Page 1

Installation Instructions

SINGLEPACKAGEHEATPUMPS

PHF & HPFM Series - 2 to 5 TON

Printed in U.S.A.

518 01 1101 01 4-25-99

LP1

Page 2

Safety Labeling and Signal Words

Danger,Warning and Caution

The signal words DANGER, WARNING and CAUTION are

used to identify levels of hazard seriousness. The signal

word DANGER is only used on product labels to signify an

immediate hazard. The signal words WARNING and

CAUTION will be used on product labels and throughout

this manual and other manuals that may apply to the

product.

Signal Words

DANGER - Immediate hazards which WILL result in

severe personal injury or death.

WARNING - Hazards or unsafe practices which COULD

result in severe personal injury or death.

CAUTION - Hazards or unsafe practices which COULD

result in minor personal injury or product or property

damage.

Signal Words in Manuals

The signal word WARNING is used throughout this manual

in the following manner:

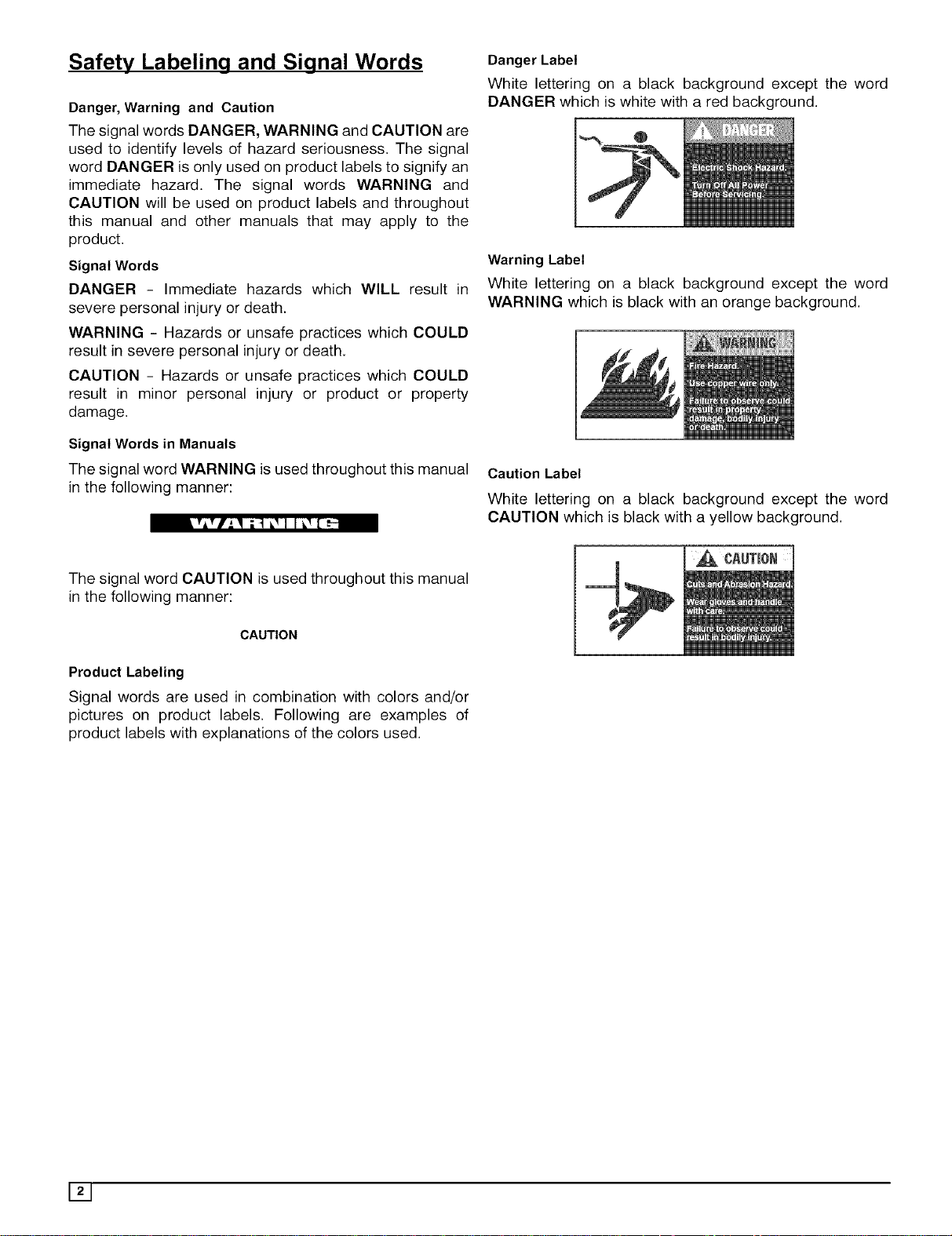

Danger Label

White lettering on a black background except the word

DANGER which is white with a red background.

Warning Label

White lettering on a black background except the word

WARNING which is black with an orange background.

Caution Label

White lettering on a black background except the word

CAUTION which is black with a yellow background.

The signal word CAUTION is used throughout this manual

in the following manner:

CAUTION

Product Labeling

Signal words are used in combination with colors and/or

pictures on product labels. Following are examples of

product labels with explanations of the colors used.

