ICP C9MPX100L20A2, H9MPX060F12A2, H9MVX080J20A1, H9MVX100L20A1, T9MPX080J16A2 Installation Guide

...Page 1

INSTALLATION INSTRUCTIONS

For the replacement of Secondary Heat Exchanger

Part Numbers 1174980, 1174981, 1174982 & 1177461

This kit is designed to replace the secondary heat exchanger on the

95% N9MPX, *gUHX, *gMPX & *gMVX Furnaces

* Denotes Brand (T, H or C)

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service,

maintenance, or use can cause explosion, fire, electrical

shock, or other conditions which may cause death,

personal injury, or property damage. Consult a qualified

installer, service agency, or your distributor or branch for

information or assistance. The qualified installer or

agency must use factory-authorized kits or accessories

when modifying this product. Refer to the individual

instructions packaged with the kits or accessories when

installing.

Follow all safety codes. Wear safety glasses, protective

clothing, and work gloves. Use quenching cloth for

brazing operations. Have fire extinguisher available. Read

these instructions thoroughly and follow all warnings or

cautions included in literature and attached to the unit.

Consult local building codes, the current editions of the

National Fuel Gas Code (NFCG) NFPA 54/ANSI Z223.1,

National Electrical Code (NEC) NFPA 70.

In Canada refer to the current editions of the National

standards of Canada CAN/CSA-B149.1 and .2 Natural

Gas and Propane Installation Codes, and Canadian

Electrical Code CSA C22.1.

Recognize safety information. This is the safety-alert

symbol _. When you see this symbol on the unit and in

instructions or manuals, be alert to the potential for

personal injury. Understand these signal words;

DANGER, WARNING, and CAUTION. These words are

used with the safety-alert symbol. DANGER identifies the

most serious hazards which will result in severe personal

injury or death. WARNING signifies hazards which could

result in personal injury or death. CAUTION is used to

identify unsafe practices which may result in minor

personal injury or product and property damage. NOTE is

used to highlight suggestions which will result in

enhanced installation, reliability, or operation.

DESCRIPTION AND USAGE

Use this secondary heat exchanger kit to replace a failed

secondary heat exchanger. This secondary heat exchanger

kit contains the following items:

Parts Supplied with Each Kit Qty.

Secondary Heat Exchanger/Panel Assembly 1

(includes insulation)

Panel Assembly Screws 20 Max

Turbulators, Short 14 Max

Turbulators, Long 14 Max

Collector Box Gasket 1

Transition Assembly Gasket 1

Inducer Assembly Gasket 1

Installation Instructions 1

FIRE EXPLOSION AND ELECTRICAL HAZARD

Failure to follow this warning could result in property damage,

personal injury, and/or death.

Turn off gas and electric supplies to unit before beginning any

installation or modification.

Turn off electric power supply at disconnect switch or service

panel beofre starting installation. Tag and lockout shutoff(s) with

appropriate device warning labels. There may be more than one

disconnect.

Follow the operating instructions on label attached to furnace.

UNIT OPERATION HAZARD

Failure to follow this caution may result in unit damage or

improper operation.

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and dangerous

operation.

Kit Part

1177461

1174980

1174981

1174982

* Denotes Brand (T, H or C)

*9UHX060F *9MPX060F

*9UHX080J *9MPX080J

*9U HX100L *9M PX100L

Used with Models

*9MVX040F

*9MVX060F

*9MVX080J

*9MVX100L

INTRODUCTION

This instruction covers installation of the secondary heat

exchanger kit part number 1174980, 1174981, 1174982 &

1177461 for all 95% furnaces.

Specifications subject to change without notice.

D'EQUIPMENT D'OPERATION

Lors des operations d'entretien des commandes, etiqueter

tousles ills avant de les deconnecter. Toute erreur de

c&blage peut 6tre une source de danger et de panne.

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs, use care and

wear appropriate protective clothing and gloves when handling

parts.

