Page 1

I-8094 and I-8094F Getting Started

Manual

(Version 2.3)

Hardware & Software & Application

Using I-8094/I-8094F PAC Motion Control Module

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

1

Page 2

Warranty

All products manufactured by ICPDAS Inc. are warranted against defective

materials for a period of one year from the date of delivery to the original

purchaser.

Warning

ICPDAS Inc. assumes no liability for damages consequent to the use of this

product. ICPDAS Inc. reserves the right to change this manual at any time without

notice. The information furnished by ICPDAS Inc. is believed to be accurate and

reliable. However, no responsibility is assumed by ICPDAS Inc. for its use, or for

any infringements of patents or other rights of third parties resulting from its use.

Copyright

Copyright 1997-2005 by ICPDAS Inc., LTD. All rights reserved worldwide.

Trademark

The names used for identification only maybe registered trademarks of their

respective companies.

License

The user can use, modify and backup this software on a single machine. The

user may not reproduce, transfer or distribute this software, or any copy, in whole

or in part.

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

2

Page 3

Contents of I8094/I8094F

1 INTRODUCTION...............................................................7

1.1 Introduction................................................................................................7

1.2 Hardware Specification .............................................................................8

1.2.1 Main Specification..................................................................................... 8

1.2.2 Interpolation Function ............................................................................... 8

1.2.3 Pulse Output............................................................................................. 8

1.2.4 Encoder Input ........................................................................................... 9

1.2.5 Position counter........................................................................................ 9

1.2.6 Auto-Homing............................................................................................. 9

1.2.7 Servo Motor Input Signal .......................................................................... 9

1.2.8 Limit Switch Input Signal......................................................................... 10

1.2.9 Other Input Signals ................................................................................. 10

1.2.10 Emergency Stop Signal Input ............................................................... 10

1.2.11 General Output Signal .......................................................................... 10

1.2.12 Integral Input Signal Filters ................................................................... 10

1.2.13 Software Limit....................................................................................... 10

1.2.14 Manual Pulse Generator....................................................................... 10

1.2.15 LED for Module status .......................................................................... 10

1.2.16 FRnet (i8094F only) .............................................................................. 10

1.3 Environment .............................................................................................11

1.4 Ordering Information..............................................................................11

2 HARDWARE INSTALLATION......................................12

2.1 Checking Package and Installation ........................................................12

2.1.1 Checking package .................................................................................. 12

2.1.2 Installation .............................................................................................. 12

2.2 DN-8468G Terminal Board......................................................................15

2.2.1 Board Layout for DN-8468G ................................................................... 15

2.2.2 Signal Connections for DN-8468G.......................................................... 15

2.2.3 Jumper and Switch Settings ................................................................... 22

2.3 Input/Output Connections.......................................................................24

2.3.1 Pulse output signals................................................................................ 24

2.3.2 Connection for Limit switch Signal.......................................................... 25

2.3.3 General Purpose Input Signals(nINPOS,nALARM) ................................ 26

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

3

Page 4

2.3.4 Encoder Signals ..................................................................................... 26

2.3.5 Emergency Stop Signal .......................................................................... 27

2.3.6 Manual Pulse Generator Input Signal (EXP+,EXP-) ............................... 27

2.3.7 General Purpose Output signals(Servo On/Off)...................................... 28

2.4 Connection Example for Motor Driver..................................................29

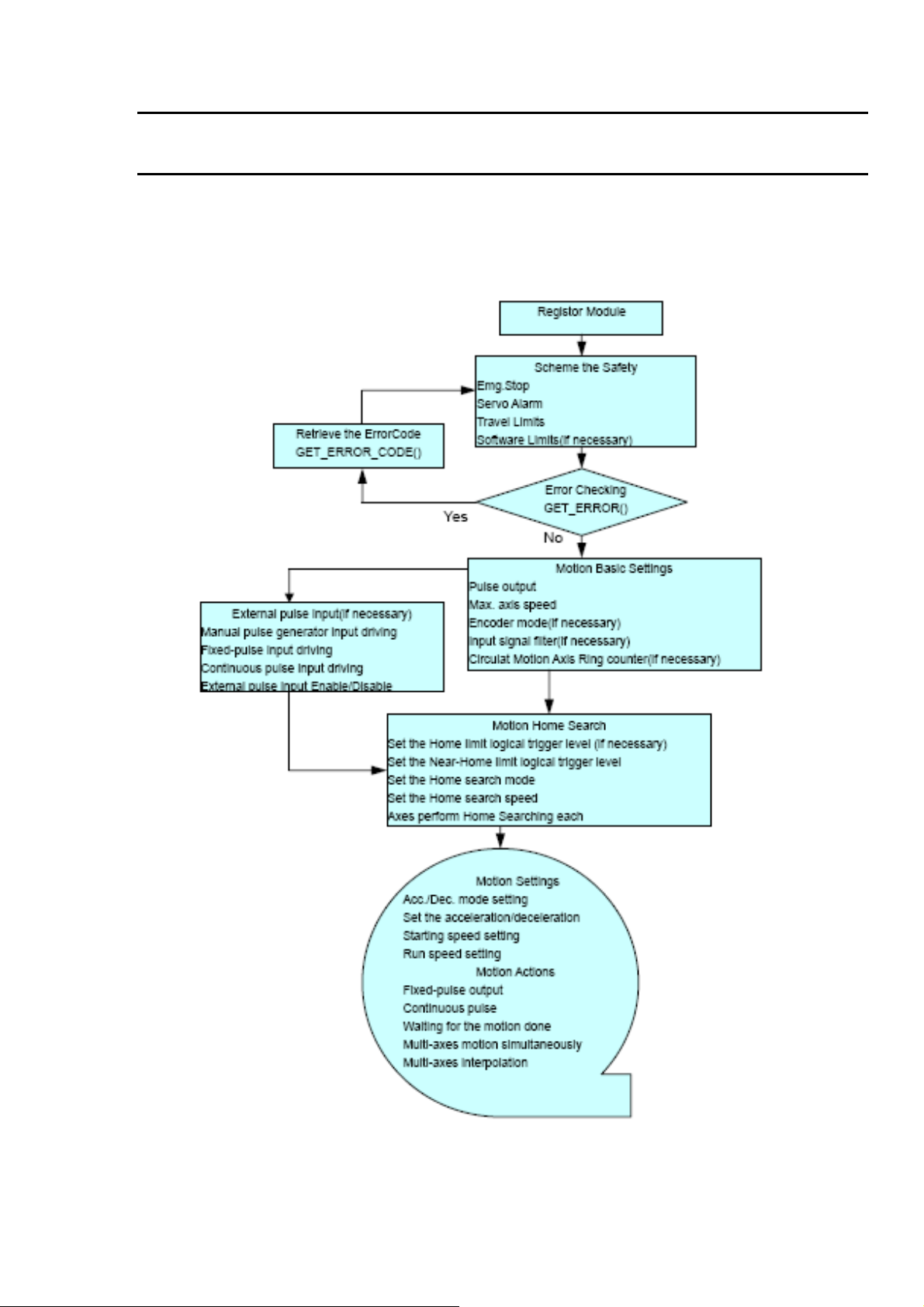

3 SOFTWARE DEVELOPMENT OVERVIEW ..............30

3.1 Software development Overview............................................................30

3.1.1 Register Module ..................................................................................... 31

3.2 Safety IO Setting.......................................................................................31

3.2.1 Emergency Stop Signal Input ................................................................. 31

3.2.2 Configure the Servo ALARM Signals...................................................... 31

3.2.3 Configure the Limit Switch Signals(±EL)................................................. 31

3.2.4 Configure the Software Limite(±SEL) ..................................................... 32

3.3 Error Checking.........................................................................................32

3.4 Basic Configuration of Motion................................................................32

3.5 Manual Pulse Generator Testing ............................................................33

3.6 Home Search.............................................................................................34

3.6.1 Home Search Configuration ................................................................... 34

3.6.2 Running the Home Search ..................................................................... 35

3.7 Basic Motion .............................................................................................36

3.7.1 Speed Profie of the Motion Control......................................................... 36

3.7.2 Basic Setting of Single Axis .................................................................... 37

3.7.3 Basic Motion of Single Axis..................................................................... 38

3.7.4 Basic Setting of Muti-Axes Interpolation ................................................. 38

3.7.5 Basic Motion of Muti-Axes Interpolation.................................................. 39

3.8 Advance Motion........................................................................................40

3.9 Synchronization Action............................................................................40

4 GETTING STARTED OF SOFTWARE.........................41

4.1 WinCon eVC++ Guideline.......................................................................41

4.1.1 Confirm the Relative Files....................................................................... 41

4.1.2 Create a new eVC++ Application Project................................................ 41

4.1.3 Add the I8094.h into eVC++ Application Project ..................................... 43

4.1.4 Add the Reference Path into eVC++ Application Project ........................ 44

4.1.5 Start the eVC++ Sample ......................................................................... 45

4.1.6 Build the Project ..................................................................................... 48

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

4

Page 5

4.1.7 Download and Run ................................................................................. 49

4.2 Microsoft Visual Studio .NET 2003(VB.NET,C#) Guideline ............50

4.2.1 Confirm the Relative Files....................................................................... 50

4.2.2 Create a new VB.NET/C# Application Project ........................................ 50

4.2.3 Add the DLL into Application Project....................................................... 52

4.2.4 Start the VB.NET/C# Sample.................................................................. 54

4.2.5 Build the Project ..................................................................................... 56

4.2.6 Download and Run ................................................................................. 56

4.3 I-8000 Turbo C Guideine.........................................................................57

4.3.1 Confirm the Relative Files....................................................................... 57

4.3.2 Create a new TC ++ Application Project ................................................. 57

4.3.3 Start the TC Sample ............................................................................... 59

4.3.4 Build the Project ..................................................................................... 65

4.3.6 Download and Run ................................................................................. 65

APPENDIX-A SETUP TOOLS & OTHERS.....................67

A.1 Setup the Development Environment of I8094.....................................67

A.1.1 eVC ++ 4.0 ............................................................................................. 67

A.1.2 Visual Studio .NET 2003(VB.NET,C#) ................................................. 67

A.1.3 Turbo C .................................................................................................. 67

A.2 I8094 Surface ...........................................................................................68

A.3 Dimensions ...............................................................................................69

A.4 The Version Upgrades Note....................................................................70

APPENDIX-B OTHERS TERMINAL BOARDS.............71

B.1 DN-8468M Daughter Board....................................................................71

B.1.1 Board Layout for DN-8468M .................................................................. 71

B.1.2 Signal Connections for DN-8468M......................................................... 72

B.1.3 Jumper and Switch Settings................................................................... 76

B.2 DN-8468P Daughter Board.....................................................................78

B.2.1 Board Layout for DN-8468P ................................................................... 78

B.2.2 Signal Connections for DN-8468P.......................................................... 79

B.2.3 Jumper and Switch Settings................................................................... 83

B.3 DN-8486Y Daughter Board.....................................................................85

B.3.1 Board Layout for DN-8468Y ................................................................... 85

B.3.2 Signal Connections for DN-8468Y.......................................................... 86

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

5

Page 6

B.3.3 Jumper and Switch Settings................................................................... 90

B.4 DN-8468D Daughter Board ....................................................................92

B4.1 Board Layout for DN-8468D.................................................................... 92

B4.2 Signal Connections for DN-8468D .......................................................... 94

B4.3 Jumper and Switch Settings.................................................................. 102

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

6

Page 7

1 INTRODUCTION

1.1 Introduction

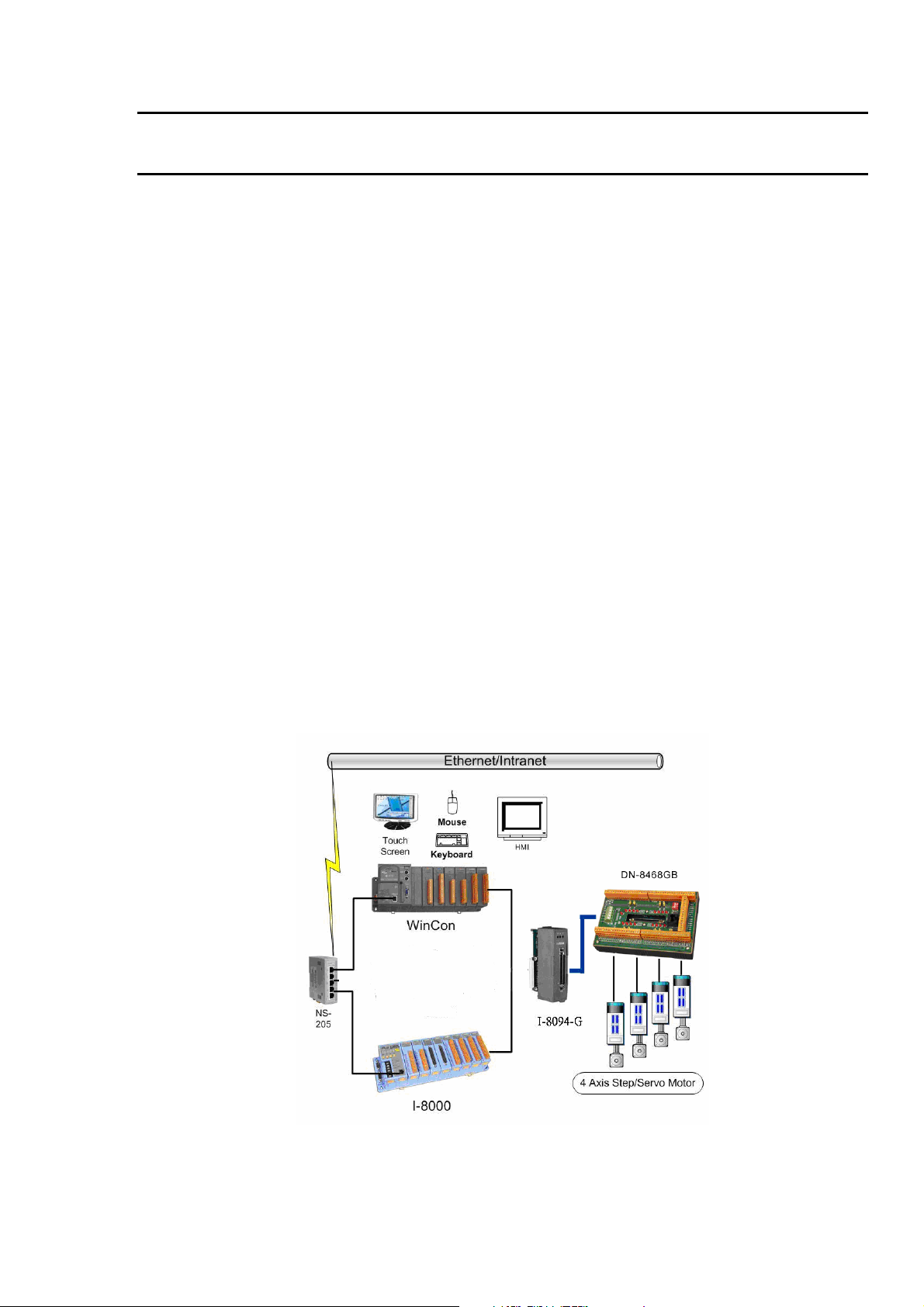

The I-8094 and I-8094F are the 4-axes pulse-type stepping/servo motor motion

control module that can be used on any of the ICPDAS I-8000 and WinCon series

controllers, and is suitable for general-purpose motion application. These modules

contain a high-performance motion ASIC. Apart from a wide speed range, these

intelligent motion controllers have a variety of motion control functions built in, such as

2~3-axes linear interpolation, 2-axes circular interpolation, T/S-curve

acceleration/deceleration, various synchronous actions, automatic homing, and others.

