Page 1

USERS GUIDE

LOGIC+ Combi

24, 30, 35

When replacing any part on this appliance, use only spare parts that you can be

assured conform to the safety and performance specification that we require.

Do not use reconditioned or copy parts that have not been clearly authorised by Ideal.

Page 2

2

Page 3

IDEAL LIDEAL L

IDEAL L

IDEAL LIDEAL L

OGIC + COMBIOGIC + COMBI

OGIC + COMBI

OGIC + COMBIOGIC + COMBI

24, 30, 35

(Natural Gas Only)

Destination Countries: GB, IE

24 G.C. Appliance No. 47-348-65

30 G.C. Appliance No. 47-348-66

35 G.C. Appliance No. 47-348-67

Ideal Stelrad Group is a member of the Benchmark scheme and fully supports the aims of the

programme. Benchmark has been introduced to improve the standards of installation and

commissioning of central heating systems in the UK and to encourage the regular servicing of all

central heating systems to ensure safety and efficiency.

THE BENCHMARK SERVICE INTERVAL RECORD MUST BE COMPLETED AFTER EACH SERVICE

3

Page 4

FOR ANY QUERIES PLEASE RING THE

IDEAL CONSUMER HELPLINE : 01482 498660

NOTE. BOILER RESET PROCEDURE To reset boiler, turn mode knob to reset position and immediately turn knob back to required setting.

The boiler will repeat the ignition sequence.

INTRODUCTION

The Logic + Combi is a wall mounted, room sealed, condensing combination boiler, featuring full sequence automatic spark

ignition and fan assisted combustion.

Due to the high efficiency of the boiler, condensate is produced from the flue gases and this is drained to a suitable disposal

point through a plastic waste pipe at the base of the boiler. A condensate 'plume' will also be visible at the flue terminal.

The Logic + Combi is a combination boiler providing both central heating and instantaneous domestic hot water.

SAFETY

Current Gas Safety (Installation & Use) Regulations or rules in force.

In your own interest, and that of safety, it is the law that this boiler must be installed by a Gas Safe Registered Engineer, in

accordance with the above regulations.

In IE, the installation must be carried out by a Registered Gas Installer (RGII) and installed in accordance with the current

edition of I.S. 813 “Domestic Gas Installations”, the current Building Regulations and reference should be made to the

current ETCI rules for electrical installation.

It is essential that the instructions in this booklet are strictly followed, for safe and economical operation of the boiler.

4

Page 5

ELECTRICITY SUPPLY

This appliance must be earthed.

Supply: 230 V ~ 50 Hz. The fusing should be 3A.

Important Notes

• This appliance must not be operated without the casing correctly fitted and forming an adequate seal.

• If the boiler is installed in a compartment then the compartment MUST NOT be used for storage purposes.

• If it is known or suspected that a fault exists on the boiler then it MUST NOT BE USED until the fault has been corrected

by a Gas Safe Registered Engineer or in IE a Registered Gas Installer (RGII).

• Under NO circumstances should any of the sealed components on this appliance be used incorrectly or tampered with.

• This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities,

or lack of experience and knowledge, unless they have been given supervision or instructions concerning use of the

appliance by a person responsible for their safety.

• Children should be supervised to ensure that they do not play with the appliance.

In cases of repeated or continuous shutdown a Gas Safe Registered Engineer or in IE a Registered Gas Installer (RGII)

should be called to investigate and rectify the condition causing this and carry out an operational test. Only the manufacturers

original parts should be used for replacement.

MINIMUM CLEARANCES

Clearances of 165mm (6 1/2") above, 100mm (4") below, 2.5mm (1/8") at the sides and 450mm (17 3/4") at the front of the

boiler casing must be allowed for servicing.

Bottom clearance

Bottom clearance after installation can be reduced to 5mm.

This must be obtained with an easily removable panel, to enable the consumer to view the system pressure gauge, and to

provide the 100mm clearance required for servicing.

