MK715

Touch Screen Controller

General Description

The MK715 Touch Screen Controller IC provides all the

screen drive, Analog to Digital converter (ADC) and

control circuits to easily interface to 4-wire analog resistive

touch screens. It also includes a general purpose A to D

converter and a clock synthesizer.

The IC continually monitors the screen waiting for a

touch. In this mode, the supply current is typically 4µA.

When the screen is touched, the IC performs analog to

digital conversions to determine the location of the touch,

stores the X and Y locations in the registers, and issues

an interrupt. This process is repeated up to 303 times per

second until no further screen touches are detected, at

which time the low current mode is resumed.

The device has a general purpose input into the 10-bit

ADC, allowing for the measurement of other inputs such

as battery voltage. The MK715 can be powered from a

3.3V supply, and uses an inexpensive 32.768kHz watch

crystal as the input reference. An internal Phase-Lock

Loop clock synthesizer provides the high speed clock for

the ADC, and the option to have a clock output to drive

other digital chips in the system.

The tiny package is the same body size as the 14 pin

SOIC, with 25 mil spacings on the leads.

Features

Tiny 20 pin SSOP (150 mil body)

4 microamp standby current

Less than 3mA active current at 3.3V, including

screen drive

Touch pressure can be measured

One or two general purpose A to D inputs

On-chip voltage reference

32.768kHz crystal/clock input

MHz clock outputs available

Operates with four wire touch screens

Ratiometric conversion eliminates screen

calibration

Automatic wake up upon screen touch

Programmable conversion rate to a maximum of

303 points per second

3.3V or 5V supply (2.7V version available)

