Page 1

695XL

OPERATOR MANUAL

WARNING: READ AND UNDERSTAND ALL SAFETY WARNINGS

AND ALL INSTRUCTIONS BEFORE YOU USE THIS EQUIPMENT.

Failure to follow the warnings and instructions may result in re, serious injury, or death.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

© 2016 ICS®, Blount International Inc. Specications are subject to

change without notice. REV030816 F/N 577452

Page 2

695XL OPERATOR MANUAL 695XL OPERATOR MANUAL

This instruction manual contains translations of a manual drafted in English and

are provided to assist those who do not speak English as their rst language.

Being a technical writing, some terms may not have a like or equivalent meaning

as translated. Therefore, you should not rely on this translation, and should

cross-reference the English version, where relying on the translated instructions

could result in harm to your person or property.

© 2016 ICS®, Blount International Inc. Specications are subject to change

2 3

without notice. REV030816 F/N 577452

Page 3

TABLE OF CONTENTS

Table of Contents

SYMBOLS AND LABELS

ICS695XL NAMES AND TERMS

PRODUCT IDENTIFICATION

INTRODUCTION

SAFETY RULES

UNPACKING AND ASSEMBLY

FUELING

OPERATION

TRANSPORTING & STORING

MAINTENANCE

TROUBLESHOOTING

EMISSIONS

TECHNICAL SPECIFICATIONS

SERVICE CENTERS

4

8

10

11

12

16

23

26

36

37

45

47

49

50

© 2016 ICS®, Blount International Inc. Specications are subject to change

without notice. REV030816 F/N 577452

Page 4

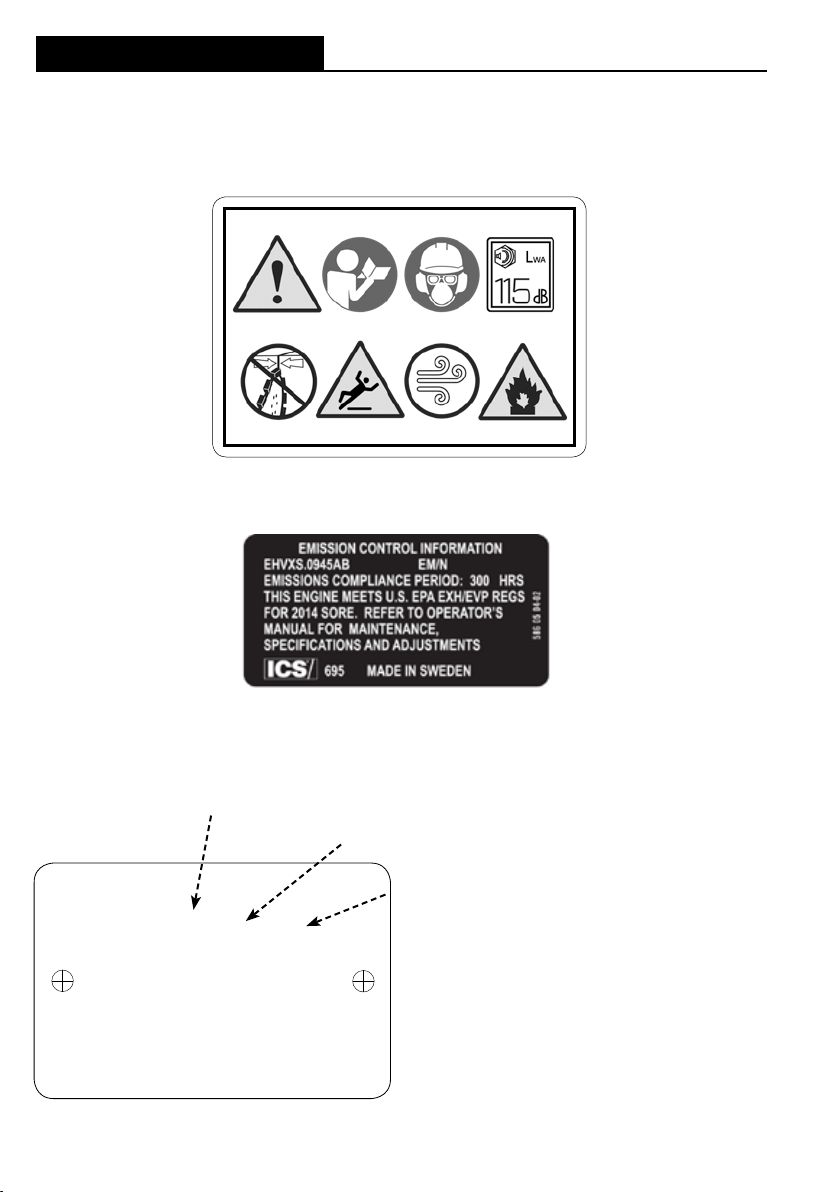

Symbols & Labels

695XL OPERATOR MANUAL 695XL OPERATOR MANUAL

SYMBOLS AND LABELS

THE FOLLOWING SYMBOLS ARE FOUND THROUGHOUT THIS MANUAL

AND/OR ON THE SAW AND ARE DESIGNED TO MAKE YOU AWARE OF POTENTIAL

HAZARDS OR UNSAFE PRACTICES.

SAFETY ALERT

Indicates that the text that

follows explains a danger,

warning or caution.

WEAR LONG PANTS

Wear long pants when operating

the saw.

READ INSTRUCTIONS

The original instruction manual

contains important safety and

operating information. Read and

follow the instructions carefully.

WEAR FOOT PROTECTION

Wear appropriate closed-toe

boots when operating the saw.

WEAR EYE, HEARING AND

RESPIRATORY PROTECTION

WEAR HEAD PROTECTION

Wear eye , hearing

and respiratory protection and a

protective helmet when

operating the saw.

WEAR HAND PROTECTION

Wear hand protection when

operating the saw.

KERF WIDTH

Do not insert tool into slot

narrower than chain.

© 2016 ICS®, Blount International Inc. Specications are subject to change

4 5

VENTILLATION REQUIRED

Use tool in a well ventillated area

without notice. REV030816 F/N 577452

Page 5

Symbols & Labels

SYMBOLS AND LABELS

THE FOLLOWING SYMBOLS ARE FOUND THROUGHOUT THIS MANUAL

AND/OR ON THE SAW AND ARE DESIGNED TO MAKE YOU AWARE OF POTENTIAL

HAZARDS OR UNSAFE PRACTICES.

SOUND POWER

Sound power level is 115 dB(A).

ONE-HANDED HOLD

Do not operate the saw

with one hand.

BEWARE OF KICKBACK

Kickback can cause severe

injuries.

DO NOT USE A LADDER

Never stand on a ladder when

using the saw.

TWO-HANDED HOLD

Operate the saw with two hands,

securely gripping both handles

FIRE DANGER

Risk of re if warnings not

followed.

SLIPPERY SURFACE

Unsure footing can lead to

accidents.

© 2016 ICS®, Blount International Inc. Specications are subject to change

without notice. REV030816 F/N 577452

Page 6

Symbols & Labels

LABELS ON YOUR SAW

SAFETY LABEL

EMISSIONS LABEL

695XL OPERATOR MANUAL 695XL OPERATOR MANUAL

LABEL SHOWN FOR REFERENCE ONLY

NAMEPLATE LABEL

ÅÅÅÅ = Year of Manufacture (ie. 2015)

VV = Week number within the year (ie. 07)

ICS 695XL

s/n ÅÅÅÅ VVXXXXX

967 29 09-01

Blount, Inc.

Portland, OR, USA

e5*97/68SH3G3*

2010/26*0152*00 (II)

