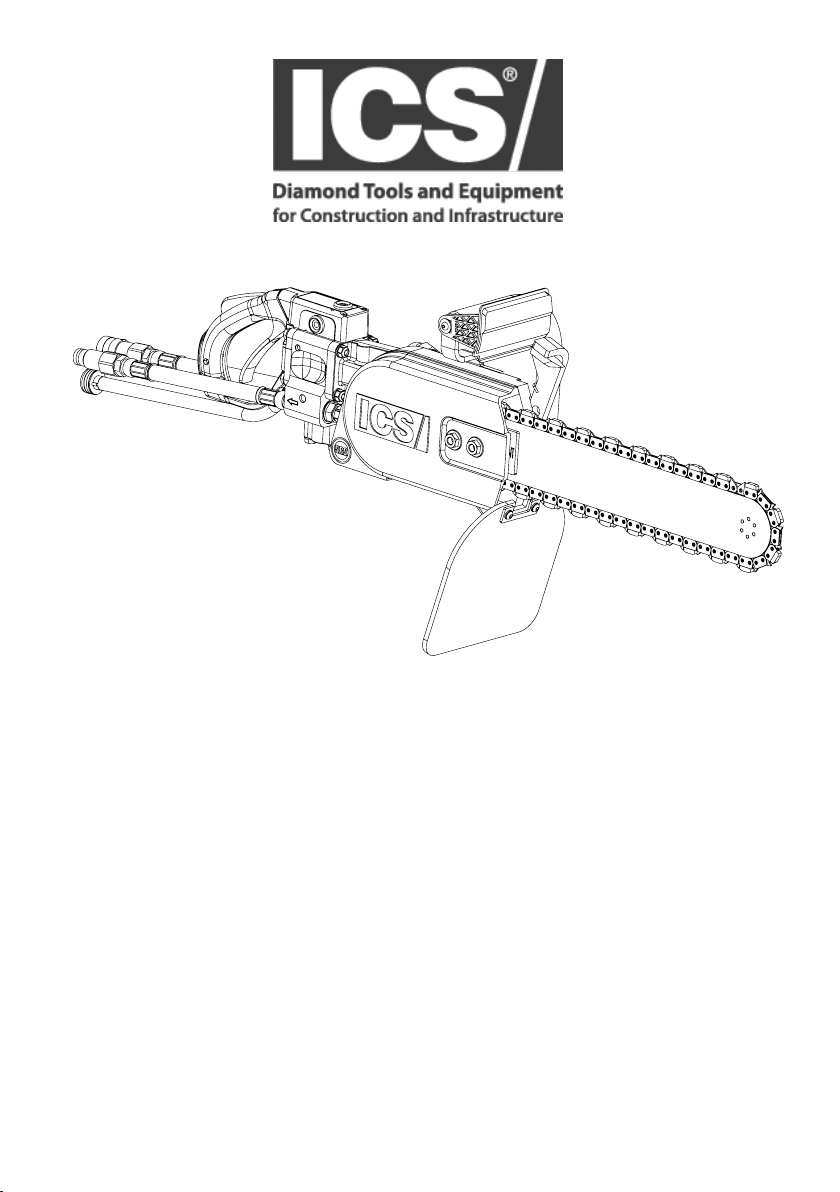

Page 1

890F4

OPERATOR MANUAL

WARNING: READ AND UNDERSTAND ALL SAFETY WARNINGS

AND ALL INSTRUCTIONS BEFORE YOU USE THIS EQUIPMENT.

Failure to follow the warnings and instructions may result in re, serious injury, or death.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

Page 2

Introduction

890F4 OPERATOR MANUAL

INTRODUCTION

The 890 power cutter is designed to cut concrete, stone, and masonry when

used with the appropriate genuine ICS Diamond Chain. Ductile iron pipe may

also be cut but ONLY if using PowerGrit® Utility Chain. This is a professional

tool and is solely intended for use by trained and experienced operators. A rst

ENGLISH

time operator should obtain practical instruction before using the power cutter,

as well as reading and understanding this Operator’s Manual.

Local legislation and/or workplace standards may regulate the use of this

power cutter. Determine what regulations are applicable in the place you work

before using the power cutter.

This instruction manual contains translations of a manual drafted in English

and are provided to assist those who do not speak English as their rst

language. Being a technical writing, some terms may not have a like or

equivalent meaning as translated. Therefore, you should not rely on this

translation, and should cross-reference the English version, where relying on

the translated instructions could result in harm to your person or property.

Specications subject to change without notice. For most up-to-date

version of this manual, please visit:

https://icsdiamondtools.com/customer-service-support/.

TABLE OF CONTENTS

SAFETY RULES

SYMBOLS AND LABELS

ICS 890F4 NAMES AND TERMS

PRODUCT IDENTIFICATION

UNPACKING AND ASSEMBLY

OPERATION

MAINTENANCE

TROUBLESHOOTING

TECHNICAL SPECIFICATIONS

SERVICE CENTERS

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

2

4

8

10

12

14

21

29

33

34

35

Page 3

890F4 OPERATOR MANUAL

EC‐DECLARATIONOFCONFORMITY

BLOUNTINTERNATIONALINC.DECLARESUNDEROURSOLERESPONSIBILITYTHATTHEFOLLOWINGPRODUCTS:

_____________________________________________ ________________________________________________________ _________________

Brand: ICS

ProductType: HydraulicCut‐offmachineequippedwithdiamondsawchain

Model: 890F4,890F4‐FL

_____________________________________________ ________________________________________________________ _________________

ARECOMPLIANTWITHTHEFOLLOWINGAPPLICABLEEUROPEANDIRECTIVESANDSTANDARDS:

MachineryDirective(MD)2006/42/EC

ENISO12100‐1,‐2:2009

ENISO5349‐1,‐2:2001

ENISO3744:2009

_____________________________________________ ________________________________________________________ _________________

TECHNICALDOCUMENTATIONFILE,LOCATIONANDCONTACT:

ISO10726:1992

BlountInternational,Inc.

4909SEInternationalWay

Portland,Oregon97222,USA

Forproductcomplianceinquiries,sendrequesttoproductcompliance@blount.com

AuthorizedRepresentative: ChristopherSewardPE

AuthorizedSignature:

Title: Director:ProductSafety&Compliance

PlaceIssued: Portland,OregonUSA

DateOriginallyIssued: 26November,2013

DateRevised: 13November,2017

4909 SE INTERNATIONAL WAY | PORTLAND, OREGON 97222-4601

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

3

Page 4

Safety Rules

890F4 OPERATOR MANUAL

SAFETY RULES

To get the maximum benet from your power cutter, and assure maximum

safety, be sure to read this manual thoroughly and follow the safety instructions

ENGLISH

provided.

EXPLANATION OF WARNING LEVELS

DANGER

Indicates a hazard with a high level of risk which, if not avoided, will result in

death or serious injury.

WARNING

Indicates a hazard with a medium level of risk which, if not avoided, could result

in death or serious injury.

