Page 1

DN-3000

AN INTELLIGENT

MULTIPLE-FUNCTION COMMUNICATIONS

INTERFACE UNIT FOR DEVICENET

U

ICP PANEL-TEC

Post Office Box 2394

Huntsville, Alabama 35804

(205) 534-8132

ser Manual

Page 2

Page 3

Warranty & Notices

WARRANTY

ICP PANEL-TEC, INC. warrants that all equipment purchased hereunder is warranted on a “RETURN

TO FACTORY” basis against all defects in workmanship and materials under normal and proper use and

service in its unmodified condition for a period of one (1) year from the date of initial shipment. ICP

PANEL-TEC, INC. sole obligation under this warranty shall be limited to furnishing parts and labor to

remedy such defects; either, at the option of ICP PANEL-TEC, INC., by replacing or repairing any

defective parts which are returned to ICP PANEL-TEC, INC. factory or by making available at a

purchaser designated facility a repaired or replaced part. All replaced equipment shall become the

property of ICP PANEL-TEC, INC. The cost of freight to and from ICP PANEL-TEC, INC. will be

borne by the purchaser. If ICP PANEL-TEC, INC. determines that the equipment returned to it for

warranty correction is not defective, as herein defined, Purchaser shall pay ICP PANEL-TEC, INC., all

costs of service, parts, handling and transportation.

IMPORTANT NOTICES

By accepting and using the DN-3000 (s) CONFIGURATION EDITOR SOFTWARE and information

proprietary to ICP PANEL-TEC, INC. USA and/or its Licensers, you agree that such software and

information (Software) constitutes valuable trade secrets and proprietary information of ICP PANEL-

TEC, INC. and/or its Licenses and that you hold the software in confidence and secrecy and shall not, in

whole or part, copy or disclose to any third party or make any unauthorized use thereof. Authorized use

shall be limited to the DN-3000 (s) upon which the Software is initially supplied. You further agree that

this agreement shall insure to the benefit of ICP PANEL-TEC, INC. and any third party holding any

right, title, or interest in the software, or any software and information from which it is derived, and their

respective transferees, successors, and assigns, and that any subsequent transferee of the unit herein

decried shall be obligated to the same terms of this agreement.

This document is based on information available at the time of its publication. While efforts have been

made to render accuracy to its content, the information contained herein does not purport to cover all

details or variations in hardware or software, nor to provide for every possible contingency in connection

with installation, operation, and maintenance.

Features may be decried herein which are not present in all hardware and software systems. ICP

PANEL-TEC, INC. assumes no obligation of notice to holders of this document with respect to changes

subsequently made.

ICP PANEL-TEC, INC. makes no representation or warranty expressed, implied, or statutory, with

respect to, and assumes no responsibility for accuracy, completeness, sufficiency or usefulness of the

information contained herein.

In no event shall ICP PANEL-TEC, INC. be responsible or liable for indirect or consequential damages

that may result from installation or use of this equipment.

(C) 1997 ICP PANEL-TEC, INC.

ALL RIGHTS RESERVED

Post Office Box 2394

Huntsville, Al. 35804-2394

i

Page 4

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Software Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Software Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Creating Project Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Project Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

DeviceNet to PLCs or Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Device Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Example Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Configuring Port #1 (DeviceNet) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Configuring Port #2 (PLCs or Devices) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Configuring Port #3 (Passthrough) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

I/O Data Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

DeviceNet to Motor Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Device Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Example Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Configuring Port #1 (DeviceNet) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Configuring Port #2 (Motor Drives) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

I/O Data Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Upper Link Configuration (Mitsubishi Drives Only) . . . . . . . . . . . . . . . . . . . . . . 38

Exception Table (Mitsubishi Drives Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Transferring Project Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Options Settings

Setting the Project Directory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Selecting the Communications Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Setting the Printer Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Load Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Save Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Default Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Technical Information

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

DIP Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

ii

Page 5

Table of Contents

Application Notes – PLCs and Devices

Allen Bradley PLCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

GE Fanuc PLCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Idec PLCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Koyo (PLC Direct and TI) PLCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Mitsubishi PLCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Modicon PLCs (and Modbus Devices) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Omron PLCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Siemens S7-200 PLCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Square D PLCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

TI505 Series PLCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Toshiba PLCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Westinghouse PLCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Application Notes – Motor Drives

Baldor Motor Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Mitsubishi Motor Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Woods Motor Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Yaskawa Motor Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Cable Diagrams

Configuration Cable Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

PLC and Device Cable Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Motor Drive Cable Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

DeviceNet Cable Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

iii

Page 6

Page 7

Introduction

INTRODUCTION

The DN-3000 is an intelligent, multiple-function DeviceNet Data Transfer Unit designed for use within

the harsh industrial environment.

Using the DN-3000 Configuration Editor Software program, the DN-3000 can be programmed to run

either of the two (2) following application types:

1) DEVICENET TO PLCS OR DEVICES Allows a DeviceNet Host to read or write data registers in

one or more PLCs or Devices that use the same protocol. One of the DN-3000’s three ports can be

used as a pass-through port in which all messages received are simply passed through to one of the

connected PLCs/Devices (if supported for that PLC/Device protocol), allowing PLC programming

software, a third party’s intelligent (MMI) Man-Machine Interface terminal or a SCADA software

program to be “connected” to the same port on the PLCs/Devices used by the DN-3000.

2) DEVICENET TO MOTOR DRIVES Allows a DeviceNet Host to control and/or monitor parameters

in up to 32 Motor Drives.

This manual is presented in two sections. Each section deals with the configuration requirements for each

of the above applications: DeviceNet to PLCs and DeviceNet to Motor Drives.

Please note that the application type is selected when a new project is created using the DN-3000

configuration software and may not be changed after the project is created.

1

Page 8

Software Installation

GENERAL INFORMATION

The Panel-Tec DN3000 Configuration Editor Software Program is designed to operate on an IBM or

compatible computer running MS-DOS 3.3 or higher.

While the Configuration Editor Software Program will run under “WINDOWS 3.1” in most

configurations, it is not recommended. As of this date, no problems have been reported running the

software under “WINDOWS 95”.

The configuration editor software will default during start-up to using “COMM 1” unless changed using

the OPTIONS menu. This may conflict with a mouse driver program and prevent up/down loading

configuration information to the DN-3000 interface unit.

INSTALLATION

Place the supplied program disk into drive “A” (or B).

At the MS-DOS prompt, C:> type in A: (or B:) and then press the “ENTER” key.

When the “A” (or B) prompt appears, A:> type in “INSTALL” and press the “ENTER” key.

The following message will appear;

DN3000 Configuration Editor Installation Program

Enter the drive where the editor is to be installed ==>

Enter “C” (or any other hard drive you care to use), then press the “ENTER” key.

A new message will appear:

Enter the sub-directory on drive C to install the editor into ==>

Suggested directory name is: DN3000

The next message to appear before the installation is started is:

The Editor will be installed from “A” to “C:\DN3000”

Is this correct (Y/N) ?

If the above information is correct, push the “Y” key, then the “ENTER” key and the software will be

installed. The last message to appear will be:

Installation Complete.

Enter “DN3000” to run the configuration Editor

C:\DN3000>

2

Page 9

Software Information

SOFTWARE START-UP

To start the DN-3000 Configuration Editor program. First start your computer and at the MS-DOS

prompt; C:> type in “CD\DN3000” (to change the directory) then press the ENTER key. At the next

MS-DOS prompt; C:\DN3000>,

Configuration Editor Software Program.

Upon starting of the configuration software program, the first screen to appear will be the “Support

Information Page”, shown below.

type in “DN3000” and press the ENTER key to start the

After pressing the computer’s ENTER key, the support information page will disappear. Use the

computer’s LEFT/RIGHT arrow keys and move the highlighted bar (very top of the screen) between the

four (4) main system selection headers. To select any one of these main selection headers, place the

highlight bar around that desired heading and then press the computer’s ENTER key. Below is a brief

description of the main project header and each internal subheading; NOTE: These brief descriptions

listed are as the system starts without any projects opened or new projects created.

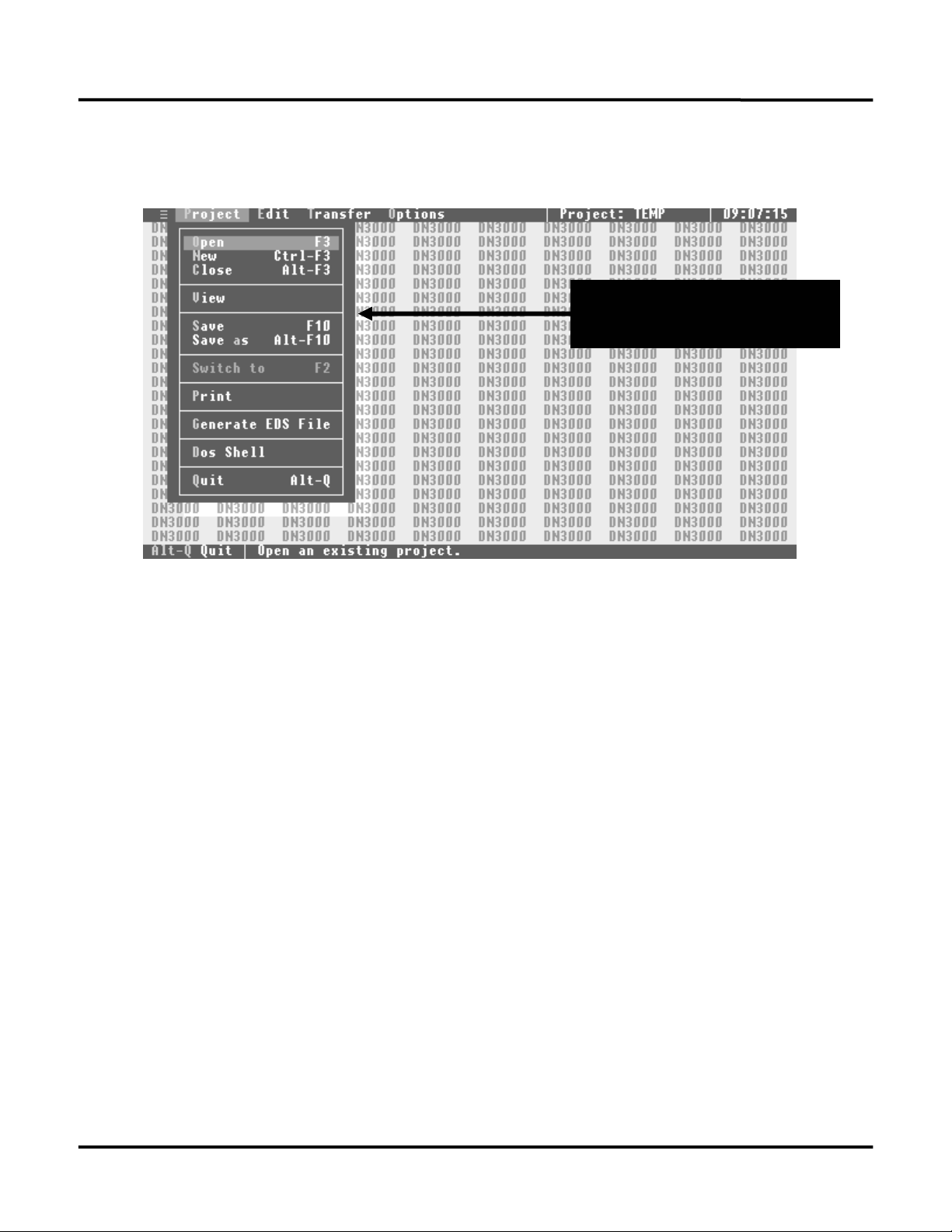

Selecting PROJECT opens a menu with the following options:

OPEN allows you to open any saved project file.