© 2016 ICS®, Blount International Inc. Specications are subject to change

6 7

without notice. REV030816 F/N 577452

XXXXX = Saw number within production

batch in sequential order beginning with

00001

Page 7

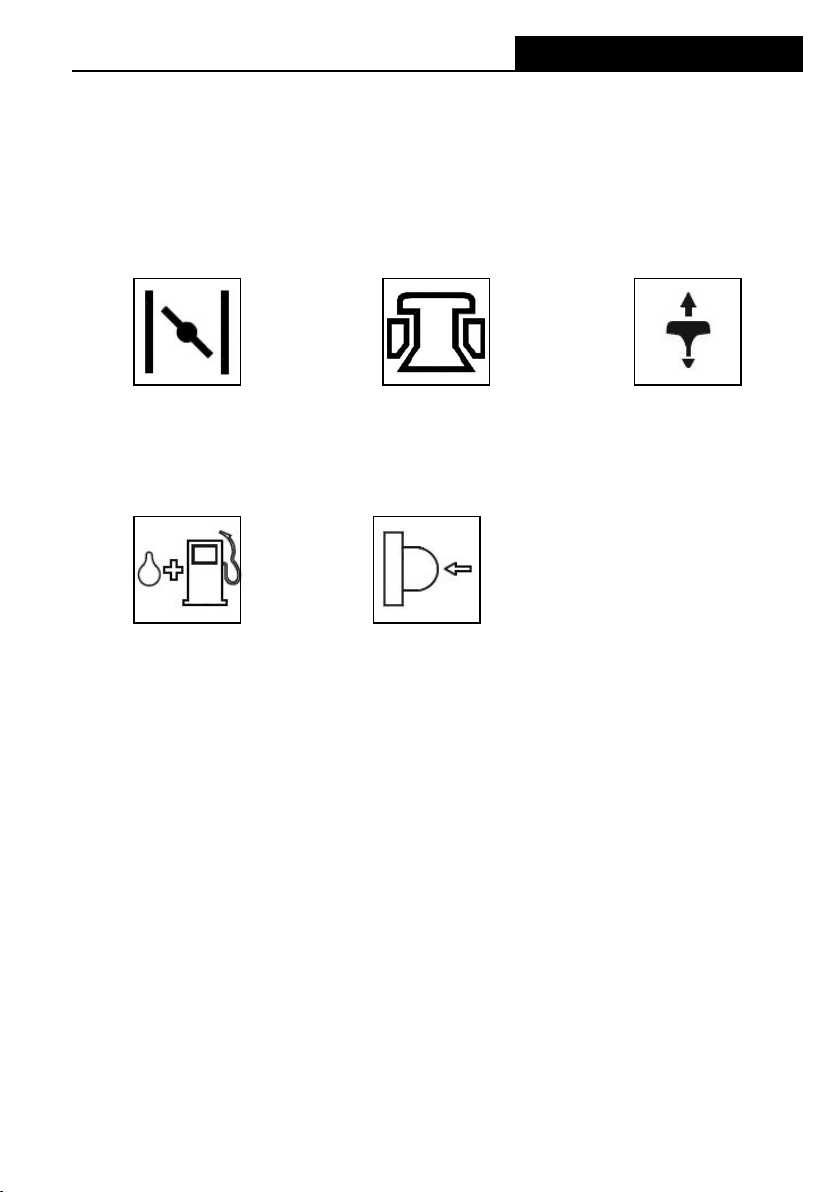

LABELS ON YOUR SAW

OPERATOR CONTROLS

Symbols & Labels

CHOKE CONTROL

MULTI-FUNCTION LEVER

REFUELING PRIMER/PURGER BULB

DECOMPRESSION VALVE STARTER HANDLE

© 2016 ICS®, Blount International Inc. Specications are subject to change

without notice. REV030816 F/N 577452

Page 8

Names & Terms

695XL OPERATOR MANUAL 695XL OPERATOR MANUAL

ICS695XL NAMES AND TERMS

Air box intake

The only entry point of air into the engine

Bar pad

The mounting pad on the powerhead that helps assure proper alignment of the

guidebar.

Bar slot

The slot feature on the guidebar that ts over the alignment block and bar stud.

Bystander safety zone

A 6 m (20 ft) circle around the operator that must remain free from bystanders,

children and pets.

Chain catcher

A device for retaining the chain if it breaks or derails.

Chain pitch

The distance between any three consecutive rivets on the chain divided by

two.

Chain tensioning screw

An adjustment screw used to set proper tension on the chain and compensate

for chain stretch from normal use.

Decompression valve

A device that relieves engine pressure to assist starting.

Front handle

The support handle located at or toward the front of the saw intended to be

gripped by the left hand.

Guidebar

A railed structure that supports and guides the chain. Sometimes simply called

the “bar”.

Kickback

The rapid backward and/or upward motion of the guidebar, occurring when the

chain near the top area of the nose of the guidebar contacts a foreign object or

snags in the workpiece.

Multi-function lever

A device for setting the choke and temporarily advancing the throttle in a

partially open position to aid starting.

Mud ap

A barrier to protect the operator from cutting debris and other projectiles.

© 2016 ICS®, Blount International Inc. Specications are subject to change

8 9

without notice. REV030816 F/N 577452

Page 9

Names & Terms

ICS695XL NAMES AND TERMS

On/O or “Stop” control

A control that allows the engine to run or causes the engine to stop.

Powerhead

A saw without the chain or guidebar.

Primer/Purger bulb

A device in the fuel system for supplying extra fuel or for evacuating air to aid

starting.

Pushback

The rapid backward motion of the guidebar, occurring when the chain on

the top straight portion of the guidebar contacts a foreign object or

snags in the workpiece.

Rear handle

The support handle located at or toward the rear of the saw intended to be

gripped by the right hand.

Rear hand guard:

A structural barrier at the bottom right side of the rear handle to protect the

operator in case the chain breaks or derails.

Side cover:

The component on the powerhead that covers the drive sprocket and directs

debris away from the operator during use.

Side cover nut:

The component on the side cover that secures the side cover and guidebar.

Throttle trigger lock-out

A device that prevents the unintentional operation of the throttle trigger until

manually released.

Throttle trigger

A mechanism that controls engine RPM.

WallWalker®

A device used as a fulcrum to provide mechanical advantage during cutting.

Water shut-o valve

A mechanism that controls water delivery and ow to the guidebar and chain.

© 2016 ICS®, Blount International Inc. Specications are subject to change

without notice. REV030816 F/N 577452

Page 10

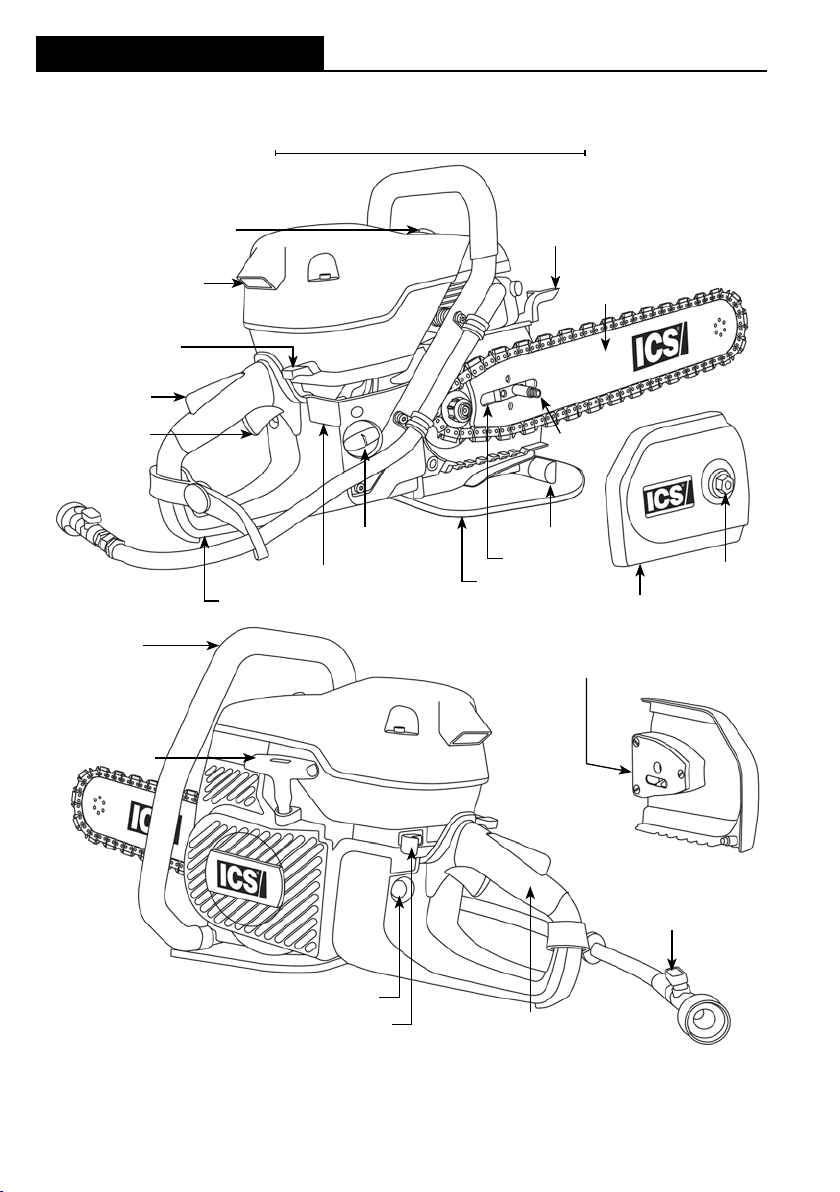

Product Identication

PRODUCT IDENTIFICATION

695XL OPERATOR MANUAL 695XL OPERATOR MANUAL

Powerhead

Decompression valve

Air box intake

Multi-function lever

Throttle trigger

lock-out

Throttle trigger

Front handle

Starter handle

Nameplate

Rear hand guard

Fuel filler cap

WallWalker®

Guidebar

Bar stud

Chain catcher

Bar slot

Mud flap

Side cover

Chain tensioning screw

Side cover nut

Water shut off valve

Primer/Purger

On/Off or Stop Control

© 2016 ICS®, Blount International Inc. Specications are subject to change

10 11

without notice. REV030816 F/N 577452

Rear handle

Page 11

Introduction

INTRODUCTION

The 695XL saw is designed to cut concrete, stone, and masonry when used with

the appropriate genuine ICS Diamond Chain. Ductile iron pipe may also be cut but

ONLY if using PowerGrit® Utility Saw Chain. This is a professional tool and

is solely intended for use by trained and experienced operators. A rst time

operator should obtain practical instruction before using the saw, as well as

reading and understanding this Operator’s Manual.

Local legislation and/or workplace standards may regulate the use of this saw.

Determine what regulations are applicable in the place you work before using

the saw.

Prop 65 statement:

California Proposition 65 (the Safe Drinking Water and Toxic Enforcement Act of

1986) refers to the California legislation that was intended by its authors to protect

California citizens and the State’s drinking water sources from chemicals known

to cause cancer, birth defects or other reproductive harm, and to inform citizens

about exposures to such chemicals. Proposition 65 requires businesses to notify

Californians about signicant amounts of chemicals in the products they purchase,

in their homes or workplaces, or that are released into the environment. By

providing this information, Proposition 65 enables Californians to make informed

decisions about protecting themselves from exposure to these chemicals.

Proposition 65 also prohibits California businesses from knowingly discharging

signicant amounts of listed chemicals into sources of drinking water.

