ICST MK712STR, MK712RITR, MK712RTR, MK712S, MK712SI Datasheet

...

MK712

ICRO

C

LOCK

Description Features

The MK712 Touch Screen Controller IC provides

all the screen drive, A to D converter and control

circuits to easily interface to 4-wire analog resistive

touch screens.

The IC continually monitors the screen waiting

for a touch. In this mode, the supply current is

typically 0.5µA. When the screen is touched, the

IC performs analog to digital conversions to

determine the location of the touch, stores the X

and Y locations in the registers, and issues an

interrupt. This process is repeated up to 197 times

per second until no further screen touches are

detected, at which time the low current mode is

resumed.

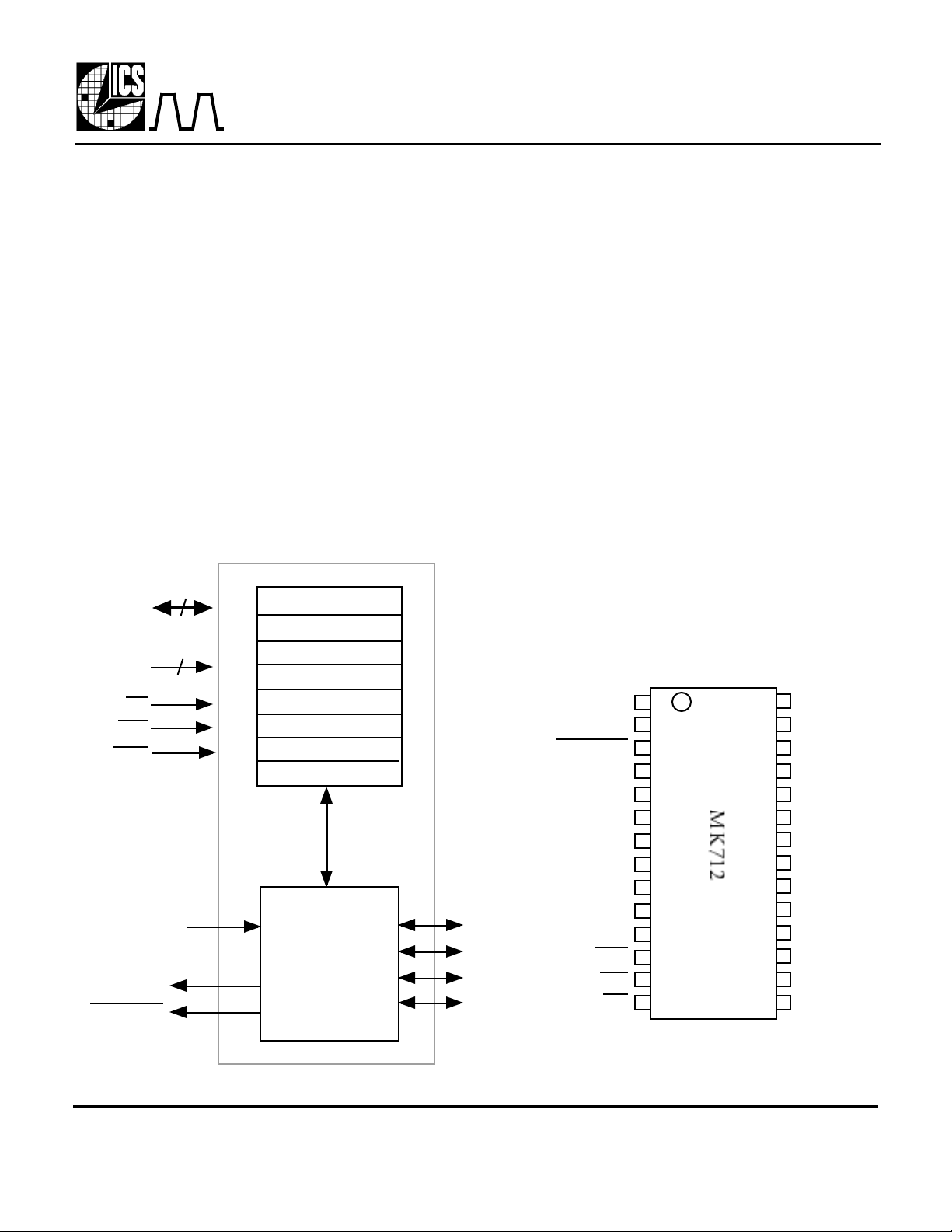

Block Diagram

8

D0-D7

3

A0-A2

CS

RD

WR

CLKIN

(14.318 MHz)