441 06 1077 02 June 2009

Page 2

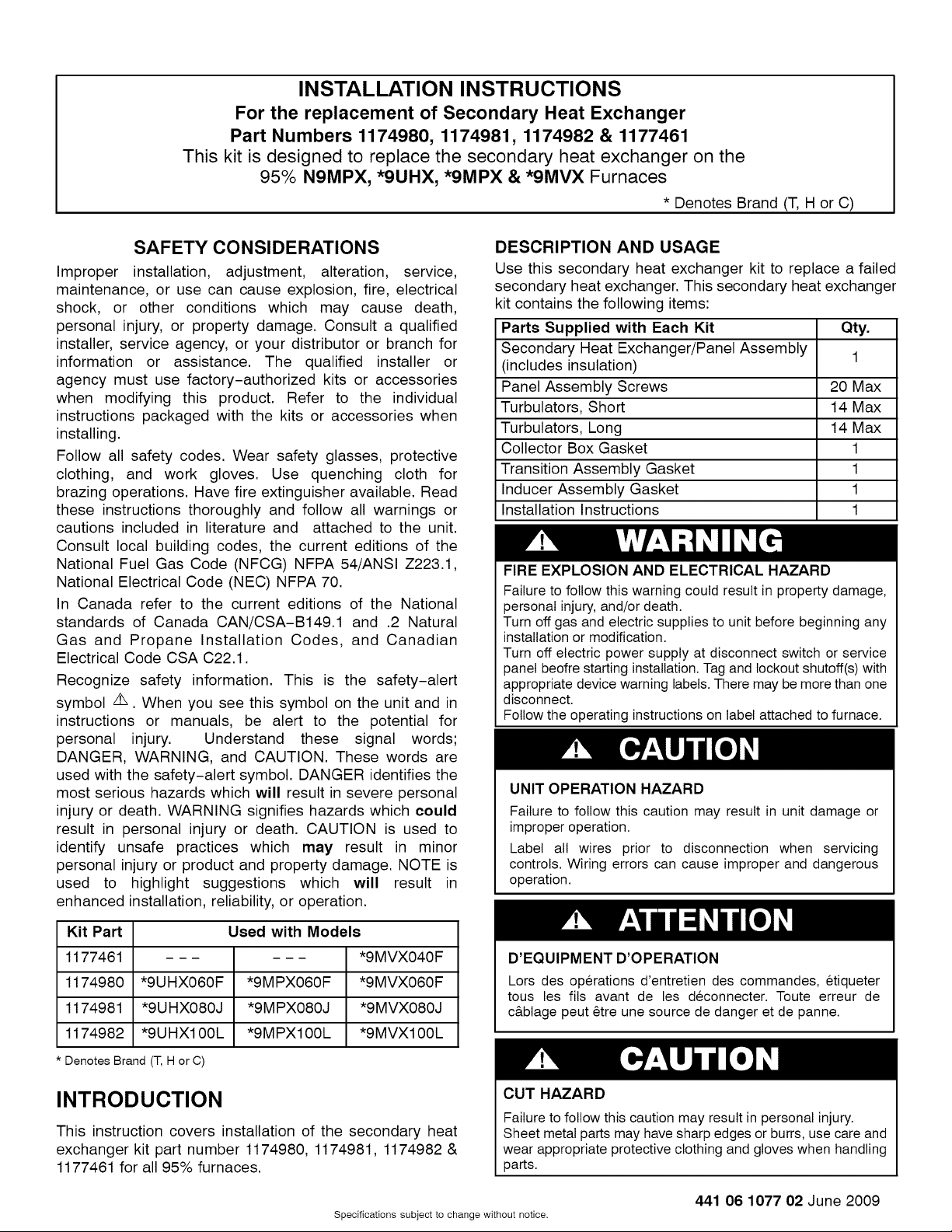

Figure 1 IFurnace

Transition Assy

Collector Box

(behind Transition

Assy.

Secondary Heat

Exchanger (behind

Collector Box)

-r

,x,

Inducer Assy

Pressure Switch

............................

Condensate Trap

INSTALLATION

Step 1 - Disconnect Wires and Tubing

Label wires and tubing prior to disconnection.

A. Turn off gas and electrical supplies to furnace.

B. Remove main furnace door.

C. Remove blower access door.

D. Detach electrical junction box.

E. Disconnect all wires from the inducer assembly.

F. Disconnect wires from the pressure switch

assembly.

