IDEAL Logic HIU 50 Indirect, Logic HIU 75 Indirect, Logic HIU 50 Direct MT, Logic HIU 50 Direct HT Product Manual

Page 1

PRODUCT GUIDE

WE HAVE IT COVERED.

LOGIC HEAT

INTERFACE UNITS

(HIUs)

Page 2

02

Ideal Commercial Boilers is the UK’s market leader of

high efficiency commercial heating solutions.

Operating from its Hull manufacturing plant and offices

since 1906, Ideal Commercial Boilers is one of the few

true British manufacturers left in the heating industry.

Your phone or tablet can let you

appreciate our Condensing Boiler range

in a new dimension.

The Ideal Commercial Eye app uses

the latest technology to project 3D

renders from the page of this brochure

on to your device.

To see this for yourself, simply download the

Ideal Commercial Eye app for free from your

device’s app store. Open the app and then

place your device over the image that has

this icon next to it:

DOWNLOAD

THE APP

BRING BOILERS TO LIFE

Page 3

03

4 HIU Introduction

Logic HIU range

6-9 Logic HIU 50 Indirect

10-13 Logic HIU 75 Indirect

14-17 Logic HIU 50 Direct MT

18-20 Logic HIU 50 Direct HT

Metering & Accessories

21 CF Echo II

21 CF UltramaxX V

21 Accessories

Condensing Boiler range

23 Evomax

24-25 Evomax Cascade

26 Imax Xtra

27 Imax Xtra EL

28 Evomod

29 Evojet

30-31 Commercial range overview

32-33 Stelrad radiators

34-35 Ideal Training & Support

Page 4

04

TYPICAL

SYSTEM.

DOWNLOAD

THE APP

LOGIC HIU

INTRODUCTION

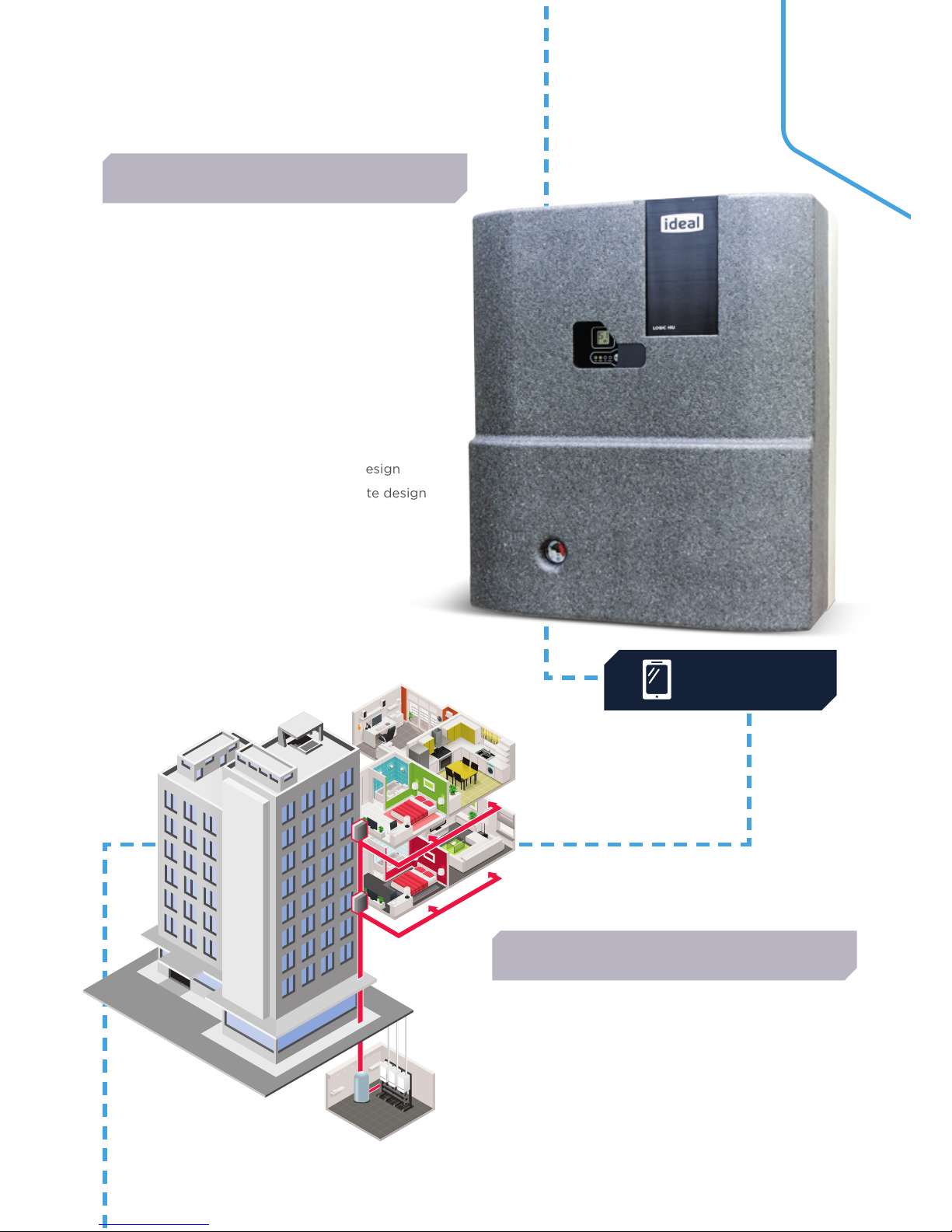

The Ideal Heat Interface Units are heat energy transfer

units. Designed for use in conjunction with centralised

boilers, district heating or central energy systems. The

function is to efficiently transfer heat from the plant

room to the individual dwelling’s central heating (CH)

and domestic hot water (DHW) systems.

TYPICAL SYSTEM

Page 5

05

Ideal HIUs incorporate an internal electronic control

unit which ensures not only maximum efficiency,

improved reaction time and control but also

incorporates other additional features.

Modulating valves control the supply of hot water to

both the space heating and domestic hot water within

the apartment.

The thermally insulated casings minimise heat loss

from the unit.

Maximum energy saving from the HIUs can only be

achieved if the system is designed correctly and HIUs

are selected and sized correctly.

To ensure maximum efficiency, reliability and

performance the system must be designed and

commissioned in accordance with CIBSE.

IDEAL LOGIC HIU

BENEFITS

THE BENEFITS OF IDEAL LOGIC HIUs ARE:

• Compact design requiring a minimum amount of space

• Minimal routine maintenance since they do not require

regular servicing or maintenance

• All the Logic HIUs incorporate a spacer piece which can

be easily removed and a heat meter fitted inside the unit.

This allows the energy used by each individual apartment

to be recorded and charged accordingly

THE LOGIC HIU RANGE HAS TWO METER

OPTI O N S AVAI L AB L E :

• CF ECHO II

• CF ULTRAMAXX V

Depending upon the meter chosen the energy used can

be monitored and recorded automatically which enables

automatic billing to the tenants.

For information on how to design Ideal Logic HIUs

into you next project please refer to the Design Guide which

covers:

• Unit selection

• Heating system layout

• Integration of low carbon heat sources

• Prediction of hot water simultaneous demands

SAP has been adopted by the Government as part of

the UK’s national standard for calculating the energy

performance of buildings.

Every new building has to have an SAP rating. It provides a

simple means of reliably estimating the energy efficiency.

SAP ratings are expressed on a scale of 1 to 100, the higher

the number the more energy efficient the building.

