Page 1

1

M-2017 User Manual

Warranty

All products manufactured by ICP DAS are under

warranty regarding defective materials for a period of one

year from the date of delivery to the original purchaser.

Warning

ICP DAS assumes no liability for damages resulting

from the use of this product. ICP DAS reserves the right

to change this manual at any time without notification.

The information furnished by ICP DAS is believed to be

accurate and reliable. However, no responsibility is

assumed by ICP DAS for its use, or for any infringements

of patents or other rights of third parties resulting from its

use.

Copyright

Copyright 1999 - 2015 ICP DAS. All rights reserved.

Trademark

The names used for identification only may be

registered trademarks of their respective companies.

Date: 2021/01/14

M-2017 User Manual, Rev: B2.5

Page 2

2

Table of Contents

1. Introduction ............................................................................................... 4

1.1 More Information ............................................................................. 6

1.2 Terminal Assignment ....................................................................... 7

1.3 Specifications ................................................................................... 9

1.4 Block Diagrams .............................................................................. 10

1.4.1 Block diagram for the M-2017 ............................................. 10

1.5 Dimensions ..................................................................................... 11

1.6 Wiring Diagrams ............................................................................ 12

1.6.1 Wiring diagram for the M-2017 ........................................... 12

1.6.2 Wiring Recommendations .................................................... 12

1.7 Quick Start ...................................................................................... 13

1.8 Default Settings .............................................................................. 15

1.9 Calibration ...................................................................................... 16

1.10 Configuration Tables .................................................................... 17

1.11 M-2000 Notes ............................................................................... 22

1.11.1 Protocol Switching ............................................................. 22

1.11.2 INIT Mode .......................................................................... 23

1.12 Technical Support......................................................................... 24

2. DCON Protocol ....................................................................................... 25

2.1 %AANNTTCCFF .......................................................................... 29

2.2 #AA ................................................................................................ 33

2.3 #AAN ............................................................................................. 35

2.4 $AA0 .............................................................................................. 37

2.5 $AA1 .............................................................................................. 39

2.6 $AA2 .............................................................................................. 41

2.7 $AA5VV ........................................................................................ 43

2.8 $AA6 .............................................................................................. 45

2.9 $AA7CiRrr ..................................................................................... 47

2.10 $AA8Ci ........................................................................................ 49

2.11 $AAA ........................................................................................... 51

2.12 $AAF ............................................................................................ 53

2.13 $AAM ........................................................................................... 54

2.14 $AAP ............................................................................................ 56

2.15 $AAPN ......................................................................................... 58

2.16 $AAS1 .......................................................................................... 60

2.17 ~AACT ......................................................................................... 62

2.18 ~AACTVV ................................................................................... 64

2.19 ~AAEV ......................................................................................... 66

2.20 ~AAO(Name) ............................................................................... 68

2.21 ~AARD ......................................................................................... 70

M-2017 User Manual, Rev: B2.5

Page 3

3

2.22 ~AARDVV ................................................................................... 72

2.23 ~** ................................................................................................ 74

2.24 ~AA0 ............................................................................................ 75

2.25 ~AA1 ............................................................................................ 77

2.26 ~AA2 ............................................................................................ 79

2.27 ~AA3EVV .................................................................................... 81

3. Modbus RTU Protocol ............................................................................ 83

3.1 02 (0x02) Read Input Status ........................................................... 84

3.2 04 (0x04) Read Input Channels ...................................................... 85

3.3 70 (0x46) Read/Write Module Settings ......................................... 86

3.3.1 Sub-function 00 (0x00) Read module name ........................ 87

3.3.2 Sub-function 04 (0x04) Set module address ........................ 88

3.3.3 Sub-function 05 (0x05) Read communication settings ........ 89

3.3.4 Sub-function 06 (0x06) Set communication settings ........... 90

3.3.5 Sub-function 07 (0x07) Read type code ............................... 91

3.3.6 Sub-function 08 (0x08) Set type code .................................. 92

3.3.7 Sub-function 32 (0x20) Read firmware version ................... 93

3.3.8 Sub-function 37 (0x25) Read channel enabled/disabled status

............................................................................................... 94

3.3.9 Sub-function 38 (0x26) Set channel enable/disable ............. 95

3.3.10 Sub-function 41 (0x29) Read miscellaneous settings ........ 96

3.3.11 Sub-function 42 (0x2A) Write miscellaneous settings ...... 97

3.4 Address Mappings .......................................................................... 98

3.4.1 M-2017 Address Mappings .................................................. 98

3.5 Engineering Data Format Table ................................................... 100

4. Troubleshooting .................................................................................... 101

4.1 Communicating with the module ................................................. 102

4.2 Reading Data ................................................................................ 103

A. Appendix .............................................................................................. 104

A.1 INIT Mode ................................................................................... 104

A.2 Dual Watchdog Operation ........................................................... 106

A.3 Frame Ground .............................................................................. 107

Revision History ........................................................................................ 108

M-2017 User Manual, Rev: B2.5

Page 4

4

1. Introduction

The M-2000 series is a family of network data acquisition

and control modules, providing analog-to-digital, digitalto-analog, digital input/output, timer/counter and other

functions. The modules can be remotely controlled using

a set of commands, which we call the DCON protocol, or

the standard Modbus RTU protocol. Communication

between the module and the host is via an RS-485 bidirectional serial bus standard. Baud Rates are software

programmable and transmission speeds of up to 115.2K

baud can be selected.

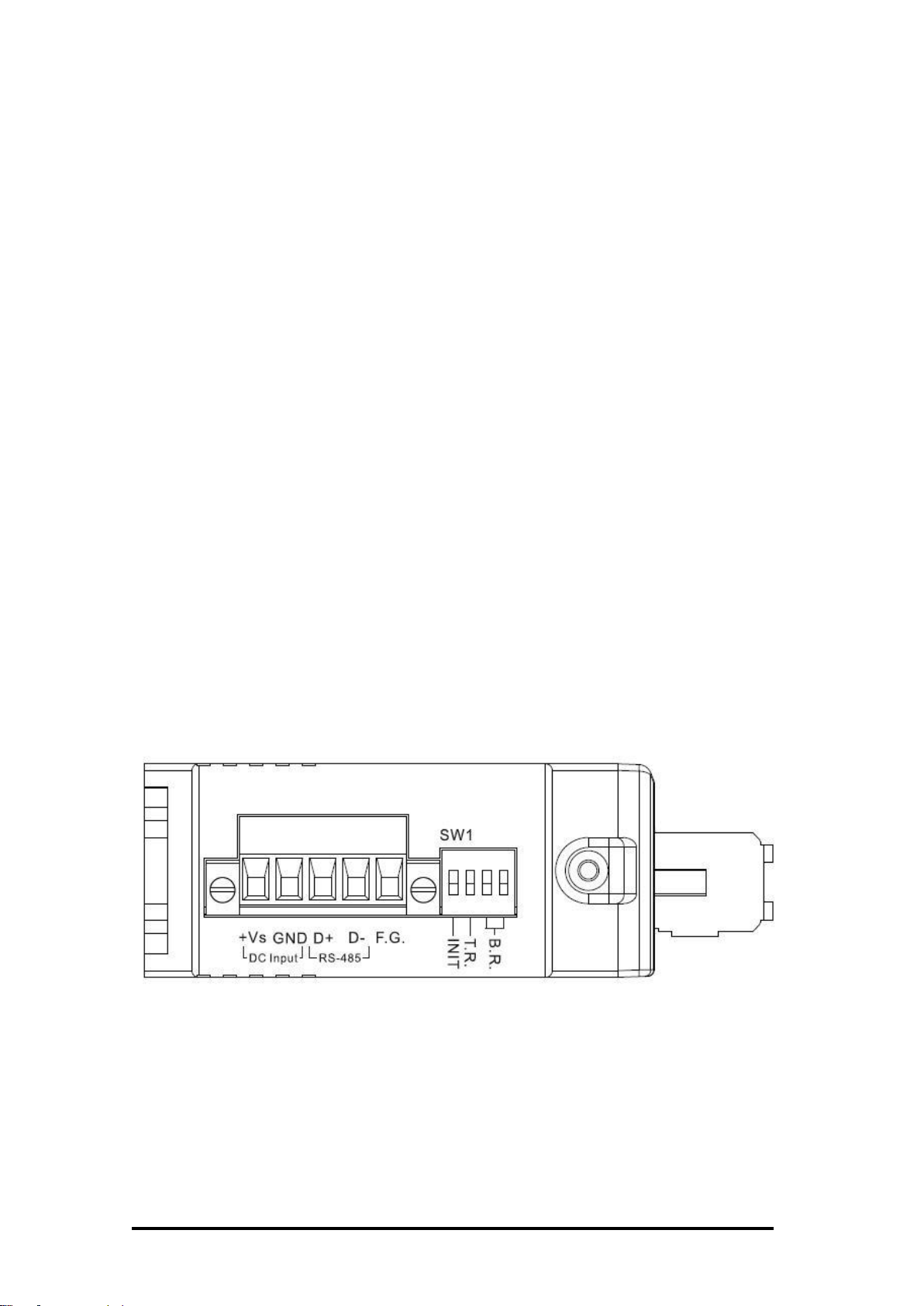

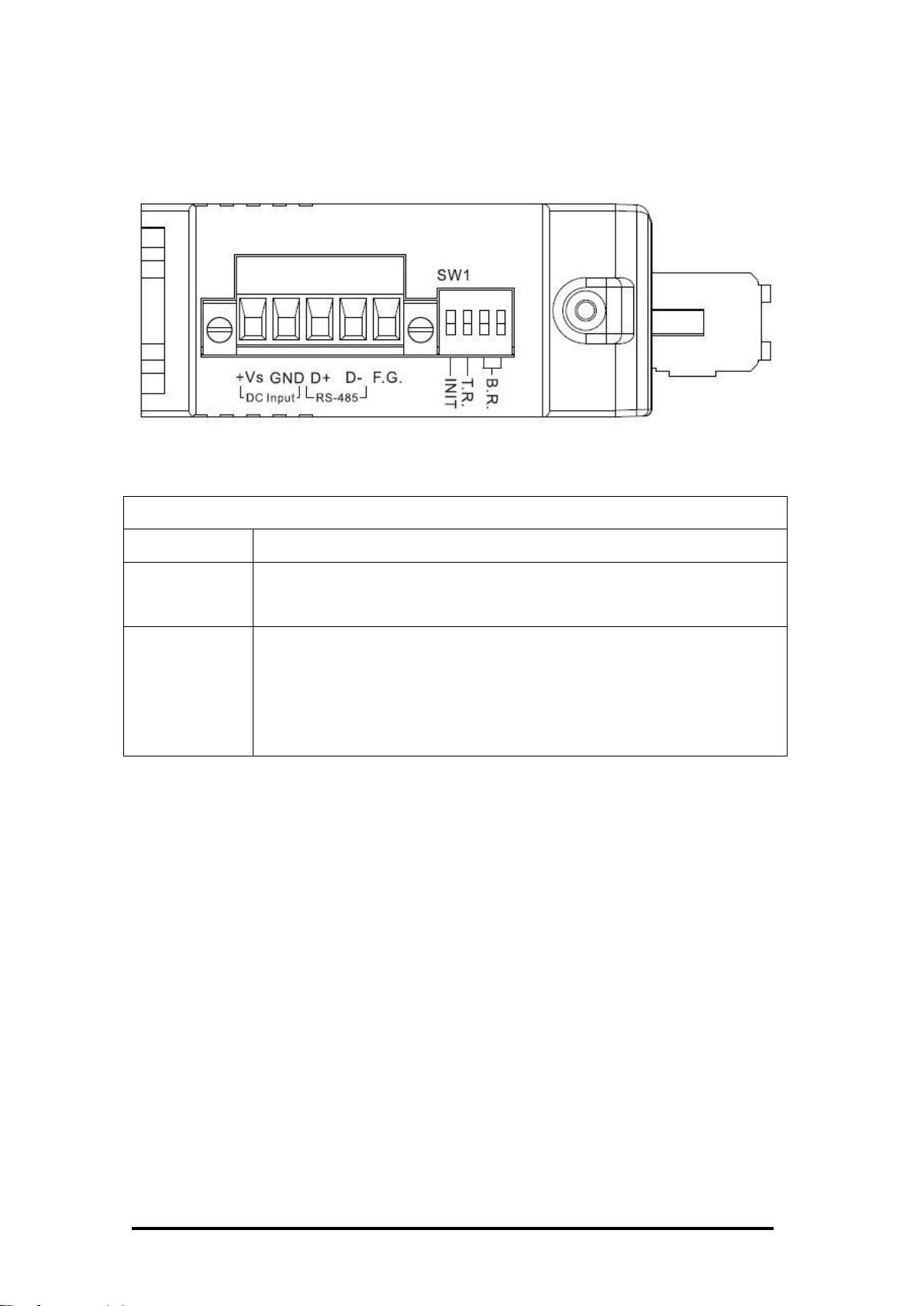

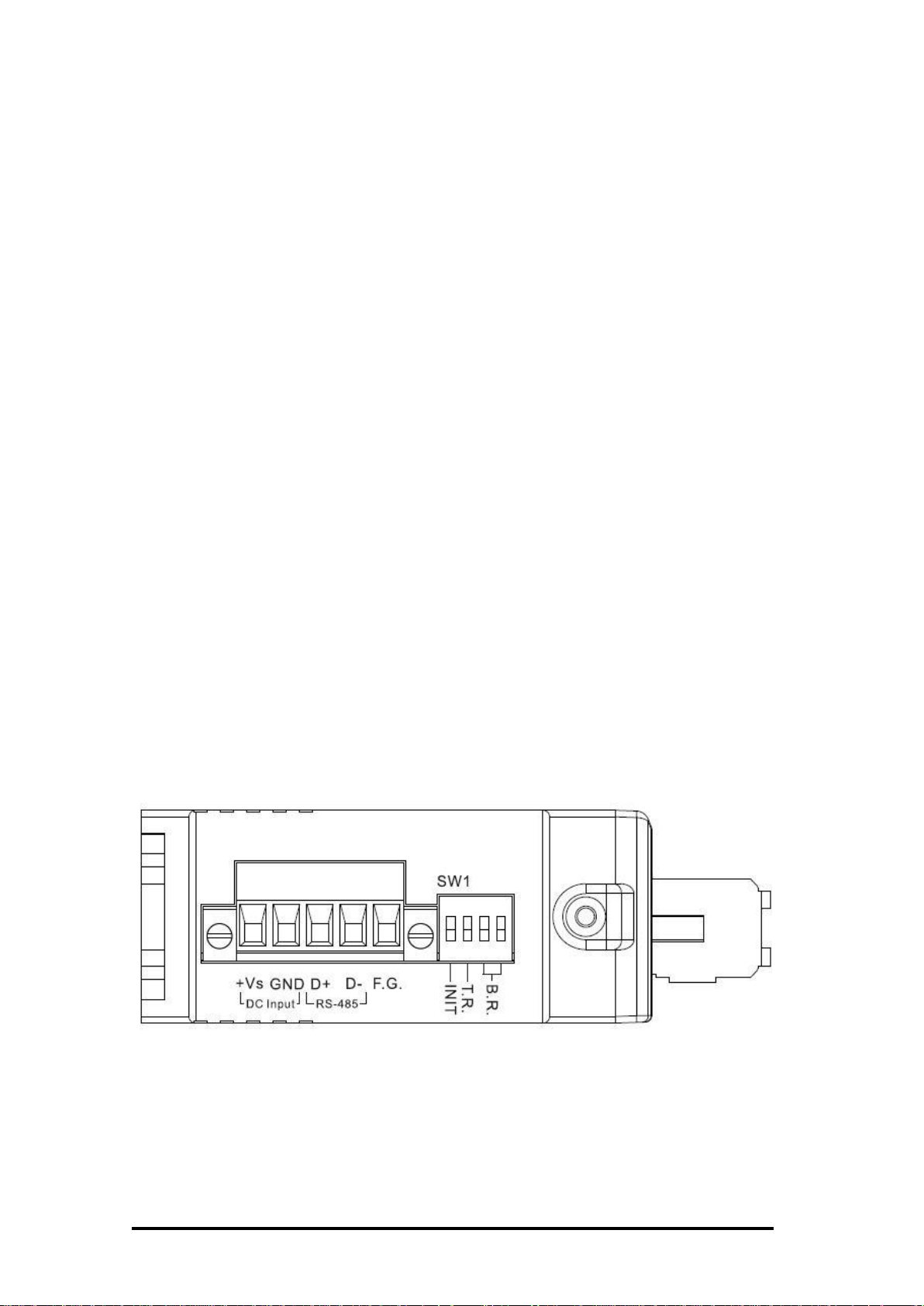

The M-2000 modules feature a new design for the frame

ground and INIT switch as shown in the figure below.

