I.C.T.C. Holdings Corporation 1150GSD User Manual

AIRLESS SPRAY EQUIPMENT

1997 VERSION

BEGINNING A T

SERIAL NUMBER

140056

SAFETY, OPERATING AND

MAINTENANCE INSTRUCTIONS

AND PARTS LIST

Do Not attempt to operate this machine until you have read and

understand ALL safety precautions and oper ating instructions.

Equipment and chemicals when used improperly can be

H.E.R.O. INDUSTRIES 1150GSD MANUAL - “B” VERSION

41

H.E.R.O. WARRANTY

H.E.R.O. INDUSTRIES LTD., guarantees this airless pump to be free of

defects in materials and workmanship to the origin al own er, for a period of

one full year from the da te of purc hase.

The warranty entitles the owner to parts replacement at no charge. The

parts replacement warranty is valid for any necessary replacement, whither

caused by material or workmanship defect or simple wear. The hydrapulse

membrane (part# 4-04-22-4500) is warranted for LIFE. Installation costs

for the hydrapulse membrane is p rovided for the first 12 months on l y. H.E .

R.O. Industries Ltd. offers no warrant y on the intake ball, outgo ball , drive

belt, hoses, gun or accessories, plastic, rubber, other soft goods or motor

used in or supplied with the H.E.R.O. sprayer.

Motor, accessories, etc., which are supplied by other manufacturers and are

attached to or supplied with the H.E.R.O. airless pu mp, are warranted only

to the extent that these parts are warranted by their respective

manufacturers. Warranty claims must be made directly to such

manufacturers or their local authorized service depots.

The warranty is only applicable to the original purchaser and the equipment

has been properly used, operated and maintained in accordance with all

instructions, precautions and warnings contained in this manual. For the

purpose of this warranty, damage resulting from accident, abuse, improper

cleaning or operat ion, fire, fl ood, or Act of G od, is not cove red.

H.E.R.O.’s liability is limited to replacing parts found to be defective or

worn and does no t includ e; transportat ion costs, da mage or other expen ses

of any kind incurred in connection with the purchase and use of this

sprayer.

Repairs claimed under warranty m ust be pe rf ormed at an authorize d H .E .R.

O. Service Center, using only genuine H.E.R.O. parts. Parts necessary

under warranty claim will be supplied by your local H.E.R.O. Service

Center.

DO NOT return worn parts to factory without authorization.

To qualify for the warranty, the warranty card (attached to this page)

supplied with this H.E.R.O. airless pump, must be completed with

H.E.R.O. INDUSTRIES 1150GSD MANUAL - “B” VERSION

1

TA BLE OF CONTENTS

For greatest user satisfaction, please familiarize

yourself with all maintenance a nd operational instr uctions

Important Safety Precautions ...................................................................................................... 3-4

Introduction .....................................................................................................................................5

Operating Instructions .....................................................................................................................5

Setting Up To Spray .................................................................................................................... 6-7

Flushing The Unit ...........................................................................................................................8

Special Notes ...................................................................................................................................9

Airless Spray Painting Suggestions ........................................................................................10-12

Trouble Shooting .....................................................................................................................13-21

Hydrapulse Membrane Replacement ...........................................................................................22

Intake Seat Replacement ...............................................................................................................23

Piston Repairs ..........................................................................................................................24-25

Outgo Valve ..................................................................................................................................26

Prime Valve Repairs .....................................................................................................................27

Pressure Control Valve Repairs ....................................................................................................28

Accessories ....................................................................................................................................29

Parts List And Descriptions ....................................................................................................30-34

Exploded Unit Diagram ..........................................................................................................35-36

Depot List ................................................................................................................................37-40

IMPORTANT

NOTE: AS WITH ALL MECHANICAL EQUIPMENT, PROPER OPERATING AND

MAINTENANCE PROCEDURES ARE REQUIRED TO KEEP YOUR H.E.R.O. AIRLESS

PUMP PERFORMING TO YOUR SATISFACTION. THE FOLLOWING SAFETY,

OPERATING AND MAINTENANCE INSTRUCTIONS ARE IMPORTANT.

Read and understand this manual completely, especially with regard to all safety precautions. Read

and follow instructions on all warning labels on your equipment. Keep the warning labels clean and

readable at all times. Order new labels from your local distributor or from H.E.R.O. Industries Ltd. if

needed.

The manufacturer shall not be responsible for any loss, damages, or injury of any kind or nature

whatsoever resulting from the use the equipment other than in strict compliance with the instructions,

cautions and warnings contained in this operating and instruction manual and as displayed on the face

of the equipment.

This system is capable of producing 2400 psi. ( spray pressure ). To avoid rupture and injury DO

NOT operate this pump with components rated less than 3000 psi. working pressure (including but

not limited to spray guns, hose and connections).

Before servicing, cleaning or removing of any part, shut off power and relieve pressure.

