Page 1

Installation Instructions

I PGAA / PGAC / PGAD - 11/2 to 5 TON

PGMD/PGME

COMBINATIONUNITS

GASHEAT/ELECTRICCOOL

TABLEOFCONTENTS

1. SAFETY LABELING AND SIGNAL WORDS .................... 2

DANGER,WARNINGAND CAUTION ............................... 2

SIGNALWORDS ............................................... 2

SignalWordsinManuals........................................ 2

PRODUCTLABELING ........................................... 2

DangerLabel ................................................ 2

WarningLabel ............................................... 2

CautionLabel................................................ 2

2. UNIT DIMENSIONS ..................................... 3-4

3. SAFE INSTALLATION REQUIREMENTS ...................... 5

4. LOCATING THE UNIT .................................... 5

ACCESSPANELS .............................................. 5

CLEARANCES................................................. 5

MinimumClearancesto CombustibleConstruction...................... 5

GROUNDLEVEL INSTALLATION................................... 5

ROOFTOPINSTALLATION...................................... 5-6

HOISTING .................................................... 6

DownflowConversion........................................... 6

HeatingVentAssembly ......................................... 6

CondensateDrain ............................................. 6

5. PRE- EXISTING COMMON VENT CHECK ...................... 7

6. GAS SUPPLY AND PIPING ................................ 7

GASPIPING .................................................. 7

GasPipeSize ............................................... 7

PIPINGAT UNIT ................................................ 7

Connections................................................. 7

ORIFICES .................................................... 7

OrificeSizes ................................................. 7

ChangingOrifices ............................................. 8

7. ELECTRICAL WIRING .................................... 8

UneVoltageWiring ............................................ 8

GroundConnections ........................................... 8

UneConnections .............................................8

THERMOSTAT/HEAT ANTICIPATOR ...............................8

FinalElectricalCheck .......................................... 8

8. DUCTWORK ........................................... 8

DuctworkInsulation ........................................ 9

DuctworkConnections.......................................... 9

FILTERS ..................................................... 9

9. START- UP PROCEDURES ................................ 9

CHECKBEFORESTARTING ...................................... 9

ReverseRotation(ScrollCompressorsOnly) .......................... 9

ManifoldGas PressureAdjustment ................................. 9

GASPRESSURES.............................................. 9

CIRCULATINGAIRBLOWER ..................................... 10

HEATINGSTAR-UPPROCEDURES................................ 10

TemperatureRiseCheck ....................................... 10

FANCONTROLCHECK ......................................... 10

SPEEDTAPS ................................................. 11

CONTINUOUSFANOPERATION .................................. 11

COOLING ................................................... 11

10. OPERATION ......................................... 12

COMBUSTIONIINDOORFANCONTROL............................. 12

SCROLLANTI-CYCLETIMER .................................... 12

11. MAINTENANCE ....................................... 12

MONTHLYMAINTENANCEANDINSPECTIONCHECKS ................. 12

Air Filters .................................................. 12

HEATINGSEASONCHECKS (MONTHLY) ........................... 12

Pilot Flame ................................................. 12

MainBurnerFlame ........................................... 12

ANNUALMAINTENANCEANDINSPECTION ......................... "12

CondenserFan Motor ......................................... 12

VENTASSEMBLY ............................................. 13

BLOWERMOTORACCESS ...................................... 13

Method1 .................................................. 13

Motorremovalandreplacement.................................. 13

Method2 .................................................. 13

Burners/ HeatExchangers/ FlueGas Passages ...................... t3

INSPECTIONANDCLEANINGOF BURNERASSEMBLY

/HEATEXCHANGERS/FLUEGASPASSAGES..................... 13-14

ForOaaiifiedServiceTechnicianOnly ........................... t3-t4

12. RIGGING INSTRUCTIONS .............................. 15

13. NOTES ............................................. 16

462 01 1004 00

10-23-01

Printed in U.S.A.

Page 2

1. Safety Labeling and Signal Words

Danger, Warning and Caution

ThesignalwordsDANGER,WARNINGandCAUTIONareusedtoidentifylevelsofhaz-

ard seriousness.The signalword DANGERis onlyusedon productlabelsto signifyan

immediatehazard.The signalwordsWARNINGandCAUTIONwillbe used onproduct

labelsandthroughoutthis manualandothermanualsthat mayapplyto theproduct.

Danger Label

Whiteletteringonablackbackgroundexceptthe wordDANGERwhichiswhitewitha red

background.

Signal Words

DANGER- ImmediatehazardswhichWILLresultin severepersonalinjuryordeath.

WARNING- HazardsorunsafepracticeswhichCOULDresultinseverepersonalinjuryor

death.

CAUTION- HazardsorunsafepracticeswhichCOULDresultinminorpersonalinjuryor

productor propertydamage.

Warning Label

Whiteletteringon ablackbackgroundexceptthe wordWARNINGwhichisblackwithan

orangebackground.

Signal Words in Manuals

Thesignal wordWARNINGisusedthroughoutthismanualinthefollowingmanner:

Thesignal wordCAUTIONisusedthroughoutthismanualin thefollowingmanner:

CAUTION

Product Labeling

Signalwords areusedin combinationwithcolors and/orpictureson productlabels.Fol-

lowingareexamplesof productlabelswith explanationsofthe colors used.

Caution Label

Whiteletteringon a blackbackgroundexceptthe wordCAUTIONwhichisblackwitha

yellowbackground.

Page 3

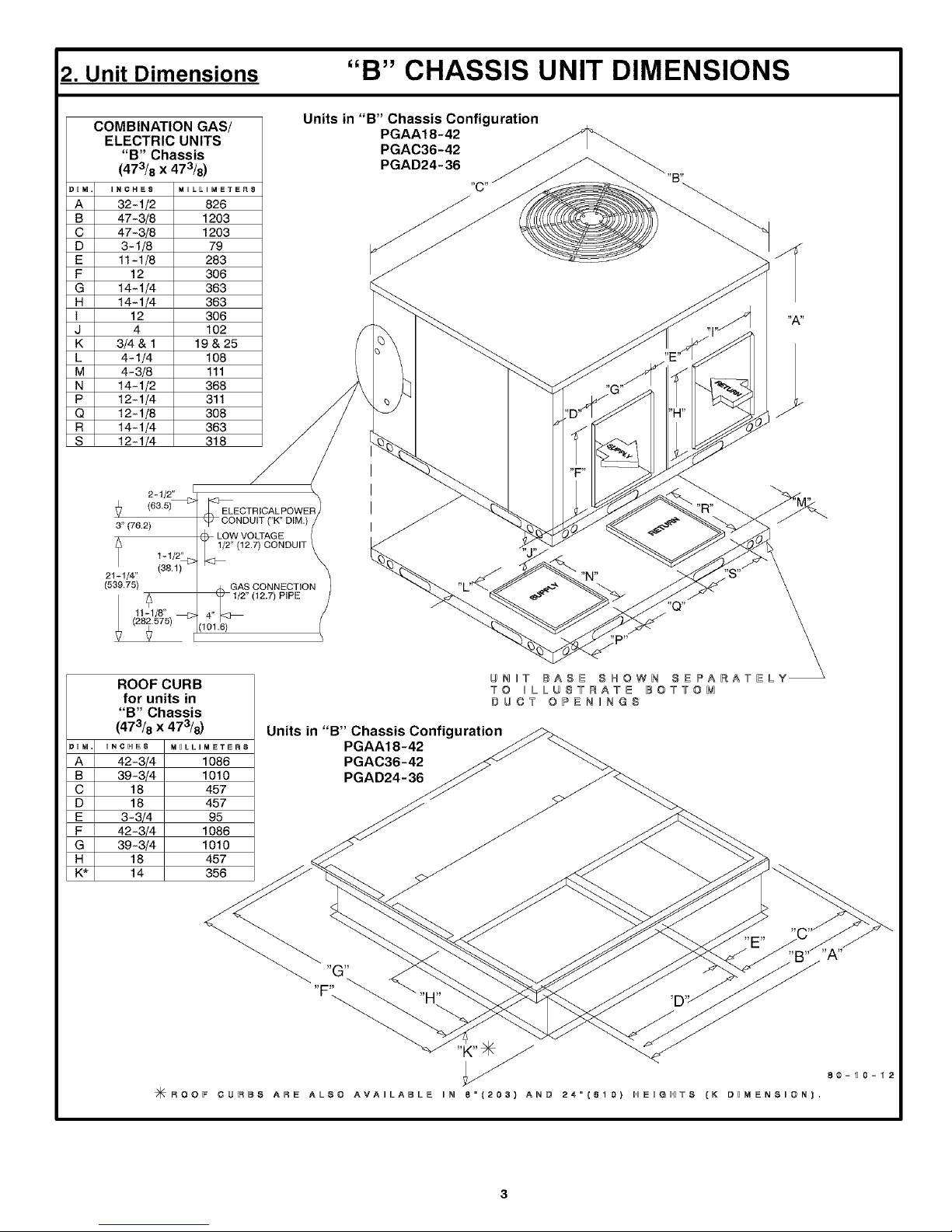

2. Unit Dimensions "B" CHASSIS UNIT DIMENSIONS

COMBINATION GAS/

A

B

C

D

E

F

G

H

I

J

K

L

M

N

P

Q

R

S

D01_<

A

B

C

D

E

F

G

H

K*

Units in "B" Chassis Configuration

PGAA18-42

ELECTRIC UNITS

"B" Chassis PGAC36-42 _ A

(473/8x473/8) PGAD24-36_ _ _ _"B"

INCHES MILLI_IETER "C" /__

32-1/2I 828

47-3/8 I 1203 / / (- _((_,(_..(_)_J))))))))]/ _. _.

