Page 1

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 1

User’s Manual

Warranty

All products manufactured by ICP DAS are under warranty regarding

defective materials for a period of one year from the date of delivery to the

original purchaser.

Warning

ICP DAS assumes no liability for damages resulting from the use of this

product. ICP DAS reserves the right to change this manual at any time without

notice. The information furnished by ICP DAS is believed to be accurate and

reliable. However, no responsibility is assumed by ICP DAS for its use, or for

any infringements of patents or other rights of third parties resulting from its use.

Copyright

Copyright 2016 by ICP DAS. All rights are reserved.

Trademark

The names used for identification only may be registered trademarks of

their respective companies.

The I-7530A-MR Modbus RTU to CAN

Converter

Page 2

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 2

Table of Contents

1. Introduction ..................................................................................................................... 4

1.1 Features ....................................................................................................... 6

1.2 Specifications .............................................................................................. 7

2. Hardware .......................................................................................................................... 9

2.1 Block Diagram ........................................................................................... 10

2.2 Pin Assignment ......................................................................................... 11

2.3 Hardware connection ................................................................................ 12

2.3.1 CAN port connection .................................................................................. 12

2.3.2 Serial port connection ................................................................................ 13

2.4 Terminator Resistor Settings .................................................................... 14

2.5 Init / Normal Dip-switch ............................................................................. 15

2.5.1 Firmware Update Mode ............................................................................. 15

2.5.2 Firmware Operation Mode ......................................................................... 17

2.5.3 Module Configuration Mode ....................................................................... 18

2.6 LED Indication ........................................................................................... 18

2.7 Cable Selection .......................................................................................... 20

3. Software Utility .............................................................................................................. 21

3.1 Install the UART2CAN Utility .................................................................... 22

3.2 Configure the module parameters ........................................................... 25

3.2.1 Connect to the I-7530A-MR module with UART2CAN Utility ..................... 25

3.2.2 Select the communication mode ................................................................ 26

3.2.3 Set the COM port parameters .................................................................... 27

3.2.4 Set the CAN parameters ............................................................................ 28

3.2.5 Set the “Pair Connection” parameter ......................................................... 28

3.2.6 Set the “Modbus Slave” parameter ............................................................ 29

3.2.7 Configuration of default value .................................................................... 30

3.2.8 Load/Save the parameter configuration ..................................................... 31

3.3 CAN Filter Configuration .......................................................................... 32

3.3.1 Create New CAN Filter .............................................................................. 32

3.3.2 Download a existed CAN Filter file ............................................................ 35

3.3.3 Read I-7530A-MR CAN Filter Configuration .............................................. 36

3.4 Pair-connection Mode Description .......................................................... 37

3.5 Testing the I-7530A-MR module ............................................................... 43

3.5.1 Normal mode ............................................................................................. 45

3.5.2 Pair Connection Mode ................................................................ ............... 47

3.5.3 Modbus Slave Mode .................................................................................. 48

4. Command list (Only for normal mode) ........................................................................ 50

Page 3

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 3

4.1 tIIILDD…[CHK]<CR> .................................................................................. 52

4.2 TIIIL[CHK]<CR> .......................................................................................... 52

4.3 eIIIIIIIILDD…[CHK]<CR> ............................................................................ 53

4.4 EIIIIIIIIL[CHK]<CR> .................................................................................... 53

4.5 S[CHK]<CR>............................................................................................... 54

4.6 P0BBDSPCR[CHK]<CR> ........................................................................... 55

4.7 P1B [CHK]<CR> ......................................................................................... 58

4.8 P2BBBBB[CHK]<CR> ................................................................................ 59

4.9 RA[CHK]<CR> ............................................................................................ 60

4.10 General Error code for all command ....................................................... 61

5. Modbus Slave Mode ...................................................................................................... 62

5.1 Supported Modbus Functions .................................................................. 64

5.2 Modbus Address ....................................................................................... 64

5.2.1 Using Modbus RTU command to get a CAN Message .............................. 79

5.2.2 Using Modbus RTU command to send a CAN message ........................... 81

5.2.2.1 Using function Code 10

hex

to send a CAN message ...................... 81

5.2.2.2 Using function Code 06

hex

to send a CAN message ...................... 83

5.2.3 Using Modbus RTU command to get a Specific CAN Message................. 86

5.2.4 Using Modbus RTU command to configure module .................................. 87

5.3 Modbus Exception Codes ......................................................................... 89

6. Modbus Master Mode ................................................................................................... 90

6.1 Supported Modbus Functions .................................................................. 90

6.2 IO Memory Size .......................................................................................... 91

6.3 Configuration and Operation .................................................................... 91

6.3.1 Modbus Read Configuration ...................................................................... 92

6.3.1.1 Modbus Read Command.................................................................. 93

6.3.1.2 Response CAN Message Configuration ......................................... 96

6.3.2 Modbus Write Configuration ...................................................................... 99

6.3.3 Common Configuration ............................................................................ 103

7. Troubleshooting .......................................................................................................... 106

Page 4

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 4

1. Introduction

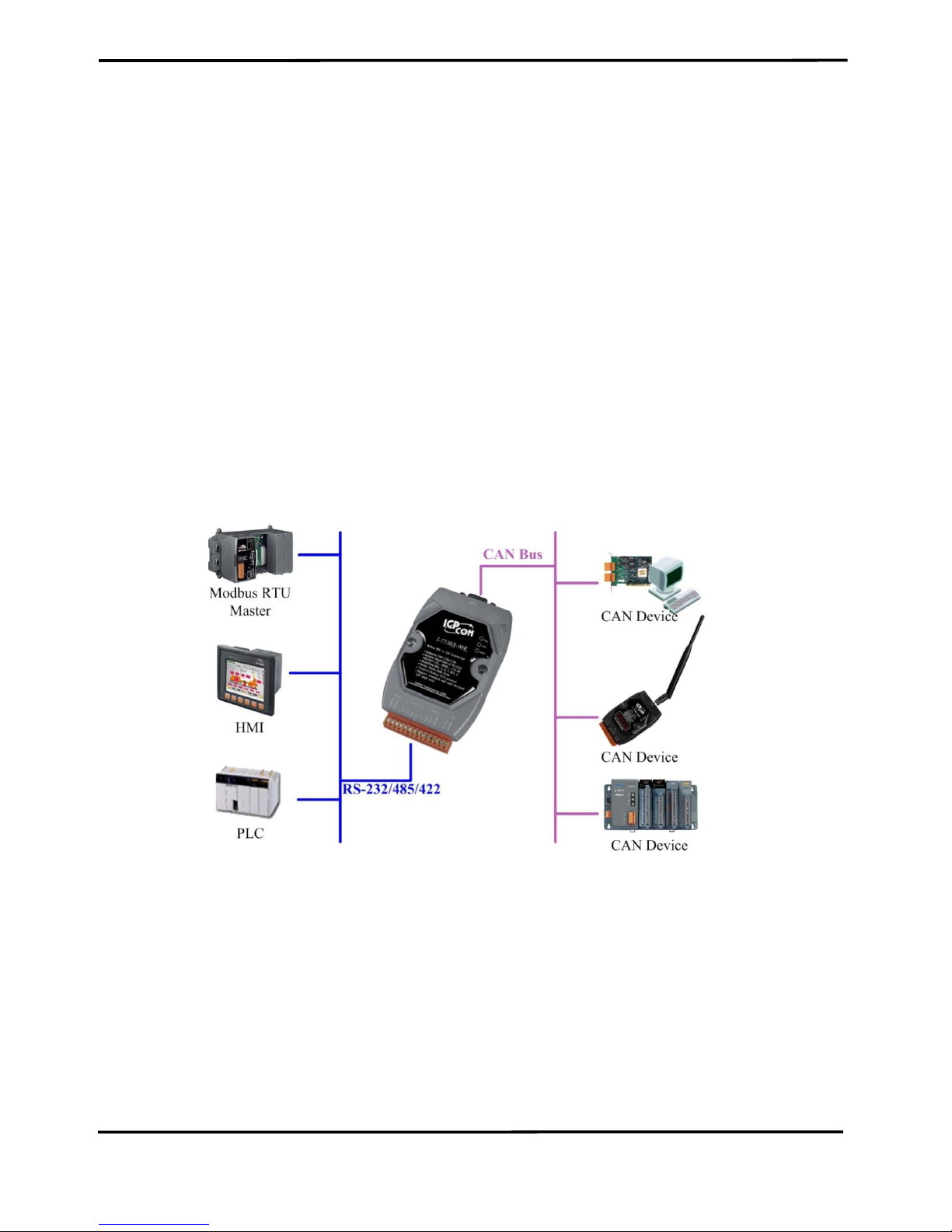

The I-7530A-MR is helpful for exchanging the data between the RS232/485/422 devices and the CAN devices. It supports four

communication modes: “Normal”, “Modbus Slave” , “Pair connection”, and

“Modbus Master” (firmware version v1.11 or later).

In the Normal mode, the I-7530A-MR is designed to unleash the power of

CAN bus via RS-232/485/422 communication method. It accurately

converts ASCII format messages and CAN messages between RS232/485/422 and CAN networks. This mode let you to communicate with

CAN devices easily from any PC or programmable devices with RS232/485/422 interface.

In the Modbus Slave mode, it allows a Modbus RTU master to

communicate with CAN devices on a CAN network. The following figure

shows the application architecture in this mode.

Figure 1-1: The application architecture in the Modbus Slave mode.

Page 5

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 5

In the pair-connection mode, this module provides the transparent

communication between the RS-232/485/422 devices via CAN bus. The

application architecture may be as follows.

Figure 1-2: The application architecture in the pair-connection mode.

In the Modbus Master mode, it allows many Modbus RTU slaves to

communicate with CAN devices on a CAN network. The following figure

shows the application architecture in this mode.

Figure 1-3: The application architecture in the Modbus Master mode.

Page 6

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 6

1.1 Features

RoHS Design

Fully compatible with ISO 11898-2 standard

Programmable CAN bus baud rate from 10 kbps to 1 Mbps or user-

defined baud rate

Max transmission speed of RS-232/485/422 port up to 230400 bps

Support CAN bus acceptance filter configuration

Support firmware update via RS-232

Utility tool for module configuration and CAN bus communication

testing

Built-in jumper to select 120Ω terminator resistor

CAN buffer: 128 data frames; UART buffer: 256 bytes.

Power, data flow and error indicator for CAN and UART status

Hardware Watchdog design

Allow special ASCII commands to send and receive CAN messages

(Normal mode)

Provide the transparent communication in the RS-232/485/422 port

through the CAN bus (Pair-connection mode)

In Modbus Slave mode, I-7530A-MR supports function code 0x03,

0x04, 0x06 (firmware version v1.11 or later), and 0x10 of Modbus RTU

command for reading or writing CAN message (Modbus Slave mode).

Besides, function code 0x10 has additional functions for configuring

module.

Support Modbus Master function (firmware version v1.11 or later).

Page 7

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 7

1.2 Specifications

UART specification:

Connector: 14-pin screw terminal connector

COM1: RS-232: (TxD, RxD, GND)

RS-422: (TxD+, TxD-, RxD+, RxD-)

RS-485: (DATA+, DATA-)

Baud Rate(bps): 300, 600, 1200, 2400, 4800, 9600, 19200, 38400,

57600, 115200, 230400

Data/Stop bits: 5, 6, 7, 8 / 1, 2

Parity bit: None, Odd, Even

Isolation voltage: 3000 VDC power protection and 2500V

rms

photo-

couple in the UART side

CAN specification:

CAN interface connector: 9-pin male D-sub (CAN_L, CAN_H,

CAN_GND, and N/A for others)

CAN Baud Rate(bps): 10 k, 20 k, 50 k, 100 k, 125 k, 250 k, 500 k, 800

k and 1 M (allow user-defined baud rate)

Isolation voltage: 3000 VDC power protection on CAN side, 3750V

rms

photo-couple on CAN bus

Terminator Resistor: Jumper for 120Ω terminator resistor

Support Protocol: ISO-11898-2, CAN 2.0A and CAN 2.0B

Power requirement:

Unregulated +10V DC ~ +30V DC

Power consumption: 1.5W

DIP switch: Init (Firmware Update, Module Configuration) / Normal

(Firmware Operation)

Module specs:

Dimensions: 72mm x 118mm x 35mm (W x L x H)

Operating temperature: -25 to 75ºC (-13 to 167ºF)

Storage temperature: -30 to 80ºC (-22 to 176ºF)

Humidity: 10 to 95%, non-condensing

LEDs: PWR LED for power

CAN LED for CAN bus communication

UART LED for UART communication

Page 8

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 8

Software Utility tool:

CAN bus baud rate configuration

CAN acceptance filter configuration

CAN 2.0A or 2.0B specific selection

RS-232/485/422 baud rate and data format configuration

Checksum function selection of the RS-232/485/422 communication

Communication mode setting

Function for transmitting or receiving CAN messages

Application:

Factory Automation

Building Automation

Home Automation

Control system

Monitor system

Vehicle Automation

Page 9

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 9

2. Hardware

Figure 2-1: Hardware profile of the I-7530A-MR

Page 10

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 10

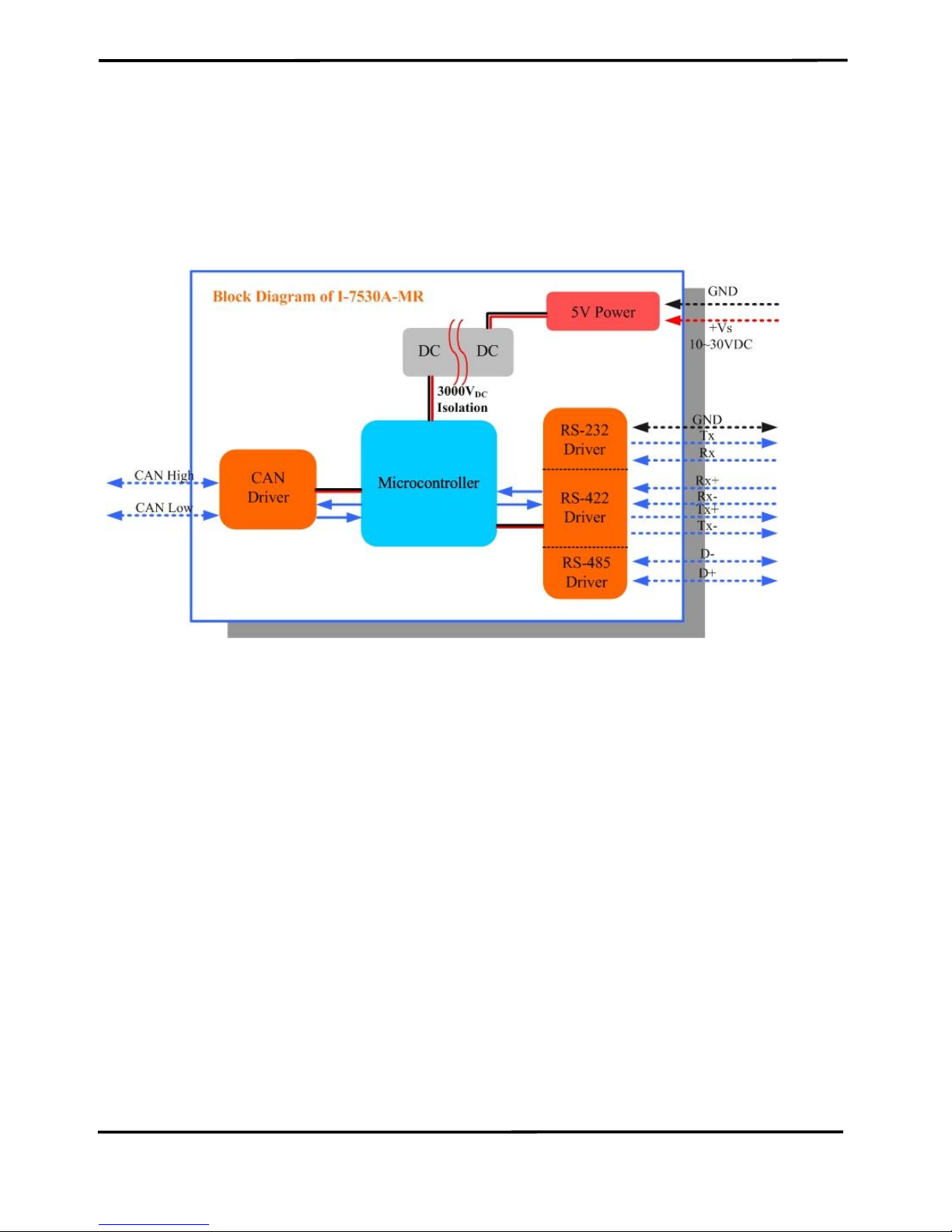

2.1 Block Diagram

Figure 2-2 is a block diagram illustrating the functions of the I-7530AMR module. It provides the 3000VDC Isolation in the CAN and UART

interface. And hardware media in RS-232 interface only adopts 3-wire

connection.

