Page 1

0

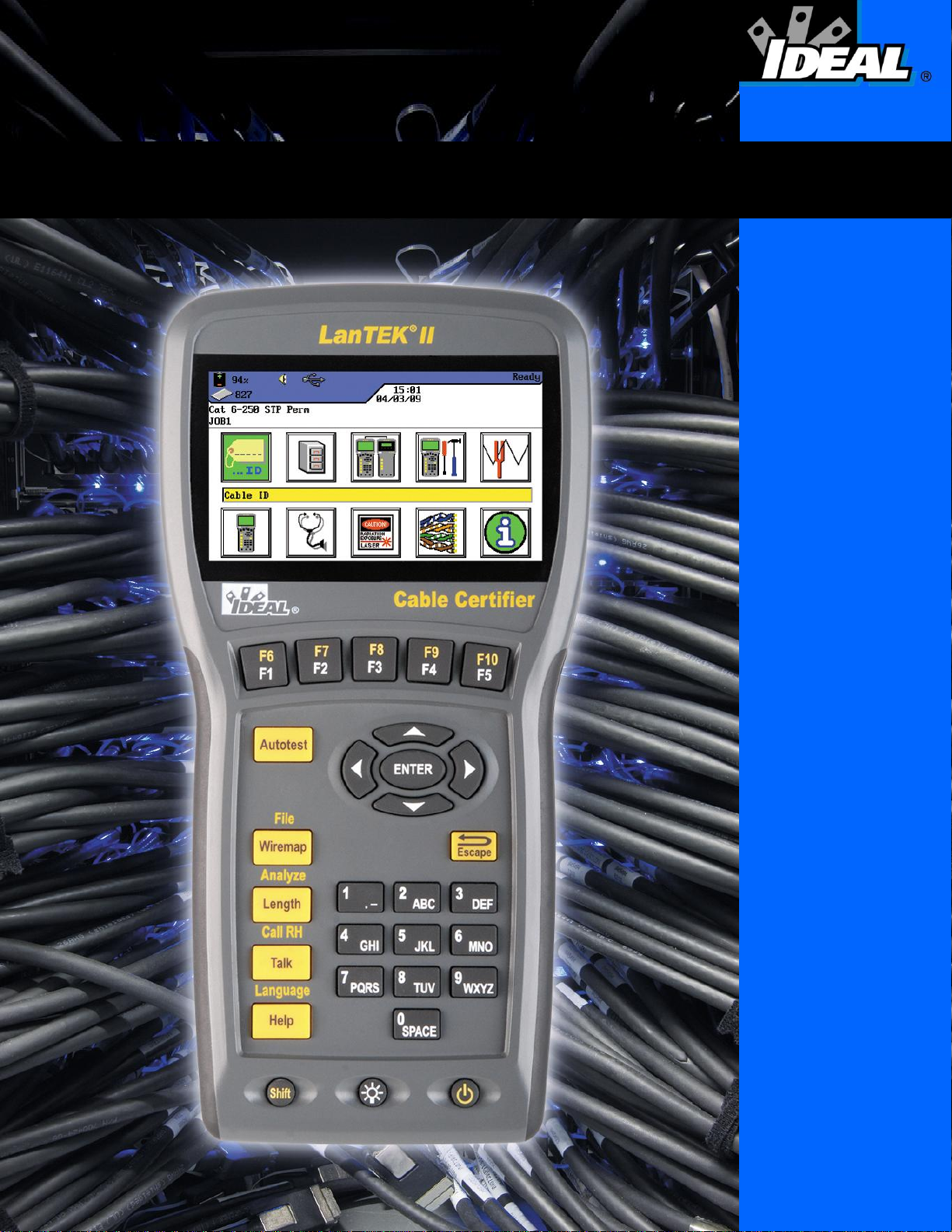

LanTEK® II Series Manual

Page 2

LanTEK®II Cable Certifier Instruction Manual

This instruction manual contains information proprietary to IDEAL INDUSTRIES, INC. The

information in this document is not to be used or duplicated in any manner without prior

written approval from IDEAL INDUSTRIES, INC.

IDEAL INDUSTRIES, INC. and the IDEAL INDUSTRIES, INC. logo are registered trademarks of

IDEAL INDUSTRIES, INC.

All other product names mentioned in this manual are trademarked or copyrighted by their

respective manufacturers.

IDEAL INDUSTRIES, INC.

9650 Chesapeake Drive

San Diego, CA 92123

Phone: (800) 854-2708

Phone: (858) 627-0100

Fax: (858) 715-7003

Manual Part No.: P-2877 Rev. B

© 2009 IDEAL INDUSTRIES, INC. 2009-12

1

Page 3

Standard Warranty Policy of IDEAL INDUSTRIES, INC.

The General Terms and Conditions of the local subsidiary of IDEAL INDUSTRIES, INC. apply.

Safety Precautions

Exercise caution when handling rechargeable batteries (accumulators)

All lithium-ion battery packs (Li-ion), regardless of their indicated charge state, are capable of

producing electrical current sufficient to cause personal injury and/or property damage.

Do not dispose of lithium-ion battery packs (Li-ion) in a fire or with regular waste. Lithiumion battery packs (Li-ion) may explode if exposed to open flame. The battery packs are

hazardous waste and may contaminate ground water sources if disposed of in landfills.

IDEAL INDUSTRIES, INC. tries to provide the maximum protection possible by installing an

automatic reset fuse in the battery packs, to help stop high current discharge as quickly as

possible. However, these fuses may not completely protect against a momentary arc

discharge, which can result if the battery pack's electrical contacts are shorted. The following

battery pack handling precautions must be closely followed to avoid risk of injury.

When a battery pack is not installed in the Display (DH) or Remote (RH) handset, it

should be kept in a clean, dry, non-conductive package.

Keep conductive materials away from the battery pack at all times.

Keep contact sides of the battery pack away from each other at all times.

Battery packs can be charged while in the Display (DH) and in the Remote (RH) handset,

but also externally with the adapter. Charging in any other manner may cause the battery

pack to explode.

Always install, remove, store, and charge the battery packs in a non-explosive

atmosphere.

Observe operating and storage temperatures (see chapter 1.3. Dimensions, Weights,

Operating Conditions).

Do not allow children or persons unfamiliar with the precautionary instructions in this

manual to handle or recharge the battery packs.

Do not open the battery pack case. There are no user-serviceable parts inside the case,

and the batteries in the case are not replaceable.

2

Page 4

Disclaimer

WARNING!

This symbol indicates potentially lethal voltages. The life

and/or health of the person performing the activity or anybody

in the vicinity is at risk.

CAUTION!

This symbol indicates that the relative activity could possibly

harm the environment or damage technical equipment.

NOTE:

Here you will find general notes, additional information, or

support.

Boldface

Refers to a button on LanTEK®II Cable Certifier.

Italics

Refers to a menu option in this Operating Manual.

Quotation marks " "

Identifies a "Screen Message".

IDEAL INDUSTRIES, INC. does not assume any liability for death, injury or damage to

equipment or property resulting from improper use of the battery packs.

IDEAL INDUSTRIES, INC. will not be liable for consequential damages that may result from

tampering with the battery packs or charger or their use thereafter.

Subject to technical changes.

Environmental Protection

If you have any questions concerning these precautions, the operating instructions, or any

other concerns about the safe use and disposal of the battery packs used in LanTEK®II, please

contact a representative of IDEAL INDUSTRIES, INC. For contact information, please refer to

Chapter Customer Service.

Using the LanTEK®II Cable Certifier

All cable parameter default settings programmed in the LanTEK®II Cable Certifier are based

on generic standards, proposed industry recommendations for cables and network links, the

latest technical information available from International LAN cabling standards committees,

the LAN industry, and IDEAL INDUSTRIES' own experience and testing.

Before performing any measurements, IDEAL INDUSTRIES, INC. recommends to request

detailed information from contractor or project manager on the standards to be used for

measuring, to ensure that relevant parameters are complied with.

Information on the use of this Instruction Manual

The following symbols used in this manual indicate that the user should exercise particular

caution in order to prevent personal injury or damage to the LanTEK®II Cable Certifier or the

system under test.

Typographical Conventions

3

Page 5

Table of contents

CHAPTER 1 Your LanTEK®II Cable Certifier................................................. 9

1.1. Technical Information ...................................................................................... 9

1.2. Product Specifications .................................................................................... 10

1.3. Dimensions, Weights, Operating Conditions ...................................................... 10

1.4. Performance Specifications ............................................................................. 11

CHAPTER 2 Product Description ............................................................... 12

2.1. The Display Handset (DH) .............................................................................. 12

2.1.1. Controls and Ports/Connectors ........................................................................ 12

2.1.2. TFT Display .................................................................................................. 14

2.1.3. Function Keys F1 to F10 ................................................................................. 15

2.1.4. Soft Key ....................................................................................................... 15

2.2. The Remote Handset (RH)............................................................................... 16

2.2.1. Controls and Ports/Connectors ........................................................................ 16

2.3. Power Management ....................................................................................... 18

2.3.1. Operating the Display and Remote handset from AC Power ................................ 18

2.3.2. Battery Charging ........................................................................................... 19

2.4. Talkset ........................................................................................................ 19

CHAPTER 3 Basics of the Cable Test ......................................................... 20

3.1. Testing of cables and relevant requirements ..................................................... 20

3.1.2. Setup for Permanent Link Test ........................................................................ 20

3.1.3. Setup for Channel Link Test ............................................................................ 20

CHAPTER 4 Preferences............................................................................ 21

4.1. Open Preferences .......................................................................................... 21

4.2. Language ..................................................................................................... 21

4.3. User Information........................................................................................... 22

4.4. Autotest Options ........................................................................................... 22

4.5. Contrast ...................................................................................................... 23

4.6. Timeout Options ........................................................................................... 23

4.7. Measurement Units ....................................................................................... 24

4.8. Talkset ........................................................................................................ 25

4.9. Date and Time .............................................................................................. 25

4.10. Restore Default ............................................................................................. 26

4.11. Clear Memory ............................................................................................... 27

4.12. Temperature ................................................................................................ 27

CHAPTER 5 Autotest ................................................................................. 28

5.1. Set Autotest Pref ......................................................................................... 29

5.2. Select Job Folder.......................................................................................... 30

5.2.1. Enable Existing Job Folder ............................................................................. 30

5.2.2. Create New Job Folder .................................................................................. 31

5.3. Set Cable Name (cable ID) ............................................................................ 33

5.3.1. Simple Cable ID ........................................................................................... 34

4

Page 6

Table of contents

5.3.2. Default Cable ID .......................................................................................... 35

5.4. Labeling Standard TIA/EIA 606-A ................................................................... 37

5.4.1. Cable Name in Format TIA/EIA 606A .............................................................. 38

5.4.2. Cable Parameter 606A Drop .......................................................................... 38

5.4.3. Cable Parameter 606A Backbone .................................................................... 39

5.4.4. Cable Parameter 606A Backbone Pair/Fiber ..................................................... 39

5.5. Select Twisted Pair Cabling............................................................................ 40

5.5.1. Specify Cable Type ....................................................................................... 41

5.5.2. Create Cable Type ........................................................................................ 41

5.5.3. Edit and Calculate NVP .................................................................................. 44

5.5.4. Enter Reference Temperature ........................................................................ 45

5.6. DualMODE™ Function for Twisted Pair Cabling ................................................. 46

5.6.1. Implement DualMODE™ ................................................................................ 46

5.7. Edit NVP Default Value of a Cable ................................................................... 47

5.8. Coaxial Cable Standards ............................................................................... 48

5.8.1. Autotest Test Series for Coaxial Cables ........................................................... 49

5.9. Calibration .................................................................................................. 50

5.9.1. Twisted Pair Cabling ..................................................................................... 50

5.9.2. Coaxial Cable ............................................................................................... 52

5.10. Perform Autotest .......................................................................................... 53

5.11. Open Job Folder of Autotest ........................................................................... 53

5.11.1. Job Options ................................................................................................. 53

5.11.2. Test Options ................................................................................................ 53

5.11.3. Copy Job Folder to USB Removable Storage .................................................... 54

5.11.4. Alien Crosstalk Measurements (AXT) ............................................................... 54

5.12. Autotest Results and Graphs .......................................................................... 54

5.12.1. Graph Formats, Layouts and Controls ............................................................. 56

CHAPTER 6 Structured Cabling Testing .................................................... 58

6.1. Test Setup for Single Test Analysis .................................................................. 58

6.2. Test Run of Single Test Analysis...................................................................... 58

6.3. Perform Single Test Analysis .......................................................................... 58

6.4. Evaluation of Analysis Test Results .................................................................. 59

6.4.1. Graphs for Analysis Tests ............................................................................... 59

6.5. Overview of Single Test Analysis ..................................................................... 59

6.6. Wiremap Test ............................................................................................... 60

6.7. Length Test .................................................................................................. 61

6.7.1. Length Test Error .......................................................................................... 61

6.8. Resistance Test............................................................................................. 61

6.8.1. Resistance Test Error ..................................................................................... 61

6.9. NEXT, ACR-F (ELFEXT) and Power Sum............................................................ 61

6.10. Power Sum NEXT, Power Sum ACR-F (ELFEXT) ................................................ 62

6.10.1. NEXT Test and ACR-F (Power Sum ELFEXT) Test Error ...................................... 63

6.11. Insertion Loss Test (Attenuation) ................................................................... 64

5

Page 7

Table of contents

6.11.1. Insertion Loss test Error ................................................................................ 64

6.12. Return Loss Test .......................................................................................... 64

6.12.1. Return Loss Test Error .................................................................................. 64

6.13. Impedance Test ........................................................................................... 65

6.13.1. Impedance Error .......................................................................................... 65

6.14. Delay and Skew Test .................................................................................... 65

6.14.1. Delay and Skew Test Error ............................................................................ 66

6.15. Capacitance Test .......................................................................................... 66

6.15.1. Capacitance Test Error .................................................................................. 66

6.16. ACR-N (ACR) Test and Power Sum ACR-N (Power Sum ACR) Test ...................... 66

6.16.1. ACR-N (ACR) Test and Power Sum ACR-N (Power Sum ACR) Test Error .............. 67

6.16.2. Troubleshooting ACR-N (ACR) Test and Power Sum ACR-N (Power Sum ACR) ..... 67

6.17. Headroom Test ............................................................................................ 67

6.17.1. Headroom Test Error .................................................................................... 67

6.18. Custom Cable Preferences and Cable Parameters ............................................. 68

6.18.1. Creating a New Customs Cable Type ............................................................... 68

6.18.2. Select Custom Cable Type ............................................................................. 69

6.18.3. Custom Cable Parameters ............................................................................. 69

CHAPTER 7 Coaxial Cable Test .................................................................. 71

7.1. Properties of Coaxial Cables ........................................................................... 71

7.2. Troubleshooting Coaxial Cables ....................................................................... 71

CHAPTER 8 Fiber Testing with FiberTEK™ FDX ......................................... 72

