Page 1

Page 2

2

Systemiser SE - Installation

Systemiser SE:

The condensing system boiler

The Ideal Systemiser SE is a wall mounted, fanned flue condensing system

boiler which serves a home's central heating system. It has been designed to

be 'friendly' to the user, installer and service engineer.

Systemiser SE:

The fit anywhere system boiler

Simple fanned 'go anywhere' flue

The Systemiser SE's flue turret simply rotates through 360° to allow horizontal

outlet in any direction. Options include horizontal flue length extensions or

simple vertical flue kits - and the flue is self-sealing, eliminating the need for

outside assembly - an important benefit in high-rise applications.

Downward or upward connections...

Water and gas connections have been designed to be as simple and fast as

possible. The Ideal Systemiser SE comes complete with a rugged mounting

frame which when fitted with the stand-off brackets can accommodate

downward or upward routed gas, water and electrical connections before the

boiler is fitted.

...and it fits inside a cupboard

Its compact size makes the Systemiser SE ideal for any kitchen. It can be

installed inside a cupboard without any ventilation.

Systemiser SE:

The system boiler you can rely on

The Systemiser SE has been designed and developed with reliability as the

number one priority. But even the finest engineered product may develop a

fault at some stage in its lifetime. To support the Systemiser SE we have

created the Ideal Care Guarantee which sets out our target to repair any fault

next day.

Free Guarantee: 1st Year Ideal Care

The home owner is entitled to 12 months free Ideal Care, which includes both

parts and labour, to restore the boiler to full function. Please encourage the

home owner to complete and return the registration form in their Householder's

pack within 30 days of installation.

Optional Extra Year Cover with Ideal Care

You may wish to offer your own annual service plan or you may wish to advise

the home owner to complete their application form for the appropriate level of

extended Ideal Care - Silver, Gold or Platinum. Full details are available in

the Ideal Care brochure.

Page 3

3

Systemiser SE - Installation

Gas supply 2H

Gas Supply Connection 22mm copper

Flow Connection Central Heating 22mm copper

Return Connection Central Heating 22mm copper

Flue Terminal Diameter 100 mm

Maximum Working Pressure (Sealed Systems) 2.65 bar

Electrical Supply / Power consumption 230 V ~ 50 Hz. / 126 W

Fuse Rating External : 3A Internal : F2A

Water content Central Heating 2.2 litre

Dry Weight 46.5 Kg

Maximum Installation Weight 38.5 Kg

Boiler Casing Size Height 800 mm

Width 450 mm

Depth 300 mm

Table 1 - General Data

GENERAL

Table 2 - Performance Data - Central Heating

Min. Max.

Boiler Input :

Nett CV kW 10.1 25.1

Btu/h 34 500 85 700

Gross CV kW 11.2 27.9

Btu/h 38 200 95 200

Gas Consumption l/s 0.29 0.72

ft

3

/h 36.8 91.5

Boiler Output :

70

o

C Mean Water Temp kW 9.6 24.0

Btu/h 32 800 81 900

40 oC Mean Water Temp kW 10.9 25.7

Btu/h 37 200 87 700

Burner Setting Pressure mbar 2.0 13.0

(HOT) in. w.g. 0.8 5.2

Seasonal Efficiency

(SEDBUK) * [88.4]%

CAUTION.

To avoid the possibility of injury during the installation, servicing or cleaning of

this appliance, care should be taken when handling edges of sheet steel components.

KEY TO SYMBOLS

IE = Ireland (Countries of

GB = United Kingdom destination)

PMS = Maximum operating pressure of water

C13 = A room sealed appliance designed for connection via

ducts to a horizontal terminal, which admits fresh air to

the burner and discharges the products of combustion

to the outside through orifices which, in this case, are

concentric. The fan is up stream of the combustion

chamber.

I

2H

= An appliance designed for use on 2nd Family gas,

Group H only.

Note. Gas consumption is calculated using a calorific value of

38.7 MJ/m

3

(1038 Btu/ft3) gross or 34.9 MJ/m3 (935 Btu/ft3) nett

To obtain the gas consumption at a different calorific value:

a. FOR L/S - divide the gross heat input (kW) by the gross

C.V. of the gas (MJ/m

3

)

b. FOR FT3/H - divide the gross heat input (Btu/h) by the gross

C.V. of the gas (Btu/ft3)

*The value is used in the UK Government's Standard

Assessment Procedure (SAP) for energy rating of dwellings.

The test data from which it has been calculated have been

certified by Gastech NV0061.

Page 4

4

Systemiser SE - Installation

CONTENTS

INTRODUCTION

The Systemiser SE is a wall mounted, low water content,

balanced flue, condensing system boiler.

Note. Due to the high efficiency of the boiler a plume of

water vapour will form at the terminal during operation.

Central Heating (CH) output is fully modulating between

9.6 kW (32 800 Btu/h) minimum and 24 kW (81 900 Btu/

h) maximum.

The boiler is supplied fully assembled with circulating

pump, pressure gauge, safety valve and central heating

(CH) expansion vessel.

A variable CH temperature control is fitted.

The boiler casing is of white painted mild steel with a

dropdown controls door.

The boiler controls are located behind the controls door.

The heat exchanger is of aluminium.

The boiler is suitable for connection to fully pumped,

sealed water systems ONLY. Adequate arrangements for

completely draining the system, by provision of drain

cocks, MUST be provided in the installation pipework.

OPTIONAL EXTRA KITS

Extension Flue Kit - Pack D

Roof Flue Kit - for vertical flue connection

Powered Vertical - for extended vertical flue connection

Flue

Flue Elbow Kits - 90 degree

- 45 degree (2 per box)

Siphon Kit - Pack S

Refer to the separate fitting instructions supplied with

each kit.

Systemiser SE (natural gas only) .......... G.C. Appliance No. 41 349 70

Gastec Certification ............................. P.I. No. 0063 AS 3355 Destination Countries: GB and IE

Air Supply ........................................................................ 6

Boiler Clearances ............................................................ 9

Boiler Exploded Diagram ............................................. 12

Commissioning and Testing ........................................ 33

Condensate Drain ......................................................... 11

Electrical Connections ................................................. 29

Electrical Supply ............................................................. 9

Fault Finding ................................................................. 54

Flow Wiring Diagram .................................................... 30

Flue Extensions ............................................................ 26

Flue Installation ............................................................. 15

Flue Lengths & Types ................................................... 14

Gas Safety ........................................................................ 6

Gas Supply ...................................................................... 7

General Data .................................................................... 3

Installation ..................................................................... 12

Mandatory Requirements ............................................... 6

Safety ............................................................................... 6

Sealed System Requirements ...................................... 10

Servicing ........................................................................ 39

Short List of Parts ......................................................... 56

Water and Systems ......................................................... 7

Water Connections ......................................................... 8

Water Treatment .............................................................. 8

Wiring Diagrams .................................................... 30 - 33

NOTE TO THE INSTALLER:

LEAVE THESE

INSTRUCTIONS ADJACENT TO THE GAS METER.

ALSO COMPLETE THE BENCHMARK LOG BOOK

AND GIVE THIS TO THE CUSTOMER.

Page 5

5

Systemiser SE - Installation

GENERAL

OPERATION

When there is a call for CH, the heating system is

supplied at the selected temperature of between 40 oC

and 82 oC,

Refer also to Frame 1- 'Boiler Water Circuit Diagram'.

The boiler features a comprehensive diagnostic system

which gives detailed information on the boiler status when

operating, and performance of key components to aid in

commissioning and fault finding.

1

BOILER WATER CIRCUIT DIAGRAM

Page 6

6

Systemiser SE - Installation

GENERAL

GAS SAFETY

Current Gas Safety (Installation and Use) Regulations,

or rules in force.

It is law that all gas appliances are installed and serviced by a

CORGI registered installer (identified by

) in accordance

with the above regulations. Failure to install appliances

correctly could lead to prosecution. It is in your own interest,

and that of safety, to ensure the law is complied with.

The installation of the boiler MUST also be in accordance with

the latest I.E.E (BS.7671) Wiring Regulations, local building

regulations, bye-laws of the local water authority, the building

regulations and the Building Standards (Scotland) and any

relevant requirements of the local authority.

Detailed recommendations are contained in the following British

Standard Codes of Practice:

BS. 5440:1 Flues (for gas appliances of rated input not

exceeding 60 kW).

BS. 5440:2 Ventilation (for gas appliances of rated input not

exceeding 60 kW).

BS. 5449 Forced circulation hot water systems.

BS. 5546 Installation of gas hot water supplies for domestic

purposes (2nd Family Gases)

BS. 6700 Design, installation testing and maintenance of

services supplying hot water for domestic use.