SAP RATING

Page 6

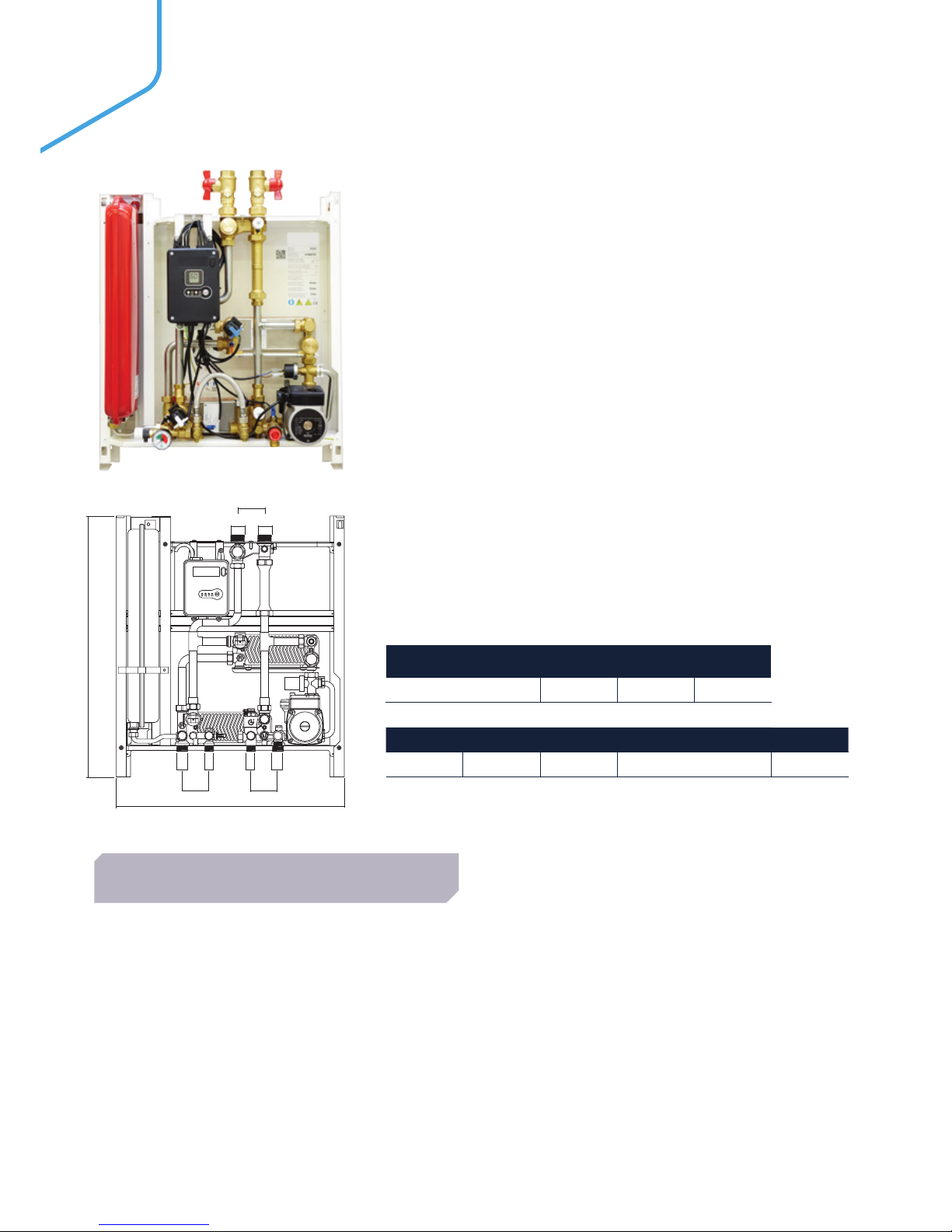

06

* After shut-off valves are installed the connections become a female 3/4’’.

CONNECTION A B C

Thread G¾” G½” G1”*

D E F Depth inc. Cover kg

65mm 550mm 630mm 265mm 19

F

A ABB

D

D

E

D

C

C

• Twin plate design hydraulically separates both domestic

and space heating from the central primary supply

• Internal electronic control unit with LCD display

• The standard unit can be set to hold a stable heating

flow temperature, to suit the installation (radiators, UFH

for example), but crucially, can also be set to vary the

heating flow temperature automatically depending on the

temperature of the heating return water

• Automatically compensates for changes due to external

influences, such as outside temperature etc. thereby

ensuring that the unit and the system operate at maximum

efficiency

• Pump bypass protection, in case of complete radiator

TRV shutdown

• Compact and lightweight

• Fully insulated EPP front cover

• Convertible to underfloor heating

• Configurable hot water priority

• Pressure independent control valve

• Ability to pre-heating of the DHW exchanger

FEATURES & BENEFITS

The Logic heat interface unit is the latest

‘intelligent’ range of HIU from Ideal. The Logic

HIU is the complete solution for instantaneous

hot water production and space heating control.

This is an indirect wall mounted HIU, providing

50 kW instantaneous priority DHW and 15 kW

modulated CH. This can be converted to under

floor heating including inbuilt safety thermostat

capability.

LOGIC HIU

50 INDIRECT

Page 7

07

Maximum working pressure: 16 bar - primar y

3 bar - secondary

Maximum temperature 85°C

Max. Percentage of glycol 30%

Max. Recommended primary

circuit flow rate

1.2 m³/h

PRIMARY PERFORMANCE

Heat Interface Unit 50

Primary ball valve set

Domestic connection flow & return valve kit

Filling loop connection kit valves

Flushing By-pass

CF Echo II

CF Ultramaxx V

UIN PRODUC T NAME METERING OPTIONS

211094 Logic HIU Indirect 50

HIU only, meter not

included

211347 Logic HIU Indirect 50

Factory fitted, CF Echo 11

MbBus 1

211351 Logic HIU Indirect 50

Factory fitted, CF

Ultramaxx V MBus PS

Power supply 230 V (ac)±10% 50 Hz

Max. Power consumption 105 W

Protection class IP 40

Actuator Stepper 24 V

Probes NTC 10 kΩ

ELECTRICAL

Frame RAL 9010 sprayed steel

Protective shell cover EPP (Expanded polypropylene)

Components Brass BS EN 12165 CW617N

Pipes Stainless steel

Exchanger Brazed stainless steel

CONSTRUCTION

INCLUDED AS STANDARD

ACCESSORIES

The temperature setting operates on the principle of set

point regulation and can be fixed within application limits.

Heating Set Point 25 to 75°C

Nom. heating exchanger net

output:

15 kW

Secondary circuit: Maximum pressure rating 3 bar

Maximum operating pressure

2.5 bar

Pump UPS 15/60

Pump bypass setting 0.45 bar

Pressure switch Opening 0.4 bar

Closing 0.8 bar

Safety relief valve setting 3 bar

Safety thermostat 55˚C ±3

Expansion vessel 7.5 litre

Under floor heating capability Optional

Heating control circuit VOLT FREE

HEATING

The DHW function takes priority over the heating function

controlled by the DHW priority flow switch.

Set Point DHW temperature 42 to 60°C

Max. Domestic hot water

pressure

10 bar

DHW circuit max. flow rate 18 l/m (0.3 l/s)

