Page 1

WARNING!

1. DO NOT UNDER ANY CIRCUMSTANCES EXCEED

THESE RATINGS:

-Voltage is not to exceed 600V AC or DC.

- Resistance, Capacitance, Logic, and Continuity

functions are not to be performed on circuits capable

of delivering greater than 500V AC or DC.

- Current measurements are not to be performed on

circuits capable of delivering greater than 600V AC

on insulated conductors, 250V AC on uninsulated

conductors.

2. To avoid electrical shock hazards and/or damage to the

meter:

- Do not exceed the voltage ratings for the meter. Use

caution when measuring voltage.

- Do not use during electrical storms. AC power

sources with inductive loads or electrical storms may

result in high voltage. High energy transients can

damage meter and present a dangerous shock hazard.

-Turn off the power to the circuit or device being measured before taking resistance and capacitance measurements. Fully discharge all capacitors before

measuring.

3. Ensure meter is in proper working order before using.

Visually inspect meter for damage. Performing a continuity check can verify proper operation. If the meter

reading goes from overload to zero, this typically means

the meter is in proper working order.

4. Visually inspect leads for damage before using. Replace

if insulation is damaged or leads appear suspect.

5. Never ground yourself when taking electrical measurements. Do not touch exposed metal pipes, outlets, fixtures, etc. Keep your body isolated from ground by

using dry clothing, rubber shoes, rubber mats, or any

other approved insulating material. Keep your fingers

behind the finger guards on the probes. Work with others.

6. Before beginning all unknown measurements, set meter

to the highest range possible.

Page 2

#61-361

IDEAL Test Pro

®

360 Series True RMS

Multimeter

Page 2

Page 4Page 3

WARNING! (cont.)

7. Before breaking a circuit for testing, turn off the power to

the circuit. When disconnecting from a circuit, disconnect the hot lead first, then the common lead.

8. Disconnect the meter from the circuit before turning off

any indicator, including motors, transformers,and solenoids.

Overload Protection

VAC+ V

DC

200m Vrange 500VDC/350VAC

for 15 sec

>200m Vrange 600V AC/DC

A

AC

+ A

DC

mA input 0.5A/250V

10A input 10A/600V

Ohms (Ω) 500V AC/DC

Diode 500V AC/DC

Continuity 500V AC/DC

Capacitance

(MFD) 500V AC/DC

Frequency

(Hz) 500V AC/DC

Phase Rotation (RST) 500V AC/DC

Unit of Measure Multipliers

For your reference, the following symbols are often used to

make measurement easier:

Symbol Verbal Multiplier

M mega x1,000,000

k kilo x1,000

m milli ÷1,000

µ micro ÷1,000,000

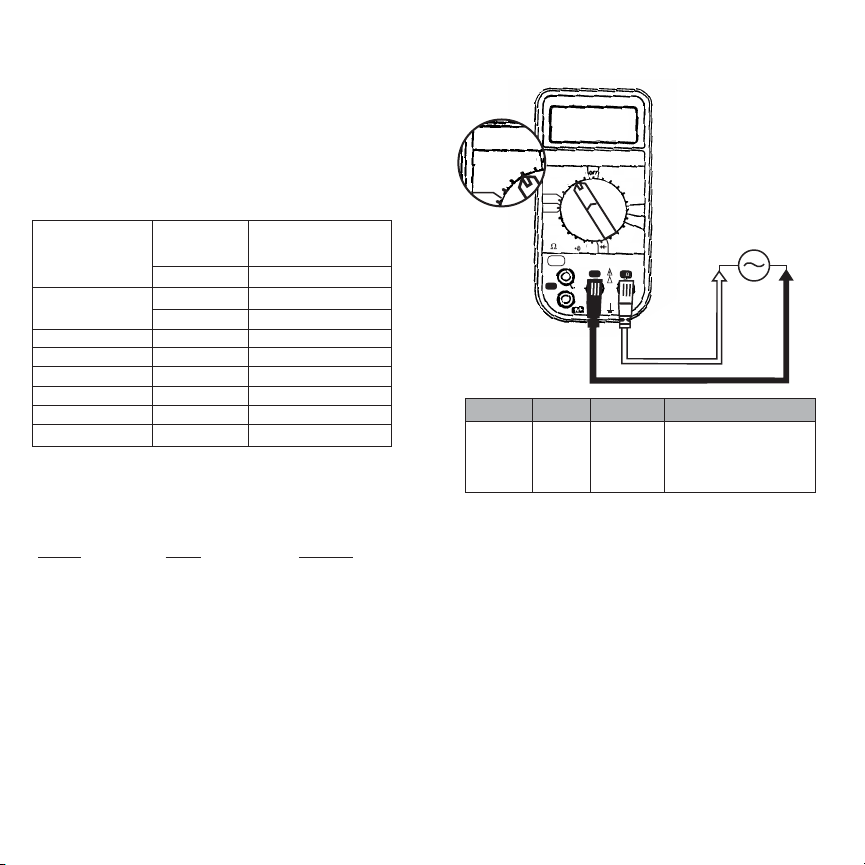

AC Voltage (VAC)