IMPORTANT SAFETY PRECAUTIONS

H.E.R.O. INDUSTRIES 1150GSD MANUAL - “B” VERSION

2

WARNING

NEVER PLACE FINGERS NEAR SPRAY TIP OF GUN. NEVER POINT GUN TOWARD

ANY PART OF YOUR BODY, OR THAT OF ANY OTHER PERSON. MATERIAL ISSUING

FROM THE SPRAY TIP IS AT HIGH PRESSURE. IF FINGERS, OR ANY PART OF THE

BODY ARE PLACED NEAR THE TIP OF THE SPRAY GUN, IT IS POSSIBLE THAT THE

SPRAY COULD BREAK THE SKIN AND INJECT SOME OF THE SPRAY MATERIAL. IF

INJURY DOES OCCUR, SEEK THE IMMEDIATE ATTENTION OF A MEDICAL DOCTOR.

BE PREPARED TO INFORM THE DOCTOR WHAT FLUID WAS INJECTED, IF THE

INJURY IS OF AN INJECTION NATURE. EQUIPMENT AND CHEMICALS WHEN USED

IMPROPERLY CAN BE DANGEROUS!

NEVER place any part of the body in front of t he spray tip or aim the gun toward an y part of the

body.

NEVER point the gun toward any individual.

NEVER treat any injury as a simple cut. If injury does occur, seek immediate medical attention. Be

prepared to inform the doctor what fluid was injected.

NEVER allow another person to use the sprayer unless he is thoroughly instructed on its

operation and has read all safety precautions in this manual and all safety warni ng labels attached to

unit.

NEVER use around children.

NEVER attempt to perform any maintenance or service on any part of the unit spray system

without first;

1. Turn off the engine.

2. Turn the engine switch to “OFF” position.

3. Relieving all pressure in the pump by triggering the gun.

4. Locking gun trigger in "LOCKED" position, with gun locked closed.

NEVER operate the sprayer without the tip guard complete and in place.

NEVER spray any material in the vicinity of open flame, pilot lights, electrical outlets or any

other source of ignition.

NEVER spray volatile materials with flash points lower than 140 F (60 C).

NEVER attempt to stop any leakage in the paint line or at any fitting with your hand or any part of

your body. Immediately shut off the unit should leakage occur.

NEVER allow paint hose to become kinked, or to vibrate against rough or sharp surfaces.

NEVER operate the unit at pressures higher than the pressure rating of the lowest rated

component in the system, or at pressure higher than factory preset.

NEVER spray in an enclosed area. The spraying area must be well ventilated to safely remove

chemical vapors.

NEVER operate the unit with worn or damaged accessories, or with accessories other than those

supplied by H.E.R.O. Industries, unless the accessories have been first specifically approved in

writing by H.E.R.O. Industries Ltd.

NEVER allow the unit to be serviced or repaired anywhere other than an authorized H.E.R.O.

Service Center, or with other than genuine H.E.R.O. parts or components.

NEVER leave unit unattended without first shutting off, triggering the gun to relieve all pump

pressure, and setting the trigger lock on gun in "LOCKED" position, with gun locked closed.

ALWAYS

ALWAYS follow H.E.R.O. recommendations for operation and safety completely.

H.E.R.O. INDUSTRIES 1150GSD MANUAL - “B” VERSION

3

ALWAYS set trigger lock on gun in "LOCKED" position when not in use, with gun locked close.

ALWAYS check connections and fittings for tightne ss before operating the unit.

ALWAYS locate the unit in a well ventilated area a minimum of 25 feet fr om the spr ay are a.

ALWAYS ground the unit, the paint containers, and the object being sprayed to eliminate static

discharge. Ensure that all these objects remain grounded throughout the entire spraying operation.

ALWAYS use accessories and components approved for at least 3000 psi (working pressure) in the

spraying system.

ALWAYS use accessories and components supplied by H.E.R.O. Industries Ltd., or specifically

approved in writing by H.E.R.O. Industries Ltd. on with the unit.

ALWAYS examine accessories for wear or damage before operating the unit.

ALWAYS use lowest possible pressure when flushing and cleaning the unit, and hold the gun firmly

against a metal container to reduce static discharge possibility.

ALWAYS wear a face filter mask when operating the unit.

ALWAYS ;

1. Turn off the engine.

2. Turn the engine switch to “OFF” position.

3. Relieve all pressure in the pump by triggering the gun.

4. Lock gun trigger in "LOCKED" position, with gun locked closed before attempting to perform

any maintenance or service on any part of the unit spray system.

ALWAYS wear safety glasses when operating the unit.

ALWAYS ensure fire extinguishing equipment is readily available and properly maintained in the spray

area.

ALWAYS observe good housekeeping and keep the spray area free from obstructions.

ALWAYS be aware that certain chemicals may react with aluminum, carbide, or other components in

the pump system. Read the manufacturer's label on all materials to be sprayed, and follow the

manufacturer's recommendations. If in doubt, consult your material supplier to be sure.