8.1. Safety Precautions ........................................................................................ 72

8.2. Notes on Cleaning Measuring Adapter and Patch Cord ....................................... 72

8.3. Performance Specification .............................................................................. 73

8.4. Test Setup According to Reference Method with Three Test Cords ...................... 74

8.5. Test setup According to Reference Method with One Test Cord .......................... 74

8.6. Set Autotest Pref .......................................................................................... 75

8.6.1. Selection of Module (fiber type) ...................................................................... 75

8.6.2. Determine Loss Budget .................................................................................. 75

8.7. Calibration ................................................................................................... 77

8.8. Performing Calibration ................................................................................... 77

8.9. Evaluation of Autotest Results for Fibers (LWL) ................................................. 78

8.9.1. Passed/Failed Rating ..................................................................................... 78

8.9.2. Saving Current Autotest Results ...................................................................... 78

8.9.3. Manual Saving of Autotest Results (Autosave off) .............................................. 79

8.9.4. Working with Jobs ......................................................................................... 79

8.9.5. Display of Result Details ................................................................................ 79

8.10. FiberTEK™ FDX Measuring Mode .................................................................... 79

8.10.1. Continuous Run ............................................................................................ 80

8.10.2. Power Meter Mode ........................................................................................ 81

8.10.3. Set Reference Value ..................................................................................... 81

6

Page 8

Table of contents

8.10.4. Light Source Mode ........................................................................................ 81

8.11. Application-specific Configuration of a Fiber Test .............................................. 82

8.11.1. Determine Loss Budget ................................................................................. 82

8.11.2. Select Fiber Standard and Determine Loss Budget ............................................ 83

CHAPTER 9 Tone Generator ...................................................................... 86

9.1. Tone Generator ............................................................................................. 86

9.1.1. Enable Tone Generator with Display handset (DH) ............................................. 86

9.1.2. Enable Tone Generator with Remote handset (RH) ............................................. 87

CHAPTER 10 IDEAL DataCENTER Software .............................................. 88

10.1. Installing Software ....................................................................................... 88

10.1.1. System Requirements ................................................................................... 88

10.1.2. Start Installation .......................................................................................... 88

10.2. Select Language .......................................................................................... 89

10.3. Software-Update .......................................................................................... 89

10.3.1. Retrieve Version ........................................................................................... 89

10.3.2. Perform Update ............................................................................................ 89

10.4. Databases ................................................................................................... 90

10.4.1. Create a new database ................................................................................. 90

10.4.2. Open an existing database ............................................................................ 91

10.5. Transfer job file ........................................................................................... 92

10.5.1. Upload from LanTEK

10.5.2. Import from the computer or an external data carriers (USB Flash Drive) ............ 94

10.5.3. Export job folder .......................................................................................... 95

10.5.4. Rename job folder ........................................................................................ 96

10.6. Manage Tests .............................................................................................. 97

10.6.1. Edit information ........................................................................................... 97

10.6.2. Edit tests and test records ............................................................................. 98

10.6.3. Test details .................................................................................................. 98

10.6.4. Graphs ........................................................................................................ 99

10.7. Produce and print reports ............................................................................ 100

10.7.1. Set up header and footer ............................................................................ 100

10.7.2. Define test selection. .................................................................................. 101

10.7.3. Print ......................................................................................................... 101

10.8. Online Help ............................................................................................... 102

®

II Cable Certifier ............................................................ 92

CHAPTER 11 LANTEK Firmware Upgrade ............................................... 103

11.1. Perform Firmware Upgrade .......................................................................... 103

11.1.1. Using the Computer .................................................................................... 103

11.1.2. Firmware Upgrade with USB Removable Storage ............................................ 104

CHAPTER 12 Specifications ................................................................... 105

12.1. Fiber (LWL) ............................................................................................... 105

CHAPTER 13 Customer Service .............................................................. 107

7

Page 9

Table of contents

13.1. Technical Support ...................................................................................... 107

13.2. Service in the US ....................................................................................... 107

13.3. Service outside the US ................................................................................ 107

13.4. Internet .................................................................................................... 109

8

Page 10

9

CHAPTER 1

Your LanTEK®II Cable Certifier

Features

LanTEK®II-350

LanTEK®II-500

LanTEK®II-1000

Frequency range

350 MHz

500 MHz

1000 MHz

Cable specification CAT 3/ISO C,

CAT 5/ISO D, 5e/D new, 6/E

Cable specification CAT 6A/ISO E

A

Upgradeable

Cable specification ISO F, ISO FA

Upgradeable

Upgradeable

(LanTEK®II)

DualMODE™-tests

Test with patch cord

CAT 6 test storage capacity with

graphs

1700

1700

1700

USB port

Serial port (concerns only Service)

Fiber (LWL) loss and length

measurement (FiberTEK™ FDX )

Optional

Optional

Optional

Communication over fiber (LWL)

and copper (Full Duplex)

LCD-display on Remote handset

(RH)

Tone generator to determine

connection on near and remote end

Lithium-ion battery packs

The LanTEK®II Cable Certifier is designed to measure twisted pair cables (TP), coaxial cables

and fiber-optic cables (LWL) used for high-speed data transmission in communications

networks.

1.1. Technical Information

Accuracy level

IV (ETL) IV (ETL) IV (ETL)

Page 11

Chapter 1

10

Your LanTEK®II Cable Certifier

1.2. Product Specifications

Standard Test Compliance

ANSI/TIA/EIA 568A, 568B, CAT 6A/6/5E/3, ISO FA/F/EA/D/C, AS/NZS 3080, IEEE 802.3

Ethernet, EN50173 – F/E/D/C

Cable Types

UTP/SCTP/FTP CAT 3/5E/6A/7 (100 Ω); Coax (50/75 Ω)

1.3. Dimensions, Weights, Operating Conditions

Dimensions:

(L) 254 mm x (W) 127 mm x (D) 53 mm

Weights:

Display handset (DH) 1180 g (incl. battery)

Remote handset (RH) 1120 g (incl. battery pack)

Battery pack 548 g

Battery Packs Display Handset (DH) and Remote Handset (RH):

Lithium-ion battery packs (Li-ion)

Operating life with Battery Pack:

18 hours under normal conditions

Charging Time:

In handset 6-8 hours

External 4 hours

Operating Temperature (min/max):

0o C to +50o C (Operate only if handset temperature is close to ambient temperature!)

Storage Temperature (min/max):

-20o C to +70o C

Relative Humidity:

5% to 90%, noncondensing

Page 12

11

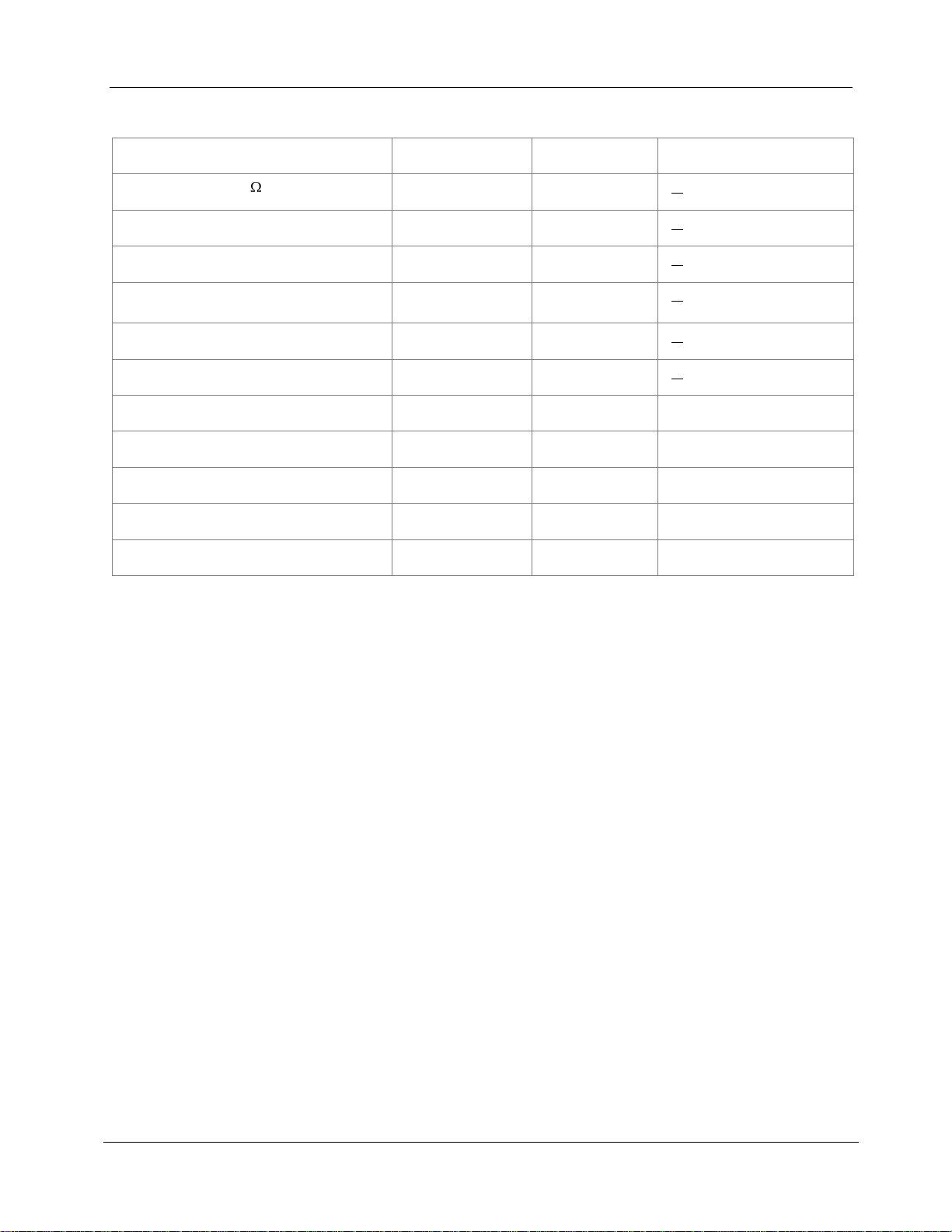

1.4. Performance Specifications

LanTEK

®

II

Range

Resolution

Accuracy

Length (50 - 100 cable)

0 – 605 m

0.1 m

+ (3 % + 1 m)

Delay

0 - 8000 ns

1 ns/0.1 m

+ (3 % + 1 ns)

Average impedance

35 – 180

0,1

+ (3 % + 1 )

Capacitance (bulk)

0 - 100 nF

1 pF or 3

digits

+ (2 % + 20 pF)

Capacitance

0 - 333 pF/m

0.1 pF

+ (2 % +1 pF)

DC loop resistance

35 -200

0,1

+ (1 % + 2 )

Attenuation

1 MHz - 1 GHz

0.1 dB

NEXT (crosstalk)

