Page 1

EN-US - english US

SERVICE UNIT

Instructions for installation and operation

Replacement unit

¡MAT 33

01-2791

Page 2

2 Service Unit iMAT 33

Page 3

1 Pictograms and symbols ........................................................................................................................4

2 Safety instructions ..................................................................................................................................4

3 Technical data ........................................................................................................................................6

4 Control and maintenance .......................................................................................................................7

5 Elements and components...................................................................................................................13

6 Recommended spare parts..................................................................................................................14

Service Unit iMAT 33 3

Page 4

Pictograms and symbols

Pos:1/Beko Technische Dokumentati on/Überschrift en/1/Piktogramm e und Symbol e @ 1\mod_12 90773595840_1 5098.docx @ 20 525 @ 1 @ 1

1 Pictograms and symbols

Pos:2/Beko Technische Dokumentati on/Piktogramm e/Anleitung b eachten blau @ 0\ mod_1213268 300255_1509 8.docx @ 15193 @ @ 1

Observe the installation and operating instructions

Pos:3/Beko Technische Dokumentati on/Piktogramm e/Anleitung b eachten s/w Type nschild @ 1\mod _12907721801 42_15098.doc x @ 20492 @ @ 1

Observe the installation and operating instructions

(on the type plate)

Pos:4/Beko Technische Dokumentati on/Piktogramm e/Gefahr Warn ung Vorsicht s/ w @ 0\mod_121 3265685174_ 15098.docx @ 15189@ @ 1

General danger symbol (danger, warning, caution)

Pos:5/Beko Technische Dokumentati on/Piktogramm e/G+W+V Netzsp annung s/ w @ 0\mod_121326 6193701_1509 8.docx @ 15 191 @ @1

General danger symbol (danger, warning, caution) for supply voltage and supply voltagecarrying plants components

Pos:6/Beko Technische Dokumentati on/Überschrift en/1/Sicherheits hinweise @ 0\m od_118363760 9261_15098.doc x @ 15102 @ 1 @1

2 Safety instructions

Pos:7/Beko Technische Dokumentati on/Sicherheit/Hi nweis Anleitung mitDocVar alsFirmenn ame @ 8\mod_ 14050627803 58_15098.doc x@ 41099@ @ 1

Please check whether or not these instructions correspond to the device type.

Adhere to all advice given in these operating instructions. They include essential information

which must be observed during the installation, operation and maintenance. Therefore it is

imperative for the service technician and the responsible operator / technical staff to read these

operating instructions prior to installation, start-up and maintenance.

The operating instructions must be accessible at any time at the place of application of the

iMAT 33.

In addition to these operating instructions, local or national regulations must be complied with,

if necessary.

Make sure that the iMAT 33 is operated only within the permissible limit values indicated on the

type plate. Any deviation involves a risk for persons and materials, and may result in

malfunction and service failures.

If you have any queries regarding these installation- and operating instructions, please contact

Independent Compressor Partners.

Pos:8/Beko Technische Dokumentati on/Sicherheit/Ge fahr Druc kluft @ 0\mod_1184 148143854_15 098.docx @ 15121@ @ 1

Danger!

Compressed air!

Risk of serious injury or death through contact with quickly or suddenly escaping

compressed air or through bursting plant components or plant components which are

Pos:9/Beko Technische Dokumentati on/Sicherheit/M aßnahmen Dr uckluft BM @ 0\ mod_11841482 84291_15098.d ocx @ 15123 @ @ 1

Measures:

• Do not exceed the maximum operating pressure (see type plate).

• Only carry out service measures when the system is pressure less.

• Use pressure-resistant installation material only.

• The feed pipe must be tubed firmly. Discharge pipe: short, fixed pressure hose onto pressure-resistant

pipe.

• Make sure that persons or objects cannot be hit by condensate or escaping compressed air.

not secured.

Pos:10/Be koT echnisch eD okumentati on/Sicherheit/Gef ahr Netzspan nung 1 s/w @ 0\ mod_118414 8186948_15098.d ocx @ 15122 @ @ 1

4 Service Unit iMAT 33

Page 5

Safety instructions

Danger!

Supply voltage!

There is the risk of an electric shock involving injury or death when coming into contact

Pos:11/Be koT echnisch eD okumentati on/Sicherheit/Maß nahmen Netzs pannung BM 31U/ 32U/33U @ 7\mod_1390467197804_150 98.docx @ 3 8070 @ @1

Measures:

• During electric installations, all regulations in force need to be adhered to (e.g. VDE 0100 / IEC 60364).

• When the control unit is open, service and installation works must only be undertaken when the

system is deactivated.