The frame ground provides enhanced static protection

(ESD) abilities and ensures the module is more reliable.

The INIT switch allows INIT mode to be accessed more

easily. Refer to Sections A.1 and A.3 for more details.

The M-2017 is an 8-channel voltage and current input

module, with the ability to connect various types of inputs

to a single module. It supports for fast mode, 60

samples/second. The M-2017 modules are designed for

industrial plant environments and have special input

M-2017 User Manual, Rev: B2.5

Page 5

5

circuits to provide 240Vrms continuous overload

protection.

M-2017 User Manual, Rev: B2.5

Page 6

6

1.1 More Information

Please visit the ICP DAS website http://www.icpdas.com

for more information regarding the M-2000 series.

M-2017 User Manual, Rev: B2.5

Page 7

7

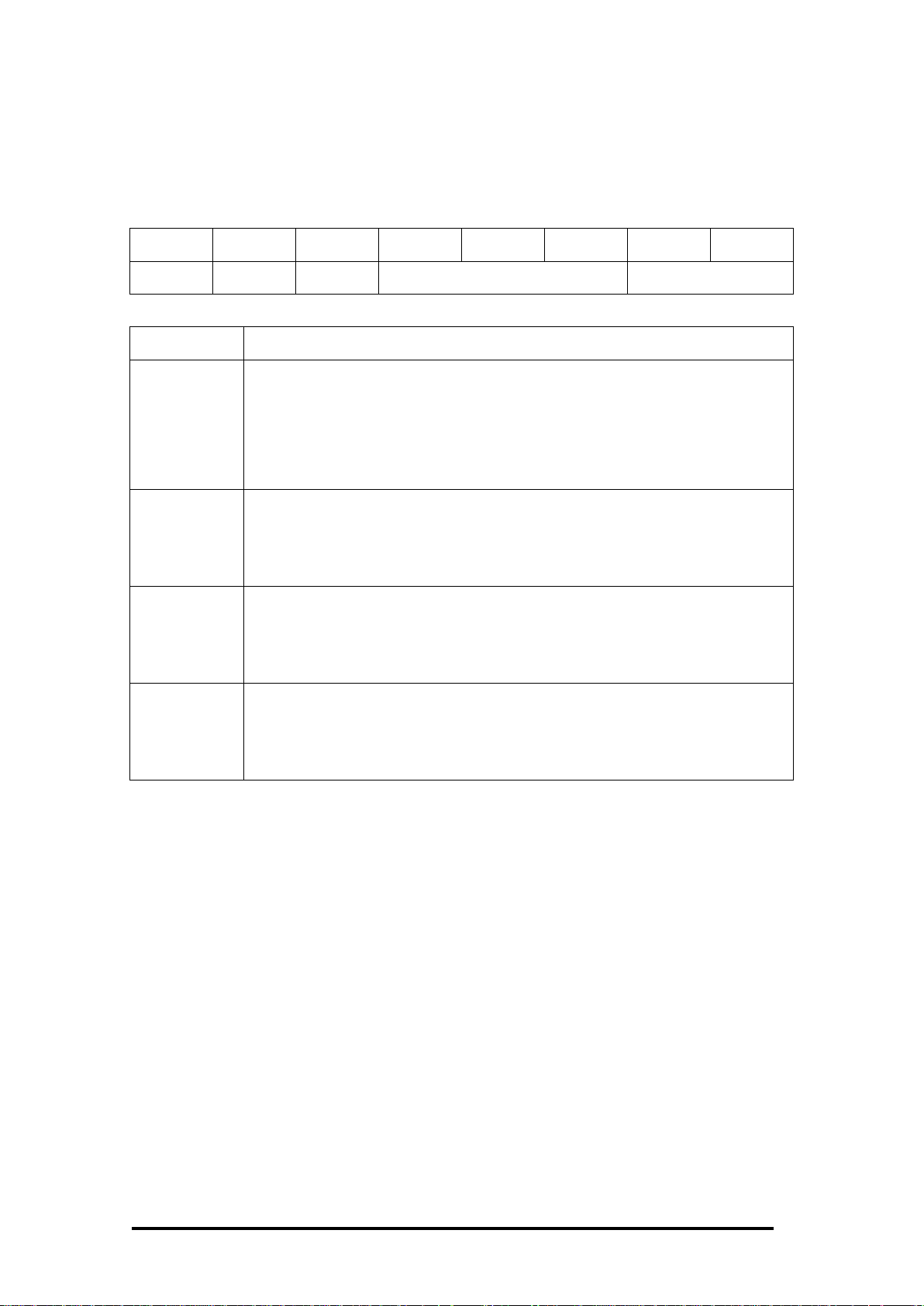

SW1

INIT

On for INIT mode

T.R.

On to provide 120 ohm terminal resistance on

the RS-485 bus

B.R.

On to provide 1k ohm bias resistance on the

RS-485 bus. If the RS-485 converter does not

provide the bias, then both of the B.R.

switches should be turned on.

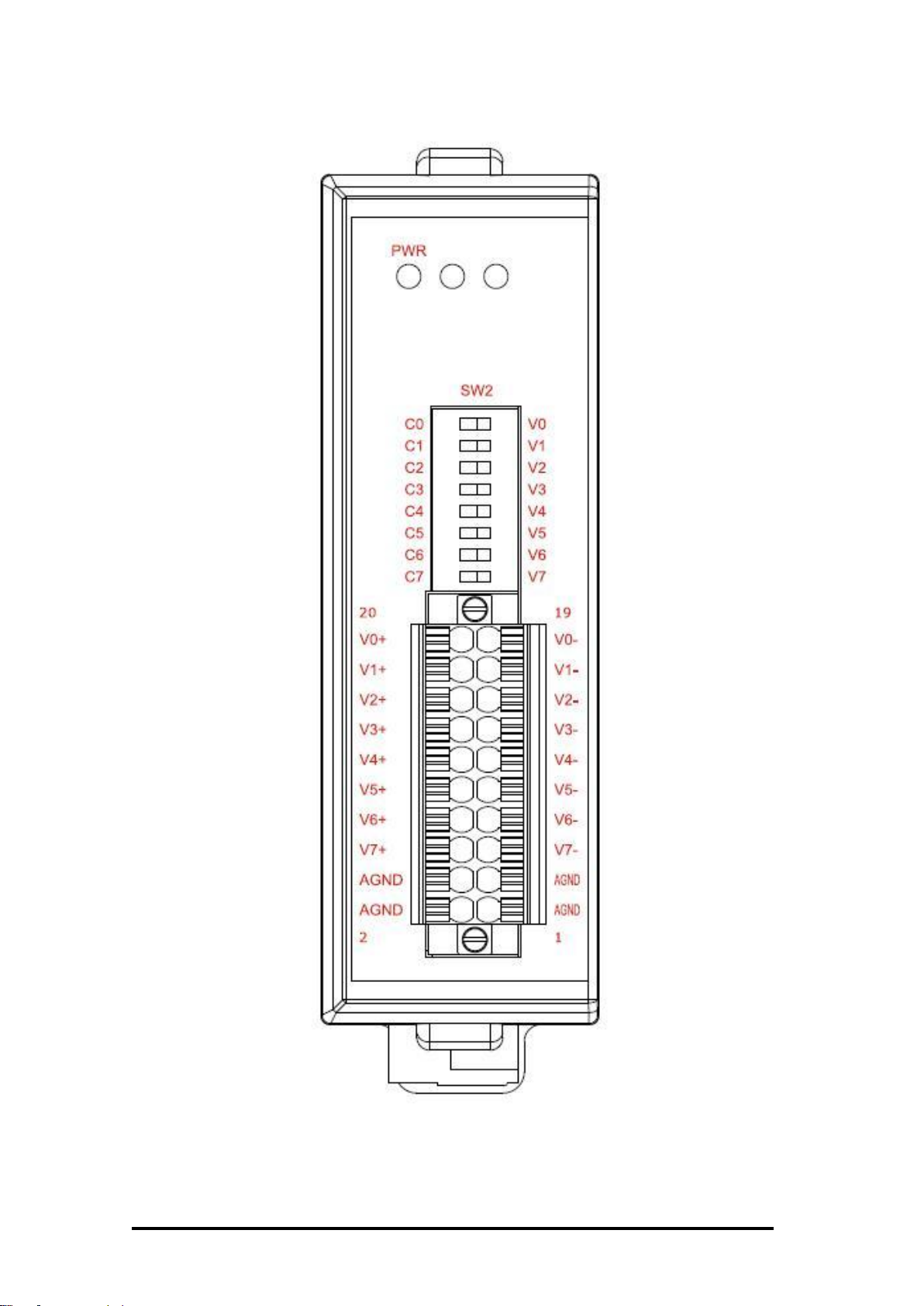

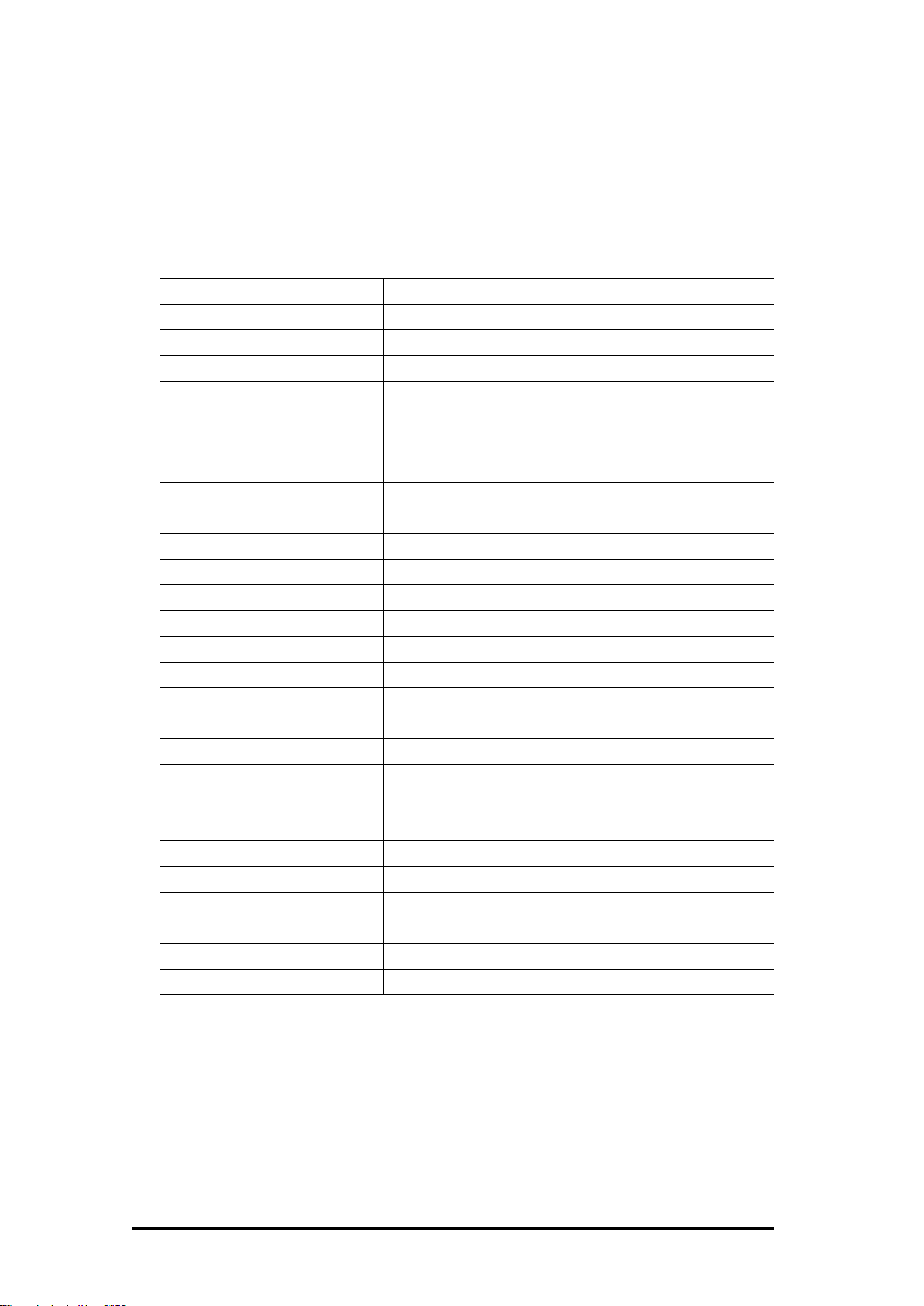

1.2 Terminal Assignment

M-2017 User Manual, Rev: B2.5

Page 8

8

M-2017 User Manual, Rev: B2.5

Page 9

9

M-2017

Analog Input

Input Channels

8 differential

Input Type

mV, V, mA (switch selectable)

Sampling Rate

10 samples/sec (normal)

60 samples/sec (fast)

Bandwidth

15.7Hz (normal)

78.7Hz (fast)

Accuracy

±0.1% (normal)

±0.5% (fast)

Zero Drift

20µV/°C

Span Drift

25ppm/°C

CMR@50/60Hz

86dB min

NMR@50/60Hz

100dB min

Input Impedance

1MΩ

Current Impedance

125Ω, 1/4W

Voltage overload

Protection

±240V

Isolation

3000V DC

Individual Channel

Configurable

Yes

Modbus RTU

Yes

Power

Requirement

+10 to +48V DC

Consumption

0.6W

Temperature Range

Operating

-25°C to +75°C

Storage

-30°C to +75°C

1.3 Specifications

Note: A warm up period of 30 minutes is recommended in order to

achieve the complete performance results described in the

specifications.