NEW allows you to create a new project file.

DOS SHELL allows you to exit to MS-DOS without closing the DN-3000 Configuration Editor

Program and return to the Configuration Editor Program by typing in EXIT and then pressing the

ENTER key.

QUIT allows you to exit the Configuration Editor Program.

3

Page 10

Creating Project Files

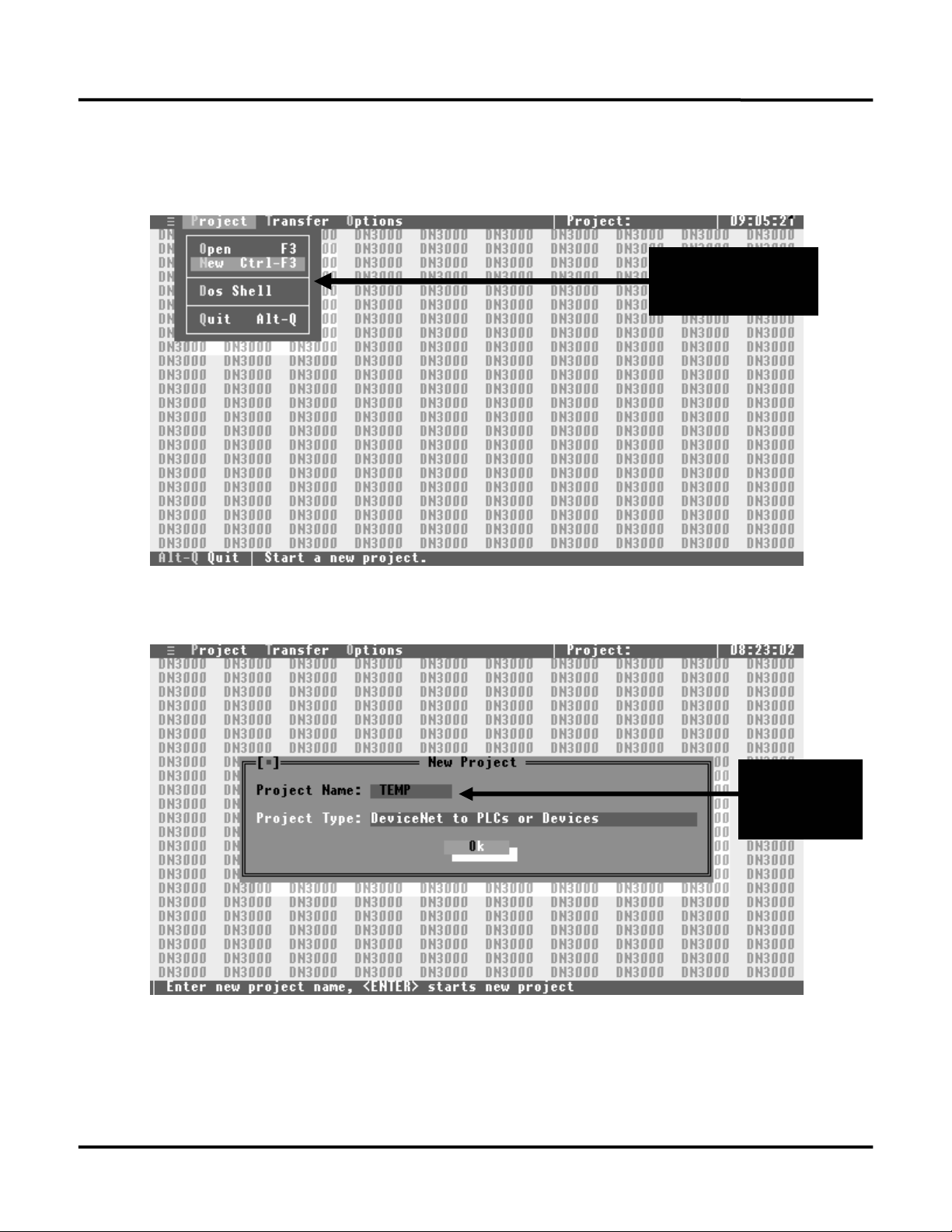

CREATING A PROJECT FILE

To create a project file, move the highlighted bar to the “PROJECT” heading and press the computer’s

ENTER key. When the menu appears move the highlight bar to the “NEW” sub-heading and press

“PROJECT”

Menu

the computer’s ENTER key. At the “Project Name” entry area, type in your file name.

Enter your

Project’s

File Name

After entering in the project’s file name, press the ENTER key. The highlighted bar now moves to

“Project Type”. Press ENTER to open the “Project Type” window (default setting is “DeviceNet to

PLCs or Devices”). Move the highlight bar by pressing the DOWN arrow key to the project type you

wish to configure and then press the ENTER key. The software enters this selection and returns to the

“PROJECT” menu.

4

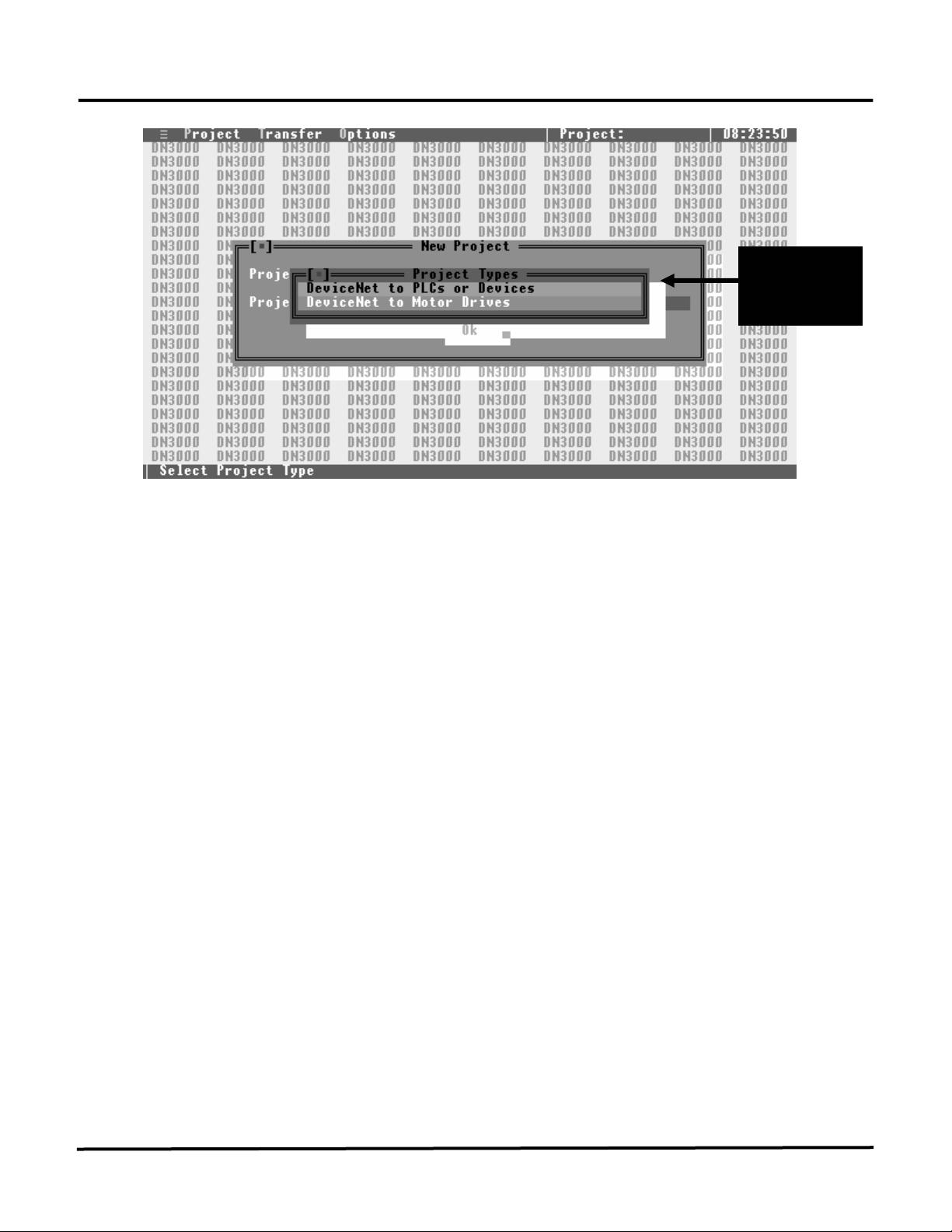

Page 11

Creating Project Files

“PROJECT

TYPE”

List

PROJECT TYPES

DeviceNet to PLCs or Devices allows a DeviceNet Host to read and write registers in up to 32

PLCs or devices.

DeviceNet to Motor Drives allows a DeviceNet Host to control and/or monitor up to 32 supported

Motor Drives.

5

Page 12

Creating Project Files

When the system returns to the “PROJECT’ menu, notice the additional sub-headings that were added to

the “PROJECT” menu and are now available for you to use. A brief description of each of these new

sub-headings are listed below:

Additional PROJECT

Menu Sub-Headings

CLOSE allows you to close a project file. More than one project file can be open at any time.

VIEW allows you to view; the project file name, project file type, and the current selections for each

of the DN-3000’s serial ports.

SAVE allows you to save the current project file.

SAVE AS allows to save the current open project file under a different file name.

SWITCH TO allows you to switch between the opened project files. (Multiple files can be open.)

PRINT allows you to print the project file’s configuration information.

GENERATE EDS FILE allows you to generate an EDS file for the current Project. The EDS file is

used to tell a DeviceNet configuration tool information about the DN-3000 and I/O sizes. If you are

using a DeviceNet configuration tool to set up your DeviceNet network, you should generate a new

EDS file for each project.

Use the RIGHT arrow key to move the highlight bar from the top “PROJECT” header to the top

“EDIT” header to proceed with editing the configuration information stored in the project file.

6

Page 13

DeviceNet to PLCs or Devices

DEVICENET TO PLCS OR DEVICES

The ”DeviceNet to Motor Drives” application allows a DeviceNet Host device to access data registers in

up to 32 serial PLCs or Devices via Explicit Messages and/or I/O Data.

Explicit Messages allows the DeviceNet Host to issue requests to the DN-3000 to read or write specific

PLC/Device data registers. The DN-3000 converts those requests into serial communications requests in

the selected serial PLC’s or Device’s protocol.

I/O Data allows the DN-3000 to exchange a fixed set of PLC/Device data registers between a DeviceNet

Host and serial PLCs or Devices. The DN-3000 writes Output Data received from the DeviceNet Host to

fixed PLC/Device data registers (see Output Data Table in this section) in the connected serial PLCs or

Devices. Input Data is read from fixed PLC/Device data registers in the connected serial PLCs or

Devices and sent to the DeviceNet Host (see Input Data Table in this section).

Important Note: The DN-3000 can be used to access only data registers in the selected PLCs or

Devices. See the Application Notes for the selected PLC/Device for more information.

DEVICE PROFILE

The DN-3000 is based on the “PLC/Device Gateway” Device Profile, a vendor-specific extension of the

“Communications Adapter” Device Profile (described in the “ODVA DeviceNet Specifications”). This

Device Profile introduces two new vendor-specific Objects: the “PLC/Device Interface Object” and the

“PLC/Device Command Object”. Documentation on this profile and these objects are available from

Panel-Tec, Inc.

