PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 1

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

Chapter 1 Introduction .................................... 4

1.1. PM-4324 introduction ........ 4

1.2. Caution ............................. 5

1.2.1. Danger .............................. 5

1.3. Warning ............................ 5

1.4. Product Warranty &

Customer Support ............. 5

1.4.1. Limitation of Warranty ....... 6

Chapter 2 Specifications ................................. 7

2.1 Specifications.................... 7

2.2 Naming Rules ................... 9

....................................................................... 9

Chapter 4 Wiring Diagrams ........................... 14

4.1 Connection ...................... 14

4.2 Wiring .............................. 16

Chapter 5 Relay output & LED Indicator ........ 18

5.1 Relay ............................... 18

5.2 LED Indicator .................. 18

Chapter 6 Modbus-RTU communication ........ 19

6.1.1 SW1-SW6 setting .......... 19

6.2 Modbus-RTU setting ....... 22

6.2.1 Specifications .................. 22

6.2.2 Modbus Register ............. 24

Chapter 7 CANopen communication ............. 44

Chapter 3 Installation .................................... 10

3.1 Inspection ....................... 10

3.2 Safety ............................. 10

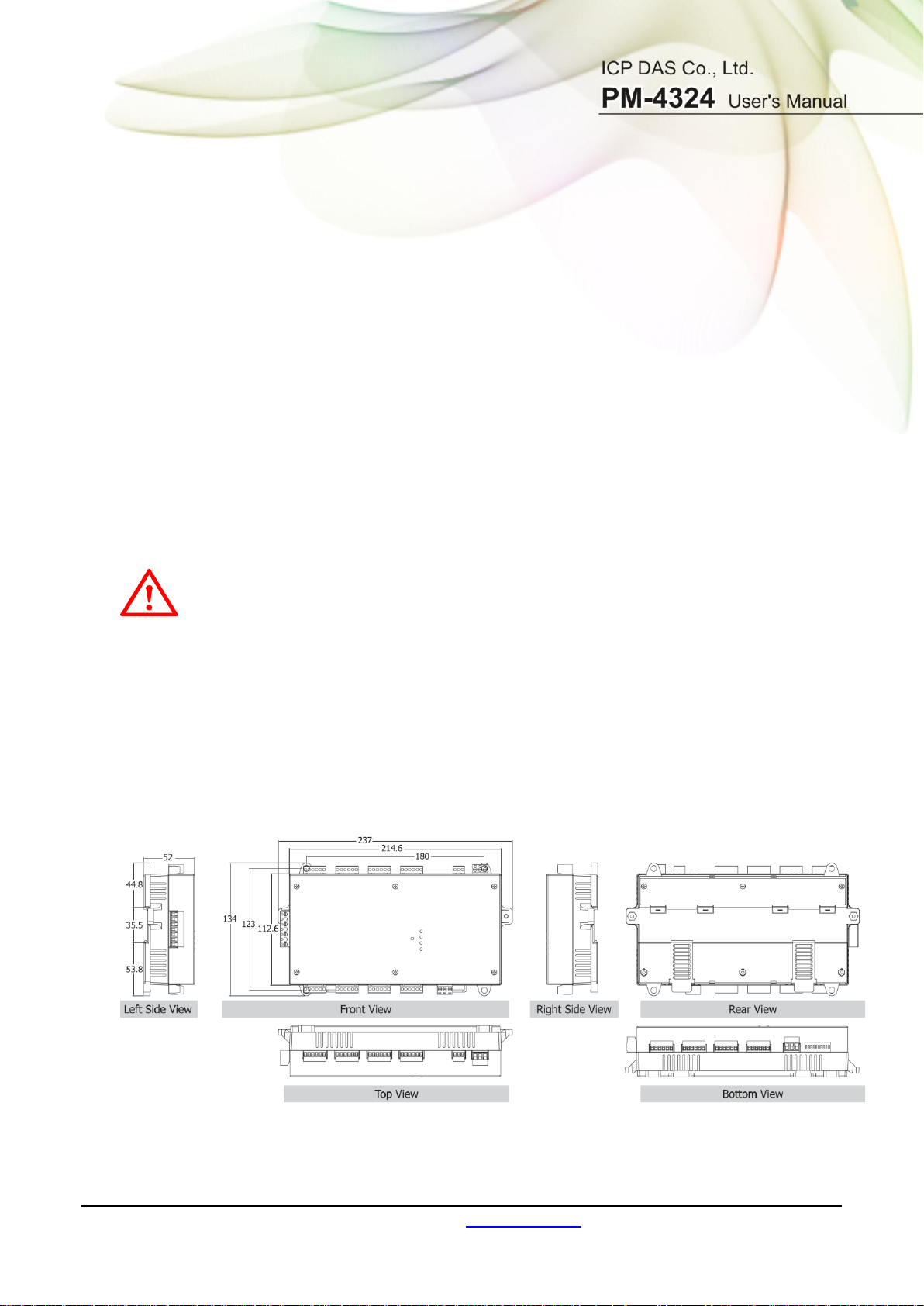

3.2.1 Dimension and Latch ...... 10

3.2.2 Mounting and Dismounting

....................................... 12

3.2.3 CT’s installation steps ..... 13

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 2

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

7.1 CANopen setting ............. 44

7.2 CANopen Protocol ........... 46

7.2.1 SDO Introduction ............. 47

7.2.1.1 Upload SDO Protocol ...... 47

7.2.1.2 Download SDO Protocol .. 49

7.2.1.3 Abort SDO Transfer Protocol

....................................... 52

7.2.2 PDO Introduction ............ 55

7.2.2.1 PDO COB-ID Parameters 55

7.2.2.2 Transmission Type.......... 56

7.2.2.3 PDO Communication Rule

....................................... 57

7.2.3 NMT Introduction ............ 59

7.2.3.1 Module Control Protocol . 59

7.2.3.2 Error Control Protocol ..... 61

7.2.4 Special Functions for

PM-4324-CPS ................. 62

7.2.4.1 Power Meter Data Table .. 62

7.2.5 Object Dictionary of

PM-4324-CPS ................. 64

7.2.5.1 Communication Profile Area

........................................ 64

7.2.5.2 Manufacturer Specific

Profile Area ..................... 71

Appendix: Questions & Answers ............. 77

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 3

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

Chapter 1 Introduction

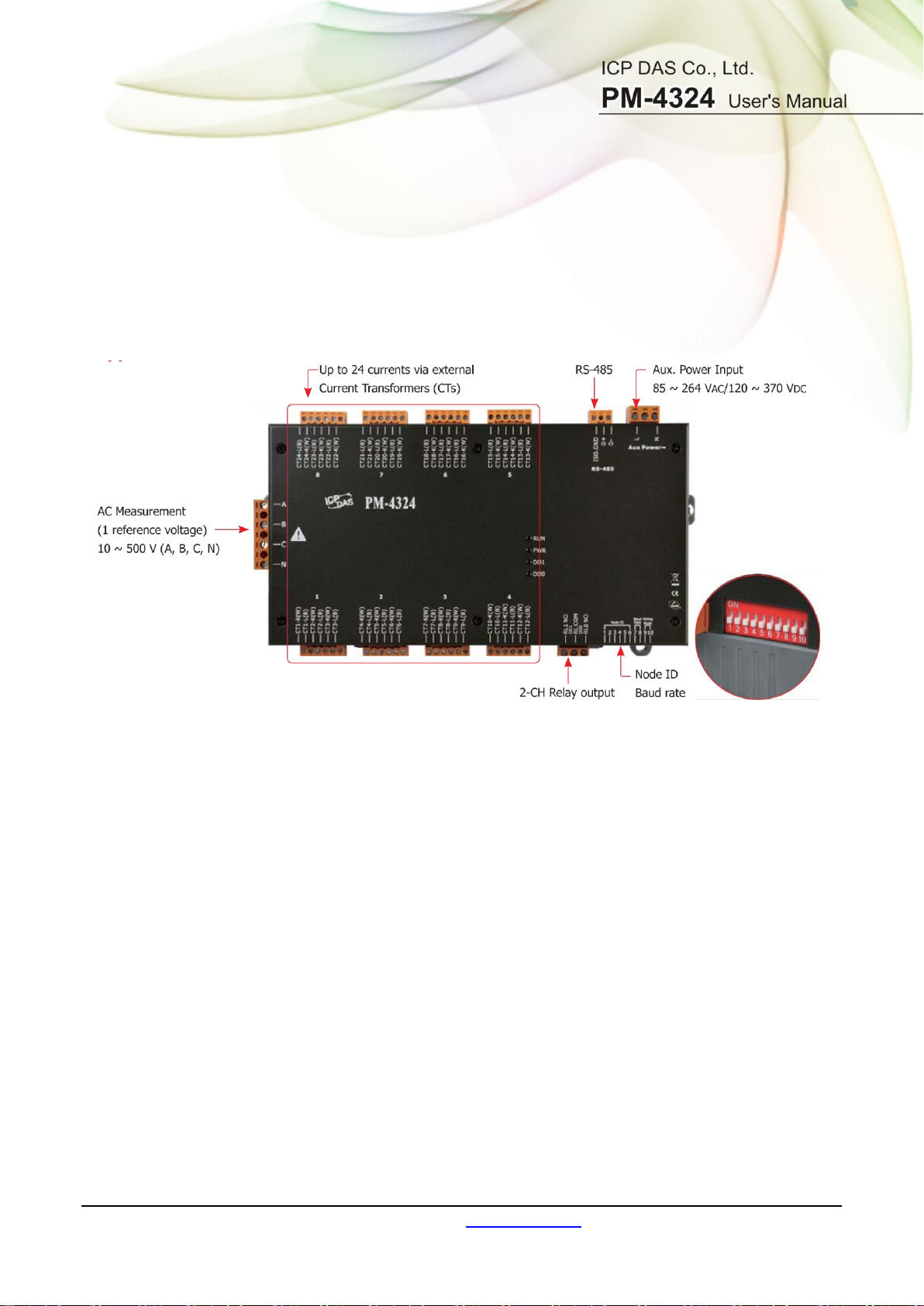

1.1. PM-4324 introduction

ICP DAS offers PM-4324 family in a full range of Single-phase and Three-phase smart

power meters for power monitoring. The products offer a rich feature set combined with

easy-to-integrate communications.

With its high accuracy (<0.5%, PF=1), the PM-4324 series products can be applied both

on low voltage primary side and/or medium/high voltage secondary side and enable the

users to obtain in real time the reliable and accurate energy consumption readings from

the monitored equipments while in operation. These compact size and cost effective

Power Meters are equipped with revolutionary wired clip-on CT (various types support

input current up to 400A) and standard Modbus communication RS-485 protocol for

easy deployment. It works with input voltages ranging 10V ~ 500V, supporting a wide

range of applications.

Features:

True RMS Power Measurements

Energy Analysis for 3P4W-3CT, 3P3W-2CT, 3P3W-3CT, 1P2W-1CT, 1P3W-2CT

Current Measurements Up to 400 A with Different CT Ratio

Voltage Measurements Up to 500 V

Clip-on CT for Easy Installation

W Accuracy Better than 0.5% (PF=1)

Supports RS-485, Ethernet Interface

Supports Modbus RTU, Modbus TCP protocols.

Supports 2-Power Relay Output (Form A)

Total Harmonic Distortion (THD)

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 4

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

1.2. Caution

1.2.1. Danger

The meter contains hazardous voltages, and should never be disassembled. Failing to

follow this practice will result in serious injury or death. Any work on or near energized

meters, meter sockets, or other metering equipment could induce a danger of electrical

shock. It is strongly recommended that all work should be performed only by qualified

industrial electricians and metering specialist. ICP DAS assumes no responsibility if

your electrical installer does not follow the appropriate national and local electrical

codes.

1.3. Warning

ICP DAS assumes no liability for any damage resulting from the use of this product. ICP

DAS reserves the right to change this manual at any time without notice. The

information furnished by ICP DAS is believed to be accurate and reliable. However, no

responsibility is assumed by ICP DAS for its use, not for any infringements of patents or

other rights of third parties resulting from its use.

1.4. Product Warranty & Customer Support

ICP DAS warrants all products free from defects in material and workmanship for a

period of one year from the date of shipping. During the warranty period, we will, at our

position, either repair or replace any product that proves to be defective. To report any

defect, please contact :+886-3- 597-3366 or service@icpdas.com.

Please have the model, serial number and a detailed problem description available

when you call. If the problem concerns a particular reading, please have all meter

readings available. When returning any merchandise to ICP DAS, a return SN. is

required.

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 5

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

1.4.1. Limitation of Warranty

This warranty does not apply to defects resulting from unauthorized modification,

misuse, or use for reason other than electrical power monitoring. The supplied meter is

not a user-serviceable product.