Figure 2-2: Block diagram of I-7530A-MR

Page 11

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 11

2.2 Pin Assignment

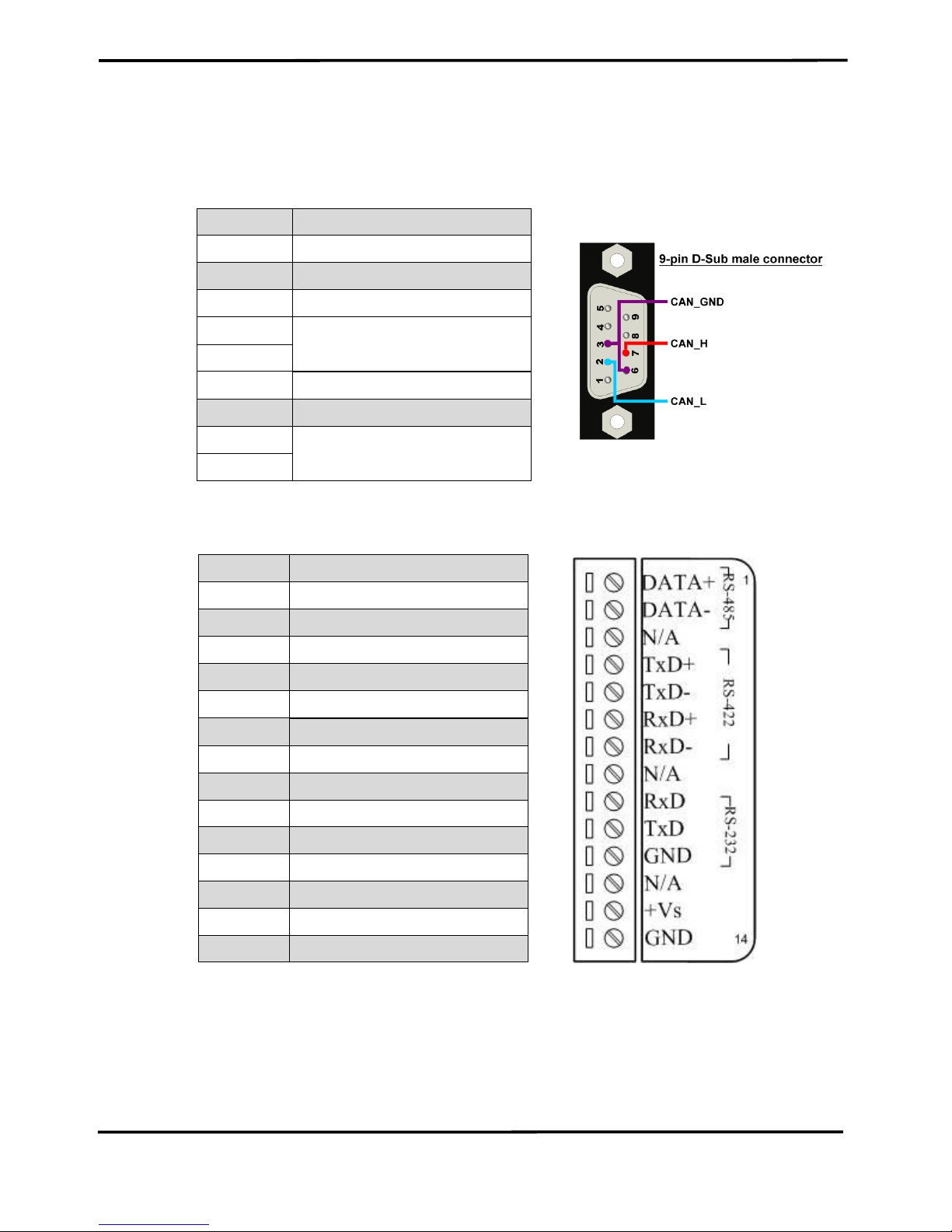

Table 2-1: CAN DB9 Male Connector

Pin

Description

1

Not Connect

2

CAN Low

3

CAN Ground

4

Not Connect

5 6 CAN Ground

7

CAN High

8

Not Connect

9

Figure 2-3: Pin Assignment on the I-7530A-MR

Pin

Description

1

RS-485 DATA+

2

RS-485 DATA-

3

No use

4

RS-422 TxD+

5

RS-422 TxD-

6

RS-422 RxD+

7

RS-422 RxD-

8

No use

9

RS-232 RXD

10

RS-232 TXD

11

RS-232 GND

12

No use

13

+Vs(+10 ~ +30 VDC)

14

GND

Page 12

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 12

2.3 Hardware connection

The I-7530A-MR module supports CAN/Serial port communication, it

offers one CAN interface for CAN network and RS-232/485/422 interfaces

for serial communication.

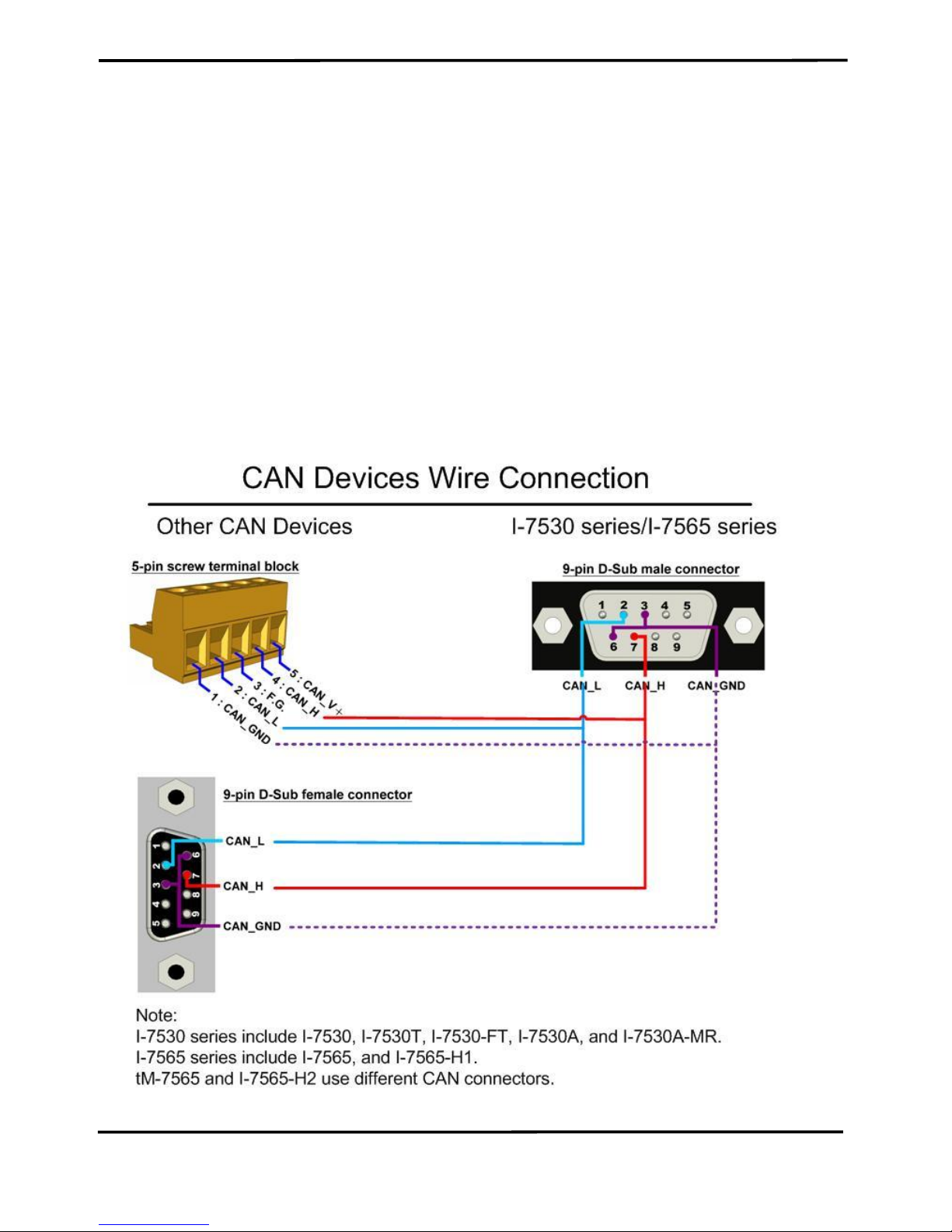

2.3.1 CAN port connection

The pin assignment of the CAN port of the I-7530A-MR (DB9 male) is

defined in both the CANopen DS102 profile and in appendix C of the

DeviceNet specifications. It is the standard pin assignment for CAN

interface. The hardware connection between the target device and the I7530A-MR is shown as Figure 2-4.

Figure 2-4: CAN Hardware Wire Connection

Page 13

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 13

2.3.2 Serial port connection

The I-7530A-MR offers three serial interfaces. It is recommended to

use only one of them at the same time. The following figures describe

these port types and the wiring method for a serial device.

Figure 2-5: RS-232 Wire Connection

Figure 2-6: RS-422 Wire Connection

Figure 2-7: RS-485 Wire Connection

Page 14

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 14

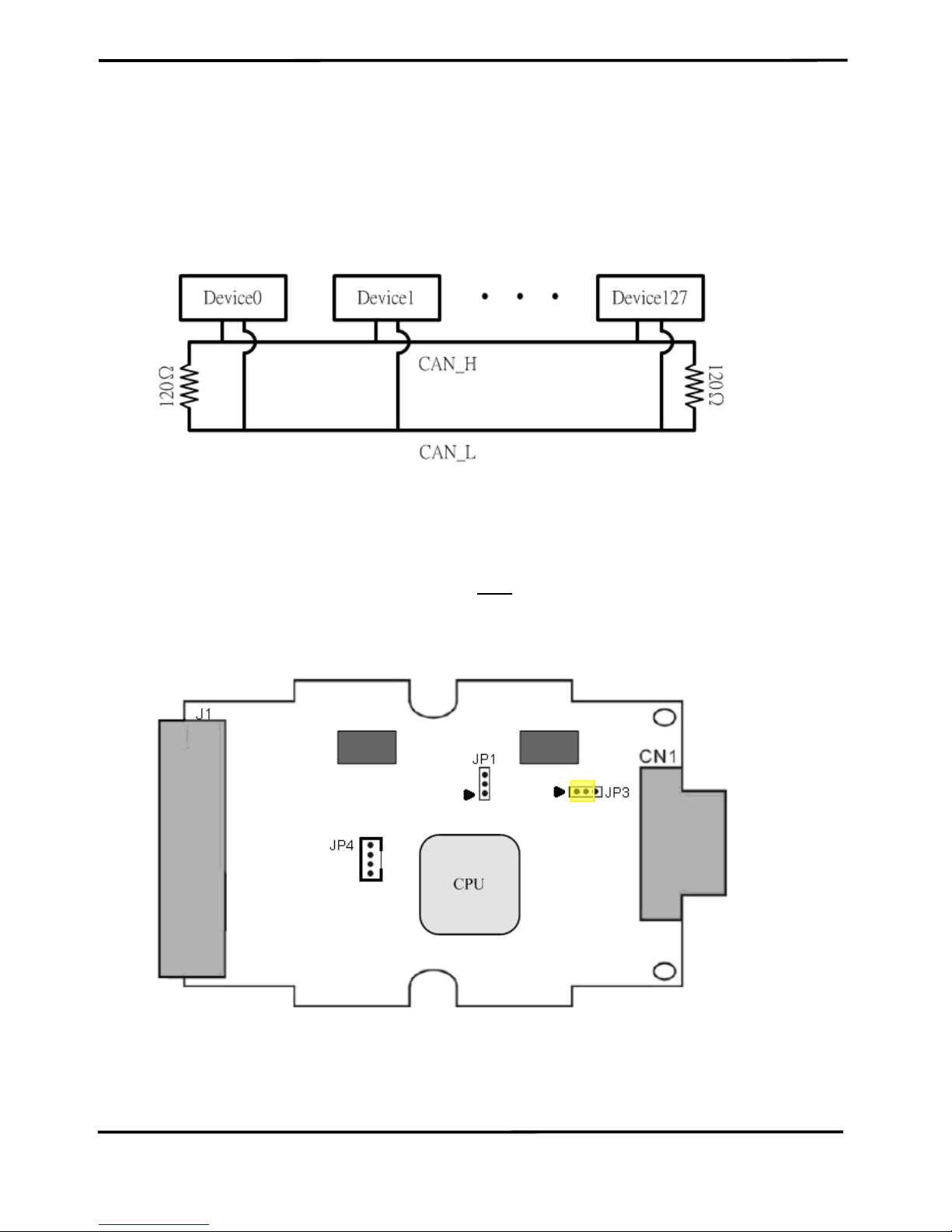

2.4 Terminator Resistor Settings

According to the ISO 11898 specifications, the CAN Bus network

must be terminated by two terminal resistors (120Ω). They are shown as

following figure.

Figure 2-8: Terminal Resistor

Therefore, the I-7530A-MR module supplies a jumper for activating

the terminal resistor. If users want to use this terminal resistor, please

open the I-7530A-MR cover and use the JP3 to activate the 120Ω terminal

resistor built in the module, as the Figure 2-9. Note that the default setting

is active.