The DN-3000 is a Group 2 Only Server utilizing the Predifined Master/Slave Connection Set (as

described in the (ODVA DeviceNet Specifications”). It supports both Explicit Messaging and Polled,

Change-of-State (COS) and Cyclic I/O connections to a DeviceNet Host. It does not support Bit-Strobed

I/O connections.

To access register data via Explicit Messaging, the DeviceNet Host must issue an explicit Get_Member or

Set_Member request to the desired “PLC/Device Interface Object” Instance (based on PLC/Device

Address) of the DN-3000.

If Polled, COS and/or Cyclic I/O connections are to be used, you must first set up the I/O

configuration of the DN-3000 with the DN3000 Configuration Editor software. See I/O Data

Configuration in this section.

7

Page 14

DeviceNet to PLCs or Devices

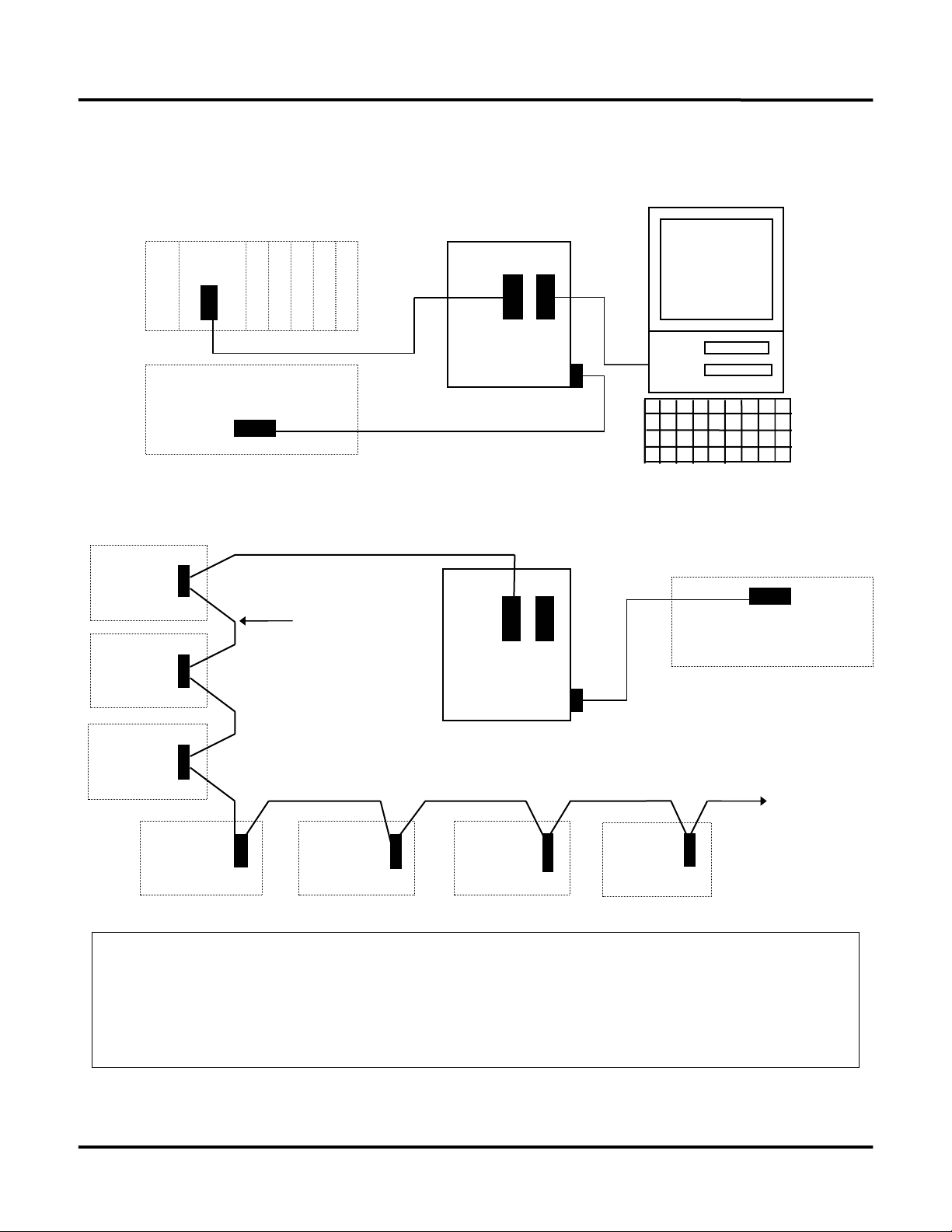

EXAMPLE APPLICATIONS

DeviceNet Host to Serial PLC with Pass-Through Connection

PLC # 1

PLC # 2

PLC # 3

NOTE: Multiple PLCs/Devices can be connected to Port 2 of a DN-3000 if:

1) All PLCs/Devices use the same protocol.

2) Each PLC/Device can be internally addressed with a network address.

3) Each PLC/Device can communicate on a RS-485/422 multi-drop communications network;

-OR- RS232 to RS485 converters (1 per PLC or Device) are used;

-OR- a 3rd Party multi-port communications expansion module (Port Expander) is used.

Supported PLC or Device

2 3

DN-3000

DeviceNet Host

DeviceNet Host to Multi-Dropped Serial PLCs

RS-422/485

Multi-Drop

Network

2 3

DN-3000

PLC # 4 PLC # 5 PLC # 6 PLC # 7

Programming

Software

(if supported)

DeviceNet Host

Up to 32

PLCs

may be

connected

8

Page 15

DeviceNet to PLCs or Devices

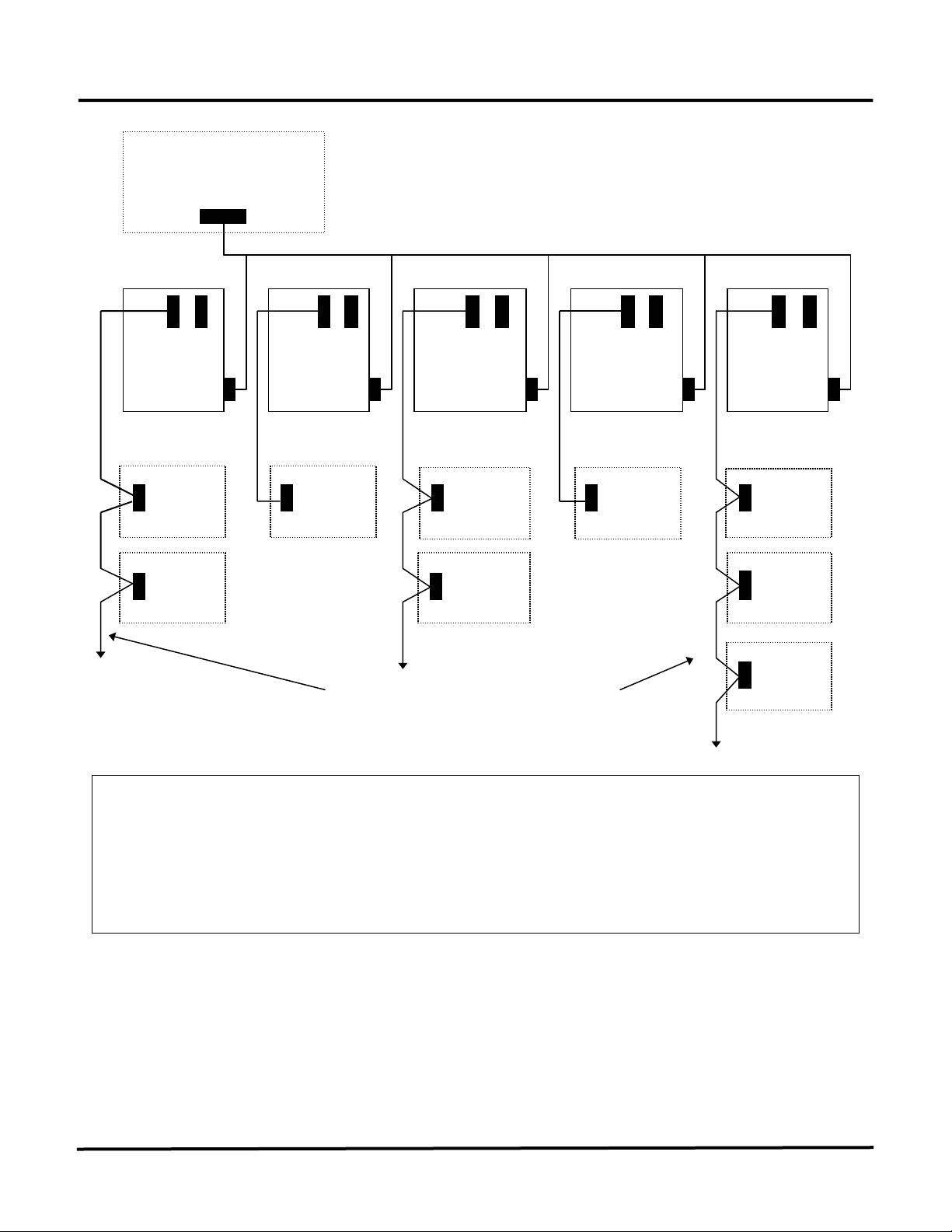

Multiple DN-3000s with Different PLC or Device Types

DeviceNet Host

2 3 2 3 2 3 2 3 2 3

DN-3000

# 1

PLC # 1

Brand A

PLC # 2

Brand A

NOTE:

1) Each DN-3000 can support up to 32 PLCs/Devices (if they are network addressable internally).

2) The DeviceNet Host can address a maximum of 63 DN-3000 units.

3) Multiple Brands of PLCs or Devices may be addressed by the DeviceNet Host by using multiple

DN-3000s, but only one PLC/Device Protocol may be used on a single DN-3000 unit.

4) If multiple DN-3000s are to be used, each DN-3000 must be configured with a unique node

address (MAC ID) on the DeviceNet network.