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 6

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

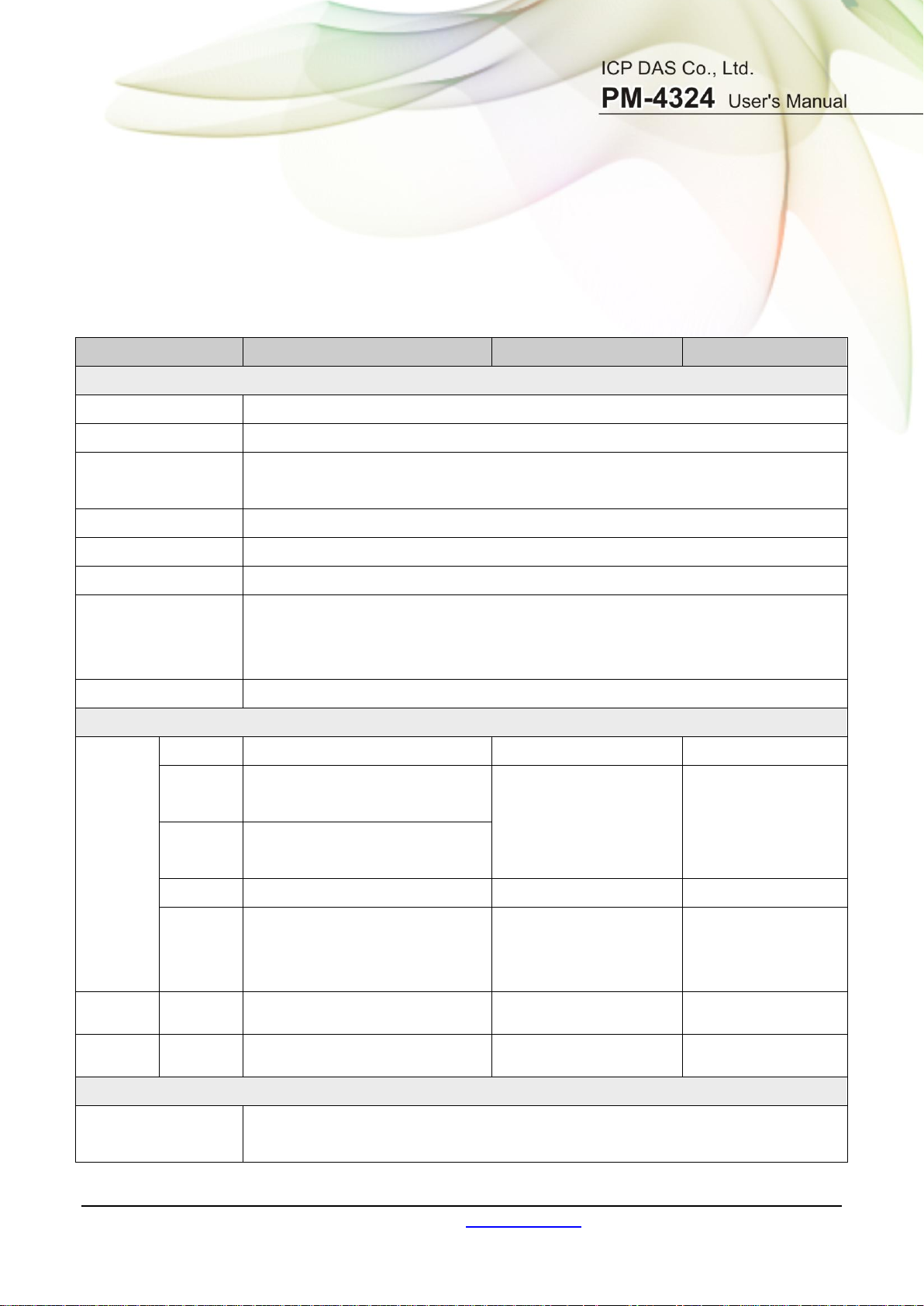

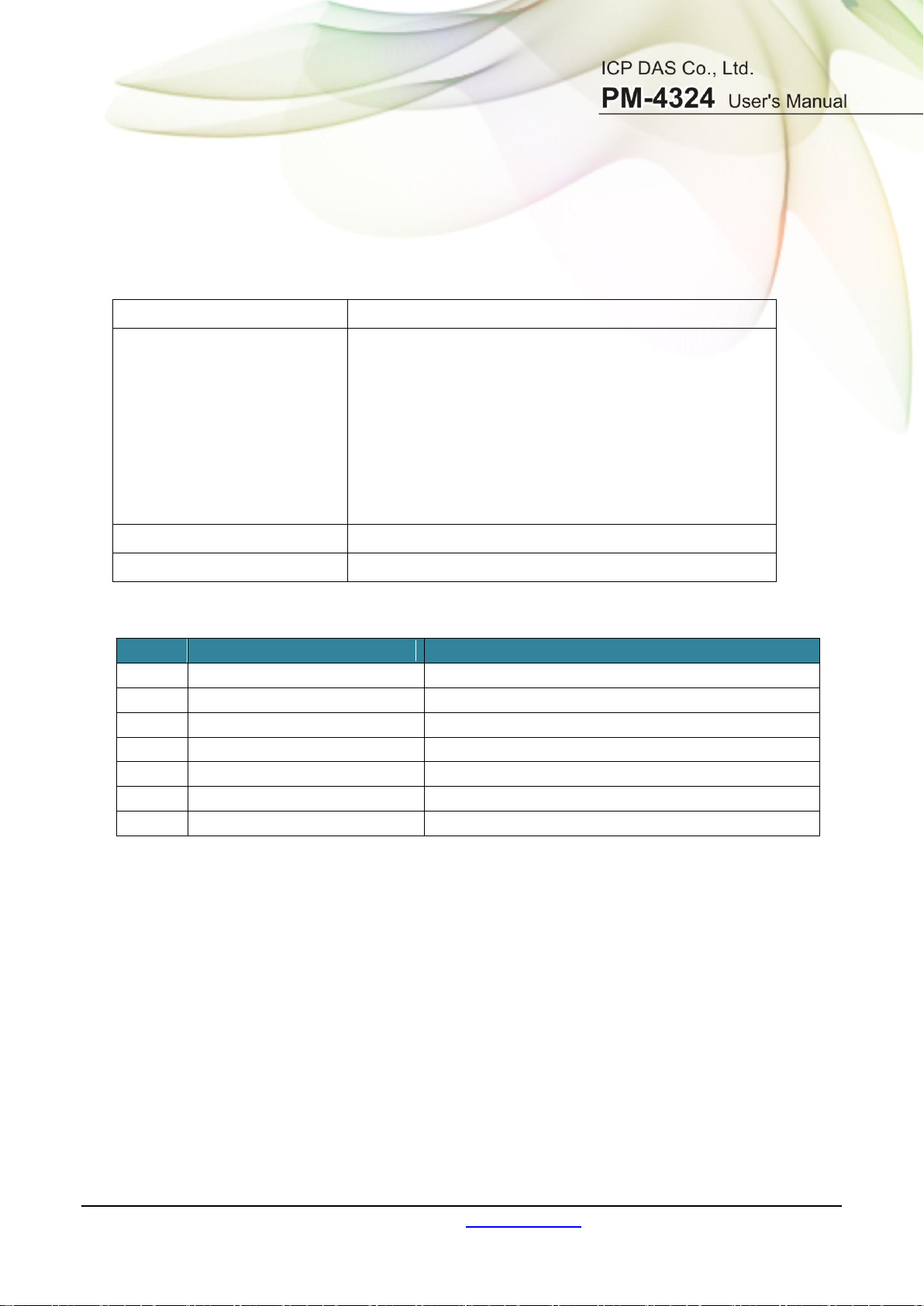

Model

PM-4324

PM-4324-MTCP

PM-4324-CPS

AC Power Measurement

Wiring

1P2W-1CT, 1P3W-2CT, 3P3W-2CT, 3P3W-3CT and 3P4W-3CT

Measurement Voltage

10 ~ 500 V (CAT III)

Measurement Current

CT Φ10 mm (60 A); CTΦ16 mm (100 A); CTΦ24 mm (200 A);

CTΦ36m (300 A); CTΦ36m (400 A)

Measurement Frequency

50-60 Hz

W Accuracy

Better than 0.5% (PF:1)

Starting Current

>0.03A ( 60A ), >0.05A (100A ), >0.09A( 200A )

Power Parameter

Measurement

True RMS voltage (Vrms), True RMS current (Irms), Active Power (kW), Active Energy

(kWh), Apparent Power (kVA), Apparent Energy (kVAh),

Reactive Power (kVAR), Reactive Energy (kVARh), Power Factor (PF), Frequency(Hz)

Data Update Rate

1 Second

Communication

RS-485

Protocol

Modbus-RTU

-

Baud rate

9600,19200 (default), 38400,

115200; DIP Switch Selectable

Data

format

N,8,1 (default); N,8,2; E,8,1; E,8,2;

O,8,1; O,8,2

Isolation

3000 VDC

-

Bias

Resistor

No (Usually supplied by the

RS-485 Master. Alternatively, add

a tM-SG4 or SG-785)

Ethernet

Protocol

-

Modbus TCP

CANoepn

Protocol

CANopen

Alarm Output

Power Relay

Form A (Normal Open) x 2; Relay Contact Voltage Range: 5 A @ 250 VAC (47 ~ 63Hz),

5 A @ 30 VDC

Chapter 2 Specifications

2.1 Specifications

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 7

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

Aux Power

Input Range

+100 ~ +240 VAC

+100 ~ +240 VAC

+100 ~ +240 VAC

Power Consumption

6 W

Dimensions (W x L x H)

237 mm x 52 mm x 134 mm

Environment

Operating Temperature

-20 ~ +70 °C

Storage Temperature

-25 ~ +80 °C

Field Wiring Terminal Markings:

3.81mm (For Measurement Current and Communication): Use Copper Conductors Only,

wires range 16-26 AWG, torque value 3.0 lb-in.

5.08mm (For Measurement Voltage, Aux Power and Alarm Output):

Use Copper Conductors Only, wires range 12-24 AWG, torque value 7.0 lb-in.

7.62mm: Use Copper Conductors Only, wires range 12-24 AWG, torque value 4.5 lb-in.

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 8

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

2.2 Naming Rules

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 9

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

Chapter 3 Installation

3.1 Inspection

The instrument is no longer safe when,

a) Shows clear signs of damage

b) Does not work

c) Long storage under extreme conditions

d) Damage during shipment

3.2 Safety

Please use the soft dry clothes to clean the instrument.

Please do not use any chemical or detergent or volatile solvents to clean the instrument,

in order to avoid any possibility of the cover damage.

3.2.1 Dimension and Latch

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 10

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

Products come with external split type clip-on CT’s. Disconnect the CT’s or use

other CT’s is highly prohibited.

Please read this operation manual carefully before using.

Please re-confirm the measure position.

PM-4324 series can be installed as rail mounting mode or embedded, no need to

drill a hole or screw to fix it (rail mounting width can up to the length of 35 mm).

Meter auxiliary power is +100 ~ +240 VAC.

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 11

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

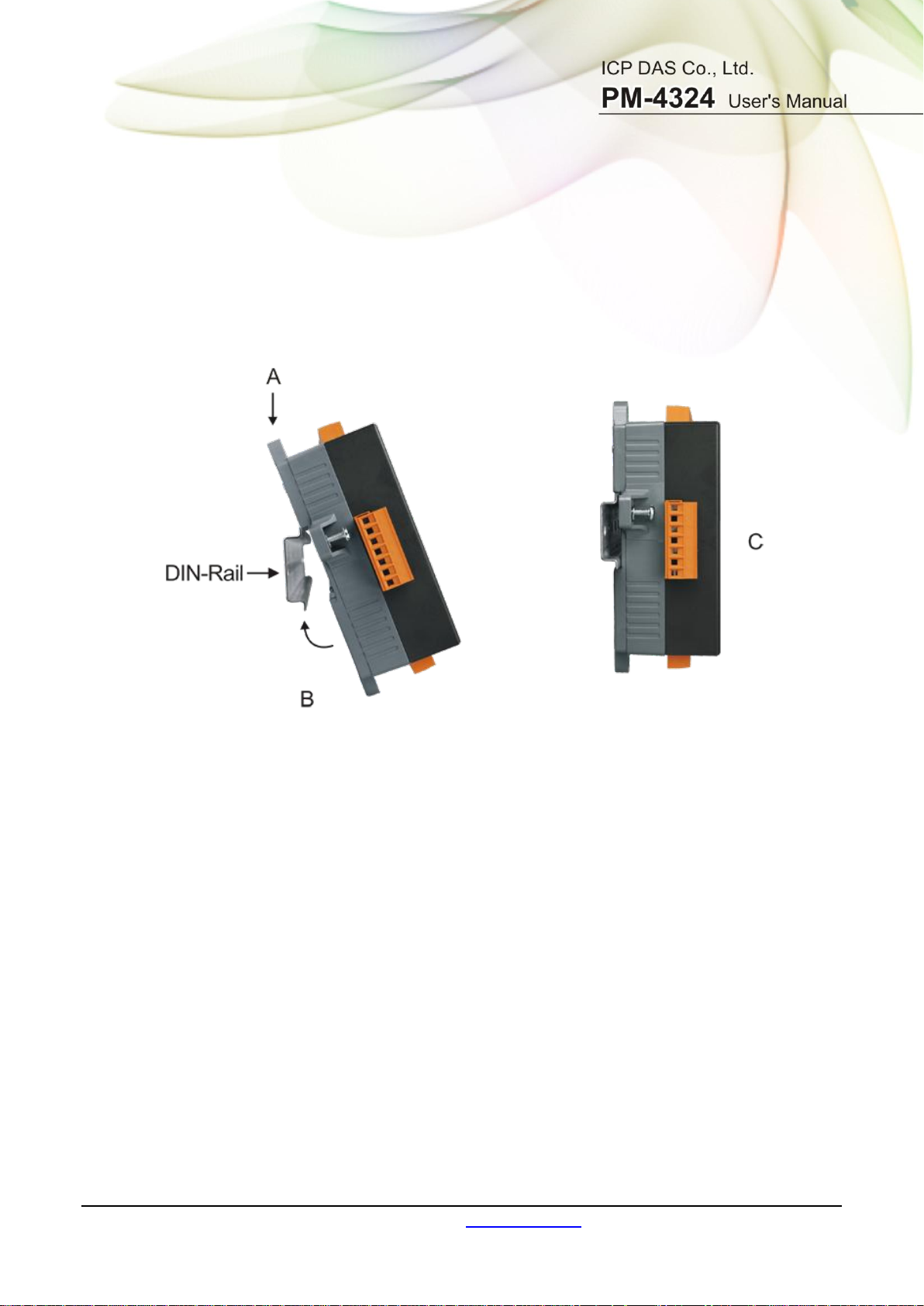

3.2.2 Mounting and Dismounting

Mounting

Assembly: Place the PM-4324 on the DIN-Rail. Push the front of the PM-4324

toward the mounting surface until it audibly snaps into place.

Dismantling: Pull out the latch and then remove the PM-4324 from the DIN-Rail.

Wire Disconnection

1. Open the CT clip to detach the CT, do not remove the CT terminal lines if

possible

Note: if you need to remove the terminal lines, always detach the CT before

removing the CT terminal lines. Otherwise the CT may develop open-circuit

secondary voltages which may be hazardous to personnel or damaging to the

CT or equipment connected in the secondary circuit.

2. Disconnect the voltage input wires from terminals and wrap the wire tips with

plastic tape.

3. Disconnect the communication wires from terminal.

4. Disconnect the auxiliary power from terminal and wrap the wire tip with plastic

tape.

