Page 1

查询ICS8431-21供应商

Integrated

Circuit

Systems, Inc.

GENERAL DESCRIPTION

ICS

HiPerClockS™

providing an output frequency range of 62.5MHz to 350MHz.

The output frequency can be programmed using the parallel interface, M0 through M8 to the configuration logic, and the output

divider control pin, DIV_SEL. Spread spectrum clocking is programmed via the control inputs SSC_CTL0 and SSC_CTL1.

Programmable features of the ICS8431-21 support four operational modes. The four modes are spread spectrum clocking (SSC), non-spread spectrum clock and two test modes

which are controlled by the SSC_CTL[1:0] pins. Unlike other

synthesizers, the ICS8431-21 can immediately change

spread-spectrum operation without having to reset the device.

In SSC mode, the output clock is modulated in order to achieve

a reduction in EMI. In one of the PLL bypass test modes, the

PLL is disconnected as the source to the differential output

allowing an external source to be connected to the TEST_I/O

pin. This is useful for in-circuit testing and allows the differential output to be driven at a lower frequency throughout the

system clock tree. In the other PLL bypass mode, the oscillator divider is used as the source to both the M and the Fout

divide by 2. This is useful for characterizing the oscillator and

internal dividers.

The ICS8431-21 is a general purpose clock frequency synthesizer for IA64/32 application and a

member of the HiPerClockS™ family of High Performance Clock Solutions from ICS. The VCO operates at a frequency range of 250MHz to 700MHz

ICS8431-21

350MHZ, LOW JITTER, CRYSTAL OSCILLATOR-

TO-3.3V LVPECL FREQUENCY SYNTHESIZER

FEATURES

• Fully integrated PLL

• Differential 3.3V LVPECL output

• Crystal oscillator interface

• Output frequency range: 62.5MHz to 350MHz

• Crystal input frequency range: 14MHz to 25MHz

• VCO range: 250MHz to 700MHz

• Programmable PLL loop divider for generating a variety

of output frequencies

• Spread Spectrum Clocking (SSC) fixed at 1/2% modulation

for environments requiring ultra low EMI

• PLL bypass modes supporting in-circuit testing and on-chip

functional block characterization

• Cycle-to-cycle jitter: 30ps (maximum)

• 3.3V supply voltage

• 0°C to 85°C ambient operating temperature

• Replaces ICS8431-01 and ICS8431-11

• Lead-Free package fully RoHS compliant

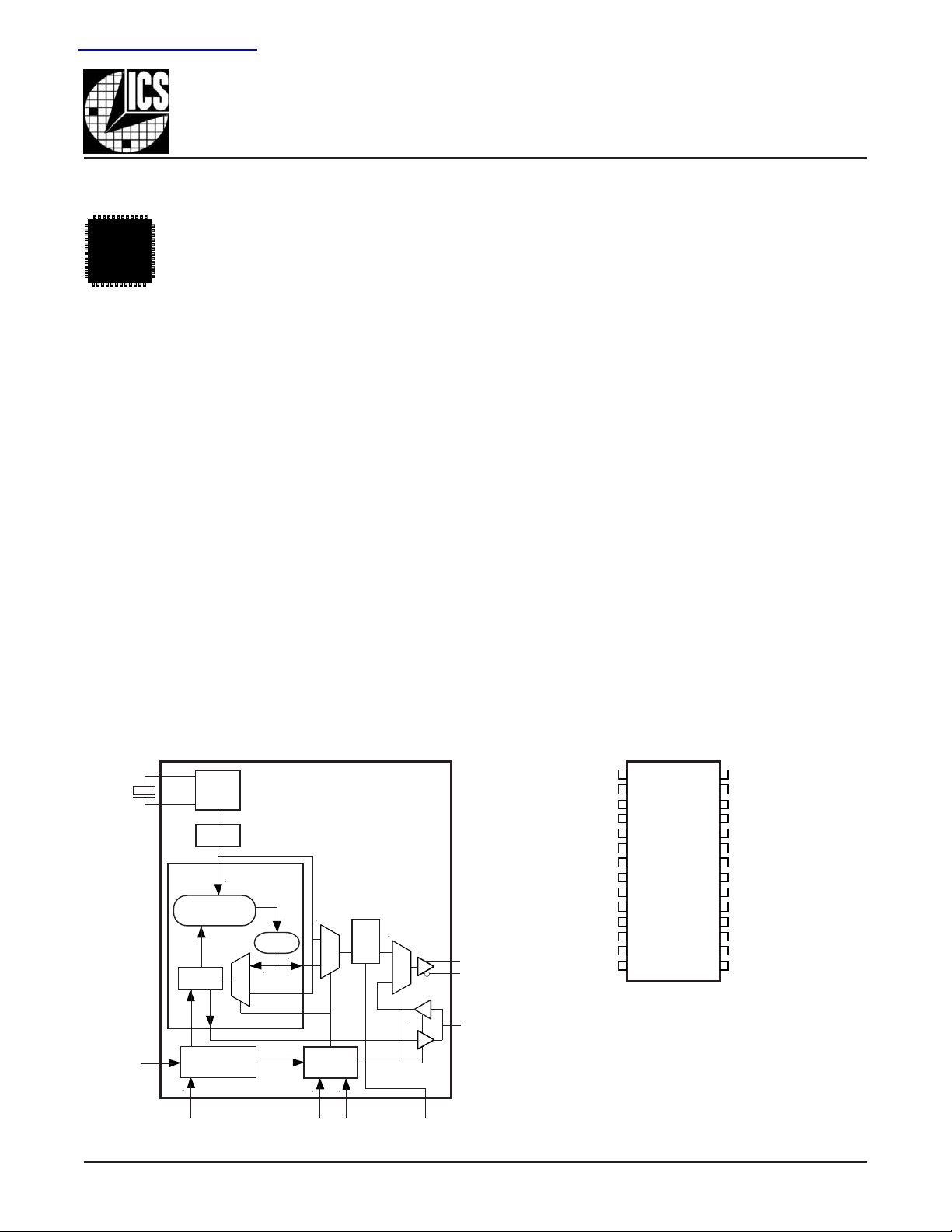

BLOCK DIAGRAM PIN ASSIGNMENT

nP_LOAD

M0

V

M1

M2

M3

M4

M5

M6

M7

M8

V

1

2

3

4

5

6

7

8

9

10

11

12

EE

13

14

CC

XTAL_IN

XTAL_OUT

OSC

÷ 16

PHASE

DETECTOR

÷ M

PLL

VCO

÷2

÷4

FOUT

nFOUT

SSC_CTL0

SSC_CTL1

TEST_I/O

ICS8431-21

TEST_I/O

M0:M8

8431AM-21 www.icst.com/products/hiperclocks.html REV. A APRIL 27, 2005

Configuration

Logic

nP_LOAD

SSC_CTL0

SSC

Control

Logic

SSC_CTL1

DIV_SEL

1

7.5mm x 18.05mm x 2.25mm package body

28-Lead SOIC

M Package

Top View

28

27

26

25

24

23

22

21

20

19

18

17

16

15

V

CC

XTAL_IN

XTAL_OUT

nc

nc

V

CCA

VEE

MR

DIV_SEL

V

CCO

FOUT

nFOUT

V

EE

Page 2

Integrated

Circuit

Systems, Inc.