47-378 I 1203 / / _ _._.___/JJJ _ "%1

3-1/8 I 79 / / ___/ _ /"

11-1/8 I 283 _ _ _/

12 I 306 _ //

14-1/4 I 363 _ //

14-1/4 I 363 _ //

12 I 306 __ _ _ "A"

4 102 'T'/"

4-1/4 to8 _ _ "E'_

12-1/4 311 // \_Xj _ _/'_ / _ -

12-118 308 / / 'D" // 'H" -"_/, /

14-1/4 363 / / y _ _O_

I

12-1/4 318

t&5)_> _._ _ ,,,

I-1/2'_

(539.75) _ } "",_ '_L"<,..,._ / _ _.. /_ \

11-1/8" _ 4"_

UNBT NAgN NHOWN 8NPARATNLY _

ROOFCURB TO ILLUSTRATE BOTTOM

for units in #UOT OPSN_I8

"B" Chassis

(473/8 x 473/8) Units in "B" Chassis Configuration_

"NCHES M,LI=IM_T_.8 PGAA18-42 _ _.

42-3/4 1086 PGAC36-42 _

3-3/4

42-3/4 1086 _ _ _ _

14 356

80-10-12

7_ROOF CU_E_S ARE ALSO AVA_LAE_LE I_ 8"(203} AND 24"(610) HEIGHTS (K D_MENSION).

Page 4

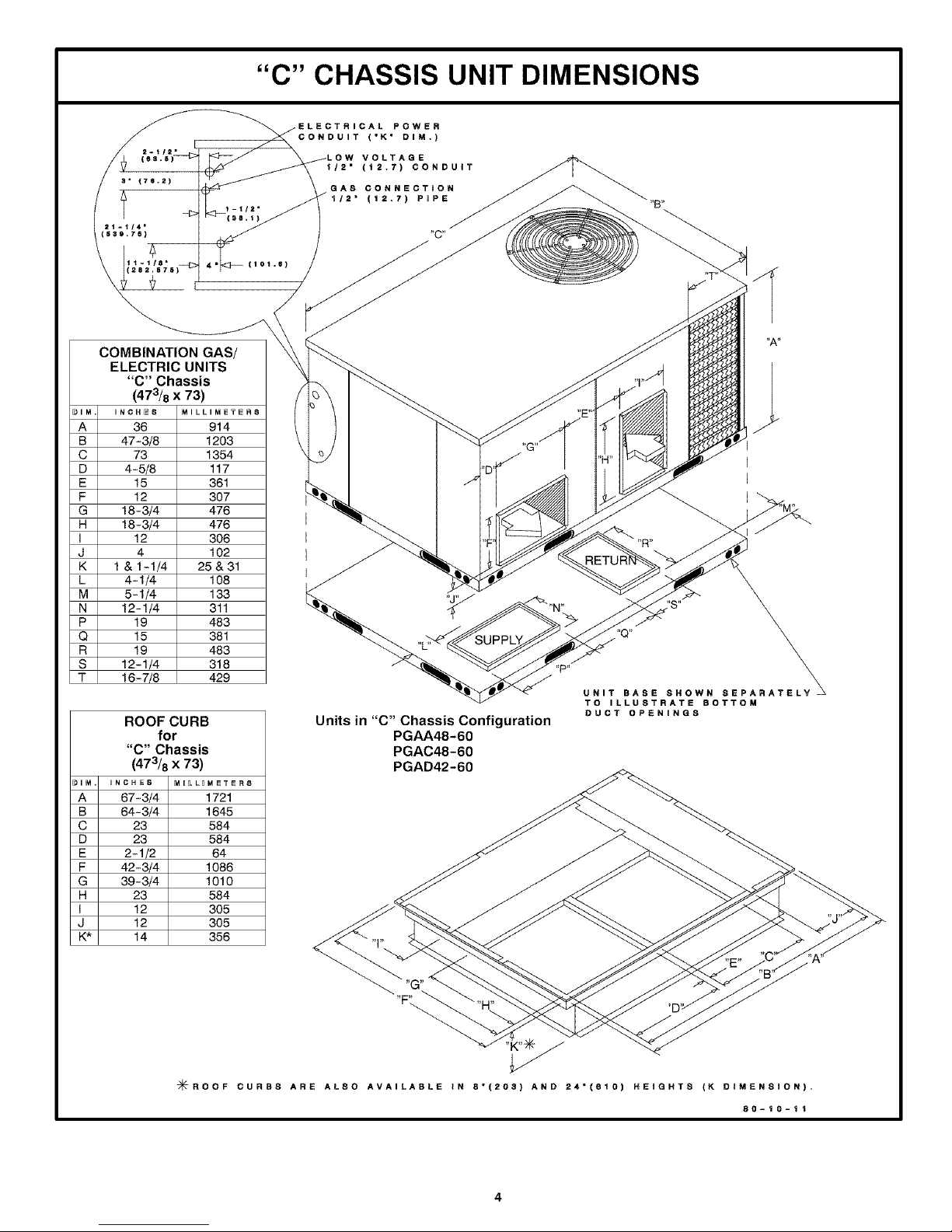

"C" CHASSIS UNIT DIMENSIONS

1-1/2"

COMBINATION GAS/

ELECTRIC UNITS

"C" Chassis

(473/8 X 73)

DgM. INCHES MILLIMETER8

A 36 914

B 47-3/8 t 203

C 73 1354

D 4-5/8 117

E 15 361

F 12 307

G 18-3/4 476

H 18-3/4 476

I 12 306

J 4 t02

K 1 & 1-1/4 25 & 31

L 4-1/4 108

M 5-1/4 133

N 12-1/4 311

P 19 483

Q 15 381

R 19 483

S 12-1/4 318

T 16-7/8 429

ROOF CURB

for

"C" Chassis

(473/8 X 73)

#_M. "NCHE8 M_LL_METER8

A 67-3/4 1721

B 64-3/4 1645

C 23 584

D 23 584

E 2-1/2 64

F 42-3/4 1086

G 39-3/4 1010

H 23 584

I 12 305

J 12 305

K* 14 356

(10t.8)

ELECTRICAL POWER

CONDUIT ('K' DIM.)

VOLTAGE

1/2" (12.7) CONDUIT

GAS CONNECTION

_/2" (12,7) P_PE

Units in "C" Chassis Configuration

PGAA48-60

PGAC48-60

PGAD42-60

UNIT BASE SHOWN SEPARAT

TO ILLUSTRATE BOTTOM

DUCT OPENINGS

"F\

-/_-ROOF CURBS ARE ALSO AVAILABLE IN 8"(208) AND 24"(810) HEIGHTS (K DIMENSION),

80-18-11

Page 5

3. SAFE INSTALLATION REQUIREMENTS

Installation or repairs made by unqualified persons can result

in hazards to you and others. Installation MUST conform with

local building codes or, in the absence of local codes, with the

ANSI Z223.1 and the National Electrical Code NFPA70-f 990 or

in Canada the National Standard CANiCGA B149-1 and CSA

C.22.1 - Canadian Electrical Code Part 1.

The information contained in this manual is intended for use

by a qualified service technician familiar with safety proce-

dures and equipped with the proper tools and test instru-

ments.

Failure to carefully read and follow all instructions in this

manual can result in furnace malfunction, property damage,

personal injury and/or death.

• DoNOT usethisfurnaceas aconstructionheater.

• Useonlythe Typeofgas approvedforthis furnace(SeeRatingPlate).

• DoNOT useopen flameto testfor gas leak.

• Sealsupplyand returnair ducts.

• Checkto seethat filtersareinstalledcorrectlyandarethepropertypeandsize.

NOTE:It isthepersonalresponsibilityandobligationofthecustomertocontacta qualified

installerto ensurethat theinstallationisadequateandconformsto governingcodesand

ordinances.

CAUTION

It is recommended that a qualified service technician check the heat

exchanger integrity every two (2) years, after the first four (4) years of

operation.

4. LOCATING THE UNIT

ACCESS PANELS

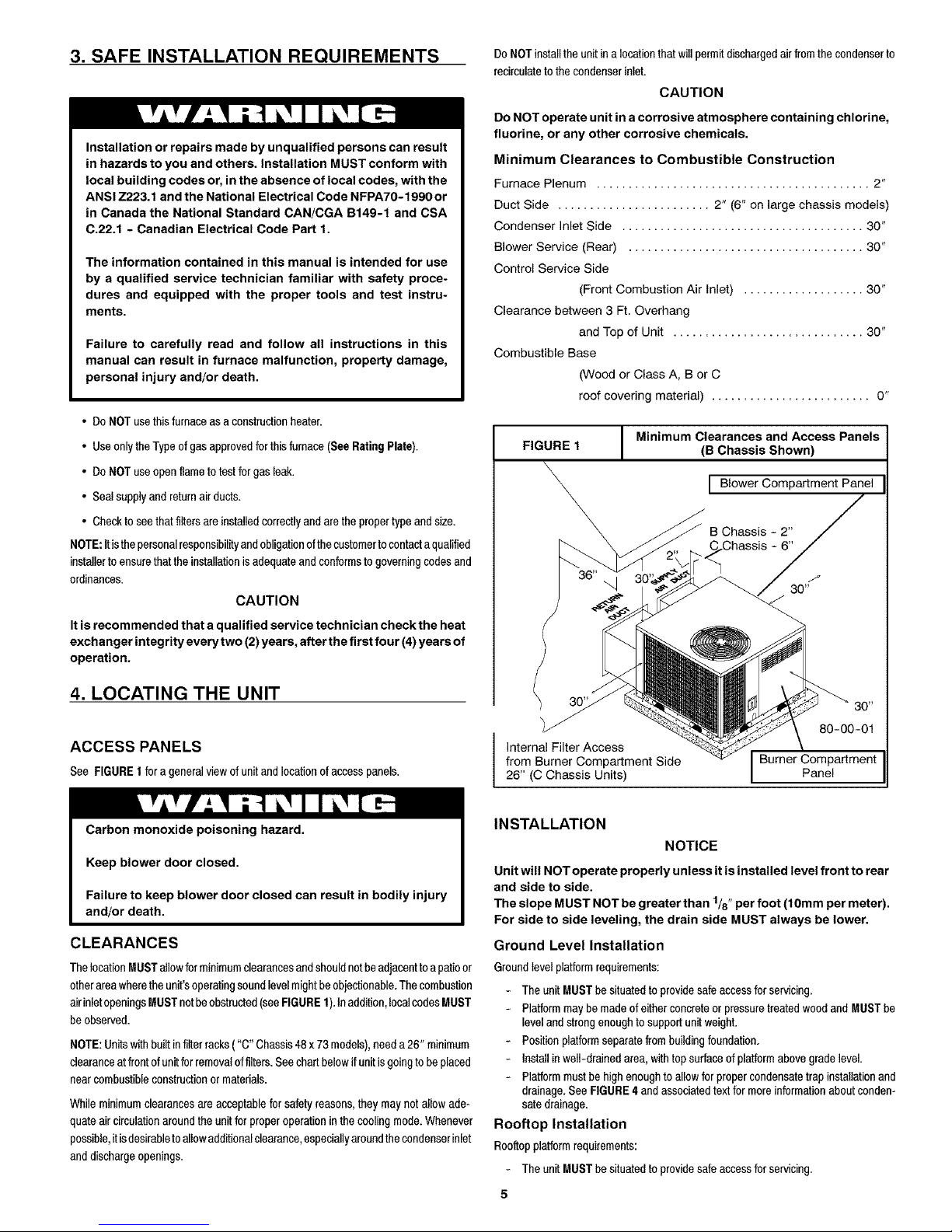

See FIGURE1forageneralviewofunitandlocationofaccesspanels.