Page 3

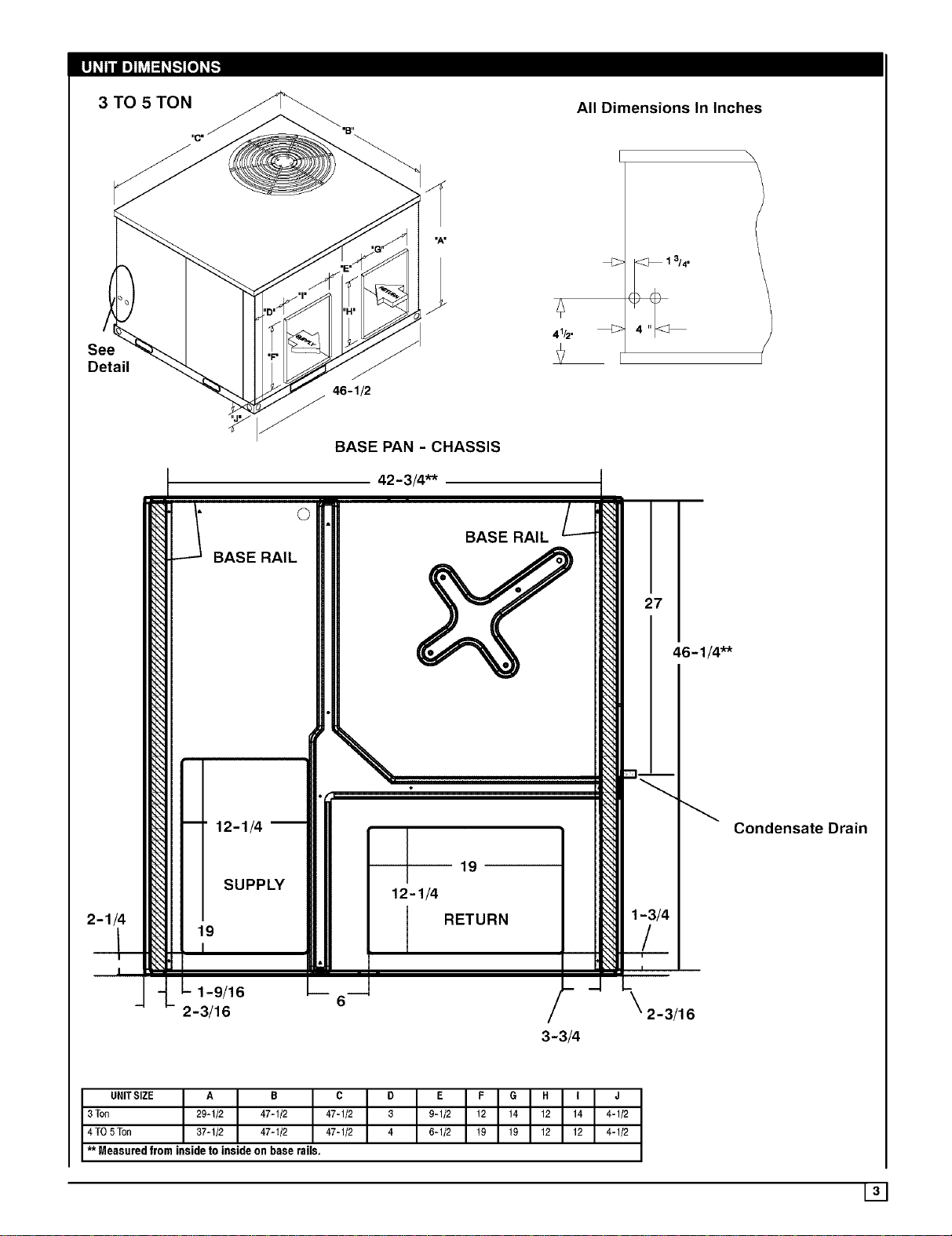

3 TO 5 TON All Dimensions In Inches

Detail

46-1/2

BASE PAN - CHASSIS

42 -3/4"*

©

BASE RAIL

-- 12-1/4

___ 19

I

1-9/16

2-3/16

SUPPLY

I

27

46- /4"*

Condensate Drain

1-3/4

/

2- 3/16

3-3/4

UNITSIZE A B C

3 Ton 29-1/2 47-1/2 47-1/2

4 TO5Ton 37-1/2 47-1/2 47-1/2

** Measured from inside to inside on base rails.

D

3

4

E F G H I J

9-1/2 12 14 12 14 4-1/2

6-1/2 19 19 12 12 4-1/2

131

Page 4

SAFE INSTALLATION

Installation or repairs made by unqualified persons can result

in hazards to you and others. Installation MUST conform with

local building codes or, in the absence of local codes, with the

ANSI Z223.1 and the National Electrical Code NFPA70-f 990 or

in Canada the National Standard CANiCGA B149-f and CSA

C.22.1 - Canadian Electrical Code Part 1.

The information contained in this manual is intended for use

by a qualified service technician familiar with safety proce-

dures and equipped with the proper tools and test instru-

ments.

Failure to carefully read and follow all instructions in this

manual can result in furnace malfunction, property damage,

personal injury and/or death.

• Seal supply and return air ducts.

• Check to see that filters are installed correctly and are

the proper type an size.