Figure 2-9: Terminal Resistor Jumper

Page 15

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 15

Enable (default) Disable

Figure 2-10: Terminal resistor JP3 Jumper Position

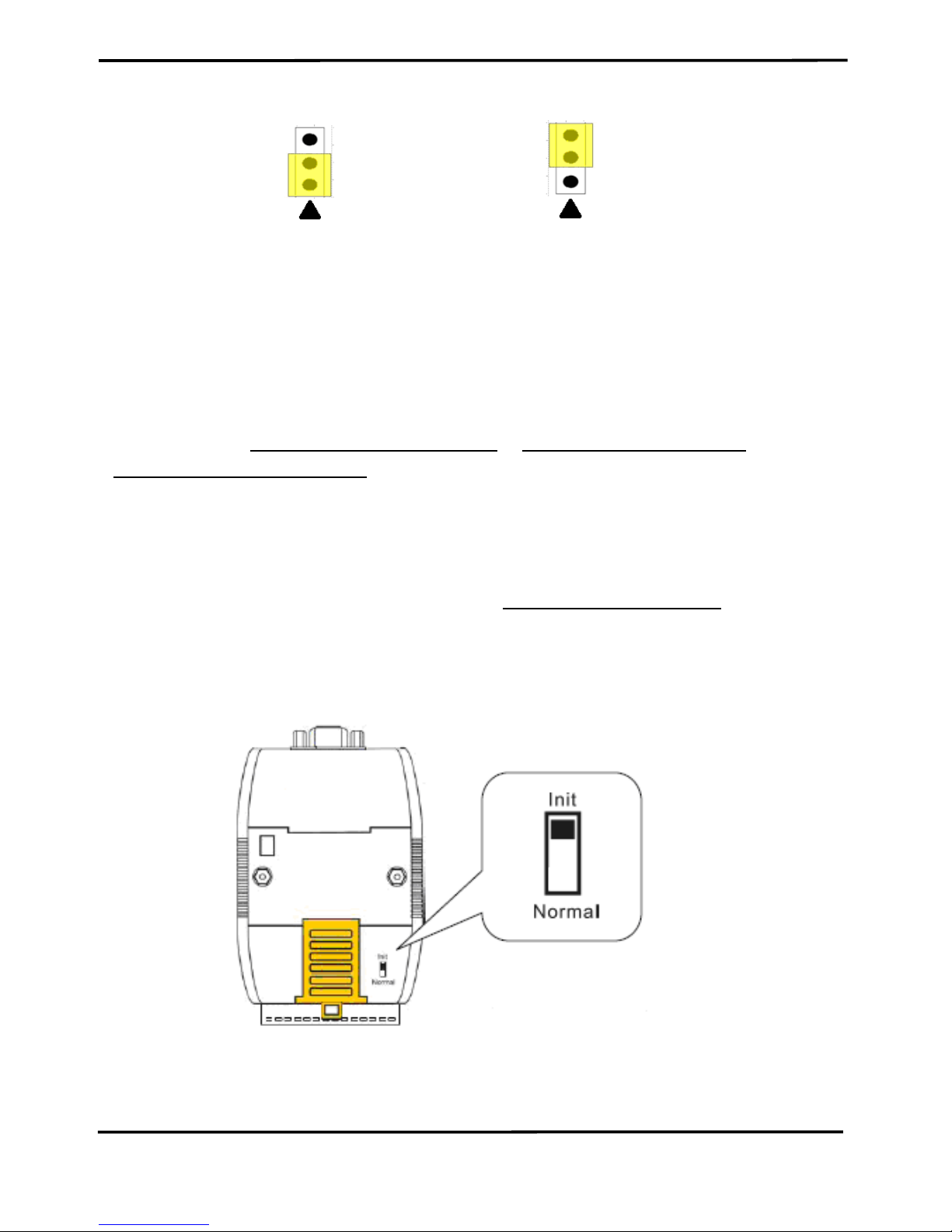

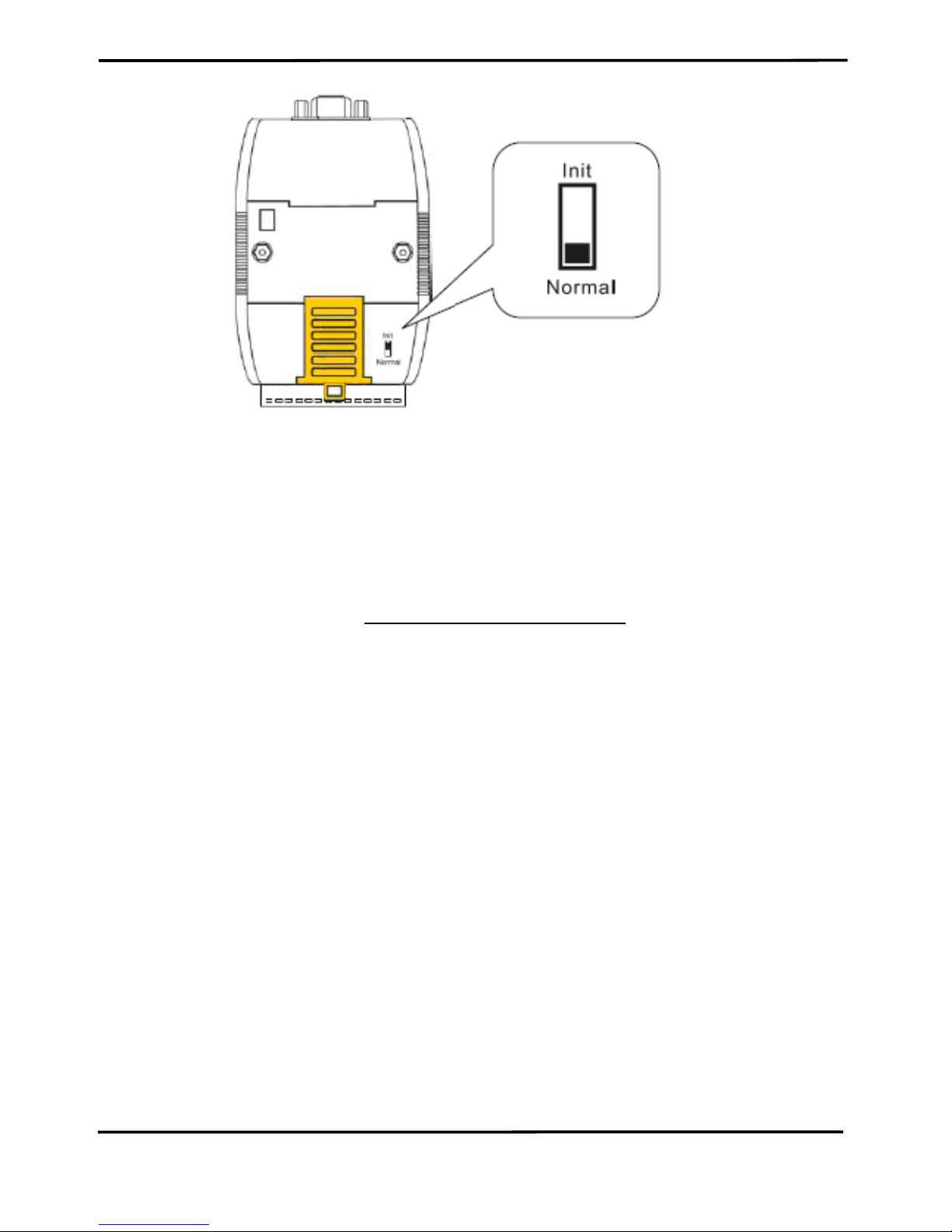

2.5 Init / Normal Dip-switch

On the back of the I-7530A-MR module, there is a DIP-switch used to

configure the “firmware operation mode”, “firmware update mode” or

“module configuration mode”. The following steps show how to use it.

2.5.1 Firmware Update Mode

Please set the DIP-switch to the “Init” (Initial) position as Figure 2-12,

and then the I-7530A-MR will work in the “Firmware Update Mode” after

resetting the power of the module. In the firmware update mode, users

can update the firmware of the I-7530A-MR module from computer’s RS232 port via CA-0910 cable, as Figure 2-12~2-14.

Figure 2-12: Init Position of DIP-Switch

Page 16

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 16

Figure 2-13: CA-0910 Cable

Figure 2-14: Firmware downloads connection

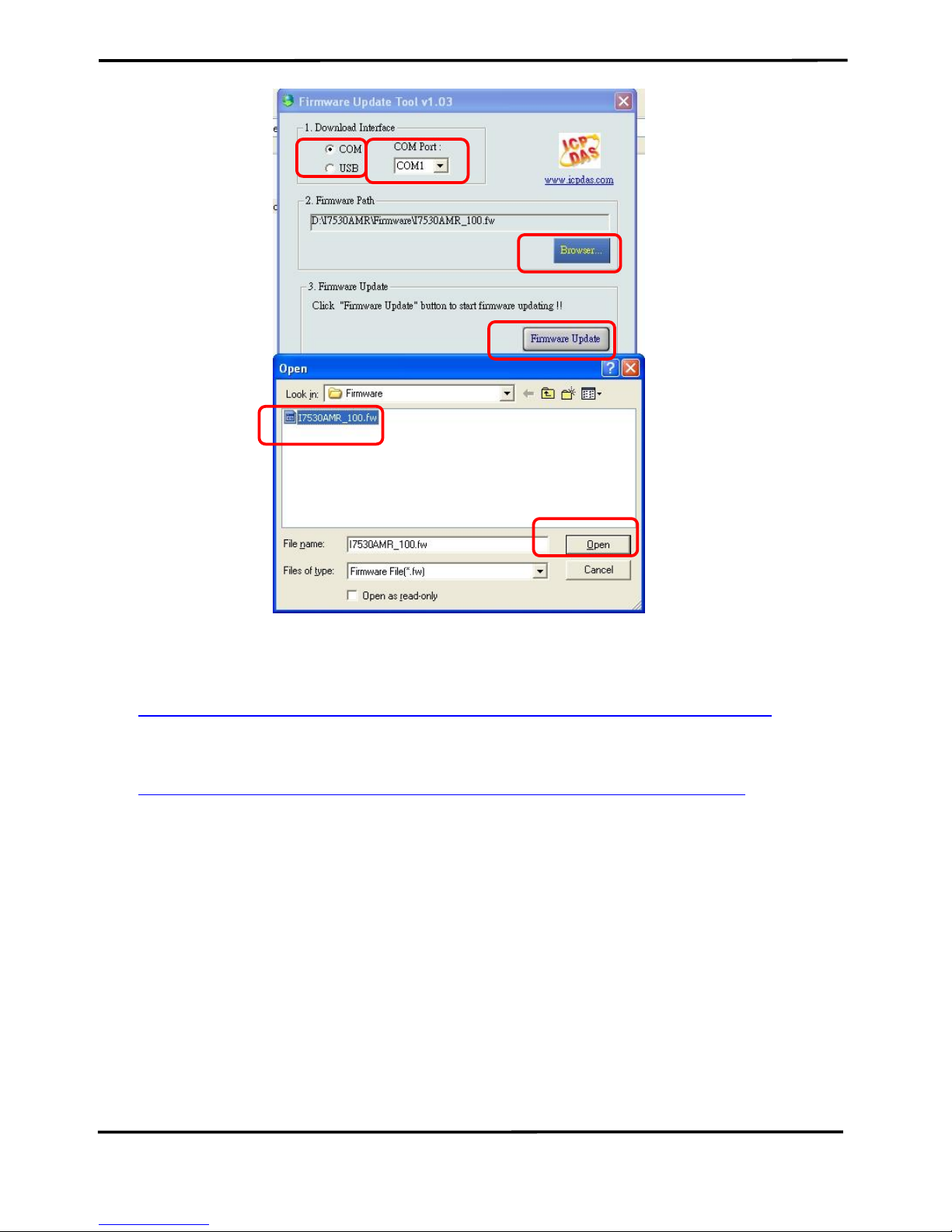

While updating the firmware, users need to execute

“Firmware_Update_Tool.exe”. The following steps show the update

procedure.

[1] Run the Firmware_Update_Tool.exe.

[2] Choose “COM” interface and “COM Port”.

[2] Click “Browser” button to choose the firmware file.

(e.g. I7530AMR_100.fw)

[3] Click “Firmware Update” button to start firmware update process.

Page 17

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 17

Figure 2-15: I-7530A-MR firmware update process

The I-7530A-MR firmware can be downloaded from

http://ftp.icpdas.com/pub/cd/fieldbus_cd/can/converter/i-7530a-mr/firmware/

The “Firmware_Update_Tool” program can be downloaded from

http://ftp.icpdas.com/pub/cd/fieldbus_cd/can/converter/i-7530a-mr/utility/

2.5.2 Firmware Operation Mode

Please set the DIP-switch to the “Normal” position as Figure 2-16 and

power on the I-7530A-MR module. The module’s PWR LED always

turned on and the others LEDs are turned off. That means the I-7530AMR module is working in the operation mode. In this mode, users can use

the RS-232/485/422 device to send/receive CAN messages via COM port.

1 2 3

4

6

5

Page 18

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 18

Figure 2-16: Normal Position of Dip-Switch

2.5.3 Module Configuration Mode

During the module is running in the Firmware Operation Mode, set the

DIP-switch to the “Init” (Initial) position as Figure 2-12 and wait for three

seconds. The module’s PWR LED still turns on and the others LEDs will

flash approximately once per second. That means the I-7530A-MR

module is working in the “Module Configuration Mode”. In this mode,

users can use UART2CAN Utility to configure the communication

parameters and communication modes of the module.

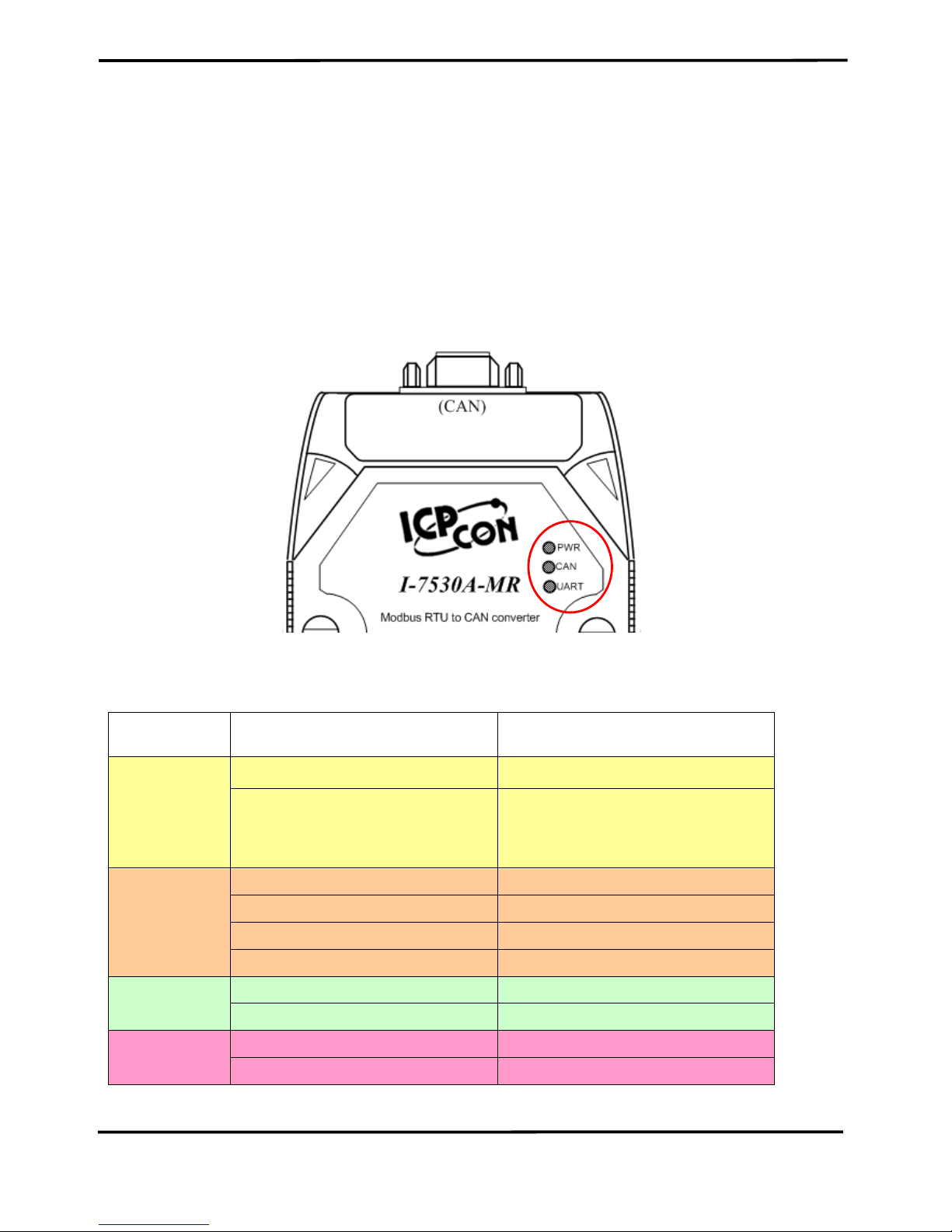

2.6 LED Indication

There are three LEDs to indicate what the state of the I-7530A-MR is

in. The positions of these three LEDs are shown as Figure 2-17.

(1) PWR LED :

It is used to help users with checking if the I-7530A-MR is standby. If

the module is supplied the proper power, the PWR LED is turned on. The

different situations of the module may cause the different blinking display.