Carbon monoxide poisoning hazard.

Do NOTinstalltheunit in alocationthatwillpermitdischargedairfromthecondenserto

recirculatetothe condenserinlet.

CAUTION

Do NOT operate unit in a corrosive atmosphere containing chlorine,

fluorine, or any other corrosive chemicals.

Minimum Clearances to Combustible Construction

Furnace Plenum ........................................... 2"

Duct Side ........................ 2" (6" on large chassis models)

Condenser Inlet Side ...................................... 30"

Blower Service (Rear) ..................................... 30"

Control Service Side

(Front Combustion Air Inlet) ................... 30"

Clearance between 3 Ft. Overhang

and Top of Unit .............................. 30"

Combustible Base

(Wood or Class A, B or C

roof covering material) ......................... 0"

FIGURE 1

\

I Minimum Clearances and Access Panels

(B Chassis Shown)

Blower Compartment Panel

I nternal Filter Access

from Burner Compartment Side

26" (C Chassis Units)

30"

80-00-01

Burner Compartment

Panel

Keep blower door closed.

Failure to keep blower door closed can result in bodily injury

and/or death.

CLEARANCES

ThelocationMUSTallowfor minimumclearancesandshouldnot beadjacentto apatioor

otherareawheretheunit'soperatingsoundlevelmightbeobjectionable.Thecombustion

airinletopeningsMUSTnotbeobstructed(seeFIGURE1).In addition,localcodesMUST

beobserved.

NOTE:Units withbuiltinfilterracks( "C" Chassis48x 73 models),need a26" minimum

clearanceatfrontofunitforremovaloffilters.Seechartbelowif unitisgoingtobe placed

nearcombustibleconstructionormaterials.

While minimumclearancesare acceptablefor safetyreasons,they may notallowade-

quateair circulationaroundthe unitfor properoperationinthecoolingmode.Whenever

possible,itisdesirabletoallowadditionalclearance,especiallyaroundthecondenserinlet

anddischargeopenings.

INSTALLATION

NOTICE

Unit will NOT operate properly unless it is installed level front to rear

and side to side.

The slope MUST NOT be greater than 1/8" per foot (10mm per meter).

For side to side leveling, the drain side MUST always be lower.

Ground Level Installation

Groundlevel platformrequirements:

- The unitMUSTbe situatedtoprovidesafo accessforservicing.

Platformmay be madeof eitherconcreteor pressuretreatedwoodand MUSTbe

level andstrongenoughto supportunitweight.

Positionplatformseparatefrom buildingfoundation.

Installin well-drainedarea,withtopsurface ofplatformabovegrade level.

Platformmust be highenoughto allowfor propercondensatetrapinstallationand

drainage.SeeFIGURE4 andassociatedtextfor moreinformationaboutconden-

satedrainage.

Rooftop Installation

Rooftopplatformrequirements:

- The unitMUST be situatedto providesafoaccessforservicing.

Page 6

- TheexistingroofstructureMUSTbeadequatetosupporttheweightoftheunitorthe

roofMUSTbereinforced.

Checktheweightoftheunitin relationtothe roofstructureandlocalbuildingcodes

orordinancesand reinforceroofstructureifnecessary.See FIGURE21onthe back

coverofthis manualforunit weights.

- Supportfortheunit MUSTbelevelandstrongenoughtocarryunitweight.Thesup-

portmayconsistof aplatformoracombinationof platformand roofbeamsorcurb.

- See Hoistingsectionbelowfor hoistinginstructions.

HOISTING

NOTE:All accesspanelsMUST besecuredin placebeforehoisting.

Theunitshouldbe hoistedwithtwo liftingslings.Attachtheslingsto riggingshacklesthat

havebeen hookedthroughholesin the baserail.

TwospreaderbarsMUSTbeplacedontop ofthe unitto protecttheunitfromdamagefrom

thepressureexertedbythe slings.Makesurethatallequipmentisadequatetohandlethe

weightofthe unit andthatthe slingswill not allowthe unitto shift.

RefertoFIGURE21on thebackcoverof thismanualforillustratedrigginginstructionsand

weightchart.

DOWNFLOW CONVERSION

These unitsare adaptableto downflowuse. Toconvert to downflowuse,follow these

steps:

1. Removethe blockoffplatesfoundin the returnaircempartmentandthe supplyair

compartment.SeeFIGURE2.

NOTE:Blockoffplateinthesupplyaircempartmentonlycontainsonescrew.Ifreinstalling

plate,backpartofplateMUSTfitintomatingdimplesonflange.Toreinstall,slantplateinto

dimples,thenput plate intopositionand fastenwithscrew.

2. Instanthe removedplateson thehorizontalreturnand supplyair openings.

3. Installroofcurb on the building.Besure to followall directionsincludedwithcurb

andallapplicablebuildingcodesinyourinstallation.(SeePages2 or3forappropri-

atecurbto usewithyour model.)

FIGURE 2 Blockoff Plate (Return Air Compartment)

I

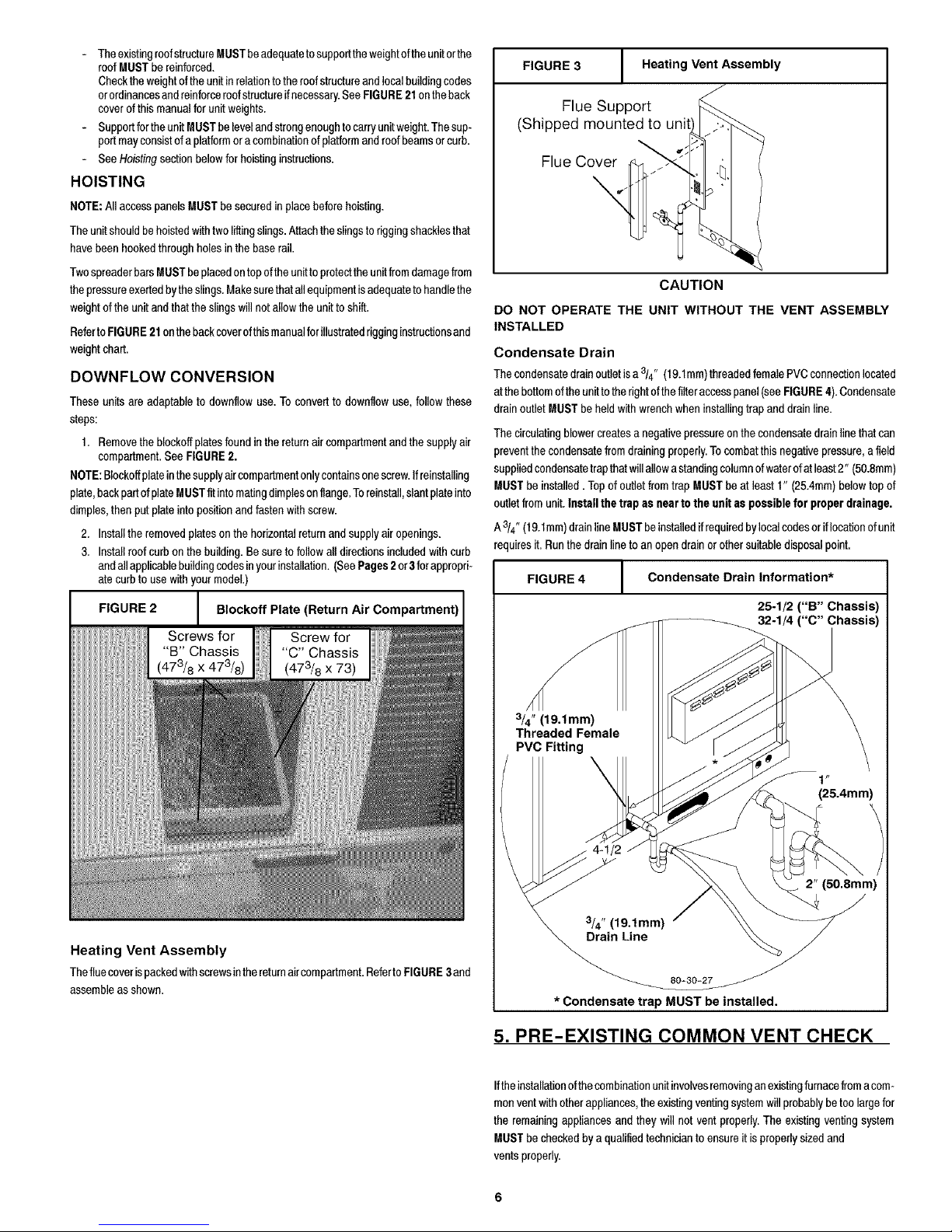

FIGURE 3 l Heating Vent Assembly

Flue Support

(Shipped mounted to unit

Flue Cover

\

CAUTION

DO NOT OPERATE THE UNIT WITHOUT THE VENT ASSEMBLY

INSTALLED

Condensate Drain

Thecondensatedrainoutletisa 3/4"(19.1mm)threadedfemalePVCconnectionlocated

atthe bottomofthe unittotherightofthe filteraccesspanel(see FIGURE4).Condensate

drainoutletMUSTbe heldwith wrenchwheninstallingtrapand drainline.