10 bit A/D converter

Full powerdown control

Touch screen is directly driven - no external

transistors are required

A to D Converter guaranteed monotonic

3 or 4 wire serial interface

Applications

Notebook Computers

Handheld Computers

PDAs

Touch-screen kiosks

MK715RevD020200

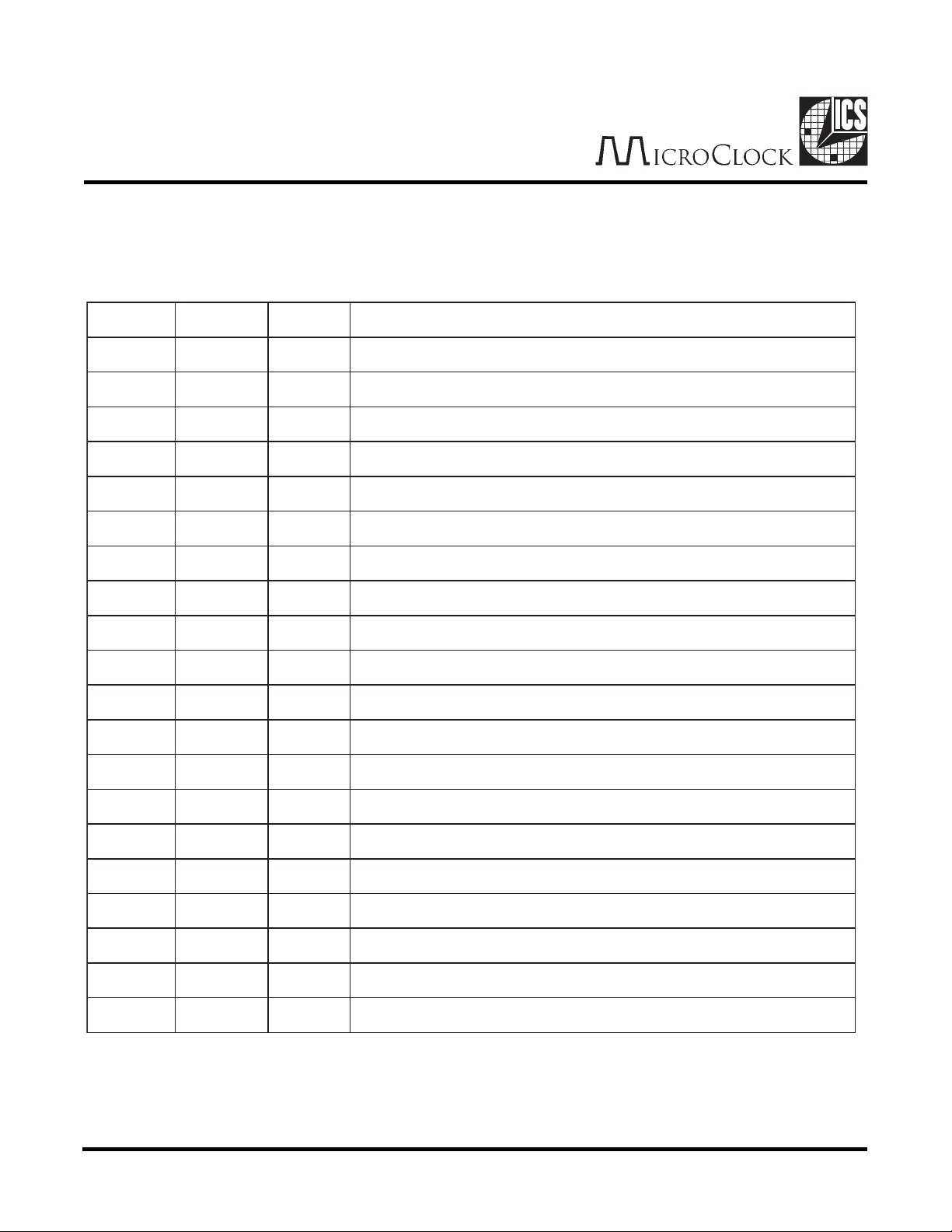

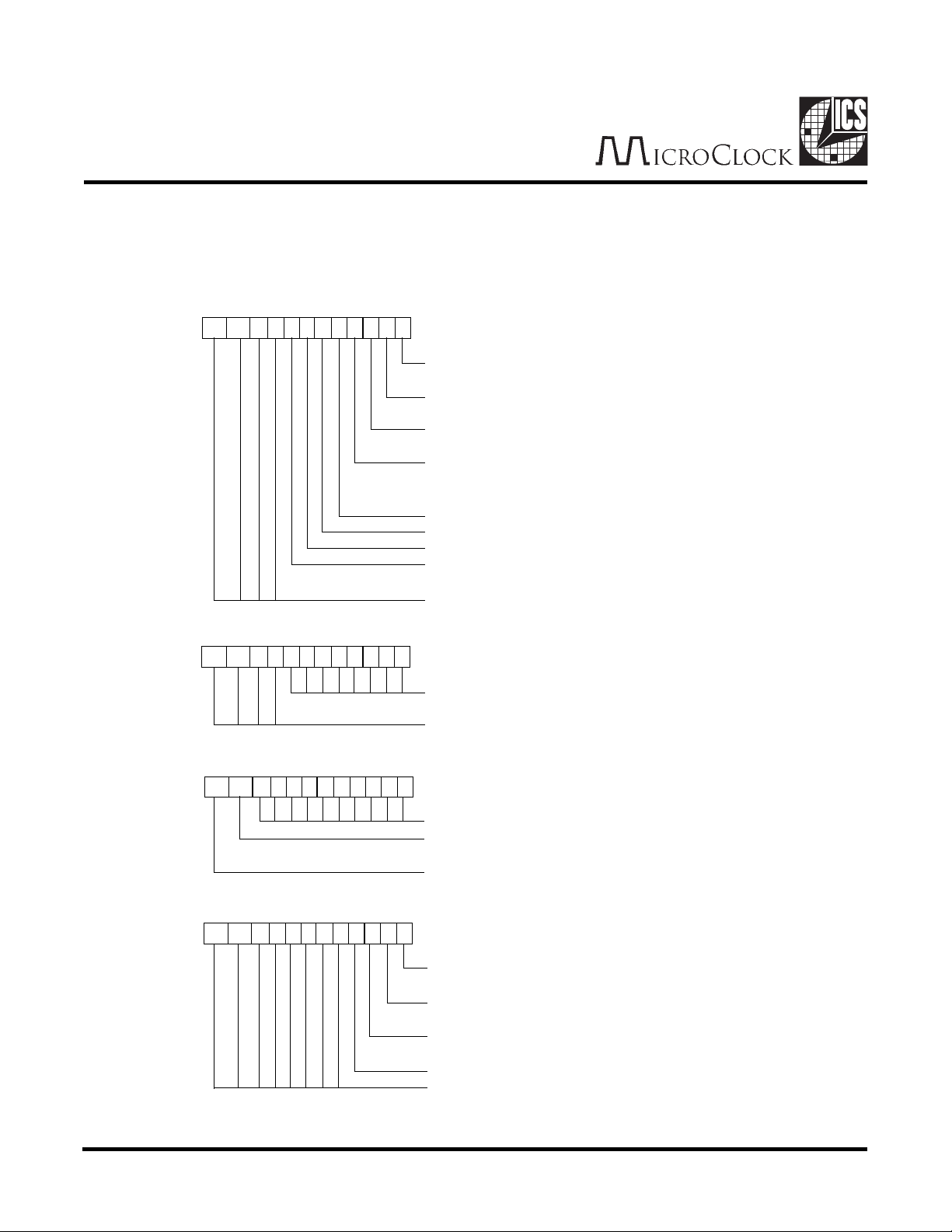

Pin Assignment

CS

SK

1

D0

2

DI

3

TOUCH#

XH

XL

YH

YL

PL

GP

4

5

6

7

8

9

10

MK715

20 pin SSOP

ICS reserves the right to make changes in the device data identified in this publication

without further notice. ICS advises its customers to obtain the latest version of all device

data to verify that any information being relied upon by the customer is current and accurate.

20

19

18

17

16

15

14

13

12

11

CLKOUT

INT

VDD

X2

X1

GND

CAP2

CAP1

CAP3

MK715

Pin Descriptions

#niPemaNepyTnoitpircseD

1KSI .kcolClaireS

2ODO .3nipottcennoc,troplaireseriw3roF.tuOataD

3IDI .2nipottcennoc,troplaireseriw3roF.nIataD