The engine exhaust from this machine and some types of dust/debris created from

its normal operation may contain chemicals known to the State of California to

cause cancer, birth defects or other reproductive harm.

© 2016 ICS®, Blount International Inc. Specications are subject to change

without notice. REV030816 F/N 577452

Page 12

Safety Rules

695XL OPERATOR MANUAL 695XL OPERATOR MANUAL

SAFETY RULES

To get the maximum benet from your saw, and assure maximum safety, be sure to

read this manual thoroughly and follow the safety instructions provided.

EXPLANATION OF WARNING LEVELS

DANGER

Indicates a hazard with a high level of risk which, if not avoided, will result in death or

serious injury.

WARNING

Indicates a hazard with a medium level of risk which, if not avoided, could result in

death or serious injury.

CAUTION

Indicates a hazard with a low level of risk which, if not avoided, could result in minor

or moderate injury.

IMPORTANT

Indicates a potential situation exists which, if not avoided, may result in damage to

your saw or property.

© 2016 ICS®, Blount International Inc. Specications are subject to change

12 13

without notice. REV030816 F/N 577452

Page 13

Safety Rules

HANDLING FUEL SAFELY

WARNING

Fuel vapors are highly ammable.

Turn o the saw, lock the o/on switch in the “STOP” position, and allow the engine

to cool a few minutes before fueling. Do not smoke or refuel the saw in close

proximity to any ignition sources. Move the saw at least 3 m (10 ft) from the fueling

area before restarting it.

Avoid spilling fuel on yourself or on the saw.

Use only approved containers to transport and store fuel. If fuel is spilled on the

saw, wipe up the spillage and allow the rest to evaporate. If fuel is spilled on

yourself or your clothes, immediately remove contaminated clothing and wash any

part of your body that has contacted fuel with soap and warm water.

CAUTION

Check saw for fuel leaks before starting.

Check regularly for leaks from the fuel caps and fuel lines and do not start saw if

any leaks are found.

WORK AREA SAFETY

Following are the basic instructions to assure work area safety.

DANGER

Breathing exhaust gases can cause asphyxiation and carbon monoxide

poisoning in high concentrations.

Use the saw only in a well-ventilated area.

WARNING

Drugs or alcohol can impair vision, dexterity, and judgment.

Do not operate the saw when tired or under the inuence of any substance.

CAUTION

Remove or control slurry to prevent slippery conditions while cutting.

This saw uses water and can cause slippery surfaces due to the slurry

produced and/or freezing temperatures.

Keep children and bystanders away from work area.

Set up a well-marked safety zone with a roped boundary and clear signs to keep

bystanders at least 6 m (20 ft) away.

© 2016 ICS®, Blount International Inc. Specications are subject to change

without notice. REV030816 F/N 577452

Page 14

Safety Rules

695XL OPERATOR MANUAL 695XL OPERATOR MANUAL

PERSONAL SAFETY

Following are the basic instructions to assure personal safety.

WARNING

Always wear protective clothing.

At a minimum always wear eye protection and/or face shield, hearing protection,

long sleeve shirt, long pants, closed toe shoes with non-slip soles, and gloves. In

many work situations, a hard hat and steel toed shoes may also be required. Avoid

loose tting clothing.

Long-term exposure to noise can result in permanent hearing impairment.

Always wear approved hearing protection.

This saw can generate hazardous dust and vapors.

Determine the nature of the material you are going to cut before proceeding with

the job. Be especially aware of cutting materials containing silica and asbestos

as inhaling dust can result in respiratory disease. Be sure to use appropriate

respiratory protection designed to lter out microscopic particles. Be sure to use

adequate water pressure.

Over-exposure to vibration can lead to circulatory and/or nerve damage to the

extremities, especially in cold temperatures (Reynaud’s Disease).

If you experience tingling, numbness, pain or changes in skin color, particularly in

your ngers, hands or wrists, stop using the saw immediately. If the problem

persists, seek medical attention.

This machine produces an electromagnetic eld during operation.

This eld may under some circumstances interfere with active or passive medical

implants. To reduce the risk of serious or fatal injury, we recommend persons with

medical implants consult their physician and the medical implant manufacturer

before operating this machine.

© 2016 ICS®, Blount International Inc. Specications are subject to change

14 15

without notice. REV030816 F/N 577452

Page 15

Safety Rules

USING THE ICS SAW SAFELY

Following are the basic instructions to assure safe use of the saw. Also read and

understand additional safety precautions specic to the operation and

maintenance of the saw throughout this manual.

DANGER

DO NOT operate the ICS saw with a saw chain or saw bar designed to cut

wood.

Using wood cutting saw chain on the ICS saw could result in severe injuries to

the operator or a bystander! Use ONLY the cutting attachments specied in this

manual on this saw.

WARNING

DO NOT operate the saw with damaged, modied, broken, or missing

components.

Below safety features are designed to protect against contact with moving parts,

ejected debris, broken chain, thrown water, and concrete slurry.

• Side cover

• Mud ap

• Mud ap bracket (Chain Catcher)

• Rear hand guard

• Throttle trigger lock-out

Use only Genuine ICS replacement parts. Use of unauthorized aftermarket parts

may result in injury or damage to the saw.

DO NOT insert the guidebar into a slot narrower than the width of the chain.

Rapid pushback, kickback and/or chain breakage could result.

DO NOT operate the saw without an adequate water supply.

The integral water supply channels in the guidebar act to cool and lubricate the

cutting system as well as to suppress dust and debris generated during cutting.

Assure that the water supply is capable of delivering 1.5 bar (20 psi) pressure to the

saw at a minimum ow rate of 4 lpm (1 gpm).

Never attempt to cut ductile iron pipe or similar pipe materials with the saw

unless using PowerGrit® Utility Saw Chain.

Using concrete saw chain in these applications can cause the chain to snag

abruptly in the cut which may result in chain breakage, pushback and/or kickback.

© 2016 ICS®, Blount International Inc. Specications are subject to change

without notice. REV030816 F/N 577452

Page 16

Unpacking & Assembly

695XL OPERATOR MANUAL 695XL OPERATOR MANUAL

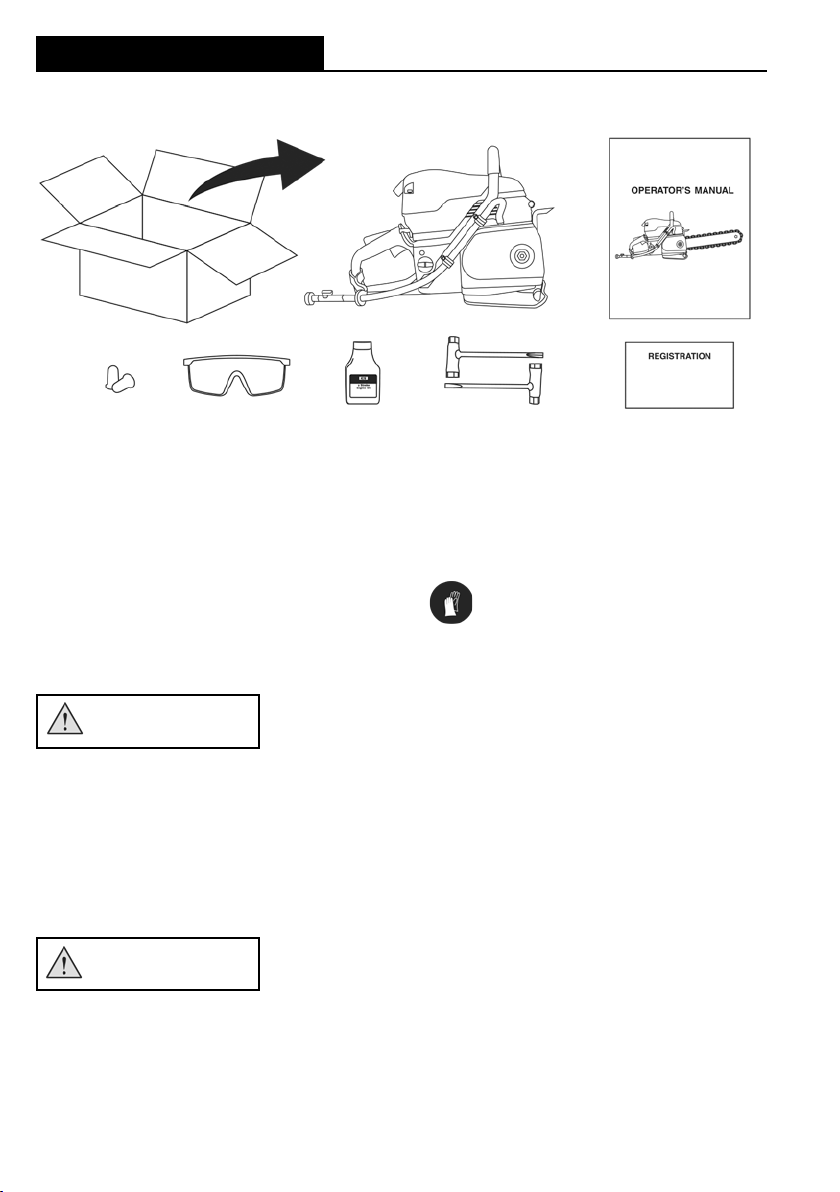

BOX CONTENTS

Minimum contents for all packages shown. Some packages also contain

guidebar and diamond chain.

See page 44 for listing of compatible guidebars and diamond chain.

GUIDEBAR AND DIAMOND CHAIN

INSTALLATION & TENSIONING

Following are the basic instructions for guidebar and diamond chain installation

and tensioning.

