I-8088W

API Reference Manual

Version 1.0.2, Oct. 2020

Service and usage information for Linux Platform

------------------------------------Written by Martin Hsu

Edited by Cindy Huang

Warranty

Warning

All products manufactured by ICP DAS are under warranty regarding

defective materials for a period of one year, beginning from the date of

delivery to the original purchaser.

ICP DAS assumes no liability for any damage resulting from the use of this

product. ICP DAS reserves the right to change this manual at any time

without notice. The information furnished by ICP DAS is believed to be

accurate and reliable. However, no responsibility is assumed by ICP DAS for

its use, not for any infringements of patents or other rights of third parties

resulting from its use.

Copyright

Copyright @ 2012 by ICP DAS Co., Ltd. All rights are reserved.

Trademark

The names used for identification only may be registered trademarks of

their respective companies.

Contact US

If you have any problem, please feel free to contact us.

You can count on us for quick response.

Email: service@icpdas.com

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 2

Table of Contents

Table of Contents ................................................................................................................ 3

1. Introduction ................................................................................................................. 5

1.1. Specification ....................................................................................................... 6

1.2. Pin Assignment ................................................................................................... 7

1.3. Block Diagram .................................................................................................... 8

1.4. Wire Connection ................................................................................................. 9

2. Software and Getting Started ................................................................................... 10

2.1. Software ............................................................................................................10

2.2. Simple PWM Operation ..................................................................................... 11

2.2.1. Flow Chart ............................................................................................... 11

2.2.2. How to Setup the Standard PWM ...........................................................12

2.3. Using DI to Trigger PWM ...................................................................................16

2.3.1. Flow Chart ...............................................................................................16

2.3.2. How to Setup the Trigger PWM ............................................................... 17

2.4. Synchronize PWM .............................................................................................21

2.4.1. Flow Chart ...............................................................................................21

2.4.2. How to Setup the Standard PWM ...........................................................22

3. API for Linux PAC ...................................................................................................... 24

3.1.1. i8088W_Init .............................................................................................24

3.1.2. i8088W_GetFirmwareVersion .................................................................25

3.1.3. i8088W_GetLibVersion ...........................................................................26

3.1.4. i8088W_SetPWMDuty ............................................................................27

3.1.5. i8088W_SetPWMDuty_Deci ...................................................................28

3.1.6. i8088W_SetPWMDuty_float ....................................................................30

3.1.7. i8088W_GetRealPWMDuty_Deci ...........................................................32

3.1.8. i8088W_SetPWMCountMode .................................................................34

3.1.9. i8088W_SetBurstCount ...........................................................................36

3.1.10. i8088W_PWM_Start ...............................................................................37

3.1.11. i8088W_PWM_Stop ................................................................................38

3.1.12. i8088W_SetSyncChannel .......................................................................39

3.1.13. i8088W_GetSyncChannel .......................................................................41

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 3

3.1.14. i8088W_Sync_Start ................................................................................42

3.1.15. i8088W_Sync_Stop ................................................................................43

3.1.16. i8088W_SetHardwareTrigChannel .........................................................44

3.1.17. i8088W_GetHardwareTrigChannel .........................................................46

3.1.18. i8088W_GetPWMActiveState .................................................................48

3.1.19. i8088W_GetDI ........................................................................................50

Appendix. Error Codes ..................................................................................................... 52

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 4

1. Introduction

PWM (Pulse width modulation) is a powerful technique for controlling analog circuits. It uses

digital outputs to generate a waveform with variant duty cycle and frequency to control

analog circuits. I-8088W has 8 PWM output channels and 8 digital inputs. It can be used to

develop powerful and cost effective analog control system.

Features:

Automatic generation of PWM outputs by hardware, without software intervention.

10 Hz ~ 500 kHz (non-continuous) PWM output frequency with 0.1% ~ 99.9% duty cycle

Software and hardware trigger mode for PWM output

Individual and synchronous PWM output Using software trigger mode, you can set

configuration for all PWM channels then trigger them one by one or all of them at the

same time.

Burst mode PWM operation for standby

DI channel can be configured as simple digital input channel or hardware trigger source

of the PWM output.

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 5

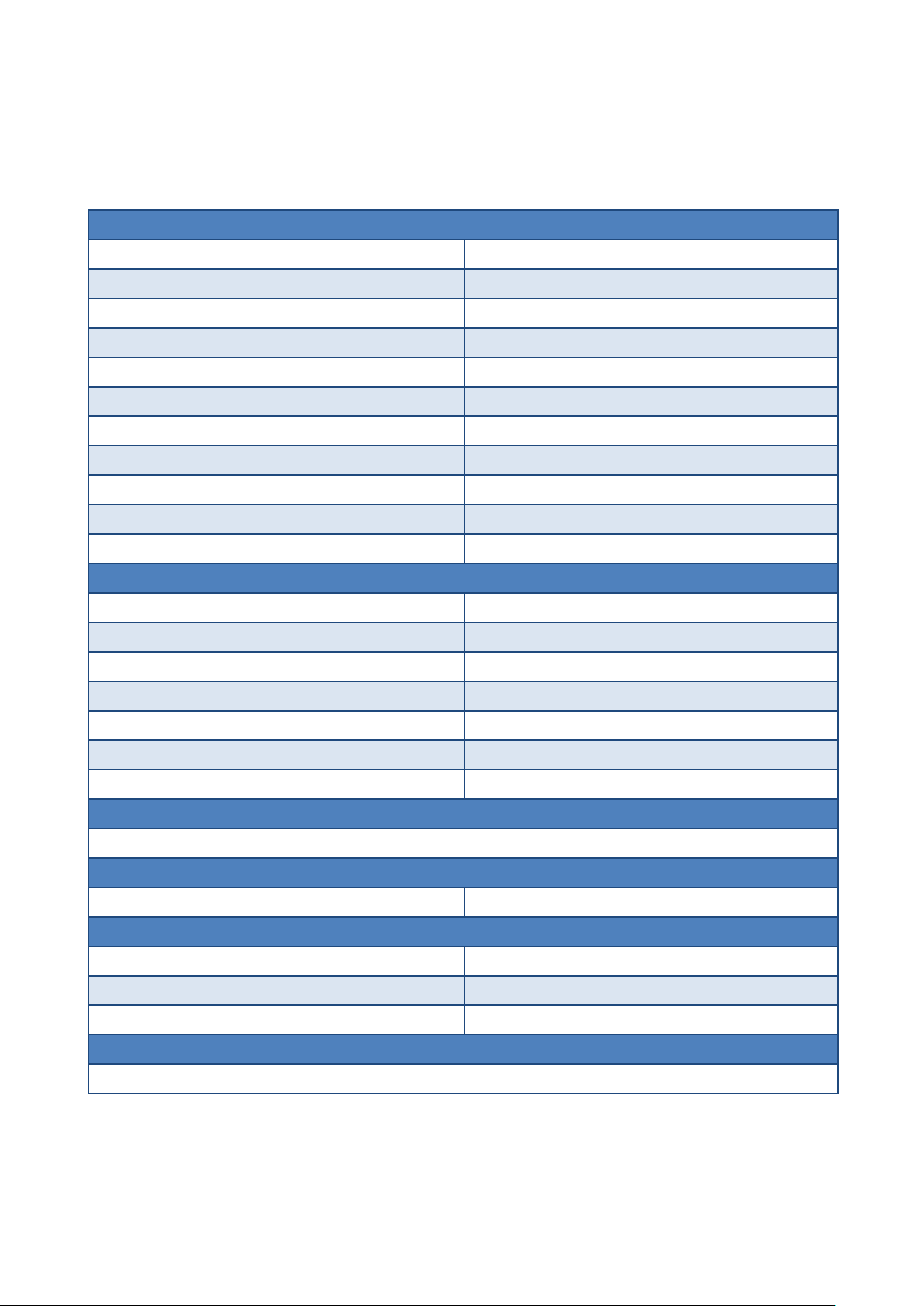

1.1. Specification

PWM Output

Channels

8

Scaling Resolution

16-bit (1 ~ 128 µs for each step)

Frequency Range

10 Hz ~ 500 kHz (non-continuous)

Duty Cycle

0.1 % ~ 99.9 %

PWM Mode

Burst counting, Continuous mode

Burst Counter

1 ~ 65535

Hardware Trigger Mode

Trigger Start and Trigger Stop

Output Type

Source

Max. Load Current

1 mA

Intra-module Isolation, Field to Logic

3,750 Vrms

ESD Protection

4 kV Contact for each channel

Digital Input

Input Channels

8 (Sink/Source)

Input Type

One common for all digital input

On Voltage Level

+5 V ~ +30 V

Off Voltage Level

< 0.8 V

Input Impedance

4.7 kΩ, 1/4 W

Intra-module Isolation, Field to Logic

3,750 Vrms

ESD Protection

4 kV Contact for each channel

LED Display

1 LED as Power Indicator/16 LED as PWM and Digital Input Indicator

Power

Power Consumption

40 mA @ 5 V, 2 W ± 5 %

Environment

Operating Temperature

-25 °C ~ +75 °C

Storage Temperature

-30 °C ~ +85 °C

Humidity

5 % ~ 95 % RH, non-condensing

Dimensions

30 mm x 102 mm x 115 mm (W x L x H)