4#HCUOTO .tuokcolClanoitpO.dehcuotsineercsnehwwolseoG.langiShcuoT

5HXST.)edisthgir(neercshcuotnohgih-XottcennoC

6LXST.)edistfel(neercshcuotnowol-XottcennoC

7HYST.)pot(neercshcuotnohgih-YottcennoC

8LYST.)mottob(neercshcuotnowol-YottcennoC

9LPI .tupniCDAesopruplareneG

01PGI .tupniCDAesopruplareneG

113PAC- .dnuorgotroticapacFu10.0atcennoC

211PAC- .noitcennocretlifpooL

312PAC- .noitcennocretlifpooL

41DNGP .dnuorgottcennoC

511XI .tupnikcolcrofdnuorgro,latsyrczHk867.23ottcennoC

612XI .tupnikcolcrolatsyrczHk867.23ottcennoC

71DDVP .V3.3+roV5+ottcennoC

81TNIO .tuptuokcolclanoitpO.tpurretnilangisothgihseoG.tpurretnI

91TUOKLCO .tuptuozHMeboslanaC.zHk867.23yllacipyT.tuptuokcolC

02SCI .hgihevitcAtcelespihC

Key: I = Input, O = Output, I/O = Input and Output, P = Power, TS = Touch Screen pin.

2

MK715

Chip Overview

The MK715 communicates via a 4 pin serial port. This may be connected as either a 3 or 4 wire

serial port. The port is connected to 4 registers that control the various modes and function of the

chip.

