Page 1

ET-7H24 Series

User Manual

Version 1.0.0, Aug 2020

Written by Sean Hsu

Edited by Anna Huang

Page 2

Warranty

All products manufactured by ICP DAS are under warranty regarding defective materials for a

period of one year, beginning from the date of delivery to the original purchaser.

Warning

ICP DAS assumes no liability for any damage resulting from the use of this product. ICP DAS

reserves the right to change this manual at any time without notice. The information

furnished by ICP DAS is believed to be accurate and reliable. However, no responsibility is

assumed by ICP DAS for its use, not for any infringements of patents or other rights of third

parties resulting from its use.

Copyright

Copyright @ 2020 by ICP DAS Co., Ltd. All rights are reserved.

Trademark

The names used for identification only may be registered trademarks of their respective

companies.

Contact US

If you have any problem, please feel free to contact us.

You can count on us for quick response.

Email: service@icpdas.com

PET-7H24M Series User Manual, version 1.0.0 P.2

Page 3

Table of Contents

1. Introduction .............................................................................................. 5

1.1. Features ......................................................................................................................... 6

1.2. Specification ................................................................................................................ 12

1.3. Overview ..................................................................................................................... 15

1.4. Wiring Diagram ............................................................................................................ 20

1.5. Block Diagram .............................................................................................................. 22

1.6. Dimension.................................................................................................................... 23

2. Getting Started ........................................................................................ 24

2.1. Mounting the Hardware .............................................................................................. 25

2.2. Deploying a Basic PET-7H24M System ........................................................................ 26

2.3. Installing the HSDAQ Utility ......................................................................................... 28

2.4. Using HSDAQ Utility to Assign an IP address ............................................................... 29

3. Operation ................................................................................................ 32

3.1. Continuous Acquisition ............................................................................................... 33

Software AD Trigger ............................................................................................. 33 3.1.1.

3.2. N Sample Acquisition .................................................................................................. 35

Software AD Trigger ............................................................................................. 35 3.2.1.

Analog Input Trigger ............................................................................................. 36 3.2.2.

4. Tools and SDKs ........................................................................................ 38

4.1. LabVIEW ...................................................................................................................... 38

4.2. HSDAQ Utility .............................................................................................................. 39

4.3. SDK API ........................................................................................................................ 41

5. Web Applications .................................................................................... 47

5.1. Overview ..................................................................................................................... 49

PET-7H24M Series User Manual, version 1.0.0 P.3

Page 4

5.2. Configuration ............................................................................................................... 50

Network Settings .................................................................................................. 51 5.2.1.

Basic Settings........................................................................................................ 52 5.2.2.

5.3. Authentication ............................................................................................................. 58

Account Management .......................................................................................... 59 5.3.1.

Accessible IP Settings ........................................................................................... 63 5.3.2.

5.4. Web HMI...................................................................................................................... 67

6. Modbus Applications .............................................................................. 68

7. Updates ................................................................................................... 72

8. Calibration .............................................................................................. 75

Appendix B. Analog Input Type and Data Format Table ............................... 83

Appendix C. Troubleshooting ...................................................................... 84

Appendix D. Revision History ...................................................................... 85

PET-7H24M Series User Manual, version 1.0.0 P.4

Page 5

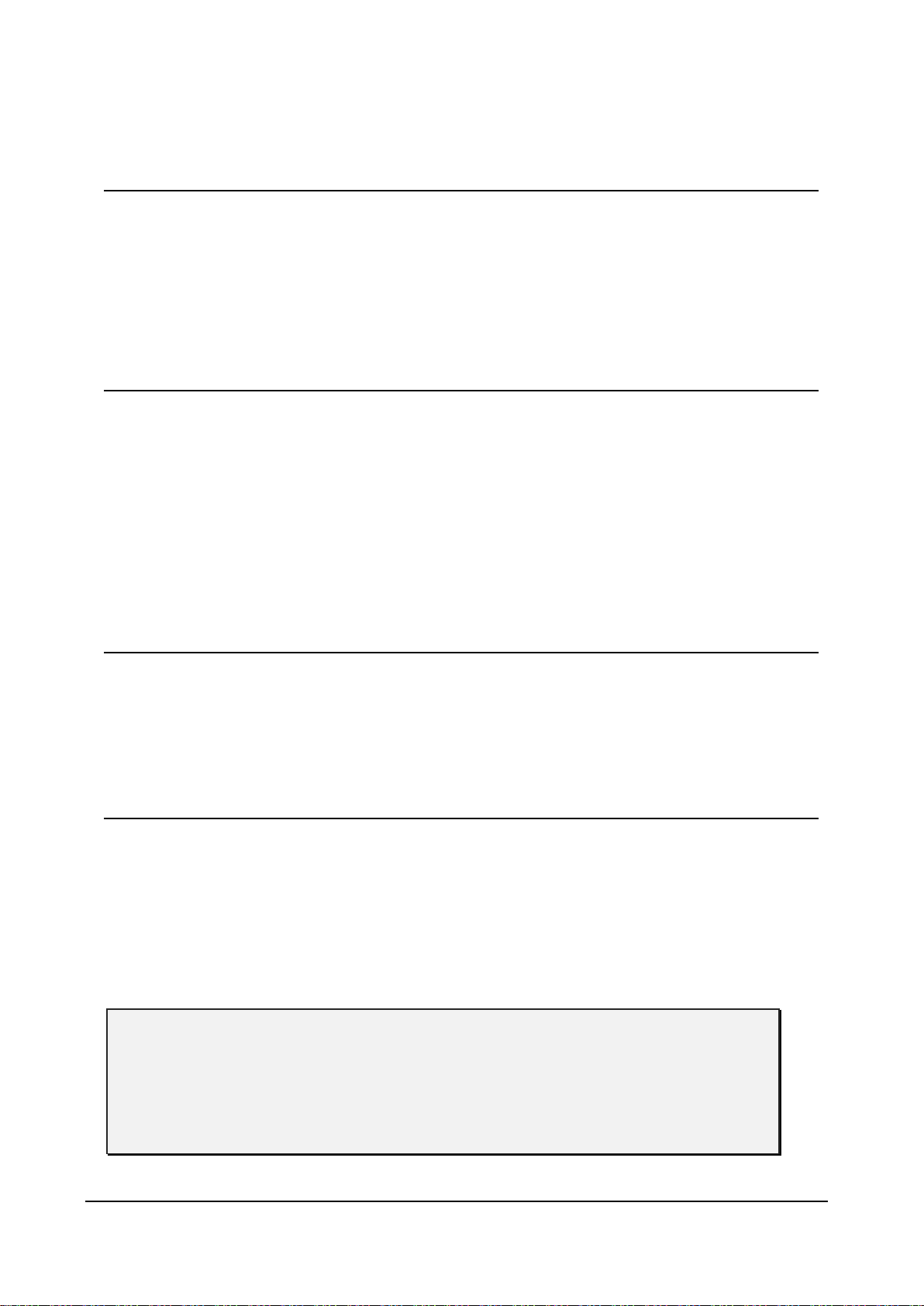

1. Introduction

The PET-7H24M is an high speed data acquisition devices built-in a Ethernet communication port

for data transfer over the network and it includes 4 high-speed 24-bit differential Analog input

channels analog inputs (128 KHz sample and hold for 4 channels), 2 Analog Output channels, 3

Digital Input channels, 4 Digital Output channels and 1 Encoder Input channel. The module

provides a programmable input range on all analog channels, and the Digital Output can be set to

output with short-circuit and over load protection. 1 Encoder Input channel can be configured as

Quadrant, Pulse/Direction or CW/CCW input mode. The PET-7H24M also provides 4 kV ESD

protection as well as 2500 VDC intra-module isolation. In addition, the 24-bit ADC includes built-in

Sinc3 filtering to adjust the appropriate sampling rate and filter out modulator and signal noise.

The PET-7H24M is not only suitable for a wide range of mobile/portable measurement

applications, but also for precision signal measurement.

PET-7H24M supports more kinds of trigger modes for A/D conversion: software trigger, analog

Input trigger. The software trigger can acquire a sample whenever needed, Analog input trigger

mode, when the analog input value is higher or lower than the set specific voltage value, it triggers,

and the A/D collection of N data is started.

PET-7H24M Series User Manual, version 1.0.0 P.5

Page 6

Total simultaneous sampling channels

Maximum sampling rate per channel

2~4

60 KHz

1.1. Features

The PET-7H24M series family offers the most comprehensive configuration to meet specific

application requirements. The following list shows the features designed to simplify installation,

configuration and application.

Data transmission mode

1. Continuous transmission (Maximum sampling rate of 60 kHz per channel)

After starting A/D acquisition, data is continuously transmitted to the Host PC.

2. After collecting N data samples, the data is transferred to the Host PC (Maximum sampling

rate of 128 kHz per channel)

a. After starting A/D acquisition, the data will be temporarily stored in the memory on the

PET-7H24M module, and wait until a command is received from the Host PC, before

transferring the collected data to the Host PC.

b. The memory capacity allows temporary storage of up to 30 million data samples,

Storage time:

(b1) 125 seconds at a sampling rate of 60 kHz

(b2) 62.5 seconds at a sampling rate of 128 kHz

PET-7H24M Series User Manual, version 1.0.0 P.6

Page 7

Total simultaneous sampling channels

Maximum sampling rate per channel

1 ~ 4

128 KHz

A/D trigger mode

1. Software A/D Data Acquisition mode

The A/D acquisition parameters are configured via a command from the Host PC. The

continuous A/D acquisition or the acquisition of N data samples begins after the

command is triggered.

2. Analog Input Trigger mode

The A/D acquisition parameters are configured via a command from the Host PC, When

the analog input value is higher or lower than the set specific voltage value, the A/D

acquisition of the N data is started.

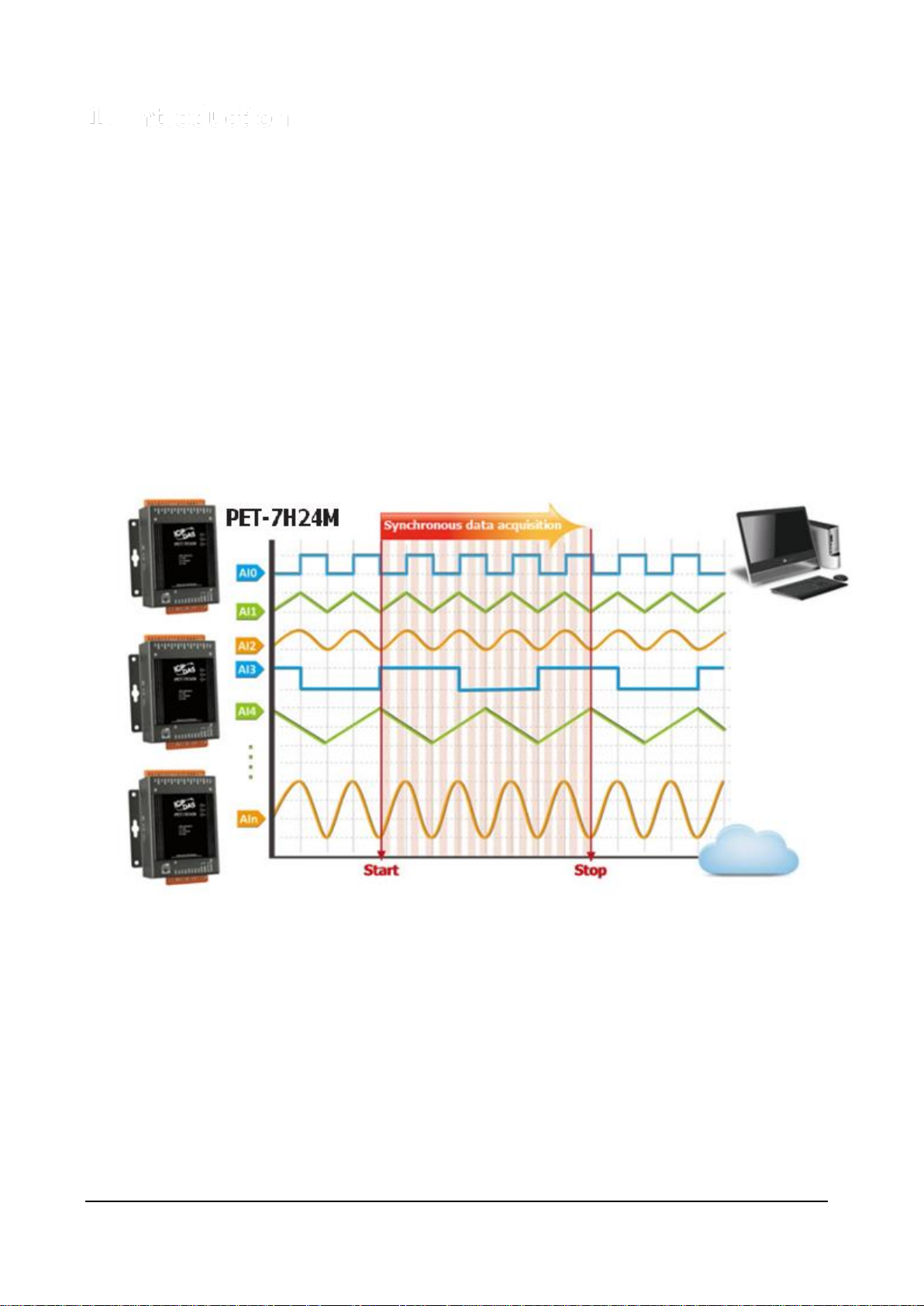

Analog Input Trigger

Analog Input Trigger is triggered when the voltage signal of the specified analog input

channel is higher or lower than a certain voltage setting. In addition, the user can also

specify the trigger voltage level range of the input signal. Once the signal leaves the high and

low level region or the signal enters the high and low level region, it is triggered to start the

acquisition.

1. Above High: The signal is triggered above the high level and collects N data.

2. Below Low: The signal is triggered below the low level and collects N data

PET-7H24M Series User Manual, version 1.0.0 P.7

Page 8

3. Leave-region: Trigger when the signal leaves the high and low level region, collect N data

4. Entry-region: Trigger when the signal enters the high and low level region, collect N data

PET-7H24M Series User Manual, version 1.0.0 P.8

Page 9

Built-in Web Server

Each PET-7H24M module has a built-in web server that allows users to easily configure,

monitor and control the module from a remote location using a regular web browser.

