IDEAL LOGIC HIU Direct MT, LOGIC HIU Direct HT, LOGIC HIU Indirect 50, LOGIC HIU Indirect 75 Installation And Servicing

INSTALLATION AND

SERVICING

LOGIC HIU (Heat Interface Unit)

Indirect 75

Indirect 50

Direct MT

Direct HT

When replacing any part on this appliance, use only spare parts that you can be assured conform to the safety and performance

specification that we require. Do not use reconditioned or copy parts that have not been clearly authorised by Ideal.

For the very latest copy of literature for specification and maintenance practices visit our website www.idealcommercialboilers.com

where you can download the relevant information in PDF format.

September 2017

UIN 211203 A04

GENERAL

2

LOGIC HIU - Installation & Servicing / Users

CONTENTS

Page

Introduction ...................................................................... 2

Safety Instructions .......................................................... 3

Logic HIU 75 Indirect & Logic HIU 50 Indirect ...... 4 to 13

Specication Indirect ....................................................... 4

Technical Specication .................................................... 5

Layout & Dimensions ....................................................... 6

Schematic & Flow Information ................................ 7 to 8

Hardware Content & Options .......................................... 9

Electronic Control System ............................................ 10

Electrical Connections ................................................... 11

Electrical Control Operation .......................................... 12

Displayed Error Codes ......................................... 12 to 13

Logic HIU Direct MT & Logic HIU Direct HT ........ 14 to 23

Specication Direct ........................................................ 14

Technical Specication .................................................. 15

Layout & Dimensions ..................................................... 16

Schematic & Flow Information ............................ 17 to 18

Hardware Content & Options ........................................ 19

Electronic Control System............................................. 20

Electronic Control Connections .................................... 21

Electrical Control Operation .......................................... 22

Displayed Error Codes ......................................... 22 to 23

Installation ....................................................................... 24

Commissioning ............................................................... 25

Heat Meter ....................................................................... 25

Maintenance .......................................................... 26 to 27

Fault diagnostics .................................................. 28 to 29

LOGIC HIU

Unit UIN No.

Logic HIU Indirect 75 211093

Logic HIU Indirect 50 211094

Logic HIU Direct MT 211095

Logic HIU Direct HT 211096

Logic HIU Indirect 75 (+ CF ECHO II Mbus 1 Meter) 211346

Logic HIU Indirect 50 (+ CF ECHO II Mbus 1 Meter) 211347

Logic HIU Direct MT (+ CF ECHO II Mbus 1 Meter) 211348

Logic HIU Direct HT (+ CF ECHO II Mbus 1 Meter) 211349

Logic HIU Indirect 75 (+ CF ULTRAMAX X V PS Meter) 211350

Logic HIU Indirect 50 (+ CF ULTRAMAX X V PS Meter) 211351

Logic HIU Direct MT (+ CF ULTRAMAX X V PS Meter) 211352

Logic HIU Direct HT (+ CF ULTRAMAX X V PS Meter) 211353

Health & Safety Document No. 635.

(The electrical at work regulations 1989). The manufacturer’s

notes must NOT be taken, in any way, as overriding statutory

obligations.

IMPORTANT. These appliances are CE certied for safety

and performance. It is, therefore, important that no external

control devices, e.g. economisers etc., are directly connected

to these appliances unless covered by these Installation and

Servicing Instructions or as otherwise recommended by Ideal

Boilers in writing, If in doubt please enquire.

Any direct connection of a control device not approved by

Ideal Boilers could invalidate the certication and the normal

appliance warranty.

INTRODUCTION

The Ideal Heat Interface Units (HIUs) are designed for use in

conjunction with an external central plant heat source. Examples

of central plant systems include centralised boilers, district heating

or central energy systems using renewable energy sources.

Detailed recommendations are contained in the following British

Standard Codes of Practice:

BSEN.12828:2003 Heating Systems in buildings:

Design for water based systems.

BSEN.12831:2003 Heating Systems in buildings: Method

for calculation of the design heat load.