FUNCTIONAL DESCRIPTION

The ICS8431-21 features a fully integrated PLL and therefore

requires no external components for setting the loop bandwidth.

The output of the oscillator is divided by 16 prior to the phase

detector. With a 16MHz crystal this provides a 1MHz reference

frequency. The VCO of the PLL operates over a range of 250MHz

to 700MHz. The output of the M divider is also applied to the phase

detector.

ICS8431-21

350MHZ, LOW JITTER, CRYSTAL OSCILLATOR-

TO-3.3V LVPECL FREQUENCY SYNTHESIZER

The PLL loop divider or M divider is programmed by using

inputs M0 through M8. While the nP_LOAD input is held LOW,

the data present at M0:M8 is transparent to the M divider. On

the LOW-to-HIGH transition of nP_LOAD, the M0:M8 data is

latched into the M divider and any further changes at the

M0:M8 inputs will not be seen by the M divider until the next

LOW transition on nP_LOAD.

The phase detector and the M divider force the VCO output

frequency to be M times the reference frequency by adjusting

the VCO control voltage. Note that for some values of M (either too high or too low), the PLL will not achieve lock. The

output of the VCO is scaled by a divider prior to being sent to

the LVPECL output buffer. The divider provides a 50% output

duty cycle.

The programmable features of the ICS8431-21 support four

output operational modes and a programmable M divider and

output divider. The four output operational modes are spread

spectrum clocking (SSC), non-spread spectrum clock and

two test modes and are controlled by the SSC_CTL[1:0] pins.

The relationship between the VCO frequency, the crystal frequency and the M divider is defined as follows:

fxtal

fVCO =

The M value and the required values of M0:M8 for programming

FOUT

Table 3B

fVCO

=

the VCO are shown in

Function Table. The frequency out is defined as follows:

For the ICS8431-21, the output divider may be set to either ÷2

or ÷4 by the DIV_SEL pin. For an input of 16 MHz, valid

M values for which the PLL will achieve lock are defined as:

250 ≤ M ≤ 511.

x

M

16

, Programmable VCO Frequency

fxtal x M

=

N

16 x N

8431AM-21 www.icst.com/products/hiperclocks.html REV. A APRIL 27, 2005

2

Page 3

Integrated

Circuit

Systems, Inc.

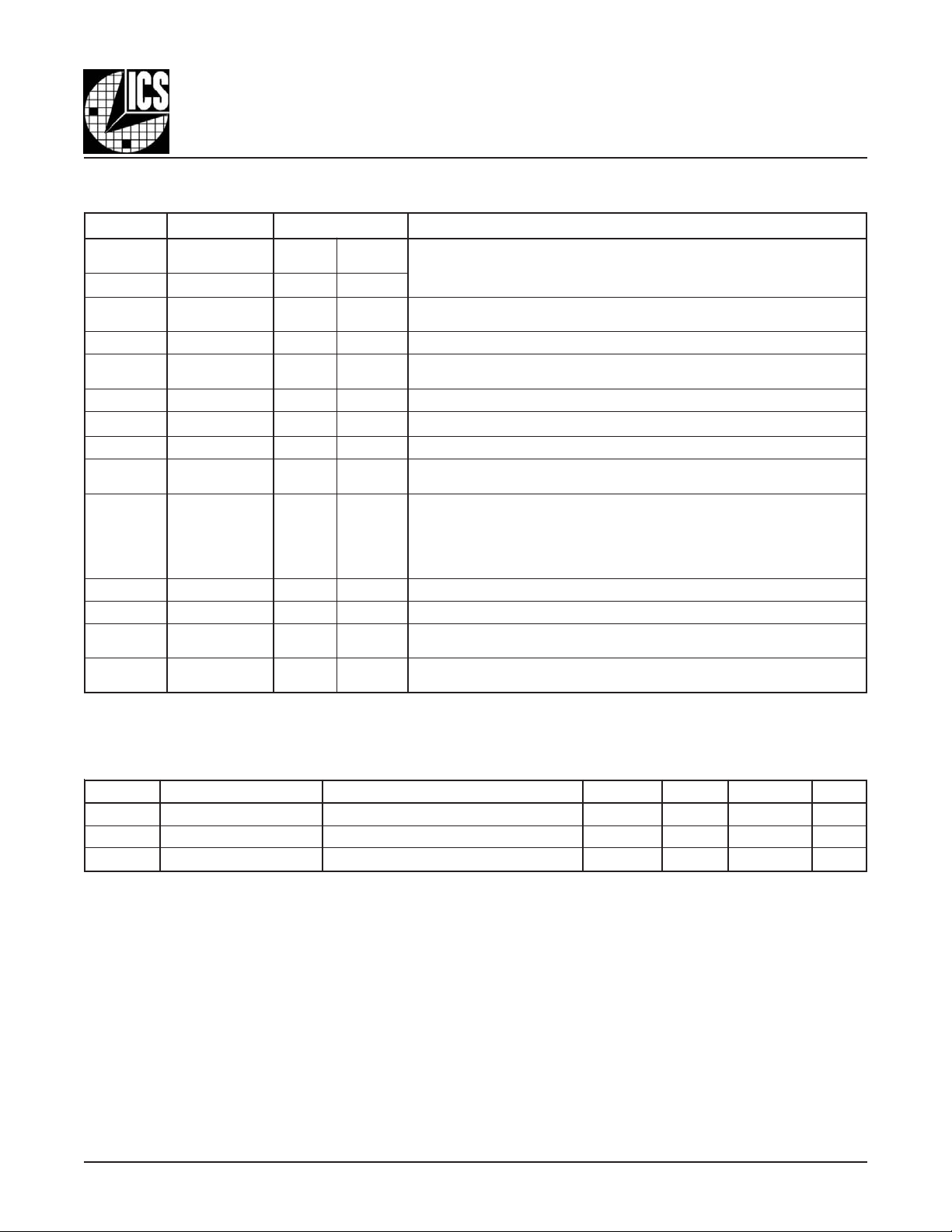

TABLE 1. PIN DESCRIPTIONS

rebmuNemaNepyTnoitpircseD

,4,3,2,1

7,6,5

9,88M-7MtupnIpulluP

11,01

12,51,21V

31O/ITSET

72,41V

71,61TUOF,TUOFntuptuO .slevelecafretniLCEPVLV3.3.rezisehtnysehtrofstuptuolaitnereffiD