Besides, it is a module that has full functions of I-8094F plus one port of FRnet. The

FRnet port allows this module to expand its fast remote I/O easily. This two-wired FRnet

can automatically scan its 128 DI and 128 DO with a period of 0.72/2.88ms. In addition,

most of the I-8094 and I-8094F motion control functions are performed with little load on

the processor. While driving the motors, the motion status, and the other I/O status on

the I-8000 or WinCon controllers, can still be monitored. As a result of the low CPU

loading requirements of I-8094 and I-8094F, one or more motion modules may be used

on a single I-8000 or WinCon controllers. ICPDAS also has provided a wide range of

functions and examples to reduce the need for programming by user, making it a highly

cost-effective solution for machine makers.

I8094 with PAC controller (WinCon-8000 and I-8000)

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

7

Page 8

1.2 Hardware Specification

1.2.1 Main Specification

ASIC Chip MCX314As

Number of controllable 4-Axes, Pulse output (stepping & servo

motor)

Up to 4M PPS pulse output

1.2.2 Interpolation Function

2-axes & 3-axes linear interpolation

Interpolation range −2,147,483,646 ~ +2,147,483,646

Vectors speed of interpolation 1 PPS ~ 4M PPS

Precision of interpolation ± 0.5 LSB

Circular interpolation

Interpolation range −2,147,483,646 ~ +2,147,483,646

Vectors Speed of interpolation 1 PPS ~ 4M PPS

Relative interpolation function

Any 2-axes or 3-axes interpolation

Fixed vectors speed

Continuous interpolation

1.2.3 Pulse Output

Output speed range 1 PPS ~ 4 MPPS

Output precision ± 0.1%

Jerk range of S-curve 954 ~ 62.5 x 10^6 PPS/S^2

477 x 10^3 ~ 31.25 x 10^9 PPS/S^2

Acceleration/deceleration range 125 ~ 1 x 10^6 PPS/S

62.5×10^3 ~ 500 x 10^6 PPS/S

Speed precision 1 PPS ~ 500PPS( Depend on the

max.speed)

Output numbers 0 ~ 4,294,967,295 / unlimited

Velocity profiles mode:

Fixed

Symmetrical & Asymmetrical Trapezoidal velocity profile

Symmetrical & Asymmetrical S-curve velocity profile

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

8

Page 9

Acceleration & Deceleration mode

Auto

By user define

Position & Speed change on the fly

Fixed pulse output by Trapezoidal and S-curve velocity profile

Pulse output option: CW/CCW, PULSE/DIR

Programmable logic level (Rising Edge/ Falling Edge)

1.2.4 Encoder Input

Encoder option: A/B phase, Up/Down

Programmable A/B phase mode: 1, 1/2, and 1/4 A/B phase

1.2.5 Position counter

Command counter range −2,147,483,648 ~ +2,147,483,647

Encoder counter range −2,147,483,648 ~ +2,147,483,647

Programmable ring counter

Programmable direction of counter

Using DI(IN3) to Clear feedback counter

Programmable read & write counter

1.2.6 Auto-Homing

Four Steps

Step 1 ( High-speed ”Near Home” searching)

Step 2 ( Low-speed ”Home” searching)

Step 3 ( Low-speed Index Z searching)

Step 4 ( High-speed offset drive)

Even though there are only 4 steps of the home searching, but user can vary

the operations into over 10 homing modes by software function since its

configurable action and direction of each step.

1.2.7 Servo Motor Input Signal

Alarm

Choose IN2: In Position or Servo Ready signal

Choose input signal: Enable/Disable and logical level.

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

9

Page 10

1.2.8 Limit Switch Input Signal

Two-limit switch signal for each axis: +Limit, −Limit

Programmable logic level

Programmable action mode( slow-down stop or immediately stop)

1.2.9 Other Input Signals

IN3 : other purpose, as a trigger of synchronal control……

1.2.10 Emergency Stop Signal Input

There is a Emergency stop signal for Each module.

1.2.11 General Output Signal

The Servo-on signal (nOUT1) can be used as servo-on control or general

purpose output signal for each axis.

1.2.12 Integral Input Signal Filters

The motion module is equipped with an integral type filter in the input step of

each input signal. User can be selected a filter time constant.

1.2.13 Software Limit

There are two software-limit for each axis: -SLimit & + SLimit ( Setting range :

−2,147,483,646 ~ +2,147,483,646)

1.2.14 Manual Pulse Generator

Fixed Pulse Driving Mode (CW/CCW pulse mode)

Continuous Pulse Driving Mode (CW/CCW pulse mode)

Manual pulsar mode(A/B phase pulse mode)

Disable Mode: Disable manual pulse function

1.2.15 LED for Module status

Red LED Æ Power light

Orange LED Æ Servo Alarm

Ex:Misuibishi driver, No Alm: turn Orange LED on

Green LED Æ during Running Motion

1.2.16 FRnet (i8094F only)

Connect to the distributed DI/DO module DI Æ max up to 128

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

10

Page 11

DO Æ max up to 128

Read the status of distributed DI

Control the status of distributed DO

Support interrupt and frequence division function

Reset function

1.3 Environment

Operating Temp: -20 ~ + 75°C

Storage Temp: -30 ~ +85°C

Operating Humidity: 10 ~ 85%,non-condensing

Storage Humidity: 5 ~ 90%,non-condensing

I/O optically isolated 2500Vrms

External Power supply( Input): 24V DC (connect to terminal board)

1.4 Ordering Information

I-8000、W-8000 PAC controllers

i8094 4-axes motion control module

DN-8468GB For general purpose usage

DN-8468MB For Mitsubishi Servo motor

DN-8468PB For Panasonic servo motor

DN-8468DB For Detal servo motor

CA-SCSI15 68-pin SCSI-II cable,length:1.5 m

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

11

Page 12

2 HARDWARE INSTALLATION

2.1 Checking Package and Installation

2.1.1 Checking package

The i8094 and i8094F are a 4-axes stepping/servo motor control module that can

be used on any of the ICPDAS I-8000 and WinCon series controllers. The base system

package is as below list:

I-8000、W-8000 Embedded PAC control system series(Two systems choose

one)

i8094/i8094F-G/S includes the following item

i8094/i8094F 4-axes motion module

DN-8468 Terminal board for i8094 and i8094F

CA-SCSI15 68-pin SCSI-II cable,length:1.5 m

2.1.2 Installation

Prepare controller

1. Choose a PAC controller of ICPDAS (I-8000 or W-8000series) and have empty

slot.

2. Turn power off

Module Plug in controller and wiring

1. Plug in the i8094/i8094F into a empty slot of I-8000/W-8000.

2. Connect the i8094/i8094F with DN-8468G by a CA-SCSI15 cable, as the below

figure:

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

12

Page 13

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

13

Page 14

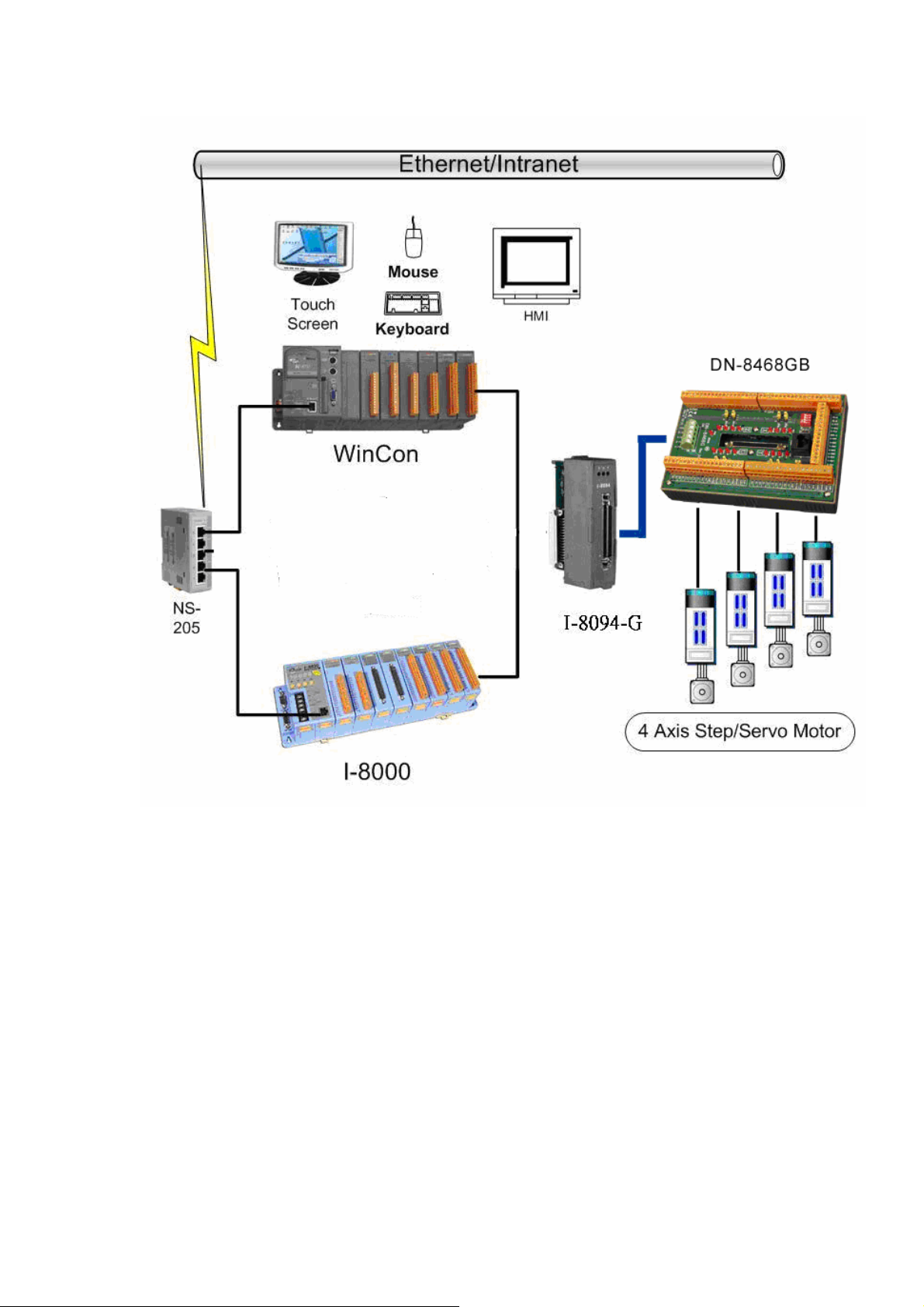

Figure. i8094 with PAC controller (WinCon-8000 and I-8000)

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

14

Page 15

2.2 DN-8468G Terminal Board

The DN-8468 is the terminal board for general purpose amplifier usage. It has 4-axis I/O signals.

2.2.1 Board Layout for DN-8468G

107mm

CON6

CON2CON4

EMG

SW

JP5 JP6

JP8

JP9

RJ1

JP7

JP11

JP10

X Y

162mm

Z U

JP13

JP12

DN-8468G

Fig. 2.0 Board layout for the DN-8468G

CON1

68 PIN SCSI

JP15

JP14

TB2

CON3CON5

2.2.2 Signal Connections for DN-8468G

Maintaining signal connections is one of the most important factors in ensuring that your

application system is sending and receiving data correctly.

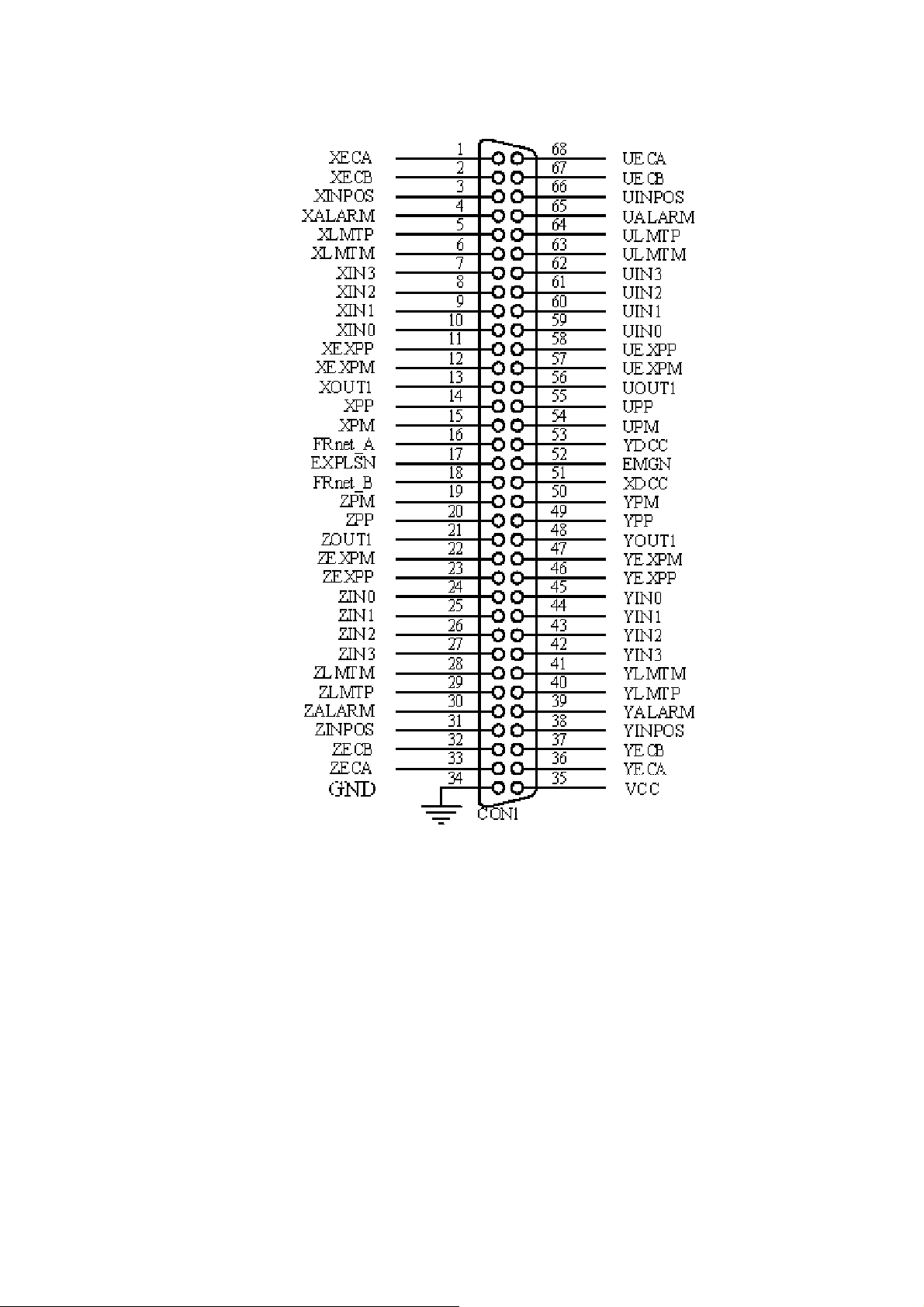

Pin Assignment for CON1

The I/O connector on the DN-8468G is a 68-pin SCSI II connector that enables you to connect to

the I8094/I8094F motion modue. Fig. 2.1 shows the pin assignment for the 68-pin I/O connector

on the DN-8468G (or on the PISO-PS400), and refer to Table 2.1, 2.2 for description of each

motion I/O signal.