Communication Security

Account and password are required when logging into the PET-7H24M web server. An IP

address filter is also included, which can be used to allow or deny connections with specific

IP addresses.

Modbus/TCP Protocol

The Modbus/TCP slave function on the Ethernet port can be used to provide data to remote

HMI/SCADA software built with Modbus/TCP driver.

Automatic MDI / MDI-X Crossover for Plug-and-play

RJ-45 port supports automatic MDI/MDI-x that can automatically detect the type of

connection to the Ethernet device without requiring special straight or crossover cables.

PET-7H24M Series User Manual, version 1.0.0 P.9

Page 10

Software Support

Supported Operating Systems

Windows 7/8/10 and Linux

Software Compatibility

Microsoft VC, C#, VB.NET SDK API and Demo

NI LabVIEW Toolkit and Demo

C/C++ library and Demo for Linux

Highly Reliable Under Harsh Environment

PET-7H24M is housed in a metal shell/case with a column-like ventilator that helps to cool

the working environment inside the shell/case.

Operating Temperature: -25 ~ +75 °C

Storage Temperature: -30 ~ +80 °C

Humidity: 10 ~ 90% RH (non-condensing)

PoE

The PET-7H24M module has integrated Power-over-Ethernet (PoE), it allows power and data

to be carried over a single Ethernet cable, so a device can operate solely from the power it

receives through the data cable. This innovation allows greater flexibility in office design,

PET-7H24M Series User Manual, version 1.0.0 P.10

Page 11

higher efficiency in systems design, and faster turnaround time in set-up and

implementation. The PET-7H24M module feature true IEEE 802.3af-compliant (classification,

Class 1) Power over Ethernet (PoE) using both Ethernet pairs (Category 5 Ethernet cable).

The PET-7H24M module can receive power from an auxiliary power sources like AC adapters

and battery in addition to the PoE enabled network. This is a desirable feature when the

total system power requirements exceed the PSE's(power sourcing equipment) load capacity.

Furthermore, with the auxiliary power option, the PET-7H24M module can be used in a

standard Ethernet (non-PoE) system.

When using PoE devices like PET-7H24M, you can choose ICP DAS “PoE”

switch —”NS-205PSE” as the power source, NS-205PSE automatically detects the connected

devices whether they are PoE devices or not. This mechanism ensures NS-205PSE to work

with both PoE and non-PoE devices coordinately at the same time.

Being as a power source for PoE devices, NS-205PSE requires its power input ranging from

+46 ~ +55VDC.

PET-7H24M Series User Manual, version 1.0.0 P.11

Page 12

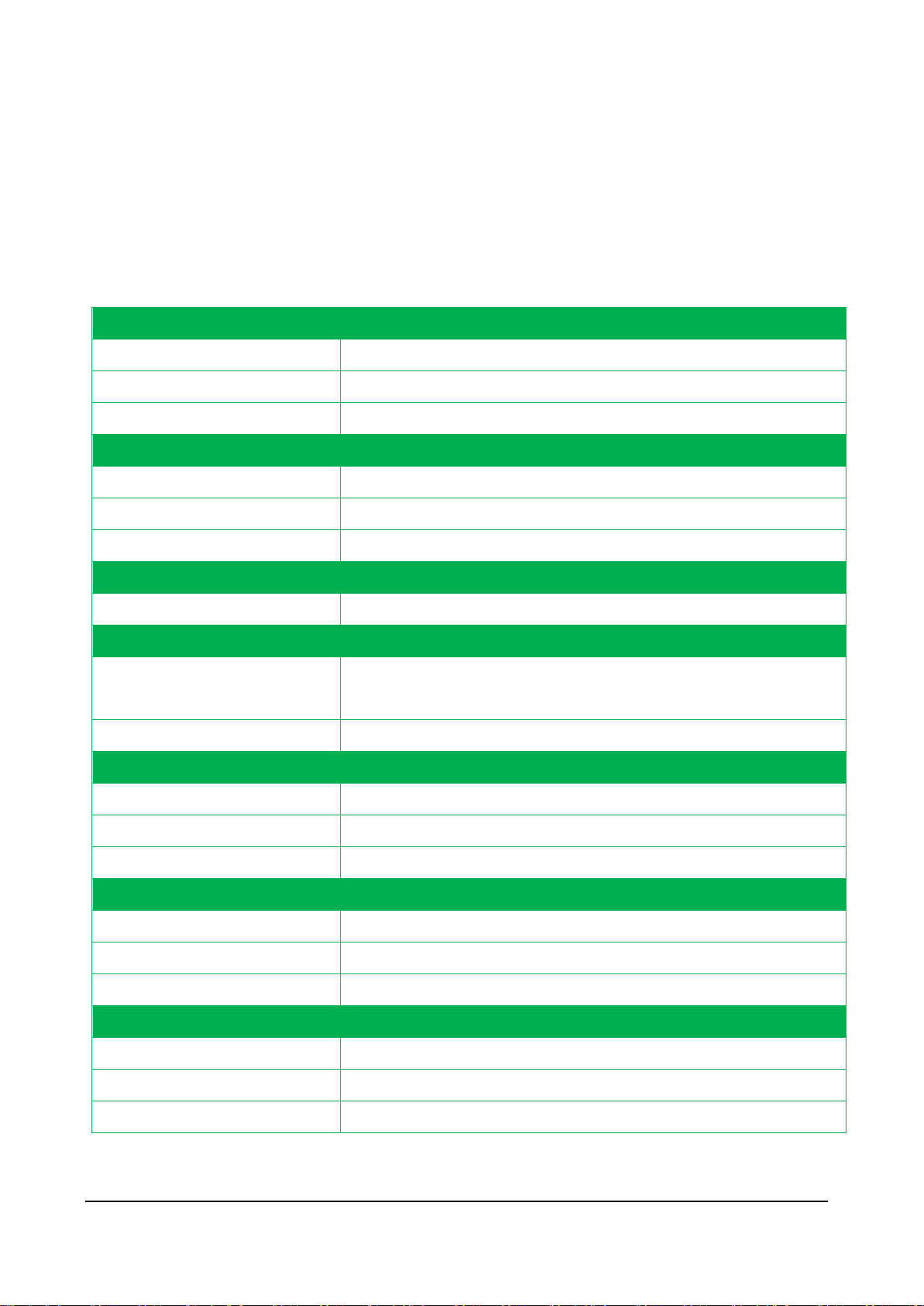

Communication

Ethernet Port

1 x RJ-45, 10/100 Base-TX (Auto-negotiating, Auto MDI/MDI-X)

PoE

Yes

Security

ID, Password and IP Filter

LED Indicators

for System Running

Yes

for Ethernet Link/Act

Yes

for POE Power

Yes

2-Way Isolation

I/O

2500 VDC

EMS Protection

ESD (IEC 61000-4-2)

+/-4 kV Contact for Each Terminal and +/-8 kV Air for Random

Point

EFT (IEC 61000-4-4)

+/-4 kV for Power

Power

Reverse Polarity Protection

Yes

Powered from Terminal Block

+12 ~ +48 VDC

Consumption

2.6 W (Max.)

Mechanical

Dimensions (W x L x H)

76 mm x 120 mm x 38 mm

Installation

DIN-Rail or Wall Mounting

Enclosures

Metal

Environment

Operating Temperature

-25 ~ +75 °C

Storage Temperature

-30 ~ +80 °C

Humidity

10 ~ 90 % RH, Non-condensing

1.2. Specification

The table below summarizes the specifications of the PET-7H24M.

System Specification

PET-7H24M Series User Manual, version 1.0.0 P.12

Page 13

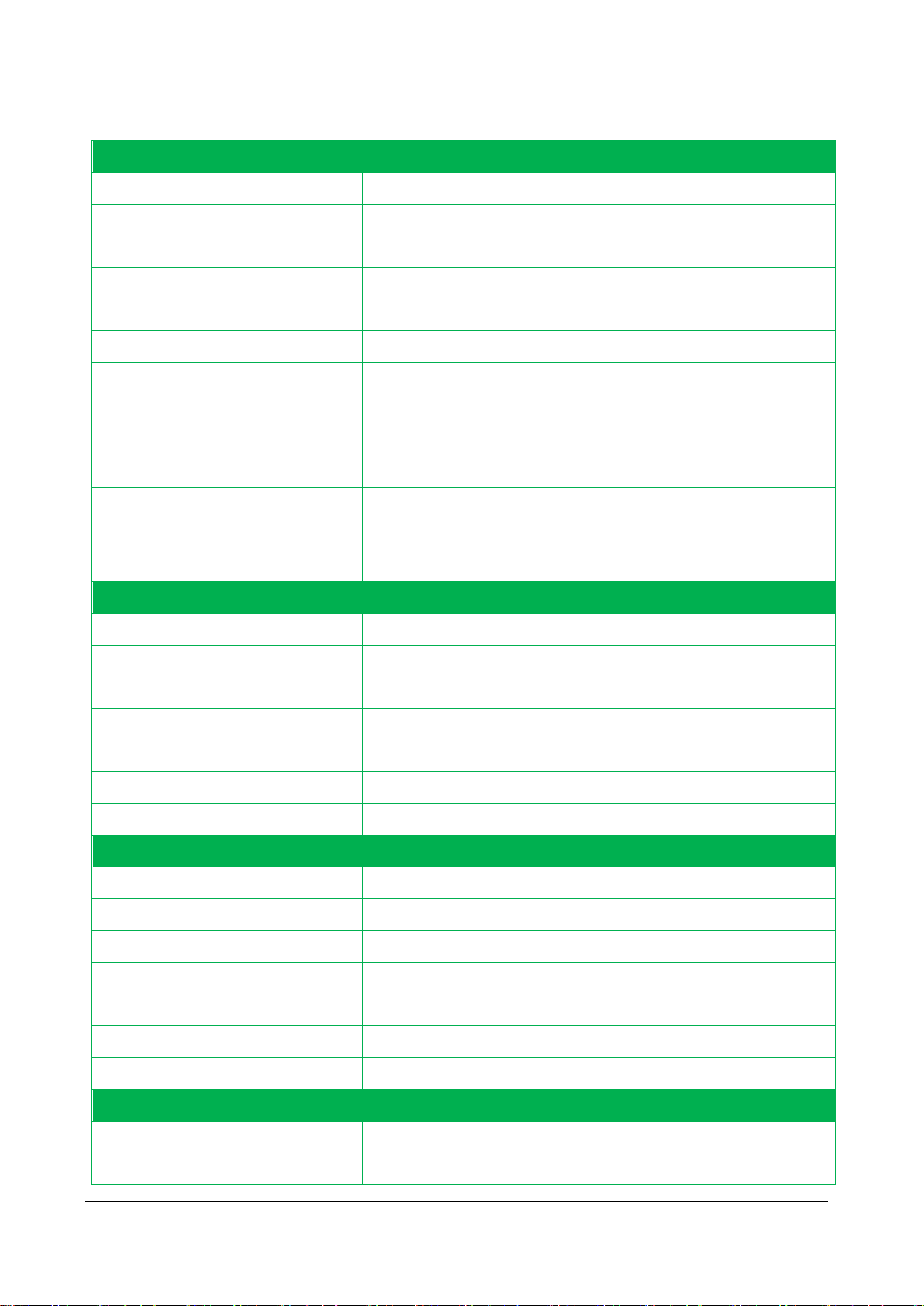

Analog Input

Channels

4 Differential (Simultaneously)

Resolution

24-bit

Sampling Rate

128 KS/s (Each Channel)

Bipolar Input (Programmable)

+/- 10 V, +/- 5 V, +/- 2.5 V, +/- 1.25 V, +/- 0.625 V, ±300mV

±150mV ±75mV ±40mV ±20mV

FIFO Size

4 K Sample

Accuracy

+/- 0.01 % of FSR @±10V

+/- 0.02 % of FSR @±5V,±2.5V,±1.25V,±0.625V

+/- 0.1 % of FSR @±300mV, ±150mV, ±75mV, ±40mV

+/- 0.2 % of FSR @±20mV

AD Trigger Mode

(Programmable)

Software 、Analog Input trigger

Input Impedance

2M Ohm

Analog Output

Channels

2 Single-ended

Type

±10V, ±5V , ±0~5V, 0~10V

Resolution

12-bit

Accuracy

+/- 0.01 % of FSR @±10V, ±5V, 0~10V

+/- 0.02 % of FSR @0~5V

Output Capacity

10V @20mA

Slew Rate

0.83V/us

Digital Input

Channels

3

Contact

Wet Contact

Sink/Source (NPN/PNP)

Sink/Source

On Voltage Level

+5 VDC ~ 30 VDC

Off Voltage Level

2 VDC Max.

Input Impedance

10K Ohm

Isolation

2500 VDC

Digital Output

Channels

4

Type

Isolated Open Collector

I/O Specification

PET-7H24M Series User Manual, version 1.0.0 P.13

Page 14

Sink/Source(NPN/PNP)