Min. flow rate to activate

domestic flow sensor

2.7 l/m ±0.3

Max. Differential pressure on

domestic water modulating

valve

Δp 1.65 bar

Min. Differential pressure on

domestic water modulating

valve

Δp 0.35 bar

Nom. DHW heat exchanger

net output

50 kW - Logic HIU

50 Indirect

DOMESTIC HOT WATER - DHW

INCLUDING OPTIONAL PRE HEAT FUNCTION

Page 8

08

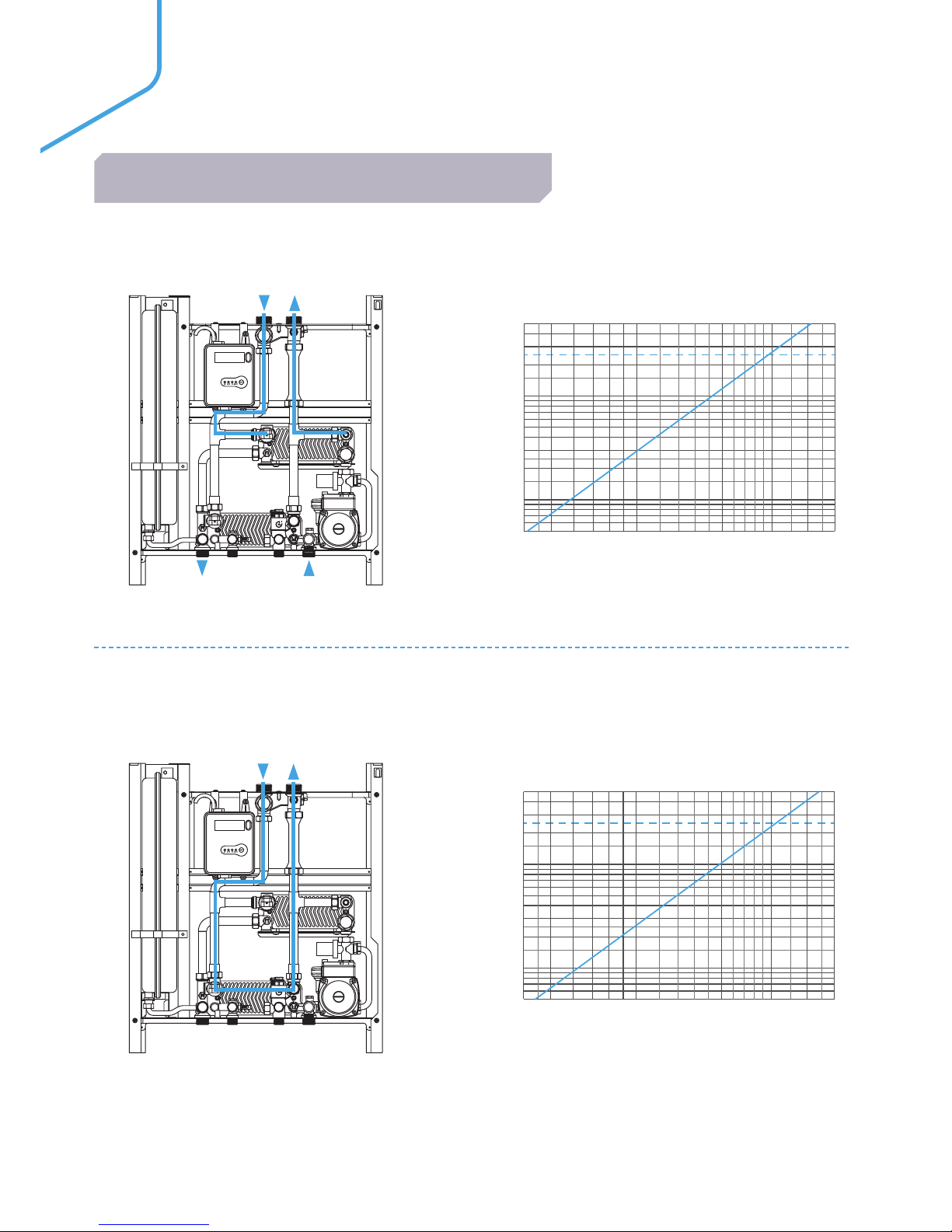

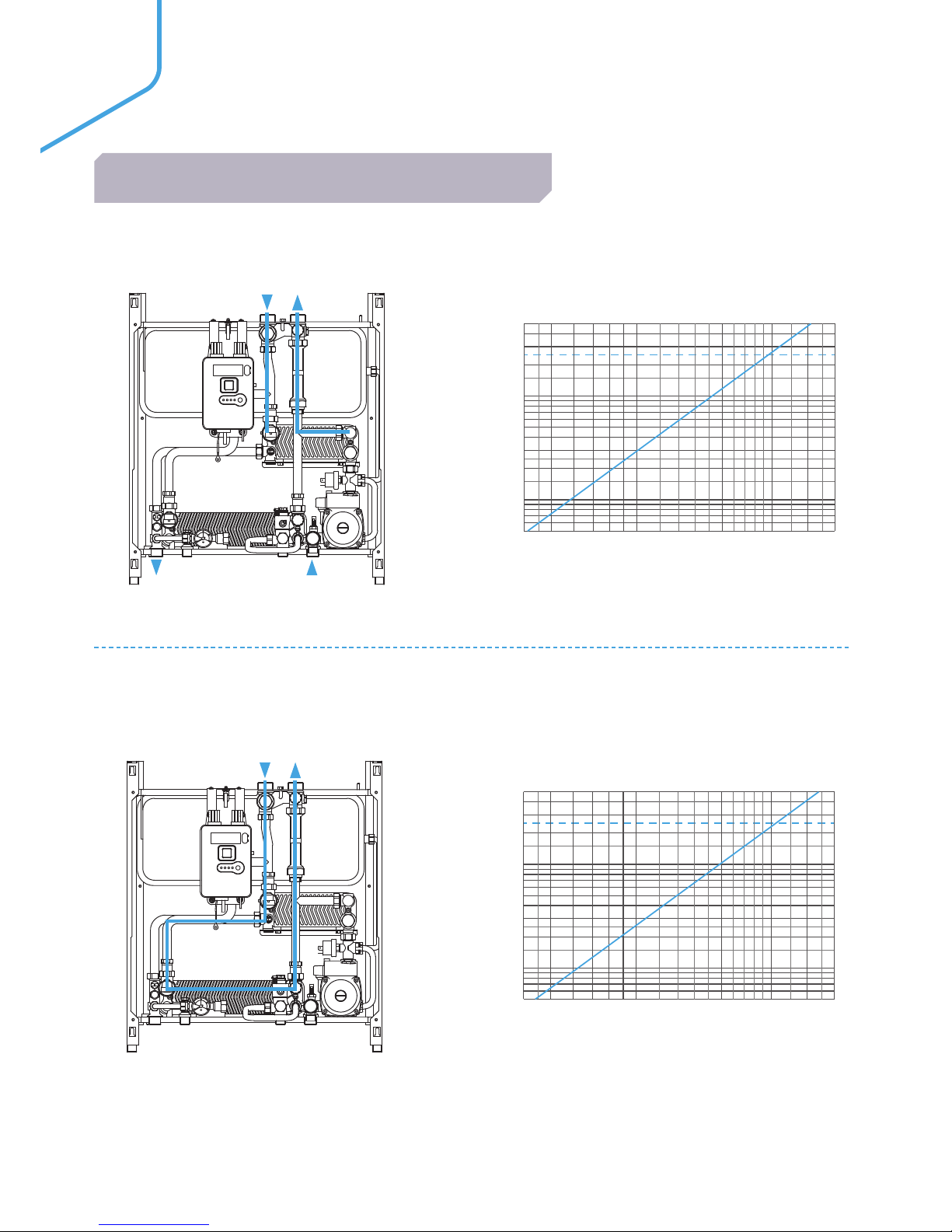

HYDRAULIC CHARACTERISTICS DOMESTIC HOT WATER - PRIMARY SIDE

HYDRAULIC CHARACTERISTICS HEATING - PRIMARY SIDE

DOMESTIC HOT WATER

0.04 0.06 0.08 0.1 0.2 0.3 0.4 0.5

Flowrate - l/s

50

10

1

0.5

20

30

2

3

5

Pressure loss - kPa

Kv = 2.03 m³/h

Flow Path

Heating - primary side

ONON DHWDHW CHCH FAFAULULTT

RRESETESET

11

22

HR

HF

CHS

HEATI N G

CHS

HRHF

DHW - heat exchanger

0.04 0.06 0.08 0.1 0.2 0.3 0.4 0.5

0.04 0.06 0.08 0.1 0.2 0.3 0.4 0.5

Flowrate - l/s

50

10

1

0.5

20

30

2

3

5

Pressure loss - kPa

Kv = 2.25 m³/h

Hydraulic Characteristics

Heating - secondary side

Flow Path

Heating - secondary side

ONON DHWDHWCHCHFAFAULULTT

RRESETESET

11

22

CHS

0

10

20

30

40

50

60

0 0.1 0.2 0.3 0.4 0.5 0.6

Flowrate -l/s

Pressure loss -kPa

3

2

1

Kv = 2.63 m³/h

UPS 15 - 60 pump settings

ONON DHWDHW CHCH FAFAULULTT

RRESETESET

11

22

CHS

HRHF

DHW - heat exchanger

Flowrate - l/s

50

10

1

0.5

20

30

2

3

5

Pressure loss - kPa

Kv = 2.03 m³/h

Flow Path

Heating - primary side

ONON DHWDHW CHCH FAFAULULTT

RRESETESET

11

22

HR

HF

CHS

CHS

PRIMARY FLOW CHARACTERISTICS

Page 9

09

HYDRAULIC CHARACTERISTICS HEATING - SECONDARY SIDE

0.04 0.06 0.08 0.1 0.2 0.3 0.4 0.5

Hydraulic Characteristics

Heating - secondary side

Flow Path

Heating - secondary side

0

10

20

30

40

50

60

0 0.1 0.2 0.3 0.4 0.5 0.6

Flowrate -l/s

Pressure loss -kPa

3

2

1

Kv = 2.63 m³/h

UPS 15 - 60 pump settings

ONON DHWDHW CHCH FAFAULULTT

RRESETESET

11

22

CHS

HRHF

Flowrate - l/s

50

10

1

0.5

20

30

2

3

5

Pressure loss - kPa

Kv = 2.03 m³/h

Flow Path

Heating - primary side

ONON DHWDHW CHCH FAFAULULTT

RRESETESET

11

22

HR

HF

CHS

CHS

HRHF

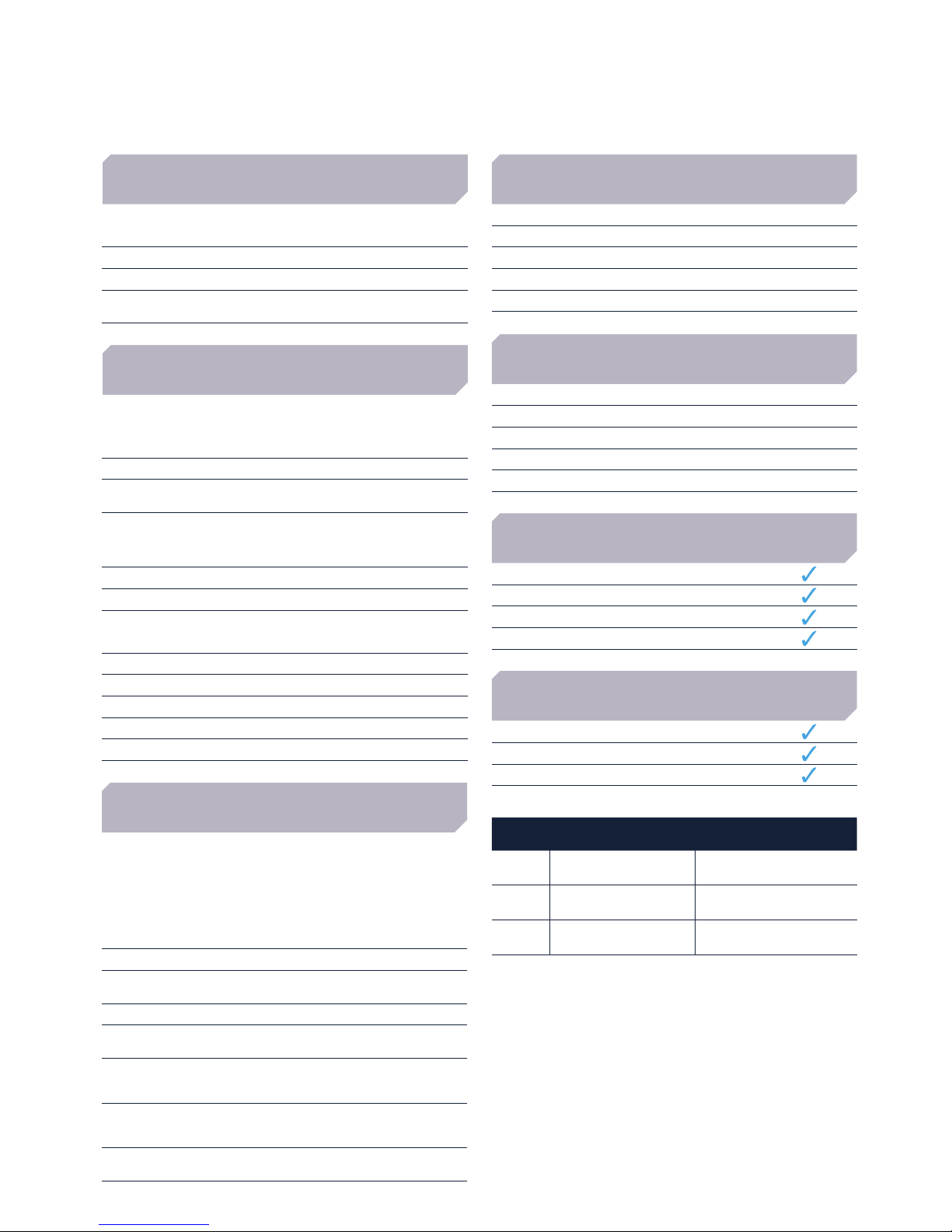

Primary Flow Rate I/h

Primary flow temperatures

1,500

1,400

1,200

1,000

800

600

400

200

0

0 100 200 300 400 500 600 700 800 900 1,000 1,100

Domestic Hot Water Flow Rate @ 48˚C - l/h

55˚C

60˚C

65˚C

70˚C

75˚C

80˚C

85˚C

Primary flow temperatures

55˚C

60˚C

65˚C

70˚C

75˚C

80˚C

85˚C

Primary flow temperatures

55˚C

60˚C

65˚C

70˚C

Primary

flow temperatures

temperatures

DOMESTIC HOT WATER OUTPUT

Page 10

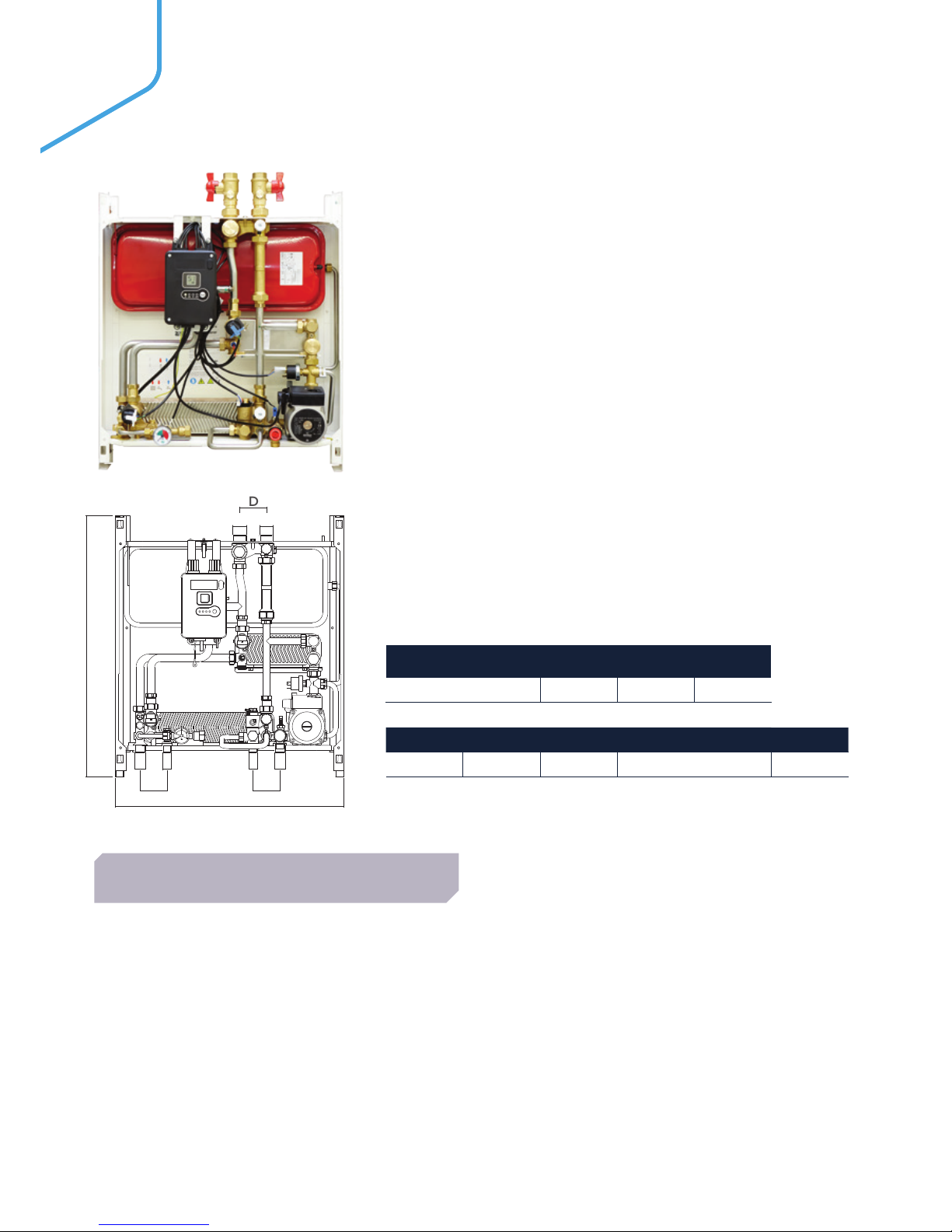

10

ON DHW CH FAULT

RESET

F

A ABB

D

D

E

D

C

C

* After shut-off valves are installed the connections become a female 3/4’’.

CONNECTION A B C

Thread G¾” G½” G1”*

D E F Depth inc. Cover kg

65mm 550mm 630mm 265mm 19