5

Page 6

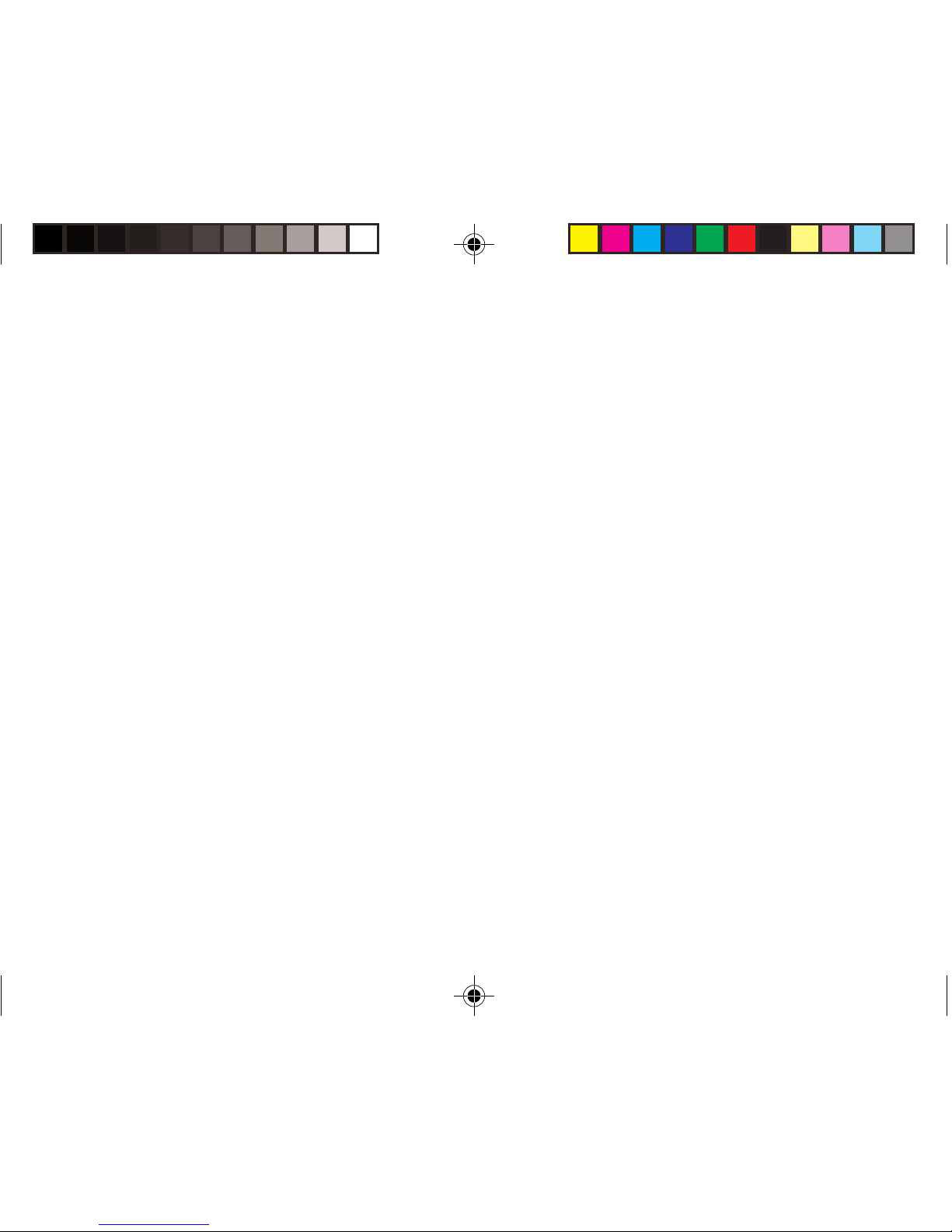

BOILER CONTROLS

A B E F C J D

LEGEND

A. Pre-heat On/off

B. DHW temperature control

C. CH temperature control

D. Mode Control

E. Boiler Status

F. Burner ‘on’ indicator

G. Pressure Gauge

H. Condensate Drain

J. Economy Mode

G

H

6

Page 7

TO LIGHT THE BOILER. (REFER TO BOILER CONTROLS)

If a programmer is fitted refer to separate instructions for the programmer before continuing.