• The removed control unit has no IP degree of protection.

• All types of electrical works must be carried out by authorized and qualified personnel only.

Pos:12/Be koT echnisch eD okumentati on/Sicherheit/Sich erheitshinweis e, weitere BM ( nicht Ex, nic htIF ) @ 0\mod_118 3616103770_ 15098.docx @ 15100@ @ 1

Further safety instructions:

• For installation and operation, the national regulations and safety codes in force must also be adhered

to.

• Do not use the iMAT 33 in hazardous areas.

• Regarding the inlet screw joints, excessive tightening forces must be avoided. This applies in particular

to conical screw joints.

• The iMAT 33 will only function when voltage is applied.

• Do not use the test button for permanent drainage.

• Use genuine spare parts only. This is imperative to ensure perfect functioning.

Pos:13/Be koT echnisch eD okumentati on/Sicherheit/Z usatz Sicherheitshi nweise BM33/ BM33U @ 0\ mod_12319268 87620_15098.d ocx @ 15288 @ @ 1

with non-insulated components carrying supply voltage.

Additional advice:

• During installation, use the spanner flat at the feed pipe (wrench size SW28 + 34) as a back rest.

• The service unit must not be dismantled.

Pos:14/Be koT echnisch eD okumentati on/Sicherheit/Vorsic htF ehlfunktio n@ 0\mod_1214378096 290_15098.docx @ 15237@ @ 1

Caution!

Malfunction during operation!

Through incorrect installation and poor maintenance, malfunction may occur at the

iMAT.

Condensate which is not discharged may cause damage to plants and in production

processes.

Pos:15/Be koT echnisch eD okumentati on/Sicherheit/Maß nahmen Fehl funktionen BM @ 0\mod_1214378434025_1 5098.docx @ 1 5238 @ @1

r

Measures:

• Condensate drainage which is reliable in performance directly optimizes the compressed-air quality.

• To prevent damage and breakdowns, it is imperative to observe the following:

• Exact compliance with the specifications of use and with the performance parameters of the iMAT,

in connection with the case of application (see "Proper use" section)

• Exact compliance with the installation- and operation instructions in this manual

• Regular maintenance and control of the iMAT in accordance with the instructions in this operating

manual

Pos:16/--- - Seitenu mbruch ---- @ 0\mod _1157028099 015_0.docx @ 15 320 @ @1

Service Unit iMAT 33 5

Page 6

Technical data

Pos:17/Be koT echnisch eD okumentati on/Überschriften/ 1/Technische D aten @ 0\mod_ 118432957096 7_15098.docx @ 15131@ 1 @ 1