WARNING

Never perform any maintenance or adjustments on the saw while the engine is

running.

Be sure the on/o control is locked in the “STOP” position before proceeding.

Improper chain tension can lead to failure of the chain or derailing of the chain

o of the guidebar.

Check tension frequently and adjust if drive links of chain hang 18 mm (3/4 in) or

more below the guidebar groove

CAUTION

Always wear gloves when handling the bar and chain.

These components can develop sharp edges and cause cuts.

© 2016 ICS®, Blount International Inc. Specications are subject to change

16 17

without notice. REV030816 F/N 577452

Page 17

GUIDEBAR AND DIAMOND CHAIN

INSTALLATION & TENSIONING

STEP 1

Loosen side cover nut and remove side cover.

Unpacking & Assembly

STEP 2

Place guidebar slot over bar stud and alignment

block, ensuring even contact with bar pad.

© 2016 ICS®, Blount International Inc. Specications are subject to change

without notice. REV030816 F/N 577452

Page 18

Unpacking & Assembly

695XL OPERATOR MANUAL 695XL OPERATOR MANUAL

GUIDEBAR AND DIAMOND CHAIN INSTALLATION & TENSIONING

STEP 3

Mount the diamond chain on the guidebar starting

at the drive sprocket and continue over the

guidebar nose.

NOTE: FORCE4® requires rim to be pulled outward

for chain installation.

STEP 4

Install the side cover and assure tensioning

adjustment pin engages in the mating hole in

the guidebar. Tighten side cover nut finger tight,

but do not fully tighten until chain is properly

tensioned.

NOTE: To ease assembly, turn tensioning screw

fully counterclockwise before installing side cover.

© 2016 ICS®, Blount International Inc. Specications are subject to change

18 19

without notice. REV030816 F/N 577452

Page 19

Unpacking & Assembly

GUIDEBAR AND DIAMOND CHAIN INSTALLATION & TENSIONING

STEP 5

Make sure all the drive links are inside the

guidebar groove then lift the bar nose and tension

the chain by turning the tensioning

screw clockwise.

STEP 6

Check for proper tension by pulling the chain

around the bar by hand. If you cannot easily pull

by hand, the chain is too tight and needs to be

loosened slightly.

CAUTION: Be aware that the guidebar rails may

develop sharp edges over time so always pull the

diamond chain by the diamond segments.

© 2016 ICS®, Blount International Inc. Specications are subject to change

without notice. REV030816 F/N 577452

Page 20

Unpacking & Assembly

695XL OPERATOR MANUAL 695XL OPERATOR MANUAL

GUIDEBAR AND DIAMOND CHAIN INSTALLATION & TENSIONING

STEP 7

Continue to lift up on the nose of the guidebar and

firmly tighten the side cover nut.

NOTE: Tighten the side cover nut to 27-33 Nm

(20 -25 f t-lbs).

CHAIN TOO TIGHT

STEP 8

Correct chain tension is achieved when drive links

of chain hang just outside of the bar groove. Chain

CHAIN TOO LOOSE

should move freely around guidebar by hand.

© 2016 ICS®, Blount International Inc. Specications are subject to change

20 21

without notice. REV030816 F/N 577452

Page 21

Unpacking & Assembly

CHECKING & ADJUSTING CHAIN TENSION

All chains have a tendency to stretch when used. ICS chains stretch more than

wood cutting chains because of the abrasive materials they are cutting.

WARNING

Improper chain tension can lead to failure of the chain or derailing of the chain

o of the guidebar.

Check chain tension frequently and adjust if drive links of chain hang 18 mm (3/4 in)

or more below the guidebar.

CAUTION

Assure that proper chain tension is maintained.

If tension is set too tight, it will lead to excessive chain stretch, and most of the

saw’s power will be used just to overcome friction. In severe cases the chain may

not turn at all, and can lead to chain breakage. If the tension is set too loose, the

chain could be thrown o of the bar, or allow the sprocket to turn without turning

the chain, which will damage the drive links.

IMPORTANT

When a chain stretches to a point where the drive links are hanging approximately

12 mm (1/2 in) to 18 mm (3/4 in) below the guidebar groove, it is time to tension

the chain.

© 2016 ICS®, Blount International Inc. Specications are subject to change

without notice. REV030816 F/N 577452

Page 22

Unpacking & Assembly

695XL OPERATOR MANUAL 695XL OPERATOR MANUAL

CONNECT TO WATER SUPPLY

Following are the basic instructions to assure correct water supply to the saw.

WARNING

ICS diamond saws require a continuous water supply to the guidebar and

chain.

A key purpose of the supply water is dust suppression. The potential for airborne

particulates depends on many factors including, but not limited to, the material

being cut, application and cutting environment. In all cases, assure that

the water supply is capable of delivering 1.5 bar (20 psi) pressure to the saw at a

minimum ow rate of 4 lpm (1gpm).

NOTE: Local and/or regional regulation can vary widely. It is the responsibility of the

operator to wear appropriate dust protection applicable in their area and suitable to

the application.

Never operate saw with insucient water supply.

Insucient water supply will result in excessive wear to the chain, which can

lead to excessive stretch, chain breakage and/or damage to the guidebar nose

sprocket.

Attach to water supply capable of delivering 1.5 bar

(20 psi) pressure to the saw at a minimum flow rate

of 4 lpm (1 gpm). The single most important factor

an operator can control to increase chain life is to

use adequate water pressure.

© 2016 ICS®, Blount International Inc. Specications are subject to change

22 23

without notice. REV030816 F/N 577452

Page 23

Fueling

FUELING

Following are the basic instructions to assure safe fueling procedures.

DANGER

Fuel vapors are highly ammable.

Turn o the saw, lock the o/on switch in the “STOP” position, and allow the

engine to cool a few minutes before fueling. Do not smoke or refuel the saw in

close proximity to any ignition sources. Move the saw at least 3 m (10 ft) from the

fueling area before restarting it.

IMPORTANT

FUEL

ICS saws require the use of high quality, 90 Octane (95 RON) or higher fuel

combined with ICS 2-stroke oil (or other high quality 2-stroke oil) specically

formulated for air-cooled power equipment at a mixture of 2% (50:1). Due to the

heavy duty cycle ICS saws are subjected to in both concrete and utility pipe

cutting applications, oil mixture and fuel quality are critical to the performance and

life of the engine.

BLENDED AND ALKYLATE FUELS

Pre-mixed (2% oil mixture) alkylate fuel (i.e. Aspen 2) is an acceptable alternative to

conventional fuel.

NOTE: If using Aspen alkylate fuel or similar, carburetor adjustments are not

necessary or recommended.

ETHANOL BLENDED FUEL

While ICS recommends using fuel that does not contain ethanol (alcohol), it is

understood that 10% Ethanol blended fuel (E10) is becoming more widespread.

ICS saws are not designed to operate with fuel containing more than 10% ethanol.

NOTE: The use of Ethanol blended fuel greater than E10 will cause improper

operation and will cause major engine failure. This type of fuel related failure is not

covered under warranty.

This saw is certied to be in conformance with Section 213 of the Clean Air Act

by the US EPA.

Failure to follow instructions on preparing the fuel and oil mixture may result in

emissions violations.

© 2016 ICS®, Blount International Inc. Specications are subject to change

without notice. REV030816 F/N 577452

Page 24

Fueling

695XL OPERATOR MANUAL 695XL OPERATOR MANUAL

FUEL MIXING INSTRUCTIONS

CAUTION

Pressure can build up in the fuel tank and container and possibly cause sudden

release of fuel vapors when the tank is opened.

Open the fuel cap slowly and always provide adequate ventilation when

handling fuel.

IMPORTANT

It is important to accurately measure the amount of oil to be mixed with petrol to

assure that the correct mixture is obtained. When mixing small amounts of fuel,

even small inaccuracies can drastically aect the ratio of the mixture.

Always mix petrol and oil in a clean container approved for use with fuel. Keep fuel

container closed tightly to prevent moisture from getting into the fuel. Do not mix

more than one month’s supply of fuel. This helps prevent the separation of the

2-stroke oil from the petrol (varnishing).

Before fueling, clean the area around fuel cap on the saw to prevent dirt from

contaminating the fuel. Contamination of the fuel tank can lead to saw malfunction.

Always begin mixing fuel by pouring half the amount of petrol to be prepared into

the mixing container. Then add the correct amount of 2-stroke oil for 2% (50:1)

mixture and nish by adding petrol to obtain the total quantity of mixed fuel. Shake

the fuel container to thoroughly mix the petrol and oil before adding to the saw.

The table below shows the correct quantity of two-cycle oil to be used.

FUEL MIXTURE: 2% (50:1) mixture petrol/oil.

PETROL OIL

US Gallon US Fl oz

1 2.6

2 1/2 6.4

5 12.8

NOTE: If the saw is not used for an extended period of time (3 months) the fuel tank

should be emptied and cleaned.

© 2016 ICS®, Blount International Inc. Specications are subject to change

24 25

without notice. REV030816 F/N 577452

PETROL OIL

Liters ml

1 20

5 100

10 200

20 400

Page 25

Fueling

FUELING THE SAW

CAUTION

Do not overll the fuel tank.

Should any fuel spill happen, wipe up the spillage and allow the rest to evaporate.

If fuel is spilled on yourself or your clothes, immediately remove contaminated

clothing and wash any part of your body that has contacted fuel with soap and

warm water.

Pressure can build up in the fuel tank and container and possibly cause sudden

release of fuel vapors when the tank is opened.

Open the fuel cap slowly and always provide adequate ventilation when

handling fuel.