NOTE: It is the personal responsibility and obligation of the

customer to contact a qualified installer to ensure that the

installation is adequate and conforms to governing codes

and ordinances.

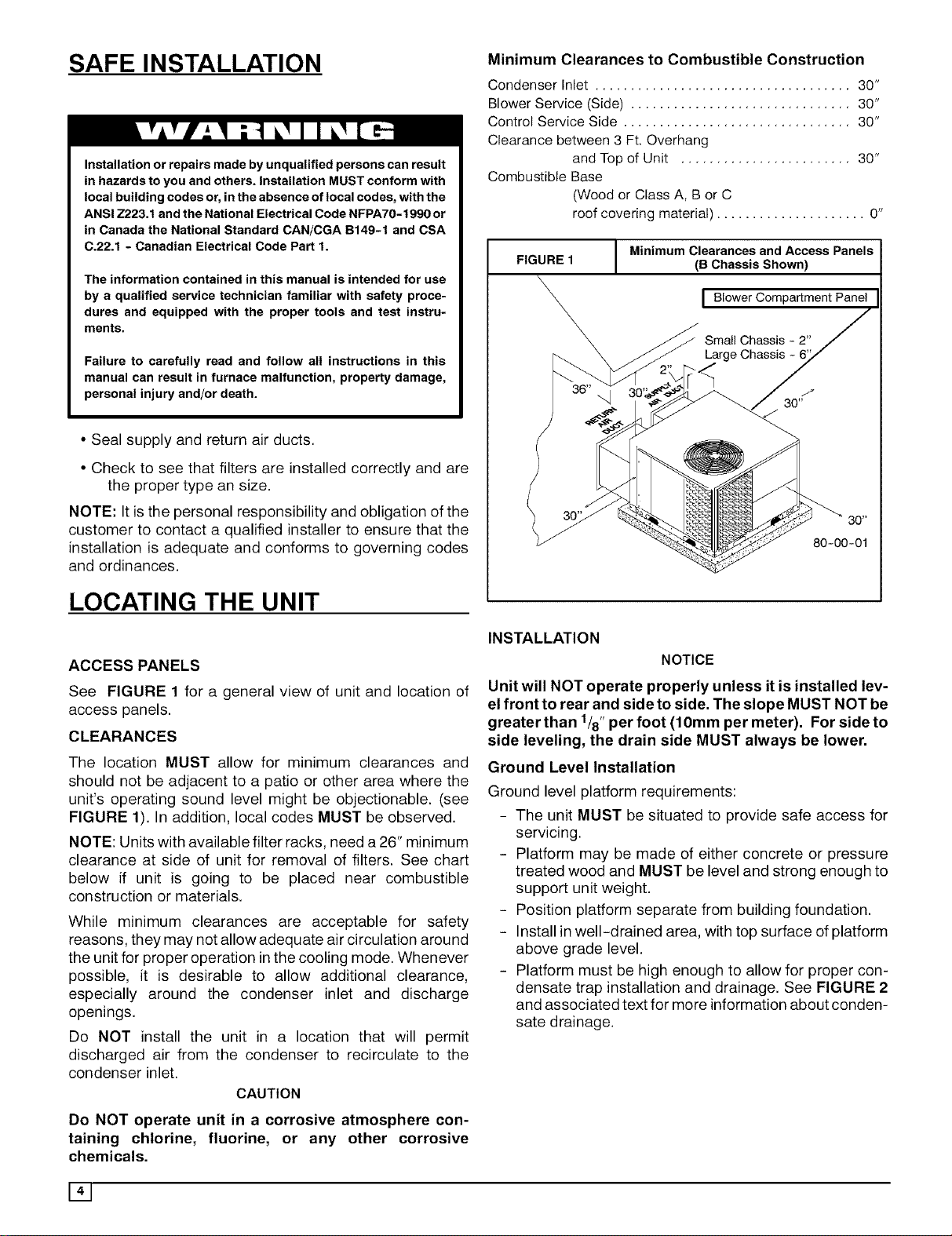

Minimum Clearances to Combustible Construction

Condenser Inlet .................................... 30"

Blower Service (Side) ............................... 30"

Control Service Side ................................ 30"

Clearance between 3 Ft. Overhang

and Top of Unit ........................ 30"

Combustible Base

(Wood or Class A, B or C

roof covering material) ..................... 0"

FIGURE 1

J Minimum Clearances and Access Panels

(B ChassisShown)

I Blower Compartment Panel

Small Chassis - 2"

Large Chassis

LOCATING THE UNIT

ACCESS PANELS

See FIGURE 1 for a general view of unit and location of

access panels.

CLEARANCES

The location MUST allow for minimum clearances and

should not be adjacent to a patio or other area where the

unit's operating sound level might be objectionable. (see

FIGURE 1). In addition, local codes MUST be observed.

NOTE: Units with available filter racks, need a26" minimum

clearance at side of unit for removal of filters. See chart

below if unit is going to be placed near combustible

construction or materials.

While minimum clearances are acceptable for safety

reasons, they may not allow adequate air circulation around

the unit for proper operation inthe cooling mode. Whenever

possible, it is desirable to allow additional clearance,

especially around the condenser inlet and discharge

openings.