BSEN.13831 Specication for: Expansion vessels

using an internal diaphragm, for sealed

hot water heating systems.

BSEN.14336:2004 Heating Systems in buildings:

Installation and commissioning of

water based heating systems.

The appliance is suitable only for installation in GB and IE and

should be installed in accordance with the rules in force.

The appropriate Building Regulations either The Building

Regulations, The Building Regulations (Scotland), Building

Regulations (Northern Ireland).

The Water Fittings Regulations or Water byelaws in Scotland.

The Current I.E.E. Wiring Regulations. In IE, the installation must

be carried out by a Competent Person and installed in accordance

with the current edition of I.S.813 and the current Building

Regulations and reference should be made to the current ETCI

rules for electrical installation. Where no specic instructions are

given, reference should be made to the relevant British Standard

Code of Practice.

GENERAL

3

LOGIC HIU -

Installation & Servicing / Users

SAFETY

These instructions need to be read and understood before

installing or maintaining these units. FAILURE TO FOLLOW

THESE INSTRUCTION COULD RESULT IN A SAFETY HAZARD.

The device must be installed, commissioned and maintained

by qualied technical personnel in accordance with national

regulations and /or relevant local requirements.

SAFE HANDLING

This HIU unit may require two or more operatives to move it to

its installation site, remove it from its packaging base and during

movement into its installation location. Maneuvering the appliance

may include the use of a sack truck and involve lifting, pushing

and pulling.

Caution should be exercised during these operations.

Operatives should be knowledgeable in handling techniques when

performing these tasks and the following precautions should be

considered:

• Grip the appliance at the base.

• Be physically capable.

• Use personal protective equipment as appropriate, e.g. gloves,

safety footwear.

During all maneuvers and handling actions, every attempt should

be made to ensure the following unless unavoidable and/or the

weight is light.

• Keep back straight.

• Avoid twisting at the waist.

• Avoid upper body/top heavy bending.

• Always grip with the palm of the hand.

• Use designated hand holds.

• Keep load as close to the body as possible.

• Always use assistance if required.

SAFE HANDLING OF SUBSTANCES

No asbestos, mercury or CFCs are included in any part of the

boiler or its manufacture.

INSTALLATION SAFE INSTRUCTIONS

• The device must be installed, commissioned and maintained

by qualied technical personnel in accordance with national

regulations and/or relevant local requirements.

• If the device is not installed, commissioned and maintained

correctly in accordance with the instructions provided in this

manual, it may not work correctly and may endanger the user.

• This device cannot be used in areas at risk of explosion or re.

• Ensure all electrical devices are protected from water when

maintaining the water based components.

• The device must not be exposed to water drops or humidity,

direct sunlight, the elements, heat sources or high intensity

electromagnetic elds.

• Flush the pipe work thoroughly (using the optional ushing

bypass UIN 211097) before installing the HIU to remove any

particles, rust, incrustations, lime scale, welding slag and any

other contaminants. The water circuits must be clean and free

from debris.

• Make sure that all connection ttings are watertight.

• When connecting water pipes, make sure that threaded

connections are not mechanically overstressed. Over time this

may result in breakage, causing water damage and/or personal

injury.

• Water temperatures higher than 50˚C may cause severe burns.

When installing, commissioning and maintaining the device,

take the necessary precautions so that these temperatures will

not be hazardous for people.

• In the case of particularly hard or impure water, there must be

suitable provision for ltering and treating the water before it

enters the device, in accordance with current legislation. Failure

to do so may result in the HIU becoming damaged or working

incorrectly.

• Any use of the HIU other than its intended use is prohibited.

• Any coupling of the device with other system components must

be made while taking the operational characteristics of both

units into consideration.

• An incorrect coupling could compromise the operation of the

device and/or system.

• Electrical installation must only be carried out by a qualied

technician, in accordance with current requirements.

• When connecting a room thermostat to this Unit NOTE IT

IS A VOLT FREE CONNECTION. DO NOT CONNECT

AN EXTERNAL VOLTAGE SUPPLY TO THE ROOM

THERMOSTAT TERMINALS.