1 MHz - 1 GHz

0.1 dB

Return loss

1 MHz - 1 GHz

0.1 dB

ELFEXT / ACR-F

1 MHz – 1 GHz

0.1 dB

ACR / ACR-N

1 MHz – 1 GHz

0.1 dB

Chapter 1

Your LanTEK®II Cable Certifier

Level IV

Level IV

Level IV

Level IV

Level IV

Page 13

12

CHAPTER 2

Product Description

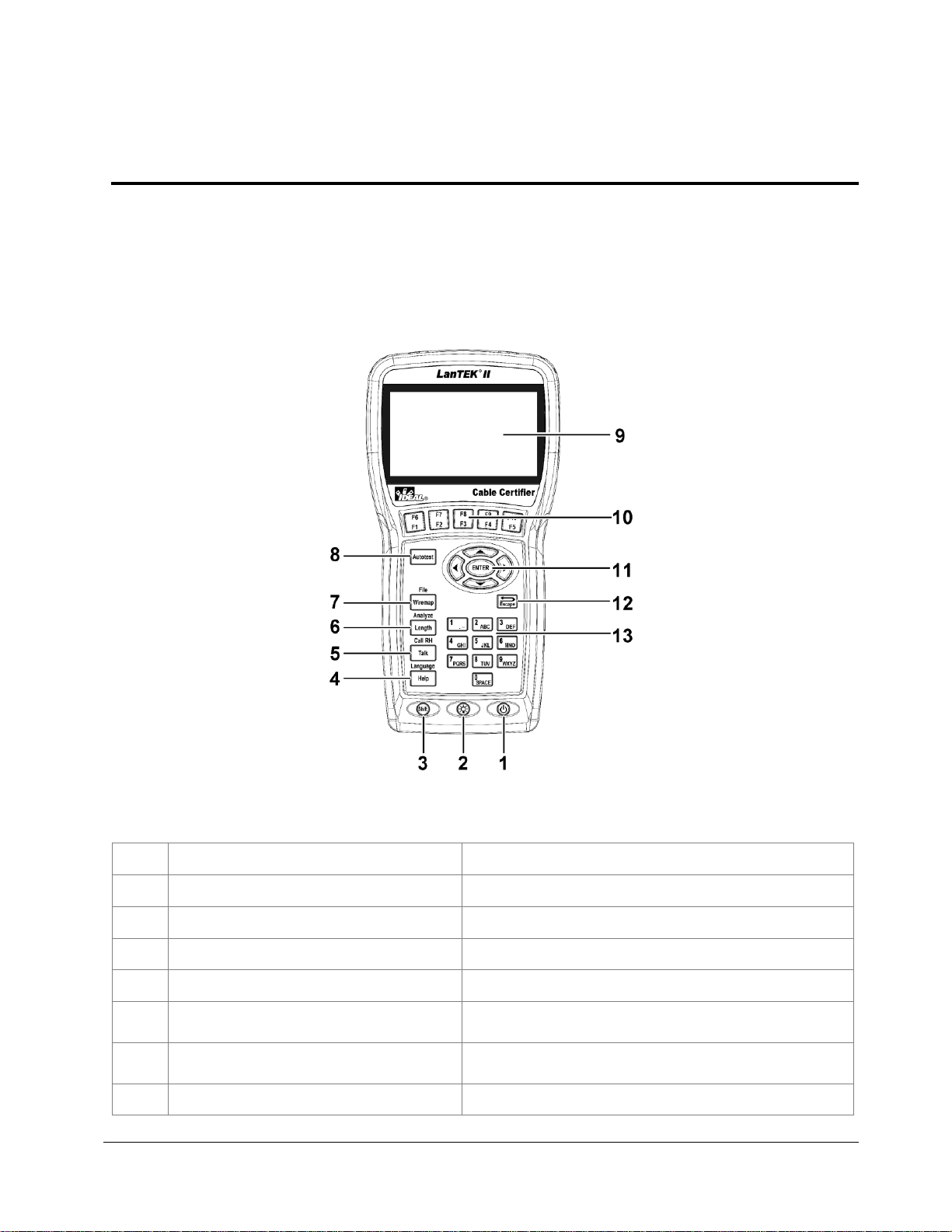

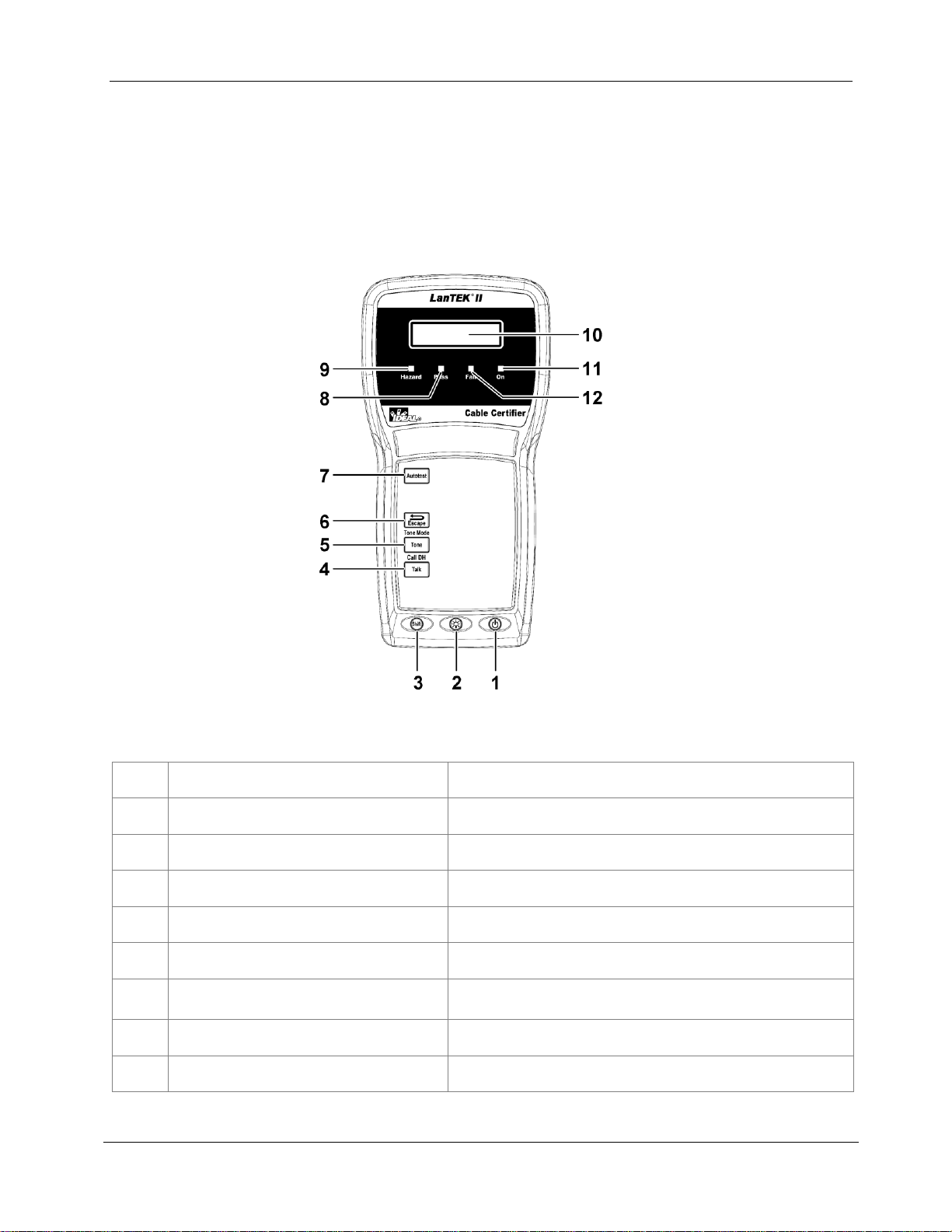

Controls

Description

1

On/Off

Power the Display handset (DH) on/off.

2

Dim Backlight

Dim Backlight in two stages.

3

Shift

Toggle key activities having dual functions.

4

Help / Language

Open Help Menu / Open Language Selection

5

Talk / Call RH

Activate Talkset function / call Remote Handset

(RH).

6

Length / Analyze

Open Length Measurement / Open Diagnostics

Menu.

7

Wiremap / File

Open analyze function "Wiremap" / Open Job List.

2.1. The Display Handset (DH)

The Display handset (DH) ensures control of preferences and test functions during individual

cable tests.

2.1.1. Controls and Ports/Connectors

Illustration 1 2.1. The Display Handset (DH)

Front view

Page 14

Chapter 2

13

Controls

Description

8

Autotest

Direct execution of test run pre-programmed for

established standards.

9

TFT-Display

Display of menus, test results, graphs, activity

selection and function keys.

10

Function keys

F1 to F5 / F6 to F10

Select menu options displayed on screen.

11

Arrow Keys / Enter

Navigate menus on TFT Display / Enter key to

activate and edit the selected menu.

12

Escape

Abort and exit the current menu without making

changes.

13

Alphanumeric Keys

Enter numbers, letters and special characters.

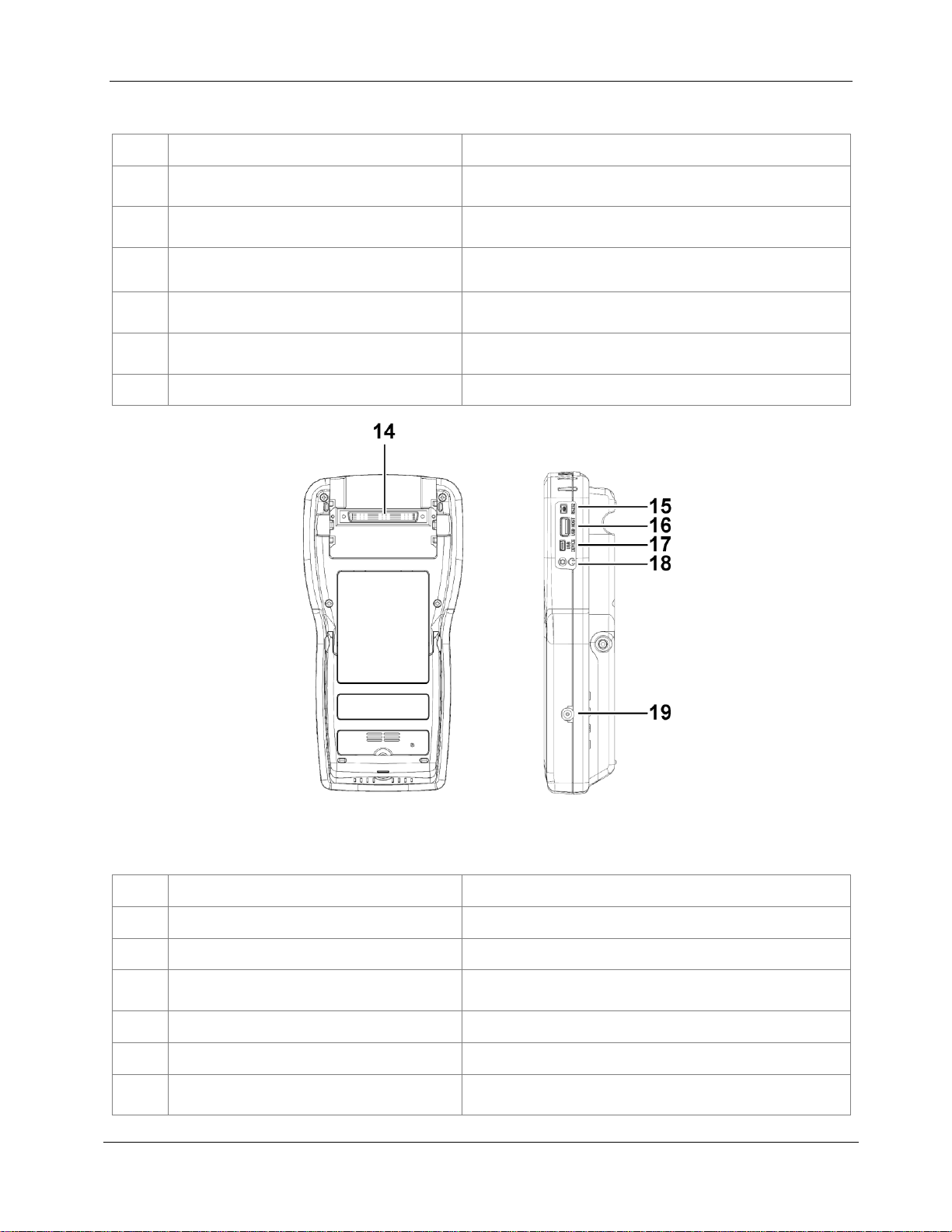

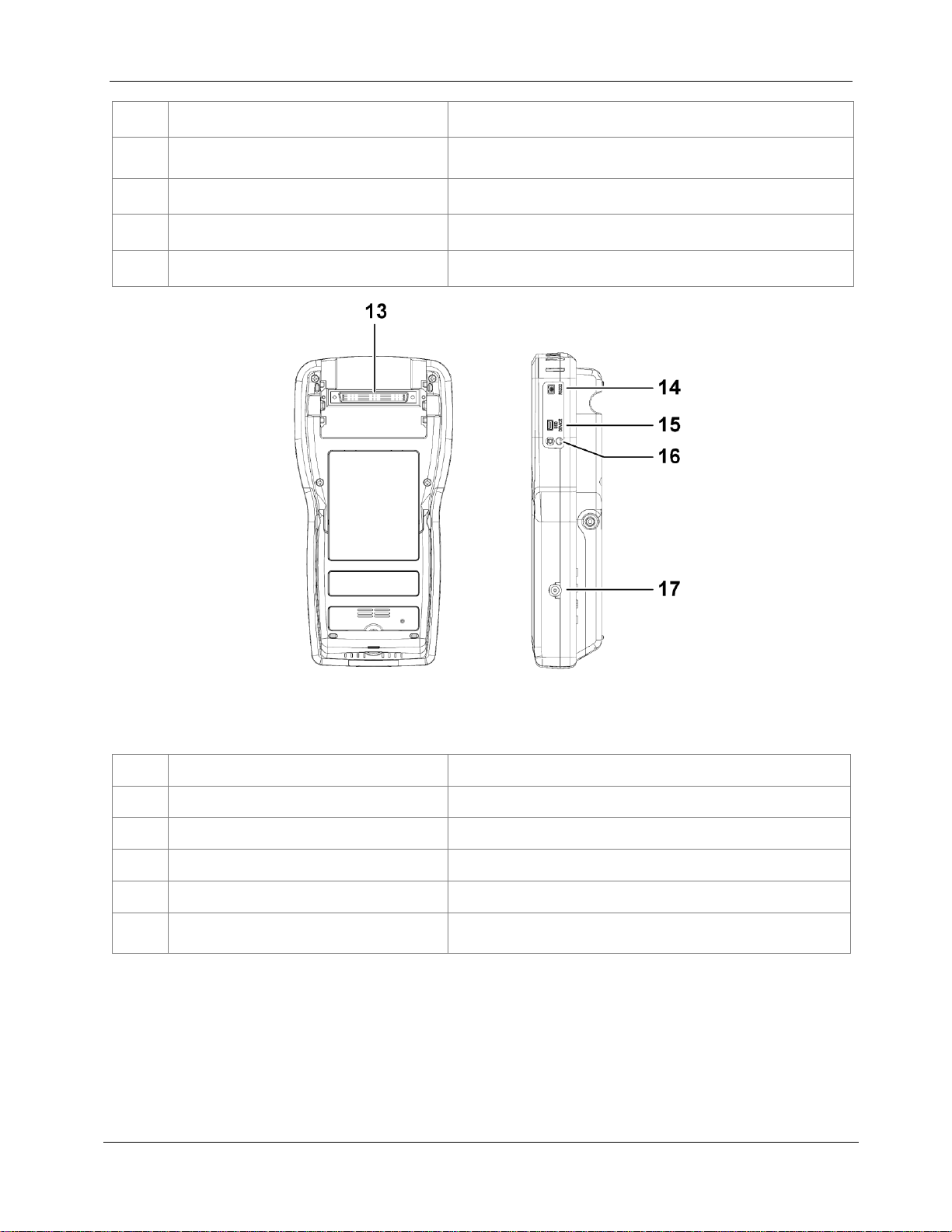

Ports/Connectors

Description

14

Low-NEXT-Connector

Connect a test adapter.

15

Service and Maintenance Jack

Connection for service and maintenance work.

16

USB Port

Connect USB removable storage to transmit data

and to load Firmware-Updates.

17

USB Device

Connect to a computer

18

Talkset Jack

Connect a Talkset.

19

DC Input Jack

Connect an external power supply and charge

battery pack.

Product Description

Illustration 2 2.1.1. The Display Handset (DH)

Rear and side view

Page 15

14

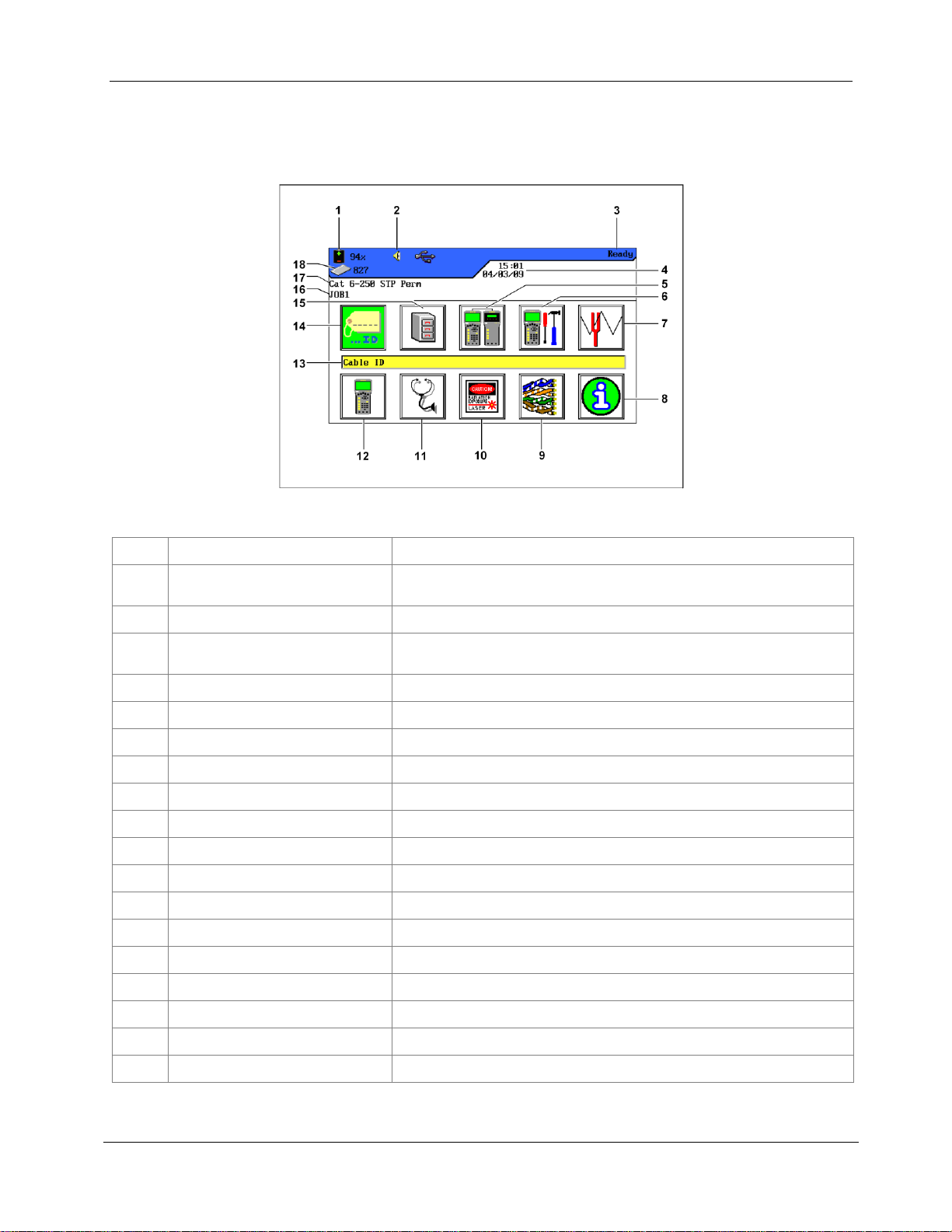

2.1.2. TFT Display

Display

Description

1

Power supply and charge

state

Indicates battery operation or external power supply and

charge state of battery pack (%).