BS. 6798 Installation of gas fired hot water boilers of rated

input not exceeding 60 kW.

BS. 6891 Low pressure installation pipes.

Health & Safety Document No. 635.

The Electricity at Work Regulations, 1989.

The manufacturer’s notes must NOT be taken, in any way, as

overriding statutory obligations.

SAFE HANDLING OF SUBSTANCES.

Care should be taken when handling the boiler insulation

panels, which can cause irritation to the skin. No asbestos,

mercury or CFCs are included in any part of the boiler.

IMPORTANT. These appliances are CE certificated for safety

and performance. It is, therefore, important that no external

control devices, e.g. flue dampers, economisers etc., are directly

connected to these appliances unless covered by these

Installation and Servicing Instructions or as otherwise

recommended by Caradon Plumbing Limited in writing. If in

doubt please enquire.

Any direct connection of a control device not approved by

Caradon Plumbing Limited could invalidate the certification

and the normal appliance warranty. It could also infringe the

Gas Safety Regulations and the above regulations.

LOCATION OF BOILER AND FLUE OUTLET

The boiler must be installed on a flat and vertical wall, capable

of adequately supporting the weight of the boiler and any

ancillary equipment.

The boiler may be fitted on a combustible wall. Insulation

between the wall and the boiler is not necessary, unless

required by the local authority.

The boiler must not be fitted outside.

Timber Framed Buildings

If the boiler is to be fitted in a timber framed building it should

be fitted in accordance with the Institute of Gas Engineering

document IGE/UP/7:1998.

Bathroom Installations

The boiler may be installed in any room or internal space,

although particular attention is drawn to the requirements of the

current I.E.E. (BS.7671) Wiring Regulations and, in Scotland,

the electrical provisions of the building regulations applicable in

Scotland with respect to the installation of the boiler in a room

or internal space containing a bath or shower.

Where a room sealed appliance is installed in a room

containing a bath or shower then the appliance and any

electrical switch or appliance control utilising mains electricity

should be so situated that it cannot be touched by a person

using the bath or shower.

Note. It is not permissible to install a mains socket in a

bathroom.

Where installation will be in an unusual location, special

procedures may be necessary and BS 6798 gives detailed

guidance on this aspect.

Compartment Installations

A compartment used to enclose the boiler should be designed

and constructed specially for this purpose.

An existing cupboard or compartment may be used, provided

that it is modified for the purpose.

In both cases, details of essential features of cupboard /

compartment design, including airing cupboard installation, are

to conform to the following:

z BS.6798.

z The position selected for installation MUST allow adequate

space for servicing in front of the boiler. Ventilation of the

compartment is not necessary.

z For the minimum clearances required for safety and

subsequent service see the wall mounting template and

Frame 3. In addition, sufficient space may be required to

allow lifting access to the wall mounting plate.

AIR SUPPLY

It is NOT necessary to have a purpose-provided air vent in the

room or internal space in which the boiler is installed. Neither is

it necessary to ventilate a cupboard or compartment in which

the boiler is installed, due to the low surface temperatures of the

boiler casing during operation; therefore the requirements of BS

6798, Clause 12, and BS 5440:2 may be disregarded.

Page 7

7

Systemiser SE - Installation

GENERAL

5. Where the lowest part of the terminal is fitted less than 2m

(6'6") above a balcony, above ground or above a flat roof to

which people have access then the terminal MUST be

protected by a purpose designed guard. The minimum

spacing in Table 3, Nos. 2, 3, 4, 5 and 6 would be 75mm, in

order to allow a terminal guard to be fitted.

Terminals guards are available from boiler suppliers - ask

for Tower Flue Guard, Model K1. In case of difficulty seek

advice from:

Tower Flue Components Ltd.,

Vale Rise, Tonbridge, Kent TN9 1TB

Telephone No. 01732 351 555

Ensure that the guard is fitted centrally.

6. Where the terminal is fitted within 850mm (34") of a plastic

or painted gutter or 450mm (18") of painted eaves then an

aluminium shield at least 750mm (30") long should be fitted

to the underside of the gutter or painted surface fitted

centrally above the flue.

7. The air inlet/products outlet duct and the terminal of the

boiler MUST NOT be closer than 25mm (1") to combustible

material. Detailed recommendations on the protection of

combustible material are given in BS. 5440: 1990.

8. Where it is essential that the terminal wall plate is fitted, i.e.

wall thicknesses over 610mm (24") or with an inaccurately

cut hole, the minimum spacing in Table 3, Nos. 2, 3, 4, 5

and 6 would be 60mm (2.4") in order to allow the terminal

wall plate to be fitted.

IMPORTANT. It is the responsibility of the installer to ensure, in

practice, that products of combustion discharging from the

terminal cannot re-enter the building or any other adjacent

building through ventilators, windows, doors, other sources of

natural air infiltration, or forced ventilation / air conditioning.

If this should occur the appliance MUST be turned OFF, labelled

as 'unsafe' until corrective action can be taken.

FLUE LENGTHS

The flue assembly can be adapted to accommodate flue

lengths up to 3 metres. Refer to Frame 10.

WATER CIRCULATION SYSTEM

The boiler is designed for connection to pressurised, fully

pumped, sealed water central heating systems ONLY.

The central heating system should be installed and

commissioned in accordance with BS. 6798 and, in addition, for

smallbore and microbore systems BS. 5449.

The domestic hot water system should be in accordance with

BS. 5546 and BS. 6700.

Copper tubing to BS 2871:1 is recommended for water carrying

pipework and MUST be used for pipework carrying potable

water.

Any soldered joints on potable water pipework MUST NOT be

made with solder containing lead.

GAS SUPPLY

The local gas supplier should be consulted, at the installation

planning stage, in order to establish the availability of an adequate

supply of gas. An existing service pipe must NOT be used without

prior consultation with the local gas supplier.

A gas meter can only be connected by the local gas supplier or by

a registered CORGI installer.

Check that the appliance is suitable for the proposed gas supply.

A working gas pressure of 20 mbar MUST be available at the

boiler inlet.

IMPORTANT.

Installation pipes MUST be fitted in accordance with BS. 6891.

Pipework from the meter to the boiler MUST be 22mm O.D.

The complete installation MUST be tested for gas soundness and

purged as described in the above code.

FLUE INSTALLATION

The flue must be installed in accordance with the

recommendations of BS. 5440: Part 1.

The following notes are intended for general guidance:

1. The boiler MUST be installed so that the terminal is

exposed to external air.

2. It is important that the position of the terminal allows the

free passage of air across it at all times.

3. Minimum acceptable spacing from the terminal to

obstructions and ventilation openings are specified in

Table 3.

4. Pluming will occur at the terminal, so where possible,

terminal positions where this could cause a nuisance

should be avoided.

Terminal Position

Minimum Spacing

1. Directly below or alongside an

opening window, air vent or other

ventilation opening 300 mm (12")

2. Below guttering, drain pipes or soil

pipes 25 mm ( 1")

3. Below eaves 25 mm ( 1")

4. Below balconies or a car port roof 25 mm ( 1")

5. From vertical drain pipes or soil pipes 25 mm ( 1")

6. From internal or external corners 25 mm ( 1")

7. Above adjacent ground, roof or

balcony level 300 mm (12")

8. From a surface facing the terminal 600 mm (24")

9. From a terminal facing a terminal 1200 mm (48")

10. From an opening in a car port

(e.g. door or window) into dwelling 1200 mm (48")

11. Vertically from a terminal on the

same wall 1500 mm (60")

12. Horizontally from a terminal on the wall 300 mm (12")

Table 3 - Balanced flue terminal position

N.B. These clearances are for horizontal flue only.

Refer to supplementary manual for roof flue kits.

Note (Positions 2-6) : Due to the terminal design, installation is

possible with clearances less than those specified in BS 5440,

Part 1.

Page 8

8

Systemiser SE - Installation

GENERAL

Ancillary pipework not forming part of the useful heating

surface should be lagged to prevent heat loss and any

possible freezing - particularly where pipes run through roof

spaces or ventilated underfloor spaces.

Draining taps should be at least 1/2" BSP nominal size and be

in accordance with BS 2879.

Maximum recommended system hydraulic losses are given in

within Frame 4.

WATER TREATMENT

The Systemiser SE has an aluminium heat exchanger. If water

treatment is used Caradon Plumbing Limited recommend only

the of Fernox-Copal or Sentinel X100 water treatment products,

which must be used in accordance with the manufacturers'

instructions.

For further information contact either:

Fernox Manufacturing Co. Ltd

Tandem House

Marlowe Way

Croydon, Surrey

CRO 4XS

Tel: 0870 5601 5000

or

Betz Dearborn Ltd.