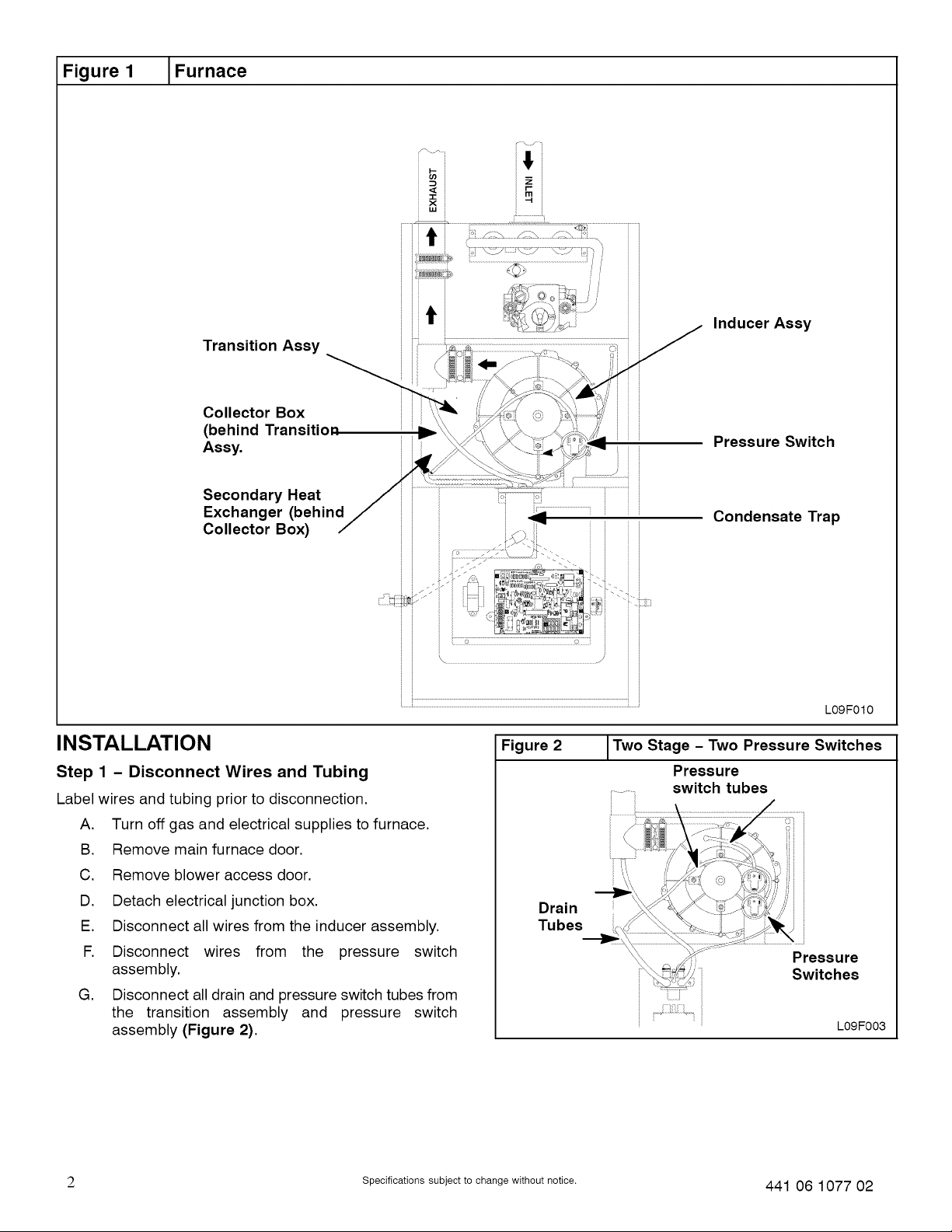

G. Disconnect all drain and pressure switch tubes from

the transition assembly and pressure switch

assembly (Figure 2).

...... ........................................................ _ ....,

Figure 2

Drain

Tubes

L09 F010

ITwo Stage - Two Pressure Switches

Pressure

switch tubes

Pressure

Switches

i

L09F003

2 Specifications subject to change without notice. 441 06 1077 02

Page 3

Step 2 - External Component removal

Note: There may be condensate left in the tubes/heat

exchanger. Spilled condensate may be slippery.

A. Remove the two (2) screws fastening the pressure

switch assembly to the blower deck and remove the

assembly from the furnace.

B. Remove the two screws (2) fastening the blower

rails to the blower deck.

C. Remove the screw from the middle of the door

switch bracket and lift the bracket out of the

compartment.

D. Remove the retainer clip supporting the corrugated

5/8" (15.9mm) ID drain tube that is connected to the

transition assembly from the condensate trap

assembly.