INT

TOUCH

REGISTERS

STATUS LOW

STATUS HIGH

X-LOW

X-HIGH

Y-LOW

Y-HIGH

CONTROL

RATE

12 Bit A/D,

Screen Driver

and

Controller

0

1

2

3

4

5

6

7

• Fully integrated, lowest power solution

• Low standby current of 0.5µA (typical) at 5.0V

• Active current while converting less than 10 mA

• Resolves 350 dots/inch on 10.5” display

• Maximum speed of 197 points/second

• Ratiometric conversion may eliminate screen

calibration

• Automatically wakes up and goes back to standby

• 3.3V or 5V supply

• 12 bit A/D converter

• Simplifies the writing of software for touch screens

• Extended temperature range available

• Capacitors are the only external components

required

• Touch screen is directly driven - no external

transistors are required

• Programmable conversion rate

• A to D Converter is monotonic

• Parallel interface

• See the MK715 for a serial interface

Pin Assignment

XH

XL

YH

YL

Touch Screen Controller

NC

INT

TOUCH

VDD

VDD

XH

XL

YH

YL

GND

GND

WR

RD

CS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

D0

D1

D2

D3

D4

VDD

D6

D7

CLKIN

A0

A1

A2

D5

GND

MDS 712 I 1 Revision 100899 Printed 11/16/00

Integrated Circuit Systems, Inc.•525 Race St.•San Jose•CA•95126•(408)295-9800tel•www.icst.com