Widnes

Cheshire

Tel. 0151 424 5351

IMPORTANT.

The application of any other treatment to this product will

render the guarantee of Caradon Plumbing Limited invalid.

The CH flow and return pipe

connections are located at the

bottom of the boiler.

2

BOILER WATER CONNECTIONS

Notes.

1. It is most important that the correct concentration of the

water treatment product is maintained in accordance with

the manufacturers' instruction.

2. If the boiler is installed in an existing system any unsuitable

additives must be removed by thorough cleansing. BS.

7593:1992 details the steps necessary to clean a domestic

central heating system.

3. In hard water areas, treatment to prevent limescale may be

necessary. However, the use of artificially softened water is

not permitted.

4. Under no circumstances should the boiler be fired before

the system has been thoroughly flushed.

THERMOSTATIC RADIATOR VALVES (TRV)

Caradon Plumbing Limited recommend that heating systems

utilising full thermostatic radiator valve control of temperature in

individual rooms should also be fitted with a room thermostat

controlling the temperature in a space served by radiators not

fitted with such a valve as stated in BS. 5449.

When thermostatic radiator valves are used a bypass should

be fitted, ensuring it is at least 3m from the boiler. The bypass

should have at least 6m of flow and return pipe of a minimum

22mm diameter.

For further information refer to the 'Good Practice Guide 143', a

publication of the Energy Efficiency Office, available from the

Building Research Establishment, Garston, Watford WD2 7JR.

Tel: 01923 664258.

Page 9

9

Systemiser SE - Installation

GENERAL

ELECTRICAL SUPPLY

WARNING. This appliance must be efficiently earthed.

Wiring external to the appliance MUST be in accordance with

the current I.E.E. (BS.7671) Wiring Regulations and any local

regulations which apply.

The point of connection to the mains should be readily

accessible and adjacent to the boiler, except for bathroom

installations where the point of connection to the mains MUST

be situated outside of the bathroom.

Note. Where a room sealed appliance is installed in a room

containing a bath or shower then the appliance and any

electrical switch or appliance control utilising mains electricity

should be so situated that it cannot be touched by a person

using the bath or shower.

The following minimum clearances must be

maintained for operation and servicing.

Additional space will be required for installation,

depending upon site conditions.

Front clearance: 450 mm from the front of the

boiler casing. The minimum front clearance

when built in to a cupboard is 5mm.

3

BOILER CLEARANCES

For side outlet flues:

Raise the centre line of the hole in

the wall by 5mm +4mm/100mm of

flue length

Dimension y

Boiler only with stand-

off brackets

139mm 219mm

(5 (

7/16") (8 5/8")

Page 10

10

Systemiser SE - Installation

4

SYSTEM REQUIREMENTS - Central Heating

GENERAL

Notes

a. The method of filling, refilling, topping up or flushing

sealed primary hot water circuits from the mains via a

temporary hose connection is only allowed if acceptable

to the local water authority.

b. Antifreeze fluid, corrosion and scale inhibitor fluids

suitable for use with boilers having aluminium heat

exchangers may be used in the central heating system.

Advice should be sought from a local water treatment

company.

General

1. The installation must comply with all relevant national and

local regulations.

2. The installation should be designed to work with flow

temperatures of up to 82

0

C.

3. All components of the system must be suitable for a

working pressure of 3 bar and temperature of 110

0

C.

Extra care should be taken in making all connections so

that the risk of leakage is minimised.

The following components are incorporated within the

appliance:

a. Circulating pump.

b. Safety valve, with a non-adjustable pre-set lift pressure

of 3 bar.

c. Pressure gauge, covering a range of 0 to 6 bar.

d. A 9-litre expansion vessel, with an initial charge

pressure of 0.75 bar.

4. 'Make-up' Water. Provision must be made for replacing

water loss from the system, either :

a. From a manually filled 'make-up' vessel with a readily

visible water level. The vessel should be mounted at

least 150mm above the highest point of the system

and be connected through a non-return valve to the

system, fitted at least 150mm below the 'make-up'

vessel on the return side of the radiators.

or

Safety valve setting bar 3.0

Vessel charge pressure bar 0.5 to 0.75

System pre-charge pressure bar None 1.0

System volume Expansion vessel

(litres) volume (litres)

25 1.6 1.8

50 3.1 3.7

75 4.7 5.5

100 6.3 7.4

125 7.8 9.2

150 9.4 11.0

175 10.9 12.9

190 11.9 14.0

200 12.5 14.7

250 15.6 18.4

300 18.8 22.1

For other system volumes

multiply by the factor across 0.063 0.074

b. Where access to a 'make-up' vessel would be difficult,

by pre-pressurisation of the system.

The maximum cold water capacity of the

system should not exceed 143 litres, if not

pressurized. However, if the system is to be

pressurized, the efficiency of the expansion

vessel will be reduced and a larger vessel (or

smaller system volume) may be necessary. If

the capacity of the vessel is not considered

sufficient for this, or for any other reason, an

additional vessel MUST be installed on the

return to the boiler.

Guidance on vessel sizing is given above.

Page 11

11

Systemiser SE - Installation

5

SYSTEM REQUIREMENTS - CH (continued)

GENERAL

5. Filling. The system may be filled by one of the following

methods:

a. Through a temporary hose connection from a 'draw-off'

tap, supplied from a service pipe under mains pressure.

Where the mains pressure is excessive, a pressure

reducing valve must be used to facilitate filling.

i. Thoroughly flush out the whole system with cold

water.

ii. Fill and vent the system until the pressure gauge

registers 1.5 bar, and examine for leaks.

iii. Check the operation of the safety valve by raising

the water pressure until the valve lifts. This should

occur within 0.3 bar of the pre-set lift pressure.

iv. Release water from the system until the minimum

system design pressure is reached; 1.0 bar if the

system is to be pre-pressurised.

Refer to Frame 33.

Refer also to the British Gas document: 'Guidance Notes for

the Installation of Domestic Gas Condensing Boilers'

(1989)

A condensate drain is provided on the boiler. This drain must

be connected to a drainage point on site.

All pipework and fittings in the condensate drainage system

MUST be made of PLASTIC - no other materials may be used.

The boiler does not normally need a bypass but at least some

radiators on the heating circuit, of load of at least 60% of the

boiler output, at minimum rate i.e. 60% of 10.1 kW (34 500

Btu's) equal 6kW (21 000 Btu's) must be provided with twin

lockshield valves so that this minimum heating load is always

available.

Note.

Systems incorporating zone valves which could completely cut

off the flow through the system, must be wired such that the

boiler will not fire or continue to fire when this occurs.

6

SYSTEM BALANCING

BALANCING

1. Set the programmer to ON.

Close the manual or thermostatic valves on all

radiators, leaving the twin lockshield valves (on the

radiators referred to above) in the OPEN position.

Turn up the room thermostat and adjust these

lockshield valves to give boiler flow and return

temperatures not more than 15

o

C apart.

These valves should now be left as set.

2. Open all manual or thermostatic radiator valves and

adjust the lockshield valves on the remaining

radiators, to give around 11 oC temperature drop at

each radiator.

3. Adjust the room thermostat and programmer to

NORMAL settings.

The drain outlet on the boiler is standard 22mm overflow

pipe.

IMPORTANT

External pipe runs must be insulated to prevent possible

freezing.

A Siphon Kit is available see instructions supplied with the

kit.

7

CONDENSATE DRAIN

Water Flow Rate and Pressure Loss

Boiler size 24

System Load 24 kW

Water Flow Rate 0.51 l/s

Temperature Differential 11

O

C

Pressure available 29 kPa

for system 2.9 m

Page 12

12

Systemiser SE - Installation

8

BOILER ASSEMBLY - Exploded View

INSTALLATION

INSTALLATION

Legend

1. Burner

3. Gas valve

4. Detection electrode

5. Ignition electrodes

13. Fan

26. Boiler flow pipe

27. System flow pipe

30. Gas inlet pipe

35. Heat exchanger

48. Prepiping frame

16. Expansion vessel

17. Pump

18. Automatic air vent

22. System return pipe

25. Pump outlet pipe

50. Control panel

72. Gas injection pipe

Page 13

13

Systemiser SE - Installation

INSTALLATION

INSTALLATION

Unpack and check the pack contents

9

UNPACKING

HARDWARE PACK

M6 x 10 Pozi pan screw - 4 off

M6 shakeproof washer - 4 off

No. 14 x 50mm slotted rd. hd. screw - 4 off

Wall plug (brown) - 4 off

Condensate drain adaptor - 1 off

1/2" sealing washer - 3 off

3/4" sealing washer - 3 off

15mm olive - 3 off

22mm olive - 2 off

Turret seal - 1 off

PACK CONTENTS

z Complete boiler assembly

z Hardware Pack (listed separately below)

z Wall mounting plate

z Wall mounting template

z These Installation and Servicing Instructions

z User's Instructions

z Stand-off brackets (optional use) (1 pair)

z Concealment panels (optional use) (1 pair)

Stand-off brackets

Concealment panels

The boiler

Piping frame

15mm compression nut - 2 off

22mm compression nut - 2 off

15mm pipe connector - 2 off

22mm - 15mm reducing coupling - 1 off

1/2" - 15mm adaptor - 1 off

15mm street elbow - 1 off

22mm street elbow - 2 off

Pressure relief valve outlet pipe - 1 off

Pressure relief valve nut - 1 off

3-way plug - 1 off

Pack B Contents

No. 8 x 8mm self tapping screws - 2 off.