M-2017 User Manual, Rev: B2.5

Page 10

10

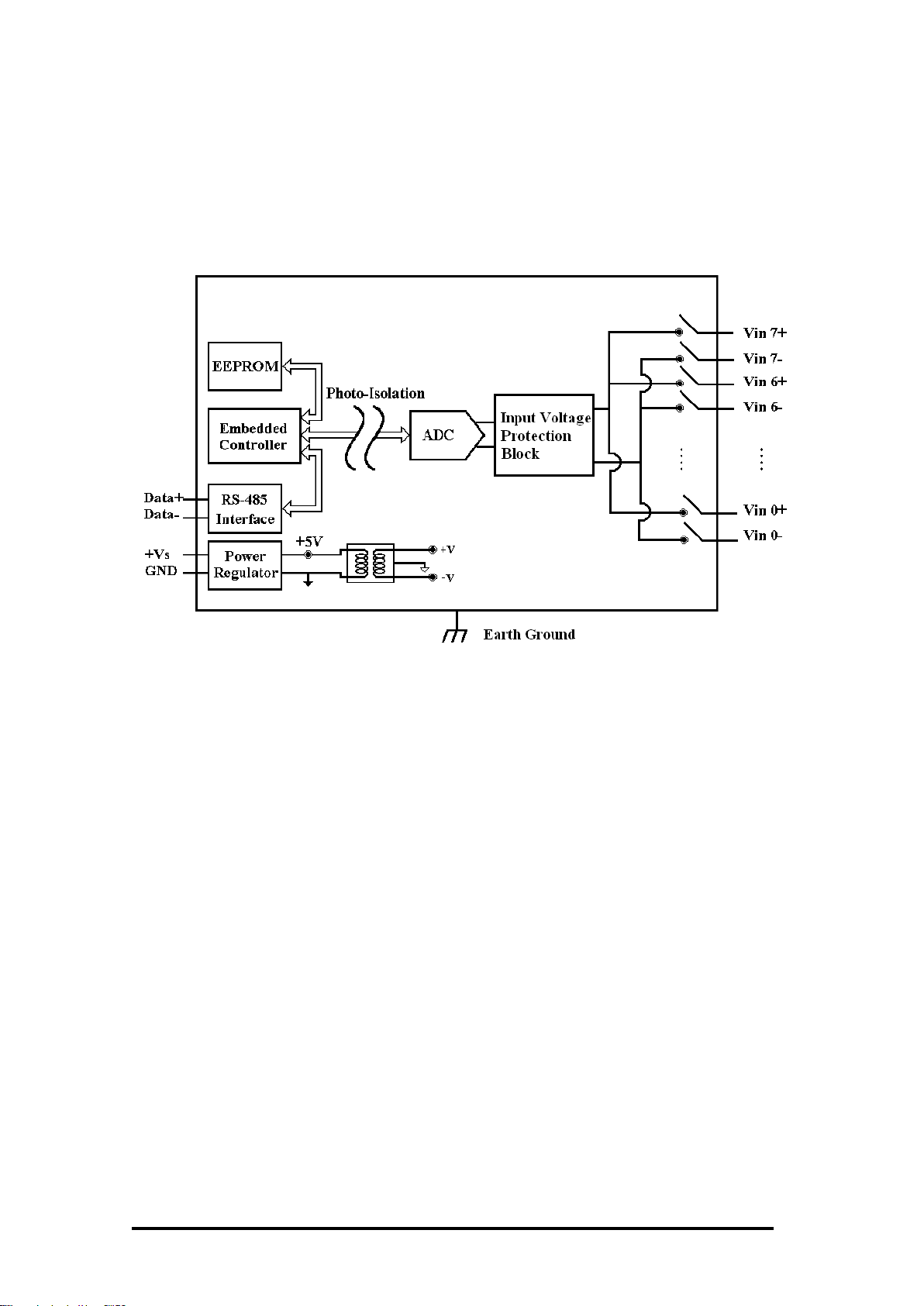

1.4 Block Diagrams

1.4.1 Block diagram for the M-2017

M-2017 User Manual, Rev: B2.5

Page 11

11

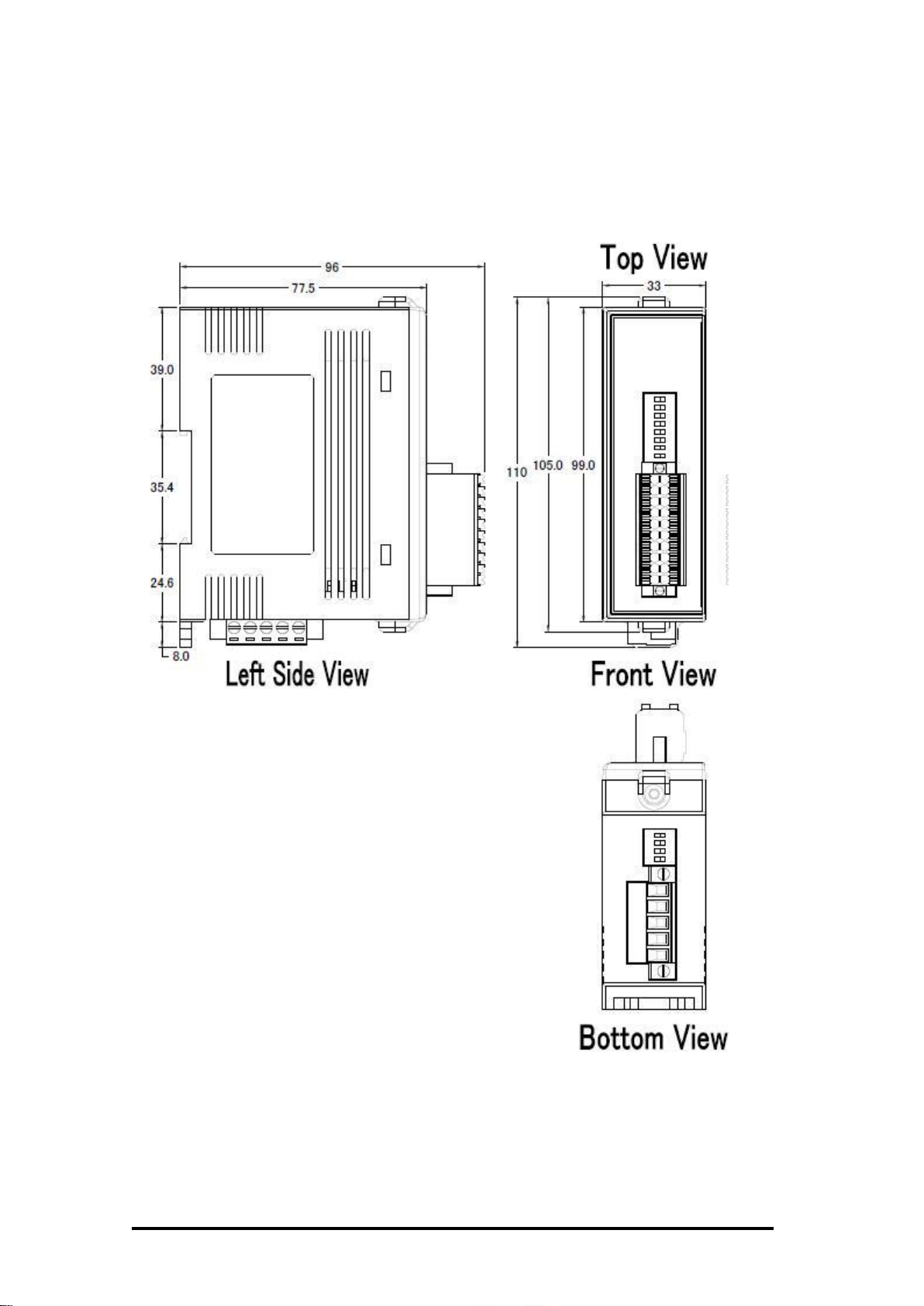

1.5 Dimensions

The dimensions of the M-2017 are as shown below.

M-2017 User Manual, Rev: B2.5

Page 12

12

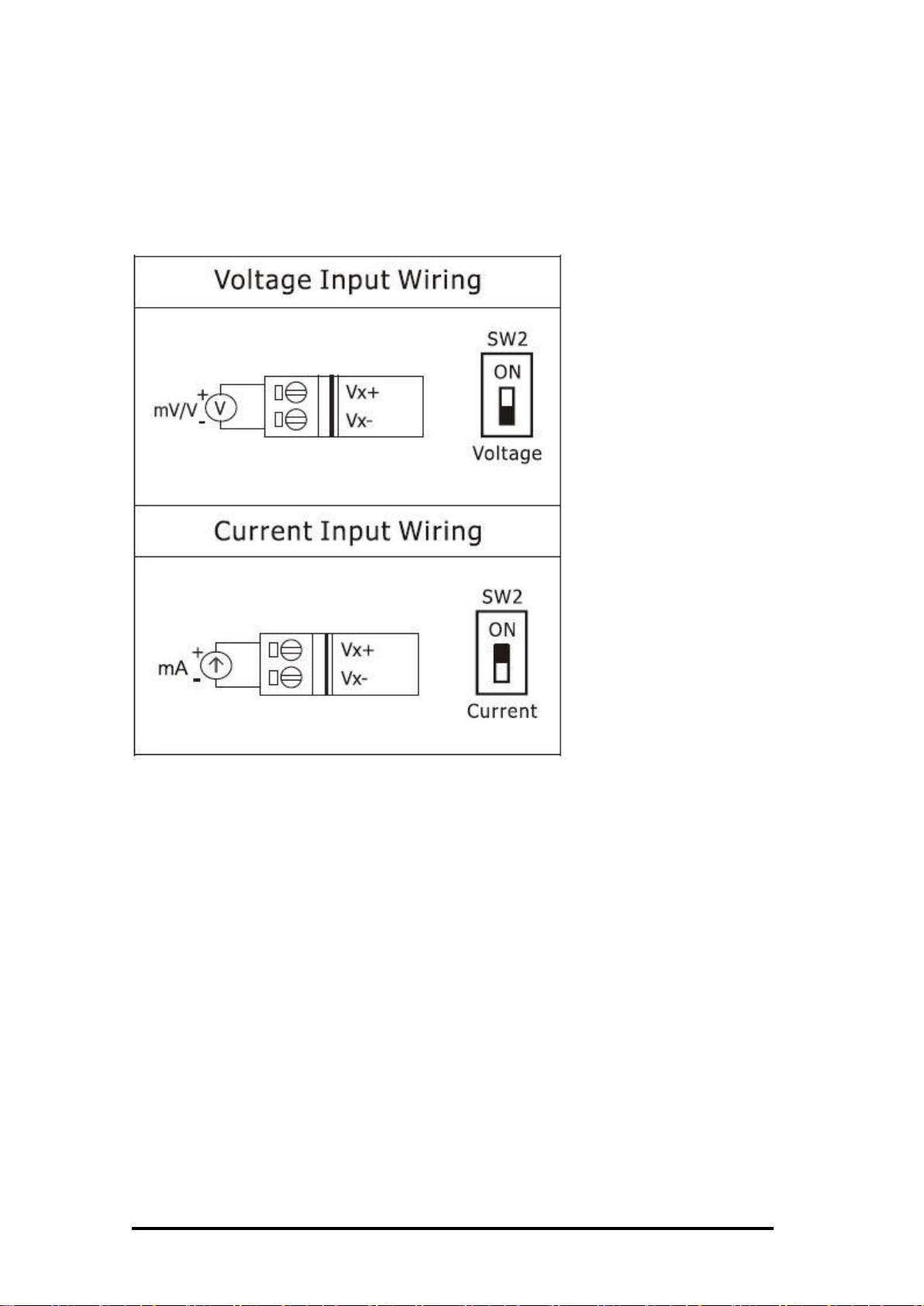

1.6 Wiring Diagrams

1.6.1 Wiring diagram for the M-2017

1.6.2 Wiring Recommendations

Use 26-12 AWG wire for signal connections.

Strip the wire to a length of 7±0.5mm.

Use a crimp terminal for wiring.

Avoid high-voltage cables and power equipment as

much as possible.

For RS-485 communication, use insulated and

twisted pair 24 AWG wire, e.g. Belden 9841.

M-2017 User Manual, Rev: B2.5

Page 13

13

1.7 Quick Start

To install the module, follow the steps below:

1. Connect the analog input. See Section 1.2 for the

terminal assignment and Section 1.6 for the wiring

diagram.

2. Connect the module to the RS-485 network using the

DATA+ and DATA- terminals. See Section 1.2 for the

terminal assignment. If the host is only equipped with

an RS-232 interface, then an RS-232 to RS-485

converter will be required. Refer to the “I-7000 Bus

Converter User’s Manual” for more information.

3. Connect the module to the power supply using the +Vs

and GND terminals. See Section 1.2 for the terminal

assignment. Note that the voltage supplied should be

in the range of +10 to +48V DC.

4. For DCON protocol, configure the module by sending

the %AANNTTCCFF and $AA7CiRrr commands.

See Section 2.1 and 2.9 for details. For Modbus RTU

protocol, configure the module using the following

Modbus registers: 40257, 40485 and 40486. See

Section 3.4.1 for details.

The default settings for the module can be found in

Section 1.8.

5. For DCON protocol, in order to read data from the

input channels, send either the #AA or #AAN

command to the module. See Sections 2.2 and 2.3 for

details. For the Modbus RTU protocol, use Function

04h to read the data from the input channels. See

Section 3.2 for details.

6. If the host is a PC with a Windows operating system

installed, the DCON Utility can be used to allow easy

configuration and reading of data. The DCON Utility

M-2017 User Manual, Rev: B2.5

Page 14

14

can be downloaded from the ICP DAS website

(http://www.icpdas.com). The documentation for the

DCON Utility can be found in the ”Getting Started

For I-7000 Series Modules” manual.

Refer to the “I-7000 Bus Converter User’s Manual”

and ”Getting Started For I-7000 Series Modules”

manuals for more details. The “Getting Started For I-

7000 Series Modules” manual can be downloaded from

the ICP DAS website (http://www.icpdas.com).