1. Check that the electricity supply to the boiler is off.

2. Set the mains Off/Summer/Winter control (D) to ‘Off’.

3. Set the Domestic Hot Water temperature control (B) and Central Heating temperature control (C) to ‘max’.

4. Set the preheat control (A) to ‘on’.

5. Ensure that all hot water taps are turned off.

6. Switch ON electricity to the boiler and check that all external controls, e.g. programmer and room thermostat, are ON.

7. Set the Off/Summer/Winter control to winter (

).

The boiler will commence the ignition sequence supplying heat to the central heating, if required.

Note. In normal operation the boiler status display (E) will display messages (see pages 14 & 15).

Boiler frost protection - boiler will fire if temperature is less than 5 degrees C.

During normal operation the burner on indicator (F) will remain illuminated when the burner is lit.

Note: If the boiler fails to light after five attempts the following fault messages will be displayed “Ignition Lockout” -

“1 Check other gas appliances” - “2 Reset boiler” - “3 Contact Installer”.

To reset boiler, turn mode knob to reset position and immediately turn knob back to required setting.The boiler will repeat the

ignition sequence. If the boiler still fails to light consult a Registered Gas Installer or in IE a Registered Gas Installer (RGII).

7

Page 8

OPERATION

Winter Mode - i.e. CH and DHW required.

Ensure the off/summer/winter control (D) is set to winter (

)

The boiler will fire and supply heat to the radiators but will give priority to DHW on demand.

The DHW preheat will operate as described under 'Summer conditions' during periods when there is no call for CH.

Summer Mode - i.e. DHW only required.

Set the mode knob control to Summer ( ).

Set the CH external controls to OFF.

Preheat will operate with the preheat switch (A) set to ON.

The boiler will fire periodically for a few seconds to maintain the DHW calorifier in a pre-heated condition. The average time

period between firing is 90 minutes. This may vary considerably due to the surrounding ambient temperature of the boiler.

The boiler will fire whenever there is a demand for DHW.

The boiler preheat facility can be immobilised by turning the preheat switch (A) to OFF. This will stop the boiler operating for

short periods. This facility is primarily provided for boiler installations in a sensitive area (i.e. bedroom etc.).

Note. If the pump and diverter valve have not operated in the last 24 hours they will run briefly to ensure they do not become

seized.

CONTROL OF WATER TEMPERATURE

Domestic Hot Water

o

The DHW temperature is limited by the boiler controls to 64

C maximum at low draw-off rate, adjustable via the DHW

temperature control (B).

Due to system variations and seasonal temperature fluctuations DHW flow rates/temperature rise will vary, requiring adjustment

at the draw off tap : the lower the rate the higher the temperature, and vice versa.

8

Page 9

Central Heating

The boiler controls the central heating radiator temperature to a maximum of 80

o

C, adjustable via the CH temperature control (C).

Approx. flow temperatures for the boiler thermostat settings are:

Knob Setting Flow Temperature

Minimum 40

Maximum 64

o

C (104oF)

o

C (147oF)

The Logic + Combi is a high efficiency combination boiler which is most efficient when operating in condensing mode.

The boiler will operate in this mode if the CH temperature control (C) is set to the ‘e’ position (economy mode) or below. This

control should be set to a maximum for very cold periods.

TO SHUT DOWN THE BOILER

Set the mode knob control to OFF.

TO RELIGHT THE BOILER

Repeat the procedure detailed in 'To light the boiler'.

FROST PROTECTION

If no frost protection is provided and frost is likely during a short absence from home, leave the heating controls (if fitted) at

a reduced temperature setting. For longer periods, the entire system should be drained.

If the system includes a frost thermostat then the timer can be left off (if fitted). The mains supply should be left switched ON,

with the boiler thermostat left in the normal running position.