MAINTENANCE SAFETY

• Before removing casing; the HIU unit should be in an off state

and cool enough to work on without the risk of burns from high

temperature components.

• The unit should be electrically isolated with the use of an

external bipolar switch. (No automated power switch systems

should be used as a direct isolation method for this HIU unit).

• During installation and maintenance operations, always avoid

direct contact with live or potentially hazardous parts.

• Take care to follow the instruction on any correctly rate pressure

equipment when working on the high pressure systems on

these units.

• Suitable automatic protection devices in compliance with

current legislation can be used in conjunction with a bipolar

isolation switch system.

• The device must always be earthed before it is connected to

the electric supply. If the device has to be removed, always

disconnect the earth connection after disconnecting the electric

supply. Check that the earth connection has been made to the

highest of standards under current legislation.

INDIRECT SPECIFICATION

4

LOGIC HIU - Installation & Servicing / Users

1 APPLIANCE TYPE

INDIRECT

LOGIC HIU INDIRECT 75

Indirect wall mounted HIU, with a 75kW instantaneous priority

DHW and 15 kW modulated CH. This can be converted to

under oor heating including inbuilt safety thermostat

capability.

LOGIC HIU INDIRECT 50

Indirect wall mounted HIU, with a 50kW instantaneous priority

DHW and 15 kW modulated CH. This can be converted to

under oor heating including inbuilt safety thermostat

capability.

Note: 75 Indirect unit is shown tted with lling loop attached (See Frame 13)

INDIRECT SPECIFICATION

5

LOGIC HIU -

Installation & Servicing / Users

2 TECHNICAL SPECIFICATION

OPERATION

Heating

The temperature setting operates on the principle of set point

regulation and can be xed within application limits.

Heating Set Point: 25 to 75°C

Nom. heating exchanger net output: 15 kW

Secondary circuit: Maximum pressure rating 3 bar Maximum

operating pressure 2.5 bar

Pump: UPM3 Auto L

Pump bypass setting: 0.45 bar

Pressure switch: opening 0.4 bar - closing 0.8 bar

Safety relief valve setting: 3 bar

Safety thermostat: 55˚C ±3

Expansion vessel: 7.5 litre

Optional Under oor heating capability

Heating control circuit is VOLT FREE

Domestic Hot Water - DHW

The DHW function takes priority over the heating

function controlled by the DHW priority ow switch

(component 10).

Set Point - DHW temperature 42 to 60°C

Domestic hot water: 10 bar

DHW circuit max. ow rate: 18 l/m (0.3 l/s)

Min.ow rate to activate domestic ow sensor: 2.7

l/m ±0.3

Max. Differential pressure on domestic water

modulating valve: Δp 1.65 bar

Min. Differential pressure on domestic water

modulating valve: Δp 0.35 bar

Heat exchanger capacity:

