla, si este dispositivo está instalado correctamente o si el circuito está protegido por un EPD.

25

Consejos para la resolución de problemas - Impedancias

Medición Resultado Problema Causas Soluciones

esperado posibles posibles

Prueba de disyuntores GFCI

Para probar el dispositivo GFCI, SureTest®crea un desequilibrio entre los conductores vivo y

neutro haciendo circular una pequeña corriente de fuga del vivo a tierra usando un resistor de

valor fijo. La corriente de disparo aplicada por SureTest®no debe ser inferior a 6 mA o superior a 9 mA según norma UL-1436. Un GFCI en buen estado de funcionamiento debe detectar

el desequilibrio y desconectar el suministro eléctrico. SureTest muestra la corriente de disparo real en miliamperios y el tiempo de disparo en milisegundos.

Para realizar la prueba de GFCI, oprima el botón GFCI para entrar al menú principal de

GFCI. El símbolo GFCI de la pantalla debe estar resaltado como prueba por defecto. Si

está encendido EPD, use la flecha lateral ( ) para resaltar el símbolo del GFCI. Luego,

oprima el botón GFCI para activar la prueba. Se muestra la corriente real que se fuga a

tierra. El icono TEST y el símbolo del reloj de arena aparecen en la pantalla para hacer

saber al usuario que se está realizando la prueba de GFCI. El dispositivo GFCI debe dispararse dentro de las pautas establecidas por UL haciendo que la pantalla quede en blanco

debido a la pérdida de la alimentación eléctrica. Cuando se restablece el dispositivo GFCI,

la unidad muestra el tiempo de disparo real que demoró el GFCI para responder al desequilibrio de corriente y abrir el circuito. Al oprimir el botón de flecha abajo ( ) el instrumento vuelve al modo de verificación de cableado. Si el GFCI no se dispara, SureTest termina la

Impedancia del

vivo y neutro

Impedancia de

tierra

<0.25Ω para

proteger a los

equipos

< 1 Ω para proteger a las personas

<0.001Ω/pie de

cable 10 AWG

<0.003Ω/pie de

cable 12 AWG

<0.0048Ω/pie de

cable 14 AWG

Cable de tamaño

insuficiente para la

longitud del tendido

Tensión del suministro

eléctrico demasiado

alta/baja

Conexión de alta

resistencia dentro del

circuito o en el tablero

Exceso de carga en el

circuito

Conexión de alta

resistencia dentro del

circuito o en el tablero

Localice la conexión/dis-

positivo de alta resistencia

y repárelo/reemplácelo

Verifique los requisitos

del código y recablee si

fuera necesario.

Redistribuya las cargas

del circuito.

Localice la conexión/

dispositivo de alta

resistencia y

repárelo/reemplácelo

Verifique los requisitos

del código y recablee si

fuera necesario.

Alta/baja

Alta impedancia a

tierra

I

T

=(

20)1.43

Donde: T = segundos (s)

I = miliamperios (mA)

ND 5481-6 61-164 165 Ins 8/28/08 1:55 PM Page 25

Page 14

28

Consulte a un electricista para comprobar el estado del cableado y el AFCI.

4) PRECAUCIÓN: Los AFCI reconocen características exclusivas de los arcos, y los

probadores de AFCI producen características que simulan algunas formas de arcos.

Debido a esto, el instrumento puede dar una indicación de que el AFCI no está funcionando correctamente. Si esto ocurre, vuelva a verificar el funcionamiento del AFCI

usando los botones de prueba y restablecimiento. La función del botón de prueba del

AFCI debe demostrar que el funcionamiento es correcto.

Nota: Tenga en cuenta que el circuito del AFCI está protegido por un sensor térmico

para asegurarle una larga vida útil. Si durante pruebas de AFCI repetidas aparece en la

pantalla el icono del termómetro, el sensor demora la continuación de la prueba hasta

que se enfríe el circuito. En este momento, la prueba se reanudará automáticamente.