Flue support cutting aid - 1 off.

No.10 x 2" screws - 4 off.

Rawlplugs - 4 off.

Page 14

14

Systemiser SE - Installation

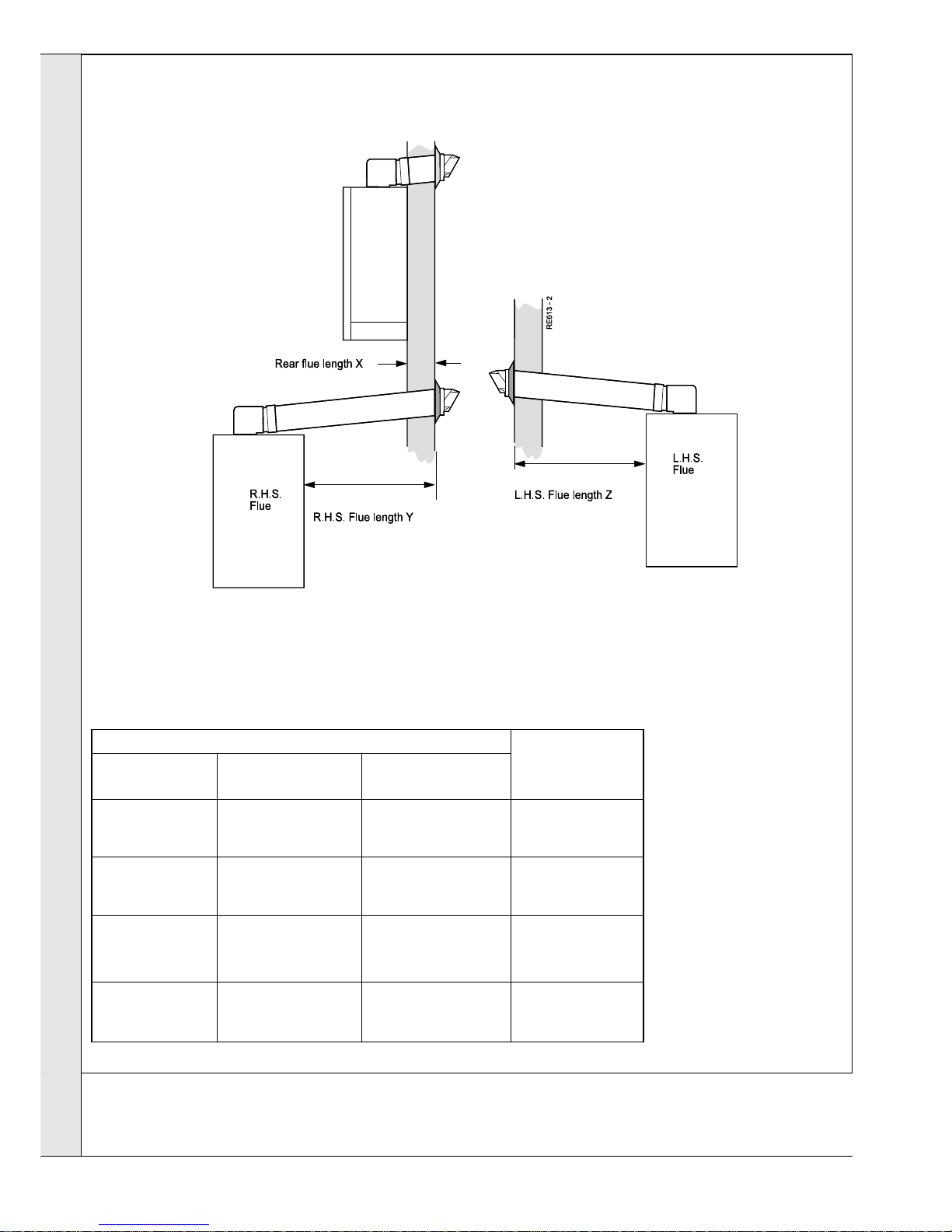

Flue length dimension Flue

Rear flue Right hand side Left hand side packs

dimn. X flue dimn. Y flue dimn. Z required

114 - 580 mm 114 - 410 mm 114 - 540 mm Pack B - 1 off

(4

1/2" - 22 3/4") (4 1/2" - 16" ) (4 1/2" - 21 1/4" )

580 - 1530 mm 410 - 1360 mm 540 - 1490 mm Pack B - 1 off &

(22 3/4" - 60 1/4") (16" - 53 1/2") (21 1/4" - 58 1/2") Pack D - 1 off

1530 - 2480 mm 1360 - 2310 mm 1490 - 2440 mm Pack B - 1 off &

(60

1/4" - 97 3/4") (53 1/2" - 90 3/4") (58 1/2" - 96") Pack D - 2 off

2480 - 3000 mm 2310 - 3000 mm 2440 - 3000 mm Pack B - 1 off &

(97 3/4" - 118") (90 3/4" - 118") ( 96" - 118") Pack D - 3 off

INSTALLATION

INSTALLATION

For REAR outlet flue Go to Frame 11

For SIDE outlet flue Go to Frame 21

10

DETERMINING THE FLUE LENGTH AND FLUE PACKS REQUIRED

Dimension X - Wall thickness

Dimension Y - Wall thickness plus

boiler spacing

(RHS)

Dimension Z - Wall thickness plus

boiler spacing

(LHS)

Calculate the total length of flue by the following:

Rear flue length = Dim. X + 40mm (1

5/8")

RHS flue length = Dim. Y + 188mm (7 3/8")

LHS flue length = Dim. Z + 61mm (2

3/8

")

Note.

These figures include the length of flue entering the

flue turret socket.

Table. Flue pack requirements

FLUE KITS

Pack B

supplied as standard.

Pack D

optional extension kit for

side flue or rear flue

outlet 1000 mm long.

Refer to 'Flue Extension

Ducts'

Vertical Flue

see optional extras.

IMPORTANT.

The boiler MUST be installed in a vertical position.

Note. The flue duct MUST be inclined at 2.5o to the

horizontal to allow condensate to drain back into the

boiler and out through the condensate drain.

Page 15

15

Systemiser SE - Installation

INSTALLATION

REAR FLUE OUTLET

11

REAR FLUE ASSEMBLY - Exploded View

1. An optional flue duct extension kit is required

for rear flue lengths greater than 580mm

(22 3/4"). Refer to Frame 11.

2. When cutting the ducts always use the

cardboard support cutting aid provided.

LEGEND

1. Terminal.

2. Weather seal.

3. Duct assembly.

4. No. 8 x 8 self-tapping screw.

12

WALL MOUNTING TEMPLATE

IMPORTANT.

For direct mounting (piping frame on wall) choose one black

circle in each group.

If using the stand-off brackets choose one dotted circle in

each group. Care MUST be taken to ensure the correct

holes are drilled.

1. Tape the template into the selected position.

2. Ensure squareness by hanging a plumbline as shown.

3. Mark onto the wall the following:

a. The 4 wall mounting plate screw positions.

b. The position of the flue duct.

Mark the centre of the hole as well as the

circumference.

4. Remove the template from the wall.

5. Flue Turret.

6. M5 x 10 pozi screw.

7. Turret Clamp.

8. Turret seal.

Page 16

16

Systemiser SE - Installation

INSTALLATION

REAR FLUE OUTLET

13

PREPARING THE WALL

Note. If the terminal is to be sited within 25-

40mm of a corner or vertical pipe then the hole

MUST be accurately cut and the rubber

weather seal trimmed around the groove

provided.

The terminal wall plate need not be fitted.

1. Cut the flue hole (preferably with a 5" core

boring tool), ensuring that the hole is

square to the wall.

Both wall faces immediately around the

cut hole should be flat.