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 12

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

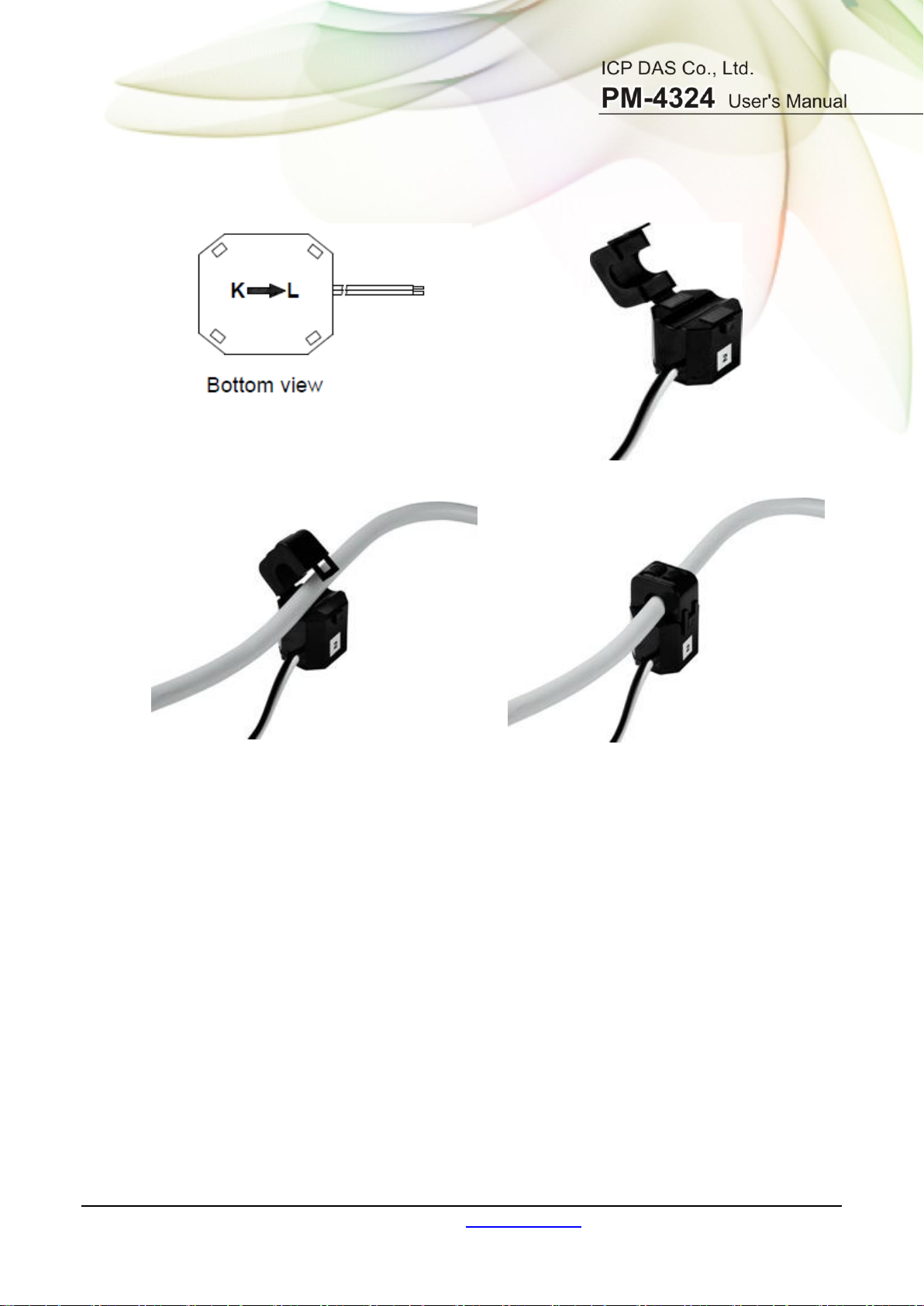

At the bottom of the CT, there is a

“K→L” mark.

Open the CT clip.

Make sure the power current

direction follow the “K→L” mark on

the CT and then close the CT clip.

Installation steps finished.

3.2.3 CT’s installation steps

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 13

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

Chapter 4 Wiring Diagrams

4.1 Connection

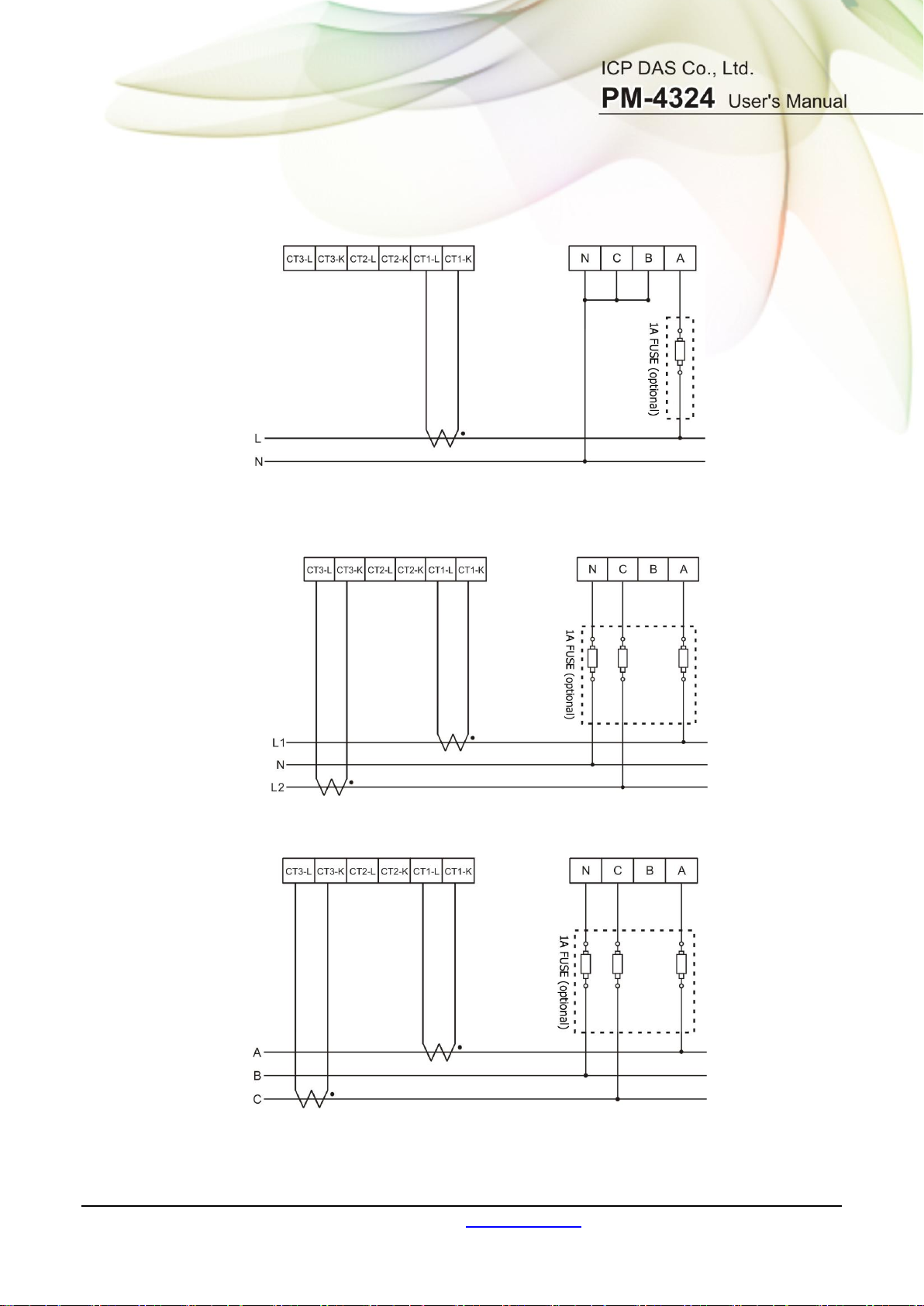

Please firstly check the current input terminal, and then in white black, white black,

white black wire sequences (CT1-K, CT1-L, CT2-K, CT2-L, CT3-K, CT3-L). Then

connect the CT’s, and close the CT clip. Make sure the arrow direction sign on CT’s

follows current flow direction(K→L)

Note: it must be in the same direction.

Connect the voltage input terminal N C B A. for PM-4324, in the three phase order

as follows on N C B A.

Attention please!! For 3P3W-2CT, connect in N C A phase sequence, do not

connect phase B (Check the diagram).

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 14

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

Voltage Input

1. PM-4324 series: Input Voltage up to 500V.

For any higher Input Voltage large than 500V, please add the PT (power transformer), and Change PT

RATIO setup.

2. Confirm the RST (ABC) phase sequence.

Current Input

1. The external CT’s are fragile, please handle with care.

2. The current input of PM-4324 series is in mA range. Only the ex-factory attached CT’s can be used.

The other CT’s, for example, from panel will damage the instrument due to its large current (around

5A)

3. When more than one smart meter (PM-4324 series) are installed, please do not disconnect the CT

with its original meter and mix use with each other. Since each set of smart meter (PM-4324 series)

and its attached split type clip-on CT are calibrated set by set. The mix use may cause wrong

measurements.

4. To install CT’s correctly, please ensure the CT lines sequences is right before clip the CT’s onto the

power cable of the monitoring equipment. (Detail will be found in next section)

5. When measuring the current, the secondary circuit of a CT should never be

opened when a load is passing through its primary. Make sure you always open

the CT clip to detach the CT before removing the terminal lines. Otherwise, it will cause severe

injury.

6. Please handle with extra care, especially when the operation space of CT’s is limited.

7. The current direction must follow K-L marked on CT’s.

8. Please select the right size CT’s for different size of monitoring equipment cables:

power cable diameter <Φ10 use 60A CT,Φ10~Φ16 use 100A CT,Φ16~Φ24 use 200A CT,

,Φ36 use 300A CT,Φ36 use 400A CT

9. The maximum current value cannot exceed the CT rating

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 15

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

4.2 Wiring

1P2W-1CT (PM-4324)

1P3W-2CT (PM-4324)

3P3W-2CT (PM-4324)

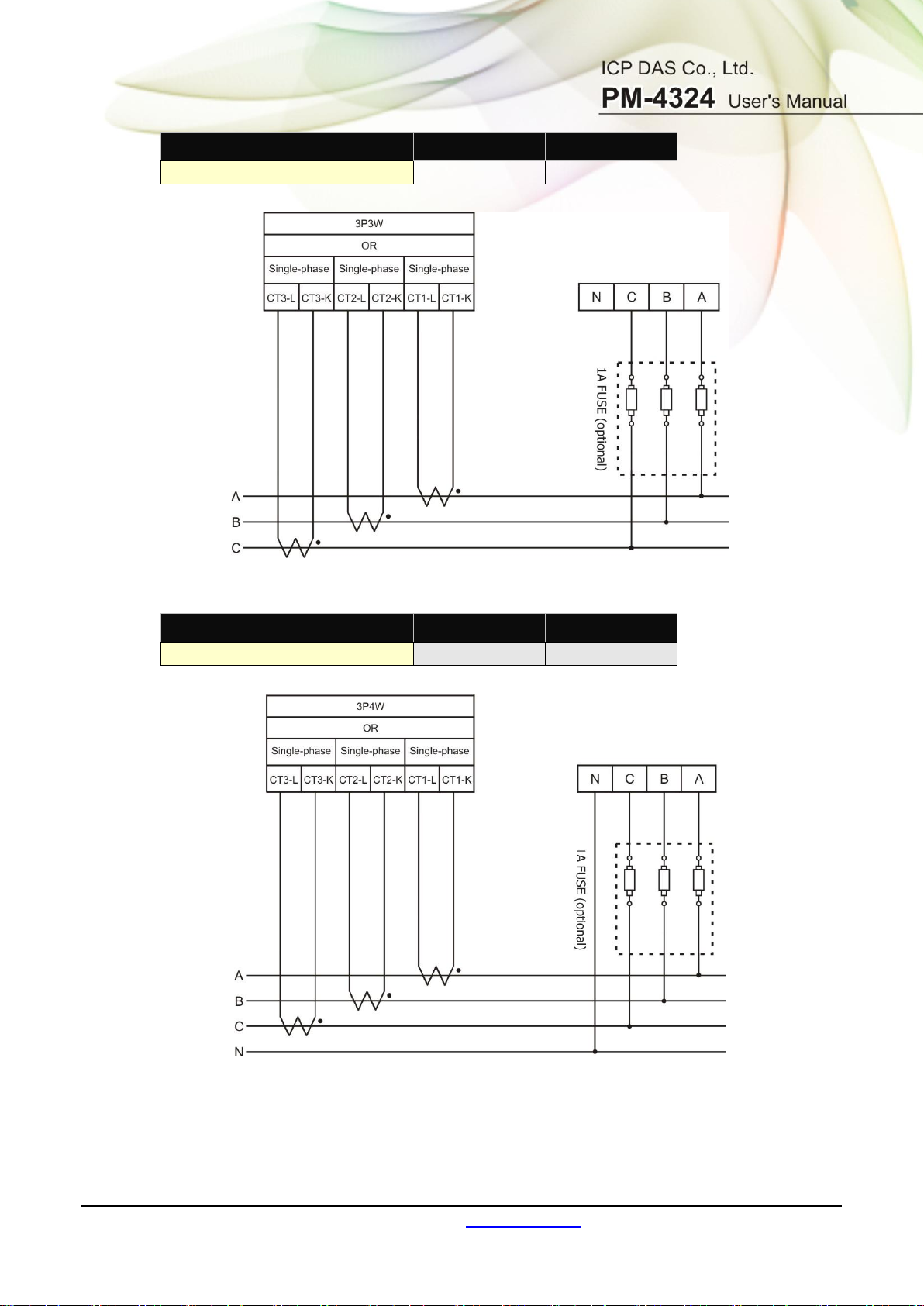

3P3W-3CT (PM-4324)

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 16

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

DIP switch: Wiring mode

SW 9

SW 10

3P3W-3CT

OFF

ON

DIP switch: Wiring mode

SW 9

SW 10

3P4W-3CT

ON

ON

3P4W-3CT (PM-4324)

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 17

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

Relay type

Power Relay, Form A (SPST N.O.)

Operating Voltage Range

250 VAC/30 VDC

Max. Load Current

5 A at 25 °C

Operate Time

6 ms

Release Time

3 ms

Chapter 5 Relay output & LED Indicator

5.1 Relay

5.2 LED Indicator

The PM-4324 has 4 LED to indicate the unit power status, RS-485 communication, and

power data calculation.

RUN: Green, light up after RS-485 ready. LED will flash when the unit is processing

RS-485 communication.

PWR: Red, Power on LED always on.

DO0: Green. LED DO0 will light up, when DO0 is “ON”.

DO1: Green. LED DO1 will light up, when DO1 is “ON”.