Function Range Resolution Accuracy

AC Voltage 200.0 mV .1 mV

2000 mV 1 mV

200.0 V .1V

600 V 1 V

To Measure AC Voltage:

1. Plug the test leads into the meter inputs as indicated in the

above diagram.

2. Select the proper range to be used within the VAC Function.

3. Connect the meter in parallel with the load or circuit.

4. Measure AC voltage.

VAC

PHASE ROTATI

HZ-MFD-A

2000m

RST

200m

200

600

Black

Red

±(2.0% + 4)

50 to 500Hz

all ranges

PHASE ROTATION-TRUE RMS

HZ-MFD-AUTO OFF

600600

VAC

2000m

200m

RST

Hz

200M

20M

200k

2A

MFD

R/L1

VDC

200

200

20

2000m

200m

ADC

AAC

200

2k

20k

20k

2k

200

MFD

CAT. LLL 600V

COM

V

!

MAX

2A

600V

FUSED

MAX

350V/15

SEC FOR

200mV

RANGE

Page 3

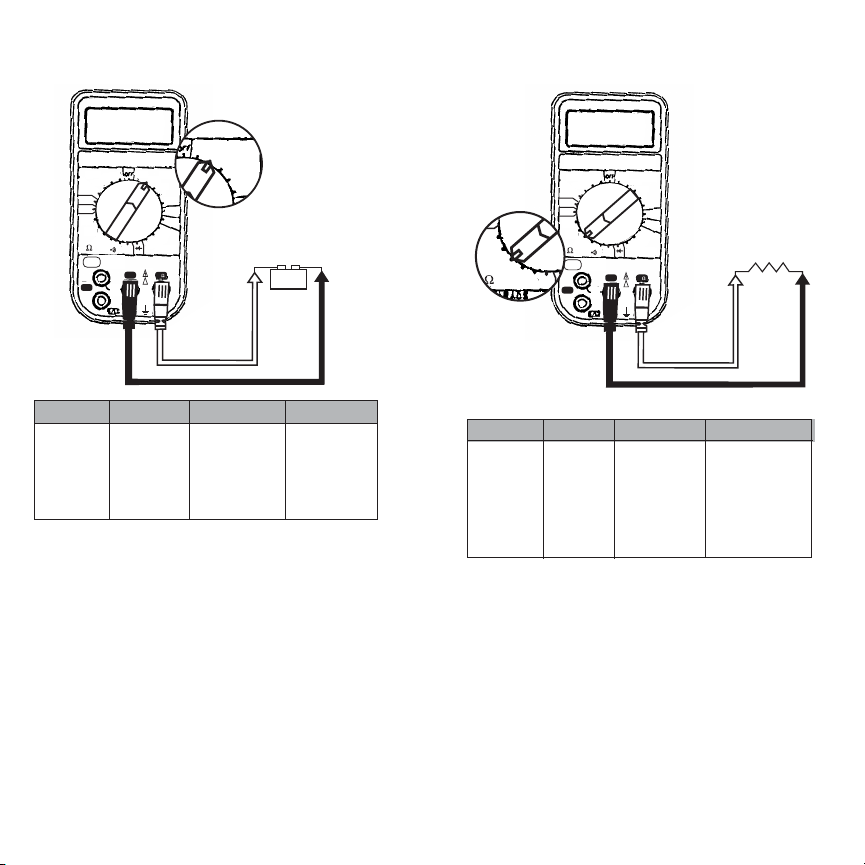

DC Voltage (VDC)

Function Range Resolution Accuracy

DC Voltage 200.0 mV .1 mV

2000 mV 1 mV

20.00 V .01 V

200.0 V .1 V

600 V 1 V

To Measure DC Voltage:

Do not attempt to measure voltage in circuits capable of delivering

more than 600V.

1. Plug the leads into meter inputs as indicated in the

diagram above.

