Page 1

TM

Managed Switch User Manual

Industrial Managed Ethernet Switch

Version 1.2

This document applied to models of

MSM-508,MSM-508FC/FCS/FT

April 29, 2008

Please print in double side

TDRS4050601

Page 2

Industrial Ethernet Layer 2 Managed Switch User Manual

Document Control

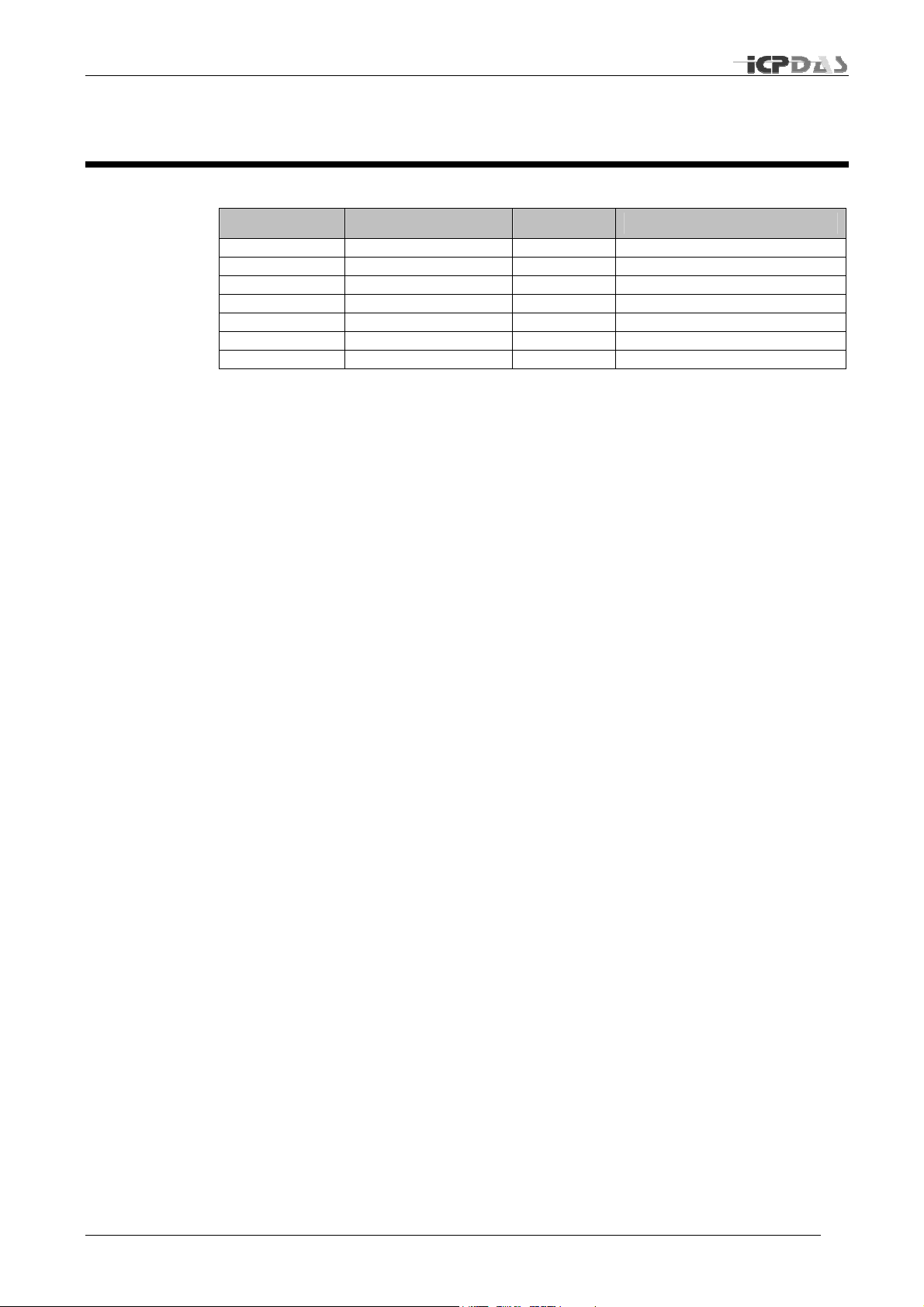

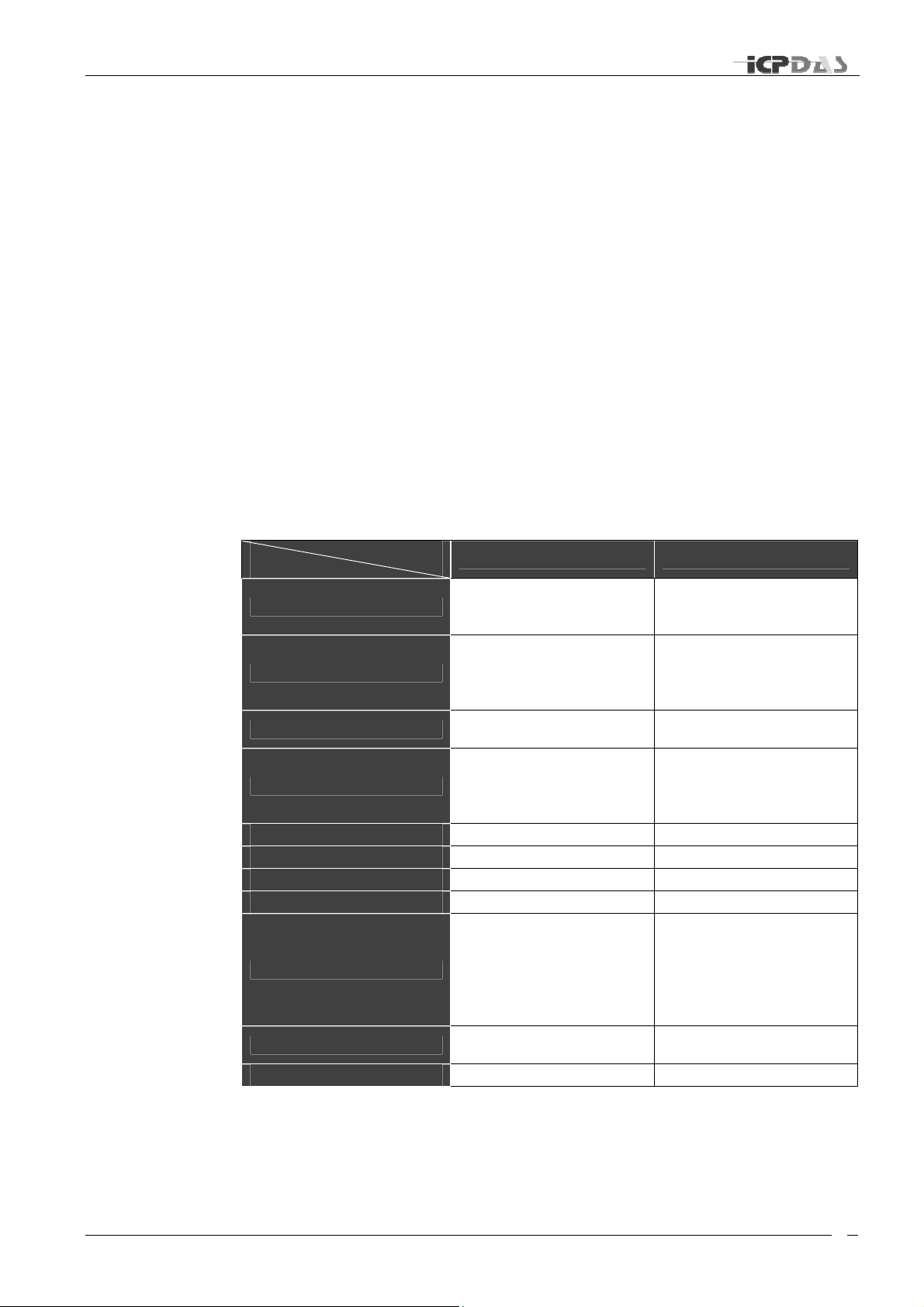

Date Author Version Description

July 1, 2006 KC Chen 1.0 First draft

Dec 2, 2010 Jerry Chiu 1.1 Add DI/O Wire Connection

Jan 1, 2011 Jerry Chiu 1.2 Modify jumper block label

i

TDRS4050601

Page 3

Industrial Ethernet Layer 2 Managed Switch User Manual

Copyright & Trademarks

All rights re served. No par t of this publ ication may be

reproduced, s tored in a ret rieval system, or

transmitted i n any form or by any means, whether

electronic, m echanical, pho to copying, re cording or

otherwise, wi thout the prio r written perm ission of the

publisher.

The names use d for identifi cation only ma y be

registered tr ademarks of th eir respective companies.

Copyright© ICP DAS Co., Ltd., Al l Rights Reserved.

TDRS4050601

ii

Page 4

Industrial Ethernet Layer 2 Managed Switch User Manual

Disclaimer

Limited Warranty

All products manufactured b y ICP DAS are warranted

against defec tive materials for a period of one year

from the date of delivery t o the original purchaser.

During this p eriod, if a cu stomer is unab le to resolve

a product pro blem with ICP DAS Technical Support, a

Return Materi al Authorizati on (RMA) will be issued. If

the product i s not under wa rranty, the cu stomer may

have ICP DAS repair the uni t on a fee bas is or return

it.

This warranty is voided if the customer u ses the

product in an unauthorized or improper wa y, or in an

environment f or which it wa s not designed .

Standards

Warning

The Ring Swit ch meets the f ollowing stand ards:

EMC immunity - IEC61326-1, IEEE C37.90

EMI emissions - FCC part 15 , ICES 003, EN 55022;

Class B

Electrical sa fety - UL 508, CSA C22/14; EN610 10-1

(IEC1010)

ICP DAS assum e no liability for damages c onsequent to

the use of th is product. IC P DAS reserves the right to

change this m anual at any t ime without no tice. The

information f urnished by IC P DAS is belie ved to be

accurate and reliable. Howe ver, no respon sibility is

assumed by IC P DAS for its use, nor for a ny

infringements of patents or other rights of third

parties resul ting from its use.

Safety

Install the Real Time Ring Switch in accordance with

local and national electrical codes.

Lightning Danger: Do not work on equipment during

periods of lightning activity.

Do not connect a telephone line into one of the

Ethernet RJ45 connectors.

iii

TDRS4050601

Page 5

Industrial Ethernet Layer 2 Managed Switch User Manual

Preface

The advent of Ethernet brings the whole world a new territory. So it does in industrial

application. More and more industrial devices and equipment now support Ethernet. To

make all these devices and equipment integrated and worked, the Ethernet switch is a

key character.

For commercial using, the Ethernet switch is very easy to choose, and also cheap. But,

in industrial field application, user must take the environment conditions and field

requirement into concern.

Harsh environ, such as extreme high or low temperature, moisture, ground

differentials and electrical noise … etc

Requirement of fault-tolerant solution.

For automation and control engineers who have been forced into this IT domain,

they really don't want to get too involved with the idiosyncrasies and maintenance

of Ethernet networks.

To satisfy these, the Managed Switch provides you a rugged, fault-tolerant, plug and

play solution.

ICP DAS industrial Switch Series

ICP DAS industrial Ethernet switch has the following series:

NS Series: Network Switch Series, a standard switch with industrial class of

quality.

RS Series: Ring Switch Series, a redundant ring switch with industrial class of

quality.

Managed Series: A redundant ring switch with industrial class of quality, and

provides lots of powerful managed functions.

How to Use this manual

This manual is intended to help user quickly understanding and easily making use of

MSM-508 (and other supported products), and the arrangement of chapters and

sections follows the steps that user need to take.

TDRS4050601

iv

Page 6

Industrial Ethernet Layer 2 Managed Switch User Manual

Contents

Document Control......................................................................................i

Copyright & Trademarks............................................................................ii

Disclaimer..................................................................................................iii

Limited Warranty.......................................................................................................iii

Standards .................................................................................................................iii

Warning.....................................................................................................................iii

Safety........................................................................................................................iii

Preface......................................................................................................iv