8

1V

91LES_VIDtupnInwodlluP

02RMtupnInwodlluP

22V

42,32cndesunU.tcennocoN

62,52

82DAOL_PntupnInwodlluP

pulluP

:ETON

6M-0MtupnInwodlluP

,0LTCCSS

1LTCCSS

EE

CC

OCC

ACC

,TUO_LATX

NI_LATX

dna

ICS8431-21

350MHZ, LOW JITTER, CRYSTAL OSCILLATOR-

TO-3.3V LVPECL FREQUENCY SYNTHESIZER

noitisnartHGIH-ot-WOLnodehctalataD.stupniredividM

slevelecafretnisnipLTTVL/SOMCVL.tupniDAOL_Pnfo

.

tupnIpulluP.sleveleca

rewoPVllatcennoC.snipylppusevitageN

/tupnI

tuptuO

rewoP.nipylppuseroC

rewoP.nipylppustuptuO

MCVL

.slevelecafretniLTTVL/SO

rewoP.nipylppusgolanA

tupnI

csolatsyrC

.tuptuoehtsiTUO_LATX

nwodlluP

fretniSOMCVL/LTTVL.sniplortnocCCS

EE

.dnuorgdraobotsnip

.elbaTnoitcnuFA3elbaTnidenifedsademmargorP

.TUOFrofeulavedividtuptuoehtsenimreteD

erasredividlanretnieht,HGIHcigolnehW.teseRretsaMhgiHevitcA

otTUOFtuptuoeurtehtgnisuacteser

tuptuodetrevniehtdnawolog

ehtdnasredividlanretnieht,WOLcigolnehW.hgihogotTUOFn

onseodRMfonoitressA.delbaneerastuptuo

TdnaMdedaoltceffet

.slevelecafretniLTTVL/SOMCVL.seulav

.tupniehtsiNI_LATX.ecafretnirotalli

0M:8MtatneserpatadnehwsenimreteD.tupnidaollellaraP

levelecafretniSOMCVL/LTTVL.redividMotnidedaolsi

.s

.seulavlacipytrof,scitsiretcarahCniP,2elbaTeeS.srotsisertupnilanretniotrefer

TABLE 2. PIN CHARACTERISTICS

lobmySretemaraPsnoitidnoCtseTmuminiMlacipyTmumixaMstinU

C

NI

R

PULLUP

R

8431AM-21 www.icst.com/products/hiperclocks.html REV. A APRIL 27, 2005

NWODLLUP

ecnaticapaCniPtupnI 4Fp

rotsiseRpulluPtupnI 15kΩ

rotsiseRnwodlluPtupnI 15kΩ

3

Page 4

Integrated

Circuit

Systems, Inc.