BOILER OVERHEAT PROTECTION

The boiler controls will shut down the boiler in the event of overheating. Should this occur, a fault code “Overheat Lockout”

- “1 Fill system to 1.0 bar” - “2 Bleed radiators” - “3 Check radiator valves open” - 4 Reset boiler” - “5

Contact Installer” will be displayed.

Reset boiler by turning the mode control knob (D) to reset position and immediately turn knob back to required setting. The

boiler will relight. If the fault recurs, turn off the boiler and consult a Gas Safe Registered Engineer or in IE a Registered Gas

Installer (RGII).

9

Page 10

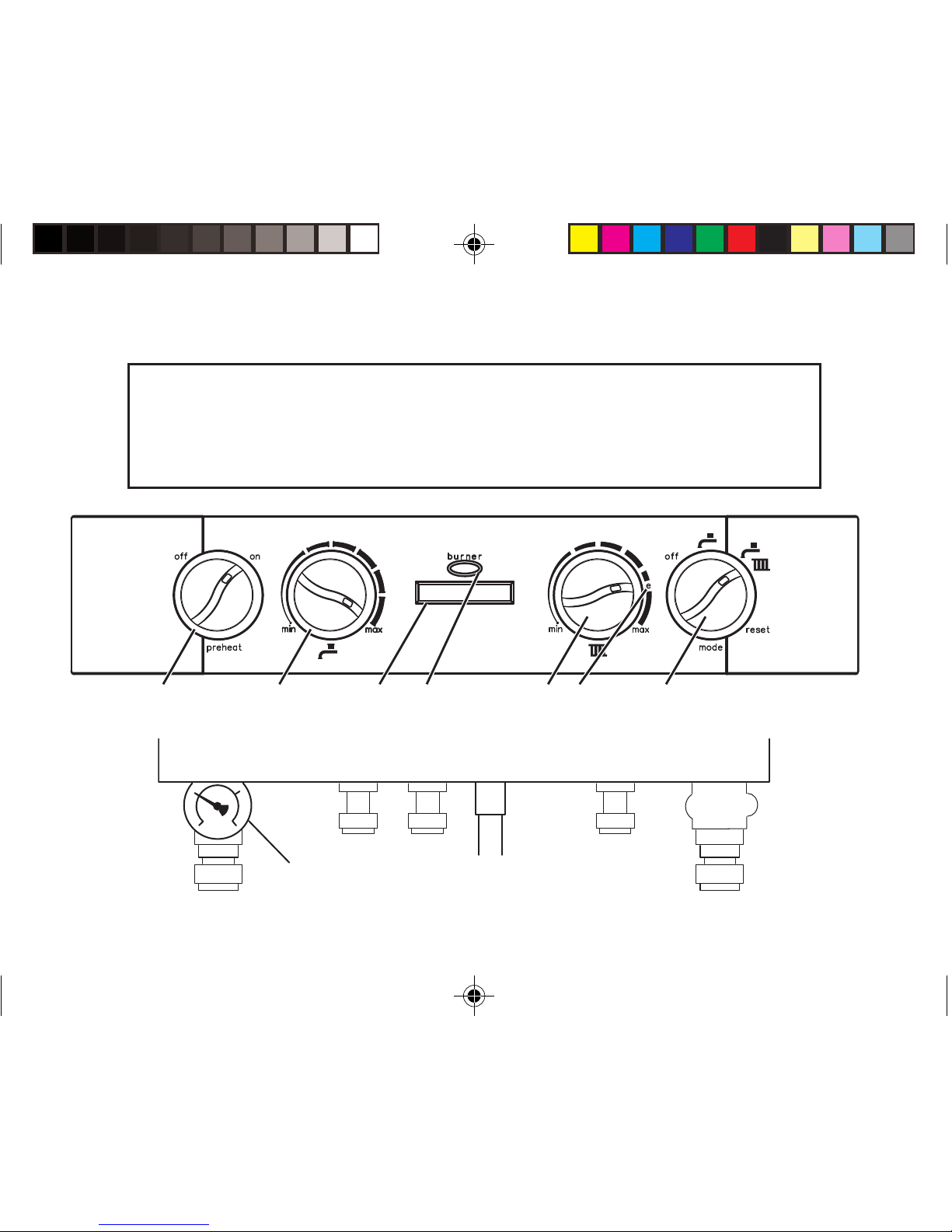

LOSS OF SYSTEM WATER PRESSURE

2

3

1

3G9866

6

CLOSED

POSITION

CLOSED

POSITION

OPEN

POSITION

4

5

PRESSURE GAUGE

7

8

The gauge (G) indicates the central heating system pressure.