2. Select the proper range to be used within the VDC Function.

3. Connect the meter in parallel with the load or circuit.

4. Measure DC voltage.

Page 5

Page 6

Resistance (Ohms)

Function Range Resolution Accuracy

Resistance 200.0Ω .1Ω ±(1.5% + 4)

2.000kΩ .001kΩ ±(1.5% + 4)

20.00kΩ .01kΩ ±(1.5% + 4)

200.0kΩ .1kΩ ±(1.5% + 4)

20.00MΩ .01MΩ ±(2.5% + 4)

200.0MΩ .1 MΩ ± (5.0% +20)

To Measure Resistance:

Resistance is measured in Ohms.

1. Turn the power off to the circuit or device that is to be measured and discharge all capacitors before attempting a measurement.

2. Plug the red test lead into the “V-

Ω” meter input.

3. Plug the black test lead into the “Com” meter input.

4. Select the proper range within the Ω function of the tester.

VDC

ADC

2000m

20

200

600

Black

Red

20M

20k

200k

2k

Hz

200M

200

Black

Red

± (1.2% +1)

all ranges

PHASE ROTATION-TRUE RMS

HZ-MFD-AUTO OFF

600

600

VAC

2000m

200m

RST

Hz

200M

20M

200k

2A

MFD

R/L1

VDC

200

200

20

2000m

ADC

200

2k

20k

20k

2k

200

MFD

CAT. LLL 600V

COM

V

!

MAX

2A

600V

FUSED

MAX

350V/15

SEC FOR

200mV

RANGE

+

-

PHASE ROTATION-TRUE RMS

HZ-MFD-AUTO OFF

600600

VAC

2000m

200m

RST

Hz

200M

20M

200k

2A

MFD

R/L1

VDC

200

200

20

2000m

200m

ADC

AAC

200

2k

20k

20k

2k

200

MFD

CAT. LLL 600V

COM

V

!

MAX

2A

600V

FUSED

MAX

350V/15

SEC FOR

200mV

RANGE

Page 4

Page 8

Page 7

Resistor Color Code Table

1st 2nd Tolerance

Color Digit Digit Multiplier (Percentage)

Black 0 0 1

Brown 1 1 10

Red 2 2 100

Orange 3 3 1,000

Yellow 4 4 10,000

Green 5 5 100,000

Blue 6 6 1,000,000

Violet 7 7 10,000,000

Gray 8 8 100,000,000

White 9 9 1,000,000,000

Gold +/- 5%

Silver +/- 10%

No Color +/- 20%

Example:

1st color band is blue so the first digit is a 6

2nd color band is red so the second digit is a 2

3rd color band is yellow so multiply 62 x 10,000

4th color band is gold so the tolerance is ±5%

Your Resistor value is 620,000 Ohms (620kΩ) with a tolerance

of ±5%.

5. Measure resistance. If necessary, perform the required multiplication to acquire the actual resistance.

5.1 Range Guide for Ohms (Ω):

200 = Meter indicates actual resistance

2k = Multiply meter display reading by 1,000 to

acquire actual resistance.

20k = Multiply meter display reading by 1,000 to

acquire actual resistance.

200k = Multiply meter display reading by 1,000 to

acquire actual resistance.

2M = Multiply meter display reading by

1,000,000 to acquire actual resistance

200M = Multiply meter display reading by

1,000,000 to acquire actual resistance.

6. The meter displays total resistance through all possi-

ble paths between the probe-tips. These multiple

paths may result in measurements that do not correspond to the ohm value indicated by the resistor

color code.

Determining Resistor Values:

To determine the value of a resistor, use the color bands on the

resistor and the table on the following page.

Blue

Red

Yellow

Gold

Page 5

Page 10Page 9

Diode Verification

Function Range Resolution Accuracy

Diode Test 2 VDC 1 mV ± (3.0% + 1)

Diode Testing:

To ensure a proper functioning diode, the meter will develop a

voltage across the component from a test current. The diode

test function allows measurements of forward and reverse bias

across diodes and transistor junctions.

1. Turn off power to the device or circuit that is being tested

and discharge all capacitors.

2. Plug the leads into the meter inputs as indicated in the

above diagram.

3. Select the diode function on the meter.

4. Check the forward bias of the diode by connecting the red

test probe to the anode (+) and the black test probe to the

cathode (-) of the diode. Read the forward voltage drop on

the meter display.

4.1 A good silicone diode will result in a reading

around 0.7 V.

