ICP DAS ZT-2018S User Manual

ICP DAS, ZT-2018/S AI Series User Manual, Version 1.0.1 Page 1

Copyright © 2013 by ICP DAS Co., Ltd. All Rights Reserved.

ZT-2018/S

User Manual

Warranty

All products manufactured by ICP DAS are under warranty regarding

defective materials for a period of one year, beginning from the date of

delivery to the original purchaser.

Warning

ICP DAS assumes no liability for any damage resulting from the use of this

product. ICP DAS reserves the right to change this manual at any time

without notice. The information furnished by ICP DAS is believed to be

accurate and reliable. However, no responsibility is assumed by ICP DAS for

its use, nor for any infringements of patents or other rights of third parties

resulting from its use.

Copyright

Copyright © 2013 by ICP DAS. All rights are reserved.

Trademarks

Names are used for identification purposes only and may be registered

trademarks of their respective companies.

Technical Support

If you have any problems, please feel free to contact us via email at

service@icpdas.com.

ICP DAS, ZT-2018/S AI Series User Manual, Version 1.0.1 Page 2

Copyright © 2013 by ICP DAS Co., Ltd. All Rights Reserved.

Table of Contents

1 Introduction ................................................. 6

1.1 Introduction to ZigBee ................................... 6

1.2 Introduction to the ZT-2000 I/O Series ................... 7

2 Hardware Information .......................................... 8

2.1 Specifications ........................................... 8

2.2 Pin Assignments ......................................... 10

2.3 Wire Connections ........................................ 10

3 Setting up the ZT-2000 I/O Device ............................ 11

3.1 Introduction to the Configuration Parameters ............ 11

3.2 Introduction to the Rotary and DIP Switches ............. 12

3.3 Starting the ZT-2000 I/O Device ......................... 15

3.4 Communications Testing .................................. 15

3.5 Examples ................................................ 16

4 Analog Input Type and Data Format ............................ 18

5 Calibration .................................................. 21

6 The DCON/Modbus RTU Command Sets ............................. 22

6.1 Communicating with the ZT-2000 I/O Device ............... 22

6.2 The DCON Protocol Command Set ........................... 22

6.2.1 Checksum ......................................... 23

6.3 Overview of the DCON Command Set ........................ 24

6.3.1 #AA .............................................. 28

6.3.2 #AAN ............................................. 29

6.3.3 $AA0 ............................................. 31

6.3.4 $AA1 ............................................. 33

6.3.5 $AA2 ............................................. 35

6.3.6 $AA3 ............................................. 36

6.3.7 $AA5 ............................................. 37

6.3.8 $AA5VV ........................................... 38

6.3.9 $AA6 ............................................. 39

6.3.10 $AA7CiRrr ........................................ 40

ICP DAS, ZT-2018/S AI Series User Manual, Version 1.0.1 Page 3

Copyright © 2013 by ICP DAS Co., Ltd. All Rights Reserved.

6.3.11 $AA8Ci ........................................... 42

6.3.12 $AA9 ............................................. 44

6.3.13 $AA9SNNNN ........................................ 45

6.3.14 $AA9Ci ........................................... 47

6.3.15 $AA9SNNNNCi ...................................... 49

6.3.16 $AAA ............................................. 51

6.3.17 $AAAi ............................................ 52

6.3.18 $AAF ............................................. 54

6.3.19 $AAM ............................................. 55

6.3.20 $AAS1 ............................................ 56

6.3.21 ~** .............................................. 57

6.3.22 ~AA0 ............................................. 58

6.3.23 ~AA1 ............................................. 60

6.3.24 ~AA2 ............................................. 61

6.3.25 ~AA3ETT .......................................... 63

6.3.26 ~AAC ............................................. 65

6.3.27 ~AACN ............................................ 66

6.3.28 ~AAEV ............................................ 67

6.3.29 ~AAO(Name) ....................................... 69

6.3.30 @AACH ............................................ 70

6.3.31 @AACHi ........................................... 71

6.3.32 @AACHCi .......................................... 73

6.3.33 @AACL ............................................ 75

6.3.34 @AACLi ........................................... 77

6.3.35 @AACLCi .......................................... 79

6.3.36 @AADHCi .......................................... 81

6.3.37 @AADI ............................................ 83

6.3.38 @AADLCi .......................................... 84

6.3.39 @AAHI(Data)CiT ................................... 86

6.3.40 @AALO(Data)CiT ................................... 88

6.3.41 @AAOD ............................................ 90

6.3.42 @AARH ............................................ 91

6.3.43 @AARHi ........................................... 92

6.3.44 @AARHCi .......................................... 93

6.3.45 @AARL ............................................ 95

6.3.46 @AARLi ........................................... 96

6.3.47 @AARLCi .......................................... 97

6.4 Modbus RTU Protocol Command set ......................... 99

6.4.1 Modbus Address Mapping .......................... 100

ICP DAS, ZT-2018/S AI Series User Manual, Version 1.0.1 Page 4

Copyright © 2013 by ICP DAS Co., Ltd. All Rights Reserved.

6.4.2 PLC Address Mapping ............................. 103

6.4.3 01 (0x01) Reading the Coils ..................... 104

6.4.4 02 (0x02) Reading the Discrete Inputs........... 105

6.4.5 03 (0x03) Reading Multiple Registers............ 106

6.4.6 04 (0x04) Reading Multiple Input Registers ..... 107

6.4.7 05 (0x05) Writing a Single Coil ................. 108

6.4.8 06 (0x06) Writing Multiple Registers............ 109

6.4.9 15 (0x0F) Writing Multiple Coils ................ 110

6.4.10 70 (0x46) Reading/Writing the Module Settings .. 111

7 Appendix .................................................... 125

7.1 Software Configuration Mode ............................ 125

7.2 Dual Watchdog Operation ................................ 126

7.3 Reset Status ........................................... 127

8 Troubleshooting ............................................. 128

ICP DAS, ZT-2018/S AI Series User Manual, Version 1.0.1 Page 5

Copyright © 2013 by ICP DAS Co., Ltd. All Rights Reserved.

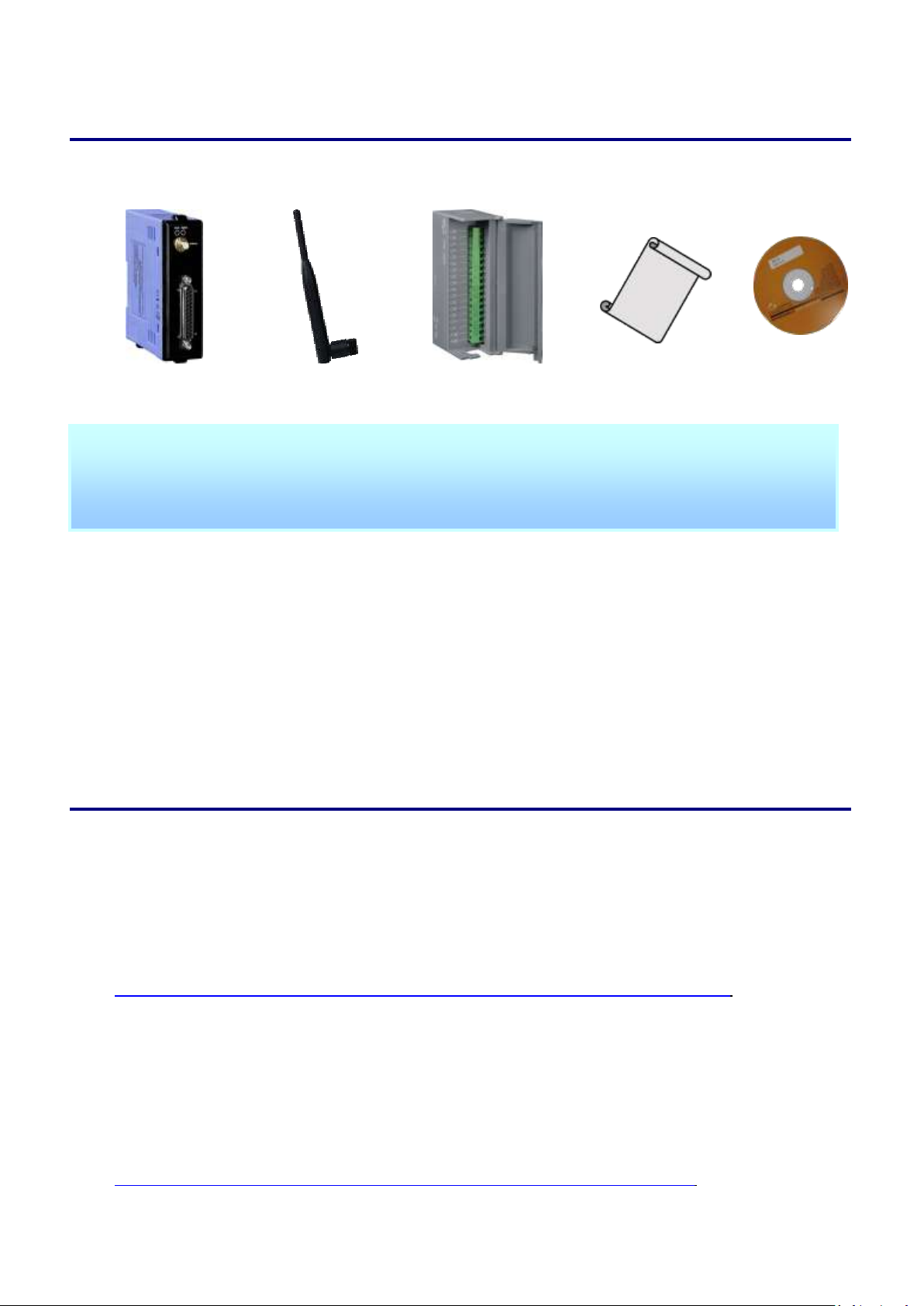

What’s in the Shipping Package?

The shipping package contains the following items:

More Information

Documentation:

All documentation related to the ZT Series of devices can be found on the

companion CD at:

CD: \Napdos\ZigBee\ZT_Series\Document

Or can be downloaded from:

HTUhttp://ftp.icpdas.com/pub/cd/usbcd/napdos/zigbee/zt_series/documentUT

Software:

Utility software for the ZT Series of devices can be found on the companion CD at:

CD: \Napdos\ZigBee\ZT_Series\Utility

Or can be downloaded from:

HTUhttp://ftp.icpdas.com/pub/cd/usbcd/napdos/zigbee/zt_series/utilityUT

ANT-124-05

ZT-2018

Quick Start

DN-1824

CD

If any of these items are missing or damaged, please contact your local distributor for more

information. Save the shipping materials and cartons in case you need to ship the module in the

future.

ICP DAS, ZT-2018/S AI Series User Manual, Version 1.0.1 Page 6

Copyright © 2013 by ICP DAS Co., Ltd. All Rights Reserved.

1 Introduction

1.1 Introduction to ZigBee

ZigBee is a specification for a suite of high-level communication protocols using

small, low-power digital radios based on the IEEE 802.15.4 standard for personal area

networks. ZigBee devices are often used in mesh network form to transmit data over

longer distances, passing data through intermediate devices to reach more distant ones.

This allows ZigBee networks to be formed ad-hoc, with no centralized control or

high-power transmitter/receiver required in order to reach all of the devices. Any

ZigBee device can be tasked with running the network.

ZigBee is targeted at applications that require a low data rate, long battery life, and

secure networking. ZigBee has a defined transmission rate of 250 kbit/s, best suited for

periodic or intermittent transmission of data, or for a single signal transmission from a

sensor or input device. Applications include wireless light switches, electrical meters

with in-home-displays, traffic management systems, and other consumer and industrial

equipment that requires short-range wireless transfer of data at relatively low rates.

The technology defined by the ZigBee specification is intended to be simpler and less

expensive than other WPANs.

ICP DAS, ZT-2018/S AI Series User Manual, Version 1.0.1 Page 7

Copyright © 2013 by ICP DAS Co., Ltd. All Rights Reserved.

1.2 Introduction to the ZT-2000 I/O Series

The ZT-2000 I/O series of devices are small wireless ZigBee I/O modules based

on the IEEE802.15.4 standard that allow data acquisition and control via personal area

ZigBee networks. See Section 3.1 for more detailed information.

The ZT-2000 I/O series is a wireless data acquisition-based client/server system.

Accordingly, a Net Server for the ZigBee (ZT-2570/ZT-2550) is essential in such

systems. For more information regarding any configuration issues related to the ZigBee

Coordinator, please refer to the “ZT-25XX ZigBee Converter Quick Start” document,

which can be found at:

http://ftp.icpdas.com/pub/cd/usbcd/napdos/zigbee/zt_series/document/

ICP DAS, ZT-2018/S AI Series User Manual, Version 1.0.1 Page 8

Copyright © 2013 by ICP DAS Co., Ltd. All Rights Reserved.