If the pressure is seen to fall below the original installation

pressure of 1-2 bar over a period of time then a water leak

may be indicated. In this event conduct the re-pressurising

procedure as shown below. If unable to do so or if the pressure

continues to drop a Gas Safe Registered Engineer or in IE a

Registered Gas Installer (RGII) should be consulted.

THE BOILER WILL NOT OPERATE IF THE PRESSURE HAS

REDUCED TO LESS THAN 0.3 BAR UNDER THIS

CONDITION.

In this case the boiler will display “Low water pressure” -

“1 fill system to 1.0 bar” - “2 Bleed radiators” “3 Contact installer”.

To re-pressurise:

1. Ensure filling loop isolation valves are closed.

2. Remove the left hand cap.

3. Attach on the filling loop.

4. Turn the filling loop isolation valves to the open position.

The system will now fill.

5. Wait for pressure gauge to reach 1 to 1.5 bar.

6. Close the filling loop isolation valves.

7. Disconnect the filling loop at left hand side and angle

upwards.

8. Replace cap.

10

Page 11

CONDENSATE DRAIN

The condensate drain (H) must not be modified or blocked.

Blockage of the condensate drain, caused by debris or freezing, can cause automatic shutdown of the boiler.

If freezing is suspected and the pipe run is accessible an attempt may be made to free the obstruction by pouring hot water

over the exposed pipe and clearing any blockage from the end of the pipe. If this fails to remedy the problem the assistance

of a Gas Safe Registered Engineer or in IE a Registered Gas Installer (RGII) should be sought.

ESCAPE OF GAS

Should a gas leak or fault be suspected contact the National Gas Emergency Service without delay.

Telephone 0800 111 999

DO NOT SEARCH FOR GAS LEAKS WITH A NAKED FLAME.

CLEANING

For normal cleaning simply dust with a dry cloth. To remove stubborn marks and stains, wipe with a damp cloth and finish

off with a dry cloth. DO NOT use abrasive cleaning materials.

MAINTENANCE

The appliance should be serviced at least once a year by a Gas Safe Registered Engineer or in IE a Registered Gas

Installer (RGII).

11

Page 12

POINTS FOR THE BOILER USER

Note. In line with our current warranty policy we would ask that you check through the following guide to identify any

problems external to the boiler prior to requesting a service engineers visit. Should the problem be found to be other

than with the appliance we reserve the right to levy a charge for the visit, or for any pre-arranged visit where access

is not gained by the engineer.

12

Page 13

TROUBLESHOOTING

NO HOT WATER

Check the mains switch (fused

spur) is turned on and ensure

mode control knob (D) is in the

summer or winter position

Is water coming out of the hot

water tap when turned on?

YES

See boiler “Display Functions”

section. If “standby mode” is

displayed then contact Ideal

Customer Services Helpline if

your appliance is under warranty

or a Gas Safe Registered

Engineer, in IE a Registered Gas

Installer (RGII), if out of warranty

Contact a Gas Safe Registered

Engineer or in IE a Registered

Gas Installer (RGII)

NO

NO CENTRAL HEATING

Check the mains switch (fused

spur) is turned on and ensure

mode control knob (D) is in the

winter position

Check the programmer (internal

or external to the boiler) is in an

“ON” position and the room

thermostat is turned up

Does the boiler operate and

provide central heating?

YES

Check the time settings on the

programmer are as you require

and adjust if necessary

See boiler “Display Functions”

section. If “standby mode” is

displayed then contact a Gas Safe

Registered Engineer or in IE a

Registered Gas Installer (RGII)

NO

NO HOT WATER OR

CENTRAL HEATING

Check the fused spur is turned

on and ensure mode control

knob (D) is in the winter position

Does the boiler have a display

showing on the front control

panel?