Do NOT install the unit in a location that will permit

discharged air from the condenser to recirculate to the

condenser inlet.

CAUTION

INSTALLATION

NOTICE

Unit will NOT operate properly unless it is installed lev-

el front to rear and side to side. The slope MUST NOT be

greater than 1/8"per foot (10mm per meter). For side to

side leveling, the drain side MUST always be lower.

Ground Level Installation

Ground level platform requirements:

- The unit MUST be situated to provide safe access for

servicing.

- Platform may be made of either concrete or pressure

treated wood and MUST be level and strong enough to

support unit weight.

- Position platform separate from building foundation.

- Install in well-drained area, with top surface of platform

above grade level.

- Platform must be high enough to allow for proper con-

densate trap installation and drainage. See FIGURE 2

and associated text for more information about conden-

sate drainage.

DO NOT operate unit in a corrosive atmosphere con-

taining chlorine, fluorine, or any other corrosive

chemicals.

141

Page 5

Rooftop Installation

Rooftop platform requirements:

- The unit MUST be situated to provide safe access for

servicing.

- The existing roof structure MUST be adequate to sup-

port the weight of the unit or the roof MUST be

reinforced.

Check the weight of the unit in relation to the roof struc-

ture and local building codes or ordinances and

reinforce roof structure if necessary. See the last page

of this manual for unit weights.

- Support for the unit MUST be level and strong enough

to carry unit weight. The support may consist of a plat-

form or a combination of platform and roof beams or

curb.

- See Hoisting section for hoisting instructions.

HOISTING

NOTE: All access panels MUST be secured in place before

hoisting.

The unit should be hoisted with two lifting slings. Attach the

slings to rigging shackles that have been hooked through

holes in the base rail.

Two spreader bars MUST be placed on top of the unit to

protect the unit from damage from the pressure exerted by

the slings. Make sure that all equipment is adequate to

handle the weight of the unit and that the slings will not allow

the unit to shift.

Refer to on the back cover of this manual for illustrated

rigging instructions and weight chart.

DOWNFLOW CONVERSION

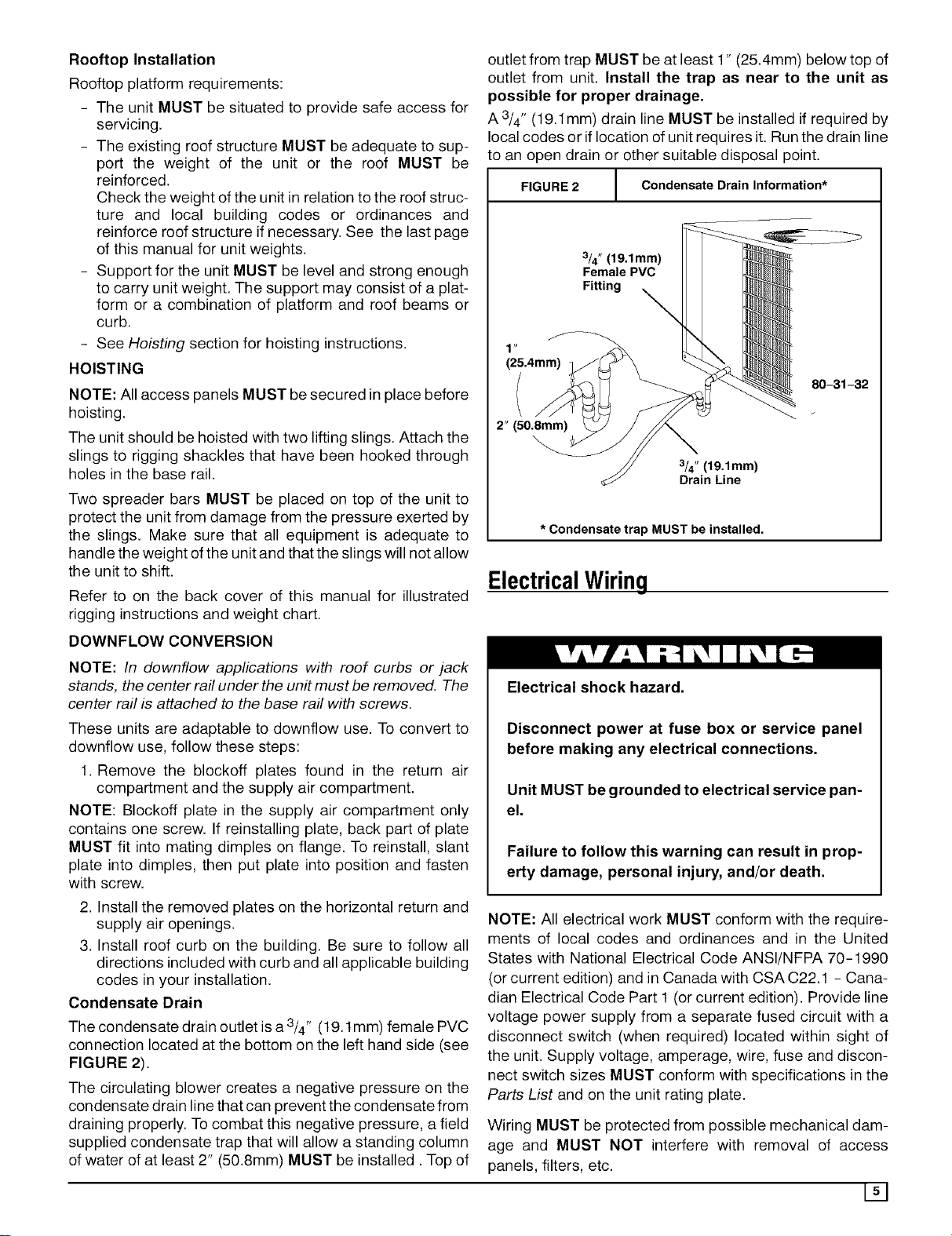

outlet from trap MUST be at least 1" (25.4mm) below top of

outlet from unit. Install the trap as near to the unit as

possible for proper drainage.