2

Talkset indicator

Indicates whether talkset function is active.

3

Screen Title

Indicates that display handset (DH) or selected function is

ready.

4

Time and Date

Displays the time and date.

5

Field calibration

Select the field calibration.

6

Preferences

Select the instrument preferences.

7

Toner

Select the tone generator.

8

General Help

Select the Help menu.

9

Cable Type

Select or edit the cable type.

10

Fiber

Select the fiber measurement.

11

Analyze

Perform individual cable tests in real time.

12

Instrument

Display the information on LanTEK®II Cable Certifier.

13

Function Name

Displays the name of highlighted function.

14

Cable ID

Select cable naming function.

15

Stored Tests

Select file manager for the stored tests.

16

Job Name

Display the current job name.

17

Test Standard

Display the cable type selected for tests.

18

Records

Number of records stored.

Ready screen appears on operational Display handset (DH).

Illustration 2.1.2. TFT Display

Chapter 2

Product Description

Page 16

Chapter 2

15

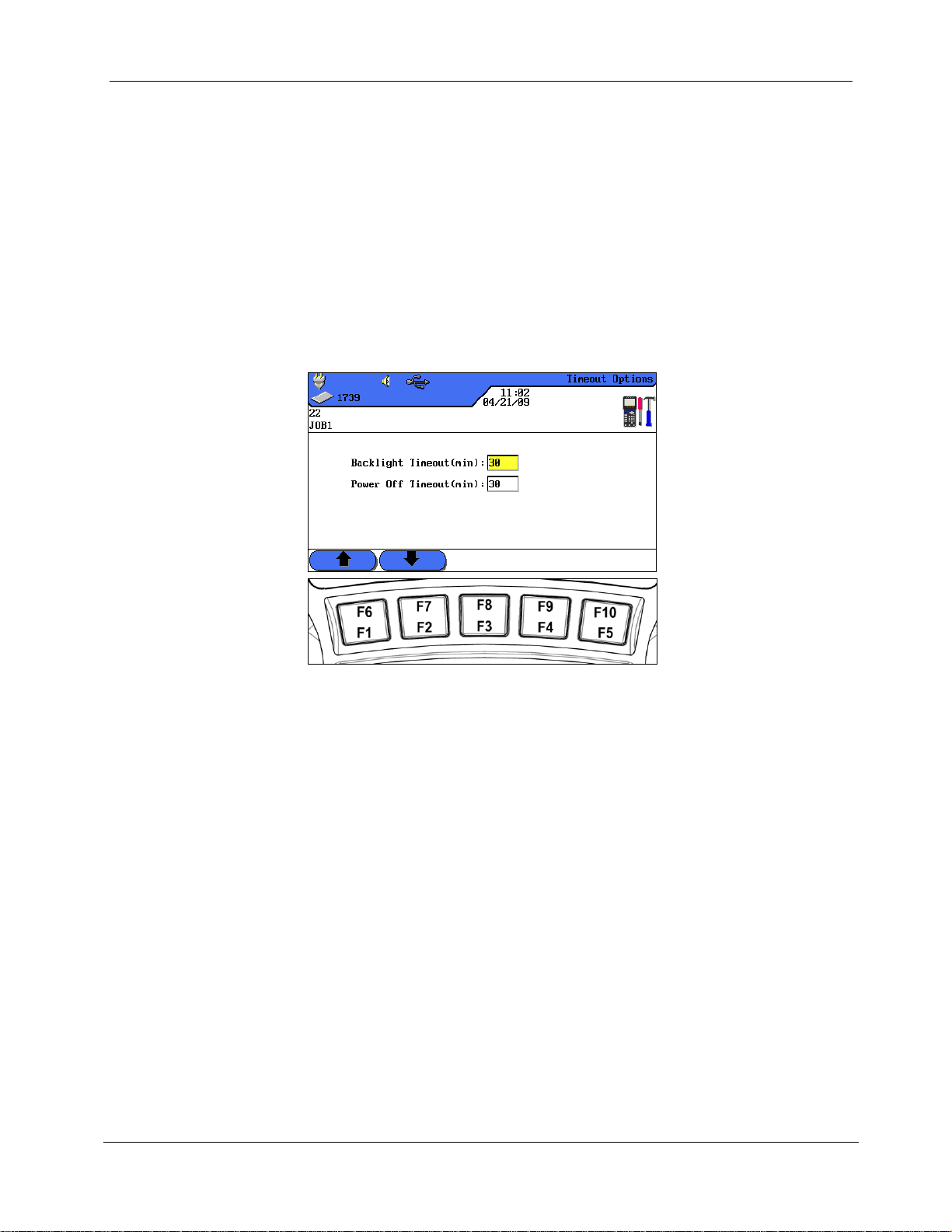

Softkeys

Function keys

Product Description

2.1.3. Function Keys F1 to F10

Function keys F1 to F5 have dual functions (F6 to F10). Pressing down the Shift key while

simultaneously pressing one of the function keys F1 to F5 will activate the 2nd function of

the function key (example: Shift + F4 equals function F8).

2.1.4. Soft Key

Soft keys indicate possible menu options at the bottom of the screen. To select the according

option, press the corresponding Function Key (F1 - F5) below the soft key.

The example below shows the setting of Timeout options by using the soft keys at the bottom

of the screen. The Value is set by Function Keys F1 (Increase) and F2 (Decrease).

Illustration 2.1. Soft keys and function keys

Page 17

Chapter 2

16

Controls

Description

1

On/Off

Power the Remote handset (RH) on/off.

2

Dim Backlight

Dim Backlight in two stages.

3

Shift

Toggle key activities having dual functions.

4

Talk / Call DH

Activate Talkset function / call Remote handset (RH).

5

Tone / Tone Mode

Power the tone generator on/off.

6

Escape

Abort and exit the current action without making

changes.

7

Autotest

Start the Autotest.

8

Pass LED

Test result: Passed.

Product Description

2.2. The Remote Handset (RH)

The Remote handset (RH) works with the Display handset (DH) to perform autotests or

individual real time analyze tests. The Remote handset (RH) is located at the end of the

cable link and communicates with the Display handset (DH). To perform measurements, the

Remote handset (RH) is automatically activated by the Display handset (DH).

2.2.1. Controls and Ports/Connectors

Illustration 2.2.1. The Remote Handset (RH)

Front view

Page 18

Chapter 2

17

Controls

Description

9

Hazard LED

Excessive line voltage (TELCO): Excessive voltage at

measurement input.

10

S/W-LCD Display

Two line alphanumeric display

11

On LED

The Remote Handset is on.

12

Fail LED

Test result: Fail.

Ports/Connectors

Description

13

Low-NEXT-Connector

Connect a test adapter.

14

Service and Maintenance Jack

Connection for service and maintenance work.

15

USB Device

Connect to a computer for firmware updates.

16

Talkset Jack

Connect a Talkset.

17

DC Input Jack

Connect an external power supply and charge battery

pack.

Product Description

Illustration 1 2.2.1. The Remote Handset (RH)

Rear and side view

Page 19

Chapter 2

18

CAUTION!

Only the adapter provided with the instrument shall be used. Other types of adapters may

cause damage to the tester.

NOTE:

Do not connect to AC power when testing shielded cables, as this may result in ground

loops which in turn can cause input protection warnings.

Product Description

2.3. Power Management

Both the Display (DH) and Remote (RH) handset use interchangeable rechargeable lithiumion battery packs (Li-ion).

The Display (DH) and Remote (RH) handsets can be run on battery power for

approximately 18 hours. Actual battery power times depends on various factors, such as

operating time versus standby time, use of the display backlight, and ambient

temperature.

When charge state of battery drops below the required voltage, a warning appears. Tester

automatically shuts down before testing results are affected.

To save battery power, the Display (DH) and Remote (RH) handset automatically power

down after a certain period of inactivity.

If the instrument will not be used for a prolonged time it is recommended that the battery

protection strips be inserted to conserve battery charge.

2.3.1. Operating the Display and Remote handset from AC Power

The Display (DH) and Remote (RH) handset can also be operated from an external DC source

(AC/DC adapter). The adapters are universally applicable.

Illustration 2.3.1. Adapter for LanTEK

®

II DH and RH

When using the AC/DC adapter to power the handsets, please note that:

Both handset batteries will receive a trickle charge.

A power plug will appear in the upper left corner of the Display handset (DH).

Page 20

Chapter 2

19

NOTE:

Charge time depends on charge state of battery.

Product Description

2.3.2. Battery Charging

The batteries of the Display (DH) and Remote (RH) handset are charged using the adapter. It

takes approximately 6-8 hours until the batteries in the instrument are fully charged. If the

batteries are charged externally, charge time is approximately 4 hours.

During recharging, the instrument is calibrated to the corresponding battery. This ensures an

accurate indication of the charge state at all times.

When the battery is removed, the Display handset (DH) data and preferences are preserved

in the flash ROM by a coin cell lithium battery.

2.4. Talkset

The LanTEK®II Cable Certifier is designed for use with a talkset. This function allows

communication between the Display (DH) and Remote (RH) handset through an externally

attached microphone/headset. For this purpose, the Display (DH) and Remote (RH) handset

must be connected to the test adapters through a cable.

Page 21

20

CHAPTER 3

Basics of the Cable Test

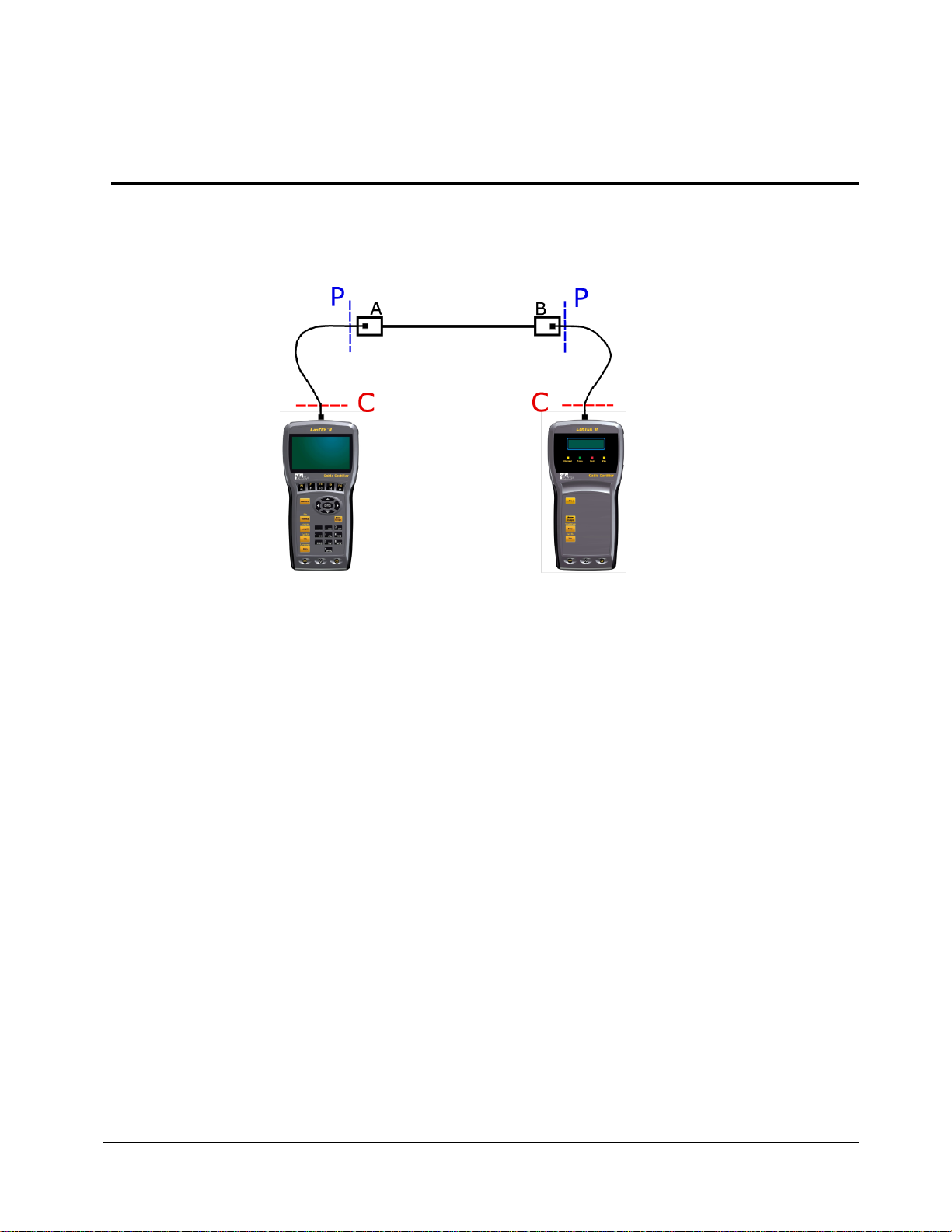

3.1. Testing of cables and relevant requirements

The following sections describe typical setup for permanent link and channel link testing.

Illustration 3.1. Illustration of test setup

The area marked with P indicates the typical test setup of a Permanent Link.

The area marked with C indicates the typical test setup of a Channel Link.

3.1.2. Setup for Permanent Link Test

The standards ANSI, EIA, TIA and ISO all differentiate between permanent link and channel

link on specifications for testing of communication networks. A permanent link consists of up

to 90 meters of horizontal cabling. (Maximum length limit applies to TIA standards only.) The

permanent link shown above serves to certify the installation of the horizontal cabling before

network connection and user hook-up. Adapters, patch cords and jumpers are excluded from

testing.

3.1.3. Setup for Channel Link Test

A channel link includes all components of a cabling system. It consists of up to 90 meters

horizontal cabling, including patch cords, jumpers, and test adapters at each cable end. The

channel link shown above serves to certify the network installation, including the horizontal

cable line and patch cord.

Page 22

21

CHAPTER 4

Preferences

Chinese

Korean

Czech

Norwegian

Dutch

Polish

English

Portuguese

French

Russian

German

Spanish

Italian

Most instrument configurations are set by using the "Preferences" menu.