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

15

Page 16

Fig. 2.1 I/O connector pin assignment for the CON1

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

16

Page 17

Table 2.1 DN-8468G I/O connector signal description (part 1)

Pin name Pin number Description

XECA 1 Encoder A-phase signal for X axis

YECA 36 Encoder A-phase signal for Y axis

ZECA 33 Encoder A-phase signal for Z axis

UECA 68 Encoder A-phase signal for U axis

XECB 2 Encoder B-Phase signal for X axis

YECB 37 Encoder B-Phase signal for Y axis

ZECB 32 Encoder B-Phase signal for Z axis

UECB 67 Encoder B-Phase signal for U axis

XINPOS 3 In-position signal for X axis

YINPOS 38 In-position signal for Y axis

ZINPOS 31 In-position signal for Z axis

UINPOS 66 In-position signal for U axis

XALARM 4 Alarm signal for X axis

YALARM 39 Alarm signal for Y axis

ZALARM 30 Alarm signal for Z axis

UALARM 65 Alarm signal for U axis

XLMTP 5 Limit switch input signal (+) for X axis

YLMTP 40 Limit switch input signal (+) for Y axis

ZLMTP 29 Limit switch input signal (+) for Z axis

ULMTP 64 Limit switch input signal (+) for U axis

XLMTM 6 Limit switch input signal (-) for X axis

YLMTM 41 Limit switch input signal (-) for Y axis

ZLMTM 28 Limit switch input signal (-) for Z axis

ULMTM 63 Limit switch input signal (-) for U axis

XIN3 7 Input 3 signal for X axis

YIN3 42 Input 3 signal for Y axis

ZIN3 27 Input 3 signal for Z axis

UIN3 62 Input 3 signal for U axis

XIN2 8 Input 2 signal for X axis

XIN2 43 Input 2 signal for Y axis

XIN2 26 Input 2 signal for Z axis

XIN2 61 Input 2 signal for U axis

XIN1 9 Input 1 signal for X axis

YIN1 44 Input 1 signal for Y axis

ZIN1 25 Input 1 signal for Z axis

UIN1 60 Input 1 signal for U axis

XIN0 10 Input 0 signal for X axis

YIN0 45 Input 0 signal for Y axis

ZIN0 24 Input 0 signal for Z axis

UIN0 59 Input 0 signal for U axis

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

17

Page 18

Table 2.2 DN-8468G I/O connector signal description (part 2)

Pin name Pin number Description

XEXPP 11 EXT pulsar input signal (+) for X axis

YEXPP 46 EXT pulsar input signal (+) for Y axis

ZEXPP 23 EXT pulsar input signal (+) for Z axis

UEXPP 58 EXT pulsar input signal (+) for U axis

XEXPM 12 EXT pulsar input signal (-) for X axis

YEXPM 47 EXT pulsar input signal (-) for Y axis

ZEXPM 22 EXT pulsar input signal (-) for Z axis

UEXPM 57 EXT pulsar input signal (-) for U axis

XDRIVE 13 Driver enable signal for X axis

YDRIVE 48 Driver enable signal for Y axis

ZDRIVE 21 Driver enable signal for Z axis

UDRIVE 56 Driver enable signal for U axis

XPP 14 Driving pulsar signal (+) for X axis

YPP 49 Driving pulsar signal (+) for Y axis

ZPP 20 Driving pulsar signal (+) for Z axis

UPP 55 Driving pulsar signal (+) for U axis

XPM 15 Driving pulsar signal (+) for X axis

YPM 50 Driving pulsar signal (+) for Y axis

ZPM 19 Driving pulsar signal (+) for Z axis

UPM 54 Driving pulsar signal (+) for U axis

XOUT1 16 Output 1 signal for X axis

YOUT1 48 Output 1 signal for Y axis

ZOUT1 21 Output 1 signal for Z axis

UOUT1 56 Output 1 signal for U axis

EXPLSN1 17 EXT pulse input signal for interpolation

EMGN1 52 Emergency stop input signal

FrnetA 16 FRnet port A

FrnetB 18 FRnet port B

XDCC 51 Deviation Counter Clear for X axis

YDCC 53 Deviation Counter Clear for Y axis

GND 34 Ground

VCC 35 External power (12~24V)

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

18

Page 19

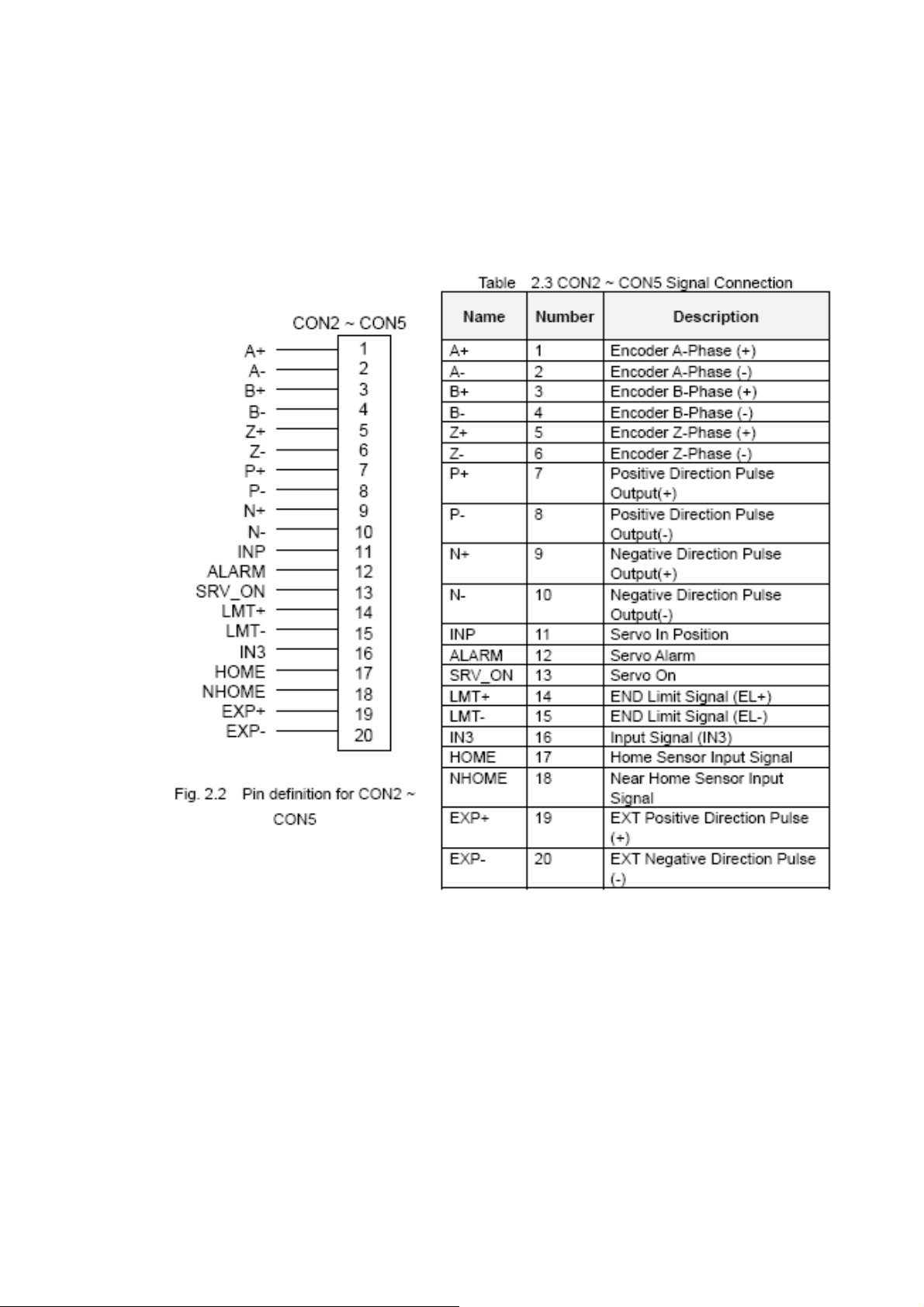

CON2 ~ CON5 (I/O connector for each AXIS)

The connectors CON2 ~ CON5 are 20-pin connectors that enable you to connect to the I/O

signals for general purpose motor drivers. Fig. 2.2 shows the pin assignment for the 20-pin

connector on the DN-8468G, and the Table 2.3 shows its I/O connector signal description.

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

19

Page 20

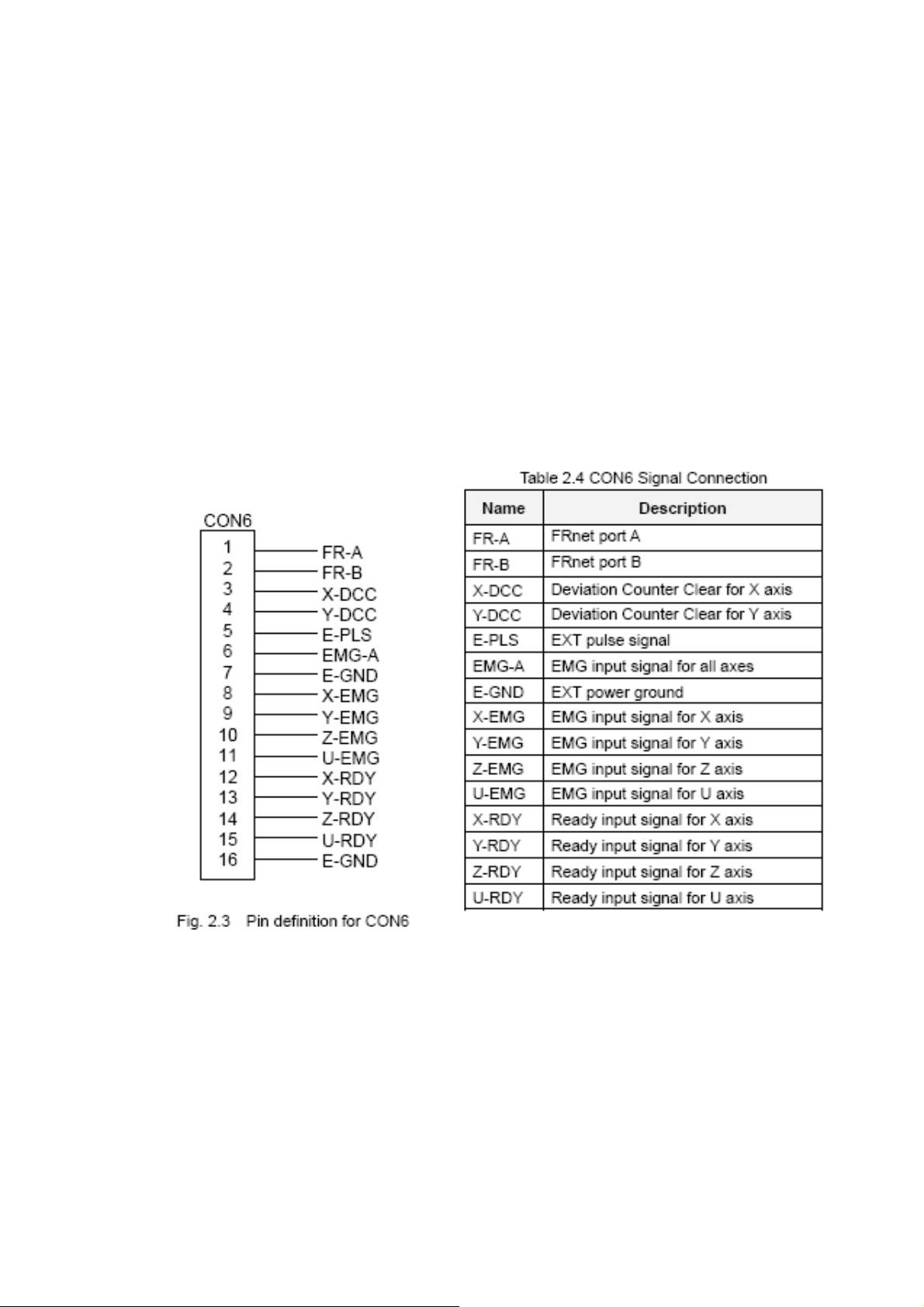

CON6

The connector CON6 is 16-pin connector that enables you to connect to the signals of your

motor drivers. The FRnet connectors, FR-A and FR-B, can be used to serially connect a I/O

module of FRnet series, as FR-2053,FR-2057…. The more information, please refer to

web-site of ICPDAS :

http://www.icpdas.com/products/Remote_IO/frnet/frnet_introduction.htm

Fig.2.3 shows the pin assignment for the 16-pin connector on the DN-8468G, and the Table 2.4

shows its I/O connector signal description.

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

20

Page 21

TB2

The connector TB2 is 5-pin connector that enables you to connect to the signals of your

motor drivers. Fig.2.4 shows the pin assignment for the 5-pin connector on the DN-8468G, and

the Table 2.5 shows its I/O connector signal description.

RJ1 (The I/O signals of the FRnet)

The connectors RJ1 is an 8-pin RJ45 connector that enable you to connect to the signals of

FRnet. The FRnet connectors, FR-A and FR-B, can be used to serially connect a I/O module of

FRnet series, as FR-2053,FR-2057…. The more information, please refer to web-site of

ICPDAS:

http://www.icpdas.com/products/Remote_IO/frnet/frnet_introduction.htm

Fig.2.5shows the pin assignment for the 8-pin connector on the DN-8468G, and the Table 2.6

shows its I/O connector signal description.