The PWR LED is always turned on when the module works in a good

condition. When the Bus-Off error is happened, the PWR LED will blink

every 500 ms until the Bus-Off condition disappears. If the CAN message

can’t be sent out successfully, the PWR LED will blink every 100 ms.

Page 19

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 19

(2) CAN LED :

It is used to show whether the I-7530A-MR is transmitting/receiving

CAN messages. The CAN LED will blink whenever a CAN message is

sending or receiving.

(3) UART LED :

It is used to show whether the I-7530A-MR is transmitting/receiving

COM messages. The UART LED will blink whenever a COM message is

sending or receiving.

Figure 2-17: LED position of the I-7530A-MR

Table 2-3: LED indication of the I-7530A-MR

LED Name

I-7530A-MR Status

LED Status

ALL LEDs

Firmware Updating Mode

All LED always turned on

Module Configuration Mode

PWR LED always be turned

on and the other LEDs blink

every 1000 ms

PWR LED

No Error

Always turned on

CAN Bus Transmission Fail

Blink every 100 ms

CAN Bus-Off

Blink every 500 ms

Power Failure

Off

CAN LED

Transmission

Blink

Bus Idle

Off

UART LED

Transmission

Blink

Bus Idle

Off

Page 20

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 20

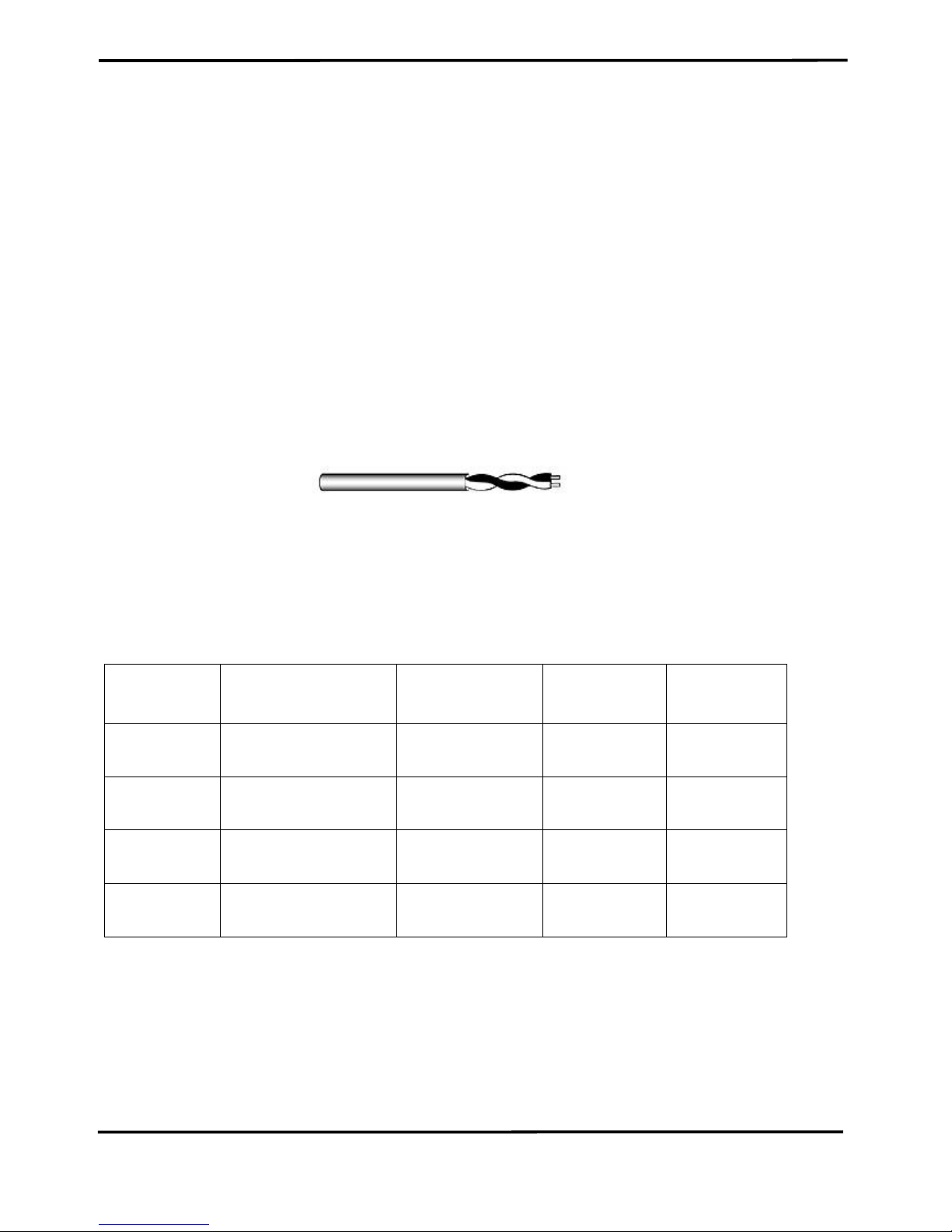

2.7 Cable Selection

The CAN bus is a balanced (differential) 2-wire interface running over

either a Shielded Twisted Pair (STP), Un-shielded Twisted Pair (UTP), or

Ribbon cable. The CAN-L and CAN-H Wire start on one end of the total

CAN network that a terminator of 120 Ohm is connected between CAN-L

and CAN-H. The cable is connected from CAN node to CAN node,

normally without or with short T connections. On the other end of the

cable again a 120Ω(Ohm) terminator resistor is connected between the

CAN lines. How to decide a cable type, cable length, and terminator

depends on the baud rate in the CAN bus network, please refer to the

following table 2-4.

Figure 2-18: Un-shielded Twisted Pair (UTP)

Table 2-4: Cable selection

Bus speed

Cable type

Cable

Resistance/m

Terminator

Bus Length

50k bit/s

at 1000m

0.75~0.8mm2

18AWG

70 mOhm

150~300

Ohm

600~1000m

100k bit/s

at 500m

0.5~0.6 mm2

20AWG

< 60 mOhm

150~300

Ohm

300~600m

500k bit/s

at 100m

0.34~0.6mm2

22AWG, 20AWG

< 40 mOhm

127 Ohm

40~300m

1000k bit/s

at 40m

0.25~0.34mm2

23AWG, 22AWG

< 40 mOhm

124 Ohm

0~40m

Note: The AWG means a standard method used to measure wire. The

numbering system works backwards from what people would think, the

thicker (heavier) the wire, the lower the number. For example: a 24AWG

wire is thicker/heavier than a 26AWG wire.

Page 21

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 21

3. Software Utility

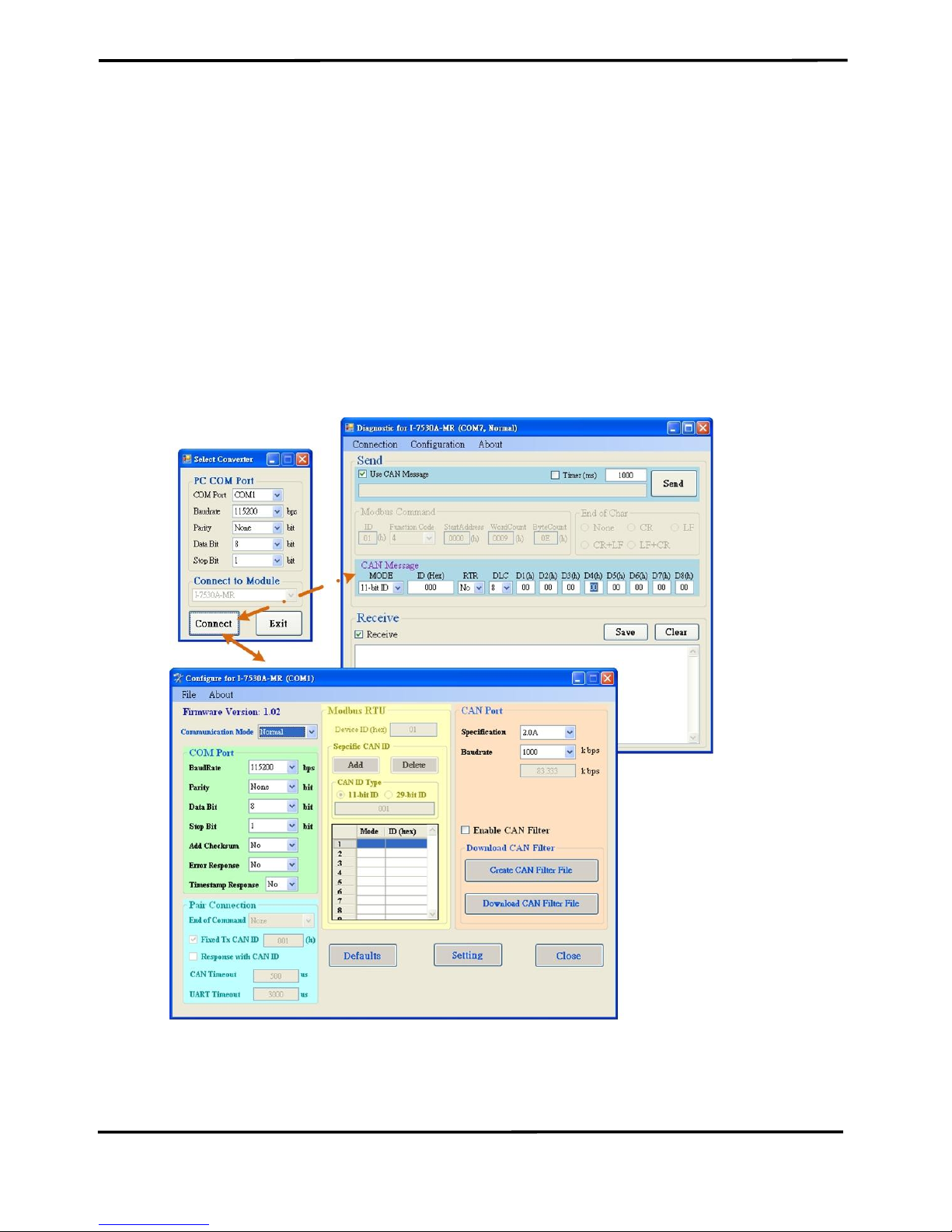

The UART2CAN Utility tool can be used to configure the operational

conditions of the I-7530A-MR between the CAN and RS-232/485/422

communications. It also can used to transmit or receive a CAN message

for simple testing. To start the “UART2CAN Utility”, please install the

UART2CAN Utility setup file and run the UART2CAN_Utility.exe file. The

screenshot of the configuration and testing screen are given in the below

figure. The next section will show you how to configure the I-7530A-MR

and test it by using UART2CAN Utility.

Figure 3-1: Configuration and testing screen for UART2CAN Utility.

Page 22

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 22

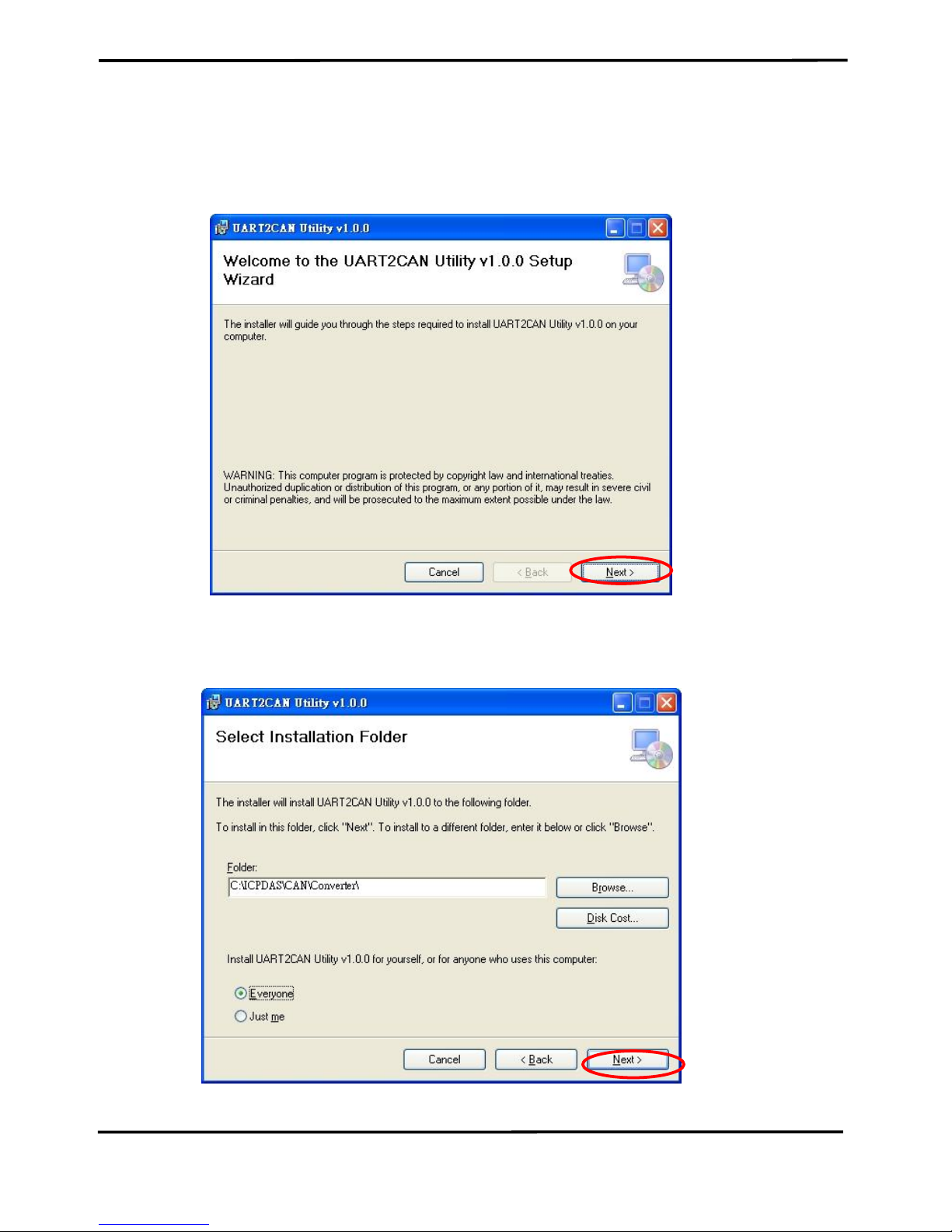

3.1 Install the UART2CAN Utility

Step 1: Get the UART2CAN Utiltiy

The software is located at:

Fieldbus_CD:\CAN\Converter\I-7530A-MR\Utility

http://ftp.icpdas.com/pub/cd/fieldbus_cd/can/converter/i-7530a-mr/utility/

Step 2: Install .NET Framework 4 Client Profile component

The UART2CAN Utility tool requires the Windows Installer 3.1 and

the .NET Framework 4 Client Profile components. These components can

be obtained from the web site.

Windows Installer 3.1:

http://ftp.icpdas.com/pub/cd/fieldbus_cd/can/converter/i-7530amr/utility/windowsinstaller3_1/

.NET Framework 4 Client Profile:

http://ftp.icpdas.com/pub/cd/fieldbus_cd/can/converter/i-7530amr/utility/dotnetfx40client/

Figure 3-2: Setup the Windows Installer and .NET Framework.

Page 23

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 23

Step 3: Install Utility tool

After installing the .Net Framework components, please run the

UART2CAN Utility setup file.

1. Click the “Next” button to continue.

Figure 3-3: Setup the UART2CAN Utility.

2. Select the installation path of the UART2CAN Utility and click the

“Next” button.

Figure 3-4: Select Installation Folder.