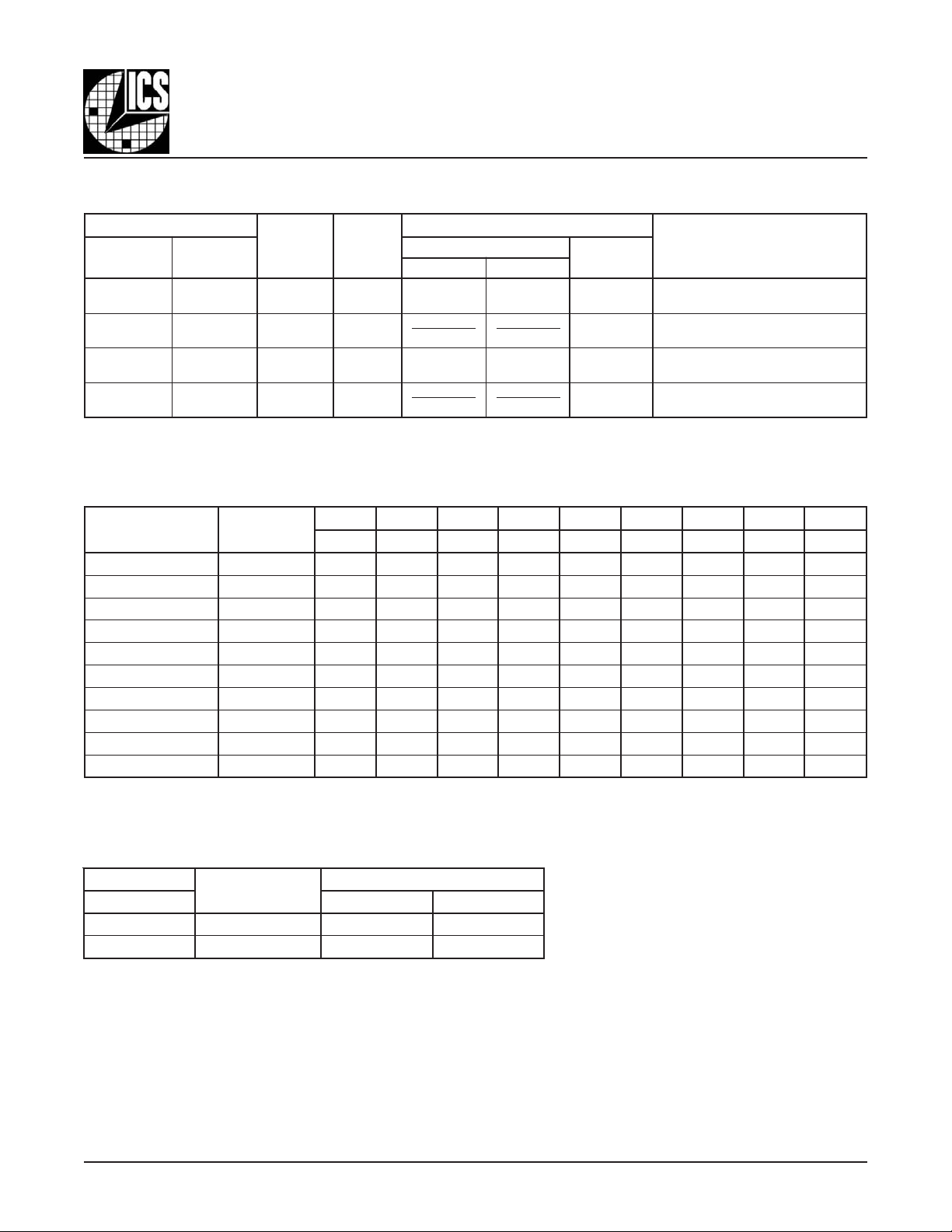

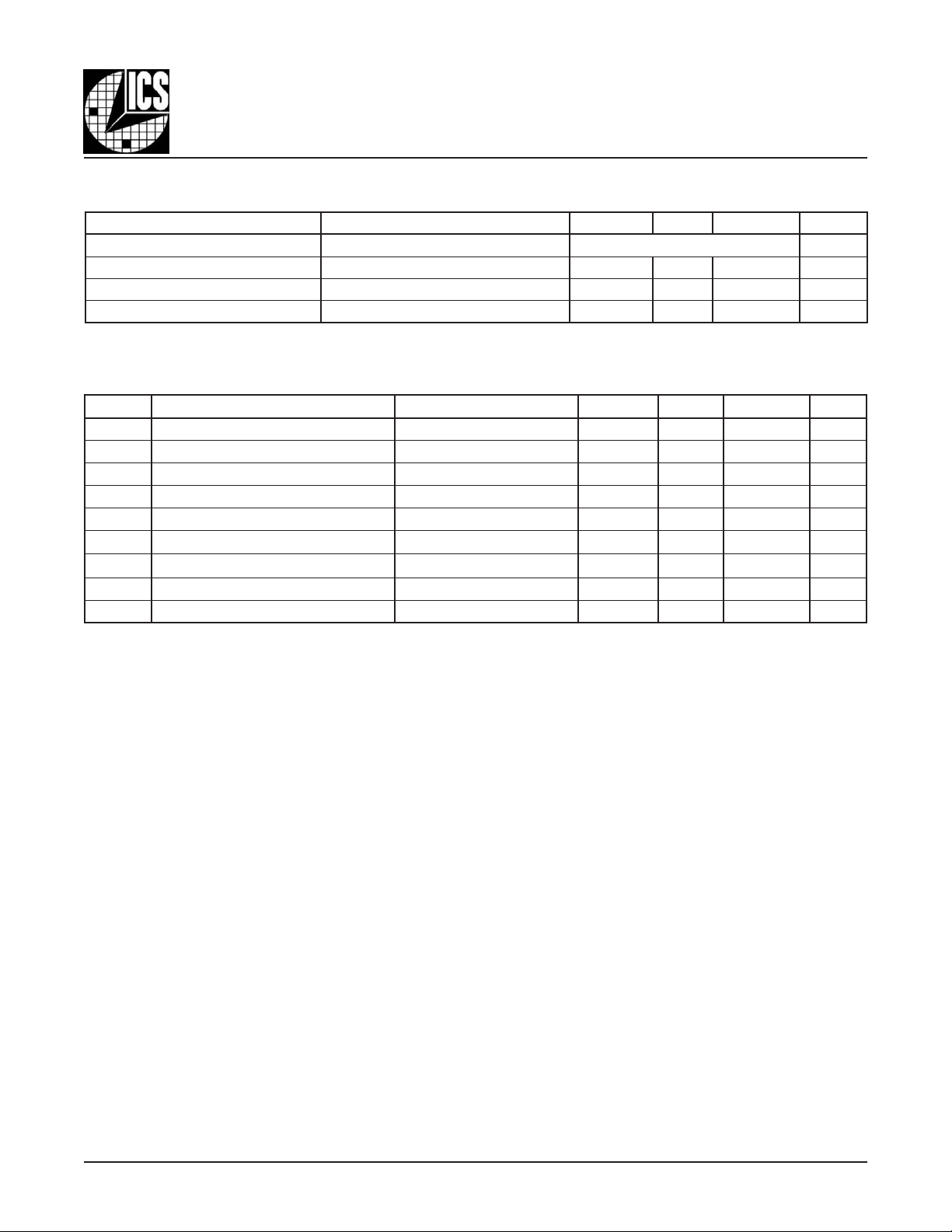

TABLE 3A. SSC CONTROL INPUT FUNCTION TABLE

ICS8431-21

350MHZ, LOW JITTER, CRYSTAL OSCILLATOR-

TO-3.3V LVPECL FREQUENCY SYNTHESIZER

stupnI

1LTC_CSS0LTC_CSS

00 lanretn

01LLPdelbanE

10 lanretxEdelbasiDklCtseTklCtseTtupnI

11 LLPdelbasiD

U:1ETON

O/I_TSET

ecruoS

IdelbasiDLATXf ÷ 23LATXf ÷ 46

CSS

0LES_VID1LES_VID

MxLATXf

23

MxLATXf

23

.noitaziretcarahcdnagubedesuohnirofdes

TUOFn,TUOF

ATXf

46

46

TABLE 3B. PROGRAMMABLE VCO FREQUENCY FUNCTION TABLE (NOTE 1)

ycneuqerFOCV

)zHM(

052052 0 11111010

152152 0 11111011

252252 0 11111100

352352 0 11111101

• • •••••••••

• • •••••••••

805805 111111100

905905 111111101

015015 111111110

115115 111111111

sA:1ETON

tnuoCM

6528214623618421

8M7M6M5M4M3M2M1M0M

.latsyrczHM61asemus

stuptuO

O/I_TSET

LATXf ÷ 61

÷ M

MxL

MxLATXf

Z-iH

( ≤ klCtseT ≤ )zHM002

Z-iHnoitaludoMCSSoN

zHM1

sedoMlanoitarepO

NdnaM,rotallicso;ssapybLLP

1ETON.edomtsetsredivid

;CSStluafeD

tnecreP½=rotcaFnoitaludoM

;1ETON,edoMssapyBLLP

TABLE 3C. FUNCTION TABLE

stupnI

LES_VIDmuminiMmumixaM

02 521053

14 5.26571

8431AM-21 www.icst.com/products/hiperclocks.html REV. A APRIL 27, 2005

eulaVrediviDN

)zHM(ycneuqerFtuptuO

4

Page 5

Integrated

Circuit

Systems, Inc.