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

21

Page 22

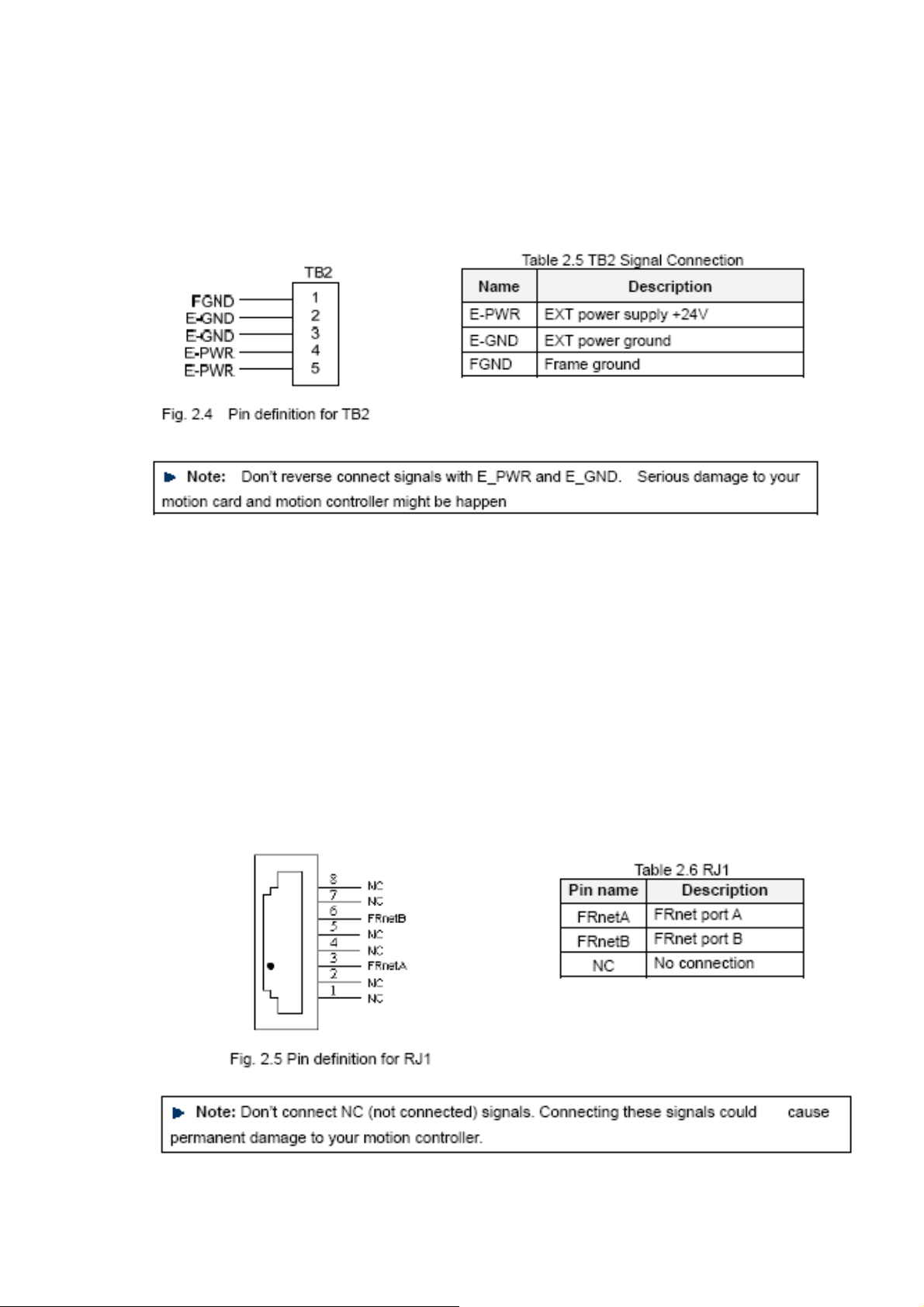

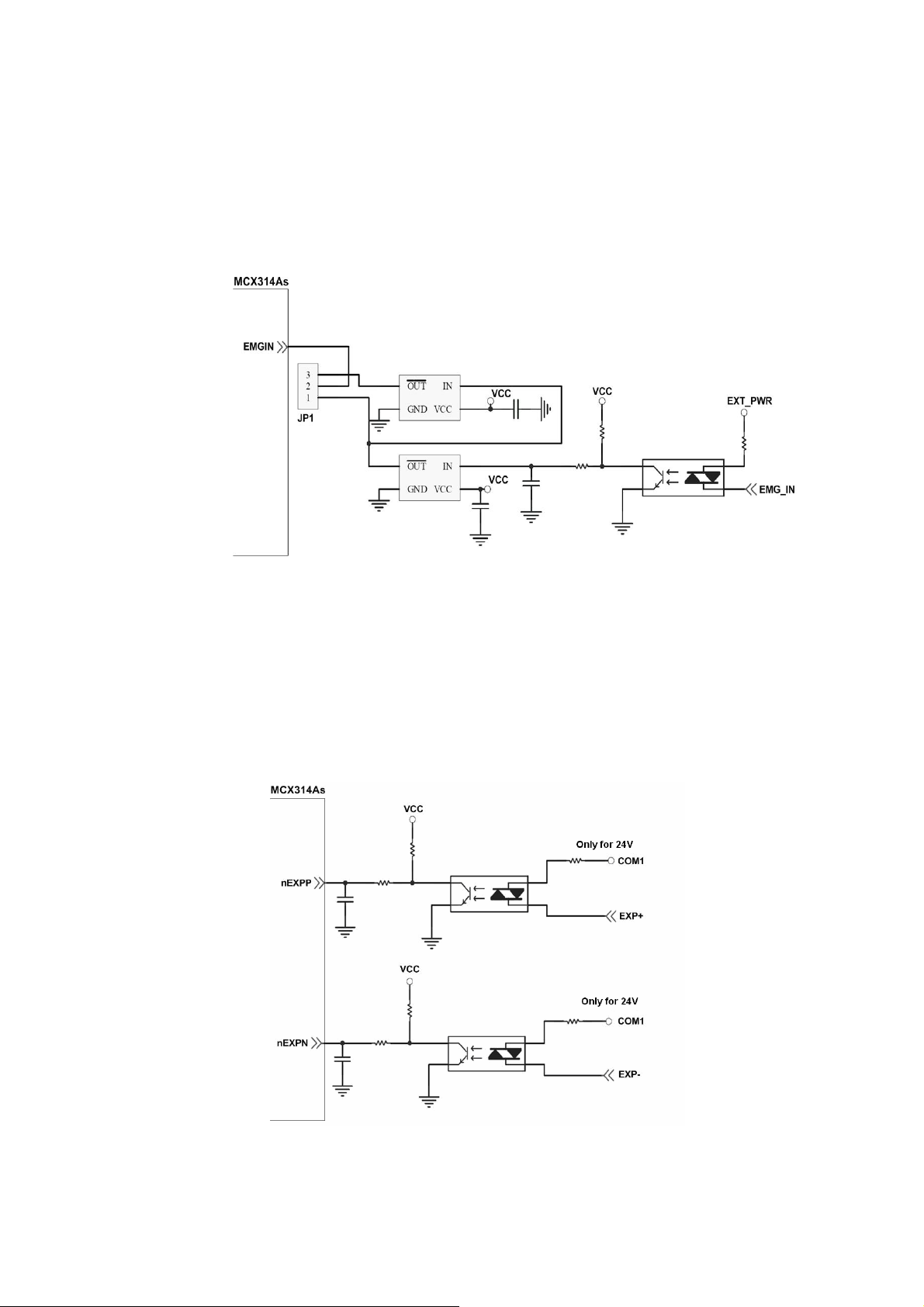

2.2.3 Jumper and Switch Settings

JP7

Jumper 7 controls the EMG-A signal of the CON6 connector. The following diagram is shown the

selection condition of the jumper 7.

Fig. 2.6 Jumper 7 setting

JP8/9, JP10/11, JP12/13, JP14/15

The Jumper8~15 are used to set the signal type of the pulse output signals. The output signal

type could be differential line driver output or open collector output. The JP8 ~JP9 are set XPP、

XPM for X-axis(CON1), JP10 ~JP11 are for Y-axis, JP12 ~JP13 are for Z-axis and JP14 ~JP15

are for U-axis. The 2-3 Pin short is the differential line driver mode. The 1-2 Pin short is the Open

Collector mode, as below example

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

22

Page 23

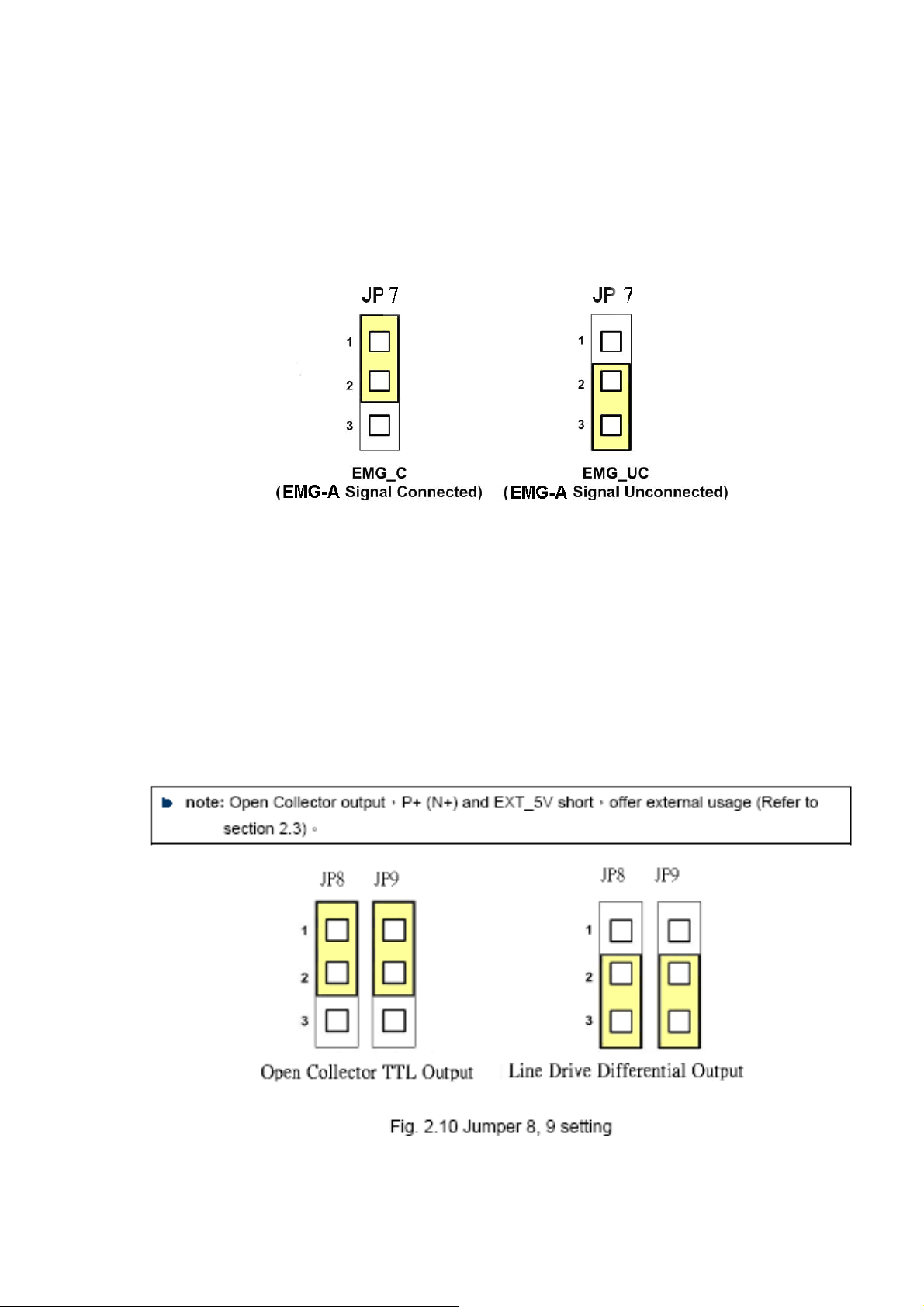

EMG SW

The emergency stop signal for each servo ampilfier can be selected from EMG SW. The

number 1, 2 , 3, 4 on EMG SW are denoted as axis X, Y, Z, U, respectively. Fig. 2.7 is the

default setting to connect the EMG singals to GND. The EMG signals from CN1 ~ CN4 will not

take effect. If the switch is disconnected as shown in Fig. 2.8, the emergency stop signals can

be controlled from EMG signals in CON6.

Fig. 2.7 EMG SW setting for normally GND (Default setting)

Fig. 2.8 EMG SW setting for user controlled signals.

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

23

Page 24

2.3 Input/Output Connections

The signal connections of all the I/O signals are described in this chapter. Please refer

the contents of this chapter befor wiring the cable between the i8094/i8094F and the

motor drivers.

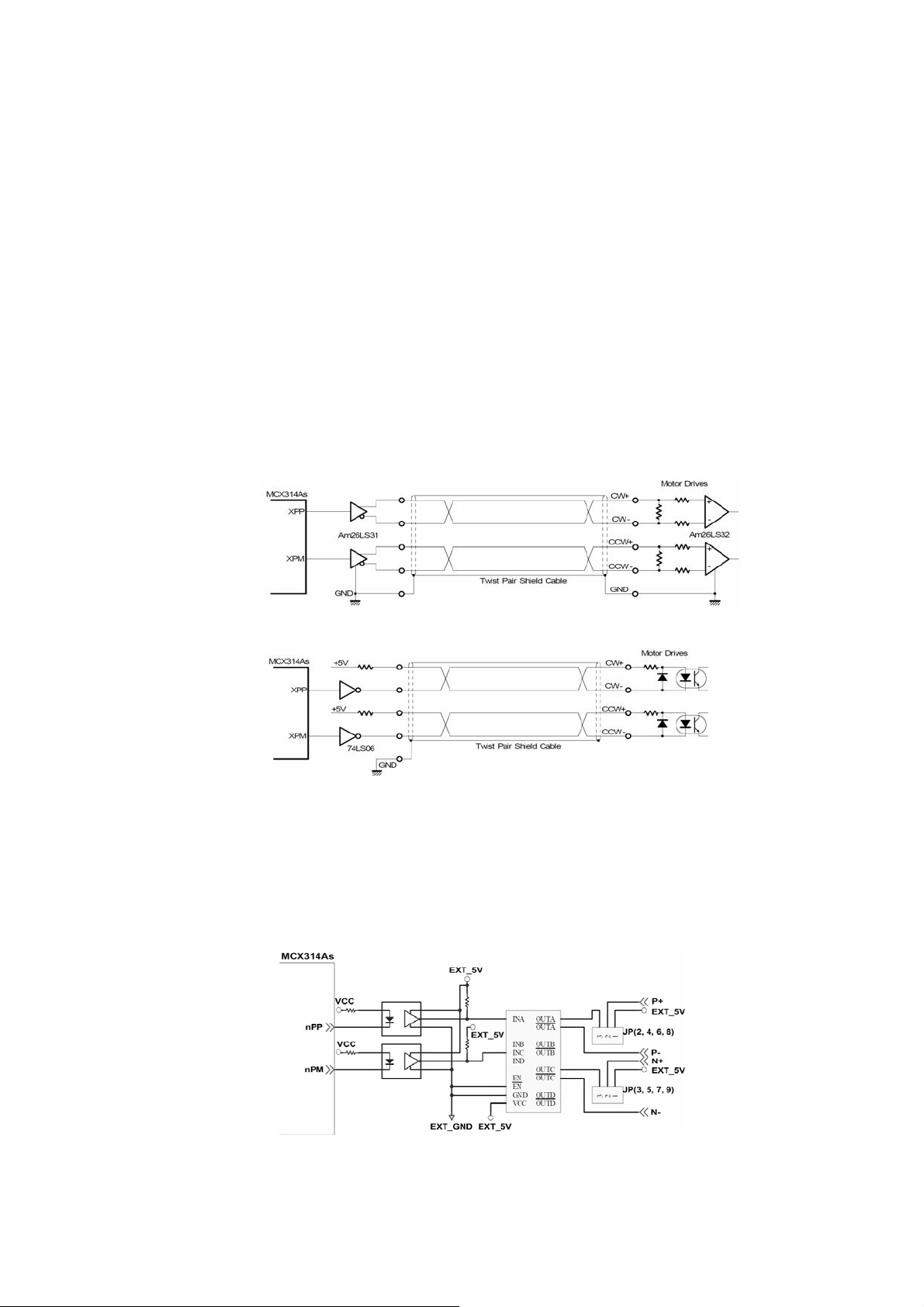

2.3.1 Pulse output signals

There are 4-axes pulse output signals on I8094/I8094F, For every axis, two pairs of CW

and CCW signals are used to send the pulse train. The CW and CCW signals can also

be programmed as PULSE and DIR signals pait.

Differential-Type and Open-Collector Type, can be selected from JP8/9, JP10/11, JP12/13, and

JP14/15 and are described in section 2.2.3.

The following wiring diagram is for the CW and

Two types of the pulse output signal,

CCW signals of the 4-axes.

Fig. 2.8 Differential-Type pulse output circuit

Fig. 2.9 The wiring is open collector output

Example: wiring of pulse signal

Two types of pulse output signal, Differential-Type and Open-Collector Type, can be

selected from JP8/9, JP10/11, JP12/13, and JP14/15 for each axis. The following wiring

diagram is an example to select pulse type of the output signal.