Prueba de neutro compartido (Sólo 61-165)

Los disyuntores AFCI son susceptibles a producir disparos injustificados cuando se

cablean con un neutro compartido o cuando el conductor neutro se pone accidentalmente a

tierra antes del tablero. El disparo del AFCI se produce porque detecta un desequilibrio

entre la corriente que sale por el vivo y la que retorna por el neutro. Un neutro compartido

entre dos conductores vivos crea este desequilibrio. Vea la ilustración de abajo para entender cómo puede ocurrir el desequilibrio.

SureTest puede probar estas condiciones aplicando una pequeña carga de 300 mA entre el

vivo y el neutro para simular una carga normal y asegurar que el disyuntor AFCI no se dispare. Para realizar la prueba del neutro compartido, oprima el botón AFCI para entrar al

menú principal de AFCI. Oprima el botón de flecha lateral ( ) para resaltar el símbolo

NEUT. Luego, oprima el botón AFCI para activar la prueba. Mientras se realiza la prueba,

el icono TEST se encenderá con luz brillante. El disyuntor AFCI no debe dispararse. Si el

disyuntor se dispara, la causa probable es un neutro compartido.

Ilustración:

Prueba de neutro compartido con SureTest y carga de 300 mA

3A Vivo 1

3.3A Neutro

300mA Vivo 2

)

)

)

)

Luces

Salida

Circuito No°1: Disyuntor

Circuio No°2: Disyuntor

27

Consejos para la resolución de problemas

Medición Resultado Problema Causas Soluciones

esperado posibles posibles

El GFCI no GFCI El puede

se dispara. estar defectuoso.

Prueba de disyuntores AFCI (Sólo 61-165)

El instrumento SureTest®con AFCI aplica 8 a 12 pulsos de corriente en menos de medio

segundo a través de vivo y neutro. Cada pulso es de menos de 8.3 ms de duración y tiene

una amplitud de 106-141 A según norma UL1436. Un disyuntor AFCI en buen estado de

funcionamiento debe reconocer estos pulsos de corriente como un arco peligroso y

desconectar la alimentación del circuito. Para restablecer la alimentación, restablezca el

disyuntor en el tablero.

Para probar correctamente el AFCI, ejecute los pasos siguientes:

1) Consulte las instrucciones de instalación del fabricante del AFCI para determinar que el

mismo esté instalado de acuerdo a las especificaciones de dicho fabricante.

2) Enchufe el instrumento SureTest y compruebe el correcto cableado del receptáculo y de

todos los receptáculos conectados a distancia en el circuito del ramal. Luego, vaya al

tablero y opere el botón de prueba del AFCI instalado en el circuito. El AFCI debe dispararse. Si no lo hace, no use el circuito y consulte a un electricista. Si el AFCI se dispara, restablézcalo.

3) Vuelva al instrumento y oprima el botón AFCI del mismo para entrar al menú principal

de AFCI. El símbolo del AFCI de la pantalla debe estar resaltado como prueba por

defecto. Si está encendido NEUT, use la flecha lateral ( ) para resaltar el símbolo del

AFCI. Luego, oprima el botón AFCI para activar la prueba. El icono TEST y el símbolo

del rayo se encienden con luz brillante en la pantalla para hacer saber al usuario que

se está realizando la prueba de AFCI. El dispositivo AFCI debe dispararse, haciendo

que la pantalla quede en blanco debido a la pérdida de la alimentación eléctrica. Si el

AFCI no se dispara, el instrumento SureTest®no perderá la alimentación y la pantalla

mostrará un rayo con luz tenue. Esta condición de ausencia de disparo puede sugerir

a) Un problema de cableado con un disyuntor AFCI totalmente operable o b) un cableado correcto con un disyuntor defectuoso.

Impedancia a

tierra de prueba

del GFCI

El GFCI se

dispara dentro

del tiempo

especificado.

El GFCI no se dispara

dentro del tiempo

especificado

El GFCI puede

estar instalado

incorrectamente.

Verifique la correcta insta-

lación del cableado de

acuerdo a las instrucciones

del fabricante y el NEC.

Verifique el cableado y la

conexión a tierra.

Reemplace el GFCI si fuera

necesario.