DN-3000

# 2

PLC # 1

Brand S

RS-422/485 Multiple-Drop Networks

DN-3000

# 3

PLC # 1

Brand O

PLC # 2

Brand O

DN-3000

# 4

PLC # 1

Brand M

DN-3000

# 5

PLC # 1

Brand I

PLC # 2

Brand I

PLC # 3

Brand I

9

Page 16

DeviceNet to PLCs or Devices

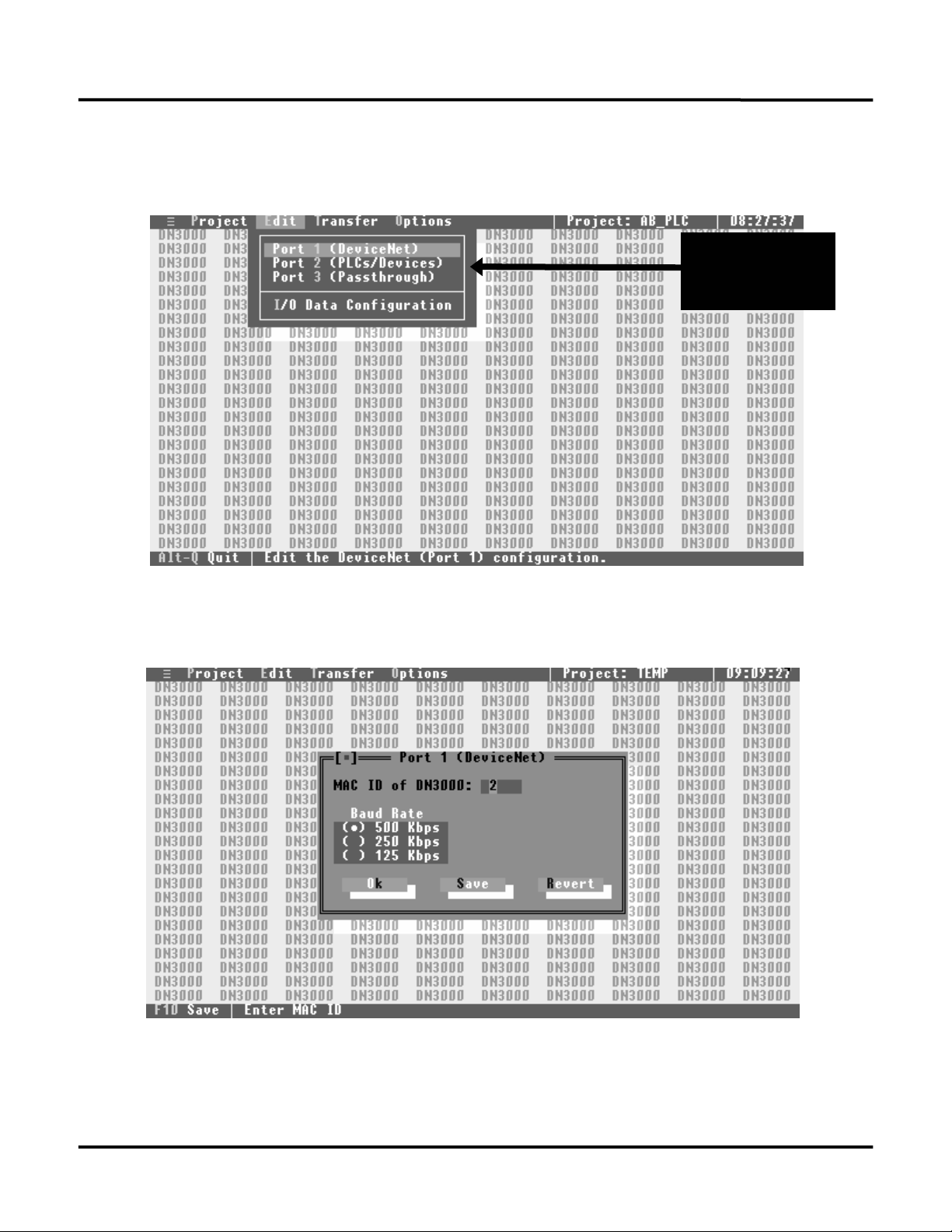

CONFIGURING PORT #1, (DEVICENET)

With the highlight bar around the “PROJECT” header use the RIGHT arrow key and move the highlight

bar to the “EDIT” header This action will close the “PROJECT” menu and open the “EDIT” menu.

DeviceNet to

PLCs or Devices

EDIT Menu

Move the highlight bar to the “Port 1 (DeviceNet)” sub-heading and press the ENTER key to open the

DeviceNet configuration screen.

10

Page 17

DeviceNet to PLCs or Devices

MAC ID of DN3000

The MAC ID of the DN-3000 is its node address on a DeviceNet Network. The MAC ID of a DN-3000

can range from 0 to 63. Type the desired value in the field and press ENTER.

Baud Rate

Baud Rate determines the rate at which the DN-3000 exchanges data on a DeviceNet network. The Baud

Rate setting must be the same for all devices on the DeviceNet network. The DN-3000 supports baud

rates of 125, 250 and 500 kbps. The dot between the brackets indicates the current selection. Use the

UP/DOWN arrow keys and the SPACEBAR to select the desired baud rate.

11

Page 18

DeviceNet to PLCs or Devices

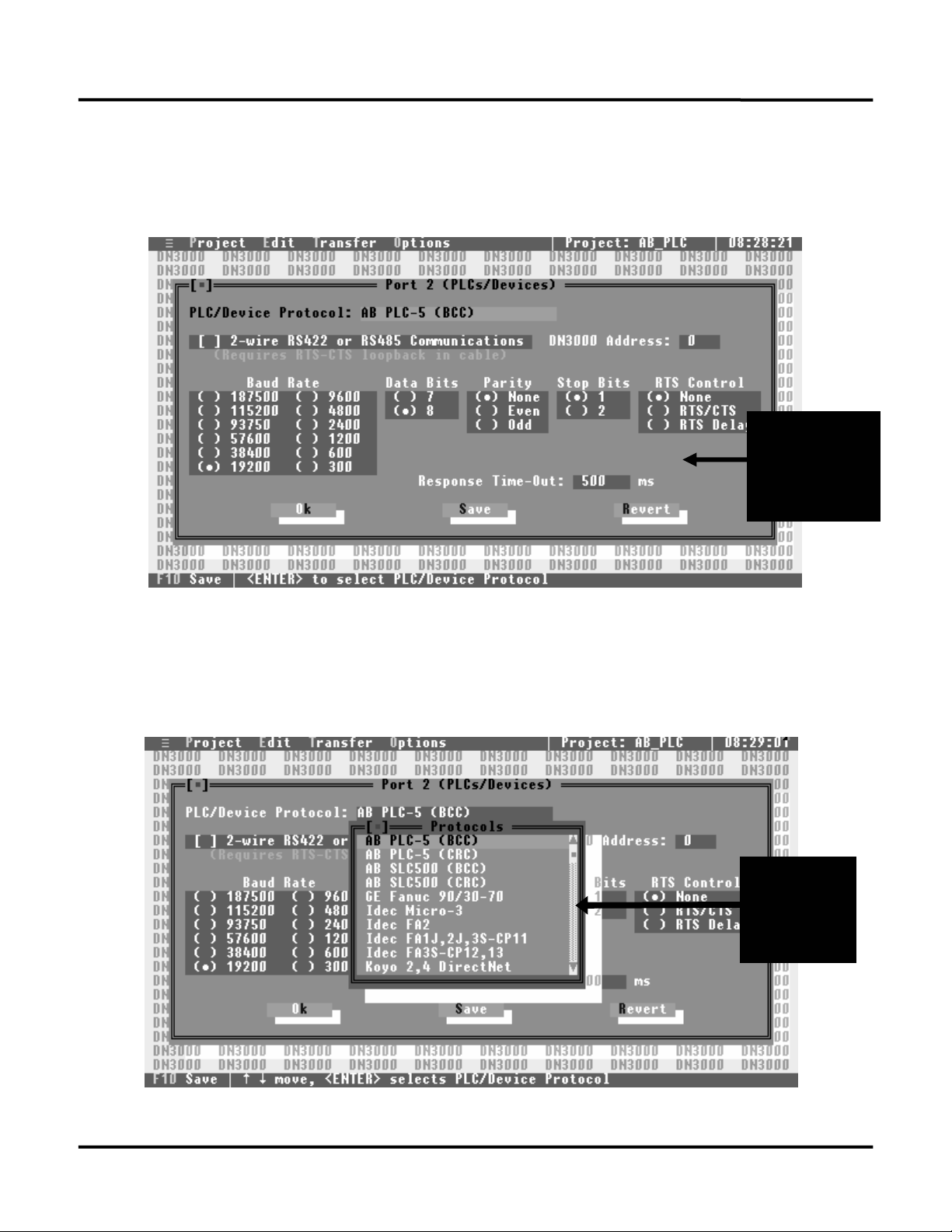

CONFIGURING PORT #2 (PLCS OR DEVICES)

When the highlight bar is around the “Port 2 (PLCs/Devices)” sub-heading, press the ENTER key. This

opens a window which allows you to select the type of PLCs or devices connected to this port and check

all of the communication settings.

PORT # 2

PLC

Configuration

Window

PLC/Device Protocol

The window for PORT # 2 Configuration will open with the highlighted bar at the “PLC/DEVICE

PROTOCOL” selection heading. If the displayed Protocol is not the one wanted, simply press the

ENTER key and a smaller window will appear.

PLC/Device

Protocol

Selection

Window

12

Page 19

DeviceNet to PLCs or Devices

Use your computer’s UP/DOWN arrow keys to move through the PLC/Device Protocol List. Place the

highlight bar on the desired Protocol and press the ENTER key. The software will enter this selection

and automatically close the Protocol selection window. After the selection window closes, you will need

to check the communications setting for the selected Protocol, making changes as necessary.

2 Wire RS422 or RS485 Communications

This box will only need to be checked if the communications with your PLC/Device is a 2-wire RS485 or

RS422 interface. When 2-wire communications are being used, RTS must be looped back to CTS on the

DN-3000 side of the cable. This can be done on the RS232 side by looping pins 4 and 5 or on the

RS422/485 side by looping 16 to 18 and 17 to 19.

DN3000 Address

Some PLC/Device protocols require each PLC or Device on a network to be assigned a unique address.

The DN3000 Address is the address assigned to the DN-3000 on the PLC/Device network.

Communications Settings

The communications settings are automatically set to the default values for each type of PLC/Device

when its Protocol is first selected. Before changing any of these settings, consult your PLC/Device

manual for the correct settings. To move between the communications settings, press the TAB or

ENTER keys. To select a setting, use the UP/DOWN arrow key to move to the desired setting and press

the SPACE BAR to enter or change your selection.

RTS Control (Request to Send Control)

RTS Control selection is an option provided for modems or for PLCs/Devices that require RTS to be

active only while the DN-3000 is transmitting to the PLC. If RTS/CTS is selected, the DN-3000 will

activate RTS and wait until CTS is active before transmitting to the PLC. If RTS Delay is selected, the

DN-3000 will activate RTS and wait for the specified delay time to pass before transmitting to the PLC.

Response Time-Out

The Response Time-Out tells the DN-3000 how long to wait after transmitting a request to a PLC/Device

if no response has been received from the PLC/Device. After this amount of time (specified in

milliseconds) passes with no response being received, the DN-3000 will assume that no response is

coming and will retry the request.

To save the configuration for Port #1, press the “Alt+S” keys or the F10 function key once and a small

window appears stating the information was saved. Press the ENTER key, then the ESC key to return to

the “EDIT” window.

13

Page 20

DeviceNet to PLCs or Devices

CONFIGURING PORT # 3 (PASSTHROUGH)

Not all PLC/Device protocols allow for the pass-through communications. If your selected Protocol on

Port 2 is capable of pass-through communications, the “Port 3 (Passthrough)” header within the “EDIT”

menu will be black (if light gray, the PLC does not support Pass-Through communications). Place the

Highlight bar around the “Port 3 (Passthrough)” header and press the ENTER key to open this screen.

(See drawing below)

A Selected PLC or

Device Protocol

that supports

Pass-Through

Communications

For descriptions of all entry fields on this screen except for the Intermessage Time-Out, refer to

CONFIGURING PORT #2 (PLCs or Devices) in this section.

Intermessage Time-Out

The DN-3000 uses the Intermessage Time-Out to determine when a complete message has been received

on the PassThrough port. Once the first character of a message has been received, if the amount of time

specified by the Intermessage Time-Out passes with no additional characters being received, the DN-3000

will consider the message to be complete and process it.

Check over the communications settings, making corrections as needed, and save this information by

pressing the letter “S” or the F10 function key(s) once. A small window will appear stating the

information was saved. Press the ENTER key, then the ESC key to return to the “EDIT” menu.