Sink

Load Voltage

+5 VDC ~ 30 VDC

Load Current

100 mA at 25°C

Short-circuit Protection

Yes

Overload Protection

1.3A

Isolation

2500 VDC

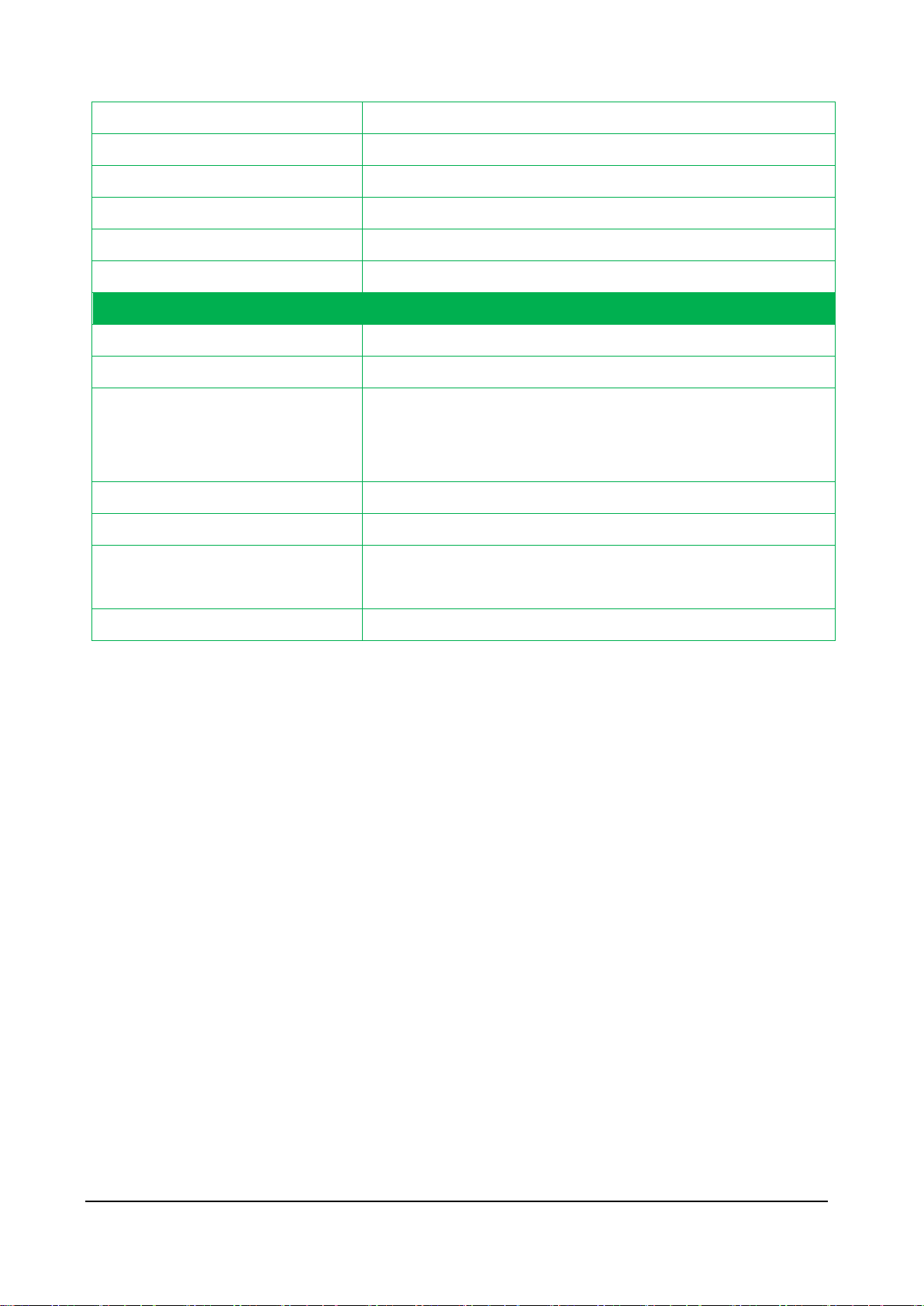

Encoder Input

Counter

32-bit

Encoder Mode

Quadrant/CW/CCW and Pulse/Dir

Counting Rate

Quadrant Counting : 2MHz(Max.)

CW/CCW : 6MHz(Max.)

Pulse/Dir : 6MHz(Max.)

On Voltage Level

+3.5 ~+5 VDC

Off Voltage Level

+0.8 VDC Max.

Programmable digital filter

0.55 ~ 33.3μs (7 steps)

Isolation

2500 VDC

PET-7H24M Series User Manual, version 1.0.0 P.14

Page 15

LED Indicators

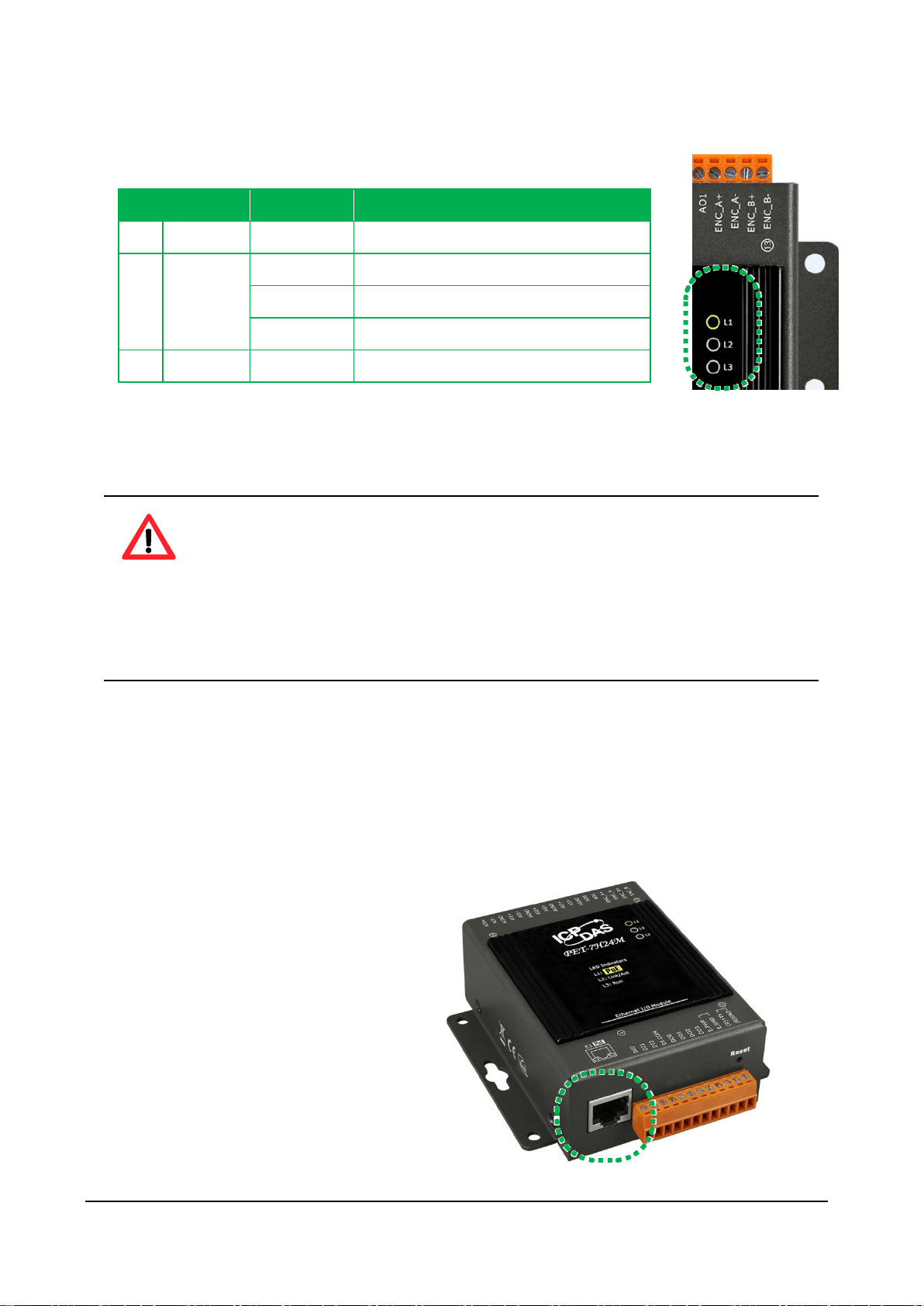

J2 Connector (Pin 13 ~ 30)

Reset Button

J1 Connector (Pin 1 ~ 12)

Ethernet Port

1.3. Overview

PET-7H24M is equipped with several interfaces and peripherals that can be integrated with

external systems. Here is an overview of the components and its descriptions.

PET-7H24M Series User Manual, version 1.0.0 P.15

Page 16

LED Indicator

LED Action

Meaning

L1

PoE

ON

When unit power is supplied via PoE.

L2

Link/ACT

ON

Ethernet link detected

OFF

No Ethernet link detected

Flashing

Ethernet packet received

L3

RUN

Flashing

Firmware is running

LED Indicators

The PET-7H24M has 3 LED indicators shown as below.

Tips & Warnings

If the Run LED does not display the information as above, the following steps

should be taken:

Step 1: Switch the power off

Step 2: Switch the power on and double-check the LED indicators

Ethernet Port

The PET-7H24M has an Ethernet port that can be connected to a computer or device via an

Ethernet cable.

The L2 indicators display the status of the

Ethernet port.

PET-7H24M Series User Manual, version 1.0.0 P.16

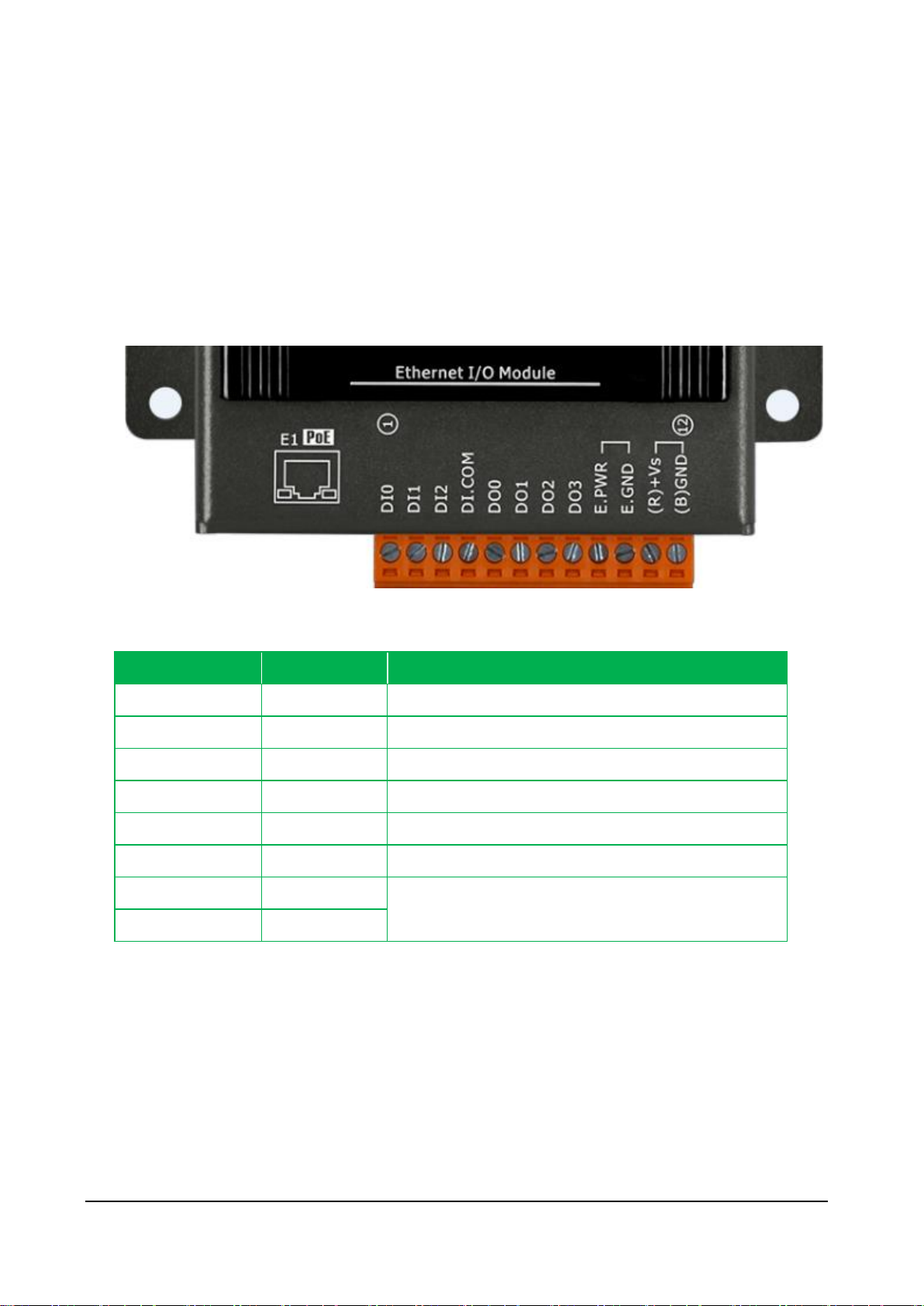

Page 17

Signal

Direction

Description

DI0 ~ DI2

Input

Digital Input channels 0 to 3.

DI.COM

Common source

DO0 ~ DO3

Output

Digital Output channels 0 to 3.

DGND

-

Digital Ground.

E.PWR

External power for Digital Output

E.GND

External Ground for Digital Output

(R) +Vs

(R) +Vs

Power Input (+12 ~ +48 VDC)

(B) GND

(B) GND

JP1 Connector

The JP1 connector has 12 pins arranged in 1 row. For more detailed information regarding

the pin assignments of the J1 Connector, please refer to “1.2. Specification”

The pin assignments of the connector are as follows:

PET-7H24M Series User Manual, version 1.0.0 P.17

Page 18

Signal

Direction

Description

AI0+ ~ AI3+

Input

Analog Input channels 0 to 3.

AI0- ~ AI3-

AGND

-

Analog Input Ground.

AO0 ~ AO1

Output

Analog Output channels 0 to 1.

ENC_A+、

ENC_B+

Input

Encoder input

ENC_A-

ENC_B-

JP2 Connector

The JP2 connector has 18 pins arranged in 1 row. For more detailed information regarding

the pin assignments of the J2 Connector, please refer to “1.2. Specification”

The pin assignments of the connector are as follows:

PET-7H24M Series User Manual, version 1.0.0 P.18

Page 19

Data Item

Factory Default Settings

IP

192.168.255.1

Gateway

192.168.0.1

Mask

255.255.0.0

DHCP

Disable

Factory Default Setting

Original factory calibration value

Factory Default Setting

A default user account consists of an account name “Admin” and a password “Admin”.

Factory Default Setting

Empty, there is no limit to allow any outgoing access.

Reset Button

The Reset button provides user with a quick

and easy way to resort the default setting.