Nom. DHW heat exchanger net output: 50 kW Logic HIU Indirect 50

Nom. DHW heat exchanger net output: 75 kW Logic HIU Indirect 75

Optional Pre heat function

Primary Performance

Maximum working pressure: 16 bar - primary

3 bar - secondary

Maximum temperature: 85°C

Medium: Water

Max. Percentage of glycol 30%

Max. Recommended primary circuit ow rate: 1.2 m³/h

Electrical

Power supply: 230 V (ac)±10% 50 Hz

Power consumption: 80 W

Protection class: IP 40

Actuator: stepper 24 V

Probes: NTC 10 kΩ

Construction

Frame: RAL 9010 sprayed steel

Protective shell cover: PPE

Components: brass BS EN 12165 CW617N

Pipes: stainless steel

Exchanger: brazed stainless steel

LOGIC HIU INDIRECT 75, LOGIC HIU INDIRECT 50

INDIRECT SPECIFICATION

6

LOGIC HIU - Installation & Servicing / Users

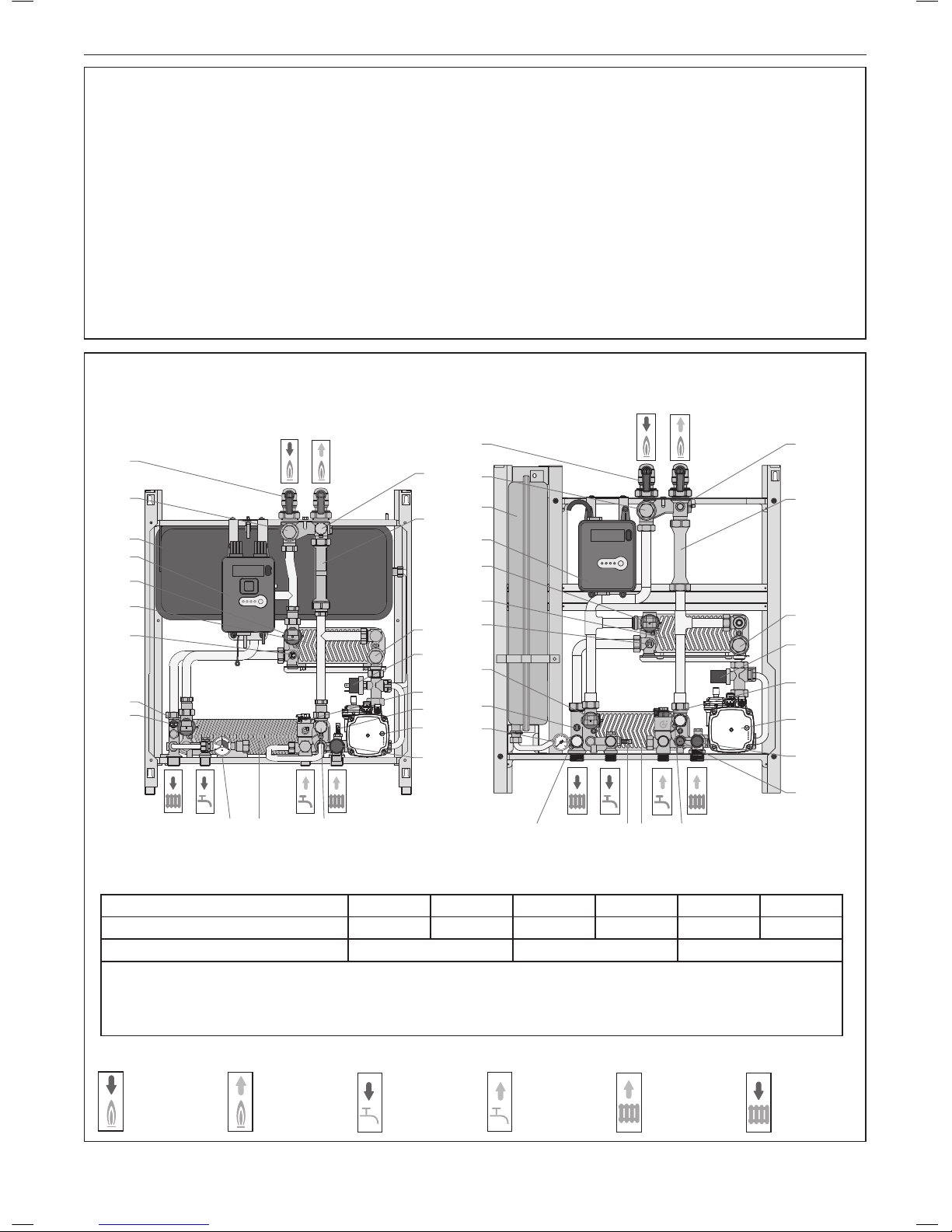

ON DHW CHFAULT

RESET

21

18

10

RESET

ON DHW CH FAULT

1

2

2

1

0

3

4

bar

20

17

16

3

2

1

19

11

5

13

7

15

4

14

822

C D

2

E F

1

19

11

5

13

7

15

4

14

22

A B

2

C D E F

9 8 2

21

20

18

10

17

16

3

2

A B

DIMENSIONS

Primary

circuit ow

Key to Symbols Schematic -

Connection A B C D E F

Threads G1” G1” G ¾’ G ½” G ½’ G ¾’