14

Page 21

DeviceNet to PLCs or Devices

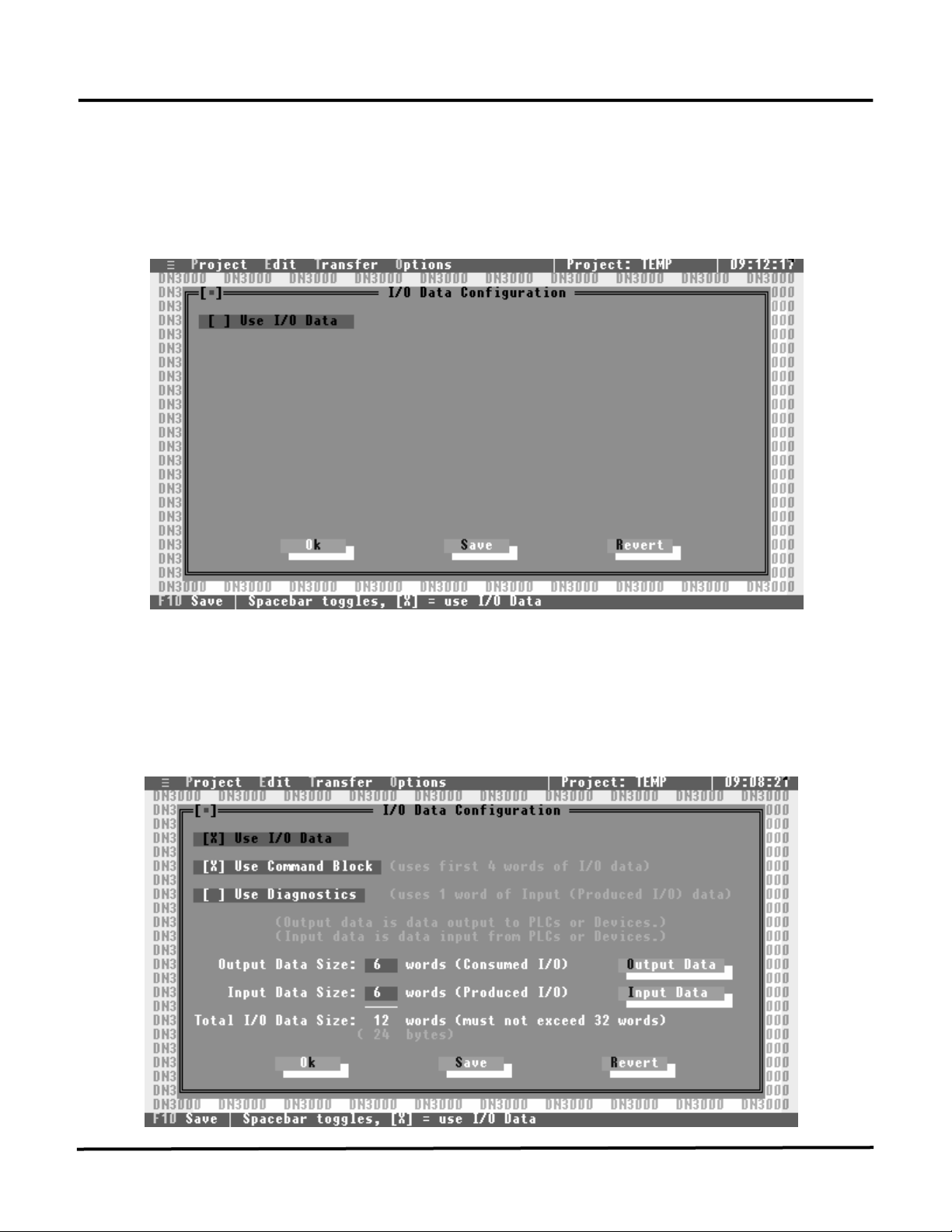

I/O DATA CONFIGURATION

Using the DOWN arrow key, move the highlight bar to the “I/O Data Configuration” sub-heading

within the “EDIT” menu and press the ENTER key. This action opens the I/O Data Configuration setup

screen to allow you to set up the I/O data parameters for your project. You should have some idea of how

you want your I/O set up before selecting this option.

Use I/O Data

If your project requires the use one or more I/O connections (Polled, Change-Of-State (COS) or Cyclic

I/O) for data exchange between the DN-3000 and a DeviceNet host, you should select this option by

pressing the SPACEBAR, ‘X’ or ‘Y’ key on your keyboard. When you select “Use I/O Data”, the other

available I/O options will appear on the screen.

15

Page 22

DeviceNet to PLCs or Devices

The DN-3000 supports up to a total of 64 bytes (32 words) of combined Input and Output data. Each

word (2 bytes) of Input or Output data can be configured to exchange data with any one valid data register

in any one of the PLCs/Devices connected to port 2 of the DN-3000 (see “CONFIGURING PORT 2” for

PLC/Device Protocol and communication parameters).

Use Command Block

In some projects it may be necessary to be able to access more than just the 32 PLC/Device registers that

can be configured in the Input and Output data. A Command Block reserves the first 4 words of Output

data for commands, and the first 4 words of Input data for command results. This reduces your total

number of words that can be used for register data to 24 words, but adds flexibility by allowing your

DeviceNet Host to issue commands to the DN-3000 to access any valid data registers in any PLC or

Device connected to port 2 of the DN-3000. Commands are issued by moving a command code,

PLC/Device address, file number (Allen-Bradley PLCs only), register number, and data into the first 4

words of the Output data (see “COMMAND BLOCK”).

Use Diagnostics

Diagnostics allows the DeviceNet Host to monitor PLC/Device connections to the DN-3000. The first

word of the Input data following the Command Result Block (if any) will be reserved for Diagnostics if

this option is selected. The DN-3000 keeps track of the connection status with each PLC/Device address

(0-255). Whenever an attempt to communicate with a PLC/Device is successful, the connection status for

that PLC/Device is set to ‘0’. Whenever an attempt to communicate with a PLC/Device is unsuccessful,

the connection status for that PLC/Device is set to ‘1’. Of course, returning 256 status bits would require

16 words of Input data (half of the available I/O data). Instead, only 16 bits (1 word) of are returned.

Each of the 16 bits of the Diagnostics word represents the status of 16 PLC/Device addresses, as follows:

bit 0 represents PLC/Device addresses 0, 16, 32, 48, 64, etc.; bit 1 represents PLC/Device addresses 1, 17,

33, 49, 65, etc.; and so forth. If the status of any of the PLC/Device addresses represented by a bit is ‘1’,

that bit will contain a ‘1’, otherwise, that bit will contain a ‘0’. Note that the status of a PLC/Device is set

to ‘1’ only if the DN-3000 attempts to communicate with that PLC/Device and that attempt is

unsuccessful.

Output Data Size

This determines the number of words of Output data that will be used in your project. Output data is data

that is output from your DeviceNet Host to the DN-3000 (commands, and register data to be written to

PLCs/Devices). This is also known as the Consumed I/O Data of the DN-3000. If a Command Block is

used, it will automatically reserve 4 words of Output data. The combined size of the Input and Output

data must not exceed 32 words.

Output Data

Pressing the Output Data button brings up a window allowing you to edit the configuration of the Output

data in your project. You can press the Output Data button by clicking on it with your mouse, or moving

the focus to the button with the arrow keys and pressing the SPACEBAR. See “OUTPUT DATA

TABLE”.

16

Page 23

DeviceNet to PLCs or Devices

Input Data Size

This determines the number of words of Input data that will be used in your project. Input data is data

that is input to your DeviceNet Host from the DN-3000 (command results, diagnostics information, and

register data read from PLCs/Devices). This is also known as the Produced I/O Data of the DN-3000. If

a Command Block is used, it will automatically reserve 4 words of Input data for command results.

Similarly, if Diagnostics is used, it will automatically reserve 1 word of Input data. The combined size of

Input and Output data must not exceed 32 words.

Input Data

Pressing the Input Data button brings up a window allowing you to edit the configuration of the Input

data in your project. You can press the Input Data button by clicking on it with your mouse, or moving

the focus to the button with the arrow keys and pressing the SPACEBAR. See “INPUT DATA TABLE”.

17

Page 24

DeviceNet to PLCs or Devices

OUTPUT DATA TABLE

Within the “I/O Data Configuration” screen, use the DOWN arrow key to move the focus to the Output

Data button and press the ENTER key. This action opens the Output Data Table setup screen to allow

you to set up the PLC/Device registers to be mapped to each word of Output data.

Output data is data received by the DN-3000 from the DeviceNet Host to be written to PLC/Device

registers. Each word of Output data (except those reserved for the Command Block) can be mapped to

specific PLC/Device registers. Output data is only written to registers when that data changes.

Use the UP/DOWN arrow keys to scroll through the list of Output data words until the highlight bar is

over the Output word you wish to edit, and press ENTER. A window will open allowing you to edit the

PLC/Device Address, File Number (Allen-Bradley PLCs only) and Register Number mapped to that

Output word.

18

Page 25

DeviceNet to PLCs or Devices

Use Output Word xx

If you want to map this word of Output data to a PLC/Device register, select this option. If this option is

not selected, any data appearing in this Output word will be ignored.

PLC/Device Address

This is the Address of the PLC/Device mapped to this word of Output data. The PLC/Device Address

must be in the range 0 to 255.

File Number (Allen-Bradley PLCs only)

This is the File Number of the register in the PLC mapped to this word of Output data.

Register Number

This is the Register Number of the PLC/Device mapped to this word of Output data. Whenever the value

in this Output word changes, the DN-3000 will write that value to the register specified by the

PLC/Device Address, File Number and Register Number.

19

Page 26

DeviceNet to PLCs or Devices

INPUT DATA TABLE

Within the “I/O Data Configuration” screen, use the DOWN arrow key to move the focus to the Input

Data button and press the ENTER key. This action opens the Input Data Table setup screen to allow you

to set up the PLC/Device registers to be mapped to each word of Input data.

Input data is data read from PLC/Device registers and sent from the DN-3000 to the DeviceNet Host.

Each word of Input data (except those reserved for the Command Block and Diagnostics) can be mapped

to specific PLC/Device registers. Mapped registers in the Input Data Table are read from the

PLCs/Devices and placed in the Input data in a round-robin fashion as quickly as the serial

communications link allows.

Use the UP/DOWN arrow keys to scroll through the list of Input data words until the highlight bar is over

the Input word you wish to edit, and press ENTER. A window will open allowing you to edit the

PLC/Device Address, File Number (Allen-Bradley PLCs only) and Register Number mapped to that Input

word.

20

Page 27

DeviceNet to PLCs or Devices

Use Input Word xx

If you want to map this word of Input data to a PLC/Device register, select this option. If this option is

not selected, the data in this Input word will be set to 0.

PLC/DeviceAddress

This is the Address of the PLC/Device mapped to this word of Input data. The PLC/Device Address must

be in the range 0 to 255.

File Number (Allen-Bradley PLCs only)

This is the File Number of the register in the PLC mapped to this word of Input data.

Register Number

This is the Register Number in the PLC/Device mapped to this word of Input data. The DN-3000 will

read the value of the register specified by the PLC/Device Address, File Number (Allen-Bradley PLCs

only) and Register Number and place that value in this word of the Input data.