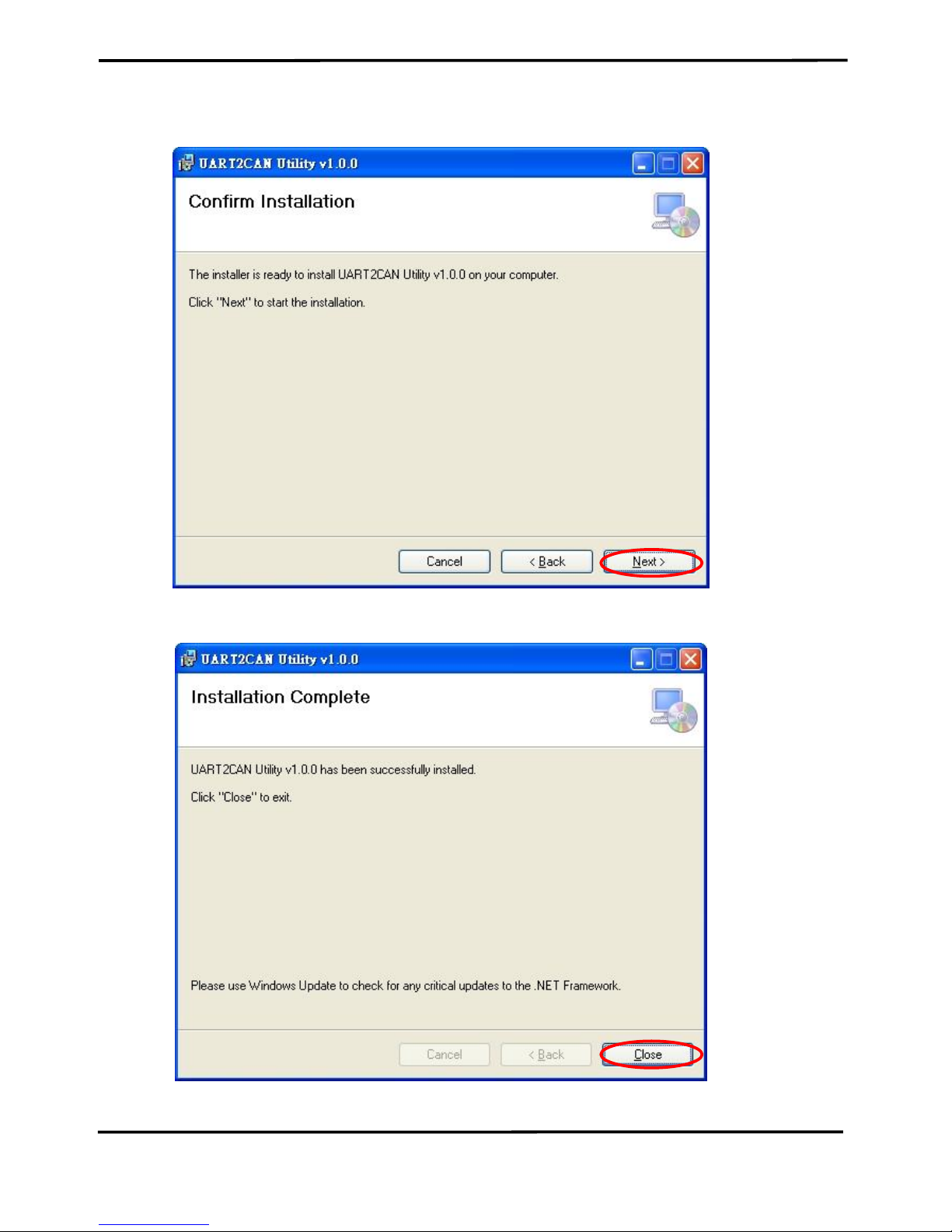

Page 24

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 24

3. Confirm the installation. Click the “Next” button to start the

installation.

Figure 3-5: Confirm Installation.

4. Installation complete. Click the “Close” button to exit.

Figure 3-6: Installation complete.

Page 25

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 25

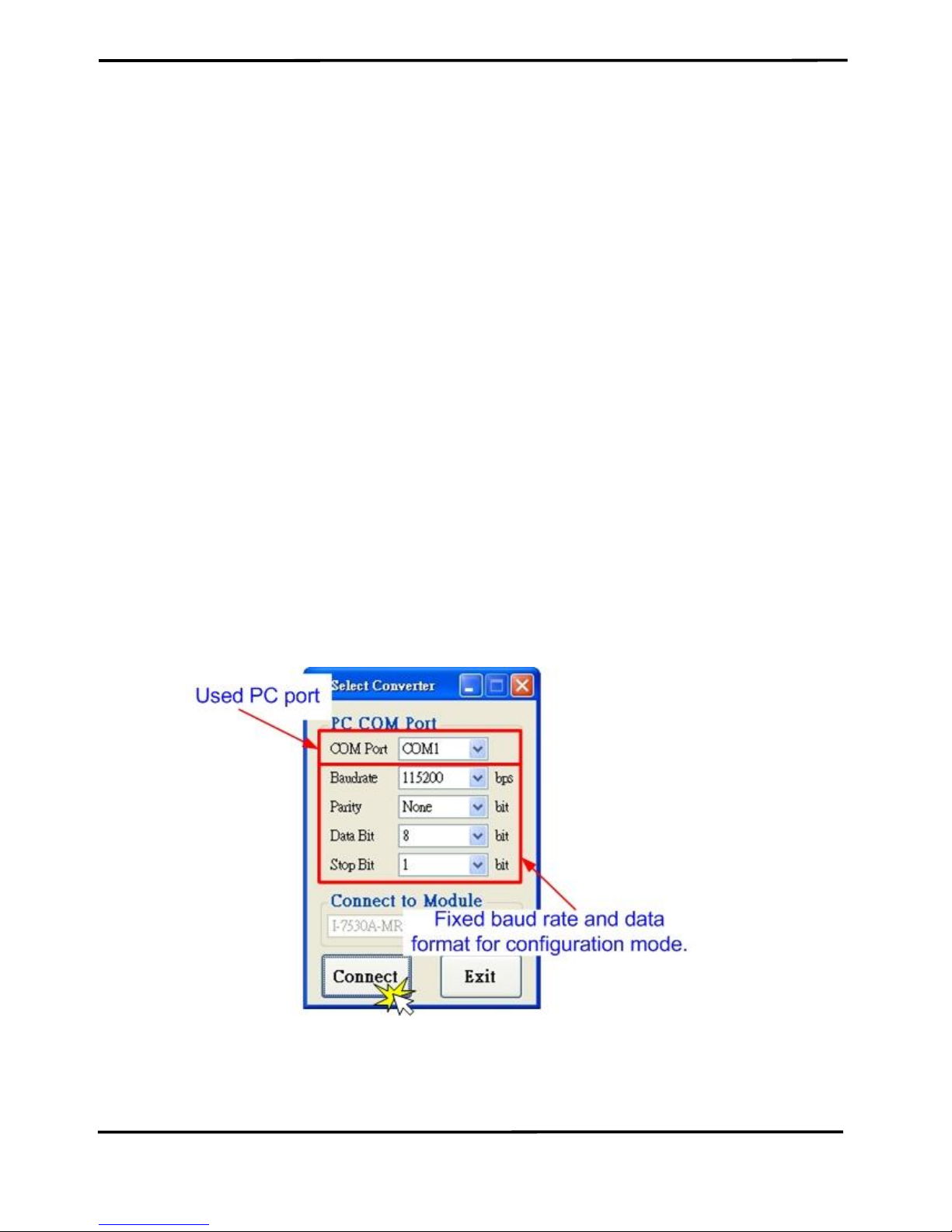

3.2 Configure the module parameters

In this section, we will describe how to configure the communication

parameters of the I-7530A-MR module with the UART2CAN Utility.

3.2.1 Connect to the I-7530A-MR module with UART2CAN Utility

1. Set the Init/Normal switch to the “Normal” position, which is found

on the back of the I-7530A-MR module.

2. Supply the proper electric power (the 10~30 DC volts) to the I7530A-MR module.

3. Set the Init/Normal switch to the “Init” (Initial) position at least three

seconds.

4. The PWR LED of the I-7530A-MR module will turned on and the

other LEDs will flash approximately once per second. That means

the I-7530A-MR module is working in the configuration mode.

5. Run the UART2CAN Utility software after connecting the PC COM

port and the I-7530A-MR RS-232 port by the cable CA-0910.

6. Select the necessary PC COM port to connect with the I-7530A-MR,

as shown in the following figure. Then click the “Connect” button.

Figure 3-7: The PC’s COM port configuration form.

Note: When the I-7530A-MR is working in the configuration mode, it can

only be communicated by using 115200 baud rate.

Page 26

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 26

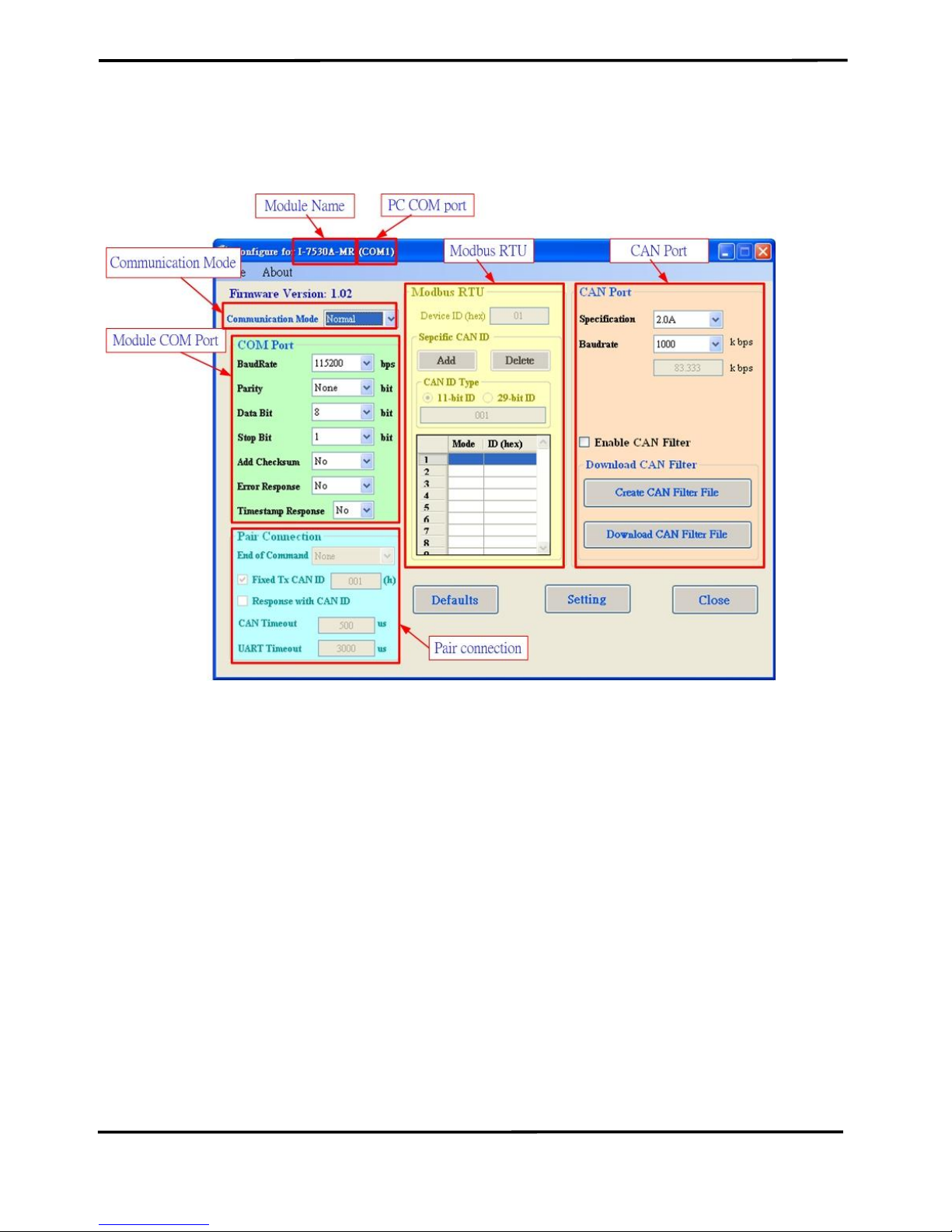

7. Then the I-7530A-MR configuration window will be brought out. The

UART2CAN Utility will show the communication information of the I7530A-MR module, as shown in the following figure.

Figure 3-8: The configuration form of the I-7530A-MR module.

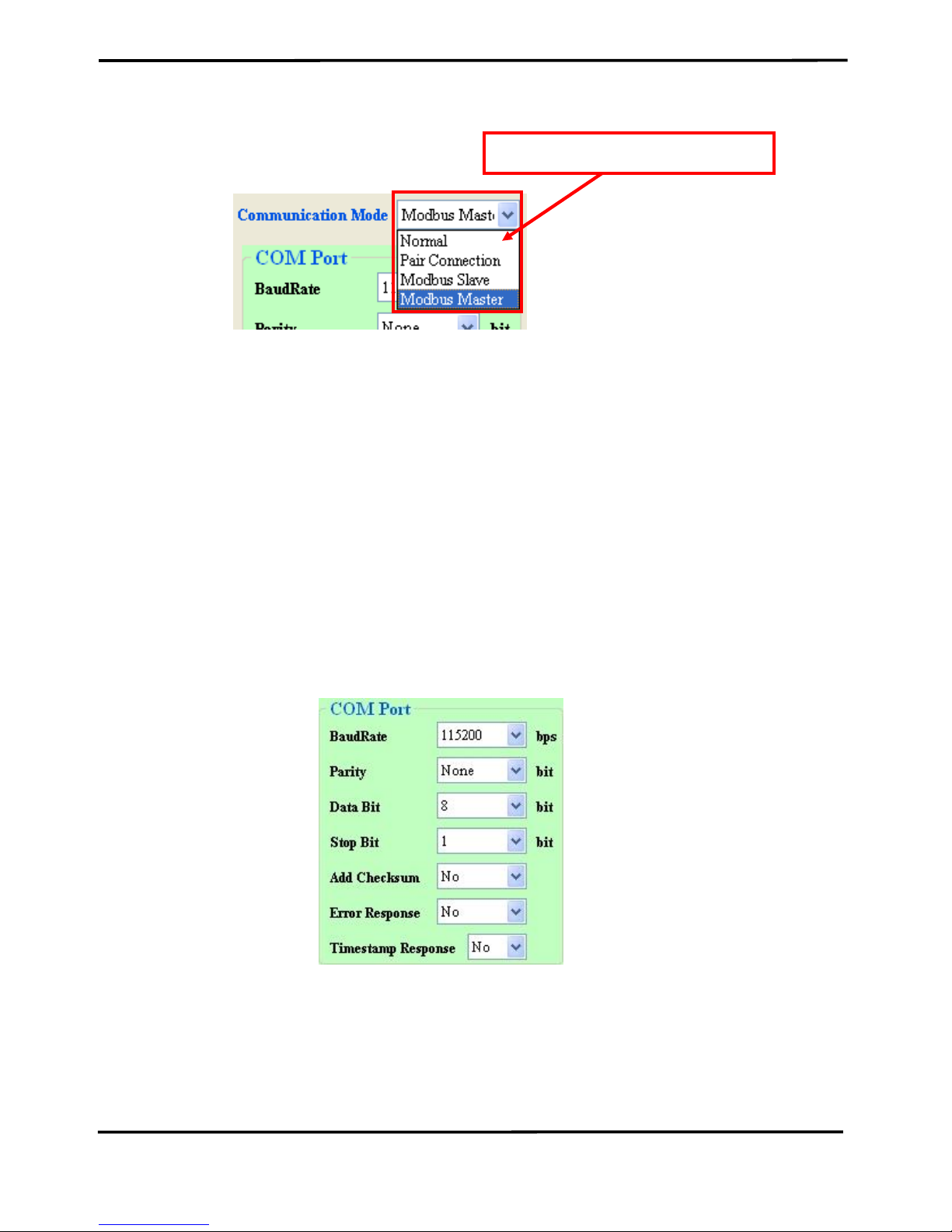

3.2.2 Select the communication mode

The I-7530A-MR supports four communication modes: “Normal”, “Pair

connection”, “Modbus Slave”,and “Modbus Master Mode”.