The primary function of the MK715 is to control resistive touchscreens. There are two ways to read

screen points, both controlled by the registers.

In the first method, which is enabled by setting the ENCONR bit, the MK715 performs periodic

conversions at a rate set by the rate register. The chip monitors the touch screen in a low power

condition (about 4 mA) until the screen is touched. When a touch is detected, the chip powers up

and starts converting screen points. The TOUCH# pin goes low and INT goes high to indicate a

change in touch status. The converter outputs a Y co-ordinate, then an X co-ordinate, then a Y coordinate, and so on. The X and Y co-ordinates are stored in the same register (RESULT) and each

conversion over-writes the previous conversion. When a co-ordinate is stored, the conversion

complete bit is asserted in the STATUS register. This bit is cleared when the RESULT register is

read. The inverted state of the TOUCH# pin also appears in the STATUS register. After each coordinate conversion, INT goes high and the screen is checked to see if it is still touched. If not,

conversions stop, TOUCH# goes high, INT goes high (to indicate a change in touch status) and

the chip reverts to the low power mode.

The second method to read a screen is to set the RD1PT (read one point) bit in the CONTROL

register. The chip will perform two conversions, a Y co-ordinate followed by an X co-ordinate. The

X co-ordinate overwrites the Y co-ordinate and so the X co-ordinate must be read before this

happens. Finally, RD1PT is cleared. The conversion pair takes about 3.5 ms.

The converter may also be used to measure voltages presented on the GP or PL pins. The range

of the converter is 0 to 1.279 V and so voltages outside this range must be scaled appropriately.

Again, the RD1PT bit is set to start the conversion but first either SELGP or SELPL must be set

to select the correct input. Only one conversion is performed. The result is stored in the RESULT

register and then RD1PT is cleared. The conversion takes about 1.7ms.

The final conversion mode is used to measure touch pressure. This is controlled identically to the

second method outlined above except that either RDPRESA or RDPRESB must first be set.

The MK715 allows for several different clocks to be generated, controlled by the registers. On the

CLKOUT pin, the output is either a a 32768 Hz clock from the crystal oscillator or a MHz - frequency

clock synthesized from the PLL. Similarly, this MHz - frequency clock can appear on the INT or

TOUCH# pins instead of their usual functions. In these cases, if the MHz clock needs to run

continuously, then the ENPLL bit must be set in order to override the automatic powerdown of the PLL.

Refer to page 12 for more details.