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 6

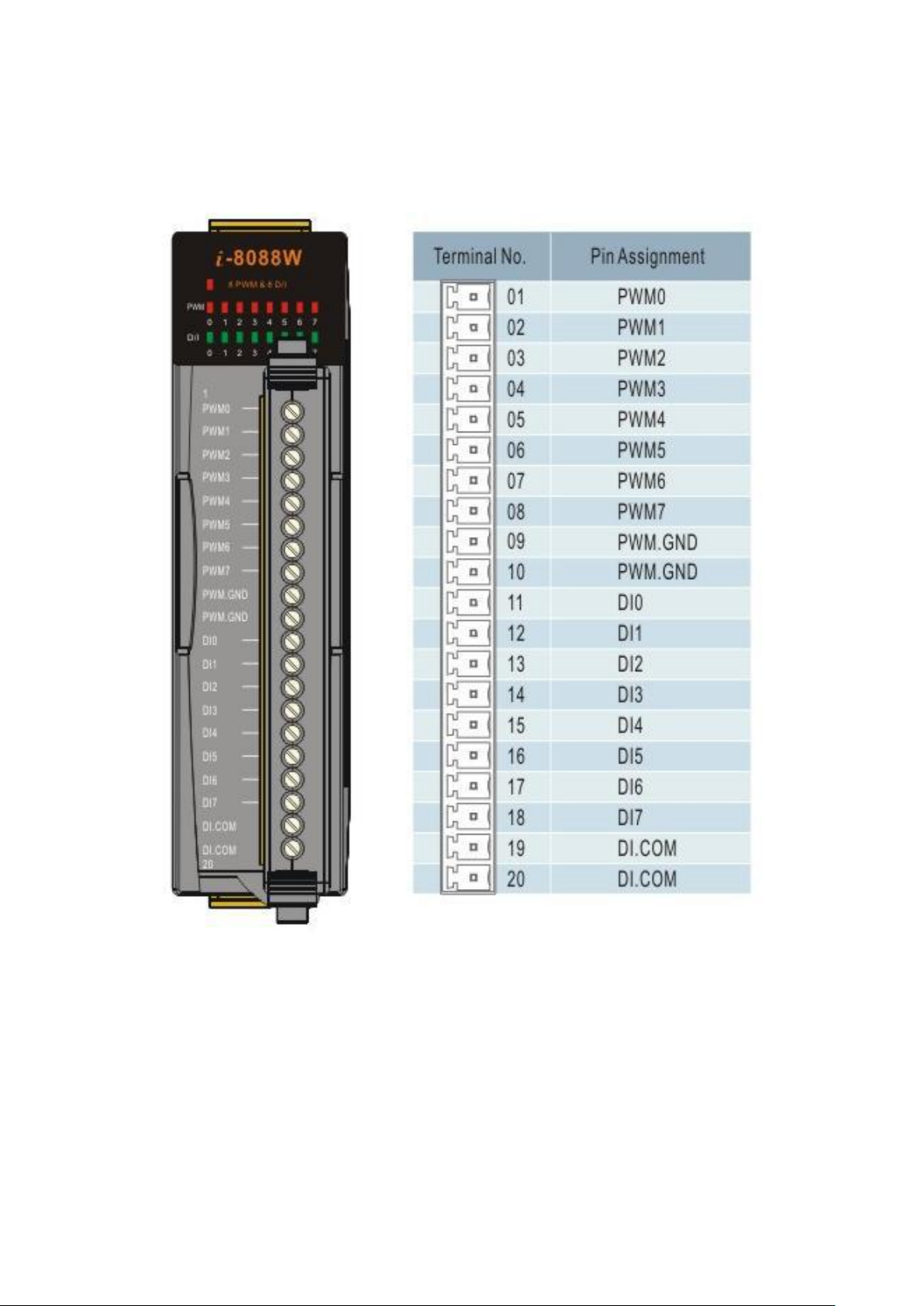

1.2. Pin Assignment

Pin 01 ~ 08: PWM0 ~ PWM7, are designed for PWM output

Pin 09 ~ 10: PWM.GND is isolated ground.

Pin 11 ~ 18: DI0 ~ DI7 are designed for digital input that also capable of setting as an

external trigger signal to start or stop its PWM pulse.

Pin 19 ~ 20: DI.COM is isolated ground.