ND 5481-6 61-164 165 Ins 8/28/08 1:55 PM Page 27

Page 15

30

Después de conectar el adaptador de continuidad de tierra, el instrumento SureTest se

puede usar para medir la impedancia a tierra del gabinete o chasis del equipo hacia el

tablero. Vea en la sección de mediciones de impedancia de línea las instrucciones para la

prueba de impedancia a tierra.

Este adaptador se puede usar también para probar receptáculos de GFCI en circuitos bifilares. Antes de probar el GFCI, conecte la pinza cocodrilo del adaptador a una de tierra, tal

como una tubería metálica de agua o de gas.

Nº 61-176 Adaptador de tierra aislada

Este adaptador permite al operador verificar que un receptáculo está completamente aislado

de la tierra del sistema que está conectada a otros dispositivos del circuito del ramal.

Pruebe la impedancia del receptáculo a tierra y registre el valor en ohmios. (Vea en la sección de prueba de impedancia de línea los detalles sobre la obtención del valor de impedancia a tierra). Retire el instrumento SureTest y enchúfelo en el adaptador de tierra aislada.

Conecte la pinza cocodrilo al tornillo central del receptáculo o a la caja de empalme metálica, reinserte el instrumento SureTest en el receptáculo y registre el valor en ohmios.

El adaptador de tierra aislada crea un camino a tierra en paralelo, que origina una lectura de

impedancia a tierra con el adaptador inferior a la del receptáculo con tierra aislada. Si las

dos lecturas son iguales, significa que el receptáculo no tiene una tierra aislada. Si la lectura tomada con el adaptador de tierra aislada es inferior, significa que el receptáculo tiene

una tierra aislada.

Mantenimiento

Limpie el estuche con un paño húmedo y un detergente suave. No use abrasivos ni solventes.

Servicio y piezas de repuesto:

Esta unidad no contiene piezas reparables por el usuario. Para solicitar información sobre

el servicio, llame al Soporte Técnico al 877 201-9005 o visite nuestro sitio web

www.testersandmeters.com.

La dirección para reparaciones es:

IDEAL INDUSTRIES, INC.

Attention: Repair Dept.

1000 Park Ave.

Sycamore, IL 60178

Consejos para la resolución de problemas

Medición Resultado Problema Causas Soluciones

esperado posibles posibles

AFCI defectuoso. Reemplace el AFCI.

.

Accesorios opcionales

Nº 61-183 - Adaptador de pinza cocodrilo

Este adaptador permite que SureTest analice la seguridad y el funcionamiento de circuitos

que no tienen tomacorrientes. Enchufe simplemente el adaptador de pinza cocodrilo en la

conexión IEC del frente del instrumento SureTest. Luego, conecte correctamente al circuito

las pinzas cocodrilo del vivo (negra), del neutro (blanca) y de tierra (verde). Los resultados

correctos de la prueba dependen de que se hagan buenas conexiones con las pinzas cocodrilo en el circuito.

ADVERTENCIA: El instrumento SureTest está diseñado para circuitos de

120/240 VCA únicamente. No exceda la especificación de SureTest con este

adaptador.

El adaptador permite también que el operador use SureTest (sólo 61-165) para verificar la

protección del AFCI en circuitos que no tienen tomacorrientes de los dormitorios, tales

como los usados para iluminación, ventiladores de techo y detectores de humo.

Nº 61-175 - Adaptador de continuidad de tierra

Este adaptador permite al operador verificar si un gabinete o el chasis de un equipo están

correctamente conectado a la tierra del sistema. Al enchufar el instrumento SureTest al

adaptador de continuidad de tierra, se lo aísla de la tierra eléctrica. Si el equipo está correctamente conectado a tierra, la conexión de la pinza cocodrilo del adaptador de continuidad de tierra al gabinete o al chasis del equipo debe proporcionar un camino a tierra y

por lo tanto una conexión de cableado normal en SureTest.

Prueba de AFCI

AFCI instalado incor-

rectamente.

Verifique la correcta insta-

lación del cableado de

acuerdo a las instruc-

ciones del fabricante.

Fuente de alta impedancia o resistencia de

línea.

Existe un neutro

compartido.

Verifique si hay una caída

de tensión elevada

Recablee el circuito

según las instrucciones

del fabricante del AFCI.