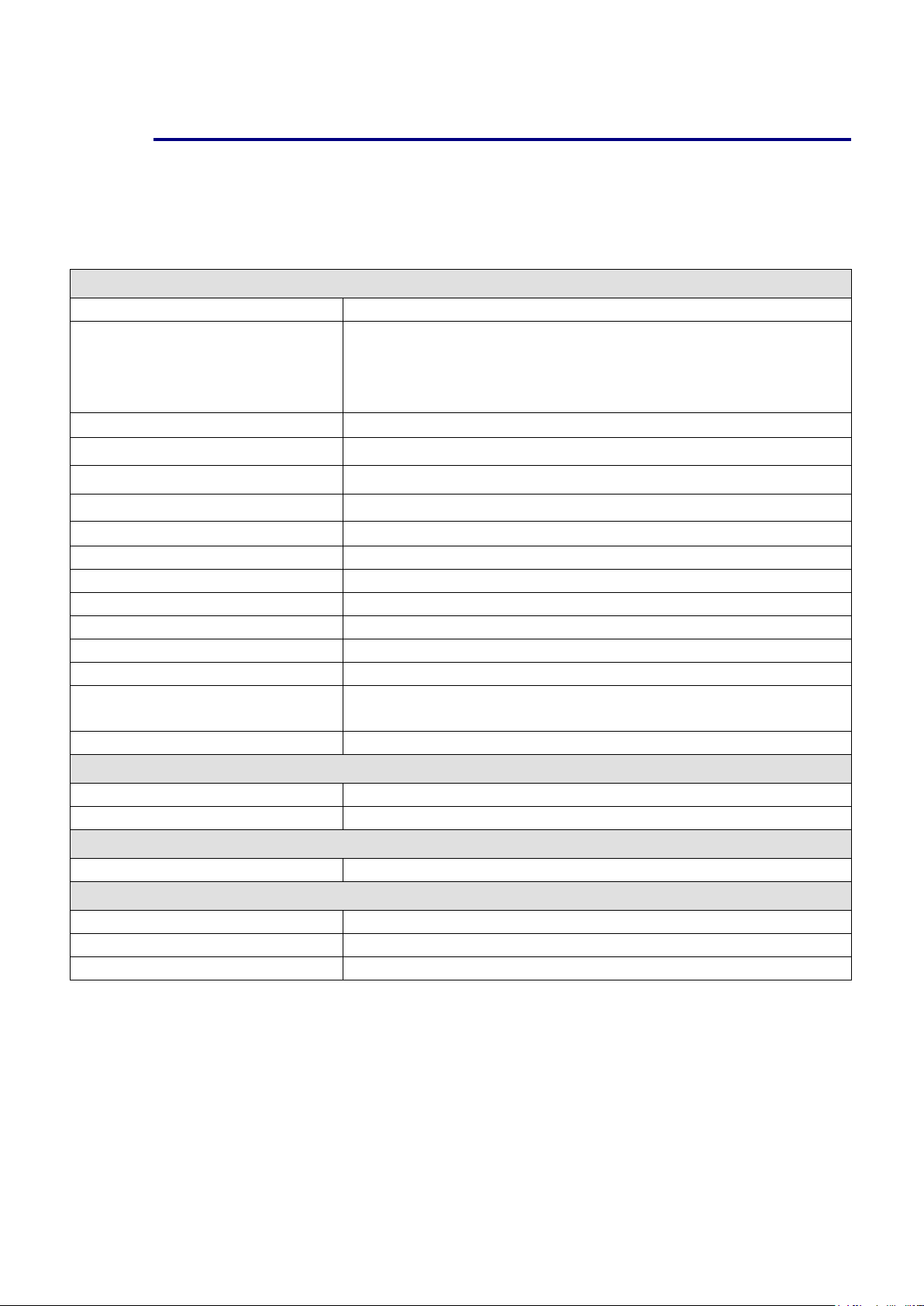

2 Hardware Information

2.1 Specifications

ZT-2018/S

Analog Input

Input Channels

8 Differential

Input Type

+/-15 mV, +/-50 mV, +/-100 mV, +/-500 mV, +/-1V,

+/-2.5V, +/-20 mA, 0 ~ 20 mA, 4 ~ 20 mA (Current Input

Requires Optional External 125 Ω Resistor). Thermocouple

(J, K, T, E. R. S, B, N, C, L, M, LDIN43710)

Resolution

16-bit

Sampling Rate

16-bit, 10 Samples/Sec. (Total)

Accuracy

+/-0.1% FSR

-3dB Bandwidth

15.7 Hz

Zero Drift

+/-10 μV/°C

Span Drift

+/-25 ppm/°C

Common Mode Rejection

86 dB

Normal Mode Rejection

100 dB

Input Impedance

>400 kΩ

Open Thermocouple Detection

Yes

Overvoltage Protection

240 Vrms

Intra-module Isolation,

Field-to-Logic

3000 VDC

ESD Protection

+/-4 kV Contact for each Channel

LED Indicators

ZigBee PWR

ZigBee Device Power

ZigBee Net

ZigBee Communication Indicator

Power

Power Consumption

0.88 W (Max.)

Environment

Operating Temperature

-25 to 75°C

Storage Temperature

-30 to 80°C

Humidity

10 to 90%, Non-condensing

ICP DAS, ZT-2018/S AI Series User Manual, Version 1.0.1 Page 9

Copyright © 2013 by ICP DAS Co., Ltd. All Rights Reserved.

Wireless

RF Channels

16

RF Transmit Power

11 dBm

Antenna (2.4 GHz)

5 dBi Omnidirectional

Transmission Range (LOS)

700 m (Typical)

Max. Slaves Supported

255

EMI Certification

CE/FCC, FCC ID

ICP DAS, ZT-2018/S AI Series User Manual, Version 1.0.1 Page 10

Copyright © 2013 by ICP DAS Co., Ltd. All Rights Reserved.

2.2 Pin Assignments

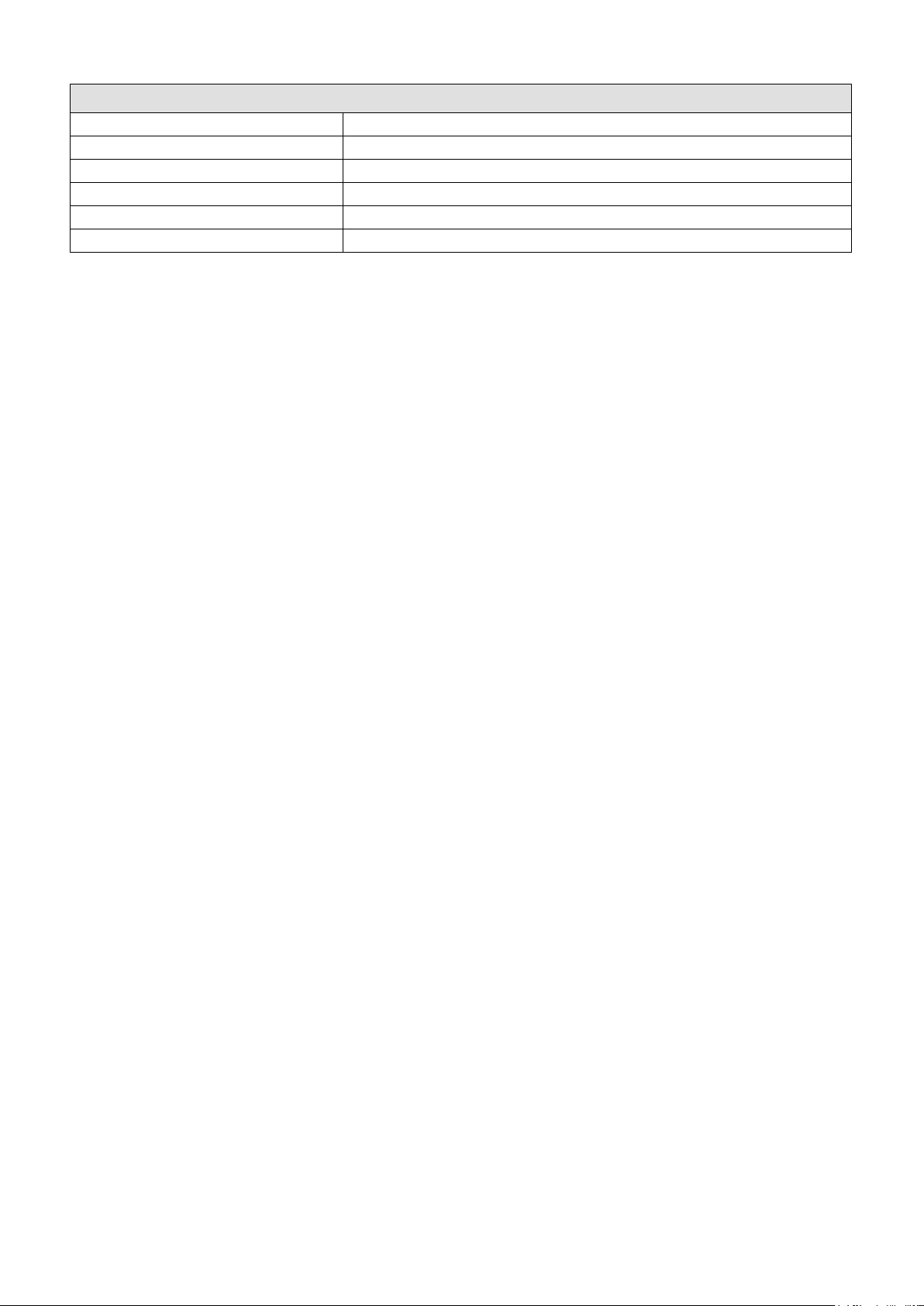

2.3 Wire Connections

ICP DAS, ZT-2018/S AI Series User Manual, Version 1.0.1 Page 11

Copyright © 2013 by ICP DAS Co., Ltd. All Rights Reserved.