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 18

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

Modbus Address

SW 1

SW 2

SW 3

SW 4

SW 5

SW 6

1

OFF

OFF

OFF

OFF

OFF

OFF

2

ON

OFF

OFF

OFF

OFF

OFF

3

OFF

ON

OFF

OFF

OFF

OFF

4

ON

ON

OFF

OFF

OFF

OFF

5

OFF

OFF

ON

OFF

OFF

OFF

6

ON

OFF

ON

OFF

OFF

OFF

7

OFF

ON

ON

OFF

OFF

OFF

8

ON

ON

ON

OFF

OFF

OFF

9

OFF

OFF

OFF

ON

OFF

OFF

10

ON

OFF

OFF

ON

OFF

OFF

11

OFF

ON

OFF

ON

OFF

OFF

12

ON

ON

OFF

ON

OFF

OFF

13

OFF

OFF

ON

ON

OFF

OFF

14

ON

OFF

ON

ON

OFF

OFF

15

OFF

ON

ON

ON

OFF

OFF

16

ON

ON

ON

ON

OFF

OFF

17

OFF

OFF

OFF

OFF

ON

OFF

18

ON

OFF

OFF

OFF

ON

OFF

19

OFF

ON

OFF

OFF

ON

OFF

20

ON

ON

OFF

OFF

ON

OFF

21

OFF

OFF

ON

OFF

ON

OFF

22

ON

OFF

ON

OFF

ON

OFF

23

OFF

ON

ON

OFF

ON

OFF

24

ON

ON

ON

OFF

ON

OFF

25

OFF

OFF

OFF

ON

ON

OFF

26

ON

OFF

OFF

ON

ON

OFF

27

OFF

ON

OFF

ON

ON

OFF

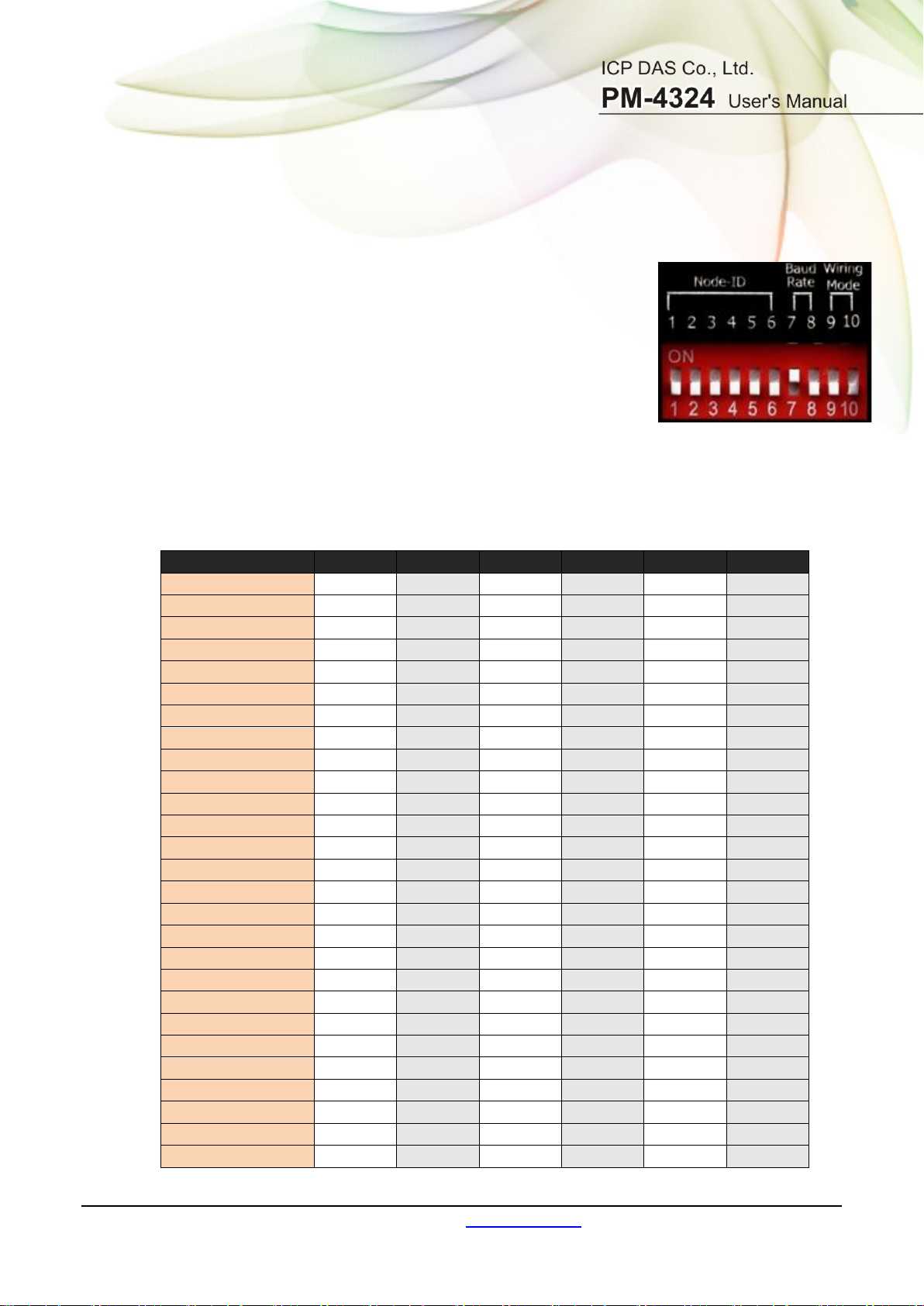

Chapter 6 Modbus-RTU communication

6.1 RS-485 setting

Default setting for RS-485: 19200, n, 8, 1

DIP switch (SW1-SW6) is used for Modbus address setting, default is 1, i.e.

all OFF

For example: Modbus address is 10,find the table of DIP switch 1-6 is

ON, OFF, OFF, ON, OFF, OFF

6.1.1 SW1-SW6 setting

Setting Modbus-RTU address for communication (1-64)

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 19

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

28

ON

ON

OFF

ON

ON

OFF

29

OFF

OFF

ON

ON

ON

OFF

30

ON

OFF

ON

ON

ON

OFF

31

OFF

ON

ON

ON

ON

OFF

32

ON

ON

ON

ON

ON

OFF

33

OFF

OFF

OFF

OFF

OFF

ON

34

ON

OFF

OFF

OFF

OFF

ON

35

OFF

ON

OFF

OFF

OFF

ON

36

ON

ON

OFF

OFF

OFF

ON

37

OFF

OFF

ON

OFF

OFF

ON

38

ON

OFF

ON

OFF

OFF

ON

39

OFF

ON

ON

OFF

OFF

ON

40

ON

ON

ON

OFF

OFF

ON

41

OFF

OFF

OFF

ON

OFF

ON

42

ON

OFF

OFF

ON

OFF

ON

43

OFF

ON

OFF

ON

OFF

ON

44

ON

ON

OFF

ON

OFF

ON

45

OFF

OFF

ON

ON

OFF

ON

46

ON

OFF

ON

ON

OFF

ON

47

OFF

ON

ON

ON

OFF

ON

48

ON

ON

ON

ON

OFF

ON

49

OFF

OFF

OFF

OFF

ON

ON

50

ON

OFF

OFF

OFF

ON

ON

51

OFF

ON

OFF

OFF

ON

ON

52

ON

ON

OFF

OFF

ON

ON

53

OFF

OFF

ON

OFF

ON

ON

54

ON

OFF

ON

OFF

ON

ON

55

OFF

ON

ON

OFF

ON

ON

56

ON

ON

ON

OFF

ON

ON

57

OFF

OFF

OFF

ON

ON

ON

58

ON

OFF

OFF

ON

ON

ON

59

OFF

ON

OFF

ON

ON

ON

60

ON

ON

OFF

ON

ON

ON

61

OFF

OFF

ON

ON

ON

ON

62

ON

OFF

ON

ON

ON

ON

63

OFF

ON

ON

ON

ON

ON

64

ON

ON

ON

ON

ON

ON

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 20

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

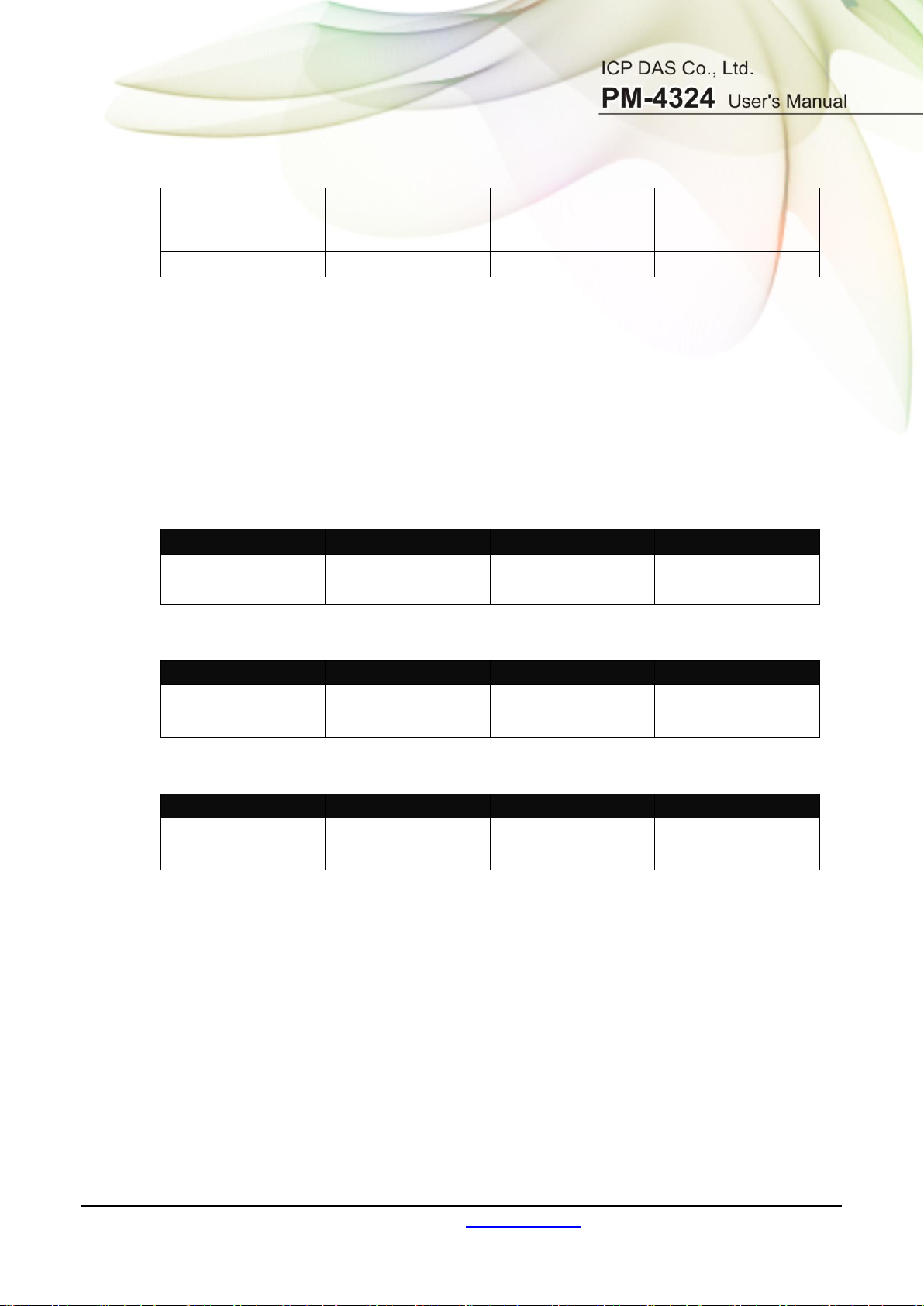

Baud Rate

SW 7

SW8

9600 bps

OFF

OFF

19200 bps (Default)

ON

OFF

38400 bps

OFF

ON

115200 bps

ON

ON

Wiring

SW 9

SW 10

Software setting

OFF

OFF

3P3W-2CT

ON

OFF

3P3W-3CT

OFF

ON

3P4W-3CT

ON

ON

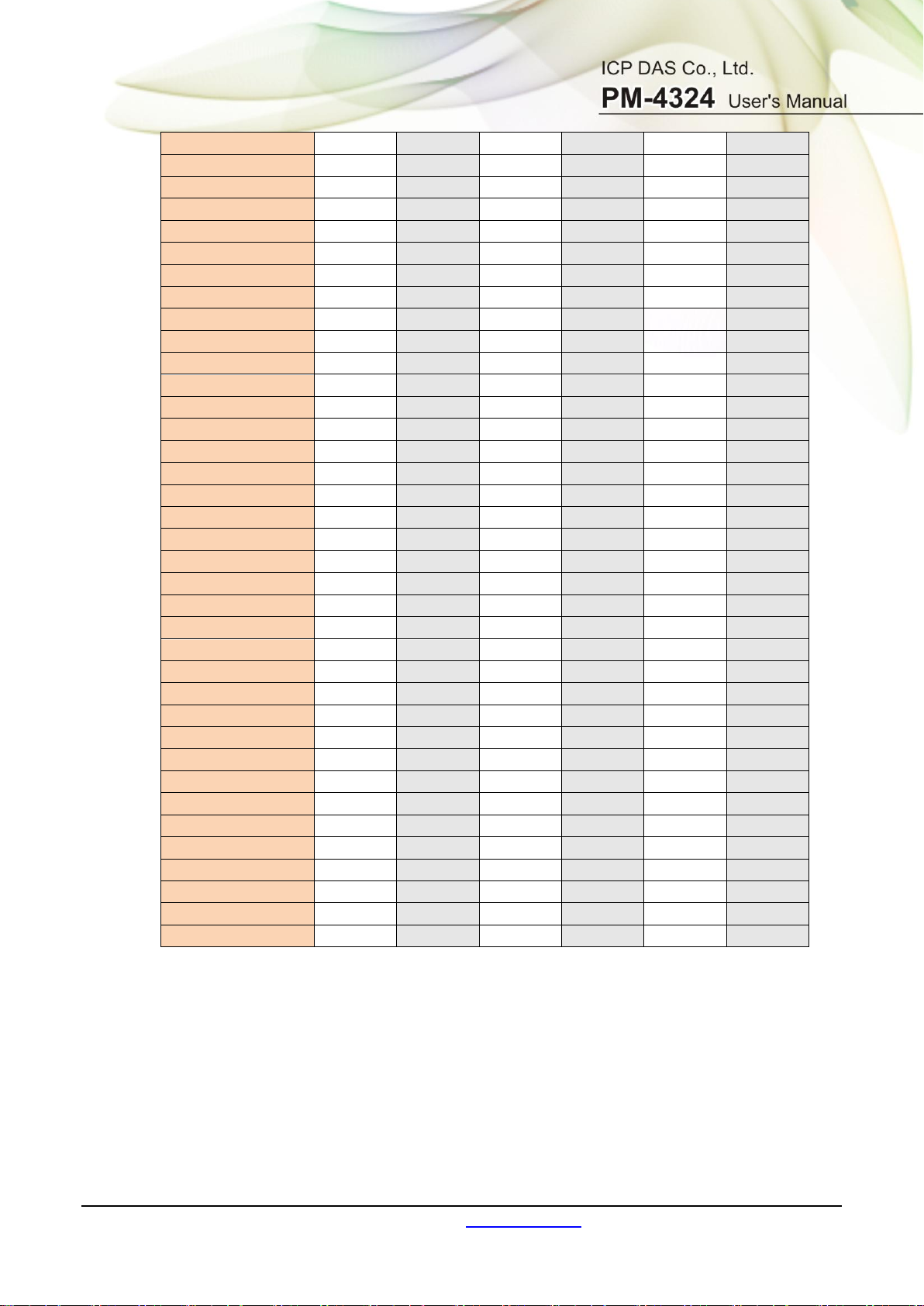

SW7-SW8 setting

PM-4324:For Baud Rate Setting

Add the Bias Resistor on RS-485 Network for stable signal

The RS-485 master is required to provide the bias for PM-4324 series. Otherwise, the tM-SG4

or SG-785 should be added to provide the bias. All ICP DAS controllers and converters provide

the bias.