CAUTION

Indicates a hazard with a low level of risk which, if not avoided, could result in

minor or moderate injury.

IMPORTANT

Indicates a potential situation exists which, if not avoided, may result in damage

to your power cutter or property.

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

4

Page 5

890F4 OPERATOR MANUAL

Safety Rules

HANDLING HYDRAULIC FLUID SAFELY

WARNING

Hydraulic uid is combustible or can become combustible.

Consult the SDS (Safety Data Sheet) for the hydraulic uid being used for

ash point and auto ignition temperature ranges. When these uids discharge

under pressure in a ne mist, they ignite easily, burn rapidly, and emit large

quantities of heat. In fact, their heats of combustion, which are over 18,000

BTU/lb (2327 kJ/kg), are comparable to fuel oil.

CAUTION

Check for hydraulic leaks before starting the hydraulic power source.

Visually check for leaks from the hydraulic ttings, and lines and do not use if

any leaks are found.

WORK AREA SAFETY

Following are the basic instructions for work area safety.

WARNING

Drugs or alcohol can impair vision, dexterity, and judgment.

Do not operate the power cutter when tired or under the inuence of

any substance.

Do not operate this product during severe inclement weather.

CAUTION

Remove or control slurry to prevent slippery conditions while cutting.

This power cutter uses water and can cause slippery surfaces due to the slurry

produced and/or freezing temperatures.

Keep bystanders away from work area.

Set up a well-marked safety zone with a roped boundary and clear signs to

keep bystanders at least 6 m (20 ft) away.

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

5

Page 6

Safety Rules

890F4 OPERATOR MANUAL

PERSONAL SAFETY

Following are the basic instructions for personal safety.

WARNING

ENGLISH

Fluids escaping under pressure can penetrate skin and cause severe

personal injury.

Do not use hands to search for leaks. Before disconnecting lines, be sure to

relieve all pressure. Do not apply pressure to damaged lines, hoses or ttings.

If any uid is injected into the skin, seek medical attention immediately to

prevent gangrene. Consult supplied hydraulic uid SDS for additional

information regarding proper handling and use instructions.

Long-term exposure to noise can result in permanent hearing impairment.

Always wear approved hearing protection.

This power cutter can generate hazardous dust and vapors.

Determine the nature of the material you are going to cut before proceeding with the job. Be especially aware of cutting materials containing silica and

asbestos as inhaling dust can result in respiratory disease. Be sure to use

appropriate respiratory protection designed to lter out microscopic particles.

Be sure to use recommended water pressure to minimize dust generation.

Over-exposure to vibration can lead to circulatory and/or nerve damage to

the extremities, especially in cold temperatures (Reynaud’s Disease).

If you experience tingling, numbness, pain or changes in skin color, particularly

in your ngers, hands or wrists, stop using the power cutter immediately. If the

problem persists, seek medical attention.

Always wear protective clothing.

At a minimum always wear eye protection and/or face shield, hearing

protection, long sleeve shirt, long pants, closed toe shoes with non-slip soles,

and gloves. In many work situations, a hard hat and steel toed shoes may also

be required. Avoid loose tting clothing.

TRANSPORTING & STORING

WARNING

Hydraulic hoses are charged with uid when the power cutter is shipped.

See the icsdiamondtools.com website for SDS information on

the hydraulic uid.

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

6

Page 7

890F4 OPERATOR MANUAL

Safety Rules

USING THE ICS POWER CUTTER SAFELY

Following are the basic instructions for safe use of the power cutter. Also read

and understand additional safety precautions specic to the operation and

maintenance of the power cutter throughout this manual.

DANGER

DO NOT operate the ICS power cutter with a saw chain or saw bar

designed to cut wood. Using wood cutting saw chain on the ICS power cutter

could result in severe injuries to the operator or a bystander! Use ONLY the

cutting attachments specied in this manual on this power cutter.

WARNING

DO NOT operate the power cutter with damaged, modied, broken, or

missing components.

Below safety features are designed to protect against contact with moving

parts, ejected debris, broken chain, thrown water, and concrete slurry.

• Side cover

• Bae drain

• Mud ap

• Mud ap bracket (Chain Catcher)

• Trigger interlock

Use only Genuine ICS replacement parts. Use of unauthorized aftermarket

parts may result in injury or damage to the power cutter.

DO NOT insert the guidebar into a slot narrower than the width of the chain.

Rapid pushback, kickback and/or chain breakage could result.

DO NOT operate the power cutter without an adequate water supply.

The integral water supply channels in the guidebar act to cool and lubricate

the cutting system as well as to suppress dust and debris generated during

cutting. Assure that the water supply is capable of delivering 1.5 bar (20 psi)

pressure to the power cutter at a minimum ow rate of 8 lpm (2 gpm).

Never attempt to cut ductile iron pipe or similar pipe materials with the

power cutter unless using PowerGrit® Utility Chain.

Using concrete cutting chain in these applications can cause the chain to

snag abruptly in the cut which may result in chain breakage, pushback

and/or kickback.