Press the Reset button continuously for 5

seconds, and then release it. The device will

restore to factory default settings.

The table below lists the default settings after pressing reset button.

Network Settings

Gain/offset value of AI calibration

Account Management

Accessible IP Settings

PET-7H24M Series User Manual, version 1.0.0 P.19

Page 20

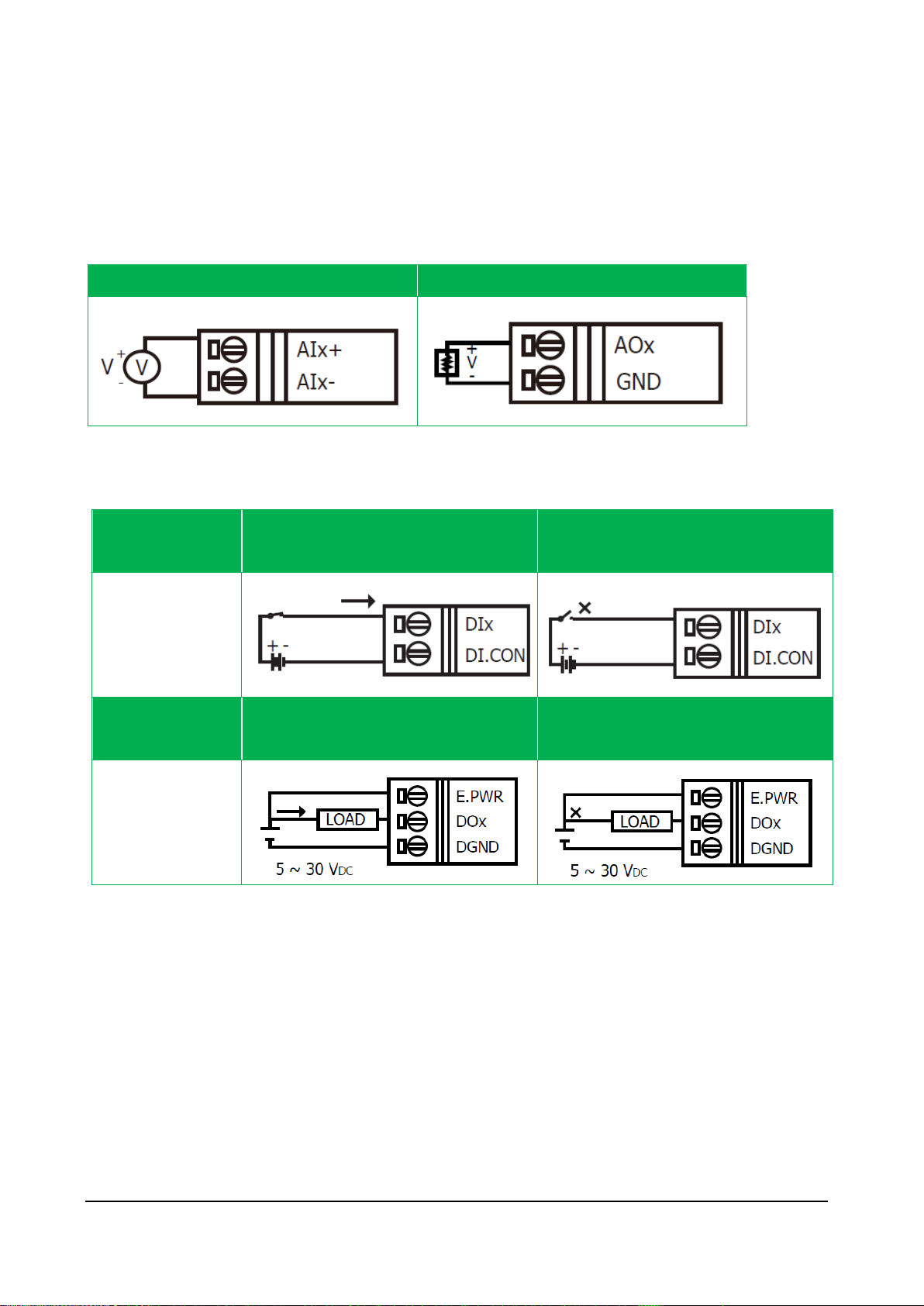

Analog Input (Voltage)

Analog Output (Voltage)

Digital

Input/Counter

ON State

Readback as 1

OFF State

Readback as 0

Wet Contact

(Sink)

Digital Output

ON State

Readback as 1

OFF State

Readback as 0

Open Collector

(Sink)

1.4. Wiring Diagram

The wiring diagram of the PET-7H24M is illustrated on the following figure.

PET-7H24M Series User Manual, version 1.0.0 P.20

Page 21

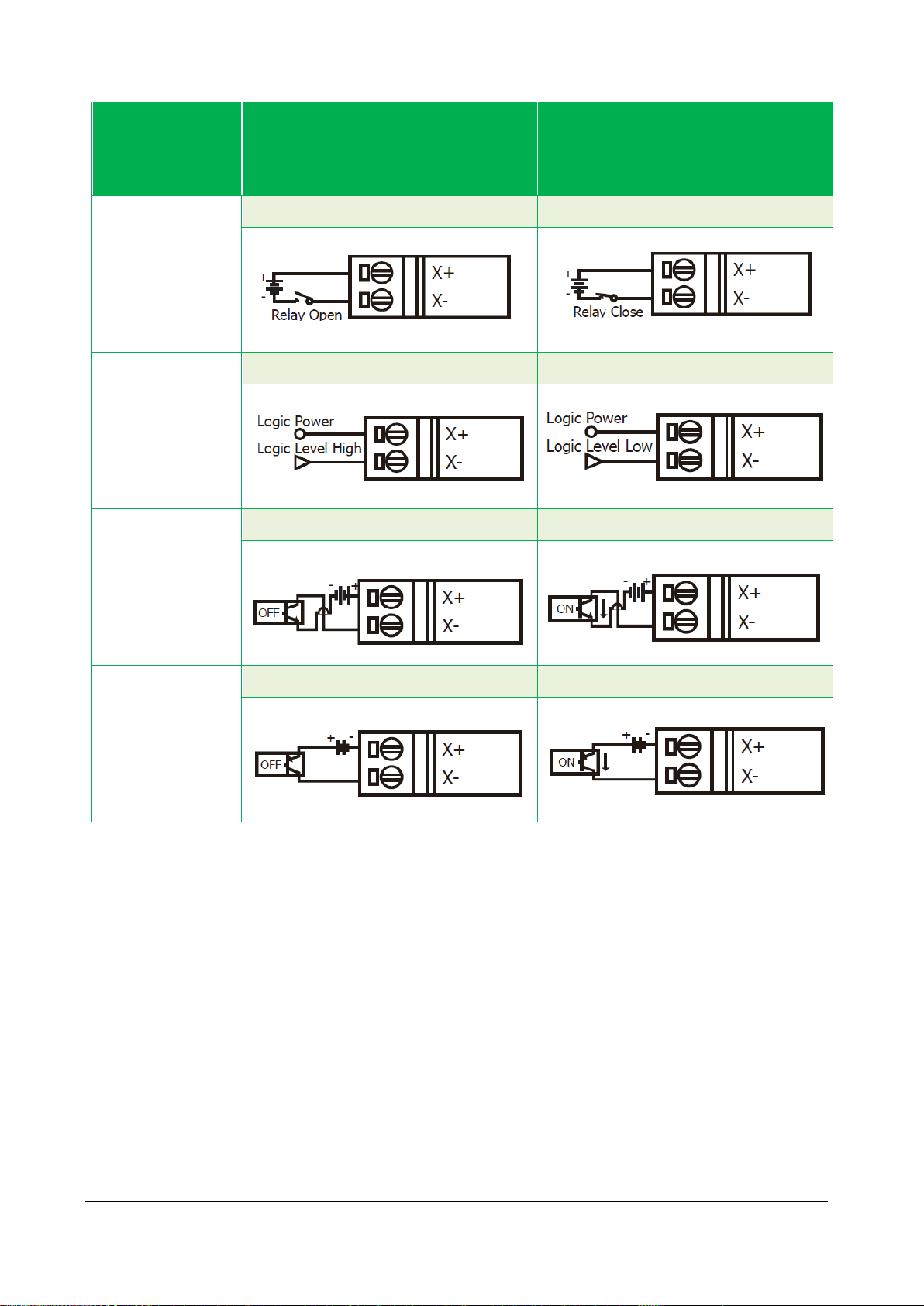

Encoder

Input/Output

Type

ON State

Readback as 0

OFF State

Readback as 1

Relay Contact

Relay ON

Relay OFF

TTL/CMOS Logic

Voltage > 3.5 V

Voltage > 0.8 V

NPN Output

Open Collector ON

Open Collector OFF

PNP Output

Open Collector ON

Open Collector OFF

PET-7H24M Series User Manual, version 1.0.0 P.21

Page 22

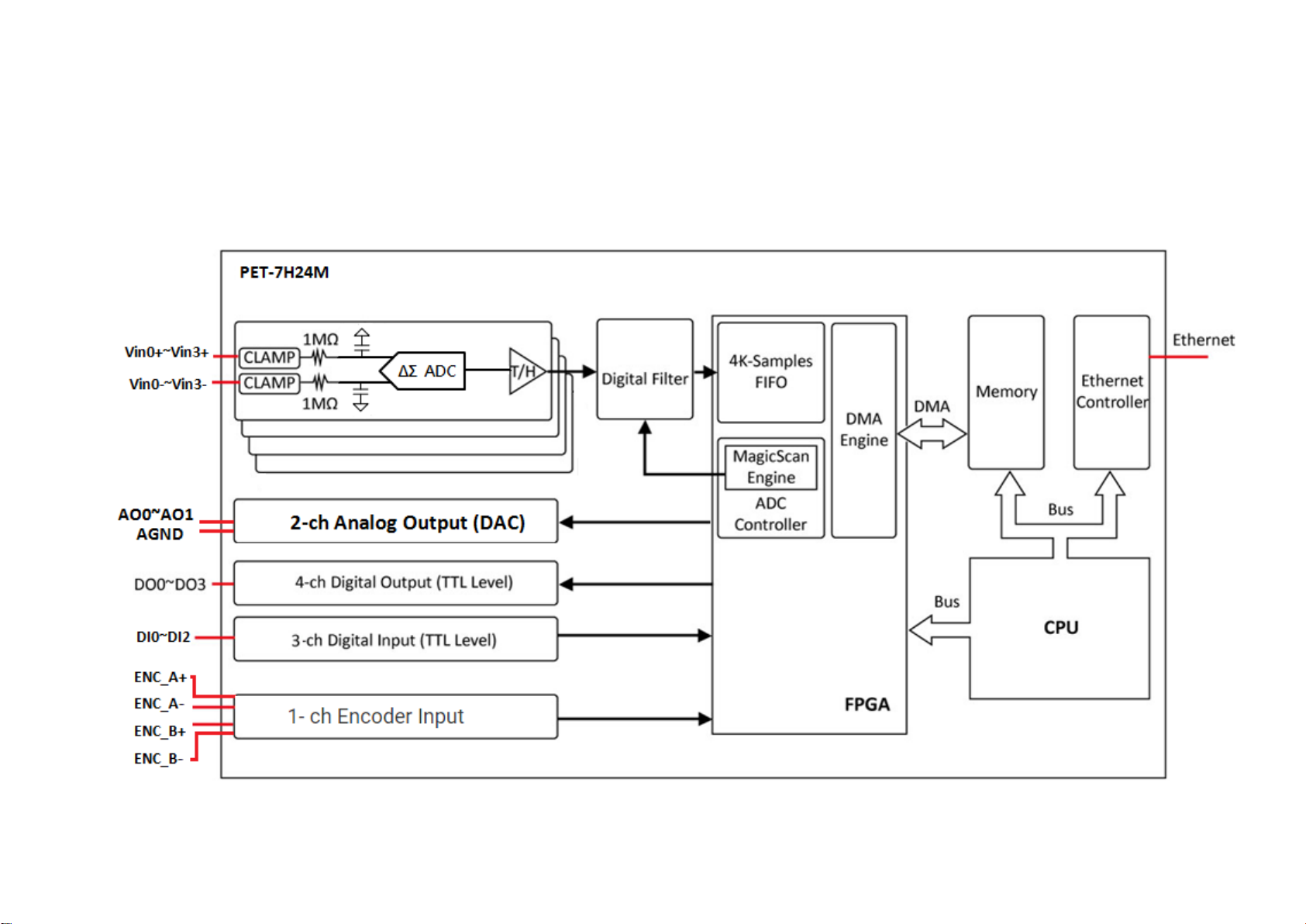

1.5. Block Diagram

PET-7H24M functions are illustrated in the block diagram shown here.