Thecirculatingblowercreatesa negativepressureonthe condensatedrainline thatcan

preventthe condensatefromdrainingproperly.Tocombatthis negativepressure,a field

suppliedcondensatetrapthatwillallowastandingcolumnofwaterofat least2" (50.8mm)

MUSTbe installed. Topofoutletfromtrap MUSTbeat least1" (25.4mm)belowtopof

outletfromunit.Install the trapas nearto the unit aspossiblefor properdrainage.

A3/4"(19.1mm)drainlineMUSTbeinstalledif requiredbylocalcodesoriflocationofunit

requiresit.Runthedrainline toan opendrainorothersuitabledisposalpoint.

I Condensate Drain Information*

FIGURE 4

A

25-1/2 ("B" Chassis)

32-1/4 ("C" Chassis)

3/4" (19.1mm)

Threaded Female

PVC Fitting

I r,

(25.4mm)

2" (50.8mm)

Heating Vent Assembly

Thefluecover ispackedwithscrewsinthereturnaircompartment.RefertoFIGURE3and

assembleas shown.

* Condensate trap MUST be installed.

5. PRE-EXISTING COMMON VENT CHECK

Iftheinstallationofthecombinationunitinvolvesremovinganexistingfurnacefromacom-

monventwithother appliances,the existingventingsystemwillprobably betoo largefor

the remainingappliancesand they willnotvent properly.The existingventingsystem

MUSTbe checkedby a qualifiedtechnicianto ensureit isproperlysizedand

ventsproperly.

Page 7

6. GAS SUPPLY AND PIPING

NOTE:Becausethere aremanytypesofliquifiedpetroleum(LP)gases,thetermLPas

usedinthis manualrefersto propanegas. Ifyouintendto useanytypeofLP gas,proper

precautionsMUSTbeusedinthehandling,piping,and useofsuchgas.NOTE:In Cana-

da,installationsMUSTbe performedby licensedLPinstallers.

TheUL/CSARatingPlatelocatedonthesidepanelonthe unitcontainsthemodelnumber,

typeof gasand gas inputrating,and otherimportantinformation.

Fire and/or explosion hazard.

Make certain the unit is equipped to operate on the type of gas

available. Models designated as natural gas are to be used with

natural gas only. Models designated for use with liquefied pe-

troleum (LP) gas are shipped with orifices sized for commer-

cially pure propane gas. They MUST not be used with butane or

a mixture of butane and propane unless properly sized orifices

are installed by a licensed LP installer.

Failure to follow this warning can result in property damage,

personal injury, and/or death.

GAS PIPING

The gassupplyline MUSTbe of adequatesize tohandlethe Btu/hr requirementsand

lengthoftherunforthe unitbeinginstalled.Determinethe minimumpipesizefor natural

gasfromthetable inFIGURE5 orFIGURE6. Basethelengthof therunfrom thegas

meterorsourcetothe unit.

Gas Pipe Size

Btu ratingsofall other gas appliancesMUSTbe consideredfor sizingof maingas line.

Checkgaslineto installationforcompliancewith localcodes or,in the absenceof local

codes,withtheNationalFuelGasCodeANSIZ223.1orin CanadatheNationalStandard

CAN/CGAB149-1 orcurrenteditions.

FIGURE 5

Gas Pipe Size, Length and Btuihr Capacity

for Schedule 40 Iron Pipe (English)

NATURAL GAS

Pipe Length Btu/hr (in thousands)

(includes

Fittings) 3/4" 1" 11/4" 11/2" 2"

20' t90 350 730 1,t00 2,100

40' t 30 245 500 760 1,450

60' t05 195 400 610 1,150

LP GAS

Pipe Length Btu/hr (in thousands)

(Includes

Fittings) 1/2" 3/4" 1" 11/4 " 11/2"

20' t89 393 732 1,496 2,299

40' t29 267 504 1,039 1,559

60' t 03 217 409 834 1,275

Gas Pipe Size, Length and Btu/hr Capacity

FIGURE 6 for Schedule 40 Iron Pipe (English)

Pipe Length

(Includes

Fittings) 3/4" 2"

6.1m 56 615

12.2m 38 425

18.3m 31 337

Pipe Length

(Includes

Fittings) 1/2" 11/2"

6.1 m 55 674

t2.2m 38 457

t8.3m 30 374

NATURAL GAS

kW**

1" 11/4" 11/2"

103 214 322

72 147 223

57 117 179

LP GAS

kW**

3/4" 1" 11/4"

1t5 215 438

78 t 48 305

64 t 20 244

**kW (Kilowatts) is the metric equivalent of Btu/hr.

PIPING AT UNIT

Connections

NOTE: The ruleslistedapplyto naturaland LP gaspipe installations.

1. Ifinstallationisfor LPgas,haveLP gasinstalleruseTW0- STAGEREGULATION

andmakeallconnectionsfromstoragetankto unit.

2. Use blackironor steelpipeandfittingsor otherpipeapprovedbylocal code.

3. Ifceppertubing isused,it MUSTcemplywith limitationsetin Fuel GasCode.

NOTE: Ifa gas connectoris used,it MUSTbe acceptableto local authority.Connector

UUST NOTbeusedinsidethefurnaceorbesecuredorsupportedbythefurnaceorduct-

work.

Fire and/or explosion hazard.

Gas connector M UST be properly installed and can NOT be

used inside the furnace.

Failure to do so can result in property damage, bodily inju-

ry or death,

4. Use pipejointcompoundonexternal(male)threadsONLY.JointcempoundMUST

beresistanttoany chemicalactionofLP gases(NOTAG). DoNOTputpipecom-

poundon last2 threadsof pipe.

5. Usegroundjoint unionsandinstalla drip legno lessthan3 inches(76ram)Iongto

trapdirtandmoisturebeforeit canentergas valve.

CAUTION

Overtightening assembly may cause damage to the gas valve and/or

wiring and may misalign the burners.

6. Use a wrenchongas valvewhenmakingconnectionsto preventgas valvefrom

turning.Do NOTusea pipewrench on the gasvalve body.

7. Providea _t8inch(3ram)NationalPipeThread(NPT)plugfortestgaugecennection

immediatelyupstreamof thegas supplyconnectionto thefurnace ifnoneis sup-

pliedwiththe gasvalveof unit.

8. Installa manualshutoffvalve andtightenanjoints securely.

9. Makesure pilottube and burnerorificesarecheckedfor leakage.

ORIFICES

Orifice Sizes

Orificesizes BUST be matchedto the heatingvalueof the gas (see FIGURE7 and

TABLE1).CheckwithyourgassupplierandtheNationalFuelGas Code ANSIZ223.1.

Page 8

FIGURE8 I Manifold/OrificeMeasurement

NOTE:An LP ConversionKit MUSTbe usedfor conversionto LP gas.

NOTE:For elevationsabove2000 feet (610meters),the Btuinputrating MUSTbe re-

ducodby 4%for each 1000feet (305meters)abovesea level,unlessthegassupplier's

Btuflt3contenthasalreadybeenadjustedfor altitude.Check Table 1.

FIGURE 7 Orifice Sizes

Pilot

Gas Specific Btuift 3 Orifice

Type Gravity (kJ/L) Sizes

Natural 0.6 1000 .018#

2500 .012#

Propane

1.53

#Adjust pilot flame as needed

TABLE 1: Equivalent Orifice Sizes at High Altitudes

(Includes 4% input reduction for each 1,000 ft.

NaturalGasManifoldOrificeSize Requiredby Elevation

BTU 0'- 2000' 4500'

INPUT 2000' 4000' 5000' 6000' 7000' 8000' 9000' 10000'

40.000to 44 45 46 47 47 48 48 49

60,00

90,000to 43 44 45 45 46 47 47 48

150,000

LPGas ManifoldOrifice Size RequiredbyElevation

BTU 0'- 2000' 4500'

INPUT 2000' 4000' 5000' 6000' 7000' 8000' 9000' 10000'

40.000to 55 56 56 56 56 56 56 57

60,000

90,000to 54 55 55 55 55 56 56 56

150,000

* 2-1/2 & 3 Ton with 3 burners.

** 3-1/2 & 4 ton with 4 burners.

Changing Orifices

Electrical shock, fire and/or explosion hazard.

Sh ut off electric power at unit discon nect or service panel and

shut off gas at manual shut off valve before beginning the fol-

lowing procedure.

Changing orifices requires a qualified service technician.

Failure to follow this warning can result in property damage,

personal injury, and/or death.

1. Shut OFFgasat manualshutoffvalve.

2. Shut OFFelectricpoweratunit disconnector servicepanel.Ifunit isstillrunning,

allow2.5 minutesafter gasshut off beforeturningoffpower.

3. Disconnectthewiresfromthe gasvalve.

4. Removethe four screwsholdingthe manifoldtothe manifoldbrackets.

5. Carefullyremovethe manifoldwiththe gas valveattached.

6. Removethe orificesfromthemanifoldwith a 7/16"box end orsocketwrench.

7. Checkto be surethat the sizeof eachorificeis correctforthe Btu inputdesired.

Measure 11/16" (27mm) from

face of orifice to back edge of

_ manifold pipe.

8. Installthecorrectorifices.Gaugethesizeoftheorificeswitha newtwistdrillbit ofthe

correctsize.

Makesurethattheorificesgoinstraightsothat theyforma rightangle (90°) to the

manifoldpipe.

Tightenthe orificessothat thereisa 11/16" (27mm)distancebetweenthefacesof

theorificesto theback ofthe manifoldpipe.

Measurethe distancewitha setof calipers.Ifyoudo nothavea calipers,you can

use an adjustablewrenchand measurebetweentheface ofthejaws.