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

7

Page 8

Symbols & Labels

890F4 OPERATOR MANUAL

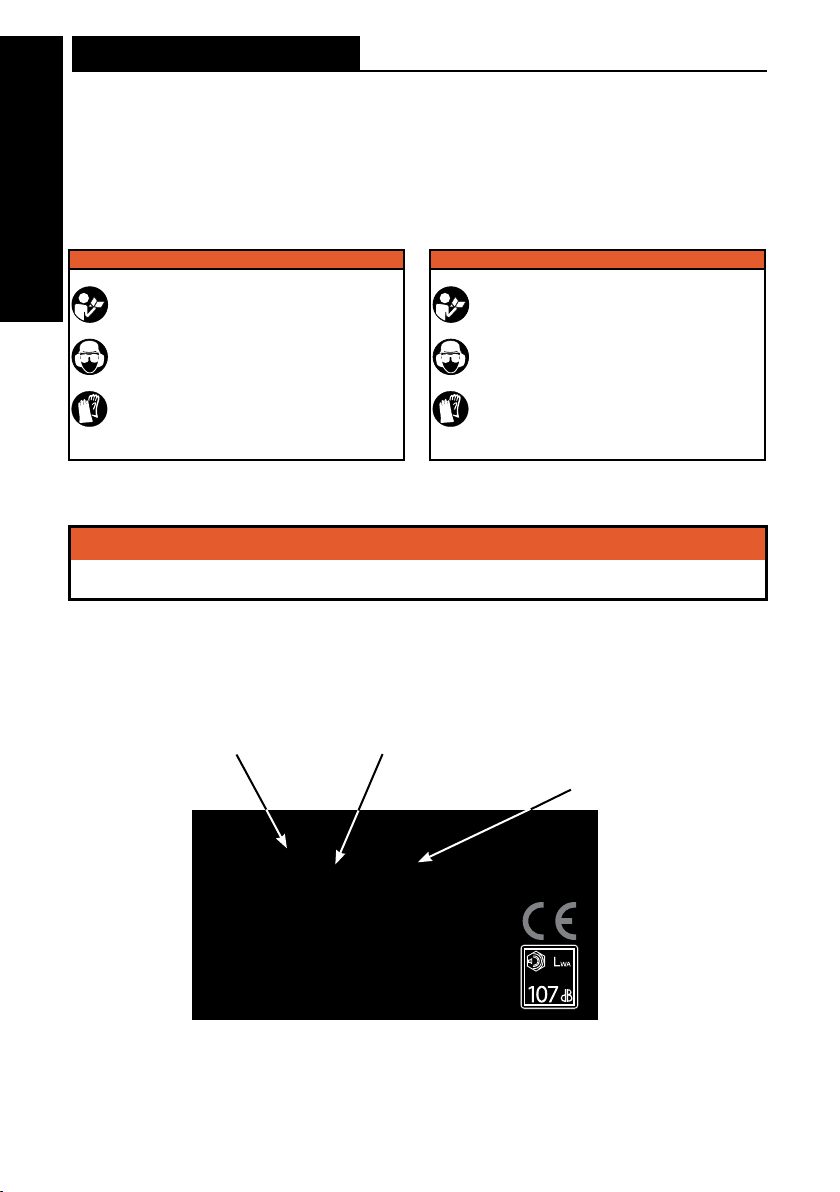

LABELS ON YOUR POWER CUTTER

SAFETY LABELS

ENGLISH

8 GPM POWER CUTTER 12 GPM POWER CUTTER

� WARNING

• Do not ex ceed 8 GPM (30 L PM) hydrau lic flow

or 2500 p si (172. 5 bar) hydr aulic pres sure

• Do NOT in sert too l into slot na rrower th an chain .

• Do NOT ru n the powe r cutter ba ckward s. The

chai n should t ravel away f rom the ope rator on

the to p of the bar an d return on t he bottom o f

the ba r.

• Do NOT op erate tool w ithout s olid footi ng and

fir m hand gri p.

• Fail ure to obser ve these p recauti ons can res ult

in ser ious inj ury. Flui ds escapi ng under

pres sure can pe netrate t he skin.

• Do not ex ceed 12 GPM (45 LPM) h ydrauli c flow

or 2500 p si (172. 5 bar) hydr aulic pres sure

• Do NOT in sert too l into slot na rrower th an chain .

• Do NOT ru n the powe r cutter ba ckward s. The

chai n should t ravel away f rom the ope rator on

the to p of the bar an d return on t he bottom o F

the ba r.

• Do NOT op erate tool w ithout s olid footi ng and

fir m hand gri p.

• Fail ure to obser ve these p recauti ons can res ult

in ser ious inj ury. Flui ds escapi ng under p ressure

can pe netrate t he skin.

� WARNING

� WARNING

• Do NOT op erate powe r cutter w ithout s ide cover.

• Do NOT op erate powe r cutter w ithout b affle drain.

• Do NOT us e this powe r cutter c over on any ot her power c utter mod el.

• Fail ure to obser ve these p recauti ons can res ult in ser ious inju ry.

NAMEPLATE LABEL

Model 890 F4

Serial# XXYYZZZZZ

Blount, Inc.

4909 SE International Way

Portland, OR 97222 USA

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

8

YY = Month of Manufacture (ie. 07)XX = Year of Manufacture (ie. 15)

ZZZZ = Saw number within

production batch in sequential

order beginning with 00001

Page 9

890F4 OPERATOR MANUAL

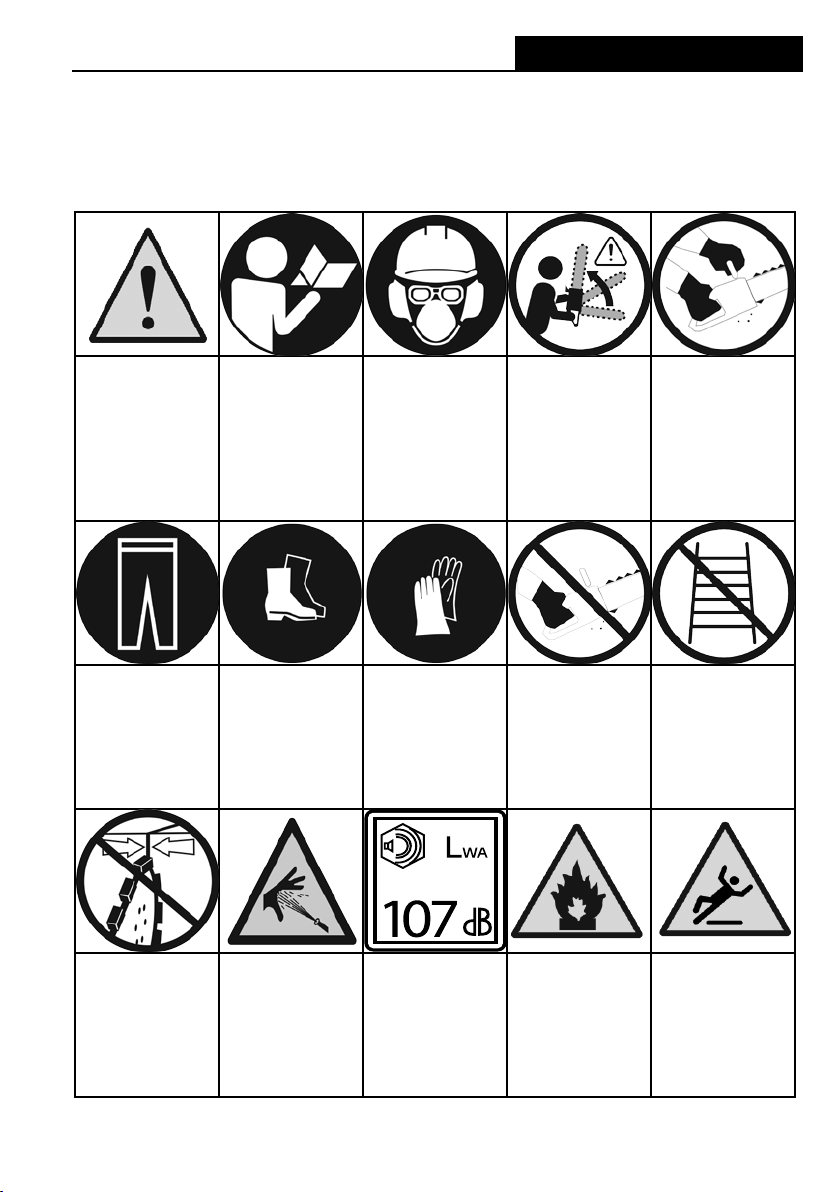

THE FOLLOWING SYMBOLS ARE FOUND THROUGHOUT THIS MANUAL

AND/OR ON THE POWER CUTTER AND ARE DESIGNED TO MAKE

YOU AWARE OF POTENTIAL HAZARDS OR UNSAFE PRACTICES.