M-2017 User Manual, Rev: B2.5

Page 15

15

1.8 Default Settings

Default settings for the M-2017 are:

▫ Protocol: Modbus RTU

▫ Module address: 01

▫ Analog input type: Type 08, -10V to 10V

▫ Baud Rate: 9600 bps

▫ Filter set at 60Hz rejection

▫ Normal mode

M-2017 User Manual, Rev: B2.5

Page 16

16

Type

Code

08

09

0A

0B

0C

0D

Zero

Input

0V

0V

0V

0mV

0mV

0mA

Span

Input

+10V

+5V

+1V

+500mV

+150mV

+20mA

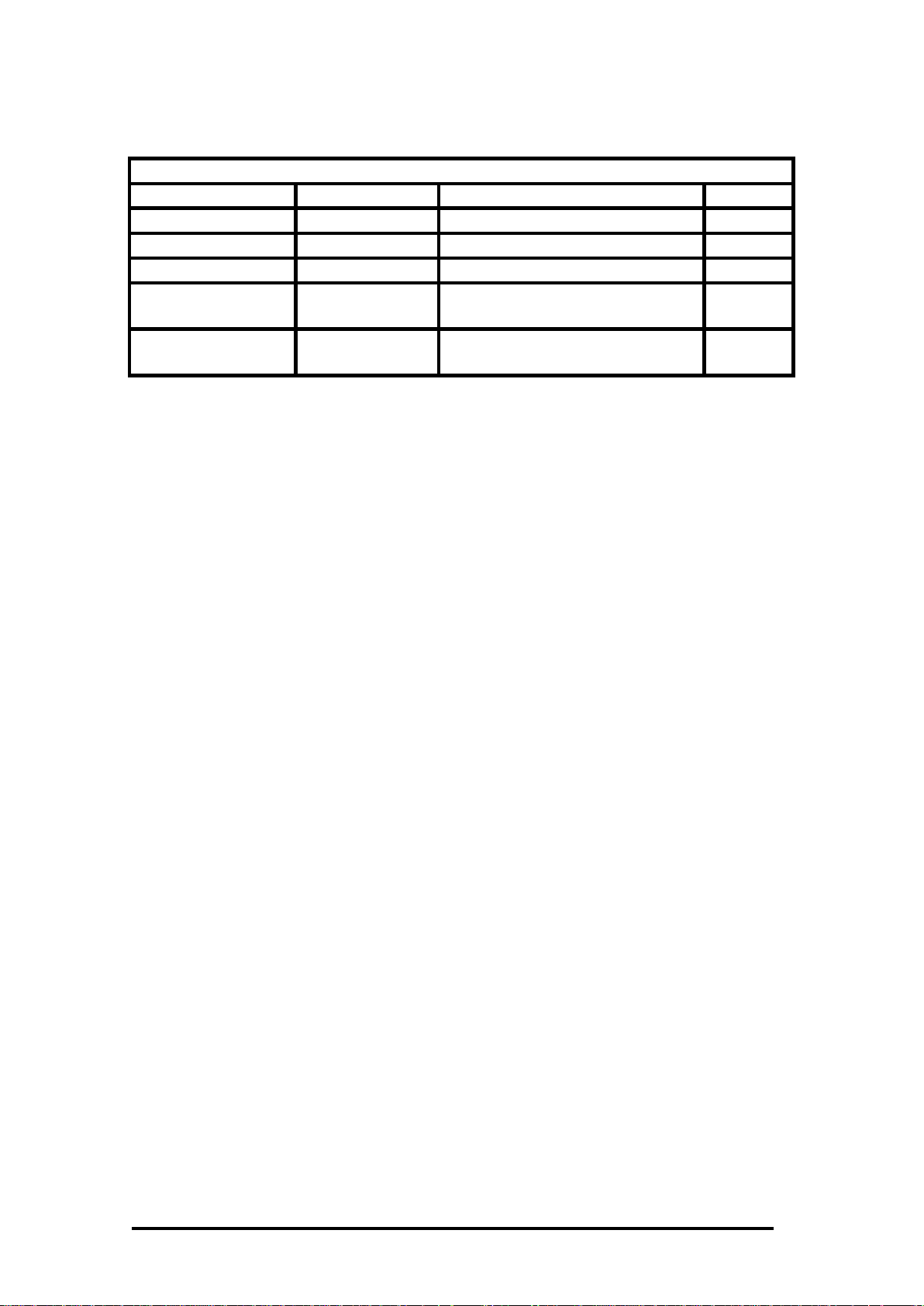

1.9 Calibration

Warning: It is not recommended that calibration be

performed until the process is fully understood.

The calibration procedure is as follows:

1. Warm up the module for 30 minutes.

2. Set the type code of channel 0 to the type you want to

calibrate. Refer to Sections 2.9 for details.

3. Enable calibration. Refer to Section 2.17 for details.

4. Apply the zero calibration voltage/current to channel 0.

5. Send the zero calibration command. Refer to Sections

2.5 for details.

6. Apply the span calibration voltage/current to channel 0.

7. Send the span calibration command. Refer to Sections

2.4 for details.

8. Repeat steps 3 to 7 three times.

Notes:

1. When calibrating type 0D for the M-2017, the SW2

switch of channel 0 should be set to the ON position.

2. Calibration voltages and currents are shown below.

3. The M-2000 series modules must be switched to the

DCON protocol mode before calibrating. Refer to

Section 1.11.1 for details of the switching protocol.

Calibration voltages/current used by the M-2017:

M-2017 User Manual, Rev: B2.5

Page 17

17

7 6 5 4 3 2 1 0 Data

Baud

Key

Description

Baud

Baud Rate

03: 1200

04: 2400

05: 4800

06: 9600

07: 19200

08: 38400

09: 57600

0A: 115200

Data

Data Format

0: N81

1: N82

2: E81

3: O81

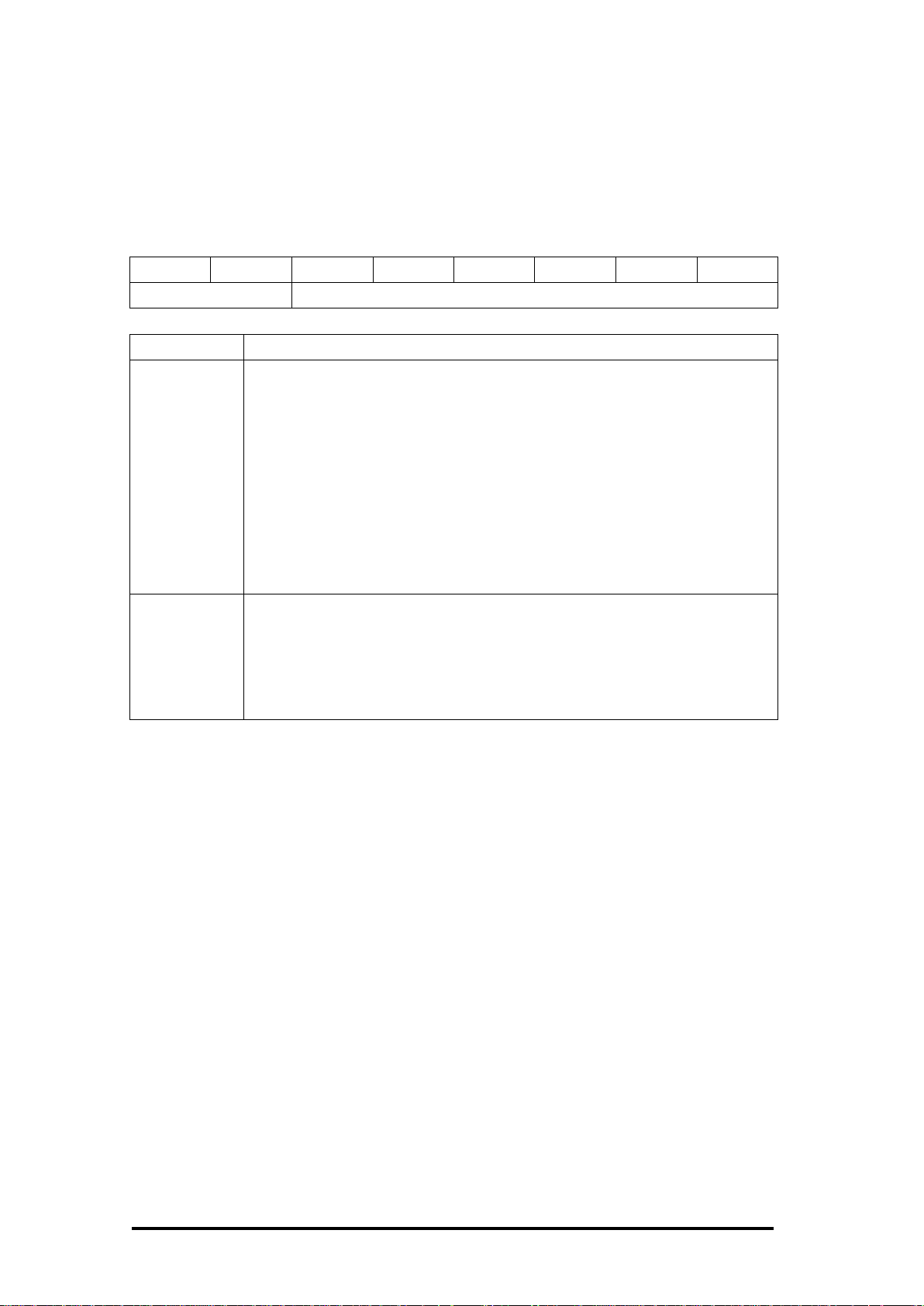

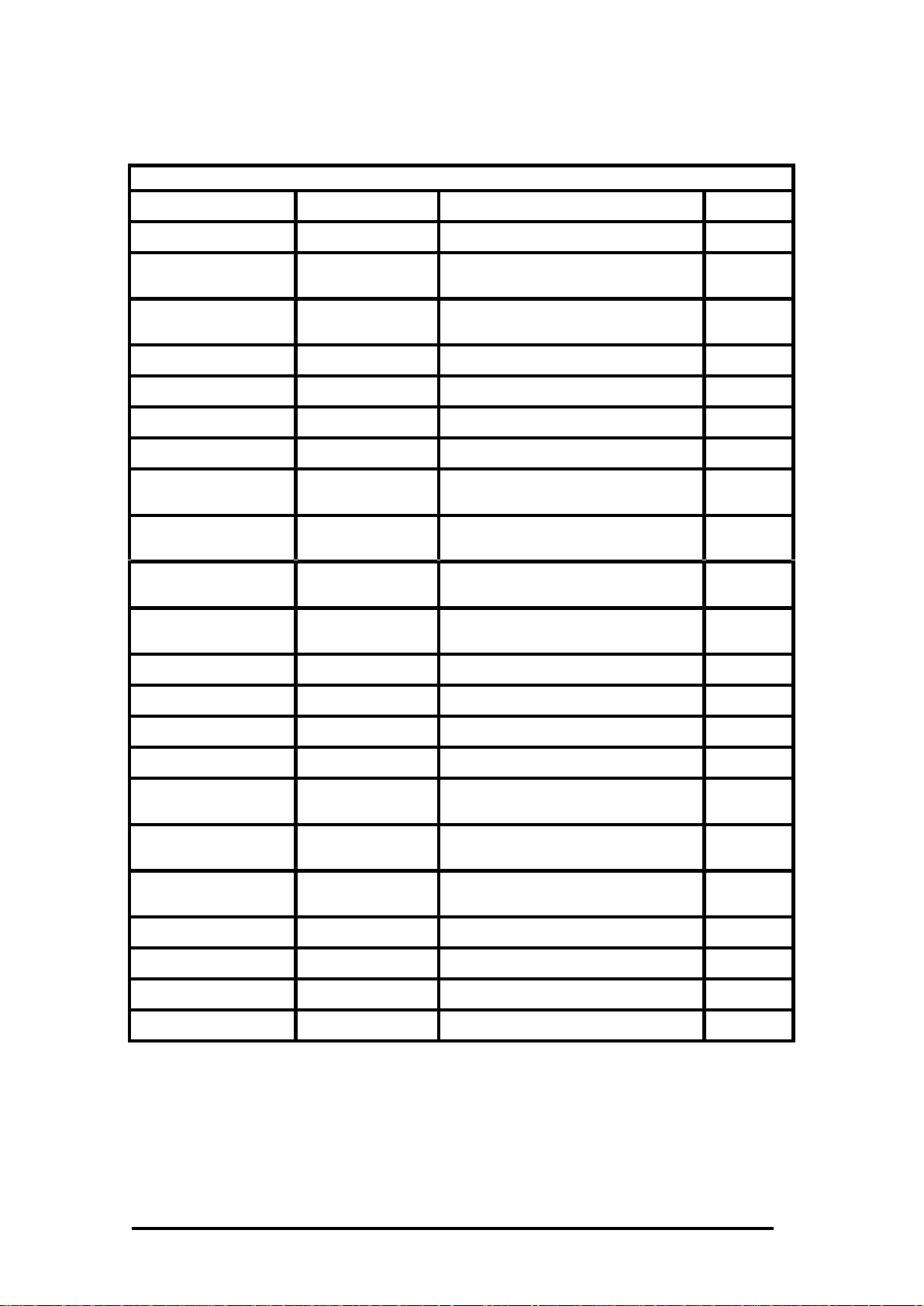

1.10 Configuration Tables

Baud Rate Setting (CC)

M-2017 User Manual, Rev: B2.5

Page 18

18

Type Code

Analog Input Type

Range

07

+4 to +20mA

4mA ~ 20mA

08

+/-10V

-10V ~ 10V

09

+/-5V

-5V ~ 5V

0A

+/-1V

-1V ~ 1V

0B

+/-500mV

-500mV ~ 500mV

0C

+/-150mV

-150mV ~ 150mV

0D

+/-20mA

-20mA ~ 20mA

1A

0 to +20mA

0 ~ 20mA

1D

+4 to +20mA

4mA ~ 20mA

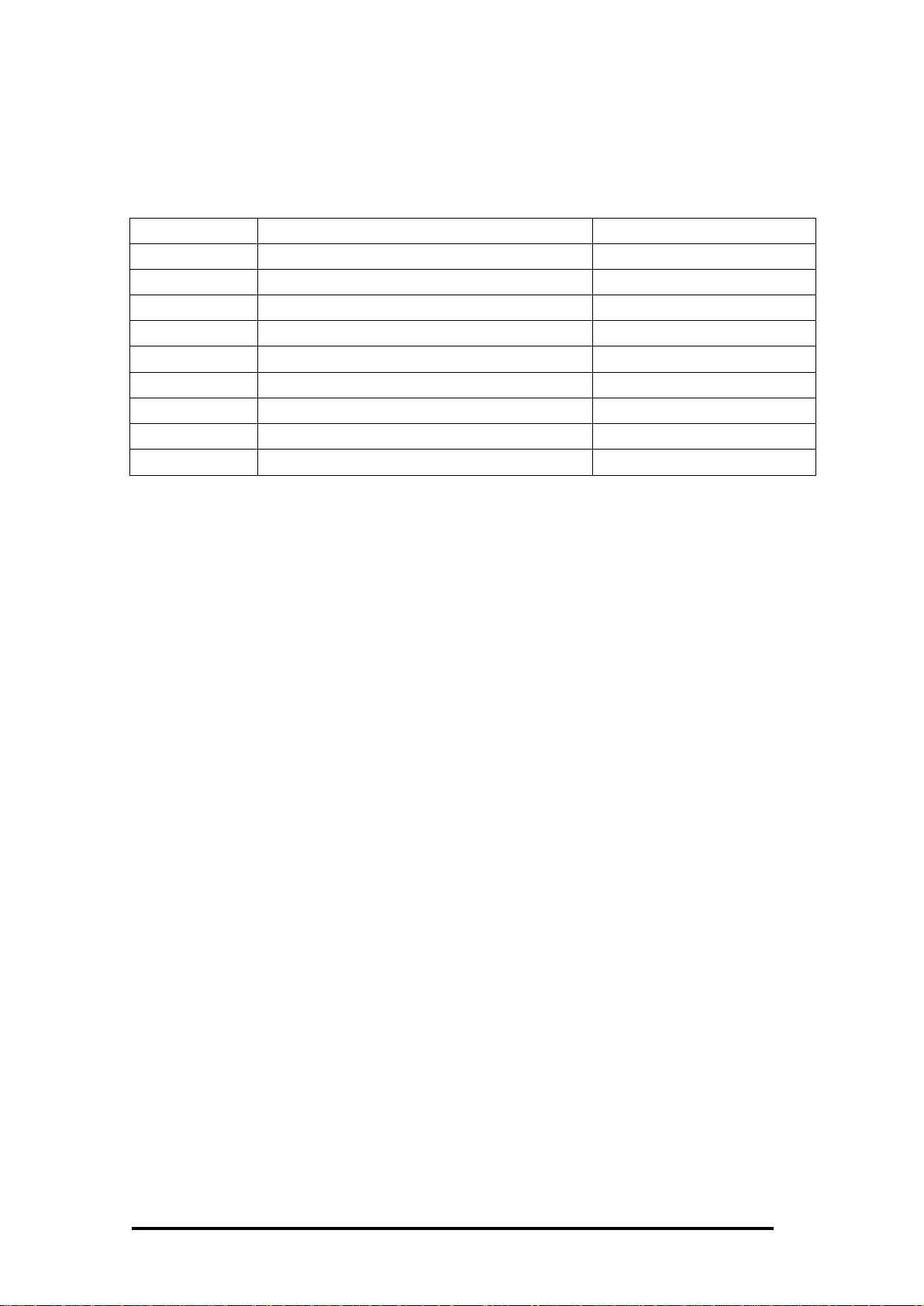

Analog Input Type Setting (TT)

M-2017 User Manual, Rev: B2.5

Page 19

19

7 6 5 4 3 2 1 0 FS

CS

MS

Reserved

DF

Key

Description

DF

Data format

00: Engineering unit

01: % of FSR (full scale range)

10: 2’s complement hexadecimal

MS

Mode settings

0: Normal mode (16 bits)

1: Fast mode (12 bits)

CS

Checksum settings

0: Disabled

1: Enabled

FS

Filter settings

0: 60Hz rejection

1: 50Hz rejection

Data Format Setting (FF)

Note: The reserved bits should be zero.