H.E.R.O. AIRLESS SPRAY PAINTING

Welcome to the world of H.E.R.O. airless paint spraying. We are sure you will enjoy owning and operating

your new H.E.R.O. model 1150GSD. With H.E.R.O. airless spray equipment you will avoid the

H.E.R.O. INDUSTRIES 1150GSD MANUAL - “B” VERSION

4

inconvenience and mess of overspray. You are spraying paint, not air, and the paint is driven to the painting

surface in a clean, fan shaped spray which penetrates all cracks and corners. To attain these results, you must

adjust the pressure as low as possible. We recommend that you become familiar with your H.E.R.O. unit.

Discuss with your dealer the useful accessory items he has to offer - various types of tips, extension poles for

hard to reach areas, extra hose, etc. Use of accessory items is often the difference between a good job and an

excellent one!

HYDRAPULSE

“B” VERSION

BEGINNING A T

SERIAL NUMBER

1997

O P E R A T I N G

INSTRUCTIONS

140056

WARNING

Do not attempt to operate this machine until you have read and understood all safety precautions and

operating instructions. Equipment and chemicals when used improperly can be dangerous.

Your H.E.R.O. airless sprayer has been fully factory tested prior to shipment.

BEFORE STARTING YOUR H.E.R.O. PUMP....

CHECK to ensure that the shipping seal has been removed from under the cap on the hydraulic tank.

Hydraulic tank should be at least 3/4 full of H.E.R.O. LVO hydraulic fluid.

CHECK all fittings and connections in the pump system, hose, and gun to ensure that they are tight.

CHECK to ensure that there is a spray tip in the gun, and that the tip is the correct size for the coating you

are to spray. ( There are various tips available, for each type of coating or configuration. See " Airless Spray

Tip " on page 11 , for proper tip selection.

CHECK to ensure that you have H.E.R.O. strainer bags, H.E.R.O. Wonder Wash, appropriate thinner for

the paint, a waste container, and any other accessories you may require for the job.

READ THIS MANUAL THOROUGHLY.