• Twin plate design hydraulically separates both domestic

and space heating from the central primary supply

• Internal electronic control unit with LCD display

• The standard unit can be set to hold a stable heating

flow temperature, to suit the installation (radiators, UFH

for example), but crucially, can also be set to vary the

heating flow temperature automatically depending on the

temperature of the heating return water

• Automatically compensate for changes due to external

influences, such as outside temperature etc. thereby

ensuring that the unit and the system operate at maximum

efficiency

• Convertible to underfloor heating

• Configurable hot water priority

• Pressure independent control valve

• Pump bypass protection, in case of complete radiator TRV

shutdown

• Ability to pre-heating of the DHW exchanger

FEATURES & BENEFITS

The Logic heat interface unit is the latest

‘intelligent’ range of Logic HIUs from Ideal.

The Logic HIU is the complete solution for

instantaneous hot water production and space

heating control.

This is an indirect wall mounted HIU, providing

75 kW instantaneous priority DHW and 15 kW

modulated CH. This can be converted to under

floor heating including inbuilt safety thermostat

capability.

LOGIC HIU

75 INDIRECT

Page 11

11

Maximum working pressure: 16 bar - primar y

3 bar - secondary

Maximum temperature 85°C

Max. Percentage of glycol 30%

Max. Recommended primary

circuit flow rate

1.2 m³/h

PRIMARY PERFORMANCE

Heat Interface Unit 75

Primary ball valve set

Domestic connection flow & return valve kit

Filling loop connection kit valves

Flushing By-pass

CF Echo II

CF Ultramaxx V

UIN PRODUC T NAME METERING OPTIONS

211093 Logic HIU Indirect 75

HIU only, meter not

included

211346 Logic HIU Indirect 75

Factory fitted, CF Echo 11

MbBus 1

211350 Logic HIU Indirect 75

Factory fitted, CF

Ultramaxx V MBus PS

Power supply 230 V (ac)±10% 50 Hz

Max. Power consumption 105 W

Protection class IP 40

Actuator Stepper 24 V

Probes NTC 10 kΩ

ELECTRICAL

Frame RAL 9010 sprayed steel

Protective shell cover EPP (Expanded polypropylene)

Components Brass BS EN 12165 CW617N

Pipes Stainless steel

Exchanger Brazed stainless steel

CONSTRUCTION

INCLUDED AS STANDARD

ACCESSORIES

The temperature setting operates on the principle of set

point regulation and can be fixed within application limits.

Heating Set Point 25 to 75°C

Nom. heating exchanger net

output:

15 kW

Secondary circuit: Maximum pressure rating 3 bar

Maximum operating pressure

2.5 bar

Pump UPS 15/60

Pump bypass setting 0.45 bar

Pressure switch Opening 0.4 bar

Closing 0.8 bar

Safety relief valve setting 3 bar

Safety thermostat 55˚C ±3

Expansion vessel 7.5 litre

Under floor heating capability Optional

Heating control circuit VOLT FREE

HEATING

The DHW function takes priority over the heating function

controlled by the DHW priority flow switch.