9. Reassembleinreverseorder.

7. ELECTRICAL WIRING

Electrical shock hazard.

Disconnect power at fuse box or service panel before making

any electrical connections.

Unit MUST be grounded to electrical service panel.

Failure to follow this warning can result in property damage,

personal injury, and/or death.

NOTE:All electricalworkMUSTconformwiththerequirementsof localcodes andordi-

nancesandthe NationalElectrical CodeANSI/NFPA-No.70-1990 or currentedition.

Providelinevoltagepowersupplyfromaseparatefusedcircuitwithadisconnectswitch

locatedwithinsight of theunit.

Foraccess,removetheheateraccesspanelandthecontrolboxcover.See FIGURE1for

accesspanellocation. Wiring MUSTbe protectedfrom possiblemechanicaldamage.

Line Voltage Wiring

Connectionsforlinevoltagearemadeinthe unitcontrolbox.Foraccess,removetheburn-

er accesspanelandthe controlboxcover.

Ground Connections

DoNOTcompletelinevoltageconnectionsuntilunitispermanentlygrounded.Alllinevolt-

ageconnectionsand theground connectionMUSTbe madewith copperwire.

Agroundlugisinstalledinthe controlboxforthegroundconnection.Useacopperconduc-

torof theappropriatesizefromthe unitto agroundedconnectionintheelectricalservice

panelor a properlydrivenand electricallygroundedgroundrod.Seewarning above.

Line Connections

Completethelineserviceconnectionstothe contactor'L'terminalsinsidethecontrolbox.

Refertoapplicablewiringdiagram.Checkallscrewterminalsto ensurethey aretight.

THERMOSTAT/HEAT ANTICIPATOR

Thelocationofthethermostathasanimportanteffectontheoperationoftheunit. FOL-

LOW THE INSTRUCTIONSINCLUDEDWITH THETHERMOSTATFOR CORRECT

MOUNTINGANDWIRING.

Set thethermostatheatanticipatorto.58 in accordancewiththermostatinstructions.

Page 9

FinalElectricalCheck

1. MakeafinaIwiringchecktobe suresystemiscerrectlywired.Inspectfieldinstalled

wiringandtheroutingtoensurethatrubbingorchafingduetovibrationwillnot occur.

NOTE:Wiring MUSTbe installedsoit isprotectedfrompossiblemechanicaldamage.

8. DUCTWORK

Maximum recommendedvelocity in trunk ducts is 1000 feet per minute.Velocity in

branchesshould notexceed 800feetper minute.

FIGURE 9 Capacities Air Delivery

Nominal Tons

Air Conditioning

Up Thru 2

21/2

3

31/2

4

41/2

5

61/3

Nominal Air

Flow Cubic Feet

per Minute

800-900

900-1100

1100-t300

Recommended Filter Sizes

Sq. In. Surface Area/Nominal Size

Disposable Filters Cleanable Filters

400 or 20 x 25 246 or 15 x 20

487 or 20 x 30 301 or 14 x 25

576 or 14 x 25 (2Req.) 356 or 16 x 25

Unit Size

Heating Input

1000 x Btuh

40 and 50

40, 50, 75 and 100

40, 50, 75 and 100

1300-1500 665 or 16 x 25 (2Req.) 411 or 20 x25 (2Req.) 75, 100 and 125

1500-1700 753 or 20 x 25 (2 Req.) 466 or 20 x 25 100 and 125

1700-1900 841 or 20 x 25 (2 Reg.) 521 or 24 x 25 125

1900-2100 960 or 20 x 30 (2 Req.) 575 or 24 x 25 125

2300-2500 1108 or 20 x 30 (2 Req.) 685 or 24 x 30 150

NOTE: Minimum recommended filter areas are based on a velocity of 325 ft./rain, for disposable filters and 525 ft./min, for high velocity filters (washable).

NOTE:Ductworksizingaffectstemperatureriseandcoolingtemperaturedifferential.Be

sureto properlysizeductworkto thecapacityandairflowcharacteristicsofyour unit.Fail-

uretodoso canaffectlimitcontrols,compressors,motors,andothercomponentsandwill

leadto prematurefailure ofcomponents. Thiswillalsoadverselyaffectday to dayunit

performance.Referto rating plateand TemperatureRiseCheck,Page21.

Ductwork Insulation

Ductworkinstalledoutdoorsshould have a minimum of2" fiberglassinsulationand a

weatherproofvapor barrier,tt shouldbe protectedagainst damage.Caulkingand flash-

ings,orother meansadequatetoprovidea permanentweatherseal,should beused.

Ductworkinstalledin atticsor other areas exposedto outsidetemperaturesshould be

installedwithaminimumof2" fiberglassinsulationandhavean indoortypevapor barrier.

Ductwork Connections

Theuseofflexible, non-combustibleconnectorsbetweenmaintrunk ductsand supply

andreturnair plenumsis recommendedto minimizevibrationtransmission.

NOTE: Connectsupplyandreturnairplenumsto unitina mannerthatwillallowthe top of

theunitto beremovedwithoutremovingplenums.PlenumsMUST beindividuallysealed

tounit casingwithductsterminatinginsidestructure.

FILTERS

Allreturnair MUSTpassthroughafilterbeforeenteringtheunit.Anelectronicaircleaner,

optionalfilterracks,or otheraccessiblefilterarrangementMUSTbeinstalledinthe return

airductwork.MinimumrecemmendedfilterareasarelistedinFIGURE9andarebasedon

avelocityof325 _min for disposablefiltersand 525 ft!minfor highvelocityfilters(wash-

able).

CAUTION

9. START-UP PROCEDURES

Fire and/or explosion hazard.

Do NOT attempt to light the pilot or burner with a match or

flame of any kind.

Failure to follow this warning can result in property damage,

personal injury, and/or death.

CHECK BEFORE STARTING

1. Checkthat the blowermotor speed terminal block or thesetting of the variable

speedpulleyisrunningthe correct heatingand coolingspeeds.

2. Checkto seethatclean, properlysizedairfilters areinstalled.

3. Replaceall serviceaccesspanels.

Reverse Rotation (Scroll Compressors Only)

ThreephasescrollcompressorequippedunitsCANrunin reverseif improperlywired.If

thecompressormakesanunusuallyloudnoise,orif highandIowsidepressuresarenear-

lyidentical,thisindicatesreverserotation.Tocorrect,reverseanytwowiresatlinevoltage

connectionsONLY. DoNOT re-wireanycircuitsinsidethe unitto attemptcorrectionof

reverserotation.

Manifold Gas Pressure Adjustment

NOTE:Makeadjustmentto manifoldpressurewithburnersoperating.

DO NOT OPERATE THE UNIT WITHOUT A FILTER.

Page 10

Fireorexplosionhazard.

NOTE: Adjustmentscrew coverMUSTbe placedon gasvalvebefore readingmanifold

pressureand operatingfurnace.

Turn OFF gas at shut off before connecting U-tube ma-

nometer.

Failure to properly seal duct can result in personal injury

and/or death.

I

FIGURE 10

[ Honeywell Gas Valve

Inlet Pressure

Tap (Hidden)

Wiring

Terminals

INLET

Outlet

Pressure

Tap

Pilot Adjustment

25-50-06

GAS PRESSURES

1. Do NOTallowgas supplypressuretofall belowthelistedminimums.Doingso wUl

decreaseinputtofurnace.Referto FIGURE11 for gassupplypressures.

2. GasinputMUSTNOT exceedratedinputshownonratingplate.

3. Do NOTallowpressuresto exceedthemaximumlimitsas listedin FIGURE11.

FIGURE 11 Gas Pressures

Natural Gas LP Gas

Minimum 4.5"W.C. (1120 Pa) 1t" W.C. (2740 Pa)

Inlet

Recommended 7" W.C. (t740 Pa) 1t" W.C. (2740 Pa)

Inlet

Maximum 13" W.C. (3230 Pa) 13" W.C. (3230 Pa)

Inlet

Manifold 3.5" W.C. (870 Pa) 10" W.C. (2490 Pa)

Pressure

Manifold Pressures

Manifoldpressuresare coveredin the startupproceduresection.Refer to Chapter 9

Start-Up Procedureson Page20.

1. Withgas OFF,ConnectU-Tubemanometertotappedopening ongas valve.Use

manometerwitha 0to 12incheswatercolumnrange.

FIGURE 12 Manifold Pressure Settings

Gas Type Manifold Pressure

Natural 3.5 Inches Water Column (870 Pa)

Propane 10 Inches Water Column (2490 Pa)

2. TurngasONand removeadjustmentscrewceverongasvalve.Turnccunterclock-

wisetodecreasepressureand clockwiseto increase.

Fire and/or explosion hazard.

Do NOT adjust manifold pressure more than ± 0.3 inches

water column to obtain rated input.

Failure to properly set input pressure can result in proper-

ty damage, personal injury and/or death.

3. Set pressuretovalueshowninFIGURE12, -+0.07kPa(0.3inches)waterceNmn.

Pressureisalsolistedonfurnaceratingplate.InNOcaseshouldfinalmanifoldpres-

surevarymorethan -+0.07kPa(0.3inches)watercolumn.

CIRCULATING AIR BLOWER

Checktheunit'soperationasoutlinedinthefollowinginstructions.If anyunusualsparking,

odorsorunusualnoisesareencountered,shutoffelectricpowerimmediately.Recheckfor

wiringerrors,or obstructionsinornear blowermotors.

1. SetthermostatHeat-Coolselectorto OFF

2. Set thermostatfan switchto AUTO.

3. TurnelectricpowerON. Nothingshouldstartrunning.

4. Turn manualgasvalve ON.

5. Turngas controlvalve ON.

6. Set thermostatfan switchto ON.

7. Resetthermostatfan switchto AUTO.

HEATING START-UP PROCEDURE

1. Adjustthermostatsetting aboveroomtemperatureandset thermostatselectorto

HEAT.The combustionair blowershouldcome ON.