READ THE HONDA ENGINE MANUAL SUPPLIED WITH THE UNIT . FOLLOW ALL THEIR

RECOMMENDED PROCEDURES FOR “START-UP” AND OPERATION

SETTING UP T O SPRAY

1. Remove unit from shipping carton.

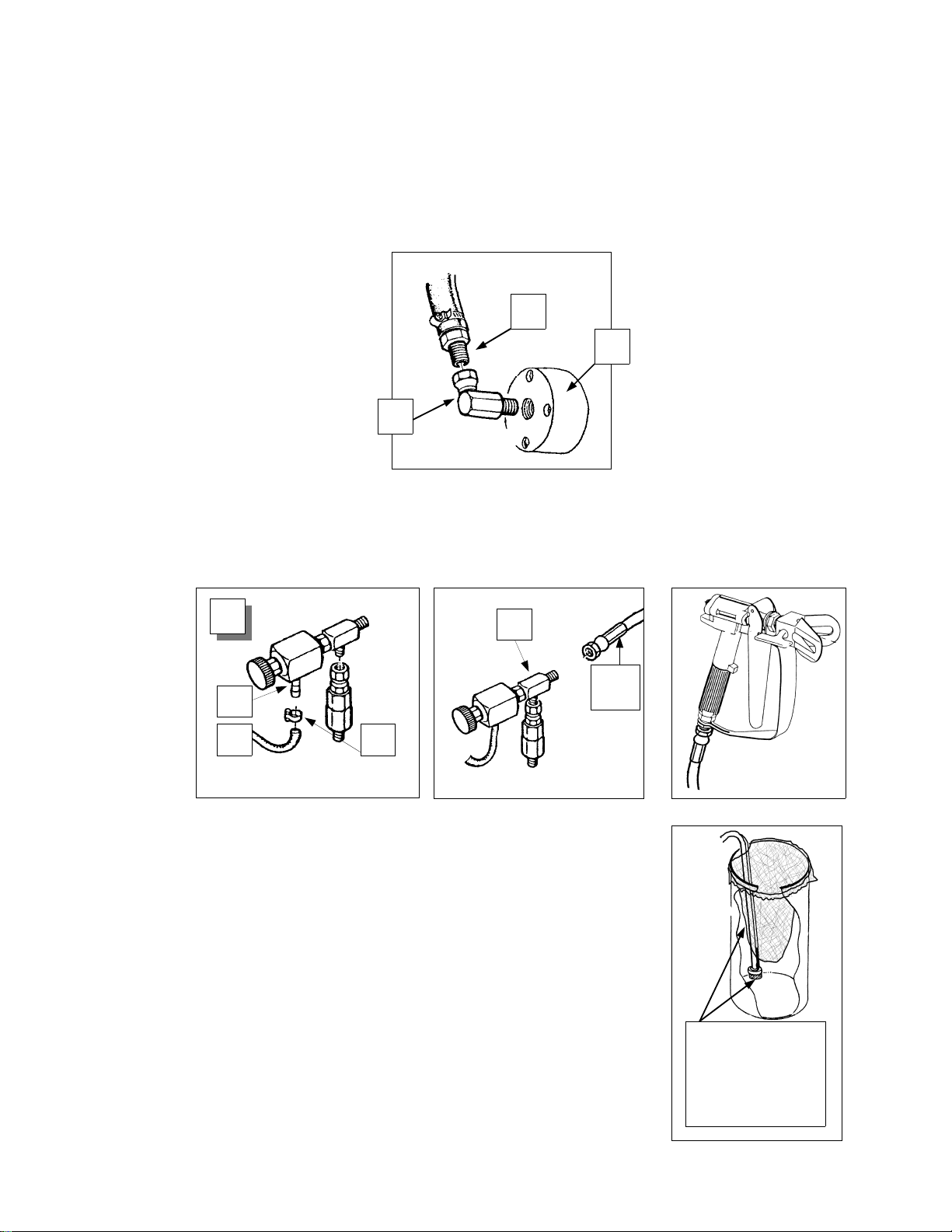

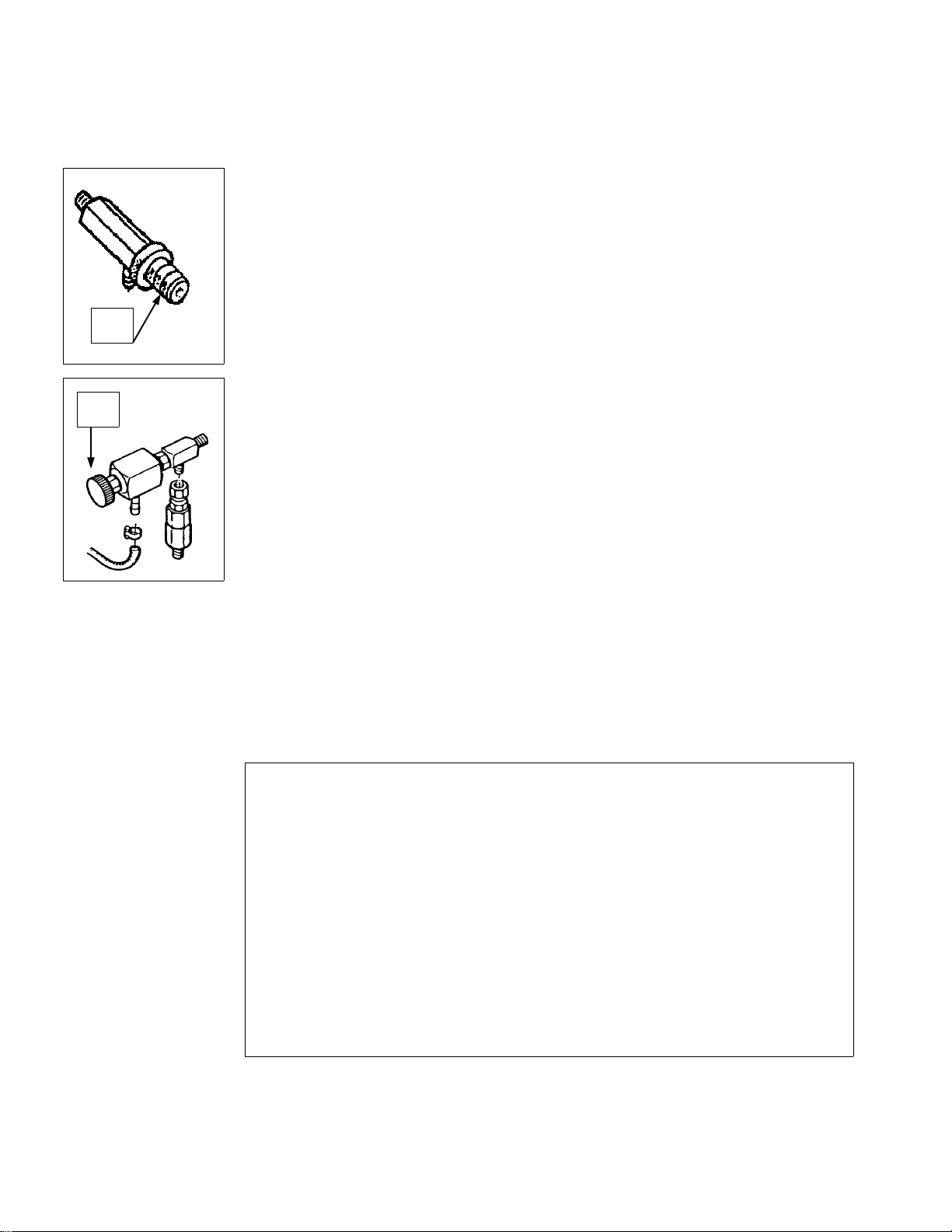

2. Attach intake siphon assembl y (ref# 1) to intake elbow (ref# 8). The intake elbow provides a swiveling

connection during assembly only. Two wre nche s ar e require d to tig hten t he se fi tting s. W hen suf ficie ntly

H.E.R.O. INDUSTRIES 1150GSD MANUAL - “B” VERSION

5

tightened the siphon hose will no longer swivel or move, as such, ensure the siphon hose is positioned in

the desired direction prior to making the final tightening. The desired position is straight back from the

intake. Use caution to avoid over tightening which may re sult in crac ked or broken fitting s.