MK712

ICRO

C

LOCK

Touch Screen Controller

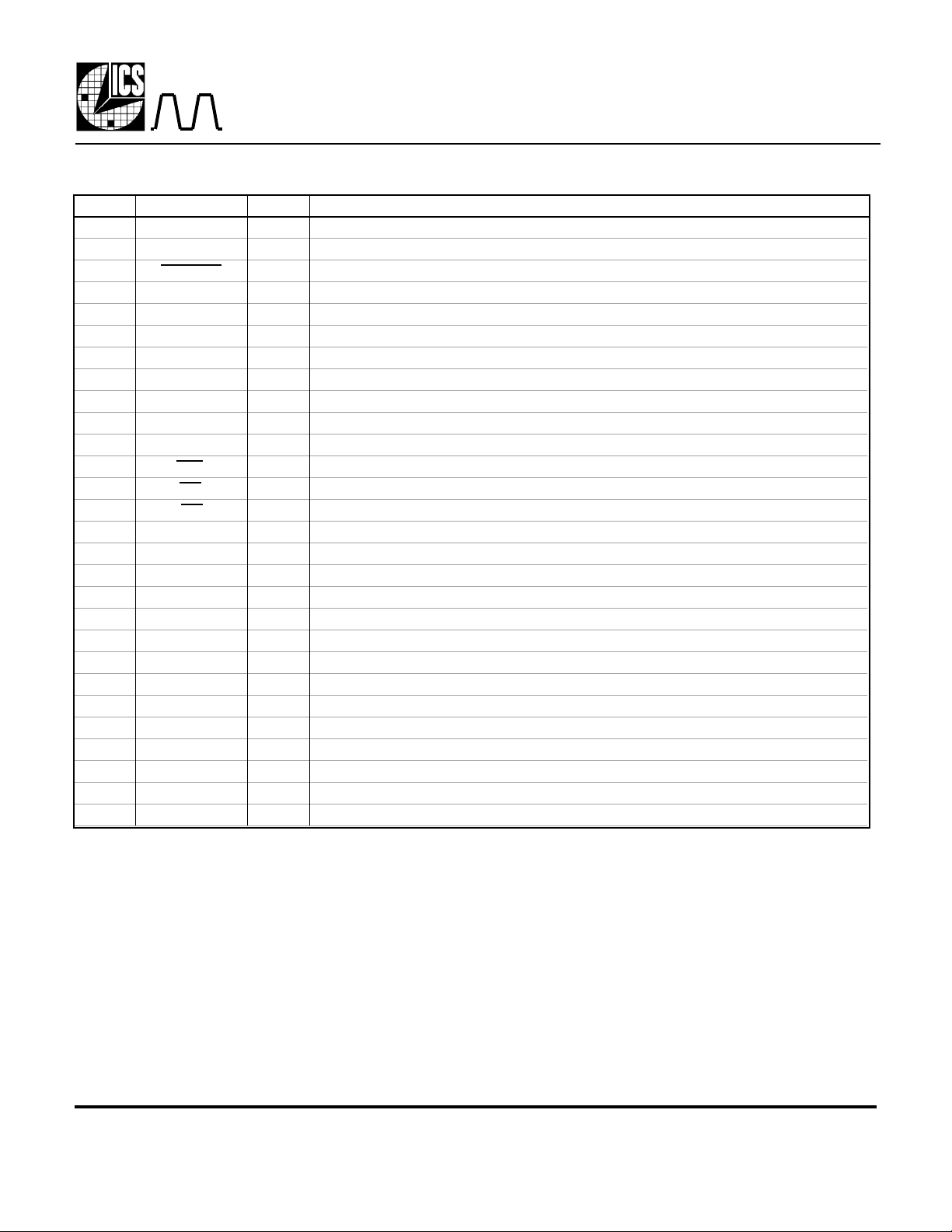

Pin Descriptions

Number Name Type Description

1 NC - No Connect

2 INT O Interrupt. Goes high to signal an interrupt. Cleared on next read.

3 TOUCH O Touch signal. Goes low when screen is touched. Goes high when not touched.

4 VDD P Connect to +5V or +3.3V.*

5 VDD P Connect to +5V or +3.3V.*

6 XH TS Connect to X-high on touch screen. (Right side)

7 XL TS Connect to X-low on touch screen. (Left side)

8 YH TS Connect to Y-high on touch screen. (Top)

9 YL TS Connect to Y-low on touch screen. (Bottom)

10 GND P Connect to ground.

11 GND P Connect to ground.

12 WR I Write enable. Active low.

13 RD I Read enable. Active low.

14 CS I Chip select. Active low.

15 A2 I Register address 2.

16 A1 I Register address 1.

17 A0 I Register address 0.

18 CLKIN I Clock input. Typically 14.3 MHz. Best if driven by a MicroClock clock synthesizer.

19 D7 I/O Data bit 7.

20 D6 I/O Data bit 6.

21 GND P Connect to ground.

22 VDD P Connect to +5V or +3.3V.*

23 D5 I/O Data bit 5.

24 D4 I/O Data bit 4.

25 D3 I/O Data bit 3.

26 D2 I/O Data bit 2.

27 D1 I/O Data bit 1.

28 D0 I/O Data bit 0.

Key: I = Input, O = Output, I/O = Input and Output, P = Power, TS = Touch Screen pin..

*Note: All VDD’s must be connected to the same voltage.

Interrupts

Interrupts are controlled by register 6 (see Register Description). The INT pin (pin 2) goes high to

signal an interrupt. Interrupts are then cleared by reading any register. However, if the MK712 is in the

process of generating an interrupt during a read cycle, then the interrupt is not cleared and INT will stay

high. This internal process may take 100ns, and so to guarantee that the interrupt is cleared, two

successive read cycles may be necessary.