A 3/4" (19.1mm) drain line MUST be installed if required by

local codes or if location of unit requires it. Run the drain line

to an open drain or other suitable disposal point.

FIGURE 2

I N

(25.4mm)

2" (50.8mm)

* Condensate trap MUST be installed.

/ Condensate Drain Information*

1

3/4" (19.1mm)

Female PVC

Fitting

80-31-32

3/4" (19.1mm)

Drain Line

ElectricalWiring

NOTE: In downflow applications with roof curbs or jack

stands, the center rail under the un# must be removed. The

center rail is attached to the base rail with screws.

These units are adaptable to downflow use. To convert to

downflow use, follow these steps:

1. Remove the blockoff plates found in the return air

compartment and the supply air compartment.

NOTE: Blockoff plate in the supply air compartment only

contains one screw. If reinstalling plate, back part of plate

MUST fit into mating dimples on flange. To reinstall, slant

plate into dimples, then put plate into position and fasten

with screw.

2. Install the removed plates on the horizontal return and

supply air openings.

3. Install roof curb on the building. Be sure to follow all

directions included with curb and all applicable building

codes in your installation.

Condensate Drain

The condensate drain outlet is a 3/4" (19.1 mm) female PVC

connection located at the bottom on the left hand side (see

FIGURE 2).

The circulating blower creates a negative pressure on the

condensate drain line that can prevent the condensate from

draining properly. To combat this negative pressure, a field

supplied condensate trap that will allow a standing column

of water of at least 2" (50.8mm) MUST be installed. Top of

Electrical shock hazard.

Disconnect power at fuse box or service panel

before making any electrical connections.

Unit MUST be grounded to electrical service pan-

el.

Failure to follow this warning can result in prop-

erty damage, personal injury, and/or death.

NOTE: All electrical work MUST conform with the require-

ments of local codes and ordinances and in the United

States with National Electrical Code ANSI/NFPA 70-1990

(or current edition) and in Canada with CSA C22.1 - Cana-

dian Electrical Code Part 1 (or current edition). Provide line

voltage power supply from a separate fused circuit with a

disconnect switch (when required) located within sight of

the unit. Supply voltage, amperage, wire, fuse and discon-

nect switch sizes MUST conform with specifications in the

Parts List and on the unit rating plate.

Wiring MUST be protected from possible mechanical dam-

age and MUST NOT interfere with removal of access

panels, filters, etc.

151

Page 6

All exposed wiring and connections MUST be made with

weatherproof cable or wire unless installed in conduit.

LowVoltageWiring

Low voltage connections are made on the electronic control

board inside the electrical control compartment (see

FIGURE 5). For access, remove the electrical control ac-

cess panel).

Refer to the Parts List for the connection wiring diagram for

the applicable model and to the instructions included with

the thermostat.

Route low voltage wires through the port located at the bot-

tom left corner of the blower access panel side of the unit.

Route low voltage wires behind unit cornerpost, through the

wire clip provided, and up to the low voltage terminal board.

NOTE: If an Electric Heat Accessory is installed, see the

Electric Heat Accessory Installation Manual for low voltage

connections.

Thermostat

FIGURE 4 Connection Diagram

I ElectronicThermostat Low Voltage

Electronic Thermostat Subbase

- (White Rodgers: 1F92-71 and 1F94-71)

P -- - "1 f - -- "1

(2) ' (3) '

I I

, , , , (1)1

[C] [G] [R] [O] [Y1] [Wl] [W2] [El]

I I

i i

,, ,,r--

1 I 1 I 1 11 I

..... [¢ [¢

[C] [G] [R] [O1 [Y1] 1] 2]

Corn Fan 24V Rev. Pump Aux.

Valve Heat Emer.

Energ Cool Heat

Cool

Low Voltage Connections on Control Board.

Thermostat Subbase Notes:

(1) Common [C] may be shown as [B] or IX] on other types

of thermostats.

(2) Jumper subbase terminals [Y1] and [Wl].

(3) Jumper subbase terminals [W2] and [El].

, ,i Jumper Wire

i

I

The location ofthe thermostat has an important effect on the

operation of the unit. FIGURE 3 and FIGURE 4 show typi-

cal wiring connections for both manual and electronic

thermostats. FOLLOW THE INSTRUCTIONS INCLUDED

WITH THE THERMOSTAT FOR CORRECT LOCATION,

MOUNTING AND WIRING .

FIGURE 3 I Mechnical Thermostat Low Voltage

Connection Diagram

1

Mechanical Thermostat Subbase

- (White Rodgers: 1F58-34)

f - -- "1

(2) '

!