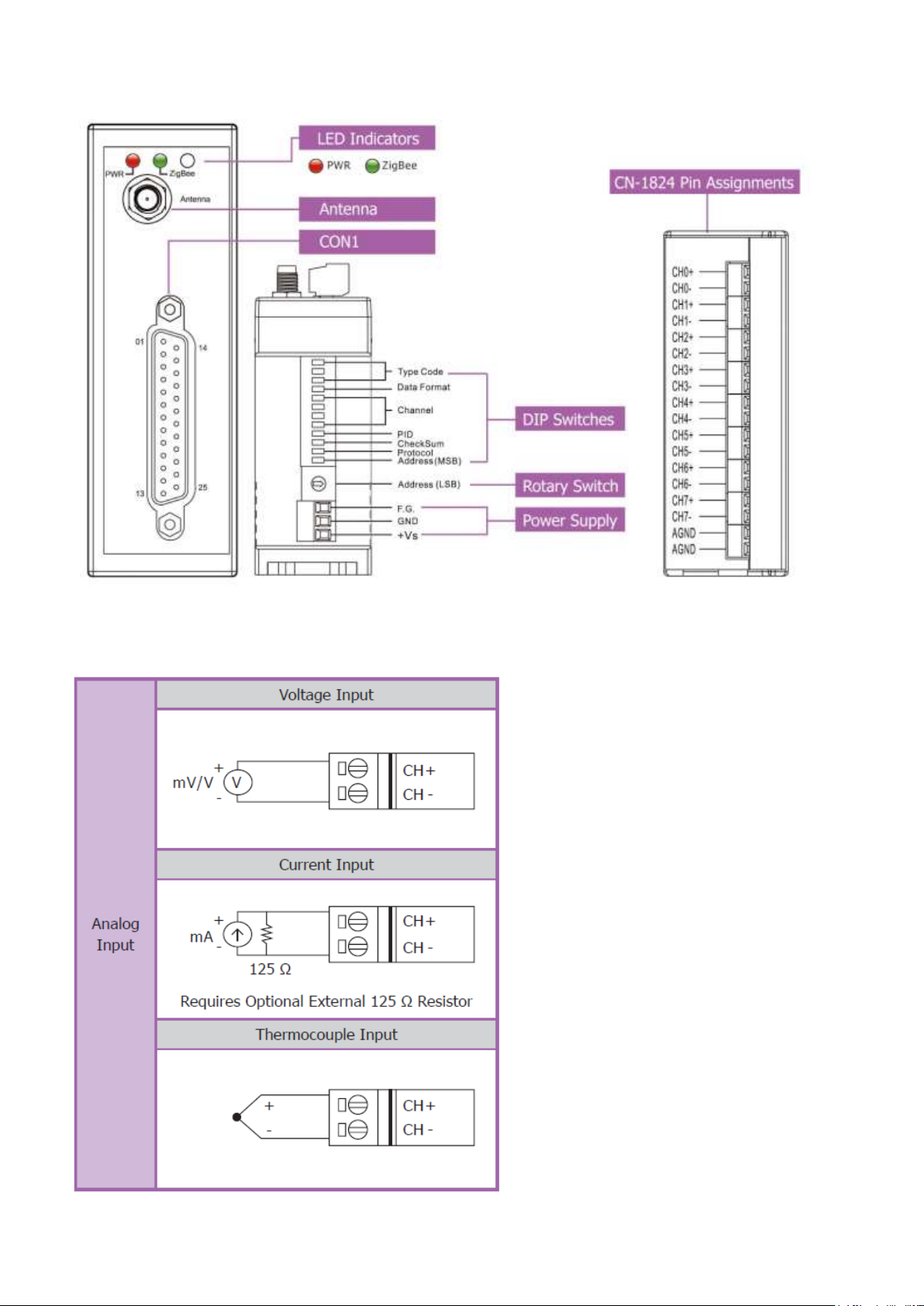

3 Setting up the ZT-2000 I/O Device

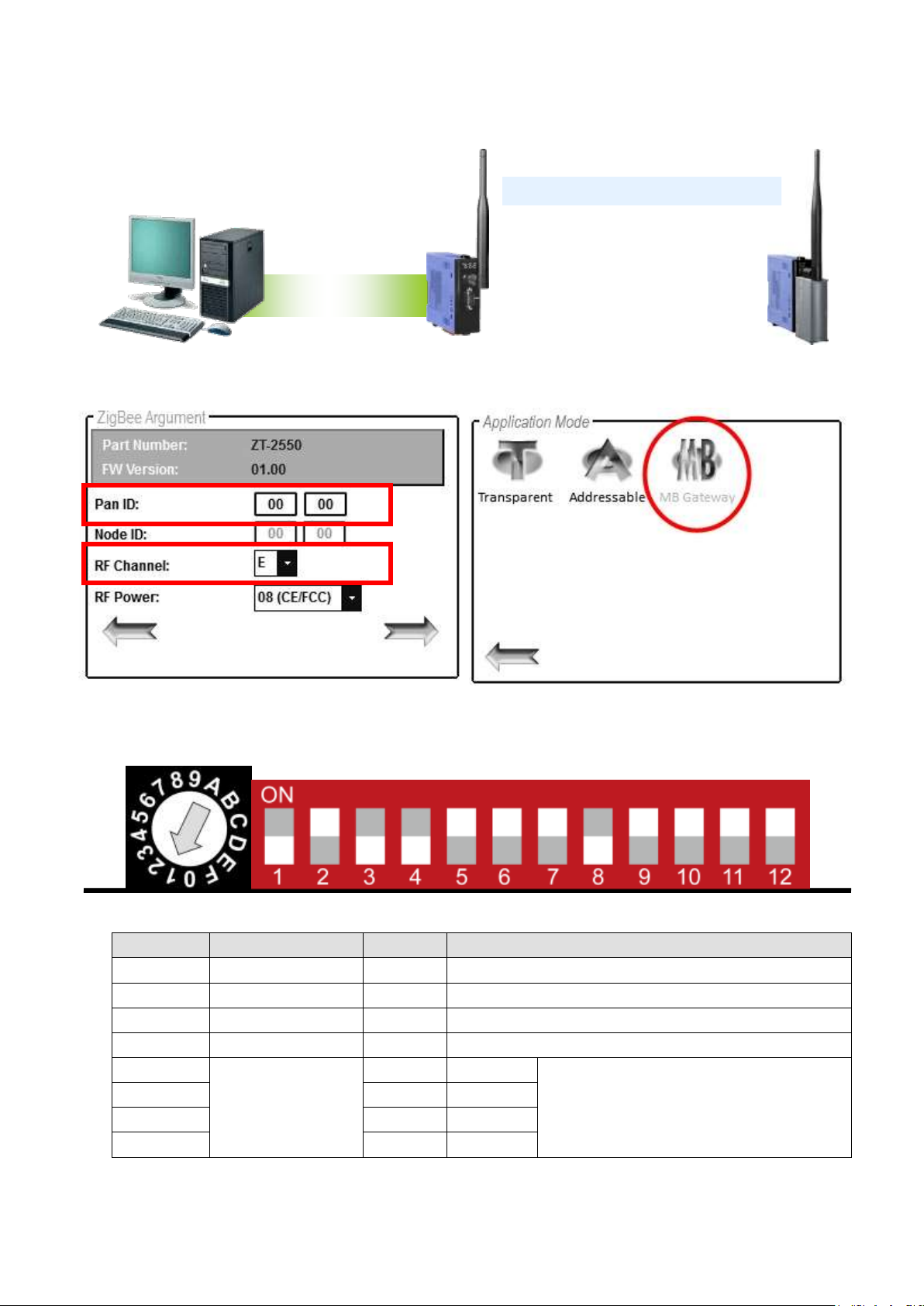

3.1 Introduction to the Configuration

Parameters

A. The “ZB PID” parameter is the group identity for a ZigBee network, and must

be the same for all devices in the same ZigBee network.

B. The “Node ID” parameter is the individual identity of the specific ZigBee

module, and must be unique for each device connected to the same ZigBee

network.

C. The “ZB Channel” parameter indicates the radio frequency channel, and must

be set to the same value as other modules on the same ZigBee network.

ZB Channel

0x00

0x01

……

0x0F

Frequency (MHz)

2405

2410

……

2480

※ ZB channels 0x04, 0x09, 0x0E or 0x0F are recommended because they do not overlap with

the Wi-Fi frequency band.

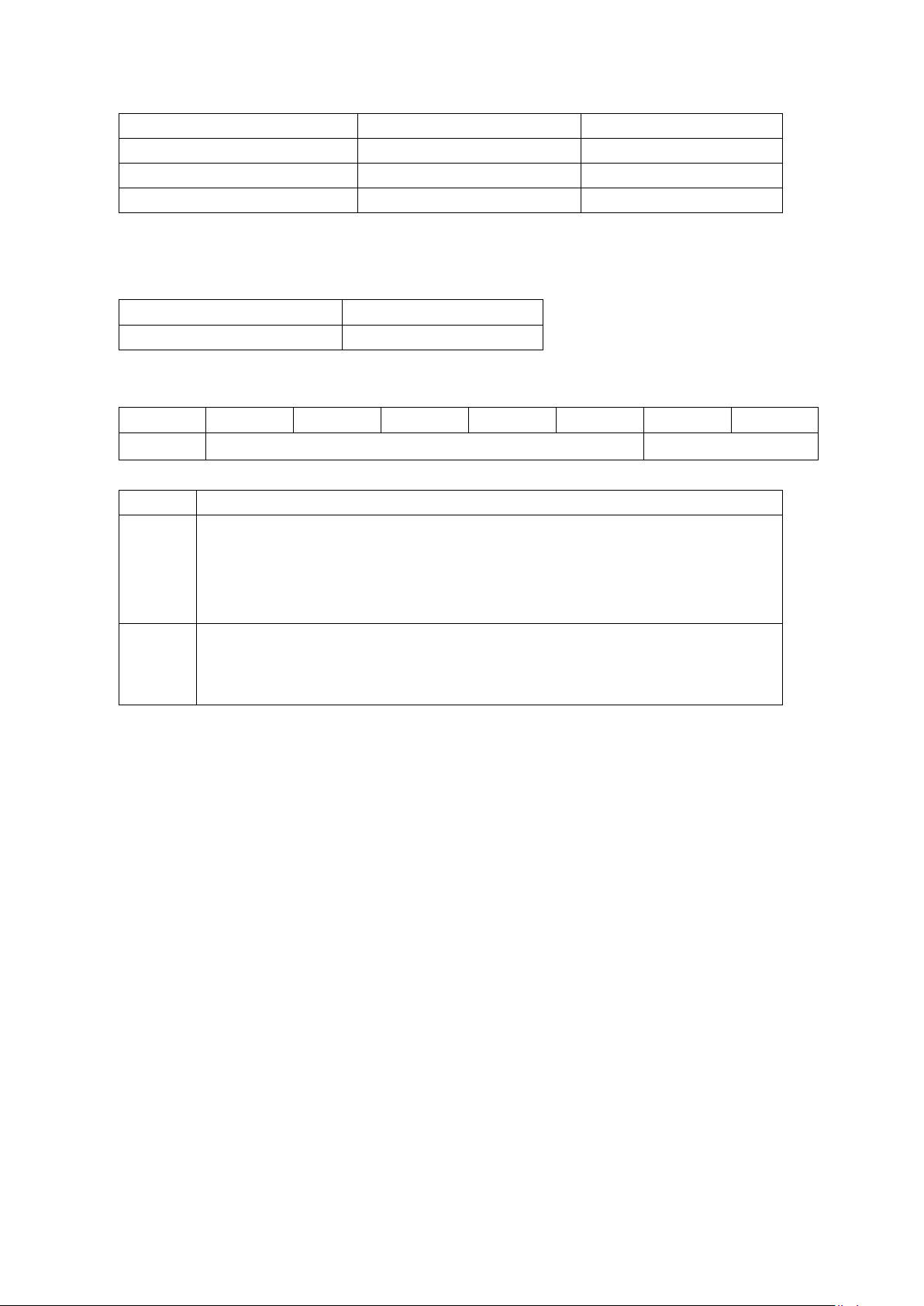

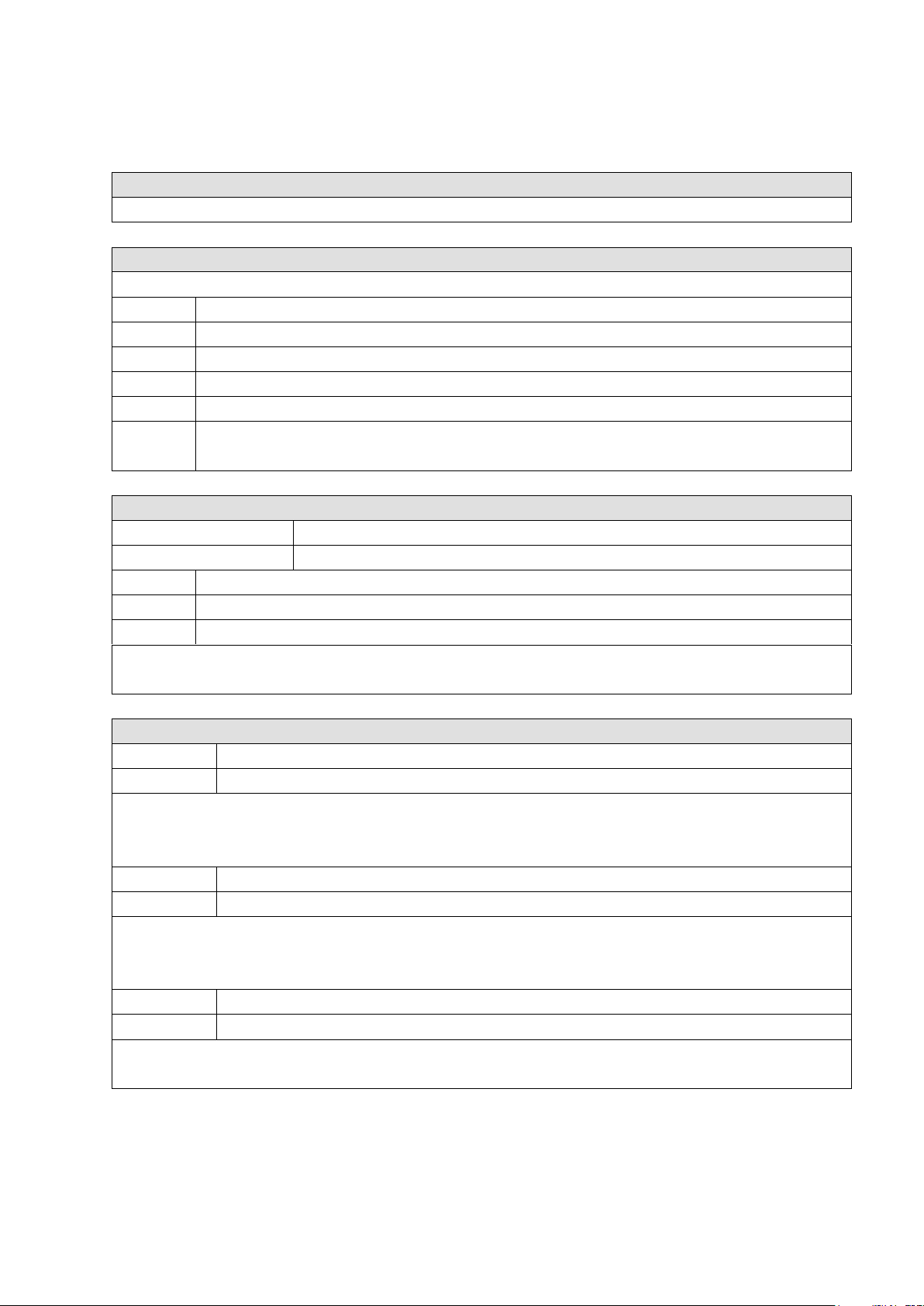

D. Protocol/Application Mode:

When implementing custom programs based on different protocols, the following

application mode(s) are recommended in order to ensure optimal performance.

User Program Protocol

ZT-2000

ZT-2550

ZT-2570

DCON

DCON

Transparent

Transparent

Modbus RTU

Modbus RTU

Transparent

Modbus Gateway

Transparent

Modbus Gateway

Modbus TCP

Modbus RTU

------

Modbus Gateway

00 01 02 03 04 05 06 07 08 09 0A 0B 0C 0D 0E 0F

802.11b/g

ZB Channel 1

802.11b/g

ZB Channel 6

802.11b/g

ZB Channel 11

802.11b/g ZB Channel (North America)

802.15.4 ZB Channel

2400

MHz

2485

MHz

ICP DAS, ZT-2018/S AI Series User Manual, Version 1.0.1 Page 12

Copyright © 2013 by ICP DAS Co., Ltd. All Rights Reserved.