Symbols & Labels

SYMBOLS AND LABELS

SAFETY ALERT

Indicates that the

text that

follows explains a

danger,

warning or caution.

WEAR LONG

PANTS

Wear long pants

when operating the

power cutter.

READ

INSTRUCTIONS

The original

instruction manual

contains important

safety and operating

information. Read

and follow the

instructions carefully.

WEAR FOOT

PROTECTION

Wear appropriate

closed-toe boots

when operating the

power cutter.

WEAR

PROTECTION

Wear eye , hearing

and respiratory

protection and a

protective helmet

when operating the

power cutter.

WEAR HAND

PROTECTION

Wear hand

protection when

operating the power

cutter.

BEWARE OF

KICKBACK

Kickback can cause

severe injuries.

ONE-HANDED

HOLD

Do not operate the

power cutter with

only one hand.

TWO-HANDED

HOLD

Operate the power

cutter with two

hands, securely

gripping both

handles

DO NOT USE A

LADDER

Never stand on a

ladder when using

the power cutter.

KERF WIDTH

Do not insert tool

into slot

narrower than chain.

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

FLUIDS UNDER

PRESSURE

Fluids escaping

under pressure

can penetrate skin

and cause severe

personal injury.

SOUND POWER

Sound power level

is 107 dB(A).

FIRE DANGER

Risk of re if

warnings not

followed.

SLIPPERY

SURFACE

Unsure footing can

lead to

accidents.

9

Page 10

Names & Terms

ICS 890F4 NAMES AND TERMS

Bae Drain

A device for controlling slurry and cutting debris in the side cover to

ENGLISH

reduce chain stretch and protect the operator from other projectiles.

Bar retaining plate

The plate between the guidebar and side cover that clamps the guidebar

to prevent movement during operation.

Bar slot

The slot feature on the guidebar that ts over the bar studs.

Bystander safety zone

A 6 m (20 ft) circle around the operator that must remain free from

bystanders, children and pets.

Chain catcher

A device for retaining the chain if it breaks or derails.

Chain pitch

The distance between any three consecutive rivets on the chain divided

by two.

Chain tensioning screw

An adjustment screw used to set proper tension on the chain and

compensate for chain stretch from normal use.

Front handle

The support handle located at or toward the front of the power cutter

intended to be gripped by the left hand.

Guidebar

A railed structure that supports and guides the chain. Sometimes simply

called the “bar”.

Kickback

The rapid backward and/or upward motion of the guidebar, occurring when

the chain near the top area of the nose of the guidebar contacts a foreign

object or snags in the workpiece.

Mud ap

A barrier to deect slurry, cutting debris and other projectiles from

operator.

890F4 OPERATOR MANUAL

10

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

Page 11

890F4 OPERATOR MANUAL

Names & Terms

ICS890 NAMES AND TERMS

Powerhead

A power cutter without the chain or guidebar.

Pushback

The rapid backward motion of the guidebar, occurring when the chain on

the top straight portion of the guidebar contacts a foreign object or

snags in the workpiece.

Rear handle

The support handle located at or toward the rear of the power cutter

intended to be gripped by the right hand.

Rear hand guard:

A structural barrier at the bottom of the rear handle to protect the operator in

case the chain breaks or derails. Does not meet ISO 14982 Requirements.

Side cover:

The component on the powerhead that covers the drive sprocket and directs

debris away from the operator during use.

Side cover nuts:

The components on the side cover that secure the side cover, bar

retaining plate and guidebar.

Trigger lock-out

A device that prevents the unintentional operation of the throttle trigger until

manually released.

Trigger

A mechanism that controls motor operation.

WallWalker®

A device used as a fulcrum to provide mechanical advantage during

cutting.

Water shut-o valve

A mechanism that controls water delivery and ow to the guidebar and chain.

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

11

Page 12

Product Identication

PRODUCT IDENTIFICATION

ENGLISH

Trigger lock-out

Trigger

Rear hand guard

Baffle drain

890F4 OPERATOR MANUAL

Bar slot

Bar studs

Bar retaining plate

WallWalker®

Side

cover

Side cover

nuts

Mud flap

Chain catcher

Guidebar

Chain tensioning screw

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

12

Powerhead

Front handle

Rear handle

Water shut

off valve

Page 13

890F4 OPERATOR MANUAL

Hydraulic Supply

Quick-Disconnect

Hydraulic Return

Quick-Disconnect

Water hose

Product Identication

Direction of hydraulic ow

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

13

Page 14

Unpacking & Assembly

890F4 OPERATOR MANUAL

BOX CONTENTS

ENGLISH

Minimum contents for all packages shown. Some packages also contain

guidebar and diamond chain.

See Z 34 for a list of compatible guidebars and diamond chain.

GUIDEBAR AND DIAMOND CHAIN

INSTALLATION & TENSIONING

Following are the basic instructions for guidebar and diamond chain

installation and tensioning.

WARNING

Never perform any maintenance or adjustments on the power cutter while

the hydraulic power source is connected.

Improper chain tension can lead to failure of the chain or derailing of the

chain o of the guidebar.

Check tension frequently and adjust if drive links of chain hang 18 mm (3/4 in)

or more below the guidebar groove

CAUTION

Always wear gloves when handling the bar and chain.

These components can develop sharp edges and cause cuts.

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

14

Page 15

890F4 OPERATOR MANUAL

STEP 1

Disconnect hydraulic power supply.

STEP 2

Loosen the side cover nuts and

remove the side cover and bar

retaining plate.

Unpacking & Assembly

GUIDEBAR AND DIAMOND CHAIN

INSTALLATION & TENSIONING

STEP 3

Turn the chain-tensioning screw

counterclockwise until the pin

comes to a stop.

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

15

Page 16

Unpacking & Assembly

GUIDEBAR AND DIAMOND CHAIN

INSTALLATION & TENSIONING

ENGLISH

STEP 4

Place the bar onto the studs

without engaging tensioner pin.

Assure bar is in contact with the

drive sprocket.

890F4 OPERATOR MANUAL

16

STEP 5

Install the chain around the drive

sprocket and then around the nose

sprocket before inserting into the

bar groove.

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

Page 17

890F4 OPERATOR MANUAL

STEP 6

Engage the tensioner pin into the

bar. Make sure all of the drive links

are inside the top and bottom bar

grooves, then pre-tension the

chain.

Unpacking & Assembly

GUIDEBAR AND DIAMOND CHAIN

INSTALLATION & TENSIONING

FRONT

STEP 8

Install the side cover over the

bar studs and finger tighten side

cover nuts.

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

STEP 7

Install the bar retaining plate over

the bar studs. Assure plate is

properly oriented so "FRONT" is

facing outward (as shown).

17

Page 18

Unpacking & Assembly

GUIDEBAR AND DIAMOND CHAIN

INSTALLATION & TENSIONING

ENGLISH

chain tensioner

STEP 9

Lift up on the nose of the bar and

tension the chain. Do not over

tension the diamond chain. Loss of

power will result.