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 7

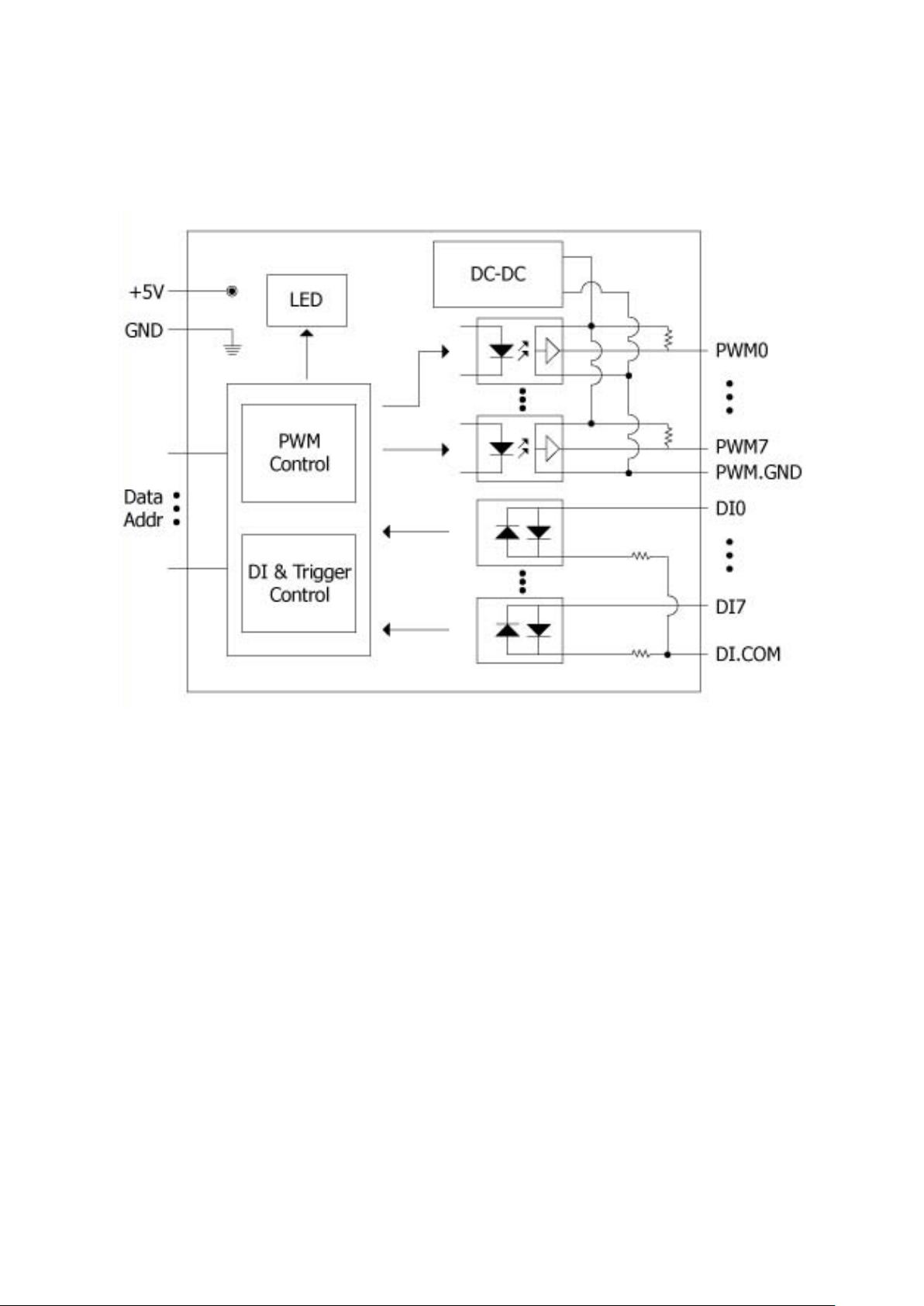

1.3. Block Diagram

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 8

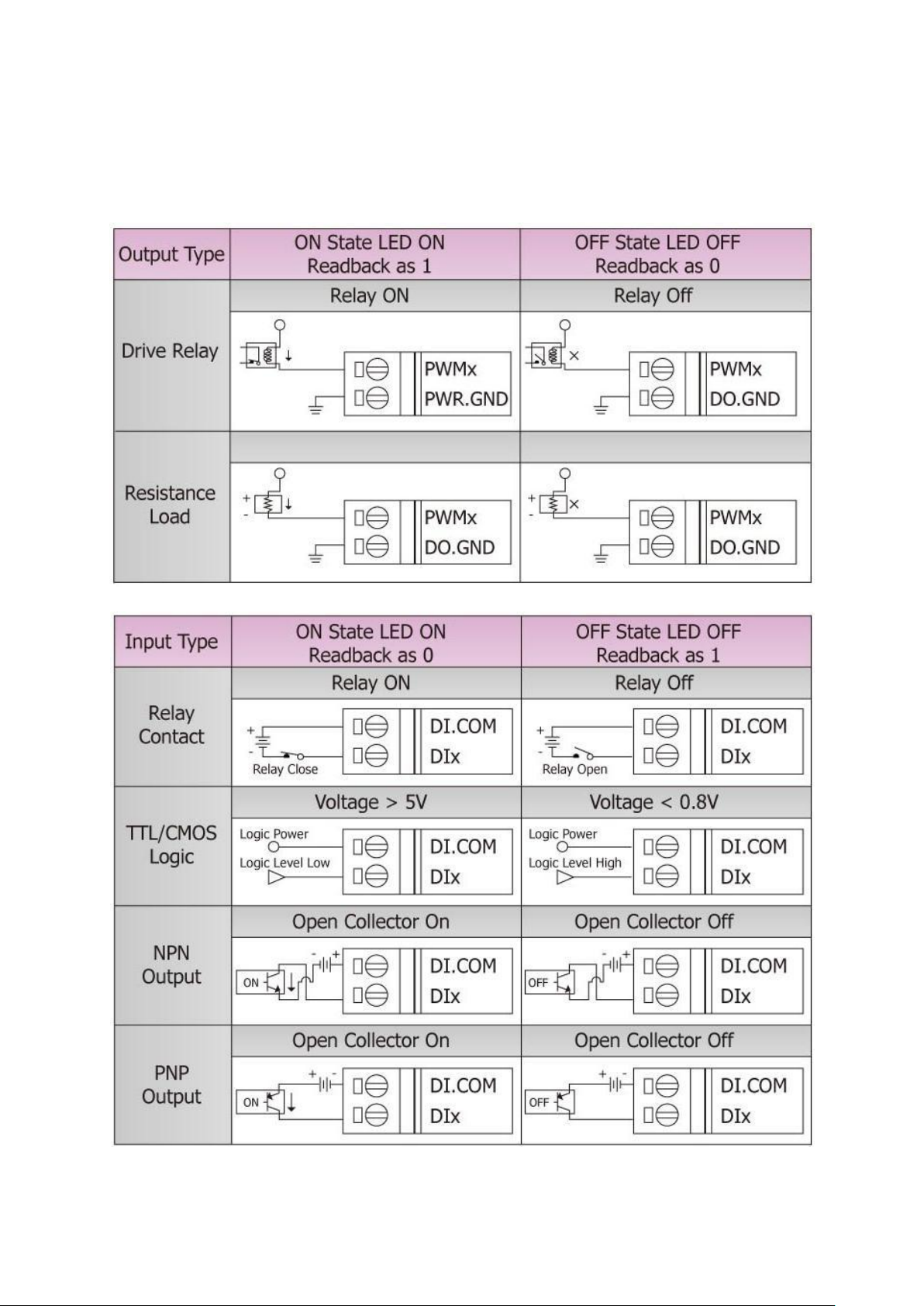

1.4. Wire Connection

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 9

2. Software and Getting Started

PRRODUCT

CPU

DOWNLOAD LINK

LP-8x4x

PXA270

http://www.icpdas.com/en/download/show.php?num=982&model=LP-8441-EN

LP-8x2x/9x2x

AM335x

http://www.icpdas.com/en/download/show.php?num=915&model=LP-8421

LX-8000/9000

x86/E38xx

http://www.icpdas.com/en/download/show.php?num=904&model=LX-9381

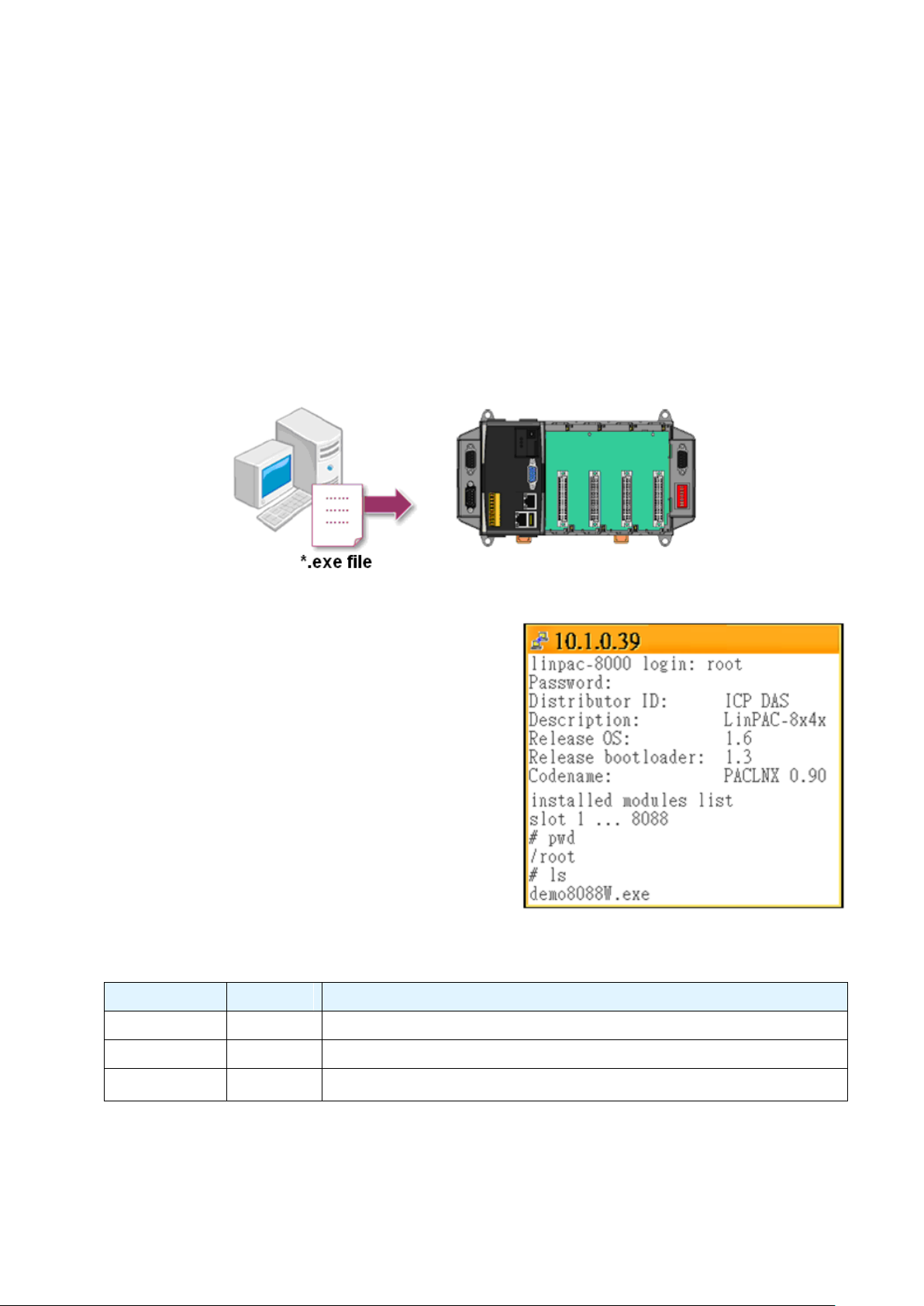

2.1. Software

In this section, we will introduce you one simple program (demo 8080W.exe) which have

three setup modes – Normal, Hardware Trigger and Synchronize. We need to check the

following steps before running the program.

1. First, user need to download LinPAC SDK,

which is includes GNU toolchain, Libraries,

header, examples files, etc.

2. Check the power cable, Ethernet cable, VGA

monitor, the communication cable between

controller and PC has been connected well,

and then check the i-8088W has been plugged

in the controller.

3. Next, check the communication between

controller and PC is fine, and download the

demo program files to the controller.

4. User can find the related files in the product CD or below website:

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 10

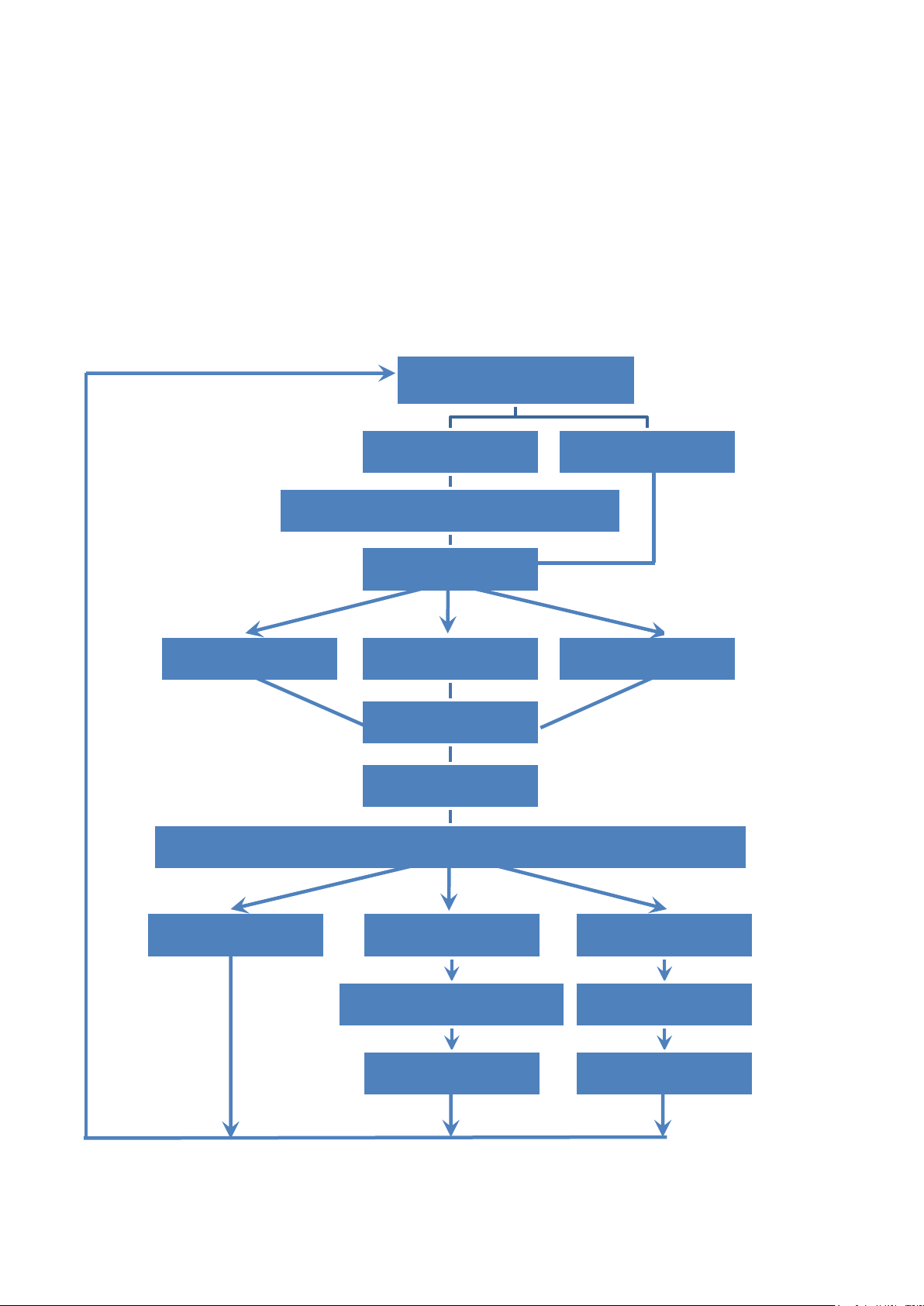

2.2. Simple PWM Operation

Set PWM Mode

Set Burst Count

Choice Burst Count Mode (1 -65535)