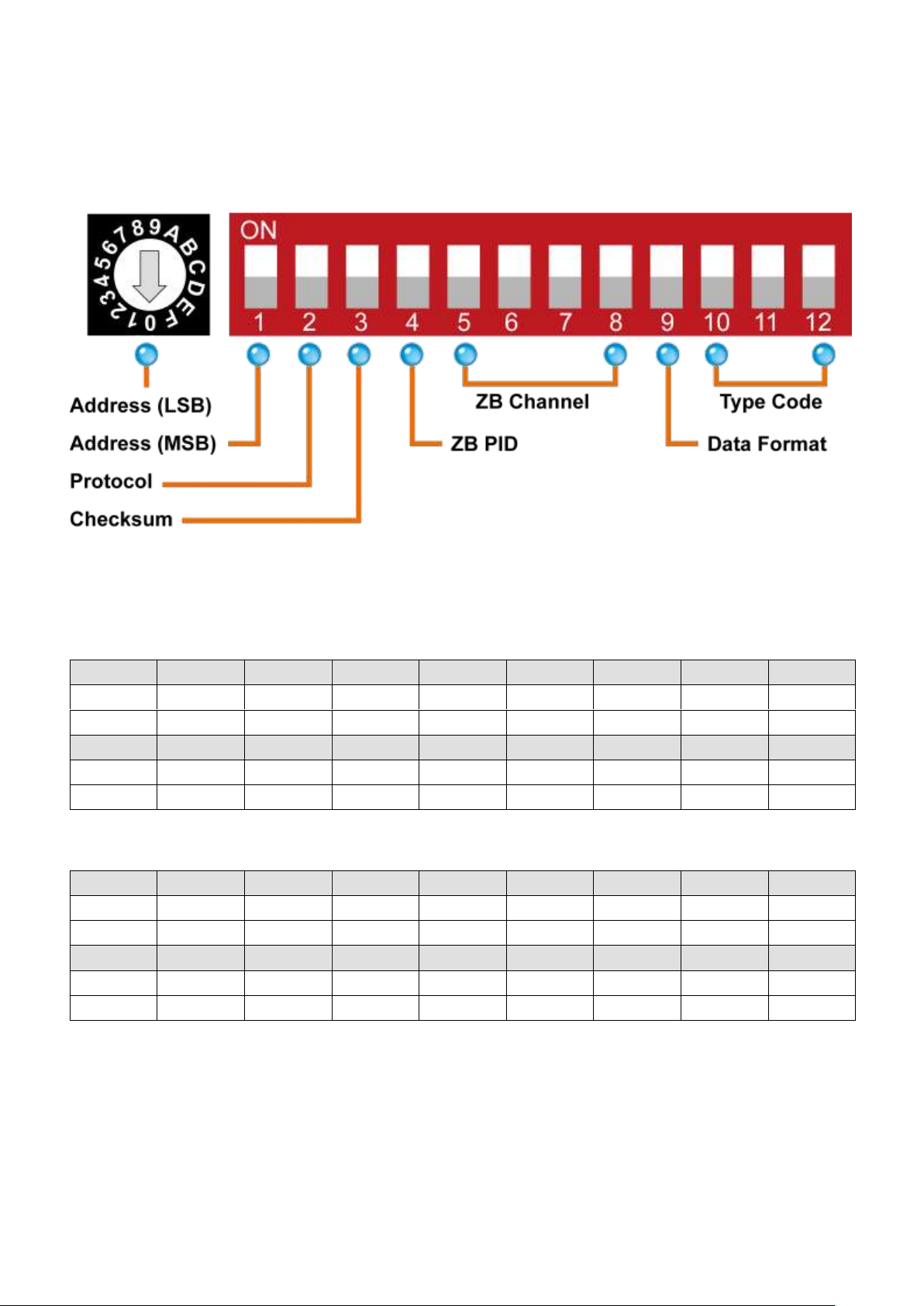

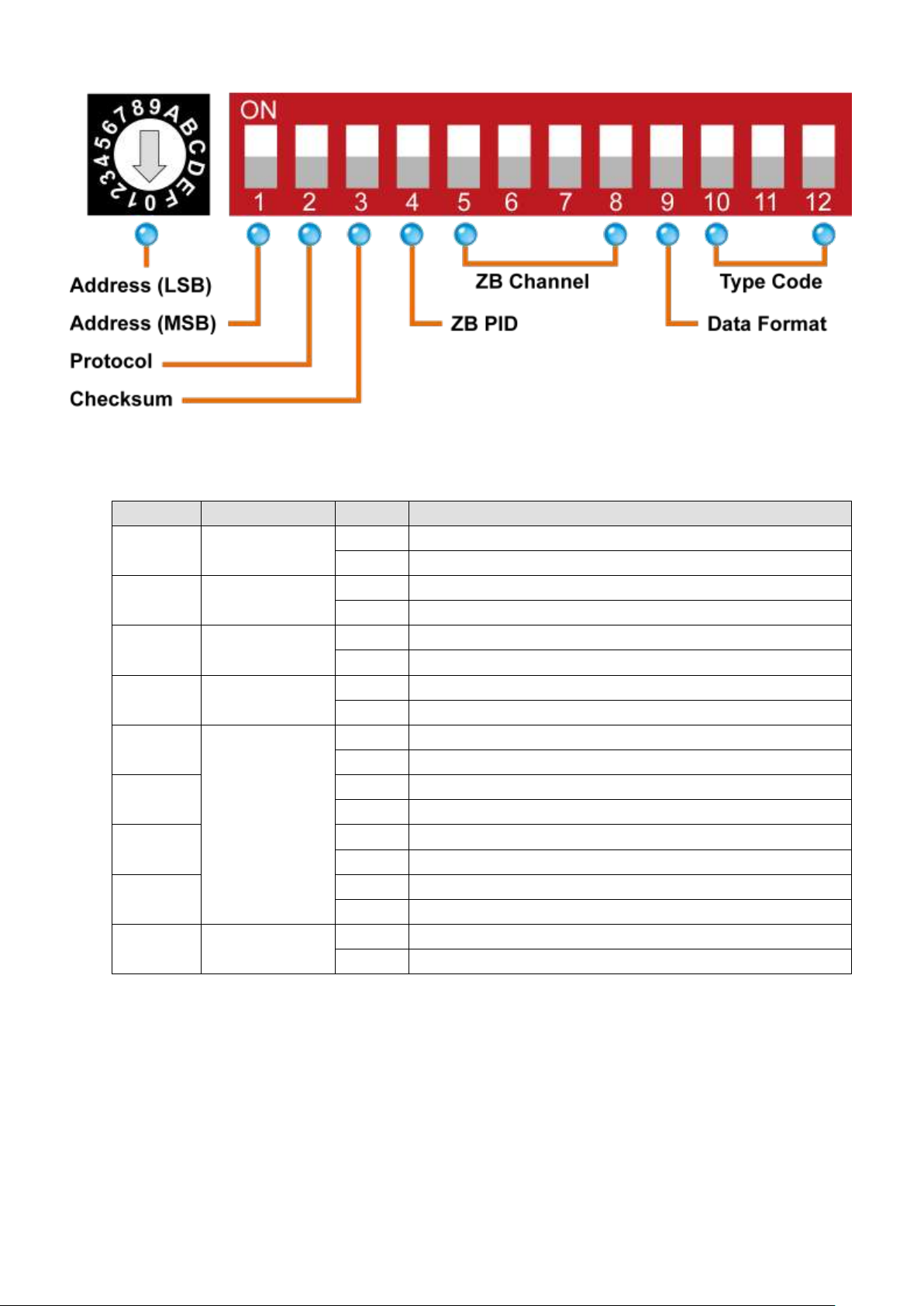

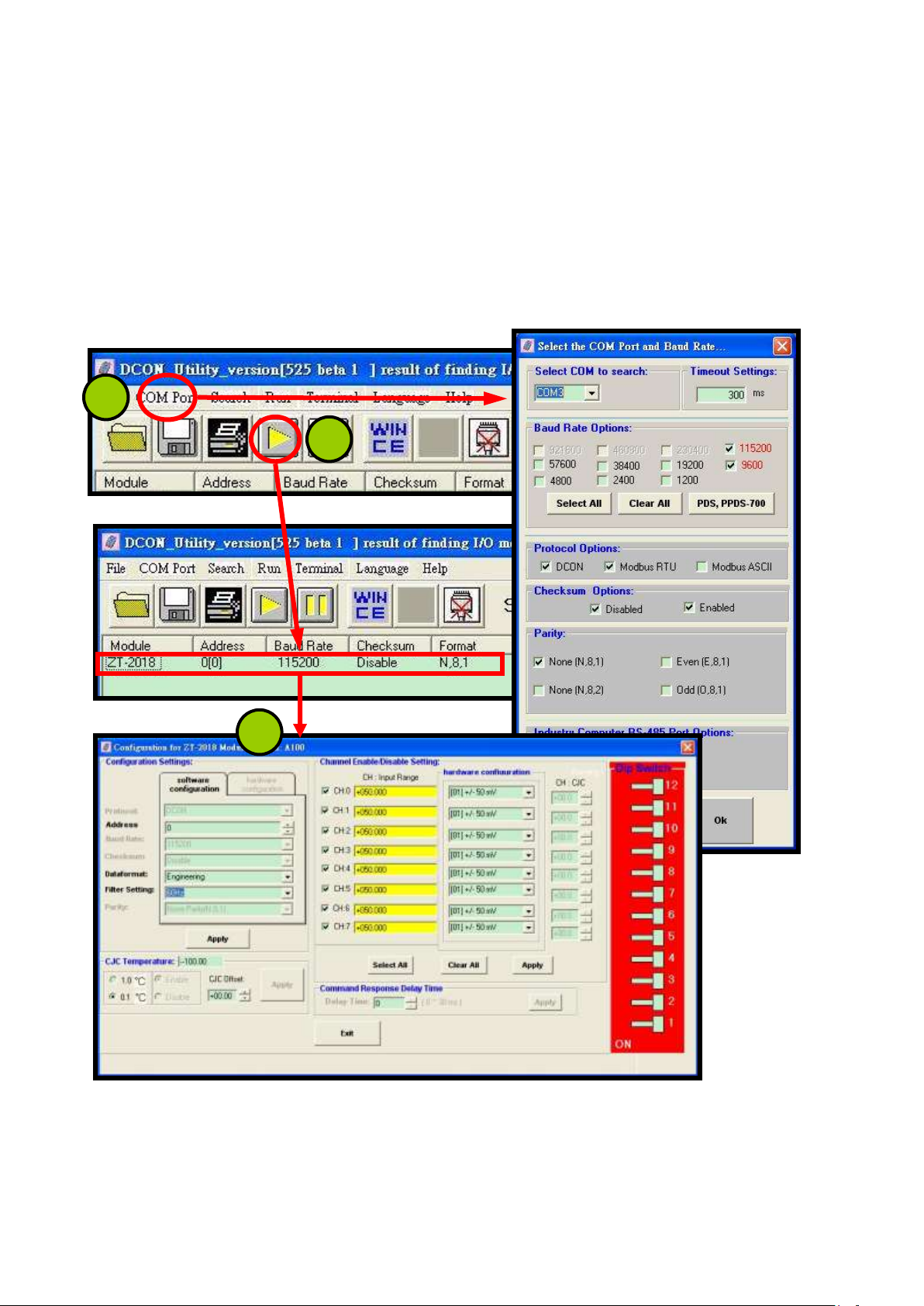

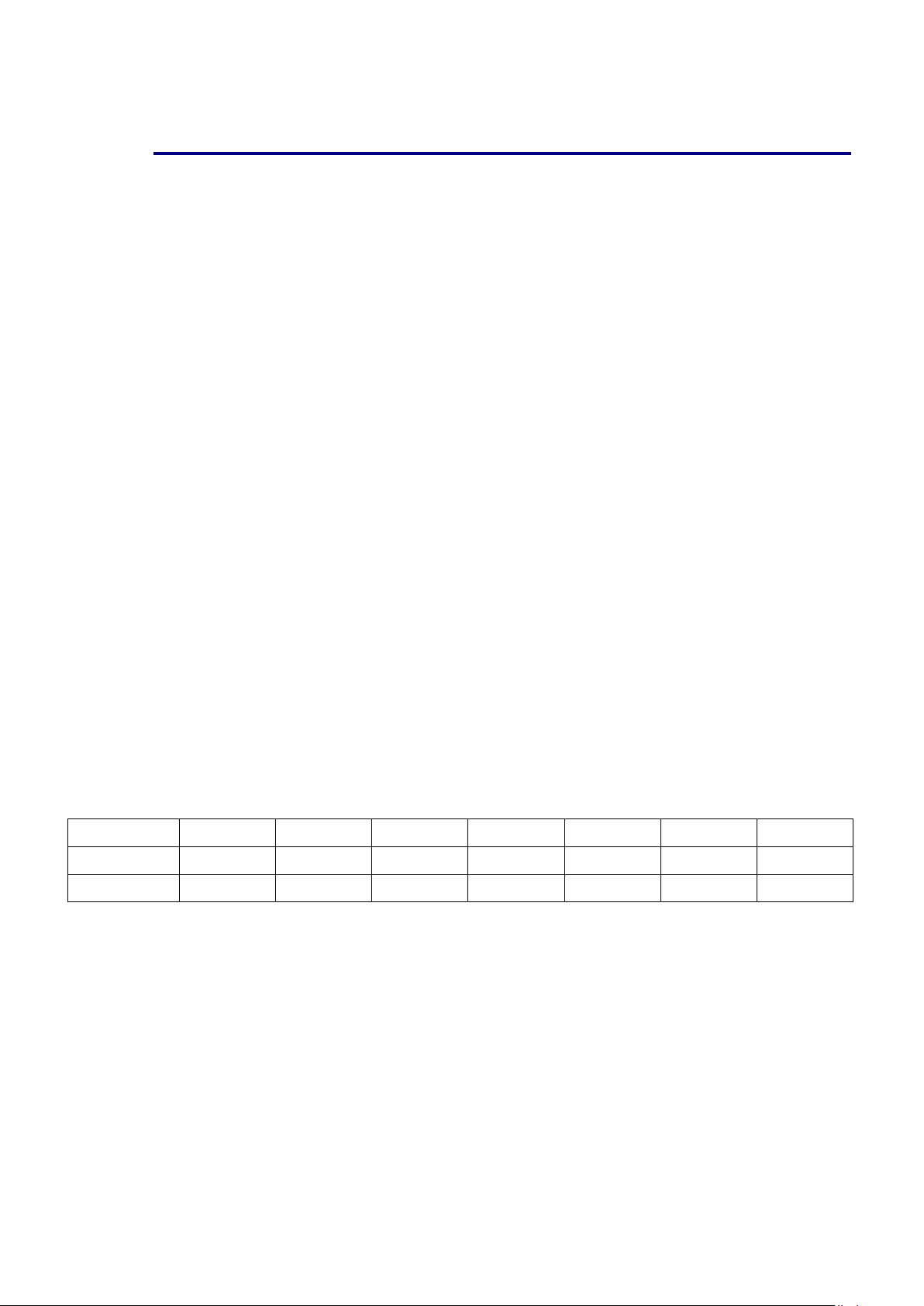

3.2 Introduction to the Rotary and DIP Switches

The configuration of the ZT-2018/S can be adjusted using a combination of the

external rotary switch and the DIP switches. The ZT-2000 device should only be

rebooted once the configuration is complete.