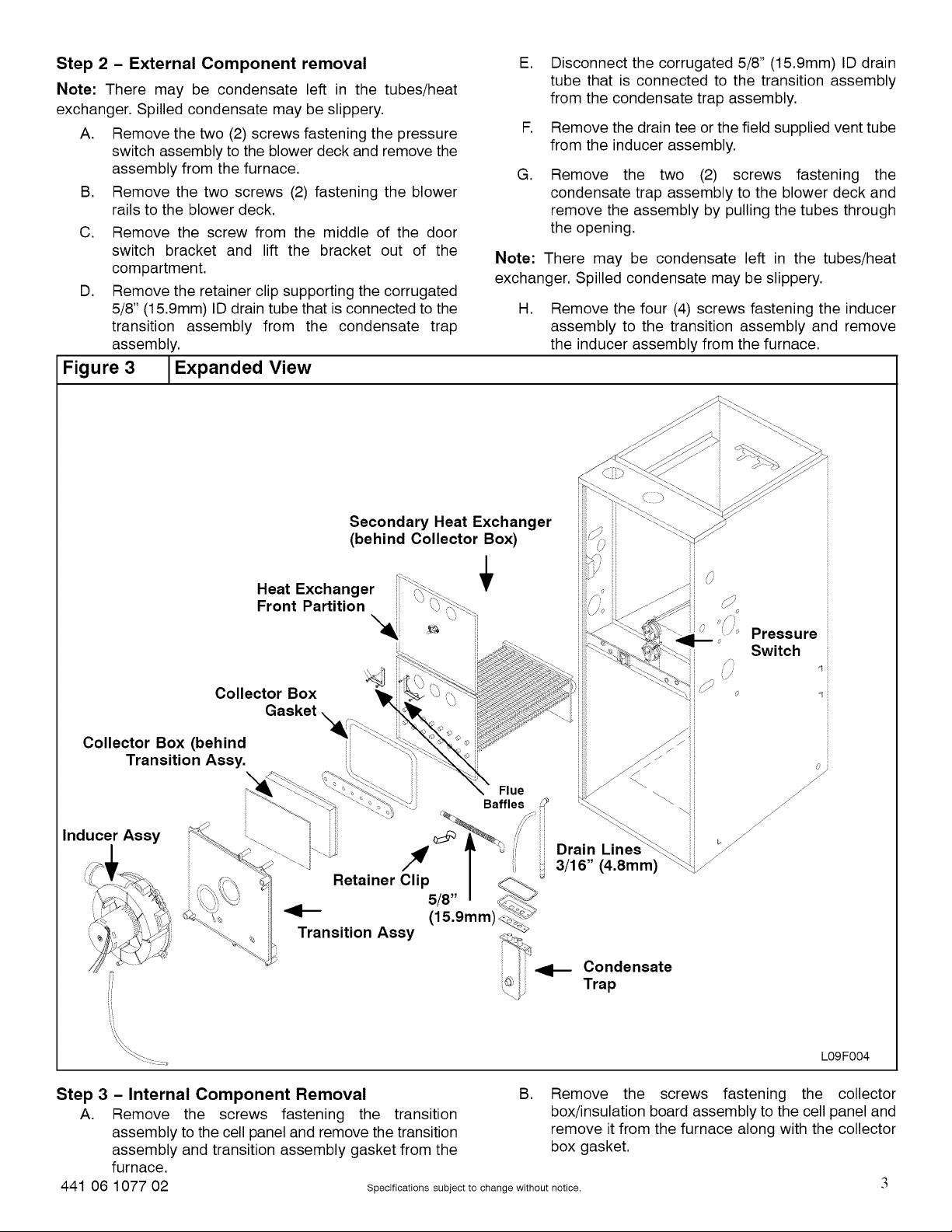

Figure 3 1Expanded View

E.

Disconnect the corrugated 5/8" (15.9mm) ID drain

tube that is connected to the transition assembly

from the condensate trap assembly.

F.

Remove the drain tee or the field supplied vent tube

from the inducer assembly.

G.

Remove the two (2) screws fastening the

condensate trap assembly to the blower deck and

remove the assembly by pulling the tubes through

the opening.

Note:

There may be condensate left in the tubes/heat

exchanger. Spilled condensate may be slippery.

H. Remove the four (4) screws fastening the inducer

assembly to the transition assembly and remove

the inducer assembly from the furnace.

Collector Box (behind

Transition Assy.