Fig. 2.10 Output pulse example

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

24

Page 25

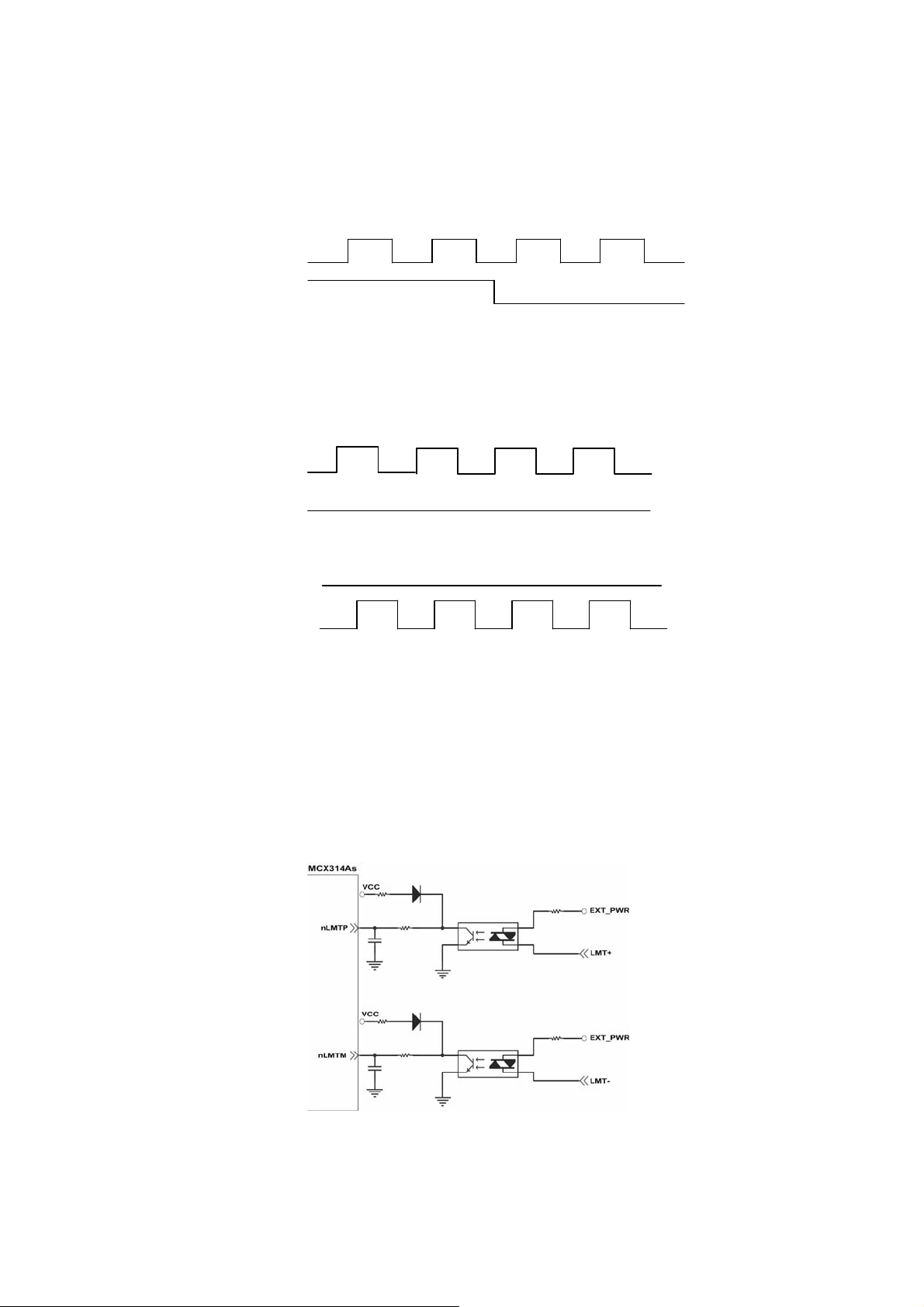

Pulse/Direction Pulse Output Mode:

In Pulse/Direction pulse output mode, the PULSE signal is output only at Pulse pins (P+,

P-). The driving direction is decided from the electric potential of Direction pins (N+, N-).

The following diagram is example signal of Pulse/Direction pulse output mode.

Positive Command Negative Command

CW/CCW Pulse Output Mode:

In CW/CCW pulse output mode, the PULSE signal is output at both CW pins (P+, P-)

and CCW pins(N+, N-). At the same time, the driving direction is determined directly.

The following diagram is example signal of CW/CCW pulse output mode.

P±

N±

P±

N±

Positive Command

Negative Command

2.3.2 Connection for Limit switch Signal

Limit Switch Signal can prevent the over traveling appearance of the motion system.

User can set the hardware limit switch signal to be normal open or normal close by the

software instruction in I8094/I8094F software manual. The following figure indicates

that the photo couplers are used to keep out the sensor noise of the Limit Switch.

Fig. 2.11 Limit switch signal circuit

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

25

Page 26

2.3.3 General Purpose Input Signals(nINPOS,nALARM)

INPOS is a digital input signal to indicate the In-Position signal of the driver. User can

enable or disable the signal from the software instruction in I8094/I8094F software

manual.

ALARM is a digital input signal to indicate the servo alarm signal of the driver. The

output pulse will be stop if PISO-PS400 receives the ALARM signal. User can enable

or disable the signal from the software instruction in I8094/I8094F software manual.

Fig. 2.12 General Digital Input circuit

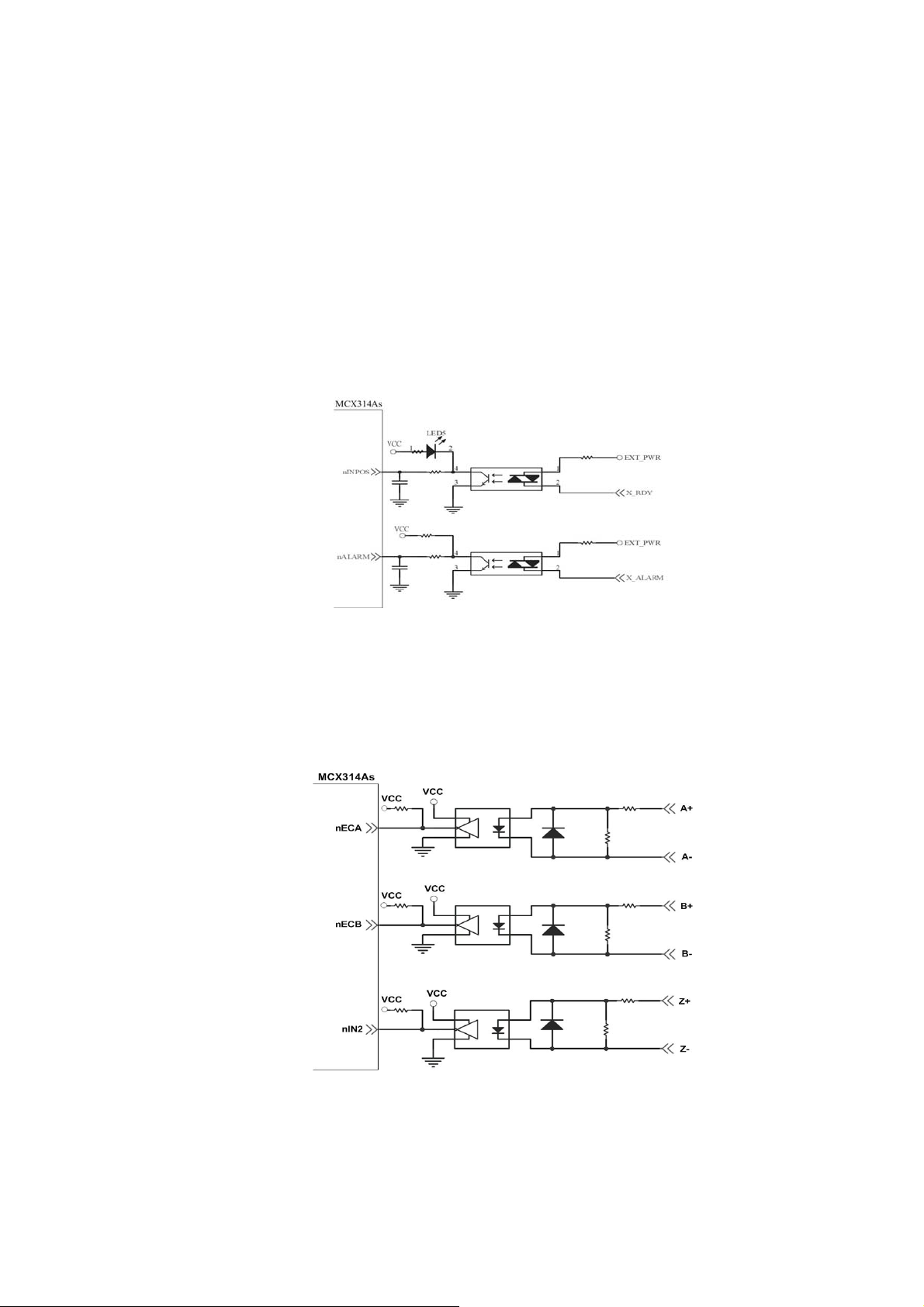

2.3.4 Encoder Signals

The following diagram is for Differential-Type encoder signals. Connect the Phase A

signal to A+ and A- pins and connect Phase B signal to B+ and B- pins. After the high

speed photo coupler isolation, the isolated encoder signals are connected to motion IC.

Fig. 2.13 Encoder signal connection

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

26

Page 27

2.3.5 Emergency Stop Signal

The following diagram is for Emergency STOP signal. If the emergency signal is

occurred, the output pulse for all axes will be STOP and the error flag will be set as 1.

After the photo coupler isolation, the isolated emergency signal is connected to motion

IC.

Fig. 2.14 Emergency Stop Signal connection

2.3.6 Manual Pulse Generator Input Signal (EXP+,EXP-)

The signals, EXP+ and EXP-, are used for manual pulsar signals. The following

diagram is an example connection for the external inputs. User can set the signals as

fixed pulse CW/CCW mode, continuous pulse CW/CCW mode, or A/B phase manual

pulsar mode by using the setting in section 3.5.

Fig. 2.15 EXP+/- connection diagram

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

27

Page 28

2.3.7 General Purpose Output signals(Servo On/Off)

The following diagram is a digital output signal for driver Servo On/Off signal. The

output signal enable or disable the driver.

Fig. 2.16 Servo On/Off signal connection diagram

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

28

Page 29

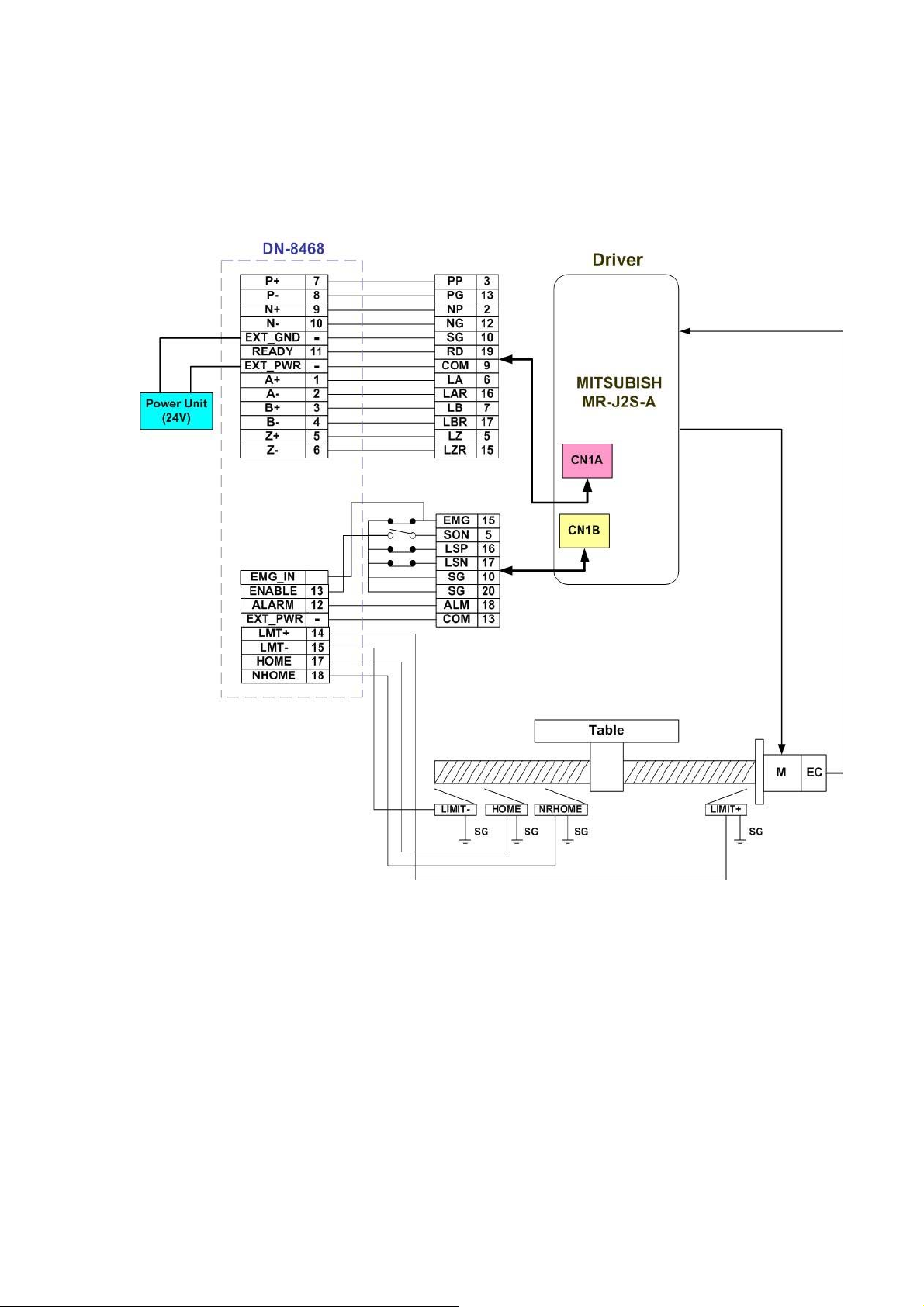

2.4 Connection Example for Motor Driver

The following diagram is the connection example between MITSUBISH MR-J2S AC servo driver

and the extension boardDN-8468G.

Fig. 2.17 The connection between MR-J2S AC servo driver and DN-8468G extension board.

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

29

Page 30

3 Software Development Overview

3.1 Software development Overview

Please refer to the demo_start sample

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

30

Page 31

3.1.1 Register Module

User must register for each I8094/I8094F module before sending command otherwise

user will get error. Please refer to i8094MF_REGISTRATION() function, the section 2.2

of I8094/I8094F user manual.

3.2 Safety IO Setting

There are many reasons to stop motion during driving. Some reasons are described in

this subsection.

3.2.1 Emergency Stop Signal Input

The EMG-A input signal in CON6 is able to perform the emergency stop function

immediately for all of the 4 axes during driving. The emergency stop function can

prevent the critical damage occurrence from the critical accident. If user don’t use this

Emergency stop signal, please closing breaks between 2 and 3 of JP7 jumper.

Otherwise, please closing breaks between 1 and 2 of JP7 jumper and connecting the

EMG-A signal to CON6.

The EMG-X, EMG-Y, EMG-Z, and EMG-U input signals in CON6 are connected directly

to the driver for each axis. These signals are able to perform the emergency stop

function immediately for each driver during driving. User have to switch the EMG-SW

to normal ON and connect external signal source to enable these signals.

3.2.2 Configure the Servo ALARM Signals

When the ALARM signals are occurred from servomotor drivers, users can be notified by these

signals and determine what to do. The operating mode (Enable or Disable) and the proper trigger

level of these signals can be set by user.

the section 2.13 of I8094/I8094F user manual.

Please refer to i8094MF_SET_ALARM() function,

3.2.3 Configure the Limit Switch Signals(±EL)

To insure the machine in safety, hardware limit switches are placed at the both ends of

machine traveling range. If the machine touch the hardware limit switch sensors,

PISO-PS400 will stop immediately. The operating mode (Enable or Disable) and the proper

trigger level of these signals can be set by user.

function, the section 2.6 of I8094/I8094F user manual.

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

Please refer to i8094MF_SET_HLMT ()

31

Page 32

3.2.4 Configure the Software Limite(±SEL)

To insure the machine in safety, hardware limit switches are placed at the both ends of

machine traveling range. In addition, user can set the software limits to avoid the happening

of the over range before the hardware limit takes effect. If the machine reach the software

limits condition, PISO-PS400 will stop immediately. The operating mode (Enable or Disable)

and the proper trigger condition of these signals can be set by user.

Please refer to

i8094MF_SET_SLMT () and i8094MF_CLEAR_SLMT() function, the section 2.10 of

I8094/I8094F user manual.

3.3 Error Checking

Check whether there is any error. If there are something wrongs, please use the

GET_ERROR_CODE() function to get the error-code, then check the reason and

remove it. Please refer to GET_ERROR_CODE() function, the section 3.6 of

I8094/I8094F manual.

User also can use i8094MF_GET_DI() function to check the all of DI status. Please refer

to i8094MF_GET_DI() function, the section 3.5 of I8094/I8094F user manual.

3.4 Basic Configuration of Motion

The basic Motion configuration is mainly aimed for general necsseary setting,

as below:

1 Pulse output mode setting: Pulse/Dir、CW/CCW…

i8094MF_SET_PULSE_MODE() (Please refer to the section 2.4 of I8094/I8094F

user manual )

2 Max. speed limitation setting for each axis

i8094MF_SET_MAX_V ()(Please refer to the section 2.5 of I8094/I8094F

user manual)

3 Encoder input setting

i8094MF_SET_ENCODER()(Please refer to the section 2.11 of I8094/I8094F

user manual)

4 DI noise filter setting( If necessary)

i8094MF_SET_FILTER()(Please refer to the section 2.15 of I8094/I8094F

user manual)

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

32

Page 33

5 Circular motion declaration( Ring counter)( If necessary)

i8094MF_VRING_ENABLE()(Please refer to the section 2.16 of I8094/I8094F

user manual )

3.5 Manual Pulse Generator Testing

User can use the manual pulse generator function directly to drive motion forward or backward.