In the Normal mode, it accurately converts ASCII format messages

and CAN messages between RS-232/485/422 and CAN interfaces. In the

Modbus Slave mode, it allows a Modbus master to communicate with

CAN devices on a CAN network. In pair-connection mode, this module

provides the transparent communication between the RS-232/485/422

devices via CAN bus. In the Modbus Master mode, this module is worked

as Modbus Master/CAN module. It can communicate with Modbus slave

device via RS-232/485/422.

Page 27

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 27

Figure 3-9: Select Communication Mode.

3.2.3 Set the COM port parameters

1. When the function “Add Checksum” is set to “Yes”, users need to

communicate to the I-7530A-MR with checksum mechanism. (For

checksum algorithm, please refer to page 51)

2. If the “Error Response” is set to “Yes”, the error code will be

responded when the incorrect communication commands are sent to

the I-7530A-MR.

3. If the “Timestamp Response” is set to “Yes”, the timestamp value will

be responded when the CAN message commands are sent out from

the COM port of I-7530A-MR.

These three parameters above can only use at the “Normal”

communication mode.

Figure 3-10: The COM port of I-7530A-MR configuration.

Select Communication mode

Page 28

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 28

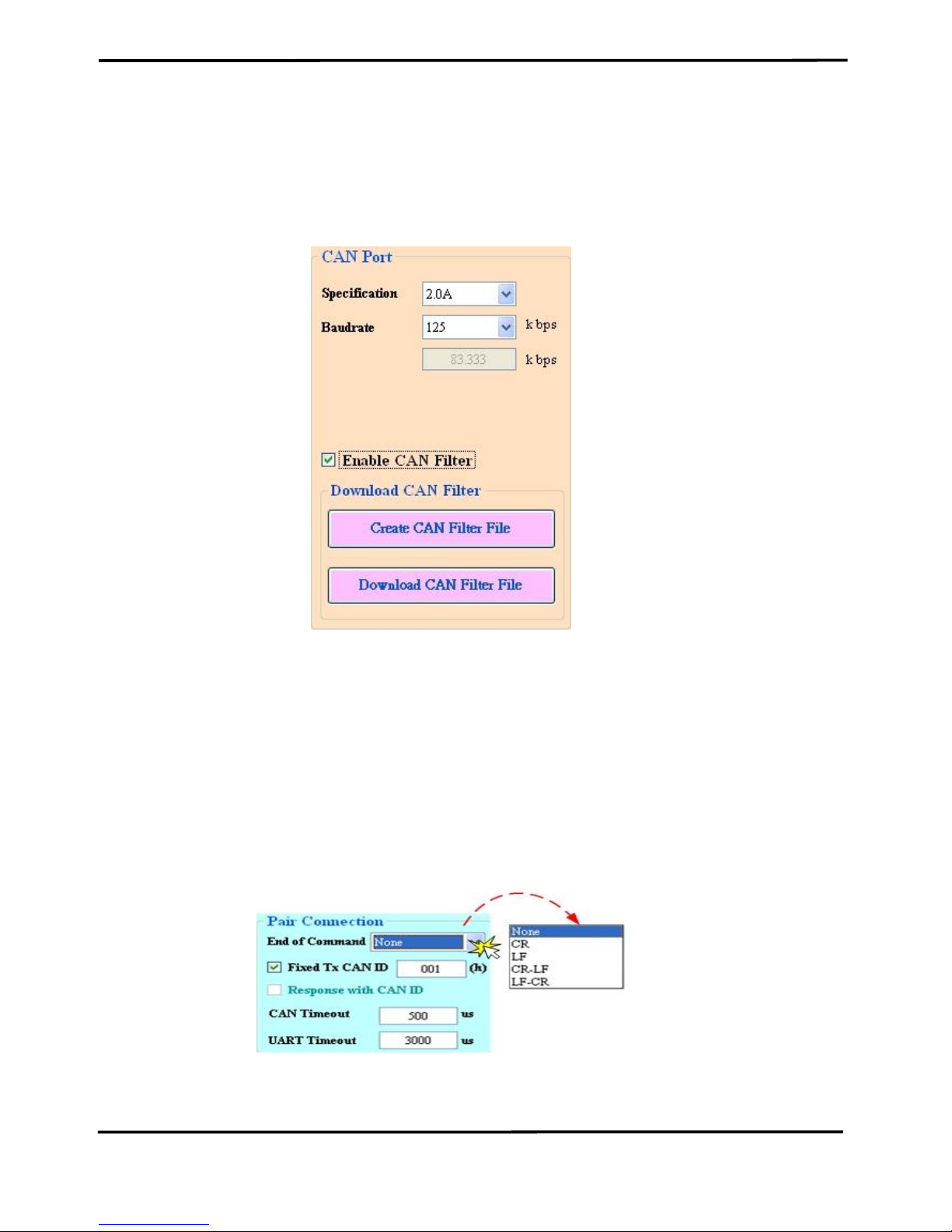

3.2.4 Set the CAN parameters

Select the communication parameters of the CAN port and check the

“Enable CAN Filter” item to make the CAN filter enable if necessary.

About how to set the CAN Filter, please refer to the section 3.3.

Figure 3-11: The CAN port of I-7530A-MR configuration.

3.2.5 Set the “Pair Connection” parameter

When users select the “Pair Connection” communication mode, the

functions, “End of Command”, “Fixed Tx CAN ID” and “Response with

CAN ID”, are useful. In pair connection mode, all commands written to I7530A-MR COM port will be transferred to the CAN bus directly. For more

detail information about pair connection mode, please refer to the section

3.4.

Figure 3-12: The configuration for Pair connection.

Page 29

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 29

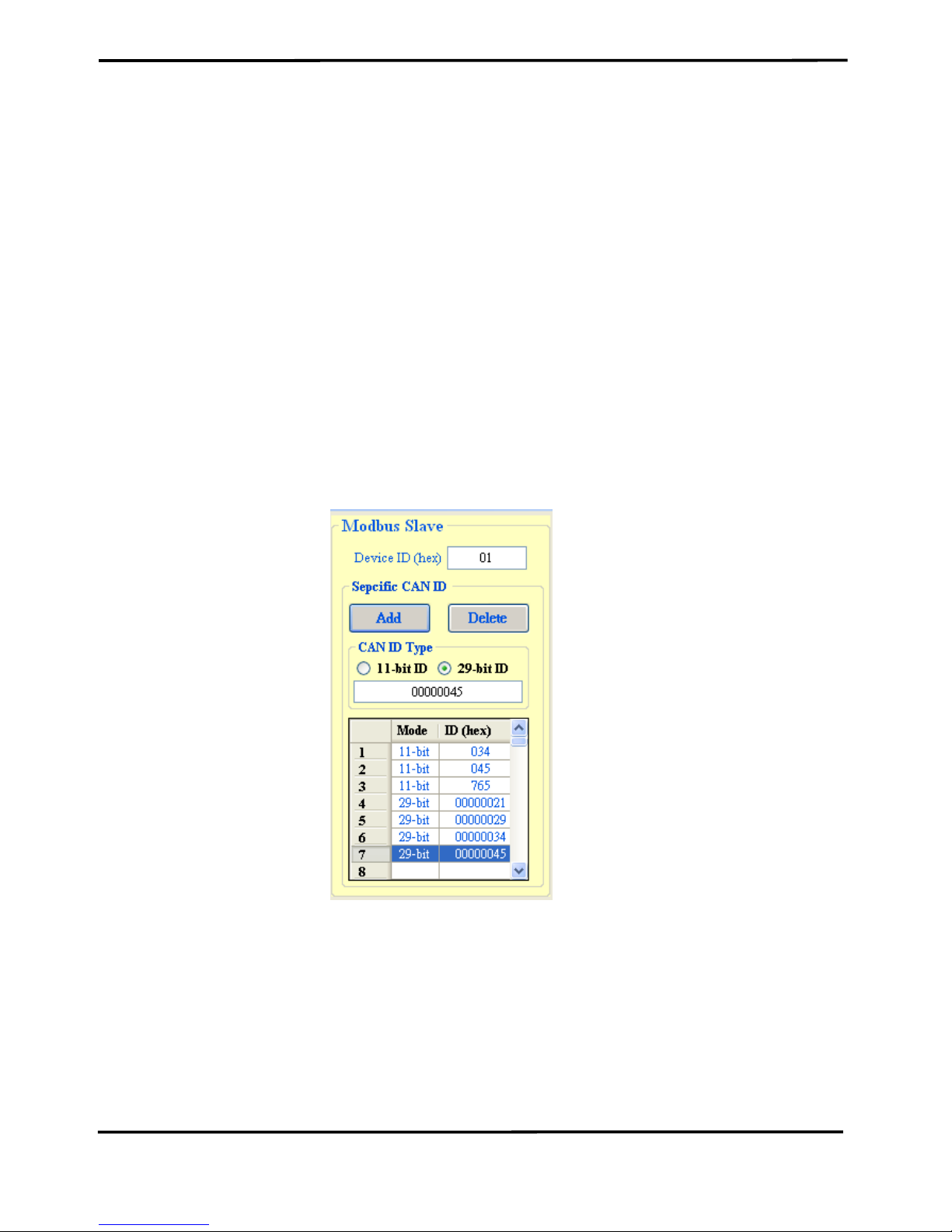

3.2.6 Set the “Modbus Slave” parameter

When users select the “Modbus Slave” communication mode, the

functions, “Device ID” and “Specific CAN ID”, are useful. In the “Specific

CAN ID” field, users can set maximum 10 CAN IDs (firmware v1.02 or

later supports 100 CAN ID of CAN messages) which indicate the

corresponding CAN messages to be stored in the specific Modbus Input

Register respectively. In the Modbus Input Register, the register range of

the “Specific CAN ID” occupies the section from 0x0800 to 0x0859. Each

CAN ID will use 9 Modbus input registers.

In Modbus Slave mode, users need to communicate with the I-7530AMR via using Modbus RTU command. The I-7530A-MR only supports

function code 03/04/06/10 of Modbus RTU commands for reading and

writing CAN messages. For more details about Modbus Slave mode,

please refer to the section 5.

Figure 3-13: The configuration for Modbus Slave mode.

Page 30

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 30

3.2.7 Configuration of default value

If users click the “Defaults” button, all of the module communication

parameters on the I-7530A-MR will be set to the factory default, which are:

Communication Mode = Normal

RS232/485/422: Baud rate = 115200 kbps

Data Bit = 8

Stop Bit = 1

Parity = None

Add Checksum = No

Error Response = No

Timestamp Response = No

CAN bus: CAN Specification = 2.0A

CAN bus Baud rate = 125 kbps

Enable CAN Filter = unchecked

Pair-connection: End of Command = None

Fixed Tx CAN ID = checked

Response with CAN ID = unchecked

Modbus Slave: Device ID = 1

Specify CAN ID Table = empty

Page 31

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 31

3.2.8 Load/Save the parameter configuration

The “Open Parameter File” function provides users to load

parameters from existing configuration file (*.INI). And the “Save

Parameter from Utility” function provides users to save the current

configuration to a file (*.INI).

Figure 3-14: Load/Save the parameter configuration from/to file.

Page 32

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 32

3.3 CAN Filter Configuration

There are two parts of the CAN filter configuration. One is “Download

CAN Filter” which are used to configure the CAN filter and download the

result into the I-7530A-MR module. The other is “Read CAN Filter” which

are used to read back the CAN filter configuration from the I-7530A-MR.

In this section, we will describe how to configure the CAN Filter with the

Utility tool.

Figure 3-15: The configuration for CAN Filter.

3.3.1 Create New CAN Filter

When users set the CAN filter first time, they need use “Download

CAN Filter” field.

Step 1: Click the “Create CAN Filter File” button to start setting CAN filter.

Then uses will see the following window.

Page 33

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 33

Figure 3-16 Create CAN filter file

Step 2: Add the CAN filter with single CAN ID or group CAN ID. Then, the

CAN ID in the list will be received and other CAN IDs which are not in list

will be dropped.

Figure 3-17 Add single or group CAN filter

Add single CAN ID filter

Add a range of CAN ID filter

End

Start

Page 34

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 34

For example, if users want to pass the CAN port with CAN ID 0x07F

in the CAN 2.0B specification.

Step1: Select “29-bit ID” item in the “CAN Single CAN ID” field.

Step2: Fill the value “7F” in the edit box.

Step3: Click “Add” button in the “CAN Single CAN ID” field.

Another example, if users want to pass the CAN port with CAN ID

from 0x04 to 0x15 in the CAN 2.0A specification.

Step1: Select “11-bit ID” item in the “CAN Group CAN ID” field.

Step2: Fill the value “4” in the “Start” field and the value “15” in the “End”

field.

Step3: Click “Add” button in the “CAN Group CAN ID” field.

After completing these two examples, users will see the follow figure.

Figure 3-18 Two CAN filter data

The “No.” field means that the sequential number of the CAN filter setting.

The “CAN Port” field means that the filter setting is belong to which CAN

port. In the I-7530A-MR module, users don’t need to care about this field.

The “Accepted IDs” field means that which CAN ID can be passed.

There are four small icon pictures which represent some information.

This icon means that this CAN filter is 11-bit and single CAN ID.

This icon means that this CAN filter is 11-bit and group CAN ID.

This icon means that this CAN filter is 29-bit and single CAN ID.

This icon means that this CAN filter is 29-bit and group CAN ID.

Step 4: When completing the CAN filter configuration, click the “Save to

File” button to save it for backup. It will save the filter data with “*.FLT”

Page 35

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 35

extension file name.

Figure 3-19 Five buttons in CAN filter configuration dialog

There are five buttons to help users to configure the CAN filter.

1. The “Clear Table” would delete all CAN filter setting in the list.

2. The “Delete Select” would delete the CAN filter setting which users

selected.

3. The “Load from File” provides users to load filter data from the

existence log file (*.FLT).

4. The “Save to File” provide users save current CAN filter setting as file

(*.FLT).

5. The “OK” would exit the configuration dialog.

3.3.2 Download a existed CAN Filter file

Click “Download CAN Filter File” to download the selected CAN filter

file into the I-7530A-MR module.

Figure 3-20 Download CAN filter data

Page 36

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 36

3.3.3 Read I-7530A-MR CAN Filter Configuration

Click the “Read from Module” item on the Utility tool bar to read CAN

filter setting from the I-7530A-MR module and save the CAN filter setting

as a file (*.FLT).

Figure 3-21 Read CAN filter form the I-7530A-MR module

Page 37

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 37

3.4 Pair-connection Mode Description

The pair connection function usually needs two I-7530A-MRs. When

these two I-7530A-MRs are in pair connection mode, all RS-232/485/422

commands transmitted from one of these two I-7530A-MRs will be put in

the data field of CAN message. This CAN message will be transferred to

RS-232/485/422 commands by another I-7530A-MR. The following

section will show each condition for different pair connection configuration.

Application 1:

This application may be used in two general RS-232 devices which

need to connect with each other, but the distance between is too long to

communicate by using RS-232.

Figure 3-22: The diagram of Application 1.

Configurations:

To apply this application, users need to configure the I-7530A-MR#1

and I-7530A-MR#2 as follows. The RS-232 configurations of the I-7530AMR#1 and I-7530A-MR#2 are decided by the Device1 and Device2 RS232 parameters.

I-7530A-MR#1 Configuration I-7530A-MR#2 configuration

Communication Descriptions:

If there are 7 bytes data, “1234567”, transmitted from Device1, the

Device2 will also receive “1234567” from the COM port of I-7530A-MR#2.

Page 38

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 38

The CAN ID in above figure is determined by the CAN specification

selected by users. If users select CAN 2.0A, the CAN ID is 11-bit ID. If

CAN 2.0B is used, the CAN ID is 29-bit ID. Here, assume users set the

Fixed Tx CAN ID field of I-7530A-MR#1 to be 0x001 ( “0x” is for

hexadecimal format) and CAN 2.0A is used, the CAN ID displayed in

above figure is 0x001.