4.1. Open Preferences

1. Use Arrow Keys to navigate to "Preferences" and press Enter.

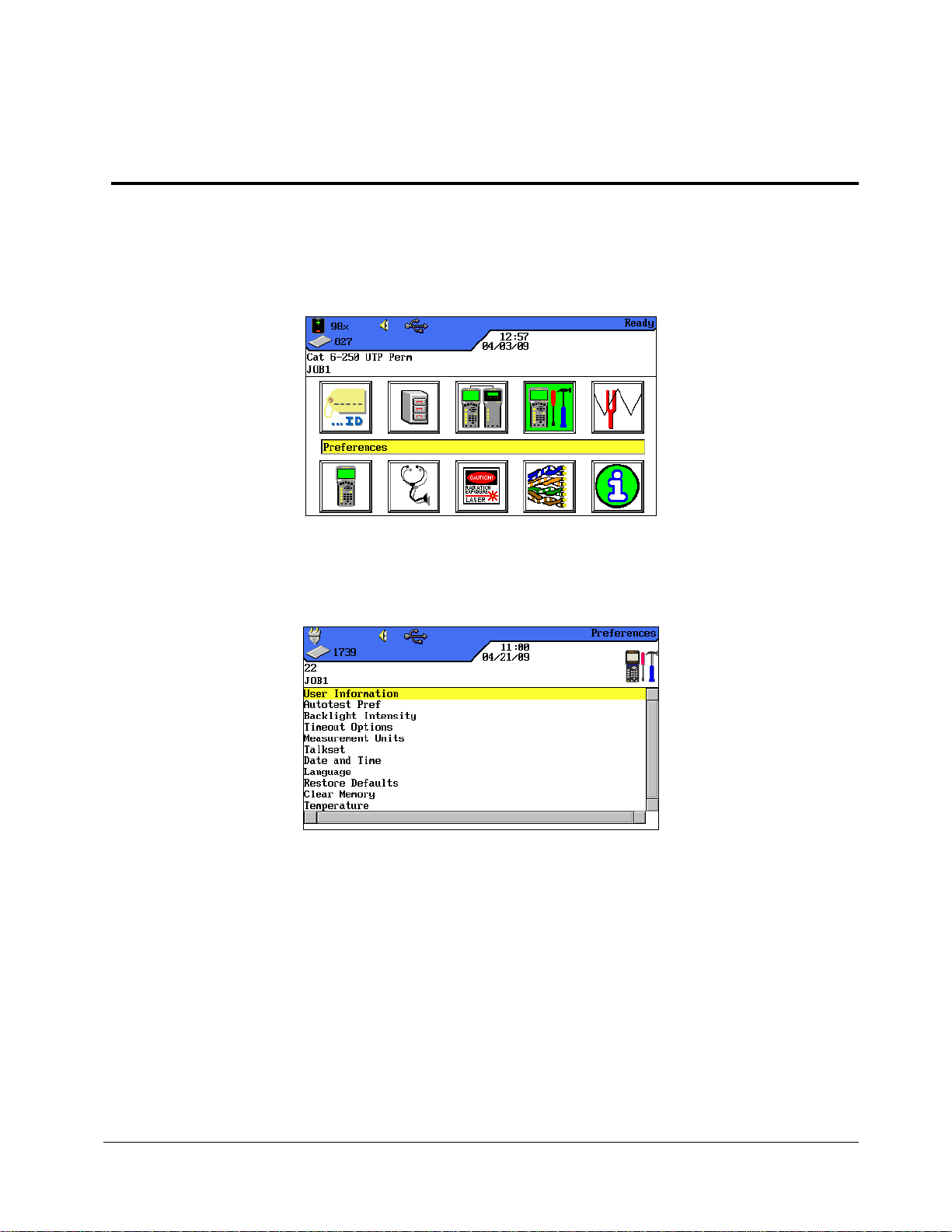

Illustration 1 4.1. Open Preferences

Next, the instrument preferences can be set by using the listed menus.

Illustration 2 4.1. Preference Selection

4.2. Language

Menu navigation of LanTEK®II Cable Certifier is available in the following languages:

Page 23

22

1. Use Arrow Keys to navigate to "Language" menu and press Enter. Alternatively,

open menu by using the Shift + Help / Language keys.

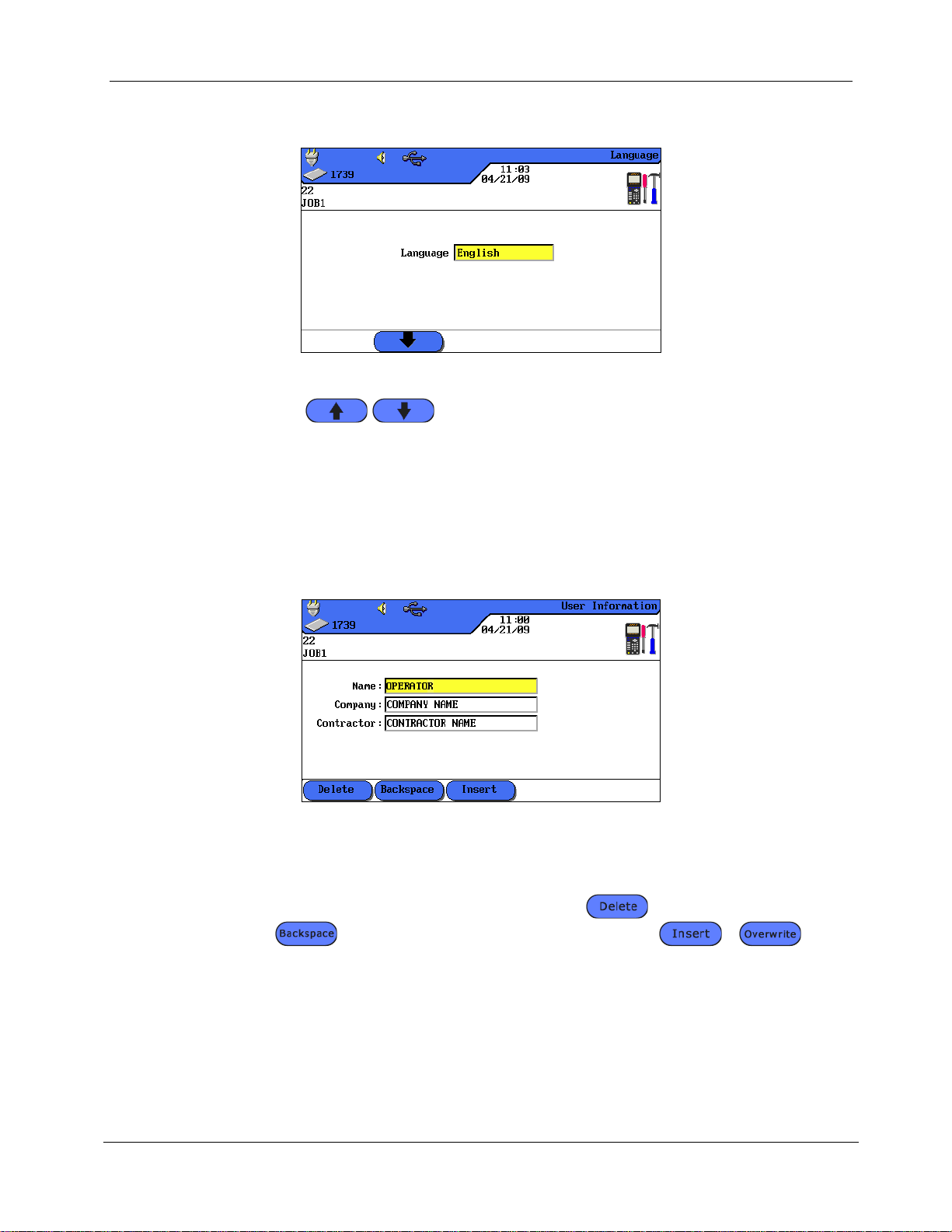

Illustration 4.2. Language

2. Use soft keys to select the desired language.

3. Press Enter to save the information entered. Escape allows you to exit the menu

without making changes.

4.3. User Information

Chapter 4

Preferences

This menu can be used to provide information on assigned Technician, Company and

Contractor.

1. Use Arrow Keys to navigate to "User Information" menu and press Enter.

Illustration 4.3. User Information

2. Use Arrow Keys to navigate to desired option Name, Company or Contractor.

3. Use Alphanumeric Keys to enter the desired information.

4. Make corrections to entries by using the soft keys (delete at cursor

position), (delete characters to the left of cursor), /

(insert alphanumeric characters at cursor position / overwrite highlighted entry).

5. Press Enter to save the information entered. Press Escape to exit the menu

without making changes.

4.4. Autotest Options

Use this menu to set Autotest options.

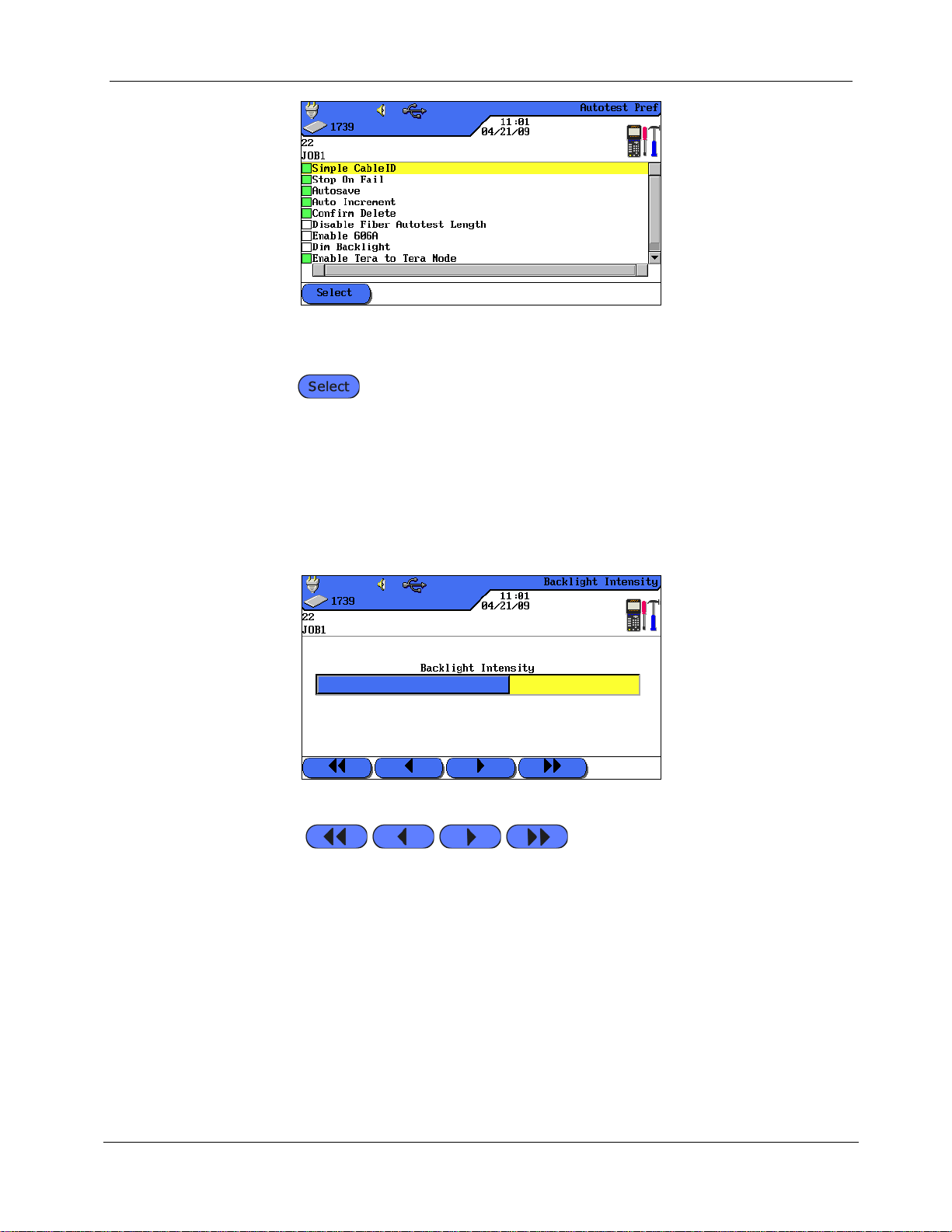

1. Use Arrow Keys to navigate to "Autotest Options" menu and press Enter.

Page 24

23

2. Use Arrow keys to select the desired option.

Backlight

1 minute

Tester

30 minutes

3. Use soft key to activate or deactivate the selected option. An activated

option is indicated by the green box.

4. Press Enter to save the information entered. Press Escape to exit the menu

without making changes.

4.5. Contrast

Chapter 4

Preferences

Illustration 4.4. Autotest Options

Use this menu to set Dim Backlight on screen.

1. Use Arrow Keys to navigate to "Contrast" menu and press Enter.

Illustration 4.5. Contrast

2. Use soft keys to set backlight intensity.

3. Press Enter to save the information entered. Press Escape to exit the menu

without making changes.

4.6. Timeout Options

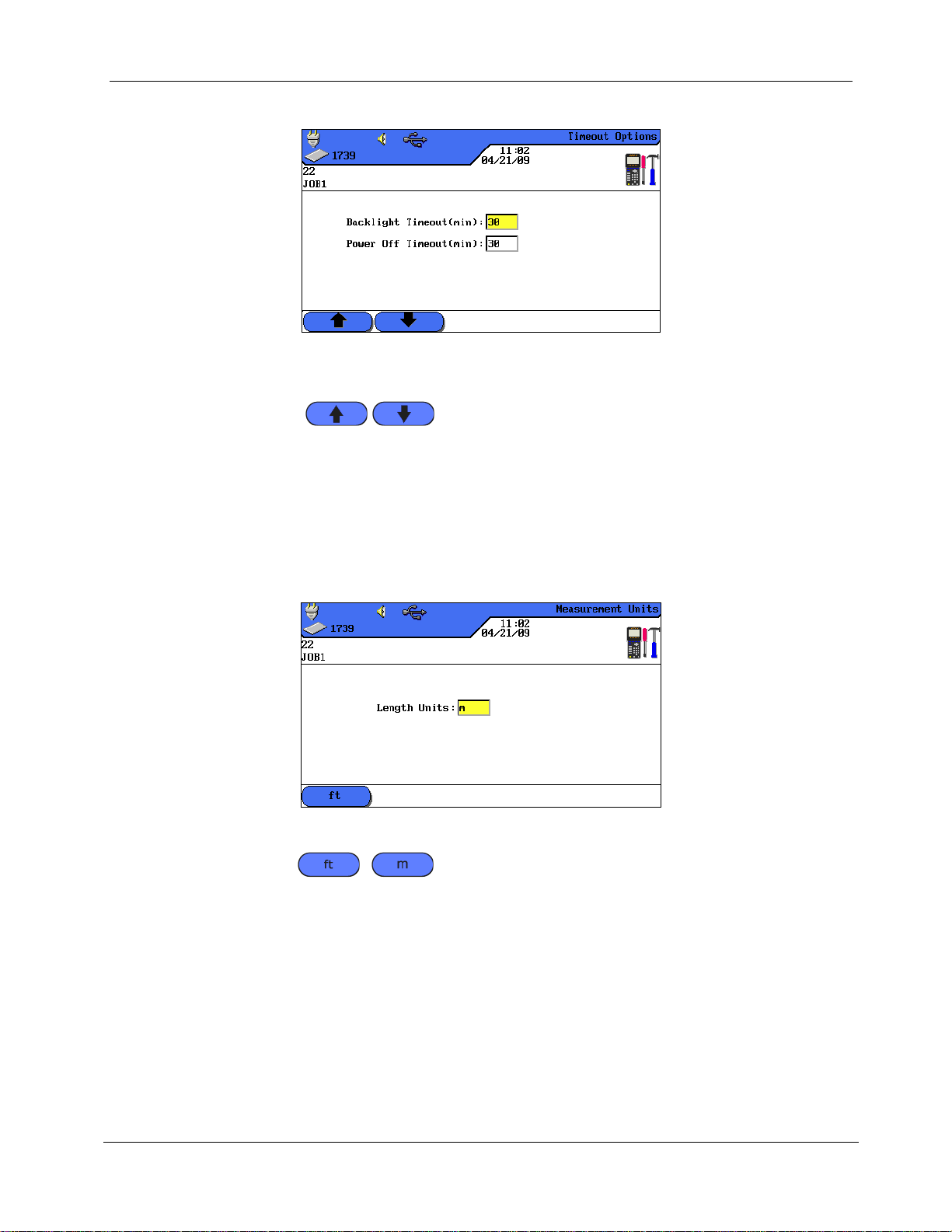

Use this menu to set the time after which backlight automatically dims and the LanTEK®II

Cable Certifier automatically shuts down when tester is not in use.