M-2017 User Manual, Rev: B2.5

Page 20

20

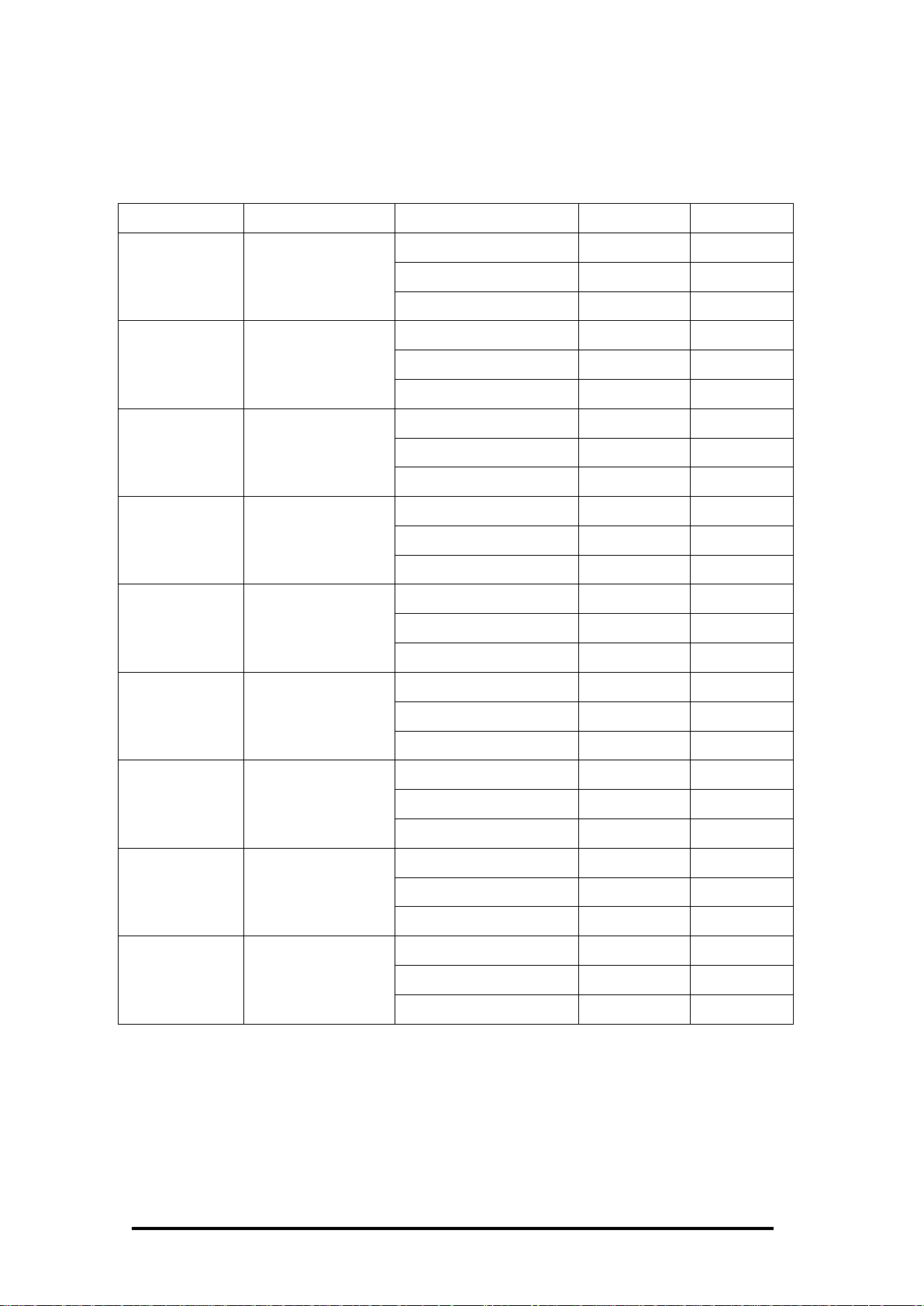

Type code

Input Type

Data Format

+F.S

-F.S.

07

+4 to +20

mA

Engineering unit

+20.000

+04.000

% of FSR

+100.00

+000.00

2’s comp HEX

FFFF

0000

08

-10 to +10

V

Engineering unit

+10.000

-10.000

% of FSR

+100.00

-100.00

2’s comp HEX

7FFF

8000

09

-5 to +5

V

Engineering unit

+5.0000

-5.0000

% of FSR

+100.00

-100.00

2’s comp HEX

7FFF

8000

0A

-1 to +1

V

Engineering unit

+1.0000

-1.0000

% of FSR

+100.00

-100.00

2’s comp HEX

7FFF

8000

0B

-500 to +500

mV

Engineering unit

+500.00

-500.00

% of FSR

+100.00

-100.00

2’s comp HEX

7FFF

8000

0C

-150 to +150

mV

Engineering unit

+150.00

-150.00

% of FSR

+100.00

-100.00

2’s comp HEX

7FFF

8000

0D

-20 to +20

mA

Engineering unit

+20.000

-20.000

% of FSR

+100.00

-100.00

2’s comp HEX

7FFF

8000

1A

0 to +20

mA

Engineering unit

+20.000

+00.000

% of FSR

+100.00

+000.00

2’s comp HEX

FFFF

0000

1D

4 to +20

mA

Engineering unit

+20.000

+04.000

% of FSR

+100.00

+020.00

2’s comp HEX

FFFF

1999

Analog Input Type and Data Format Table

M-2017 User Manual, Rev: B2.5

Page 21

21

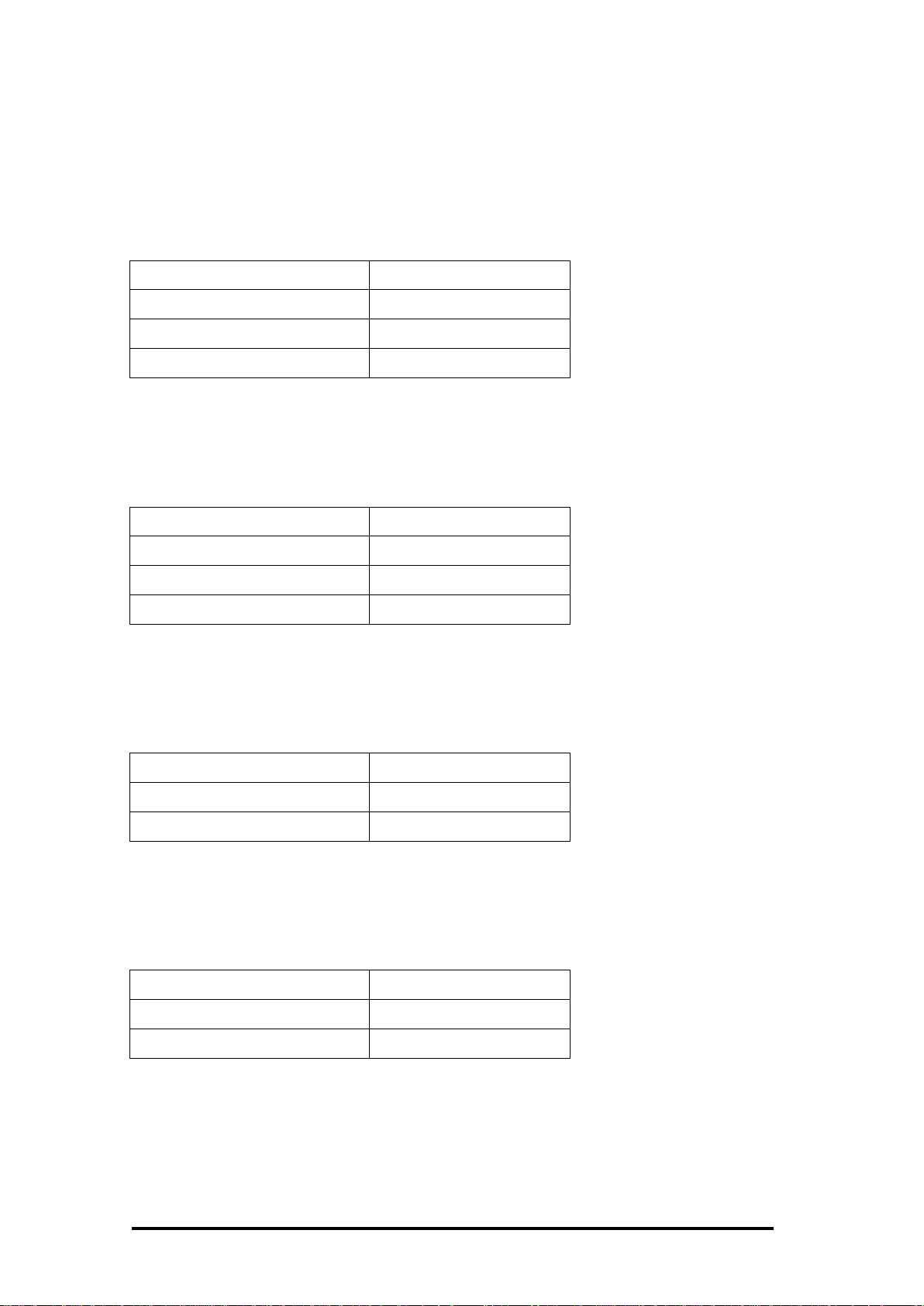

Under Range

Engineering Unit

-9999.9

% of FSR

-999.99

2’s Complement HEX

0000

Under Range

Engineering Unit

-00.000

% of FSR

-000.00

2’s Complement HEX

0000

Under Range

Engineering Unit

-32768

2’s Complement HEX

0000

Under Range

Engineering Unit

0

2’s Complement HEX

0000

4 ~ 20 mA, type code 07, and 0 ~ 20 mA under range

reading with DCON protocol

4 ~ 20 mA, type code 1D, under range reading with

DCON protocol

4 ~ 20 mA, type code 07, and 0 ~ 20 mA under range

reading with Modbus protocol

4 ~ 20 mA, type code 1D, under range reading with

Modbus protocol

M-2017 User Manual, Rev: B2.5

Page 22

22

1.11 M-2000 Notes

The M-2000 series support for the Modbus RTU

communication protocol, which is the default protocol of

the M-2000 series. The communication Baud Rates for

the Modbus RTU protocol can be in the range of 1200 bps

to 115200 bps.

Modbus functions supported by the module are described

in Chapter 3.

1.11.1 Protocol Switching

To switch to the DCON protocol:

1. Set the Modbus register 00257 to 0. See Section 3.4.1

for details.

2. After a power-on reset, the communication protocol

will be changed to DCON.

To switch to the Modbus RTU protocol:

1. Sends the $AAPN command and set N to a value of 1.

Note that the SW1 INIT switch on the bottom side of

the module should be set to the ON position, see the

figure on the next page. See Section 2.15 for details.

2. After a power-on reset, the communication protocol

will be changed to the Modbus RTU protocol.

M-2017 User Manual, Rev: B2.5

Page 23

23

1.11.2 INIT Mode

When the module is powered on, with the SW1 INIT

switch set to the ON position as shown in the figure below,

the module is in INIT mode, (see Section A.1 for details),

and the communication settings are as follows:

1. Address: 00

2. Baud Rate: 9600 bps

3. No checksum

4. Protocol: DCON

If communication with the module is not possible, set the

module to the INIT mode and use the above settings to

communicate with the module. To read the current

settings, send the commands $AA2, (see Section 2.6), and

$AAP, (see Section 2.14). To set new settings, send the

commands %AANNTTCCFF, (see Section 2.1) and

$AAPN, (see Section 2.15). The new communication

settings will be effective after the next power-on reset.

M-2017 User Manual, Rev: B2.5

Page 24

24

1.12 Technical Support

Should you encounter problems while using the M-2000

module, and are unable to find the help you need in this

manual or on our website, please contact ICP DAS

Product Support.

Email: service@icpdas.com

Website: http://www.icpdas.com.tw/contact_us/contact_us.html

When requesting technical support, be prepared to provide

the following information about your system:

1. Module name and serial number: The serial number can

be found printed on the barcode label attached to the

cover of the module.

2. Firmware version: See Section 2.12 and 3.4, Modbus

registers 40481 and 40482, for information regarding

the command used to identify the firmware version.

3. Host configuration (type and operating system)

4. If the problem is reproducible, please give full details

describing the procedure used to reproduce the problem.

5. Specific error messages displayed. If a dialog box with

an error message is displayed, please include the full

text of the dialog box, including the text in the title bar.

6. If the problem involves other programs or hardware

devices, please describe the details of the problem in

full.

7. Any comments and suggestions related to the problem

are welcome.

ICP DAS will reply to your request by email within three

business days.

M-2017 User Manual, Rev: B2.5

Page 25

25

Leading

Character

Module

Address

Command

[CHKSUM]

CR

Leading

Character

Module

Address

Data

[CHKSUM]

CR

2. DCON Protocol

All communication with M-2000 modules consists of

commands generated by the host and responses

transmitted by the M-2000 modules. Each module has a

unique ID number that is used for addressing purposes and

is stored in non-volatile memory. The ID is 01 by default

and can be changed using a user command. All

commands to the modules contain the ID address,

meaning that only the addressed module will respond.

The only exception to this is command ~** (Section 2.23),

which are sent to all modules, but in these cases, the

modules do not reply to the command.