ABSOLUTE MAXIMUM RATINGS

ICS8431-21

350MHZ, LOW JITTER, CRYSTAL OSCILLATOR-

TO-3.3V LVPECL FREQUENCY SYNTHESIZER

Supply Voltage, V

Inputs, V

I

Outputs, I

Continuous Current 50mA

CC

O

4.6V

-0.5V to V

+ 0.5V

CC

Surge Current 100mA

Package Thermal Impedance, θ

Storage Temperature, T

STG

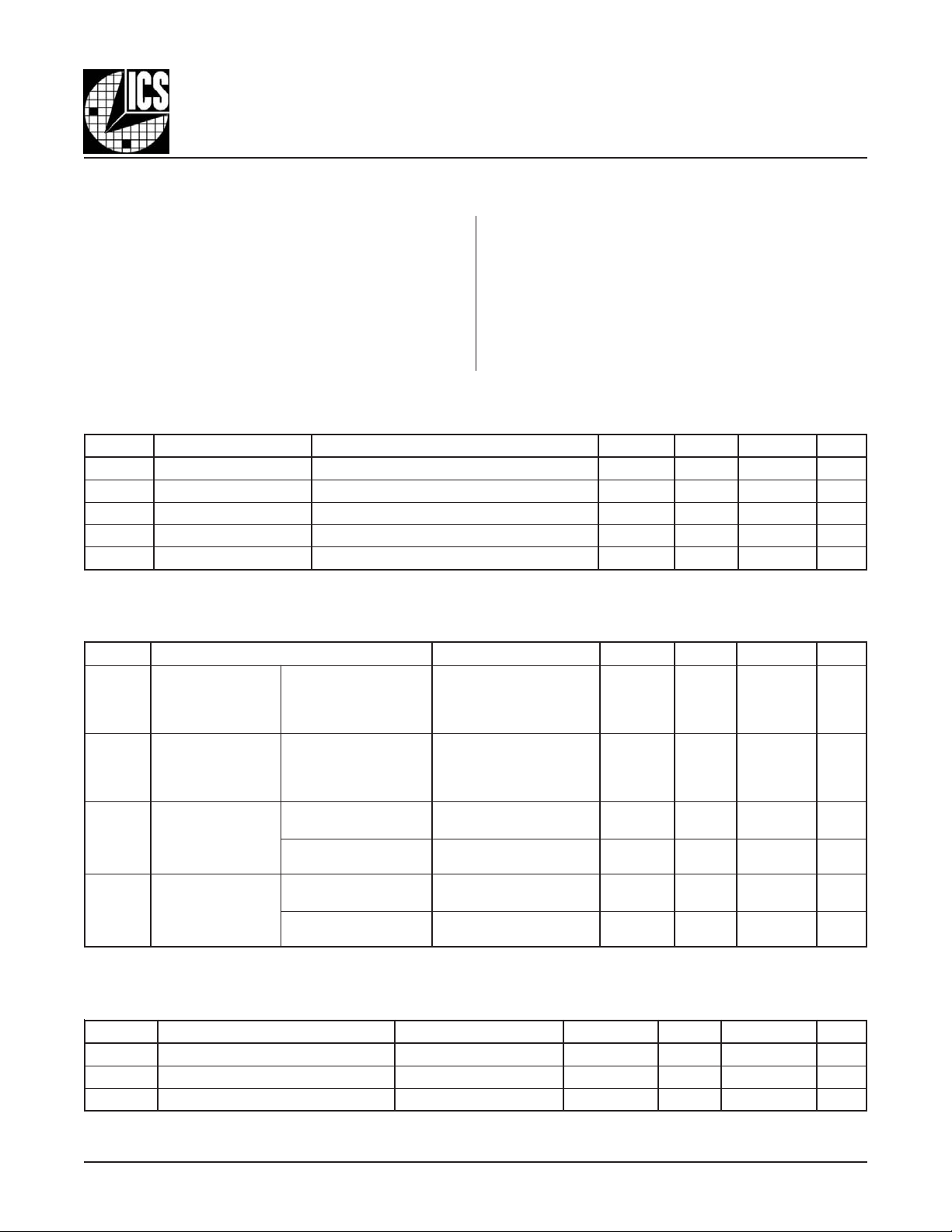

TABLE 4A. POWER SUPPLY DC CHARACTERISTICS, V

46.2°C/W (0 lfpm)

JA

-65°C to 150°C

CC

= V

lobmySretemaraPsnoitidnoCtseTmuminiMlacipyTmumixaMstinU

V

CC

V

OCC

V

ACC

I

EE

I

ACC

egatloVylppuSeroC 531.33.3564.3V

egatloVylppuStuptuO 531.33.3564.3V

egatloVylppuSgolanA 531.33.3564.3V

tnerruCylppuSrewoP 551Am

tnerruCylppuSgolanA 61Am

TABLE 4B. LVCMOS / LVTTL DC CHARACTERISTICS, V

lobmySretemaraPsnoitidnoCtseTmuminiMlacipyTmumixaMstinU

,0LTC_CSS,8M:0M

V

HI

egatloVhgiHtupnI

DAOL_Pn

V

LI

egatloVwoLtupnI

DAOL_Pn

I

HI

I

LI

tnerruChgiHtupnI

tnerruCwoLtupnI

,RM,1LTC_CSS

,O/I_TSET,LES_VID

,0LTC_CSS,8M:0M

,RM,1LTC_CSS

,O/I_TSET,LES_VID

,0LTC_CSS,8M,7M

OI_TSET,1LTC_CSS

LES_VID,6M:0M

RM,DAOL_Pn

,0LTC_CSS,8M,7M

OI_TSET,1LTC_CSS

LES_VID,6M:0M

RM,DAOL_Pn

CC

CCA

= V

V

V

NOTE: Stresses beyond those listed under Absolute

Maximum Ratings may cause permanent damage to the

device. These ratings are stress specifications only. Functional

operation of product at these conditions or any conditions beyond those listed in the

istics

is not implied. Exposure to absolute maximum rating

DC Characteristics

or

conditions for extended periods may affect product reliability.

= V

= 3.3V±5%, TA = 0°C TO 85°C

CCO

= V

CCA

= 3.3V±5%, TA = 0°C TO 85°C

CCO

2V

CC

3.0-8.0V

V

V=

CC

NI

V=

V

CC

NI

CC

CC

V564.3=5Aµ

V564.3=051Aµ

V,V564.3=

V0=051-Aµ

NI

V,V564.3=

V0=5-Aµ

NI

AC Character-

3.0+V

TABLE 4C. LVPECL DC CHARACTERISTICS, V

CC

= V

CCA

= V

= 3.3V±5%, TA = 0°C TO 85°C

CCO

lobmySretemaraPsnoitidnoCtseTmuminiMlacipyTmumixaMstinU

V

HO

V

LO

V

GNIWS

8431AM-21 www.icst.com/products/hiperclocks.html REV. A APRIL 27, 2005

egatloVwoLtuptuO1ETON;V

1ETON;egatloVhgiHtuptuOV

4.1-V

OCC

0.2-V

OCC

9.0-V

OCC

7.1-V

OCC

gniwSegatloVtuptuOkaeP-ot-kaeP6.00.1V

05htiwdetanimrettuptuO:1ETON Ω Vot

OCC

5

.tiucriCtseTdaoLtuptuOV3.3,noitceStnemerusaeMretemaraPeeS.V2-

Page 6

Integrated

Circuit

Systems, Inc.

TABLE 5. CRYSTAL CHARACTERISTICS

retemaraPsnoitidnoCtseTmuminiMlacipyTmumixaMstinU

noitallicsOfoedoM latnemadnuF

ycneuqerF 416152zHM

RseireStnelaviuqE 04

ecnaticapaCtnuhS 37Fp

ICS8431-21

350MHZ, LOW JITTER, CRYSTAL OSCILLATOR-

TO-3.3V LVPECL FREQUENCY SYNTHESIZER

)RSE(ecnatsise

Ω

TABLE 6. AC CHARACTERISTICS, V

CC

= V

CCA

= V

= 3.3V±5%, TA = 0°C TO 85°C

CCO

lobmySretemaraPsnoitidnoCtseTmuminiMlacipyTmumixaMstinU

F

TUO

t

j)cc(ti

ycneuqerFtuptuO 5.26053zHM

5,1ETON;rettiJelcyC-ot-elcyCF

≥ zHM0019103sp

TUO

cdoelcyCytuDtuptuO 840525%

t

Rt/F

F

F

F

t

latx

M

FM

CSS

der

ELBATS

emiTllaF/esiRtuptuO%08ot%02002007sp

3,2ETON;egnaRtupnIlatsyrC 416152zHM

4ETON;ycneuqerFnoitaludoMCSSF

4ETON;rotcaFnoitaludoMCSSF

;noitcudeRlartcepS4ETONF

TUO

TUO

TUO

zHM002=9233.33zHK

zHM002=4.06.0%

zHM002=701Bd

tuptuOkcolCelbatSotpu-rewoP 01sm

.noitcesnoitamrofnItnemerusaeMretemaraPehtniserugiFeeS

cnamrofreprettiJ:1ETON

.stupniLATXgnisue

.egnargnitarepoOCVehtnihtiwdilavylnO:2ETON

3ETON

.etoNnoitacilppAotrefer,tupniLATXroF:

:4ETON.delbanegnikcolcmurtcepSdaerpS

.56dradnatSCEDEJhtiwecnadroccanidenifedsiretemarapsihT:5ETON

8431AM-21 www.icst.com/products/hiperclocks.html REV. A APRIL 27, 2005

6

Page 7

2V

Integrated

Circuit

Systems, Inc.