Set PWM Duty

(Frequency and Duty)

Set Integer Duty Set x10 Integer Duty

Start or Stop PWM

Start PWM

Stop PWM

Set Float Duty

Set Continous

0

1

0

1

2

Frequency:

Select 0: 1 – 00000 Hz

Select 1: 1 – 500000 Hz

Select 2: 0.1 – 500000.0 Hz

Duty:

Select 0: 1 – 99 %

Select 1: 1 – 99 %

Select 2: 0.1 – 99.9 %

Note: Each time you change the settings of “PWM Duty", you have to re-send the

“Start PWM” command to ensure the operation properly.

2.2.1. Flow Chart

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 11

2.2.2. How to Setup the Standard PWM

Please make sure you have completed the steps in section 2.1 before operating the

following steps.

Description of the demo:

In this example, we will use the demo to set I-8088W as “Continuous” mode and its

frequency is 10 Hz, PWM duty is 50%. When we send the “Start Normal PWM” commend,

the DI0 will blinking per 0.5s.

Wire connection of I-8088W:

To do this, you need to wire PW0 to DI0, DI.COM to External 5V, PWM.GND to External

GND. (Please refer to section 1.2 Pin Assignment)

Now, follow the steps to configure the related parameter:

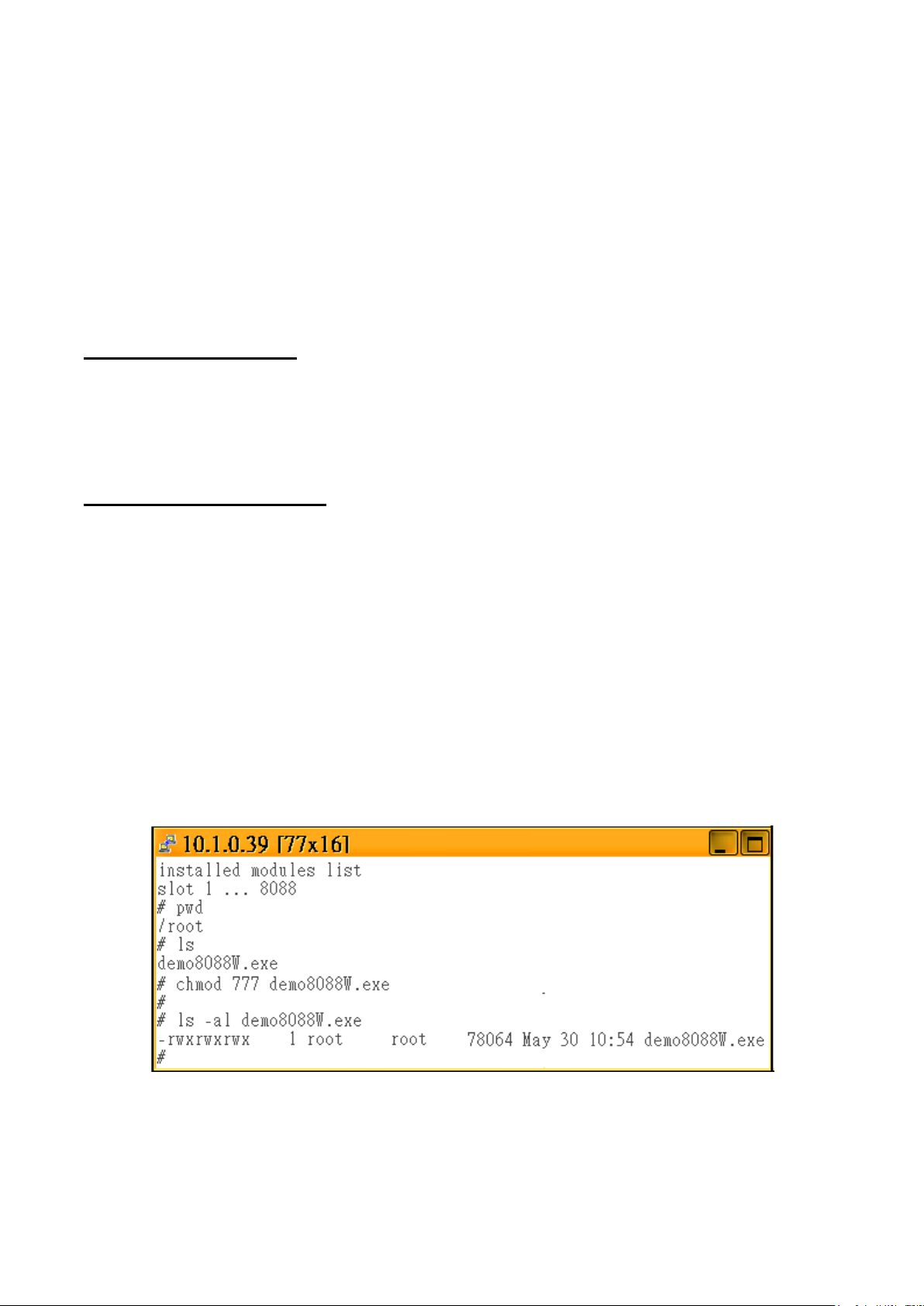

Step 1: Change the authority of “demo8088W.exe”

For example, my LP-8x4x’s IP address is 10.1.0.39, and telnet to the LP-8x4x by pietty.exe

as below:

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 12

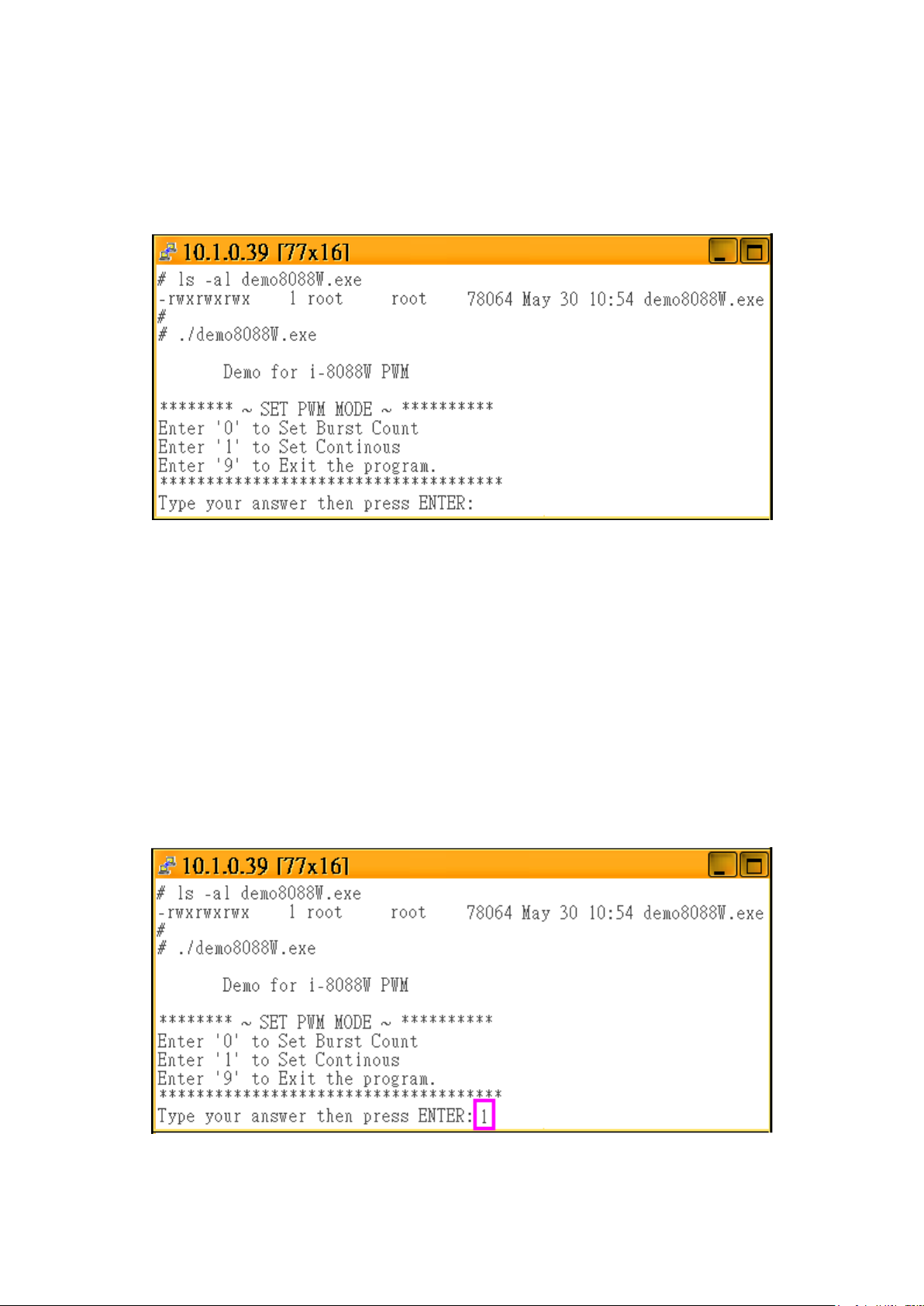

Step 2: Change the authority of “demo8088W.exe”

When you run the program, it will initialize the i-8088W module and obtain the related

information as shown below.