890F4 OPERATOR MANUAL

18

CORRECT CHAIN TENSION

STEP 9

Continue to lift up on the nose

of the bar and firmly tighten the

side cover nuts using the scrench

(approximately 20 -25 ft. lbs (27-33

Nm). Improper torque can cause the

bar to slip.

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

CHAIN TOO TIGHT CHAIN TOO LOOSE

Page 19

890F4 OPERATOR MANUAL

Unpacking & Assembly

CHECKING & ADJUSTING CHAIN TENSION

All chains have a tendency to stretch when used. Diamond chains stretch

more than wood cutting chains because of the abrasive materials they

are cutting.

WARNING

Improper chain tension can lead to breakage of the chain or derailing of the

chain o of the guidebar.

Check chain tension frequently and adjust if drive links of chain hang 18 mm

(3/4 in) or more below the guidebar.

IMPORTANT

When a chain stretches to a point where the drive links are hanging

approximately 12 mm (1/2 in) to 18 mm (3/4 in) below the guidebar groove, it is

time to tension the chain.

A tight chain may rob power reducing cutting performance and increasing

chain friction, resulting in chain stretch. If the tension is set too loose the chain

could be thrown o of the bar or allow the sprocket to turn without turning the

chain which will damage the drive links.

CONNECTING TO HYDRAULIC SUPPLY

Assure hydraulic hoses are connected to power cutter with the proper ow

direction. The chain should travel away from the operator on the top of the bar

and return on the bottom of the bar. If hydraulic motor does not turn when

trigger is depressed, this may be an indication that the hydraulic ow direction

is likely reversed. Refer to diagram on page 13 for more details.

hydraulic ow direction

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

19

Page 20

Unpacking & Assembly

890F4 OPERATOR MANUAL

CONNECT TO WATER SUPPLY

Following are the basic instructions for correct water supply to the

power cutter.

CAUTION

ENGLISH

Insucient water supply will result in excessive chain stretch and may

cause chain breakage, damage to the guidebar, nose sprocket and drive

sprocket.

Never operate the power cutter with insucient water supply. In all cases,

assure that the water supply is delivering 1.5 bar (20 psi) pressure to the power

cutter at a minimum ow rate of 4 lpm (1gpm).

Inadequate water can result in increased potential for harmful airborne

particulates.

ICS® power cutters require a continuous water supply to the guidebar and

chain for the key purposes of cooling, lubrication and dust suppression. The

potential for airborne particulates depends on many factors including, but not

limited to, the material being cut, application and cutting environment.

NOTE: Local and/or regional regulation can vary widely. It is the responsibility

of the operator to wear appropriate dust protection applicable in their area and

suitable to the application.

Attach to water supply capable of delivering 1.5 bar (20 psi) pressure

to the power cutter at a minimum flow rate of 2 gpm/8 lpm. The single

most important factor an operator can control to increase chain life is

to use adequate water pressure.

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

20

Page 21

890F4 OPERATOR MANUAL

Operation

OPERATION

Following are the basic instructions for safe operation of the power cutter.

WARNING

Never start the power cutter without the bar, chain and side cover properly

assembled.

Unintentional contact with moving chain or components may occur.

DO NOT operate the power cutter with loose, missing, damaged or improperly

installed or repaired parts.

Check that the components shown below are intact, undamaged, and installed

correctly:

• Side cover nuts torqued down properly. Loose or improperly torqued side

cover nuts can lead to chain tensioner breakage

• Side cover not damaged and bae drain not plugged

• Handles not loose, gripping areas are clean and undamaged

• Mud ap is not ripped, torn or missing and is fully attached to the power cutter

• Guidebar not bent or otherwise damaged such as rails dished and uneven

• Nose sprocket not excessively worn or broken, and turns freely

• Diamond chain does not have loose rivets, chassis or drive link damage or

missing diamond segments

• Chain tensioner mechanism functions properly and pin is not bent or broken

• Drive sprocket not excessively worn

• Check alignment of drive sprocket and guidebar

• Assure proper chain tension: The chain should be easily pulled around the

guidebar by hand

• Assure all safety devices are properly mounted and functional and that all

controls are in proper working order

• Adequate water supply and pressure

Minimum flow: 2 gpm (8 lpm)

Minimum water pressure: 20 psi (1.5 bar)

• Proper hydraulic supply to the power cutter:

Maximum flow: 8 gpm (30 lpm) or 12 gpm (45 lpm), depending on power

cutter model

Maximum hydraulic pressure: 2,500 psi (172.5 bar)

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

21

Page 22

Operation

890F4 OPERATOR MANUAL

PRE-OPERATION SAFETY CHECKS

• Assure proper chain tension: The chain should be easily pulled around

the guidebar by hand.

• Assure all safety devices are properly mounted and functional and that

ENGLISH

all controls are in proper working order.

• Be sure there are no obstructions (plumbing, electrical conduit, air

ducts, etc.) and no unnecessary people present

• Always wear protective clothing, including hard hat, eye protection,

hearing protection, non-slip safety boots, gloves. Avoid wearing loose

fitting clothing.

• Adequate water supply and pressure

Minimum flow: 2 gpm (8 lpm)

Minimum water pressure: 20 psi (1.5 bar)

• Proper hydraulic supply to the power cutter:

Maximum flow: 8 gpm (30 lpm) or 12 gpm (45 lpm),

depending on power cutter model

Maximum hydraulic pressure: 2,500 psi (172.5 bar)

IMPORTANT

The single most important factor an operator can control to increase chain

life is to use adequate water pressure. Insufficient water supply may result

in excessive wear to the chain, which can lead to loss of strength and chain

breakage, and/or damage to the guidebar nose sprocket.

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

22

Page 23

890F4 OPERATOR MANUAL

Operation

PRECUT CHECKLIST

WARNING

Be sure that no part of the cutting system is contacting a solid object when

starting the power cutter.

The power cutter may react unexpectedly if the chain contacts a solid object.

WARNING

Sudden contact of the guidebar nose with a foreign object may generate

kickback.

Remove and/or avoid any obstructions (plumbing, water supply hoses,

electrical conduit, air ducts, etc.) that may interfere with the cut.

To avoid electrocution, check for live electrical wires.

Wires may be hidden within or behind walls and/or laying around the

workspace. Assure that any ancillary electrical equipment (fans, pumps,

vacuums, etc.) are properly grounded and certied for use in the intended

environment.

Always operate the power cutter with solid footing and both hands on the

power cutter.

Keep your left hand on the front handle and your right hand on the rear handle.

Wrap your thumbs around the handles to assure you maintain a secure grip on

both handles.

Always wear protective clothing.

At a minimum always wear eye protection and/or face shield, hearing

protection, long sleeve shirt, long pants, closed toe shoes with non-slip soles,

and gloves. In many work situations, a hard hat, steel toed shoes and a

respirator may also be required. Avoid loose tting clothing. Follow all local

regulations regarding PPE.

Cutting with the power cutter may generate sparks, especially when cut-

ting through metal (such as rebar), and may start a re in combustible

materials such as dry grass, wood and fuel.