Default settings:

Page 25

24

1. Use Arrow Keys to navigate to "Timeout Options" menu and press Enter.

Illustration 4.6. Timeout Options

2. Use Arrow keys to select the desired option.

3. Use soft keys to set the desired value.

4. Press Enter to save the information entered. Press Escape to exit the menu

without making changes.

4.7. Measurement Units

Chapter 4

Preferences

Use this menu to specify the measurement unit for length measurements ft or m (foot or

meter). The default setting depends on the language selected.

1. Use Arrow Keys to navigate to "Measurement Units" menu and press Enter.

Illustration 4.7. Measurement Units

2. Use soft key / (foot / meter) to select the desired unit.

3. Press Enter to save the information entered. Press Escape to exit the menu

without making changes.

Page 26

Chapter 4

25

Preferences

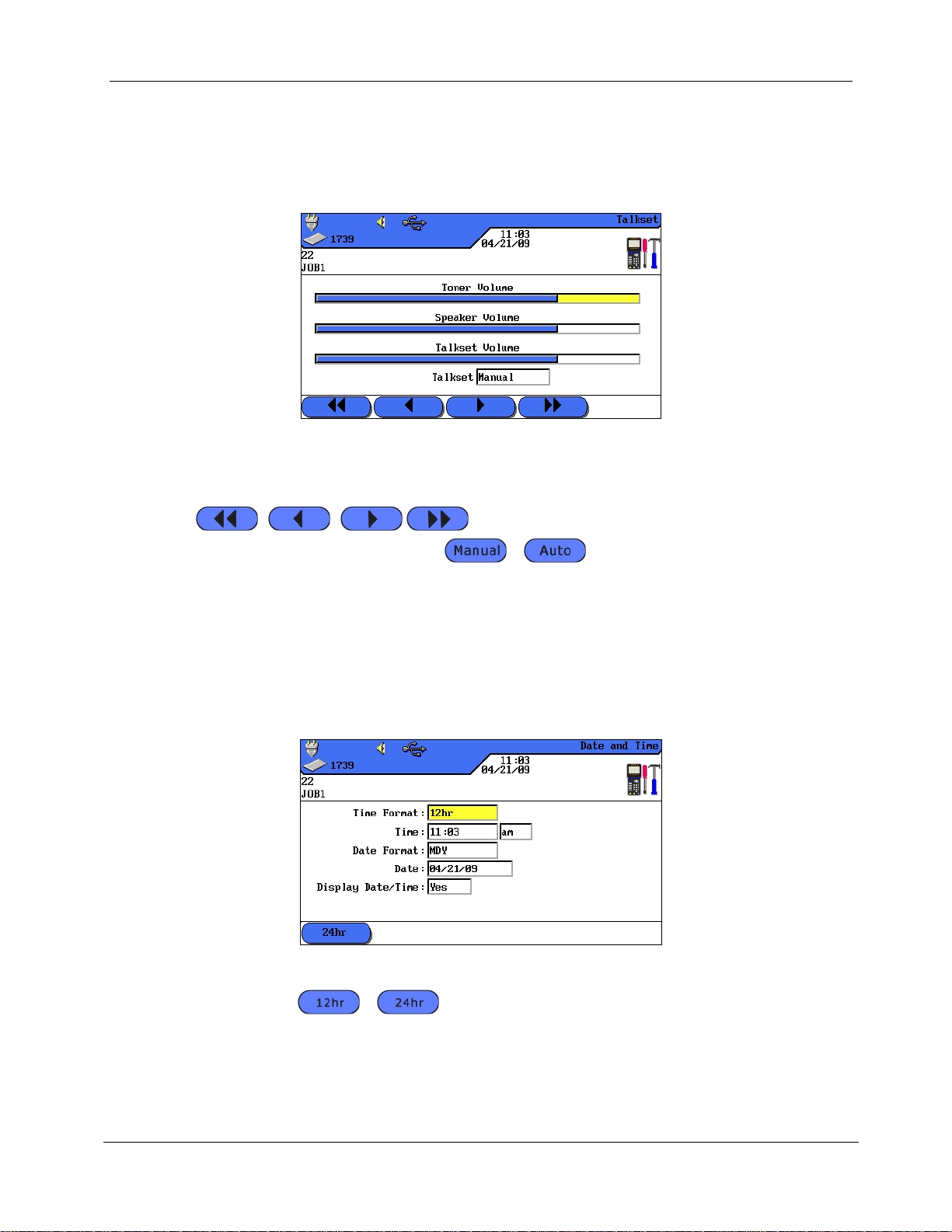

4.8. Talkset

Use this menu to set signal strength of tone generator, volume of internal speaker and

volume of talkset. Also use this menu to change the talkset mode.

1. Use Arrow Keys to navigate to "Talkset" menu and press Enter.

Illustration 4.8. Talkset

2. Use Arrow Keys to select the desired option.

3. On options Toner Volume, Speaker Volume or Talkset Volume, use soft keys

to set signal strength and volume.

4. On option Talkset, use soft key / to select desired setting.

5. Press Enter to save the information entered. Press Escape to exit the menu

without making changes.

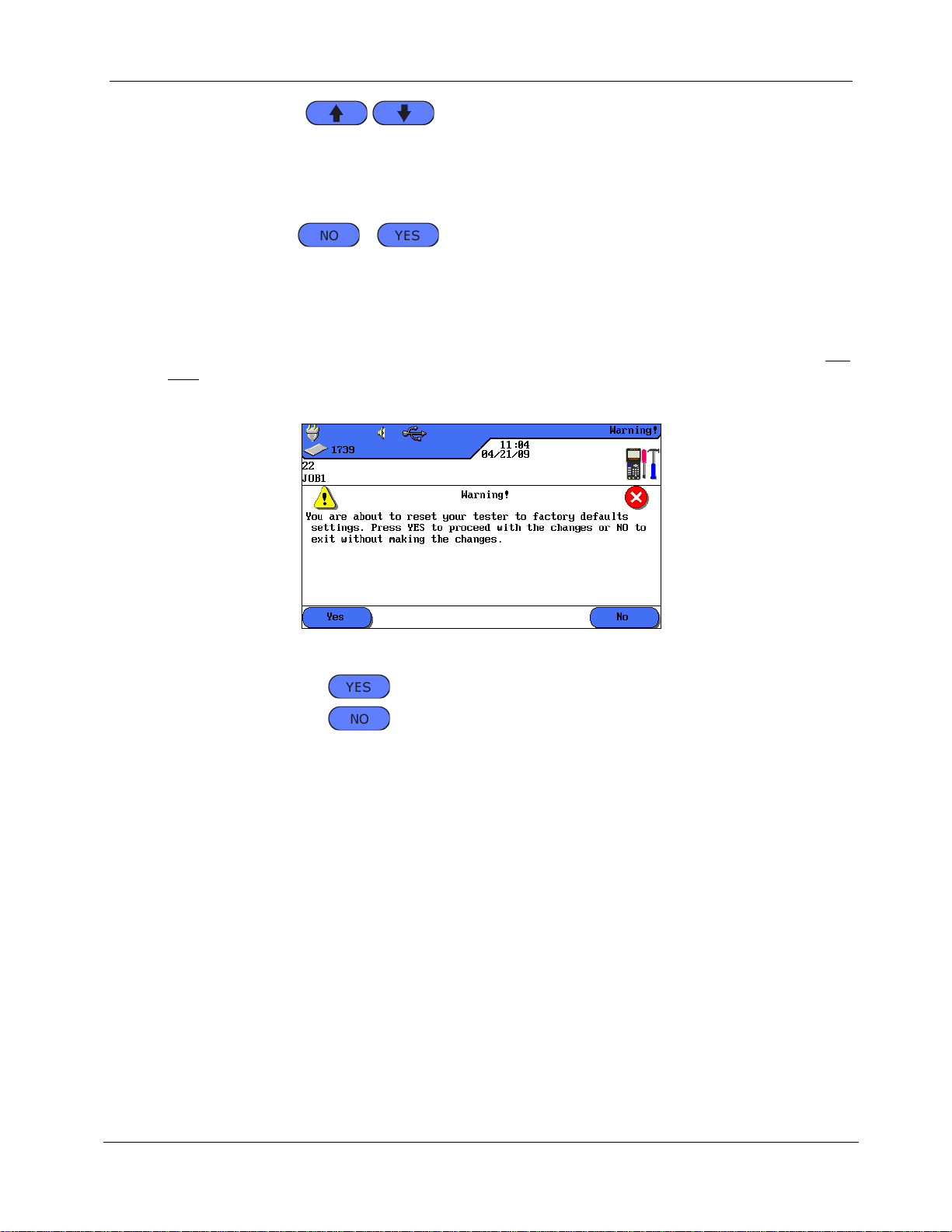

4.9. Date and Time

Accurate date and time settings are important for the reliable identification of records and

test reports.

1. Use Arrow Keys to navigate to "Date and Time" menu and press Enter.

Illustration 4.9. Date and Time

2. Use soft key / to set the desired Time format.

3. Use Arrow Keys to navigate to option Time.

4. Use Alphanumeric Keys to enter the time.

5. Use Arrow Keys to navigate to option Date Format.

Page 27

26

6. Use soft keys to select the desired format MDY (month/day/year),

DMY (day/month/year) or YMD (year/month/day).

7. Use Arrow Keys to navigate to option Date.

8. Use Alphanumeric Keys to enter the date.

9. Use Arrow Keys to navigate to option Date/Time Display.

10. Use soft key / to select the desired setting.

11. Press Enter to save the information entered. Press Escape to exit the menu

without making changes.

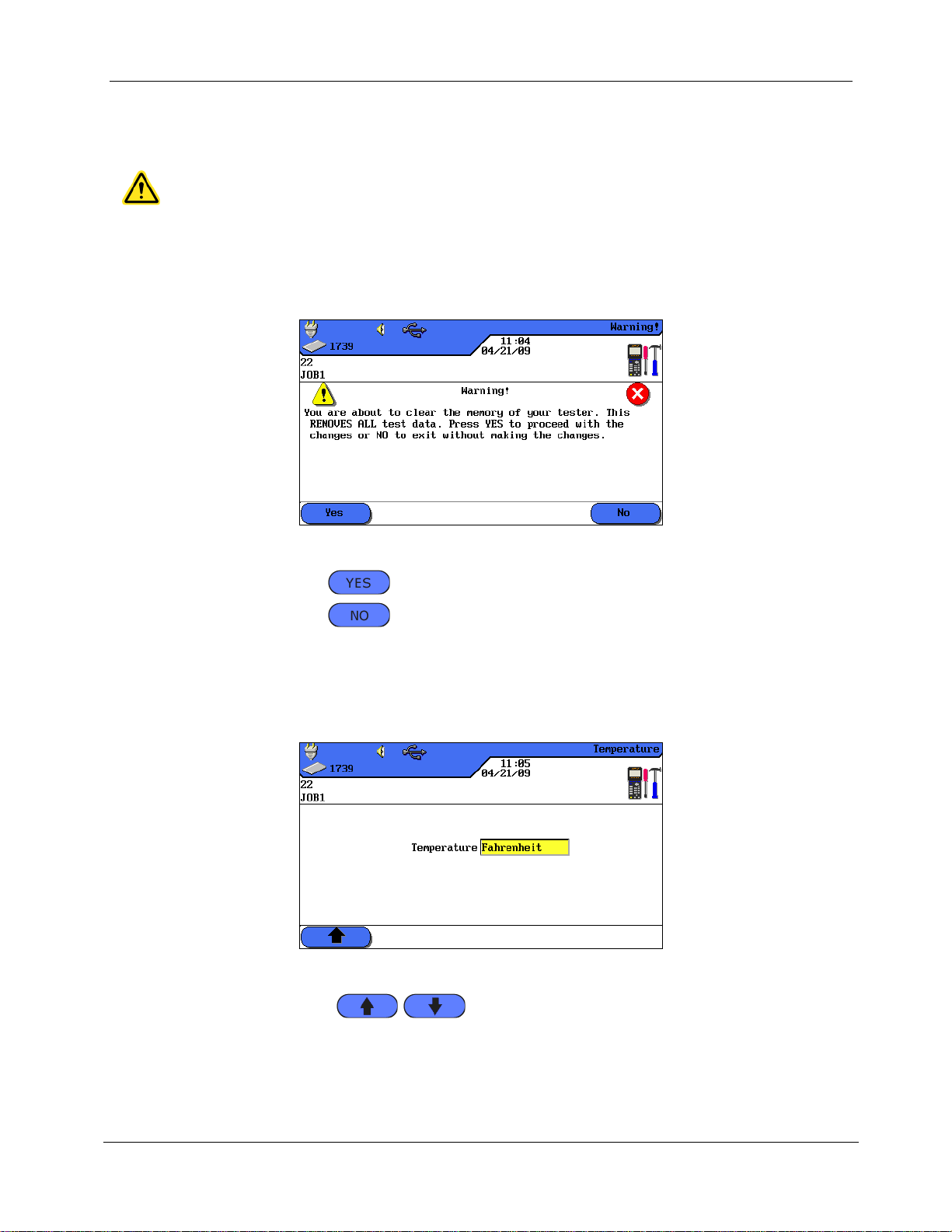

4.10. Restore Default

Use this menu to reset all tester settings to their factory defaults. Using this option will

not delete stored tests.

1. Use Arrow Keys to navigate to "Restore Defaults" menu and press Enter.

Chapter 4

Preferences

Illustration 4.10. Restore Defaults

2. Use the soft key to accept default settings.

3. Use the soft key to exit the screen without making changes.

Page 28

27

4.11. Clear Memory

CAUTION!

When using the "Clear Memory" menu, the records cannot be restored. This will

permanently delete all stored tests.

Use this menu to clear all records from the tester memory at one time.

1. Use Arrow Keys to navigate to Clear Memory menu and press Enter.

Chapter 4

Preferences

Illustration 4.11. Clear Memory

2. Use the soft key to clear the memory of the Cable Certifier.

3. Use the soft key to exit the screen without making changes.

4.12. Temperature

Use this menu to select the required temperature in Celsius or Fahrenheit.

1. Use Arrow Keys to navigate to "Temperature" menu and press Enter.

Illustration 4.12. Temperature

2. Use the soft keys to select the desired temperature.

3. Press Enter to save the information entered. Escape allows you to exit the menu

without making changes.

Page 29

28

CHAPTER 5

Autotest

NOTE:

If during the last 7 days no calibration has been performed on the identified Remote

handset (RH), the Autotest is cancelled and the user receives a message that a field

calibration is required.

Using Autotest, the installation can be measured and tested in a simple and fast way. After

pressing the AUTOTEST key, LanTEK®II Cable Tester automatically performs a number of

pre-programmed single tests. Autotest can be enabled from the Display (DH) or Remote (RH)

handset.

Selection of single tests from the test series depends on the type of cabling to be tested.