For further wiring and parameter tuning, user have to check the correction of the DI signals and

the moving direction.

The manual pulse generator can be achieved from three driving methods described

below:

1. A/B phase Manual Pulse Generator:

Use the A/B phase Manual Pulse Generator for forward/backward moving.

i8094MF_EXD_MP()( Please refer to the section 2.18.1 of I8094/I8094F user

manual)

2. Fixed-pulse driving Manual Pulse Generator:

User have to preset fixed driving pulses. After setting, user can push the forward

or backward button to drive fixed pulses for each direction.

i8094MF_EXD_FP()( Please refer to the section 2.18.2 of I8094/I8094F usere

manual)

3.

Continuous- pulse driving Manual Pulse Generator:

User can preset output-pulse frequency. After setting, user can push the forward or

backward button to drive fixed velocity for each direction. If user release the button, the

motion will be stop immediately.

i8094MF_EXD_CP ()( Please refer to section 2.18.3 of I8094/I8094F user

manual).

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

33

Page 34

4 Disable external pulse input:

Disable external pulse input by this command after operating anyone of three

functions above.

i8094MF_EXD_DISABLE() ( Please refer to section 2.18.4 of I8094/I8094F user

manual)

3.6 Home Search

I8094 provides the home function of automatic search. Operate that automatically after

setting properly. The main steps is as bellow:

z Near-home sensor searching under high-speed motion.

z Home sensor searching under low-speed motion.

z Servomotor Z-phase searching under low-speed motion.

z Offset movement to the origin of the working area under high-speed motion.

User can select which steps are ignored when setting for the actual operation. It

performs automatically that economize the CPU resource and program code reducing.

Although there are four home search steps,but user can create more than 10 types of

different home search mode by vary with the software functions. It is attributed to the

configurable home search direction and perform it or not of each step.

3.6.1 Home Search Configuration

1. Logic level setting for Near home sensor and Home sensor ( If necessary)

i8094MF_SET_NHOME() ( Please refer to section 2.8 of I8094/I8094F user

manual)

2 Home sensor logic level setting

i8094MF_SET_HOME_EDGE() ( Please refer to section 2.9 of I8094/I8094F user

manual)

3 Home-speed setting

i8094MF_SET_HV() ( Please refer to section 5.1 of I8094/I8094F user manual)

i8094MF_SET_SV() ( Please refer to section 6.1.2 of I8094/I8094F user manual)

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

34

Page 35

4 Home mode setting

i8094MF_SET_HOME_MODE()( Please refer to section 5.3 of I8094/I8094F user

manual)

3.6.2 Running the Home Search

1 Start homing

i8094MF_HOME _START()( Please refer to section 5.4 of I8094/I8094F user

manual)

2 Waiting for homing completion

i8094 _HOME_WAIT()( Please refer to section 5.5 of I8094/I8094F user manual)

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

35

Page 36

3.7 Basic Motion

3.7.1 Speed Profie of the Motion Control

1 Symmetrical T-profile of motion volicety

(If SV is larger than V or equal to V, perform constant velocity driving)

2 Asymmetrical T-profile of motion velocity

3 Symmetrical S-curve of motion velocity

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

36

Page 37

4 Asymmetrical S-curve of motion velocity

3.7.2 Basic Setting of Single Axis

1 Setting the mode of Acceleration/deceleration: There are four speed modes

0 Æ Symmetrical T-Profile (SV、V、A、AO)

1 Æ Symmetrical S-curve (SV、V、K、AO)

2 Æ Asymmetrical T-profile (SV、V、A、D、AO)

3 Æ Asymmetrical S-curve (SV、V、K、L、AO)

i8094MF_NORMAL_SPEED()( Please refer to section 6.1.1 of I8094/I8094F user

manual)

2 Setting the start velocity: Set lowest speed

i8094MF_SET_SV ()( Please refer to section 6.1.2 of I8094/I8094F user manual)

3 Setting the Velocity: Set the desired speed

i8094MF_SET_V ()( Please refer to section 6.1.3 of I8094/I8094F user manual)

4 Setting the Acceleration/Deceleration speed: Set the Acceleration/Deceleration speed.

i8094MF_ SET_A ()( Please refer to section 6.1.4 of I8094/I8094F user manual)

i8094MF_ SET_D ()( Please refer to section 6.1.5 of I8094/I8094F user manual)

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

37

Page 38

3.7.3 Basic Motion of Single Axis

1 Fixed-pulse driving output: Perform fixed-quantity of single axis pulse output.

i8094MF_FIXED_MOVE()( Please refer to section 6.1.9 of I8094/I8094F user

manual)

2 Continuous-pulse driving output: Perform continuous pulse output of single axis.

i8094MF_CONTIUNE_MOVE ()( Please refer to section 6.1.10 of I8094/I8094F

user manual)

3 Waiting for motion done: Waiting for the axis driving accomplished.

i8094MF_STOP_WAIT()( Please refer to section 6.5.3 of I8094/I8094F user

manual)

3.7.4 Basic Setting of Muti-Axes Interpolation

1 Setting axes of interpolation: Select axes to do the interpolation.

i8094MF_AXIS_ASSIGN()( Please refer to section 6.2.1 of I8094/I8094F user

manual)

2 Setting the mode of Acceleration/Deceleration of vector: There are twelve mode as

below:

0 Æ 2-axes( Linear & ARC & Circular) Fixed-vector velocity (VV)

1 Æ 2-axes linear symmetrical T-profile (VSV、VV、VA、VAO)

2 Æ 2-axes linear symmetrical S-curve (VSV、VV、VK、VAO)

3 Æ 2-axes linear asymmetrical T-profile (VSV、VV、VA、VD、VAO)

4 Æ 2-axes linear asymmetrical S-curve (VSV、VV、VK、VL、VAO)

5 Æ 2-axes (ARC & Circular) symmetrical T-profile (VSV、VV、VA、VAO)

6 Æ 2-axes (ARC & Circular) asymmetrical T-profile (VSV、VV、VA、VD、VAO)

7 Æ 3-axesFixed-vector velocity (VV)

8 Æ 3-axes linear symmetrical T-profile (VSV、VV、VA、VAO)

9 Æ 3-axes linear symmetrical S-curve (VSV、VV、VK、VAO)

10 Æ 3-axes linear asymmetrical T-profile (VSV、VV、VA、VD、VAO)

11 Æ 3-axes linear asymmetrical S-curve (VSV、VV、VK、VL、VAO )

i8094MF_VECTOR_SPEED()( Please refer to section 6.2.2 of I8094/I8094F user

manaul)

2 Setting the start vector velocity: Set the lowest vector speed.

i8094MF_SET_VSV()( Please refer to section 6.2.3 of I8094/I8094F user

manual)

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

38

Page 39

3 Setting the vector velocity: Set the desired vector speed

i8094MF_SET_VV()( Please refer to section 6.2.4 of I8094/I8094F user manual)

4 Setting the velocity of Acceleration/Deceleration of vector: Set the speed of

Acceleration/Deceleration of vector.

i8094MF_SET_VA()( Please refer to section 6.2.5 of I8094/I8094F user manual)

i8094MF_SET_VD()( Please refer to section 6.2.6 of I8094/I8094F user manual)

3.7.5 Basic Motion of Muti-Axes Interpolation

1 2-axes linear interpolation: Perform 2-axes linear interpolation.

i8094MF_LINE_2D()( Please refer to section 6.2.10 of I8094/I8094F user

manual)

2 3-axes linear interpolation: Perform 3-axes linear interpolation.

i8094MF_LINE_3D()( Please refer to section 6.2.11 of I8094/I8094F user

manual)

3 2-axes ARC interpolation: Perform 2-axes ARC interpolation.

i8094MF_ARC_CW ()( Please refer to section 6.2.12 of I8094/I8094F user

manual)

i8094MF_ARC_CCW ()( Please refer to section 6.2.12 of I8094/I8094F user

manual)

4 2-axesCircular interpolation: Perform 2-axes Circular interpolation.

i8094MF_ CIRCLE _CW ()( Please refer to section 6.2.13 of I8094/I8094F user

manual)

i8094MF_ CIRCLE _CCW ()( Please refer to section 6.2.13 of I8094/I8094F user

manual)

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

39

Page 40

3.8 Advance Motion

1 2-axes continuous interpolation of rectangle: Perform2-axes continuous

interpolation of rectangle.

i8094MF_RECTANGLE()( Please refer to section 6.4.1 of I8094/I8094F user

manual)

2 2-axes continuous interpolation of line:

Initial setting continuous interpolation of 2-axes line( Symmetrical T-profile).

i8094MF_LINE_2D_INITIAL()( Please refer to section 6.4.2 of I8094/I8094F user

manual)

Perform 2-axes continuous interpolation of line.

i8094MF_LINE_2D_CONTINUE()( Please refer to section 6.4.2 of I8094/I8094F

user manual)

3 3-axes continuous interpolation of line:

Initial setting continuous interpolation of line( symmetrical T-profile).

i8094MF_LINE_3D_INITIAL()( Please refer to section 6.4.3 of I8094/I8094F user

manual)

Perform 3-axes continuous interpolation of line.

i8094MF_LINE_3D_CONTINUE() ( Please refer to section 6.4.3 of I8094/I8094F

user manual)

4 Others continuous interpolation: Muti-point continuous interpolation, 3-axes Helix

interpolation, 2-axes Ratio motion ( Please refer to section 6.4.4~6.4.7 of I8094/I8094F

user manual)

3.9 Synchronization Action

i8094 also offer many function of Synchronization Action, as compare EP, LATCH….and

so on( Please refer to section 6.3 of I8094/I8094F user manaul)

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

40

Page 41

4 GETTING STARTED OF SOFTWARE

4.1 WinCon eVC++ Guideline

4.1.1 Confirm the Relative Files

Please confirm you have the following relevance files:

1. I8094.lib

2. I8094.dll

3. I8094.h

If you don’t have, please look for CD or download the latest edition from

ICPDAS’s website http://www.icpdas.com/download/download-list.htm .

4.1.2 Create a new eVC++ Application Project

Please execute the Microsoft eVC++ 4.0. Then click“File” -> “New” to create a new

application project. In the “Projects“ property page, choose“WCE MFC AppWizard

(exe)"option and specifythe project name ”Demo_First”, then key in the disk path in

the “Location” field, then select the“Win 32[WCE ARMV4]“ in CPU list. If necessary,

please also select others options together. And then click "OK".

Choose “ Dialog based “ and click “NEXT”

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

41

Page 42

Click “Finish” and finish the new project establishment.

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

42

Page 43

4.1.3 Add the I8094.h into eVC++ Application Project

Add the i8094h into the WorkSpace of application project, as below:

Click the right key of mouse on Header Files, then choose “Add Files to Folder….”

It will appear on a dialog of selecting file, find out the I8094.h and click OK.

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

43

Page 44

4.1.4 Add the Reference Path into eVC++ Application Project

A. Open the “Options” dialog in “Tools” menu.

B. Select “Directories“ , then select the “SA_IA” in “Platform” item. Then select the

“Win32 [WCE ARMV4]” in “CPUS” item and select the “include files” in “Show

directories“ item.

C. Add in the path of including files. Double-click the rectangle in the buttom of

Directories"List-Box. Please key in the specific path that your header files

located. For instance, C:\DAQPRO\Wincon\inc, as below snapshot.

D. Then select the “Library files” in “Show directories” item.

E. Add in the path of library files. Double-click the rectangle in the buttom of

Directories"List-Box. Please key in the specific path that your header files

located. For instance, C:\DAQPRO\Wincon\lib, as below snapshot.

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

44

Page 45

4.1.5 Start the eVC++ Sample

Add a BUTTON on Dialog, as below snapshot:

Double-click on BUTTON and generate subprogram, then add ”#include “i8094.h”,

“WinConSDK.h”, and declare CI8094MF I8094MF & bool Driver_Open & BYTE

cardNo=0 in start point, as below snapshot:

Because we have built a class “CI8094MF(For Macro function)”, it is convenient to guide

in designing program. User also can use the function of manual directly. Double-click on

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

45

Page 46

BUTTON that will generate a subprogram, then key in “I8094MF”, then it will appear a

windows guide to help user to select a relevance function.

Select “i8094MF.REGISTRATION” and key in (cardNo,3), that indicate the i8094( or

i8094F) on third slot is registered to 0th module. The detailed procedure is as below:

//====='Step 1 Driver init

if (!Driver_Open)

{

I8094MF.REGISTRATION(cardNo,3);

Driver_Open = true;

}

//====='Step 2 CONFIG IO

I8094MF.RESET_CARD (cardNo);

I8094MF.SET_PULSE_MODE (cardNo, AXIS_XYZU, 2); //set the pulse output mode

I8094MF.SET_ALARM (cardNo, AXIS_XYZU, 0, 0); //disable the SERVO ALARM Input

I8094MF.SET_ENCODER (cardNo, AXIS_XYZU, 0, 0, 0); //set the encoder input type

I8094MF.SET_MAX_V (cardNo, AXIS_XYZU, 16000); //set the max speed for XYZU

I8094MF.EXD_DISABLE (cardNo, AXIS_XYZU); //set the external input Off

I8094MF.SET_LP (cardNo, AXIS_XYZU, 0); //set the Logic position =0

I8094MF.SET_EP (cardNo, AXIS_XYZU, 0); //set the Encoger p o sition =0

I8094MF.SET_A (cardNo, AXIS_XYZU, 1000); //set th e Acc =1000

I8094MF.SERVO_ON (cardNo, AXIS_XYZU); //set the Servo_ON to servo motors

//======'Step 3 Check ERROR

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

46

Page 47

WORD KK=0;

KK= I8094MF.GET_ERROR(cardNo);

CString MSGG;

if (KK != YES)

{

//No ERROR: Step 4 Move X axis

BYTE axis=AXIS_X; //for AXIS_X it can be to AXIS_XYZU

I8094MF.SET_MAX_V(cardNo, axis, 20000);

I8094MF.NORMAL_SPEED(cardNo, axis, 0); //set axis as Symmetrical T curve mode

I8094MF.SET_V(cardNo, axis, 20000); //set v=10000 PPS

I8094MF.SET_A(cardNo, axis, 100000); //set acc=100000 PPS/S

I8094MF.SET_SV(cardNo, axis, 10); //set start speed=1000 PPS

I8094MF.SET_AO(cardNo, axis, 0); //set offset pulse (at SV speed)= 0 PS

I8094MF.FIXED_MOVE(cardNo, axis, 10000); //run the fixed 10000 Pulse move.

while (I8094MF.STOP_WAIT(cardNo, axis) == NO)

{

DoEvents();

Sleep(1);

//wait for axis to stop

}

long AA= I8094MF.GET_LP(cardNo,axis); //Get X Now position

}

else

{

//Please check the ERROR CODE

//Get X ERROR CODE

KK= I8094MF.GET_ERROR_CODE(cardNo, AXIS_X);

//Get Y ERROR CODE

KK= I8094MF.GET_ERROR_CODE(cardNo, AXIS_Y);

//Get Z ERROR CODE

KK= I8094MF.GET_ERROR_CODE(cardNo, AXIS_Z);

//Get U ERROR CODE

KK= I8094MF.GET_ERROR_CODE(cardNo, AXIS_U);

//====================================

}

Please refer to the example “demo_First”

After you finished that, please choose the “Project”->”Setting” menu will appear the a

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

47

Page 48

dialgo as below, then select the “Link” item and key in “WinConSDK.lib i8094.lib”(as

below snapshot) into the Object/library modules box and the click OK.

4.1.6 Build the Project

Please select the “Build” -> ”Build All” in the menu, then you will be finished this example

program if there isn’t any wrong.