4.2 A good germanium diode will result in a reading

around 0.3 V.

4.3 A short is indicated by a continuous beep and a

reading of .000 V.

4.4 An open is indicated by an “OL” reading.

5. Check the reverse bias of the diode by reversing the test

lead connections to the diode (red probe to cathode and

black probe to anode).

5.1 A reading of “OL” indicates reverse blocking and a

good diode.

5.2 A reading of .000 V and a continuous beep indicates

high reverse leakage current or a short.

VAC

PHASE ROTATION-TRUE RMS

HZ-MFD-AUTO OFF

VDC

ADC

AAC

2000m

20

20M

20k

200k

2k

2000m

RST

Hz

200m

200M

200

200

600600

200m

200

20k

2k

200

2A

MFD

!

600V

MAX

350V/15

SEC FOR

200mV

RANGE

CAT. LLL 600V

R/L1

COM

V

MAX

2A

FUSED

MFD

Forward Bias

+

-

+

-

Reverse Bias

A

A

2k

200

20k

2k

200

MFD

Black

Red

Page 6

Page 12

Page 11

Continuity Beeper

(beeps at resistance <150Ω)

To Verify Continuity:

A continuity test ensures that all circuit connections are intact.

1. Plug the test leads into the meter inputs as indicated in the

diagram above.

2. Turn the power off to the circuit or device that is to be verified.

3. Select the continuity function on the meter. See

switch position below. The continuity function is located at

the 2kΩ setting.

4. Test for continuity by connecting the meter to the circuit.

5. If the beeper sounds, the circuit is complete.

20k

200k

2k

200

20k

D

Black

Red

Current (AAC and ADC)

Function Range Resolution Accuracy

AC Current 2.000 A .001 A ± (3.0% + 4)

DC Current 2.000 A .001 A 50 to 500Hz

To Measure Current:

Current is measured in amps.

Do not attempt to measure current in circuits capable of delivering greater than 600V.

1. Connect the test leads into the meter inputs as indicated in

the diagram above.

2. Select the AAC or ADC function.

3. Turn the power off.

4. Connect the meter in series with the load or circuit.

5. Turn power on.

6. Measure the Current.

ADC

AAC

200m

20k

2k

200

MFD

Black

Red

PHASE ROTATION-TRUE RMS

HZ-MFD-AUTO OFF

600600

VAC

2000m

200m

RST

Hz

200M

20M

200k

2A

MFD

R/L1

VDC

200

200

20

2000m

200m

ADC

AAC

200

2k

20k

20k

2k

200

MFD

CAT. LLL 600V

COM

V

!

MAX

2A

600V

FUSED

MAX

350V/15

SEC FOR

200mV

RANGE

PHASE ROTATION-TRUE RMS

HZ-MFD-AUTO OFF

600600

VAC

2000m

200m

RST

Hz

200M

20M

200k

2A

MFD

R/L1

VDC

200

200

20

2000m

200m

ADC

AAC

200

2k

20k

20k

2k

200

MFD

CAT. LLL 600V

COM

V

!

MAX

2A

600V

FUSED

MAX

350V/15

SEC FOR

200mV

RANGE

Page 7

Frequency (Hz)

Function Range Resolution Accuracy

Frequency 10 Hz to 100 kHz for AC

10 Hz to 100 Hz for DC* .001 kHz

±(2% + 3 digits)

Sensitivity : 3.5 V rms

Frequency is measured in Hertz:

Do not attempt to measure frequency in circuits capable of

delivering greater than 600V.

1. Plug test leads into the meter inputs as indicated in the

diagram above.

2. Select the Hz function on the meter.

3. Connect the meter in series with the load or circuit.

4. Measure the frequency.

Page 14

Page 13

Phase Rotation (RST)

Function Frequency Range Voltage Range

Phase LCD indicates

Rotation sequence of

Indicator three-phases.

To Determine Phase Rotation (RST):

This test function correctly identifies each of the 3-Phases in a

power panel as R, S, T. Note: The displayed numerical value has

no meaning when performing this procedure. Maximum 3 phase

voltage allowed in this mode is 500 VAC.

1. Turn power off to the circuit that is to be tested.

2. Place the function switch on the meter to “RST.”

3. Plug the test leads into the meter inputs labeled as R, S, T in

the diagram above. Note that test lead colors are insignificant.

4. Attach the three test leads to each of the 3-Phase cables in

any order.

5. Turn the power on.

6. If all three supply lines have power, the meter will indicate a

R, S, T (in the upper left corner).

