Page 1

V. 1.1.17

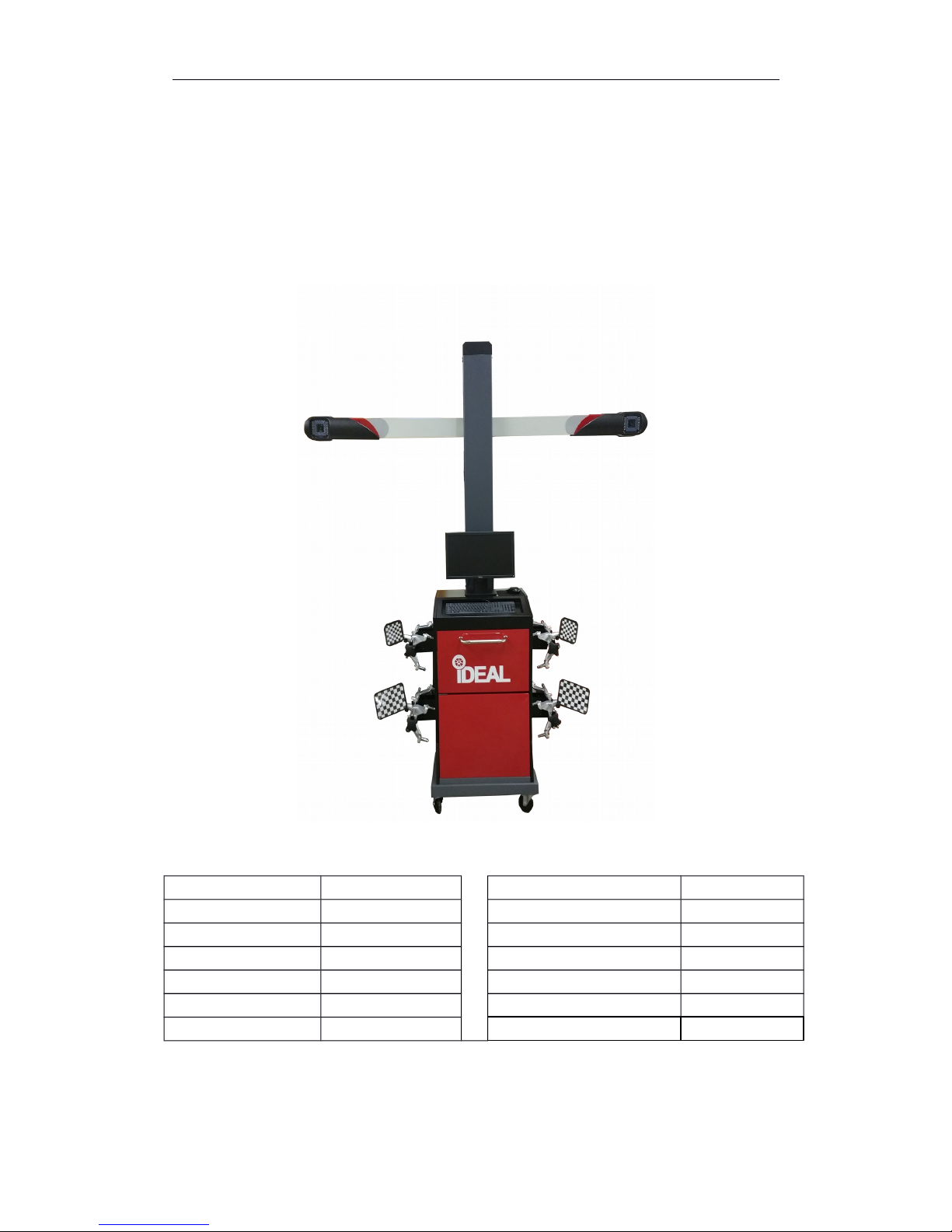

3D Wheel Aligner

Manual

IWA-60-1500-K

Page 2

IDEAL 60-1500 Wheel Aligner Manual

Table of Contents

———————————————————————————————————————-

I. Introduction...........................................................................................................3

1.1 Warning..................................................................................................................3

1.2 Safety warning.......................................................................................................3

II. Getting Started......................................................................................................5

2.1 Equipment transport conditions.............................................................................5

Uncrating Instructions..................................................................................................5

2.2 Smart LED board...................................................................................................6

2.3 Equipment and Servicing.......................................................................................8

1. Check List.........................................................................................................8

2. Camera Care....................................................................................................9

3. Target Care.......................................................................................................9

III. Installation Guide................................................................................................10

3.1 Installation Dimensions........................................................................................10

3.1.1 Camera Beam Position..............................................................................10

3.1.2 Level Lift.....................................................................................................11

3.2 Positioning............................................................................................................13

3.3 Installing wheel clamps and target.......................................................................14

3.3.1 Installing wheel clamps..............................................................................14

3.3.2 Fixing targets.............................................................................................14

3.4 Installing/Removing brake depressor..................................................................15

3.5 Installing/Removing steering wheel holder..........................................................15

IV. Software..............................................................................................................16

4.1 Opening/Closing Alignment software...................................................................16

4.2 Hot keys...............................................................................................................17

4.3 Visual Check........................................................................................................18

4.4 Standard Measurement.......................................................................................18

4.5 Quick Measurement.............................................................................................37

4.6 Aligner Management............................................................................................40

V.Technical data.............................................................................................................45

5.1 Measuring Range.................................................................................................45

5.2 Power supply unit.................................................................................................45

Appendix I . Troubleshooting.............................................................................................46

2

Page 3

IDEAL 60-1500 Wheel Aligner Manual

I.