7

11

3. Attach prime hose (ref# 51) to prime valve (ref# 36) hose barb

(ref#50). Secure with clamp (ref# 52).

4. Attach paint hose to outgo tee (ref# 35).

8

5. Attach gun to paint hose.

NOTE; Spray tip and tip guard

should be attached to gun prior to

attaching to hose.

36

35

50

Paint

Hose

6. P l a c e

51

52

intake

siphon

assembly into a

clean 5 gallon pail.

7. Install strainer bag (accessory item 5GAL SB) in pail and secure

with large rubber band (accessory item 106).

NOTE; Strainer bag must remain 4 inches from the bottom of pail

8. Trigger gun to release any pressure in the unit. Use extreme caution

to ensure that the gun is not directed towards anyone or any object

which may be damaged.

NOTE; Unit may contain storage solution.

9. To remove storage solution, add one gallon of thinner, compatible

with the type of paint to be used, to the siphon pail.

Strainer bag and si-

phon tube.

ALWAYS

strain paint before

starting

H.E.R.O. INDUSTRIES 1150GSD MANUAL - “B” VERSION

6

46

75

SETTING UP T O SPRAY - CONTINUED

10. Turn pressure control knob (ref# 75) counter clockwise to lowest pressure

setting.

11. Observe and perform all pre-operation checks as required by the engine

manufacturer, ( Honda ). See your Honda owner’s manual.

12. Start engine. See Honda owner’s manual for correct procedures.

13. Turn prime valve knob (ref# 46) counter clockwise until fully open. Allow

thinner to circulate back into the siphon pail for a few minutes. Then turn the

prime valve knob clockwise to close the valve ( close tightly ), and direct the

flow to the paint hose and gun. Leave the pressure setting low.

14. Trigger gun into a waste container.

15. Remove rinse / prime fluid and pour paint through strainer bag into siphon pail.

16. Repeat step 13, until paint flows freely.

NOTE; Never turn prime valve back to "prime" position when the unit is

under pressure.

NOTE: The thicker paint will require a longer time to complete the initial

prime circulation through the prime valve. Leave the valve in the prime

position to ensure the complete removal of all air and pre-prime fluid. Several

minutes may be required, particularly with thicker viscosity products.

17. Spray a test pattern. Begin by spraying a test pattern onto old newspaper or

other scrap material.

18. Increase the pressure, slowly at first, by turning the pressure control knob

clockwise. Continue increasing the pressure until the spray pattern is

uniformed from top to bottom, with no heavy areas. Secure pressure control

setting, by turning the silver lock ring ( ref# 77) counter clockwise until snugly

against the face of the pressure control knob. If heavy areas are still visible at

maximum pressure setting, thin the paint with the correct thinner, according to

the paint manufacturer's recommendations.

19. Spray paint.

Paint Straining

It is recommended that all products entering the sprayer, be pre-strained to

remove any large particles and contaminants, BEFORE they are drawn into

the sprayer. The strainer bag should remain in place throughout the painting

operation. This will prevent foreign matter from falling into the bucket and

contaminating the previously strained paint. The gun filter should not be relied upon to do all the paint filtration. Any dirt, grime or other undesirable

particles which reach the gun filter have passed through the entire paint

pump and have possibly created unnecessary damage and inconvenience.

Always strain the paint before siphoning.