MDS 712 I 2 Revision 100899 Printed 11/16/00

Integrated Circuit Systems, Inc.•525 Race St.•San Jose•CA•95126•(408)295-9800tel•www.icst.com

MK712

ICRO

C

LOCK

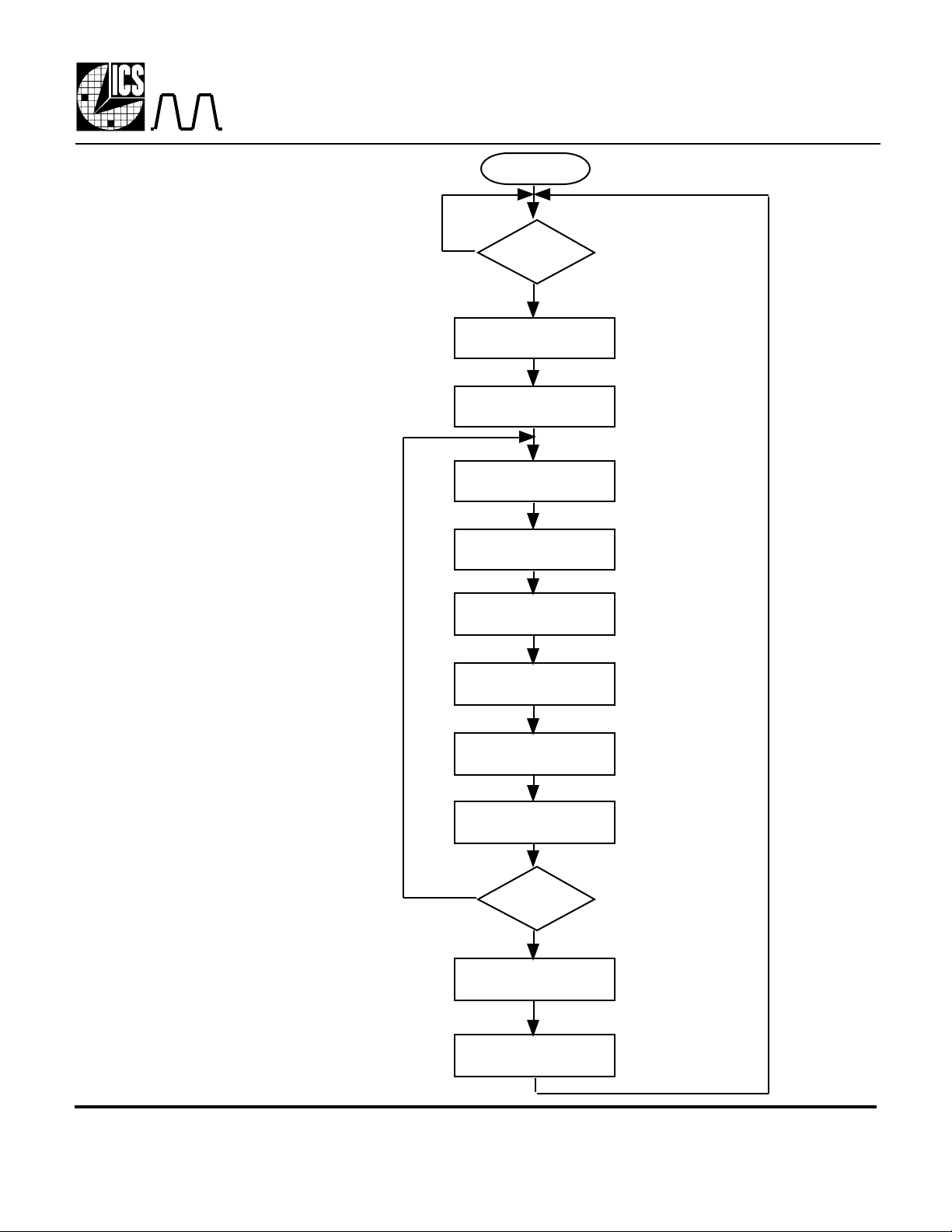

IC Operation

(Periodic Conversions Enabled)

Power ON

Is

Screen

N

Touched?