' ' (1)

[C] [G] [R] [O] [Y] [W2] [E]

Jumper Wire

[C] [G] [R] [O] [Y1] [Wl] [W2]

Corn Fan 24V Rev. Pump Aux.

Valve Heat Emer.

Ener Coo! Heat

Cool

Low Voltage Terminal Board at the Unit.

Thermostat Subbase Notes:

(1) Terminals [W2] and [E] already jumpered at subbase.

GroundConnections

A ground lug is installed on the control plate for the ground

connection (see FIGURE 5). Use a copper conductor of the

appropriate size from the unit to a grounded connection in

the electrical service panel or to a properly driven and elec-

trically grounded ground rod. See warning above.

LineVoltageWiring

Do NOT complete line voltage connections until unit is per-

manently grounded. All line voltage connections and the

ground connection MUST be made with copper wire.

Connections for line voltage are made on the unit electrical

control plate (see FIGURE 5). For access, remove the elec-

trical access panel.

Refer to applicable wiring diagram in the Parts List. Com-

plete the line service connections to the contactor 'U

terminals on the electrical control plate. Check all screwter-

minals to ensure they are tight.

NOTE: If an Electric Heat Accessory is installed, refer to the

Electric Heat Accessory Installation Manual to determine

line voltage connections. The Electric Heat Accessory

mounts inside the unit. Field supplied line voltage wires for

the Electric Heat Accessory (separate from the field sup-

plied line voltage wires to the unit) connect to the circuit

breaker(s) in the Electric Heat Accessory.

161

Page 7

Converting 230V Units to 208V

To convert 230V units to 208V:

and located, MUST NOT exceed the temperature limita-

tions for type T wire and MUST be installed according to the

manufacturer's instructions for the devices.

1. Turn electric power OFF.

2. Remove the electrical access panel.

3. Locate the 24V control transformer.

4. Remove wires from the terminal labeled "240V" onthe

24V control transformer and reconnect them to the

208V terminal of the 24V control transformer.

5. Replace the electrical access panel.

FieldInstalled Equipment

Wiring to be done in the field between the unit and other de-

vices, or between separate devices which are field installed

FIGURE 5 Typical Wiring Installation

FinalElectricalCheck

Make a final wiring check to be sure system is correctly

wired. Inspect field installed wiring and the routing to ensure

that rubbing or chafing due to vibration will not occur.

NOTE: Wiring MUST be installed so it is protected from pos-

sible mechanical damage.

t©

,ml

Control -_

Board

/ l _ _..._ "_

/

LT°Wrt.Vn°'_age [_ / ___ .._

Connections _"_ " _

, , ' " "_ Contactor

Transfo_

RI o w,lw_ GIo

Ground lug

171

Page 8

AirDistributionSystem

For airflow data (blower performance data, blower speed

tap settings, etc.) see the Parts List.

Ductwork

NOTE: The total heat gain/heat loss from the structure as

expressed in total Btu/hr MUST be calculated by manufac-

turer's method or in accordance with "A.S.H.R.A.E. Guide"

or "Manual J - Load Calculations" published by the Air

Conditioning Contractors of America or in Canada"H.R.A.I.

Residential Heating and Cooling Load Calculation Manual."

The total heat gain calculated should be equal to or less

than the cooling capacity output based on D.O.E. test

procedures, steady state efficiency times input.

Ductwork, supply registers, and return air grilles MUST be

designed and sized to handle the unit's cooling air vol-

ume requirements. If the unit is connected to an existing

system, the ductwork MUST be checked to make sure it is

adequate. Extra runs or larger duct sizes may have to be

installed.

Maximum recommended velocity intrunk ducts is 1000 feet

per minute (5.08m/s). Velocity in branches should not ex-

ceed 800 feet per minute (4.06m/s). Refer to the Parts List

for unit air volume requirements and system sizing recom-

mendations.

DuctworkConnections

The use of flexible, non -combustible connectors between

main trunk ducts and supply and return air plenums is rec-

ommended to minimize vibration transmission.

NOTE: Connect supply and return air plenums to unit in a

manner that will allow the top of the unit to be removed with-

out removing plenums. Plenums MUST be individually

sealed to unit casing. Ducts MUST be terminated inside

structure.

Filters

All return air MUST pass through a filter before entering the

unit. An electronic air cleaner, optional filter racks or other

accessible filter arrangements MUST be installed in the re-

turn air ductwork. Minimum recommended filter areas are

based on a velocity of 300 ft/min (1.2m/s) for disposable fil-

ters and 500 ft/min (2.54m/s) for washable high velocity

filters.

CAUTION

Do NOT operate the unit without all filters in place.

NOTE: Ductwork sizing affects temperature rise and cool-

ing temperature differential. Be sure to properly size

ductwork to the capacity and airflow characteristics of your

unit. Failure to do so can affect limit controls, compressors,

motors, and other components and will lead to premature

failure ofcomponents. This will also adversely affect day to

day unit performance.

Refer to unit rating plate for proper Electric Heat Accessory

sizing and see the Temperature Rise Check section in the

Electric Heat Accessory Installation Instructions.