Pitch A to B 65mm C to D 65mm E to F 65mm

Height 630mm

Width 550mm

Depth (inc cover) 265mm

Weight 19 Kg

3 ITEM COMPONENT REFERENCE: LOGIC HIU INDIRECT 75, LOGIC HIU INDIRECT 50

1 Primary isolation valve (incorporating pressure test points)

2 Drain cock

3 Heat meter spacer piece - replaced by heat meter when tted

4 Primary lter and heat meter probe pocket

5 Heating circuit control valve

7 Modulating primary control valve (DHW)

8 Plate heat exchanger (DHW)

9 DHW temperature sensor

10 DHW ow switch

11 Electronic control unit

12 Room controller (not supplied)*

13 Plate heat exchanger (space heating)

14 Heating ow temperature sensor

15 Temperature control stat

16 Strainer (heating circuit)

17 Pump safety bypass and DP switch

18 Pump

19 Expansion vessel

20 Safety relief valve - 3 bar

21 Heating return temperature sensor

22 Pressure gauge

23 Filling loop isolation valve*

24 Filling loop double check valve*

25 Filling loop*

* Not shown on Components illustration.

4 TECHNICAL SPECIFICATION

LOGIC HIU INDIRECT 75 LOGIC HIU INDIRECT 50

Primary

circuit return

Domestic

hot water

outlet

Domestic

cold water

inlet

Heating

circuit return

Heating

circuit ow

INDIRECT SPECIFICATION

Flowrate - l/s

Flowrate - l/s

COMMON

HEATING

SYSTEM

COMMON

HEATING

SYSTEM

7

LOGIC HIU -

Installation & Servicing / Users

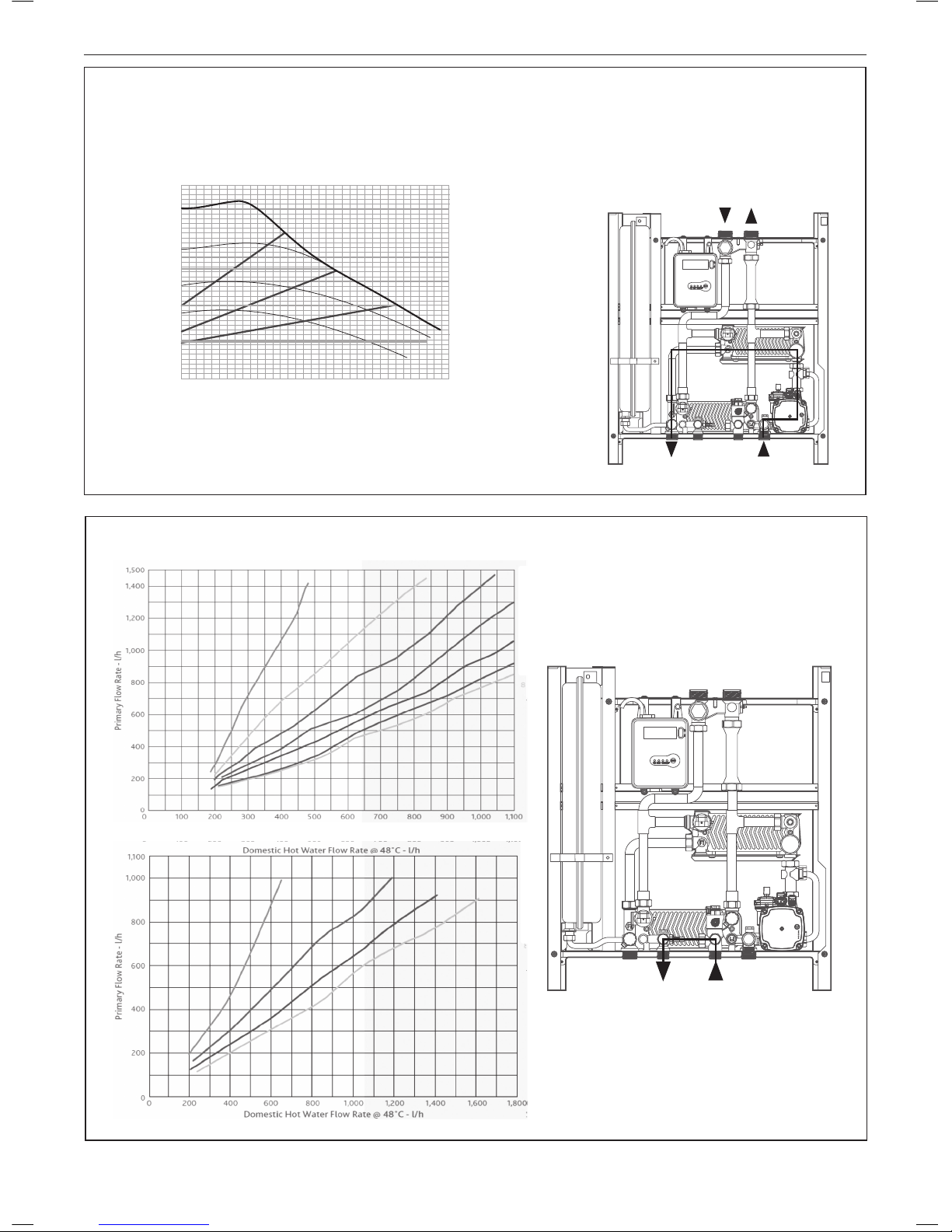

FLOW PATH

Heating Primary Circuit

5 SCHEMATIC LOGIC HIU INDIRECT 75 & LOGIC HIU INDIRECT 50

6 PRIMARY FLOW CHARACTERISTICS

7 PRIMARY FLOW CHARACTERISTICS

FLOW PATH

DHW - Primary Circuit

RESET