21

Page 28

DeviceNet to PLCs or Devices

COMMAND BLOCK

Using I/O data to update and/or monitor motor drive parameters requires very little programming in your

DeviceNet Host device – the configuration of the DN-3000 specifies which PLC/Device registers are

mapped to which words of I/O data. However, you can only access a total of 32 registers this way, and

those registers are fixed when the DN-3000 is configured. If your application requires that you access

more than 32 registers, you must either use multiple DN-3000s, or use a Command Block.

A Command Block allows your DeviceNet Host to issue commands at run-time to read or write any valid

register in any PLC/Device connected to Port 2 of the DN-3000. The Command Block reserves the first 4

words of Output data for commands issued by the Host, and the first 4 words of Input data for the results

of those commands (along with any returned data). Commands are issued by moving a PLC/Device

Address, File Number, Register Number, any required Register Data (for write commands only), and a

Command code into the Command Block, as follows:

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

word 1

word 2

word 3

word 4

The DN-3000 looks for changes in the Command Block data to determine when there is a new request to

be processed, “throwing out” any invalid commands received. Valid Commands are 1 (read) and 2

(write). To ensure that partial commands are not processed (in systems where it is possible that Output

data could be sent by the host before all 4 words of data have been moved into the command block), you

should set the Command to 0 (indicating no command), then place the data in words 2-4, and only set the

Command to 1 or 2 after all of the other data is in place. After a command has been processed by the DN3000, it will “echo” the command in the Command Result Block in the Input data, and set the Result Code

and any Returned Register Data, as follows:

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

word 1

word 2

word 3

word 4

If a read command (1) was issued, the Returned Register Data will contain the register data read from the

specified PLC/Device. If a write command (2) was issued, the Returned Register Data will be the same

as for the issued command. The Result Code indicates the result of processing the issued command.

Valid Result Codes are as follows:

Result Code Meaning

0 Command was completed successfully.

1 DN-3000 could not communicate with indicated PLC/Device.

7 Command was invalid.

PLC/Device Address (0-255) 0 0 0 0 Command

File Number

Register Number

Register Data (write command only)

PLC/Device Address 1 Result Code Command

File Number

Register Number

Returned Register Data (read command only)

22

Page 29

DeviceNet to Motor Drives

DEVICENET TO MOTOR DRIVES

The ”DeviceNet to Motor Drives” application allows a DeviceNet Host device to access parameters in up

to 32 serial Motor Drives via Explicit Messages and/or I/O Data.

Explicit Messages allows the DeviceNet Host to issue requests to the DN-3000 to read or write specific

Motor Drive parameters. The DN-3000 converts those requests into serial communications requests in

the selected serial Motor Drive’s protocol.

I/O Data allows the DN-3000 to exchange a fixed set of Motor Drive parameters between a DeviceNet

Host and serial Motor Drives. The DN-3000 writes Output Data received from the DeviceNet Host to

fixed Motor Drive parameters (see Output Data Table in this section) in the connected serial Motor

Drives. Input Data is read from fixed Motor Drive parameters in the connected serial Motor Drives and

sent to the DeviceNet Host (see Input Data Table in this section).

DEVICE PROFILE

This application of the DN-3000 is based on the “Motor Drive Gateway” Device Profile, a vendorspecific extension of the “Communications Adapter” Device Profile (described in the “ODVA

DeviceNet Specifications”). This Device Profile introduces two new vendor-specific Objects: the

“Motor Drive Interface Object” and the “Motor Drive Command Object”. Documentation on this

profile and these objects are available from Panel-Tec, Inc.

The DN-3000 is a Group 2 Only Server utilizing the Predifined Master/Slave Connection Set (as

described in the (ODVA DeviceNet Specifications”). It supports both Explicit Messaging and Polled,

Change-of-State (COS) and Cyclic I/O connections to a DeviceNet Host. It does not support Bit-Strobed

I/O connections.

To access Motor Drive Parameter data via Explicit Messaging, the DeviceNet Host must issue an explicit

Get_Member or Set_Member request to the desired “Motor Drive Interface Object” Instance (based on

Motor Drive Address) of the DN-3000.

If Polled, COS and/or Cyclic I/O connections are to be used, you must first set up the I/O

configuration of the DN-3000 with the DN3000 Configuration Editor software. See I/O

Configuration in this section.

23

Page 30

DeviceNet to Motor Drives

EXAMPLE APPLICATIONS

DeviceNet Host to Serial Motor Drive

Drive #1

Drive # 2

Drive # 3

Drive # 4 Drive # 5 Drive # 6 Drive # 7

NOTE: Multiple Motor Drives can be connected to Port 2 of a DN-3000 if:

1) All Motor Drives use the same protocol.

2) Each Motor Drive can be internally addressed with a network address.

3) Each Motor Drive can communicate on a RS-485/422 multi-drop communications network;

-OR- RS232 to RS485 converters (1 per Motor Drive) are used;

-OR- a 3rd Party multi-port communications expansion module (Port Expander) is used.

Supported

Motor Drive

2 3

DN-3000

DeviceNet Host to Multi-Dropped Serial Motor Drives

RS-422/485

Multi-Drop

Network

2 3

DN-3000

DeviceNet Host

DeviceNet Host

Up to 32

Drives

may be

connected

24

Page 31

DeviceNet to Motor Drives

Multiple DN-3000s with Different Motor Drive Types

DeviceNet Host

2 3 2 3 2 3 2 3 2 3

DN-3000

# 1

Drive # 1

Brand A

Drive # 2

Brand A

NOTE:

1) Each DN-3000 can support up to 32 Motor Drives (if they are network addressable internally).

2) The DeviceNet Host can address a maximum of 63 DN-3000 units.

3) Multiple Brands of Motor Drives may be addressed by the DeviceNet Host by using multiple

DN-3000s, but only one Motor Drive Type may be used on a single DN-3000 unit.

4) If multiple DN-3000s are to be used, each DN-3000 must be configured with a unique node

address (MAC ID) on the DeviceNet network.

DN-3000

# 2

Drive # 1

Brand S

DN-3000

# 3

Drive # 1

Brand O

Drive # 2

Brand O

DN-3000

# 4

Drive # 1

Brand M

DN-3000

# 5

Drive # 1

Brand I

Drive # 2

Brand I

Drive # 3

RS-422/485 Multiple-Drop Networks

Brand I

25

Page 32

DeviceNet to Motor Drives

CONFIGURING PORT #1, (DEVICENET)

With the highlight bar around the “PROJECT” header use the RIGHT arrow key and move the highlight

bar to the “EDIT” header This action will close the “PROJECT” menu and open the “EDIT” menu.

DeviceNet to

Motor Drives

EDIT Menu

Move the highlight bar to the “Port 1 (DeviceNet)” sub-heading and press the ENTER key to open the

DeviceNet configuration screen.

26

Page 33

DeviceNet to Motor Drives

MAC ID of DN3000

The MAC ID of the DN-3000 is its node address on a DeviceNet Network. The MAC ID of a DN-3000

can range from 0 to 63. Type the desired value in the field and press ENTER.

Baud Rate

Baud Rate determines the rate at which the DN-3000 exchanges data on a DeviceNet network. The Baud

Rate setting must be the same for all devices on the DeviceNet network. The DN-3000 supports baud

rates of 125, 250 and 500 kbps. The dot between the brackets indicates the current selection. Use the

UP/DOWN arrow keys and the SPACEBAR to select the desired baud rate.

27

Page 34

DeviceNet to Motor Drives

CONFIGURING PORT # 2 (MOTOR DRIVES)

Using the DOWN arrow key, move the highlight bar to the “Port 2 (Motor Drives)” sub-heading (within

the “EDIT” menu) and press the ENTER key. This action opens the Motor Drive selection screen to

allow you to select the drive manufacturer and to check all the motor drive’s communications settings.

Motor Drive Type

The Port 2 (Motor Drives) Configuration screen will open with the highlight bar at the “MOTOR DRIVE

TYPE” selection area. Simply press the ENTER key to open the current list of supported motor drives.

Use your UP/DOWN arrow keys to move through the drive list and place the highlight bar around the

drive of your choice, then press the ENTER key to enter your selection. The software automatically

saves your entry and closes the “MOTOR DRIVE SELECTION” window.

Motor Drive

Selection

Window

28

Page 35

DeviceNet to Motor Drives

2-Wire RS422 or RS485 Communications

This box will only need to be checked if the communications with your Motor Drive is a 2-wire RS485 or

RS422 interface. When 2-wire communications are being used, RTS must be looped back to CTS on the

DN-3000 side of the cable. This can be done on the RS232 side by looping pins 4 and 5 or on the

RS422/485 side by looping 16 to 18 and 17 to 19.

Communications Settings

The communications settings are automatically set to the default values for each type of Motor Drive

when the Motor Drive is first selected. Before changing any of these settings, consult your drive manual

for the correct settings. To move between the communications settings, press the TAB or ENTER keys.

To select a setting, use the UP/DOWN arrow keys to move to the desired setting and press the SPACE

BAR to enter or change your selection.

RTS Control (Request to Send Control)

RTS Control selection is an option provided for modems or for Motor Drives that require RTS to be

active only while the DN-3000 is transmitting to the drive. If RTS/CTS is selected, the DN-3000 will

activate RTS and wait until CTS is active before transmitting to the drive. If RTS Delay is selected, the

DN-3000 will activate RTS and wait for the specified delay time to pass before transmitting to the drive.

Response Time-Out

The Response Time-Out is tells the DN-3000 how long to wait after transmitting a request to the Motor

Drive if no response has been received from the drive. After this amount of time (specified in

milliseconds) passes with no response being received, the DN-3000 will assume that no response is

coming and will retry the request.

Minimum Delay Between Messages

The Minimum Delay Between Messages is only needed for Motor Drives that get “confused” when

consecutive requests are sent too close together. The Mitsubishi Z200 Series of Motor Drives is the only

currently known drive that requires this delay (set to 60 ms for Mitsubishi Z200 drives).

Save this information by pressing the Alt+S” or F10 function keys. After the “Information Saved”

window appears, press the ENTER key, then the ESC key to return to the “EDIT” window.

29

Page 36

DeviceNet to Motor Drives

I/O DATA CONFIGURATION

Using the DOWN arrow key, move the highlight bar to the “I/O Data Configuration” sub-heading

within the “EDIT” menu and press the ENTER key. This action opens the I/O Data Configuration setup

screen to allow you to set up the I/O data parameters for your project. You should have some idea of how

you want your I/O set up before selecting this option.

Use I/O Data

If your project requires the use of Polled, Change-Of-State (COS) or Cyclic I/O to be exchanged between

the DN-3000 and a DeviceNet host, you should select this option.

30

Page 37

DeviceNet to Motor Drives

The DN-3000 supports up to a total of 64 bytes (32 words) of combined Input and Output data. Each

word (2 bytes) of Input or Output data can be configured to exchange data with any one valid parameter

in any one of the motor drives connected to port 2 of the DN-3000 (see “CONFIGURING PORT 2” for

motor drive type and communication parameters).

Use Command Block

In some projects it may be necessary to be able to access more than just the 32 motor drive parameters

that can be configured in the Input and Output data. A Command Block reserves the first 3 words of

Output data for commands, and the first 3 words of Input data for command results. This reduces your

total number of words that can be used for parameter data to 26 words, but adds flexibility by allowing

your DeviceNet Host to issue commands to the DN-3000 to access any valid parameter in any motor drive

connected to port 2 of the DN-3000. Commands are issued by moving a command code, motor drive

address, parameter number, and data into the first 3 words of the Output data (see “COMMAND

BLOCK”).