3

MK715

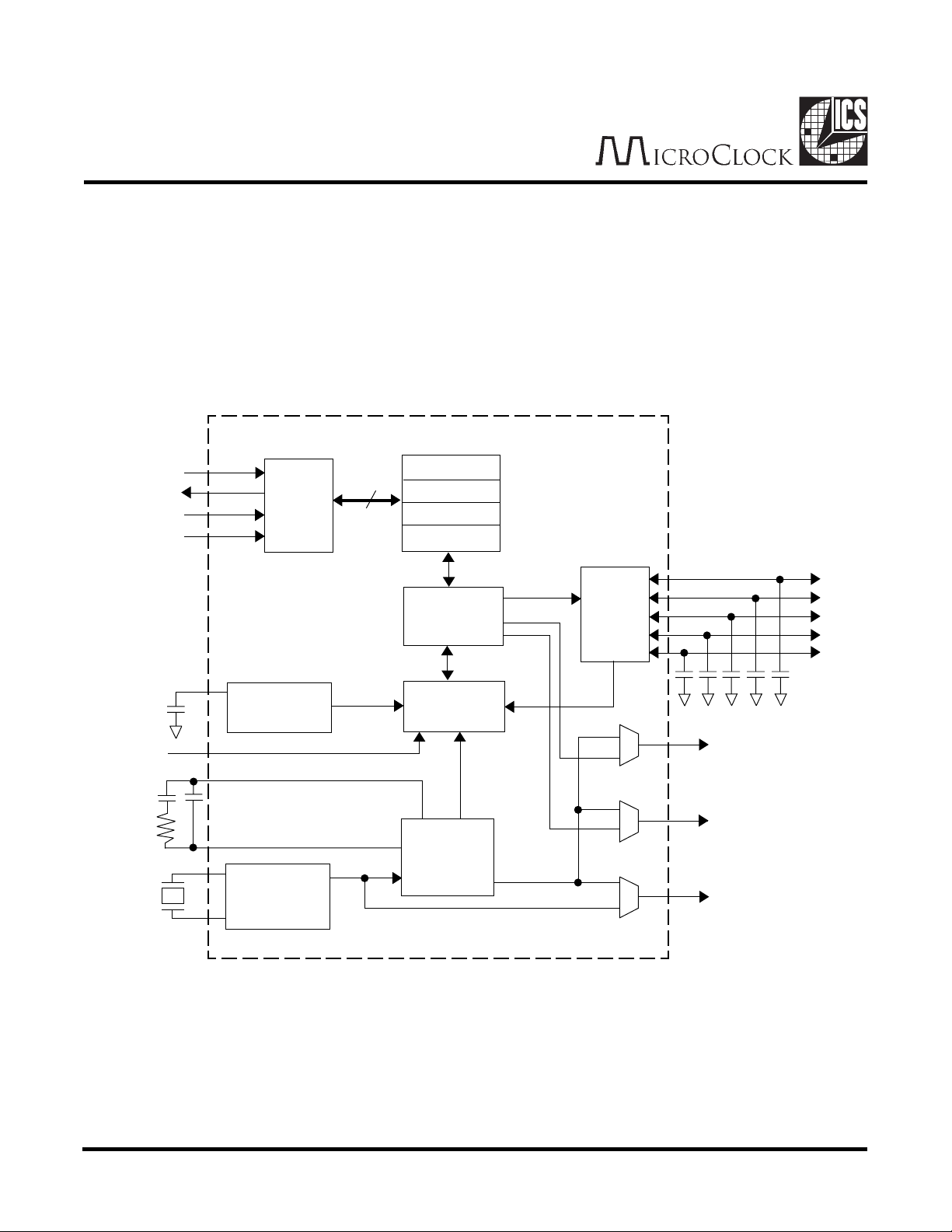

Block Diagram

Registers

CAP3

GP

CAP1

CAP2

DI

D0

CS

SK

X1

X2

Serial

Port

Voltage

Reference

32.768kHz

Oscillator

12

Status

Rate

Result

Control

Controller

10 Bit A-D

Converter

Phase

Locked

Loop

0

1

2

3

XH

Screen

Drive

1

0

1

0

1

0

INT

TOUCH#

CLKOUT

XL

YH

YL

PL

4

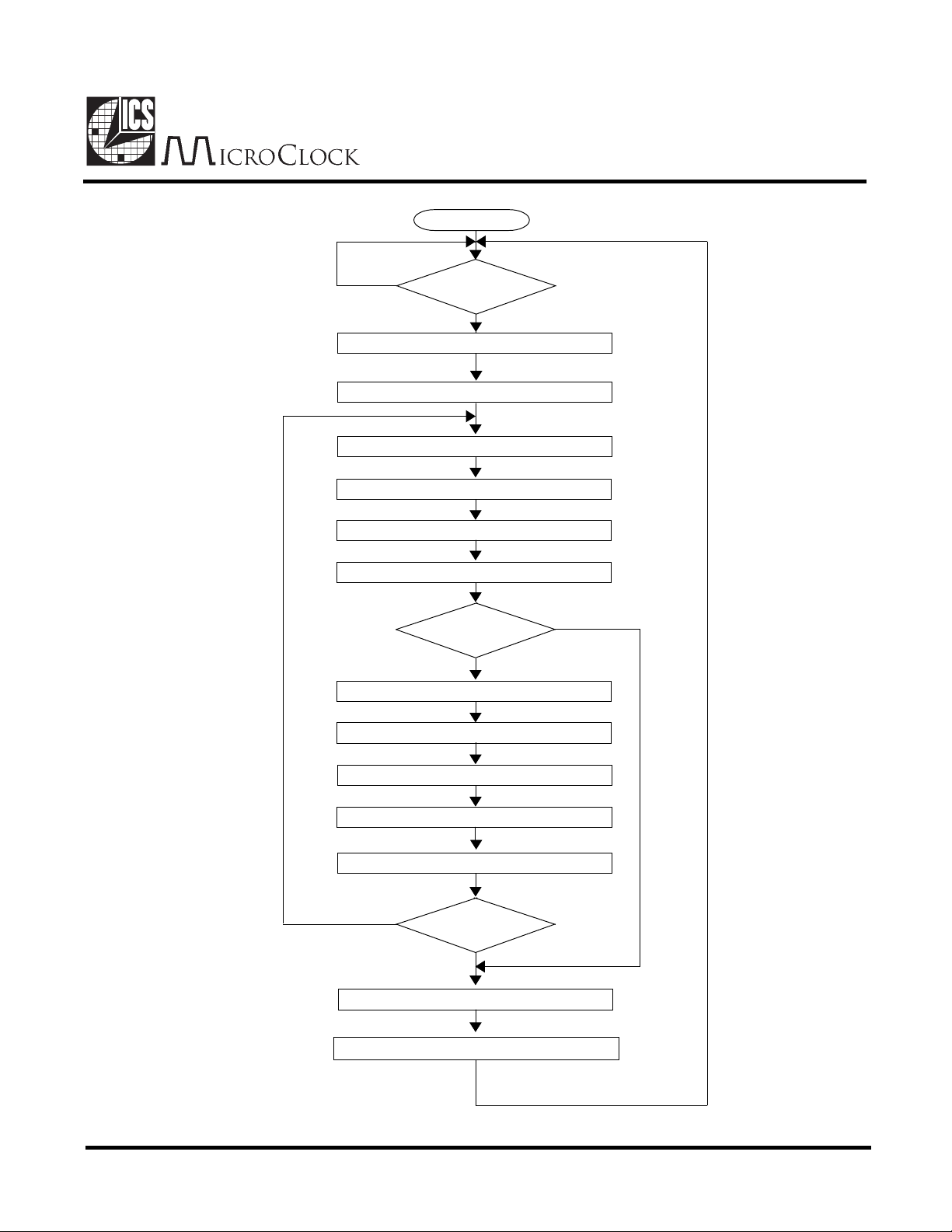

MK715

IC Operation

(Periodic Conversions Enabled)

Power ON

N

Is screen

touched?

Y

Write D6 Reg 0 to 1 and TOUCH# = 0

Issue Interrupt, power-up ADC and PLL

Convert Y co-ordinates

Store Y co-ordinates in Register 2

Write D7 register 0 to 1

Issue interrupt

Is screen

touched?

N

Y

Convert X co-ordinates

Store X co-ordinates in Register 2

Write D7 register 0 to 1

Issue Interrupt

Wait. Duration controlled by Rate Register

Y

Is screen

touched?

N

Write D6 Reg 0 to 0 and TOUCH# = 1

Issue Interrupt, power-down ADC and PLL

5

MK715

Register Description

The MK715 has four 12 bit registers. However, only 8 bits in each register can be written (D0-D7). The other 4 bits (D8D11) can never be written and are always read only.The RESULT register contains 2 levels, a read only level and a write

only level. Reading this register gives the conversion results. Writing this register changes 4 control bits.