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

48

Page 49

4.1.7 Download and Run

Please copy the ”i8094Demo.exe” and “I8094.dll” into the same floder of WinCon ( User

can use the eVC++ Online Download/FTP/USB disk to do), then execute it.

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

49

Page 50

4.2 Microsoft Visual Studio .NET 2003(VB.NET,C#) Guideline

Because the Microsoft Visual Studio .NET 2003 has similar environment, therefore we

make an example with VB.NET.

4.2.1 Confirm the Relative Files

Please confirm you have the following relevance files:

i8094.dll

i8094_NET.dll

If you don’t have, please look for CD or download the latest edition from

ICPDAS’s website http://www.icpdas.com/download/download-list.htm

4.2.2 Create a new VB.NET/C# Application Project

Please execute the Microsoft Visual Studio .NET 2003. Then create a new application

project of VB and select “ Smart Device Application”, as below snapshot:

Click “OK” after finishing all of the selecting, then go to next step.

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

50

Page 51

Select the “WinDows CE” and “Windows Application”, then click “OK”.

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

51

Page 52

4.2.3 Add the DLL into Application Project

Click the right key of mouse on”Solution Explorer” =>add Reference

=>Select “Browse” button.

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

52

Page 53

Select the i8904 _NET.DLL

Select the “Open” button, as above snapshot:

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

53

Page 54

4.2.4 Start the VB.NET/C# Sample

Add a “BUTTON” on the Form1, then double-click the BUTTON, then it will appear a

code of Form1.vb, then add the “imports i8094MF_NET” in top, as below snapshot:

Add the “i8094MF” into the Button1_Click, then it will appear a windows guide to help

user to select a relevance function.

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

54

Page 55

Detailed code as below:

'====='Step 1 Driver init

If Not Driver_Open Then

i8094MF.i8094MF_REGISTRATION(cardNo, 1)

Driver_Open = True

End If

'====='Step 2 CONFIG IO

i8094MF.i8094MF_RESET_CARD(cardNo)

i8094MF.i8094MF_SET_PULSE_MODE(cardNo, AXIS_XYZU, 2) 'set the pulse output mode

i8094MF.i8094MF_SET_ALARM(cardNo, AXIS_XYZU, 0, 0) 'disable the SERVO ALARM Input

i8094MF.i8094MF_SET_ENCODER(cardNo, AXIS_XYZU, 0, 0, 0) 'set the encoder input type

i8094MF.i8094MF_SET_MAX_V(cardNo, AXIS_XYZU, Convert.ToUInt32(16000)) 'set the max speed for XYZU

i8094MF.i8094MF_EXD_DISABLE(cardNo, AXIS_XYZU) 'set the external input Off

i8094MF.i8094MF_SET_LP(cardNo, AXIS_XYZU, 0) 'set the Logic position =0

i8094MF.i8094MF_SET_EP(cardNo, AXIS_XYZU, 0) 'set the Encoger position =0

i8094MF.i8094MF_SET_A(cardNo, AXIS_XYZU, Convert.ToUInt32(1000)) 'set the Acc =1000

i8094MF.i8094MF_SERVO_ON(cardNo, AXIS_XYZU) 'set the Servo_ON to servo motors

'======'Step 3 Check ERROR

Dim KK As Long = 0

KK = i8094MF.i8094MF_GET_ERROR(cardNo)

Dim MSGG As String

If (KK <> YES) Then

'No ERROR: Step 4 Move X axis

Dim axis As UInt16 = AXIS_X 'for AXIS_X it can be to AXIS_XYZU

i8094MF.i8094MF_SET_MAX_V(cardNo, axis, Convert.ToUInt32(20000))

i8094MF.i8094MF_NORMAL_SPEED(cardNo, axis, Convert.ToUInt16(0)) 'set axis as Symmetrical T curve

mode

i8094MF.i8094MF_SET_V(cardNo, axis, Convert.ToUInt32(20000)) 'set v=10000 PPS

i8094MF.i8094MF_SET_A(cardNo, axis, Convert.ToUInt32(100000)) 'set acc=100000 PPS/S

i8094MF.i8094MF_SET_SV(cardNo, axis, Convert.ToUInt32(10)) 'set start speed=1000 PPS

i8094MF.i8094MF_SET_AO(cardNo, axis, 0) 'set offset pulse (at SV speed)= 0 PS

i8094MF.i8094MF_FIXED_MOVE(cardNo, axis, 10000) 'run the fixed 10000 Pulse move.

Do While (i8094MF.i8094MF_STOP_WAIT(cardNo, axis) = NO)

i8094MF.system.DoEvents()

System.Threading.Thread.Sleep(1)

'wait for axis to stop

Loop

Dim AA As Long = i8094MF.i8094MF_GET_LP(cardNo, axis) 'Get X Now position

Else

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

55

Page 56

'Please check the ERROR CODE

'Get X ERROR CODE

KK = Convert.ToInt32(i8094MF.i8094MF_GET_ERROR_CODE(cardNo, AXIS_X))

'Get Y ERROR CODE

KK = Convert.ToInt32(i8094MF.i8094MF_GET_ERROR_CODE(cardNo, AXIS_Y))

'Get Z ERROR CODE

KK = Convert.ToInt32(i8094MF.i8094MF_GET_ERROR_CODE(cardNo, AXIS_Z))

'Get U ERROR CODE

KK = Convert.ToInt32(i8094MF.i8094MF_GET_ERROR_CODE(cardNo, AXIS_U))

'====================================

End If

Please refer to a example “ demo_First”

4.2.5 Build the Project

Please select the “Build” -> ”Build Solution” in pull-down menu, then you will be finished

this example program if there isn’t any wrong.

4.2.6 Download and Run

Please copy the ”Demo_First.exe”, “I8094.dll” and “I8094_NET.dll” into the same floder

of WinCon ( User can use the VS.NET Online Download/FTP/USB disk to do), then

execute it.

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

56

Page 57

4.3 I-8000 Turbo C Guideine

4.3.1 Confirm the Relative Files

Please confirm you have the following relevance files:

I8094.lib

I8094.h

I8000.lib

I8000.h

If you don’t have, please look for CD or download the latest edition from

ICPDAS’s website http://www.icpdas.com/download/download-list.htm

4.3.2 Create a new TC ++ Application Project

1. Execute the TC.EXE in the demo100 folder, then create a new

Project( demo100.prj).

2. Add the contents of project:demo100.cpp and ..\lib\8000l.lib,I8094.lib

3. Setting the relevance option

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

57

Page 58

Compiler -> Code Generation item as below:

Compiler -> Advance Code Generation item as below:

Debugger setting as below, close the Source debugging.

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

58

Page 59

4.3.3 Start the TC Sample

1. Add the declared contents into the demo100.cpp:

#include <dos.h>

#include <math.h>

#include "8000.h"

#include "I8094.h"

BYTE cardNo;

long x_value, y_value, z_value, u_value;

2. Add the relevance code into the main program( Please refer to demo100.cpp):

void main ()

{

//=================== I-8000 ===================

//Set (slot0~slot7) = cardNO (1~8)。

BYTE slot;

int Found = 0;

for (slot = 0; slot < 8; slot++)

{

cardNo = slot + 1;

if (i8094MF_REGISTRATION(cardNo, slot) == YES)

{

//Found Axis Card。

i8094MF_RESET_CARD(cardNo);

Found++;

}

}

if (Found == 0)

{

//Not Found。

Print("I-8094 card not found ! \r\n");

return;

}

cardNo = 1;

i8094MF_INIT_CARD(cardNo);

i8094MF_SET_PULSE_MODE(cardNo, AXIS_XYZU, 2);

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

59

Page 60

i8094_IN3_LEVEL(cardNo,AXIS_XYZU, 1);

i8094MF_SET_ALARM(cardNo, AXIS_XYZU, 1, 1);

i8094MF_SET_ENCODER(cardNo, AXIS_XYZU, 0, 0, 0);

i8094MF_SET_MAX_V(cardNo, AXIS_XYZU, 16000);

//==========================================================================

BYTE ret1 = 0;

BYTE chkey;

DWORD sv; //PPS

DWORD v; //PPS

DWORD a; //PPS/s

i8094MF_SERVO_ON(cardNo, AXIS_XYZU);

do

{

Print(" (0:Exit, 1:HELIX_3D_1, 2:HELIX_3D_2, 3:RATIO, 4:FRnet output, 5:FRnet input)

\r\n");

Print(" (6:Reset Encoder, 7:Stop, 8:Clear Error) \r\n");

Print(" (X:Jog X, Y:Jog Y, Z:Jog Z, U:Jog U, S:Stop Jog) \r\n");

Print("\n");

Print("----------------------LOGIC AND REAL POSITION COUNTER----------------------\n");

x_value = i8094MF_GET_LP(cardNo, AXIS_X);

y_value = i8094MF_GET_LP(cardNo, AXIS_Y);

z_value = i8094MF_GET_LP(cardNo, AXIS_Z);

u_value = i8094MF_GET_LP(cardNo, AXIS_U);

Print("LOGIC POSITION: x=%10ld, y= %10ld, z= %10ld, u=%10ld \r\n", x_value, y_value,

z_value, u_value);

x_value = i8094MF_GET_EP(cardNo, AXIS_X);

y_value = i8094MF_GET_EP(cardNo, AXIS_Y);

z_value = i8094MF_GET_EP(cardNo, AXIS_Z);

u_value = i8094MF_GET_EP(cardNo, AXIS_U);

Print("REAL POSITION: x=%10ld, y= %10ld, z= %10ld, u=%10ld \r\n", x_value, y_value,

z_value, u_value);

while (!Kbhit());

chkey=Getch();

Print("%s\r\n",&chkey);

switch (chkey)

{

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

60

Page 61

case '0':

i8094MF_RESET_CARD(cardNo);

Print("EXIT! \r\n");

return;

//---------------------------------------------------------------

case '1':

v=50000;//PPS。

i8094MF_SET_MAX_V(cardNo, AXIS_XYZU,160000L);

ret1=i8094MF_HELIX_3D(cardNo, AXIS_Y, AXIS_Z, AXIS_X, 1, v, 0,

1000, 5, -2000);

Delay(1000);

Print("HELIX_3D_1 ! \r\n");

Print("ret1= %d \r\n",ret1);

break;

//---------------------------------------------------------------

case '2':

v=100000;//PPS。

i8094MF_SET_MAX_V(cardNo, AXIS_XYZU,1600000L);

ret1=i8094MF_HELIX_3D(cardNo, AXIS_Y, AXIS_Z, AXIS_U, 1, v, 0,

25000, 10, 3600);

Delay(2000);

Print("HELIX_3D_2 ! \r\n");

Print("ret1= %d \r\n",ret1);

break;

//---------------------------------------------------------------

case '3':

sv=300;//PPS。

v=30000;//PPS。

a=500000;//PPS/s。

int loop1;

int loop2;

float ratio;

i8094MF_SET_MAX_V(cardNo, AXIS_XYZU,160000L);

Print("RATIO_2D ratio ? \r\n");

Scanf("%f", &ratio);

Print("ratio= %f \r\n",ratio);

i8094MF_RATIO_INITIAL(cardNo,AXIS_U, AXIS_X, sv, v, a, ratio);

for (loop2 = 0; loop2 < 5; loop2++)

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

61

Page 62

{

for (loop1 = 0; loop1 < 5; loop1++)

{

i8094MF_RATIO_2D(cardNo, 0, 3600, 0);

i8094MF_RATIO_2D(cardNo, 0, 3600, 1);

}

i8094MF_RATIO_2D(cardNo, 0, 7200, 0);

i8094MF_RATIO_2D(cardNo, 0, 3600, 1);

}

i8094MF_RATIO_2D(cardNo, 1, 7200, 1);

Delay(3000);

Print("RATIO_2D OK ! \r\n");

break;

//---------------------------------------------------------------

case '4':

WORD wSA;

WORD data;

Print("FRnet wSA ? \r\n");

Scanf("%d", &wSA);

Print("FRnet 16 bits data ? \r\n");

Scanf("%d", &data);

i8094MF_FRNET_SA(cardNo, wSA, data);

break;

//---------------------------------------------------------------

case '5':

WORD wRA;

Print("FRnet wRA ? \r\n");

Scanf("%d", &wRA);

long data1 = i8094MF_FRNET_RA(cardNo, wRA);

Print("FRnet 16 bits data = %10ld \r\n", data1);

break;

//---------------------------------------------------------------

case '6':

i8094MF_SET_LP(cardNo, AXIS_XYZU, 0);

i8094MF_SET_EP(cardNo, AXIS_XYZU, 0);

Print("RESET Encoder ! \r\n");

break;

//---------------------------------------------------------------

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

62

Page 63

case '7':

i8094MF_STOP_SLOWLY(cardNo, AXIS_XYZU);

Print("STOP! \r\n");

break;

//---------------------------------------------------------------

case '8':

i8094MF_CLEAR_ERROR(cardNo);

Print("CLEAR ERROR ! \r\n");

break;

//---------------------------------------------------------------

case 88:

case 120:

BYTE m_Axis=AXIS_X;

i8094MF_SET_MAX_V(cardNo, m_Axis, 32000);

i8094MF_NORMAL_SPEED(cardNo, m_Axis, 0); //set axis as

Symmetrical T curve mode

i8094MF_SET_A(cardNo, m_Axis, 50000); //set Acc =50000

PPS/S

i8094MF_SET_V(cardNo, m_Axis, 50000);

i8094MF_EXD_MP(cardNo, AXIS_X, 100);

i8094MF_EXD_DISABLE(cardNo, AXIS_Y);

i8094MF_EXD_DISABLE(cardNo, AXIS_Z);

i8094MF_EXD_DISABLE(cardNo, AXIS_U);

break;

//---------------------------------------------------------------

case 89:

case 121:

m_Axis=AXIS_Y;

i8094MF_SET_MAX_V(cardNo, m_Axis, 32000);

i8094MF_NORMAL_SPEED(cardNo, m_Axis, 0); //set axis as

Symmetrical T curve mode

i8094MF_SET_A(cardNo, m_Axis, 50000); //set Acc =50000

PPS/S

i8094MF_SET_V(cardNo, m_Axis, 100000);

i8094MF_EXD_MP(cardNo, AXIS_Y, 100);

i8094MF_EXD_DISABLE(cardNo, AXIS_X);

i8094MF_EXD_DISABLE(cardNo, AXIS_Z);

i8094MF_EXD_DISABLE(cardNo, AXIS_U);

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

63

Page 64

break;

//---------------------------------------------------------------

case 90:

case 122:

m_Axis=AXIS_Z;

i8094MF_SET_MAX_V(cardNo, m_Axis, 32000);

i8094MF_NORMAL_SPEED(cardNo, m_Axis, 0); //set axis as

Symmetrical T curve mode

i8094MF_SET_A(cardNo, m_Axis, 50000); //set Acc =50000

PPS/S

i8094MF_SET_V(cardNo, m_Axis, 10000);

i8094MF_EXD_MP(cardNo, AXIS_Z, 100);

i8094MF_EXD_DISABLE(cardNo, AXIS_X);

i8094MF_EXD_DISABLE(cardNo, AXIS_Y);

i8094MF_EXD_DISABLE(cardNo, AXIS_U);

break;

//---------------------------------------------------------------

case 85:

case 117:

m_Axis=AXIS_U;

i8094MF_SET_MAX_V(cardNo, m_Axis, 32000);

i8094MF_NORMAL_SPEED(cardNo, m_Axis, 0); //set axis as

Symmetrical T curve mode

i8094MF_SET_A(cardNo, m_Axis, 50000); //set Acc =50000

PPS/S

i8094MF_SET_V(cardNo, m_Axis, 10000);

i8094MF_EXD_MP(cardNo, AXIS_U, 5);

i8094MF_EXD_DISABLE(cardNo, AXIS_X);

i8094MF_EXD_DISABLE(cardNo, AXIS_Y);

i8094MF_EXD_DISABLE(cardNo, AXIS_Z);

break;

//---------------------------------------------------------------

case 83:

case 115:

i8094MF_EXD_DISABLE(cardNo, AXIS_X);

i8094MF_EXD_DISABLE(cardNo, AXIS_Y);

i8094MF_EXD_DISABLE(cardNo, AXIS_Z);

i8094MF_EXD_DISABLE(cardNo, AXIS_U);

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

64

Page 65

break;

//---------------------------------------------------------------

default:

break;

}

} while (1);

}

4.3.4 Build the Project

Click F9 to compile program, LINK or demo100.EXE。

4.3.6 Download and Run

1. Please execute the “7188.EXE” on computer (The “7188.EXE” is a executed

file of DOS, it can be used in DOS or DOS BOX of Win9X/WINNT/WIN2K).