H.E.R.O. INDUSTRIES 1150GSD MANUAL - “B” VERSION

7

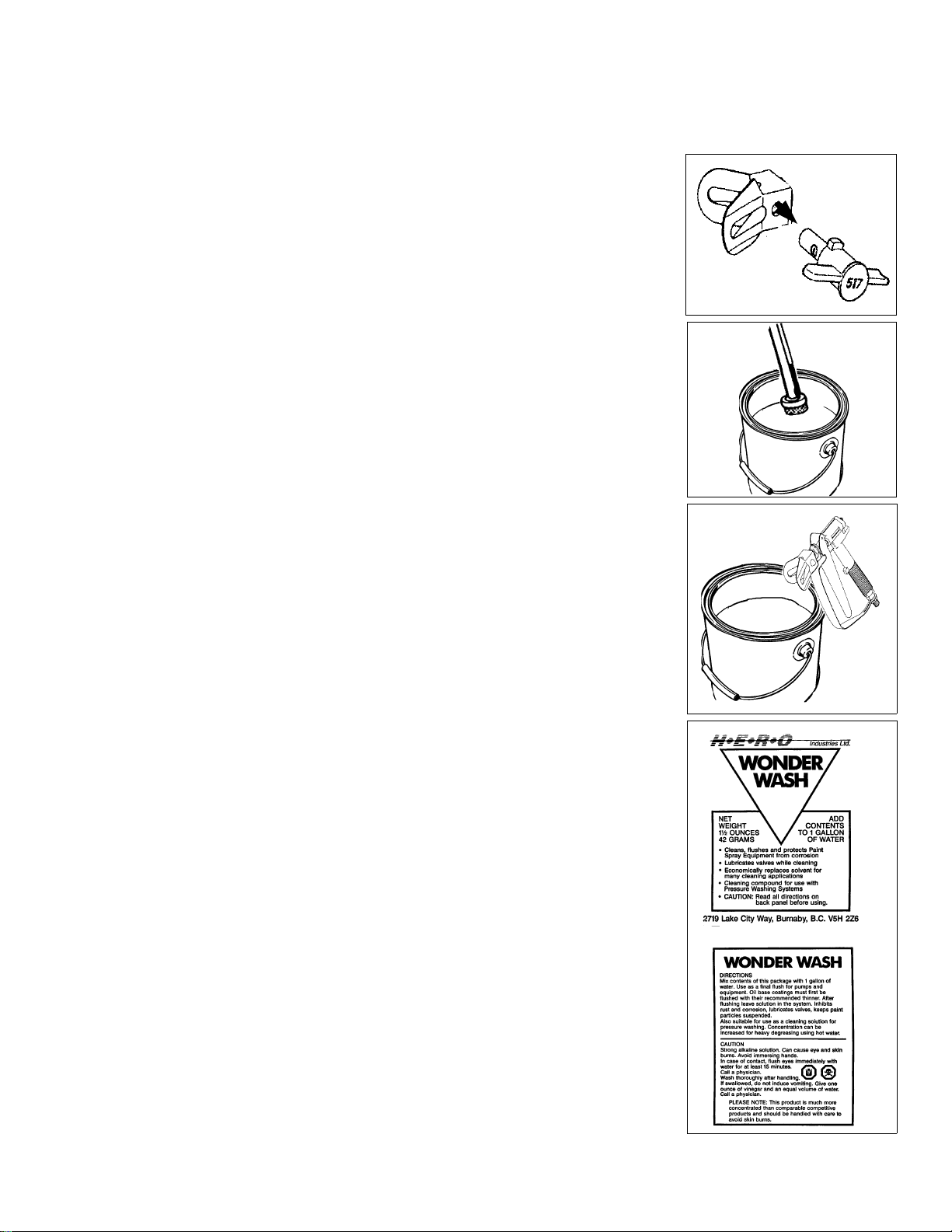

FLUSHING THE UNIT AT SHUTDOWN

OR COLOR CHANGE

If shutting down for a short period of time, it is sufficient to trigger the gun to

relieve pressure. Then set the safety lock on gu n to "locked" position with the

gun locked closed and immerse the gu n in a con tainer of the correct th inner fo r

the paint you are spraying.

1. Remove spray tip from gun.

2. Turn pressure control knob counter clockwise to low pressure setting. Only

use sufficient pressure to allow material to move through the sprayer. DO

NOT operate at or near full pressure.

3. Remove siphon assembly from paint container.

4. Trigger gun, back into paint container, until unit runs dry.

NOTE: Pump and spray hose will continue to contain paint. This paint may

be recovered by placing prime hose into paint container and draining the

remainder while re- priming with c leaning fluid. See step 5* and 6*.

5. Place siphon assembl y in container of correct thinner, for the spray product

being used,, and prime the pump as shown in step 13, of "Spra ying". *See

special notes from step 4. Allow thinner to circulate back into the container

for a few minutes to flush the prime valve.

6. Close prime valve.

7. Trigger gun into paint container until thinner comes through. *See special

notes from step 4. Re-direct flow into waste container and continue spraying

until thinner runs clear. Heavily soiled thinners may have to be changed to

complete cleaning job.

8. Lift siphon assembly and allow pump to run dry.

9. Repeat procedure using a gallon of H.E.R.O. Equipment Wonder Wash

solution. If not using Wonder Wash, unit must not be stored with water. Only

store with a non corrosive material ( Paint thinner, solvent ).

10. Switch unit "off" and trigger gun to relieve remaining pressure.

11. Remove and rinse gun handle filter in correct thinner.

SPECIAL STORAGE INSTRUCTIONS

In areas where the sprayer is NOT used 12 months of the year, special preparations

must be used for winter or off season storage. Because solvents evaporate quickly,

they should not be used for long term storage. A petroleum based solution ( solvent

and oil ) should be used as an extended storage material. DO NOT allow storage

solution to freeze in the spray er.