Inducer Assy

Secondary Heat Exchanger

(behind Collector Box)

Heat Exchanger

Front Partition

Pressure

Switch

Collector Box

Gasket

Flue _

Baffles -_ __

Drain

3/16" (4.8mm)

Retainer CliPs/8,, I

_1_ (15.9mm)

Transition Assy

_1_ Condensate

Trap

L09F004

Step3- Internal Component Removal B. Remove the screws fastening the collector

A. Remove the screws fastening the transition box/insulation board assemblyto the cell panel and

assembly to the cell panel and remove the transition remove it from the furnace along with the collector

assembly and transition assembly gasket from the box gasket.

furnace.

441 06 1077 02 Specifications subject to change without notice. 3

Page 4

Step 4 - Secondary Heat Exchanger Removal

A. Remove the screws fastening the secondary heat

exchanger cell panel to the cabinet and primary

heat exchanger assembly.

B. Begin sliding the secondary heat exchanger

assembly out and lift it over the door divider plate.

C. Remove the flue baffles and resuse when installing

the new heat exchanger. (See Figure 3)

Note: Flue baffles are not provided as a part of the

replacement kit.

PROPERTY DAMAGE RISK

Failure to follow this caution could result in property

damage.

The turbulators are loose in the tubes and there may be

condensate in the tubes. If condensate is present, pos-

sible water damage could occur during removal.

Step 5

- Install New Secondary Heat Exchanger

A.

After removing the new secondary heat exchanger

from the box and removing any protective material,

slide the assembly into the furnace.

B.

Line the mating screw holes up and install all the

screws that fasten the assembly to the cabinet and

primary heat exchanger assembly. New screws

were provided with this kit in case any of the screws

were damaged during removal.

C.

Long turbulators are located in the secondary heat

exchanger closest to the circulating air blower and

short turbulators are closest to the supply air.

Turbulators -

KitPart

1177461

1174980

1174981

1174982

* Denotes Brand (T, H or C)

*9UHX060F *9MPX060F

*9UHX080J *9MPX080J

*9UHX100L *9MPX100L

Usedwith Models

*9MVX040F

*9MVX060F

*9MVX080J

*9MVX100L

Quantity

Short Long

8 8

11 11

14 14

14 14

Note: Some furnaces may not have the full amount of

turbulators. When installing the new turbulators, make

sure to install a full set.

Step 6 - Installing Internal Components

A. Inspect the collector box gasket and replace with

the new one from the kit if needed.

B. Fasten the collector box/insulation board assembly

to the cell panel using the screws that were

removed from Step 3B.

C. Inspect the transition assembly gasket and replace

with the new one from the kit if needed.

D. Fasten the transition assembly to the cell panel

using the screws that were removed from Step 3A.

E. Inspect the inducer assembly gasket located on the

front of the transition assembly and replace with the

new one from the kit if needed.

Note: This gasket has an adhesive on one side which is

used to secure it to the transition assembly.

Step 7 - Installing External Components

A. Install the inducer assembly with the four (4) screws

removed during Step 2C in the same venting

position as it was prior to removal.

Note: It is recommended to install these screws with a

hand tool to prevent damaging/stripping the mating holes

in the transition assembly.

B. Feed the drain tubes through the rectangular

opening in the blower deck with the condensate trap

drain stub facing outwards and fasten the assembly

to the blower deck with the screws removed from

Step 2D. Do not forget to install the gasket in this

Step.

C. Install the drain tee or field supplied vent tube into

the inducer assembly.

D. Connect the corrugated 5/8" (15.9mm) ID drain tube

from the transition assembly to the condensate trap

assembly.

E. Relocate retainer clip, between the door switch

plate and the blower shelf, supporting the

corrugated 5/8" (15.9mm) ID drain tube that is

connected to the transition assembly from the

condensate trap assembly.

F. Replace the screw in the middle of the door switch

plate.

G. Place the pressure switch assembly on the blower

deck and fasten in place with the screws removed

from Step 2C.

H. Replace the two (2) blower rail screws.

Step 8 - Connect Wires and Tubes

A. Connect all drain and pressure tubes. Ensure that

the tubes are not kinked or pinched.

B. Connect the wires to the pressure switch(es).

C. Connect all the wires for the inducer assembly.

D. Fasten the electrical junction box to the cabinet.

Now that the secondary heat exchanger replacement is

complete, install the blower access door and turn on the gas

and electrical supply. Check furnace operation through two

(2) cycles. Finally, check for condensate leaks and install the

main furnace door.

Note: You must prime the trap or furnace may cycle on

error until the trap fills.

International Comfort Products, LLC

Lewisburg, TN 37091 U.S.A.

specifications subject to change without notice.

441 06 1077 02

Loading...

Loading...