YES

See boiler “Display Funcitons”

section

Contact a Gas Safe Registered

Engineer or in IE a Registered

Gas Installer (RGII)

NO

13

Page 14

NORMAL OPERATION MESSAGE 1 MESSAGE 2 MESSAGE 3

Mode knob in standby (off) position and

no heat demand

Standby mode For hot water turn mode

knob clockwise

For central heating turn

mode knob clockwise twice

Mode knob in summer ( ) position and

no heat demand

Summer mode For central heating turn

mode knob clockwise

Mode knob in winter ( ) position and

no heat demand

Winter mode Timer or room stat off

Domestic hot water operation Hot water Temperature 64ºC High efficiency

Central heating operation Radiator Temp 80ºC High efficiency

Pre-heat operation Pre heat

Central heating

Temperature 59ºC High efficiency

Boiler frost protection Boiler frost protection Temperature 5ºC

Pump overrun Pump overrun

Fan post-purge Fan post-purge

High efficiency

Note. High efficiency will not be shown for central heating operation if the central heating flow temperature knob (c) is set to greater than 73ºC.

3G9711b

DISPLAY FUNCTIONS - NORMAL OPERATION MODE

The display scrolls through a maximum of 3 messages under any operational condition, as shown below.

Note. The temperatures shown below are for illustration purposes only. The measured temperatures will be shown on the boiler.

14

Page 15

NORMAL OPERATION MESSAGE 1 MESSAGE 2 MESSAGE 3

Pre-heat knob moved to off position Pre heat off

Pre-heat knob moved to on position Pre heat on

DHW temperature knob moved 64ºC DHW temp Hot water

temperature 64ºC

CH temperature knob moved 80ºC CH temp Maximum radiator

temperature 80ºC

May not be achieved for

high flow rates in winter

Mode knob moved to standby (off) position Central heating off Hot water off

Mode knob moved to summer ( ) position Summer mode

Standby mode

Central heating off Hot water on

Mode knob moved to winter ( ) position Winter mode Central heating on

Mode knob moved to reset position Reset

Hot water on

3G9712b

DISPLAY FUNCTIONS - SETTINGS CHANGED

Note. The temperatures shown below are for illustration purposes only. The measured temperatures will be shown on the boiler.

15

Page 16

DISPLAY FUNCTIONS - FAULT MESSAGES

BOILER DISPLAY MESSAGE DESCRIPTION ACTION

Outside Sensor Fault

Contact Installer

Outside Sensor Failure

3G9911

Reset the appliance - if the boiler fails to operate then please

contact Ideal (if under warranty) or alternatively a Gas Safe

Registered Engineer if outside of the warranty period. In IE

contact a Registered Gas Installer (RGII).

Low Mains Voltage

Contact Electricity Provider

Low Mains Voltage

Contact a qualified electrician or your electricty provider.

PCB Fault

Contact Installer

Unconfigured PCB

Unconfigured PCB. Please contact Ideal (if under warranty) or

alternatively a Gas Safe Registered Engineer if outside of the

warranty period. In IE contact a Registered Gas Installer

(RGII).

No Water Flow Thermistor Fault

Contact Installer

No Water Flow Thermistor

Reset the appliance - if the boiler fails to operate then please

contact Ideal (if under warranty) or alternatively a Gas Safe

Registered Engineer if outside of the warranty period. In IE

contact a Registered Gas Installer (RGII).

Lockout 6

Contact Installer

False Flame Lockout

Reset the appliance - if the boiler fails to operate then please

contact Ideal (if under warranty) or alternatively a Gas Safe

Registered Engineer if outside of the warranty period. In IE

contact a Registered Gas Installer (RGII).

Too Many Resets

Contact Installer

5 Boiler Resets in 15 Minutes

1. Turn power off and on at the fused spur.

2. If the boiler fails to operate please contact Ideal (if under

warranty) or alternatively a Gas Safe Registered Engineer if

outside of the warranty period. In IE contact a Registered Gas

Installer (RGII).