Step3: Set PWM Mode

This setting includes two modes – “Burst Count Mode” and “Continuous Mode”.

“Burst Count Mode” means it can output multiple fixed pulse in a period time and then stop

output. “Continuous Mode” means it can output one fixed pulse in a period time and continue

output.

In this example, we enter "1" to set it as "Continuous mode".

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 13

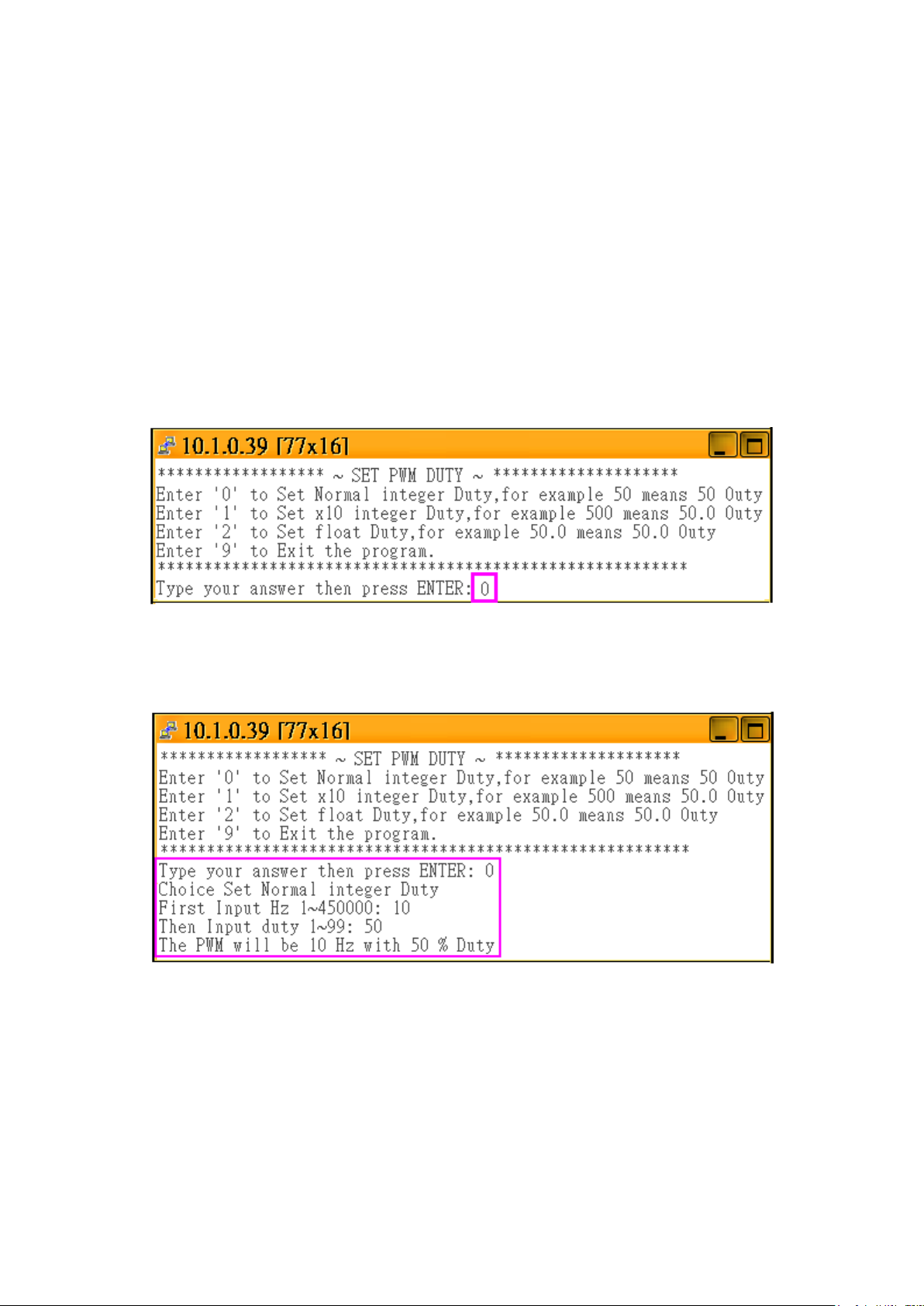

Step 4: Set PWM Duty

There are three options in this setting, if you choose:

"0" means you can enter an integer value (ex. input 50 to set it as 50 %)

"1" means you can enter an integer value to set it as one decimal place value. (ex. input

999 to set it as 99.9 %)

"2" means you can enter a one decimal place value. (ex. input 99.9 to set it as 99.9 %)

In this example, please enter "0" to set it as “Normal integer Duty”

Then, we will set its frequency as 10 Hz, PWM duty as 50 %.

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 14

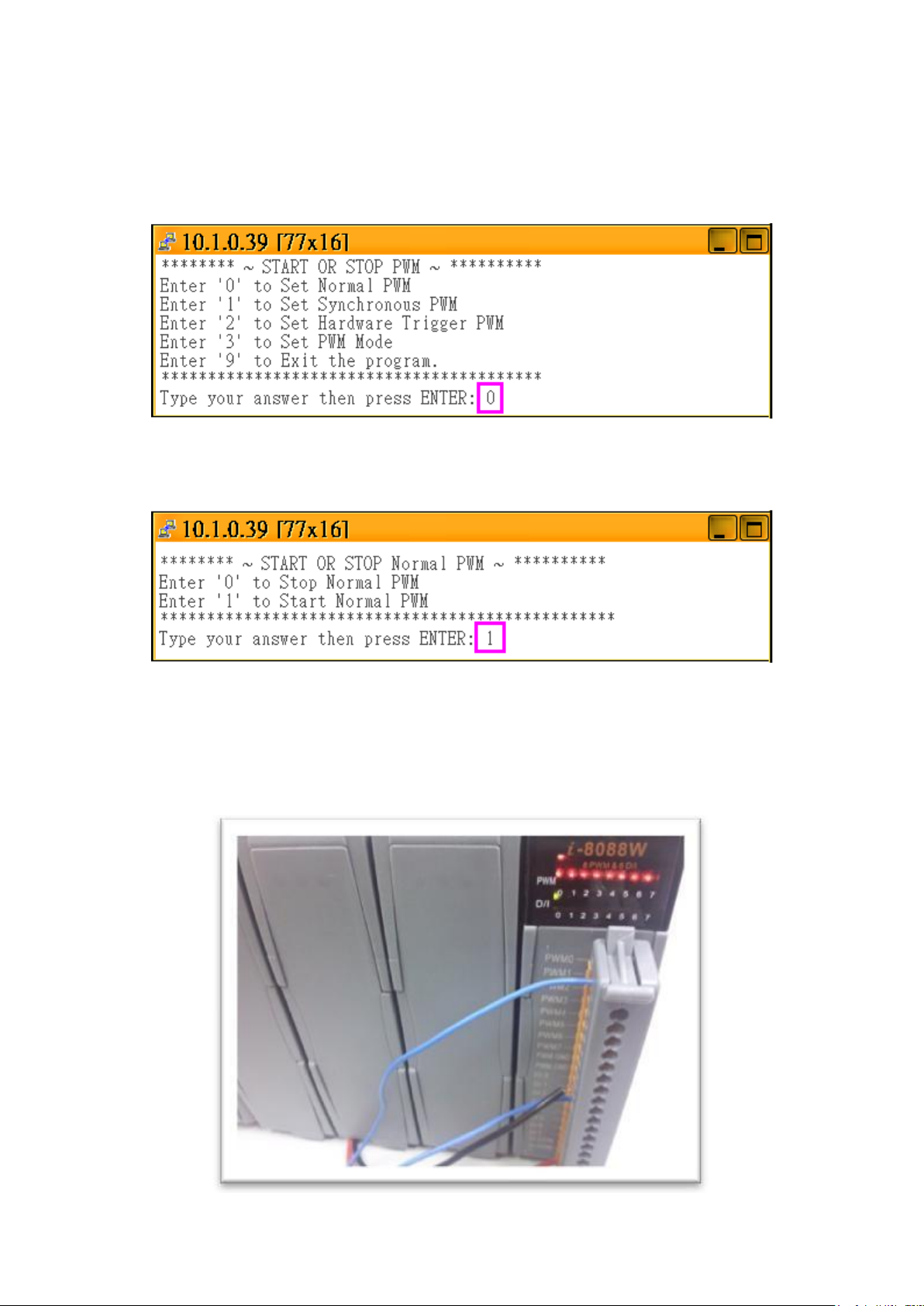

Step 5: Start PWM

You will see three modes in below picture, please enter “0” to set it as “Normal PWM”

Then enter “0” to start the PWM.