If there are 9 bytes data, “123456789”, transmitted from Device1, the

Device2 will also receive “123456789” from the COM port of the I-7530AMR#2.

Note1: If users use 115200bps for RS-232 port of I-7530A-MR, it is

recommended that the configuration of the I-7530A-MR CAN baud rate is

closed to the configuration of RS-232 baud rate, such as 125K bps. When

you use pair connection function of the I-7530A-MR, the baud rate under

125K bps is proper. (Max. 256 bytes data at the same time)

Note2: “CAN Timeout” and “UART Timeout” parameters are the timeout

values for I-7530A-MR to check when to send message to the other side.

When receiving a message, the timeout will be refreshed. And when the

timeout reach to zero, message will be sent. The units of these two

values are micro-second.

Page 39

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 39

Application 2:

This application architecture is the same as the one of application1.

The application architecture is show below. The difference will be

discussed in the following paragraph.

Figure 3-23: The diagram of Application 2.

Configurations:

To apply this application, user need to configure the I-7530A-MR#1

and I-7530A-MR#2 as follows. The RS-232 configurations of the I-7530AMR#1 and I-7530A-MR#2 are decided by the Device1 and Device2 RS232 parameters.

I-7530A-MR#1 Configuration I-7530A-MR#2 Configuration

Communication Descriptions:

The communication of this condition is similar with the communication

of condition 1. The difference is that the I-7530A-MR#2 of the application

1 will transfer the RS-232 commands to Device2 immediately if it receives

any CAN message from the I-7530A-MR#1. The I-7530A-MR#2 of

application 2 will not transfer the RS-232 commands to Device2 until it

has checked the end character of RS-232 command (The end of RS-232

command is ‘CR’). For example, if the Device1 sends RS-232 commands

“123456789”, the Device2 in application 1 will receive the data

“12345678” immediately, and receive the data “9” with a little delay. But,

Device2 in application 2 will receive the data “123456789” at the same

time (Max. 256 bytes data at the same time).

Page 40

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 40

Application 3:

This application may be used to construct a RS-232 device network

via CAN bus. The architecture is shown below.

Figure 3-24: The diagram of Application 3.

Configurations:

In order to apply this application, users need to configure the I-7530AMR#1, I-7530A-MR#2, and I-7530A-MR#3 as follows. The RS-232

configurations of these I-7530A-MRs are decided by the connected RS232 device.

Figure 3-25: I-7530A-MR#1 Configuration.

Page 41

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 41

Figure 3-26: I-7530A-MR#2 Configuration.

Figure 3-27: I-7530A-MR#3 Configuration.

Communication Descriptions:

When the Device1 want to transmit the RS-232 command “1234567”

to Device2, the command written to I-7530A-MR#1 by the Device1 needs

to be “0021234567” because the Device1 is set to dynamic Tx CAN ID

(Fixed Tx CAN ID is not checked). The first three bytes of “0021234567”

is “002”, it means that the CAN ID is 0x002 while the I-7530A-MR#1

receives the RS-232 commands from the Device1 and transfers it to CAN

message. Afterwards, this CAN message is only accepted by Device2

because the configurations of acceptance code and acceptance mask of

Device2. Similarly, if Device1 wants to send the RS-232 command

“1234567” to Device3, it needs to send “0031234567” to the COM port of

the I-7530A-MR#1. When the Device2 or Device3 respond the RS-232

commands “456789”, the CAN message will have CAN ID “0x002” and

“0x003” because of the configurations of the “Fixed Tx CAN ID” of the I7530A-MR#2 and I-7530A-MR#3. Due to the response CAN ID of the I-

Page 42

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 42

7530A-MR#1 I-7530A-MR#2, the Device1 will receive the RS-232

commands “002456789” or “003456789”. Therefore, Device1 can decide

the target device which RS-232 commands will be sent to. Also, Device1

knows where the RS-232 commands come from. The general concept of

transmitting data from Device1 to Device2 is shown below.

Note: In pair connection mode, all command strings listed in the section 4

are useless.

Page 43

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 43

3.5 Testing the I-7530A-MR module

The following procedure will guide users to learn how to

transmit/receive CAN messages to/from other devices/PCs by using the I7530A-MR converter.

1. Set the Init/Normal switch to the Normal position, which is found on the

back of the I-7530A-MR module.

2. Connect the I-7530A-MR’s CAN port into the CAN network, which must

at least have one CAN device on the network.

3. Supply the 10~30 VDC power into the I-7530A-MR module through the

power terminal.

4. The PWR LED on the I-7530A-MR module will be turned on and the

other LEDs will be turned off. That means the I-7530A-MR is working in

the operation mode.

5. Run the UART2CAN Utility software after connecting the PC and the I-

7530A-MR via cable CA-0910. Please refer to the figure 2-14.

6. Select the PC COM port, baud rate and data format, which will be used

to connect with the COM port of the I-7530A-MR.

Figure 3-28: The configuration for the PC COM port.

7. Press the “Connect” button. Then the UART2CAN Utility will show the

diagnostic window, as the figure below.

Page 44

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 44

Figure 3-29: Description of diagnostic form

8. Then users can transmit or receive CAN messages via the I-7530A-MR

module.

In this Utility tool, it supports three communication modes to

transmit/receive CAN messages to/from other devices/PCs by using the I7530A-MR. There are the Normal mode, Pair connection mode and

Modbus Slave mode. In the next section, we will describe how to use it.

Figure 3-30: Select communication mode for the Utility.

Page 45

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 45

3.5.1 Normal mode

In this mode, there are two methods for users to send messages to

the I-7530A-MR. The Utility screenshot is shown below.

Figure 3-31: The active area of the Utility in Normal mode.

The first method (check “Use CAN Message”) requires users to

understand what message they want to send. Users need to key-in each

part data of a CAN message. The second method (uncheck “Use CAN

Message”) allows the use of the command string found in table 4-1 to

transmit messages. Both methods require the user to click the “Send”

button to transmit the information to the CAN network. When checking the

“Timer (ms)”, the Utility will transmit the message periodically. If the

function “Add Checksum” is set to “Yes”, it means that messages sent to

the I-7530A-MR by the Utility will be run with checksum mechanism.

Page 46

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 46

Figure 3-32: Enable the checksum mechanism in the Utility.

If the “Receive” is checked, the messages sent from the I-7530A-MR

will automatically be received and displayed in the “Receive” text box.

Besides, users can click the “Clear” button to remove the messages in the

text box. In addition, users can click the “Save” button to save the CAN

messages in the “Receive” text box into the “I-7530AMR_N_yyyyMMddmmss.txt” file. The indication of the file name is

described as the figure below.

Figure 3-33: The indication of the message log file name.

Page 47

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 47

3.5.2 Pair Connection Mode

The testing Utility screenshot is shown below.

Figure 3-34: The active area of the Utility in the Pair connection mode.

User can key-in any information to the edit box and select the end of

character. Then click the “Send” button to transmit the information to the

CAN network. When checking the “Timer (ms)”, the Utility will transmit the

message periodically.

If the “Receive” is checked, the message sent from the I-7530A-MR

will automatically be received and displayed in the “Receive” text box.

Besides, users can click the “Clear” button to remove the messages on

the text box. In addition, users can click the “Save” button to save the

messages in the “Receive” text box into the “I-7530AMR_P_yyyyMMddmmss.txt ” file. The indication of the file name is

described below.

Page 48

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 48

Figure 3-35: The indication of the name in the Pair connection mode.

3.5.3 Modbus Slave Mode

In this mode, there are two methods for users to send command to

the I-7530A-MR. The screenshot of the Utility is shown below.

Figure 3-36: The active area of the Utility in the Modbus Slave mode.

Through the first method (check “Use Modbus RTU Command”) users

can use the function code 0x03, 0x04, 0x06(firmware version v1.11 or

later), 0x10 of Modbus RTU commands for reading and writing CAN

message. The second method (uncheck “Use Modbus RTU Command”)

requires users to understand the Modbus RTU protocol. Then key-in the

correct Modbus RTU command in the text box. Both of the methods

Modbus Slave Mode

Received Message

Fill Message

Page 49

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 49

require users to click the “Send” button to transmit the command to the I7530A-MR module. When checking the “Timer (ms)”, the Utility will

transmit the command periodically.

If the “Receive” is checked, the messages sent from the I-7530A-MR

will automatically be received and displayed in the “Receive” text box.

Besides, users can click the “Clear” button to remove the messages on

the text box. In addition, users can click the “Save” button to save the

messages in the “Receive” text box into the “I-7530AMR_M_yyyyMMddmmss.txt ” file. The indication of the file name is

described below.

Figure 3-37: The indication of the file name in the Modbus Slave mode.

Page 50

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 50

4. Command list (Only for normal mode)

In order to simplify the application, we provide 9 command strings to

send/receive commands through the I-7530A-MR. It can cover most of

the applications. The general formats of the commands for the I-7530AMR are given below:

Command Format: <Command>[CHK]<CR>

<Command>

:

RS-232/485/422 commands of the I-7530A-MR

[CHK]

:

2-character checksum value. It is effective only if the

checksum mechanism is set to enable by using

UART2CAN Utility. For checksum algorithm, please refer

to page 51

<CR>

:

All RS-232/485/422 commands of the I-7530A-MR must

be ended with the character “<CR>” (The ASCII value is

13).

The 9 command formats are given in the following table. More

detailed information related to the each command will be described in the

following sub sections.

Table 4-1: Command list table

Command

Description

tIIILDD…[CHK]<CR>

Send or receive a standard data frame.

TIIIL[CHK]<CR>

Send or receive a standard remote frame.

eIIIIIIIILDD…[CHK]<CR>

Send or receive an extended data frame.

EIIIIIIIIL[CHK]<CR>

Send or receive an extended remote frame.

S[CHK]<CR>

Read the status value of the I-7530A-MR

P0BBDSPCE[CHK]<CR>

*Change the RS-232/485/422 configuration

P1B [CHK]<CR>

*Change the CAN Baud rate configuration

P2BBBBB[CHK]<CR>

*Change the user-defined CAN baud rate

configuration

RA[CHK]<CR>

Reboot the I-7530A-MR module.

* NOTE:

This command will write parameters into EEPROM and

EEPROM is limited to 10,000,000 erase/write cycles.

Page 51

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 51

Checksum algorithm:

The checksum [CHK] is 2-characters of the sum of the command

message, from the first character to the character before <CR>.

For example:

Command: Reboot the I-7530A-MR module, “RA[CHK]<CR>”.

1. Sum of the string = ‘R’ + ‘A’ = 52h + 41h = 93h.

2. Therefore the checksum is 93h and so [CHK]=”93”.

3. The command string with checksum =”RA93<CR>”.

Page 52

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 52

4.1 tIIILDD…[CHK]<CR>

Description: Send or receive a standard CAN data frame.

Syntax: tIIILDD…[CHK]<CR>

t Represent a standard (2.0A) data frame.

III 11 bits Identifier (000~7FF)

L Data length (0~8)

DD… Input data frame value according to the data length (00~FF)

Response: Valid command: No response

Invalid command: ?<Error Code><CR>

Note: It is necessary to enable the “Error Response” function while using

the UART2CAN Utility in order to receive Syntax and/or communication

error information.

Example:

Command: t03F6112233445566<CR>

Send a CAN message with a standard data frame. ID=03F, DLC=6,

data1=11, data2=22, data3=33, data4=44, data5=55 and data6=66.

4.2 TIIIL[CHK]<CR>

Description: Send or receive a standard CAN remote frame.

Syntax: TIIIL[CHK]<CR>

T Represents a standard (2.0A) remote frame.

III 11 bits Identifier (000~7FF)

L Data length (0~8)

Response: Valid command: No response

Invalid command: ?<Error Code><CR>

Note: It is necessary to enable the “Error Response” function while using

the UART2CAN Utility in order to receive Syntax and/or communication

error information.

Example:

Command: T2E88<CR>

Page 53

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 53

Send a CAN message with a standard remote frame. ID=2E8,

DLC=8.

4.3 eIIIIIIIILDD…[CHK]<CR>

Description: Send or receive an extended CAN data frame.

Syntax: eIIIIIIIILDD…[CHK]<CR>

e Stands for the extended (2.0B) data frame.

IIIIIIII 29 bits Identifier (00000000~1FFFFFFF)

L Data length (0~8)

DD… Input data frame value according to the data length (00~FF)

Response: Valid command: No response

Invalid command: ?<Error Code><CR>

Note: It is necessary to enable the “Error Response” function while using

the UART2CAN Utility in order to receive Syntax and/or communication

error information.

Example:

Command: e1234567851122334455<CR>

Send a CAN message with an extended data frame. ID=12345678,

DLC=5, data1=11, data2=22, data3=33, data4=44 and data5=55.

4.4 EIIIIIIIIL[CHK]<CR>

Description: Send or receive an extended CAN remote frame.

Syntax: EIIIIIIIIL[CHK]<CR>

E Stands for the extended (2.0B) CAN remote frame.

IIIIIIII 29 bits Identifier (00000000~1FFFFFFF)

L Data length (0~8)

Response: Valid command: No response

Invalid command: ?<Error Code><CR>

Note: It is necessary to enable the “Error Response” function while using

Page 54

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 54

the UART2CAN Utility in order to receive Syntax and/or communication

error information.

Example:

Command: E010156786<CR>

Send a CAN message with an extended remote frame.

ID=01015678, DLC=6.

4.5 S[CHK]<CR>

Description: Read the I-7530A-MR CAN baud rate and error flag message.

Syntax: S[CHK]<CR>

S Command character.

Response: Valid Command: !CFFTTRRO[CHK]<CR>

Invalid command: ?<Error Code>[CHK]<CR>

! Delimiter for valid command

C current baud rate setting of CAN

FF CAN status register

TT CAN transmit error counter

RR CAN receive error counter

O CAN or RS-232/485/422 FIFO Overflow flag

Note: It is necessary to enable the “Error Response” function while using

the UART2CAN Utility in order to receive Syntax and/or communication

error information. Furthermore, all response results are shown in the ASCII

format. Users need to make an ASCII to hex format transformation in order

to understand what the meaning is. The following table shows all the

indications of the response of this command.

Table 4-2: CAN baud rate list

AsciiToHex(C)

Description

0

10K baud rate of CAN

1

20K baud rate of CAN

2

50K baud rate of CAN

3

100K baud rate of CAN

Page 55

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 55

4

125K baud rate of CAN

5

250K baud rate of CAN

6

500K baud rate of CAN

7

800K baud rate of CAN

8

1000K baud rate of CAN

F

User-defined baud rate of CAN

Table 4-3: CAN status register list

AsciiToHex(FF)

Description

Bit 7

Bus Status (0: Bus-On, 1: Bus-Off)

Bit 6

Error Status (0: OK, 1: Error)

Bit 5

Transmit Status (0: idle, 1: transmit )

Bit 4

Receive Status (0:idle, 1: Receive)

Bit 3

Transmit Complete Status (0: incomplete, 1: complete)

Bit 2

Receive Complete Status (0: incomplete, 1: complete)

Bit 1

Data Overrun Status (0: absent, 1: overrun)

Bit 0

Receive Buffer Status (0: empty, 1: full)

Table 4-4: CAN and RS-232/485/422 FIFO overflow flag list

AsciiToHex(O)

Description

Bit 3

Reserved

Bit 2

Reserved

Bit 1

RS-232/485/422 FIFO Overflow

Bit 0

CAN FIFO Overflow

Example:

Command: S<CR>

Receive: !50000000<CR>

Obtain some current information on the I-7530A-MR module. The

response will show the following results: CAN baud rate=250K, CAN

status register= normal, CAN transmit error counter=0, CAN receive

error counter=0 and CAN & RS232/485/422 FIFO= normal.

4.6 P0BBDSPCR[CHK]<CR>

Description: Change the RS-232/485/422 configuration on the I-7530A-MR

module and then reboot the I-7530A-MR module.