ICP DAS industrial Switch Series .............................................................................iv

How to Use this manual............................................................................................iv

Contents....................................................................................................v

Acronyms ..................................................................................................1

Introduction................................................................................................4

Ethernet Switch.........................................................................................................5

Industrial Ethernet.....................................................................................................5

Industrial Fiber Optic.................................................................................................7

Why Fiber Optics? 7

Industrial vs. Commercial 8

Managed Switch Key Features.................................................................................8

Package Contents ....................................................................................................8

Appearance...............................................................................................9

Dimensions.............................................................................................................10

Dimensions.............................................................................................................10

Front Panel .............................................................................................................11

On Case Quick Guide.............................................................................................12

Hardware Installation.................................................................................13

DIN-Rail Mounting Installation ................................................................................14

Wall-Mounting Installation.......................................................................................15

Connecting Input Power .........................................................................................15

Connecting Input Power .........................................................................................16

Connecting Output Relay........................................................................................17

Connecting Digital Input & Output ..........................................................................18

Connecting Ethernet Ports......................................................................................20

Connecting Fiber Ports (only for models with fiber port) ........................................21

Configuration.............................................................................................22

One Ring Topology.................................................................................................23

Two Rings Coupling................................................................................................24

Two Rings Coupling with Two Phase Recovering..................................................25

Troubleshooting.........................................................................................26

No power to the switch. 27

No link light on a switch port. 27

Master LED keep on Flashing 27

Service Information....................................................................................28

v

TDRS4050601

Page 7

Industrial Ethernet Layer 2 Managed Switch User Manual

On-line support .......................................................................................................28

Contact Worldwide..................................................................................................28

Appendix A................................................................................................a

Glossaries.................................................................................................................a

Appendix B................................................................................................c

Specifications............................................................................................................ c

Appendix C................................................................................................d

Modbus Table...........................................................................................................d

Appendix E................................................................................................f

Ingress Protection (IP)...............................................................................................f

Appendix F ................................................................................................g

Accessories ..............................................................................................................g

TDRS4050601

vi

Page 8

Industrial Ethernet Layer 2 Managed Switch User Manual

Acronyms

ATM Acronym for Asynchronous Transfer Mode, a high performance

networking technology based on the switching of fixed length, 53 byte

cells. ATM switching supports the switching of voice, video, and data;

also supports isochronous communication.