ON DHW CHFAULT

1

2

RESET

ON DHW CHFAULT

1

2

Kv = 2.25 m3/h

Kv = 2.03 m3/h

Pressure loss - kPa Pressure loss - kPa

INDIRECT SPECIFICATION

8

LOGIC HIU - Installation & Servicing / Users

8 HEATING FLOW CHARACTERISTICS FOR LOGIC HIU INDIRECT 75 & 50

9 DHW FLOW CHARACTERISTICS FOR LOGIC HIU INDIRECT 75 & 50

RESET

ON DHW CHFAU LT

1

2

RESET

ON DHW CH FAULT

1

2

55ºC

65ºC

55ºC

85ºC

75ºC

85ºC

80ºC

75ºC

70ºC

65ºC

60ºC

HEATING SECONDRY

FLOW CHARACTERISTICS

LOGIC HIU INDIRECT 50 & 75

DHW SECONDRY FLOW

CHARACTERISTICS

LOGIC HIU INDIRECT 50 & 75

HEATING

FLOW

HEATING

RETURN

DHW

OUT

MAINS

DHW

FEED

COMMON HEATING

SYSTEM

Δ

H (m c.a.)

H (m c.a.)

p (bar)

3 3,5

G (m3/h)

0,6

0,4

0,3

0,2

0,1

0

2,521,5

0,5

0,5

1

6

4

3

2

1

5

70,7

0,8 8

Flowrate - l/s

Pressure loss - kPa

INDIRECT HARDWARE CONTENTS

9

LOGIC HIU -

Installation & Servicing / Users

11 PRIMARY BALL VALVE SET

Flow & Control Valves (with sample points). (Inc. sealing washer to appliance)

CONTENT

Item Qty Component

1 2 16 Bar primary inlet ball valves with integrated pressure sampling points ¾”

BSP Union connection x ¾” BSP ball valve with union end and male threaded

connection joint*.

2 2 Rubber washers for union end connection and

2 Fibre washes for ¾” BSP connection face

12 DOMESTIC CONNECTION FLOW & RETURN VALVE KIT

(Inc. sealing washer to appliance)

CONTENT

Item Qty Component CH inlet and outlet connection valves (Inc. sealing washer to appliance)

2 2 22mm x ¾” ball valve with union end and compression joint* - one blue and one red handle.