Page 23

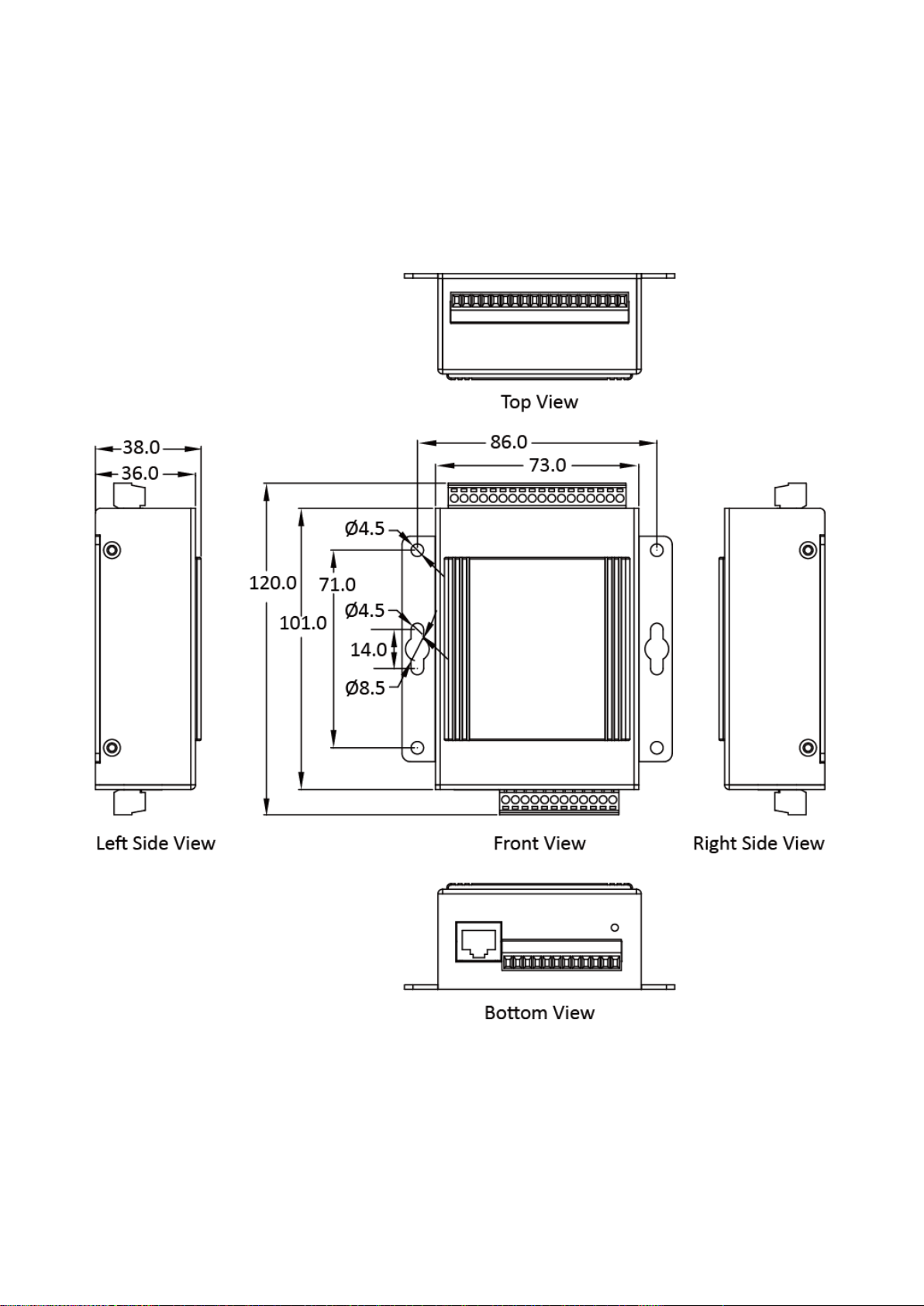

1.6. Dimension

The diagrams below provide the dimensions of the PET-7H24M to use in defining your enclosure

specifications. All dimensions are in millimeters.

Page 24

PET-7H24M

Quick Start Guide

2.4 mm Screw Driver

M3 x 6L Screw * 4

44 mm DIN-Rail clip

2. Getting Started

If you are a new user, begin with this chapter, it includes a guided tour that provides a basic

overview of installing, configuring and using the PET-7H24M.

Before starting any task, please check the package contents. If any of the following package

contents are missing or damaged, contact your dealer on distributor.

Before you work with the PET-7H24M, you should have a basic understanding of hardware

specification, such as the dimensions, the usable input-voltage range of the power supply, and the

type of communication interfaces.

For more information about the hardware details, please refer to “1.2. Specification”

For more information about the hardware dimensions, please refer to “1.6. Dimension”

PET-7H24M Series User Manual, version 1.0.0 P.24

Page 25

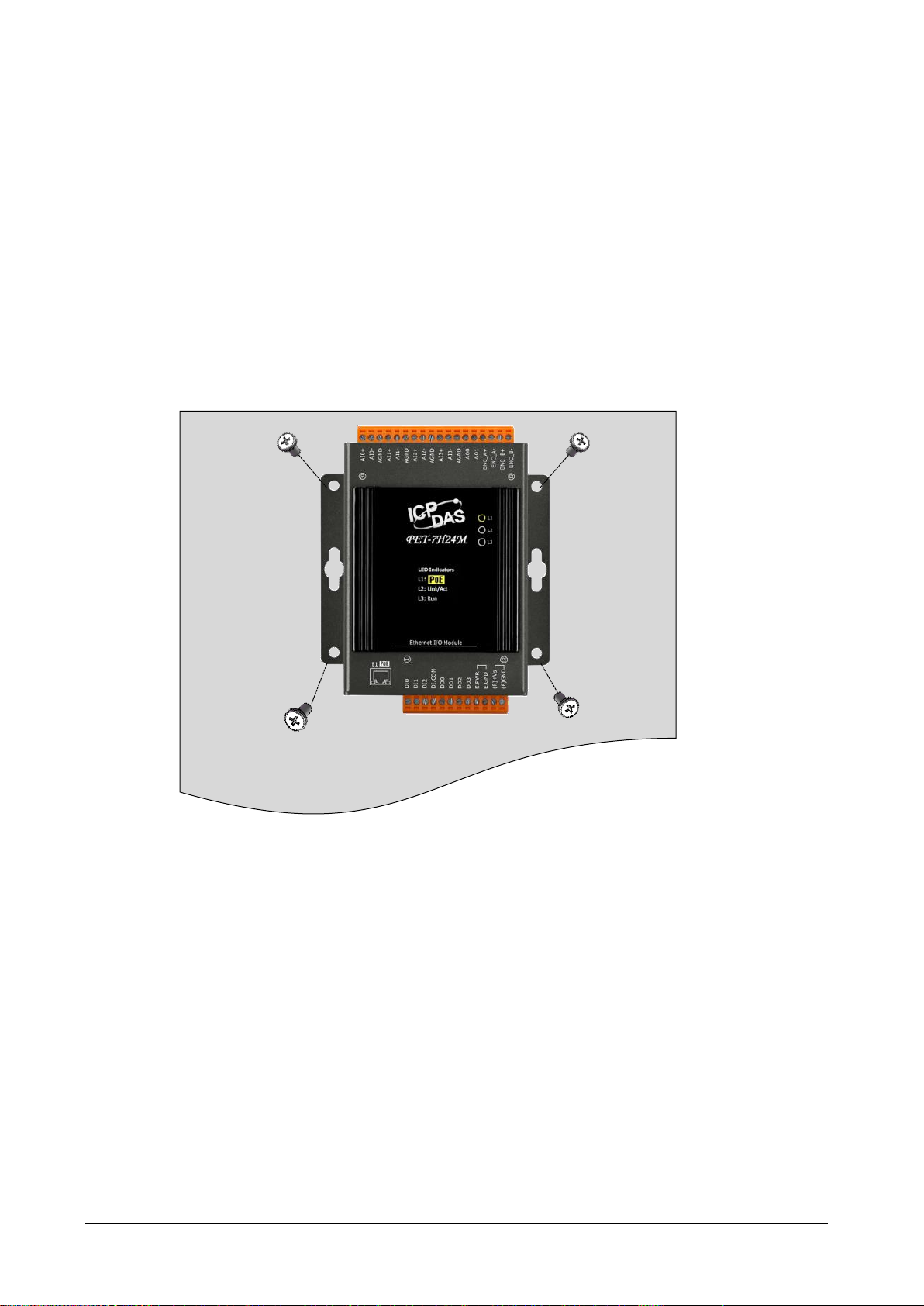

2.1. Mounting the Hardware

The PET-7H24M can be mounted either directly to a wall/panel.

Step 1: Use the included screws and a screw driver to attach the PET-7H24M to the wall/panel

Step 2: Fasten the screws securely

PET-7H24M Series User Manual, version 1.0.0 P.25

Page 26

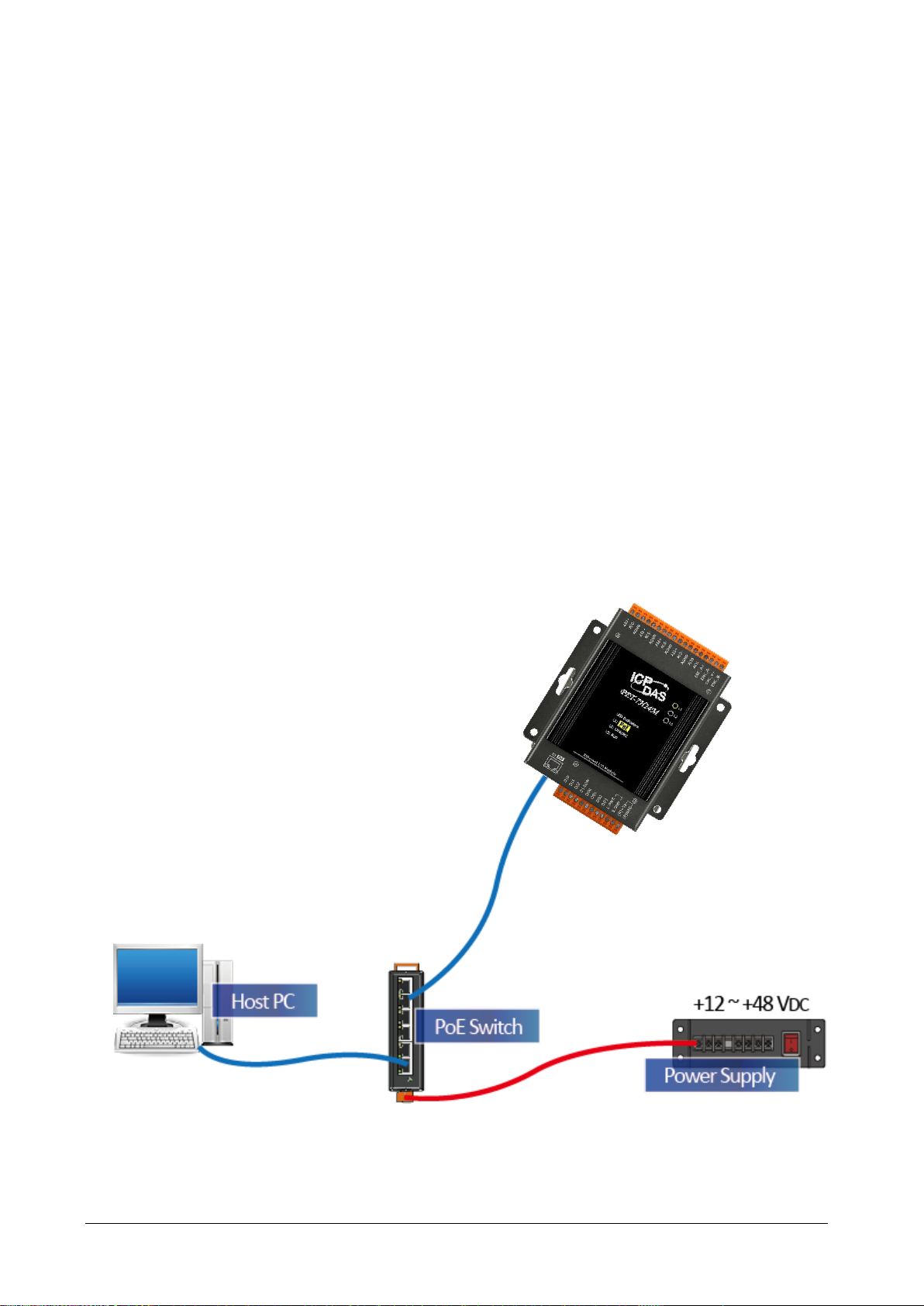

2.2. Deploying a Basic PET-7H24M System

Here is a simple application for using the PET-7H24M that is shown below.

There are two ways for the PET-7H24M module getting the power. One is through Ethernet by a

PoE switch; the other is as usual through wiring by an external power. External power should

range from +12 VDC to 48 VDC. The reason we keep the second way is because it might be useful

if someday or somehow you have different applications. PET-7H24M module is equipped with a

LED, which indicates whether the power is supplied by a PoE switch.

PoE

i. Connect PC to the Ethernet port via the PoE switch.

ii. Connect the power supply to the PoE switch, which supplies power to the PET-7H24M.

PET-7H24M Series User Manual, version 1.0.0 P.26

Page 27

External Power supply

i. Connect PC to the Ethernet port via the Ethernet switch.

ii. Connect the power supply to the switch and PET-7H24M.

Tips & Warnings

Network: connections with fewer switches between the PC and the HSDAQ

device(s) can improve AI acquisition performance. It is recommended to connect

the PC and the HSDAQ device(s) to the same switch/hub.

PET-7H24M Series User Manual, version 1.0.0 P.27

Page 28

2.3. Installing the HSDAQ Utility

The HSDAQ Utility is a useful tool that provides a quick and easy way to update firmware,

configure Ethernet settings, and download files to PET-7H24M from PC.

Refer to chapter 4.2. HSDAQ Utility for more details.

Step1: Get the HSDAQ Utility tool

The HSDAQ Utility can be obtained from the following link:

http://www.icpdas.com/en/download/show.php?num=2327&model=PET-7H24M

Step 2: Follow the prompts to complete the installation

After the installation has been

completed, there will be a new

short-cut for HSDAQ Utility on the

desktop.

PET-7H24M Series User Manual, version 1.0.0 P.28

Page 29

Item

Default

IP Address

192.168.255.1

Subnet Mask

255.255.0.0

Gateway

192.168.0.1

2.4. Using HSDAQ Utility to Assign an IP address

The PET-7H24M is an Ethernet device, which comes with a default IP address, therefore, you must

first assign a new IP address to the PET-7H24M.

The factory default IP settings are as follows:

Step 1: Run the HSDAQ Utility

Double-click the HSDAQ Utility shortcut on your desktop.

PET-7H24M Series User Manual, version 1.0.0 P.29

Page 30

Step 2: Press choose “Search” from the “Tools” menu

After choosing Search from Tools menu, that will search all of the PET-7H24M modules on

your network.

Step 3: Choose the field “192.168.255.1” and then choose “IP setting” from the toolbar

Choose default value “192.168.255.1” for fields in the list and double-click.

PET-7H24M Series User Manual, version 1.0.0 P.30

Page 31

Step 4: Assign a new IP address and then choose “Set” button

You only can manually assign an IP address.

Step 5: Click “OK” button

When the setup is completed, click the "OK" button.