DESCRIPTION

Read

and

Write

Read

and

Write

STATUS (ADDRESS 0)

11 10 9 8 7 6 5 34210

RATE (ADDRESS 1)

11 10 9 8 7 6 5 34210

RD1PT. Read one point. Cleared when

conversion complete.

ENCONR. Enable periodic screen conversions

at rate set by RATE register.

PD. Power Down. Chip powers down. See

CONTROL register bit 7.

ENPLL. Overrides automatic powerdown of

PLL between conversions and forces

continuous running.

SELGP. Select GP input to ADC.

SELPL. Select PL input to ADC.

Touch Status. 1 = touch.

Conversion complete. Cleared on next read

of RESULT register.

Always set to zero.

Controls frequency of screen conversions

when periodic conversions are enabled.

Always set to zero.

TYPE

R/W

R/W

R/W

R/W

R/W

R/W

RO

RO

RO

R/W

RO

Power-up

State

0

0

0

0

0

0

0

0

0

32

0

Read

Write

RESULT (ADDRESS 2)

11 10 9 8 7 6 5 34210

RESULT (ADDRESS 2)

11 10 9 8 7 6 5 34210

10-bit conversion result.

XSEL. Screen conversion status. 0 = Y

coordinate, 1 = X coordinate.

Conversion type. 0 = non-screen

conversion, 1 = screen conversion.

RDPRESA. Read pressure A. See

description of measuring touch pressure.

RDPRESB. Read pressure B. See

description of measuring touch pressure.

PLZERO. Forces PL pin to ground. Can be

used to control an external resistor divider.

Test mode. ALWAYS WRITE TO 0.

Don't Care.

6

RO

RO

RO

WO

WO

WO

WO

-

X

0

1

0

0

0

0

X

Register Description (cont.)

MK715

DESCRIPTION

Read

CONTROL (ADDRESS 3)

11 10 9 8 7 6 5 34210

and

Write

SEL0. Clock select 0. See page 11.

SEL1. Clock select 1. See page 11.

SEL2. Clock select 2. See page 11.

SEL3. Clock select 3. See page 11.

SEL4. Clock select 4. See page 11.

CLKSEL. Clock frequency select.

See page 11. 0 = 14.3196 MHz

1 = 14.7456 MHz

Set to 0.

DIS32. Determines state of 32.768 kHz

oscillator when PD asserted (STATUS register).

Always set to zero.

R/W = Read/Write, RO = Read Only, WO = Write Only

Converter Control

BSERPDRASERPDRLPLESPGLESRNOCNETP1DRDEMROFREPNOISREVNOC

000001ot0

000010

TYPE

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

RO

Power-up

State

0

0

0

0

0

0

0

0

0

ehtnosnoisrevnoc2smrofreP

XnanehtdnaYa-neercs

.deraelcnehtsiTP1PR.noisrevnoc

tessaetartasnoisrevnocelbanE

sineercsnehW.retsigerETARni

setareporetrevnoc,dehcuot

sihcuotonlitnuylsuonitnoc

yllacitamotuanehtpihC.detceted

.etatsybdnats,rewopwolotseog

000101ot0

001001ot0

010001ot0

.deraelc

100001ot0

.deraelc

PGnonoisrevnocenosmrofreP

.deraelcsiTP1DR.tupni

LPnonoisrevnocenosmrofreP

.deraelcsiTP1DR.tupni

dnaYa,snoisrevnocowtsmrofreP

erusserphcuotevigot,Xnaneht

hcuotnonoitceseeS.atad

siTP1DR.tnemerusaemerusserp

dnaYa,snoisrevnocowtsmrofreP

erusserphcuotevigot,Xnaneht

hcuotnonoitceseeS.atad

siTP1DR.tnemerusaemerusserp

The converter must be sequenced correctly - before writing RD1PT to one, the appropriate bit (e.g. SELGP) must

first be set in a previous write. Only the combinations shown above are permitted. Other combinations will give

unpredictable behavior.

7

Loading...

Loading...