Y

Write D4, D5 Reg 0 And

D2, D3 Reg 1 To 1

Issue Interrupt

(If Enabled)

Convert

Y Co-Ordinates

Store Y Co-Ordinates In

Reg 4 and Reg 5

Touch Screen Controller

Convert

X Co-Ordinates

Store X Co-Ordinates in

Reg 2 and Reg 3

Write D7 Reg 0 To 1

Issue Interrupt

(If Enabled)

Is

Screen

Y

Touched?

N

Write D4, D5 Reg 0 And

D2, D3 Reg 1 To 0

Issue Interrupt

(if Enabled)

MDS 712 I 3 Revision 100899 Printed 11/16/00

Integrated Circuit Systems, Inc.•525 Race St.•San Jose•CA•95126•(408)295-9800tel•www.icst.com

MK712

ICRO

C

LOCK

Touch Screen Controller

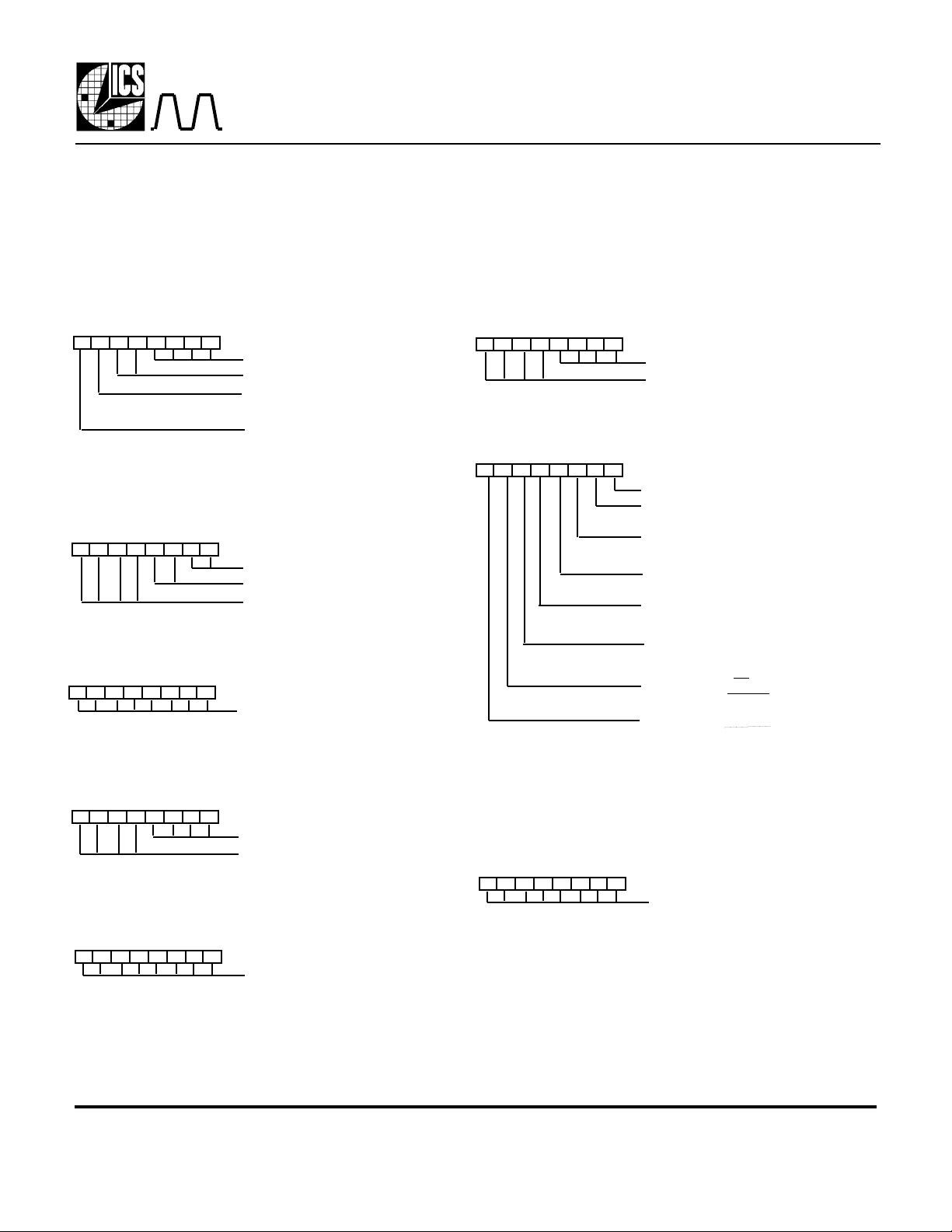

Register Description

The MK712 register set is designed to be compatible with the Gazelle pen digitizer registers allowing a