SW9-SW10 setting

PM-4324:Select the different wiring mode

(Please select the Software setting, if 1P2W-1CT or 1P3W-2CT is used)

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 21

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

Protocol

Modbus-RTU

Transmission

Specifications

Bits per Byte:

1 start bit

8 data bits, least significant bit sent first

None Parity

1 stop bits

Error Check:

Cyclical Redundancy Check (CRC)

Baud Rate

9600, 19200 (Default), 38400, 115200

Modbus slave address

1-64 (Default = 1)

Code

MODBUS_ name

Description

01h

Read Coils

Read boolean values of read/write location

05h

Write Single Coil

Set one boolean value of read/write location

0Fh

Write Multiple Coil

Set boolean values of read/write location

03h

Read Holding Registers

Read the contents of read/write location

06h

Write Single Register

Set the content of one read/write location

10h

Write Multiple Registers

Set the contents of read/write location

04h

Read Input Registers

Read the contents of read only location

6.2 Modbus-RTU setting

6.2.1 Specifications

Modbus Function Code:01h, 03h, 04h, 05h, 06h, 0Fh, 10h

Note: the max. data reading of Function 03 and Function04 is 125 registers

Data format

Integer:16 bits with sign, each with 1 register

Unsigned Integer:16 bits without sign, each with 1 register

Float:IEEE 754 Format ,each with 2 registers,

Low Word is first priority while transmit

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 22

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

Data Hi Word,

Hi Byte

Data Hi Word,

Lo Byte

Data Lo Word,

Hi Byte

Data Lo Word,

Lo Byte

SEEE EEEE

EMMM MMMM

MMMM MMMM

MMMM MMMM

1 2 3

4

Data Low Word,

High Byte

Data Low Word,

Low Byte

Data High Word,

High Byte

Data High Word,

Low Byte

1 2 3

4

Data High Word,

High Byte

Data High Word,

Low Byte

Data Low Word,

High Byte

Data Low Word,

Low Byte

1 2 3

4

Data Low Word,

High Byte

Data Low Word,

Low Byte

Data High Word,

High Byte

Data High Word,

Low Byte

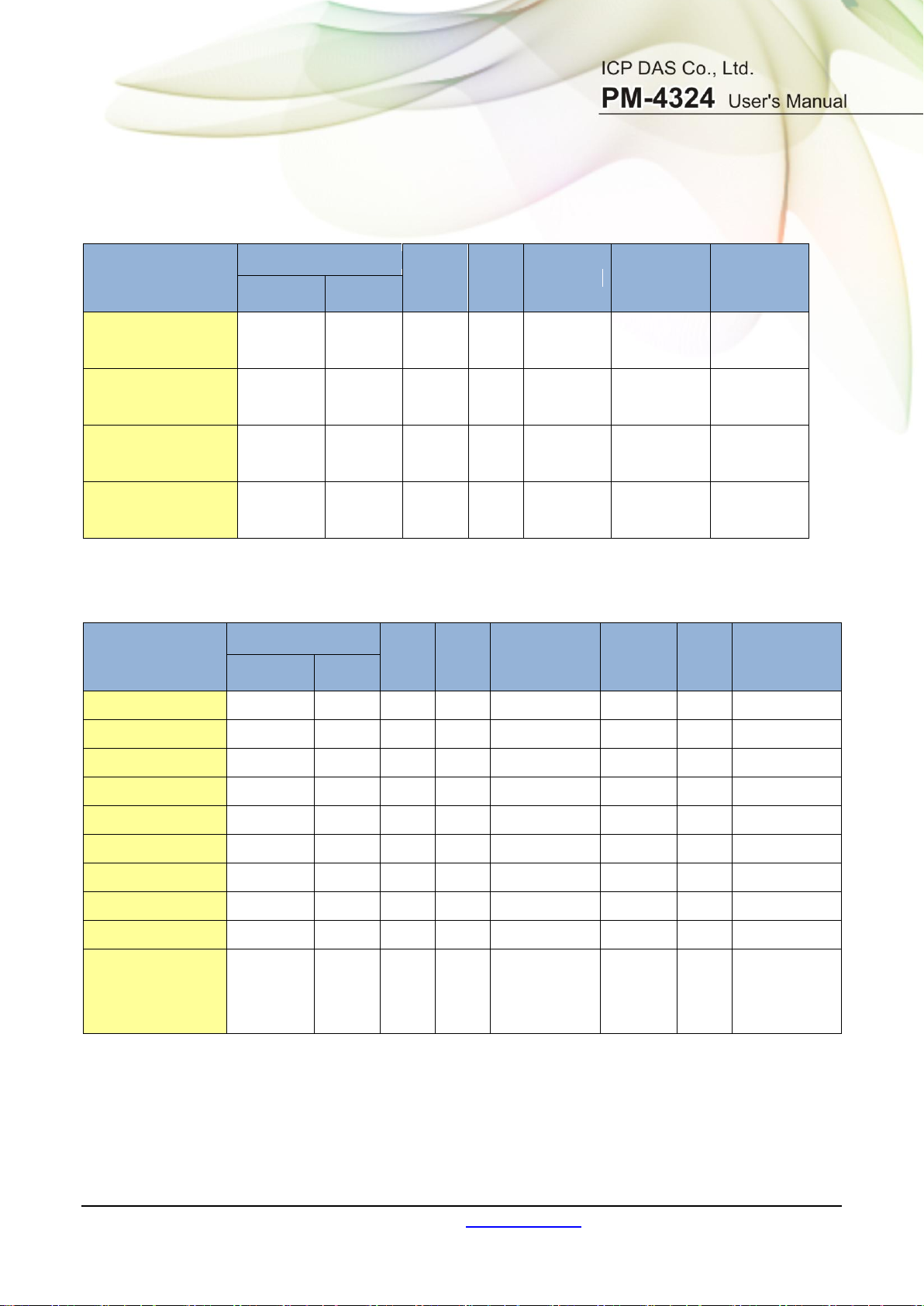

IEEE 754 Format

Definition of the floating format of the Bits

Value = (- 1)S x (1.M) x 2

S represents the sign bit where 1 is negative and 0 is positive

E is the two’s complement exponent with an offset of 127.

i.e. an exponent of zero is represented by 127, an exponent of 1 by 128 etc.

M is the 23-bit normal mantissa. The highest bit is always 1 and,

therefore, is not stored.

Transfer sequence (Float)

E -127

0 < E < 255

Transfer sequence (Inverse Integer)

Transfer sequence (Integer)

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 23

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

Parameter name

Modbus Register

Len

Data

Type

Range

Default

value

Comment

Modicom

Format

Hex

DO 0

04097

0x1000

Word

Byte

0 = OFF

1 = ON

0

DO 1

04098

0x1001

Word

Byte

0 = OFF

1 = ON

0

DO 0

Power On Value

04113

0x1010

Word

Byte

0 = OFF

1 = ON

0

DO 1

Power On Value

04114

0x1011

Word

Byte

0 = OFF

1 = ON

0

Parameter name

Modbus Register

Len

Data

Type

Range

Default

value

Units

Comment

Modicom

Format

Hex

PT_Ratio

44097

0x1000

Word

UInt

1-65535

100

0.01 CT_Ratio_1

44098

0x1001

Word

UInt

1-65535

1

For Submeter1

CT_Ratio_2

44099

0x1002

Word

UInt

1-65535

1

For Submeter2

CT_Ratio_3

44100

0x1003

Word

UInt

1-65535

1

For Submeter3

CT_Ratio_4

44101

0x1004

Word

UInt

1-65535

1

For Submeter4

CT_Ratio_5

44102

0x1005

Word

UInt

1-65535

1

For Submeter5

CT_Ratio_6

44103

0x1006

Word

UInt

1-65535

1

For Submeter6

CT_Ratio_7

44104

0x1007

Word

UInt

1-65535

1

For Submeter7

CT_Ratio_8

44105

0x1008

Word

UInt

1-65535

1

For Submeter8

Default Frequency

44106

0x1009

Word

UInt

0x0055: Auto

0x0064: 50Hz

0x0078: 60Hz

0x0055

Re-power the

module after

setting

6.2.2 Modbus Register

Modbus Module #1 – Coil: Relay Value

Modbus Module #2 – Holding Register : System Parameter Setting

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 24

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

Wiring Mode

44107

0x100A

Word

UInt

1: 1P2W

2: 1P3W

3: 3P3W2CT

4: 3P3W3CT

5: 3P4W3CT

5

Only work when

SW9-SW10 is all

off

Set Energy to Zero

44108

0x100B

Word

UInt

1: submeter1

2: submeter2

3: submeter3

4: submeter4

5: submeter5

6: submeter6

7: submeter7

8: submeter8

0x0055: ALL

Only Write

Reset to Factory

Settings

44109

0x100C

Word

UInt

0x0055

Only Write,

Re-power the

module after

setting

Parity

44110

0x100D

Word

UInt

0: None

1: Odd Parity

2: Even Parity

0

Only work for

RS-485

Interface

Stop Bit

44111

0x100E

Word

UInt

1: 1 stop bit

2: 2 stop bits

1

Only work for

RS-485

Interface

Energy Absolute

Accumulated Mode

44113

0x1010

Word

UInt

0: Enable

1: Disable

0

Harmonic Phase

Select 1

44114

0x1011

Word

UInt

0: Disable

1: Phase A

2: Phase B

3: Phase C

0

For Submeter1

Harmonic Phase

Select 2

44115

0x1012

Word

UInt

0: Disable

1: Phase A

2: Phase B

3: Phase C

0

For Submeter2

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 25

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

Harmonic Phase

Select 3

44116

0x1013

Word

UInt

0: Disable

1: Phase A

2: Phase B

3: Phase C

0

For Submeter3

Harmonic Phase

Select 4

44117

0x1014

Word

UInt

0: Disable

1: Phase A

2: Phase B

3: Phase C

0

For Submeter4

Harmonic Phase

Select 5

44118

0x1015

Word

UInt

0: Disable

1: Phase A

2: Phase B

3: Phase C

0

For Submeter5

Harmonic Phase

Select 6

44119

0x1016

Word

UInt

0: Disable

1: Phase A

2: Phase B

3: Phase C

0

For Submeter6

Harmonic Phase

Select 7

44120

0x1017

Word

UInt

0: Disable

1: Phase A

2: Phase B

3: Phase C

0

For Submeter7

Harmonic Phase

Select 8

44121

0x1018

Word

UInt

0: Disable

1: Phase A

2: Phase B

3: Phase C

0

For Submeter8

Display Voltage

44122

0x1019

Word

UInt

0: Automatic

1: Show as Vln

2: Show as Vll

0

Refer to Q15

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 26

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

Parameter name

Modbus Register

Len

Data

Type

Range

Default

value

Units

Comment

Modicom

Format

Hex

Wiring Type

30513

0x0200

Word

UInt

9: 1P2W

10: 1P3W

11: 3P3W2CT

12: 3P3W3CT

13: 3P4W3CT

14: 3P3W2CT

(HW)

15: 3P3W3CT

(HW)

16: 3P4W3CT

(HW)

13

(HW):set

wiring by

hardware Dip

Switch

Phase Sequence

30514

0x0201

Word

UInt

0: Negative

(ACB)

1: Positive

(ABC)

Only work

when

3P4W3CT

Model Name

30515

0x0202

Word

UInt

4324: PM-4324

4324

Model Type

30516

0x0203

Word

UInt

0x0001: 50Hz

0x0002: 60Hz

0x0002

Firmware Version

30517

0x0204

Word

BCD

0x0100

Ver. 1.0

Modbus Module #3 - Input Register : System Information

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 27

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

Parameter

name

Modbus Register

Len

Data Type

Range

Units

Comment

Modicom Format

Hex

V_a

34353-34354

0x1100-

0x1101

DWord

Float Volt

For CT_1

I_a

34355-

34356

0x1102-

0x1103

DWord

Float Amp

kW_a

34357-

34358

0x1104-

0x1105

DWord

Float kW

kvar_a

34359-

34360

0x1106-

0x1107

DWord

Float kvar

kVA_a

34361-

34362

0x1108-

0x1109

DWord

Float kVA

PF_a

34363-

34364

0x110A-

0x110B

DWord

Float

kWh_a

34365-

34366

0x110C-

0x110D

DWord

Float

kvarh_a

34367-

34368

0x110E-

0x110F

DWord

Float

kVAh_a

34369-

34370

0x1110-

0x1111

DWord

Float

V_b

34371-

34372

0x1112-

0x1113

DWord

Float Volt

For CT_2

I_b

34373-

34374

0x1114-

0x1115

DWord

Float Amp

kW_b

34375-

34376

0x1116-

0x1117

DWord

Float kW

kvar_b

34377-

34378

0x1118-

0x1119

DWord

Float kvar

kVA_b

34379-

34380

0x111A-

0x111B

DWord

Float kVA

PF_b

34381-

34382

0x111C-

0x111D

DWord

Float

kWh_b

34383-

34384

0x111E-

0x111F

DWord

Float

kvarh_b

34385-

34386

0x1120-

0x1121

DWord

Float

kVAh_b

34387-

34388

0x1122-

0x1123

DWord

Float

V_c

34389-34390

0x1124-0x1125

DWord

Float

Volt

For CT_3

I_c

34391-34392

0x1126-0x1127

DWord

Float

Amp

kW_c

34393-34394

0x1128-0x1129

DWord

Float

kW

kvar_c

34395-34396

0x112A-0x112B

DWord

Float

kvar

kVA_c

34397-34398

0x112C-0x112D

DWord

Float

kVA

PF_c

34399-34400

0x112E-0x112F

DWord

Float

kWh_c

34401-34402

0x1130-0x1131

DWord

Float

kvarh_c

34403-34404

0x1132-0x1133

DWord

Float

kVAh_c

34405-34406

0x1134-0x1135

DWord

Float

V_avg

34407-34408

0x1136-0x1137

DWord

Float

Volt

I_avg

34409-34410

0x1138-0x1139

DWord

Float

Amp

kW_tot

34411-34412

0x113A-0x113B

DWord

Float

kW

kvar_tot

34413-34414

0x113C-0x113D

DWord

Float

kvar

kVA_tot

34415-34416

0x113E-0x113F

DWord

Float

kVA

Modbus Module #4 - Input Register :Power value (Float) for Submeter1

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 28

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

PF_tot

34417-34418

0x1140-0x1141

DWord

Float

kWh_tot

34419-34420

0x1142-0x1143

DWord

Float

kvarh_tot

34421-34422

0x1144-0x1145

DWord

Float

kVAh_tot

34423-34424

0x1146-0x1147

DWord

Float

Freq_a

34425-34426

0x1148-0x1149

DWord

Float

45~65

Hz

For CT_1

Freq_b

34427-34428

0x114A-0x114B

DWord

Float

45~65

Hz

For CT_2

Freq_c

34429-34430

0x114C-0x114D

DWord

Float

45~65

Hz

For CT_3

Freq_max

34431-34432

0x114E-0x114F

DWord

Float

45~65

Hz

VTHD

34459-34460

0x116A-0x116B

DWord

Float

0~4

Phase set by

Harmonic Phase

Select 1 Register

ITHD

34461-34462

0x116C-0x116D

DWord

Float

0~4

Bi_Positive

_kWh

34463-34464

0x116E-0x116F

DWord

Float

Bi_Negative

_kWh

34465-34466

0x1170-0x1171

DWord

Float

Bi_Net

_kWh

34467-34468

0x1172-0x1173

DWord

Float

Bi_Total

_kWh

34469-34470

0x1174-0x1175

DWord

Float

Note:

The definition of bi-direction energy registers :

Bi_Positive_kWh: = Sum( absolute( all channel's positive kWh in every sec.))