2. Drill 4 holes with a 7mm (

1/4") masonry

drill and insert the plastic plugs provided,

for the wall piping frame.

WARNING. Ensure that, during the cutting operation, masonry falling

outside of the building does not cause damage or personal injury.

14

FITTING THE PIPING FRAME

Fit the wall mounting frame either:

a. Directly to the wall

zz

zz

z Insert wall plugs.

zz

zz

z Put the screws into the wall plugs and leave

10mm proud

zz

zz

z Hang the frame onto the screws and tighten up.

or

b. Use stand-off brackets

(To allow pipework to be taken upwards).

zz

zz

z Insert wall plugs.

zz

zz

z Put the screws into the wall plugs and leave 10mm

proud.

zz

zz

z Fasten each bracket to the frame with the 6mm screws

and washers provided.

zz

zz

z Hang the brackets and frame onto the screws and

tighten up.

Note. If the clearances above and below the boiler are

less than the length of the pipes it will be necessary to

position the pipes behind the wall mounting plate

BEFORE the plate is screwed to the wall.

Page 17

17

Systemiser SE - Installation

INSTALLATION

15

WATER CONNECTIONS

REAR FLUE OUTLET

Extend a gas supply pipe of not less than 22mm O.D.

copper or 3/4" BSP iron to the boiler.

A working gas pressure of 20mb (8" w.g) must be

available at the boiler inlet, with the boiler firing at full

rate.

16

GAS CONNECTION

Bottom and top connections

1. Solder the 1/2" connector, street elbow, straight pipe and

reducing coupling together.

2. Remove the gas cock bracket complete with gas cock.

3. Screw the connector into the gas cock in the correct

orientation.

4. Screw the complete assembly back onto the mounting

frame.

For top connections: Reverse elbow

Note.

1. Do not subject any of the isolating valves to heat as the seals may

be damaged.

2. In areas where the mains water pressure is known to be high

(greater than 10 bar) it is recommended that a water governor is

fitted on the cold inlet supply to the boiler.

CH CONNECTIONS TANK CONNECTIONS

Top Connection

Page 18

18

Systemiser SE - Installation

INSTALLATION

2. Undo the 2 screws and remove the

boiler bottom panel.

3. Lift the boiler on to the wall, locating the

CH flow and return pipes and gas pipe

to the service pipes.

Tighten all pipe connections.

17

MOUNTING THE BOILER

REAR FLUE OUTLET

1. Remove the boiler casing:

a. Undo the securing screw.

b. Disengage the casing from the back panel and lift it

from the boiler.

18

CUTTING THE FLUE Rear Flue Length of 114 to 580mm

Note.

If the optional standoff bracket kit is used

it is essential that 80mm is added to the

measured wall thickness when marking

the flue (to allow for the thickness of the

brackets).

1. Measure and note wall thickness X.

2. Add 40mm (1

5/8") to dimension X and,

measuring from the groove, cut the tube.

IMPORTANT

Measure from the groove marked 'TOP' not

the larger groove.

3. To ensure the tube is cut square, mark the

flue all the way round.

4. Cut to length, using the cardboard support

aid.

5. Remove the cardboard support and any

burrs.

Page 19

19

Systemiser SE - Installation

INSTALLATION

19

ASSEMBLING THE FLUE

REAR FLUE OUTLET

PROCEED TO FRAME 32

20

CONNECTING THE FLUE TO THE BOILER

1. Fit the 'cut to length' flue on to the flue turret.

Note. Ensure the top groove in the flue aligns with

the top of the turret.

2. Drill a 3.2mm dia. hole through the flue via the hole

present in the turret.

3. Secure the turret to the flue, using the self tapping

screw provided.

Note.

BEFORE fitting the flue turret, fill the

condensate trap within the boiler by pouring a

cupful of water into the flue outlet A.

1. Insert the flue assembly through the

prepared hole in the wall far enough to

allow the rubber seal to unfold completely

and form an adequate seal on the

outside wall.

2. Pull the flue back and locate the flue

turret on the top of the boiler ensuring

that the seal is in place.

3. Secure the flue turret on top of the boiler

by inserting the open ends of the turret

clamp under the 2 studs and fixing it in

the middle with the single M5 x 10mm

pozi-hex screw provided.

4. Now make good the inside wall face

around the flue.

Page 20

20

Systemiser SE - Installation

INSTALLATION

SIDE FLUE OUTLET

2. When cutting the

ducts always use the

cardboard support

cutting aid provided.

1. An optional flue duct extension kit is

required for flue lengths greater than:

410 mm (16") for RHS flue

540 mm (21 1/4") for LHS flue

(Refer to Frame 11).

21

SIDE FLUE ASSEMBLY - Exploded view

IMPORTANT.

For direct mounting (piping frame on wall)

choose one black circle in each group.

If using the stand-off brackets choose one

dotted circle in each group. Care MUST be

taken to ensure the correct holes are drilled.

1. Tape the template into the selected

position.

2. Ensure squareness by hanging a

plumbline as shown.

3. Mark onto the wall the following:

a. The 4 wall mounting plate screw

positions.

b. The position of the flue duct.

Mark the centre of the hole as well as

the circumference.

Note. Allow for stand-off brackets if

being used. Use the table on the

walling mounting template.

4. Remove the template from the wall.

22

WALL MOUNTING TEMPLATE

LEGEND

1. Terminal.

2. Weather seal.

3. Duct assembly.

4. No. 8 x 8 self-tapping screw.

5. Flue Turret.

6. M5 x 10 pozi screw.

7. Turret clamp.

8. Turret seal.

Page 21

21

Systemiser SE - Installation

INSTALLATION

23

PREPARING THE WALL

WARNING.

Ensure that, during the cutting operation, masonry falling

outside of the building does not cause damage or personal

injury.

1. Cut the flue hole (preferably with a 5" core boring tool),

ensuring that the hole is square to the wall. Both wall

faces immediately around the cut hole should be flat.

2. Drill 4 holes with a 7mm (

1/4") masonry drill and insert

the plastic plugs, provided, for the wall mounting piping

frame.

Note. If the terminal is to be sited within 25-40mm of a

corner or vertical pipe then the hole MUST be

accurately cut and the rubber weather seal trimmed

around the groove provided. The terminal wall plate

need not be fitted.

24

FITTING THE PIPING FRAME

Fit the wall mounting frame either:

a. Directly to the wall

zz

zz

z Insert wall plugs.

zz

zz

z Put the screws into the wall plugs and leave 10mm proud

zz

zz

z Hang the frame onto the screws and tighten up.

or

b. Use stand-off brackets

(To allow pipework to be taken upwards).

zz

zz

z Insert wall plugs.

zz

zz

z Put the screws into the wall plugs and leave 10mm proud.

zz

zz

z Fasten each bracket to the frame with the 6mm screws

provided.

zz

zz

z Hang the brackets and frame onto the screws and tighten up.

Note. If the clearances above and below the boiler are less

than the length of the pipes it will be necessary to position the

pipes behind the wall mounting plate BEFORE the plate is

screwed to the wall.

SIDE FLUE OUTLET

Page 22

22

Systemiser SE - Installation

INSTALLATION

SIDE FLUE OUTLET

25

WATER CONNECTIONS

26

GAS CONNECTION

Bottom and top connections

1. Solder the 1/2" connector, street elbow, straight pipe and

reducing coupling together.

2. Remove the gas cock bracket complete with gas cock.

3. Screw the connector into the gas cock in the correct

orientation.

For top connections: Reverse elbow .

Notes.

1. Do not subject any of the isolating valves to heat as the seals may be

damaged.

2. In areas where the mains water pressure is known to be high (greater than 10

bar) it is recommended that a water governor is fitted on the cold inlet supply

to the boiler.

4. Screw the complete assembly back onto the

mounting frame.

Extend a gas supply pipe of not less than 22mm O.D.

copper or 3/4" BSP iron to the boiler.

A working gas pressure of 20mb (8" w.g) must be

available at the boiler inlet, with the boiler firing at full

rate.

Tank Connection

Top Connection

Page 23

23

Systemiser SE - Installation

INSTALLATION

SIDE FLUE OUTLET

27

MOUNTING THE BOILER

FOR FLUE LENGTHS GREATER THAN 600mm REFER TO FRAMES 34, 35 & 36 - FLUE EXTENSION DUCTS

28

CUTTING THE FLUE - For flue lengths 114 to 600mm ONLY

1. The flue cut length is calculated as follows:

a. Measure and note the wall thickness X

b. Add dimension H, measured in Frame 22.

c. For right hand side flue add 188mm (7

3/8")

d. For left hand side flue add 61mm (2

3/8")

i.e. X + H + 188mm (7

3/8") for RHS

X + H + 61mm (2 3/8") for LHS

2. Measure from the groove and cut the

tube.