Rotary Switch

Case 1: Address MSB = 0

0 1 2 3 4 5 6 7

Address

*Note 1

01

02

03

04

05

06

07

Node ID

*Note 1

0x0001

0x0002

0x003

0x0004

0x0005

0x0006

0x0007

8 9 A B C D E F

Address

08

09

0A

0B

0C

0D

0E

0F

Node ID

0x008

0x0009

0x000A

0x000B

0x000C

0x000D

0x000E

0x000F

Case 2: Address MSB = 1

0 1 2 3 4 5 6 7

Address

10

11

12

13

14

15

16

17

Node ID

0x0010

0x0011

0x0012

0x013

0x0014

0x0015

0x0016

0x0017

8 9 A B C D E F

Address

18

19

1A

0B

0C

1D

1E

1F

Node ID

0x018

0x0019

0x001A

0x001B

0x001C

0x001D

0x001E

0x001F

*Note 1: The “Address” and “Node ID” values are defined via the $AANNTTCCFF command.

In software configuration mode, the DIP switches for “Address”, “Data Format”

and “Type Code” are ignored and can also be set via the %AANNTTCCFF and $AACiRrr

commands.

ICP DAS, ZT-2018/S AI Series User Manual, Version 1.0.1 Page 13

Copyright © 2013 by ICP DAS Co., Ltd. All Rights Reserved.

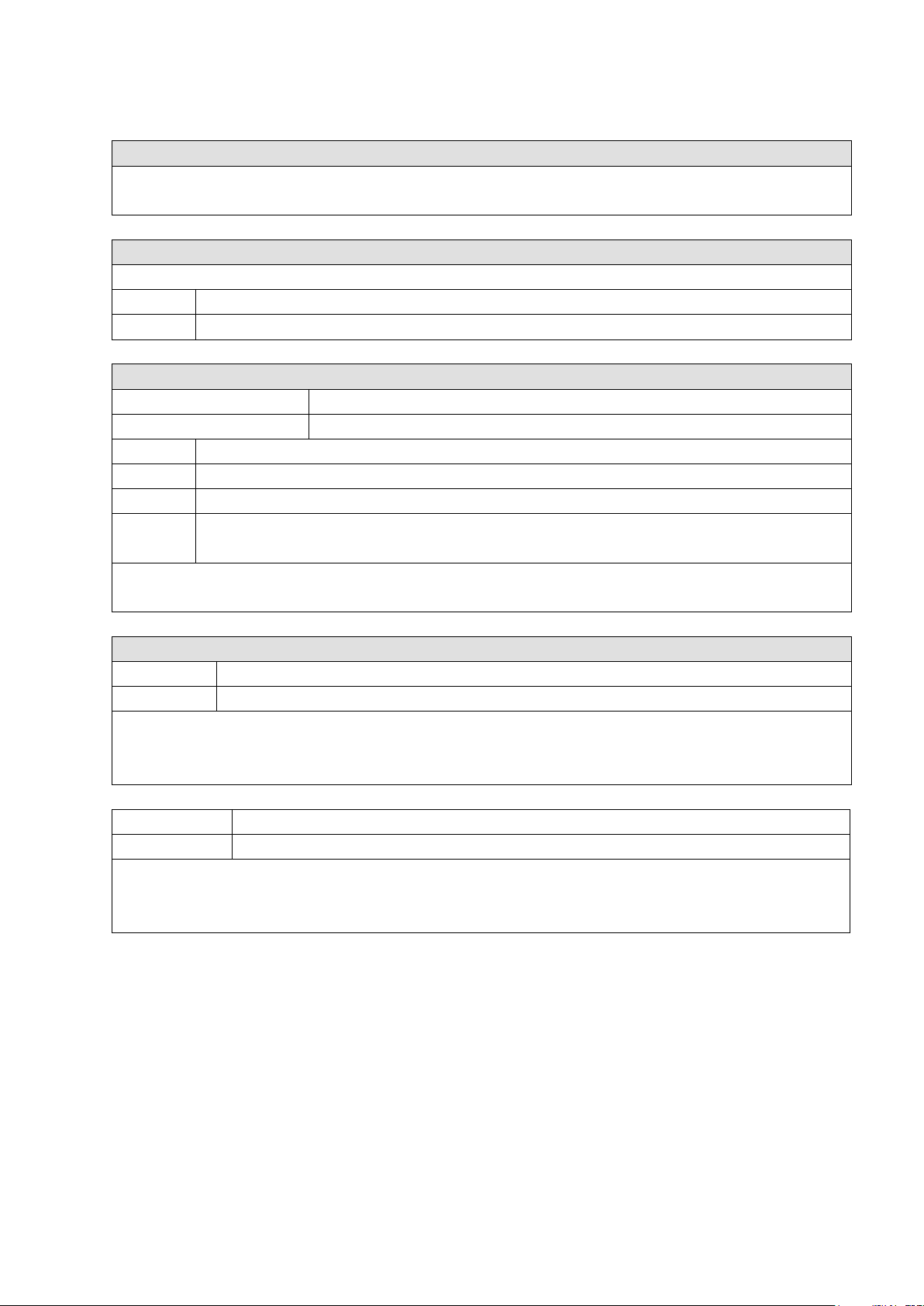

DIP Switches

Number

Item

Status

Description

1

Address MSB

OFF

Valid Address (Node ID) from 0x01 to 0x0F

ON

Valid Address (Node ID) from 0x10, 0x01 to 0x1F

2

Protocol

OFF

DCON Protocol

ON

Modbus RTU Protocol

3

Checksum

OFF

Disabled (DCON Protocol)

ON

Enabled (DCON Protocol)

4

ZB PID

OFF

ZigBee Pan ID = 0x0000

ON

ZigBee Pan ID = 0x0001

5

ZB Channel

OFF

------

ON

0x08 6 OFF

------

ON

0x04 7 OFF

------

ON

0x02

8

OFF

------

ON

0x01

9

Data Format

OFF

Engineering Units Format

ON

Hexadecimal Format

ICP DAS, ZT-2018/S AI Series User Manual, Version 1.0.1 Page 14

Copyright © 2013 by ICP DAS Co., Ltd. All Rights Reserved.