Set Point DHW temperature 42 to 60°C

Max. Domestic hot water

pressure

10 bar

DHW circuit max. flow rate 26.6l/m (0.44l/s)

Min. flow rate to activate

domestic flow sensor

2.7 l/m ±0.3

Max. Differential pressure on

domestic water modulating

valve

Δp 1.65 bar

Min. Differential pressure on

domestic water modulating

valve

Δp 0.35 bar

Nom. DHW heat exchanger

net output

75 kW - Logic HIU

75 Indirect

DOMESTIC HOT WATER - DHW

INCLUDING OPTIONAL PRE HEAT FUNCTION

Page 12

12

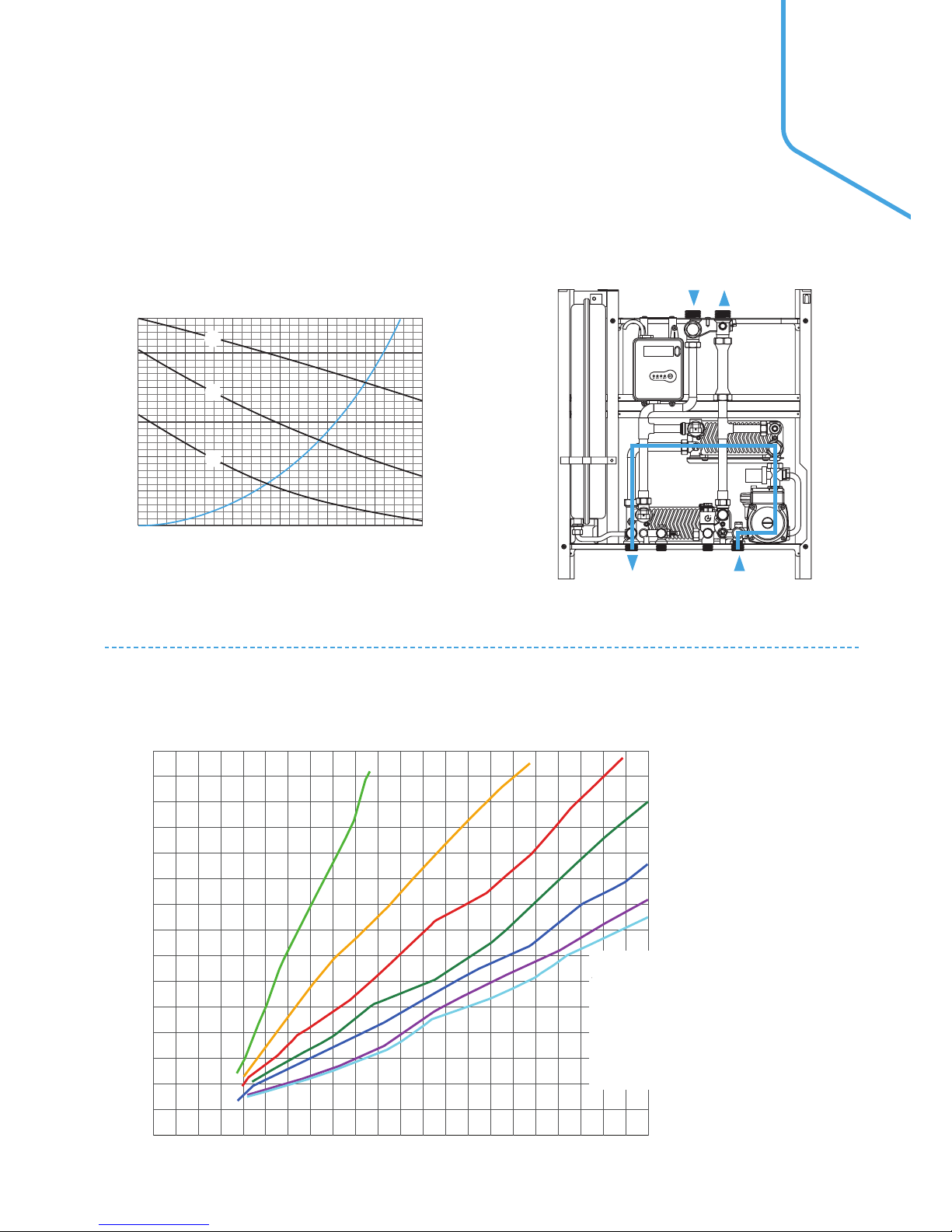

HYDRAULIC CHARACTERISTICS DOMESTIC HOT WATER - PRIMARY SIDE

HYDRAULIC CHARACTERISTICS HEATING - PRIMARY SIDE

DOMESTIC HOT WATER

0.04 0.06 0.08 0.1 0.2 0.3 0.4 0.5

Flowrate - l/s

50

10

1

0.5

20

30

2

3

5

Pressure loss - kPa

Kv = 2.03 m³/h

Flow Path

Heating - primary side

ONON DHWDHW CHCH FAFAULULTT

RRESETESET

11

22

HR

HF

CHS

HEATI N G

DHW - heat exchanger

0.04 0.06 0.08 0.1 0.2 0.3 0.4 0.5

0.04 0.06 0.08 0.1 0.2 0.3 0.4 0.5

Flowrate - l/s

50

10

1

0.5

20

30

2

3

5

Pressure loss - kPa

Kv = 2.25 m³/h

Hydraulic Characteristics

Heating - secondary side

Flow Path

Heating - secondary side

ONON DHWDHWCHCHFAFAULULTT

RRESETESET

11

22

CHS

0

10

20

30

40

50

60

0 0.1 0.2 0.3 0.4 0.5 0.6

Flowrate -l/s

Pressure loss -kPa

3

2

1

Kv = 2.63 m³/h

UPS 15 - 60 pump settings

ONON DHWDHW CHCH FAFAULULTT

RRESETESET

11

22

CHS

HRHF

DHW - heat exchanger

Flowrate - l/s

50

10

1

0.5

20

30

2

3

5

Pressure loss - kPa

Kv = 2.03 m³/h

Flow Path

Heating - primary side

ONON DHWDHW CHCH FAFAULULTT

RRESETESET

11

22

HR

HF

CHS

PRIMARY FLOW CHARACTERISTICS

ON DHW CH FAULT

RESET

CHS

ON DHW CH FAULT

RESET

CHS

HRHF

Page 13

13

1,100

1,000

800

600

400

200

0

0 200 400 600 800 1,000 1,200 1,400 1,600 1,800

Domestic Hot Water Flow Rate @ 48˚C - l/h

Primary Flow Rate I/h

Primary flow temperatures

55˚C

65˚C

75˚C

85˚C

Primary

flow temperatures

temperatures

Primary flow temperatures

55˚C

65˚C

Primary flow temperatures

55˚C

65˚C

75˚C

85˚C

HYDRAULIC CHARACTERISTICS HEATING - SECONDARY SIDE

0.04 0.06 0.08 0.1 0.2 0.3 0.4 0.5

Hydraulic Characteristics

Heating - secondary side

Flow Path

Heating - secondary side

0

10

20

30

40

50

60

0 0.1 0.2 0.3 0.4 0.5 0.6

Flowrate -l/s

Pressure loss -kPa

3

2

1

Kv = 2.63 m³/h

UPS 15 - 60 pump settings

ONON DHWDHW CHCH FAFAULULTT

RRESETESET

11

22

CHS

HRHF

Flowrate - l/s

50

10

1

0.5

20

30

2

3

5

Pressure loss - kPa

Kv = 2.03 m³/h

Flow Path

Heating - primary side

ONON DHWDHW CHCH FAFAULULTT

RRESETESET

11

22

HR

HF

CHS

DOMESTIC HOT WATER OUTPUT

ON DHW CH FAULT

RESET

CHS

HRHF

Page 14

14

* After shut-off valves are installed the connections become a female 3/4’’.

** Not shown on components illustration.

CONNECTION A B C

Thread G¾” G½” G1”*

D E F Depth inc. Cover kg

65mm 450mm 550mm 265mm 16

• Single plate design hydraulically separates the domestic

water with the space heating supplied directly from the

central primary supply

• Internal electronic control unit with LCD display

• Can be set to modulate the heating flow circuit for greater

efficiency and to compensate for changes in the external

environment

• Complete with a heating support pump, as standard,

including a pump bypass loop in case of complete radiator

TRV shutdown

• Compact and lightweight

• Fully insulated EPP front cover

• Includes differential pressure control valve (DPCV)**

supplied and fitted to the base of the unit

• Ability to pre-heating of the DHW exchanger

FEATURES & BENEFITS

The Logic heat interface unit is the latest

‘intelligent’ range of Logic HIUs from Ideal.

The Logic HIU is the complete solution for

instantaneous hot water production and space

heating control.

This is a direct wall mounted HIU, providing 50

kW indirect instantaneous priority Domestic

Hot Water (DHW). Central Heating (CH) is

dependent upon the primary system design

and pump specification.

LOGIC HIU

50 DIRECT MEDIUM TEMP

F

AB

D

E

D

A B

D

C

C

Page 15

15

Maximum working pressure: 10 bar

Maximum temperature 85°C

Max. Percentage of glycol 30%

Max. Recommended primary

circuit flow rate

1.2 m³/h

PRIMARY PERFORMANCE

Heat Interface Unit MT

Primary ball valve set

Central heating flow & return valves

DHW inlet and outlet connection valves

Differential pressure control (DPC)

UIN PRODUC T NAME METERING OPTIONS

211095 Logic HIU Direct MT

HIU only, meter not

included

211348 Logic HIU Direct MT

Factory fitted, CF Echo 11

MbBus 1

211352 Logic HIU Direct MT

Factory fitted, CF

Ultramaxx V MBus PS

Power supply 230 V (ac)±10% 50 Hz

Max. Power consumption 105 W

Protection class IP 40

Actuator Stepper 24 V

Probes NTC 10 kΩ

ELECTRICAL

Frame RAL 9010 sprayed steel

Protective shell cover EPP (Expanded polypropylene)

Components Brass BS EN 12165 CW617N

Pipes Stainless steel

Exchanger Brazed stainless steel

CONSTRUCTION

INCLUDED AS STANDARD

The temperature setting operates on the principle of set

point regulation and can be fixed within application limits.

HEATING

The DHW function takes priority over the heating function

controlled by the DHW priority flow switch.