IMPORTANT.

Measure from the groove marked 'TOP'

not the larger groove.)

3. To ensure the tube is cut square, mark

the flue all the way round.

4. Cut to length, using the cardboard

support aid.

5. Remove the cardboard support and

remove any burrs.

Lift the boiler onto the wall mounting piping frame, as shown.

Page 24

24

Systemiser SE - Installation

INSTALLATION

SIDE FLUE OUTLET

29

ASSEMBLING THE FLUE

30

CONNECTING THE FLUE TO THE BOILER

1. Fit the 'cut to length' flue on to the flue

turret.

Note.

Ensure the groove in the flue aligns

with the top of the turret.

2. Drill a 3.2mm dia. hole through the flue

via the hole present in the turret.

3. Secure the turret to the flue, using the

self tapping screw provided.

Note. BEFORE fitting the flue turret, fill the condensate trap within

the boiler by pouring a cupful of water into the flue outlet A.

1. Insert the flue assembly through the

prepared hole in the wall far enough to

allow the rubber seal to unfold

completely and form an adequate seal

on the outside wall.

2. Pull the flue back and locate the flue

turret on the top of the boiler ensuring

that the seal is in place.

3. Secure the flue turret on top of the boiler

by inserting the open ends of the turret

clamp under the 2 studs and fixing it in

the middle with the single M5 x 10mm

pozi-hex screw provided.

4. Flues over 1 metre long.

Fix the flue support bracket to the wall,

using the wall plug and wood screw.

For standard installations use the short

wood screw.

If the stand-off option is used, secure

the support bracket using the spacer

bracket and long wood screw.

5. Now make good the inside wall face

around the flue.

Page 25

25

Systemiser SE - Installation

INSTALLATION

32

CONDENSATE DRAIN

31

TERMINAL WALL PLATE

This plate allows neat concealment and full

compression of the rubber seal. Its use is not

essential if the flue hole and flue ducts have been

accurately cut and the outside wall face is flat.

1. Position the terminal wall plate over the

terminal.

2. Drill 4 fixing holes with a 7mm (

1/4") masonry

drill.

3. Insert the 4 plastic plugs provided.

4. Secure the plate with 4 of the No.10 x 2"

screws provided.

INSTALLATION

The condensate drain provided on the boiler

must be connected to a drainage point,

preferably within the building.

The routing of the drain must be made to allow

a minimum fall of 1 in 20 away from the boiler,

throughout its length.

The drainage pipework must be arranged so

that obstruction (e.g. through freezing) of

external drainage pipe does not give rise to

spillage within the dwelling.

Excessive external pipe runs should be avoided

in order to prevent possible freezing.

All pipework and fittings in the condensate drain

system must be made of plastic. No other

materials may be used.

The drain outlet on the boiler is standard 22mm

overflow pipe. This size must not be reduced in

any part of its length.

In order to defer the onset of freezing of the

condensate drain when the pipe is run

externally the pipe should be run as far as

possible within the building.

The boiler condensate drain connection is

suitable for Bartol 'Polypipe' tubing. An adaptor

is supplied to allow the use of Marley 'Terrain'

tubing, which is slightly larger. This adaptor

should be sealed to the Marley 'Terrain' tubing

and to the boiler condensate drain, using a

suitable plastic tube adhesive.

Page 26

26

Systemiser SE - Installation

INSTALLATION

INSTALLATION

The safety valve is located at the bottom LHS of the boiler.

1. Using the pressure relief valve outlet pipe, nut and olive

from the hardware pack, assemble into safety valve as

shown.

2. If access to the nut is difficult remove the socket screw

from inside of fitting and pull the valve from the pipe to

allow the piping nut to be tightened.

3. Replace valve and tighten socket screw.

The position of the safety valve discharge pipe should be

such that any discharge of water or steam does not create a

hazard.

33

SAFETY VALVE DRAIN

35

FLUE EXTENSION DUCTS - continued

Pack D Flue Extension Duct Kit contents

34

FLUE EXTENSION DUCTS - For overall flue lengths greater than 600mm (23 5/8")

1. A maximum of 3 extension ducts (one suitably

cut) plus the standard flue duct may be used

together.

2. Flue extensions of greater length than 1m (39")

should be supported with the bracket provided,

suitably adjusted - refer to Frame 34.

Use a maximum of 3m extended flue ONLY

Note. Side flue shown

GENERAL ARRANGEMENT

Page 27

27

Systemiser SE - Installation

INSTALLATION

INSTALLATION

36

FITTING THE KIT

Appliances fitted with a REAR outlet flue; please refer to Frame 11

Appliances fitted with a

SIDE

outlet flue; please refer to Frame 21

1. Remove the cardboard support aid from the flue

and place safely to one side.

2. Fit the inner flue extension duct onto the inner flue

duct.

3. Fit the outer flue extension duct onto the outer air

duct.

4. Drill one 3.2mm (1/8") dia hole through the outer air

duct.

Do not drill the inner flue duct.

5. Insert the self tapping screw provided to fix the air

duct in position.

6. Repeat steps 1-5 if a second flue extension is

required.

7. Measure and mark the flue length required onto the

flue, measuring from the groove near the terminal.

8. To ensure a square cut, mark the flue all the way

round.

9. Cut to length using the cardboard support aid.

10. Remove the cardboard offcuts and deburr the

metal edges.

Page 28

28

Systemiser SE - Installation

37

FILLING - Central Heating

1. Ensure that the CH isolating valves are open.

2. Release the securing screw and swing the control panel

down.

3. Fill and vent the system. Check for water soundness

Refer also to Frame 5

INSTALLATION

Front elevation layout of boiler components (control panel open)

Legend

A Boiler heat exchanger

B Gas valve

C Safety valve

D Condensate & safety drains

E CH flow

F Gas inlet

G CH return

H Pump

I CH expansion vessel

J Automatic air vent

K Flue sensing point

INSTALLATION

Page 29

29

Systemiser SE - Installation

38

FILLING - continued

INSTALLATION

INSTALLATION

WARNING. This appliance must be efficiently earthed.

A mains supply of 230 V ~ 50 Hz is required.

The fuse rating should be 3A.

Wiring external to the boiler MUST be in accordance with the

current I.E.E. (BS.7671) Wiring Regulations and any local

regulations.

All external controls and wiring must be suitable for mains

voltage.

Wiring should be 3 core PVC insulated cable, not less than

0.75 mm

2

(24 x 0.2mm).

Wiring external to the boiler MUST be in accordance with the

current wiring regulations and any local regulations.

Connection must be made in a way that allows complete

isolation of the electrical supply such as a double pole switch

having a 3mm (1/8") contact separation in both poles, or a

plug and socket, serving only the boiler and system controls.

The means of isolation must be accessible to the user after

installation.

IMPORTANT - WHEN FILLING:

The cap on the automatic air vent MUST be

loose at all times.

When filling, there may be a slight water leak from the vent therefore

electrical connections should be protected.

i. Remove the vent plug

ii. Using a screwdriver, rotate the shaft several times

iii. Replace the vent plug.

Note. Some slight water leakage will occur.

39

ELECTRICAL CONNECTIONS

Page 30

30

Systemiser SE - Installation

INSTALLATION

INSTALLATION

1. Route the mains cable into the bottom rear

RHS of the boiler.

2. Wire the live, neutral and earth into the 5way remote plug terminals, 3 (Live) N &

as shown.

Note.

Ensure that the lengths of the current

carrying conductors are shorter than the

earth conductor so that if the cable slips in

its anchorage the current carrying

conductors become taut before the earth

conductor.

3. If a room thermostat is fitted wire across

the 5-way remote plug terminals 1 & 2 in

place of link wire.

4. Secure the mains lead with the cable

clamp in the plug.

40

INTERNAL WIRING

41

FLOW WIRING DIAGRAM

Note.

12 - Room thermostat connections

Page 31

31

Systemiser SE - Installation

INSTALLATION

INSTALLATION

42

PICTORIAL WIRING DIAGRAM

Page 32

32

Systemiser SE - Installation

INSTALLATION

INSTALLATION

43

MID POSITION VALVE

Pumped only

44

TWO SPRING CLOSED VALVE

Notes.

1. Some earth wires are omitted for clarity. Ensure proper

earth continuity when wiring.

2. Numbering of terminals on thermostats is specific to the

manufacturer.

3. This is fully controlled system - set the boiler thermostat

to maximum.

4. Switchmaster 'Midi' is similar in operation, but the wiring

differs slightly; see manufacturer's literature.