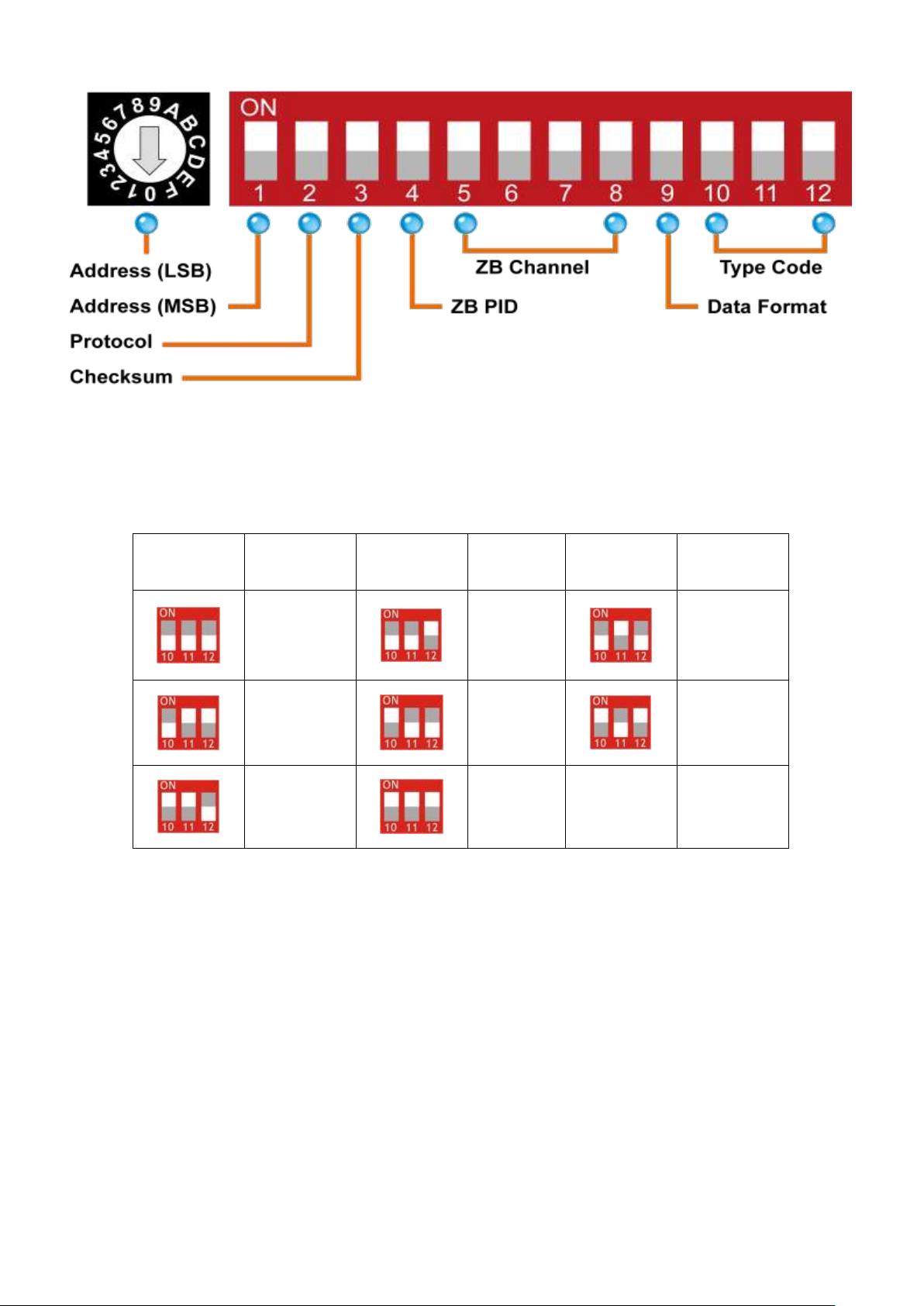

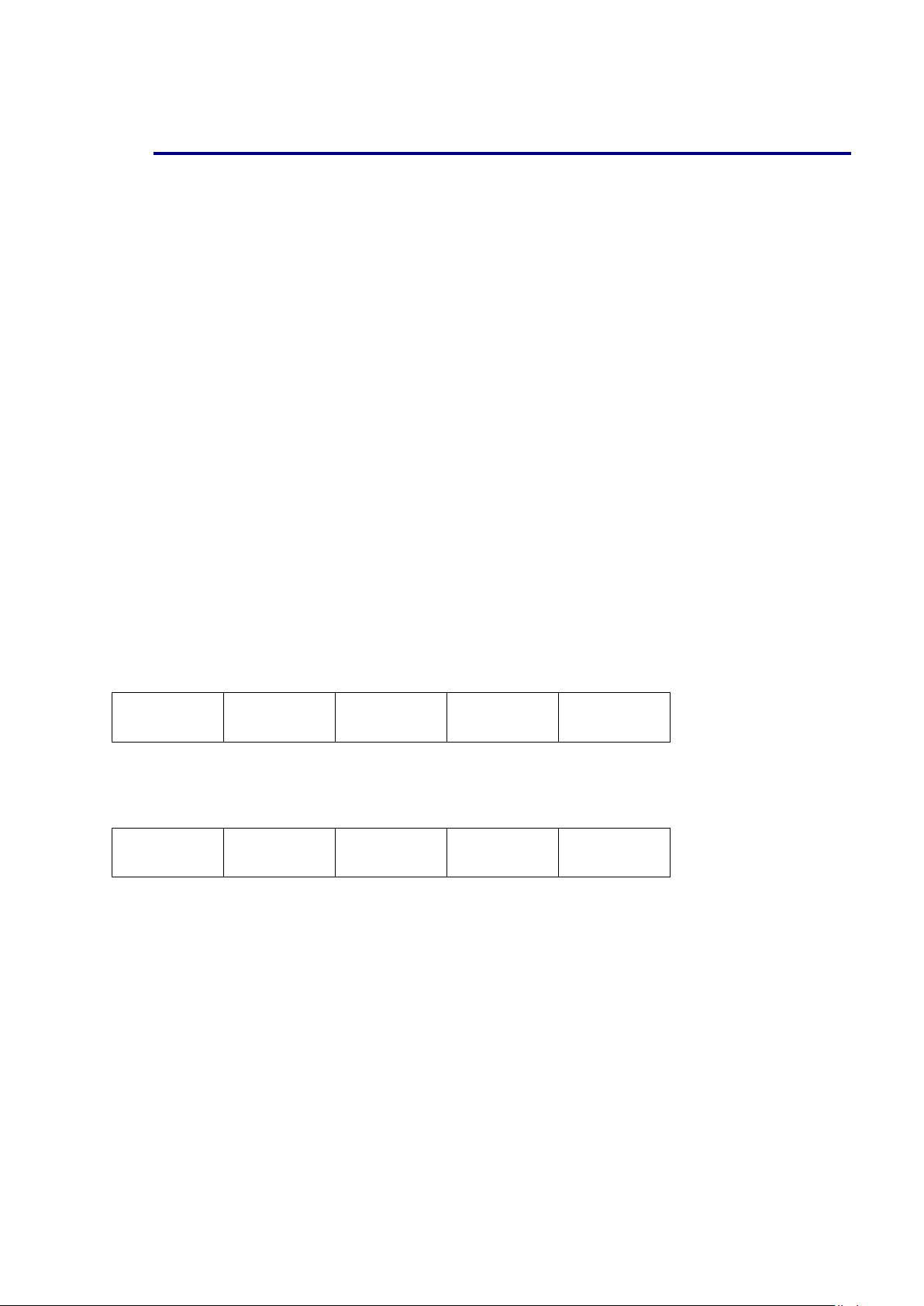

Type Code

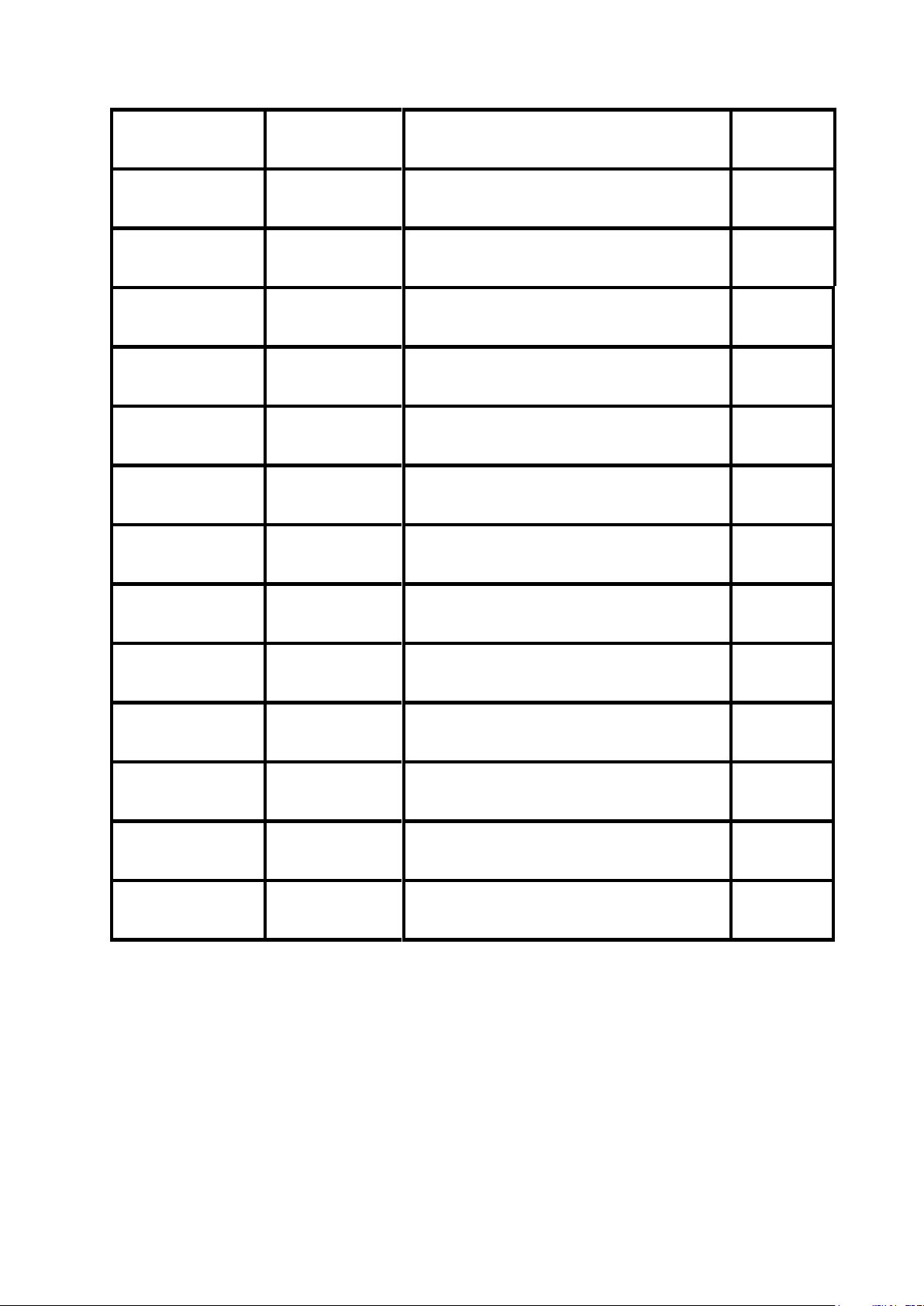

DIP switches 10-12 are used to define the input Type Code for the ZT-2018/S, as

shown below.

Switch

Position

Type Code

Switch

Position

Type

Code

Switch

Position

Type Code

0x00

0x01

0x02

0x03

0x04

0x05

0x06

0x07

ICP DAS, ZT-2018/S AI Series User Manual, Version 1.0.1 Page 15

Copyright © 2013 by ICP DAS Co., Ltd. All Rights Reserved.

3.3 Starting the ZT-2000 I/O Device

As the ZigBee network is controlled by the ZigBee Coordinator, the ZT-2550/ZT-2570

(ZigBee Coordinator) must be configured first. Refer to the documents section below

for full details of how to configure these devices.

Once configuration of the ZigBee Coordinator has been completed, set the “ZB PID”

and “ZB Channel” values for the ZT-2000 I/O device to the same values as the

network, and then reboot the device. The module will automatically start to function on

the ZigBee network using the default protocol.

※ Documents

Helpful documentation related to the ZT-2550 and ZT-2570 can be found at:

http://ftp.icpdas.com.tw/pub/cd/usbcd/napdos/zigbee/zt_series/document/zt-255x/

http://ftp.icpdas.com.tw/pub/cd/usbcd/napdos/zigbee/zt_series/document/zt-257x/

※ Configuration Utility

A utility that can be used to configure the ZT-2000 I/O device Coordinator is available

for download from:

http://ftp.icpdas.com.tw/pub/cd/usbcd/napdos/zigbee/zt_series/utility/

3.4 Communications Testing

Once the ZT-2000 I/O device has joined the ZigBee network, the signal quality can be

confirmed by monitoring the status of the ZigBee Net LED indicators. If the LED

indicator shows a steady light, communication with the ZT-2000 I/O device has been

successfully established for data acquisition and control.

ICP DAS provides the “DCON Utility” which can be used to simulate DCON/Modbus

communication. This software can also be used to verify the device settings and the

ZigBee I/O functions.

The DCON Utility can be downloaded from:

http://ftp.icpdas.com/pub/cd/8000cd/napdos/driver/dcon_utility/

ICP DAS, ZT-2018/S AI Series User Manual, Version 1.0.1 Page 16

Copyright © 2013 by ICP DAS Co., Ltd. All Rights Reserved.

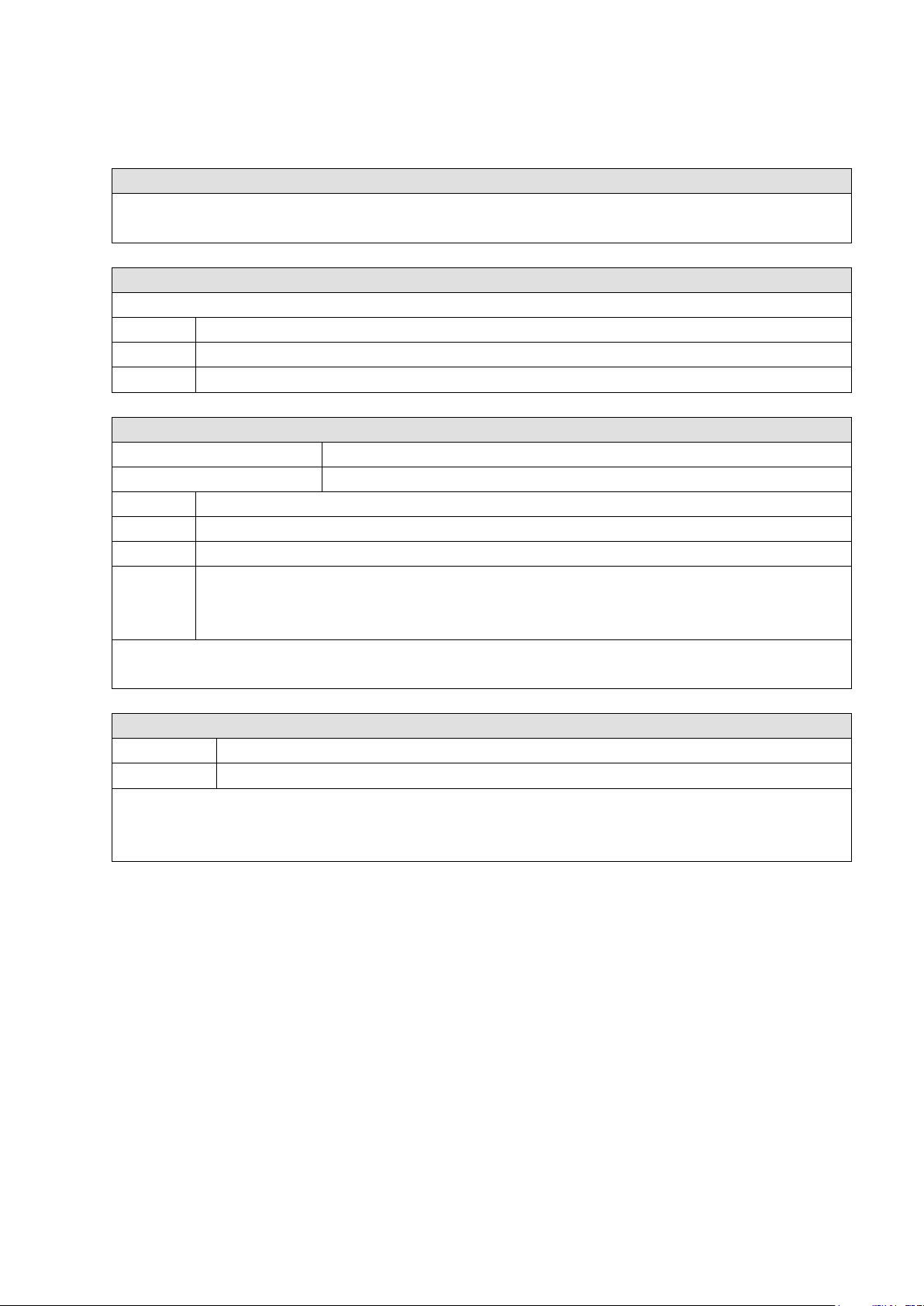

3.5 Examples

Architecture Diagram

Configuring the ZT-2550/ZT-2570

Configuring the ZT-2000 I/O device

Number

Item

Status

Description

1

Address MSB

OFF

Address/Node ID is 01 (Rotary Switch=1)

2

Protocol

ON

Use the Modbus RTU Protocol

3

Checksum

OFF

Disabled

4

ZB PID

OFF

ZigBee Pan ID=0x0000

5

ZB Channel

ON

0x08

ZigBee RF Channel = 0x0E

6

ON

0x04 7 ON

0x02 8 OFF

------

RS-232/RS-485

ICP DAS, ZT-2018/S AI Series User Manual, Version 1.0.1 Page 17

Copyright © 2013 by ICP DAS Co., Ltd. All Rights Reserved.

Simulating I/O channel operation via the DCON Utility

1. Launch the DCON Utility and select the appropriate COM Port settings to

connect to the ZigBee Coordinator (ZT-2550/ZT-2570).

2. Click the “Search” button to start searching for ZT-2000 I/O devices

connected to the same ZigBee network.

3. If any ZT-2000 I/O devices are found, they will be displayed in the device list

windows. Double-click the name of the name of the module to start the

operatiion.

2

3

1

ICP DAS, ZT-2018/S AI Series User Manual, Version 1.0.1 Page 18

Copyright © 2013 by ICP DAS Co., Ltd. All Rights Reserved.

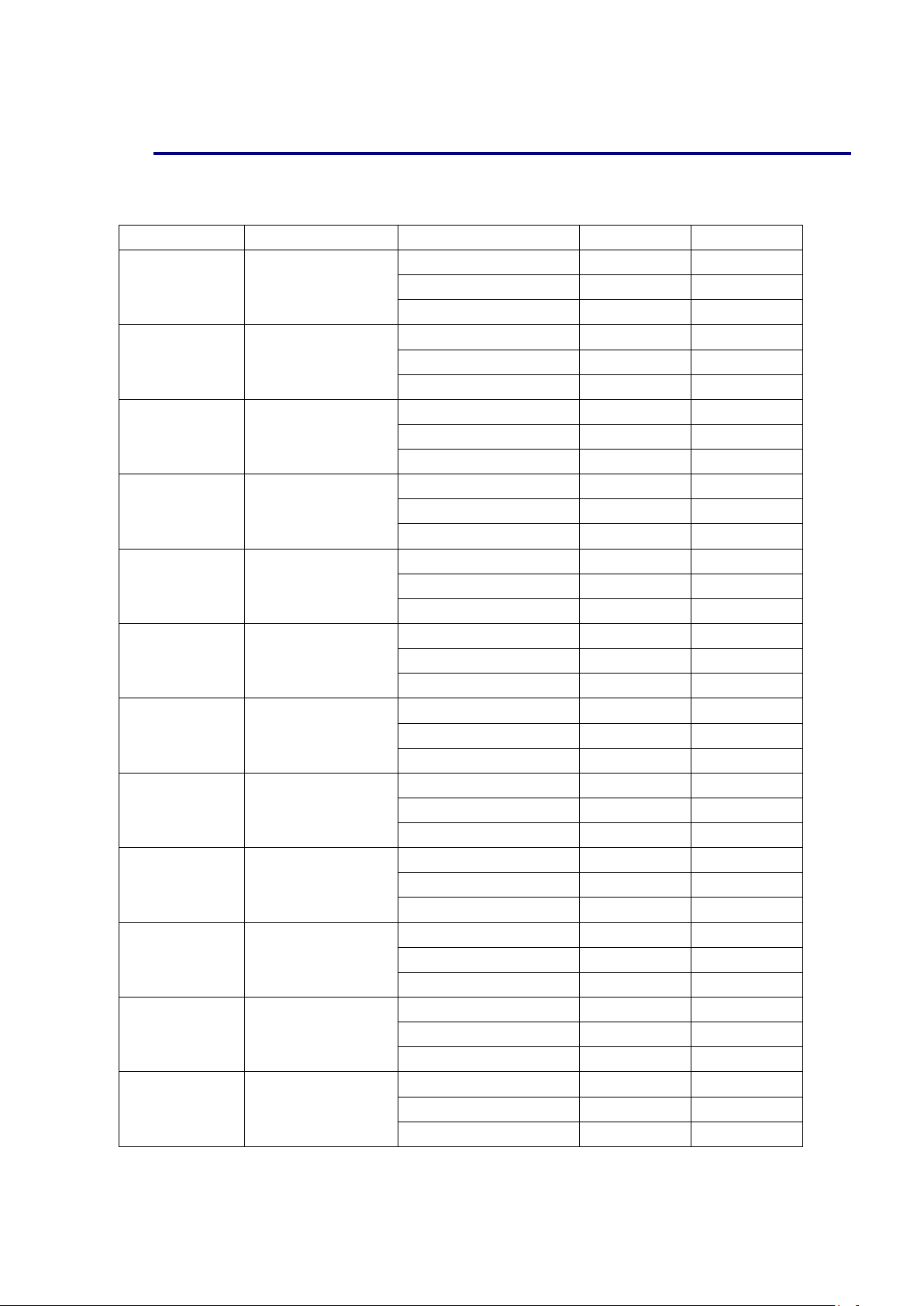

4 Analog Input Type and Data Format

Type Code

Input Type

Data Format

+F.S.