Use Diagnostics

Diagnostics allows the DeviceNet Host to monitor motor drive connections to the DN-3000. The first

word of the Input data following the Command Result Block (if any) will be reserved for Diagnostics if

this option is selected. The DN-3000 keeps track of the connection status with each motor drive address

(0-255). Whenever an attempt to communicate with a motor drive address is successful, the connection

status for that address is set to ‘0’. Whenever an attempt to communicate with a motor drive address is

unsuccessful, the connection status for that address is set to ‘1’. Of course, returning 256 status bits

would require 16 words of Input data (half of the available I/O data). Instead, only 16 bits (1 word) of are

returned. Each of the 16 bits of the Diagnostics word represents the status of 16 motor drive addresses, as

follows: bit 0 represents motor drive addresses 0, 16, 32, 48, 64, etc.; bit 1 represents motor drive

addresses 1, 17, 33, 49, 65, etc.; and so forth. If the status of any of the motor drive addresses represented

by a bit is ‘1’, that bit will contain a ‘1’, otherwise, that bit will contain a ‘0’. Note that the status of a

motor drive address is set to ‘1’ only if the DN-3000 attempts to communicate with that motor drive

address and that attempt is unsuccessful.

Output Data Size

This determines the number of words of Output data that will be used in your project. Output data is data

that is output from your DeviceNet Host to the DN-3000 (commands, and parameter data to be written to

motor drives). This is also known as the Consumed I/O Data of the DN-3000. If a Command Block is

used, it will automatically reserve 3 words of Output data. The combined size of the Input and Output

data must not exceed 32 words.

Output Data

Pressing the Output Data button brings up a window allowing you to edit the configuration of the Output

data in your project. You can press the Output Data button by clicking on it with your mouse, or moving

the focus to the button with the arrow keys and pressing the SPACEBAR. See “OUTPUT DATA

TABLE CONFIGURATION”.

31

Page 38

DeviceNet to Motor Drives

Input Data Size

This determines the number of words of Input data that will be used in your project. Input data is data

that is input to your DeviceNet Host from the DN-3000 (command results, diagnostics information, and

parameter data read from motor drives). This is also known as the Produced I/O Data of the DN-3000. If

a Command Block is used, it will automatically reserve 3 words of Input data for command results.

Similarly, if Diagnostics is used, it will automatically reserve 1 word of Input data. The combined size of

Input and Output data must not exceed 32 words.

Input Data

Pressing the Input Data button brings up a window allowing you to edit the configuration of the Input

data in your project. You can press the Input Data button by clicking on it with your mouse, or moving

the focus to the button with the arrow keys and pressing the SPACEBAR. See “INPUT DATA TABLE

CONFIGURATION”.

32

Page 39

DeviceNet to Motor Drives

OUTPUT DATA TABLE

Within the “I/O Data Configuration” screen, use the DOWN arrow key to move the focus to the Output

Data button and press the ENTER key. This action opens the Output Data Table setup screen to allow

you to set up the motor drive parameters to be mapped to each word of Output data.

Output data is data received by the DN-3000 from the DeviceNet Host to be written to motor drive

parameters. Each word of Output data (except those reserved for the Command Block) can be mapped to

specific motor drive parameters. Output data is only written to motor drive parameters when that data

changes.

Use the UP/DOWN arrow keys to scroll through the list of Output data words until the highlight bar is

over the Output word you wish to edit, and press ENTER. A window will open allowing you to edit the

Motor Drive Address and Parameter Number mapped to that Output word.

33

Page 40

DeviceNet to Motor Drives

Use Output Word xx

If you want to map this word of Output data to a motor drive parameter, select this option. If this option

is not selected, any data appearing in this Output word will be ignored.

Motor Drive Address

This is the Address of the Motor Drive mapped to this word of Output data. The Motor Drive Address

must be in the range 0 to 255.

Parameter Number

This is the Parameter Number of the Motor Drive mapped to this word of Output data. Whenever the

value in this Output word changes, the DN-3000 will write that value to the motor drive parameter

specified by the Motor Drive Address and Parameter Number.

34

Page 41

DeviceNet to Motor Drives

INPUT DATA TABLE

Within the “I/O Data Configuration” screen, use the DOWN arrow key to move the focus to the Input

Data button and press the ENTER key. This action opens the Input Data Table setup screen to allow you

to set up the motor drive parameters to be mapped to each word of Input data.

Input data is data read from motor drive parameters and sent from the DN-3000 to the DeviceNet Host.

Each word of Input data (except those reserved for the Command Block and Diagnostics) can be mapped

to specific motor drive parameters. Mapped motor drive parameters in the Input Data Table are read from

the motor drives and placed in the Input data in a round-robin fashion as quickly as the motor drives’

serial communications link allows.

Use the UP/DOWN arrow keys to scroll through the list of Input data words until the highlight bar is over

the Input word you wish to edit, and press ENTER. A window will open allowing you to edit the Motor

Drive Address and Parameter Number mapped to that Input word.

35

Page 42

DeviceNet to Motor Drives

Use Input Word xx

If you want to map this word of Input data to a motor drive parameter, select this option. If this option is

not selected, the data in this Input word will be set to 0.

Motor Drive Address

This is the Address of the Motor Drive mapped to this word of Input data. The Motor Drive Address

must be in the range 0 to 255.

Parameter Number

This is the Parameter Number of the Motor Drive mapped to this word of Input data. The DN-3000 will

read the value of the motor drive parameter specified by the Motor Drive Address and Parameter Number

and place that value in this word of the Input data.

36

Page 43

DeviceNet to Motor Drives

COMMAND BLOCK

Using I/O data to update and/or monitor motor drive parameters requires very little programming in your

DeviceNet Host device – the configuration of the DN-3000 specifies which motor drive parameters are

mapped to which words of I/O data. However, you can only access a total of 32 motor drive parameters

this way, and those parameters are fixed when the DN-3000 is configured. If your application requires

that you access more than 32 motor drive parameters, you must either use multiple DN-3000s, or use a

Command Block.

A Command Block allows your DeviceNet Host to issue commands at run-time to read or write any valid

parameter of any motor drive connected to Port 2 of the DN-3000. The Command Block reserves the first

3 words of Output data for commands issued by the Host, and the first 3 words of Input data for the

results of those commands (along with any returned data). Commands are issued by moving a Motor

Drive Address, Parameter Number, any required Parameter Data (for write commands only), and a

Command code into the Command Block, as follows:

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

word 1

word 2

word 3

The DN-3000 looks for changes in the Command Block data to determine when there is a new request to

be processed, “throwing out” any invalid commands received. Valid Commands are 1 (read) and 2

(write). To ensure that partial commands are not processed (in systems where it is possible that Output

data could be sent by the host before all 4 words of data have been moved into the command block), you

should set the Command to 0 (indicating no command), then place the data in words 2-3, and only set the

Command to 1 or 2 after all of the other data is in place. After a command has been processed by the DN3000, it will “echo” the command in the Command Result Block in the Input data, and set the Result Code

and any Returned Parameter Data, as follows:

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

word 1

word 2

word 3

If a read command (1) was issued, the Returned Parameter Data will contain the parameter data read

from the specified Motor Drive. If a write command (2) was issued, the Returned Parameter Data will be

the same as for the issued command. The Result Code indicates the result of processing the issued

command. Valid Result Codes are as follows:

Result Code Meaning

0 Command was completed successfully.

1 DN-3000 could not communicate with indicated motor drive.

2-6 Drive specific error code (see “Application Notes” for motor drive).

7 Command was invalid.

Motor Drive Address (0-255) 0 0 0 0 Command

Parameter Number

Parameter Data (write command only)

Motor Drive Address (0-255) 1 Result Code Command

Parameter Number

Returned Parameter Data (read command only)

37

Page 44

DeviceNet to Motor Drives

UPPER LINK CONFIGURATION (Mitsubishi Drives Only)

The “Upper Link Configuration” screen is only used with Mitsubishi Drives. To open this screen, place

the highlighted bar around the “Upper Link Table” sub-heading (within the “EDIT” menu) and press the

ENTER key. The Upper Link Table is used to select which drive or drives support Upper Parameter

Numbers. If a particular drive supports upper parameters, it must be set in this table to insure proper

communications with the motor drive.

To enable the Upper Link for any drive, use the computer’s arrow KEYS to move the highlighted

brackets to the desired drive number and press the SPACE BAR. This places an “X” between the

brackets. The Upper Link Activity time-out is used by the DN-3000 to ensure the state of the link setting

in the drive when it has not had any communications with the drive for a certain period of time.

Numbers

represent

the drive

addresses

Mitsubishi’s

Upper Link

Configuration

Window

Operation of the Link Switch

When the parameter number 128 or higher is being accessed, the DN-3000 will automatically set the link

switch to Upper Parameters if not already set. When parameter number 127 or lower is being accessed,

the DN-3000 will automatically set the link switch to Lower Parameters if not already set. If the Upper

Link Activity time-out value is reached without any communications activity to a particular drive, the

DN-3000 will consider the state of the link switch for that drive to be indeterminate and will set the upper

link switch to the appropriate setting for the next parameter that is being accessed regardless of what the

previous setting was.

38

Page 45

DeviceNet to Motor Drives

y

EXCEPTION TABLE (Mitsubishi Drives Only)

There are some parameters within Mitsubishi Drives that must be written to the drive as 2-byte ASCII

numbers instead of the usual 4-byte ASCII numbers. These parameter numbers need to be entered for

each drive that requires these “exceptions” to the usual 4-byte ASCII format. A total of eight (8)

exceptions may be entered for each drive.

To enter the exception numbers, move the highlight bar (while in the “EDIT” menu) to the

“EXCEPTION TABLE” sub-heading and press the ENTER key. The “EXCEPTION TABLE” screen

will open with the highlight bar at motor drive zero (0).

List of

Exceptions for

each Motor

Drive

Parameter

Exception

Entr

Area

To enter exceptions, press the ENTER, TAB or RIGHT arrow key(s) to move into the Exception Entry

Area. Press the SPACE BAR and a “X” will be placed between the brackets of the first exception area

and a small shaded area will appear to allow entry of the parameter number. Press the DOWN arrow key

and the system will move to the next exception entry area. Repeat all the steps until all exceptions for this

drive have been entered, then move the highlight to the “SAVE” button and then press the ENTER key.

After the “Information Saved” screen appears, press the ESC key and the highlight returns to the

“Drive/Exception List”. Press the DOWN arrow key once and the highlighted bar will move to the

second drive in the list. Repeat all the steps to enter exceptions for each drive and then save this

information.

NOTE: If all the drives are to have the same exceptions, move the highlight to the “SETALL”

button and press the ENTER key. This will allow you to enter the exceptions that will be set for all

32 drives.

Your next step is to transfer this created project file into the DN-3000. Refer to the section

“TRANSFERRING PROJECT FILES.”

39

Page 46

Transferring Project Files

TRANSFERRING PROJECT FILES

From the “TRANSFER” menu you will be able to:

1) Transfer (Download) a completed project file to the DN-3000

2) Upload a project file from the DN-3000

3) Compare a loaded project file within the DN-3000 to a stored project file within the computer.

4) Check the current application within the DN-3000

Use the computer’s RIGHT arrow key to move the highlight bar to the top “TRANSFER” heading and

press the ENTER key to open the “TRANSFER” menu.