Be sure to use adequate water pressure and have re ghting equipment

readily available.

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

23

Page 24

Operation

890F4 OPERATOR MANUAL

CUTTING WITH THE POWER CUTTER

WARNING

DO NOT insert the guidebar into a slot narrower than the width of the chain.

ENGLISH

Rapid pushback, kickback and/or chain breakage could result.

Be sure cut concrete cannot fall and injure the operator or bystanders.

Assure cut piece is controlled and does not fall unexpectedly.

NOTE: Concrete is very heavy; one cubic foot = 30 cm x 30 cm x 30 cm = 68 kg

(12 in x 12 in x 12 in = 150 lbs).

CAUTION

Slippery or unstable surfaces such as ladders may cause a loss of balance

or control of the power cutter.

Always keep proper footing and operate the power cutter only when standing

on xed, secure and level surface.

Unexpected loss of control of the power cutter and loss of balance can

result in injury.

Do not overreach and do not cut above shoulder height.

Do not allow workpiece to pinch the guidebar and chain, or rapid pushback

could result.

Always cut bottom of opening rst and assure workpiece is secure and does

not shift during cutting operations.

Do not operate power cutter upside down.

Cutting debris can be directed back towards the operator.

Take special precautions when cutting in horizontal orientation.

Be aware that debris may be ejected dierently than when cutting in a vertical

position.

IMPORTANT

Always operate power cutter at full throttle.

For best results, always operate the power cutter at full power.

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

24

Page 25

890F4 OPERATOR MANUAL

Operation

CUTTING WITH THE POWER CUTTER

To assure the best performance from your ICS power cutter, follow all safety

precautions and recommended techniques. Additional helpful information can be

obtained at icsdiamondtools.com.

CONCRETE/MASONRY CUTTING

Planning the Cut

1. Select the proper chain type for the material being cut. Refer to the chain

selection guide in this manual (page 32).

2. Outline the cut with a permanent marker for a visual cutting guide.

WARNING

3. Avoid pinching the guidebar and chain by using shims or

other anchoring devices to stabilize the workpiece. Always

plan to cut the bottom of an opening rst, then

top or sides. Save the easiest cut for last. (see

image at right)

4. Be sure cut concrete cannot fall and injure the operator

or bystanders. As the cut is being completed, assure that

appropriate bracing is in place to control the cut section

of the workpiece. Concrete is very heavy,

one cubic foot = 30 cm x 30 cm x 30 cm = 68 kg (12 in x 12 in x 12 in = 150 lbs)

3

22

1

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

25

Page 26

Operation

890F4 OPERATOR MANUAL

CONCRETE/MASONRY CUTTING

Recommended Concrete Cutting Techniques

ENGLISH

1. Plunge in

2. Cut down to open slot

3. Insert WallWalker® rotate rear handle up,

to rotate the nose down

4. Rotate rear handle down, to rotate the

nose up.

5. Reengage WallWalker® and repeat Steps

3 and 4

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

26

Page 27

890F4 OPERATOR MANUAL

Operation

CUTTING TIPS

• For the straightest cuts use the “Step Cut” method:

• First score the entire cut line approximately a half-inch deep using

the nose of the guidebar.

• Next, deepen the cut by about two inches

• Then plunge all the way through and complete the cut using the

WallWalker® as a pivot point and pull on the rear handle to rotate

the bar into the cut.

• When the WallWalker is extended in the mechanical mode, the Wall Walker

provides a 4:1 mechanical advantage.

• Always operate the concrete power cutter at full throttle. If too much force

is applied, the power cutter will lug or stall. The chain will not have enough

speed to cut eectively. If too little feed force is applied, the diamonds will

skid and glaze over.

• Plunge cut instead of starting at the top surface of the wall. This will

reduce chatter, extend diamond life, create a straighter cut and more

quickly enable the use of the WallWalker.

• When cutting heavy rebar, slowly “rock” the power cutter so that you’re

always cutting concrete as well as steel. This will help keep the diamonds

exposed. Also, expect less chain life when cutting heavy rebar.

• Expect more chain stretch when making nose-buried cuts for extende

periods of time, as the chain does not have a chance to “throw” the slurry

away from the nose of the guidebar (use step cut method).

• If the power cutter begins to cut consistently crooked, stop the power

cutter, remove the bar and chain and turn the bar over and use the other

side. Dress worn rails with a belt sander, at le or bar rail dresser.

Note: The normal life of a guidebar is two to three diamond chains (with

rotation after every chain). Heavy rebar can shorten guidebar life.

• The guidebar is solely a guide track for the chain. Never use the guidebar

to lift, twist or pry concrete material.

• When using a new chain, you can increase the initial cutting speed by

“opening up the diamonds”. This can be accomplished by rst making a

few cuts in an abrasive material such as a cinder block or brick.

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

27

Page 28

Operation

890F4 OPERATOR MANUAL

PIPE CUTTING USING

POWERGRIT® UTILITY CHAIN

To assure the best performance from your ICS® power cutter when cutting

ductile iron pipe or similar pipe materials, follow all safety precautions and recommended cutting techniques.

ENGLISH

WARNING

Never attempt to cut ductile iron pipe or similar pipe materials with the

power cutter unless using PowerGrit® Utility Chain.

Using concrete diamond chain in these applications can cause the chain to

snag abruptly in the cut which may result in chain breakage, pushback and/or

kickback.

Always assure that pipe is properly evacuated before cutting.

Pipes may contain sewage, gas or other hazardous materials.

Always support the pipe on both sides of the cut to assure the cut remains

open throughout the cutting operation, including when the cut is nished.

An improperly supported pipe can cause the cut to close, pinching the chain

and guidebar which may result in chain breakage, pushback and/or kickback.

Recommended Pipe Cutting Techniques

1. Make a small plunge cut into the lower quadrant

of the pipe to relieve internal pressure and allow

contents to drain from pipe in a controlled manner.

2. With pipe drained, cut from the top of pipe and

continue through bottom of the pipe.

3. To assure straightness of cut, guidebar should

extend completely through the pipe during the cut.

4. To assist with cutting, engage the WallWalker®

in the cut when possible to provide additional

leverage and alternate cutting between the near

and far side walls of the pipe.

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

28

Page 29

890F4 OPERATOR MANUAL

Maintenance

MAINTENANCE

IMPORTANT

SYSTEM CLEAN-UP

• After cutting, run the power cutter for at least 15 seconds with the water on

to flush slurry and debris from diamond chain, guidebar and drive sprocket.

• Wash concrete slurry and debris from power cutter assembly.

• Remove guidebar and chain. Flush out the chain tensioner and side cover

with water. Lubricate tensioner with waterproof grease.

• After cleaning the power cutter, spray the entire power cutter body, chain,

guidebar, and drive sprocket with lightweight oil. Using lightweight oil on

the power cutter will minimize rust and help reduce slurry build up.