Bi_Negative_kWh: = Sum( absolute( all channel's negative kWh in every sec.))

Bi_Net_kWh: = Sum( all channel's kWh in every sec. )

Bi_Total_kWh: = Sum( absolute( all channels kWh in every sec. ))

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 29

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

Parameter

name

Modbus Register

Len

Data Type

Range

Units

Comment

Modicom Format

Hex

V_a

34609-34610

0x1200-

0x1201

DWord

Float Volt

For CT_4

I_a

34611-

34612

0x1202-

0x1203

DWord

Float Amp

kW_a

34613-

34614

0x1204-

0x1205

DWord

Float kW

kvar_a

34615-

34616

0x1206-

0x1207

DWord

Float kvar

kVA_a

34617-

34618

0x1208-

0x1209

DWord

Float kVA

PF_a

34619-

34620

0x120A-

0x120B

DWord

Float

kWh_a

34621-

34622

0x120C-

0x120D

DWord

Float

kvarh_a

34623-

34624

0x120E-

0x120F

DWord

Float

kVAh_a

34625-

34626

0x1210-

0x1211

DWord

Float

V_b

34627-

34628

0x1212-

0x1213

DWord

Float Volt

For CT_5

I_b

34629-

34630

0x1214-

0x1215

DWord

Float Amp

kW_b

34631-

34632

0x1216-

0x1217

DWord

Float kW

kvar_b

34633-

34634

0x1218-

0x1219

DWord

Float kvar

kVA_b

34635-

34636

0x121A-

0x121B

DWord

Float kVA

PF_b

34637-

34638

0x121C-

0x121D

DWord

Float

kWh_b

34639-

34640

0x121E-

0x121F

DWord

Float

kvarh_b

34641-

34642

0x1220-

0x1221

DWord

Float

kVAh_b

34643-

34644

0x1222-

0x1223

DWord

Float

V_c

34645-34646

0x1224-0x1225

DWord

Float

Volt

For CT_6

I_c

34647-34648

0x1226-0x1227

DWord

Float

Amp

kW_c

34649-34650

0x1228-0x1229

DWord

Float

kW

kvar_c

34651-34652

0x122A-0x122B

DWord

Float

kvar

kVA_c

34653-34654

0x122C-0x122D

DWord

Float

kVA

PF_c

34655-34656

0x122E-0x122F

DWord

Float

kWh_c

34657-34658

0x1230-0x1231

DWord

Float

kvarh_c

34659-34660

0x1232-0x1233

DWord

Float

kVAh_c

34661-34662

0x1234-0x1235

DWord

Float

V_avg

34663-34664

0x1236-0x1237

DWord

Float

Volt

I_avg

34665-34666

0x1238-0x1239

DWord

Float

Amp

kW_tot

34667-34668

0x123A-0x123B

DWord

Float

kW

kvar_tot

34669-34670

0x123C-0x123D

DWord

Float

kvar

kVA_tot

34671-34672

0x123E-0x123F

DWord

Float

kVA

Modbus Module #5 - Input Register :Power value (Float) for Submeter2

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 30

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

PF_tot

34673-34674

0x1240-0x1241

DWord

Float

kWh_tot

34675-34676

0x1242-0x1243

DWord

Float

kvarh_tot

34677-34678

0x1244-0x1245

DWord

Float

kVAh_tot

34679-34680

0x1246-0x1247

DWord

Float

Freq_a

34681-34682

0x1248-0x1249

DWord

Float

45~65

Hz

For CT_4

Freq_b

34683-34684

0x124A-0x124B

DWord

Float

45~65

Hz

For CT_5

Freq_c

34685-34686

0x124C-0x124D

DWord

Float

45~65

Hz

For CT_6

Freq_max

34687-34688

0x124E-0x124F

DWord

Float

45~65

Hz

VTHD

34715-34716

0x126A-0x126B

DWord

Float

0~4

Phase set by

Harmonic Phase

Select 2 Register

ITHD

34717-34718

0x126C-0x126D

DWord

Float

0~4

Bi_Positive

_kWh

34719-34720

0x126E-0x126F

DWord

Float

Bi_Negative

_kWh

34721-34722

0x1270-0x1271

DWord

Float

Bi_Net

_kWh

34723-34724

0x1272-0x1273

DWord

Float

Bi_Total

_kWh

34725-34726

0x1274-0x1275

DWord

Float

Note:

The definition of bi-direction energy registers :

Bi_Positive_kWh: = Sum( absolute( all channel's positive kWh in every sec.))

Bi_Negative_kWh: = Sum( absolute( all channel's negative kWh in every sec.))

Bi_Net_kWh: = Sum( all channel's kWh in every sec. )

Bi_Total_kWh: = Sum( absolute( all channels kWh in every sec. ))

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 31

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

Parameter

name

Modbus Register

Len

Data Type

Range

Units

Comment

Modicom Format

Hex

V_a

34865-34866

0x1300-

0x1301

DWord

Float Volt

For CT_7

I_a

34867-

34868

0x1302-

0x1303

DWord

Float Amp

kW_a

34869-

34870

0x1304-

0x1305

DWord

Float kW

kvar_a

34871-

34872

0x1306-

0x1307

DWord

Float kvar

kVA_a

34873-

34874

0x1308-

0x1309

DWord

Float kVA

PF_a

34875-

34876

0x130A-

0x130B

DWord

Float

kWh_a

34877-

34878

0x130C-

0x130D

DWord

Float

kvarh_a

34879-

34880

0x130E-

0x130F

DWord

Float

kVAh_a

34881-

34882

0x1310-

0x1311

DWord

Float

V_b

34883-

34884

0x1312-

0x1313

DWord

Float Volt

For CT_8

I_b

34885-

34886

0x1314-

0x1315

DWord

Float Amp

kW_b

34887-

34888

0x1316-

0x1317

DWord

Float kW

kvar_b

34889-

34890

0x1318-

0x1319

DWord

Float kvar

kVA_b

34891-

34892

0x131A-

0x131B

DWord

Float kVA

PF_b

34893-

34894

0x131C-

0x131D

DWord

Float

kWh_b

34895-

34896

0x131E-

0x131F

DWord

Float

kvarh_b

34897-

34898

0x1320-

0x1321

DWord

Float

kVAh_b

34899-

34900

0x1322-

0x1323

DWord

Float

V_c

34901-34902

0x1324-0x1325

DWord

Float

Volt

For CT_9

I_c

34903-34904

0x1326-0x1327

DWord

Float

Amp

kW_c

34905-34906

0x1328-0x1329

DWord

Float

kW

kvar_c

34907-34908

0x132A-0x132B

DWord

Float

kvar

kVA_c

34909-34910

0x132C-0x132D

DWord

Float

kVA

PF_c

34911-34912

0x132E-0x132F

DWord

Float

kWh_c

34913-34914

0x1330-0x1331

DWord

Float

kvarh_c

34915-34916

0x1332-0x1333

DWord

Float

kVAh_c

34917-34918

0x1334-0x1335

DWord

Float

V_avg

34919-34920

0x1336-0x1337

DWord

Float

Volt

I_avg

34921-34922

0x1338-0x1339

DWord

Float

Amp

kW_tot

34923-34924

0x133A-0x133B

DWord

Float

kW

kvar_tot

34925-34926

0x133C-0x133D

DWord

Float

kvar

kVA_tot

34927-34928

0x133E-0x133F

DWord

Float

kVA

Modbus Module #6 - Input Register :Power value (Float) for Submeter3

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 32

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

PF_tot

34929-34930

0x1340-0x1341

DWord

Float

kWh_tot

34931-34932

0x1342-0x1343

DWord

Float

kvarh_tot

34933-34934

0x1344-0x1345

DWord

Float

kVAh_tot

34935-34936

0x1346-0x1347

DWord

Float

Freq_a

34937-34938

0x1348-0x1349

DWord

Float

45~65

Hz

For CT_7

Freq_b

34939-34940

0x134A-0x134B

DWord

Float

45~65

Hz

For CT_8

Freq_c

34941-34942

0x134C-0x134D

DWord

Float

45~65

Hz

For CT_9

Freq_max

34943-34944

0x134E-0x134F

DWord

Float

45~65

Hz

VTHD

34971-34972

0x136A-0x136B

DWord

Float

0~4

Phase set by

Harmonic Phase

Select 3 Register

ITHD

34973-34974

0x136C-0x136D

DWord

Float

0~4

Bi_Positive

_kWh

34975-34976

0x136E-0x136F

DWord

Float

Bi_Negative

_kWh

34977-34978

0x1370-0x1371

DWord

Float

Bi_Net

_kWh

34979-34980

0x1372-0x1373

DWord

Float

Bi_Total

_kWh

34981-34982

0x1374-0x1375

DWord

Float

Note:

The definition of bi-direction energy registers :

Bi_Positive_kWh: = Sum( absolute( all channel's positive kWh in every sec.))

Bi_Negative_kWh: = Sum( absolute( all channel's negative kWh in every sec.))

Bi_Net_kWh: = Sum( all channel's kWh in every sec. )

Bi_Total_kWh: = Sum( absolute( all channels kWh in every sec. ))

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 33

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

Parameter

name

Modbus Register

Len

Data Type

Range

Units

Comment

Modicom Format

Hex

V_a

35121-35122

0x1400-

0x1401

DWord

Float Volt

For CT_10

I_a

35123-35124

0x1402-

0x1403

DWord

Float Amp

kW_a

35125-35126

0x1404-

0x1405

DWord

Float kW

kvar_a

35127-35128

0x1406-

0x1407

DWord

Float kvar

kVA_a

35129-35130

0x1408-

0x1409

DWord

Float kVA

PF_a

35131-35132

0x140A-

0x140B

DWord

Float

kWh_a

35133-35134

0x140C-

0x140D

DWord

Float

kvarh_a

35135-35136

0x140E-

0x140F

DWord

Float

kVAh_a

35137-35138

0x1410-

0x1411

DWord

Float

V_b

35139-35140

0x1412-

0x1413

DWord

Float Volt

For CT_11

I_b

35141-35142

0x1414-

0x1415

DWord

Float Amp

kW_b

35143-35144

0x1416-

0x1417

DWord

Float kW

kvar_b

35145-35146

0x1418-

0x1419

DWord

Float kvar

kVA_b

35147-35148

0x141A-

0x141B

DWord

Float kVA

PF_b

35149-35150

0x141C-

0x141D

DWord

Float

kWh_b

35151-35152

0x141E-

0x141F

DWord

Float

kvarh_b

35153-35154

0x1420-

0x1421

DWord

Float

kVAh_b

35155-35156

0x1422-

0x1423

DWord

Float

V_c

35157-35158

0x1424-0x1425

DWord

Float

Volt

For CT_12

I_c

35159-35160

0x1426-0x1427

DWord

Float

Amp

kW_c

35161-35162

0x1428-0x1429

DWord

Float

kW

kvar_c

35163-35164

0x142A-0x142B

DWord

Float

kvar

kVA_c

35165-35166

0x142C-0x142D

DWord

Float

kVA

PF_c

35167-35168

0x142E-0x142F

DWord

Float

kWh_c

35169-35170

0x1430-0x1431

DWord

Float

kvarh_c

35171-35172

0x1432-0x1433

DWord

Float

kVAh_c

35173-35174

0x1434-0x1435

DWord

Float

V_avg

35175-35176

0x1436-0x1437

DWord

Float

Volt

I_avg

35177-35178

0x1438-0x1439

DWord

Float

Amp

kW_tot

35179-35180

0x143A-0x143B

DWord

Float

kW

kvar_tot

35181-35182

0x143C-0x143D

DWord

Float

kvar

kVA_tot

35183-35184

0x143E-0x143F

DWord

Float

kVA

Modbus Module #7 - Input Register :Power value (Float) for Submeter4

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 34

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

PF_tot

35185-35186

0x1440-0x1441

DWord

Float

kWh_tot

35187-35188

0x1442-0x1443

DWord

Float

kvarh_tot

35189-35190

0x1444-0x1445

DWord

Float

kVAh_tot

35191-35192

0x1446-0x1447

DWord

Float

Freq_a

35193-35194

0x1448-0x1449

DWord

Float

45~65

Hz

For CT_10

Freq_b

35195-35196

0x144A-0x144B

DWord

Float

45~65

Hz

For CT_11

Freq_c

35197-35198

0x144C-0x144D

DWord

Float

45~65

Hz

For CT_12

Freq_max

35199-35200

0x144E-0x144F

DWord

Float

45~65

Hz

VTHD

35227-35228

0x146A-0x146B

DWord

Float

0~4

Phase set by

Harmonic Phase

Select 4 Register

ITHD

35229-35230

0x146C-0x146D

DWord

Float

0~4

Bi_Positive

_kWh

35231-35232

0x146E-0x146F

DWord

Float

Bi_Negative

_kWh

35233-35234

0x1470-0x1471

DWord

Float

Bi_Net

_kWh

35235-35236

0x1472-0x1473

DWord

Float

Bi_Total

_kWh

35237-35238

0x1474-0x1475

DWord

Float

Note:

The definition of bi-direction energy registers :

Bi_Positive_kWh: = Sum( absolute( all channel's positive kWh in every sec.))

