I.C.T.C. Holdings Corporation 1240 User Manual

2719 Lake City Way, Burnaby, BC, V5A 2Z6 ? P.O. Box 75, Custer WA 98240-0052 ? Phone: (604) 420-6543 Fax: (604) 420-8725

OPERATOR’S MANUAL

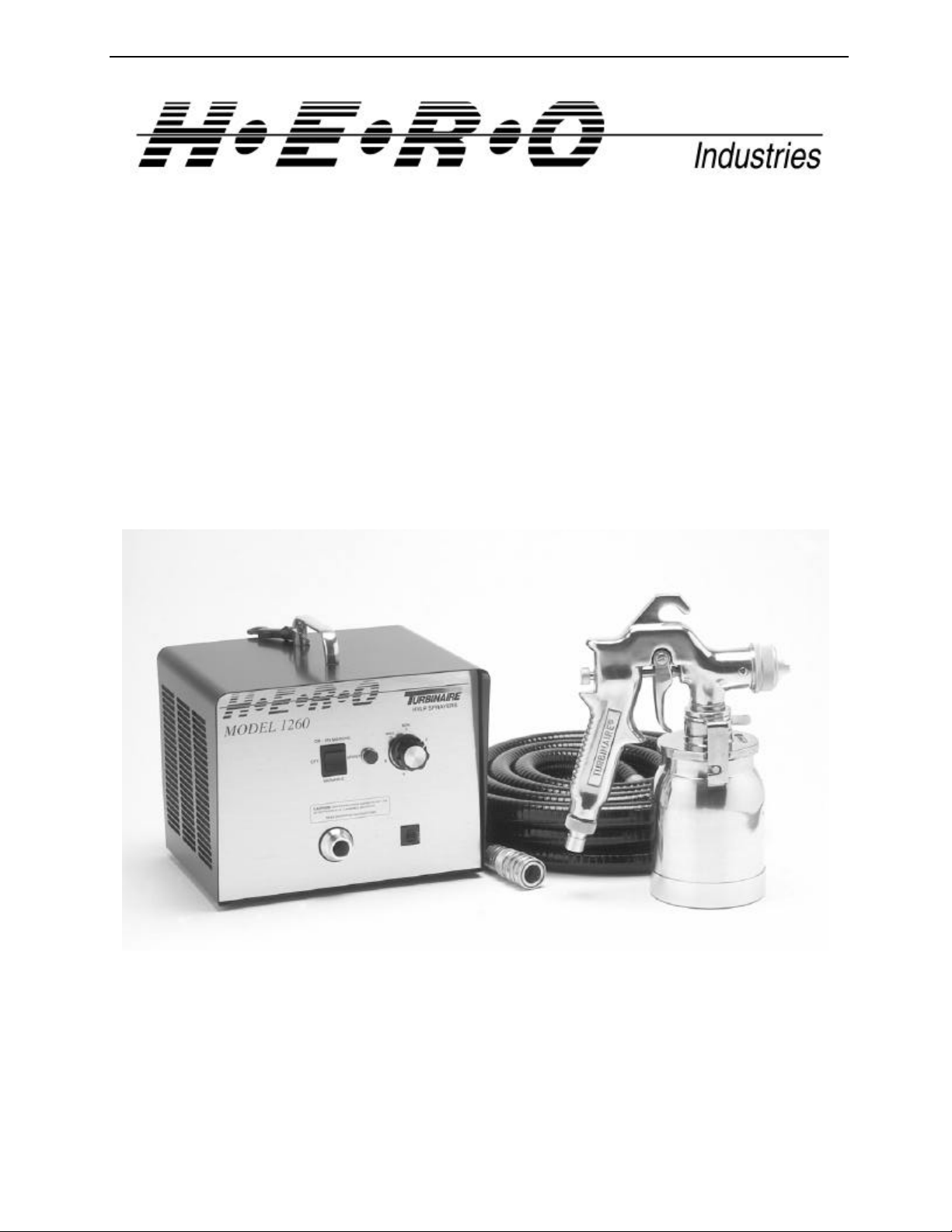

Model 1240

Model 1260

Model 2260

PROFESSIONAL CONTRACTOR PRODUCTS

Thank you for choosing HERO HVLP (High-Volume Low -Pressure) sprayers for your spraying needs.