After adding fuel, carefully install the fuel cap and tighten rmly by hand. Tip the

saw slightly to one side and check for leaks. Should any fuel leaks be observed, do

not start the saw.

Customers are encouraged to remain consistent in the fuel option they choose for

ICS saws. Alternating between options, such as going between traditional fuel to

Alkylate fuel (Aspen) and back again may have negative impacts on the engine.

© 2016 ICS®, Blount International Inc. Specications are subject to change

without notice. REV030816 F/N 577452

Page 26

Operation

695XL OPERATOR MANUAL 695XL OPERATOR MANUAL

OPERATION

Following are the basic instructions to assure safe operation of the saw.

WARNING

Never start the saw without the bar, chain and side cover properly assembled.

DO NOT operate the saw with loose, missing, damaged or improperly

installed or repaired parts.

Check that the components shown below are intact, undamaged, and installed

correctly:

• Side cover nut torqued down properly

• Side cover not damaged and discharge port not plugged

• Handles not loose, gripping area is clean and undamaged

• Mud ap is not ripped, torn or missing and fully attached to the saw

• Cylinder cover is properly secured in place

• Muer not damaged and is adequately secured to cylinder

• Guidebar not bent or otherwise damaged such as rails dished and uneven

• Nose sprocket not excessively worn or broken, and turns freely

• Diamond chain does not have loose rivets, chassis damage, or missing

diamond segments

• Chain tensioner mechanism functions properly and pin is not bent or broken

• Drive sprocket not excessively worn and slides easily on adapter

• Check alignment of drive sprocket and guidebar

© 2016 ICS®, Blount International Inc. Specications are subject to change

26 27

without notice. REV030816 F/N 577452

Page 27

Operation

PRE-OPERATION SAFETY CHECKS

Perform the following safety checks each day to be sure that the safety features

designed into the saw are functioning properly. If any items are excessively worn or

damaged, replace before use.

• With on/o switch locked in the “STOP” position, without starting saw and with

decompression valve depressed, pull starter rope slowly and inspect for

fraying, wear and abrasion

• Assure vibration isolators are intact

• With engine running and without depressing thottle trigger lockout, pull throttle

trigger and assure continuous chain movement does not occur

• Verify at engine idle speed that the chain does not move

© 2016 ICS®, Blount International Inc. Specications are subject to change

without notice. REV030816 F/N 577452

Page 28

Operation

695XL OPERATOR MANUAL 695XL OPERATOR MANUAL

STARTING & STOPPING THE SAW

WARNING

Be sure that no part of the cutting system is contacting a solid object when

starting the saw.

When the choke and/or throttle advance is engaged for starting, the chain may

move and cause the saw to react if the chain contacts a solid object.

CAUTION

Move the saw at least 3 m (10 ft) from the fueling area before starting it.

Assure that secure footing is established and chain is not contacting any

objects.

When starting the saw, place the saw on clear and level ground.

IMPORTANT

Failure to break-in an engine may result in piston seizure.

It is very important to break-in a new engine to “seat” all moving parts, especially

the piston rings. To break-in the engine, run one full tank of 2% (50:1) fuel at idle,

cycling the throttle every 5 to 10 minutes to prevent loading.

Do not obstruct air intake.

Loose clothing can inadvertently be drawn into air intake and obstruct air ow

which may result in engine stall.

STOPPING THE SAW

To turn the engine o, push the on/o control briey to the right until engine stops.

Once released, control will automatically return to the “START” position. If control is

pushed beyond the detent, it will lock in the “STOP” position and prevent starting.

Close water valve completely.

© 2016 ICS®, Blount International Inc. Specications are subject to change

28 29

without notice. REV030816 F/N 577452

Page 29

Operation

COLD ENGINE STARTING PROCEDURE

1. Assure on/o control is not locked in the “STOP” position.

2. Pull the multi-function lever out, which also sets the throttle advance.

3. Depress primer/purger bulb until fuel is visible in bulb. May take 10 or more

pushes.

4. Push in decompression valve.

5. Open the water valve 1/4 turn.

6. Place foot on the base of the rear handle, and place one hand on front handle.

7. With opposite hand, slowly pull starter handle until you feel the starter pawls

engage.

8. Pull the starter cord (hard, fast, short pulls) until engine initially res or “pops”.

Could be as many as 10-15 pulls.

9. Push the multi-function lever in, this will keep throttle in advance position.

10. Pull the starter cord until engine starts - should be 1 to 2 pulls.

11. Release the throttle advance by pulling and releasing the throttle trigger, which

allows engine to return to normal idle speed.

12. Allow the engine to idle briey then pull throttle trigger several times to help

warm up the engine.

13. Open the water valve completely.

WARM ENGINE STARTING PROCEDURE

1. Assure on/o control is not locked in the “STOP” position.

2. Pull multi-function lever out, and immediately push back in to set the throttle

advance. If the multi-function lever is left in the out position on a warm engine,

the carburetor will ood with petrol. If this occurs, see Troubleshooting section.

3. Push in decompression valve.

4. Open the water valve 1/4 turn.

5. Place foot on the base of the rear handle, and place one hand on front handle.

6. With opposite hand, slowly pull starter handle until you feel the starter pawls

engage.

7. Pull the starter cord until engine starts. Should be 1-2 pulls.

8. Release the throttle advance by pulling and releasing the throttle trigger, which

allows engine to return to normal idle speed.

9. Allow the engine to idle briey then pull throttle trigger several times to help

warm up the engine.

10. Open the water valve completely.

© 2016 ICS®, Blount International Inc. Specications are subject to change

without notice. REV030816 F/N 577452

Page 30

Operation

695XL OPERATOR MANUAL 695XL OPERATOR MANUAL

PRECUT CHECKLIST

WARNING

Sudden contact of the guidebar nose with a foreign object may generate

kickback.

Remove and/or avoid any obstructions (plumbing, water supply hoses, electrical

conduit, air ducts, etc.) that may interfere with the cut.

To avoid electrocution, check for live electrical wires.

Wires may be hidden within or behind walls and/or laying around the workspace.

Assure that any ancillary electrical equipment (fans, pumps, vacuums, etc.) are

properly grounded and certied for use in the intended environment.

Always operate the saw with solid footing and both hands on the saw.

Keep your left hand on the front handle and your right hand on the rear handle.

Wrap your thumbs around the handles to assure you maintain a secure grip on

both handles.

Never operate the saw during severe inclement weather.

Freezing conditions, lightening and sudden downpours can create hazardous job

site conditions.

Always wear protective clothing.

At a minimum always wear eye protection and/or face shield, hearing protection,

long sleeve shirt, long pants, closed toe shoes with non-slip soles, and gloves. In

many work situations, a hard hat, steel toed shoes and a respirator may also be

required. Avoid loose tting clothing.

Cutting with the saw may generate sparks, especially when cutting through

metal (such as rebar), and may start a re in combustible materials such as dry

grass, wood and fuel.

Be sure to use adequate water pressure and have re ghting equipment readily

available.

© 2016 ICS®, Blount International Inc. Specications are subject to change

30 31

without notice. REV030816 F/N 577452

Page 31

Operation

CUTTING WITH THE SAW

WARNING

DO NOT insert the guidebar into a slot narrower than the width of the chain.

Rapid pushback, kickback and/or chain breakage could result.

Be sure cut concrete cannot fall and injure the operator or bystanders.

Assure cut piece is controlled and does not fall unexpectedly.

NOTE: Concrete is very heavy; one cubic foot = 30 cm x 30 cm x 30 cm = 68 kg (12

in x 12 in x 12 in = 150 lbs).

CAUTION

Slippery or unstable surfaces such as ladders may cause a loss of balance or

control of the saw.

Always keep proper footing and operate the saw only when standing on xed,

secure and level surface.

Unexpected loss of control of the saw and loss of balance can result in injury.

Do not overreach and do not cut above shoulder height.

Do not allow workpiece to pinch the guidebar and chain, or rapid pushback

could result.

Always cut bottom of opening rst and assure workpiece is secure and does not

shift during cutting operations.

Do not operate saw upside down.

Cutting debris can be directed back towards the operator.

Take special precautions when cutting in horizontal orientation.

Be aware that debris may be ejected dierently than when cutting in a vertical

position.

IMPORTANT

Always operate saw at full throttle.

For best results, always operate the saw at full power.

© 2016 ICS®, Blount International Inc. Specications are subject to change

without notice. REV030816 F/N 577452

Page 32

Operation

695XL OPERATOR MANUAL 695XL OPERATOR MANUAL

CUTTING WITH THE SAW

To assure the best performance from your ICS saw, follow all safety precautions

and recommended techniques. Additional helpful information can be obtained at

icsdiamondtools.com.

CONCRETE/MASONRY CUTTING

Planning the Cut

1. Select the proper chain type for the material being cut. Refer to the chain

selection guide in this manual. See page 44.

2. Outline the cut with a permanent marker for a visual cutting guide.

3. Avoid pinching the guidebar and chain by using shims or

other anchoring devices to stabilize the workpiece. Always

plan to cut the bottom of an opening rst, then

top or sides. Save the easiest cut for last (see

image at right).

4. Be sure cut concrete cannot fall and injure the operator

or bystanders. As the cut is being completed, assure that

appropriate bracing is in place to control the cut section

of the workpiece. Concrete is very heavy,

one cubic foot = 30 cm x 30 cm x 30 cm = 68 kg (12 in x 12 in x 12 in = 150 lbs)

.