BPV Acronym for Bi-Polar Violation.

B-ISDN Broadband ISDN. A network standard from the CCITT and ANSI

committee. It supports voice, data and video in the same network.

CCITT Acronym for Consultative Committee, International Telephone and

Telegraph. An international standards body responsible for setting

international communications standards that allow interoperability

among telephony and data communications equipment.

CD (DCD) Acronym for Carrier Detect (Detect Carrier Detect).

CDDI The use of unshielded or shielded twisted pair cable to transmit the

FDDI signal.

CO Acronym for Central Office. The local telephone company switch that

terminates subscribers' lines for switching and connecting to the

public network.

CSMA/CD Acronym for Carrier Sense Multiple Access with Collision Detection.

Access protocol for Ethernet.

CSU Acronym for Channel Service Unit, a device furnished as an integral

part of a digital access line where a user wishes to supply the bipolar

signals. It provides the network with protection against user side

electrical anomalies such as surges, and provides the user with

network clocking.

CTS Acronym for Clear To Send.

DCE Acronym for Data Communication Equipment, aka. Data Circuit-

Terminating Equipment.

DCR Acronym for Data Communication Ready.

DS1 Digital Signal, Level 1 is the North American data rate used for T1

carriers. It operates at 1.544Mbps and supports 24 phone lines.

DS2 Digital Signal, Level 2 is the North American data rate used for T2

carriers. It operates at 6.312 Mbps and supports four T1 lines or 96

phone calls

DS3 Digital signal, Level 3 is the North American data rate used for T3

carriers. It operates at 44.736 Mbps and supports 28 T1 lines.

DSU Acronym for Data Service Unit, a DCE used with digital

communications circuits to provide digital data services interface.

Located on the users premises, the DSU interfaces directly with the

DTE, and provides loop equalization, remote and local test

1

TDRS4050601

Page 9

Industrial Ethernet Layer 2 Managed Switch User Manual

capabilities, and the logic and timing necessary to provide a standard

EIA/TIA or CCITT interface. Converts signals between those used at

the DTE's serial interface and bipolar signals used on the digital

network. Also Network Terminal Unit (NTU).

DTE Acronym for Data Terminating or Data Terminal Equipment.

DTR Acronym for Data Terminal Ready.

E1 The European standard for high speed, point to point transmission

operating at 2.048 Mbps and defines 64 Kbps sub-channels.

EIA Acronym for Electronic Industries Association. EIA, a standards body,

has a set of standards which includes data communications and

interface standards among others.

EMI Acronym for Electro-Magnetic Interference.

FEP Stands for Front End Processor. It is an IBM communication controller

that routes traffic to and from cluster controllers.

FDDI Acronym for Fiber Distributed Data Interface, is a shared medium, ring

topology LAN that operates at 100 Mbps. It is ANSI standard X3T9.5,

using fiber optic cable as the medium.

FPGA Acronym for Field Programmable Gate Array.

LAN A local area network is a group of PCs connected over a common

medium within a building.

MAC Acronym for Medium Access Control. A designated hardware address

for each device on a LAN or MAN. This address is burnt into The

network interface card (NIC) by its manufacturer.

MAN A metropolitan area network is a group of PCs connected over a

common medium within a campus environment or the same city.

NA Acronym for Numerical Aperture.

OC1 Optical Carrier Signal Level 1 refers to SONET data transmission at

51.840Mbps.

OC3 Acronym for Optical Carrier 3, a transmission rate standard for fiber

optic telephony or data communications circuits. OC3 operates at 155

Mbps speed and is part of the SONET hierarchy.

OC12 Optical Carrier Signal Level 12 refers to SONET data transmission at

622.080Mbps.

OSI (Open Data Interconnection Reference Model) - This is the

International Standards Organization (ISO) model of how data

communications systems can be interconnected. Communication is

partitioned into seven function layers. Each layer builds on the

services provided by those under it.

PBX Acronym for Private Branch Exchange, is a small private version of a

phone company's larger central switching office.

TDRS4050601

2

Page 10

Industrial Ethernet Layer 2 Managed Switch User Manual

PCM Acronym for Pulse-Coded Modulation, a means of converting analog

to digital form.

RING Path or channel; usually electrical, where devices along the path

receive transmissions sequentially from one device to the next along

the ring.

RS-232 An interface used between DTE and DCE employing serial binary

data interchange, defined by EIA, aka. EIA-232. Similar to standard

V.24 of CCITT.

RS-422 Standard defined by EIA, aka. EIA-422. Deals with the electrical

characteristics of balanced voltage digital interface circuits. Similar to

standard V.11 of CCITT.

RS-423 Standard defined by EIA, aka. EIA 423. Deals with electrical

characteristics of unbalanced voltage digital interface circuits. Similar

to standard V.10 of CCITT.

RS-449 Standard defined by EIA, aka. EIA-449. Deals with general-purpose

37- and 9-position interface for data terminal equipment and data

circuit-terminating equipment employing serial binary data

interchange.

RS-485 Standard defined by EIA, aka. EIA-485. Standard for electrical

characteristics of generators and receivers for use in balanced

multipoint systems.

RTS Acronym for Request To Send.

SCADA Acronym for Supervisory Control and Data Acquisition.

SNMP Acronym for Simple Network Management Protocol. A standard

management protocol used to provide a common means of managing

network devices.

SONET Acronym for Synchronous Optical NETwork, is a hierarchical standard

for a high speed (45 Mbps to 2.4 Gbps) transport network.

T1 Transmission rate standard for telephony or data communications

circuits. T1 operates at 1.544 Mbps speed. Usually this circuit is

subdivided into many 64 Kb channels.

TCP/IP Acronym for Transmission Control Protocol/Internet Protocol.

WAN Acronym for Wide Area Network, a computer network interconnected

over distances beyond a city or metropolitan area.

802.3 Commonly referred to as Ethernet. It is a local area network protocol

that operates at 10Mbps.

802.5 Commonly referred to as Token Ring. Operates at either 4 or 16Mbps.

3

TDRS4050601

Page 11

Industrial Ethernet Layer 2 Managed Switch User Manual

Introduction

Welcome to ICP DAS Managed Industrial Ethernet Switch one of

Ethernet Switch

Industrial Ethernet

Industrial Fiber Optic

Key Features

Package Contents

the world’s best Industrial Ethernet Switch designed for connecting

Ethernet-enabled devices in industrial field applications. This manual

is for the ICP DAS Managed Switch.

Overview

The Managed Industrial Ethernet Switch is designed upon concepts

of reliability, quick recovery, easy configuration, self-healing and

SCADA for status monitoring. Besides, all models in Managed Switch

mechanism is also designed to meet IP301 above for working under

harsh environment.