Command Format:

Response Format:

CHKSUM A 2-character checksum that is present

when the checksum setting is enabled. See

Section 1.10 and 2.1 for details.

CR End of command character, carriage return

(0x0D)

M-2017 User Manual, Rev: B2.5

Page 26

26

Checksum Calculation:

1. Calculate the ASCII code sum of all the characters in

the command/response string except for the carriage

return character (CR).

2. The checksum is equal to the sum masked by 0ffh.

Example:

Command string: $012(CR)

1. Sum of the string = “$”+”0”+”1”+”2” =

24h+30h+31h+32h = B7h

2. Therefore the checksum is B7h, and so

CHKSUM = “B7”

3. The command string with the checksum = $012B7(CR)

Response string: !01200600(CR)

1. Sum of the string =

“!”+”0”+”1”+”2”+”0”+”0”+”6”+”0”+”0” =

21h+30h+31h+32h+30h+30h+36h+30h+30h = 1AAh

2. Therefore the checksum is AAh, and so

CHKSUM = “AA”

3. The response string with the checksum

= !01200600AA(CR)

Note:

All characters should be in upper case.

M-2017 User Manual, Rev: B2.5

Page 27

27

General Command Sets

Command

Response

Description

Section

%AANNTTCCFF

!AA

Set Module Configuration

2.1

#AA

>(Data)

Reads the Analog Inputs of All

Channels

2.2

#AAN

>(Data)

Reads the Analog Input of the

Specified Channel

2.3

$AA0

!AA

Performs a Span Calibration

2.4

$AA1

!AA

Performs a Zero Calibration

2.5

$AA2

!AANNTTCCFF

Reads the Module Configuration

2.6

$AA5VV

!AA

Enables/Disables the Channel

2.7

$AA6

!AAVV

Reads the Channel Enable/Disable

Status

2.8

$AA7CiRrr

!AA

Sets the Single Channel Range

Configuration

2.9

$AA8Ci

!AACiRrr

Reads the Single Channel Range

Configuration

2.10

$AAA

>(data)

Reads the Analog Inputs of All

Channels in Hex Format

2.11

$AAF

!AA(Data)

Reads the Firmware Version

2.12

$AAM

!AA(Data)

Reads the Module Name

2.13

$AAP

!AASC

Reads the Protocol

2.14

$AAPN

!AA

Sets the Protocol

2.15

$AAS1

!AA

Reloads the Default Calibration

Parameters

2.16

~AACT

!AAVV

Reads the 4mA under range

threshold

2.17

~AACTVV

!AA

Sets the 4mA under range

threshold

2.18

~AAEV

!AA

Enables/Disables the Calibration

2.19

~AAO(Name)

!AA

Sets the Module Name

2.20

~AARD

!AAVV

Reads the response delay setting

2.21

~AARDVV

!AA

Sets the response delay setting

2.22

M-2017 User Manual, Rev: B2.5

Page 28

28

Host Watchdog Command Sets

Command

Response

Description

Section

~**

No Response

Host OK

2.23

~AA0

!AASS

Reads the Host Watchdog Status

2.24

~AA1

!AA

Resets the Host Watchdog Status

2.25

~AA2

!AAETT

Reads the Host Watchdog

Timeout Settings

2.26

~AA3ETT

!AA

Sets the Host Watchdog Timeout

Settings

2.27

M-2017 User Manual, Rev: B2.5

Page 29

29

2.1 %AANNTTCCFF

Description:

Sets the configuration of an analog input module.

Syntax:

%AANNTTCCFF[CHKSUM](CR)

% Delimiter character

AA Address of the module to be configured in

hexadecimal format (00 to FF)

NN New address of the module in hexadecimal format

(00 to FF)

TT New type code, see Section 1.11 for details. Not

used by the M-2017. For the M-2017, use the

$AA7CiRrr command to set the type of each

channel, see Section 2.9 for details.

CC New Baud Rate code, see Section 1.10 for details.

To change the Baud Rate, the INIT switch must be

switched to the ON position. See Section A.1 for

details.

FF Used to set the data format, checksum, and filter

settings (Section 1.10). To change the checksum

setting, the INIT switch must be switched to the

ON position. See Section A.1 for details.

M-2017 User Manual, Rev: B2.5

Page 30

30

Response:

Valid Response: !AA[CHKSUM](CR)

Invalid Response: ?AA[CHKSUM](CR)

! Delimiter character for a valid response

? Delimiter character for an invalid response. If

changing the Baud Rate or checksum settings

without switching the INIT switch to the ON

position, the module will return an invalid

command.

AA Address of the module in hexadecimal format (00

to FF)

There will be no response if the command syntax is

incorrect, there is a communication error, or there is no

module with the specified address.

M-2017 User Manual, Rev: B2.5

Page 31

31

Examples:

Command: %0102000600 Response: !02

Change the address of module 01 to 02. The module

returns a valid response.

Command: %0202000602 Response: !02

Set the data format of module 02 to be 2 (2’s

complement hexadecimal). The module returns a

valid response.

Command: %0101000A00 Response: ?01

Change the Baud Rate of module 01 to 115200bps.

The module returns an invalid command, because it

is not in INIT* mode.

Command: %0101000A00 Response: !01

Change the Baud Rate of module 01 to 115200bps

and the module is in INIT* mode. The module

returns a valid response.

Related Commands:

Section 2.6 $AA2

Related Topics:

Section 1.10 Configuration Tables, Section A.1 INIT

Mode

M-2017 User Manual, Rev: B2.5

Page 32

32

Notes:

1. Changes to the address, type code, data format and

filter settings take effect immediately after a valid

command is received. Changes to the Baud Rate and

checksum settings take effect on the next power on

reset.

M-2017 User Manual, Rev: B2.5

Page 33

33

2.2 #AA

Description:

Reads the data from every analog input channel.

Syntax:

#AA[CHKSUM](CR)

# Delimiter character

AA Address of the module to be read (00 to FF)

Response:

Valid Response: >(Data)[CHKSUM](CR)

Invalid Response: ?AA[CHKSUM](CR)

> Delimiter character for a valid response

? Delimiter character for an invalid response

(Data) Data from every analog input channels, see

Section 1.10 for the details of data format.

There will be no response if the command syntax is

incorrect, there is a communication error, or there is no

module with the specified address.

M-2017 User Manual, Rev: B2.5

Page 34

34

Examples:

Command: #01 Response:

>+025.12+020.45+012.78+018.97+003.24+015.35+008.0

7+014.79

Reads module 01 and receives the data in engineering

format.

Command: #02 Response:

>4C532628E2D683A20F2ADBA16284BA71

Reads module 02 and receives the data in hexadecimal

format.

Command: #03 Response:

>-9999.9-9999.9-9999.9-9999.9-9999.9-9999.9-9999.9-

9999.9

Reads module 03 and the data is under range.

Related Commands:

Section 2.1 %AANNTTCCFF, Section 2.6 $AA2

Related Topics:

Section 1.10 Configuration Tables

M-2017 User Manual, Rev: B2.5

Page 35

35

2.3 #AAN

Description:

Reads the analog input of channel N.

Syntax:

#AAN[CHKSUM](CR)

# Delimiter character

AA Address of the module to be read (00 to FF)

N The channel to be read, zero based.

Response:

Valid Response: >(Data)[CHKSUM](CR)

Invalid Response: ?AA[CHKSUM](CR)

> Delimiter character for a valid response

? Delimiter character for an invalid response. An

invalid command is returned if the specified

channel is incorrect.

(Data) Analog input data of the specified channel, see

Section 1.10 for details of the data format.

AA Address of the responding module (00 to FF)

There will be no response if the command syntax is

incorrect, there is a communication error, or there is no

module with the specified address.

M-2017 User Manual, Rev: B2.5

Page 36

36

Examples:

Command: #032 Response: >+025.13

Reads data from channel 2 of module 03.

Command: #029 Response: ?02

Reads data from channel 9 of module 02. An error is

returned because channel 9 is invalid.

Related Commands:

Section 2.1 %AANNTTCCFF, Section 2.6 $AA2

Related Topics:

Section 1.10 Configuration Tables

M-2017 User Manual, Rev: B2.5

Page 37

37

2.4 $AA0

Description:

Performs a span calibration.

Syntax:

$AA0[CHKSUM](CR)

$ Delimiter character

AA Address of the module to be calibrated (00 to FF)

0 Command for the span calibration

Response:

Valid Response: !AA[CHKSUM](CR)

Invalid Response: ?AA[CHKSUM](CR)

! Delimiter character for a valid response

? Delimiter character for an invalid response

AA Address of the responding module (00 to FF)

There will be no response if the command syntax is

incorrect, there is a communication error, or there is no

module with the specified address.

M-2017 User Manual, Rev: B2.5

Page 38

38

Examples:

Command: $010 Response: !01

Performs a span calibration on module 01 and returns

a valid response.

Command: $020 Response: ?02

Performs a span calibration on module 02. An

invalid command is returned because the “enable

calibration” command was not sent in advance.

Related Commands:

Section 2.5 $AA1, Section 2.19 ~AAEV

Related Topics:

Section 1.9 Calibration

Notes:

1. This command is only applicable to M-2017 modules.

2. The “enable calibration” command, ~AAEV, must be

sent before this command is used, see Section 1.9 for

details.

M-2017 User Manual, Rev: B2.5

Page 39

39

2.5 $AA1

Description:

Performs a zero calibration.

Syntax:

$AA1[CHKSUM](CR)

$ Delimiter character

AA Address of the module to be set (00 to FF)

1 Command for the zero calibration

Response:

Valid Response: !AA[CHKSUM](CR)

Invalid Response: ?AA[CHKSUM](CR)

! Delimiter character for a valid response

? Delimiter character for an invalid response

AA Address of the responding module (00 to FF)

There will be no response if the command syntax is

incorrect, there is a communication error, or there is no

module with the specified address.

M-2017 User Manual, Rev: B2.5

Page 40

40

Examples:

Command: $011 Response: !01

Performs a zero calibration on module 01 and

returns a valid response.

Command: $021 Response: ?02

Performs a zero calibration on module 02. An

invalid command is returned because the “enable

calibration” command was not sent in advance.

Related Commands:

Section 2.4 $AA0, Section 2.19 ~AAEV

Related Topics:

Section 1.9 Calibration

Notes:

1. This command is only applicable to M-2017 modules.

2. The “enable calibration” command, ~AAEV, must be

sent before this command is used, see Section 1.9 for

details.

M-2017 User Manual, Rev: B2.5

Page 41

41

2.6 $AA2

Description:

Reads the module configuration.

Syntax:

$AA2[CHKSUM](CR)

$ Delimiter character

AA Address of the module to be read (00 to FF)

2 Command to read the module configuration

Response:

Valid Response: !AATTCCFF[CHKSUM](CR)

Invalid Response: ?AA[CHKSUM](CR)

! Delimiter character for a valid response

? Delimiter character for an invalid response

AA Address of the responding module (00 to FF)

TT Type code of the module, see Section 1.10 for

details. It is 00 for M-2017.

CC Baud Rate code of the module, see Section 1.10

for details.

FF Data format, checksum settings and filter

settings of the module, see Section 1.10 for

details.

There will be no response if the command syntax is

incorrect, there is a communication error, or there is no

module with the specified address.

M-2017 User Manual, Rev: B2.5

Page 42

42

Examples:

Command: $012 Response: !01050600

Reads the configuration of module 01.

Command: $022 Response: !02030602

Reads the configuration of module 02.

Related Commands:

Section 2.1 %AANNTTCCFF

Related Topics:

Section 1.10 Configuration Tables, Section A.1 INIT

Mode

M-2017 User Manual, Rev: B2.5

Page 43

43

2.7 $AA5VV

Description:

Specifies the channel(s) to be enabled.

Syntax:

$AA5VV[CHKSUM](CR)

$ Delimiter character

AA Address of the module to be set (00 to FF)

5 Command to set the channel(s) to enabled

VV A two-digit hexadecimal value, where bit 0

corresponds to channel 0, bit 1 corresponds to

channel 1, etc. When the bit is 1 it means that

the channel is enabled and 0 means that the

channel is disabled.

Response:

Valid Response: !AA[CHKSUM](CR)

Invalid Response: ?AA[CHKSUM](CR)

! Delimiter character for a valid response

? Delimiter character for an invalid response. An

invalid command is returned if an attempt is

made to enable a channel that is not present.

AA Address of the responding module (00 to FF)

M-2017 User Manual, Rev: B2.5

Page 44

44

There will be no response if the command syntax is

incorrect, there is a communication error, or there is no

module with the specified address.

Examples:

Command: $0153A Response: !01

Enables channels 1, 3, 4, and 5 and disables all other

channels of module 01. The module returns a valid

response.

Command: $016 Response: !013A

Reads the channel status of module 01 and returns a

response of 3A, meaning that channels 1, 3, 4, and 5

are enabled and all other channels are disabled.

Related Commands:

Section 2.8 $AA6

Note:

1. It is recommended that only the channels that will be

used are enabled.

M-2017 User Manual, Rev: B2.5

Page 45

45

2.8 $AA6

Description:

Reads the enabled/disabled status of each channel.

Syntax:

$AA6[CHKSUM](CR)

$ Delimiter character

AA Address of the module to be read (00 to FF)

6 Command to read the channel status

Response:

Valid Response: !AAVV[CHKSUM](CR)

Invalid Response: ?AA[CHKSUM](CR)

! Delimiter character for a valid response

? Delimiter character for an invalid response

AA Address of the responding module (00 to FF)

VV A two-digit hexadecimal value, where bit 0

corresponds to channel 0, bit 1 corresponds to

channel 1, etc. When the bit is 1 it means that

the channel is enabled and 0 means that the

channel is disabled.

There will be no response if the command syntax is

incorrect, there is a communication error, or there is no

module with the specified address.

M-2017 User Manual, Rev: B2.5

Page 46

46

Examples:

Command: $0153A Response: !01

Enables channels 1, 3, 4, and 5 and disables all other

channels of module 01. The module returns a valid

response.

Command: $016 Response: !013A

Reads the channel status of module 01 and returns a

response of 3A, meaning that channels 1, 3, 4, and 5

are enabled and all other channels are disabled.

Related Commands:

Section 2.7 $AA5VV

M-2017 User Manual, Rev: B2.5

Page 47

47

2.9 $AA7CiRrr

Description:

Sets the type code of a channel.

Syntax:

$AA7CiRrr[CHKSUM](CR)

$ Delimiter character

AA Address of the module to be set (00 to FF)

7 Command to set the channel range code

Ci i specifies the input channel to be set (0-7 for M-

2017).

Rrr rr represents the type code of the channel to be

set. Refer to the Analog Input Type Setting table

in Section 1.10 for details.

Response:

Valid Response: !AA [CHKSUM](CR)

Invalid Response: ?AA[CHKSUM](CR)

! Delimiter character for a valid response

? Delimiter character for an invalid response or

invalid type code

M-2017 User Manual, Rev: B2.5

Page 48

48

There will be no response if the command syntax is

incorrect, there is a communication error, or there is no

module with the specified address.

Examples:

Command: $017C0R0B Response: !01

Sets the type code for channel 0 of module 01 to be

0B (-500~+500mV) and the module returns a valid

response.