2. Theignitorshouldbeginto glowand pilotflameshouldlight.Referto Lighting/Oper-

atingInstructionslabel locatedon BurnerAccess Panelof unit.

NOTE:On acall forheat theignitorand pilotvalvewill remainenergizeduntila flameis

detectedby the flamesensor. It maytakeseveralminutesto purgethe air outof thegas

linesat initialstart-up ofthe unit.

3. Once theflame sensordetectsthata flameis present,the hotsurfaceignitorwill

de-energizeand themain burnerswill lightfrom the pilot.

4. 30 secondsafterthe burnerslight,the circulatingblowershouldbeginto run.

Fire and/or explosion hazard.

Do NOT attempt to light the pilot or burner with a match or

flame of any kind.

Failure to follow this warning can result in property damage,

personal injury, and/or death.

Temperature Rise Check

NOTE:Air temperatureriseisthe temperaturedifferencebetweensupplyand returnair.

Witha properlydesigneddistributionsystem,the properamountoftemperaturerisewill

normallybeobtainedwhentheunitis operatingatratedinputwiththe recommendedblow-

er speed.

The temperature rise must be within the specifications marked on the unit

rating plate.

To check the temperature rise through the unit, place thermometers in the

supply and return air ducts as close to the unit as possible,

Open ALL registers and duct dampers, Operate unit AT LEAST 15 minutes

before taking readings.

If the correctamountof temperatureriseis not obtainedwhenoperatingonthe recom-

mendedblowerspeed,itmay be necessarytochangetheblowerspeed.A fasterblower

speedwilldecreasethe temperaturerise.Aslowerblowerspeedwillincreasethetemper-

aturerise.

10

Page 11

NOTE:TheblowerspeedMUSTbesettogivethe correctairtemperaturerisethroughthe

furnaceas markedon theratingplate. SeeFIGURE14 for moreinformation.

3. After 15minutesofoperationcheckthelimitcontrolfunction byblockingthe

returnairgrille(s).

AfterseveralminutesthemainburnersandpilotshouldgoOFEThe circulatingair

blowershould continuetorun.

Removeairrestrictions.Pilotandmainburnersshouldrelightafteracooldownperi-

odof afew minutes.

4. Adjustthethermostatsettingbelow roomtemperature.

Pilotand mainburnersandcombustionair blowershouldgo OFE

Thecirculatingairblowershouldcontinueto runfor 60, 100, t40 or t80 seconds.

Thistime isadjustable. See FIGURE13formore information.

5. Set thermostatHeat-Cool selectortoOFE

FAN CONTROL CHECK

FIGURE 13 / Fan Delay DIP Switch Settings

1

Fan Off Delay (140 sec. is factory setting)

60 sec 100 sec 140 sec 180 sec

Fan On Delay (30 sec. is factory setting)

1 2 3

60 sec

1 2 3

30 sec

The FanControlhasadjustablesettingsforthecirculatingairblowertodelay it "ON" and

"OFF".

1. The"ON" delayisfactorypre-setat 30seconds. Itcanbe adjustedto60seconds.

2. The"OFF" delayisfactorypresetat 140seconds. Itcanbeadjustedto60,100 and

150seconds,respectively.

Referto FIGURE13for properDIP switchsettings.

3. Operatethefurnaceand ensurethatthe blowerturnsON and OFFattheappropri-

atetimeto providethedesiredcomfortlevel.

SPEED TAPS

AfterdeterminingnecessaryCFMandspeed tapdata,followthesteps belowto change

speeds.

1. Referto FIGURE14 andlocatethespeedtap blockonblower motor.

2. TheyeUowleadMUSTalwaysbe connectedtothespeedtap blockatthe common

quickconnectterminal.Theterminalisidentifiedas COM.Also,this isthe onlylead

whichis3116"wide.All otherquickconnectsare 114"wide.

3. Ifit hasbeen determinedthatcoolingandheatingspeedsareneededonthe same

speedtap, removethered heatingleadfromthe speedtap blockandconnectitto

theinsulatedmaleterminalonthe blackcoolinglead.Then placetheinsulatedblack

femalequickconnectto the requiredspeedtap.

CONTINUOUS FAN OPERATION

Anoptionalterminalmaybe providedon theelectronicfan controllocatedinthe electrical

controlbox foroperationofthe continuousfanoption. Thisconnectionisintendedforthe

lowspeedmotortap,andhas a lowercontactrating(8amps)thantheheatandcooltaps.

Whenthelowspeedblowerleadisconnectedto thisterminal,thiswillprovidelowspeed

bloweroperationwheneverthe othertwospeeds (Heator Cool) arenot energized.

Thoroughlycheckthe systemaftermodificationtoensuretheproperoperationofthecircu-

latingair blowerinallmodesof operation.

Separate Speed Selections for Heat, Cool and Continuous

Fan

Connectlowspeedleadfromcirculatingmotortothe"Cent"terminal atthe electronicfan

control. The appropriatemotor leadsshould already be connectedto the "Heat" and

"Cool" terminals.

Note: Seenextsection"Heatingand ContinuousBlowerSpeedthe Same"iflowspeedis

requiredfor heatingto obtaindesiredtemperaturerise.

Heating and Continuous Blower Speed the Same

If is is necessaryto operate theheatingspeedand continuousblowerspeed usingthe

sameblowerspeed, connecta jumperbetweenthe "Heat" and"Cont" terminalsonthe

blower.

Note: Thereshouldbe onlyONEmotor lead goingto the"Heat" and "Cont" terminals.

COOLING

1. Turnelectricpower OFF

2. Set thermostatHeat-Cool selectto COOL

3. Adjustthermostatsettingto belowroomtemperature.

4. TurnpowerON,forapproximatelyone minute,then OFE Duringpowerapplication

checkthefollowing:

a.Contactor- ContactsClosing

b.Compressor- ON

c. Condenserfanmotor - ON

d.CirculatingAir Blower - ON aftera 30seconddelay

5. Turn powerOFF,checkthefollowing:

a. Contactorcontactsopening.

b. Compressor- OFF

c. Condenserfanmotor- OFF

d. Circulatingblower - OFF aftera 30seconddelay.

Page 12

FIGURE 14 I Blower Motor Speed Taps (3-Speed and 4-Speed Motors)

I BE SURE TO CHECK BLOWER MOTOR I

SPEED DATA IN UNITS

TECHNICAL INFORMATION LABEL

ON THE UNIT

10. OPERATION

Electrical shock hazard.

Turn off electric power supply at disconnect switch or service

panel before removing any access or service panel from unit.

Failure to follow this warning can result in property damage,

personal injury, and/or death.

COMBUSTION/INDOOR FAN CONTROL

Allfunctionsofthecembustionandindoorblowerarecontrolledbythefancontrolmodule.

Ona callfor heat:

Thefancontrolenergizesthecembustionblower.Oncethecombustionairprovingswitch

closes,theignitionsequencebegins.Thefan controlwillsensewhenthemainoperatorof

gasvalvehasbeenenergizedtherebyfiringtheburnersandstartingthe "delayon"timing

sequenceof the indoorblower.

NOTE: Ifthecontrolsensesthatone ofthe safety limitshasopened,thecombustionand

indoorfans willoperateuntilthe limitresets.

Ona callfor cooling:

Thefancontroldelaysthestartoftheindoorblowerfor30ceconds.0ncethethermostatis

satisfied,thefan controlwilloperatetheblowerfor30 additionalseconds.

\

-\

\

SCROLL ANTI-CYCLE TIMER

Single phasescrollcompressorequippedunits are equipped withan anti-cycle device

whichdelaysstartofthecompressorinthe eventofa powerinterruption.Thisfeatureisto

allowpressureequalizationthroughoutthe systemandto preventpossiblereverserota-

tion ofthescrollcompressor.Three phaseunitsdo notrequirethis device.

11. MAINTENANCE

MONTHLY MAINTENANCE AND INSPECTION

CHECKS

Air Filters

CAUTION

Do NOT operate without air filters.

Inspectfiltersat leastmonthlyandreplaceorcleanasrequired.Washablefiltersmaybe

cleanedbysoakinginmilddetergentandrinsingwithcoldwater.Replacefilterswiththe

arrowsonthesidepointinginthedirectionofairflow.Dirtyfiltersarethemostcommon

causeofinadequateheatingorcoolingperformance,andofcompressorfailures.

HEATING SEASON CHECKS (MONTHLY)

Pilot Flame

Whilethemainburnerison,theflameshouldenveloptheupperpartoftheflamesensor.

Main Burner Flame

Flamesshouldbestableandsolidblue,(dustmaycauseorangetipsortheymayhave

wispsofyellow,buttheyMUSTnothavesolidyellowtips).Theyshouldextenddirectlyinto

12

Page 13

theheatexchangertubesandtheturbulatorsshouldgloworange(afteraboutfiveminutes

ofoperation).Mainburnerflameshouldbeinspectedmonthly.

FIGURE 15 I Normal Flame

i

Turbulator will glow

orange when hot.

Flame should be

stable and solid

blue.

Usingalightand mirror (asrequired)inspecttheinsideofthe venthood and theinlet air

openinginthe burnercompartment. Lookfor sootand severerustorcorrosionandany

obstructionsdueto leaves,spiderwebs,etc. Cleanas required.

COOLING SEASON CHECKS (MONTHLY)

Condenser Coil

Keepthe condenserinletandoutletareacleanandfreeofleaves,grassclippingsorother

debris. Grassshouldbe kept shortin frontof the condenserinlet. Shrubbery MUSTbe

trimmedbackso it is nocloserthan 30 inchesto unit.

Condensate Drain

Checkfor condensatedrainage. Cleanas required.

NOTE: Whenunit isoperatingincooling modeunderhighhumidityambientconditions,

condensatecan form in the burner compartmentand may drip from the front of the

compartment.Thisconditionis NOTharmfulto the unit.

ANNUAL MAINTENANCEANDINSPECTION

Electrical shock hazard.

Turn off electric power supply at disconnect switch or service

panel before removing any access or service panel from unit.

Failure to follow this warning can result in property damage,

personal injury, and/or death.