3

22

1

© 2016 ICS®, Blount International Inc. Specications are subject to change

32 33

without notice. REV030816 F/N 577452

Page 33

CONCRETE/MASONRY CUTTING

Recommended Concrete Cutting Techniques

1. Plunge in

2. Cut down to open slot

3. Insert WallWalker® rotate rear handle up

Operation

4. Pull saw out, rotate rear handle down,

press bottom of saw to leading edge of cut

and rotate rear handle up

5. Reengage WallWalker® and repeat Steps

3 and 4

© 2016 ICS®, Blount International Inc. Specications are subject to change

without notice. REV030816 F/N 577452

Page 34

Operation

695XL OPERATOR MANUAL 695XL OPERATOR MANUAL

CUTTING TIPS

• For the straightest cuts use the “Step Cut” method:

• First score the entire cut line approximately a 12 mm (1/2 in) deep

using the nose of the guidebar

• Next, deepen the cut by about two inches

• Then plunge all the way through and complete the cut using the

WallWalker® as a pivot point and pull on the rear handle to rotate the

bar into the cut

• Always operate the concrete saw at full throttle. If too much force is

applied, the saw will lug or stall. The chain will not have enough speed to cut

eectively. If too little feed force is applied, the diamonds will skid and glaze

over.

• Plunge cut instead of starting at the top surface of the wall. This will reduce

chatter, extend diamond life, create a straighter cut and more quickly enable

the use of the WallWalker.

• When cutting heavy rebar, slowly “rock” the saw so that you’re always cutting

concrete as well as steel. This will help keep the diamonds exposed. Also,

expect less chain life when cutting heavy rebar.

• Expect more chain stretch when making nose-buried cuts for extended

periods of time, as the chain does not have a chance to “throw” the slurry

away from the nose of the guidebar.

• If the saw begins to cut consistently crooked, stop the saw, remove the bar and

chain and turn the bar over and use the other side. Dress worn rails with a belt

sander.

Note: The normal life of a guidebar is two to three diamond chains. Heavy rebar

can shorten guidebar life.

• The guidebar is solely a guide track for the chain. Never use the guidebar to lift,

twist or pry concrete material

• When using a new chain, you can increase the initial cutting speed by “opening

up the diamonds”. This can be accomplished by rst making a few cuts in an

abrasive material such as a cinder block or brick.

© 2016 ICS®, Blount International Inc. Specications are subject to change

34 35

without notice. REV030816 F/N 577452

Page 35

Operation

PIPE CUTTING USING

POWERGRIT® UTILITY SAW CHAIN

To assure the best performance from your ICS® saw when cutting ductile iron pipe

or similar pipe materials, follow all safety precautions and recommended cutting

techniques.

WARNING

Always assure trench walls are adequately supported before entering work space.

Consult applicable regional regulations and obtain necessary approvals before entering

a trench or any excavated areas.

Never attempt to cut ductile iron pipe or similar pipe materials with the saw

unless using PowerGrit® Utility Saw Chain. Using concrete diamond saw chain in

these applications can cause the chain to snag abruptly in the cut which may result in

chain breakage, pushback and/or kickback.

Always assure that pipe is properly evacuated before cutting.

Pipes may contain sewage, gas or other hazardous materials.

Always support the pipe on both sides of the cut to assure the cut remains open

throughout the cutting operation, including when the cut is nished.

An improperly supported pipe can cause the cut to close, pinching the chain and

guidebar which may result in chain breakage, pushback and/or kickback.

Recommended Pipe Cutting Techniques

1. Make a small plunge cut into the lower quadrant of

the pipe to relieve internal pressure and allow contents

to drain from pipe in a controlled manner.

2. With pipe drained, cut from the top of pipe and

continue through bottom of the pipe.

3. To assure straightness of cut, guidebar should

extend completely through the pipe during the cut.

4. To assist with cutting, engage the WallWalker®

in the cut when possible to provide additional

leverage and alternate cutting between the near and

far side walls of the pipe.

© 2016 ICS®, Blount International Inc. Specications are subject to change

without notice. REV030816 F/N 577452

Page 36

Transporting & Storing

695XL OPERATOR MANUAL 695XL OPERATOR MANUAL

TRANSPORTING & STORING

WARNING

Fuel and vapors are highly ammable

When transporting or storing fuel, always use a container approved for fuel and

assure it is sealed against leaks and/or escaping fumes. Contact with an ignition

source could cause re or explosion.

CAUTION

Always carry the saw by the front handle with the on/o control in the locked

“STOP” position and away from your body

When transporting the saw, assure it is secured to avoid damage and/or personal

injury. Proper handling of the saw will reduce the likelihood of accidental contact

with the guidebar and chain.

IMPORTANT

ICS recommends mixing fuel in small batches, to be used within 30 days. Fuel

stabilizers (additives) can prolong the life of the fuel, but still should not be stored

longer than 90 days.

© 2016 ICS®, Blount International Inc. Specications are subject to change

36 37

without notice. REV030816 F/N 577452

Page 37

Maintenance

MAINTENANCE

AFTER EACH USE

IMPORTANT

1. After cutting, pull trigger to spin the chain for at least 15 seconds with the

water on to ush slurry and debris from chain, guidebar and drive sprocket.

2. Stop saw and wash concrete slurry from saw assembly with special attention

to the starter housing and ywheel. Do not let slurry dry on saw as it will be

very dicult to remove later.

3. Avoid getting any water in the carburetor or exhaust system. If water enters

the exhaust port, it can enter the carburetor. To make sure there is no water in

the exhaust system, assure the on/o control is locked in the “STOP” position,

point the guidebar tip down and pull the starter handle several times to expel

water from muer.

4. Remove the chain and guidebar. Flush out the chain tensioner and side cover

with water. Lubricate tensioner with waterproof grease.

5. After cleaning the saw, spray the entire saw body, chain, guidebar, and drive

sprocket with lightweight oil. Using lightweight oil on the saw will minimize rust

and help reduce slurry build up.

6. Inspect and tighten all fasteners as necessary.

7. Inspect drive sprocket for wear. Replace if tooth tips are pointed, or if groove

cuts through top of tooth.

8. Check clutch cup needle bearing for wear. Assure clutch cup spins freely and

without excessive play.

9. Check starter cord for wear or damage. Replace as necessary.

10. Inspect air lter. Replace lter if dirty or wet.

11. Spray lightweight oil into the air intake slots on the starter housing and ywheel

(this will prevent the starter pawls from sticking).

AFTER EVERY 10 HOURS OF USE

1. Remove the starter cover and clean the ywheel ns and the starter pawls with

a wire brush, then apply waterproof grease to the starter pawls.

2. Remove the spark plug and clean with a wire brush. Check the electrode gap.

The correct gap is 0.5 mm (0.020 in). Replace if necessary.

AFTER EVERY 40 HOURS OF USE

1. Change the spark plug. Adjust the electrode to 0.5 mm (0.020 in).

2. Check the fuel lter located inside the fuel tank. Clean or replace if clogged.

© 2016 ICS®, Blount International Inc. Specications are subject to change

without notice. REV030816 F/N 577452

Page 38

Maintenance

After each use After every 10 hours After every 40 hours

External Cleaning Clean Starter Housing Replace Spark Plug

Fasteners/Screws Check Spark Plug Check Fuel Filter

Air Intake

Functional Inspection Functional Inspection Functional Inspection

General Inspection Vibration Isolators Fuel System

Throttle Trigger Lockout Muer Fuel Filter

On/O Switch Carburetor Air Filter

Mud Flap Starter Housing Clutch Cup

Guidebar and Chain Sprocket Clutch

695XL OPERATOR MANUAL 695XL OPERATOR MANUAL

AIR FILTER

The polyester air lter must be kept clean for the

engine to operate properly. If the saw is not reaching

full RPM, most likely the air lter is dirty or wet.

• The air lter should be free of holes and white

in color

• Replace the air lter when dirty or wet

• When replacing the air lter, clean the area inside

the air box with a clean towel prior to installing

new lter

• Inspect air box seals for wear or damage. Replace if damaged

FUEL SYSTEM

• Clean area around fuel cap before removing

• Check the fuel cap and seal for damage

• Check the fuel line for damage

• Check fuel lter, assure it is free of debris

• Replace fuel lter if it is stained dark or clogged (fuel lter cannot be cleaned)

© 2016 ICS®, Blount International Inc. Specications are subject to change

38 39

without notice. REV030816 F/N 577452

Page 39

Maintenance

SPARK PLUG

• Clean the spark plug with a wire brush and check to assure the plug gap is 0.5

mm (0.020 in)

• Inspect the spark plug boot, replace if needed

• Inspect lead wire for wear or damage. Replace if necessary (lead wire cannot

be replaced separately from ignition module)

IMPORTANT

• Replace spark plug after 40 hours of use, or if the electrode is corroded or

eroded

• Always use a recommended spark plug (resistor type) to prevent damage to

the piston and cylinder (NGK #BPMR7A or Champion RCJ6Y or equivalent)

CARBURETOR

• The function of the carburetor is to mix fuel with air. Adjustments other than

idle speed should only be made by an Authorized Service Center

• Before adjusting the engine idle speed, make

sure the air lter is clean, the engine is running,

warmed up and the guidebar and chain are

assembled on the saw

• Adjust idle screw so that the engine idles smoothly

but the clutch does not engage. If the chain begins

to spin, turn the idle screw counter-clockwise until the

chain stops

• If saw has been running satisfactorily and there is a

gradual decrease in power and drop in RPM at full

throttle, the lter may have become dirty or wet. (See

air lter section)

Carburetor idle screw

STARTER RECOIL HOUSING

It is common for concrete slurry to get inside the starter

housing assembly during cutting. This can cause starter

pawls to stick and not engage when the rope is pulled.