Command: $027C5R1A Response: !02

Sets the type code for channel 5 of module 02 to be

1A (+0~+20mA) and the module returns a valid

response.

Command: $037C1R30 Response: ?03

Sets the type code for channel 1 of module 03 to be

30. The module returns an invalid response because

the type code is invalid.

Related Commands:

Section 2.10 $AA8Ci

Related Topics:

Section 1.10 Configuration Tables

M-2017 User Manual, Rev: B2.5

Page 49

49

2.10 $AA8Ci

Description:

Reads the type code information of a channel.

Syntax:

$AA8Ci[CHKSUM](CR)

$ Delimiter character

AA Address of the module to be read (00 to FF)

8 Command to read the type code of a channel

Ci Specifies which channel to access for the type

code information (i=0-7 for M-2017).

Response:

Valid Response: !AACiRrr[CHKSUM](CR)

Invalid Response: ?AA[CHKSUM](CR)

! Delimiter character for a valid response

? Delimiter character for an invalid response or

invalid channel

AA Address of the responding module (00 to FF)

Ci Specifies which input channel to access to

retrieve the type code information.

Rrr Represents the type code of the specified input

channel. Refer to the Analog Input Type Setting

table in Section 1.10 for details.

M-2017 User Manual, Rev: B2.5

Page 50

50

There will be no response if the command syntax is

incorrect, there is a communication error, or there is no

module with the specified address.

Examples:

Command: $018C0 Response: !01C0R0C

Reads the channel 0 input range of module 01 and

returns 0C (-150~+150mV).

Related Commands:

Section 2.9 $AA7CiRrr

Related Topics:

Section 1.10 Configuration Tables

M-2017 User Manual, Rev: B2.5

Page 51

51

2.11 $AAA

Description:

Reads the data from every analog input channel in hex

format.

Syntax:

$AAA[CHKSUM](CR)

$ Delimiter character

AA Address of the module to be read (00 to FF)

A Command to read every analog input

Response:

Valid Response: >(Data)[CHKSUM](CR)

Invalid Response: ?AA[CHKSUM](CR)

> Delimiter character for a valid response

? Delimiter character for an invalid response

(Data) Data from every analog input channels in hex

format.

There will be no response if the command syntax is

incorrect, there is a communication error, or there is no

module with the specified address.

M-2017 User Manual, Rev: B2.5

Page 52

52

Examples:

Command: $01A

Response: >0000012301257FFF1802744F98238124

Reads module 01 and receives the data in hex format.

Related Commands:

Section 2.2 #AA

M-2017 User Manual, Rev: B2.5

Page 53

53

2.12 $AAF

Description:

Reads the firmware version of a module.

Syntax:

$AAF[CHKSUM](CR)

$ Delimiter character

AA Address of the module to be read (00 to FF)

F Command to read the firmware version

Response:

Valid Response: !AA(Data)[CHKSUM](CR)

Invalid Response: ?AA[CHKSUM](CR)

! Delimiter character for a valid response

? Delimiter character for an invalid response

AA Address of the responding module (00 to FF)

(Data) A string indicating the firmware version of the

module

There will be no response if the command syntax is

incorrect, there is a communication error, or there is no

module with the specified address.

Examples:

Command: $01F Response: !01A2.0

Reads the firmware version of module 01, and shows

that it is version A2.0.

M-2017 User Manual, Rev: B2.5

Page 54

54

2.13 $AAM

Description:

Reads the name of a module.

Syntax:

$AAM[CHKSUM](CR)

$ Delimiter character

AA Address of the module to be read (00 to FF)

M Command to read the module name

Response:

Valid Response: !AA(Name)[CHKSUM](CR)

Invalid Response: ?AA[CHKSUM](CR)

! Delimiter character for a valid response

? Delimiter character for an invalid response

AA Address of the responding module (00 to FF)

(Name) A string showing the name of the module

There will be no response if the command syntax is

incorrect, there is a communication error, or there is no

module with the specified address.

M-2017 User Manual, Rev: B2.5

Page 55

55

Examples:

Command: $01M Response: !012017

Reads the module name of module 01 and returns the

name “2017”.

Related Commands:

Section 2.20 ~AAO(Name)

M-2017 User Manual, Rev: B2.5

Page 56

56

2.14 $AAP

Description:

Reads the communication protocol information.

Syntax:

$AAP[CHKSUM](CR)

$ Delimiter character

AA Address of the module to be read (00 to FF)

P Command to read the communication protocol

Response:

Valid Response: !AASC[CHKSUM](CR)

Invalid Response: ?AA[CHKSUM](CR)

! Delimiter character for a valid response

? Delimiter character for an invalid response

AA Address of the responding module (00 to FF)

S The protocols supported by the module

0: only DCON protocol is supported

1: both the DCON and Modbus RTU protocols

are supported

C Current protocol saved in EEPROM that will be

used at the next power on reset

0: the protocol set in EEPROM is DCON

1: the protocol set in EEPROM is Modbus RTU

There will be no response if the command syntax is

incorrect, there is a communication error, or there is no

module with the specified address.

M-2017 User Manual, Rev: B2.5

Page 57

57

Examples:

Command: $01P Response: !0110

Reads the communication protocol of module 01 and

returns a response of 10 meaning that it supports both

the DCON and Modbus RTU protocols and the

protocol that will be used at the next power on reset

is DCON.

Related Commands:

Section 2.15 $AAPN

M-2017 User Manual, Rev: B2.5

Page 58

58

2.15 $AAPN

Description:

Sets the communication protocol.

Syntax:

$AAPN[CHKSUM](CR)

$ Delimiter character

AA Address of the module to be read (00 to FF)

P Command to set the communication protocol

N 0: DCON protocol

1: Modbus RTU protocol

Before using this command, the SW1 INIT

switch must be in the ON position, see Section

A.1 for details. The new protocol is saved in the

EEPROM and will be effective after the next

power on reset.

Response:

Valid Response: !AA[CHKSUM](CR)

Invalid Response: ?AA[CHKSUM](CR)

! Delimiter character for a valid response

? Delimiter character for an invalid response

AA Address of the responding module (00 to FF)

There will be no response if the command syntax is

incorrect, there is a communication error, or there is no

module with the specified address.

M-2017 User Manual, Rev: B2.5

Page 59

59

Examples:

Command: $01P1 Response: ?01

Sets the communication protocol of module 01 to

Modbus RTU and returns an invalid response

because the module is not in INIT mode.

Command: $01P1 Response: !01

Sets the communication protocol of module 01 to

Modbus RTU and returns a valid response.

Related Commands:

Section 2.14 $AAP

Related Topics:

Section A.1 INIT Mode

M-2017 User Manual, Rev: B2.5

Page 60

60

2.16 $AAS1

Description:

Reloads the factory default calibration parameters,

including the internal calibration parameters.

Syntax:

$AAS1[CHKSUM](CR)

$ Delimiter character

AA Address of the module to be reloaded (00 to FF)

S1 Command to reload the factory default

calibration parameters

Response:

Valid Response: !AA[CHKSUM](CR)

Invalid Response: ?AA[CHKSUM](CR)

! Delimiter character for a valid response

? Delimiter character for an invalid response

AA Address of the responding module (00 to FF)

There will be no response if the command syntax is

incorrect, there is a communication error, or there is no

module with the specified address.

Examples:

Command: $01S1 Response: !01

Sends the command to reload the factory default

calibration parameters and returns a valid response.

M-2017 User Manual, Rev: B2.5

Page 61

61

Related Topics:

Section 1.9 Calibration

M-2017 User Manual, Rev: B2.5

Page 62

62

2.17 ~AACT

Description:

Reads the under range threshold of the range with type

code 1D, 4mA ~ 20mA.

Syntax:

~AACT[CHKSUM](CR)

~ Delimiter character

AA Address of the module to be read (00 to FF)

CT Command to read the under range threshold of

the range with type code 1D

Response:

Valid Response: !AAVV[CHKSUM](CR)

Invalid Response: ?AA[CHKSUM](CR)

! Delimiter character for a valid response

? Delimiter character for an invalid response

AA Address of the responding module (00 to FF)

VV Two hexadecimal digits to represent the under

range threshold value in 0.1 mA, for example,

01 denotes 0.1mA and 1E denotes 3mA. The

max allowable value is 40 (28h).

There will be no response if the command syntax is

incorrect, there is a communication error, or there is no

module with the specified address.

M-2017 User Manual, Rev: B2.5

Page 63

63

Examples:

Command: ~01CT Response: !011E

Sends a command to read the under range threshold

of module 01 and shows that it is 3.0mA.

Related Commands:

Section 2.18 ~AACTVV

M-2017 User Manual, Rev: B2.5

Page 64

64

2.18 ~AACTVV

Description:

Sets the under range threshold value for the range with

type code 1D, 4 ~ 20mA.

Syntax:

~AACTVV[CHKSUM](CR)

~ Delimiter character

AA Address of the module to be read (00 to FF)

CT Command to set the under range threshold for

the range with type code 1D

VV Two hexadecimal digits to represent the under

range threshold value in 0.1 mA, for example,

01 denotes 0.1mA and 1E denotes 3mA. The

max allowable value is 40 (28h).

Response:

Valid Response: !AA[CHKSUM](CR)

Invalid Response: ?AA[CHKSUM](CR)

! Delimiter character for a valid response

? Delimiter character for an invalid response

AA Address of the responding module (00 to FF)

There will be no response if the command syntax is

incorrect, there is a communication error, or there is no

module with the specified address.

M-2017 User Manual, Rev: B2.5

Page 65

65

Examples:

Command: ~01CT14 Response: !01

Sends a command to set the under range threshold of

the range with type code 1D of module 01 to 2.0mA

and returns a valid response.

Related Commands:

Section 2.17 ~AACT

M-2017 User Manual, Rev: B2.5

Page 66

66

2.19 ~AAEV

Description:

Enable/Disable module calibration.

Syntax:

~AAEV[CHKSUM](CR)

~ Delimiter character

AA Address of the module to be set (00 to FF)

E Command to enable/disable calibration

V 1: enable calibration

0: disable calibration

Response:

Valid Response: !AA[CHKSUM](CR)

Invalid Response: ?AA[CHKSUM](CR)

! Delimiter character for a valid response

? Delimiter character for an invalid response

AA Address of the responding module (00 to FF)

There will be no response if the command syntax is

incorrect, there is a communication error, or there is no

module with the specified address.

M-2017 User Manual, Rev: B2.5

Page 67

67

Examples:

Command: $010 Response: ?01

Sends the command to perform a span calibration on

module 01. It returns an invalid response because the

“enable calibration” command was not sent in

advance.

Command: ~01E1 Response: !01

Enables calibration on module 01 and returns a valid

response.

Command: $010 Response: !01

Sends the command to perform a span calibration on

module 01 and returns a valid response.

Related Commands:

Section 2.4 $AA0, Section 2.5 $AA1

Related Topics:

Section 1.9 Calibration

M-2017 User Manual, Rev: B2.5

Page 68

68

2.20 ~AAO(Name)

Description:

Sets the name of a module.

Syntax:

~AAO(Name)[CHKSUM](CR)

~ Delimiter character

AA Address of the module to be set (00 to FF)

O Command to set the module name

(Name) New name of the module (max. 6 characters).

Response:

Valid Response: !AA[CHKSUM](CR)

Invalid Response: ?AA[CHKSUM](CR)

! Delimiter character for a valid response

? Delimiter character for an invalid response

AA Address of the responding module (00 to FF)

There will be no response if the command syntax is

incorrect, there is a communication error, or there is no

module with the specified address.

M-2017 User Manual, Rev: B2.5

Page 69

69

Examples:

Command: ~01O2017A Response: !01

Sets the name of module 01 to be “2017A” and

returns a valid response.

Command: $01M Response: !012017A

Reads the name of module 01 and returns “2017A”.

Related Commands:

Section 2.13 $AAM

M-2017 User Manual, Rev: B2.5

Page 70

70

2.21 ~AARD

Description:

Reads the response delay time value of a module.

Syntax:

~AARD[CHKSUM](CR)

~ Delimiter character

AA Address of the module to be read (00 to FF)

RD Command to read the response delay time value

Response:

Valid Response: !AAVV[CHKSUM](CR)

Invalid Response: ?AA[CHKSUM](CR)

! Delimiter character for a valid response

? Delimiter character for an invalid response

AA Address of the responding module (00 to FF)

VV Two hexadecimal digits to represent the

response delay time value in milli-second, for

example, 01 denotes 1ms and 1E denotes 30ms.

The max allowable value is 30 (1Eh).

There will be no response if the command syntax is

incorrect, there is a communication error, or there is no

module with the specified address.

M-2017 User Manual, Rev: B2.5

Page 71

71

Examples:

Command: ~01RD Response: !0102

Reads the response delay time value of module 01

and returns 02, which denotes that the response delay

time value is 2ms.

Related Commands:

Section 2.22 ~AARDVV

M-2017 User Manual, Rev: B2.5

Page 72

72

2.22 ~AARDVV

Description:

Sets the response delay time value of a module.

Syntax:

~AARDVV[CHKSUM](CR)

~ Delimiter character

AA Address of the module to be read (00 to FF)

RD Command to set the communication protocol

VV Two hexadecimal digits to represent the

response delay time value in milli-second, for

example, 01 denotes 1ms and 1E denotes 30s.

The max allowable value is 30 (1Eh).

Response:

Valid Response: !AA[CHKSUM](CR)

Invalid Response: ?AA[CHKSUM](CR)

! Delimiter character for a valid response

? Delimiter character for an invalid response

AA Address of the responding module (00 to FF)

There will be no response if the command syntax is

incorrect, there is a communication error, or there is no

module with the specified address.

M-2017 User Manual, Rev: B2.5

Page 73

73

Examples:

Command: ~01RD06 Response: !01

Sets the response delay time value to 6ms. The

module returns a valid response.

Command: ~01RD Response: !0106

Reads the response delay time value of module 01.

The module returns 06, which denotes that the

response delay time value is 6ms.

Related Commands:

Section 2.21 ~AARD

M-2017 User Manual, Rev: B2.5

Page 74

74

2.23 ~**

Description:

Informs all modules that the host is OK.

Syntax:

~**[CHKSUM](CR)

~ Delimiter character

** Host OK command

Response:

No response.

Examples:

Command: ~** No response

Sends a “Host OK” command to all modules.

Related Commands:

Section 2.24 ~AA0, Section 2.25 ~AA1, Section 2.26

~AA2, Section 2.27 ~AA3EVV

Related Topics:

Section A.2 Dual Watchdog Operation

Note:

After sending this command, there must be a 2ms delay

before the next command can be sent.

M-2017 User Manual, Rev: B2.5

Page 75

75

2.24 ~AA0

Description:

Reads the host watchdog status of a module.

Syntax:

~AA0[CHKSUM](CR)

~ Delimiter character

AA Address of the module to be read (00 to FF)

0 Command to read the module status

Response:

Valid Response: !AASS[CHKSUM](CR)

Invalid Response: ?AA[CHKSUM](CR)

! Delimiter character for a valid response

? Delimiter character for an invalid response

AA Address of the responding module (00 to FF)

SS Two hexadecimal digits that represent the host

watchdog status, where:

Bit 7: 0 indicates that the host watchdog is

disabled and 1 indicates the host watchdog is

enabled,

Bit 2: 1 indicates that a host watchdog time out

has occurred and 0 indicates that no host

watchdog time out has occurred.