At HERO Industries, we take pride in our precision-engineered products and want you to obtain all the

benefits that your HERO sprayer has to offer.

To ensure the proper use and maintenance of your HERO sprayer, please carefully read the information

contained in this manual before using your system. Should you require any further information, please

contact your nearest HERO distributor, or HERO directly for assistance - we will be pleased to assist you.

IMPORTANT: READ BEFORE USING

SAFETY PRECAUTIONS

?? CAUTION: Arcing parts. Keep the turbine at least 20 feet away from explosive vapors to avoid risk

of fire or explosion.

?? Never spray flammable materials near any source of open flame or spark.

?? Always spray in a properly ventilated area.

?? Never point the spray gun at anyone.

?? Always wear a spray mask and protective eyewear when spraying toxic substances.

IMPORTANT OPERATING TIPS

?? For simple Operating Instructions and Painting Tips, please refer to the laminated card supplied with

your system, attached to the handle of the turbine.

?? Most sprayable coatings must be diluted to be sprayed. Always follow the paint or coating

manufacturer’s instructions regarding thinning solvents and dilution ratios when preparing the coating

to be sprayed.

?? Select the appropriate Needle, Fluid Tip and Air Cap based on the coating being sprayed, the film

thickness required, and the application speed and finish required.

?? For optimum results, always test spraying distance, pattern size, coating thickness, Needle/Fluid Tip/

Air Cap combination and finish, on a sample of the surface to be coated.

?? When using a Cup Gun, do not turn the gun upside -down. The Pressure Feed Tube that pressurizes

the paint cup is internal and if blocked, will prevent the pressurization of the paint cup.

?? Make sure you clean your spray gun after each use as outlined in this manual. Proper cleaning is

essential to ensure the smooth operation of your system.

WARRANTY

?? Where applicable, please complete the enclosed warranty information card and return it to HERO

Industries

HERO Operator’s Manual – Page 1 of 23

CONTENTS

Page

1. THE HERO HVLP ADVANTAGE 3

2. GETTING STARTED

2.1 Unpacking Your HERO System 4

2.2 Testing The Turbine 4

2.3 Testing The Variable Speed Control 4

2.4 Connecting The Hose To The Turbine 5

2.5 Connecting The Spray Gun And Test Spray 5

3. GENERAL OPERATING INSTRUCTIONS

3.1 Operating Instructions And Painting Tips 6

3.2 Paint Preparation And Viscosity Chart 6

3.3 Needle, Fluid Tip And Air Cap Selection 7

3.4 Surface Preparation 9

3.5 Operating The Turbine 9

3.6 Spray Gun Terminology 9

3.7 Operating The Spray Gun 10

3.8 Testing Prior To Spraying 11

3.9 Basic Spraying Techniques 12

4. CLEANING AND MAINTENANCE

4.1 Basic Clean Up 14

4.2 Maintaining Turbine Air Filters 14

4.3 Complete Disassembly And Cleaning Of Spray Gun 15

4.4 Changing The Needle, Fluid Tip And Air Cap 16

4.5 Replacing The Cup Top Gasket 16

4.6 Replacing The Gland Seal 17

5. TROUBLESHOOTING

5.1 Basic Troubleshooting Cha rt 18

5.2 Troubleshooting Finish Problems 20

6. OPTIONS, ACCESSORIES, AND REPLACEMENT PARTS

6.1 Cup-Fed Systems 21

6.2 Volume-Fed Systems With Built -In Compressor 21

6.3 Volume-Fed Systems For Use With Shop Compressors 21

6.4 Needles, Fluid Tips and Air Caps 21

6.5 Gun Extension Wands, Touch-Up Cup Kit and Other Accessories 22

6.6 Replacement Parts and Technical Specifications 22

7. WARRANTY INFORMATION 23

HERO Operator’s Manual – Page 2 of 23

THE HERO HVLP ADVANTAGE

HERO Turbine -Powered HVLP Sprayers are powered by an electric turbine which supplies a consistent

flow of high volume, low pressure air (4-6 PSI @ 95-130 CFM) to the spray gun to atomize the paint or

coating (dye, lacquer, adhesive, etc.) being applied.