Theannualinspectionshouldincludelubricationandcleaningas requiredtoensureeffi-

cientoperationoftheunit.Tosimplifyaccess,removeallaccesspanelsandthe top from

theunit ifpossible.

Condenser Fan Motor

Oilthecondenserfanmotor afterfiveyears of operationandeveryfive yearsthereafter.

VENT ASSEMBLY

Burn hazard.

Flue cover may be hot! Allow adequate time for flue cover to

cool.

Failure to follow this warning can result in property damage

or personal injury.

UseSAE 10W30motoroil.Tooil,removetheholeplugsfromthemotorendbellsand add

severaldrops(approximately1/2teaspoonful)ofoilwithasqueezetype,flexibletubeoiler.

Replacehole plugsafteroiling. Donot overoil.

Cleanthesurroundingareaandthecondenserandevaporatorcoils.Usecautiontoavoid

damagetocoil fins.

BLOWER MOTOR ACCESS

RefertoFIGURE16foraviewofblowermotorandcompartment.

FIGURE 16 Blower Motor and Housing

Method 1

Thismethodallowsyoutoworkonthemotorandhousingwhilestillintheunit.The blower

motorcanbe replacedwiththismethod,butsomemaypreferto work onthe housingas-

semblyseparately.Ifthis is your preference,usemethod2.

1. Removethe bloweraccesspanel

2. Removethe fourscrewssecuringtheblower motorhousing.Ifunit hasa support

bracket,removethetwo screwssecuringthebracket.

3. Removethe two redwiresattachedto the limitswitch.

4. Slideentirehousingtowardyou.Thiswillalloweasieraccesstothespeedtapblock,

motor,and wires.

5. After access,replaceall wires,screws,andconnections.

Motor removal and replacement

Theblower motormaybereplacedwhile accessingit usingmethod1. Toreplacemotor,

reach behindblowerhousingand locate blowerwheelsetnut. Loosenset nut,allwires

frommotor,andfourpinsonmountingcradle.Pullmotortowardsyou.Toreplacemotor,

reversethisprocedure.

Method 2

Thismethodisrequiredtoreplaceorrepairblowerwheel,blowerhousing,oranyunreach-

able componentsbehindblowerassembly.

1. Repeatsteps 1through 4in method 1.

13

Page 14

2.Removeallscrewsaroundrimofunittop,(exceptscrewswhichareinaccessible

becauseofproximitytostructure).

3.Raiseunittopatcernerofunitctosesttobloweratleast2"andplaceasturdybrace

atleast2"thickbetweentopandunitcorner.SeeFIGURE17.A2X4pieceofwood

isidealforthis.

4.Disconnectallwiresfromhousingandslidehousingoutofunit.Reversethisprom

cesstoreinstall.

FIGURE 17

Circulating Air Blower

Blower Access Showing Lid

Propped with 2X4

Visuallyinspectthe blowerwheelfor accumulationsof dirtorlint. Cleanthecompartment

andthe blower wheel.If accumulationisexcessiveonblower wheel,or does noteasily

remove,itwillbe necessaryto removethe blowerassembly.

Oilblowermotorby adding1I2teaspoonful(lcc) of SAE 10W30to eachmotorbearing.

The blowermotorshouldbe oiledafterfiveyearsof operationandevery fiveyearsafter.

CAUTION

Do not use 3 in I oil, penetrating oil, WD40 or similar oils to oil motor

bearings.

Burners / Heat Exchangers / Flue Gas Passages

Toinspectthe burners,heat exchangerand interiorflue gas passages,usea light and

smallmirroron an extensionhandle.

Checktheexteriorofthe heatexchangerandthe interiorflue gaspassagesforany evi-

denceof deteriorationdueto corrosion,crackingor other causes.Ifsigns ofscalingor

sootingexist,removethe burnersand clean theheat exchanger,asrequired.

INSPECTION AND CLEANING OF BURNER

ASSEMBLY/HEAT EXCHANGERS/FLUE GAS

PASSAGES

For Qualified Service Technician Only

See FIGURE18, FIGURE19 and FIGURE20foridentificationofparts.

1. Disconnectelectricalpowertounit.

2. TurnOFFgasatmanualshutoftvalve.

3. Removeburneraccesspanel.

4. Removetheventassemblyfluecover.

5. Disconnectgas pipeatunion.

6. Disconnectwiresfrom gasvalve,noteconnections.

7. Removescrewsthatsecuretheflameshieldand removegascontrolvalve,man-

ifoldand burnersas anassembly.

8. Removecollectorbox,injectorplate,and restrictorplate, includinggaskets.See

FIGURE19.

9. Holdthe burnerassemblyverticallyandlightly tapit againsta woodblock. Clean

alsowithastiffbrush.Severecasesoflintcloggingmayrequirewashingtheburners

in hotwater.

10.Removeturbulatorsand clean with small brush.Reinspectaftercleaningand re_

placeturbulatorsif defective.

11.Cleanfluegas passagesbyusingsmall brushesanda vacuumcleaner.It maybe

necessarytofabricatehandleextensionsforthebrushestoreachtheareasthat re-

quire cleaning. Reinspect after cleaning and replace the heat exchanger if

defective.

12.Reinstallpartsand gasketsin reverseorder.Onsparktopilotmodelscheck

thesparkgap. 1t8inchis requiredbetweenthe igniterand pilot hood.

13.Turn gason and checkfor leaks.

14.Installall accesspanels,turnpoweronand checkfor normaloperation.

FIGURE 18 Access to Burners

FIGURE 19

Burners, Valve, and Burner Box

Removed

FIGURE 20 Burner Assembly Removed

Gas Valve

14

Page 15

RIGGINGINSTRUCTIONS

A WARNING

FAILURE TO FOLLOW THESE INSTRUCTIONS

CAN RESULT IN PROPERTY DAMAGE,

BODILY INJURY OR DEATH.

ALL PANELS MUS] BE IN PLACE WHEN RGGING AND I FliNG.

HOOK RIGGNG SHACKLES _HROUGH HOLES IN BASE RAL, AS SHOWN IN DEw,AlL A

USE SPREADER BARS, WHLN RGGNG, TO PREVLNT UNIT DAMAGE.

BE SURE RIGGNG AND SHACK ES ARE SUFFCIENT TO HAND E WEGHT ISTED BE OW.

SPREADER BARS

DETAIL A

HEIGHT

CAB NET

B

C

LENGTH /

WIDTH

COOING

CAPAC TY

RANGE

.53.5 TONS

.}6.3 TONS

LENGIH

N MM

48,00 1219

73.00 185

WIDTH

IN MM

48.00 1219

48,00 1219

HEIGHT

iN MM

35_00 838

36.50 927

MAX_ WEGql

LB KG

450 204

700 318

"11

0

C

m

c

o

m_

o

Page 16

14. Notes

16

Page 17

INTERNATIONAL COMFORT PRODUCTS

LIMITED WARRANTY CERTIFICATE

For Cooling & Heating Products

SAVE THIS CERTIFICATE. It gives you specific legal rights, and you may also have other rights which may vary from state to state and

province to province.

If your unit needs servicing, contact a qualified dealer or qualified service technician of your choice. When requesting service, please have the model

and serial number from each unit in your heating and/or cooling system readily available. Ifyour dealer needs assistance, the distributor is available to

provide support and we, in turn, support its efforts.

Fill in the installation date and model and serial numbers of the unit in the space provided below and retain this Limited Warranty for your files.

GENERAL TERMS

Subject to the conditions and limitations stated herein, during the term of this Limited Warranty, we will provide a replacement for any functional

component part (as defined below) of your unit found to be defective in materials or workmanship. The term of this Limited Warranty is five years from

installation on Residential Products and one year from installation on Commercial Products. Except as otherwise stated in the "Additional Terms"

section, this Limited Warranty covers only the original purchaser and subsequent transferees, and only while the unit remains at the site of the original

installation (except for mobile home installations), and onty if the unit is installed inside the continental United States, Puerto Rico, Alaska, Hawaii or

Canada. In addition, the Limited Warranty applies only if the unit is installed and operated in accordance with the printed instructions accompanying the

unit, and in compliance with alt applicable installation and building codes and good trade practices. As used in this Limited Warranty, "installation"

means the original installation of the unit.

TH ERE ARE EXCEPTIONS to this Limited Warranty as described on the reverse side of this page. All replacement parts will be warranted for the

unused portion of the warranty coverage period on the unit. The part to be replaced must be returned by the dealer to a distributor that sells products for

International Comfort Products, in exchange for the replacement part. In lieu of providing areplacement part, we may, at our sole option, refund to you

an amount equal tothe distributor's component purchase price from us, orprovide to you acredit equal to that amount to be applied toward the purchase

of any new unit that we distribute. Ifa credit for a new unit is given in tieu of a replacement part, the rating plate from the unit being replaced must be

submitted on a warranty claim, and you rdealer must make the unit being replaced available to our distributor for disposition. As acondition towarranty

coverage, the unit must receive yearly maintenance, as described in the owner's manual, by a dealer. Satisfactory proof of yearly service by adealer

may be required.

"Functional component parts" include only the following: blower motor, unit-mounted sensors & timers, condenser motor, evaporator coil, condenser

coil, condenser fan, capacitor, transformer, single-phase strip heat elements, expansion device, reversing valve, solenoid valve, service valve,

electronic and electro-mechanical control board, ignitor, ignition module, draft inducer assembly, burner pilot, gas valve, limit control, pressure switch,

relays and contactors, blower wheel, interlock switch, crosslighter, pilot shield, gas & oil burners, oil pump assembly, accumulators and factory installed

driers and strainers.

This Limited Warranty DOES NOT COVER any labor, material, refractory chambers, oii nozzles, refrigerant, refrigerant inspection and refrigerant

reclaiming, freight and/or handling charges associated with any repair or replacement and such charges will be your responsibility.

Toestablish the installation date for any purpose under this Limited Warranty, you must retain the original records that can establish the installation date

ofyour unit. Ifyou donot providesuchdocumentsthe start dateoftheterm ofthis LimitedWarrantywillbe based uponthedate ofunit manufacture, ptus

thirty (30) days. In establishing that the required yearly service has occurred, you must furnish proof of yearly service by a qualified service technician.