Set Point DHW temperature 42 to 60°C

Max. Domestic hot water

pressure

10 bar

DHW circuit max. flow rate 18 l/m (0.3 l/s)

Min. flow rate to activate

domestic flow sensor

2.7 l/m ±0.3

Max. Differential pressure on

domestic water modulating

valve

Δp 0.9 bar

Min. Differential pressure on

domestic water modulating

valve

Δp 0.35 bar

Nom. DHW heat exchanger

net output

50 kW - Logic HIU 50

Direct MT

DOMESTIC HOT WATER - DHW

INCLUDING OPTIONAL PRE HEAT FUNCTION

Flushing By-pass

CF Echo II

CF Ultramaxx V

ACCESSORIES

Heating Set Point 50 to 75°C

Nom. heating net output As primary and heating circuit

controls permit

Heating circuit Maximum pressure rating: 10

bar as primary and heating

circuit

controls permit

Pump UPS 15/60

Pump bypass setting 0.45 bar

Heating control circuit VOLT FREE

Page 16

16

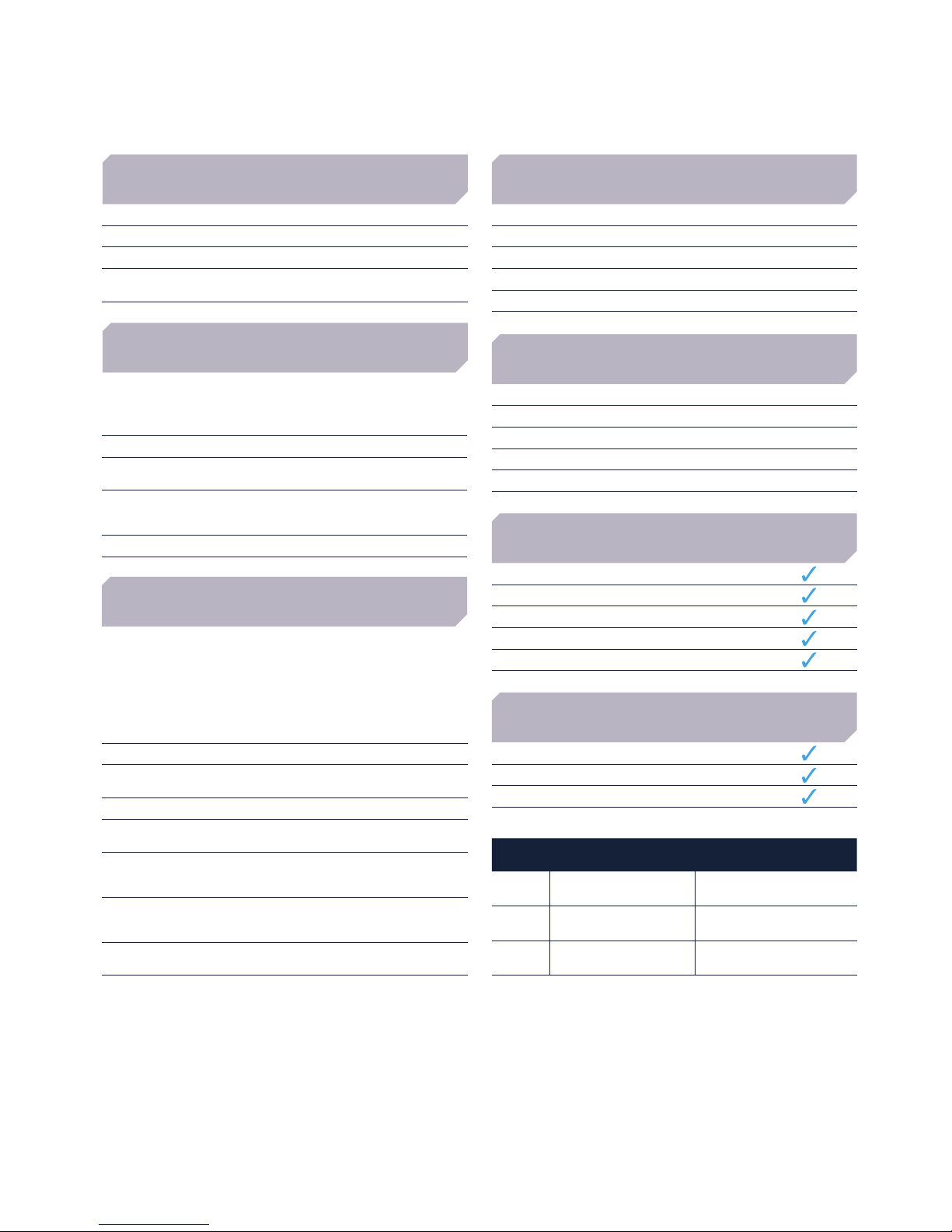

DHW - heat exchanger

0.04 0.06 0.08 0.1 0.2 0.3 0.4 0.5

0.04 0.06 0.08 0.1 0.2 0.3 0.4 0.5

Flowrate - l/s

50

10

1

0.5

20

30

2

3

5

Pressure loss - kPa

Kv = 2.25 m³/h

Hydraulic Characteristics

Heating - secondary side

Flow Path

Heating - secondary side

ONON DHWDHWCHCHFAFAULULTT

RRESETESET

11

22

CHS

0

10

20

30

40

50

60

0 0.1 0.2 0.3 0.4 0.5 0.6

Flowrate -l/s

Pressure loss -kPa

3

2

1

Kv = 2.63 m³/h

UPS 15 - 60 pump settings

ONON DHWDHW CHCH FAFAULULTT

RRESETESET

11

22

CHS

HRHF

DHW - heat exchanger

Flowrate - l/s

50

10

1

0.5

20

30

2

3

5

Pressure loss - kPa

Kv = 2.03 m³/h

Flow Path

Heating - primary side

ONON DHWDHW CHCH FAFAULULTT

RRESETESET

11

22

HR

HF

CHS

Kv = 2.04 m³/h

0

10

20

30

40

50

60

Flowrate -l/s

Pressure loss -kPa

3

2

1

0

10

20

30

40

50

60

0 0.1 0.2 0.3 0.4 0.5 0.6

0 0.1 0.2 0.3 0.4 0.5 0.6

0 0.1 0.2 0.3 0.4 0.5 0.6

Flowrate -l/s

Pressure loss -kPa

Kv = 2.12 m³/h

3

2

1

Flowrate - l/s

50

10

1

0.5

20

30

2

3

5

Pressure loss - kPa

Kv = 2.20 m³/h

0

10

20

30

40

50

60

Flowrate -l/s

Pressure loss -kPa

Kv = 2.12 m³/h

3

2

1

0.04 0.06 0.08 0.1 0.2 0.3 0.4 0.5

CHS

HYDRAULIC CHARACTERISTICS HEATING - PRIMARY SIDE

HYDRAULIC CHARACTERISTICS DOMESTIC HOT WATER - PRIMARY SIDE

HEATI N G

DOMESTIC HOT WATER

PRIMARY FLOW CHARACTERISTICS

CHS

HRHF

Page 17

17

Primary Flow Rate I/h

Primary flow temperatures

1,500

1,400

1,200

1,000

800

600

400

200

0

0 100 200 300 400 500 600 700 800 900 1,000 1,100

Domestic Hot Water Flow Rate @ 48˚C - l/h

55˚C

60˚C

65˚C

70˚C

75˚C

80˚C

85˚C

Primary flow temperatures

55˚C

60˚C

65˚C

70˚C

75˚C

80˚C

85˚C

Primary flow temperatures

55˚C

60˚C

65˚C

70˚C

Primary flow temperatures

temperatures

DOMESTIC HOT WATER OUTPUT

Page 18

18

* After shut-off valves are installed the connections become a female 3/4’’.

** Not shown on components illustration.

CONNECTION A B C

Thread G¾” G½” G1”*

D E F Depth inc. Cover kg

65mm 450mm 550mm 265mm 16

• Single plate design hydraulically separates the domestic

water with the space heating supplied directly from the

central primary supply

• Internal electronic control unit with LCD display

• Compact and lightweight

• Fully insulated EPP front cover

• Includes differential pressure control valve (DPCV)**

supplied and fitted to the base of the unit

• Ability to pre-heating of the DHW exchanger

FEATURES & BENEFITS

The Logic heat interface unit is the latest

‘intelligent’ range of Logic HIUs from Ideal.

The Logic HIU is the complete solution for

instantaneous hot water production and space

heating control.

This is a direct wall mounted HIU, providing 50

kW indirect instantaneous priority Domestic

Hot Water (DHW). Central Heating (CH) is

dependent upon the primary system design

and pump specification.

LOGIC HIU

50 DIRECT HIGH TEMP

F

AB

D

E

D

A B

D

C

C

Page 19

19

Maximum working pressure: 10 bar

Maximum temperature 85°C

Max. Percentage of glycol 30%

Max. Recommended primary

circuit flow rate

1.2 m³/h

PRIMARY PERFORMANCE

Heat Interface Unit HT

Primary ball valve set

Central heating flow & return valves

DHW inlet and outlet connection valves

Differential pressure control (DPC)

UIN PRODUC T NAME METERING OPTIONS

211096 Logic HIU Direct HT

HIU only, meter not

included

211349 Logic HIU Direct HT

Factory fitted, CF Echo 11

MbBus 1

211353 Logic HIU Direct HT

Factory fitted, CF

Ultramaxx V MBus PS

Power supply 230 V (ac)±10% 50 Hz

Max. Power consumption 105 W

Protection class IP 40

Actuator Stepper 24 V

Probes NTC 10 kΩ

ELECTRICAL

Frame RAL 9010 sprayed steel

Protective shell cover EPP (Expanded polypropylene)

Components Brass BS EN 12165 CW617N

Pipes Stainless steel

Exchanger Brazed stainless steel

CONSTRUCTION

INCLUDED AS STANDARD

The temperature setting operates on the principle of set

point regulation and can be fixed within application limits.