By spraying at low pressure, the coating does not bounce back from the surface as with conventional high

pressure spraying systems powered by a pump or a compressor. As a result, HERO systems reduce paint

consumption, virtually eliminate overspray, and offer a transfer efficiency of up to 90%, as compared to

30-40% with conventional systems! The end results are substantial savings in paint and operating costs, a

cleaner, safer working environment and a superior quality finish.

HERO ® HVLP Paint Spraying Systems: Features, Advantages, and Benefits

?? HERO HVLP systems virtually eliminate overspray offering up to 90% transfer efficiency. Increased

transfer efficiency provides for a cleaner working environment and drastically reduces paint and spray

booth costs while saving time and energy.

?? HERO all-inclusive portable systems operate from a standard power outlet of 110v or 220v for

increased versatility. With no compressor or complicated hook-up required, the user is free to paint

virtually anywhere.

?? Simple design makes HERO systems easy to learn, use, and particularly maintain.

?? Solid construction of HERO products prevent downtime and assure durability and long life.

?? HERO guns contain few parts, making them easy to clean and limiting the need for replacement parts.

?? The warm, dry air generated by the turbine not only reduces drying time for most coatings, but

eliminates the possibility of airline moisture and oil contaminants as well. As a result, HERO

turbine-powered systems eliminate the need for costly airline maintenance equipment such as those

required for compressor -powered systems.

?? All HERO systems use tangential turbines to provide the highest CFM (Cubic Feet per Minute) rating

in the industry, thus offering the highest-quality finish.

?? Built-in Variable Speed Controllers on models 1235 and 1537 allow operator to adjust the speed of

the turbine to deliver the minimum amount of air required to properly atomize the coating being

applied, while maintaining the desired coating thickness and finish. This limits the amount of

overspray and increases transfer efficiency.

Turbine-powered HVLP sprayers have literally changed the way people do spray finishing. Whether you

are a professional or novice painter/finisher, we are confident that once you are familiar with your new

HERO sprayer, you will enjoy the benefits of this professional tool for many years, and appreciate the

ease and simplicity of its use.

HERO Operator’s Manual – Page 3 of 23

GETTING STARTED

2.1 UNPACKING YOUR HERO SYSTEM

Unpack your new HERO system from the box. Ensure that all items are included with your system:

Cup-Fed Systems include: turbine, air hose and spray gun

Volume-Fed Systems With Built-In Compressors include: turbine, Lower Deck Fluid Delivery System

(including paint tank), air hose, flu id line, and spray gun

Volume-Fed Systems For Use With Shop Compressors include: turbine, air hose, fluid line, paint tank

(with regulator and pressure gauge), and spray gun

All systems can also be ordered with a Gun Accessory Kit. The Gun Accessory Kit includes a practical

selection of (4) Needles, (4) Fluid Tips, (2) Air Caps, (1) gun cleaning brush, and (8) siphon tube paint

filters. The Kit ensures the ability to spray virtually any sprayable coating and can be purchased for a

reduced price at time of purchase of a complete system.

2.2 TESTING THE TURBINE

With the power switch in the OFF position, place the turbine as far away from the spray area as

comfortably possible and plug into a standard power outlet (110V or 220V, as applicable). Verif y that the

turbine foam air filters are properly covering the motor air vents on either side of the turbine cabinet.

Turn the turbine ON and ensure that air is blowing out the air outlet.