Step 6: Wait for PET-7H24M reboot

PET-7H24M Series User Manual, version 1.0.0 P.31

Page 32

Acquisition

Trigger

Continuous

N Sample

Software AD

20~60KHz

60 kHz ~ 128 KHz

Analog Input Trigger

-

20 Hz ~ 128 KHz

3. Operation

Once connected to the network, the PET-7H24M module can be remotely accessed and configured

through software from anywhere on the network and the sampling data only can be acquired by

software over Ethernet. So far, the device doesn’t operate as a stand-along data logger. The only

one connection at a time is allowed to acquire data from PET-7H24M.

There are two different data acquisition modes and several trigger modes of analog input

operation.

The following chart shows the acquisition and trigger modes and their operation frequency of

each combination.

Tips & Warnings

Maximum 30,000,000 records in N Sample Mode

125 sec (60 KHz), 62.5 sec (128 KHz) of 30,000,000 records in software AD

trigger.

PET-7H24M Series User Manual, version 1.0.0 P.32

Page 33

Ethernet

AI0

AI3

…

Software trigger

DMA

Internal Clock

CON1

PGA

Sampling

Hold

FIFO

Memory

ADC

3.1. Continuous Acquisition

Software AD Trigger 3.1.1.

In continuous acquisition and software AD trigger, Send a start command from PC over the

Ethernet to PET-7H24M to start the AD conversion. The analog input value is continuously

acquired and converted to digital data. The data accumulated to a network packet size returns to

the PC. The process of acquiring data is continuous until a stop command is sent over the

Ethernet.

The sample rate can range from 20 to 60K Hz on local networks. (Lower over the Internet or

wireless networks).

There are parameters below that need to be specified:

Sampling rate (20~60KHz)

Scan channels

The trigger mode is software AD trigger

PET-7H24M Series User Manual, version 1.0.0 P.33

Page 34

PET-7H24M Series User Manual, version 1.0.0 P.34

Page 35

3.2. N Sample Acquisition

Software AD Trigger 3.2.1.

In N sample acquisition and software AD trigger, Send a start command from PC over the Ethernet

to PET-7H24M to start the AD conversion. The analog input value is continuously acquired and

converted to digital data until the total number of samples reaches. Send a command to get the all

acquisition data over the Ethernet.

The sample rate can range from 20 Hz to 128K Hz.

There are some parameters that need to be specified:

Sampling rate

Scan channels

Sampling Count (Maximum 30,000,000 records)

The trigger mode sets to the software AD trigger.

PET-7H24M Series User Manual, version 1.0.0 P.35

Page 36

AI0

AI3

…

DMA

Internal Clock

CON1

PGA

Sampling

Hold

FIFO

Memory

ADC

Ethernet

Analog Input Trigger 3.2.2.

The analog input trigger is triggered when the input voltage signal is above or below a certain

voltage setting. In addition, the analog trigger can be used to detect the instantaneous change in a

continuous voltage signal. The user can specify the trigger voltage level range of the input signal.

Once the range is exceeded or the voltage level is entered, the data is triggered to start collecting

data.

There are some parameters that need to be specified:

Sampling rate (20~128KHz)

Scan channels

Sampling Count (Maximum 30,000,000 records)

Set the high or low level voltage value

Trigger mode set to analog input trigger

AI trigger

PET-7H24M Series User Manual, version 1.0.0 P.36

Page 37

PET-7H24M Series User Manual, version 1.0.0 P.37

Page 38

4. Tools and SDKs

PET-7H24M supports a number of external tools to aid in developing your applications

4.1. LabVIEW

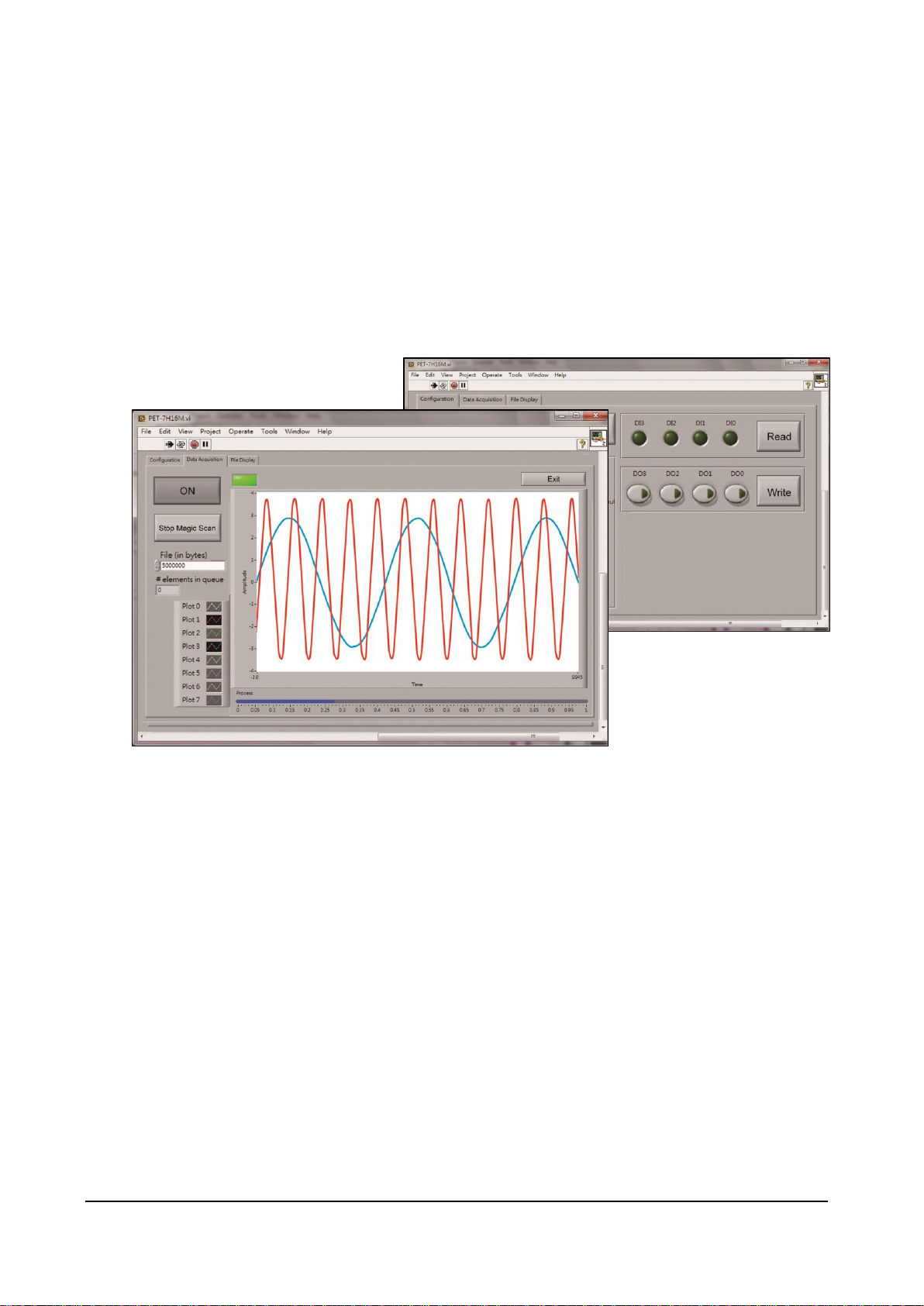

LabVIEW is the best way to acquire, analyze, and present data. LabVIEW delivers a graphical

development environment that can be used to quickly build data acquisition quickly,

instrumentation and control systems, boosting productivity and saving development time. With

LabVIEW, it is possible to quickly create user interfaces that enable interactive control of software

systems. To specify your system functionality, simply assemble block diagram – a natural design

notation for scientists and engineers.

The document containing the detailed instructions for linking to the PET-7H24M using the Modbus

protocol is located on the shipped

http://www.icpdas.com/web/product/download/io_and_unit/ethernet/pet-7h16m/software/utili

ty/LabVIEW.zip

PET-7H24M Series User Manual, version 1.0.0 P.38

Page 39

4.2. HSDAQ Utility

HSDAQ Utility is used to graphically display and easily data logging for ET-7H24 module.

HSDAQ Utility tool as ET-7H24 Data Logger

ET-7H24 Data Logger provides a single ET-7H24 connect as Data Logger function.

1. When connect to ET-7H24, it will get the parameters of gain and offset for calibration, they

are used to calibrate the raw data from ET-7H24.

2. It also gets the configurations for sampling, set the new configurations for application then

start, it will begin to get the sampling data from ET-7H24 and save the data to files.

3. After finish sampling data or stop data logger, it can show the sampling result as plot view.

PET-7H24M Series User Manual, version 1.0.0 P.39

Page 40

System requirement

Minimum system requirements for HSDAQ Utility are given below:

266MHz 32-bit(x86) or 64-bit(x64) processor

64 MB of system memory

Support for Super VGA graphics

At least 20 MB of available space (Need more)

Microsoft Windows 2000 or later(32-bit or 64-bit Windows Operating System)

Operating system of Windows requirement

32-bit(x86) 64-bit(x64)

Microsoft Windows 2000 -

Microsoft Windows XP 32-bit Microsoft Windows XP 64-bit

Microsoft Windows 2003 32-bit Microsoft Windows 2003 64-bit

Microsoft Windows Vista 32-bit Microsoft Windows Vista 64-bit

Microsoft Windows 7 32-bit Microsoft Windows 7 64-bit

Microsoft Windows 2008 32-bit Microsoft Windows 2008 64-bit

Microsoft Windows 8 32-bit Microsoft Windows 8 64-bit

Microsoft Windows 2012 64-bit

PET-7H24M Series User Manual, version 1.0.0 P.40

Page 41

File

Description

HSDaq.dll

Used for VC programs

HSDaqNet.dll

Used for .Net programs

4.3. SDK API

This chapter provides a brief overview of ET-7H24 APIs that have been designed for ET-7H24.

ET-7H24 SDK library supports 32/64 bit Windows 2003/Vista/7/8/10.

Get the latest version of ET-7H24 SDK library at the location below.

The latest version of the installation package from the following link:

http://www.icpdas.com/en/download/show.php?num=2326&model=PET-7H24M

Before using HSDAQ.dll & HSDAQNet.dll, you must install HSDAQ_SDK_package.exe to use the dll

correctly. The program and SDK get the same path. Need to restart the computer after installation.

For installation steps, please refer to "ET-7H24 Standard API User Manual".

For full usage information regarding the description, prototype and the arguments of the functions,

please refer to the “ET-7H24 Standard API User Manual”

http://www.icpdas.com/web/product/download/io_and_unit/ethernet/pet-7h16m/document/m

anual/pet-7h16m_api_reference_manual_en.pdf

PET-7H24M Series User Manual, version 1.0.0 P.41

Page 42

HSDAQ.dll Functions

HSDAQNet.dll Functions

Description

HS_Device_Create

Sys.HS_Device_Create

Create a connection to the device and initialize the device. This

function is the driver entry.

HS_Device_Release

Sys.HS_Device_Release

Release the device from system.

HS_Reboot

Sys.Reboot

This function reboots the ET-7H24.

HS_GetFirmwareVersion

Sys.GetFirmwareVersion

Read the firmware version of ET-7H24

HS_GetSDKVersion

Sys.GetSDKVersion

This function retrieves the version number of the current HSDAQ.dll

Sys.GeHSDAQNetVersion

This function retrieves the version number of the current

HSDAQNet.dll

HS_ReadGainOffset

Config.HS_ReadGainOffset

Read the gain/offset values for application to calibrate each

channel’s analog data

HS_SetConfig

Config.HS_SetConfig

Set the configuration option for a device.

HS_SetConfigString

Config.HS_SetConfigString

Set the configuration option for a device with the string.

HS_GetConfig

Config.HS_GetConfig

Read the configuration option for a device.

HS_GetConfigString

Config.HS_GetConfigString

Read the configuration option for a device with the string.

HS_ReadAIALL

IO. ReadAIALL

Reads all the AI values of all channels in engineering-mode.

HS_ReadAI

IO. ReadAI

Reads the AI value of a channel in engineering-mode

HS_WriteAO

IO.WriteAO

Write the AO value

HS_WriteAOHEX

IO.WriteAOHEX

Write the AO HEX value

HS_ReadDIO

IO. ReadDIO

Reads the DI and DO values

HS_WriteDO

IO. WriteDO

Writes the DO value

The following API functions are used to access ET-7H24 modules.

Page 43

HS_WriteDOBit

IO. WriteDOBit

Writes a DO value to a channel

HS_GetEncoderMode

IO. HS_GetEncoderMode

Get the Encoder setting parameter from PET-7H24M

HS_SetEncoderMode

IO. HS_SetEncoderMode

Set the Encoder parameter for PET-7H24M

HS_ReadEncoder

IO. HS_ReadEncoder

Read the Encoder value

HS_ClearEncoder

IO. HS_ClearEncoder

Clear the Encoder value

HS_GetAIScanParam

HSIO.HS_GetAIScanParam

Get the AI scan parameter from PET-7H24M regarding of the

sampling rate, scan channels, pacer gain, trigger mode.

HS_SetAIScanParam

HSIO.HS_SetAIScanParam

Set the AI scan parameter for PET-7H24M regarding of the sampling

rate, scan channels, pacer gain, trigger mode.

HS_StartAIScan

HSIO.HS_StartAIScan

Start data acquisition. The data is stored in memory and transfer to

the data buffer on PC.

HS_StopAIScan

HSIO.HS_StopAIScan

Stop data acquisition.

HS_GetAIBuffer

HSIO.HS_GetAIBuffer

Get the floating-point value from data buffer on PC

HS_GetAIBufferHex

HS_GetAIBufferStatus

HSIO.HS_GetAIBufferHex

Get the binary data from data buffer on PC

HSIO.HS_GetAIBufferStatus

Get the status and data number from data buffer on PC.

HS_ClearAIBuffer

HSIO.HS_ClearAIBuffer

Clear the data buffer on PC

HS_GetTotalSamplingStatus

HSIO.HS_GetTotalSamplingStatus

Read the module status of ET-7H24 during data sampling

HS_TransmitDataCmd

HSIO.HS_TransmitDataCmd

Notify ET-7H24 module to send data to PC through TCP data port

HS_SetEventCallback

HSIO.HS_SetEventCallback

Bind the event condition to a user-defined callback function

HS_RemoveEventCallback

HSIO.HS_RemoveEventCallback

Disable the event condition and callback function.