If you have completed the correct setup, you will see below picture. In this example, it will

send the “start PWM“ command to channel 0 ~ 7, the condition is 10 Hz with 50% duty, and

we has connected the PWM0 to DI0, so the DI0 will blink per 0.5 seconds.

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 15

2.3. Using DI to Trigger PWM

Set PWM Mode

Set Burst Count

Choice Burst Count Mode (1~65535)

Set PWM Duty

Set Integer Duty Set x10 Integer Duty

Input Frequency

Input Duty

Configure DI as external trigger source for each channel

Set DI as Normal

PWM

DI signal to Start

PWM

Wait DI signal to Start PWM

Stop PWM

DI signal to Stop

PWM

Start PWM

Wait DI signal to Stop

PWM

Set Float Duty

Set Continous

0 1 0

1

2 0 1

2

Frequency:

Select 0: 1 ~ 00000 Hz

Select 1: 1 ~ 500000 Hz

Select 2: 0.1 ~ 500000.0 Hz

Duty:

Select 0: 1 ~ 99 %

Select 1: 1 ~ 99 %

Select 2: 0.1 ~ 99.9 %

2.3.1. Flow Chart

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 16

2.3.2. How to Setup the Trigger PWM

There are 8 DI pins on I-8088W, normally these DI pin just acts as digital input channels. We

can also configure them as external trigger signal pins to start or stop the PWM output.

Step 1: Follow the same way in section 2.2.2 to configure PWM output mode and set

PWM duty and frequency.

Step 2: Enter “1” to set “Hardware Trigger PWM”

There are three options to set the DI channels as PWM trigger signal:

“0”: Normal DI. If you set it as "Normal DI" mode, it will be unrelated to the PWM

function.

“1”: Accept DI signal to start the PWM output.

“2”: Accept DI signal to stop the PWM output.

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 17

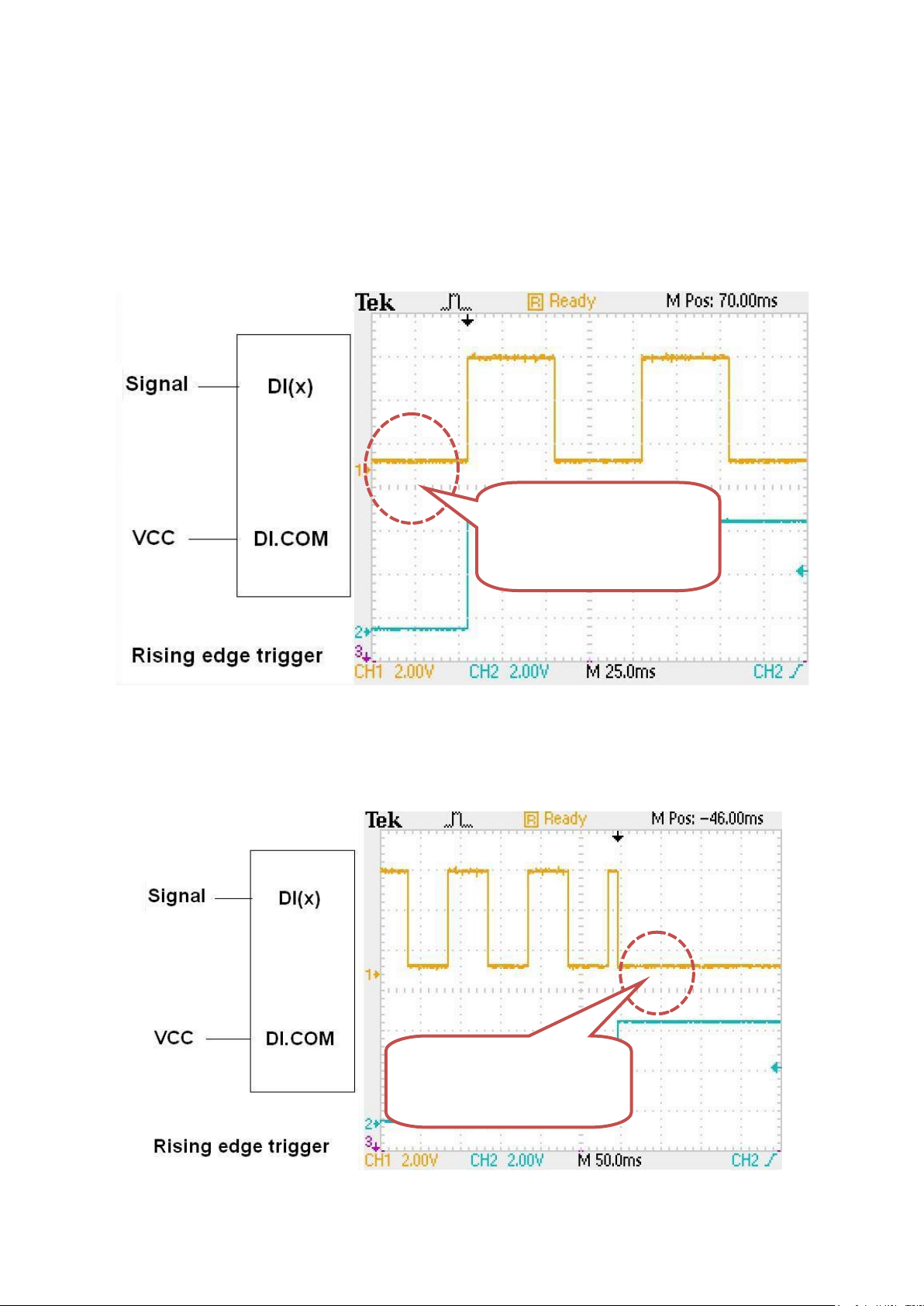

There are two ways to configure the DI signal to start or stop the PWM output. One is rising

“Rising edge” to trigger

the PWM to START.

“Rising edge” to trigger

the PWM to STOP.

edge to trigger the PWM to start or stop, the wiring like below two pictures.

Rising edge to Start PWM

Rising edge to Stop PWM

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 18

“Falling edge” to

trigger the PWM to

START.

“Falling edge” to trigger

the PWM to STOP.

The other is falling edge to trigger the PWM to start or stop, the wiring like below two

pictures.

Falling edge to Start PWM

Falling edge to Stop PWM

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 19

Step 3: Start the PWM

You can enter “1” to start the PWM output. It will start PWM when received an external

trigger signal.

Step 4: Stop the PWM:

In Normal PWM mode, the signal will continue transfer until you go back to enter “2” to stop

the PWM output.

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 20

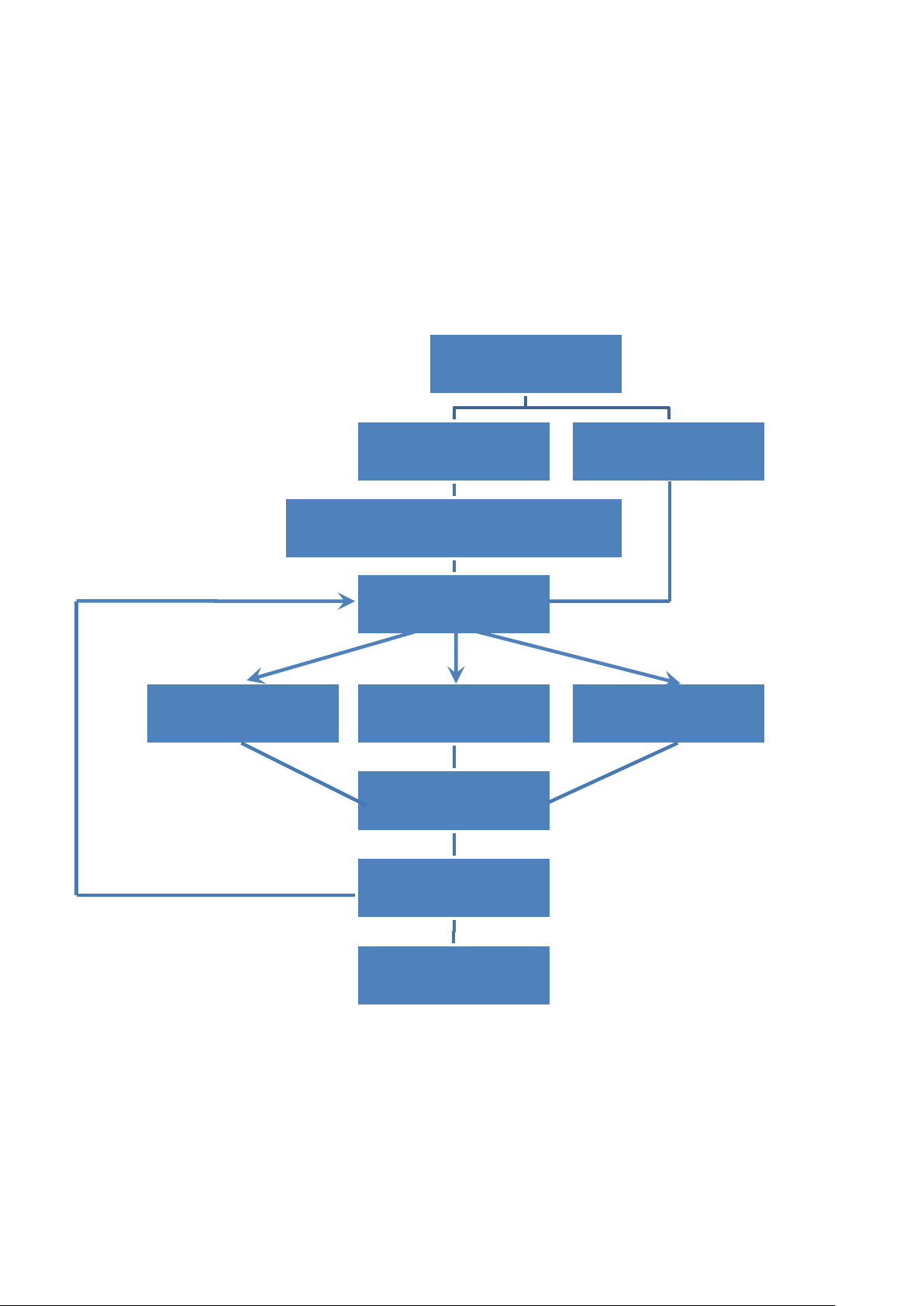

2.4. Synchronize PWM

Set PWM Mode

Set Burst Count

Choice Burst Count Mode (1 -65535)