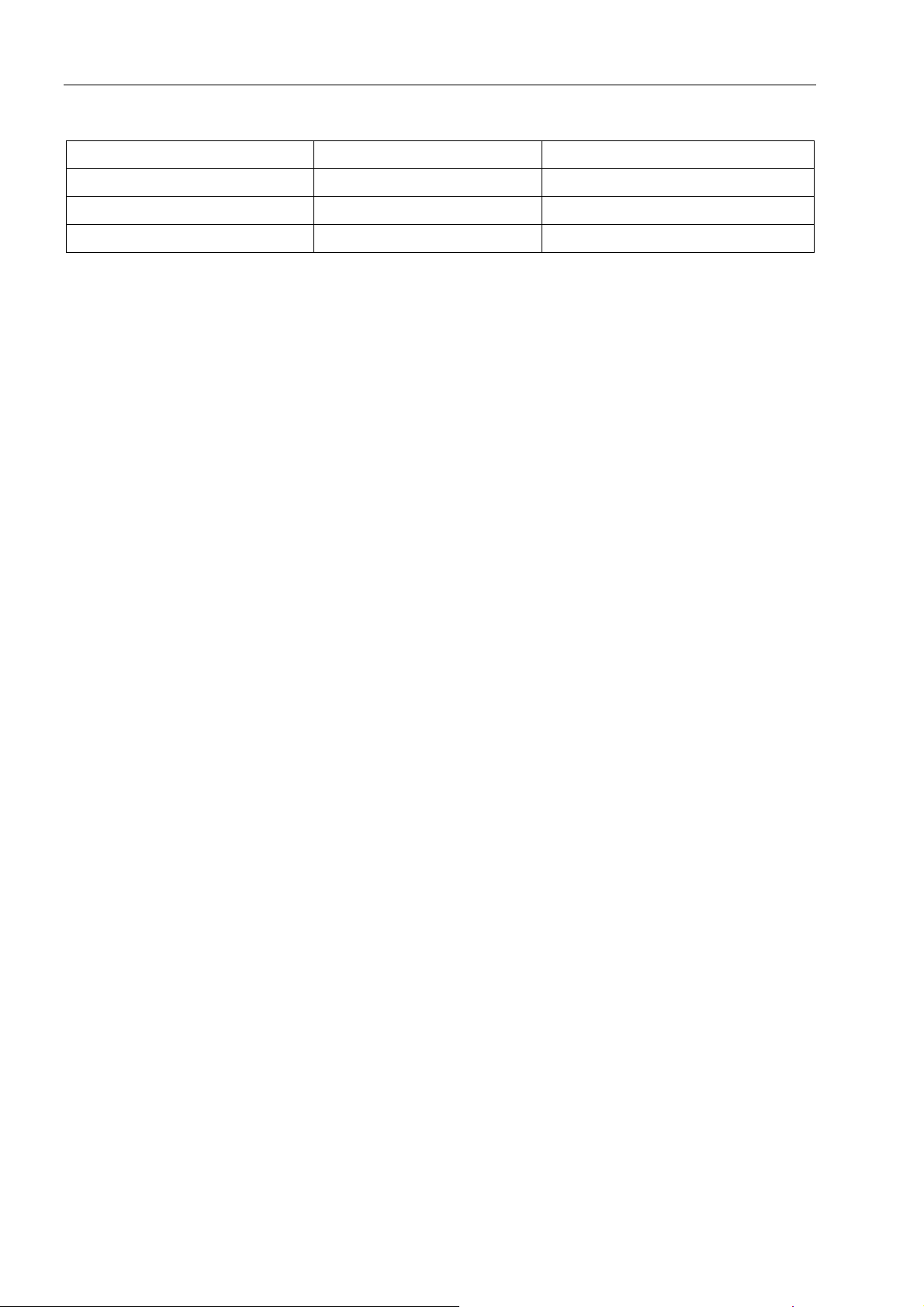

3 Technical data

Pos:18/Be koT echnisch eD okumentati on/Technische Dat en/BEKOMAT/T echn. Daten BM 3xU+ UC + GOST(o.L eistg.) @ 5\m od_13588435 78945_15098.d ocx @ 30477 @ @ 1

min./max. operating pressure

(see type plate)

min./max. temperature

(see type plate)

0,8...16 bar (12...230 psi)

or

1,2...16 bar (17...230 psi)

+1...+60 °C (+34...+140 °F)

or

+1...+70 °C (+34...+158 °F)

Condensate inflow Inlet via condensate receiver tank

Condensate outflow G ½ Ø 13 mm hose connector

Condensate oil-contaminated + oil-free

Housing aluminium + plastic, glass fibre-reinforced

Weight (empty) 0,78 kg (1.71 lbs)

Pos:19/--- - Seitenu mbruch ---- @ 0\mod _1157028099 015_0.docx @ 15 320 @ @1

6 Service Unit iMAT 33

Page 7

Control and maintenance

Pos:20/Be koT echnisch eD okumentati on/Überschriften/ 1/Kontrolle und Wartung@ 0\mod_1183637885371_15 098.docx @ 151 06 @ 1 @ 1

4 Control and maintenance

Pos:21/Be koT echnisch eD okumentati on/Sicherheit/Gef ahr Druckluft @ 0 \mod_1184 148143854_150 98.docx @ 1512 1@ @ 1

Danger!

Compressed air!

Risk of serious injury or death through contact with quickly or suddenly escaping

compressed air or through bursting plant components or plant components which are

Pos:22/Be koT echnisch eD okumentati on/Sicherheit/Maß nahmen Druc kluft BM @ 0\ mod_118414828 4291_15098. docx@ 15123 @ @1

Measures:

• Do not exceed the maximum operating pressure (see type plate).

• Only carry out service measures when the system is pressure less.

• Use pressure-resistant installation material only.

• The feed pipe must be tubed firmly. Discharge pipe: short, fixed pressure hose onto pressure-resistant

pipe.

• Make sure that persons or objects cannot be hit by condensate or escaping compressed air.

Pos:23/Be koT echnisch eD okumentati on/Sicherheit/Gef ahr Netzspan nung 1 s/w @ 0\ mod_118414 8186948_15098.d ocx @ 15122 @ @ 1

Pos:24/Be koT echnisch eD okumentati on/Sicherheit/Maß nahmen Netzs pannung BM 31U/ 32U/33U @ 7\mod_1390467197804_150 98.docx @ 3 8070 @ @1

Measures:

• During electric installations, all regulations in force need to be adhered to (e.g. VDE 0100 / IEC 60364).