HEATING

The DHW function takes priority over the heating function

controlled by the DHW priority flow switch.

DOMESTIC HOT WATER - DHW

INCLUDING OPTIONAL PRE HEAT FUNCTION

Flushing By-pass

CF Echo II

CF Ultramaxx V

ACCESSORIES

Heating Set Point Dependent on primary system

Nom. heating exchanger net

output

As primary and heating circuit

controls permit

Heating circuit Maximum pressure rating: as

primary and heating circuit

controls permit

Heating control circuit VOLT FREE

Set Point DHW temperature 42 to 60°C

Max. Domestic hot water

pressure

10 bar

DHW circuit max. flow rate 18 l/m (0.3 l/s)

Min. flow rate to activate

domestic flow sensor

2.7 l/m ±0.3

Max. Differential pressure on

domestic water modulating

valve

Δp 0.9 bar

Min. Differential pressure on

domestic water modulating

valve

Δp 0.35 bar

Nom. DHW heat exchanger

net output

50 kW - Logic HIU 50 Direct

HT

Page 20

20

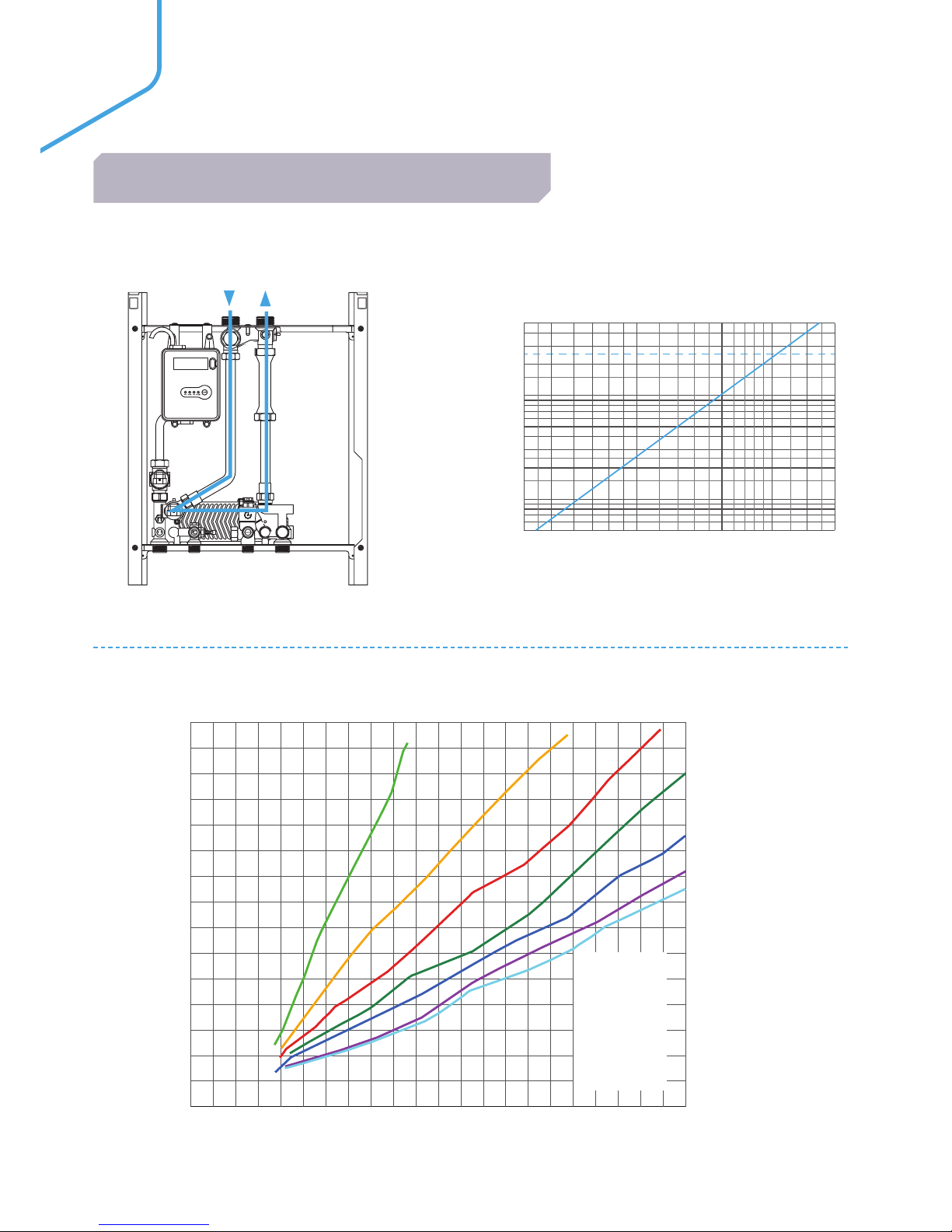

Primary Flow Rate I/h

Primary flow temperatures

1,500

1,400

1,200

1,000

800

600

400

200

0

0 100 200 300 400 500 600 700 800 900 1,000 1,100

Domestic Hot Water Flow Rate @ 48˚C - l/h

55˚C

60˚C

65˚C

70˚C

75˚C

80˚C

85˚C

Primary flow temperatures

55˚C

60˚C

65˚C

70˚C

75˚C

80˚C

85˚C

Primary flow temperatures

55˚C

60˚C

65˚C

70˚C

Primary

flow

temperatures

temperatures

DOMESTIC HOT WATER OUTPUT.

DHW - heat exchanger

0.04 0.06 0.08 0.1 0.2 0.3 0.4 0.5

0.04 0.06 0.08 0.1 0.2 0.3 0.4 0.5

Flowrate - l/s

50

10

1

0.5

20

30

2

3

5

Pressure loss - kPa

Kv = 2.25 m³/h

Hydraulic Characteristics

Heating - secondary side

Flow Path

Heating - secondary side

ONON DHWDHWCHCHFAFAULULTT

RRESETESET

11

22

CHS

0

10

20

30

40

50

60

0 0.1 0.2 0.3 0.4 0.5 0.6

Flowrate -l/s

Pressure loss -kPa

3

2

1

Kv = 2.63 m³/h

UPS 15 - 60 pump settings

ONON DHWDHW CHCH FAFAULULTT

RRESETESET

11

22

CHS

HRHF

DHW - heat exchanger

Flowrate - l/s

50

10

1

0.5

20

30

2

3

5

Pressure loss - kPa

Kv = 2.03 m³/h

Flow Path

Heating - primary side

ONON DHWDHW CHCH FAFAULULTT

RRESETESET

11

22

HR

HF

CHS

HYDRAULIC CHARACTERISTICS DOMESTIC HOT WATER - PRIMARY SIDE

DOMESTIC HOT WATER

PRIMARY FLOW CHARACTERISTICS

CHS

Page 21

21

• RHI compliant

• Ultrasonic pulse measurement

• MID certified (Measuring instruments directive)

• MBus + 1 water meter

CF ECHO II

FLUSHING BYPASS

SALES CODE 211097

FLUSHING BYPASS:

• Connects to primary flow on boiler plant side

• Enables main system pipework to be flushed

and cleaned whilst HIU remains isolated

• Blanking ports as standard to allow for

measuring differential pressure

(test points required)

ACCESSORIES

MODEL METER SALES CODE

Logic HIU 75 Indirect

Factory fitted

CF Echo 11 MBus 1

211346

Logic HIU 50 Indirect 211347

Logic HIU 50 Direct MT 211348

Logic HIU 50 Direct HT 211349

• RHI compliant

• Ultrasonic pulse measurement

• MID compliant (Measuring instruments directive)

• MBus PS

CF ULTRAMAXX V.

MODEL METER SALES CODE

Logic HIU 75 Indirect

Factory fitted CF

Ultramaxx V MBus

PS

211350

Logic HIU 50 Indirect 211351

Logic HIU 50 Direct MT 211352

Logic HIU 50 Direct HT 211353

METERING &

ACCESSORIES

Page 22

CONDENSING

COMMERCIAL

BOILERS

Page 23

23

EVOMAX

30 - 150kW

Available in outputs of 30, 40, 60, 80, 100, 120 and 150kW, the

Evomax is designed to ensure all installation requirements can be

achieved. There is also an LPG Evomax range from 30 - 80 kW for

off mains installations.

• 5 year warranty*

• Robust & light aluminium silicon alloy

heat exchanger

• Up to 110% part load efficiency

• High 5:1 turndown

• Compact – one width & height for easy siting

• Simple controls interface with large

backlit display

• Comprehensive range of flue, fixing and

control options

• Designed for easy installation, commissioning

and servicing

• Proven reliability through design, component

selection and proving

• NOx <40mg/kWh (Class 5) for all natural gas

models for maximum BREEAM points

FEATURES & BENEFITS

*5 year warranty subject to Terms and Conditions. 5 years parts and labour warranty available subject to being commissioned by Ideal Boilers.

DOWNLOAD

THE APP

Page 24

24

EVOMAX CASCADE

FRAME & HEADER KITS

BOILER FRAME AND HEADER KITS

The Frame and Header Kits are suitable for modular (cascade) boiler

installations, and are available up to a maximum output of

600 kW, in both in-line and back-to-back arrangements.