VAC

20M

2000m

RST

Hz

200m

200M

200

20M

200k

2000m

RST

Hz

200m

200M

Red

Black

*DC Voltage higher than 3.5 V rms

80V to 500V

50 Hz to 500 Hz

PHASE ROTATION-TRUE RMS

HZ-MFD-AUTO OFF

VAC

200

2000m

200m

RST

Hz

200M

20M

200k

20k

2k

200

2A

MFD

COM

MAX

R/L1

2A

FUSED

600600

CAT. LLL 600V

PHASE ROTATION-TRUE RMS

HZ-MFD-AUTO OFF

600600

VAC

VDC

200

20

2000m

200m

ADC

AAC

200

2k

20k

MFD

V

!

600V

MAX

350V/15

SEC FOR

200mV

RANGE

2000m

200m

RST

Hz

200M

20M

200k

2A

MFD

R/L1

R

VDC

200

200

20

2000m

200m

ADC

AAC

200

2k

20k

20k

2k

200

MFD

CAT. LLL 600V

COM

V

!

MAX

2A

600V

FUSED

MAX

350V/15

SEC FOR

200mV

RANGE

T

S

Page 8

Phase Rotation (continued)

7. If the meter indicates “OK” in the display (upper left-hand side),

a. Turn power off to the circuit.

b. Label each phase cable as R, S, or T following the test

lead connections to the labeled meter inputs.

8. If the meter indicates an message in the display (lower

left-hand side), the phase rotation is counter-clockwise.

a. Turn power off to the circuit.

b. Switch any two test lead connections to the phase cables.

c. Turn power on.

d. The meter will now indicate “OK” in the display.

e. Turn the power off.

f. Label each phase cable as R, S, or T following the test

lead connections to the labeled meter inputs.

Capacitance (MFD)

Function Range Resolution Accuracy

Capacitance 200.0 µF .1 µF

2.000 mF .001 mF

20.00 mF .01 mF

To Measure Capacitance:

Capacitance is measured in micro-farads (MFD). Turn off

power and discharge the capacitor before attempting a measurement. The meter measures capacitance by charging the

capacitor with a predetermined current, measuring the resultant

voltage, and then calculating the capacitance.

1. Plug the test leads into the meter inputs as indicated in the

diagram above.

2. Select the proper range to be used within the MFD area on

the meter.

3. Connect the red test lead to the anode (+) of the capacitor,

and the black test lead to the cathode (-) of the capacitor.

4. Measure capacitance.

Page 16

Page 15

ADC

AAC

200m

200

20k

2k

200

MFD

Black

Red

±(4.0% + 10)

all ranges

PHASE ROTATION-TRUE RMS

HZ-MFD-AUTO OFF

600600

VAC

2000m

200m

RST

Hz

200M

20M

200k

2A

MFD

R/L1

VDC

200

200

20

2000m

200m

ADC

AAC

200

2k

20k

20k

2k

200

MFD

CAT. LLL 600V

COM

V

!

MAX

2A

600V

FUSED

MAX

350V/15

SEC FOR

200mV

RANGE

Page 9

Accessories

Optional Clamp Adaptor

To Use Accessories:

Clamp adapters allow multimeters the versatility to measure

large amounts of current safely through a clamphead. IDEAL

clamp adapters convert amps measured into mV signals that the

multimeter can display. Since the clamp adapters convert the

amps measurement into mVAC, the clamp adapter leads must

be inserted into the volts and com inputs and the meter must

be set to the mVAC range. The conversion ratio is one-to-one

(1Amp=1mV). So, when the meter displays 50.0 mV, the clamp

adapter is measuring 50.0 Amps.

For 300 AAC Current Clamp (61-450) with model 61-363:

1. Plug test leads into the meter inputs as indicated in the

diagram above.

2. Remove the probe tips from the end of the leads.

3. Attach the leads to the current clamp (polarity will not affect

reading).

4. a. Select 200 mVAC range for measuring less than 200 Amps.

b. Select 2000 mVAC range for measuring more than 200 Amps.

5. Snap the jaw of the current clamp around one of the current

carrying conductors.

6. Take the reading.

For all other Clamp Adaptors (61-451, 61-334, 61-436):

1. Plug test leads into the meter inputs as indicated in the

diagram above.

2. a. Select 200 mVAC range for measuring less than 200 Amps.

b. Select 2000 mVAC range for measuring more than 200 Amps.

3. Snap the jaw of the current clamp around one of the current

carrying conductors.