This Limited Warranty does not cover: (a) failure or damages caused by accident, abuse, negligence, misuse, riot, fire, flood, or Acts of God (b)

damages caused by operating the unit where there is a corrosive atmosphere containing chlorine, fluorine, or any other damaging chemicals (other

than those found in a normal residential environment) (c) damages caused by an unauthorized alteration or repair of the unit affecting its stability or

performance (d) damages caused by improper matching or application of the unit or the unit's components (e) damages caused by failing to provide

proper maintenance and service to the unit in accordance with this Limited Warranty Certificate and the printed instructions originally provided with the

unit (f) any expenses incurred for erecting, disconnecting, or dismantling the unit (g) parts or supplies used in connection with service or maintenance,

such as refrigerant, refractory chambers, oil nozzles, filters, or belts (h) damage, repairs, inoperation or inefficiency resulting from faulty installation or

application (i) electricity or fuel costs or any increase in electricity or fuel cost whatsoever including additional or unusual use of supplemental electric

heat (j) units which have not had the required yearly maintenance described elsewhere in this limited warranty.

In no event shall we be liable for any incidental, consequential, or special damages or expenses in connection with any use or failure of this unit.

We have not made. do not make. and hereby disclaim any implied condition or implied warranty of fitness for a particular use or purpose, and

anv implied condition or implied warrantv of merchantabilitv, to the fu Ilest extent allowed bv law. We make no express or implied warranties

except as stated in this Limited Warrantv certificate.

No one is authorized to change this Limited Warranty or to create for us any other obligation or liability in connection with this unit. Any implied

warranties shall last for the term of the expressed warranty contained herein. Some states and provinces do not allow the exclusion or limitation of

incidental or consequential damages or do not allow limitations on how long an implied warranty or condition lasts, so the above limitations or exclusions

may not apply to you. The provisions of this Limited Warranty are in addition to and not amodification of orsubtraction from any statutory warranties and

other rights and remedies provided by law.

Please refer to reverse side of this page for additional terms.

Model No.

Serial No. Date Installed

Effective on units installed After July 1, 2002,

USA: International Comfort Products Corporation (USA) • 650 Hell-Quaker Avenue * P.O. Box 128 • Lewisburg, Tennessee 37091 • (931-270-4100)

CANADA: International Comfort Products division of UTC Canada Corporation • 6060 Burnside Court, Unit 1, Mississauga, Ontario L5T 2T5

(905-795-8113).

Manufacturers of Airquest, Arcoaire, Clare, Comfortmaker, Dettson, Hell, Keeprite, Lincoln, Tempstar and other quality brand name private label

products.

Part No. 401 06 1010 18 (Orig. 8/9/2002)

Page 18

ADDITIONAL TERMS FOR RESIDENTIAL APPLICATIONS ONLY

The Additional Terms for the components listed below are in addition to, and subject to, the General Terms on the reverse side of this page.

Warranty coverage is limited to parts that fail due to defect in materials or workmanship during the specified term.

CENTRAL GAS & OIL FURNACE HEAT EXCHANGERS*

Gas Model Series: C9MPV. HgMPV. TgMPV. CgMPT. H9MPT. T9MPT. C9MPD. HgMPD. TgMPD: Limited Lifetime Warranty on heat exchangers. If

a heat exchanger on one of these furnaces fails due to defect in the part, we will provide a replacement part or, at our option, credit toward the purchase

of a new furnace manufactured by us. This additional Limited Warranty runs only to the original purchaser, and tasts only for as tong as the originat

purchaser tives in the home where the furnace is initially installed.** Itis not transferable to any subsequent owner. Ifthe furnace was not installed in the

home owned by the original purchaser, if the original purchaser setls the home to a subsequent owner, or if proof of originat purchase cannot be

provided, then the limited warranty is only for 20 years from the date of original installation.

Gas Model Series: GDL. GNL. TNE. TDE. NTC7. NDC7. NTP6. NDP6. TDE. NTV6. VNE: A replacement heat exchanger will be provided for any

heat exchanger that fails in one of these furnaces due to defect for 25 years from the originat date of installation.

Gas Model Series: NTC6. GNE. GDE. NDN6. NTG3. NDN3. FBF. NBF. NDF. NTN3. NTN6. NNE. N9MPI. N9MP2. FUH: A replacement heat

exchanger witt be provided for any heat exchanger that faits in one of these furnaces due to defect for 20 years from original date of installation.

Oil Model Series: OLR(105, 160, 182), OCF, OLE OUF, NOLE NOUF, OLB, OHB, ODH, FLO, MBO, LBO, NOMF: Limited Lifetime Warranty on

heat exchangers. Ifa heatexchangerononeofthesefurnacesfailsduetodefectinthepart, wewitl provide a replacement part or, at our option, credit

toward the purchase of a new furnace manufactured by us. This additional Limited Warranty runs only to the original purchaser, and tasts only for as

long as the original purchaser lives in the home where the furnace is initially installed.** It is not transferable to any subsequent owner. If the furnace

was not installed in the home of the original purchaser, ifthe original purchaser sells the home to a subsequent owner, or if proof of original purchase

cannot be provided, then the limited warranty is only for 20 years from the date of original installation.

Oil Fired Floor Furnace: NFO: A replacement heat exchanger witl be provided for any heat exchanger that faits due to defect for 10 years from

installation with the following limitation: during the sixth through tenth year, any credit toward your purchase of a component or toward the purchase of

any new unit wilI be in an amount equal to the distributor's purchase price reduced by 20 percent for each year after the fifth year.

ADDITIONAL TERMS FOR OIL FURNACE APPLICATIONS ONLY

1) OIL BURNERS - A replacement for 5 years from date of original installation for Oil Burner Parts.

2) OPTIONAL ACCESSORIES AND FUNCTIONAL PARTS: A replacement for 5 years from date of original installation. (Refractory and

oil nozzles not included)

GAS/ELECTRIC PACKAGED UNITS HEAT EXCHANGERS

Model series: PGAD. PGAA. PGMD. PGME. PGF. GPFM. PGC. GPCM: A replacement for 10 years from original date of installation.

COMPRESSORS:*

1) Premium Model Units: HAC0. HAC2. HAC4. CAC0. CAC2. CAC4. KAC0. TCA0. TCA2. TCA4. HHP0. HHP2. HHP4. CliP0. CliP2. CliP4.

TCH0. TCH2. TCH4. PGME. PYMC. PHAD. PGAD. PA95. PAPC. PAK. APK: Tothe original purchaser a replacement for 10 years from original date

of installation, only if the unit is installed with factory matched coils, except air conditioner condensing units with a nominal SEER of 10 may be matched

with evaporator coils of the same nominal tonnage regardless of manufacturer and in accordance to factory recommendations. This limited 10-year

warranty is not transferable to any subsequent owner. HOWEVER, ifthe unit was not installed in the home owned by the original purchaser, if the

purchaser sells the home to a subsequent owner, or if proof of original purchase cannot be provided, then the limited warranty is only for 5years from the

original date of installation.**

2) All Other Models: Air Conditioners. Heat PumPs. & Combination Gas/Electric Units: NAC0. NAC2. NHP0. NHP2. AO. A2. HO. H2. PGF.

PGC, GPFM, GPCM, PAE APFM, PHE HPFM, PGAA, PGMD, PA55, PH55, PAPA, PYPA: A replacement for 5 years from date of original

installation, onty if: (a) air conditioner condensing units with SEER rating in the range of 10 to 11 SEER are matched with evaporator coils of the same

nominal tonnage regardless of manufacturer and in accordance to factory recommendations, or (b) heat pump condensing units are used with factory

matched coils, unless written approval to do otherwise is obtained from manufacturer.

ADDITIONAL TERMS FOR COMMERCIAL APPLICATIONS ONLY

For purposes of this warranty a commercial application isone in which: the product has over 5 tons nominal cooling capacity, or is designed

for operation with 3 phase electrical power, or is installed in a commercial establishment such as a beauty or hair salon, hospital, school,

restaurant, church, hotel etc..

3-Phase Models: PGF, GPFM, GPF, PGAD, PGME, PGB, PGMG, PGMF, PGS, PGE, APE, PAE, PAB, PAMD, PAS, PAl=,APFM, APF, PHB, PHE,

PYMD, HPB, PHS, CAC, ACC, CAE, ACE, CHC, HCC, CHE, HCE:

The additional Terms of the components listed below are in addition to and subject to the General Terms on the reverse side of this page.

1) GAS FIRED HEAT EXCHANGERS (ALL MODELS):* A replacement for 10 years from date of originat installation.

2) COMPRESSORS (ALL MODELS):* A replacement for 5 years from date of original installation.

3) OPTIONAL ACCESSORIES AND FUNCTIONAL COMPONENT PARTS (ALL MODELS):*

A replacement for 1 year from date of original installation.

4) COMMERCIAL OIL MODELS: OLR210, OLR350, OTF210, AMT3, AMT4, AMP3: Ten(10) Year Limited Warranty on heat exchangers.

*To receive advantage of your limited warranty, you must provide proof of yearly service by a qualified service technician.

**To receive advantage of your warranty, you must retain the original records that can establish the installation date and proof of purchase of the unit.

MINI SPLITS:

Summary - Mini Splits Warranted for one (1) year on all replacement parts.

Additional terms for Mini Splits:

The additional Terms of the components listed below are in addition to, and subject to, the General Terms on the reverse side of this page.

1) Compressors (All Models): A replacement compressor wili be provided for atIcompressors that faii due to defect for 5 years from date of original

installation.

2) Optional Accessories and Functional Components Parts (All Models):

A replacement part will be provided for alt parts that fail due to defect for one (1) year from date of original installation.

Failu re to maintain the equipment through annual maintenance by a qualified service technician shall void the warranty. Proof of service wili berequired

with ati warranty claims. Proof of purchase and installation date must be submitted with ali claims.

Loading...

Loading...