All HERO systems are equipped with a re-settable circuit breaker. If the turbine is not functioning

properly, check your power supply and/or re-set the breaker switch on the face of the unit by pressing it

once.

NOTE: Due to the high speed of the turbine (18,000 to 24,000 RPM) and the frictional forces this

causes, it is normal for the turbine, hose and gun to heat up slightly during operation. Generally, the

system will heat up and then remain at a constant temperature during use.

2.3 TESTING THE VARIABLE SPEED CONTROLLER (VSC)

The purpose of the Variable Speed Controller (VSC) is to determine the minimum amount of air volume

required to atomize the coating being applied, while maintaining the desired coating thickness and finish.

By using the VSC properly you will reduce overspray and increase transfer efficienc y.

All HERO systems equipped with a VSC have a three way power switch: On/Off/On. When the switch is

in the “up” position, the turbine will operate at maximum air volume. When the switch is in the “middle”

position, the turbine is off. When the switch is in the “down” position, the air volume output of the

turbine can be adjusted based on the coating being sprayed and the finish required.

Most coatings do not require maximum air volume to be atomized. When spraying non-viscous coatings

(i.e.: stains, dyes, etc.) the air output can be reduced to eliminate over-atomization and unnecessary

overspray. When spraying viscous coatings (i.e.: latex paint, multi-color, adhesives, etc.) the air output

can be increased to provide a fine finish, or decreased to provide a textured finish.

HERO Operator’s Manual – Page 4 of 23

2.4 CONNECTING THE HOSE TO THE TURBINE

With the power switch in the OFF position, uncoil the air hose and screw it hand-tight to the turbine air

outlet.

Although the hose is designed for industrial use, it is not crushproof. Do not stand on the hose for

extended periods. For information on wire-bound crushproof hoses, please contact your local HERO

distributor or HERO directly. Also, the hose should never be used to pull the turbine or form a sharp

angle at the air outlet – this can cause premature wear of the hose, restriction of the airflow and/or

overheating of the hose.

2.5 CONNECTING THE SPRAY GUN AND TEST SPRAY

Always ensure that the gun is clean prior to being used. Any paint residue and/or particles left in the

paint cup and/or fluid tubes from previous use can spoil a finish and possibly affect the performance of

your sprayer.

Using the information provided in the Gun Accessory Kit or in Section 3.3 of this manual, determine

whether the Needle, Fluid Tip and Air Cap combination in the gun is suitable as a starting point for your

application. If not, refer to Section 3.3 of this manual for Needle, Fluid Tip and Air Cap selection, and

Section 4.4 for instructions on Changing The Needle, Fluid Tip and Air Cap.

To install the hose on the gun, pull back the ring on the Quick Disconnect Coupler to connect it to the

male tail piece on the end of the gun handle. If your unit is not equipped with a Quick Disconnect

Coupler, connect the air hose to the gun by screwing it hand-tight to the male threads at the base of the

handle of the gun.

For proper Testing Prior To Spraying, refer to Section 3.8 of this manual.

HERO Operator’s Manual – Page 5 of 23

GENERAL OPERATING INSTRUCTIONS

3.1 OPERATING INSTRUCTIONS AND PAINTING TIPS

For the specific Operating Instructions and Painting Tips of your HERO sprayer, please refer to the

laminated card attached to the turbine handle of your system. If this card is missing or has been lost,

please contact your local HERO distributor or HERO directly, we will be pleased to mail, fax, or e-mail

you a new copy.

The following general instructions are meant to be a guideline for success with your HERO sprayer.

Although practice makes perfect, there are a number of books, videos and courses available on the market

to help you further refine your knowledge and skills of spraying in general, should you wish to do so.

3.2 PAINT PREPARATION AND VISCOSITY CHART

Most sprayable coatings must be diluted to be sprayed. If so, always follow the paint or coating

manufacturers’ instructions regarding thinning solvents and dilution ratios when preparing the coating to

be sprayed. Always mix and store your thinned material in a separate container, and label your containers

based on original coating, thinning solvent used and percent dilution.