Set PWM Duty

Set Integer Duty

Set x10 Integer Duty

Input Frequency

Input Duty

Enable Synchronous PWM for each channel

Start PWM

Synchronous Start PWM

Stop PWM

Set Float Duty

Set Continous

0

1

0

1

2

Frequency:

Select 0: 1 ~ 00000 Hz

Select 1: 1 ~ 500000 Hz

Select 2: 0.1 ~ 500000.0 Hz

Duty:

Select 0: 1 ~ 99 %

Select 1: 1 ~ 99 %

Select 2: 0.1 ~ 99.9 %

2.4.1. Flow Chart

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 21

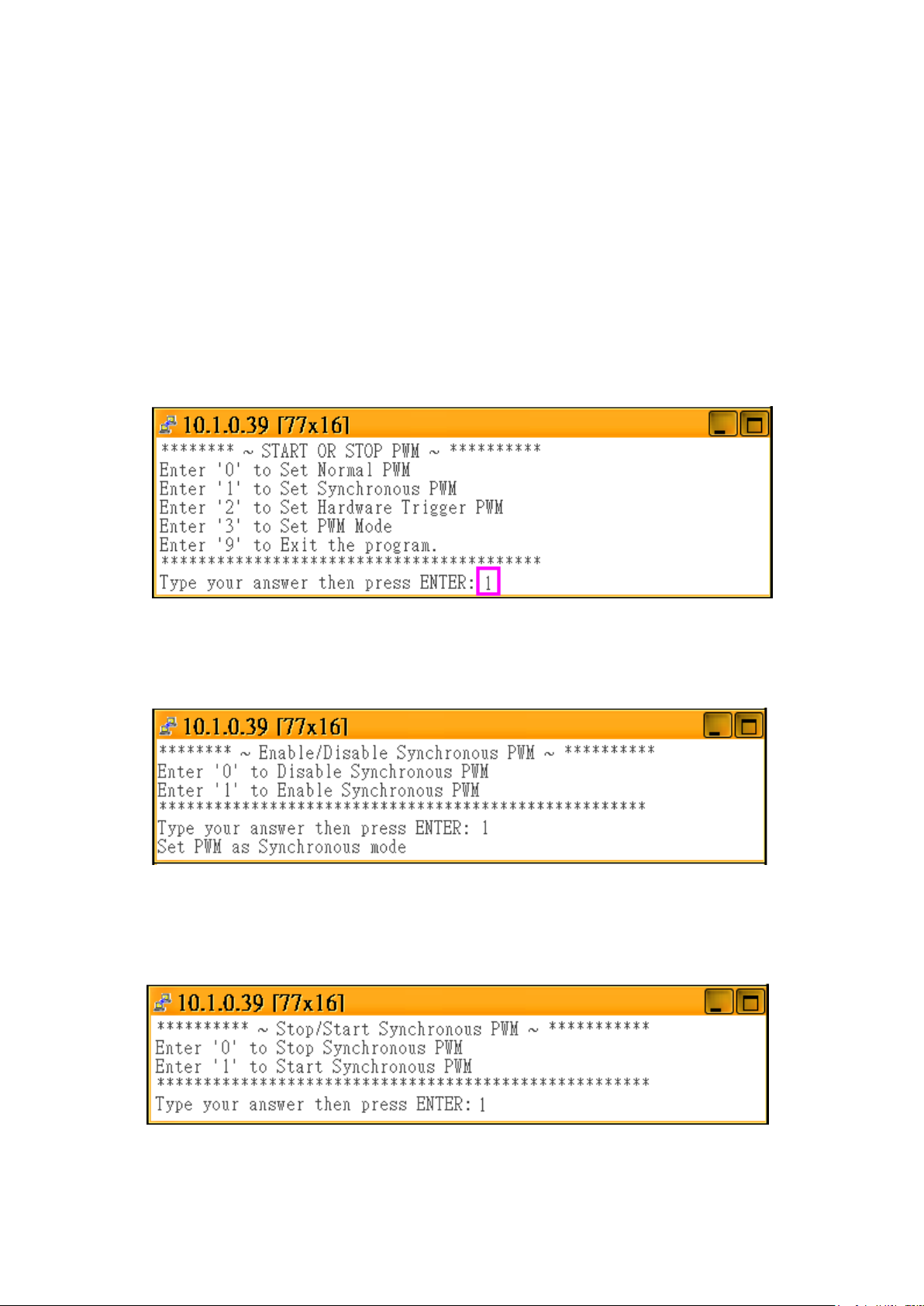

2.4.2. How to Setup the Standard PWM

I-8088W can configure each PWM output channel as synchronous mode.

Step 1: Follow the same way in section 2.2.2 to configure PWM output mode and set

PWM duty and frequency.

Step 2: Enter “2” to set “Synchronous PWM”

Step 3: Enter“1” to enable

Step 4: Enter“1” to start Synchronous PWM.

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 22

You will see the different between following two pictures.

Non-synchronous

Synchronous

Start PWM:

In previous sections, we can start PWM by software command or DI trigger signal, but you

can see the signal is non-synchronous in below picture.

Start Synchronous PWM:

So, we can call i8088W_Sync_Start or pac_i8088W_Sync_Start to start the PWM output

and synchronize the rising edge for each synchronous PWM pulse.

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 23

3. API for Linux PAC

3.1.1. i8088W_Init

The function can initialize the I-8088W and then check the hardware ID for each slot. If the return

value is “0” that means there is an I-8088W module in that slot. If return “-1” that means there is

no I-8088W module.

Syntax

short i8088W_Init(int slot);

Parameters

slot: 1 ~ 8

Return Value

Please refer to Error Code Table.

Example

[C]

int slotIndex, err;

err=i8088W_Init(slotIndex);

Open_Slot(slotIndex);

if(err==0)

printf(“There is an I-8088W at slot %d\n”,slotIndex);

else

printf(“There is no I-8088W at slot %d\n”,slotIndex);

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 24

3.1.2. i8088W_GetFirmwareVersion

The function is used to get the firmware version of I-8088W.

Syntax

short i8088W_GetFirmwareVersion(int slot);

Parameters

slot: 1 ~ 8

Return Value

The firmware version of I-8088W hardware.

Example

[C]

short firmware_version;

Open_Slot(slot);

firmware_version = i8088W_GetFirmwareVersion(int slot);

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 25

3.1.3. i8088W_GetLibVersion

The function is used to get the version of library file.

Syntax

short i8088W_GetLibVersion(void);

Parameters

None

Return Value

The versions of library file.

Example

[C]

short version;

Open_Slot(slot);

version = i8088W_GetLibVersion();

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 26

3.1.4. i8088W_SetPWMDuty

The function is used to set the related PWM parameters.

Syntax

short i8088W_SetPWMDuty(int slot,int ch,unsigned long hz,unsigned int duty);

Parameters

slot: 1 ~ 8

ch: 0 ~ 7

hz: 0 ~ 450K

duty High part: 0 ~ 99

Low part: 100 - High part

Return Value

Please refer to Error Code Table.

Example

[C]

int ch, slot = 1;

Open_Slot(slot);

for(ch=0;ch<8;ch++)

{

i8088W_ SetPWMDuty (slot, ch, 50);

}

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 27

3.1.5. i8088W_SetPWMDuty_Deci

The function is used to set the PWM parameters precisely.

Syntax

short i8088W_SetPWMDuty_Deci (int slot,int ch,unsigned long deci_Hz,unsigned

int deci_duty);

Note

i8088W_SetPWMDuty_Deci is the same as i8088W_SetPWMDuty_float in usage,

but the i8088W_SetPWMDuty_Deci will run faster than i8088W_SetPWMDuty_floa

for the floating calculation reason

Parameters

slot: 1 ~ 8

ch: 0 ~ 7

deci_Hz example: 10 deci_Hz = 10 Hz

deci_duty 0~999, for example: 503 deci_duty = 50.3% High Part

Low Part=1000 - 503= 497 => 49.7% Low Duty cycle

Return Value

Please refer to Error Code Table.

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 28

Example

[C]

int slot,ch;

slot = 1;

Open_Slot(slot);

for(ch=0;ch<8;ch++)

{

i8088W_ SetPWMDuty_Deci(slot,ch,50.3);

}

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 29

3.1.6. i8088W_SetPWMDuty_float

The function is used to set the PWM parameters precisely

Syntax

short i8088W_SetPWMDuty_Float(int slot,int ch,float f_Hz,float f_Duty);

Note

i8088W_SetPWMDuty_Deci is the same as i8088W_SetPWMDuty_float in usage,

but the i8088W_SetPWMDuty_Deci will run faster than i8088W_SetPWMDuty_floa

for the floating calculation reason

Parameters

slot: 1 ~ 8

ch: 0 ~ 7

f_Hz 100 means f_Hz = 10 Hz

f_Duty 0.0~99.9, for example: 50.3 means 50.3% High Part

Low Part =100.0- f_Duty = 49.7 means = 49.7%

Return Value

Please refer to Error Code Table.