IN-LINE KITS

Kits include flow & return headers with mixing header and gas

header, all with fixing brackets. For easy connection flexible stainless

steel pipe and connections are supplied together with pressure relief

valves, boiler shut off valves and drain cock.

Appropriately sized ErP modulating shunt pumps are also included.

Flow, return and low loss headers together with the flexible boiler

connections are all pre insulated. Separate single boiler frame kits

are available for use with in-line kits if required.

BACK-TO-BACK KITS

Kits include all the in-line contents plus the required special frame

kits for such compact installations. Both types of kit are available

for the following number of boilers and sizes. Mixing header kits and

modulating pump kits are also available separately.

In-line kits do not include the support frame as the boilers can be wall mounted, but a frame kit is

available if the wall is unsuitable to facilitate boiler mounting.

For full details of all configurations & specifications, please refer to the installation manual.

2 boilers 30-100 DN80

2 boilers 120-150 DN80

3 boilers 30-100 DN80

3 boilers 120-150 DN100

4 boilers 30-100 DN100

4 boilers 120-150 DN100

5 boilers 30-100 DN100

5 boilers 120 DN100

6 boilers 30-100 DN100

Please note, the Evomax boilers are to be ordered separately.

AVAILABLE OPTIONS

DOWNLOAD

THE APP

Page 25

25

LOW HEIGHT FRAME & HEADER KITS

BOILER FRAME AND HEADER KITS

The Low Height Frame and Header Kits make installation much simpler in circumstances of reduced headroom,

offering an option of replacing a floor standing atmospheric boiler with a high efficiency model.

Three options are available allowing for outputs from 30 kW to 450 kW.

• Frame and Header Kits fit easily through

standard doorways

• Lift weights are as low as possible

• The Low Height Frame and Header Kit is supplied on one

palette shrink wrapped together with all ancillary fittings

needed for assembly

• All pipe work connections are supplied with either the

boiler, header kit or are pre assembled to the header kit

• Pre assembled to header; the boiler the flow and return

flexible connections, which reduce installation time

• Delivered with header kit; connection pipe assembly, non

return valves & pipe work connector, all isolation valves,

pressure relief valve, drain cock and associated fittings

• The Low Height Frame and Header Kit can be installed

with either an Ideal Commercial Sequencer offering direct

modulation of the system, reducing running costs, or a

proprietary option

• The extremely compact dimensions allow for replacement

of existing standard efficiency floor standing boilers,

using a single wall mounted condensing boiler up to 150

kW allowing sufficient space to install flue system, pump

and pipe headers

• High quality and well-finished components

• Supplied with frames and low energy modulating pumps

(ErP approved)

FEATURES & BENEFITS

AVAILABLE OPTIONS

1 Boiler 30-150 DN50 (2”BSP)

2 Boiler 60-300 DN65

3 Boiler 90-450 DN80

Page 26

26

IMAX XTRA

80 - 280kW

The Imax Xtra range of condensing boilers is offered in six models with

outputs from 80 to 280 kW suitable for floor standing application in

either single or multiple applications.

• Robust cast aluminium silicon alloy heat exchanger

• In-built commissioning and fault diagnostics

• Volt free contacts and BMS operation standard

• Meets Building Regulations (Part L2)

• Compact size - small footprint

• High 5:1 turndown

• Up to 107.5% net efficiency (fully condensing)

• Fits through standard doorways

• Conventional or room sealed flue options

• Direct weather compensation option

• NOx <40mg/kWh (Class 5) for maximum

BREEAM points

• 2 year parts and labour warranty

FEATURES & BENEFITS

DOWNLOAD

THE APP

Page 27

27

IMAX XTRA EL

320 - 1240kW

The Imax Xtra EL range of condensing boilers is available in 10

models with outputs from 320 to 1240kW. Suitable for floor standing

applications in either single or multiple installations.

• Simple control interface with large backlit display

• Volt free contacts

• 0-10V BMS operation standard

• Robust aluminium silicon alloy heat exchanger

• Suitable for single or multiple installations

• Up to 109.8% part load at 30% output

• 2 year parts and labour warranty

• NOx <40mg/kWh

• Natural Gas

• ErP compliant (320 - 395kW)

• Building Regulation Part L2 compliant

(470 - 1240kW)

FEATURES & BENEFITS

DOWNLOAD

THE APP

Page 28

28

EVOMOD

250 - 1000kW

Available in 250, 500, 750 and 1000 kW modules, the Evomod will achieve

an output up to 1MW from a single unit solution together with a minimum

footprint that enables the product to be installed where space is limited. Each

module provides a maximum of 250 kW heat output and will modulate down

through a sophisticated control system.

• Modules up to 3 high stacking

• Stainless steel heat exchanger

• Built in module diagnostics, sequencing and

remote indication

• Plain text display for fast and easy use

• Single flue outlet, system, gas and

electrical connections

• Up to 20:1 turndown: 1MW boiler can modulate

down to just 46.7kW

• Easy access for servicing

• Minimum footprint with easy site handling and

standard doorway access allowing simplified

plant replacement

• NOx <40mg/kWh (Class 5) for maximum

BREEAM points

• 2 year parts and labour warranty

• Up to 108.5% net efficiency (fully condensing)

• Single boiler control for all module options

FEATURES & BENEFITS

DOWNLOAD

THE APP

Page 29

29

EVOJET

150 - 1450kW

The Evojet condensing range of pressure jet boilers are available in

10 models with outputs from 150-1450kW. Floor standing boilers for

applications in either single or multiple configurations.

• Up to 109.3% part load efficiency

• Designed to operate up to 40°C ΔT providing

minimum flow rates are achieved

• Dedicated low temp return

• Stainless steel heat exchanger

• Natural gas, LPG, oil and dual fuel models

• Triple flue pass for high operating efficiencies

• Natural gas/LPG burner options - modulating or

high / low operation

• Modulation via 0-10 volt BMS, or RWF controller

FEATURES & BENEFITS

DOWNLOAD

THE APP

Page 30

3030

VANGUARD L

420-7000kW

• Steel Shell and Tube

• Floor Standing

• Range of matched burners

VICEROY GTS

450-780 kW

• Cast Iron heat exchanger

VISCOUNT GTS

754-1450 kW

• Cast Iron heat exchanger

CONDENSING BOILERS

PRESSURE JET BOILERS

EVOMAX

• Wall Hung

• Aluminium

Alloy Heat

Exchanger

• 30-150 kW

• 30-80kW LPG

IMAX XTRA

• Floor Standing

• Aluminium

Alloy Heat

Exchanger

• 80-280 kW

EVOMOD

• Floor Standing

• Stainless Steel

Heat Exchanger

• Modular

• 250-1000 kW

EVOJET

• Floor Standing

• Stainless Steel

Heat Exchanger

• 150-1450kW

• Condensing

Pressure Jet

• Natural Gas, LPG,

Oil or Dual Fuel

IMAX XTRA EL

• Floor Standing

• Aluminium

Alloy Heat

Exchanger

• 320-1240 kW

COMMERCIAL RANGE OVERVIEW.

Page 31

3131

• Indirect 50 & 75 units with twin plate design

• Direct 50 MT & HT units with single plate design

• Light weight and compact

• Ultrasonic metering options available

MODELS AVAILABLE:

LOGIC HIU 50 INDIRECT

LOGIC HIU 75 INDIRECT

LOGIC HIU 50 DIRECT

MEDIUM TEMP. (MT)

LOGIC HIU 50 DIRECT

HIGH TEMP. (HT)

The Ideal Heat Interface Units are heat energy transfer

units. Designed for use in conjunction with centralised

boilers, district heating or central energy systems. The

function is to efficiently transfer heat from the plant

room to the individual dwelling’s central heating (CH)

and domestic hot water (DHW) systems.

HEAT INTERFACE UNITS (HIU)

TYPICAL SYSTEM

DOWNLOAD

THE APP

Page 32

32

Page 33

33

Page 34

Page 35

3535

At Ideal, we are committed to delivering the highest

levels of customer service. With over a century of

experience in the heating industry, we know how

important confidence and trust is to our customers.

NEED HELP?

BOILER TRAINING

GET IN TOUCH WITH US TODAY

WE’VE GOT TRAINING COVERED

You can be confident to know that you’re partnering with a British manufacturer

that’s supported by a dedicated national service team, delivering help and

advice to you and your customers throughout the year.

SALES

Tel: 0844 5436060

Fax: 0844 5436181

TECHNICAL

Tel: 01482 440237 Fax: 01482 498621

commercial.services@idealboilers.com

BOOK ONLINE AT:

idealcommercialboilers.com

Our comprehensive one-day courses can be mixed and matched for individual

installation and servicing companies. Each course uses a simple step-bystep approach with hands on training to ensure all aspects of commissioning,

servicing, and fault finding can be dealt with quickly and efficiently.

HERE FOR YOU.

Page 36

211345 08.17

P.O. Box 103, National Avenue

Kingston Upon Hull, HU5 4JN

T: 0844 5436060

F: 0844 5436181

APPROVAL

These appliances are certified to G.A.D. 90/396 and B.E.D. 92/42 Safety and Performance Directives for gas boilers.

Ideal Commercial Boilers pursues a policy of continuous improvement in design and performance of its products and

reserves the right to vary specification without notice. Statutory rights of the consumer are not affected.

PLEASE NOTE:

The information in this brochure was correct at the time of going to print. Ideal Commercial Boilers reserve the

right to make any modifications to product specifications or any other details, without prior notification. For further

clarification, please enquire in writing to the head office address (address below).

Loading...

Loading...