• After each usage, thoroughly ush the starter housing

assembly with water

• Spray lightweight oil into the air intake slots on the

starter housing and ywheel (this will prevent the starter pawls from sticking)

• Inspect the starter cord for fraying, replace if necessary

© 2016 ICS®, Blount International Inc. Specications are subject to change

without notice. REV030816 F/N 577452

Page 40

Maintenance

695XL OPERATOR MANUAL 695XL OPERATOR MANUAL

STARTER ROPE REPLACEMENT

• Loosen the four screws that attach the starter cover assembly to the

crankcase, and remove the starter cover assembly from the saw

• Pull rope out from pulley approximately 30 cm (12 in)

and hook rope into the notch in the pulley. Relax

the recoil spring by placing thumb on the pulley

and gently allow the pulley to rotate

backwards to unwind the spring entirely

• Loosen center screw to remove pulley from starter

recoil housing and remove the old starter rope

• Thread new starter rope through hole in the starter

recoil housing and then through hole in pulley

• Wrap the starter rope counter clockwise around

the raised center of the pulley, looping over top

and under the beginning of the wrap. Tighten the

knot rmly and assure that free end of rope is as short as possible. Secure the

other end of the rope in the starter handle

• Reinstall pulley in starter recoil housing and tighten center screw

TENSIONING THE RECOIL SPRING

• Hook the rope in the notch of pulley and wind the rope clockwise three times

around the raised center of the pulley

• Pull the starter rope with the handle until the rope is unwound, tensioning the

spring. Repeat this process, but this time, wind the rope clockwise four times

around and then pull the rope with the handle to complete the tensioning of

the spring

NOTE: When released, the starter handle should be drawn to the correct start

position after tensioning the spring.

IMPORTANT

Check that the pulley can be turned an additional 1/2 turn when the starter cord

is pulled all the way out.

© 2016 ICS®, Blount International Inc. Specications are subject to change

40 41

without notice. REV030816 F/N 577452

Page 41

Maintenance

STARTER RECOIL HOUSING ASSEMBLY

• To reattach the starter cover assembly, rst pull the

starter cord out, then hold the starter recoil housing

against the crankcase

• Slowly release the starter cord to enable the pulley

to t between the pawls

• Insert and tighten the screws. Use blue Loctite®

#242

CHAIN TENSIONER

The chain tensioner can become clogged with concrete slurry during cutting.

• After each use thoroughly ush the chain tensioner with water and apply a

liberal amount of waterproof grease covering the chain tensioner screw

NOTE: The chain tensioner is located on the side cover.

Chain Tensioner

Chain Tensioner

© 2016 ICS®, Blount International Inc. Specications are subject to change

without notice. REV030816 F/N 577452

Page 42

Maintenance

695XL OPERATOR MANUAL 695XL OPERATOR MANUAL

DRIVE SPROCKET

• The drive sprocket (rim sprocket) is a wear

item and should be replaced every two to

three chains, or when the teeth become

pointed or if groove cuts through top of

tooth.

• Inspect the sprocket for wear

• The needle bearing inside of the clutch cup

is self-lubricating through the crank shaft,

spin the clutch cup to assure it spins freely

and without excessive play

Clutch Cup

DRIVE SPROCKET REMOVAL/INSTALLATION

Drive Sprocket

Half Collar

Spring Clip

Retaining Washer

Splined Adapter

CAUTION

Wear safety glasses.

• Remove the side cover, diamond chain and guidebar

• Using a screwdriver, carefully pry the spring clip from the half collars.

NOTE: Cup your hand over the end of shaft to prevent spring clip from being

ejected.

• Remove the half collars and retaining washer from the shaft

• Slide the drive sprocket o of the splined adapter

• Reengage the clutch cup onto the shaft and slide the drive sprocket onto the

splined adapter, either side out

• Install the retaining washer and half collars onto the shaft

• Place the spring clip atop the half collars, assuring the half collars are

symmetrical with equal gap on either side

• Engage the spring clip onto the half collars by

rmly pressing down with a screwdriver over

top of one of the gaps

NOTE: Hold your thumb on the spring clip over the

opposite side gap to maintain placement.

• Once the spring clip is partially engaged on

one side, perform the same technique to

the other side, again pressing rmly over

top of the gap

• Visually check proper spring clip engagement

in groove of half collars. Both half collars should be

rmly secured to the shaft

© 2016 ICS®, Blount International Inc. Specications are subject to change

42 43

without notice. REV030816 F/N 577452

Page 43

Maintenance

CHAINS & GUIDEBARS

IMPORTANT

Inspect chain segments and drive links for damage or excessive wear. Chains

with damage or excessive wear should not be used or repaired, they should be

replaced.

NOTE: Guidebars are designed to be used on both sides. If the cut is consistently

leading to one side, turn the guidebar over. It is recommended to turn the guidebar

over with every new chain.

• A table mounted belt or disc sander can be used to square the rails of a worn

guidebar. A badly worn guidebar can quickly damage the chain. If the chain is

touching the bottom of the guidebar groove, replace the guidebar

• Check the guidebar for straightness

• Proper chain tension will extend guidebar life

• Under some circumstances, especially low water pressure, the sprocket nose

can wear out before the guidebar body. Sprocket nose assemblies may be

replaced by an Authorized Service Center

• Periodically clean the water ports inside the groove of the guidebar using a

small diameter piece of wire or pipe cleaner

• The guidebar is solely a guide track for the chain. Never use the guidebar to lift,

twist or pry concrete material

• Prior to storage, spray the chain and guidebar with lightweight oil

© 2016 ICS®, Blount International Inc. Specications are subject to change

without notice. REV030816 F/N 577452

Page 44

Maintenance

695XL OPERATOR MANUAL 695XL OPERATOR MANUAL

695XL CHAIN SELECTION GUIDE & CONSUMABLES

3/8” Pitch Chain Selection Guide

Chain &

Applications

™

TwinMAX

General Purpose

™

Plus

TwinMAX

For harder materials

TwinMAX™ Abrasive

For brick & block

Soft Stone/

Abrasive/Brick

◊

Natural Stone

◊ ◊

◊ ◊ ◊

Medium

Concrete/Light

Reinforcement

3/8” Pitch Consumables

30 cm (12 in) 35 cm (14 in) 40 cm (16 in)

™

Diamond Chain p/n 71400 p/n 71486 p/n 71607

TwinMAX

TwinMAX™ Plus Diamond Chain p/n 71704 p/n 71705 p/n 71706

™

Abrasive Diamond Chain p/n 71554 p/n 71610 p/n 71611

TwinMAX

3/8” Pitch Guidebar p/n 553207 p/n 73600 p/n 71600

3/8” Pitch Drive Sprocket p/n 70949

Hard

Concrete/ Heavy

Reinforcement

Ductile Iron/Cast

Iron/PVC/HDPE

© 2016 ICS®, Blount International Inc. Specications are subject to change

44 45

without notice. REV030816 F/N 577452

Page 45

TROUBLESHOOTING

PROBLEM Possible Cause

SAW WON'T REACH FULL RPM Dirty air filter

Troubleshooting

SLOW CHAIN SPEED

POOR CUTTING SPEED

PREMATURE CHAIN STRETCH

CHAIN TENSIONER BREAKAGE

WATER NOT FLOWING

WON'T START

DIFFICULT TO START

Chain tension too tight. Chain should always be able to

be pulled around the guidebar by hand. It is normal for the

drive links of the chain to hang below the guidebar.

All of the above, plus diamonds may be glazed over. Make

a few cuts in an abrasive material to expose the diamonds.

Not enough water pressure. The minimum water pressure

required is 1.5 bar (20 psi). Insufficient water supply may

result in excessive wear to the chain, which can lead to

stretch and chain breakage.

Side cover nut is not tight enough. Torque to 27-33 Nm

(20-25 ft-lbs ).

Tensioning with side cover nut already tight

Water hose is kinked or water supply not turned on

Water ports plugged with debris

Aged or bad fuel

Corroded or eroded spark plug

Stop switch locked in "STOP" position

Flooded engine. Push Multi-function lever in, hold throttle

on full with foot and pull starter cord (hard, short, fast pulls)

until engine starts.

Fouled spark plug. Remove spark plug, clean, and re-gap

to 0.5 mm (0.020 in).

Improper chain tension

Insufficient water pressure

CHAIN BREAKAGE

© 2016 ICS®, Blount International Inc. Specications are subject to change

without notice. REV030816 F/N 577452

Inserting saw into slot narrower than diamond chain

segments

Using chain that is already stretched beyond ability to

tension

Page 46

695XL OPERATOR MANUAL 695XL OPERATOR MANUAL

THIS PAGE INTENTIONALLY LEFT BLANK

© 2016 ICS®, Blount International Inc. Specications are subject to change

46 47

without notice. REV030816 F/N 577452

Page 47

Emissions

FEDERAL EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS

The U.S. Environmental Protection Agency (EPA), Environment Canada and

ICS, Blount Inc. are pleased to explain the Emissions Control System Warranty

on your 2009 and later small non-road engine. In the U.S. and Canada, new

small non-road engines must be designed, built and equipped to meet federal

emission regulations.

ICS must warrant the emission control system on your small non-road engine

for the period of time listed below provided there has been no abuse, neglect or

improper maintenance of your unit.

Your emission control system includes parts such as the carburetor and the

ignition system. Also included may be hoses, connectors and other emission

related assemblies.

Where a warrantable condition exists, ICS will repair your saw engine at no cost

to you. Expenses covered under warranty include diagnosis, parts and labor.