DuctworkInsulation

It is recommended that ductwork installed outdoors have a

minimum of 2" (51mm) of fiberglass insulation and be cov-

ered by a weatherproof vapor barrier that is protected

against damage. Caulking and flashings, or other means

adequate to provide a permanent weather seal, must be

used.

It is recommended that ductwork installed in attics or other

areas exposed to outdoor temperatures have a minimum of

2" (51mm) fiberglass insulation and have an indoor type va-

por barrier.

181

Page 9

Start-up Procedures

Electrical shock hazard.

Use extreme care during all of the following

checks and procedures.

Make sure electric power is turned OFF as

instructed in appropriate steps.

Cooling, Heating (Heat Pump) and Auxiliary Electric

Strip Heat

NOTE: The cooling, heat pump and strip heat airflows

are all on the same speed tap. The refrigerant system

requires the same specific CFM for proper operation in

the cooling and the heat pump mode. For this reason,

cooling and heating airflow must be the same. DO NOT

SPLITOUT INTO A COOLING SPEED AND HEATING

SPEED.

Failure to follow this warning can result in prop-

erty damage, personal injury, and/or death.

CirculatingAir Blower

DeterminingBlower Speed

1. Turn electric power OFF.

2.

From the system design, determine the external static

pressure (ESP) for the supply ducts, return ducts and

registers, diffusers, grilles, dampers, heaters and fil-

ters.

3. To your system ESP determined in Step 2, add 0.05

In. W.C. for a wet coil.

4. From the system design, determine the desired cool-

ing airflow in cubic feet per minute (CFM).

. Locate the unit's Blower Performance Data table in

the tech data sheet for the unit's voltage. (The tech

data sheet is attached to the inside of the electrical ac-

cess panel and is also published in the Parts List.)

From the table, determine the speed tap the desired

airflow requires.

6. See next section, Speed Taps, to set the blower motor

speed terminal block (speed taps) determined in the

following steps.

SpeedTaps

After determining the required CFM and speed tap data

from the tech data sheet, follow the steps below to change

speeds if necessary.

NOTE: The yellow lead MUST always be connected to the

speed tap block atthe common quick connect terminal. The

terminal is identified as COM. Also, this is the only lead

which is 3/16" wide. All other quick connects are 1/4" wide.

Refer to the unit's wiring diagram, which is attached to the

inside of the electrical access panel and is also published in

the Parts List for the desired speed tap to achieve the re-

quired CFM for the applicable model.

CheckBefore Starting

Check that the blower motor speed terminal block is

set to the proper speed. Refer to the unit wiring dia-

gram and the Technical Labels in the Parts List.

2.

Check to see that clean, properly sized field supplied

air filters are installed in the return air duct.

3.

Inspect the inside of the unit to be sure that all wires

are in place and all tools, etc. are removed.

4. Replace all service access panels.

Check the unit's operation as outlined in the following

instructions. If any unusual sparking, odors or noises are

encountered, shut OFF electric power immediately. Re-

check for wiring errors, or obstructions in or near blower

motors.

Sequenceof Operation

CoolingMode:Energized(R,G,O,Y1)

De-energized(N/A)

(a)When high and low voltage is initially applied to

unit:

(1) On a call for cooling ......... :

The compressor and condenser fan will have a delay

on and will energize after 5 minutes. The evaporator

blower motor will energize immediately. The delay on

for the compressor and the condenser fan can be by-

passed by jumpering the test pins on the defrost

board control.

(2) When the cooling setpoint has been satis-

fied ......... :

The compressor and condenser fan will de-energize

immediately. The evaporator blower motor will have a

delay off and will de-energize after 30 seconds.

(b) When high and low voltage has been applied

to unit for morethan 5 minutes:

(1) On a call for cooling ......... :

The compressor and condenser fan will energize im-

mediately. The evaporator blower motor energize

immediately.

Page 10

(2) When the cooling setpoint has been satis-

fied ......... :

The compressor and condenser fan will de-energize

immediately. The evaporator blower motor will have a

delay off and will de-energize after 30 seconds.

(2) When the heating setpoint has been satis-

fied ......... :

The compressor and condenser fan will de-energize

immediately. The evaporator blower motor will have a

delay off and will de-energize after 30 seconds.

HeatingMode:Energized(R,G,Y1)

De-energized(0)

(a)When high and low voltage is initially applied to

unit:

(1) On a call for heating ......... :

The compressor and condenser fan will have a delay

on and will energize after 5 minutes. The evaporator

blower motor will have a delay on and will energize af-

ter 30 seconds. The delay on for the compressor and

the condenser fan can be by-passed by jumpering

the test pins on the defrost board control.

(2) When the heating setpoint has been satis-

fied ......... :

The compressor and condenser fan will de-energize

immediately. The evaporator blower motor will have a

delay off and will de-energize after 30 seconds.

(b) When high and low voltage has been appliedto

unitfor morethan 5 minutes

(1) On a call for heating ......... :

The compressor and condenser fan will energize im-

mediately. The evaporator blower motor will have a

delay on and will energize after 30 seconds.

Defrost Mode:Energized (R,G,Y1) De-energized (0)

Defrost Sensor Closed

On a call for defrost .........