Prueba de neutro

compartido

El AFCI no se

dispara.

El GFCI no se

dispara.

El AFCI se

dispara

El GFCI no se dispara

dentro del tiempo

especificado.

29

ND 5481-6 61-164 165 Ins 8/28/08 1:55 PM Page 29

Page 16

32

Medición Rangos Resolución Exactitud

Tensión de línea 85.0 - 250.0 VCA 0.1 V 1.0 % ± .2 V

Tensión de línea pico 121.0 - 354.0 VCA 0.1 V 1.0 % ± .2 V

Frecuencia 45.0 - 65.0 Hz 0.1 Hz 1.0 % ± .2 Hz

% de caída de tensión 0.1% - 99.9% 0.1 % 2.5 % ± .2 %

Tensión en carga 10.0 - 250.0 VCA 0.1 V 2.5 % ± .2 V

Tensión neutro-tierra 0.0 - 10.0 VCA 0.1 V 2.5 % ± .2 V

Impedancia - Vivo, neutro y tierra 0.0Ω - 3.00Ω 0.01Ω 2.5 % ± .2Ω

>3Ω sin especificar

Tiempo de disparo de GFCI Contador de 1 ms 1 ms 1.0 % ± .2 mS

a 6,500s.

Corriente de disparo de GFCI 6.0 - 9.0 mA 0.1 mA 1.0 % ±.2 mA

Corriente de disparo de EPD 30.0 - 37,0 mA 0.1 mA 1.0 % ± .2 mA

Garantía limitada

Se garantiza este instrumento al comprador original contra defectos de material o mano de

obra durante un período de dos años contados a partir de la fecha de compra. Durante este

período de garantía, IDEAL INDUSTRIES, INC. podrá, a la sola opción de IDEAL, reemplazar

o reparar la unidad defectuosa, sujeto a verificación del defecto o falla. Esta garantía no se

aplica a defectos resultantes del mal uso, negligencia, accidente, reparación no autorizada,

alteración o uso irracional de este instrumento.

Cualquier garantía implícita originada en la venta de un producto IDEAL, incluidas -pero sin

limitarse a ellas- las garantías implícitas de comerciabilidad y adecuación para un propósito particular, se limitan a lo indicado anteriormente. El fabricante no será responsable por la

pérdida del uso del instrumento u otros daños y perjuicios incidentales o consecuentes,

gastos o pérdidas económicas, ni por ninguna reclamación de dichos daños y perjuicios,

gastos o pérdidas económicas.

Las leyes estatales varían, por lo que las limitaciones o exclusiones anteriores pueden no

aplicarse en su caso. Esta garantía le da derechos legales específicos, y es posible que

tenga otros derechos que varían de un estado a otro.

La garantía está limitada solamente a la reparación o reemplazo; no existe ninguna garantía

de comerciabilidad, adecuación para un propósito particular o daños y perjuicios consecuentes.

31

Especificaciones generales

Características Descripción

Pantalla 128 x 64 LED con luz de fondo

Actualización de pantalla para tensión Menos que 2.5 veces por segundo.

Indicación de fuera de rango en "OL"

todas las funciones:

Ambiente operacional:

Humedad relativa: 32 a 122°F (0 a 50°C) a HR<80%

Ambiente de almacenamiento: 32 a 122°F (0 a 50°C) a HR<80%

Construcción del estuche: ABS, clasificación UL de 94 V/0/5 VA

Altitud: 6561.7 pies (2000 m)

Dimensiones: 6.4 x 3 (W) x 1.4" (D)

162 (long.) x 76 (ancho) x 36 (prof.) mm

Peso: 9.4 onzas (267 g)

Seguridad: UL61010B-1, Cat III-300 V

UL-1436 para AFCI, GFCI y tomacorriente

Accesorios: Incluye adaptador con enchufe de 1 pie (30 cm),

estuche de transporte y manual de instrucciones.

Disponible un adaptador de pinzas cocodrilo

opcional.

Aislamiento doble

Este instrumento ha sido evaluado y se comprobó que cumple la categoría de aislamiento

III (categoría de sobretensión III). Grado 2 de contaminación, de acuerdo a IEC-644. Uso

en interiores.