3 Small component pack consisting of: 2 ¾” seal for union joint

DHW inlet and outlet connection valves (Inc. sealing washer to appliance)

1 2 15mm x ½” ball valve with union end and compression joint*.

2 15mm compression nut

2 15mm olive

13 FILLING LOOP CONNECTION KIT VALVES

(Inc. sealing washer to appliance & water check valve incorporated into inlet connection)

The lling loop and ball valves are used to ll and pressurise the secondary heating system,

the lling loop must be disconnected after pressurisation to comply with the Water Regulations.

CONTENT

Item Qty Component CH inlet and outlet connection valves

1 1 Ball valve with integral check valve and union joint.

2 1 Ball valve with union joint

3 1 Flexible hose 250mm long

4 2 ½” rubber sealing washer for union joint - black

5 2 Sealing washer for exible hose – green.

14 OPTIONAL FLUSHING BY-PASS

(Inc. Union built in rubber sealing washer)

Check the components in the kit before commencing. It is strongly

recommended the ushing by-pass option kit is tted as it allows for

cleaning of the primary water system loop whilst the HIU is tted.

1 ‘H’ pattern ushing bypass valve

2 Threaded male union tail piece - 4 off.

Install tails into HIU inlet connections

Fit Flushing by pass

Connect to primary pipe work

Turn screw driver slot horizontal to bypass.

Turn Vertical to connect the HIU to the primary circuit

10 LOGIC HIU INDIRECT 50 OR LOGIC HIU INDIRECT 75

* Compression ends complying with BS EN 1254-2 for use with R250 (half hard) copper tube