Specification of the test series is based on approved or recommended standards, as well as

specific parameters.

After the test series is completed, LanTEK®II Cable Tester displays an overall passed/failed

result, as well as the individual passed/failed results.

Preferences on Display handset (DH)

Set Autotest Pref.

Select job folder.

Set cable name (cable ID).

Select cable type.

Connections

Separate cable line to be tested from all network components.

Using suitable patch cords, connect the Display handset (DH) to one end of the cable line

(link), and the Remote handset (RH) to the opposite end of the cable line (link).

Test run

By pressing the AUTOTEST key, the test procedures described below are initiated:

First, the Display handset (DH) attempts to establish a connection to the Remote handset

(RH) via a correctly connected wire pair. If connection cannot be established, the Display

handset (DH) will show the message "Searching for Remote (RH). The search is continued

until the Autotest is manually cancelled or the Remote handset (RH) is located.

After connection to the Remote handset (RH) has been successfully established, its serial

number is read out to check if current configuration data are available.

Display handset (DH) continues the Autotest if serial number is valid. Most Autotests start

with the Wiremap test for twisted pair cables.

Following the Wiremap test, the other single tests that have been defined for the currently

selected cable type are performed.

After completion of Autotest, all test data can be displayed, saved and printed.

The test results of the last Autotest are stored in the non-volatile memory and remain

available for viewing even after the LanTEK®II Cable Tester is powered on or powered

down.

Page 30

Chapter 5

29

Symbol

Overall Autotest Result

The overall Autotest receives a passing grade if all single tests have been passed or

passed*.

The overall Autotest receives a failing grade if at least one single test has failed or

failed*.

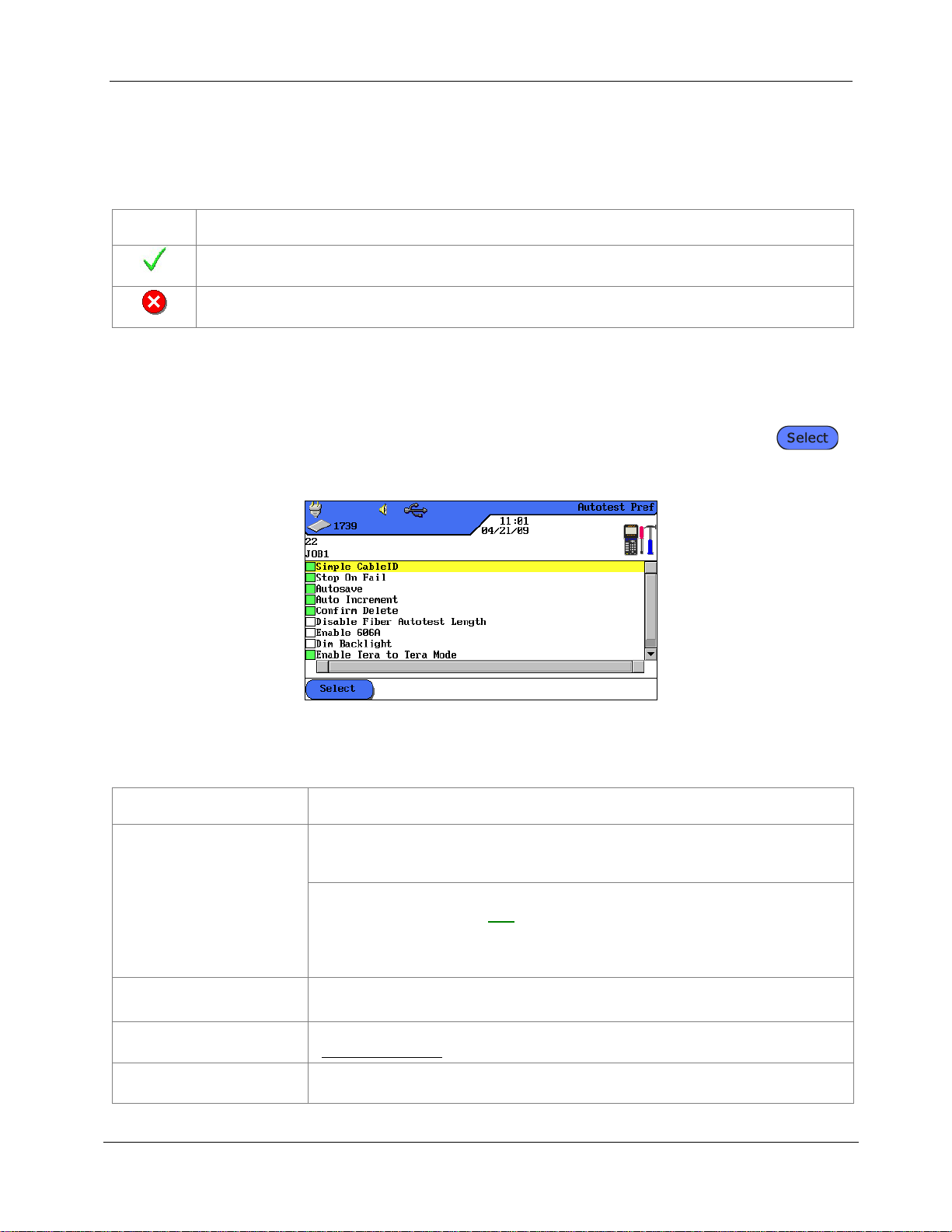

Autotest Pref

Description

Simple cable ID

Assign name to cable line and set/reset meter reading of tests. The name

can be assigned as simple cable ID or double cable ID (Cable From/Cable

To).

NOTE:

If Simple Cable ID is not enabled, the cable name assigned will be

the default cable ID. In addition to cable name and test meter, an

initial value and a final value can be set, and the way of counting

can be specified.

Stop on Fail

The Autotest is stopped after the first failed test.

Autosave

The LanTEK®II Cable Tester automatically names and saves all results of

passed Autotests in the current job folder.

Auto Increment

The test meter for the cable ID is automatically advanced after each

Autotest.

Autotest

The test results of the last Autotest remain in the non-volatile memory until they are

overwritten by new test results, the memory is deleted or an analysis test is conducted.

Overall Passed/Failed Result

The overall result of Autotest is displayed after test series is completed.

5.1. Set Autotest Pref

1. Open "Preferences" on start screen.

2. In "Preferences" open Autotest Pref.

3. Use Arrow Keys to navigate to the according Autotest Pref. Use soft key

to enable or disable the selected Autotest Pref. Enabled Autotest Pref are indicated

by green boxes.

Illustration 5.1. Autotest Pref

4. Press Enter to save the information entered. Escape allows you to exit the menu

without making changes.

Page 31

30

Autotest Pref

Description

This will permanently

delete the Tests / Jobs

from the tester

Enables confirmation prompt prior to deleting data.

Disable Fiber Autotest

Length

Enable / disable length measurement of fiber (LWL) with FiberTEK™ FDX

during Autotest.

Enable 606A

Enable labelling standard TIA/EIA 606-A for telecommunication

infrastructure as cable ID.

NOTE:

If labelling standard TIA/EIA 606-A is enabled; the selected cable

name (simple cable ID/default cable ID) is not applied.

Enable Tera to Tera

Mode

Enables Tera to Tera Mode instead of Tera to RJ45 Mode.

Enable Wiremap On

Failed Autotest.

In case of failed Autotest, it determines whether another fault analysis

will automatically be performed.

5.2. Select Job Folder

Chapter 5

Autotest

The name of the current job folder is shown in the TFT display on the ready screen. To save

the Autotest it is possible to keep this job folder, enable another existing job folder, or create

a new job folder.

5.2.1. Enable Existing Job Folder

1. Use Arrow keys to navigate to "File" and press Enter to open the job list.

Illustration 1 5.2.1. File

Page 32

Chapter 5

31

Autotest

Use Arrow Keys to navigate to the desired job folder. The display is highlighted yellow.

Illustration 2 5.2.1. Job List

2. Use soft key to open job options.

3. Use Arrow Keys to navigate to option Make Job Current. The display is

highlighted yellow.

Illustration 3 5.2.1. Job Options (example Current Job Info)

4. Press Enter to save the information entered. Escape allows you to exit the menu

without making changes.

5. When confirming with Enter, the name of the selected job folder will appear on

the ready screen.

5.2.2. Create New Job Folder

1. Use soft key to open job options in job list.

Illustration 1 5.2.2. Job List

Page 33

32

2. Use Arrow Keys to navigate to option New Job and press Enter.

Illustration 2 5.2.2. Job Options

3. Use Alphanumeric Keys to enter the desired information.

Chapter 5

Autotest

Illustration 3 5.2.2. New Job

4. Make corrections to entries by using the soft keys (delete at cursor

position), (delete characters to the left of cursor), /

(insert alphanumeric characters at cursor position / overwrite highlighted entry).

5. Press Enter to save the information entered. Escape allows you to exit the menu

without making changes.

6. When confirming with Enter, the name of the new job folder will appear on the

ready screen.

Page 34

Chapter 5

33

Autotest

5.3. Set Cable Name (cable ID)

The cable name of the cable lines in an Autotest consists of a fixed Cable Name and a

variable Current Value (4-digit test meter) that automatically increments. Depending on

selected Autotest Pref it is also possible to specify structure and way of counting.

1. Use Arrow keys to navigate to "Cable ID" and press Enter.

Illustration 5.3. Cable ID

The name used last will appear:

Single Cable ID (1 name is assigned to each cable).

or

Double Cable ID (2 names are assigned to each cable, one for the start and one for the

end of the cable).

Illustration 5.3. Cable ID

Increment… when pressing Enter, the current value of the test meter, shown in view

below, is incremented by one position.

Set… opens menu for cable name.

Select… switches between Single Cable ID and Double Cable ID.

Page 35

34

5.3.1. Simple Cable ID

2. Use Arrow keys to navigate in "Cable ID" view to option Set… and press Enter.

Single Cable ID (1 cable name)

3. Use Alphanumeric Keys to enter a Cable Name for the test portion.

4. Use Alphanumeric Keys to reset the Current Value of the test meter, or enter an

arbitrary value.

5. Make corrections to entries by using the soft keys (delete at cursor

position), (delete characters to the left of cursor), /

(insert alphanumeric characters at cursor position / overwrite highlighted entry).

Chapter 5

Autotest

Illustration 1 5.3.1. Single Cable ID

6. Press Enter to save the information entered. Escape allows you to exit the menu

without making changes.

Double Cable ID (2 cable names, start/end)

7. Use Alphanumeric Keys to enter a Cable Name for the Cable From/Cable To of

test portion.

8. Use Alphanumeric Keys to reset the Current Value of the test meter, or enter an

arbitrary value.

9. Make corrections to entries by using the soft keys (delete at cursor

position), (delete characters to the left of cursor), /

(insert alphanumeric characters at cursor position / overwrite highlighted entry).

Illustration 2 5.3.1. Double Cable ID

10. Use soft keys and to switch between the views Cable From and

Cable To.

Page 36

35

11. Use Alphanumeric Keys to enter a Cable Name for the Cable From/Cable To of

test portion.

12. Use Alphanumeric Keys to reset the Current Value of the test meter, or enter an

arbitrary value.

13. Make corrections to entries by using the soft keys (delete at cursor

position), (delete characters to the left of cursor), /

(insert alphanumeric characters at cursor position / overwrite highlighted entry).

14. Press Enter to save the information entered. Escape allows you to exit the menu

without making changes.

5.3.2. Default Cable ID

Simple cable ID was not selected in Autotest Pref.

1. Use Arrow keys to navigate in "Cable ID" view to option Set… and press Enter.

Simple Cable ID (1 cable name)

2. Use Alphanumeric Keys to enter a Cable Name for the test portion.

3. Use Alphanumeric Keys to reset the Current Value of the test meter, or enter an

arbitrary value.

4. Use Alphanumeric Keys to enter an arbitrary value for Start and End. Meter is

reset after reaching final value.

Chapter 5

Autotest

5. Make corrections to entries by using the soft keys (delete at cursor

position), (delete characters to the left of cursor), /

(insert alphanumeric characters at cursor position / overwrite highlighted entry).

6. Use symbol to lock a position into entered value. Use symbol to enable

Auto Increment of a character.

Illustration 1 5.3.2. Single Cable ID

7. Press Enter to save the information entered. Escape allows you to exit the menu

without making changes.

Double Cable ID (2 cable names, start/end)

1. Use Alphanumeric Keys to enter a Cable Name for the Cable From/Cable To of

test portion.

2. Use Alphanumeric Keys to reset the Current Value of the test meter, or enter an

arbitrary value.

Page 37

Chapter 5

36

Autotest

3. Use Alphanumeric Keys to enter an arbitrary value for Start and End. Meter is

reset after reaching final value.

4. Make corrections to entries by using the soft keys (delete at cursor

position), (delete characters to the left of cursor), /

(insert alphanumeric characters at cursor position / overwrite highlighted entry).

5. Use symbol to lock a position into entered value. Use symbol to enable

Auto Increment of a character.

Illustration 2 5.3.2. Double Cable ID

6. Use soft keys and to switch between the views Cable From and

Cable To.

7. Use Alphanumeric Keys to enter a Cable Name for the Cable From/Cable To of

test portion.

8. Use Alphanumeric Keys to reset the Current Value of the test meter, or enter an

arbitrary value.

9. Use Alphanumeric Keys to enter an arbitrary value for Start and End. Meter is

reset after reaching final value.

10. Make corrections to entries by using the soft keys (delete at cursor

position), (delete characters to the left of cursor), /

(insert alphanumeric characters at cursor position / overwrite highlighted entry).

11. Use symbol to lock a position into entered value. Use symbol to enable

Auto Increment of a character.

12. Press Enter to save the information entered. Escape allows you to exit the menu

without making changes.

Page 38

Chapter 5

37

Default

Example 1

Example 2

Example 3

"Cable From"

"Cable To"

Cable name:

TEST

Current: 0 0 0 0

Start: 0 0 0 0

End: 9 9 9 9

Cable name:

PANEL 1

Current: 0 0 0 0

Start: 0 0 0 0

End: 0 0 2 2

Cable name:

PANEL 2

Current: 0 1 8 A

Start: 0 0 0 A

End: 0 9 9 D

Cable name:

OFFICE 2

Current: 0 0 0 0

Start: 0 0 0 0

End: 9 9 9 9

Cable name:

Distributor

Current:0 0 0

A

Start: 0 0 0 A

End: 0 0 9 D

0 0 0 0

0 0 0 0

0 1 8 A

0 0 0 0

0 0 0 A

0 0 0 1

0 0 0 1

0 1 8 B

0 0 0 1

0 0 0 B

0 0 0 2

0 0 0 2

0 1 8 C

0 0 0 2

0 0 0 C

0 0 0 3

0 0 1 0

0 1 8 D

0 0 0 3

0 0 0 D

0 0 0 4

0 0 1 1

0 1 9 A

0 0 0 4

0 0 1 A

0 0 0 5

0 0 1 2

0 1 9 B

0 0 0 5

0 0 1 B

0 0 0 6

0 0 2 0

0 1 9 C

0 0 0 6

0 0 1 C

0 0 0 7

0 0 2 1

0 1 9 D

0 0 0 7

0 0 1 D

0 0 0 8

0 0 2 2

0 2 0 A

0 0 0 8

0 0 2 A

0 0 0 9

0 0 0 0

0 2 0 B

0 0 0 9

0 0 2 B

0 0 1 0

0 0 0 1

0 2 0 C

0 0 1 0

0 0 2 C

0 0 1 1

0 0 0 2

0 2 0 D

0 0 1 1

0 0 2 D

0 0 1 2

0 0 1 0

0 2 1 A

0 0 1 2

0 0 3 A

Autotest

Examples for Default Cable ID

In default setting, the meter starts at 0000 and ends at 9999. The four (4) positions are

enabled and incrementing.