Bi_Negative_kWh: = Sum( absolute( all channel's negative kWh in every sec.))

Bi_Net_kWh: = Sum( all channel's kWh in every sec. )

Bi_Total_kWh: = Sum( absolute( all channels kWh in every sec. ))

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 35

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

Parameter

name

Modbus Register

Len

Data Type

Range

Units

Comment

Modicom Format

Hex

V_a

35377-35378

0x1500-

0x1501

DWord

Float Volt

For CT_13

I_a

35379-35380

0x1502-

0x1503

DWord

Float Amp

kW_a

35381-35382

0x1504-

0x1505

DWord

Float kW

kvar_a

35383-35384

0x1506-

0x1507

DWord

Float kvar

kVA_a

35385-35386

0x1508-

0x1509

DWord

Float kVA

PF_a

35387-35388

0x150A-

0x150B

DWord

Float

kWh_a

35389-35390

0x150C-

0x150D

DWord

Float

kvarh_a

35391-35392

0x150E-

0x150F

DWord

Float

kVAh_a

35393-35394

0x1510-

0x1511

DWord

Float

V_b

35395-35396

0x1512-

0x1513

DWord

Float Volt

For CT_14

I_b

35397-35398

0x1514-

0x1515

DWord

Float Amp

kW_b

35399-35400

0x1516-

0x1517

DWord

Float kW

kvar_b

35401-35402

0x1518-

0x1519

DWord

Float kvar

kVA_b

35403-35404

0x151A-

0x151B

DWord

Float kVA

PF_b

35405-35406

0x151C-

0x151D

DWord

Float

kWh_b

35407-35408

0x151E-

0x151F

DWord

Float

kvarh_b

35409-35410

0x1520-

0x1521

DWord

Float

kVAh_b

35411-35412

0x1522-

0x1523

DWord

Float

V_c

35413-35414

0x1524-0x1525

DWord

Float

Volt

For CT_15

I_c

35415-35416

0x1526-0x1527

DWord

Float

Amp

kW_c

35417-35418

0x1528-0x1529

DWord

Float

kW

kvar_c

35419-35420

0x152A-0x152B

DWord

Float

kvar

kVA_c

35421-35422

0x152C-0x152D

DWord

Float

kVA

PF_c

35423-35424

0x152E-0x152F

DWord

Float

kWh_c

35425-35426

0x1530-0x1531

DWord

Float

kvarh_c

35427-35428

0x1532-0x1533

DWord

Float

kVAh_c

35429-35430

0x1534-0x1535

DWord

Float

V_avg

35431-35432

0x1536-0x1537

DWord

Float

Volt

I_avg

35433-35434

0x1538-0x1539

DWord

Float

Amp

kW_tot

35435-35436

0x153A-0x153B

DWord

Float

kW

kvar_tot

35437-35438

0x153C-0x153D

DWord

Float

kvar

kVA_tot

35439-35440

0x153E-0x153F

DWord

Float

kVA

Modbus Module #8 - Input Register :Power value (Float) for Submeter5

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 36

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

PF_tot

35441-35442

0x1540-0x1541

DWord

Float

kWh_tot

35443-35444

0x1542-0x1543

DWord

Float

kvarh_tot

35445-35446

0x1544-0x1545

DWord

Float

kVAh_tot

35447-35448

0x1546-0x1547

DWord

Float

Freq_a

35449-35450

0x1548-0x1549

DWord

Float

45~65

Hz

For CT_13

Freq_b

35451-35452

0x154A-0x154B

DWord

Float

45~65

Hz

For CT_14

Freq_c

35453-35454

0x154C-0x154D

DWord

Float

45~65

Hz

For CT_15

Freq_max

35455-35456

0x154E-0x154F

DWord

Float

45~65

Hz

VTHD

35483-35484

0x156A-0x156B

DWord

Float

0~4

Phase set by

Harmonic Phase

Select 5 Register

ITHD

35485-35486

0x156C-0x156D

DWord

Float

0~4

Bi_Positive

_kWh

35487-35488

0x156E-0x156F

DWord

Float

Bi_Negative

_kWh

35489-35490

0x1570-0x1571

DWord

Float

Bi_Net

_kWh

35491-35492

0x1572-0x1573

DWord

Float

Bi_Total

_kWh

35493-35494

0x1574-0x1575

DWord

Float

Note:

The definition of bi-direction energy registers :

Bi_Positive_kWh: = Sum( absolute( all channel's positive kWh in every sec.))

Bi_Negative_kWh: = Sum( absolute( all channel's negative kWh in every sec.))

Bi_Net_kWh: = Sum( all channel's kWh in every sec. )

Bi_Total_kWh: = Sum( absolute( all channels kWh in every sec. ))

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 37

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

Parameter

name

Modbus Register

Len

Data Type

Range

Units

Comment

Modicom Format

Hex

V_a

35633-35634

0x1600-

0x1601

DWord

Float Volt

For CT_16

I_a

35635-35636

0x1602-

0x1603

DWord

Float Amp

kW_a

35637-35638

0x1604-

0x1605

DWord

Float kW

kvar_a

35639-35640

0x1606-

0x1607

DWord

Float kvar

kVA_a

35641-35642

0x1608-

0x1609

DWord

Float kVA

PF_a

35643-35644

0x160A-

0x160B

DWord

Float

kWh_a

35645-35646

0x160C-

0x160D

DWord

Float

kvarh_a

35647-35648

0x160E-

0x160F

DWord

Float

kVAh_a

35649-35650

0x1610-

0x1611

DWord

Float

V_b

35651-35652

0x1612-

0x1613

DWord

Float Volt

For CT_17

I_b

35653-35654

0x1614-

0x1615

DWord

Float Amp

kW_b

35655-35656

0x1616-

0x1617

DWord

Float kW

kvar_b

35657-35658

0x1618-

0x1619

DWord

Float kvar

kVA_b

35659-35660

0x161A-

0x161B

DWord

Float kVA

PF_b

35661-35662

0x161C-

0x161D

DWord

Float

kWh_b

35663-35664

0x161E-

0x161F

DWord

Float

kvarh_b

35665-35666

0x1620-

0x1621

DWord

Float

kVAh_b

35667-35668

0x1622-

0x1623

DWord

Float

V_c

35669-35670

0x1624-0x1625

DWord

Float

Volt

For CT_18

I_c

35671-35672

0x1626-0x1627

DWord

Float

Amp

kW_c

35673-35674

0x1628-0x1629

DWord

Float

kW

kvar_c

35675-35676

0x162A-0x162B

DWord

Float

kvar

kVA_c

35677-35678

0x162C-0x162D

DWord

Float

kVA

PF_c

35679-35680

0x162E-0x162F

DWord

Float

kWh_c

35681-35682

0x1630-0x1631

DWord

Float

kvarh_c

35683-35684

0x1632-0x1633

DWord

Float

kVAh_c

35685-35686

0x1634-0x1635

DWord

Float

V_avg

35687-35688

0x1636-0x1637

DWord

Float

Volt

I_avg

35689-35690

0x1638-0x1639

DWord

Float

Amp

kW_tot

35691-35692

0x163A-0x163B

DWord

Float

kW

kvar_tot

35693-35694

0x163C-0x163D

DWord

Float

kvar

kVA_tot

35695-35696

0x163E-0x163F

DWord

Float

kVA

Modbus Module #9 - Input Register :Power value (Float) for Submeter6

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 38

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

PF_tot

35697-35698

0x1640-0x1641

DWord

Float

kWh_tot

35699-35700

0x1642-0x1643

DWord

Float

kvarh_tot

35701-35702

0x1644-0x1645

DWord

Float

kVAh_tot

35703-35704

0x1646-0x1647

DWord

Float

Freq_a

35705-35706

0x1648-0x1649

DWord

Float

45~65

Hz

For CT_16

Freq_b

35707-35708

0x164A-0x164B

DWord

Float

45~65

Hz

For CT_17

Freq_c

35709-35710

0x164C-0x164D

DWord

Float

45~65

Hz

For CT_18

Freq_max

35711-35712

0x164E-0x164F

DWord

Float

45~65

Hz

VTHD

35739-35740

0x166A-0x166B

DWord

Float

0~4

Phase set by

Harmonic Phase

Select 6 Register

ITHD

35741-35742

0x166C-0x166D

DWord

Float

0~4

Bi_Positive

_kWh

35743-35744

0x166E-0x166F

DWord

Float

Bi_Negative

_kWh

35745-35746

0x1670-0x1671

DWord

Float

Bi_Net

_kWh

35747-35748

0x1672-0x1673

DWord

Float

Bi_Total

_kWh

35749-35750

0x1674-0x1675

DWord

Float

Note:

The definition of bi-direction energy registers :

Bi_Positive_kWh: = Sum( absolute( all channel's positive kWh in every sec.))

Bi_Negative_kWh: = Sum( absolute( all channel's negative kWh in every sec.))

Bi_Net_kWh: = Sum( all channel's kWh in every sec. )

Bi_Total_kWh: = Sum( absolute( all channels kWh in every sec. ))

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 39

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

Parameter

name

Modbus Register

Len

Data Type

Range

Units

Comment

Modicom Format

Hex

V_a

35889-35890

0x1700-

0x1701

DWord

Float Volt

For CT_19

I_a

35891-35892

0x1702-

0x1703

DWord

Float Amp

kW_a

35893-35894

0x1704-

0x1705

DWord

Float kW

kvar_a

35895-35896

0x1706-

0x1707

DWord

Float kvar

kVA_a

35897-35898

0x1708-

0x1709

DWord

Float kVA

PF_a

35899-35900

0x170A-

0x170B

DWord

Float

kWh_a

35901-35902

0x170C-

0x170D

DWord

Float

kvarh_a

35903-35904

0x170E-

0x170F

DWord

Float

kVAh_a

35905-35906

0x1710-

0x1711

DWord

Float

V_b

35907-35908

0x1712-

0x1713

DWord

Float Volt

For CT_20

I_b

35909-35910

0x1714-

0x1715

DWord

Float Amp

kW_b

35911-35912

0x1716-

0x1717

DWord

Float kW

kvar_b

35913-35914

0x1718-

0x1719

DWord

Float kvar

kVA_b

35915-35916

0x171A-

0x171B

DWord

Float kVA

PF_b

35917-35918

0x171C-

0x171D

DWord

Float

kWh_b

35919-35920

0x171E-

0x171F

DWord

Float

kvarh_b

35921-35922

0x1720-

0x1721

DWord

Float

kVAh_b

35923-35924

0x1722-

0x1723

DWord

Float

V_c

35925-35926

0x1724-0x1725

DWord

Float

Volt

For CT_21

I_c

35927-35928

0x1726-0x1727

DWord

Float

Amp

kW_c

35929-35930

0x1728-0x1729

DWord

Float

kW

kvar_c

35931-35932

0x172A-0x172B

DWord

Float

kvar

kVA_c

35933-35934

0x172C-0x172D

DWord

Float

kVA

PF_c

35935-35936

0x172E-0x172F

DWord

Float

kWh_c

35937-35938

0x1730-0x1731

DWord

Float

kvarh_c

35939-35940

0x1732-0x1733

DWord

Float

kVAh_c

35941-35942

0x1734-0x1735

DWord

Float

V_avg

35943-35944

0x1736-0x1737

DWord

Float

Volt

I_avg

35945-35946

0x1738-0x1739

DWord

Float

Amp

kW_tot

35947-35948

0x173A-0x173B

DWord

Float

kW

kvar_tot

35949-35950

0x173C-0x173D

DWord

Float

kvar

kVA_tot

35951-35952

0x173E-0x173F

DWord

Float

kVA

Modbus Module #10 - Input Register :Power value (Float) for Submeter7

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 40

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

PF_tot

35953-35954

0x1740-0x1741

DWord

Float

kWh_tot

35955-35956

0x1742-0x1743

DWord

Float

kvarh_tot

35957-35958

0x1744-0x1745

DWord

Float

kVAh_tot

35959-35960

0x1746-0x1747

DWord

Float

Freq_a

35961-35962

0x1748-0x1749

DWord

Float

45~65

Hz

For CT_19

Freq_b

35963-35964

0x174A-0x174B

DWord

Float

45~65

Hz

For CT_20

Freq_c

35965-35966

0x174C-0x174D

DWord

Float

45~65

Hz

For CT_21

Freq_max

35967-35968

0x174E-0x174F

DWord

Float

45~65

Hz

VTHD

35995-35996

0x176A-0x176B

DWord

Float

0~4

Phase set by

Harmonic Phase

Select 7 Register

ITHD

35997-35998

0x176C-0x176D

DWord

Float

0~4

Bi_Positive

_kWh

35999-36000

0x176E-0x176F

DWord

Float

Bi_Negative

_kWh

36001-36002

0x1770-0x1771

DWord

Float

Bi_Net

_kWh

36003-36004

0x1772-0x1773

DWord

Float

Bi_Total

_kWh

36005-36006

0x1774-0x1775

DWord

Float

Note:

The definition of bi-direction energy registers :

Bi_Positive_kWh: = Sum( absolute( all channel's positive kWh in every sec.))

Bi_Negative_kWh: = Sum( absolute( all channel's negative kWh in every sec.))