AFTER EACH USE

• Inspect drive sprocket for wear

• Inspect and tighten all fasteners as necessary.

• Flush and rinse the power cutter, guidebar and chain with water

• Check trigger function assembly

• Check mud ap for tears or damage

• Check guidebar and chain for damage or missing segments

• Check trigger cover bubble levels

• With power cutter disconnected from power source, check hose whips

for leaks or damage.

• Inspect drive sprocket for wear.

• Replace when the drive teeth are worn more than half way through.

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

29

Page 30

Maintenance

890F4 OPERATOR MANUAL

DRIVE SPROCKET

Drive teeth

• The drive sprocket is a wear item and

should be replaced every two to three

chains, or when the teeth become pointed

ENGLISH

or if a groove cuts through top of tooth.

• Inspect the sprocket for wear.

• Inspect drive shaft for wear.

Snap Ring

DRIVE SPROCKET ASSEMBLY

REMOVAL/INSTALLATION

• Disconnect power cutter from the

power source

• Remove the side cover, bar retainer plate,

guidebar and diamond chain

• Remove snap ring from shaft

• Slide drive sprocket off shaft

• Slide new sprocket onto shaft

• Replace snap ring onto shaft and assure complete engagement

in shaft groove

• Installation of new drive sprocket is complete.

• Reinstall guidebar, diamond chain, bar retainer plate and side cover.

• Assure diamond chain and guidebar are in good, useable condition. Worn

or damaged guidebar and chain can damage the new drive sprocket.

Drive Sprocket

30

Snap Ring

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

Drive Shaft

Drive Sprocket

Page 31

890F4 OPERATOR MANUAL

Maintenance

CHAINS & GUIDEBARS

IMPORTANT

Inspect chain segments and drive links for damage or excessive wear. Chains

with damage or excessive wear should not be used or repaired, they should be

replaced.

NOTE: Guidebars are designed to be used on both sides. If the cut is consistently

leading to one side, turn the guidebar over. It is recommended to turn the guidebar

over with every new chain.

• A table mounted belt, disc sander, at le or bar rail dressercan be used to

square the rails of a worn guidebar. A badly worn guidebar can quickly damage

the chain. If the chain is touching the bottom of the guidebar groove, replace

the guidebar.

• Check the guidebar for straightness.

• Proper chain tension will extend guidebar life.

• Under some circumstances, especially low water pressure, the sprocket nose

can wear out before the guidebar body. Sprocket nose assemblies may be

replaced by an Authorized Service Center.

• Periodically clean the water ports inside the groove of the guidebar using a

small diameter piece of wire or pipe cleaner.

• The guidebar is solely a guide track for the chain. Never use the guidebar to lift,

twist or pry concrete material.

• Prior to storage, spray the chain and guidebar with lightweight oil.

CHAIN TENSIONER

The chain tensioner can become clogged with concrete slurry during cutting.

• After each use thoroughly ush the chain tensioner with water and apply a

liberal amount of waterproof grease covering the chain tensioner screw.

Chain Tensioner

FRONT

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

31

Page 32

Maintenance

890F4 OPERATOR MANUAL

890F4 CHAIN SELECTION GUIDE & CONSUMABLES

890 F4 Chain Selection Guide

Medium

Concrete/Light

Reinforcement

◊ ◊

ENGLISH

FORCE4®

General Purpose

FORCE4® Premium L

Longer Cutting Life

FORCE4® Premium S

Faster Cutting Speed

FORCE4®

Ideal for brick & block

PowerGrit

For Utility Pipe

Chain &

Applications

Abrasive

®

Soft Stone/

Abrasive/Brick

◊

Natural Stone

◊ ◊ ◊

◊ ◊ ◊

890F4 Consumables

10 in (25 cm) 15 in (38 cm) 20 in (50 cm) 25 in (63 cm)

FORCE4® Diamond Chain p/n 531743 p/n 525342 p/n 531749 p/n 525345

Premium L Diamond Chain p/n 531745 p/n 525343 p/n 531751 p/n 525346

FORCE4®

FORCE4® Premium S Diamond Chain p/n 531739 p/n531735 p/n 531741 p/n 531737

FORCE4® Abrasive Diamond Chain p/n 531747 p/n 525344 p/n 531753 p/n 525347

®

Diamond Chain p/n 537764 p/n 537765 p/n 545017

PowerGrit

FORCE4® Guidebar p/n 529829 p/n 523080 p/n 529767 p/n 525320

Drive Sprocket 565065

Hard

Concrete/ Heavy

Reinforcement

Ductile Iron/Cast

Iron/PVC/HDPE

◊

32

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

Page 33

890F4 OPERATOR MANUAL

TROUBLESHOOTING

PROBLEM Possible Cause

Low hydraulic oil.

POWER CUTTER WON'T REACH

FULL RPM

SLOW CHAIN SPEED

POOR CUTTING SPEED

PREMATURE CHAIN STRETCH

Worn hydraulic power cutter motor

Worn hydraulic val ve assembly.

Worn powerpack pump

All of the above, plus chain tension too tight. Chain should al ways be

able to be pulled around the guidebar by hand. It i s norm al for the drive

links of the chain to hang below the guidebar. See pages 15-19 for chain

tensioning instructions.

All of the above, plus d iamonds may be glazed over. Make a few cuts in an

abrasive material to expose the diamonds.

Chain or diamonds m ay be worn out.

Worn dr ive sprocket.

Init ial chain tension too tight.

Bar nose buried in cu t.

Not enough water pressure. The minimum water pressure required is 1.5

bar (20 psi).

Chain comes i n contact with ground, dirt, g ravel a nd/or sand.

Troubleshooting

CHAIN TENSIONER BREAK AGE

WATER NOT FLOWING

MOTOR DOES NOT TURN

CHAIN BREAKAGE

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

Side cover nuts are not tight e nough. Torque to 27-33 Nm (20 -25 ft-lbs).

Tensioning with side cover nu ts already tight.

Tensioner pin not aligned and side cover tightened.

Water hose is kinked or water supply not turned on.

Water ports plugged with debris.

Damaged or worn water valve in power cutter.

Hydraulic lines connected backwards or power pack is set to reverse.

Chain tension is too tight.

Improper chain tension.

Insufficient water pressure.

Inserting power cutter into slot nar rower t han di amond chain segments.

Using chain that is a lready stretched beyond abilit y to tension .

Contact with exposed rebar or steel.

33

Page 34

Technical Speccations

TECHNICAL SPECIFICATIONS

890 Series 8 gpm (30 lpm) 890 Series 12 gpm (45 lpm)

890F4 OPERATOR MANUAL

Weight w/out bar and

ENGLISH

chain (1' hose whips)

Length 23 inches (58.5 cm)

Height 10.5 inches (26.5 cm)

Width 9.5 inches (24 cm)

Hydraulic Supply

Hydraulic Fluid

Requirements (Type)

Water Pressure Minimum: 20 psi (1.4 bar)

Water Flow 2 gpm (8 lpm) minimum

Operating Speed

Torque(1) 7.0 ft-lbs (9.6 Nm) 10.0 ft-lbs (13.5 Nm)

Horsepower (1) 6 hp (4.5 kW) 8 hp (6.0 kW)

Guaranteed Sound Power

Level Lwa (2)

Equivalent Sound Pressure

at the Operator's E ar L

Vibration a

Vibration a

(1)Measured using 18HP hydraulic power pack (8 gpm/30 lpm and 23HP hydraulic power pack (12 gpm/45 lpm) at 2000psi/138 bar.