2. Please depend on actual wiring "COM PORT" that assign to "COM1(ALT_1)" or

"COM2(ALT_2)" and set the transmission speed to “115200,N,8,1”.

3. Turn on the power of I-8000. It will have two situation:

o It will appear a version of MiniOs7 message if the ” INIT*” connected to

“ INIT*COM”, then appear I-8000>。

o The I-8000 will run the “AUTOEXEC.BAT” if the “INIT*“ unconnected, then

appear I-8000>。

4. User can start to make a command of I-8000 after appearing the “I-8000>”, as

below drawing:

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

65

Page 66

5. Press the F2 button on the keyboard, then key in “demo100.exe”, then press the

F10 button to download and execute demo100.exe, as following drawing:

Please refer to the 7188 getting started manual.

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

66

Page 67

APPENDIX-A Setup Tools & Others

A.1 Setup the Development Environment of I8094

A.1.1 eVC ++ 4.0

1. Microsoft eVC++ 4.0: at least ServicPack2 (Have already got at present

ServicPack4)

2. WinCon8000_EVC4_SP1: WinCon in eVC++ Development Environment

(SA_IA)

3. WinConSDK:WinCon Software Tool(inc,lib,dll,demo…)

A.1.2 Visual Studio .NET 2003(VB.NET,C#)

1. Above Microsoft Visual Studio.NET 2003 professional, including a

SmartDeviceApplication item

2. Debug Tool: Windows CE .NET Utilities v1.1 for Visual Studio .NET 2003

3. WinConSDK:WinCon software Tool(inc,lib,dll,demo…)

A.1.3 Turbo C

1. Above boland Turbo C 2.0

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

67

Page 68

A.2 I8094 Surface

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

68

Page 69

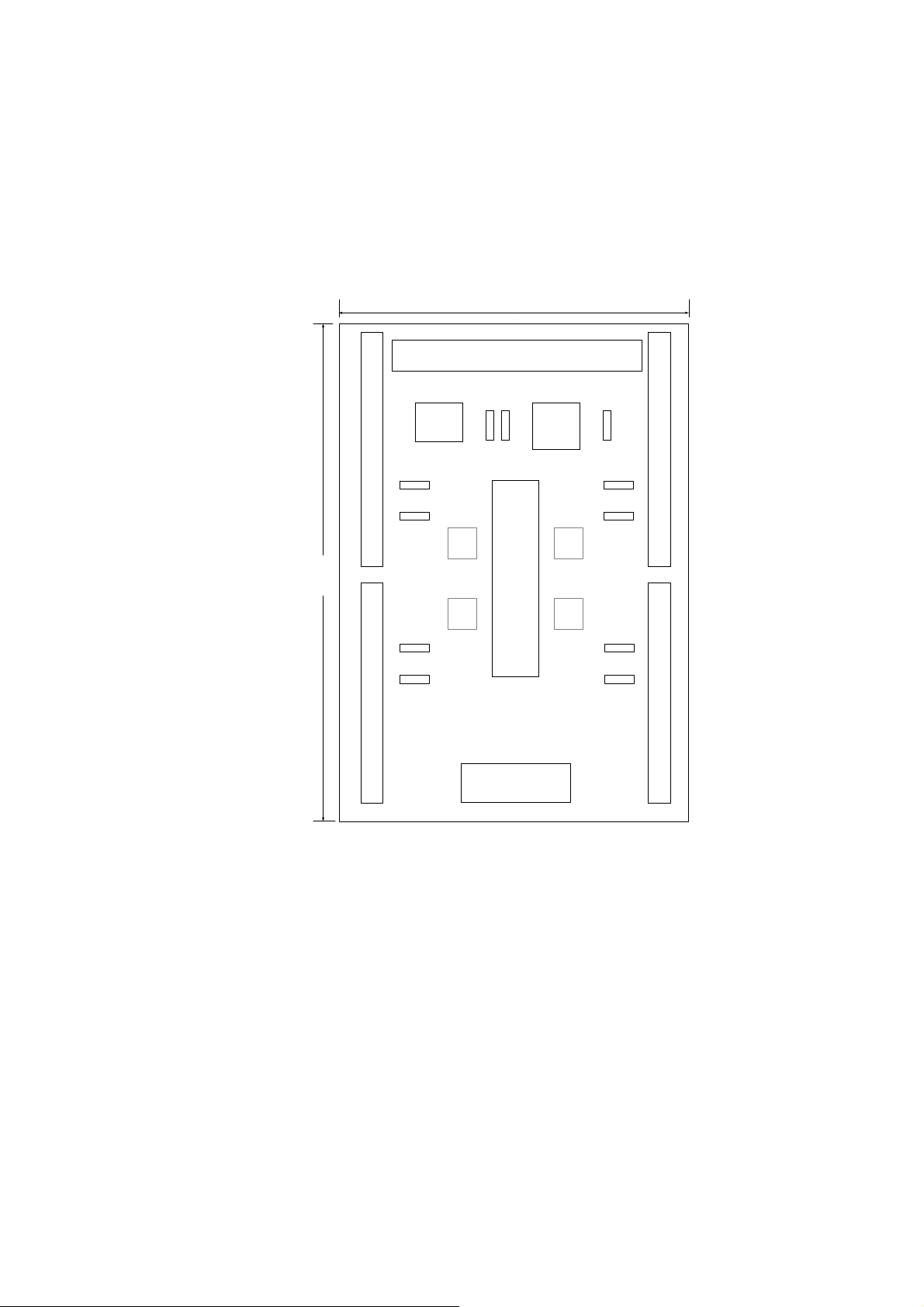

A.3 Dimensions

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

69

Page 70

A.4 The Version Upgrades Note

//========= V 1.5.1.1 ==================

Changed the FUNCTION section

Add section 3.9 Synchronization Motion

//========= V 1.4.0.1 ==================

i8094_* ==>i8094MF_* (All Macro Function)

i8094_MF. DLL ==>i8094.DLL

i8094_MF. h ==>i8094.h

i8094_MF_NET. DLL ==>i8094_NET.DLL

i8094 Macro Function Manual ==> Getting Start manual of i8094 motion

controlmodule

Demo_First Changed(eVC++ and VB.NET)

Add section 5.1 Setup the Development Environment of I8094

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

70

Page 71

APPENDIX-B Others Terminal Boards

B.1 DN-8468M Daughter Board

The DN-8468M is the daughter board for Mitsubitch J2 Series Amplifier. It has 4-axis I/O

signals.

B.1.1 Board Layout for DN-8468M

107mm

TB1

162mm

CN5

CN1CN7 CN3

CN-XACN-XBCN-ZBCN-ZA

JP4 JP3

JP1 JP2

X Y

Z U

DN-8468M

RJ1

CN6CN2CN8 CN4

CN-YACN-YBCN-UBCN-UA

JP5

CON1

68 PIN SCSI

EMG

SW

TB2

Fig. 1-1 Board layout for the DN-8468M

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

71

Page 72

B.1.2 Signal Connections for DN-8468M

Maintaining signal connections is one of the most important factors in ensuring that your

application system is sending and receiving data correctly.

Pin Assignment for CON1

The I/O connector on the DN-8468M is a 68-pin SCSI II connector that enables you to connect to

the I-8094/I8094F motion card. Please refer to the section 2.2.2( page 14).

TB1

The connector TB1 is 7-pin connector that enables you to connect to the signals of your motor

drivers. Fig.1-3 shows the pin assignment for the 7-pin connector on the DN-8468M, and the

Table 1-4 shows its I/O connector signal description.

Table 1-4 TB1 Signal Connection

Fig. 1-3 Pin definition for TB1

TB2

The connector TB2 is 5-pin connector that enables you to connect to the signals of your motor

drivers. Fig.1-4 shows the pin assignment for the 5-pin connector on the DN-8468M, and the

Table 1-5 shows its I/O connector signal description.

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

72

Page 73

Table 1-5 TB2 Signal Connection

Fig. 1-4 Pin definition for TB2

CN-XA, CN-YA, CN-ZA, CN-UA (CNA connector for each AXIS )

The connectors CN-XA, CN-YA, CN-ZA, and CN-UA are 20-pin connectors that enable you to

connect to the CNA connector of Mitsubishi motor drivers. Fig.1-5 shows the pin assignment for

the 20-pin connector on the DN-8468M, and the Table 1-6 shows its I/O connector signal

description.

Fig. 1-5 Pin definition for CN-XA,

CN-YA, CN-ZA, CN-UA

Table 1-6 CNA Signal Connection

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

73

Page 74

CN-XB, CN-YB, CN-ZB, CN-UB (CNB connector for each AXIS )

The connectors CN-XB, CN-YB, CN-ZB, and CN-UB are 20-pin connectors that enable you to

connect to the CNB connector of your motor drivers. Fig.1-6 shows the pin assignment for the

20-pin connector on the DN-8468M, and the Table 1-7 shows its I/O connector signal description.

Table 1-7 CNB Signal Connection

Fig. 1-6 Pin definition for CN-XB, CN-YB

CN-ZB, CN-UB

CN1~CN4 (The I/O signals of the X, Y, Z, U AXIS )

The connectors CN1~CN4 are 11-pin connectors that enable you to connect to the signals of

your motor drivers. Fig.1-7 shows the pin assignment for the 20-pin connector on the DN-8468M,

and the Table 1-8 shows its I/O connector signal description.

Table 1-8 CN1~4 Signal Connection

Fig. 1-7 Pin definition for CN1~CN4

http:/www.icpdas.com I8094Getting Started ManualVer.2.3 2008/4/28

74

Page 75

CN5~CN8 (The I/O signals of the X, Y, Z, U AXIS )

The connectors CN5~CN8 are 15-pin connectors that enable users to connect the signals to

external motor drivers. Fig.1-8 shows the pin assignment for the 15-pin connector on the

DN-8468M, and the Table 1-9 shows its I/O connector signal description.

Table 1-9 CN5~8

Fig. 1-8 Pin definition for CN5~CN8

http:/www.icpdas.com I8094Getting Started ManualVer.2.0 2007/6/28

75

Page 76

RJ1 (The I/O signals of the FRnet)

The connectors RJ1 is an 8-pin RJ45 connector that enable you to connect to the signals of

FRnet. Fig.1-9 shows the pin assignment for the 8-pin connector on the DN-8468M, and the

Table 1-10 shows its I/O connector signal description.

Fig. 1-9 Pin definition for RJ1

B.1.3 Jumper and Switch Settings

JP5

Jumper 5 controls the EMG-A signal of the TB1 connector. The following diagram is shown the

selection condition of the jumper 5.

Fig. 1-10 Jumper 5 setting

JP1, JP2

The encoder signals of axis X and axis Y can be chosen from servo driver encoder or external

encoder. Fig. 1-11 shows that the encoder signals are selected from servo driver encoder. In

meantime, Fig. 1-12 shows that the encoder signals are selected from external encoder.

http:/www.icpdas.com I8094Getting Started ManualVer.2.0 2007/6/28

76

Page 77

Fig. 1-11 Primary encoder signals setting

Fig. 1-12 External encoder signals setting

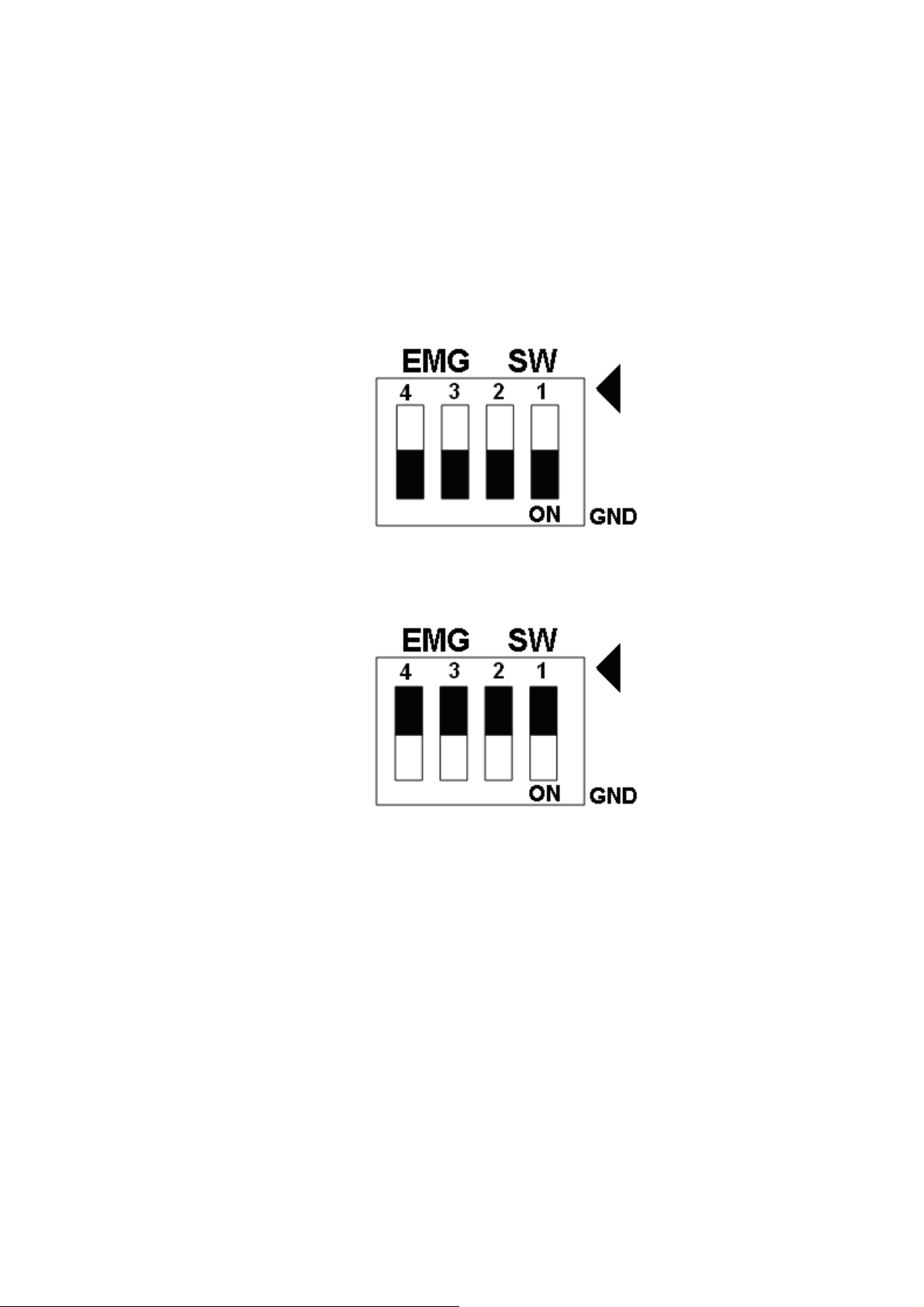

EMG SW

The emergency stop signal for each servo ampilfier can be selected from EMG SW. The

number 1, 2 , 3, 4 on EMG SW are denoted as axis X, Y, Z, U, respectively. Fig. 1-13 is the

default setting to connect the EMG singals to GND. The EMG signals from CN1 ~ CN4 will not

take effect. If the switch is disconnected as shown in Fig. 1-14, the emergency stop signals can

be controlled from EMG signals in CN1 ~ CN4.

Fig. 1-13 EMG SW setting for normally GND (Default setting)

Fig. 1-14 EMG SW setting for user controlled signals.