• When the control unit is open, service and installation works must only be undertaken when the

system is deactivated.

• The removed control unit has no IP degree of protection.

• All types of electrical works must be carried out by authorized and qualified personnel only.

not secured.

Danger!

Supply voltage!

There is the risk of an electric shock involving injury or death when coming into contact

with non-insulated components carrying supply voltage.

Pos:25/Be koT echnisch eD okumentati on/Sicherheit/Vorsic htF ehlfunktio n@ 0\mod_1214378096 290_15098.docx @ 15237@ @ 1

Caution!

Malfunction during operation!

Through incorrect installation and poor maintenance, malfunction may occur at the

iMAT.

Condensate which is not discharged may cause damage to plants and in production

processes.

Pos:26/Be koT echnisch eD okumentati on/Sicherheit/Maß nahmen Fehl funktionen BM @ 0\mod_1214378434025_1 5098.docx @ 1 5238 @ @1

r

Measures:

• Condensate drainage which is reliable in performance directly optimizes the compressed-air quality.

• To prevent damage and breakdowns, it is imperative to observe the following:

• Exact compliance with the specifications of use and with the performance parameters of the iMAT,

in connection with the case of application (see "Proper use" section)

• Exact compliance with the installation- and operation instructions in this manual

• Regular maintenance and control of the iMAT in accordance with the instructions in this operating

manual

Service Unit iMAT 33 7

Page 8

Control and maintenance

Pos:27/Be koT echnisch eD okumentati on/Sicherheit/Hin weis Vorschrifte n Werkzeug R einigung Konde nsat Entsorgung @ 0\mod_123323966682 3_15098.docx @ 15301@ @ 1

Note

It is imperative to observe all hazard statements and warnings listed here.

Please also observe all regulations and notes regarding industrial safety and fire prevention at the place of

installation.

As a matter of principle, only use suitable and appropriate tools and materials in a proper condition.

Do not use aggressive cleaners and improper devices such as high-pressure cleaners.

Please note that condensates may contain aggressive or harmful components. Therefore, skin contact

should be avoided.

Condensate is subject to mandatory waste disposal. As such, it must be collected in suitable containers, and

disposed of or processed properly.

Pos:28/Be koT echnisch eD okumentati on/Wartung/BEKOM AT/Wartung BM33U Ser vice-Unit (ohn e Wartungsempf ehlung) @ 6\ mod_13787237 67212_15098.doc x @ 33567 @ @ 1

Maintenance including the cleaning of the

condensate receiver tank:

1. Prior to the replacement of the service unit, a

reset needs to be carried out.

The control unit is released by actuating the

arresting hook.

When removed, the TEST button below the

LED must be pressed and held for at least five

seconds.

2. Unfasten the iMAT 33 from the outlet.

3. Detach the iMAT 33 from the tubing at the inlet.

4. Unscrew both M6 cross recessed head screws

(22) and remove the service unit (9) by slightly

pulling and lifting it.

5. Remove the design shell (11) using a

screwdriver.

6. Unscrew the four cover screws (16) and remove

the cover (17).

7. Clean the condensate receiver tank (19).

8 Service Unit iMAT 33

Page 9

Control and maintenance

8. Insert new cover O-ring (18) (gasket kit)

according to the diagram.

9. Clean the sealing surfaces of the cover.

10.Put on the cover (17) with the new O-ring and

carefully tighten the four cover screws (16)

crosswise (8 Nm).

Service Unit iMAT 33 9

Page 10

Control and maintenance

11.Clean the sealing surfaces (←) at the

condensate receiver tank (19).

10 Service Unit iMAT 33

Page 11

Control and maintenance

13

12

9

11

12.Check whether or not the service unit (9) goes

with the control unit (1) (model designation and

color of the arresting hook).

13.Check the O-rings at the new service unit (12,

13).

14.Mount the design shell (11).

15.Mount the service unit along with the design

shell at the condensate receiver tank (19) and

tighten both cross recessed head screws (22)

(2,5 Nm).

16.Re-install the iMAT at the inlet tubing and outlet,

in reverse order to disassembly.

19

Service Unit iMAT 33 11

22

Page 12

Control and maintenance

Control unit with cord

packing

(previous version)

Control unit without

cord packing

(current version)

Prior to placing a previous version of the control

unit with cord packing (24) in the lower part of the

cover, the sealing mat (11) must be removed from

the service unit.

Installation of the control unit on the iMAT:

1. Check whether or not the service unit (9) goes

with the control unit (1) (model designation and

colour of the arresting hook).

2. Check whether or not the sealing mat (8) and

the contact springs (28) are clean, dry, and free

from impurities.