(2) Measured in accordance with ISO3744:2010

(3) Measured in accordance with ISO5349-1:2001

hv, eq

Cutting (3)

hv, eq

Cutting (3)

pA

Concrete

PowerGrit

(2)

8 gpm (30 lpm) @

2,500 psi (172.5 bar)

6,100 rpm (avg. free running)

5,500 sfm (avg. free running chain)

23.5 lbs (10.6 kg)

PC HYDREX MV32 or equi valent

107 dB(A) (K=0.2 dB(A ))

98 dB(A) (K=0.7 dB(A ))

2.0 m/s2 (K=0.1 m/s2) Front Handle

6.0 m/s2 (K=1.4 m/s2) Rear Handle

4.6 m/s2 (K=0.1 m/s2) Front Handle

4.8 m/s2 (K=0.3 m/s2) Rear Handle

12 gpm (45 lpm) @

2,500 psi (172.5 bar)

6,500 rpm (avg. free r unning)

5,80 0 sfm (avg. free running chain)

34

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

Page 35

890F4 OPERATOR MANUAL

Service Centers

AUTHORIZED SERVICE CENTERS

KENNEDY EQUIPMENT CO INC 714.771.7324 748 N. LEMON ST ORANGE CA 92867

ABLE TOOL EQUIPMENT 860.289.2020 410 BURNHAM STREET SOUTH WINDSOR CT 06074

EQUIPSERV LLC 770.709.5101 6225 MABELTON PARKWAY SW MABLETON GA 30126

STAR EQUIPMENT 515.283.2215 1401 2nd AVE DES MOINES IA 50314

MCCANN INDUSTRIES, INC. 630.627.8700 543 SOUTH ROHLWING RD ADDISON IL 60101

CLEAN RITE TECH 504.468.7997 1332 FULTON ST KENNER LA 70062

ACE CUTTING EQUIPMENT 248.449.4944 25806 NOVI RD. NOVI MI 48375

CONCRETE CUTTING & CORING 952.882.0980 12690 CREEK VIEW AVE SAVAGE MN 55378

ACME ELECTRIC 218.628.3523 4332 GRAND AVE DULUTH MN 55807

MERLIN STELZER SALES CO., INC. 314.535.7540 4109 PAPIN ST ST. LOUIS MO 63110

ACME ELECTRIC 701.258.1267 3840 E. ROSSER AVE BISMARCK ND 58501

ACME ELECTRIC 701.746.6481 1705 12TH AVE NORTH GRAND FORKS ND 58203

ACME ELECTRIC 701.476.4600 920 36TH STREET S.W. FARGO ND 58103

ACME ELECTRIC 701.839.2263 700 20TH AVE S.E. MINOT ND 58701

ADMAR SUPPLY 585.272.9390 1950 BRIGHTON-HENRIETTA TL RD ROCHESTER NY 14623

ADMAR SUPPLY 315.433.5000 6014 DROTT DR EAST SYRACUSE NY 13057

ADMAR SUPPLY 518.690.0750 878 ALBANY SHAKER RD LATHAM NY 12110

ADMAR SUPPLY 607.754.4700 2305 OLD VESTAL RD VESTAL NY 13850

ADMAR SUPPLY 716.873.8000 1394 MILITARY RD BUFFALO NY 14217

CESSCO, INC. 503.288.1242 4222 N.E. COLUMBIA BLVD. PORTLAND OR 97218

TRI-BORO CONST. SUPPLIES 800.632.9018 435 LOCUST ST DALLASTOWN PA 17313

LEHIGH CONSTRUCTION SUPPLY CO. 570.654.3981 295 SCHOOLEY AVE EXETER PA 18643

DRIVEKORE, INC. 717.766.7636 101 WESLEY DRIVE MECHANICSBURG PA 17055

ECKHART CONSTRUCTION 803.802.6635 1019 SOCIETY LANE FORT MILL SC 29707

STAN HOUSTON EQUIPMENT 605.336.3727 501 SOUTH MARION ROAD SIOUX FALLS SD 57106

STAN HOUSTON EQUIPMENT 605.348.1155 1210 DEADWOOD AVENUE RAPID CITY SD 57702

LINCOLN CONTRACTORS SUPPLY 414.541.1327 11111 WEST HAYES AVE MILWAUKEE WI 53227

LINCOLN CONTRACTORS SUPPLY 608.249.6476 901 WALSH RD MADISON WI 53714

LINCOLN CONTRACTORS SUPPLY 715.359.6111 5207 WESTFAIR AVE SCHOFIELD WI 54476

LINCOLN CONTRACTORS SUPPLY 920.757.1901 5663 NUEBERT RD APPLETON WI 54913

LINCOLN CONTRACTORS SUPPLY 920.432.8697 1654 MORROW ST GREEN BAY WI 54302

LINCOLN CONTRACTORS SUPPLY 715.874.4100 7840 PARTRIDGE AVE EAU CLAIRE WI 54703

LEE JENSEN SALES CO, INC 815 459-0929 101 WEST TERRA COTTA CRYSTAL LAKE IL 60014

ROCK-CRETE EQUIPMENT LTD. 604 464-1448 50 BURBIDGE STREET COQUITLAM BC V3K 6B1

CONCUT DIAMOND PRODUCTS 561-989-8895 6500 W ROGERS CIRCLE SUITE 6000 BOCA RATON FL 33487

AUSTECH SUPPLIES PTY LTD 61298541200 UNIT 12, 197 POWER STREET GLENDENNING NSW 2761

HATCH BUILDING SUPPLY COMPANY 608 222-0011 5601 MANUFACTURERS DRIVE MADISON WI 53704

AMERICAN TOOL AND FASTENER 972-801-9909 1331 E PLANO PKWY STE #B PLANO TX 75074

HENARD UTILITY PRODUCTS, INC 501 268-1987 1920 S. MAIN STREET SEARCY AR 72143

DEALER PHONE ADDRESS CITY STAT E POSTAL CODE

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

35

Page 36

890F4 OPERATOR MANUAL

ICS, Blount, Inc.

4909 SE International Way

Portland, OR 97222, USA

Tel 800.321.1240 Fax 503.653.4393

ICS, Blount Europe S.A.

Rue Emile Francqui, 5

1435 Mont-Saint-Guibert, Belgium

Tel +32 10 301 251 Fax +32 10 301 259

icsdiamondtools.com

© 2018 ICS®, Blount International Inc. REV07192018 P/N 566594

Loading...

Loading...