Notes.

1. Some earth wires are omitted for clarity. Ensure proper

earth continuity when wiring.

2. Numbering of terminals on thermostats is specific to the

manufacturer.

3. This is fully controlled system - set the boiler thermostat

to maximum.

4. Switchmaster valve has grey & orange auxiliary switch

leads but the grey wire must be connected to the live

supply.

LEGEND

b blue

bk black

br brown

r red

y yellow

w white

g/y green/yellow

or orange

v violet

LEGEND

b blue

bk black

br brown

r red

y yellow

w white

g/y green/yellow

or orange

v violet

pk pink

Pumped only

Page 33

33

Systemiser SE - Installation

INSTALLATION

INSTALLATION

WARNING. Whilst effecting the required gas soundness test and purging air from the gas installation,

open all windows and doors, extinguish naked lights and DO NOT SMOKE.

45

EXTERNAL WIRING

WARNING. This appliance must be efficiently earthed.

A mains supply of 230 V ~ 50 Hz is required.

The fuse rating should be 3A.

Wiring external to the boiler MUST be in accordance with the

current I.E.E. (BS.7671) Wiring Regulations and any local

regulations.

All external controls and wiring must be suitable for mains voltage.

Wiring should be 3 core PVC insulated cable, not less than 0.75

mm

2

(24 x 0.2mm).

Connection must be made in a way that allows complete isolation

of the electrical supply such as a double pole switch having a

3mm (1/8") contact separation in both poles, or a plug and socket,

serving only the boiler and system controls. The means of

isolation must be accessible to the user after installation.

The wiring diagrams illustrated in Frames 44-45 cover the

systems most likely to be fitted to this appliance.

For wiring external controls to the Systemiser SE boiler,

reference should be made to the system wiring diagrams

supplied by the relevant manufacturer, in conjunction with the

wiring diagrams shown.

Difficulty in wiring should not arise, providing the following

directions are observed:

1. Controls that switch the system on or off, e.g. a time

switch must be wired, in series, to connection 1 in the 5way plug.

2. Controls that override an on/off control e.g. frost

thermostat, must be wired to connection 1 in the 5-way

plug, in parallel, with the control(s) to be overridden.

3. If a proprietary system is used, follow the instructions

supplied by the manufacturer.

Advice on required modifications to the wiring may be

obtained from the component manufacturers.

47

COMMISSIONING AND TESTING

B. Gas Installation

1. The whole of the gas installation, including the meter,

should be inspected and tested for soundness, and

purged.

2. Purge air from the gas installation by loosening the gas

cock union and purge until gas is smelled.

3. Retighten the union and test for gas soundness.

A. Electrical Installation

1. Checks to ensure electrical safety should be carried out by

a competent person.

2. ALWAYS carry out the preliminary electrical system

checks, i.e. earth continuity, polarity, resistance to earth

and short circuit, using a suitable test meter.

46

FROST PROTECTION

This is provided automatically by the Gasmodul control.

If the boiler flow temperature T

1

falls below 7

o

C the pump runs

without the boiler firing until the temperature exceeds 10 oC

If the flow temperature falls below 3

o

C the boiler will fire until

the temperature exceeds 10 oC.

Central heating systems fitted wholly inside the house do not

normally require frost protection as the house acts as a 'storage

heater' and can normally be left at least 24 hours without frost

damage. However, if parts of the pipework run outside the house

or if the boiler will be left off for more than a day or so, then a

frost thermostat should be wired into the system.

This is usually done at the programmer, in which case the

programme selector switches are set to 'off' - all other controls

MUST be left in the running position. The frost thermostat should

be sited in a cold place but where it can sense heat from the

system. Wiring should be as shown, with minimal disturbance to

other wiring of the programmer. Designation of the terminals will

vary, but the programmer and thermostat manufacturers leaflets

will give full details.

Diagram A shows a double pole frost thermostat, which

should suffice for all systems which do not use the OFF

terminals of the programmer.

Diagram B shows a 'change-over' frost thermostat, which will

cover most systems which do use CH OFF. If, however, on such

a system the HW pipework is in an isolated part of the house, a

second frost thermostat may be used to protect it. If in doubt,

ask your installer for advice.

Page 34

34

Systemiser SE - Installation

48

INITIAL LIGHTING

INSTALLATION

INSTALLATION

LEGEND

A. Gas control valve

B. Inlet pressure test point

C. Burner pressure test point

D. Offset adjuster (sealed)

E. Fan pressure test point (Hi)

F. Fan pressure test point (Lo)

G. Control panel

H. Display board

I. Gas service cock (hidden)

J. On/Off switch

K. Central heating (CH) on/off switch

L. Central heating pressure gauge

M. Flue thermostat (behind sealing panel)

N. Automatic air vent

O. Cover plate

1. Check that the system has been filled and that the boiler

is not airlocked. Ensure the automatic air vent screw is

open (N)

2. Check that all the drain cocks are closed and that the

CH isolating valves are OPEN.

3. Check that the electrical supply is OFF.

4. Check that the gas service cock (I) is OPEN.

5. Remove screw and swing the control panel down .

6. Remove the screw in the burner pressure test point (C)

and connect a gas pressure gauge via a flexible tube.

7. Swing the control panel into its working position.

8. Ensure that the external CH controls are calling for

heat and set the CH switch (K) to ON.

9. Switch the electricity supply ON.

10. Set the on/off switch (J) to ON.

11. The boiler ignition sequence should now start.

Note.

A self check cycle will take place whenever the

RESET button on the control panel is pressed, and

also once every 24 hours without a call for heat, to

ensure movement of the components once a day.

Control panel: contains digital display and 6 buttons

Button Function

RESET Reset of system

MODE Mode of display

STEP Step within the mode

Button Function

STORE Storage of setting

UP(+) Increase of setting

DOWN (-) Decrease of setting

Page 35

35

Systemiser SE - Installation

49

INITIAL LIGHTING - continued

INSTALLATION

INSTALLATION

Sequence Boiler Status

0 No heat request.

1 Fan pre-purge for 8 seconds.

2 Gas valve opens and spark commences.

3 Burner ignition and flame detection (CH).

If ignition does not occur within 8 seconds or if the burner

lights and flame presence is not detected then the ignition

sequence is repeated for a maximum of 5 times.

If ignition is still unsuccessful the display flashes:

continuously,

indicating a FAULT mode, and the boiler will shut down.

Press the RESET button to return the boiler to STANDBY

mode and the ignition sequence will be repeated.

If the boiler again locks out refer to the Fault -Finding

section.

13. Check that the burner lights smoothly and that sequence

number :

is displayed, indicating that central heating is being

supplied.

Note. The burner will reduce to minimum rate for a few

seconds before increasing to maximum rate.

14. Test for gas soundness around ALL boiler gas

components, using leak detection fluid.

15. Operate the boiler for 20 minutes to stabilise the burner

temperature.

16. The boiler central heating control is fully modulating,

operating between burner pressures of:

13.0 mbar (± 0.2 mbar) MAXIMUM

2.0 mbar (± 0.2 mbar ) MINIMUM

These are factory set.

To check the maximum pressure

Remove the controls button cover plate (O).

Select TEST mode by pressing MODE and ' + ' buttons

simultaneously (to simulate a call for maximum heat).

The display will read:

To check the minimum pressure

Select TEST mode by pressing MODE and ' - ' buttons

simultaneously (to simulate a call for minimum heat).

The display will read:

17. To check the fan pressure signal

Connect a suitable pressure gauge to the pressure tappings

(E) and (F) on the gas valve.

Equilibrium fan pressures should be as follows (± 0.2 mbar):

Boiler size Fan pressure mbar (ins. wg.) 300mm flue

kW (Btu) Max Min

24 (81 900) 3.5 (1.4) 0.5 (0.24)

This will reduce within acceptable levels up to 3m flue.

18. To return the boiler to normal running STANDBY mode,

press + and - buttons simultaneously.

Page 36

36

Systemiser SE - Installation

50

GENERAL CHECKS

INSTALLATION

INSTALLATION

8. Finally, set the controls to the User's requirements.

9. Refit the boiler bottom panel.

10. If an optional programmer kit is fitted then refer to the

instructions supplied with the kit.

Make the following checks for correct operation:

CENTRAL HEATING (CH)

1. Ensure that the CH external controls are calling for heat.

2. Set the central heating switch (K) to ON.

The boiler should complete the self-check cycle - refer to

Frame 49 - then the boiler should fire at maximum rate to

supply the central heating.

Note.

The burner will reduce to minimum rate for a few seconds

before increasing to maximum rate.