The thickness of a coating is defined by its “viscosity in seconds”: “viscous coatings” are thicker

materials; “non-viscous coatings” are thinner materials. To properly measure the viscosity of a coating,

use the Zahn B viscosity cup supplied with your HERO sprayer.

1. Completely submerge the viscosity cup in

the coating to be measured.

2. Lift the viscosity cup out of the coating and

begin timing.

3. Measure the time in seconds until the first

break in the stream of coating.

4. The time lapsed will determine the viscosity

of the coating, i.e.: 25 seconds in a Zahn B.

Once you have prepared the estimated quantity of coating required, refer to Section 3.3 of this

manual for information about Needle, Fluid Tip and Air Cap Selection based on the coating being sprayed

and its viscosity, once diluted. Refer to Section 4.4 for information about Changing The Needle, Fluid

Tip and Air Cap.

Once you have chosen and installed the appropriate size Needle, Fluid Tip and Air Cap, detach the

paint cup from the gun, pour the diluted material (paint, coating, etc.) into the cup, and re-attach it to the

gun. All material should be strained with a cone filter when poured into the paint cup and/or a Siphon

Tube Paint Filter (included in Gun Accessory Kit) should be installed on the siphon tube.

For optimum results, always test coating viscosity, spraying distance, pattern size, film thickness,

Needle/Fluid Tip/ Air Cap combination and finish, on a sample of the surface to be coated.

HERO Operator’s Manual – Page 6 of 23

Viscosity Chart

Properties and thickness of coatings vary from one manufacturer to another. The following chart is a

guideline only. Use these times as a guideline in determining the appropriate viscosity based on your

spraying technique and finish standards. Some high solids coatings may exceed a reasonable viscosity

and still be sprayable.

Material To Be Sprayed Time To First Break In Stream

Acrylic Finishes

Acrylic Metallic

Acrylic Primer

Adhesives

Automotive Lacquer

Chromates

Dyes

Enamel

Hammer Finishes

Hard Gloss Synthetics

Imron

Lacquer

Latex

Marine Paint

Masonry Paint

Oil-bound Heavy-bodied Primers

Polyurethane Paint

Stains

Synthetic & Lacquer Metallic

Water Sealer

10-15 seconds

10-15 seconds

20-40 seconds

40-60 seconds

20-30 seconds

20-25 seconds

10-20 seconds

25-50 seconds

30-40 seconds

30-40 seconds

30-45 seconds

10-30 seconds

30-45 seconds

30-45 seconds

30-50 seconds

35-40 seconds

20-40 seconds

10-20 seconds

20-25 seconds

10-20 seconds

3.3 NEEDLE, FLUID TIP AND AIR CAP SELECTION

The proper Needle, Fluid Tip and Air Cap combination is critical to the optimal performance of any

spraying system. Needles and Fluid Tips are sized together – when changing the Needle, the Fluid Tip

must be changed as well. Air Caps are sized separately and can be changed without necessarily changing

the Needle and Fluid Tip. HERO manufacturers seven different sizes of Needles and Fluid Tips ranging

from 0.50mm to 3.0mm, and three different sizes of Air Caps.

Identifying Needle, Fluid Tip and Air Cap sizes

The size of a Needle can be determined by the number of annular grooves in the brass sleeve on the

Needle. Every wide groove represents one millimeter, every narrow groove represents one-half of a

millimeter, i.e.: a Needle with one wide groove and one narrow groove is a 1.5mm Needle; a Needle with

two wide grooves is a 2.0mm Needle. The only Needle that differs from this is the 0.75mm, which has no

grooves at all.

The size of the Fluid Tip can be determined by placing it on the tip of the Needle. If the tip of the

Needle protrudes from the Fluid Tip, they do not match. When the Needle and Fluid Tip match, the

Needle will be flush with the end of the Fluid Tip.

HERO Operator’s Manual – Page 7 of 23

Loading...

Loading...