Bi_Net_kWh: = Sum( all channel's kWh in every sec. )

Bi_Total_kWh: = Sum( absolute( all channels kWh in every sec. ))

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 41

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

Parameter

name

Modbus Register

Len

Data Type

Range

Units

Comment

Modicom Format

Hex

V_a

36145-36146

0x1800-

0x1801

DWord

Float Volt

For CT_22

I_a

36147-36148

0x1802-

0x1803

DWord

Float Amp

kW_a

36149-36150

0x1804-

0x1805

DWord

Float kW

kvar_a

36151-36152

0x1806-

0x1807

DWord

Float kvar

kVA_a

36153-36154

0x1808-

0x1809

DWord

Float kVA

PF_a

36155-36156

0x180A-

0x180B

DWord

Float

kWh_a

36157-36158

0x180C-

0x180D

DWord

Float

kvarh_a

36159-36160

0x180E-

0x180F

DWord

Float

kVAh_a

36161-36162

0x1810-

0x1811

DWord

Float

V_b

36163-36164

0x1812-

0x1813

DWord

Float Volt

For CT_23

I_b

36165-36166

0x1814-

0x1815

DWord

Float Amp

kW_b

36167-36168

0x1816-

0x1817

DWord

Float kW

kvar_b

36169-36170

0x1818-

0x1819

DWord

Float kvar

kVA_b

36171-36172

0x181A-

0x181B

DWord

Float kVA

PF_b

36173-36174

0x181C-

0x181D

DWord

Float

kWh_b

36175-36176

0x181E-

0x181F

DWord

Float

kvarh_b

36177-36178

0x1820-

0x1821

DWord

Float

kVAh_b

36179-36180

0x1822-

0x1823

DWord

Float

V_c

36181-36182

0x1824-0x1825

DWord

Float

Volt

For CT_24

I_c

36183-36184

0x1826-0x1827

DWord

Float

Amp

kW_c

36185-36186

0x1828-0x1829

DWord

Float

kW

kvar_c

36187-36188

0x182A-0x182B

DWord

Float

kvar

kVA_c

36189-36190

0x182C-0x182D

DWord

Float

kVA

PF_c

36191-36192

0x182E-0x182F

DWord

Float

kWh_c

36193-36194

0x1830-0x1831

DWord

Float

kvarh_c

36195-36196

0x1832-0x1833

DWord

Float

kVAh_c

36197-36198

0x1834-0x1835

DWord

Float

V_avg

36199-36200

0x1836-0x1837

DWord

Float

Volt

I_avg

36201-36202

0x1838-0x1839

DWord

Float

Amp

kW_tot

36203-36204

0x183A-0x183B

DWord

Float

kW

kvar_tot

36205-36206

0x183C-0x183D

DWord

Float

kvar

kVA_tot

36207-36208

0x183E-0x183F

DWord

Float

kVA

Modbus Module #11 - Input Register :Power value (Float) for Submeter8

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 42

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

PF_tot

36209-36210

0x1840-0x1841

DWord

Float

kWh_tot

36211-36212

0x1842-0x1843

DWord

Float

kvarh_tot

36213-36214

0x1844-0x1845

DWord

Float

kVAh_tot

36215-36216

0x1846-0x1847

DWord

Float

Freq_a

36217-36218

0x1848-0x1849

DWord

Float

45~65

Hz

For CT_22

Freq_b

36219-36220

0x184A-0x184B

DWord

Float

45~65

Hz

For CT_23

Freq_c

36221-36222

0x184C-0x184D

DWord

Float

45~65

Hz

For CT_24

Freq_max

36223-36224

0x184E-0x184F

DWord

Float

45~65

Hz

VTHD

36251-36252

0x186A-0x186B

DWord

Float

0~4

Phase set by

Harmonic Phase

Select 8 Register

ITHD

36253-36254

0x186C-0x186D

DWord

Float

0~4

Bi_Positive

_kWh

36255-36256

0x186E-0x186F

DWord

Float

Bi_Negative

_kWh

36257-36258

0x1870-0x1871

DWord

Float

Bi_Net

_kWh

36259-36260

0x1872-0x1873

DWord

Float

Bi_Total

_kWh

36261-36262

0x1874-0x1875

DWord

Float

Note:

The definition of bi-direction energy registers :

Bi_Positive_kWh: = Sum( absolute( all channel's positive kWh in every sec.))

Bi_Negative_kWh: = Sum( absolute( all channel's negative kWh in every sec.))

Bi_Net_kWh: = Sum( all channel's kWh in every sec. )

Bi_Total_kWh: = Sum( absolute( all channels kWh in every sec. ))

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 43

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

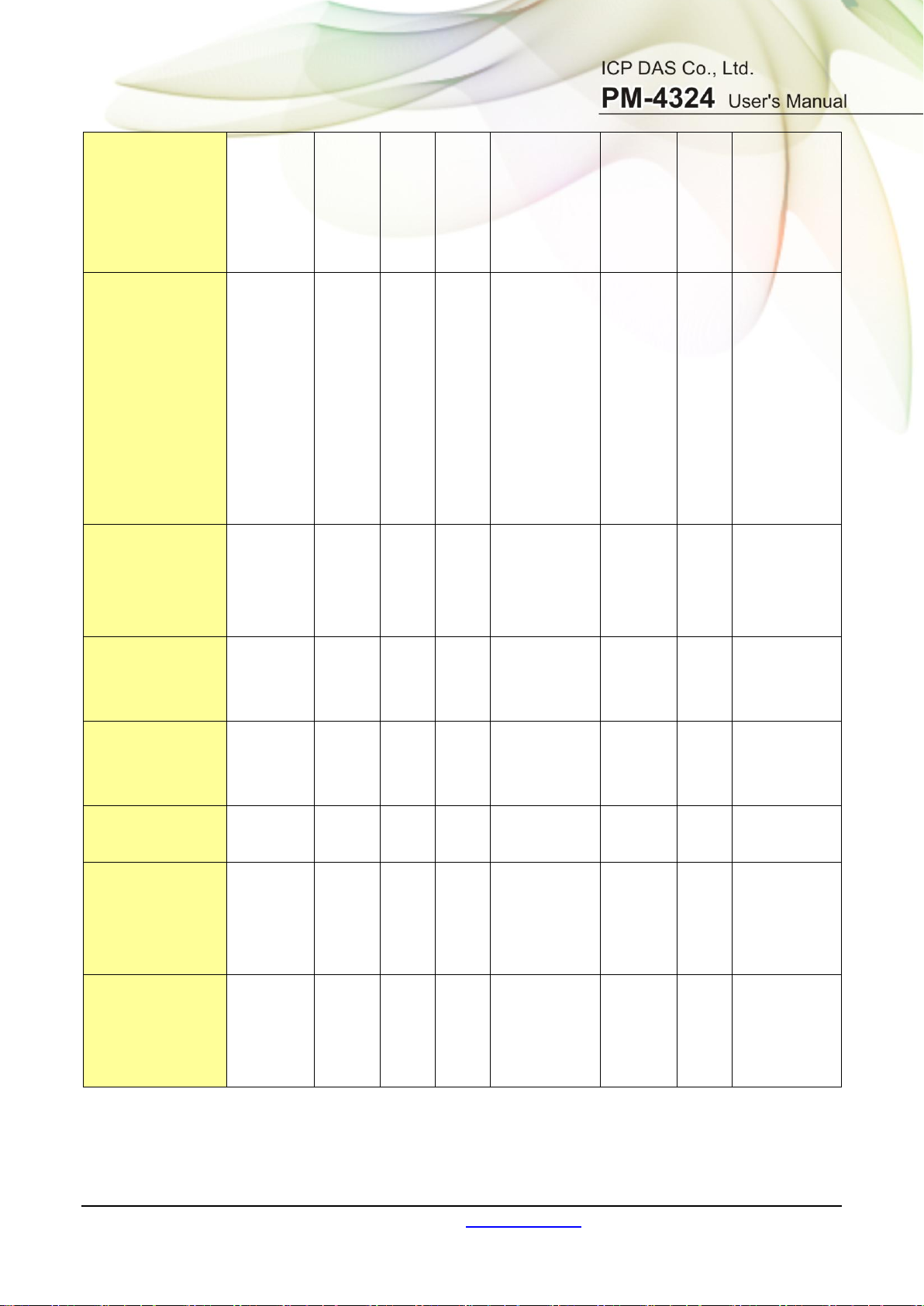

Modbus Address

SW 1

SW 2

SW 3

SW 4

SW 5

SW 6

1

OFF

OFF

OFF

OFF

OFF

OFF

2

ON

OFF

OFF

OFF

OFF

OFF

3

OFF

ON

OFF

OFF

OFF

OFF

4

ON

ON

OFF

OFF

OFF

OFF

5

OFF

OFF

ON

OFF

OFF

OFF

6

ON

OFF

ON

OFF

OFF

OFF

7

OFF

ON

ON

OFF

OFF

OFF

8

ON

ON

ON

OFF

OFF

OFF

9

OFF

OFF

OFF

ON

OFF

OFF

10

ON

OFF

OFF

ON

OFF

OFF

11

OFF

ON

OFF

ON

OFF

OFF

12

ON

ON

OFF

ON

OFF

OFF

13

OFF

OFF

ON

ON

OFF

OFF

14

ON

OFF

ON

ON

OFF

OFF

15

OFF

ON

ON

ON

OFF

OFF

16

ON

ON

ON

ON

OFF

OFF

17

OFF

OFF

OFF

OFF

ON

OFF

18

ON

OFF

OFF

OFF

ON

OFF

19

OFF

ON

OFF

OFF

ON

OFF

20

ON

ON

OFF

OFF

ON

OFF

21

OFF

OFF

ON

OFF

ON

OFF

22

ON

OFF

ON

OFF

ON

OFF

23

OFF

ON

ON

OFF

ON

OFF

24

ON

ON

ON

OFF

ON

OFF

25

OFF

OFF

OFF

ON

ON

OFF

26

ON

OFF

OFF

ON

ON

OFF

27

OFF

ON

OFF

ON

ON

OFF

28

ON

ON

OFF

ON

ON

OFF

29

OFF

OFF

ON

ON

ON

OFF

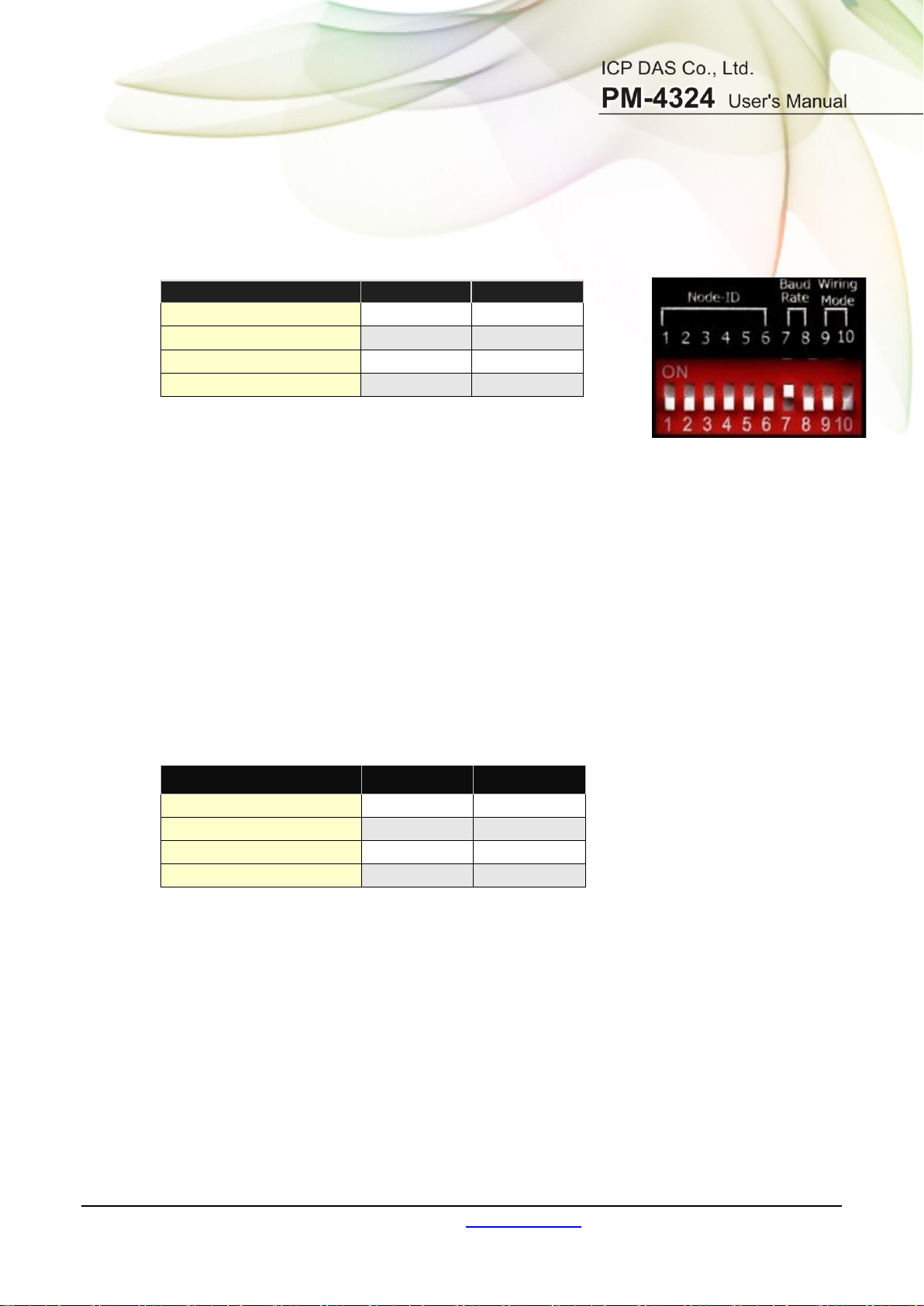

Chapter 7 CANopen communication

7.1 CANopen setting

Default setting for CANopen: Baud rate:125 K b.p.s. , Node ID:1

DIP switch (SW1-SW6) is used for Node ID setting, default is 1, i.e. all OFF

For example: Node ID is 10,find the table of DIP switch 1-6 is

ON, OFF, OFF, ON, OFF, OFF

SW1-SW6 setting

Setting CANopen Node ID for communication (1-64)

PM-4324 User’s Manual v1.03 Last Revised: Feb. 2021 Page: 44

Copyright © ICP DAS Co., Ltd. All Rights Reserved. www.icpdas.com E-mail: service@icpdas.com

30

ON

OFF

ON

ON

ON

OFF

31

OFF

ON

ON

ON

ON

OFF

32

ON

ON

ON

ON

ON

OFF

33

OFF

OFF

OFF

OFF

OFF

ON

34

ON

OFF

OFF

OFF

OFF

ON

35

OFF

ON

OFF

OFF

OFF

ON

36

ON

ON

OFF

OFF

OFF

ON

37

OFF

OFF

ON

OFF

OFF

ON

38

ON

OFF

ON

OFF

OFF

ON

39

OFF

ON

ON

OFF

OFF

ON

40

ON

ON

ON

OFF

OFF

ON

41

OFF

OFF

OFF

ON

OFF

ON

42

ON

OFF

OFF

ON

OFF

ON

43

OFF

ON

OFF

ON

OFF

ON

44

ON

ON

OFF

ON

OFF

ON

45

OFF

OFF

ON

ON

OFF

ON

46

ON

OFF

ON

ON

OFF

ON

47

OFF

ON

ON

ON

OFF

ON

48

ON

ON

ON

ON

OFF

ON

49

OFF

OFF

OFF

OFF

ON

ON

50

ON

OFF

OFF

OFF

ON

ON

51

OFF

ON

OFF

OFF

ON

ON

52

ON

ON

OFF

OFF

ON

ON

53

OFF

OFF

ON

OFF

ON

ON

54

ON

OFF

ON

OFF

ON

ON

55

OFF

ON

ON

OFF

ON

ON

56

ON

ON

ON

OFF

ON

ON

57

OFF

OFF

OFF

ON

ON

ON

58

ON

OFF

OFF

ON

ON

ON

59

OFF

ON

OFF

ON

ON

ON

60

ON

ON

OFF

ON

ON

ON

61

OFF

OFF

ON