Especificaciones de las mediciones:

Todas las especificaciones son a 23 ± 5°C con menos de 80% de humedad relativa. La

precisión se expresa como ± ([% del rango] + [unidades]).

El convertidor de CA es de detección de valor eficaz verdadero.

ND 5481-6 61-164 165 Ins 8/28/08 1:55 PM Page 31

CUS

Page 17

pris : câblage correct, inversion de polarité, inversion de conducteurs chargé/de terre et

absence de terre selon la norme UL-1436. Un simple menu donne accès aux mesures de tension de secteur, de chute de tension sous pleine charge, de tension terre-neutre et d'impédances de ligne. Le contrôle du disjoncteur de fuite de terre s'effectue séparément selon la

norme UL-1435 et perturbe l'alimentation en présence d'un différentiel fonctionnel.

Le SureTest®à interruption de circuit sur défaut d'arc N° 61-165 effectue également le contrôle des interrupteurs de circuits sur défaut d'arc (ICDA) afin de vérifier que les disjoncteurs

protégeant le circuit ont été installés correctement. Cet essai perturbe l'alimentation électrique

en présence d'un interrupteur de circuits sur défaut d'arc fonctionnel. Cet outil vérifie l'existence éventuelle d'un état de neutre partagé entraînant le déclenchement intempestif de l'ICDA.

Pour préserver les précisions énoncées pendant l'usage répété, attendre 20 secondes entre les

insertions afin de dissiper adéquatement la chaleur accumulée lors de l'essai de charge.

Analyseur de circuit

SureT est

1. Structure du menu

2. Boutons de navigation

3. Bouton de contrôle de

disjoncteur de fuite de terre

4. Bouton de contrôle d'ICDA

Navigation du menu

Les priorités principales du microprocesseur consistent à relever des mesures sous tension

et à analyser les données. C'est pourquoi, il peut se produire que la puce ne reconnaisse

pas les boutons du pavé numérique quand on les actionne en succession rapide pendant

qu'elle exécute ces routines. Pour éviter ce problème, maintenir le bouton du pavé

numérique enfoncé à chaque fois jusqu'à ce que le menu change.

Les mesures relevées par le SureTest sont subdivisées dans cinq menus principaux positionnés sur le côté gauche de l'affichage : Configuration de câblage (•••), Tension (V),

Chute de potentiel (VD), Intensité (A) et Impédance (Z). Pour naviguer vers chacun de ces

menus principaux, utiliser le bouton à flèche descendante ( ).

L'écran de Configuration de câblage (•••) indique le câblage correct, la polarité inversée,

inversion des fils actif/terre et absence de terre en ordonnant les trois boules. L'étiquette

figurant au verso du produit explique les indications sur l'ordre de câblage.

33

#61-164

#61-165

#61-165

GFCI

AFCI

RM

S

True

S

u

r

e

e

T

s

t

SureTest®

Circuit Analyzer

Introduction

A l'aide d'une technologie brevetée, les analyseurs de circuits

SureTest® « regardent à travers les murs » pour identifier les

problèmes de câblage susceptibles d'entraîner des risques d'électrocution des personnes,

des incendies d'origine électrique ou un mauvais fonctionnement du matériel. Les risques

d'électrocution des personnes résultent d'une mauvaise mise à la terre, de fausses terres ou

d'une protection inexistante contre les fuites à la terre. Les incendies d'origine électrique

sont causés principalement par des défauts d'arc et des points de résistance élevée provoquant des connexions incandescentes dans le câblage du circuit. Quant aux problèmes de

fonctionnement, ils résultent de l'insuffisance de la tension disponible sous la charge, d'une

mauvaise impédance de terre et d'une tension terre à neutre élevée. En fait, on estime que

80 % des problèmes de rendement dus à la qualité de l'alimentation sont liés aux problèmes de câblage défectueux énoncés ci-dessus.

Caractéristiques du produit

• Valeurs efficaces vraies

• Mesure les chutes de tension sous des charges de 12, 15 et 20 A.