2

1

10

LOGIC HIU - Installation & Servicing / Users

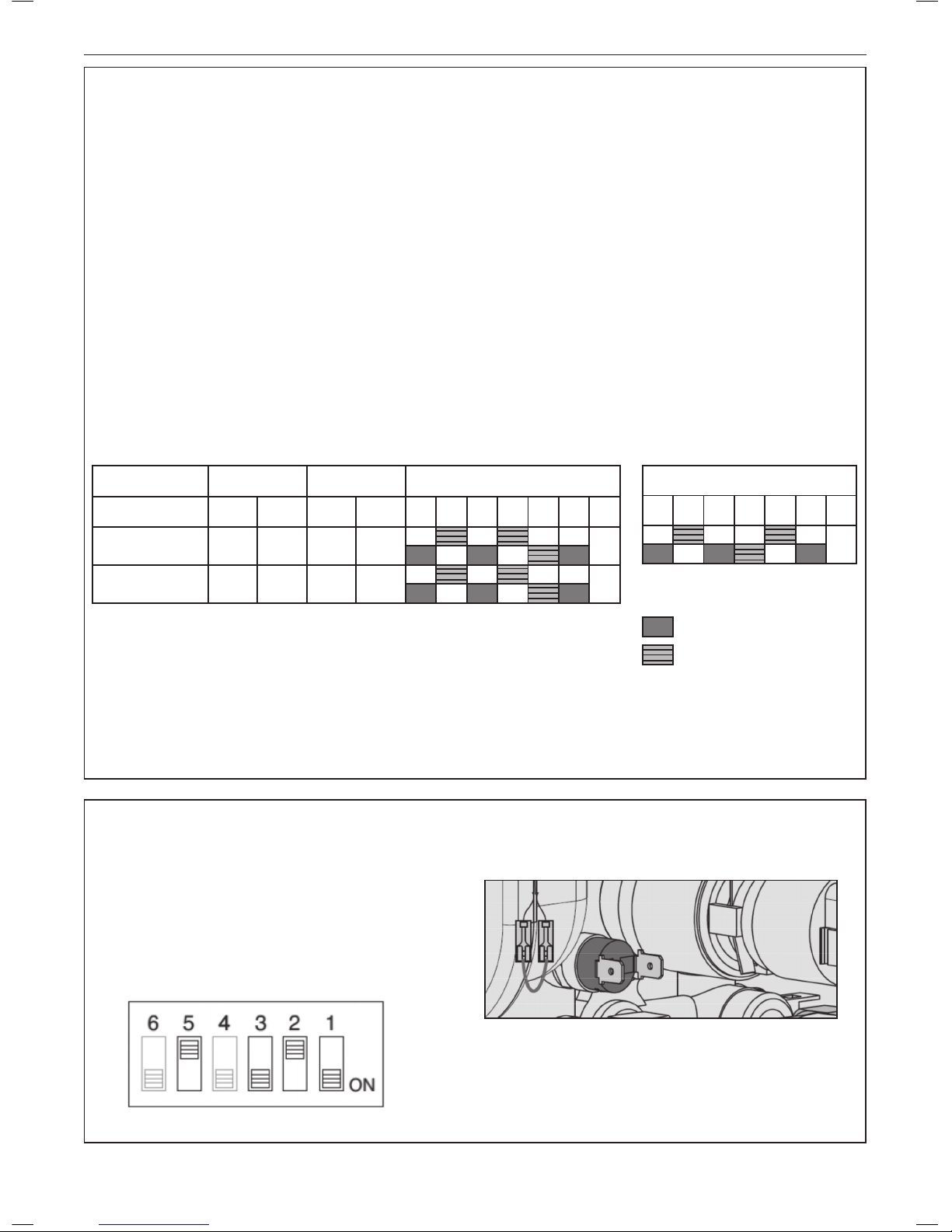

15 ELECTRONIC CONTROLLER

LOGIC HIU INDIRECT 50 & 75 KW UNITS

All the heating and domestic hot water functions offered by the

Logic Indirect HIUs are controlled by a digital controller.

The controller is factory set with the parameters for the HIU

unit ordered.

The Logic Indirect HIU versions offer the optional capability

to be converted for use on under oor heating by controlling

the CH central heating temperature below 45 C and the

activation of the safety thermostat that prevent the CH circuit

going above 45 °C. This can be achieved by setting the DIP

switches found inside the control box to the positions shown in

the sub table below (right-hand side).

Automatic controller functions

Reset mixing/modulating valve to zero - Immediately after the

power supply has been switched on, the position of the mixing/

modulating valves is reset to zero.

Pump anti-sieze - When the pump is not in use, it is powered

on for a period of 5 seconds every 24 hours.

Mixing valve/modulating valve anti-sieze - The anti-sieze cycle

for the mixing/modulating valve is run every 24 hours.

IMPORTANT

These DIP switches congure the control for different units

within the range. It is important that they are not changed

from those shown below. If they carehanged outside of these

requirements, it will cause the HIU to operate incorrectly and

may result in hazardous operational conditions.

Electronic Control

Dip Switch Settings

Factory Settings Setting Capability Production settings

Type Heating DHW Heating DHW 6 5 4 3 2 1

Logic HIU Indirect 50 75 54 25 to 75 42 to 60

ON

Logic HIU Indirect 75 75 54 25 to 75 42 to 60

ON

Underoor Low Temp Settings

6 5 4 3 2 1

ON

Do not change

Can be Changed

OPTION Indirect only

Switch 1 Modulating temperature regulation with compensated set point

Switch 2 & 3 Conversion to & from Low temperature to high temperature CH

Switch 5 Domestic water pre heating function

TABLE 1

To modify the factory settings, and enable the HIU to support low temperature systems 25 to 45ºC proceed as follows

16 CONVERTING THE UNIT TO UNDERFLOOR OPERATION

(LOGIC HIU INDIRECT 50 & 75KW UNITS)

To convert the unit to an underoor low temperature system

(25 to 45°C operation range)

1 Switch off the electricity power supply to the HIU

2 Set the switches 2 and 3 with the ON-OFF setting

3 Remove the safety thermostat jumper cable and connect

the cables to the thermostat.

4 Switch on the electricity power supply to the HIU.

INDIRECT ELECTRONIC CONTROL

Loading...

Loading...