PET-7H24M Series User Manual, version 1.0.0 P.43

Page 44

HS_StartLogger

DATALOG.HS_StartLogger

Start the data logging and save data to the specified folder on

storage disk of the host PC

HS_StartLoggerW

HS_StartLoggerW is a wide-character version of HS_StartLogger. The

specified folder can included wild-character.

HS_StopLogger

DATALOG.HS_StopLogger

Stop the data logging.

HS_GetAllLogFiles

DATALOG.HS_GetAllLogFiles

Search all log files in the specified folder with the specified file type

and return the total number of files

HS_LogFile_Open_byIndex

DATALOG.HS_LogFile_Open_byIndex

Open a data log file by the index number searched by HS_GetAllLogFiles

HS_LogFile_Open

DATALOG.HS_LogFile_Open

Open a data log file by the specified path and file name.

HS_LogFile_OpenW

HS_LogFile_OpenW is a wide-character version of HS_LogFile_Open. The

specified folder and file name can be included wild-character.

HS_LogFile_Close

DATALOG.HS_LogFile_Close

Closes a data log file opened by HS_LogFile_Open.

HS_GetLogFileInfo

HS_GetLogFile_AIScanConfigInfo

DATALOG.HS_GetLogFileInfo

Get the data log file information including the file version and file size.

DATALOG.HS_GetLogFile_AIScanConfigInfo

Get the data log file information regarding of the sampling rate, scan

channels, pacer gain and trigger mode.

HS_GetLogFile_GainOffset

DATALOG.HS_GetLogFile_GainOffset

Get the data log file information regarding of the gain/offset values for

each AI channel.

HS_GetLogFile_AIScanSampleInfo

DATALOG.HS_GetLogFile_AIScanSampleInfo

Get the total sampling counts and the starting time of first triggered

sampling data in the data log file

HS_GetLogFile_AIData

DATALOG.HS_GetLogFile_AIData

Reads AI input data from the text file

HS_GetLogFile_AIDataHex

DATALOG.HS_GetLogFile_AIDataHex

Read AI input data(Hex) from the binary file

PET-7H24M Series User Manual, version 1.0.0 P.44

Page 45

HS_GetLastError

ErrHandling.GetLastError

Retrieves the last-error code value.

HS_SetLastError

ErrHandling.SetLastError

Sets the last-error code.

HS_GetLastErrorMessage

ErrHandling.GetErrorMessage

Retrieves a message string.

HS_ClearLastError

ErrHandling.ClearLastError

Clears the last-error code.

PET-7H24M Series User Manual, version 1.0.0 P.45

Page 46

Visual C++ Samples

The ET-7H24 VC demo includes the following samples that demonstrate the use of the

ET-7H24 Standard APIs in a Visual C++ language environment. The following samples can be

found by downloading the latest version from ICP DAS web site.

For Visual C++ applications, these demo programs can be obtained from:

http://www.icpdas.com/web/product/download/io_and_unit/ethernet/pet-7h16m/software

/demo/VC.zip

C# Samples

The ET-7H24 C# demo includes the following samples that demonstrate the use of the

ET-7H24 Standard APIs in a C# language environment. The following samples can be found

by downloading the latest version from ICP DAS web site.

For C# applications, these demo programs can be obtained from:

http://www.icpdas.com/web/product/download/io_and_unit/ethernet/pet-7h16m/softwar

e/demo/C%23.zip

VB.net Samples

The ET-7H24 VB.net demo includes the following samples that demonstrate the use of the

ET-7H24 Standard APIs in a VB.net language environment. The following samples can be

found by downloading the latest version from ICP DAS web site.

For C# applications, these demo programs can be obtained from:

http://www.icpdas.com/web/product/download/io_and_unit/ethernet/pet-7h16m/softwar

e/demo/VB.Net.zip

Page 47

Item

Default

User name

Admin

Password

Admin

5. Web Applications

The PET-7H24M contains an advanced web configuration system that provides users with access

PET-7H24M applications through a standard web browser.

Note: The web page function is only suitable for configuration settings. Do not enable this TCP

communication when the module is acquitting the data via Ethernet.

Logging in to the PET-7H24M Web site

You can log in to the PET-7H24M web site from any computer that has Internet access.

Step 1 : Open a browser

In several browsers, Mozilla Firefox and Internet Explorer are both reliable and popular

Internet browsers.

Step 2: Type the URL address of the PET-7H24M

If you haven’t changed the default IP address of the PET-7H24M, please refer section “2.4.

Using HSDAQ Utility to Assign an IP address” to configure it.

Step 3: Fill out the User name and Password

After entering the IP address, the login dialog box will appear and prompt you to enter your

username and password.

The factory default user name and

password are as follows:

PET-7H24M Series User Manual, version 1.0.0 P.47

Page 48

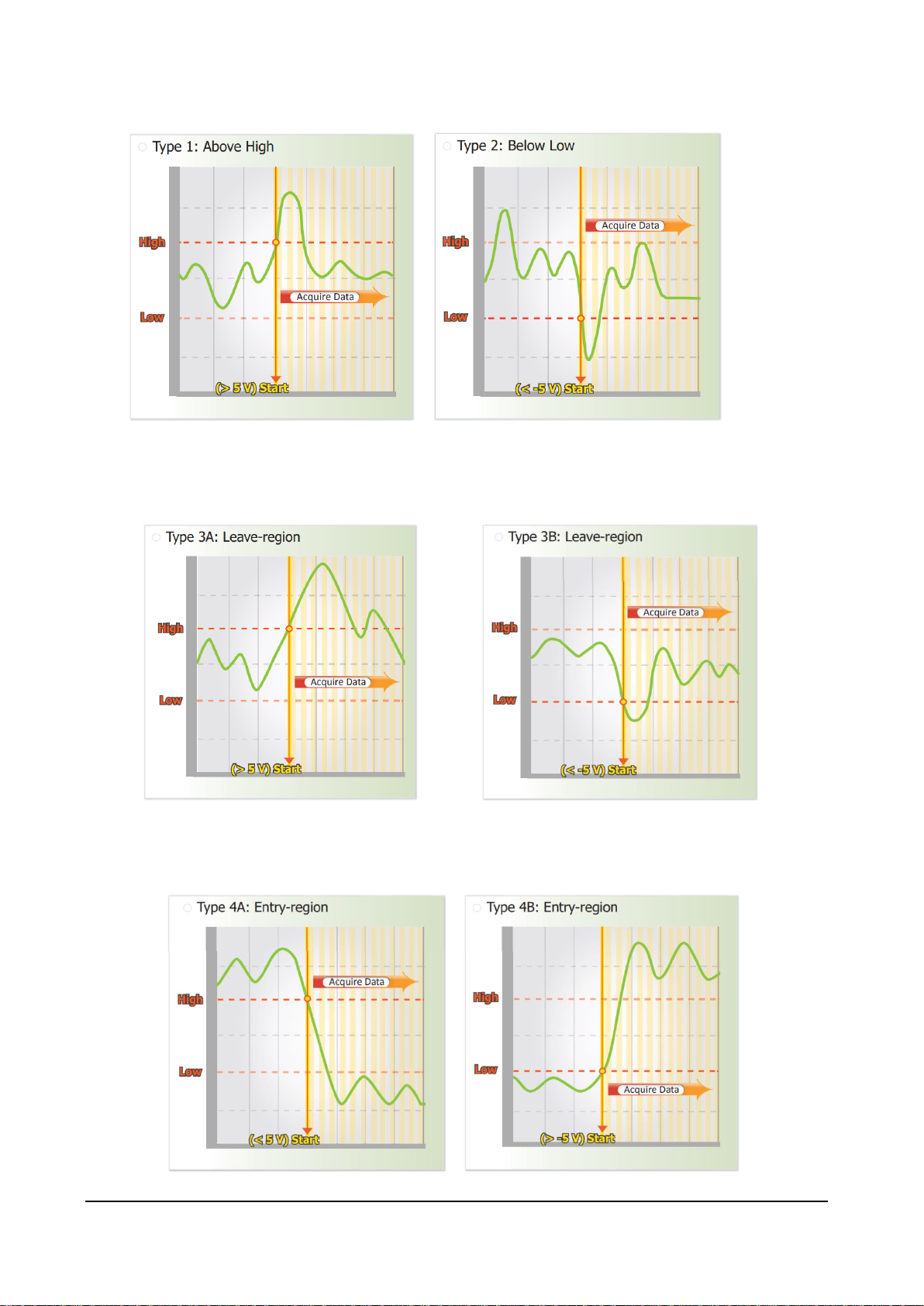

Step 4: Welcome to PET-7H24M web site

After logging into the PET-7H24M web site, the welcome page will appear.

This site serves several functions. You can easily access

these functions through the menu on the left side.

The Overview of the Main menu provides a brief

introduction and explanation of this site.

PET-7H24M Series User Manual, version 1.0.0 P.48

Page 49

5.1. Overview

The Overview links to the welcome page that provides functions to monitor necessary system

information of PET-7016M. The information is the most important note of version control for

upgrading system.

This page provides basic information about the PET-7H24M.

Firmware Ver: Current firmware version

Hardware Version:Current hardmware version

Gain: Current input type

Channels: Current trigger channels

Trigger mode: Current trigger mode

Sample Rate: Current sample rate

TransMethod: Current transfer method

Sample Count: Current sample count

PET-7H24M Series User Manual, version 1.0.0 P.49

Page 50

5.2. Configuration

The Configuration menu consists of the following menu:

Network Settings: This menu links to the Network

Settings page that allows you to access the IP

settings.

Basic Settings: This menu links to the Basic Settings

page that allows you to configure the basic

information of this site.

Module I/O Settings: This menu links to the

Common Functions page that allows you to

configure the settings of the Modbus

PET-7H24M Series User Manual, version 1.0.0 P.50

Page 51

1

2

3

Network Settings 5.2.1.

The Network Settings page provides functions to configure either DHCP (Roaming) or manually

configured (Static) network settings.

Manually Configured Network Settings

1. Disable the DHCP

2. Assign an IP address

3. Click SUBMIT to finished configuring the network settings

PET-7H24M Series User Manual, version 1.0.0 P.51

Page 52

Basic Settings 5.2.2.

The Basic Settings page provides the following functions:

Configure the module information

Configure the web site information

Reset all settings to default

PET-7H24M Series User Manual, version 1.0.0 P.52

Page 53

1

2

5.2.2.1. Configuring the Module Information

The module information includes the following data items:

● Module Name: The name of the module that can be modified. It has an initial value depending

on the name of the module.

● Module Information: The module information indicates the name of the alias that is used to

identify the module.

To configure the module information

1. Enter the Module information

2. Click SUBMIT to finish configuring the module information

PET-7H24M Series User Manual, version 1.0.0 P.53

Page 54

Page Header Information (First line)

Page Header Information (Second line)

5.2.2.2. Configuring the Web site Information

The module information includes the following data items:

● Page Header Information (First line) and Page Header Information (Second line): The title of

the website that can be modified; you can view the title information in the top-left corner. The

title information can be determined as follows:

● Web Server TCP Port: A port number of the TCP/IP port. By default, TCP/IP uses port 80.

PET-7H24M Series User Manual, version 1.0.0 P.54

Page 55

1

2

To configure the web site information

1. Enter the web site information

2. Click Submit to finish configuring the module information

PET-7H24M Series User Manual, version 1.0.0 P.55

Page 56

2

1

5.2.2.3. Resetting All Settings to the Factory Default

According to the menu selection of this web, the reset function can be divided into the following

categories. You can use this function to reset the settings to their factory default.

Configuration

Authentication

All

To reset the settings to their factory default

1. Enable the reset selection

2. Click SUBMIT to finish resetting the settings to their factory default

PET-7H24M Series User Manual, version 1.0.0 P.56

Page 57

Data Item

Factory Default Settings

IP

192.168.255.1

Gateway

192.168.0.1

Mask

255.255.0.0

DHCP

Disable

Data Item

Factory Default Setting

Module Name

Depending on the module name

Module Information

Empty

Top page Information (First line)

ICP DAS

Top page Information (Second line)

http://www.icpdas.com

More Information URL

http://www.icpdas.com/products/Remote_I

O/et-7000/et-7000_introduction.htm

Web Server TCP Port

80

Factory Default Setting

A default user account consists of an account name “Admin” and a password “Admin”.

Factory Default Setting

Empty, there is no limit to allow any outgoing access.

Factory Default Settings for Configuration Menu

The table below lists the factory default settings of the configuration menu.

Network Settings

Basic Settings

Factory Default Settings for Authentication Menu

The table below lists the factory default settings of the Authentication menu.

Account Management

Accessible IP Settings

PET-7H24M Series User Manual, version 1.0.0 P.57

Page 58

5.3. Authentication

The Authentication menu consists of the following menu:

Account Management: This menu links to the

Privilege management page that allows you to

manage the user accounts and their privileges.

Accessible IP Settings: This menu links to the IP filter

Settings page that allow you to control access to the

web site

PET-7H24M Series User Manual, version 1.0.0 P.58

Page 59

Account Management 5.3.1.

The Basic Settings page provides the following functions:

Configure the user accounts

Load the factory default user account

PET-7H24M Series User Manual, version 1.0.0 P.59

Page 60

5.3.1.1. Configuring the user accounts

The PET-7H24M web site supports up to 5 user accounts.

A built-in administrator account

The built-in Administrator is basically a setup and disaster recovery account that can be

deleted. You can change the administrator account’s password.

Four user-defined accounts

Each user account consists of

An account name: Specifies the name of This can be your name or another alias

A password: The system will ask you to type this in twice to ensure it is correct.

The authority: that determines what operations the user is allowed to perform.

The authority has the following roles to determine what operations the user is allowed to perform.

Admin: Enables access to all PET-7H24M website features, functions, and commands.

User: Enables limited access to PET-7H24M website features, functions, and commands. In

general, operators cannot change configuration settings.