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 30

Example

[C]

int slot,ch;

slot = 1;

Open_Slot(slot);

for(ch=0;ch<8;ch++)

{

i8088W_ SetPWMDuty_Float (slot,ch,50.3);

}

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 31

3.1.7. i8088W_GetRealPWMDuty_Deci

The function will get real frequency and duty that can be produced by 8088W.

Syntax

short i8088W_GetRealPWMDuty_Deci (int slot,int ch,unsigned long*

deci_hz,unsigned int* deci_duty);

Note

The duty and frequency of 8088W PWM is discrete not continuous,when we use

i8088W_SetPWMDuty to configure the duty and frequency, we have to use this function

to check the real duty and frequency which can be produced by 8088W normally, at low

frequency 10K, the configued frequency will be closer to real frequcncy can be

generated.

Parameters

slot: 1 ~ 8

ch: 0 ~ 7

deci_hz: the real frequency produced by 8088W unit (x10Hz)

deci_duty: the real duty produced by 8088W (x10 %)

Return Value

Please refer to Error Code Table.

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 32

Example

[C]

unsigned long deci_hz;

unsigned int deci_duty

slot = 1;

Open_Slot(slot);

for(ch=0;ch<8;ch++)

{

i8088W_GetRealPWMDuty_Deci(slot,ch,& deci_hz, & deci_duty);

printf(“CH[%d] PWM Hz = %lu ; Duty = %u\n”, ch, deci_hz, deci_duty);

}

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 33

3.1.8. i8088W_SetPWMCountMode

The function is used to set the count mode of I-8088W.

Syntax

short i8088W_SetPWMCountMode(int slot,int ch,unsigned char countMode);

Parameters

slot: 1 ~ 8

ch: 0 ~ 7

count Mode

1: Continuos

0: Burst count

Return Value

Please refer to Error Code Table.

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 34

Example

[C]

int slot,ch;

slot = 1;

mode=0; //burst mode

Open_Slot(slot);

for(ch=0;ch<8;ch++)

{

i8088W_ SetPWMCountMode(slot,ch,mode);

}

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 35

3.1.9. i8088W_SetBurstCount

The function is used to set the BurstCount of I-8088W.

Syntax

short i8088W_SetBurstCount(int slot,int ch,unsigned int burstCount);

Parameters

slot: 1 ~ 8

ch: 0 ~ 7

burstCount: 0~65536

Return Value

Please refer to Error Code Table.

Example

[C]

int slot=1, ch, burstCount=10000;

Open_Slot(slot);

for(ch=0;ch<8;ch++)

{

i8088W_ SetBurstCount (slot, ch, burstCount);

}

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 36

3.1.10. i8088W_PWM_Start

The function is used to start the PWM pulse.

Syntax

short i8088W_PWM_Start(int slot,int ch);

Parameters

slot: 1 ~ 8

ch: 0 ~ 7

Return Value

Please refer to Error Code Table.

Example

[C]

int slot,ch;

slot = 1;

Open_Slot(slot);

for(ch=0;ch<8;ch++)

{

i8088W_PWM_Start (slot,ch);

}

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 37

3.1.11. i8088W_PWM_Stop

The function is used to stop the PWM pulse.

Syntax

short i8088W_PWM_Stop(int slot,int ch);

Parameters

slot: 1 ~ 8

ch: 0 ~ 7

Return Value

Please refer to Error Code Table.

Example

[C]

int slot=1, ch;

Open_Slot(slot);

for(ch=0;ch<8;ch++)

{

i8088W_PWM_Stop(slot, ch);

}

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 38

3.1.12. i8088W_SetSyncChannel

The function is used to set the specific channel as synchronous.

Syntax

short i8088W_SetSyncChannel(int slot,int ch,int enBit);

Parameters

slot: 1 ~ 8

ch: 0 ~ 7

enBit

1: define channel as synchronous mode,

0: not synchronous mode

Return Value

Please refer to Error Code Table.

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 39

Example

[C]

int slot, ch, enBit;

slot = 1;

enBit=1;

Open_Slot(slot);

for(ch=0;ch<8;ch++)

{

i8088W_ SetSyncChannel(slot, ch, enBit);

}

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 40

3.1.13. i8088W_GetSyncChannel

The function is used to get the synchronous channel by using array.

Syntax

short i8088W_GetSyncChannel(int slot,int syncArr[]);

Parameters

slot: 1 ~ 8

syncArr[] is an 8 bit array

syncArr[i]=1 means channel[i] is set as synchronous1: define

Return Value

Please refer to Error Code Table.

Example

[C]

int slot, syncArr[];

slot = 1;

Open_Slot(slot);

i8088W_ GetSyncChannel (slot, syncArr);

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 41

3.1.14. i8088W_Sync_Start

The function is used to start the synchronization of PWM pulse.

Syntax

short i8088W_Sync_Start(int slot);

Parameters

slot: 1 ~ 8

Return Value

Please refer to Error Code Table.

Example

[C]

int slot;

slot = 1;

Open_Slot(slot);

i8088W_Sync_Start (slot);

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 42

3.1.15. i8088W_Sync_Stop

The function is used to stop the synchronization of PWM pulse.

Syntax

short i8088W_Sync_Stop(int slot);

Parameters

slot 1 ~ 8

Return Value

Please refer to Error Code Table.

Example

[C]

int slot;

slot = 1;

Open_Slot(slot);

i8088W_Sync_Stop (slot);

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 43

3.1.16. i8088W_SetHardwareTrigChannel

The "DI" pin of I-8088W can be set as hardware trigger pin or simply DI pin. The user can

call this function to specify the status of channels.

Syntax

short i8088W_SetHardwareTrigChannel(int slot,int ch,int triggerState);

Parameters

slot: 1 ~ 8

ch: 0 ~ 7

triggerState

0, disabled hardware trigger (Normal DI pin)

1, means this DI has been configured as external trigger signal for I-8088W to

startup its PWM pulse.

2, this DI has been configured as external trigger signal for I-8088W to stop its

PWM pulse.

Return Value

Please refer to Error Code Table.

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 44

Example

[C]

int slot,ch, triggerState;

slot = 1;

Open_Slot(slot);

triggerState=0;

for(ch=0;ch<8;ch++)

{

i8088W_ SetHardwareTrigChannel (slot,ch, triggerState);

}

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 45

3.1.17. i8088W_GetHardwareTrigChannel

The "DI" pin of I-8088W can be set as hardware trigger pin or simply DI pin. The user can

call this function to know the status of channels.

Syntax

short i8088W_GetHardwareTrigChannel(int slot,int ch,int* triggerState);

Parameters

slot: 1 ~ 8

ch: 0 ~ 7

triggerState

0, disabled hardware trigger (Normal DI pin)

1, means this DI has been configured as external trigger signal for I-8088W to

startup its PWM pulse.

2, this DI has been configured as external trigger signal for I-8088W to stop its

PWM pulse.

Return Value

Please refer to Error Code Table.

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 46

Example

[C]

int slot,ch, triggerState;

slot = 1;

Open_Slot(slot);

triggerState=0;

for(ch=0;ch<8;ch++)

{

i8088W_ GetHardwareTrigChannel(slot,ch,& triggerState);

}

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 47

3.1.18. i8088W_GetPWMActiveState

The function is used to get PWM status.

Syntax

short i8088W_GetPWMActiveState(int slot,unsigned int *State,int ActiveArr[]);

Parameters

slot: 1 ~ 8

*State: the PWM output status of i-8088 value 0~0xff

ActiveArr[]: the *State value will be parse into Bit Array

When PWM generate pulse output, the state will be 1, we can know which PWM

channel is sending PWM output. If we configure PWM as Burst Count mode, the

PWM output will be stop when it sends confgured count of PWM pulse (for example

1000 pulse) by using this function, we can know the actural PWM output state.

Return Value

Please refer to Error Code Table.

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 48

Example

[C]

int slot=1,ch,activatedBit[8];

unsigned int activatedState=0;

Open_Slot(slot);

i8088W_GetPWMActiveState (slot,& activatedState, activatedBit);

for(ch=0;ch<8;ch++)

{

if(activatedBit[ch])

printf(“PWM CH[%d] is activated\n”,ch);

}

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 49

3.1.19. i8088W_GetDI

The function is used to get DI status. The user can view which channels have received the

signals.

Syntax

short i8088W_GetDI(int slot,unsigned int *diVal,int diArr[]);

Parameters

slot: 1 ~ 8

diVal: the DI status of i-8088 value 0~0xff

diArr[]: the *DI value will be parse into Bit Array

Return Value

Please refer to Error Code Table.

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 50

Example

[C]

int slot;

ch,enBit[8];

Slot=1;

unsigned int dival=0;

Open_Slot(slot);

i8088W_GetDI(slot, &diVal,enBit);

printf ("DI Vaule = %02X\n",diVal);

for (ch=0; ch< 8; ch++)

{

printf ("DI[%d]= %d\n",ch, enBit[ch]);

}

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 51

Appendix. Error Codes

0

OK

-1

ID_ERROR

-2

SLOT_OUT_RANGE

-3

CHANNEL_OUT_RANGE

-4

SELECT_CHANNEL_ERROR

-5

HI_DUTY_OUT_RANGE

-6

LO_DUTY_OUT_RANGE

I-8088W API Reference Manual, Version 1.0.2, Oct. 2020 -- 52

Loading...

Loading...