PARAMETER MEASUREMENT INFORMATION

ICS8431-21

350MHZ, LOW JITTER, CRYSTAL OSCILLATOR-

TO-3.3V LVPECL FREQUENCY SYNTHESIZER

VCC,

V

, V

CCA

CCO

LVPECL

V

EE

-1.3V ± 0.165V

3.3V OUTPUT LOAD AC TEST CIRCUIT

80%

Clock

Outputs

20%

t

R

Qx

nQx

80%

t

F

SCOPE

V

SWI NG

20%

nFOUT

FOUT

➤

t

cycle n

t

jit(cc) = tcycle n –tcycle n+1

CYCLE-TO-CYCLE JITTER

nFOUT

FOUT

Pulse Width

1000 Cycles

t

PERIOD

t

odc =

t

PERIOD

➤

t

➤

PW

cycle n+1

➤

OUTPUT RISE/FALL TIME

8431AM-21 www.icst.com/products/hiperclocks.html REV. A APRIL 27, 2005

OUTPUT DUTY CYCLE/PULSE WIDTH/PERIOD

7

Page 8

Integrated

Circuit

Systems, Inc.

APPLICATION INFORMATION

POWER SUPPLY FILTERING T ECHNIQUES

As in any high speed analog circuitry, the power supply pins

are vulnerable to random noise. The ICS8431-21 provides

separate power supplies to isolate any high switching noise

, V

from the outputs to the internal PLL. V

, and V

CC

CCA

be individually connected to the power supply plane through

vias, and bypass capacitors should be used for each pin. To

achieve optimum jitter performance, better power supply isolation is required.

Figure 3

illustrates how a 10Ω along with a

10μF and a .01μF bypass capacitor should be connected to

each V

CCA

pin.

CCO

should

ICS8431-21

350MHZ, LOW JITTER, CRYSTAL OSCILLATOR-

TO-3.3V LVPECL FREQUENCY SYNTHESIZER

3.3V

V

CC

.01μF

V

CCA

.01μF

FIGURE 3. POWER SUPPLY FILTERING

10Ω

10μF

TERMINATION FOR LVPECL OUTPUTS

The clock layout topology shown below is typical for

IA64/32 platforms. The two different layouts mentioned are

recommended only as guidelines.

FOUT and nFOUT are low impedance follower outputs that

generate ECL/LVPECL compatible outputs. Therefore, terminating resistors (DC current path to ground) or current sources

must be used for functionality. These outputs are designed to

Z

= 50Ω

o

FOUT

= 50Ω

Z

o

RTT = Z

((V

OH

1

+ VOL) / (VCC – 2)) – 2

50Ω 50Ω

o

RTT

FIN

VCC - 2V

drive 50Ω transmission lines. Matched impedance techniques

should be used to maximize operating frequency and minimize

signal distortion.

Figures 2A and 2B

show two different layouts

which are recommended only as guidelines. Other suitable clock

layouts may exist and it would be recommended that the board

designers simulate to guarantee compatibility across all printed

circuit and clock component process variations.

3.3V

125Ω 125Ω

= 50Ω

Z

o

FOUT FIN

= 50Ω

Z

o

84Ω 84Ω

FIGURE 2B. LVPECL OUTPUT TERMINATIONFIGURE 2A. LVPECL OUTPUT TERMINATION

8431AM-21 www.icst.com/products/hiperclocks.html REV. A APRIL 27, 2005

8

Page 9

Integrated

Circuit

Systems, Inc.

CRYSTAL INPUT INTERFACE

The ICS8431-21 has been characterized with 18pF parallel resonant

crystals. The capacitor values, C1 and C2, shown in

were determined using a 25MHz, 18pF parallel resonant crystal and

Figure 3

below

C1

22p

18pF Parallel Crystal

X1

C2

22p

Figure 3. CRYSTAL INPUT INTERFACE

ICS8431-21

350MHZ, LOW JITTER, CRYSTAL OSCILLATOR-

TO-3.3V LVPECL FREQUENCY SYNTHESIZER

were chosen to minimize the ppm error. The optimum C1 and C2

values can be slightly adjusted for different board layouts.

XTAL_OUT

XTAL_IN

SPREAD SPECTRUM

Spread-spectrum clocking is a frequency modulation technique for EMI reduction. When spread-spectrum is enabled,

a 30kHz triangle waveform is used with 0.5% down-spread

(+0.0% / -0.5%) from the nominal 200MHz clock frequency.

An example of a triangle frequency modulation profile is shown

Figure 4A

in

• Fnom = Nominal Clock Frequency in Spread OFF mode

(200MHz with 16MHz IN)

• Fm = Nominal Modulation Frequency (30kHz)

• δ = Modulation Factor (0.5% down spread)

(1 - δ) fnom + 2 fm x δ x fnom x t when 0 < t < ,

(1 - δ) fnom - 2 fm x δ x fnom x t when < t <

(1 - δ) Fnom

below. The ramp profile can be expressed as:

1

2 fm

➤

Fnom

1

2 fm

1

fm

The ICS8431-21 triangle modulation frequency deviation will

not exceed 0.6% down-spread from the nominal clock frequency (+0.0% / -0.5%). An example of the amount of down

spread relative to the nominal clock frequency can be seen in

the frequency domain, as shown in

this width to the fundamental frequency is typically 0.4%, and

will not exceed 0.6%. The resulting spectral reduction will be

greater than 7dB, as shown in

note the ICS8431-21 7dB minimum spectral reduction is the

component-specific EMI reduction, and will not necessarily

be the same as the system EMI reduction.

B

➤

δ = .4%

➤

Figure 4B.

Figure 4B

Δ − 10 dBm

A

The ratio of

. It is important to

➤

0.5/fm 1/fm

FIGURE 4A. TRIANGLE FREQUENCY MODULATION

8431AM-21 www.icst.com/products/hiperclocks.html REV. A APRIL 27, 2005

FIGURE 4B. 200MHZ CLOCK OUTPUT IN FREQUENCY DOMAIN

(A) SPREAD-SPECTRUM OFF (B) SPREAD-SPECTRUM ON

9

Page 10

Integrated

Circuit

Systems, Inc.