16

cont’d . . . . . . .

Page 17

DISPLAY FUNCTIONS - FAULT MESSAGES

BOILER DISPLAY MESSAGE DESCRIPTION ACTION

Boiler Type Card Fault

Contact Installer

BCC Activation Fault

3G9912

Reset the appliance - if the boiler fails to operate then please

contact Ideal (if under warranty) or alternatively a Gas Safe

Registered Engineer if outside of the warranty period. In IE

contact a Registered Gas Installer (RGII).

Low Water Pressure

1 Fill System to 1.0 Bar

2 Bleed Radiators

3 Contact Installer

Low Water Pressure

Check system pressure is between 1 & 1.5bar on the pressure

gauge. If the fails to operate then please contact Ideal (if under

warranty) or alternatively a Gas Safe Registered Engineer if

outside of the warranty period. In IE contact a Registered Gas

Installer (RGII).

Check system pressure is between 1 & 1.5bar on the pressure

gauge. Reset the appliance. If the boiler fails to operate then

please contact Ideal (if under warranty) or alternatively a Gas

Safe Registered Engineer if outside of the warranty period. In

IE contact a Registered Gas Installer (RGII).

PCB Replacement

Reset Boiler

BCC Fault

Reset the appliance - if the boiler fails to operate then please

contact Ideal (if under warranty) or alternatively a Gas Safe

Registered Engineer if outside of the warranty period. In IE

contact a Registered Gas Installer (RGII).

Overheat Lockout

1 Fill System to 1.0 Bar

2 Bleed Radiators

3 Check Radiator Valves Open

4 Reset Boiler

5 Contact Installer

Flow Temperature Overheat

No Water Flow Lockout

1 Fill System to 1.0 Bar

2 Bleed Radiators

3 Check Radiator Valves Open

4 Reset Boiler

5 Contact Installer

No Water Flow

17

cont’d . . . . . . .

Page 18

DISPLAY FUNCTIONS - FAULT MESSAGES

BOILER DISPLAY MESSAGE DESCRIPTION ACTION

Flame Loss

1

Check Other Gas Appliances Work

2 Contact Installer

Flame Loss

3G9913

1. Check other gas appliances in the house are working to

confirm a supply is present in the property.

2. If other appliances do not work or there are no other

appliances, check the gas supply is on at the meter and/or pre

payment meter has credit. If the boiler fails to operate then

please contact Ideal (if under warranty) or alternatively a Gas

Safe Registered Engineer if outside of the warranty period. In

IE contact a Registered Gas Installer (RGII).

Fan Fault

Contact Installer

Fan Fault

Reset the appliance - if the boiler fails to operate then please

contact Ideal (if under warranty) or alternatively a Gas Safe

Registered Engineer if outside of the warranty period. In IE

contact a Registered Gas Installer (RGII).

Flow Thermistor Fault

Contact Installer

Flow Thermistor

Reset the appliance - if the boiler fails to operate then please

contact Ideal (if under warranty) or alternatively a Gas Safe

Registered Engineer if outside of the warranty period. In IE

contact a Registered Gas Installer (RGII).

Return Thermistor Fault

Contact Installer

Return Thermistor

Reset the appliance - if the boiler fails to operate then please

contact Ideal (if under warranty) or alternatively a Gas Safe

Registered Engineer if outside of the warranty period. In IE

contact a Registered Gas Installer (RGII).

Ignition Lockout

1 Check Other Gas Appliances Work

2 Reset Boiler

3 Contact Installer

18

Page 19

19

Page 20

Ideal Stelrad Group pursues a policy of continuing improvement in the design and performance

of its products. The right is therefore reserved to vary specification without notice.

Ideal, P.O. Box 103, National Ave, Kingston Upon Hull, HU5 4JN. Tel. 01482

492251 Fax. 01482 448858. Registration No. London 322 137.

February 2010 UIN 204979 A03

Loading...

Loading...