Unlike other existing ring switch or managed Ethernet switch on the

market, the ICPDAS Managed Switch is much more easy to use and

absolutely free of software setting.

1

Ingress Protection, see “Appendix B” for detail information.

TDRS4050601

4

Page 12

Industrial Ethernet Layer 2 Managed Switch User Manual

Ethernet Switch

Ethernet is an ideal medium to transport large volumes of data, at speed, across great

distances. Previously, multiple networks carrying specific protocols were installed side by

side to carry out unique tasks. This inevitably led to project costs increasing as additional

fiber optic or copper cables were installed to deal with the increasing volume of data.

Using Ethernet a single fiber optic cable can carry multiple protocols. Furthermore,

manufacturers are exporting their legacy protocols onto Ethernet, designing new IP

based communication protocols and providing embedded Web-Pages within devices that

offer real-time information using simple tools like Internet Explorer and Netscape

Navigator.

Unfortunately, although network hardware has dramatically increased in speed and

technology over the past decade the poor perception of Ethernet has remained; namely

as being difficult to fault-find and critically being a non-deterministic network. A key

development that overcame some of these issues was the advent of the Ethernet Switch.

Early Ethernet networks were based on a hub or repeater. These units have no

intelligence and therefore are unable to identify any information contained within the

Header frame of an Ethernet packet. This means that it is not capable of determining

which port to send the frame to. Therefore, every frame is sent to every port. A network of

repeaters and hubs is called a ‘Shared Ethernet’ or ‘Collision Domain’. Various devices

will all compete with each other before sending data using ‘Carrier Sense Multiple Access

/ Collision Detect’ (CSMA/CD) protocol. This means that only one system is allowed to

proceed with a transmission of a frame within a Collision Domain at any one time. This is

a major disadvantage when using Hubs and Repeaters within a network.

A switch, like a hub, has to forward and receive packets from one network or device to

another. The switch could forward all packets, but if this was the case it would have

similar behaviour to a hub. It would be more intelligent if the switch only forwarded

packets which needed to travel from one network or device to another. To do this, the

switch must learn which devices or networks are connected to each port. In simplistic

terms; it needs to learn the destination and source ports of each and every packet

received on each individual Switch port. Once learnt, any identically addressed packet

will be automatically be forwarded. With today’s enhanced processing power the

introduction of a Switch has significantly increase network bandwidth.

Industrial Ethernet

Industrial rated Switches are intended to be installed in both harsh climatic environments

and noisy electrical installations. Such Switches are an excellent example of true

industrial design principles –

very high operating temperatures (down to -30°C an d up to 75°C)

dual input power supplies

wide DC operating voltages

In Roadside and tunnel applications distances between cabinets with a suitable power

supply can be challenging. Naturally, fiber optic cable is the preferred solution. Using

single mode fiber, runs of up to 85km are possible. Even using standard CAT5e copper

cable the Industrial Switch supports the long cable specification and distances of up to

185m are viable. However, the domain of Ethernet has always been controlled by the IT

department who normally configured office networks with an iron fist and dictated to the

organisation how the network would be designed. Complex network recovery protocols

5

TDRS4050601

Page 13

Industrial Ethernet Layer 2 Managed Switch User Manual

like spanning tree, and SNMP to help with fault finding and system analysis were often

employed to enhance network resilience. If a network failure occurred the IT department

would casually look at repairing the equipment; there was no real rush as it was an office

network.

However, with industrial Ethernet you need very fast repair time and with an IT

department not readily available on the roadside, maintenance personnel need to be

made aware of the fault, find the error and repair it - quickly. To aid this, unique network

recovery features are employed to significantly enhance network recovery times. When

an IT department requires a level of redundancy a common method is to employ the

spanning tree protocol. However, spanning tree can be complex to program and

critically can take over 30 seconds to detect and recover from the fault – far to long for

critical applications!

ICP DAS Managed Switch incorporates propriety protocols that enable multiple Switches

to be placed into a redundant ring. A single Switch, configured as the network focal point

will monitor, detect and recover from a fiber or copper link failure within approximately

50mS – for the majority of applications a seamless process. The configuration process

of the network focal point is simple as it must be remembered that as the switches are to

be installed on the roadside the first to be called to rectify a fault will more than likely be

Maintenance personnel.

Module

Feature

Communication Protocol

Managed Interface

Service

Redundancy

Amount of Rings

Single Coupling

Redundant Coupling

Router/IP sharing

IEEE standards

Alarm

Convenience

ICPDAS Managed Switch General Managed Switch

Modbus/TCP

Modbus/RTU

Serial Console,

Utility

Web

telnet

OoS, HTTP, VLAN, SMTP. QoS, CoS, VPN, FTP, HTTP,

Cyber-Ring

(Variable recovery time from 100

ms to 1.5s)

Spanning Tree.

2 1

Yes No

Yes No

No Yes

802.3

802.3x

802.3u

802.1D

802.1p

802.1q

Relay Output

Modbus

Easy to use/configure N/A

SNMP

IGMP

Serial Console

Utility

Web

telnet

HTTPS, SSH, VLAN

Trunking, Spanning Tree, Rapid

Spanning Tree

802.3

802.3x

802.3u

802.1D/w

802.1p

802.1q

SNMP

TDRS4050601

6

Page 14

Industrial Ethernet Layer 2 Managed Switch User Manual

It is likely that these people will not be fully trained on Ethernet and the protocols that are

in operation, nor will they fully understand the principles of SNMP etc. However, with a

fault contact, fault LED’s and graphical interface implemented they have a multi-level

approach to fault finding:

The fault contact is hard-wired to an alarm on a control panel or as an input to a DCS. If a

link failure occurs (between two switches or an Ethernet Device) or a network failure

occurs the fault contact on the Switches will be energized. The Maintenance Engineer

can easily locate the fault.

With the increased use of Ethernet in the field to pass critical data the greater the

reliability in network infrastructure. Where multiple rings are configured in a system it is

also critical that the links between the rings are also duplicated to provide enhanced

redundancy. This can be achieved using Multi-ring Redundancy

Industrial Fiber Optic

Why Fiber Optics?

The utilization of fiber optic data transmission for industrial automation and process

control has become increasingly popular over the past decade.

A basic fiber optic system, using an optical transceiver circuit and fiber optic media, offers

a wide array of benefits that are not available with traditional copper conductors.