software driver for the Gazelle digitizer to be used with the MicroClock MK712. The eight 8-bit registers

are defined below:

STATUS LOW (0 READ)

7 1 03 25 46

Always zero

1 = touch

Always zero

1 = conversion complete,

cleared on Y-HIGH read

NOTE: When the screen is touched bits 4 and 5,

register 0, and bits 2 and 3 of register 1 are all set to one.

STATUS HIGH (1 READ)

7 1 03 25 46

Always zero

1 = touch

Always zero

X-LOW (2 READ)

7 1 03 25 46

Low order bits of X co-ordinate

X-HIGH (3 READ)

7 1 03 25 46

High order bits of X co-ordinate

Always zero

Y-LOW (4 READ)

7 1 03 25 46

Low order bits of Y co-ordinate

Y-HIGH (5 READ)

7 1 03 25 46

High order bits of Y co-ordinate

Always zero

CONTROL (6 R/W)

7 1 03 25 46

1 = enable interrupts

1 = interrupt on conversion

complete ( if bit 0 = 1)

1 = interrupt on change in

touch status (if bit 0 = 1)

1 = interrupt on change in

touch status (if bit 0 = 1)

1 = enable periodic conversions at

rate indicated by RATE register

1 = read one point. Cleared when

conversion complete. Only functions

when bit 4 = 0

0 = powerdown (PD). Conversions,

interrupts and TOUCH output disabled

1 = powerdown (PD). Conversions,

interrupts and TOUCH output

disabled.

NOTE: Bits 2 or 3 and bits 6 or 7 are logically OR’d. For

example writing bit 2 or bit 3 to a one will enable interrupts

on change in touch status.

RATE (7 R/W)

7 1 03 25 46

Count controls frequency of

conversion when periodic

conversions are enabled. See

table on page 5.

MDS 712 I 4 Revision 100899 Printed 11/16/00

Integrated Circuit Systems, Inc.•525 Race St.•San Jose•CA•95126•(408)295-9800tel•www.icst.com