Introduction

The purpose of this manual is to provide safe and practical instructions for

operation and maintenance of the imaging wheel aligner.

1.1 Warning

This aligner is designed for INDOOR USE ONLY. Exposure to damp or wet

locations can cause damage to the aligner’s components or injury to the

user and will void warranty.

The computer in this aligner is capable of connecting to a network and/or the

Internet. This functionality is only for use when receiving support for the

aligner. The computer should be connected to the Internet if possible,

however it should never be used for recreational or administrative purposes.

Any malfunctions due to unauthorized software, malware, viruses, or similar

web based threats are not

Do not plug in the cabinet power cord until all connections have

been verified. Damage or injury can result.

1.2 Safety Warning

This imaging aligner is intended for use by properly trained automotive

technicians. The safety messages presented in this section and throughout

the manual are reminders to exercise extreme care when performing wheel

alignments with this product.

There are many variations in procedure, technique, tools, and parts for

servicing vehicles. The manufacturer cannot possibly anticipate or provide

advice or safety messages to cover every situation. It is the automotive

technician’s responsibility to be knowledgeable about the vehicle to be

aligned. It is essential to use proper servicing methods. Always perform wheel

alignments in an appropriate manner, that does not endanger operator safety,

the safety of others in the work area, the equipment, or the vehicle being

serviced.

Read this manual carefully before powering up the aligner. Save this manual,

and all supplied illustrative material, in a folder near the aligner cabinet, where

it is readily accessible for reference by operators.

3

Page 4

IDEAL 60-1500 Wheel Aligner Manual

The technical documentation supplied is considered an integral part of this

equipment; in the event of sale all relative documentation must remain with

the system.

This manual is only valid for the equipment model and serial number indicated

on the nameplate of the included aligner. The nameplate is attached to the

back of the cabinet.

WARNING!

Any modifications to this aligner may cause serious injury or

damage to the aligner. The manufacturer and distributors are not

responsible for any injury caused by improper use, abuse, or unauthorized

repair.

4

Page 5

IDEAL 60-1500 Wheel Aligner Manual

II.

Getting Started

2.1 Equipment Transport Conditions

The aligner must be shipped in its original packing and stowed in the position

indicated on the outside.

To avoid damage, never place other items on top of the packaging.

Handling of the crated aligner must be performed only with an appropriate

lifting device such as a forklift or pallet jack.

Only personnel who are experienced and qualified in freight handling

procedures should handle any transportation or moving of the crated aligner.

Inspect for any damage to the crate and notify your local distributor (and/or

freight company) immediately if any damage is observed.

Uncrating Instructions:

Carefully remove packing materials. Be careful when cutting banding material

as items may loosen and fall, causing personal harm or injury.

Always wear gloves when uncrating to prevent scratches, abrasions, or cuts

due to the contact with packing materials.

Retain all packaging in case you need to return any parts for warranty or

servicing. Carefully unpack and inventory all items. Familiarize yourself with

all components before beginning set up and assembly.

5

Page 6

IDEAL 60-1500 Wheel Aligner Manual

2.2 Smart LED Board

Smart LED board includes the following features

:

Target Level Indication

LR Target LF Target RF Target RR Target

If the target is not leveled, LED lights will turn red. When all the lights turn

green and the middle two lights start to blink, the target is leveled.

Forward/Backward Moving Car Indication

Position Direction Position Direction

The left line of LED lights represents the position of the vehicle. The right line

6

Page 7

IDEAL 60-1500 Wheel Aligner Manual

of LED lights shows the direction, forward or backward, of the measured

vehicle.

Swing Caster Indication

Direction Angle Direction Angle

The left line of LED lights represents the direction of turning angle, clockwise

or counterclockwise, of the measured vehicle. The right line of LEDs show the

progress of the turning angle.

Target Blocking Indication

LR Target LF Target RF Target RR Target

When the middle two lights turn red and start to blink, the corresponding

target is blocked.

7

Page 8

IDEAL 60-1500 Wheel Aligner Manual

2.3 Equipment and Servicing

1. Check List

Standard Configuration

:

Computer 1 Wheel Clamp 4

Post 1 Wheel Stopper 2

Monitor 1 Steering Wheel Holder 1

Cabinet 1 Brake Depressor 1

Software 1 Manual 1

Printer 1 Power Cord 1

Target 1 Set of 4

8

UPS AVR 1

Page 9

IDEAL 60-1500 Wheel Aligner Manual

Warning!

Please use the original accessories provided by the manufacturer.

The manufacturer and distributors are not liable for any damage or injury

caused by improper use.

2. Camera Care

Keep hand and tools away from camera.

Warning: Keep grease away from the lenses. Do not use water, detergents,

or ammonia when cleaning the lenses. Do not use heavy pressure when

cleaning. Do not use a shop rag, they may contain particles and chemicals

that can damage the lenses.

A non-ammonia cleaner may be sprayed onto a clean, lint free cloth to gently

clean the lenses. Non-ammonia glass wipes may also be used, such as Armor

All glass wipes..

Do not spray cleaners directly onto the targets.