Advantages of Fiber Optic Data Transmission Technology

High data rate and wide bandwidth

Immunity to EMI/RFI and lightning damage

No ground loops

Low attenuation (data loss)

Longer distance – up to 1.8 miles (3 km) with Muliti Mode fiber and over 15 miles

(25 km) with Single Mode fiber

Small cable diameter fits almost anywhere - requires less duct space

Light weight

No sparks if cut – ideal for Hazardous Area applications

No electric shock hazard

Secure communications

Flexible networking topologies

Corrosion resistant

Longer life expectancy than copper or coaxial cable

Economical total system cost

Disadvantages of Electronic Cabling (Twisted Pair (TP), Coax, Twinax)

In selecting the signal/data transmission technology for your Industrial Automation and

Process Control networking, the following limitations of electronic cabling should be

considered:

Cabling hassles: weight, routing, size, attenuation and cross-talk

Distance between terminals and hosts is severely limited

Large diameter cable fills plenums and conduits

Needs to be routed away from power cabling

Poor security

Limited topologies

7

TDRS4050601

Page 15

Industrial Ethernet Layer 2 Managed Switch User Manual

Cost can be high relative to Fiber

Industrial vs. Commercial

Most process plants and factories have unique requirements for communications

networks that differ from those of commercial grade networks. Industrial network

components must withstand much harsher environmental conditions that can include

extreme temperatures, lightning strikes, electromagnetic interference and, in many

instances, installation in hazardous area locations.

Mounting and space requirements can also be an issue since industrial networking

components are often installed in the same control panel or cabinet with other

measurement and control equipment. At ICP DAS, our goal is to meet the demanding

requirements of industrial communication networks. Our industry standard, Managed

Switch of industrially hardened fiber optic communication products addresses these

issues and provides you with optimal solutions for your factory automation and process

control needs.

Managed Switch Key Features

Connectors locate in front panel, reducing wiring complexity and easy maintenance.

Dual input power supply for non-stop connectivity

Patent pending Cyber-Ring Protocol

Versatile DIN-rail, surface, and wall-mountable design

Rugged aluminium case with IP30 rated protection

Provides redundant dual DC power inputs with reverse polarity protection and alarm

Non-blocking, store-and-forward switching architecture

Watch dog

Support SCADA via Modbus/TCP or Serial Console for status monitoring

Support 2 rings

Support multiple single coupling and redundant coupling

Provides easy-to-use GUI configuration utility

Supports email warning via Simple Mail Transfer Protocol ( by GUI configuration

utility)

Support VLAN, QoS, Port Trunking, TELNET…etc. variety protocols.

Package Contents

One Industrial Ethernet Switch

Quick Installation Guide

User Manual

RJ-45 Covers

4PCA-090510 cable line

TDRS4050601

8

Page 16

Industrial Ethernet Layer 2 Managed Switch User Manual

Appearance

Dimensions

Front Panel

On Case Quick Guide

Overview

The Managed Switch provides useful interfaces to configure the

switch functions. For hardware installation, we provide easy DIN rail

mounting, wall mounting modes, and come with aluminum case.

All of connectors are well arranged on the front panel, so it is easier

to stack with other devices and to maintain in a small installation

space.

9

TDRS4050601

Page 17

Industrial Ethernet Layer 2 Managed Switch User Manual

Dimensions

TDRS4050601

10

Page 18

Industrial Ethernet Layer 2 Managed Switch User Manual

Front Panel

Terminal block

Left :

1. DO PWR

2. DO GND

3. DO #2

4. DO #1

5. DO #0

6. Relay (R.NO)

7. Relay (R.COM)

8. Power 2 +Vs

9. Power 2 GND

10. Frame Ground

Serial line via Ethernet port

Jumper block

Repair Mode

Normal Mode

Upgrade Firmware Mode

Rignt :

11. -

12. DI COM

13. DI #2

14. DI #1

15. DI #0

16. Data+

17. Data-

18. Power 1 +Vs

19. Power 1 GND

20. Frame Ground

Master switch LED indicator

Power 1 LED indicator

Power 2 LED indicator

RJ-45 Ethernet ports

Interconnection port for 2

phase recovering coupling

11

TDRS4050601

Page 19

Industrial Ethernet Layer 2 Managed Switch User Manual

On Case Quick Guide

LED status and Default Setting have been printed on left side of front panel. After

acquainted with Managed Switch features, field engineers could deploy switches quickly

by referencing those information.

TDRS4050601

12

Page 20

Industrial Ethernet Layer 2 Managed Switch User Manual

Hardware Installation

DIN-Rail Mounting

Installation

Wall-Mounting Installation

Connecting Input Power

Connecting Output Relay

Connecting Ethernet Ports

Connecting Fiber Ports

For hardware installation, we provide both easy DIN rail mounting

and wall mounting modes.

Overview

Managed Switch support redundant power, output relay and

enhanced isolation to make device much robust. With ICP DAS

patent DIN-Clip® design, the installation is just as easy as plugging

power cord into outlet.

13

TDRS4050601

Page 21

Industrial Ethernet Layer 2 Managed Switch User Manual

Push &

DIN-Rail Mounting Installation

Up Clip

Down Clip

Clip

With ICPDAS patent DIN-Clip® design, DIN-Rail mounting installation becomes very easy.

Following 3 steps completes installation.

➊

➋

Pull the down rail clip out.

Obliquing the switch and insert the upper clip onto the upper lip of the DIN-

➌

rail track. Then push down the switch to fit into DIN rail as shown below.

Push up down rail clip to lock the switch on the DIN rail.

TDRS4050601

14

Page 22

Industrial Ethernet Layer 2 Managed Switch User Manual

Wall-Mounting Installation

With ICP DAS patent DIN-Clip® design, Wall-Mounting installation becomes very easy.

Following 1 step completes installation.

➊

Use the slotted holes at each corner of the wall-mounting clip to attach the unit

to the wall or other flat surface. Then fasten it on the wall with screw.

15

TDRS4050601

Page 23

Industrial Ethernet Layer 2 Managed Switch User Manual

Connecting Input Power

IMPORTANT: It is good practice to turn off input and load power, and unplug the power

terminal block before making wire connections. Otherwise, your screwdriver blade can

inadvertently short your terminal connections to the grounded enclosure.

➊

➋

Identify PWR1, GND, PWR2, GND contacts on terminal block. Then identify

power wire and ground wire.

Insert the wire of your DC supply or Battery supply into the PWN1 and/or

PWN2 contacts of the terminal block connector, and fastening the terminal

screws to prevent the wires from coming loose.

NOTE: For best reliability, please install both of PWN1 and PWN2 for power redundant.

TDRS4050601

16

Page 24

Industrial Ethernet Layer 2 Managed Switch User Manual

Connecting Output Relay

The diagram of output relay:

➊

➋

Identify R.NO and R.COM contacts on terminal block.

Insert the relayed device such as a light bulb or a buzzer pair of wire, and

fastening the terminal screws to prevent the wires from coming loose.

17

TDRS4050601

Page 25

Industrial Ethernet Layer 2 Managed Switch User Manual

Connecting Digital Input & Output

The diagram of digital input and output:

Wire Connection

TDRS4050601

18

Page 26

Industrial Ethernet Layer 2 Managed Switch User Manual

➊

➋

Identify digital input and output contacts on terminal block.

Fastening the terminal screws to prevent the wires from coming loose.

19

TDRS4050601

Page 27

Industrial Ethernet Layer 2 Managed Switch User Manual

Connecting Ethernet Ports

Managed Switch includes all RJ-45 ports with automatic MDI/MDI-X crossover, and

automatic 10/100Mbps data rate sensing for 10Base-T or 100Base-TX connections.