-F.S.

00

-15 to +15

mV

Engineering Units

+15.000

-15.000

% of FSR*2

+100.00

-100.00

2’s Comp. Hex

7FFF

8000

01

-50 to +50

mV

Engineering Units

+50.000

-50.000

% of FSR*2

+100.00

-100.00

2’s Comp. Hex

7FFF

8000

02

-100 to +100

mV

Engineering Units

+100.00

-100.00

% of FSR*2

+100.00

-100.00

2’s Comp. Hex

7FFF

8000

03

-500 to +500

mV

Engineering Units

+500.00

-500.00

% of FSR*2

+100.00

-100.00

2’s Comp. Hex

7FFF

8000

04

-1 to +1

V

Engineering Units

+1.0000

-1.0000

% of FSR*2

+100.00

-100.00

2’s Comp. Hex

7FFF

8000

05

-2.5 to +2.5

V

Engineering Units

+2.5000

-2.5000

% of FSR*2

+100.00

-100.00

2’s Comp. Hex

7FFF

8000

06

-20 to +20

mA

Engineering Units

+20.000

-20.000

% of FSR*2

+100.00

-100.00

2’s Comp. Hex

7FFF

8000

07

4 to +20

mA

Engineering Units

+20.000

+04.000

% of FSR*2

+100.00

+000.00

2’s Comp. Hex

FFFF

0000

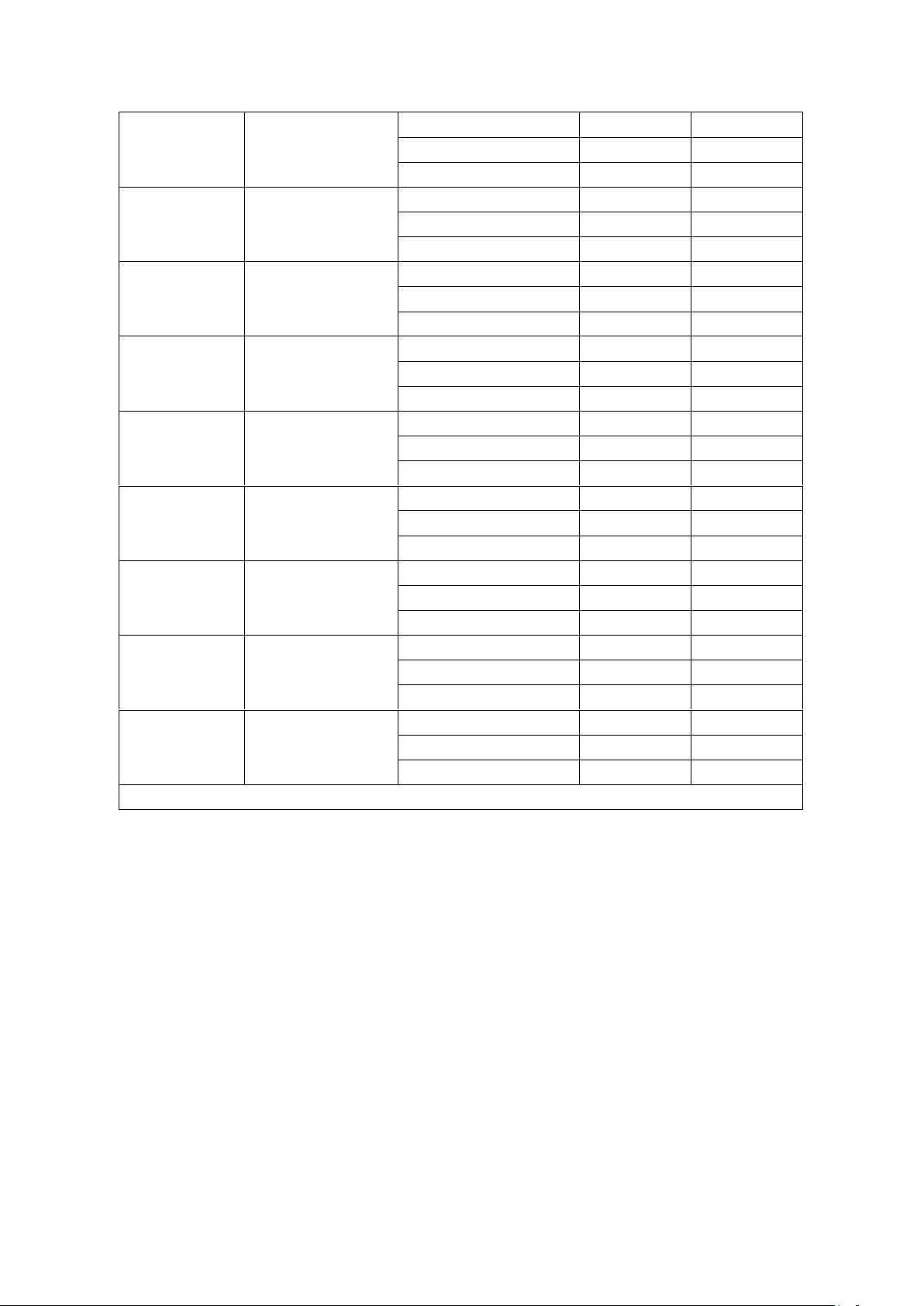

0E

Type J

Thermocouple

-210 ~ +760°C

Engineering Units

+760.00

-210.00

% of FSR*2

+100.00

-027.63

2’s Comp. Hex

FFFF

DCA2

0F

Type K

Thermocouple

-270 ~ +1372°C

Engineering Units

+1372.0

-0270.0

% of FSR*2

+100.00

-019.68

2’s Comp. Hex

7FFF

E6D0

10

Type T

Thermocouple

-270 ~ +400°C

Engineering Units

+400.00

-270.00

% of FSR*2

+100.00

-067.50

2’s Comp. Hex

7FFF

DCA2

11

Type E

Thermocouple

-270 ~ +1000°C

Engineering Units

+1000.0

-0270.0

% of FSR*2

+100.00

-027.00

2’s Comp. Hex

7FFF

DD71

ICP DAS, ZT-2018/S AI Series User Manual, Version 1.0.1 Page 19

Copyright © 2013 by ICP DAS Co., Ltd. All Rights Reserved.

12

Type R

Thermocouple

0 ~ +1768°C

Engineering Units

+1768.0

-0000.0

% of FSR*2

+100.00

-000.00

2’s Comp. Hex

7FFF

0000

13

Type S

Thermocouple

0 ~ +1768°C

Engineering Units

+1768.0

-0000.0

% of FSR*2

+100.00

-000.00

2’s Comp. Hex

7FFF

0000

14

Type B

Thermocouple

0 ~ +1820°C

Engineering Units

+1820.0

-0000.0

% of FSR*2

+100.00

-000.00

2’s Comp. Hex

7FFF

0000

15

Type N

Thermocouple

-270 ~ +1300°C

Engineering Units

+1300.0

-0270.0

% of FSR*2

+100.00

-020.77

2’s Comp. Hex

7FFF

E56B

16

Type C

Thermocouple

0 ~ +2320°C

Engineering Units

+2320.0

-0000.0

% of FSR*2

+100.00

-000.00

2’s Comp. Hex

7FFF

0000

17

Type L

Thermocouple

-200 ~ +800°C

Engineering Units

+800.00

-200.00

% of FSR*2

+100.00

-025.00

2’s Comp. Hex

7FFF

E000

18

Type M

Thermocouple

-200 ~ +100°C

Engineering Units

+100.00

-200.00

% of FSR*2

+050.00

-100.00

2’s Comp. Hex

4000

8000

19

Type LDIN43710

Thermocouple

-200 ~ +800°C

Engineering Units

+900.00

-200.00

% of FSR*2

+100.00

-022.22

2’s Comp. Hex

7FFF

E38E

1A

0 to +20

mA

Engineering Units

+20.000

+00.000

% of FSR*2

+100.00

+000.00

2’s Comp. Hex

FFFF

0000

*1: FSR (Full Scale Range)

ICP DAS, ZT-2018/S AI Series User Manual, Version 1.0.1 Page 20

Copyright © 2013 by ICP DAS Co., Ltd. All Rights Reserved.

Analog Input Over/Under Range Readings

Over Range

Under Range

Engineering Units

+9999.9

-9999.9

% of FSR

+999.99

-999.99

2’s Complement Hex

7FFF

8000

Analog Input Over/Under Range Readings when using the

Modbus RTU protocol

Over Range

Under Range

7FFFh

8000h

Data Format Settings (FF)

7 6 5 4 3 2 1

0

FS

Reserved

DF

Key

Description

DF

Data Format

00: Engineering Units

01: % of FSR

10: 2’s Complement Hexadecimal

FS

Filter Settings

0: 60 Hz Rejection

1: 50 Hz Rejection

ICP DAS, ZT-2018/S AI Series User Manual, Version 1.0.1 Page 21

Copyright © 2013 by ICP DAS Co., Ltd. All Rights Reserved.

5 Calibration

Warning

Performing calibration is not recommended until the process is fully understood.

The calibration procedure is as follows:

1. Warm up the module for at least 30 minutes.

2. Set the Type Code to the type you wish to calibrate. Refer to Section 4 and Section

6.2.13 for details.

3. Enable calibration. Refer to Section 6.2.31 for details.

4. Apply the zero calibration voltage/current.

5. Send the zero calibration command. Refer to Section 6.2.7 for details.

6. Apply the span calibration voltage/current.

7. Send the span calibration command. Refer to Section 6.2.6 for details.

8. Repeat steps 3 to 7 three times.

Notes

1. The calibration voltage/current source should be connected to channel 0.

2. Calibration voltages and currents are shown below.

3. Switch to DCON protocol mode before calibrating the module. Refer to Section 3.2

for details of how to switch protocols.

Calibration Voltage Types used by the ZT-2018/S

Type Code

00

01

02

03

04

05

06

Zero Input

0 mV

0 mV

0 mV

0 mV

0 V

0 V

0 mA

Span Input

+15 mV

+50 mV

+100 mV

+500 mV

+1 V

+2.5 V

+20 mA

ICP DAS, ZT-2018/S AI Series User Manual, Version 1.0.1 Page 22

Copyright © 2013 by ICP DAS Co., Ltd. All Rights Reserved.

6 The DCON/Modbus RTU Command Sets

6.1 Communicating with the ZT-2000 I/O Device

ICP DAS ZT-2000 I/O devices can be operated using either the DCON or the Modbus

RTU protocol, which can be selected by adjusting the position of DIP switch 2 to OFF

(DCON) or ON (Modbus RTU) and then rebooting the ZT-2000 I/O device to user the

new protocol.

6.2 The DCON Protocol Command Set

All ZT-2000 I/O series devices are controlled via wireless broadcast commands, so

each device must have a unique address that is saved in the EEPROM of the device.

Consequently, all command and response formats contain the address of the

destination module. When an I/O device receives a command, it will determine whether

or not to respond based on the address contained in the command. However, there are

two exceptions to this, the #** and ~** commands.

DCON Command Format

Delimiter

Character

Module

Address

Command

[CHECKSU

M]

CR

DCON Response Format

Delimiter

Character

Module

Address

Data

[CHECKSU

M]

CR

※ Note: ‘CR’ is the end of command (carriage return) character used to end a frame.

※ All characters should be expressed in capital letters.

ICP DAS, ZT-2018/S AI Series User Manual, Version 1.0.1 Page 23

Copyright © 2013 by ICP DAS Co., Ltd. All Rights Reserved.

6.2.1 Checksum

Calculating the Checksum:

Sum the ASCII codes of all the characters contained in the command in addition to the

‘CR’ terminator. The Checksum is the sum value expressed in Hexadecimal format.

Example: Command “$012(CR)”

Sum = ‘$’ + ‘0’ + ‘1’ + ‘2’ = 24h + 30h + 31h + 32h = B7h

Checksum = “B7”

DCON Command with Checksum =“$012B7(CR)”

Example: Response “!01200600(CR)”

Sum = ‘!’ + ‘0’ + ‘1’ + ‘2’ + ‘0’ + ‘0’ + ‘6’ + ‘0’ + ‘0’

= 21h+30h+31h+32h+30h+30h+36h+30h+30h

= 1AAh

Checksum = “AA”

DCON Response with Checksum = “!01200600AA(CR)”

※ Note: The Checksum is the sum value expressed in capital letters.

ICP DAS, ZT-2018/S AI Series User Manual, Version 1.0.1 Page 24

Copyright © 2013 by ICP DAS Co., Ltd. All Rights Reserved.