The host watchdog status is stored in EEPROM

and can only be reset using the ~AA1 command.

M-2017 User Manual, Rev: B2.5

Page 76

76

There will be no response if the command syntax is

incorrect, there is a communication error, or there is no

module with the specified address.

Examples:

Command: ~010 Response: !0100

Reads the host watchdog status of module 01 and

returns 00, meaning that the host watchdog is

disabled and no host watchdog time out has occurred.

Command: ~020 Response: !0204

Reads the host watchdog status of module 02 and

returns 04, meaning that a host watchdog timeout has

occurred.

Related Commands:

Section 2.23 ~**, Section 2.25 ~AA1, Section 2.26 ~AA2,

Section 2.27 ~AA3EVV

Related Topics:

Section A.2 Dual Watchdog Operation

M-2017 User Manual, Rev: B2.5

Page 77

77

2.25 ~AA1

Description:

Resets the host watchdog time out status of a module.

Syntax:

~AA1[CHKSUM](CR)

~ Delimiter character

AA Address of the module to be set (00 to FF)

1 Command to reset the host watchdog time out

status

Response:

Valid Response: !AA[CHKSUM](CR)

Invalid Response: ?AA[CHKSUM](CR)

! Delimiter character for a valid response

? Delimiter character for an invalid response

AA Address of the responding module (00 to FF)

There will be no response if the command syntax is

incorrect, there is a communication error, or there is no

module with the specified address.

M-2017 User Manual, Rev: B2.5

Page 78

78

Examples:

Command: ~010 Response: !0104

Reads the host watchdog status of module 01 and

shows that a host watchdog time out has occurred.

Command: ~011 Response: !01

Resets the host watchdog time out status of module

01 and returns a valid response.

Command: ~010 Response: !0100

Reads the host watchdog status of module 01 and

shows that no host watchdog time out has occurred.

Related Commands:

Section 2.23 ~**, Section 2.24 ~AA0, Section 2.26 ~AA2,

Section 2.27 ~AA3EVV

Related Topics:

Section A.2 Dual Watchdog Operation

M-2017 User Manual, Rev: B2.5

Page 79

79

2.26 ~AA2

Description:

Reads the host watchdog time out value of a module.

Syntax:

~AA2[CHKSUM](CR)

~ Delimiter character

AA Address of the module to be read (00 to FF)

2 Command to read the host watchdog time out

value

Response:

Valid Response: !AAEVV[CHKSUM](CR)

Invalid Response: ?AA[CHKSUM](CR)

! Delimiter character for a valid response

? Delimiter character for an invalid response

AA Address of the responding module (00 to FF)

E 1: the host watchdog is enabled

0: the host watchdog is disabled

VV Two hexadecimal digits to represent the time out

value in tenths of a second, for example, 01

means 0.1 seconds and FF means 25.5 seconds.

There will be no response if the command syntax is

incorrect, there is a communication error, or there is no

module with the specified address.

M-2017 User Manual, Rev: B2.5

Page 80

80

Examples:

Command: ~012 Response: !011FF

Reads the host watchdog time out value of module

01 and returns FF, meaning that the host watchdog

is enabled and the host watchdog time out value is

25.5 seconds.

Related Commands:

Section 2.23 ~**, Section 2.24 ~AA0, Section 2.25 ~AA1,

Section 2.27 ~AA3EVV

Related Topics:

Section A.2 Dual Watchdog Operation

M-2017 User Manual, Rev: B2.5

Page 81

81

2.27 ~AA3EVV

Description:

Enables/disables the host watchdog and set the host

watchdog time out value of a module.

Syntax:

~AA3EVV[CHKSUM](CR)

~ Delimiter character

AA Address of the module to be set (00 to FF)

3 Command to set the host watchdog

E 1: enable the host watchdog

0: disable the host watchdog

VV Two hexadecimal digits to represent the time out

value in tenths of a second, for example, 01

means 0.1 seconds and FF means 25.5 seconds.

Response:

Valid Response: !AA[CHKSUM](CR)

Invalid Response: ?AA[CHKSUM](CR)

! Delimiter character for a valid response

? Delimiter character for an invalid response

AA Address of the responding module (00 to FF)

There will be no response if the command syntax is

incorrect, there is a communication error, or there is no

module with the specified address.

M-2017 User Manual, Rev: B2.5

Page 82

82

Examples:

Command: ~013164 Response: !01

Enables the host watchdog of module 01 and sets

the host watchdog time out value to 10.0 seconds.

The module returns a valid response.

Command: ~012 Response: !01164

Reads the host watchdog time out value of module

01. The module returns 164, meaning that the host

watchdog is enabled and the host watchdog time

out value is 10.0 seconds.

Related Commands:

Section 2.23 ~**, Section 2.24 ~AA0, Section 2.25 ~AA1,

Section 2.26 ~AA2

Related Topics:

Section A.2 Dual Watchdog Operation

M-2017 User Manual, Rev: B2.5

Page 83

83

Function Code

Description

Section

02 (0x02)

Read input status

3.1

04 (0x04)

Read input channels

3.2

70 (0x46)

Read/write module settings

3.3

00

Address

1 Byte

1 to 247

01

Function code

1 Byte

Function code | 0x80

02

Exception code

1 Byte

01

3. Modbus RTU Protocol

The Modbus protocol is developed by Modicon Inc., originally

developed for Modicon controllers. Detailed information can be

found at http://www.modicon.com/techpubs/toc7.html. You can

also visit http://www.modbus.org to find more valuable

information.

M-2000 series modules support the Modbus RTU protocol. The

communication Baud Rates range from 1200bps to 115200bps.

The following Modbus functions are supported.

If the function specified in the message is not supported, then the

module responds as follows.

Error Response

If a CRC mismatch occurs, the module will not respond.

M-2017 User Manual, Rev: B2.5

Page 84

84

00

Address

1 Byte

1 to 247

01

Function code

1 Byte

0x02

02 ~ 03

Starting channel

2 Bytes

0x80 to 0x87, where 0x80

corresponds to channel 0, 0x81

corresponds to channel 1, etc

04 ~ 05

Number of input

channels

2 Bytes

N, 1 to 8; (Starting channel + N)

should be less than or equal to

0x88

00

Address

1 Byte

1 to 247

01

Function code

1 Byte

0x02

02

Byte count

1 Byte

1

03

Data of input

channels

1 Byte

A bit corresponds to a channel.

When the bit is 1 it denotes that

the channel is enabled and is either

over-range, under-range or wire

opening. If the bit is 0 it denotes

that the channel is disabled or

normal.

00

Address

1 Byte

1 to 247

01

Function code

1 Byte

0x82

02

Exception code

1 Byte

02: starting channel out of range

03: (starting channel + number of

input channels) out of range,

incorrect number of bytes

received

3.1 02 (0x02) Read Input Status

This function code is used to read the under range status of a

module.

Request

Response

Error Response

M-2017 User Manual, Rev: B2.5

Page 85

85

00

Address

1 Byte

1 to 247

01

Function code

1 Byte

0x04

02 ~ 03

Starting channel

2 Bytes

0 to 7 for reading analog inputs

04 ~ 05

Number of input

channels (N)

2 Bytes

1 to 8; (Starting channel + N) <= 8

for reading analog inputs.

00

Address

1 Byte

1 to 247

01

Function code

1 Byte

0x04

02

Byte count

1 Byte

2 x N

03 ~

Data of input

channels

2 x N

Bytes

00

Address

1 Byte

1 to 247

01

Function code

1 Byte

0x84

02

Exception code

1 Byte

02: starting channel out of range

03: (starting channel + number of

input channels) out of range,

incorrect number of bytes

received

3.2 04 (0x04) Read Input Channels

This function code is used to read from contiguous analog input

channels.

Request

Response

Error Response

M-2017 User Manual, Rev: B2.5

Page 86

86

Sub-function Code

Description

Section

00 (0x00)

Read the module name

3.3.1

04 (0x04)

Set the module address

3.3.2

05 (0x05)

Read the communication settings

3.3.3

06 (0x06)

Set the communication settings

3.3.4

07 (0x07)

Read the type code

3.3.5

08 (0x08)

Set the type code

3.3.6

32 (0x20)

Read the firmware version

3.3.7

37 (0x25)

Read the channel enable/disable

status

3.3.8

38 (0x26)

Set the channel enable/disable

3.3.9

41 (0x29)

Read the miscellaneous settings

3.3.10

42 (0x2A)

Write the miscellaneous settings

3.3.11

00

Address

1 Byte

1 to 247

01

Function code

1 Byte

0xC6

02

Exception code

1 Byte

02: invalid sub-function code

3.3 70 (0x46) Read/Write Module Settings

This function code is used to read the settings of the module or

change the settings of the module. The following sub-function

codes are supported.

If the module does not support the sub-function code specified in

the message, then it responds as follows.

Error Response

M-2017 User Manual, Rev: B2.5

Page 87

87

00

Address

1 Byte

1 to 247

01

Function code

1 Byte

0x46

02

Sub function code

1 Byte

0x00

00

Address

1 Byte

1 to 247

01

Function code

1 Byte

0x46

02

Sub function code

1 Byte

0x00

03 ~ 06

Module name

4 Bytes

0x4D 0x20 0x17 0x00 for M-2017

00

Address

1 Byte

1 to 247

01

Function code

1 Byte

0xC6

02

Exception code

1 Byte

03: incorrect number of bytes

received

3.3.1 Sub-function 00 (0x00) Read module name

This sub-function code is used to read the name of a module.

Request

Response

Error Response

M-2017 User Manual, Rev: B2.5

Page 88

88

00

Address

1 Byte

1 to 247

01

Function code

1 Byte

0x46

02

Sub function code

1 Byte

0x04

03

New address

1 Byte

1 to 247

04 ~ 06

Reserved

3 Bytes

0x00 0x00 0x00

00

Address

1 Byte

1 to 247

01

Function code

1 Byte

0x46

02

Sub function code

1 Byte

0x04

03

Set address result

1 Byte

0: OK,

others: error

04 ~ 06

Reserved

3 Bytes

0x00 0x00 0x00

00

Address

1 Byte

1 to 247

01

Function code

1 Byte

0xC6

02

Exception code

1 Byte

03: new address out of range,

reserved bytes should be filled

with zero, incorrect number of

bytes received

3.3.2 Sub-function 04 (0x04) Set module address

This sub-function code is used to set the address of a module.

Request

Response

Error Response

M-2017 User Manual, Rev: B2.5

Page 89

89

00

Address

1 Byte

1 to 247

01

Function code

1 Byte

0x46

02

Sub function code

1 Byte

0x05

03

Reserved

1 Byte

0x00

00

Address

1 Byte

1 to 247

01

Function code

1 Byte

0x46

02

Sub function code

1 Byte

0x05

03

Reserved

1 Byte

0x00

04

Baud Rate

1 Byte

Baud Rate code, see Section 1.10

for details.

05 ~ 07

Reserved

3 Bytes

0x00 0x00 0x00

08

Mode

1 Byte

0: DCON protocol

1: Modubs RTU protocol

09 ~ 10

Reserved

2 Bytes

0x00 0x00

00

Address

1 Byte

1 to 247

01

Function code

1 Byte

0xC6

02

Exception code

1 Byte

03: reserved byte should be filled

with zero, incorrect number of

bytes received

3.3.3 Sub-function 05 (0x05) Read communication

settings

This sub-function code is used to read the communication

protocol settings of a module.

Request

Response

Note: This information is the data saved in the EEPROM and will be used

for the next power-on reset. It is not the currently used settings.

Error Response

M-2017 User Manual, Rev: B2.5

Page 90

90

00

Address

1 Byte

1 to 247

01

Function code

1 Byte

0x46

02

Sub function code

1 Byte

0x06

03

Reserved

1 Byte

0x00

04

Baud Rate

1 Byte

Baud Rate code, see Section 1.10

for details.

05 ~ 07

Reserved

3 Bytes

0x00 0x00 0x00

08

Mode

1 Byte

0: DCON protocol

1: Modubs RTU protocol

09 ~ 10

Reserved

2 Bytes

0x00 0x00

00

Address

1 Byte

1 to 247

01

Function code

1 Byte

0x46

02

Sub function code

1 Byte

0x06

03

Reserved

1 Byte

0x00

04

Baud Rate

1 Byte

0: OK, others: error

05 ~ 07

Reserved

3 Bytes

0x00 0x00 0x00

08

Mode

1 Byte

0: OK, others: error

09 ~ 10

Reserved

2 Bytes

0x00 0x00

00

Address

1 Byte

1 to 247

01

Function code

1 Byte

0xC6

02

Exception code

1 Byte

03: Baud Rate or mode out of

range, reserved bytes should

be filled with zero, incorrect

number of bytes received

3.3.4 Sub-function 06 (0x06) Set communication

settings

This sub-function code is used to set the communication protocol

of a module.

Request

Response

Note: The new Baud Rate and protocol will be effective after the next

power-on reset.

Error Response

M-2017 User Manual, Rev: B2.5

Page 91

91

00

Address

1 Byte

1 to 247

01

Function code

1 Byte

0x46

02

Sub function code

1 Byte

0x07

03

Reserved

1 Bytes

0x00

04

Channel

1 Byte

0x00 ~ 0x07 for M-2017

00

Address

1 Byte

1 to 247

01

Function code

1 Byte

0x46

02

Sub function code

1 Byte

0x07

03

Type code

1 Byte

Type code, see Section 1.10 for

details.

00

Address

1 Byte

1 to 247

01

Function code

1 Byte

0xC6

02

Exception code

1 Byte

03: reserved bytes should be filled

with zero, channel out of

range for M-2017 modules,

incorrect number of bytes

received

3.3.5 Sub-function 07 (0x07) Read type code

This sub-function code is used to read the type code information

of a module.

Request

Response

Error Response

M-2017 User Manual, Rev: B2.5

Page 92

92

00

Address

1 Byte

1 to 247

01

Function code

1 Byte

0x46

02

Sub function code

1 Byte

0x08

03

Reserved

1 Byte

0x00

04

Channel

1 Byte

0x00 ~ 0x07 for M-2017

05

Type code

1 Byte

Type code, see Section 1.10 for

details.

00

Address

1 Byte

1 to 247

01

Function code

1 Byte

0x46

02

Sub function code

1 Byte

0x08

03

Type code

1 Byte

0: OK

others: error

00

Address

1 Byte

1 to 247

01

Function code

1 Byte

0xC6

02

Exception code

1 Byte

03: type code out of range, channel

out of range for M-2017

modules, reserved bytes

should be filled with zero,

incorrect number of bytes

received

3.3.6 Sub-function 08 (0x08) Set type code

This sub-function code is used to set the type code of a module.

Request

Response

Error Response

M-2017 User Manual, Rev: B2.5

Page 93

93

00

Address

1 Byte

1 to 247

01

Function code

1 Byte

0x46

02

Sub function code

1 Byte

0x20

00

Address

1 Byte

1 to 247

01

Function code

1 Byte

0x46

02

Sub function code