Automatic MDI/MDI-X crossover allows you to connect to other switches, hubs, or

workstations, without regard to using straight-through or crossover cabling. The following

figures depict the schematic diagram of straight-through and crossover cabling. Note that

crossover cables simply cross-connect the transmit lines at each end to the receive lines

at the opposite end.

Straight-through Cabling Schematic Crossover Cabling Schematic

Note that Ethernet cables use pins 1, 2, 3, and 6 of an 8-pin RJ45 connector. The signals

of these pins are converted by the automatic MDI-X function, as shown in the table below:

Connect one side of an Ethernet cable into any switch port and connect the other side to

your attached device. The green LNK LED will light up when the cable is correctly

connected. Always make sure that the cables between the switches and attached devices

(e.g. switch, hub, or workstation) are less than 100 meters (328 feet).

Two switches are now up-linked together. If we change the up-link port manually at this

time, the MAC address table will change as well. After the MAC address table changes,

then the data can be transmitted between these two switches. This period of time is

called the MAC address table aging time. The switch’s default aging time is 5 minutes,

which means that if you manually change the up-link port, you will need to wait up to 5

minutes before the data can be sent. If the aging time is too short, the MAC address table

will constantly refresh, resulting in excess consumption of switch computing resources.

For this reason, a longer aging time is recommended.

TDRS4050601

20

Page 28

Industrial Ethernet Layer 2 Managed Switch User Manual

Connecting Fiber Ports (only for models with fiber port)

The automatic MDI/MDI-X crossover function does not apply to fiber connections, as

these must be crossed over manually. To connect the fiber port on one switch to the fiber

port of another switch, simply cross-connect the transmit channel at each end to the

receive channel at the opposite end as illustrated in the figure below.

These models have two 100Base-FX ports with SC type connectors (in multi-mode and

single mode versions).

A fiber segment using single-mode cable must use 9/125 or 10/125 micrometer singlemode fiber cables. For single-mode, the connection distance can be up to 30 km.

A fiber segment using multi-mode must use 50 or 62.5/125 micrometer multi-mode fiber

cables. For multi-mode, the connection distance can be up to 2 km.

21

TDRS4050601

Page 29

Industrial Ethernet Layer 2 Managed Switch User Manual

Configuration

One Ring Topology

Two Rings Coupling

Two Rings Coupling with

Two Phase Recovering

This chapter provide basic techniques to form a redundant ring on

your demand.

Overview

To successfully form a robust industrial Ethernet network, the

designing of network pattern is the most important stage. A welldesigned network pattern could dramatically reduce the risk network

failure in critical situation.

TDRS4050601

22

Page 30

Industrial Ethernet Layer 2 Managed Switch User Manual

One Ring Topology

A ring topology ensures the network having one more chance to keep connection alive

when any connection between 2 switches (nodes) has been broken inside the ring.

When we have formed a ring network, the focal point (master) will choose any one and

only one path as Redundant Path. It is actually inactive when the ring network works

properly. At the moment of any connection failure, the focal point will activate the

Redundant Path and fire alarm to output relay.

Managed Switch come with 2 ring pair by default. A ring pair can form a ring with other

network devices as below:

23

TDRS4050601

Page 31

Industrial Ethernet Layer 2 Managed Switch User Manual

Two Rings Coupling

As a ring network is a small group of switches by geography, functionalities, or

subsystem, 2 or more rings could be coupled together to form a whole picture of industrial

network for an integrated system.

Single coupling point uses a switch to bridge 2 rings. Each ring still keeps original ring

topology features.

TDRS4050601

24

Page 32

Industrial Ethernet Layer 2 Managed Switch User Manual

Two Rings Coupling with Two Phase Recovering

Redundant coupling gives one more chance to keep connection alive when any

connection between 2 rings has been broken. It is much safe than Single Coupling, but it

takes 3 more switches to form Redundant Coupling.

Be sure to use port 5 (interconnection port) to form two phase recovering coupling and

only ring pair 2 can be used in this topology.

25

TDRS4050601

Page 33

Industrial Ethernet Layer 2 Managed Switch User Manual

Troubleshooting

No Power to the Switch

No Link Light on a Switch

Port

Master LED Keep on

Flashing

Overview

This chapter includes some information for general troubleshooting

as follows:

No Power to the Switch

No Link Light on a Switch Port

Master LED Keep on Flashing

TDRS4050601

26

Page 34

Industrial Ethernet Layer 2 Managed Switch User Manual

No power to the switch.

• Check for faulty power cord.

• Check for loose or broken power connections.

• Check connections to ensure the power and ground are attached to the correct terminals.

• Check for power loss or power surges at the AC power outlet.

• Check Voltage of power coming into PWR1 or PWR2 to ensure it is within +10 - +30V DC.

• Ensure there are no shorts between power and ground.

No link light on a switch port.

• Check for faulty or loose Cables(both ends). Visually inspect for loose or faulty connections at all

connectors and cables. If that does not correct the problem, try replacing the cable.

• Check the other device to see if it is powered up and operating correctly.

• Try moving the Ethernet cable that has the possible faulty connection to another port in the

switch and check for link light.

Master LED keep on Flashing

•

Check if the topology is accurate.

•

Check if network is functioning properly.

•

Check if power supply is connected properly.

•

Check if there is devices failure exit (including ring switch or other devices connected to the

switch)

•

Check if MAC address is duplicated or illegal.

•

Check if the length of recovery time (rtime) is adequate; if the recovery time is too short, set a

longer time interval.

•

Check if the firmware is the newest version , please go to

http://www.icpdas.com/download/download-list.htm for downloading newest firmware version.

•

Check if the firmware upgrading process is completed. If not, redo the upgrading sequence to

complete firmware upgrading process.

27

TDRS4050601

Page 35

Industrial Ethernet Layer 2 Managed Switch User Manual

Service Information

We sincerely hope that you never experience a problem with any ICP DAS product. If you

do need service, call ICP DAS at 886-3-5973366 and ask for Applications Engineering.

Our well-trained specialist will help you to quickly determine the source of the problem.

Many problems are easily resolved with a single phone call.

On-line support

HTTP

://

WWW.ICPDAS.COM.TW/SEVICES/SUPPORT.HTM

E-

MAIL: SUPPORT@ICPDAS.COM

Contact Worldwide

TELEPHONE FAX

Taiwan

Hsinchu Headquarter

Banchiao Office

Hsintien Office

Taichung Office

Kaoshiung Office

USA USA Office

Europe Europe Office

Shanghai Shanghai Office

Beijing Beijing Office

886-3-5973366 886-3-5973733

886-2-29500655 886-2-29500807

886-2-89192220 886-2-89192221

886-4-23582815 886-4-23589114

886-7-2157688 886-7-2162602

1-310-517-9888 x101 1-310-517-0998

0049-711-9 97 37 75 0049-711- 9 97 37 84

8621-6247-1722 8621-6247-1725

8610-6298-0933 8610-6296-2890

TDRS4050601

28

Page 36

Industrial Ethernet Layer 2 Managed Switch User Manual

Appendix A

Glossaries

ANSI X3T9 Commonly referred to as FDDI. A local area network protocol that operates at

100Mbps.