• Mesure la tension : de secteur, de terre à neutre, de crête, fréquence

• Mesure les impédances des conducteurs de phase, neutre et de terre

• Identifie le câblage dans les prises à 3 fils

• Identifie les fausses terres (terre au neutre)

• Contrôle le bon fonctionnement des disjoncteurs de fuite de terre.

• Contrôle le bon fonctionnement des interrupteurs de circuits sur défaut d'arc (ICDA)

(61-165)

• Identifie les neutres partagés qui entraînent le déclenchement intempestifs des

interrupteurs de circuits sur défaut d'arc (61-165)

• Vérifie les circuits spécialisés (avec l'adaptateur 61-176)

• Comprend une rallonge de 30 cm (1 pi) et un étui de transport

Fonctionnement général

Il ne faut que quelques secondes à l'analyseur de circuit SureTest®pour tester chaque prise et

circuit sous une pleine charge. Cet outil d'essai contrôle plusieurs états de câblage, y com-

Analyseur de circuit SureTest

®

Manuel d'instructions

AVERTISSEMENT: Ne pas utiliser sur des prises de système d'alimentation permanente, sur des gradateurs de lumière ou sur du matériel générateur de signaux carrés

cela risquant d'endommager l'analyseur.

#61-165

GFCI

AFCI

RMS

True

S

u

r

e

e

T

s

t

SureTest®

Circuit Analyzer

2

3

4

1

34

ND 5481-6 61-164 165 Ins 8/28/08 1:55 PM Page 33

Page 18

36

Procédure de contrôle

Contrôle de câblage

Dès son introduction dans une prise, le SureTest affiche le

logo IDEAL pendant qu'il exécute une série de contrôles. Le

premier résultat affiché est l'état du câblage. Le SureTest

contrôle les états suivants et affiche le résultat du contrôle.

Etat du câblage Indication de l'affichage

HGN

Câblage correct

Pas de terre

Inversion de polarité

Ouvert/Actif Neutre

Fausse terre

Si l'état de câblage est autre que normal, le SureTest est limité quant aux mesures

susceptibles d'être exécutés. S'il n'y a pas de terre, seules les mesures de tension de

secteur et de chute de tension sont disponibles. Dans un état d'inversion d'actif/terre,

de neutre ouvert ou d'actif ouvert, l'appareil ne sera pas alimenté et son affichage

demeurera vide.

Remarques :

1) Ne détecte pas deux fils sous tension dans un circuit.

2) Ne détecte pas une combinaison de défauts.

3) Ne détecte pas l'inversement des connecteurs à la terre et de mise à la terre.

Indication de fausse terre

Le Sure Test signale un état de fausse terre dû à une métallisation inadéquate résultant d'un

pontage la terre et le neutre (cavalier de terre au dispositif de prise) ou d'un contact involontaire entre le fil de terre et la connexion neutre. Noter que si le SureTest est à une distance

comprise entre 5 et 7 mètres du tableau principal, l'appareil signalera un état de fausse terre

sur un circuit adéquatement câblé du fait de sa proximité immédiate avec la bonne métallisation terre-neutre du tableau principal.

Mesures de tension

La tension de secteur doit être de 120 V c.a. avec une fluctuation de +/- 10 % à 60 Hz. La tension de crête doit être équivalente à1,414 fois la lecture de tension efficace de secteur pour une

forme d'onde sinusoïdale propre. La tension terre à neutre doit être inférieure à 2 V c.a. Dans

un circuit uniphasé, une tension terre-neutre élevée indique des fuites excessives de courant

entre les conducteurs neutre et terre. Dans un circuit triphasé avec un neutre partagé, une ten-

Légende

Allumé

Eteint

Clignotant

F

Le menu de tension (V) affiche en temps réel la véritable tension efficace de secteur. Ce menu

principal a un sous-menu positionné horizontalement en bas de l'écran qui affiche la tension

de ligne (RMS HN), la tension terre-à-neutre (RMS GN), la tension de crête (Peak), et la

Fréquence (Hz). Pour naviguer dans le sous-menu, utiliser le bouton à flèche latérale ( ).

L'écran de Chute de tension (VD) affiche simultanément le pourcentage de chute de tension

avec une charge de 15 A et la tension chargée (VL) résultante. Ce menu a un sous-menu qui