H.E.R.O. Equipment Wonder Wash, available from your H.E.R.O. distributor,

will provide the added cleaning benefits of solvent at a much lower cost. Suitable

as a short term ( 1-2 days ) storage solution only

SPECIAL NOTES AND INSTRUCTIONS

H.E.R.O. INDUSTRIES 1150GSD MANUAL - “B” VERSION

8

NEVER LEAVE THE UNIT UNDER PRESSURE WHEN NOT SPRAYING (ENGINE TURNED

OFF). RELIEVE PRESSURE BY TRIGGERING GUN. NEVER STORE THE UNIT WITH PAINT

OR WATER IN THE PUMP SYSTEM, EV EN OVERNIG HT.

NEVER attempt to start the engine when the unit is under pressure. Relieve pressure and follow

instructions in "Setting up to spr ay"

Avoid oper ating the unit while til ted. Kee ping it leve l assures g reater operating efficiency .

Alway s follow flushing and cleaning instructions exac tly.

I n hot weather, locate unit in shade.

Reg ularly check the level of H.E.R.O. LVO hydraulic fluid in the hydraulic tank. It should be kept near

full, top up as needed with only genuine H.E.R.O. LVO hydraulic fluid.

Crankshaft eccentric bearing should be greased at regular intervals consistent with hours of use. Use

MO-2 grease (i.e. common auto grease) approximately every 10 hours of operation.

A minimu m 50’ and a maximum of 300’ of airless spray hose may be used.

NOTE: 50’ x 3/8” paint hose ( part # 117 ) should be used for every 50’ x 1/4” paint hose

( part # 114 ) over 100’.

100’ total length of paint hose = 2 of 50’ x 1/4” paint hose.

150’ total length of paint hose = 2 of 50’ x 1/4” paint hose and 1 of 50’ x 3/8 paint hose.

200’ total length of paint hose = 2 of 50’ x 1/4” paint hose and 2 of 50’ x 3/8 paint hose.

250’ total length of paint hose = 3 of 50’ x 1/4” paint hose and 2 of 50’ x 3/8 paint hose.

300’ total length of paint hose = 3 of 50’ x 1/4” paint hose and 3 of 50’ x 3/8 paint hose.

Product viscosity, altitude ( feet above sea level ) and vertical reach can effect pump performance and

special accessories may be required. Product viscosity may have to be further reduced at higher

elevations. The larger diameter 3/8” paint hose should be used.

Check drive belts ( part# 66/100 ) tension frequently. The belt will stretch with use, and should be

adjusted after 20 hours of operation and again after 50 hours. Periodic checks after 50 hours should be

made. Failure of the drive belt is not covered by the equipment warranty, so proper maintenance of the

belt is important.

Regularly check fittings, bolts, nuts and connections for damage. Tighten, adjust or replace as required.

Check crankshaft alignment often. An out of alignment crankshaft will cause the damage to the

eccentric bearing.

GAS ENGINE

Check the engine oil level daily. Top up only with the manufacturer’s recommended oil. Running the

engine with insufficient oil can cause serious engine damage.

Check the engine air cleaner daily. NEVER operate without an air cleaner.

Use only UNLEADED or lowleaded gasoline.

The engine requires regular operation and should not be stored for prolonged periods without operating.

Run for a minimum 15 minutes each week while in storage.

Remove gas before storing.

Have the engine professionally serviced by an approved service technician on a regular bases as

recommended by the manufacturer ( Honda ).

DO NOT adjust engine operating speed ( RPM ). The e ngine is f actory set for optimum performanc e.

DO NOT use engine RPM to control spray performance, always adjust pressure with “Pressure Control”

AIRLESS SPRA Y P AINTING

H.E.R.O. INDUSTRIES 1150GSD MANUAL - “B” VERSION

9

SUGGESTIONS AND TECHNIQUE

A good airless spray application is the result of many factors. Surface preparation, which includes cleaning

and degreasing, priming, material compatibility, quality finish product and correct application technique, are

all important to the finished re sults.

The key to all good applications is a good spray gun technique. The finished results are what the client will

look at and base his opinion on. Your skill and abilities are as important as good equipment and good paint.

Proper application techniques can easily be learned by using the following simple guidelines. If you are not

familiar with the basic spray techniques we recommend that you study this portion of the manual and

practice the techniques shown. Practice your technique on scrap cardboard or old newspaper until you feel

confident.