MK712

ICRO

C

LOCK

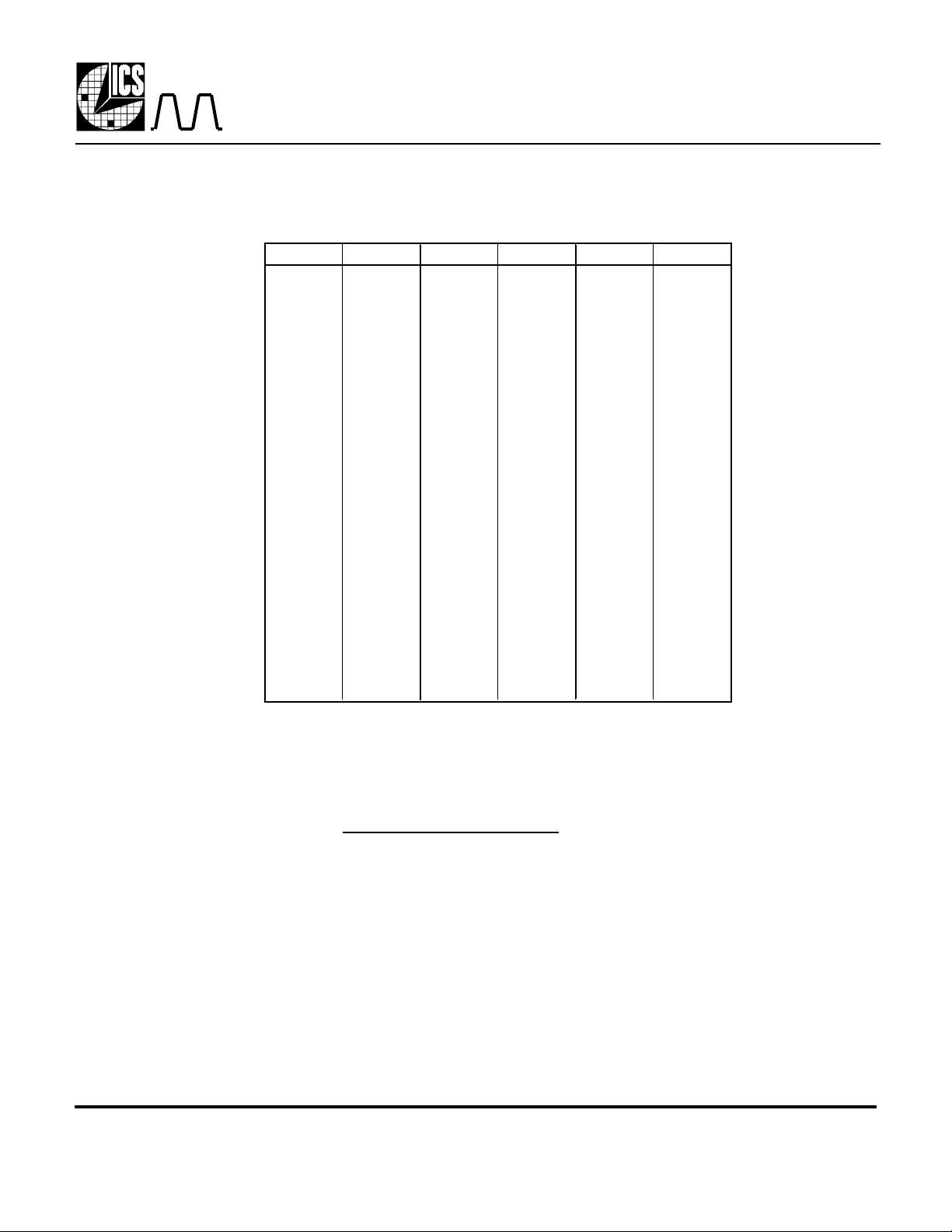

Rate Register (Register 7) Programming

Count P.P.S. Count P.P.S. Count P.P.S.

0 to 8

10 187 30 90 110 29

11 177 31 88 115 28

12 169 32 86 120 27

13 161 33 84 125 26

14 154 34 82 130 25

15 147 35 80 135 24

16 141 40 72 140 24

17 136 45 65 145 23

18 131 50 60 150 22

19 126 55 55 155 21

20 122 60 51 165 20

21 118 65 47 175 19

22 114 70 44 185 18

23 110 75 42 195 17

24 107 80 39 205 16

25 104 85 37 225 15

26 101 90 35 235 14

27 98 95 34 255 13

Not Permitted

9 197 29 93 105 31

Touch Screen Controller

28 95 100 32

P.P.S. = Points Per Second. With a 14.318 MHz clock.

Calculating Points Per Second

The formula for determining P.P.S. is:

fin

P.P.S. =

35716 + (4096 x COUNT)

Where fin is the frequency

of the CLKIN input.

Power-On Reset

On application of power, an internal reset is generated that clears all bits in registers 0, 1, and 6. Register 7 is

set to 32 giving a rate of 86 PPS. Note that clearing register 6 puts the IC into the power down condition.

Initializing the MK712

The interrupt on the MK712 can only be cleared by reading a register or by writing register 6 to the

power down condition. After a fault condition, initialize the MK712 by writing register 6 to zero and

then writing register 6 to the desired value. This will always clear pending interrupts.

MDS 712 I 5 Revision 100899 Printed 11/16/00

Integrated Circuit Systems, Inc.•525 Race St.•San Jose•CA•95126•(408)295-9800tel•www.icst.com

Loading...

Loading...