(1)

When the defrost sensor closes (this can be simu-

lated by placing a jumper across the DFST and

T'STAT terminals on the control board) in the heating

mode,there is a 30,60 or 90 minute defrost on delay

before the defrost mode begins. This delay is deter-

mined by the jumper selection on the control board.

See Figure 7.

(2)

When defrost has been completed .........

This condition will be maintained until the defrost sen-

sor opens or for a mzximum of 10 minutes, whichever

comes first.

The TEST selection will speed up the defrost/heating cycle

for diagnostic purposes. When the jumper is in the TEST

position and Y is energized, the unit will cycle from heating

(10 seconds) to defrost (2 seconds) to heating (10 seconds)

to defrost (2 seconds) for a maximum of 8 times. If the

jumper is left in the TEST position, the control will ignore the

call for TEST and default to a 90 minute defrost cycle. If the

jumper is not installed, the control will default to a 90 minute

defrost cycle.

NOTE: A jumper across the DFST and T'STAT terminals is

not necessary in order to check out the defrost control.

11ol

Page 11

FIGURE 6 I Blower Motor Speed Taps (3-Speed and 4-Speed Motors)

SPEED DATA IN UNITS

TECHNICAL INFORMATION LABEL

I BE SURE TO CHECK BLOWER MOTOR I

ON THE UNIT

Operation

Electrical shock hazard.

Turn OFF electric power supply at disconnect

switch or service panel before removing any ac-

cess or service panel from unit.

Failure to follow this warning can result in prop-

erty damage, personal injury, and/or death.

Features

ScrollAnti-CycleTimer

All single phase heat pumps with scroll compressors are

equipped with a defrost control board which features an in-

ternal anti-short cycle timer that delays the start of the

compressor in the event of a power interruption. This fea-

ture is to allow pressure equalization throughout the system

\-_\ /

and prevent possible reverse rotation of the scroll compres-

sor.

Lossof Charge PressureSwitch

A low pressure switch on the liquid line (high side) has been

installed to prevent system damage due to a loss of charge.

The switch will open and de-energize the contactor if the

high side pressure drops below the set point of the switch.

DefrostControlTime IntervalAdjustment

Electrical shock hazard.

Turn OFF electric power supply at disconnect

switch or service panel before removing any ac-

cess or service panel from unit.

Failure to follow this warning can result in prop-

erty damage, personal injury, and/or death.

illl

Page 12

To adjust defrost interval:

TurningThe Unit Off

1.

Turn off all power to Heat Pump.

2.

Remove control box cover.

3.

Locate electronic control board.

4.

The Control Board has a jumper that allows you to

change the defrost time interval. (See Figure Below)

Change the desired time by removing the jumper and

placing the jumper on 30, 60, or 90.

30 = 30 minutes, 60 = 60minutes, 90 = 90 minutes.

FIGURE 7 Defrost Control

C°2trrd°l

_ ]__ _ Jumper placed

Maintenance

Air Filters,CondenserCoil and Condensate

DrainMaintenance

Refer to Home Owners Manual supplied with your heat

pump for information on filter sizes, condenser coil clear-

ances from shrubbery and condensate drainage

allowances.

CAUTION

Do NOT operate unit without filters in place. Inspect fil-

ters monthly and clean and/or replace as needed.

RefrigerationAccess Ports

This unit is equipped with refrigeration access ports

mounted onthe side of the unit. Refer to FIGURE 9 for iden-

tification of ports.

This unit is also equipped with internal access ports on the

suction and discharge tubing line which can be used for

evacuation, pull down and recharging of the refrigeration

system.

FIGURE 9 Typical Access Ports

Oil the condenser fan motor after five years of operation and

every five years thereafter.

Use SAE 10W30 motor oil. To oil, remove the hole plugs from

the motor end bells and add several drops (approximately

1/2 teaspoonful) of oil with a squeeze type, flexible tube oil-

er. Replace hole plugs after oiling. Do NOT over oil.

Clean the surrounding area and the condenser and evapo-

rator coils. Use caution to avoid damage to coil fins. Do not

use an acid-based cleaner on coated fin material.

BlowerMotorAccess

To remove the blower motor and/or the blower motor hous-

ing assembly, remove the blower access panel.

Refer to FIGURE 10 for a view of blower motor and

compartment.

FIGURE 10 1 Blower Motor and Housing

AnnualMaintenanceand Inspection

CondenserFan Motor

CAUTION

Do NOT use 3 in 1oil, penetrating oil, WD40 or similar

oils to oil motor bearings.

BlowerWire Color Identification

Use FIGURE 11 to identify wires on blower motor.

To change speed tap settings, see Speed Taps in the Start-

up Procedures section of this manual.

1131

Page 14

FIGURE 11 Wire Colors

8@ @@ 16b

CirculatingAir Blower

Visually inspect the blower wheel for accumulations of dirt

or lint. Clean the compartment and the blower wheel. Ifac-

cumulation is excessive on blower wheel, or does not easily

remove, it will be necessary to remove the blower assembly.

CAUTION

Do NOT use 3 in 1oil, penetrating oil, WD40 or similar

oils to oil motor bearings.

Oil the blower motor by adding 1/2 teaspoonful (lcc) of SAE

10W30 to each motor bearing. The blower motor should be

oiled after five years of operation and every five years there-

after.

1141

Loading...

Loading...