Asynchronous Having a variable time interval between successive data or information in the form

of characters, operations, events. Transmission in which the data or information is

individually synchronized or timed usually by start and stop bits (S/S).

Attenuation A general term describing the loss of power between two points, measured in

decibels per kilometer (dB/km) at a specified wavelength (nm).

Backbone Network A main or high speed transmission facility or medium usually designed to connect

lower speed channels or clusters of terminals. May describe common carrier main

transmission path.

Bandwidth A range of frequencies available for signaling; the differences between the highest

and lowest frequencies of a band are expressed in (Hz).

Bridge A device used to connect two separate LANs or used to divide a large LAN into

smaller LANs. Each LAN acts as its own LAN, but uses a bridge device to

communicate from one LAN to another.

Bus Path or channel, usually electrical, with one or more conductors, where all devices

are able to receive all transmissions at the same time.

Counter-Rotating

Ring

Crosstalk The unwanted transfer of energy from the disturbing circuit to another called the

Dispersion The spreading of light pulses that takes place in multimode fiber optic transmission.

Ethernet Product name for one of the first popular LAN technologies, later standardized as

Fiber Optic Cable Thin filaments of glass or other transparent material sheathed in an insulator

Aka. Self-Healing Ring; has two physical transmission lines or rings with

transmitting and receiving signals in each ring travelling in opposite directions. If the

line or a device along the ring fails, the ring re-anneals by bypassing the device and

or line and forms with the other ring to form a new single ring.

disturbed circuit. Usually from an adjacent analog channel.

Dispersion limits the potential transmission distance because the spread out light

pulses reach the destination at different times making the signal unreadable.

IEEE 802.3.

through which a light beam may be transmitted for long distances by means of

multiple internal reflections. A waveguide used to transmit digital information.

Flow Control A method for a receiver to control the information flow from a transmitter. It

eliminates data overflow at the receiver.

Full Duplex A communication method where both ends can transmit and receive

simultaneously.

Half Duplex A communication method where one end transmits while the other end receives,

then reverses the process.

a

TDRS4050601

Page 37

Industrial Ethernet Layer 2 Managed Switch User Manual

Hub A device for local area networks (LANs) that is used to interconnect multiple

devices over an internal bus.

Jitter Aka. phase jitter, caused by power line harmonics and perceived in the form of

minor phase changes.

Multi-Drop Line Aka. Multipoint Line, a data link supporting multiple DTE connections, usually with

one DTE controlling the link by polling the other DTEs for input and addressing

output to the other DTEs. Utilizing frequency division or statistical MUX, a multipoint

line can support multiple independent point-to-point channels.

Multimode fiber An optical fiber that supports more than one propagating mode of light propagation.

Multiplexer Aka. or Multiplexor or Mux,. A device using several communications channels at the

same time, transmits and receives messages and controls communications lines,

may be a microprocessor.

Node A network-connected device, such as a server or PC.

Order Wire Voice channel used to communicate between two locations.

Packet A grouping of data, usually consisting of data and an address header prior to being

sent over a network.

Point-of Presence

(POP)

Polling The method used for terminal to controller communications. The controller

Protocol A set of rules for data communication. All devices communicating together must

Router Similar to a bridge but provides more complex and flexible networking support. It

Single mode fiber An optical fiber that supports only one mode of light propagation above the cutoff

Star Network in which all terminals are connected through a single point or node, such

Synchronous

Transmission

Time Division

Multiplexing

Time Slot Unit of backbone bandwidth allocated for each port.

The physical access location within a specific location of the long distance or

common carrier.

systematically asks for each terminal if it needs to transmit to the controller.

adhere to the same rules.

usually also supports WANs.

wavelength.

as a star coupler.

Having a constant time interval between successive bits of data or information.

A type of multiplexer that allocates a defined amount of backbone bandwidth for

each connected device.

Token Ring A LAN topology where a control packet or token is passed from station to station in

sequential order. The stations wishing to access must wait for the token before

transmitting data, in the token ring the next logical station is also the next physical

station.

Virtual Path A software-controlled point-to-point connection between two devices or segments.

TDRS4050601

b

Page 38

Industrial Ethernet Layer 2 Managed Switch User Manual

Appendix B

Specifications

Ethernet switch type

RJ45 ports (shielded)

RJ45 speed (auto-negotiating)

RJ45 auto-mdi/mdi-x

Ethernet protocols supported

Memory bandwidth

Completely compliant

Full or half duplex operation

MAC addresses supported

Ethernet isolation

Required supply voltage

Power input isolation

Power consumption

(Redundant input terminals)

Operating temperature

Storage temperature

Vibration

EMC immunity

Intelligent store & forward

10/100BaseT(x)

10 Mbps or 100 Mbps

All 8 ports

All standard IEEE 802.3

3.2 Gbps

IEEE 802.3, IEEE 802.3u, IEEE802.3x

Auto-sensing

2K

1500 VRMS 1 minute

+12 ~ +48 VDC

1KV

5 W

(typical - all ports active at 100 Mbps)

-30 ~ +75°C

-40 ~ +85°C

EN 50155 and EN11373.

EN61326-1 (EN61000-4-2, 3, 4, 5, 6)