Syntax: P0BBDSPCR[CHK]<CR>

Page 56

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 56

P0 Command character

BB RS-232/485/422 Baud rate

D Data bit

0 = 5 bits Data formation

1 = 6 bits Data formation

2 = 7 bits Data formation

3 = 8 bits Data formation

S Stop bit (0=1 stop bit, 1=2 stop bits)

P Parity (0=None, 1=Odd, 2=Even)

C Checksum (0=No, 1=Yes)

R Other response

Table 4-5: RS-232/485/422 baud rate list

BB

Description

00

Reserved

01

Reserved

02

300 bps baud rate of RS-232/485/422

03

600 bps baud rate of RS-232/485/422

04

1200 bps baud rate of RS-232/485/422

05

2400 bps baud rate of RS-232/485/422

06

4800 bps baud rate of RS-232/485/422

07

9600 bps baud rate of RS-232/485/422

08

19200 bps baud rate of RS-232/485/422

09

38400 bps baud rate of RS-232/485/422

0A

57600 bps baud rate of RS-232/485/422

0B

115200 bps baud rate of RS-232/485/422

0C

230400 bps baud rate of RS-232/485/422

Table 4-6: Other response list

AsciiToHex(R)

Description

Bit 3

Reserved

Bit 2

Reserved

Bit 1

Enable timestamp response (0: No, 1: Yes)

Bit 0

Enable error response (0: No, 1: Yes)

Page 57

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 57

Response: A valid command will write the RS-232/485/422 configuration

parameters into the EEPROM and then reboot the I-7530A-MR module.

Invalid command: ?<Error Code><CR>

Note: It is necessary to enable the “Error Response” function while using

the UART2CAN Utility in order to receive Syntax and/or communication

error information.

Example:

Command: P00B30000<CR>

Set the RS-232/485/422 baud rate=115.2 kbps, data bit=8, stop

bit=1, none parity, no checksum, no error responses and no

timestamp responses into the I-7530A-MR module and then reboot

the I-7530A-MR module.

Page 58

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 58

4.7 P1B [CHK]<CR>

Description: Change the CAN Baud rate configuration of the I-7530A-MR

module and then reboot the I-7530A-MR module.

Syntax: P1B[CHK]<CR>

P1 Command character

B CAN Baud rate

Table 4-7: CAN baud rate list

B

Description

0

10 kbps baud rate of CAN

1

20 kbps baud rate of CAN

2

50 kbps baud rate of CAN

3

100 kbps baud rate of CAN

4

125 kbps baud rate of CAN

5

250 kbps baud rate of CAN

6

500 kbps baud rate of CAN

7

800 kbps baud rate of CAN

8

1000 kbps baud rate of CAN

9,A,B,C,D,E

Reserved

F

User-defined baud rate of CAN

Response: A valid command will write the CAN configuration baud rate

into the EEPROM and then reboot the I-7530A-MR module.

Invalid command: ?<Error Code><CR>

Note: It is necessary to enable the “Error Response” function while using

the UART2CAN Utility in order to receive Syntax and/or communication

error information.

Example:

Command: P14<CR>

Set the CAN baud rate=125 kbps into the I-7530A-MR module and

then reboot the I-7530A-MR module.

Page 59

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 59

4.8 P2BBBBB[CHK]<CR>

Description: Change the user-defined CAN baud rate configuration of I-7530A-

MR module and then reboot the I-7530A-MR module.

Syntax: P2BBBBB[CHK]<CR>

P2 Command character

BBBBB User-defined CAN baud rate

Response: A valid command will write the user-defined CAN baud rate

configuration into the EEPROM and then reboot the I-7530A-MR module.

Invalid command: ?<Error Code><CR>

Note: It is necessary to enable the “Error Response” function while using

the UART2CAN Utility in order to receive Syntax and/or communication

error information. Furthermore, the value of BBBBB is the baud rate value

multiplied 1000 and then converted into HEX format. For example, assume

that users want to set the CAN baud rate as 83.333 kbps. The value

BBBBB is the hex format of the value14585 (83.333 x 1000).

Example:

Command: P214585<CR>

Set the CAN baud rate=83.333 kbps into the I-7530A-MR module

and then reboot the I-7530A-MR module.

.

Page 60

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 60

4.9 RA[CHK]<CR>

Description: Reboot the I-7530A-MR module. This command is usually used

while the status of CAN bus is bus-off. In this case, users can use this

command to reboot the module to work it again.

Syntax: RA[CHK]<CR>

RA Command character

Response: Valid command will reboot the I-7530A-MR module.

Invalid command: ?<Error Code><CR>

Note: It is necessary to enable the “Error Response” function while using

the UART2CAN Utility in order to receive Syntax and/or communication

error information.

Example:

Command: RA<CR>

The I-7530A-MR module will reboot after it had received this command.

Page 61

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 61

4.10 General Error code for all command

If the Error response function on the I-7530A-MR_MR module is set to be

“Yes”(that means enable) via the I-7530A-MR Utility when configuration, the I7530A-MR will automatically send the error code to the RS-232/485/422 device

or the host PC through the RS-232/485/422 media when the I-7530A-MR

produces an error message during the operation mode. The meanings of these

error codes are given below:

Table 4-8: Error code table

Error

code

Description

Possible causes & solutions

1

Invalid header

The header of the RS-232/485/422

command string is not

“t”,”T”,”e”,”E”,”S”,”P0”, ”P1”,”P2” nor “RA”.

2

Invalid length

The numbers of data of the CAN message

does not match the data length of the CAN

message. For example:

Error: t001512345<CR>

Right: t00150102030405<CR>

3

Invalid checksum

The checksum of the RS-232/485/422

command string does not match with the

checksum calculated by the I-7530A-MR. For

example:

Error: t0012112209<CR>

Right: t00121122FD<CR>

4

Buffer overrun

The transmission buffer verrun is happened,

users should retransmit the message later

when this module is normal.

5

Timeout

The ASCII command strings are sent

incomplete.

For example:

Error: T0018

Right: T0018<CR>

Page 62

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 62

5. Modbus Slave Mode

The I-7530A-MR, Modbus RTU to CAN converter, supports the Modbus

RTU protocol. It can act as a Modbus RTU slave on the Modbus network. There

are some mechanisms for data-exchanging between the CAN register and the

Modbus RTU register as the figure at the next page.

In the Modbus Input Register, according to the different purposes these

register are divided into three fields, “Normal CAN Message Field”, “Specific

CAN Message Field” and “Module Status Field”. When a CAN message

received from the CAN network, the I-7530A-MR will check if the Specific CAN

Message filed is used or not. If it is not used, this CAN message will be stored

into the “Normal CAN Message” field. This filed is similar with a kind of FIFO

(first-in first-out buffer). Users can only read this field with the start address of

this field by applying the Modbus commands. After users read the CAN

messages from this filed, the rest unread CAN messages will be moved to the

buffer with the start address of this field. This field can store maximum 200 CAN

messages. Therefore, if the unread CAN messages exceed 200 records, the

data is lost.

If the Specific CAN Message filed is used, the CAN messages which are

marked in the specific CAN message table of the Utility tool are directly moved

to the Specific CAN Message field. CAN messages with different CAN IDs will

be stored in different parts of the Specific CAN Message field. Users can set

maximum 10 different CAN ID of CAN messages (firmware v1.02 or later

support 100 CAN ID of CAN messages). Besides, a kind of CAN ID only has

one record buffer. If there are two CAN messages with the same ID, the later

will over-write the former. Therefore, the Specific CAN Message filed always

keeps the newest information of the corresponding CAN messages with the

specific CAN IDs.

If a CAN message is sent to a CAN network from a Modbus network via the

I-7530A-MR, the CAN message will be temporarily stored in Output Register

and not be transmitted until the CAN bus idle. The Output Register is only one

message buffer. If the data overrun is happened, users will get an error code for

replying. Users can also use Modbus RTU command to read the CAN message

transmitted before. It is helpful for checking the last sent record.

Page 63

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 63

Figure 5-1: Architecture diagram for the Modbus mode.

Page 64

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 64

5.1 Supported Modbus Functions

The Modbus function codes supported by the I-7530A-MR are shown in the

following table.

Table 5-1: Supported Modbus Function Codes

Function Code

Function Name

Description

3 (03 Hex)

Reading Output

Register

Read multiple registers for a sent

CAN messages

4 (04 Hex)

Reading Input

Register

Read multiple input registers for

reading CAN messages

6 (06 Hex)

Write Output

Register

1. Write single registers for

sending a CAN message.

2. This function is implemented

in firmware version v1.11 or

later.

16 (10 Hex)

Preset Multiple

Registers

1. Write multiple registers for

sending a CAN message

2. Configuration Command

(00256~00512)

5.2 Modbus Address

According to the different purposes these register are divided into three

fields, “Normal CAN Message Field”, “Specific CAN Message Field” and

“Module Status Field”. The diagram of Input Register are shown below:

Page 65

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 65

Figure 5-2: The address definition of Input Register and Output Register of

the I-7530A-MR.

Modbus Input Register:

(1) Normal CAN Message Field:

In this field, the address range of “Normal CAN Message” is

00000~01799 (protocol addresses). It is used to store the CAN message

received from the CAN network. One CAN message will occupy 9-byte

address space in the “Normal CAN Message” field. Therefore, it can

store maximum 200 CAN messages. The detailed Modbus address

arrangement of “Normal CAN Message” field is described as the table 5-

2.

Page 66

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 66

Table5-2: Modbus address arrangement of “Normal CAN Message” field.

Protocol Addresses

(Base 0)

PLC Addresses

(Base 1)

Word

Count

Description

Decimal rule

00000 ~ 00008

30001 ~ 30009

9

RX CAN Message #001

00009 ~ 00017

30010 ~ 30018

9

RX CAN Message #002

…

…

… … 01782 ~ 01790

31783 ~ 31791

9

RX CAN Message #199

01791 ~ 01799

31792 ~ 31800

9

RX CAN Message #200

The format of each received CAN Message is described below:

Word number

Description

1

Bit 15: 0valid data, 1invalid data

Bit 6~14: Reserved

Bit 5: CAN Specification, 02.0A, 12.0B

Bit 4: RTR, 0No, 1Yes

Bit 0~3: Data length, value=0~8

2

Most significant two bytes of CAN identifier. (Bigendian)

3

Least significant two bytes of CAN identifier. (Bigendian)

4

The data 1 and data 2 of CAN data field.

5

The data 3 and data 4 of CAN data field.

6

The data 5 and data 6 of CAN data field.

7

The data 7 and data 8 of CAN data field.

8

Most significant two bytes of the RX timestamp

message. (Big-endian)

9

Least significant two bytes of the RX timestamp

message. (Big-endian)

Page 67

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 67

(2) Module Status Field:

The I-7530A-MR’s status information is defined in the following address.

Users can use the Modbus RTU command (function code 04

hex

) to read

these informations from the “Module Status” field.

Table5-3: Modbus address of “Modbus Status” field.

Protocol Addresses

(Base 0)

PLC Addresses

(Base 1)

Word

Count

Description

Decimal rule

01920

31921

1

Counter

01921

31922

1

Read Standard

CAN baud rate

configuration

01922~01923

31923~31924

2

Read user-defined

CAN baud rate

configuration

01924

31925

1

CAN state register

01925

31926

1

CAN error counter

01926

31927

1

CAN/UART

overflow flag

01927

31928

1

Firmware version

01928~01932

31929~31933

5

Module name

01933~01935

31934~31936

3

Manufacturer

The detailed information of the “Module Status” field is described below.

Status Name

Description

Counter

The unread number of CAN message in the

Normal CAN Message Field of Input Register.

Read Standard

CAN baud rate

configuration

The current baud rate setting of CAN bus.

Please refer to Table 4-2 for more information.

Read user-defined

CAN baud rate

configuration

The current user-defined baud rate setting of

CAN bus. Please refer to Table 4-8 for more

information.

CAN state register

Most significant byte: Reserved.

Least significant byte: register status. Please

refer to Table 4-3 for more information.

Page 68

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 68

CAN Error Counter

Most significant byte: CAN receive error

counter.

Least significant byte: CAN transmit error

counter.

CAN/UART

Overflow flag

Bit 0: CAN overflow flag, 0Not full, 1 Full.

Bit 1: UART overflow flag, 0Not full, 1 Full.

Firmware Version

Most significant byte major field of firmware

version

Least significant byte minor field of firmware

version

For example, if the responded value is “01 02”.

That means the firmware version is 1.02.

Module Name

“I-7530A-MR” in ASCII format.

Manufacturer

“ICPDAS” in ASCII format.

Page 69

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 69

(3) Specific CAN Message Field:

The I-7530A-MR supports a “Specific CAN Message” field to store ten

special CAN messages with specific the CAN IDs(Note1). When the I7530A-MR receive the CAN messages whose CAN IDs are defined in

the Specific CAN Message Field by the Utility tool, the I-7530A-MR put

this CAN message into the corresponding register of the Specific CAN

Message field. Each CAN message will occupy 9 address space of the

register, and the range of this field is listed in following table.

Table5-4: Modbus address of “Specific CAN Message” field.

Protocol Address

(Base 0)

PLC Address

(Base 1)

Word

Count

Description

Decimal rule

02048~02056

32049~302057

9

Specific RX CAN

Message #001

02057~02065

32058~32066

9

Specific RX CAN

Message #002

… … …

02129~02137

32130~32138

9

Specific RX CAN

Message #010

02138~02147

32139~32148

9

Specific RX CAN

Message #011

(Note1)

… … …

…

02930~02938

32931~32939

9

Specific RX CAN

Message #099

(Note1)

02939~02947

32940~32948

9

Specific RX CAN

Message #100

(Note1)

Note1:

1. firmware v1.02 (or later) support #011 to #100

2. After saving all configuration into an “ini” file (section3.2.8), there will create

an “I7530AMR_SpecCANID_MBTable.txt” on the Utility folder.

This file is a mapping table for specific CAN ID and Modbus address.

Page 70

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 70

Modbus Output Register:

There are two fields on Modbus output register, one is TX CAN message

field and the other is Configuration command field. The addresses of these

fields are described below.

Table5-5: Modbus output register address

Protocol Address

(Base 0)

PLC Address

(Base 1)

Description

Decimal rule

00000 ~ 00006

40001 ~ 40007

TX CAN Message

00256 ~ 00511

40257 ~ 40512

Configuration command

(1) TX CAN Message Field:

The “TX CAN Message” in the Modbus Output Register is used to stored a

CAN message which will be transmitted to the CAN network.

The TX CAN Message formats are described below:

Word

number

Description

1

Bit 6~15: Reserved

Bit 5: CAN Specification, 0CAN 2.0A, 1CAN 2.0B

Bit 4: RTR, 0No, 1Yes

Bit 0~3: Data length, value = 0~8

2

Most significant two bytes of CAN Identifier. (Big

endian)

3

Least significant two bytes of CAN Identifier. (Big

endian)

4

The data 1 and data 2 of CAN data field.

5

The data 3 and data 4 of CAN data field.

6

The data 5 and data 6 of CAN data field.

7

The data 7 and data 8 of CAN data field.

Page 71

I-7530A-MR Modbus RTU to CAN Converter User’s Manual (Version 1.07, 06/2016) ------------- 71

(2) Configuration command Field:

The “Configuration command” in the Modbus Output Register is used for user

to use Modbus command to configure module, including reboot module, reset CAN

bus, change RS-232/RS-422/RS-485 setting, change CAN bus baud rate, change

user-defined CAN baud rate.

These configuration commands are described below:

1. Reboot Module

This command is used to reboot module. After successfully setting, the

module will response a successful setting message, and then reboots.

Request command:

Field Name

Size

Value Range

Example

Hexadecimal rule

Node ID

1 byte

0x01~0xF7

0x01

Function Code

1 byte

0x10

0x10

Start Address

2 bytes

0x0100

0x0100

Word Count

2 bytes

0x0002

0x0002

Byte Count

1 byte

0x04

0x04

Data-1