3. Target Care

Keep targets clean, keep hands and tools away from the surface of targets.

Check that wheel clamps and targets are firmly attached and avoid dropping

the targets.

Note: When the targets are not in use, detach the targets and

clamps. Store them on the cabinet. Do not put the target faces

downward onto any surface.

Warning: Do not use water, detergents, or ammonia when cleaning the

targets. Do not use heavy pressure when cleaning. Do not use a shop rag,

they may contain particles and chemicals that can damage the targets.

A non-ammonia cleaner may be sprayed onto a clean, lint free cloth to gently

clean the targets. Non-ammonia glass wipes may also be used, such as

Armor All glass wipes.

Do not spray cleaners directly onto the targets.

9

Page 10

IDEAL 60-1500 Wheel Aligner Manual

III.

Installation Guide

3.1 Installation Dimensions

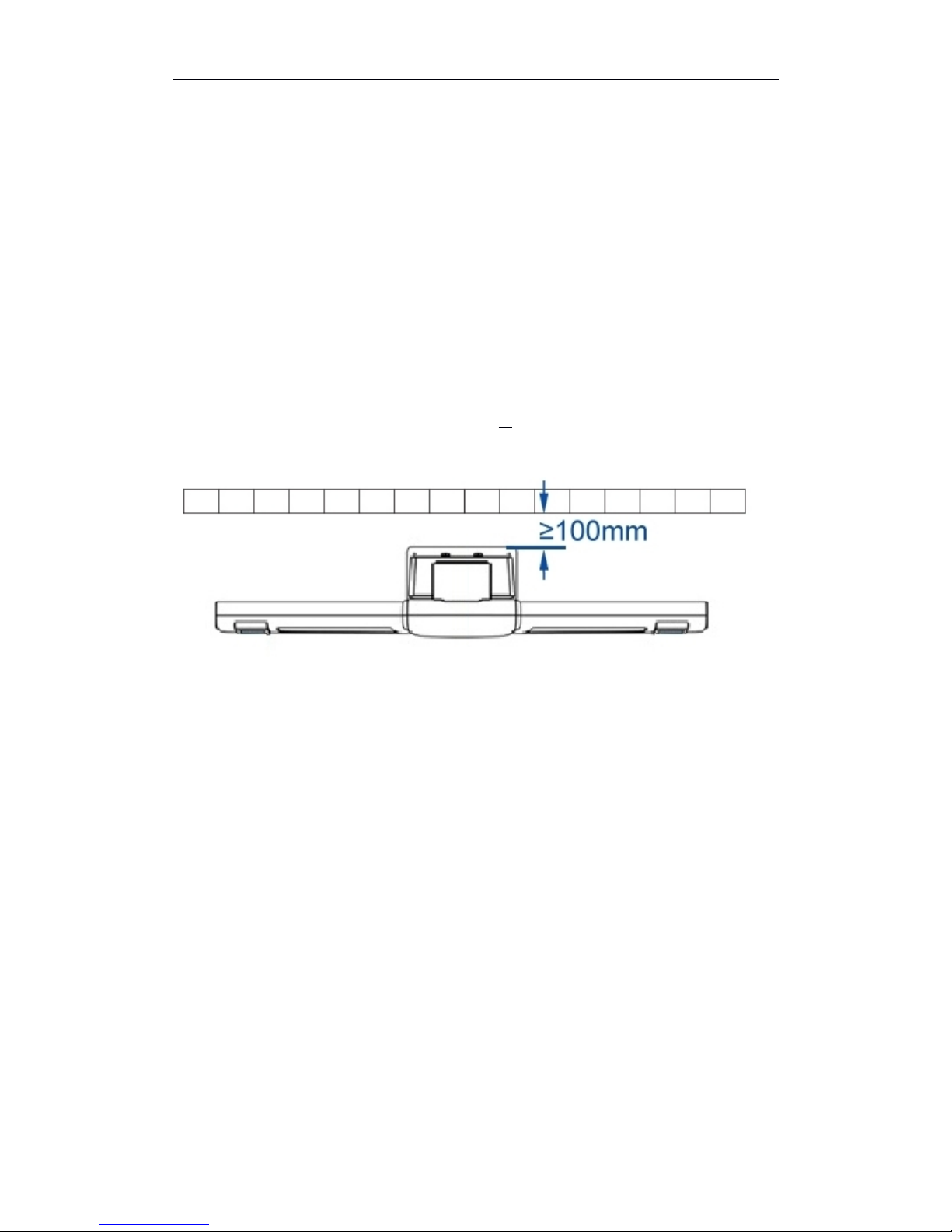

3.1.1 Camera Beam Position >100mm (4 Inches)

Diagram: Distance between post and wall

10

Page 11

IDEAL 60-1500 Wheel Aligner Manual

Diagram: Distance between cameras to center of turn table.