c

TDRS4050601

Page 39

Industrial Ethernet Layer 2 Managed Switch User Manual

Appendix C

Modbus Table

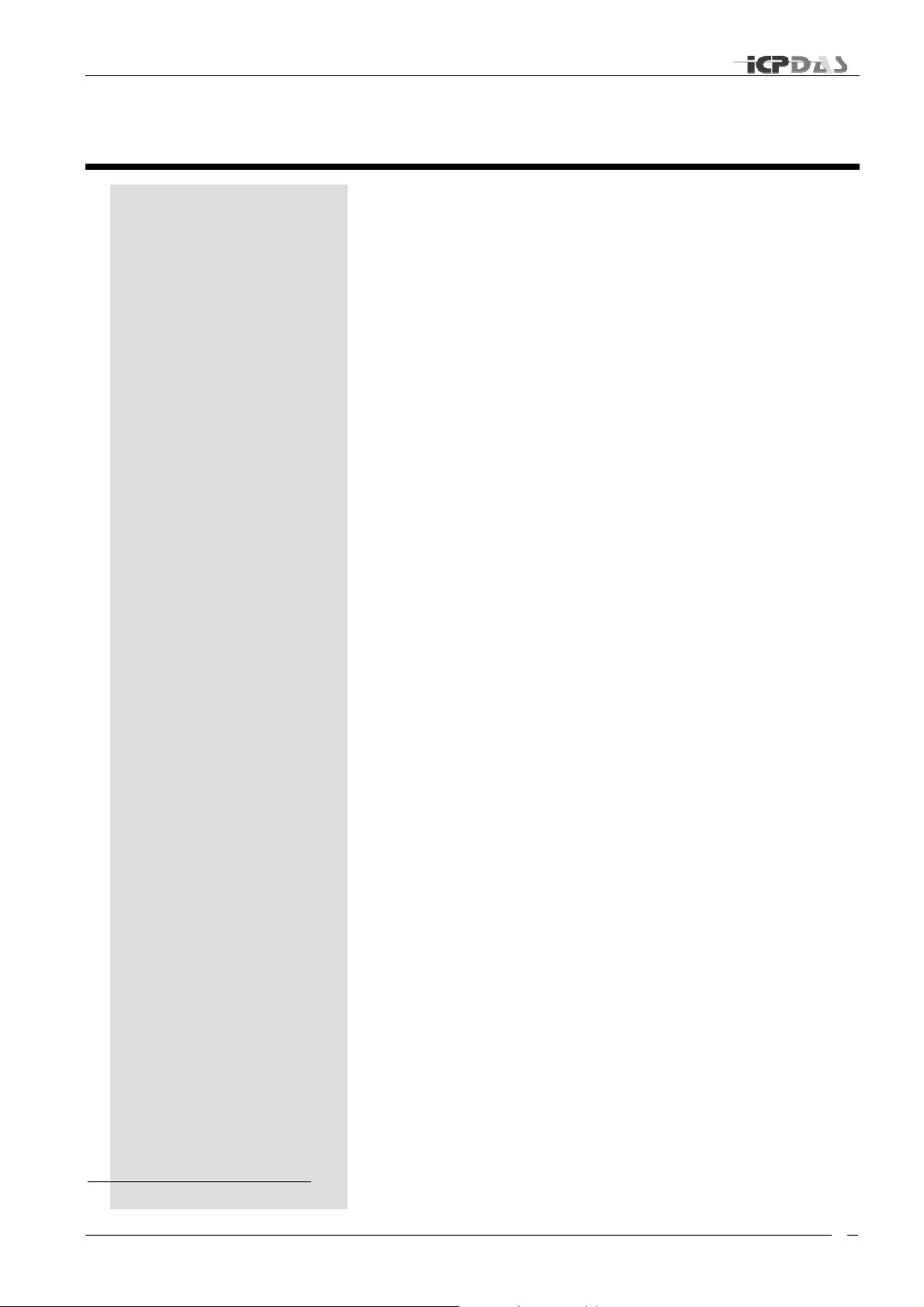

Switch Status

Address Status Address

10000 Ring Pair 1 Enable 10004 Power 1 Fail

10001 Ring Pair 2 Enable 10005 Power 2 Fail

10002 0 : Ring Protocol

1 : Spanning Tree Protocol

10003 Secondary switch 10007 Master

Link Status

Address Status Address

10008 Link on port 1 10016 Link on port 9

10009 Link on port 2 10017 Link on port 10

10010 Link on port 3 10018 Link on port 11

10011 Link on port 4 10019 Link on port 12

10012 Link on port 5 10020 Link on port 13

10013 Link on port 6 10021 Link on port 14

10014 Link on port 7 10022 Link on port 15

10015 Link on port 8 10023 Link on port 16

10006 Relay output

Forwarding Status

Address Status Address

10024 Port 1 is forwarding 10032 Port 9 is forwarding

10025 Port 2 is forwarding 10033 Port 10 is forwarding

10026 Port 3 is forwarding 10034 Port 11 is forwarding

10027 Port 4 is forwarding 10035 Port 12 is forwarding

10028 Port 5 is forwarding 10036 Port 13 is forwarding

10029 Port 6 is forwarding 10037 Port 14 is forwarding

10030 Port 7 is forwarding 10038 Port 15 is forwarding

10031 Port 8 is forwarding 10039 Port 16 is forwarding

Communication Status

Address Status Address

10040 Port 1 lose pair port 10048 Port 9 lose pair port

10041 Port 2 lose pair port 10049 Port 10 lose pair port

10042 Port 3 lose pair port 10050 Port 11 lose pair port

10043 Port 4 lose pair port 10051 Port 12 lose pair port

10044 Port 5 lose pair port 10052 Port 13 lose pair port

10045 Port 6 lose pair port 10053 Port 14 lose pair port

10046 Port 7 lose pair port 10054 Port 15 lose pair port

10047 Port 8 lose pair port 10055 Port 16 lose pair port

TDRS4050601

d

Page 40

Industrial Ethernet Layer 2 Managed Switch User Manual

Digital Input & Output

Address Status Address

10057 Digital Input channel 1 00001 Digital Output channel 1

10058 Digital Input channel 2 00002 Digital Output channel 2

10059 Digital Input channel 3 00003 Digital Output channel 3

10060 Digital Input channel 4 00004 Digital Output channel 4

10061 Digital Input channel 5 00005 Digital Output channel 5

10062 Digital Input channel 6 00006 Digital Output channel 6

10063 Digital Input channel 7 00007 Digital Output channel 7

10064 Digital Input channel 8 00008 Digital Output channel 8

e

TDRS4050601

Page 41

Industrial Ethernet Layer 2 Managed Switch User Manual

f

Appendix E

Ingress Protection (IP)

An IP number is used to specify the environmental protection of enclosures around electronic

equipment. These ratings are determined by specific tests.

The IP number is composed of two numbers, the first referring to the protection against solid objects

and the second against liquids. The higher the number is, the better the protection.

Note: All ICP DAS MS Series devices are manufactured and tested to IEC IP30 standards.

First Number

0 No protection (Sometimes X)

1 Protected against solid objects up to 50mm³

2 Protected against solid objects up to 12mm³

3 Protected against solid objects up to 2.5mm³

4 Protected against solid objects up to 1mm³

5 Protected against dust, limited ingress (no harmful deposit)

6 Totally protected against dust

Second Number

0 No protection (Sometimes X)

1 Protection against vertically falling drops of water (e.g. condensation)

2 Protection against direct sprays of water up to 15 degrees from vertical

3 Protection against direct sprays of water up to 60 degrees from vertical

4 Protection against water sprayed from all directions - limited ingress permitted

5 Protected against low pressure jets of water from all directions - limited ingress permitted

6 Protected against low pressure jets of water, limited ingress permitted (e.g. ship deck)

7 Protected against the effect of immersion between 15cm and 1m

8 Protected against long periods of immersion under pressure

TDRS4050601

Page 42

Industrial Ethernet Layer 2 Managed Switch User Manual

Appendix F

Accessories

Power Supply (KA-52F/DIN-KA52F)

Features & Specifications

•

Input Range : 100~250AC

•

Input Frequency : 50Hz to 60 Hz

•

Output : 24Vdc/1Amp max.

•

Output Power : 25Watts

•

Operating Temperature:0 to 70℃

•

Storage Temperature : -40 to 85 ℃

•

Demension :

65 x 105 x 36mm (KA-52F)

68 x 107 x 50mm (DIN-KA52F)

Part No. Information

KA-52F

DIN-KA52F

24V/1A output power supply

24V/1A output power supply with DIN-Rail Mount

g

TDRS4050601

Loading...

Loading...