4. Take the reading.

General Specifications:

Indicators: Continuity: (<150Ω) indicated by a continuous

“beep” within 100 msec. Low Battery indicator displayed in the

LCD when battery is below operating range. Overrange: “OL”

displayed.

Environmental: Operating temperature 32°F to 122°F, storage

0°F to 140°F with batteries removed, RH<70%.

LCD: 3.5 digits.

Size: 4.0”W x 7.5”H x 2.5”D

Weight: 18 oz. including battery.

Battery life: >200 hours typical (9V NEDA 1604 type, JIS006P,

IEC6F22 battery).

Accessories: Comes with a pair of test leads ground lead with

clip, operator’s manual, and battery.

Overload Protection: 600V for DCV, ACV, and phase indication. 500VAC/500VDC for capacitance, ohms, frequency and

diode test. Current protected by 2A/600V (6.35mm x 25.4mm)

fuse model LA-3893 and 0.1A/250V (5mm x 20mm) fuse model

LA-3898.

User Maintenance

Regular operator maintenance of the multimeter consists of

cleaning case and window, and battery replacement. All other

repairs must be performed by a factory service center or other

qualified instrument service personnel.

Cleaning Case and window

Periodically wipe the case with a damp cloth and detergent,

allow to dry completely before using; do not use abrasives or

solvents.

Battery Replacement

When the multimeter displays the the battery must be

replaced to maintain proper operation.

Page 18

Page 17

VAC

PHASE ROTATION-TRUE RMS

HZ-MFD-AUTO OFF

VDC

ADC

AAC

2000m

20

20M

20k

200k

2k

2000m

RST

Hz

200m

200M

200

200

600600

200m

200

20k

2k

200

2A

MFD

!

600V

MAX

350V/15

SEC FOR

200mV

RANGE

CAT. LLL 600V

R/L1

COM

V

MAX

2A

FUSED

MFD

VAC

2000m

RST

Hz

200m

200

Black

Red

Page 10

WARNING

To prevent electrical shock hazard, turn off the multimeter and disconnect test leads before removing the back cover.

1. Disconnect the test leads and turn the meter off. Remove the

test leads from the front terminals.

2. Position the meter face down. Remove the screws from the

case bottom.

3. Lift the end of the case back until it gently unsnaps.

4. Lift the battery from the case back.

5. Replace battery.

6. Replace the case top. Reinstall screws.

Fuse Replacement

1. Disconnect the test leads and turn the meter off. Remove the

test leads from the front terminals.

2. Position the meter face down. Remove the screws from the

case back.

3. Lift the end of the case back until it gently unsnaps.

4. Remove the fuse by gently prying one end of the fuse loose and

sliding the fuse out of the bracket.

5. Verify continuity across the fuse.

6. If the fuse is good, return to tester.

7. If the fuse is blown, install a new fuse of the same size and rating.

8. Replace the case top. Reinstall screws.

Troubleshooting

The meter has been designed to be accurate, reliable and easy-touse. However, it is possible that you may experience difficulties

during operation. If there appears to be any kind of problem during

use of the multimeter, please perform the following steps to help

determine the source:

1. Review and comply with the operating instructions section of

this instruction manual.

2. Test the battery, replace as necessary.

3. Test the fuses, replace as necessary.

4. Check to see that the Function/Range Switch is in the correct

position for the type of parameter and range of values being

measured, and that the measurement value is within the capability of the multimeter.

5. Inspect the test leads for breaks or cracks, and ensure that the

test leads are inserted fully into the input connectors.

6. If problem persists, meter should be inspected by a qualified

service person.

Page 19

LIFETIME LIMITED WARRANTY

This meter is warranted to the original purchaser against defects

in material or workmanship. During the warranty period, IDEAL

INDUSTRIES, INC. will, at its option, replace or repair the defective unit, subject to verification of the defect or malfunction.

This warranty does not apply to defects resulting from abuse,

neglect, accident, unauthorized repair, alteration, or unreasonable

use of the instrument.

Any implied warranties arising out of the sale of an IDEAL product, including but not limited to implied warranties of merchantability and fitness for a particular purpose, are limited to the

above. The manufacturer shall not be liable for loss of use of the

instrument or other incidental or consequential damages,

expenses, or economic loss, or for any claim or claims for such

damage, expenses, or economic loss.

State laws vary, so the above limitations or exclusions may not

apply to you. This warranty gives you specific legal rights, and

you may also have other rights which vary from state to state.

Page 20

Loading...

Loading...