(See Table on page 11)

Diagram: Offset between Camera beam and turn table

L H

1800mm / 71” 550mm / 21.5”

2000mm / 78.75” 550mm / 21.5”

2200mm / 86.5” 600mm / 23.5”

2500mm / 98.5” 600mm / 23.5”

2800mm / 110.25” 600mm / 23.5”

11

Page 12

IDEAL 60-1500 Wheel Aligner Manual

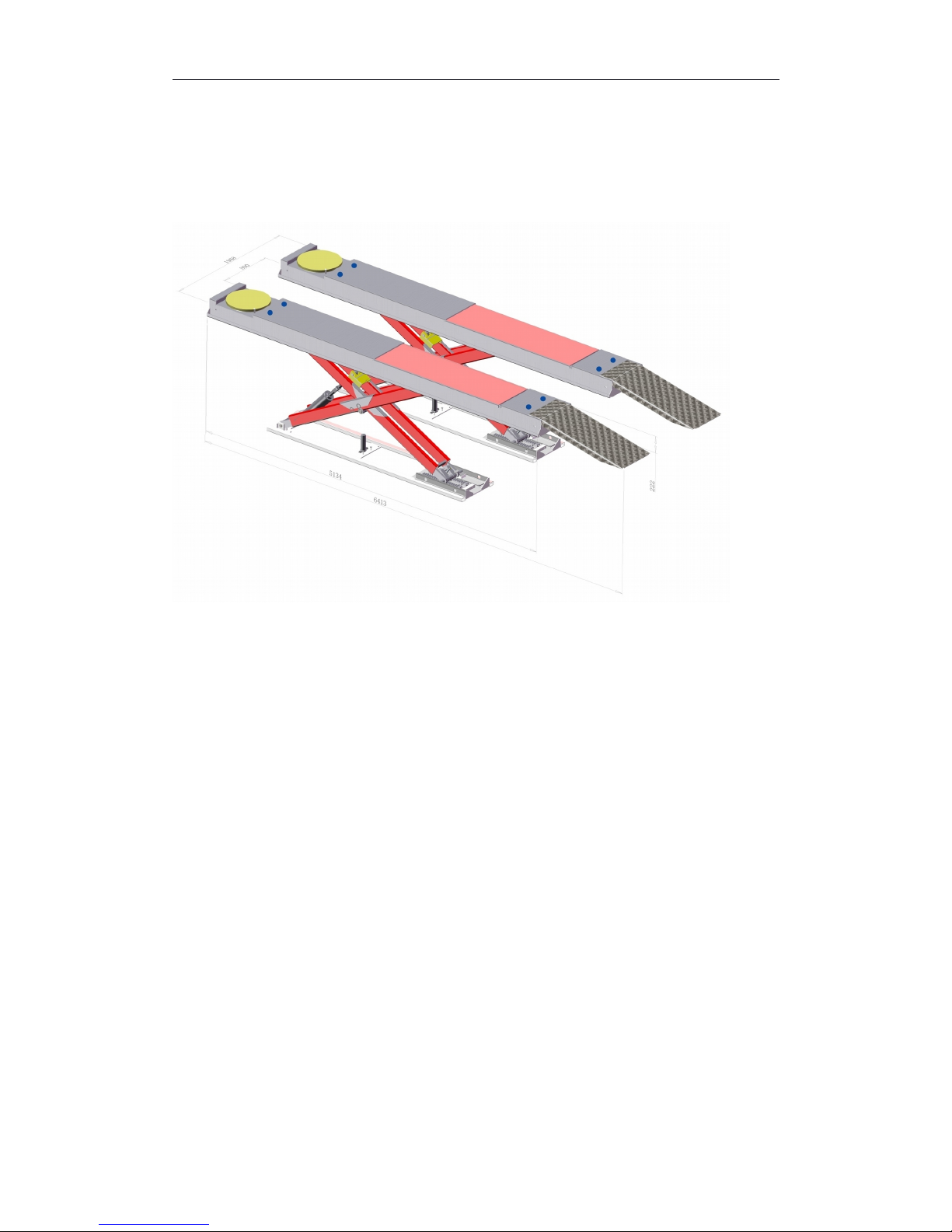

3.1.2 Lift Levelness

All eight measurement points need to be within 2mm (1/8”)

Diagram: Requirement for leveling lift.

12

Page 13

IDEAL 60-1500 Wheel Aligner Manual

3.2 Positioning

Diagram: Positioning for fixed camera post & beam assembly.

Measure the distance between the inner sides of the runways on the lift and

find the center point. Shown as A and B. Find the center line of the lift using

these two points.

With turn table locked, at the alignment level, find the center point of the turn

table. Link the two center points of the turn table, as shown at C.

From the center line of the turn table, measure L1. Mark the first position of

the post

Mark the four point for the base of the post. Shown as E and D.

NOTE:This is also the optimum positioning for mobile units.

13

Page 14

IDEAL 60-1500 Wheel Aligner Manual

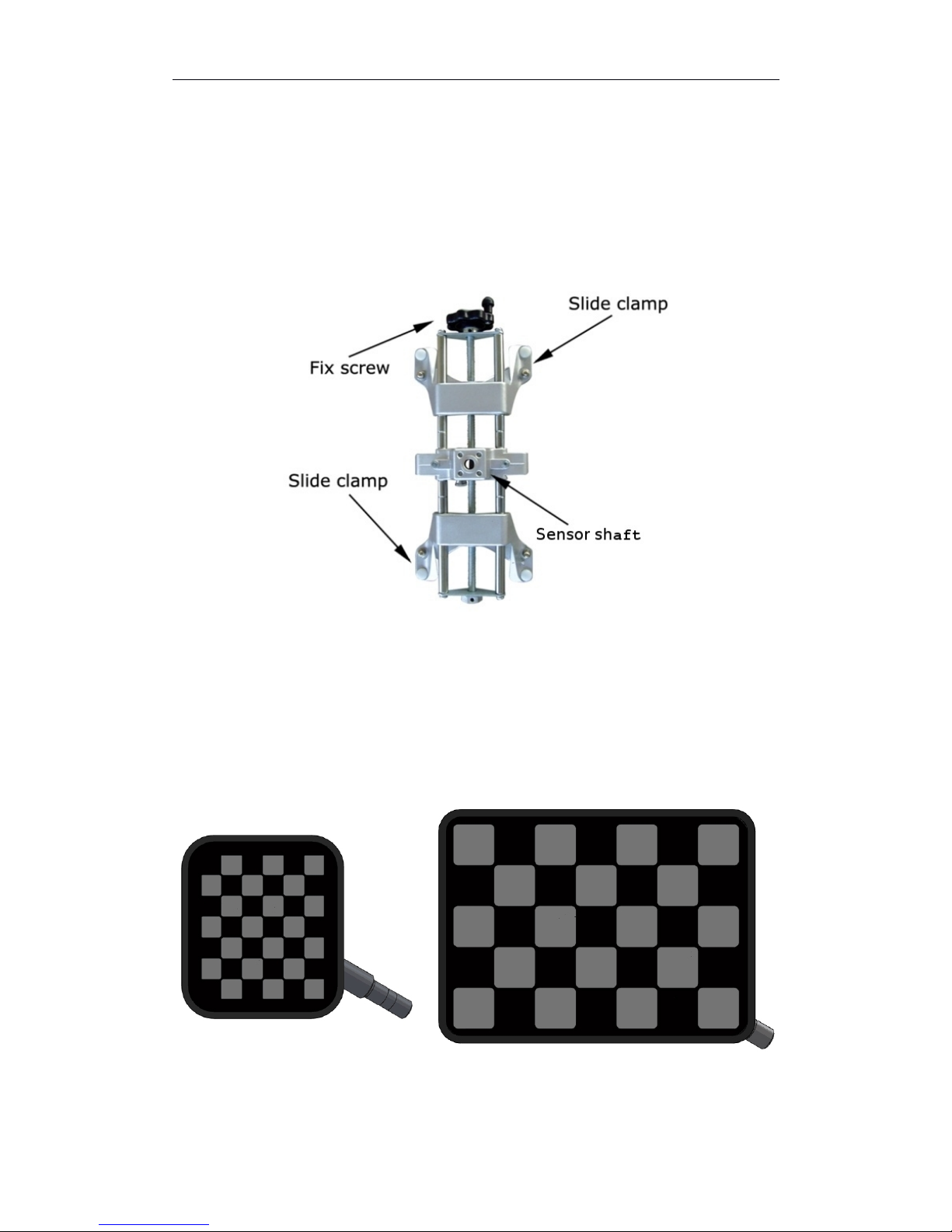

3.3 Installing Wheel Clamps and Target

3.3.1 Installing Wheel Clamps

Caution: Different wheels may have different clamping surfaces. Special

fingers may be required when used on specialty or high end wheels.

3.3.2 Attaching Targets

Always check that wheel clamps are firmly attached to wheels. Socket pins of

the measurement board may be lightly lubricated to protect the pin and

14

Page 15

IDEAL 60-1500 Wheel Aligner Manual

socket. Mount the two small targets in the front and the two larger targets in

the rear. Keep the bubble level on top.

3.4 Installing/Removing Brake Depressor

Place a cloth underneath the depressor to protect the seat if necessary. After

run out compensation, install the brake depressor for further measurements.

3.5 Installing/Removing Steering Wheel Holder.

The steering wheel holder holds the steering wheel in position and locks the

wheels.

1.

Place the steering wheel holder on the seat and press the plate against

the seat.

2.

Slide the arms downwards against the seat.

3.

Release the arms so that pressure is exerted on the steering wheel.

4.

Remove in the reverse order.

15

Page 16

IDEAL 60-1500 Wheel Aligner Manual

IV.

Software

4.1 Opening/Closing Alignment Software

Switch on power supply and push the power button to start the computer. The

computer should start the alignment software automatically. In case the

alignment software does not start, click on the icon to start the

alignment software.

If you do not see a shortcut for the alignment software, please make sure your

alignment software is properly installed; contact your local service center if

necessary.

NOTICE: If running this software on win8 or win10, please set to “Run as

administrator.”

4.2 Hot keys

This aligner uses an IBM standard keyboard, there are 12 function keys from

F1 to F12 located on the top of the keyboard. There are also specific function

keys located on the right side of the keyboard, such as “Page Up”, “Page

Down”, “Enter” “Home” and arrow directional keys. Instructions for these

function keys will be explained in following sections.

F10 - Help Version

PgUp - Previous PgDn - Next

Home - Press HOME key under any screen to go back to

software main menu screen

Warning: Do NOT directly switch off the power supply to shut down the

computer. Switching off power directly may affect proper operation of the

Operating System.

16

Page 17

IDEAL 60-1500 Wheel Aligner Manual

Diagram: Main screen

Help Previous

Next Clear Run Out

ESC –Exit Program Version Info

Management

4.3 Visual Check

Click or press F1 to enter visual check.

17

Page 18

IDEAL 60-1500 Wheel Aligner Manual

Diagram: Visual Check

Defective, replacement needed.

Warning, repair needed.

Normal, no action needed.

Next: Enter next screen.

Print: Print check table or check report as desired.

4.4 Standard Measurement

After visual check,click standard measurement to enter measurement

screen. Or click or press F2.

Standard measurement: Select customer → Select vehicle manufacturer →

18

Page 19

IDEAL 60-1500 Wheel Aligner Manual

Run out compensation → Caster Measurement → Rear Axle Measurement →

Live Caster Adjustment → Front Axle Measurement → Print.

1.

Select Enter customer info. Click “New Customer” and enter

customer info.

Diagram: Standard Measurement- Select Customer

Diagram: Enter license plate number.

2.

Select vehicle model . Select vehicle specification, Select

vehicle manufacturer, year and model.

19

Page 20

IDEAL 60-1500 Wheel Aligner Manual

Diagram: Standard Measurement - Select vehicle model.

Click next to enter manufacturer spec page.

Diagram: Standard Measurement – Manufacturer Spec

3.

Click next or to enter run out compensation.

During the alignment process, run out compensation is very important.

Skipping compensation will cause inaccurate alignment readings.

Before continuing, make sure both turn tables are locked and wheel stoppers

are in place.

20

Page 21

IMPORTANT: If the turntables are not level with the runways, you will need

to use a metal plate, board, or other material to maintain a level plane to

roll along.

Be sure to eliminate any gaps greater than 1/2” between the turntable and

added material.

The vehicle should roll smoothly without any bumps or jolts.

An inconsistent run out compensation will cause all measurements to be

inaccurate.

Use blocks or sheets of material such as wood

and metal to eliminate gaps and changes in

elevation.

Page 22

IDEAL 60-1500 Wheel Aligner Manual

Place the rear wheel stopper away from the tire, the distance may differ

depending on the size of the tire.

Follow the on screen instructions:

1)

Level Targets

2)

Install Steering Wheel Holder

22

Page 23

IDEAL 60-1500 Wheel Aligner Manual

3)

Release Brake

Diagram: Standard Measurement- Run Out Compensation

Click Next or press PgDn to continue.

Note: The top corner of the screen may show a “STOP” sign. If it appears,

keep the vehicle still. While the “STOP” sign is shown on the screen, any

movement may cause inaccurate alignment readings.

Diagram: Standard Measurement: Run Out Compensation

After first measurement, push vehicle backwards 40 degrees, software

displays “STOP” to guide the operator.

23

Page 24

IDEAL 60-1500 Wheel Aligner Manual

Diagram: Standard Measurement: Run Out Compensation

Once the bar is fully green, software reads 2nd value.

Diagram: Standard Measurement: Run Out Compensation

Push vehicle forward to its original position until the progress bar is green.

Note: Placing one of the wheel stoppers at the original position will allow the

vehicle to stop very close to the correct position. Move wheel stopper if

needed.

24

Page 25

IDEAL 60-1500 Wheel Aligner Manual

Diagram: Standard Measurement: Run Out Compensation

Push vehicle back to original position, unlock turn tables and click next to

continue.

Diagram: Standard Measurement: Run Out Compensation

Click next to finish run out compensation.

25

Page 26

IDEAL 60-1500 Wheel Aligner Manual

4.

Caster measurement .

Note: Caster measurement is disabled until full run out compensation is

completed.

Option of 10 or 20 degree can be selected in settings.

Center steering wheel first and then follow the instructions on screen. After

centering steering wheel, the screen will confirm and start caster

measurement.

Diagram: Standard Measurement – Caster

26

Page 27

IDEAL 60-1500 Wheel Aligner Manual

Diagram: Standard Measurement - Caster

Turn steering wheel left 10 or 20 degree (depending on settings) until screen

shows “Stop.” Keep steering wheel still until the 10 or 20 degree with red

background changes to “OK” with a green background.

Diagram: Standard Measurement - Caster

Turn wheel to the right until the screen shows “Stop.” Follow the same

procedure as previously indicated.

27

Page 28

IDEAL 60-1500 Wheel Aligner Manual

Diagram: Standard Measurement - Caster

Diagram: Standard Measurement - Caster

Center steering wheel after taking readings at both sides.

5.

Rear Axle

After caster measurement, the rear axle reading opens

automatically. Follow the instruction and physically center the steering wheel.

28

Page 29

IDEAL 60-1500 Wheel Aligner Manual

Diagram: Standard Measurement – Rear Axle

Diagram: Standard Measurement – Rear Axle

Rear axle screen displays rear camber, individual toe, total toe and thrust

angle. All meters have manufacturer spec and tolerance, displayed in order of:

minimum acceptable value, manufacturer value, maximum acceptable value.

29

Page 30

IDEAL 60-1500 Wheel Aligner Manual

The background of a meter indicates if the value is an acceptable reading or

not.

Red background indicates out of tolerance.

Green background indicates within acceptable

tolerance.

Blue background indicates close to

manufacturer value.

When the reading is out of manufacturer tolerance, the wheel diagram beside

the meter indicates the direction of the wheel that is out of tolerance.

Zoom In :Double clicking the live reading value can zoom in or

use arrow key on the keyboard and click enter to zoom in.

Illustration Diagram: Indicates an illustration diagram is

available.

Raised Mode: Raise the vehicle and lock camber value.

6.

Live caster adjustment

.

After rear axle reading, enter the live caster adjustment screen.

30

Page 31

IDEAL 60-1500 Wheel Aligner Manual

Diagram: Standard measurement – Live Caster

Live caster display: Camber, Caster and toe.

Note: Live caster function is an estimated value of caster.

7.

Front Axle

31

Page 32

IDEAL 60-1500 Wheel Aligner Manual

Diagram: Standard Measurement – Front Axle

Front Axle Displays: Camber, individual toe, total toe, and setback.

Toe+: Toe Adjustment

Diagram : Toe+

Enter super toe screen. The screen will instruct you to turn the steering wheel

straight ahead. Level and lock targets. Press Page Dn.

32

Page 33

IDEAL 60-1500 Wheel Aligner Manual

Diagram: Toe+

Turn steering wheel to the left adjustment position, level the target and follow

instruction on the screen.

Diagram: Toe+

Adjust left toe.

33

Page 34

IDEAL 60-1500 Wheel Aligner Manual

Diagram: Toe+

Turn steering whee to the right adjustment position and follow instruction on

screen.

Diagram: Toe+

After the measurement, the software will gather required data and compare its

data to manufacturer data, adjust the value to green or blue.

34

Page 35

IDEAL 60-1500 Wheel Aligner Manual

Diagram: Toe+

Toe Curve: VAG Adjustment

Diagram: Toe Curve

35

Page 36

IDEAL 60-1500 Wheel Aligner Manual

8.

Print

Diagram: Standard Measurement - Results

The result page displays all measurement values. Red indicates out of range,

black indicates normal. The left column is measurements before adjustment,

the center is manufacturer specs, and the right column is after adjustment.

Print: Prints a report with all readings and customer info.

Manufacturer Value: Enter the manufacturer spec page.

Compare: Compare values with previous measurements.

36

Page 37

IDEAL 60-1500 Wheel Aligner Manual

4.5 Quick Measurement

From the main screen, click or F3 to enter quick measurement.

Quick Measurement:Select Vehicle → Run Out Compensation → Front/Rear

Axle→ Print.

1.

Select Vehicle

Diagram: Quick Measurement – Select vehicle manufacturer, year, and

model.

37

Page 38

IDEAL 60-1500 Wheel Aligner Manual

Diagram: Quick Measurement – Manufacturer spec

2.

Run out compensation

.

After selecting vehicle spec, perform run out compensation and follow the on

screen instructions.

Diagram: Quick Measurement – Run Out Compensation

38

Page 39

IDEAL 60-1500 Wheel Aligner Manual

3.

Front/Rear Axle .

Note: Front/Rear Axle screen is disabled before performing a complete run

out compensation.

Diagram: Quick Measurement –Front / Real Axle

The Front/Rear Axle screen displays front and rear camber, front and rear toe,

front and rear total toe, and thrust angle.

4.

Print .

39

Page 40

IDEAL 60-1500 Wheel Aligner Manual

4.6 Aligner Management

From main screen, click or press F5 on keyboard to enter aligner

management. Use this screen to access version number, settings, and

maintenance.

Diagram: Aligner Management

Click the icon or press F1 to display software versions.

Click the icon or press F2 to changes aligner settings:

F1:Language: Use “PgDn” to confirm.

F2

:

Demo mode: Software displays each screen without connecting

cameras. In demo mode, use

Ctrl+left arrow key to demo vehicle moving forward and turning steering left or

Ctrl+right arrow for vehicle moving backward or turning steering right.

F3:Caster Sweep: 10 or 20 Degrees

F4:Measurement Mode

40

Page 41

IDEAL 60-1500 Wheel Aligner Manual

Diagram: Measurement Mode

Choose Four Wheel Alignment Mode, and select “Spacial Dynamics”, then

confirm.

Diagram: Standard-Axis is turned on.

41

Page 42

IDEAL 60-1500 Wheel Aligner Manual

F5:Unit of measurement:Choose 1/60 degree or 1/100 degree.

F6: Unit of rim diameter and distance display: choose mm or inch.

F7:Toe value unit:Choose degrees, inches, or millimeters.

If millimeters or inches is selected as the toe unit, you must enter the tire

diameter before taking measurements.

F8:Value precision:Choose 0.01, 0.05 or 0.1, rounding of measurement

result.

F9:ROC, Press Ctrl+F9, and the item F9 turns blue.

Diagram: Smart-LED-Board is turned on.

F11:Lift Height Checking: Measurement Mode, Spacial Dynamics feature

should be enabled. (Not available in the USA and Canada.)

Click or F4 to use customer management.

42

Page 43

IDEAL 60-1500 Wheel Aligner Manual

Diagram: Customer Info Management

Customer names are listed on the left side of screen. Select customer name

by Up or Down arrow direction key.

Press F8 or F9 or F11 to sort customer names by specified filter.

Press F1 to add a new customer. Operators can input new customer data

under the new customer screen.

Press F2 to edit customer information.

Press F3 to delete selected customer. Press PgDn to confirm.

Press Page Down to exit customer information manager screen.

Press HOME to go back to main menu screen.

Click or F5 to set workshop info.

43

Page 44

IDEAL 60-1500 Wheel Aligner Manual

Diagram: Workshop Information

In this screen, you can customize shop info. Enter shop name, telephone

number, fax or slogan. This info will show on the printed reports.

44

Page 45

IDEAL 60-1500 Wheel Aligner Manual

V.Technical data

5.1 Measuring Range

Options Range

Total Toe(Front and Rear Axle) ±50°

Individual toe(Front Axle) ±25°

Camber(Front and Rear Axle

)

±15°

Setback ±9°

Thrust Angle ±9°

Caster ±22°

King Pin ±22°

Wheelbase 1.6-2.1m (63”-82.5”)

Track Width 1.8-4.5m (71”-177”)

5.2 Power Supply Unit

Function Specification

Power Supply(Voltage)

110V

Frequency

50/60Hz

Power

Single Phase

45

Page 46

IDEAL 60-1500 Wheel Aligner Manual

Appendix I . Troubleshooting

Description Remedy

Computer does

not start.

Check if power cable is firmly connected, and if the

computer switch light is on.

Check the power strip is working properly.

Check fuses in cabinet.

Check power cable.

Check if power cable has output voltage.

Contact local authorized service center.

No display on

monitor.

Check if monitor is switched on.

Check power cable.

Check if display cable is connected.

Contact local authorized service center.

Computer shuts

off due to power

surge. After

restart,

alignment

software does

not start.

After a power surge, computer software may become

corrupted. Use backup software if available, to restore to a

previous working point. If a reload of the OS is needed,

contact a local authorized service center.

Screen shows a

black screen in

alignment

software and

does not close.

1. Check on screen if the target has color lines, or if the

target is in the measuring range. Adjust the target position

if needed.

2. If the target does not have color lines, but both targets

are in range, both targets maybe overlapping, or blocked.

3. If the target does not have color lines, but both targets

are in range, with no blocking, targets may be dirty. Clean

targets with care. (See Pages 9-10)

4. Cannot see target clearly, but red LEDs beside the

camera are flashing. Use a cellphone camera to check if

the LEDs are lighting up. Use the front camera, as the

rear camera of some phones have a special filter. Check

the power adapter for the correct output voltage.

45

Page 47

IDEAL 60-1500 Wheel Aligner Manual

5. No target seen on the screen, exit software and rerun

alignment software.

Contact local authorized service center if needed.

After runout

compensation,

camber or toe

value is too

high.

If measurement is interrupted during the measurement,

redo the run out compensation and check value.

Contact local authorized service center if needed

Windows starts,

but alignment

software does

not start

1.

HASP key not found:

No software key is found on the computer

Software key is plugged in but no red light on it. Check

that the driver is properly installed.

If the driver is not installed properly, download

software key driver from HASP.com

。

Contact local authorized service center if needed.

Camera screen

shows white?

Reconnect USB cable from camera to computer first. If

this does not solve the problem, check the connection

from computer to camera. Check cable.

Contact local authorized service center if needed.

For support, contact:

Northwest Equipment

877-349-2327

406-755-0805

47

Page 48

Mar 2016

LIMITED WARRANTY

Structural Warranty:

The following parts and structural components carry a five year warranty:

Columns Arms Uprights Swivel Pins

Legs Carriages Overhead Beam

Tracks Cross Rails Top Rail Beam

Limited One-Year Warranty:

Tuxedo Distributors, LLC (iDEAL) offers a limited one-year warranty to the original purchaser of Lifts and Wheel Service

equipment in the United States and Canada. Tuxedo will replace, without charge, any part found defective in materials or

workmanship under normal use, for a period of one year after purchase. The purchaser is responsible for all shipping

charges. This warranty does not apply to equipment that has been improperly installed or altered or that has not been

operated or maintained according to specifications.

Other Limitations:

This warranty does not cover:

1. Parts needed for normal maintenance

2. Wear parts, including but not limited to cables, slider blocks, chains, rubber pads and pulleys

3. Replacement of lift and tire changer cylinders after the first 30 days. A seal kit and installation instructions will be

sent for repairs thereafter.

4. On-site labor

Upon receipt, the customer must visually inspect the equipment for any potential freight damage before signing clear on

the shipping receipt. Freight damage is not considered a warranty issue and therefore must be noted for any potential

recovery with the shipping company.

The customer is required to notify Tuxedo of any missing parts within 72 hours. Timely notification must be received to be

covered under warranty.

Tuxedo will replace any defective part under warranty at no charge as soon as such parts become available from the

manufacturer. No guarantee is given as to the immediate availability of replacement parts.

Tuxedo reserves the right to make improvements and/or design changes to its lifts without any obligation to previously

sold, assembled or fabricated equipment.

There is no other express warranty on the Tuxedo lifts and this warranty is exclusive of and in lieu of all other warranties,

expressed or implied, including all warranties of merchantability and fitness for a particular purpose.

To the fullest extent allowed by law, Tuxedo shall not be liable for loss of use, cost of cover, lost profits, inconvenience,

lost time, commercial loss or other incidental or consequential damages.

This Limited Warranty is granted to the original purchaser only and is not transferable or assignable.

Some states do not allow exclusion or limitation of consequential damages or how long an implied warranty lasts,

so the above limitations and exclusions may not apply. This warranty gives you specific legal rights and you may

have other rights, which may vary from state to state.

1905 N Main St Suite C, Cleburne, TX 76033

Ph 817-558-9337 / Fax 817-558-9740

Loading...

Loading...