The display sequence number should read:

3. Set the central heating external controls to OFF. The

burner should go off and the pump continue to run for 3

minutes.

The display sequence should read:

returning to

when the pump stops.

4. Check the correct operation of the programmer (if fitted)

and all other system controls. Operate each control

separately and check that the main burner corresponds.

5. Swing panel down and remove the pressure gauge and

tube. Tighten the sealing screw in the pressure test point,

ensuring that a gas-tight seal is made.

6. Swing the control panel back to its working position and

secure.

7. Refit the boiler bottom panel.

8. Refit the boiler casing.

WATER CIRCULATION SYSTEM

1. With the system COLD, check that the initial pressure is

correct to the system design requirements.

For pre-pressurised systems, this should be 1.0 bar.

2. With the system HOT, examine all water connections for

soundness. The system pressure will increase with

temperature rise but should not exceed 2.5 bar.

3. With the system still hot, turn off the gas, water and

electricity supplies to the boiler and drain down to

complete the flushing process.

Note. A flushing solution should be used during the

flushing procedure. Flushing solutions; Fernox Superfloc,

Sentinel X300 (new systems) or X400 (existing systems).

Refer to page 8.

4. Refill and vent the system, add inhibitor (see Frame 4),

clear all air locks and again check for water soundness.

5. Reset the system initial pressure to the design

requirement.

6. Balance the system. Refer to Frame 6.

7. Check the condensate drain for leaks and check that it is

discharging correctly.

WATER TEMPERATURES

The design water Central Heating output temperatures is 82

o

C

maximum.

This temperatures can be checked and setting changed (if

required) as follows:

1. To check the temperature:

a. Select MONITOR mode by pressing the MODE button

until the decimal point after the first digit on the display

flashes.

The first digit now gives the step number and the last

two the temperature.

b. Select the required step number by pressing the STEP

button.

c. To return the control to the normal running STANDBY

mode press the RESET button.

Step number Temperature oC.

1 CH flow temp

o

C.

2 CH return temp

o

C.

4 Outside temp

o

C. (if fitted)

5 Maximum set value of CH flow temp

o

C

2. To change the temperature settings:

a. Select PARAMETER mode by pressing the MODE

button until the decimal point after the first digit on the

display shows steadily.

The first digit now gives the step number and the last

two the value of the setting

Note. In this mode it is also possible to switch the boiler

on or off .

b. Select the required step number by pressing the STEP

button.

c. Reset the temperature to the required value by pressing

+ and - buttons.

d. Store the new value by pressing the STORE button. The

display should flash twice.

e. To return the control to the normal running STANDBY

mode press the RESET button.

f. Refit the controls button cover plate.

Stepnumber Temperature oC.

3 00 = CH OFF

01 = CH ON

4 Max CH temp ( 20

o

to 82 oC)

Page 37

37

Systemiser SE - Installation

51

HANDING OVER

INSTALLATION

INSTALLATION

After completing the installation and commissioning of the

system the installer should hand over to the householder by

the following actions:

1. Hand the User Instructions to the householder and

explain his / her responsibilities under

current Gas Safety

(Installation and Use) Regulations, or rules in force.

2. Draw attention to the Lighting Instruction label affixed to

the inside of the casing drop down door.

3. Explain and demonstrate the lighting and shutting down

procedures.

4. The operation of the boiler, and the use and adjustment of

all system controls, should be fully explained to the

householder, to ensure the greatest possible fuel economy

consistent with the household requirements of both

heating and hot water consumption.

Advise the User of the precautions necessary to prevent

damage to the system and to the building, in the event of

the system remaining inoperative during frosty conditions.

5. Explain the function and the use of the boiler central

heating controls.

6. Explain the function of the boiler fault mode.

Emphasise that if a fault is indicated, the boiler should be

turned off and a registered local heating installer

consulted.

7. Explain and demonstrate the function of time and

temperature controls, radiator valves etc., for the

economic use of the system.

8. If an optional programmer kit is fitted then draw

attention to the Programmer Kit User Instructions and

hand them to the householder.

9. Loss of system water pressure

Explain that the dial on the control panel indicates the

central heating system pressure and that if the normal

COLD pressure of the system is seen to decrease over

a period of time then a water leak is indicated. In this

event a registered local heating installer should be

consulted.

WARNING.

Do not fire the boiler if the pressure has reduced to

zero from the original setting.

10. After installation, commissioning and customer hand-over

instructions please complete the

appliance

log book and leave this with the customer.

11. IMPORTANT

A comprehensive service should be carried out AT

LEAST ONCE A YEAR.

Stress the importance of regular servicing by the local

gas region or by a CORGI registered installer.

As the installer you may wish to undertake the service

contract your self or alternatively offer to the customer

the benefits of the Ideal Care Scheme, details of

which are outlined in the householder pack supplied

with this boiler.

Page 38

38

Systemiser SE - Installation

52

SERVICING SCHEDULE

INSTALLATION

INSTALLATION

53

SAFETY

IMPORTANT.

Always turn OFF the gas supply at the gas service cock,

and switch OFF and disconnect the electricity supply to the

appliances before servicing.

WARNING.

After completing the servicing or exchange of components

always:

z Test for gas soundness and carry out functional

checks as appropriate.

z Check the sealing panel is correctly refitted, ensuring

that a good seal is made.

Do NOT OPERATE the boiler if the

sealing panel is not fitted

Note.

In order to carry out servicing, the boiler casing and

sealing panel must be removed. Refer to Frames 54

and 55.

To ensure the continued safe and efficient operation of

the appliance it is recommended that it is checked at

regular intervals and serviced as necessary. The

frequency of servicing will depend upon the installation

condition and usage but should be carried out at least

annually.

It is the law that any service work must be carried out

by a registered installer.

As the installer you may wish to undertake the service

contract yourself or, alternatively, to the customer the

benefits of the Ideal Care scheme, details of which are

outlined in the Householder pack supplied with this

boiler.

Note.

Some aluminium oxide build-up on the heat exchanger

fins is quite usual with this type of condensing boiler.

Though removal is recommended annually, the heat

exchanger must be inspected and cleaned after a

maximum of 2 years operation.

1. Light the boiler and carry out a pre-service check, noting

any operational faults.

Run the boiler for at least 20 minutes and check the gas

consumption.

2. Optional test

Connect a suitable gas analyser to the sampling point on

the boiler.

For correct boiler operation, the CO/CO

2

content of the

boiler should not be greater than 0.004 ratio. If this is the

case, and the gas input is at least 90% of the nominal, then

no further action need be taken. If not, proceed to Step 3.

3. Clean the main burner.

4. Clean the heat exchanger.

Note. This must be done with the heat exchanger and

deposit in a dry condition.

5. Clean the condensate trap and check the drain for

blockage.

6. Check that the flue terminal is unobstructed and that the

flue system is sealed correctly.

The servicing procedures are covered more fully in Frames

54 to 60 and MUST be carried out in sequence.

Page 39

39

Systemiser SE - Installation

SERVICING

SERVICING

55

BOILER SEALING PANEL REMOVAL

1. Release the 2 retaining clips.

2. Swing the panel open to the left and disengage it from

the boiler.

54

CASING REMOVAL

1. Undo the securing screw.

2. Lift to disengage the casing from the back panel and

withdraw it from the boiler.

Page 40

40

Systemiser SE - Installation

56

FAN REMOVAL AND CLEANING

SERVICING

SERVICING

4. Inspect the spark and detection electrodes. Ensure that

they are clean and in good condition - replace if

necessary.

5. Check that the spark and electrode gaps are correct.

6. Check that the spark and detection leads are in good

condition ,and renew as necessary.

Legend

A Venturi B Sensing pipe

1. Undo the fan inlet venturi top securing screw.

2. Slacken the other 2 securing screws.

3. Slide the venturi upward to disengage the sensing

pipe from the gas manifold.

4. Withdraw the venturi, complete with sensing pipe,

from the boiler.

5. Depress the retaining clip and rotate the fan to the

right to disengage the bayonet fixing on the fan

outlet.

6. Draw the fan forward and unplug the electrical lead

from the motor.

7. Withdraw the fan from the boiler.

Check that the fan impeller runs freely. Clean with a

soft brush and renew as necessary.

Note. Always take care when handling the fan, in

order to preserve the balance of the impeller.

57

BURNER REMOVAL AND CLEANING

1. Disconnect the ignition and detection leads from the

electrodes.

2. Undo the 3 fixing screws securing the burner assembly.

Withdraw the burner assembly downward and out of the

heat exchanger.

3. Brush off any deposits that may have collected on the

burner, ensuring that the flame ports are unobstructed.

Note. Brushes with metallic bristles must NOT be used.

Page 41

41