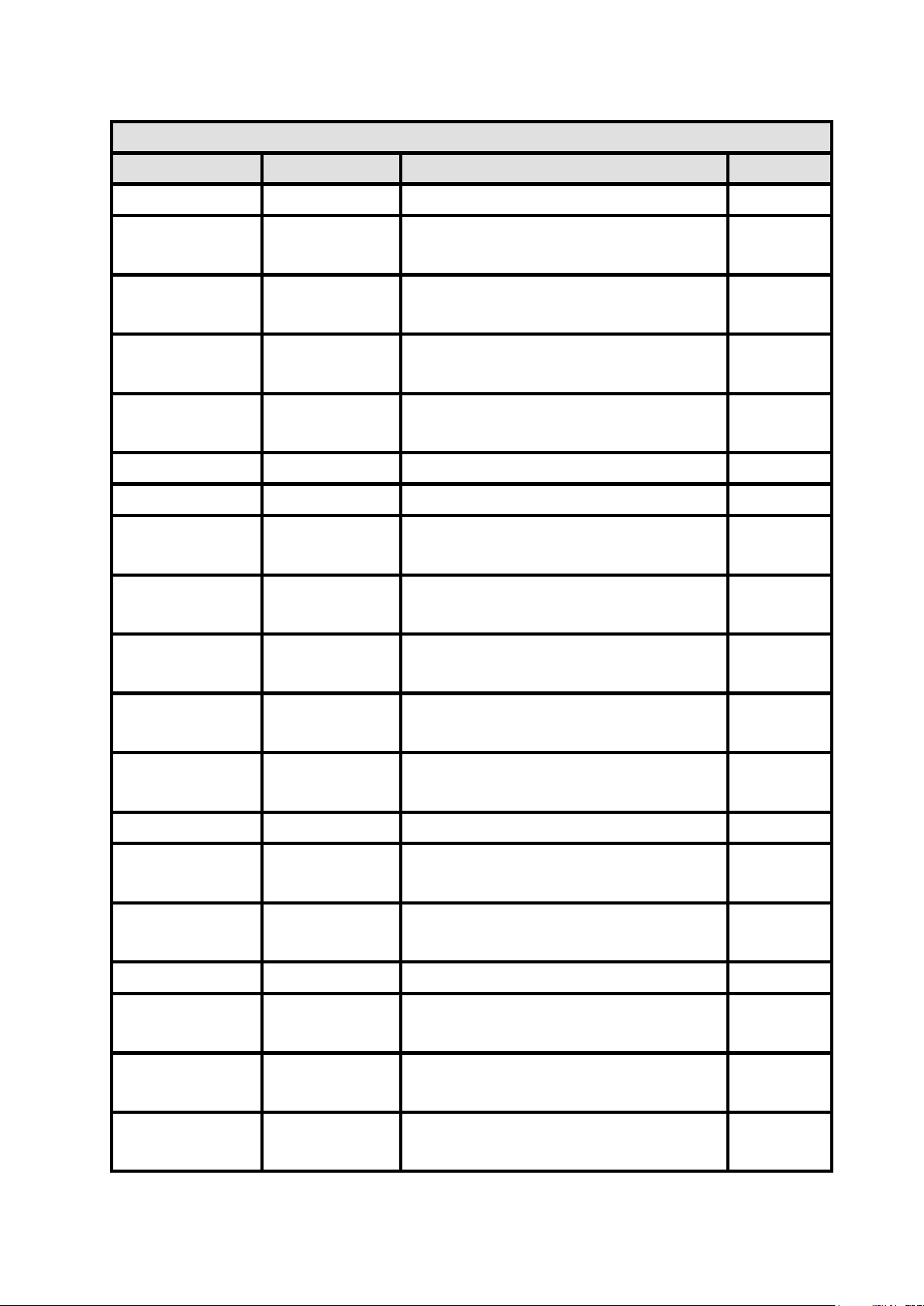

6.3 Overview of the DCON Command Set

General Command Set

Command

Response

Description

Section

%AANNTTCCFF

!AA

Sets the Configuration of the Module

6.2.3

#AA

>(Data)

Reads the Analog Input Data from all

Channels

6.2.4

#AAN

>(Data)

Reads the Analog Input Data from a

Specific Channel

6.2.5

$AA0

!AA

Performs an Analog Input Span

Calibration

6.2.6

$AA1

!AA

Performs an Analog Input Zero

Calibration

6.2.7

$AA2

!AANNTTCCFF

Reads the Configuration of the Module

6.2.8

$AA5

!AAS

Reads the Reset Status of the Module

6.2.10

$AA5VV

!AA

Enables or Disables Specific Analog

Input Channels

6.2.11

$AA6

!AAVV

Reads whether each Analog Input

Channel is Enabled or Disabled

6.2.12

$AA7CiRrr

!AA

Sets the Type Code for a Specific

Analog Input Channel

6.2.13

$AA8Ci

!AACiRrr

Reads the Type Code for a Specific

Analog Input Channel

6.2.14

$AAF

!AA(Data)

Reads the Firmware Version of the

Module

6.2.21

$AAM

!AA(Data)

Reads the Name of the Module

6.2.22

$AAS1

!AA

Reloads the Default Calibration

Parameters

6.2.23

~AAEV

!AA

Enables or Disables Calibration for the

Module

6.2.31

~AAO(Name)

!AA

Sets the Name of the Module

6.2.32

@AACH

!AA

Clears the High Latch Values for all

Analog Input Channels

6.2.33

@AACHi

!AA

Clears the High Latch Value for a

Specific Analog Input Channel

6.2.34

@AACHCi

!AA

Clears the Status of the High Alarm for

a Specific Analog Input Channel

6.2.35

ICP DAS, ZT-2018/S AI Series User Manual, Version 1.0.1 Page 25

Copyright © 2013 by ICP DAS Co., Ltd. All Rights Reserved.

@AACL

!AA

Clears the Low Latch Values for all

Analog Input Channels

6.2.36

@AACLi

!AA

Clears the Low Latch Value for a

Specific Analog Input Channel

6.2.37

@AACLCi

!AA

Clears the Status of the Low Alarm for

a Specific Analog Input Channel

6.2.38

@AADHCi

!AA

Disables the High Alarm for a Specific

Analog Input Channel

6.2.39

@AADI

!AAHHLL

Reads the Status of the Alarms for all

Analog Input Channels

6.2.40

@AADLCi

!AA

Disables the Low Alarm for a Specific

Analog Input Channel

6.2.41

@AAHI(Data)CiT

!AA

Sets the High Alarm Value and Type

for a Specific Analog Input Channel

6.2.42

@AALO(Data)CiT

!AA

Sets the Low Alarm Value and Type for

a Specific Analog Input Channel

6.2.43

@AARH

!AA(Data)

Reads the High Latch Values for all

Analog Input Channels

6.2.45

@AARHi

!AA(Data)

Reads the High Latch Value for a

Specific Analog Input Channel

6.2.46

@AARHCi

!AA(Data)S

Reads the High Alarm Value for a

Specific Analog Input Channel

6.2.47

@AARL

!AA(Data)

Reads the Low Latch Values for all

Analog Input Channels

6.2.48

@AARLi

!AA(Data)

Reads the Low Latch Value for a

Specific Analog Input Channel

6.2.49

@AARLCi

!AA(Data)S

Reads the Low Alarm Value for a

Specific Analog Input Channel

6.2.50

ICP DAS, ZT-2018/S AI Series User Manual, Version 1.0.1 Page 26

Copyright © 2013 by ICP DAS Co., Ltd. All Rights Reserved.

CJC Command Sets

Command

Response

Description

Section

$AA3

>(Data)

Reads the CJC Temperature

6.2.9

$AA9

!AA(Data)

Reads the CJC Offset Value

6.2.15

$AA9SNNNN

!AA

Sets the CJC Offset Value

6.2.16

$AA9Ci

!AA(Data)

Reads the CJC Offset Value for a

Specific Analog Input Channel

6.2.17

$AA9SNNNNCi

!AA

Sets the CJC Offset Value for a

Specific Analog Input Channel

6.2.18

$AAA

!AAi

Reads the CJC Temperature Update

Settings

6.2.19

$AAAi

!AA

Sets the CJC Temperature Update

Settings

6.2.20

~AAC

!AAN

Read whether the CJC Function is

Enabled or Disabled

6.2.29

~AACN

!AA

Enables or Disables the CJC Function

6.2.30

@AAOD

!AAS

Reads the Status of the CJC

Connection

6.2.44

Host Watchdog Command Sets

Command

Response

Description

Section

~**

No Response

The command to inform all module that

the Host is OK

6.2.24

~AA0

!AASS

Reads the Status of the Host

Watchdog

6.2.25

~AA1

!AA

Resets the Status of the Host

Watchdog Timeout

6.2.26

~AA2

!AAETT

Reads the Timeout Settings for the

Host Watchdog

6.2.27

~AA3ETT

!AA

Enables or Disables the Host

Watchdog and sets the Host Watchdog

Timeout Value

6.2.28

ICP DAS, ZT-2018/S AI Series User Manual, Version 1.0.1 Page 27

Copyright © 2013 by ICP DAS Co., Ltd. All Rights Reserved.

%AANNTTCCFF

Description

This command is used to set the configuration of a specific module.

Syntax

%AANNTTCCFF[CHECKSUM](CR)

%

Delimiter character

AA

The address of the module to be configured in hexadecimal format (00 to FF)

NN

The new address of the module in hexadecimal format (00 to FF)

TT

00 (Reserved)

CC

0A (Reserved)

FF

The command used to set the data format, checksum, and filter settings.

See Section 4 for details of the data format.

Response

Valid Command

!AA[CHECKSUM](CR)

Invalid Command

?AA[CHECKSUM](CR)

!

Delimiter character to indicate a valid command

?

Delimiter character to indicate an invalid command

AA

The address of the responding module in hexadecimal format (00 to FF)

There will be no response if the command syntax is incorrect, there is a

communication error, or there is no module with the specified ad dress.

Examples

Command

%0320000A80

Response

!03

In Normal mode, the address 0x20 is saved to the EEPROM and the data format for

module 03 is set to 80 (50 Hz rejection). The module returns a response indicating that

the command was successful.

Command

%0320000A80

Response

!20

In Software Configuration mode, the address 0x20 is saved to the EEPROM and the

data format for module 03 is set to 80 (50 Hz rejection). The module returns a

response indicating that the command was successful.

Command

%0303000000

Response

?03

Attempts to set the configuration for module 03, but returns a response indicating

that an error occurred because the “CC”parameter must be 0A.

※Related Commands: Section 6.2.8 $AA2

※Related Topics: Section 4 Analog Input Type and Data Format

ICP DAS, ZT-2018/S AI Series User Manual, Version 1.0.1 Page 28

Copyright © 2013 by ICP DAS Co., Ltd. All Rights Reserved.

6.3.1 #AA

Description

This command is used to read data from all the Analog Input channels of a specified

module.

Syntax

#AA[CHECKSUM](CR)

#

Delimiter character

AA

The address of the module to be read in hexadecimal format (00 to FF)

Response

Valid Command

>(Data)[CHECKSUM](CR)

Invalid Command

?AA[CHECKSUM](CR)

>

Delimiter character to indicate a valid command

?

Delimiter character to indicate an invalid command

AA

The address of the responding module in hexadecimal format (00 to FF)

(Data)

The data from all the Analog Input channels. See Section 4 for details of the

data format. Data from disabled channels is filled with space characters.

There will be no response if the command syntax is incorrect, there is a

communication error, or there is no module with the specified address.

Examples

Command

#03

Response

>+15.000+15.000+15.000+15.000+15.000+15.000+15.000+15.000

Reads data from the Analog Input channels of module 03 and returns a response

indicating that the command was successful, with the data from all Analog Input

channels in engineering units format.

Command

#03

Response

>-9999.9-9999.9-9999.9-9999.9-9999.9-9999.9

Attempts to read data from the Analog Input channels of module 03, but returns a

response indicating that the command was unsuccessful because the data is not

within the valid range.

※Related Commands: Section 6.2.3 %AANNTTCCFF, Section 6.2.8 $AA2, Section 6.2.13

$AA7CiRrr

※Related Topics: Section 4 Analog Input Type and Data Format.

Section 7.1 Software Configuration Mode

ICP DAS, ZT-2018/S AI Series User Manual, Version 1.0.1 Page 29

Copyright © 2013 by ICP DAS Co., Ltd. All Rights Reserved.

6.3.2 #AAN

Description

This command is used to read data from a specific Analog Input channel of a specified

module.

Syntax

#AAN[CHECKSUM](CR)

#

Delimiter character

AA

The address of the module to be read in hexadecimal format (00 to FF)

N

The Analog Input channel to be read, zero based

Response

Valid Command

>(Data)[CHECKSUM](CR)

Invalid Command

?AA[CHECKSUM](CR)

>

Delimiter character to indicate a valid command

?

Delimiter character to indicate an invalid command.

AA

The address of the responding module in hexadecimal format (00 to FF)

(Data)

The data from the specified Analog Input channel. See Section 4 for details

of the data format. If the specified channel is disabled, then the data field

will be filled with space characters.

There will be no response if the command syntax is incorrect, there is a

communication error, or there is no module with the specified address.

Examples

Command

#032

Response

>+025.13

Reads data from Analog Input channel 2 of module 03 and returns a response

indicating that the command was successful, and the Analog Input value is +025.13

(+25.13mV).

ICP DAS, ZT-2018/S AI Series User Manual, Version 1.0.1 Page 30

Copyright © 2013 by ICP DAS Co., Ltd. All Rights Reserved.

Command

#039

Response

?03

Attempts to read data from Analog Input channel 9 of module 03, but returns a

response indicating that the command was unsuccessful because Analog Input

channel 9 does not exist.

※Related Commands: Section 6.2.3 %AANNTTCCFF, Section 6.2.8 $AA2, Section 6.2.13

$AA7CiRrr

※Related Topics: Section 4 Analog Input Type and Data Format.

Section 7.1 Software Configuration Mode

Loading...

Loading...