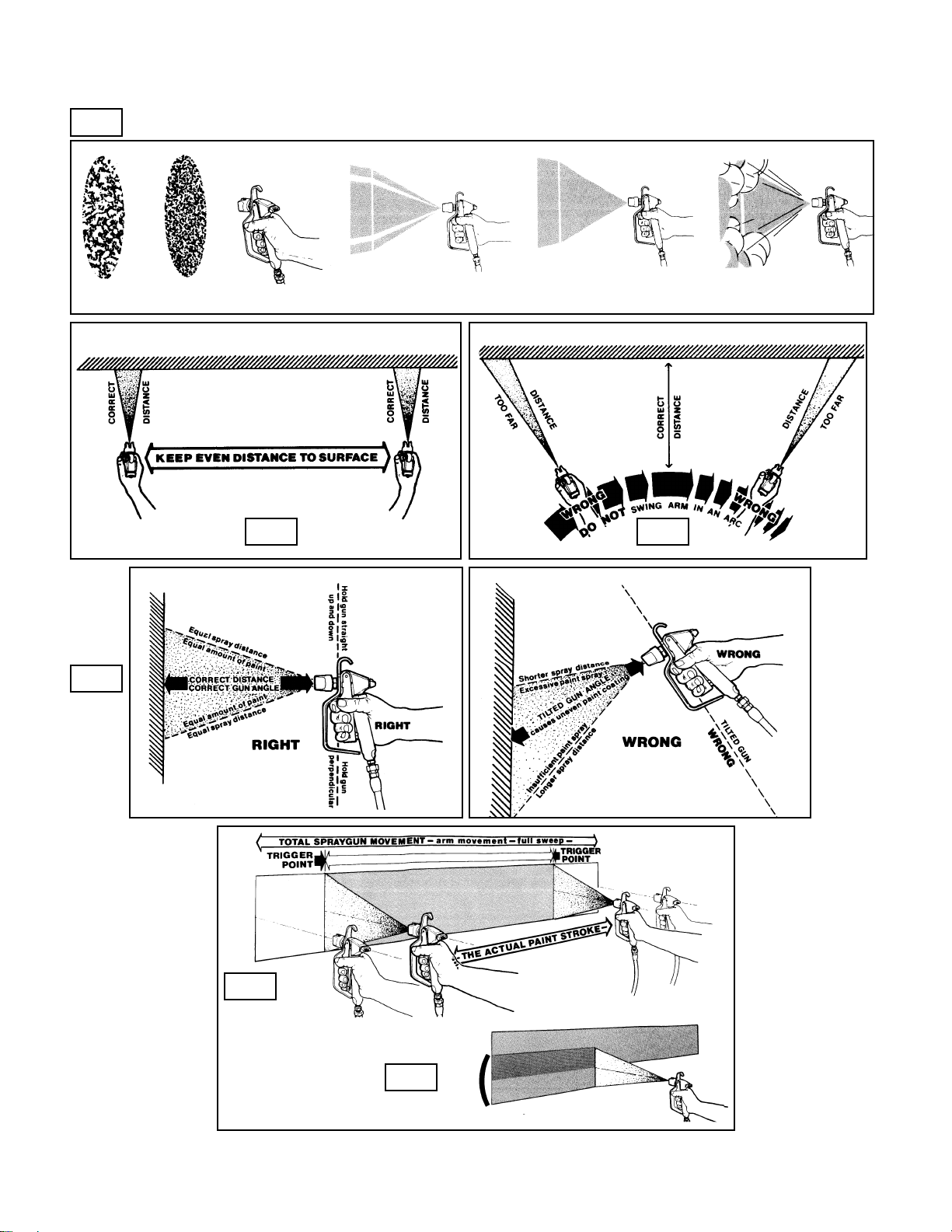

FOR EXCELLENT RESULTS, READ AND PRACTICE THESE TECHNIQUES

1. Always strain all paint throug h a H.E.R.O. strainer bag.

The most common reason for airless sprayers to malfunction is foreign matter jamming the valves or

plugging the tip. Always strain the paint before putting through the pump.

2. Always spray a t the lowest pressur e setting which will provide a unif orm spray fan. (fig . 1, page 10)

Adjust pressure control knob so that paint is completely atomized . Insufficient pressure will result in

"tailing". Too much pressure will result in excess fog and over spray, excess tip wear, and increased

sprayer wear and tear. See setting up to spray , page 5.

3. Always spray at right angles to the surface being sprayed. (fig. 2, page 10)

Angling or arcing the nozzle toward the surface will cause uneven coverage and excessive

overspray.

4. Always hold spray gun 12-15 inches from spray surface. (fig. 3, page 10)

Too close and the fan width will be reduced a nd material will be applied too he avily (runs).

Too far from the surface and you will have excessive overspray and light coverage (transparent).

5. Always move the gun parallel to the surface being sprayed, at a consistent speed.

This avoids uneven coverage (thick or thin areas).

6. Alwa ys start the spray stroke before triggering the gun and release the tri gger before completing the

stroke. (fig. 4, page 10)

This avoids heavy build up of paint at either end of the spray stroke.

7. Always lap your spray pattern by one half. (fig. 5, page 10)

This assures full coverage of the surface being painted.

AIRLESS SPRAY PAINTING

SUGGESTIONS AND TECHNIQUE

H.E.R.O. INDUSTRIES 1150GSD MANUAL - “B” VERSION

10

SPRAY TIP SELECTION

FIG.

Poor Good Tailing Good Pattern Fog, Overspray

FIG.

FIG. FIG.

FIG.

FIG.

H.E.R.O. INDUSTRIES 1150GSD MANUAL - “B” VERSION

11

Loading...

Loading...