MANUFACTURER’S WARRANTY COVERAGE

The emission control system on 2009 and later small non-road engines is

warranted for two years. If any emission related part on your engine (as listed

above) is defective, the part will be repaired or replaced by ICS.

© 2016 ICS®, Blount International Inc. Specications are subject to change

without notice. REV030816 F/N 577452

Page 48

Emissions

695XL OPERATOR MANUAL 695XL OPERATOR MANUAL

FEDERAL EMISSION CONTROL WARRANTY STATEMENT

OWNER'S WARRANTY RESPONSIBILITIES

As the saw owner, you are responsible for the performance of the required

maintenance listed in your Operator's Manual. ICS recommends that you

retain all receipts covering maintenance on your saw engine, but ICS cannot

deny warranty solely for the lack of receipts or for your failure to assure the

performance of all scheduled maintenance. However, ICS reserves the right to

deny warranty coverage if your saw engine, or a part of it, has failed due to abuse,

neglect, improper maintenance, unapproved modifications or the use of parts

not made or approved by the original equipment manufacturer.

You are responsible for presenting your saw engine to an ICS authorized

servicing dealer as soon as a problem exists. The warranty repairs should be

completed in a reasonable amount of time, typically not to exceed 30 days.

If you have any questions regarding your warranty rights and responsibilities,

please contact an ICS customer service representative at 1.800.321.1240.

www.icsdiamondtools.com

LENGTH OF COVERAGE

ICS warrants to the initial purchaser and each subsequent owner that the engine

is free from defects in materials and workmanship which cause the saw engine to

fail to conform with applicable emission regulations for a period of two years.

WARRANTY PERIOD

The warranty period begins on the date of sale of the saw engine to the initial

purchaser.

© 2016 ICS®, Blount International Inc. Specications are subject to change

48 49

without notice. REV030816 F/N 577452

Page 49

Technical Speccations

TECHNICAL SPECIFICATIONS

Engine Type 2-stroke, Air Cooled

Displacement 94 cc (5.7 cu-in)

Horsepower 4.8 kW (6.4 hp) @ 9000 rpm

Torque 5.7 Nm (50.4 in-lbs) @ 7,200 rpm

Engine Speed

Chain Speed at Maximum Power 28 m/s (5500 ft/min)

Weight 9.5 kg (21 lbs) powerhead only

Dimensions

46 cm (18 in) length 36 cm (14 in) height

Air Filter Water resistant polyester

Carburetor Walbro RWJ-7

Starter Recoil, dust and water resistant

Ignition Special water resistant electronic ignition

Clutch Centrifugal, three shoe, three spring

9,300 +/- 150 rpm (max)

2,700 +/- 100 rpm (idle)

30 cm (12 in) width

Fuel ratio 2% (50:1) petrol-to-oil

Fuel Capacity 1 liter (0.26 gallon)

Water Supply Requirement Minimum 1.5 bar (20 psi)

Water Flow Requirement Minimum: 4lpm (1 gpm )

Guaranteed Sound Power Level, L

Equivalent Sound Pressure at the

Operator's Ear L

Vibration, a

Vibration, a

Concrete Cutting (2)

hv, eq

Pipe Cutting (2)

hv, eq

pA

(1) 115 dB(A); (Kwa=1.0 dB(A))

wa

104.6 dB(A) (K=1.0 dB( A))

3.6 m/s2 (K=1.0 m/s2) Front Handle

3.1 m/s2 (K=1.0 m/s2) Rear Handle

5.62 m/s2 (K=0.2 m/s2) Front Handle

5.28 m/s2 (K=0.2 m/s2) Rear Handle

Engine Break-in Period One tank, without cutting, cycling throttle

Spark Plug

(1) Measured in accordance with ANSI S12.51-2012/ISO3741:2010

(2) Measured in accordance with ISO5349-1:2001, ISO22867:2011 and ISO19432:2012

© 2016 ICS®, Blount International Inc. Specications are subject to change

without notice. REV030816 F/N 577452

NGK BPMR7A or Champion RCJ6Y

Electrode gap 0.5 mm (0.020 in)

Page 50

Service Centers

695XL OPERATOR MANUAL 695XL OPERATOR MANUAL

AUTHORIZED SERVICE CENTERS

DEALER PHONE ADDRESS CITY STATE ZIP CODE

KENNEDY EQUIPMENT CO INC 714.771.7324 748 N. LEMON ST ORANGE CA 92867

ABLE TOOL EQUIPMENT 860.289.2020 410 BURNHAM STREET SOUTH WINDSOR CT 06074

EQUIPSERV LLC 770.709.5101 6225 MABELTON PARKWAY SW MABLETON GA 30126

STAR EQUIPMENT 515.283.2215 1401 2nd AVE DES MOINES IA 50314

MCCANN INDUSTRIES, INC. 630.627.8700 543 SOUTH ROHLWING RD ADDISON IL 60101

CLEAN RITE TECH 504.468.7997 1332 FULTON ST KENNER LA 70062

ACE CUTTING EQUIPMENT 248.449.4944 25806 NOVI RD. NOVI MI 48375

CONCRETE CUTTING & CORING 952.882.0980 12690 CREEK VIEW AVE SAVAGE MN 55378

ACME ELECTRIC 218.628.3523 4332 GR AND AVE DULUTH MN 55807

MERLIN STELZER SALES CO., INC. 314.535.7540 4109 PAPIN ST ST. LOUIS MO 63110

ACME ELECTRIC 701.258.1267 3840 E. ROSSER AVE BISMARCK ND 58501

ACME ELECTRIC 701.746.6481 1705 12TH AVE NORTH GRAND FORKS ND 58203

ACME ELECTRIC 701.476.4600 920 36TH STREET S.W. FARGO ND 58103

ACME ELECTRIC 701.839.2263 700 20TH AVE S.E. MINOT ND 58701

ADMAR SUPPLY 585.272.9390 1950 BRIGHTON-HENRIETTA TL RD ROCHESTER NY 14623

ADMAR SUPPLY 315.433.5000 6014 DROTT DR EAST SYRACUSE NY 13057

ADMAR SUPPLY 518.690.0750 878 ALBANY SHAKER RD LATHAM NY 12110

ADMAR SUPPLY 607.754.4700 2305 OLD VESTAL RD VESTAL NY 13850

ADMAR SUPPLY 716.873.8000 1394 MILITARY RD BUFFALO NY 14217

CESSCO, INC. 503.288.1242 4222 N.E. COLUMBIA BLVD. PORTLAND OR 97218

TRI-BORO CONST. SUPPLIES 800.632.9018 435 LOCUST ST DALLASTOWN PA 17313

LEHIGH CONSTRUCTION SUPPLY CO. 570.654.3981 295 SCHOOLEY AVE EXETER PA 18643

DRIVEKORE, INC. 717.766.7636 101 WESLEY DRIVE MECHANICSBURG PA 17055

ECKHART CONSTRUCTION 803.802.6635 1019 SOCIETY LANE FORT MILL SC 29707

STAN HOUSTON EQUIPMENT 605.336.3727 501 SOUTH MARION ROAD SIOUX FALLS SD 57106

STAN HOUSTON EQUIPMENT 605.348.1155 1210 DEADWOOD AVENUE RAPID CIT Y SD 57702

LINCOLN CONTRACTORS SUPPLY 414.541.1327 11111 WEST HAYES AVE MILWAUKEE WI 53227

LINCOLN CONTRACTORS SUPPLY 608.249.6476 901 WALSH RD MADISON WI 53714

LINCOLN CONTRACTORS SUPPLY 715.359.6111 5207 WESTFAIR AVE SCHOFIELD WI 54476

LINCOLN CONTRACTORS SUPPLY 920.757.1901 5663 NUEBERT RD APPLETON WI 54913

LINCOLN CONTRACTORS SUPPLY 920.432.8697 1654 MORROW ST GREEN BAY WI 54302

LINCOLN CONTRACTORS SUPPLY 715.874.4100 7840 PARTRIDGE AVE EAU CLAIRE WI 54703

LEE JENSEN SALES CO, INC 815 459-0929 101 WEST TERRA COTTA CRYSTAL LAKE IL 60014

ROCK-CRETE EQUIPMENT LTD. 604 464-1448 50 BURBIDGE STREET COQUITLAM BC V3K 6B1

CONCUT DIAMOND PRODUCTS 561-989-8895 6500 W ROGERS CIRCLE SUITE 6000 BOCA RATON FL 33487

AUSTECH SUPPLIES PTY LTD 61298541200 UNIT 12, 197 POWER STREET GLENDENNING NSW 2761

HATCH BUILDING SUPPLY COMPANY 608 222-0011 5601 MANUFACTURERS DRIVE MADISON WI 53704

AMERICAN TOOL AND FASTENER 972-801-9909 1331 E PLANO PKWY STE #B PLANO TX 75074

HENARD UTILITY PRODUCTS, INC 501 268-1987 1920 S. MAIN STREET SEARCY AR 72143

© 2016 ICS®, Blount International Inc. Specications are subject to change

50 51

without notice. REV030816 F/N 577452

Page 51

THIS PAGE INTENTIONALLY LEFT BLANK

© 2016 ICS®, Blount International Inc. Specications are subject to change

without notice. REV030816 F/N 577452

Page 52

695XL OPERATOR MANUAL

ICS | BLOUNT, INC.

4909 SE INTERNATIONAL WAY

PORTLAND, OR 97222

800.321.1240

icsdiamondtools.com

© 2016 ICS®, Blount International Inc. Specications are subject to

change without notice. REV030816 F/N 577452

Loading...

Loading...