LAYOUT GUIDELINE

The schematic of the ICS8431-21 layout example used in this

layout guideline is shown in

Figure 5A.

ommended PCB board layout for this example is shown in

The ICS8431-21 rec-

ICS8431-21

350MHZ, LOW JITTER, CRYSTAL OSCILLATOR-

TO-3.3V LVPECL FREQUENCY SYNTHESIZER

Figure 5B.

The layout in the actual system will depend on the selected

component types and the density of the P.C. board.

VCC=3.3V

SP=Spare, not installed

This layout example is used as a general guideline.

Logic Input Pin Examples

VCC

Set Logic

Input t o

'1'

VCC

Set Logic

Input t o

'0'

VCC

U1

1

M0

2

M1

3

M2

4

M3

5

M4

6

M5

7

M6

8

M7

9

M8

10

SSC_CTL0

11

SSC_CTL1

12

VEE

13

TEST_IO

14 15

VCC VEE

C1

0.1uF

ICS8431-21

nP_LOAD

XTA L _O U T

DIV_SEL

VCC

XTAL_IN

NC

NC

VCC A

VEE

MR

VCC O

FOUT

nFOU T

VCC

28

27

26

25

24

23

22

21

20

19

18

17

16

VCC

C6

0.01uF

X1

VCC A

C3

0.01uF

C2

0.1uF

C8 22pF

C7 22pF

C4

10uF

FIGURE 5A. SCHEMATIC EXAMPLE

R5

VCC

10

Zo = 50 Ohm

Zo = 50 Ohm

RU1

1K

RD1

SP

To Logic

Input

pins

VCC

R1

125

R2

84

R3

125

R4

84

RU2

SP

RD2

1K

To Logic

Input

pins

+

-

8431AM-21 www.icst.com/products/hiperclocks.html REV. A APRIL 27, 2005

10

Page 11

Integrated

Circuit

Systems, Inc.

ICS8431-21

350MHZ, LOW JITTER, CRYSTAL OSCILLATOR-

TO-3.3V LVPECL FREQUENCY SYNTHESIZER

The following component footprints are used in this layout

example:

All the resistors and capacitors are size 0603.

POWER AND GROUNDING

Place the decoupling capacitors C1, C2 and C6, as close as

possible to the power pins. If space allows, placment of the

decoupling capacitor on the component side is preferred. This

can reduce unwanted inductance between the decoupling capacitor and the power pin generated by the via.

Maximize the power and ground pad sizes and number of vias

capacitors. This can reduce the inductance between the power

and ground planes and the component power and ground pins.

The RC filter consisting of R5, C3, and C4 should be placed as

close to the V

pin as possible.

CCA

CLOCK TRACES AND TERMINATION

Poor signal integrity can degrade the system performance or

cause system failure. In synchronous high-speed digital systems,

the clock signal is less tolerant to poor signal integrity than other

signals. Any ringing on the rising or falling edge or excessive ring

back can cause system failure. The shape of the trace and the

trace delay might be restricted by the available space on the board

and the component location. While routing the traces, the clock

signal traces should be routed first and should be locked prior to

routing other signal traces.

• The 50Ω output trace pair should have same length.

• Avoid sharp angles on the clock trace. Sharp angle turns

cause the characteristic impedance to change on the

transmission lines.

• Keep the clock traces on the same layer. Whenever possible, avoid placing vias on the clock traces. Placement

of vias on the traces can affect the trace characteristic

impedance and hence degrade signal integrity.

• To prevent cross talk, avoid routing other signal traces in

parallel with the clock traces. If running parallel traces is

unavoidable, allow a separation of at least three trace

widths between the differential clock trace and the other

signal trace.

• Make sure no other signal traces are routed between the

clock trace pair.

• The matching termination resistors should be located as

close to the receiver input pins as possible.

The matching termination resistors R1, R2, R3 and R4 should

be located as close to the receiver input pins as possible.

Other termination scheme can also be used but is not shown

in the example.

CRYSTAL

The crystal X1 should be located as close as possible to the pins

25 (XTAL_OUT) and 26 (XTAL_IN). The trace length between the

X1 and U1 should be kept to a minimum to avoid unwanted parasitic inductance and capacitance. Other signal traces should not

be routed near the crystal traces.

C8

GND

U1

ICS8431-21

C6

X1

C3

C1

C4

R5

C7

C2

Zo=50 Ohm

Zo=50 Ohm

VCC

Signals

VIA

FIGURE 5B. PCB BOARD LAYOUT FOR ICS8431-21

8431AM-21 www.icst.com/products/hiperclocks.html REV. A APRIL 27, 2005

11

Page 12

Integrated

Circuit

Systems, Inc.

350MHZ, LOW JITTER, CRYSTAL OSCILLATOR-

ICS8431-21

TO-3.3V LVPECL FREQUENCY SYNTHESIZER

POWER CONSIDERATIONS

This section provides information on power dissipation and junction temperature for the ICS8431-21.

Equations and example calculations are also provided.

1. Power Dissipation.

The total power dissipation for the ICS8431-21 is the sum of the core power plus the power dissipated in the load(s).

The following is the power dissipation for V

NOTE: Please refer to Section 3 for details on calculating power dissipated in the load.

= 3.3V + 5% = 3.465V, which gives worst case results.

CC

• Power (core)

• Power (outputs)

If all outputs are loaded, the total power is 1 * 30mW = 30mW

Total Power

= V

MAX

MAX

(3.465V, with all outputs switching) = 537.1mW + 30mW = 567.1mW

_MAX

* I

CC_MAX

= 30mW/Loaded Output pair

= 3.465V * 155mA = 537.1mW

EE_MAX

2. Junction Temperature.

Junction temperature, Tj, is the temperature at the junction of the bond wire and bond pad and directly affects the reliability of the

device. The maximum recommended junction temperature for HiPerClockS

The equation for Tj is as follows: Tj = θ

Tj = Junction Temperature

= Junction-to-Ambient Thermal Resistance

θ

JA

Pd_total = Total Device Power Dissipation (example calculation is in section 1 above)

= Ambient Temperature

T

A

In order to calculate junction temperature, the appropriate junction-to-ambient thermal resistance θ

moderate air flow of 200 linear feet per minute and a multi-layer board, the appropriate value is 39.7°C/W per Table 7 below.

Therefore, Tj for an ambient temperature of 85°C with all outputs switching is:

85°C + 0.567W * 39.7°C/W = 107.5°C. This is below the limit of 125°C.

This calculation is only an example. Tj will obviously vary depending on the number of loaded outputs, supply voltage, air flow,

and the type of board (single layer or multi-layer).