PET-7H24M Series User Manual, version 1.0.0 P.60

Page 61

1

2

To Create an User Account

When you create user accounts, you can Enable or Disable user accounts.

1. Enter the user account information, and then select the enable checkbox

2. Click SUBMIT to finish configuring the user accounts

PET-7H24M Series User Manual, version 1.0.0 P.61

Page 62

5.3.1.2. Loading the factory default user accounts

The PET-7H24M has a built-in administrator account named Admin that is created when it is

installed by default. The default account cannot be deleted.

Click RESET SETTINGS to configure the user account to the factory default settings.

PET-7H24M Series User Manual, version 1.0.0 P.62

Page 63

Accessible IP Settings 5.3.2.

The IP filter Settings page provides the following functions:

Configure IP filtering

PET-7H24M Series User Manual, version 1.0.0 P.63

Page 64

To Configure the IP filter

The PET-7H24M with an IP filter that enables you to restrict or grant user access based an

IP filter list you create.

The filter can be enabled or disable by selecting the Enable the IP filter table checkbox

Tips & Warnings

By default, there is no limit to allow any outgoing access.

PET-7H24M Series User Manual, version 1.0.0 P.64

Page 65

1

2

3

4

Here we provide two basic methods for configuring the IP filter.

Method 1 : Allows access from a single IP address

1. Select the Enable the IP filter table

2. Enter the same IP address in the From (IP Address) and To (IP Address)

3. Select the Active the rule checkbox

4. Click SUBMIT to finish configuring the list of IP filter

PET-7H24M Series User Manual, version 1.0.0 P.65

Page 66

1

2

3

4

Method 2: Allow access from a group of IP addresses

1. Select the Enable the IP filter table

2. Enter a range of IP addresses in the From (IP Address) and To (IP Address)

3. Select the Active the rule checkbox

4. Click SUBMIT to finish configuring the IP filter list

PET-7H24M Series User Manual, version 1.0.0 P.66

Page 67

5.4. Web HMI

The Web HMI menu consists of the following menu:

Web HMI: This menu links to the I/O monitor page

that allows you to monitor and control the I/O status

on PET-7H24M module remotely.

By default, this page displays summary information about

I/O channels that are classified according to the module

type.

PET-7H24M Series User Manual, version 1.0.0 P.67

Page 68

6. Modbus Applications

The PET-7H24M is a Modbus device that allows you to access terminals data via Ethernet and

communicates using a master-slave technique in which only one device (the master) can initiate

transactions (called queries). The other devices (slaves) respond by supplying the requested data

to the master, or by taking the action requested in the query.

PET-7H24M Series User Manual, version 1.0.0 P.68

Page 69

Register Map

Modbus devices usually include a Register Map. Modbus functions operate on register map

registers to monitor, configure, and control module I/O. The users should refer to the register map

for the PET-7H24M to gain a better understanding of its operation.

PET-7H24M Series User Manual, version 1.0.0 P.69

Page 70

Begin

address

Points

Description

Registers

per Point

Range

Access

Type

0

4

Digital Out

1

0 = off

1 = on

R/W

34

1

The data order of long value

to Modbus register

1

0: low byte, high byte

1: high byte, low byte

R/W

36

1

Reset the I/O settings to the

factory default state

1

1: Reset

W (Pulse)

37

1

Reset the web settings to

the factory default state

1

1: Reset

W (Pulse)

112

1

Reboot the module

1

1: Reboot

W (Pulse)

Begin

address

Points

Description

Registers

per Point

Range

Access

Type

0

4

Digital input value

1

0 = off

1 = on

R

Begin

address

Points

Description

Registers

per Point

Range

Access

Type

0

8

Analog Input

word

-32768 ~ +32767

R

16

8

Use Channel Gain Value

word

0 ~ 65535

R

32

8

Use Channel Offset Value

word

-32768 ~ +32767

R

80

1

Number of the DI channel

word

0 ~ 65535

R

81

1

Number of the DO channel

word

0 ~ 65535

R

82

1

Number of the AI channel

word

0 ~ 65535

R

90

1

OS image version

word

0 ~ 65535

R

91

1

Firmware version

word

0 ~ 65535

R

92

1

ET7H24 Library version

word

0 ~ 65535

R

94

1

TCP library version

word

0 ~ 65535

R

95

1

Web server library version

word

0 ~ 65535

R

100

1

Read module name

word

0 ~ 65535

R

0xxxx address table

1xxxx address table

3xxxx address table

PET-7H24M Series User Manual, version 1.0.0 P.70

Page 71

Begin

address

Points

Description

Registers

per Point

Range

Access

Type

32

1

Set AI type

word

0: +/- 5V

1: +/- 10V

R/W/E

33

1

Scan Channel Count

word

1 ~ 8

R/W

34

1

Trigger Type

word

0: Software start

1: External Trigger

2: Post-Trigger

3: Pre-Trigger

…

R/W/E

35

2

Sample Rate

word

R/W/E

37

2

Target Count

word

R/W/E

50

1

Read the boot count of the

module

word

R/W/E

60

1

The factory default value is 0

when the settings are set to

the factory default values

word

0 ~ 65535

R/W/E

4xxxx address table

PET-7H24M Series User Manual, version 1.0.0 P.71

Page 72

7. Updates

The firmware is stored in flash memory and can be updated to fix functionality issues or add

additional features, so we advise you to periodically check the ICP DAS web site for the latest

updates.

Step 1: Get the latest version of the firmware and the autoexec.bat file

The latest version of the PET-7H24M firmware and autoexec.bat file can be obtained from:

http://www.icpdas.com/en/download/show.php?num=2941&model=PET-7H24M

Step 2: Run the HSDAQ Utility

Double-click the HSDAQ Utility shortcut on your desktop.

PET-7H24M Series User Manual, version 1.0.0 P.72

Page 73

Step 3: Establish a connection to PET-7H24M

Click “Connect” button

Step 4: Choose “Erase Disk” from the “Command” menu

After establishing a connection, then choose upload Firmware from Tools menu.

Then confirm the IP of PET-7H24M, then click “…” button.

PET-7H24M Series User Manual, version 1.0.0 P.73

Page 74

Step 5: Choose the ET7H24_VXXXX.hex to upload

Select ET7H24_VXXXX.hex to upload, then click "Open File" and then click "Upload".

Step 6: End of upload

After uploading the file, the progress bar will be as shown below..

Tips & Warnings

You have to reboot the PET-7H24M after uploading the firmware.

PET-7H24M Series User Manual, version 1.0.0 P.74

Page 75

8. Calibration

When shipped from the factory, PET-7H24M is already fully calibrated, including the calibration

coefficients that are stored in the onboard EEPROM. For a more precise application of voltages in

the field, the procedure described below provides a method that allows the board installed in a

specific system to be calibrated so that the correct voltages can be achieved for the field

connection. This calibration allows the effects of voltage drops caused by IR loss in the cable

and/or the connector to be eliminated.

At first the user has to prepare the equipment for calibration

Precise multi-meter (The more precise meter is better)

Stable power supply

The calibration procedure will be described in detail in the following.

Connect the AI channels to the meter and power supply, as shown below:

PET-7H24M Series User Manual, version 1.0.0 P.75

Page 76

Step 1: Entering the IP and Port, and click Connect

After the connection is successful, the firmware version will be read back.

PET-7H24M Series User Manual, version 1.0.0 P.76

Page 77

Step 2:Output voltage 4.8V to ch0 ~ ch3 and the meter, and select +/-5V in Gain combo box.

Enter the value reading from the meter in Meter 1 textbox (the following example is

4.7990)

Tips & Warnings

The range of output voltage is 5V~0V and it’s better to output voltage value

near to 5V.

PET-7H24M Series User Manual, version 1.0.0 P.77

Page 78

Step 3: Click Point_1 button and get the raw data of each channel as following

Step 4:Output a voltage, -4.8V to ch0 ~ ch3 and the meter, enter the value reading from meter

in Meter 2 textbox (the following example is -4.7916)

PET-7H24M Series User Manual, version 1.0.0 P.78

Page 79

Step 5: Click Point_2 button and get the raw data of each channel as following(And write the

corrected value into EEPROM)

Step 6: Select +/- 10V in Gain combo box

Step 7: Repeat the Step2 ~ Step5, and the upper limit voltage outputs 9.8V in Step 2 and the

lower limit voltage outputs -9.8V in Step 5

The calculated Gain Offset will be stored in the EEPROM. After pressing "point_1" and then

pressing "point_2", the calibration is completed

Step 8: After completing the calibration, click on ShowGainOffset button to read Gain and Offset

value

PET-7H24M Series User Manual, version 1.0.0 P.79

Page 80

Address

Function Code

Data

Checksum

1 byte

1 byte

0 to 252 bytes

2 bytes

Appendix A. What is Modbus TCP/IP?

Modbus is a communication protocol developed by Modicon in 1979.

Different versions of Modbus used today include Modbus RTU (based on serial communication like

RS485 and RS232), Modbus ASCII and Modbus TCP, which is the Modbus RTU protocol embedded

into TCP packets.

Modbus TCP is an Internet protocol. The protocol embeds a Modbus frame into a TCP frame so

that a connection oriented approach is obtained thereby making it reliable. The master query’s the

slave and the slave responds with the reply. The protocol is open and hence highly scalable.

Modbus Message Structure

Modbus devices communicate using a master-slave (client-server) technique in which only one

device (the master/client) can initiate transactions (called queries). The other devices

(slaves/servers) respond by supplying the requested data to the master, or by taking the action

requested in the query.

A master’s query will consist of a slave address (or broadcast address), a function code defining

the requested action, any required data, and an error checking field. A slave’s response consists of

fields confirming the action taken, any data to be returned, and an error checking field.

Address specifies the address of the receiver.

Function Code specifies the message type.

Data is the data block.

Checksum specifies the numerical check value for testing the validity of the protocol.

PET-7H24M Series User Manual, version 1.0.0 P.80

Page 81

Reference

Description

0xxxx

Read/Write Discrete Outputs or Coils. A 0x reference address is used

to device output data to a digital output channel.

1xxxx

Read Discrete Inputs. The ON/OFF status of a 1x reference address is

controlled by the corresponding digital input channel.

3xxxx

Read Input Registers. A reference register contains a 16-bit number

received from an external source --- e.g. an analog signal.

4xxxx

Read/Write Output or Holding Registers. A 4x register is used to store

16-bits of numerical dada (binary or decimal), or to send the data from

the CPU to an output channel.

Code

Function

Reference

01 (01H)

Read Coils (Output) Status

0xxxx

02 (02H)

Read Input Status

1xxxx

03 (03H)

Read Holding Registers

4xxxx

04 (04H)

Read Input Registers

3xxxx

05 (05H)

Force Single Coil (Output)

0xxxx

06 (06H)

Preset Single Register

4xxxx

15 (0FH)

Force Multiple Coils (Outputs)

0xxxx

16 (10H)

Preset multiple Registers

4xxxx

A.1. Address

The first byte of information in the message structure of Modbus is the receiver’s address. The

valid addresses are in the range of 0 to 247. Addresses from 1 to 247 are given to individual

Modbus devices and 0 is used for broadcast.

A.2. Function Codes

The second byte in the frame structure is the function code. The function code describes what the

slave is required to do. Valid function codes are between 1 and 255. The slave uses the same

function code as the request to answer it. Only when error occurs in the system, the highest bit of

the function code will be made ‘1’. Hence the master will know if the message has been

transmitted correctly or not.

PET-7H24M Series User Manual, version 1.0.0 P.81

Page 82

A.3. Data Field

The data field consists of messages sent between master and slave. The messages contain

additional information about the action to be taken by the slave or any information requested by

the slave. When the slave does not require this information the data field can be nonexistent.

A.4. Error Check

The error check performed in Modbus/RTU is Cyclic Redundancy Check (CRC). Both the

transmitting device and the receiver compute CRC. Two bytes are used for this purpose and

generally one bit errors are detected by this method.

PET-7H24M Series User Manual, version 1.0.0 P.82

Page 83

Type Code

Input Range

Data Format

+F.S

-F.S

02

-10 to +10V

Engineering Unit

+10000

-10000

2’s comp HEX

7FFF

8000

01

-5 to +5V

Engineering Unit

+5000

-5000

2’s comp HEX

7FFF

8000

Appendix B. Analog Input Type and Data Format Table

PET-7H24M Series User Manual, version 1.0.0 P.83

Page 84

Symptom/Problem

Possible cause

Solution

The Run LED doesn’t light

Internal power has failed

Return the module for repair.

The Run LED indicator is ON

(light), but not flashing.

The module has possibly

crashed.

Reboot the module

Cannot communicate via the

Ethernet port, but the

PET-7H24M is still operating.

The IP/Mask/Gateway

address isn’t within the IP

address range of the LAN.

Change the IP/Mask/Gateway

address to match the LAN, or

ask the MIS administrator for

assistance.

The IP address has

restricted by the IP filter

settings

Check the IP filter setting using

the Web configuration.

There are more than 30

TCP/IP connections.

Reboot the module.

Able to explore the web page

through port 80 using a web

browser, but Modbus/TCP

program cannot access the

module through port 502.

Port 502 has been

restricted by the firewall.

Consult your MIS administrator

for assistance.

Modbus/TCP program can

access the module through

port 502, but Web browser

cannot explore the web page

through port 80 using a web

browser.

The Port 502 has restricted

by the firewall.

Consult your MIS administrator

for assistance.

The Web Configuration

function has been disabled.

(Shown on the Basic

Settings page)

Enable the Web Configuration

function using either the SMMI

or the console.

The Web server TCP port

has been changed from

port 80 (Shown on the Basic

Settings page)

Change the TCP port to 80 or

reconnect the PET-7H24M using

the specific TCP port.

Appendix C. Troubleshooting

A number of common problems are easy to diagnose and fix if you know the cause.

PET-7H24M Series User Manual, version 1.0.0 P.84

Page 85

Revision

Date

Description

1.0.0

August 2020

Initial issue

Appendix D. Revision History

This chapter provides revision history information to this document.

The table below shows the revision history.

PET-7H24M Series User Manual, version 1.0.0 P.85

Loading...

Loading...