3. Introduce the sensor (5) into the service unit (9).

4. Hang the hook (29) of the control unit (1) in the

service unit (9).

5. Press the control unit (1) against the service

unit (9) and snap into place.

Pos:29/--- - Seitenu mbruch ---- @ 0\mod _1157028099 015_0.docx @ 15 320 @ @1

Start-up subsequent to maintenance measures:

Always carry out prior to the start-up:

• Leak test of the screwed connector of the

condensate receiver tank and of the connection

of this tank to the service unit

• Check of the electrical connections

• Check of the correct engagement of the control

unit

12 Service Unit iMAT 33

Page 13

Pos:30/Be koT echnisch eD okumentati on/Überschriften/ 1/Bauteile un d Komponenten @0\mod_11 83638014355 _15098.docx @ 15 108 @ 1 @ 1

5 Elements and components

Pos:31/Be koT echnisch eD okumentati on/Bauteile und Komponenten/BEKOMAT/B auteile BM 33U Service-Unit@ 6\mod_1378727213754_1 5098.docx @ 3 3601 @ @ 1

Elements and components

1 Screw 3.5 x 10

2 Upper part of the cover

3 Gasket

4 Printed circuit board

5 Sensor

6 Lower part of the cover

7 Cable bushing

8 Sealing mat

9 Service unit

10 Hose connector

11 Design shell

12 O-ring 8 x 4

Pos:32/--- - Seitenu mbruch ---- @ 0\mod _1157028099 015_0.docx @ 15 320 @ @1

13 O-ring 18,5 x 2

14 Screw plug

15 Flat gasket

16 Hexagon socket head screw M6 x 16

17 Cover

18 O-ring 48.9 x 2.62

19 Condensate receiver tank

20 Flat gasket

21 Screw plug

22 Cross recessed head screw M6 x 16

24 Cord packing (only previous version)

27 Deflector plate (only)

Service Unit iMAT 33 13

Page 14

Recommended spare parts

Pos:33/Be koT echnisch eD okumentati on/Überschriften/ 1/Empfohlene Ersatzteile@ 0\mod_1183638186183_15 098.docx @ 15111@ 1 @ 1

6 Recommended spare parts

Pos:34/Be koT echnisch eD okumentati on/Ersatzteile Verbr auchsmaterialie n Zubehör/B EKOMAT/Ersatz teile ICP 33 (BM 33U USA FKM) @ 9\mod_141511391225 6_15098.docx @ 42505@ @ 1

Available sets of spare parts Contents Order number

Service Unit iMAT 33 8, 9, 12, 13 4028459-ICP

Gasket kit 3, 8, 12, 13, 18 4024397-ICP

Design shell 11 4010167-ICP

Pos:35/Be koT echnisch eD okumentati on/Globale Texte /Hinweis Überset zg. d. Orig .anleitg. @ 1\mod _12604334783 58_15098.doc x @ 17131 @ @ 1

Pos:36/Be koT echnisch eD okumentati on/Globale Texte /Hinweis Orig inalanleitung @ 1\ mod_1260433 346280_1509 8.docx @ 17097 @ @ 1

Pos:37/Be koT echnisch eD okumentati on/Globale Texte /Vorbehalts klausel @ 0\mod_1 21370403315 3_15098.docx @ 15236@ @ 1

===Ended er Liste für T extmarke Inhalt ===

14 Service Unit iMAT 33

Page 15

C

P

Components 13

Control 7

D

Danger compressed air 4, 7

Danger supply voltage 5, 7

Data 6

Degree of protection 5, 7

E

Elements 13

I

Installation and operating instructions 4

Installations- und Betriebsanleitung 4

Instructions, safety instructions 4

L

Lower part of the cover 13

M

Maintenance 7

Maintenance including the cleaning of the

condensate receiver tank 8

Piktogramme 4

Printed circuit board 13

Q

Qualified personnel 5, 7

R

Recommended spare parts 14

S

Safety instructions 4

Screw plug 13

Sensor 13

Sensor tube plate 12

Service measures 4, 7

Service unit 13

Sets of spare parts 14

Spare parts 5, 14

Symbole 4

T

Technical data 6

U

O

Order number 14

Upper part of the cover 13

Service Unit iMAT 33 15

Page 16

Independent Compressor Partners, LLC

P.O. Box 206

Jeffersonville, IN 47131

www.icompressorpartners.com

Translation of the original manual/instructions.

Original instructions are in German

Subject to technical modifications without notice / errors accepted.

ICP_iMAT33_Service_Unit_en_us_2014_12.

Printed in Germany

Service Unit iMAT 33

Loading...

Loading...