TRANSFER

Menu

Move the highlight bar (DOWN arrow key) to the operation you wish to perform and press the ENTER

key to begin this function. A message screen will appear as you start the transfer operation and will

always appear as a warning screen for any of the four transferring operations:

“Connect Configuration Cable from PC to DN3000, Port 3.”

“Change DN3000 DIP switch to position 3 ON, and the rest OFF.”

Next, check to see the following has been completed before you transfer any files:

1) Power is applied to the DN-3000 unit.

2) The configuration cable is connected between the computer serial port and port 3 of the DN-3000

unit. (for cable pin-out information see Application Notes.)

3) DIP switch number 3 is in the ON position and the rest of the switches are in the OFF position.

40

Page 47

Transferring Project Files

Communication

“Startup”

Screen

TRANSFER OPTIONS

Download Project to DN3000

Allows you to transfer (download) any created project file from the PC to the DN-3000.

Upload Project from DN3000

Allows you to transfer (upload) the project file stored in the DN-3000 to the PC. The computer will

upload the project file under the name “NONAME.” You must save this uploaded project file using the

“SAVE AS” command from the “PROJECT” window and enter your own file name.

Verify

This feature allows you to verify a project file within your computer against the current project file stored

in the DN-3000 unit. After completing the verification process, if the project files are

message will appear stating “Data Verified OK”. If the files are different, a message will be displayed

stating which part of the project files are different.

Check Application in DN3000

This is allows you to check what type of project file is loaded (DeviceNet to PLC, DeviceNet to Motor

Drives) and which protocols have been loaded for each of the communication ports.

the same, a

41

Page 48

Options Settings

OPTIONS SETTINGS

Use the LEFT/RIGHT arrow keys to highlight the top “OPTIONS” heading and press the ENTER key.

This will open the OPTIONS” menu. From within the “OPTIONS” menu you can change the directory

where project files are stored, select the PC communications port to use, and set up your printer.

Any changes you make will only be effective while you are operating within this software. When you

close the configuration software, all settings for the project directory, communications port and will

return to the default, unless you save the new options to Disk.

OPTIONS

Menu

SET DIRECTORY

All saved project files will be stored in the selected “PROJECT DIRECTORY”. Changing the directory

setting is not usually required unless you wish to group “like” project types in one directory and other

“like” project types in another directory.

ADDING A DIRECTORY

Before you save your project file, use the UP/DOWN arrow keys to move the highlight bar to the “Set

Directory” sub-heading, press the ENTER key and a directory selection screen (see next page) will

appear.

The computer’s cursor will automatically appear at the “Directory Name.” Type in your new directory

path and press the ENTER key. A small window will appear with the following message, “Directory

does not exist, Make the directory?” Pressing the ENTER key creates the new directory and returns you

to the “OPTIONS” menu.

42

Page 49

Options Settings

NOTE: Each time you start the “DN-3000 Configuration Software Program” it defaults (unless you

saved the directory information to disk - see “Save Options to Disk”) to the “Projects” sub-directory

allowing you to open only those files saved within this sub-directory. To access project files saved in a

different directory, you will need to use the “Set Directory” screen. Only the current directory and subdirectory will be shown. To view all sub-directories, move the highlight bar into the graphic directory

area. Place the highlight bar on the configuration software’s main directory (example: DN-3000) and

press the ENTER key. All sub-directories within this main directory will appear. Move the highlight bar

to the sub-directory desired and press the ENTER key. To enter this change and return to the

“OPTIONS” menu, tab to the OK box and press ENTER or press the ALT+K keys.

Current

Directory

Path

Directory

Graphic

Area

43

Page 50

Options Settings

SET COM PORT

To change the communications port (default setting = COM 1) setting, move the highlight bar to the “Set

Com Port” sub-heading and press the ENTER key. When the “Set Communications Port” screen

appears, use the LEFT/RIGHT arrow keys to highlight the communications port desired and then press

the SPACE BAR to enter this new selection. Press the ALT+S (save this entry) and then the ESC key to

return to the “OPTIONS” window.

44

Page 51

Options Settings

SET PRINTER OPTIONS

To change the printer port (default = LPT 1) setting, move the highlight bar to the “Setup Printer” subheading and press the ENTER key. When the “Setup Printer” screen appears (see following page), use

the arrow keys to highlight the “LPTx” or “FILE” setting as required and press the SPACE BAR to

enter your selection. To print to a file, enter the drive\directory\file name and press the ALT+S keys

(saves this entry) and then the ESC key to return to the “OPTIONS” menu.

Print File

Setup

Window

LOAD OPTIONS FROM DISK

The “Load Options from Disk” option will retrieve the options settings that were last saved to disk using

“Save Options to Disk”.

SAVE OPTIONS TO DISK

The “Save Options to Disk” option will save all currently selected options settings to disk. The next time

the configuration software is loaded, these options will automatically be loaded from disk during startup.

DEFAULT OPTIONS

The “Default Options” option is a quick way to reset all option settings to the original configuration

software default settings for directory, communications port and printer options.

45

Page 52

Technical Information

.62

POWER REQUIREMENTS

9 - 28 VDC , 7 WATT with optional Earth Ground. A 9 VDC power supply (Part # 4000-0203) is

available from Panel-Tec.

PHYSICAL DIMENSIONS

5.6”

5.54”

.95”

3.64”

.95”

”

1.9”

7.485

6.75”

8.30”

46

Page 53

Technical Information

DIP SWITCH SETTINGS

OPERATING MODE Switch # 1 Switch # 2 Switch # 3 Switch # 4

Normal

Configuration

Diagnostic ON ON

VISUAL (LED) INDICATORS

The DN3000 has 5 tri-color LEDs: 2 Communication Port LEDs (Ports 2 and 3), a Status LED and 2

DeviceNet LEDs (Module Status and Network Status). The Module Status and Network Status LEDs are

located on the side of the DN-3000, with the Network Status LED closest to the DeviceNet Port. The

LEDs change color and go from a steady glow to flashing depending on the current operating mode. The

following tables describe the LED indications in the three operating modes: Normal, Configuration and

Diagnostic.

NORMAL MODE:

LED COLOR MEANING

Communication Port LEDs

Status LED

Module Status LED

Network Status LED

Off Off Off Off

Off Off

ON

Off

Off Off

Green Transmitting Data

Red Receiving Data

Green DeviceNet Initialized/Ok

Red DeviceNet Error

Off No Power

Flashing Green Device in Standby

Green Device Operational

Flashing Red Minor Fault

Red Unrecoverable Fault

Flashing Red-Green Device Self Testing

Off Not Powered/Not Online

Flashing Green Online, Not Connected

Green Link OK, Online, Connected

Flashing Red

Red

One or more I/O Connections are in

the Timed-Out state

Critical Link Failure (Duplicate

Mac ID or Bus-off)

Flashing Red-Green Device Self Testing

47

Page 54

Technical Information

CONFIGURATION MODE:

LED COLOR MEANING

Communication Port # 3

LED

Status LED Flashing Green Configuration Mode

DIAGNOSTIC MODE:

LED COLOR MEANING

Communication Port LEDs

Status LED Flashing Red Diagnostics Mode

DN-3000 TROUBLESHOOTING INFORMATION

The DN-3000 performs a self-test each time the unit is powered up or when the Mode Selection DIP

Switch is changed. When it detects a failure, it will report the type of failure on the Status LED. All

failures are reported as a flash code in which the DN-3000 will flash its Status LED yellow a designated

number of times followed by a pause. The flash code will repeat itself until the unit is powered off. The

possible errors that can be reported and the recommended actions are:

2 flashes followed by a pause

Random Access Memory Failure (RAM Failure)

Send the unit in for repair (Obtain RMA number first).

3 flashes followed by a pause

Firmware stored in ROM failed checksum test (ROM Failure)

Send the unit in for repair (Obtain RMA number first).

4 flashes followed by a pause

Unit Not Configured or EEPROM failure

If transferring your project file to the DN-3000 does not correct this error, send the unit in for

repair (Obtain RMA number first).

5 flashes followed by a pause

Invalid DIP Switch Setting

Verify that the DIP Switch is properly set to a valid operating mode (See DIP Switch Settings

in this section). If the DIP Switch is properly set, send the unit in for repair (Obtain RMA

number first).

Flashing Red-Green Communicating with Computer

Flashing Green Port is Operational

Flashing Red or

Yellow

Port not Operational or Loopback

Connector not Installed

48

Page 55

Application Notes – PLCs and Devices

ALLEN-BRADLEY PLC 5, SLC500 AND MICROLOGIX PLCS

Registers Accessed

The DN-3000 will only access registers in Integer files in the PLC memory (N file types). When

specifying register numbers in the DN-3000 Configuration Software, the file number is entered into the

File Number field and the element number within the file is entered into the Register Number field.

Protocols Supported

The DN-3000 uses the DF1 protocol, which is also known as Full Duplex or Point to Point. It supports both the CRC and BCC methods of error checking.

Please note that the MicroLogix PLC only supports the CRC method of error checking. Therefore, when

using a MicroLogix PLC, the protocol selected on the port configuration screen in the DN-3000

Configuration Editor must be “AB SLC500 (CRC)”.

GE FANUC 90/20, 90/30 AND 90/70 PLCS

Registers Accessed

The DN-3000 will only access registers in the Data Register Area of PLC memory (%R1 to %R9999).

When entering register numbers, only the offset into this area (1-9999) should be entered. For example,

to access register number %R1, the value 1 should be entered. To access register number %R9999, the

value 9999 should be entered.

49

Page 56

Application Notes – PLCs and Devices

IDEC MICRO-3 PLCS

Registers Accessed

The DN-3000 will only access registers in the Data Register Area of PLC memory (D0 to D9999). When

entering register numbers, only the offset into this area (0-9999) should be entered. For example, to

access register number D1, the value 1 should be entered. To access register number D9999, the value

9999 should be entered.

Link Adapter Requirement

The DN-3000 requires an Idec Link Adapter or equivalent to be used when communicating with any of

the FA Series PLCs.

I

DEC FA SERIES PLCS

Registers Accessed

The DN-3000 will only access registers in the Data Register Area of PLC memory (D0 to D9999). When

entering register numbers, only the offset into this area (0-9999) should be entered. For example, to

access register number D1, the value 1 should be entered. To access register number D9999, the value

9999 should be entered.

Link Adapter Requirement

The DN-3000 requires an Idec Link Adapter or equivalent to be used when communicating with any of

the FA Series PLCs.

50

Page 57

Application Notes – PLCs and Devices

KOYO / PLC DIRECT 205 SERIES PLCS

Registers Accessed

The DN-3000 can access all register types in the 205 Series PLC through the use of the V-Memory

assignments shown in the following table:

V-Memory Address PLC Registers Accessed

V00000 – V00177 Timer T0 – T177 Current Values

V01000 – V01177 Counter CT0 – CT177 Current Values

V02000 – V03777 Data Words V2000 – V3777

V04000 – V04377 Non-Volatile Data Words V4000 – V4377

V40400 – V40423 Input Points X0 – X477 (16 per V-Memory word)

V40500 – V40523 Output Points Y0 – Y477 (16 per V-Memory word)

V40600 – V40617 Control Relays C0 – C377 (16 per V-Memory word)

V41000 – V41037 Stages S0 – S777 (16 per V-Memory word)

V41100 – V41107 Timer T0 – T177 Status Bits (16 per V-Memory word)

V41140 – V41147 Counter CT0 – CT177 Status Bits (16 per V-Memory word)