* Pd_total + T

JA

A

TM

devices is 125°C.

must be used. Assuming a

JA

Table 7. THERMAL RESISTANCE

θθ

θJA FOR 28-PIN SOIC, FORCED CONVECTION

θθ

θθ

θJA by Velocity (Linear Feet per Minute)

θθ

0 200 500

Single-Layer PCB, JEDEC Standard Test Boards 76.2°C/W 60.8°C/W 53.2°C/W

Multi-Layer PCB, JEDEC Standard Test Boards 46.2°C/W 39.7°C/W 36.8°C/W

NOTE: Most modern PCB designs use multi-layered boards. The data in the second row pertains to most designs.

8431AM-21 www.icst.com/products/hiperclocks.html REV. A APRIL 27, 2005

12

Page 13

Integrated

Circuit

Systems, Inc.

350MHZ, LOW JITTER, CRYSTAL OSCILLATOR-

TO-3.3V LVPECL FREQUENCY SYNTHESIZER

3. Calculations and Equations.

The purpose of this section is to derive the power dissipated into the load.

ICS8431-21

LVPECL output driver circuit and termination are shown in

FIGURE 6. LVPECL DRIVER CIRCUIT AND TERMINATION

Figure 6.

V

CCO

Q1

RL

50

V

CCO

V

OUT

- 2V

To calculate worst case power dissipation into the load, use the following equations which assume a 50Ω load, and a termination

voltage of V

• For logic high, V

• For logic low, V

Pd_H is power dissipation when the output drives high.

Pd_L is the power dissipation when the output drives low.

Pd_H = [(V

[(2V - 0.9V)/50Ω] * 0.9V = 19.8mW

Pd_L = [(V

[(2V - 1.7V)/50Ω] * 1.7V = 10.2mW

Total Power Dissipation per output pair = Pd_H + Pd_L = 30mW

CCO

(V

CCO_MAX

(V

CCO_MAX

OH_MAX

OL_MAX

- 2V.

– (V

- V

- V

– (V

OUT

OH_MAX

OUT

OL_MAX

CCO_MAX

CCO_MAX

= V

)

= 0.9V

= V

)

= 1.7V

- 2V))/RL] * (V

- 2V))/RL] * (V

OH_MAX

OL_MAX

= V

= V

CCO_MAX

CCO_MAX

CCO_MAX

CCO_MAX

– 0.9V

– 1.7V

- V

- V

OH_MAX

OL_MAX

) = [(2V - (V

) = [(2V - (V

CCO

CCO

_MAX

_MAX

- V

- V

OH_MAX

OL_MAX

))

/RL] * (V

))

/RL] * (V

CCO_MAX

CCO_MAX

- V

- V

OH_MAX

OL_MAX

) =

) =

8431AM-21 www.icst.com/products/hiperclocks.html REV. A APRIL 27, 2005

13

Page 14

Integrated

Circuit

Systems, Inc.

ICS8431-21

350MHZ, LOW JITTER, CRYSTAL OSCILLATOR-

TO-3.3V LVPECL FREQUENCY SYNTHESIZER

RELIABILITY INFORMATION

TABLE 8. θ

TRANSISTOR COUNT

The transistor count for ICS8431-21 is: 4790

VS. AIR FLOW TABLE FOR 28 LEAD SOIC

JA

θθ

θJA by Velocity (Linear Feet per Minute)

θθ

0 200 500

Single-Layer PCB, JEDEC Standard Test Boards 76.2°C/W 60.8°C/W 53.2°C/W

Multi-Layer PCB, JEDEC Standard Test Boards 46.2°C/W 39.7°C/W 36.8°C/W

NOTE: Most modern PCB designs use multi-layered boards. The data in the second row pertains to most designs.

8431AM-21 www.icst.com/products/hiperclocks.html REV. A APRIL 27, 2005

14

Page 15

Integrated

Circuit

Systems, Inc.

PACKAGE OUTLINE - M SUFFIX FOR 28 LEAD SOIC

ICS8431-21

350MHZ, LOW JITTER, CRYSTAL OSCILLATOR-

TO-3.3V LVPECL FREQUENCY SYNTHESIZER

T

ABLE 9. PACKAGE DIMENSIONS

LOBMYS

N82

A--56.2

1A01.0--

2A50.255.2

B33.015.0

C81.023.0

D07.7104.81

E04.706.7

eCISAB72.1

H00.0156.01

h52

L04.072.1

α

Reference Document: JEDEC Publication 95, MS-013, MO-119

MUMINIMMUMIXAM

.057.0

°0°8

sretemilliM

8431AM-21 www.icst.com/products/hiperclocks.html REV. A APRIL 27, 2005

15

Page 16

Integrated

Circuit

Systems, Inc.

TABLE 10. ORDERING INFORMATION

rebmuNredrO/traPgnikraMegakcaPgnigakcaPgnippihSerutarepmeT

12-MA1348SCI12-MA1348SCICIOSdaeL82ebuTC°58otC°0

T12-

MA1348SCI12-MA1348SCICIOSdaeL82leeR&epaT0001C°58otC°0

FL12-MA1348SCIDBTCIOS"eerF-daeL"daeL82ebuTC°58otC°0

TFL12

-MA1348SCIDBTCIOS"eerF-daeL"daeL82leeR&epaT0001C°58otC°0

ICS8431-21

350MHZ, LOW JITTER, CRYSTAL OSCILLATOR-

TO-3.3V LVPECL FREQUENCY SYNTHESIZER

muntrapehtotxiffus"FL"nahtiwderedroeratahtstraP:ETON

.tnailpmocSHoReradnanoitarugifnoceerF-bPehterareb

The aforementioned trademark, HiPerClockS™ is a trademark of Integrated Circuit Systems, Inc. or its subsidiaries in the United States and/or other countries.

While the information presented herein has been checked for both accuracy and reliability, Integrated Circuit Systems, Incorporated (ICS) assumes no responsibility for either its use

or for infringement of any patents or other rights of third parties, which would result from its use. No other circuits, patents, or licenses are implied. This product is intended for use

in normal commercial applications. Any other applications such as those requiring extended temperature range, high reliability, or other extraordinary environmental requirements are

not recommended without additional processing by ICS. ICS reserves the right to change any circuitry or specifications without notice. ICS does not authorize or warrant any ICS

product for use in life support devices or critical medical instruments.

8431AM-21 www.icst.com/products/hiperclocks.html REV. A APRIL 27, 2005

16

Page 17

Integrated

Circuit

Systems, Inc.

350MHZ, LOW JITTER, CRYSTAL OSCILLATOR-

ICS8431-21

TO-3.3V LVPECL FREQUENCY SYNTHESIZER

TEEHSYROTSIHNOISIVER

veRelbaTegaPegnahCfonoitpircseDetaD

A

01T

1

61

itceSserutaeF

tellubeerF-daeLdnatellubtnemecalperdedda-no

.rebmuntrapeerF-daeLdedda-elbaTnoitamrofnIgniredrO

50/72/4

8431AM-21 www.icst.com/products/hiperclocks.html REV. A APRIL 27, 2005

17

Loading...

Loading...