5.4. Labeling Standard TIA/EIA 606-A

The standards TIA/EIA 606-A for telecommunication infrastructure include the following

elements:

Horizontal cable arrangements and cabling.

Backbone cable arrangements and cabling.

Grounding/potential equalization for telecommunication systems.

Rooms (e.g. service connection room, telecommunication room, equipment

Room and fire protection installations.

The mentioned standards affect the administration of telecommunication infrastructure by:

Assigning identifiers to infrastructure components.

Specifying information elements on which the infrastructure is based.

Specifying the relation between these records to ensure the contents.

Specifying reports that contain information on record groups and

Specifying the requirements on graphs and symbols.

Page 39

Chapter 5

38

AAA

A - AA

0000

Floor

Telecom room

Panel

Port

Autotest

5.4.1. Cable Name in Format TIA/EIA 606A

To determine cable name, a structure for the test portion is created. The three (3) cable

parameters 606A Drop, 606A Backbone and 606A Backbone Pair/Fiber are available.

1. Use Arrow keys to navigate to "Cable ID" and press Enter.

Illustration 5.4. Cable ID

5.4.2. Cable Parameter 606A Drop

Name of horizontal cable line (e.g. 1 building, 1 floor, 1 distribution, sockets)

2. Use soft key Drop to select cable parameter 606A Drop.

Illustration 1 5.4.2. Cable Parameter 606A Drop

3. Use Left/Right Arrow Keys to navigate to desired position in port area. Use

Up/Down Arrow Keys to assign characters and numbers.

4. Proceed in the same manner with positions Panel, Telecom Room and Floor.

5. Use soft key to hide individual positions. Assembling the cable line

automatically generates the 606A-Name.

6. Press Enter to save the cable name. Use Escape to exit menu without making

changes.

Page 40

Chapter 5

39

AAA

A / AAA

A - 00

Floor

Telecom room

Floor

Telecom room

Port

5.4.3. Cable Parameter 606A Backbone

Name of a horizontal and vertical cable line (e.g. several floors, several distributions,

sockets).

1. Use soft key Backbone to select cable parameter 606A Backbone.

Illustration 1 5.4.3. Cable Parameter 606A Backbone

Autotest

2. Use Left/Right Arrow Keys to navigate to desired position in port area. Use

Up/Down Arrow Keys to assign characters and numbers.

3. Proceed in the same manner with positions Telecom Room and Floor.

4. Use soft key to hide individual positions. Assembling the cable line

automatically generates the 606A-Name.

5. Press Enter to save the cable name. Use Escape to exit menu without making

changes.

5.4.4. Cable Parameter 606A Backbone Pair/Fiber

Name of a horizontal and vertical cable line with a pair/fiber connection (e.g. building, several

floors, several distributions, sockets).

1. Use soft key to select cable parameter 606A Backbone Pair/Fiber.

Illustration 1 5.4.4. Cable Parameter 606A Backbone Pair/Fiber

Page 41

40

AAA

A / AAA

A - 00 . 000

Floor

Telecom room

Floor

Telecom room

Port

Pair

2. Use Left/Right Arrow Keys to navigate to desired position in Pair area. Use

Up/Down Arrow Keys to assign characters and numbers.

3. Proceed in the same manner with positions Port, Telecom Room, and Floor.

4. Proceed in the same manner with positions Telecom Room and Floor.

5. Use soft key to hide individual positions. Assembling the cable line

automatically generates the 606A-Name.

6. Press Enter to save the information entered. Escape allows you to exit the menu

without making changes.

5.5. Select Twisted Pair Cabling

1. Open "Cable Type" on start screen.

2. Use Arrow Keys to navigate to installation type of cable line to be tested (Twisted

Pair Perm, Twisted Pair Basic or Twisted Pair Channel) and confirm with Enter.

Chapter 5

Autotest

Illustration 1 5.5. Cable Type

3. Use Arrow Keys to navigate to desired cable type.

Illustration 2 5.5. Example Twisted Pair Perm

4. Press Enter to save the information entered. Escape allows you to exit the menu

without making changes.

Or

Page 42

41

5. Use available soft key options to specify a cable type, create a cable type, edit NVP

values or enter reference temperature.

5.5.1. Specify Cable Type

1. Use soft key to open select menu to specify the selected cable type.

2. Use Arrow keys to navigate to desired specification and confirm with Enter.

Illustration 5.5.1. Specification of Cable Type

3. Press Enter to save the information entered. Escape allows you to exit the menu

without making changes.

Chapter 5

Autotest

5.5.2. Create Cable Type

1. Use soft key to open select menu for individual creation of a cable type.

2. Use Arrow keys in Select Menu to navigate to option Frequency Range and

confirm with Enter.

Illustration 1 5.5.2. Select Menu

3. Use Arrow Keys to navigate to the individual boxes and use Alphanumeric Keys

to assign start and stop frequencies for Certification and Performance Range.

Page 43

Chapter 5

42

Autotest

Illustration 2 5.5.2. Frequency range

4. Press Enter to save the information entered. Escape allows you to exit the menu

without making changes.

5. Use Arrow keys in Select Menu to navigate to option Connector Pinout and

confirm with Enter.

6. Use Arrow keys to navigate to desired pairings and enable or disable your

selection with soft key . An enabled pairing is indicated by the green box.

Illustration 3 5.5.2. Connector Pinout

7. Press Enter to save the information entered. Escape allows you to exit the menu

without making changes.

8. Use Arrow keys in Select Menu to navigate to option Test Limits and confirm with

Enter.

9. Use Arrow keys to navigate to the individual boxes and assign desired limit with

the Alphanumeric Keys.

Illustration 4 5.5.2. Test Limits

Page 44

Chapter 5

43

Autotest

10. Press Enter to save the information entered. Escape allows you to exit the menu

without making changes.

11. Use Arrow keys in Select Menu to navigate to option Link Models and confirm

with Enter.

12. Use soft key to select the link model Perm, Basic, Channel, EIA, Flat Rate,

Ignore or Skip.

Illustration 5 5.5.2. Link Models

13. Use Arrow Keys to navigate to the individual boxes and use Alphanumeric Keys

to assign the values for NEXT, Insertion Loss, Return Loss and ACR-F (ELFEXT).

14. Press Enter to save the information entered. Escape allows you to exit the menu

without making changes.

15. Use Arrow keys in Select Menu to navigate to option Select Autotest and confirm

with Enter.

16. Prepare the desired measuring modes for the Autotest by using Arrow Keys to

navigate to the desired measuring modes. Enable or disable your selection with

soft key . An enabled measuring mode is indicated by the green box.

Illustration 6 5.5.2. Select Autotests

17. Press Enter to save the information entered. Escape allows you to exit the menu

without making changes.

18. Use Arrow keys in Select Menu to navigate to option Custom Name/NVP and

confirm with Enter.

19. Use Alphanumeric Keys to assign a name for the created cable type.

Page 45

Chapter 5

44

Autotest

20. Make corrections to entries by using the soft keys (delete at cursor

position), (delete characters to the left of cursor), /

(insert alphanumeric characters at cursor position / overwrite highlighted entry).

Illustration 7 5.5.2. Custom Name/NVP

21. Use Arrow keys to navigate to the individual boxes and assign desired NVP with

the Alphanumeric Keys.

22. Press Enter to save the information entered. Escape allows you to exit the menu

without making changes.

5.5.3. Edit and Calculate NVP

1. Use soft key to open Select Menu for editing and calculating NVP.

2. Use Arrow keys to navigate to the individual boxes and assign desired NVP with

the Alphanumeric Keys.

Illustration 1 5.5.3. NVP

3. Use soft key to open menu for entering cable length.

4. Use Arrow Keys to navigate to box and use Alphanumeric Keys to assign Cable

Length (m).

5. Connect cable to be tested.

Page 46

45

Illustration 2 5.5.3. Cable Length

6. Use soft key to start calculation of NVP.

7. Press Enter to save NVP. Use Escape to exit menu without making changes.

5.5.4. Enter Reference Temperature

1. Use soft key to open Select Menu for changing ambient temperature.

2. Use Alphanumeric Keys to assign reference temperature.

Chapter 5

Autotest

Illustration 5.5.4. Reference Temperature

3. Press Enter to save the reference temperature. Use Escape to exit menu without

making changes.

Page 47

Chapter 5

46

Autotest

5.6. DualMODE™ Function for Twisted Pair Cabling

The DualMODE™ function of LanTEK®II Cable tester allows measurement in compliance with 2

limits in one single Autotest. Thus, for instance, simultaneous Channel Link and Permanent

Link measurements can be performed.

With DualMODE™ it is possible to perform other important tests. Let us assume you are

installing a Cat-6 system in a country whose government agency uses a national standard

based on ISO. But you are working with cables and connection components manufactured by

a company in the US. The government agency can request a certification according to ISO

Class E from the installer. However, for warranty reasons the US company might insist on TIA

568 Category 6. Therefore, in the past both certifications were required - in compliance with

ISO and TIA - and the increased costs had to be passed on to the customer. In contrast,

DualMODE™ makes it possible to perform both certifications at the same time, in compliance

with ISO Class E Permanent Link and TIA 568B Category 6. The costs are the same as for one

test.

Another example for the use of DualMODE™ is the calculation of margins in relation to higher

bandwidth for future applications. Up to now you had to check the certification documents for

Category 6 Permanent Link and assess whether adequate margins for transmission of

applications at higher bandwidth are available. However, assessment of the complete final

data would also require a certification according to Category 6A. Due to higher test costs,

these measures would usually not be performed.

With DualMODE™ you can certify the system in compliance with Category 6, and perform

tests with the limits of Category 6A. Due to unmistakable data, your customer would know

exactly what cable lines support higher bandwidths in future applications. This information

would be of great importance when making a decision on whether to assemble cables with

connectors of a higher category, or to pull in cables of a higher category.

5.6.1. Implement DualMODE™

1. Open "Cable Type" on start screen.

2. Use Arrow Keys to navigate to function Twisted Pair DualMODE™ and confirm

with Enter.

Illustration 1 5.6.1. Twisted Pair DualMODE™

3. Use Arrow Keys to navigate to desired cable types. Use soft key to

enable, and soft key Deselect All to disable your selection. An enabled pairing is

indicated by the green box.

4. If you would like another link model, or edit and calculate NVP for the DualMODE™

pairing, press Shift.

Page 48

Chapter 5

47

Autotest

5. Press AUTOTEST. The passed/failed results are displayed. For each DualMODE™

test, the worst case margins and values for NEXT, RL, ACR und Loss are indicated.

Illustration 2 5.6.1. Overall DualMODE™ Result

6. Use Enter to load the corresponding graphical result displays of the highlighted

test.

5.7. Edit NVP Default Value of a Cable

To perform length measurement, the nominal velocity of propagation (NVP) of the cable must

be known. This value can be found in the technical cable information. If this information is

not available, a cable of known length (ca. 30 – 60 meter) should be connected, and the NVP

calculated by LanTEK®II Cable Tester.

1. Open "Cable Type" on start screen.

2. Use Arrow Keys to navigate to desired cable type.

Illustration 1 5.7. NVP Default Value

3. Use soft key to open menu for entering NVP.

Page 49

48

Illustration 2 5.7. Enter NVP

NOTE:

This concerns a channel measurement. When entering the cable length, the length of both

patch cords must be considered.

CATV standards

Ethernet standards

Other cable types

RG59 31 or 92 m

(3-fold or 4-fold shield)

10Base 2

IBM Coax

RG6 31 or 92 m

(3-fold or 4-fold shield)

10Base 5

TWINAXIAL

ARCNET

4. Use Alphanumeric keys to enter one or several NVP.

5. For automatic calculation of a new NVP, press .

Chapter 5

Autotest

Illustration 3 5.7. Calculation of NVP

6. Connect a cable of known length.

7. Use Arrow Keys and Number Keys to enter known cable length.

8. For automatic calculation of a new NVP, press . After calculation of new

NVP, the display returns to the NVP main screen.

5.8. Coaxial Cable Standards

The LanTEK

®

II Cable Tester supports the following coaxial cable standards:

1. Open "Cable Type" on start screen.

Page 50

Chapter 5

49

Cable Types

Resistance

Length

Loss

Return loss

Impedance

RG59 31 or 92 m

X

X

X X X

RG6 31 or 92 m

X

X X X

X

IBM Coax

X X X

TWINAX, ARCNET

X X X

10BASE2

(IEEE 802.3)

X X X

10BASE5

(IEEE 802.3)

X X X

Autotest

2. Use Arrow Keys to navigate to option Ethernet and confirm with Enter.

Illustration 1 5.8. Ethernet

3. Use Arrow Keys to navigate to desired cable type and confirm with Enter.

Illustration 2 5.8. Cable Type

5.8.1. Autotest Test Series for Coaxial Cables

Page 51

Chapter 5

50

NOTE:

It is imperative not to mix up the corresponding patch cords for Display handset (DH) and

Remote handset (RH), and they must also be used for the cable test. We recommend to

mark the patch cords accordingly.

Autotest

5.9. Calibration

A field calibration must be performed if:

During the last 7 days no calibration has been performed. The user receives a message,

informing him that a field calibration is required.

The test adapter has been changed.

A patch cord has been changed.

5.9.1. Twisted Pair Cabling

1. Use Arrow Keys to navigate to "Calibration" and press Enter to open job list.

Illustration 1 5.9.1. Ready screen

Calibration requires one patch cord each for the Display handset (DH) and the Remote

handset (RH).

2. Connect Display handset (DH) and Remote handset (RH) with patch cord for

Remote handset (RH), as shown on the display. Remember which connection of

the patch cord is connected to the Remote handset (RH).

Illustration 2 5.9.1. Patch Cord (RH)

3. Use soft key to initiate calibration. The Remote handset (RH) indicates

calibration, and a progress bar shows the status.

Page 52

Chapter 5

51

Autotest

4. Connect Display handset (DH) and Remote handset (RH) with patch cord for

Display handset (DH), as shown on the display. Remember which connection of the

patch cord is connected to the Display handset (DH).

Illustration 3 5.9.1. Patch Cord (DH)

5. Use soft key to continue calibration. The Remote handset (RH) indicates

calibration, and a progress bar shows the status.

6. Perform the same patch cord connections to Display handset (DH) and Remote

handset (RH) as during the previous test steps.

Illustration 5.9. Open Patch Cord

7. On Display handset (DH) use soft key to start the last step of calibration.

8. On Remote handset (RH) use Autotest to start the last step of calibration.

Illustration 4 5.9.1. Calibration Complete

9. On Display handset (DH) press Escape to return to screen. The Remote handset

(RH) briefly displays that calibration was successful, and then shows ready state.

Page 53

Chapter 5

52

NOTE:

The LanTEK®II Cable Tester COAX adapters are equipped with BNC connections. COAX

cables applied by the user must convert from/to BNC and F (CATV) or other plug types.

Autotest

5.9.2. Coaxial Cable

Calibration must be performed if: