I.C.T.C. Holdings Corporation HRO-ST3131 User Manual

WARNING

DO NOT ATTEMPT TO OPERATE THIS MACHINE UNTIL YOU HAVE READ AND

UNDERSTOOD ALL SAFETY PRECAUTIONS AND OPERATING INSTRUCTIONS.

EQUIPMENT AND CHEMICALS WHEN USED IMPROPERLY CAN BE DANGEROUS.

Page 1 HRO-ST3131 Mar 8, 2004

H.E.R.O. WARRANTY

H.E.R.O. INDUSTRIES , guarantees this airless pu mp to be free of defects in

materials and workmanship to the original owner, for a period of one full year

from the date of purchase.

The warranty entitles the owner to parts replacement at no charge. The parts

replacement warranty is valid for any necessary replacement, whither caused

by material or workmanship defect or si mple wear. H.E.R.O. Industries offers

no warranty on the intake ball, outgo ball, drive belt, hoses, gun or

accessories, plastic, rubber, other soft goods or motor used in or supplied with

the H.E.R.O. sprayer .

Motor, accessories, etc., which are supplied by other manufacturers and are

attached to or supplied with th e H.E.R.O. airl ess pu mp, are warran ted only t o

the extent that these parts are warranted by their respective manufacturers.

Warranty claims must be made directly to such manufacturers or their local

authorized service depots.

The warranty is only applicable to th e original purchaser and the equipment

has been properly used, operated and maintained in accordance with all

instructions, precautions and warnings contained in this manual. For the

purpose of this warranty, damage resulting from accident, abuse, improper

cleaning or operat ion, fire, flo od, or Act of God, is not covere d.

H.E.R.O.’s liabilit y is li mited to repl acing parts found to b e d efectiv e or worn

and does not include; transportation costs, damage or other expenses of any

kind incurred in connection with the purchase and use of this sprayer.

Repairs claim ed un der w arranty m ust be perf orm ed at an a uthor iz ed H.

E.R.O. Service Center, using only genuine H.E.R.O. parts. Parts necessary

under warranty claim will be supplied by your local H.E.R.O. Service Center.

DO NOT

To qualify for the warranty, the warranty card (attached to this page) supplied

with this H.E.R.O. airless pump, must be completed with equipment serial

number and signed by the purchaser, and postmarked within ten (10) days of

purchase.

return worn parts to factory without authorization.

Page 2 HRO-ST3131 Mar 8, 2004

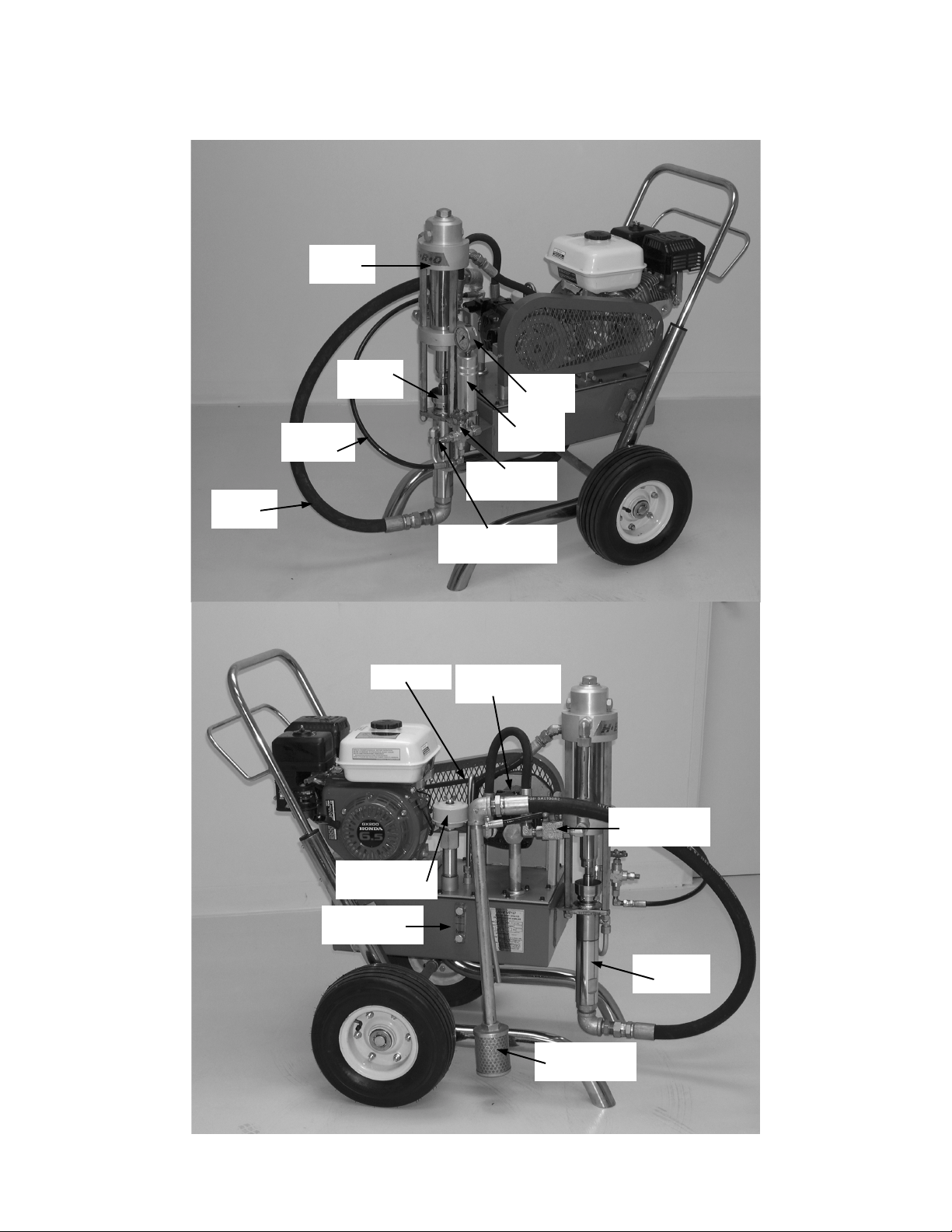

Hydraulic

Motor

UNIT LAYOUT

Suction

Hose

Prime/Drain

Hose

Pump

Wet Cup

Drive Belt

Pressure

Gauge

Filter

Manifold

Prime/Drain

Valve

Pump Outlet

Spray Hose Hook Up

Hydraulic Pump

& Pressure Control

Hydraulic Pump

Shut Off Valve

Hydraulic Fluid

Fill & Vent

Hydraulic Fluid

Level Gauge

Paint Piston

Pump

Suction Tube &

Suction Filter

Page 3 HRO-ST3131 Mar 8, 2004

SAFETY WARNING!

Use of this high-pressure equipment could result in serious injury and is for

•

professional use only!

You must operate this equipment only after the instruction manual is clearly understood.

•

Workman and assistant must always wear protective eyewear, gloves, clothing,

•

and respirators as recommended by the material manufacturer.

GAS / HYDRAULIC POWERED AIRLESS

SPRAY PUMPS.

Gas / Hydraulic powered airless spray equipment is an

industrial paint sprayer which uses a gas engine to drive a

hydraulic pump which in turns produces hydraulic pressure. This pump delivers pressure fluid to a hydraulic motor which drives a high pressure airless piston pump. All

of these components make this unit a heavy duty portable

airless sprayer which is capable of high volume and high

production able to pump and spray light to very high viscous materials. Airless spray is fast, economical and

needs no atomizing air.

Airless spray systems use a high pressure pump

to supply fluid to the spray tip, where it is atomized

by the pressure and sprayed onto a desired surface.

Control of the atomizing pressure is done by regulating

the hydraulic fluid pressure in the hydraulic pump.

The spray is controlled by triggering a hand gun,

or activating the controls of an automated system.

The spray pattern and flow rate is controlled by

choosing the spray tip best suited to your needs.

GENERAL SAFETY WARNING

•

High pressure spray can cause serious injury.

•

Because of the high pressure and velocity of the fluid

being atomized, paint, solvent or other fluids could

penetrate through your skin, into your body or eyes.

•

Never point the spray gun at yourself or anyone else.

•

Never put your hands, fingers or any part of the

body over the spray tip/nozzle.

•

Even after you shut off the pump, there is still high

pressure in the system, You must always follow the

“PRESSURE RELIEF PROCEDURE”

vicing, or removal of the spray tip/nozzle.

before ser-

SPRAY GUN SAFETY WARNING

•

Never

point the gun at yourself or anyone

else: This can result in serious injury.

Safety latch:

•

Engage trigger safety latch in

the closed or “LOCK” Position see FIG 1,

whenever you stop spraying, even for a moment. Failure to engage trigger safety latch

can result in serious injury.

Trigger safety guard:

•

This prevents the

gun from triggering accidentally when it is

dropped or bumped. You must not operate

without the trigger safety guard.

When

•

treme caution and follow the “

RELIEF PROCEDURE”

cleaning or changing the tips use ex-

PRESSURE

then remove the

spray tip.

the spray gun into a grounded metal

Aim

•

pail using the lowest pressure possible,

then trigger the spray gun.

the fluid sprayed is not diffused into a

If

•

irregular stream, replace the diffuser at once.

the spray tip clogs while spraying, engage

If

•

trigger safety latch in “SAFE” position

immediately.

•

Never

wipe off around the spray tip until

pressure is fully relieved and the trigger

safety latch in “SAFE” position.

Fig 1

Trigger safety lock

Push up to engage

lock

Page 4 HRO-ST3131 Mar 8, 2004

Loading...

Loading...