Page 1

Installation

Instructions

• Safety Labeling and Rules

• Installation Requirements

• Location/Clearances

• Air Distribution

• Wiring

• Ductwork Connections

• Start-Up

• Operation

• Maintenance

• Inspection

• Hoisting/Rigging

3 thru 7-1/2 Ton

Belt Drive Models

Electric Cool & Heat

Printed in U.S.A. 513 01 1302 00 10/23/01

Page 2

I Installation Instructions Combination Units I

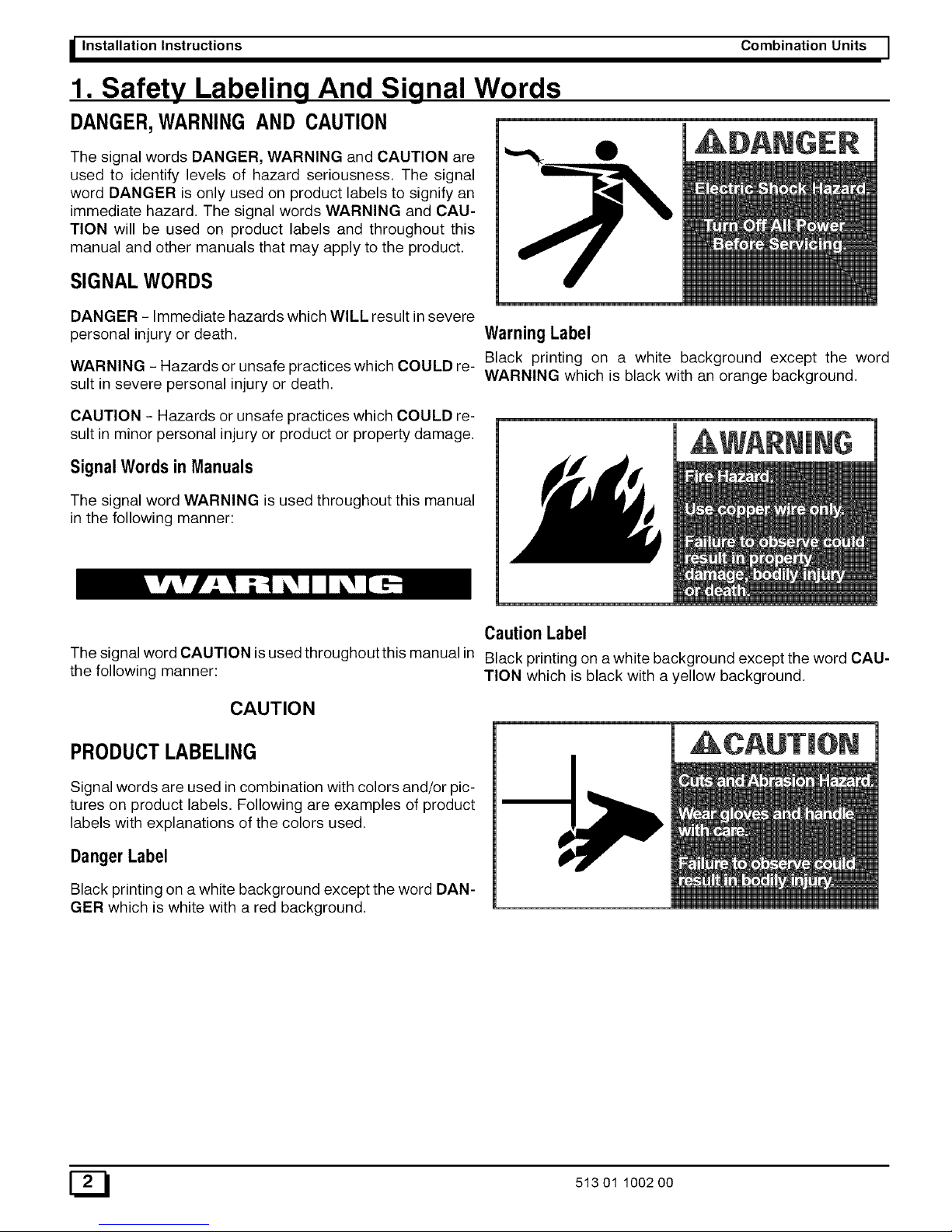

1. Safety Labeling And Signal Words

DANGER,WARNING AND CAUTION

The signal words DANGER, WARNING and CAUTION are

used to identify levels of hazard seriousness. The signal

word DANGER is only used on product labels to signify an

immediate hazard. The signal words WARNING and CAU-

TION will be used on product labels and throughout this

manual and other manuals that may apply to the product.

SIGNALWORDS

DANGER - Immediate hazards which WILL result in severe

personal injury or death.

WARNING - Hazards or unsafe practices which COULD re-

sult in severe personal injury or death.

Warning Label

Black printing on a white background except the word

WARNING which is black with an orange background.

CAUTION - Hazards or unsafe practices which COULD re-

sult in minor personal injury or product or property damage.

Signal Wordsin Manuals

The signal word WARNING is used throughout this manual

in the following manner:

Caution Label

The signal word CAUTION is used throughoutthis manual in Black printing on awhite background except the word CAU-

the following manner: TION which is black with a yellow background.

CAUTION

PRODUCTLABELING

Signal words are used incombination with colors and/or pic-

tures on product labels. Following are examples of product

labels with explanations of the colors used.

DangerLabel

Black printing on a white background except the word DAN-

GER which is white with a red background.

E_ 513 01 1002 O0

Page 3

I Combination Units Installation Instructions I

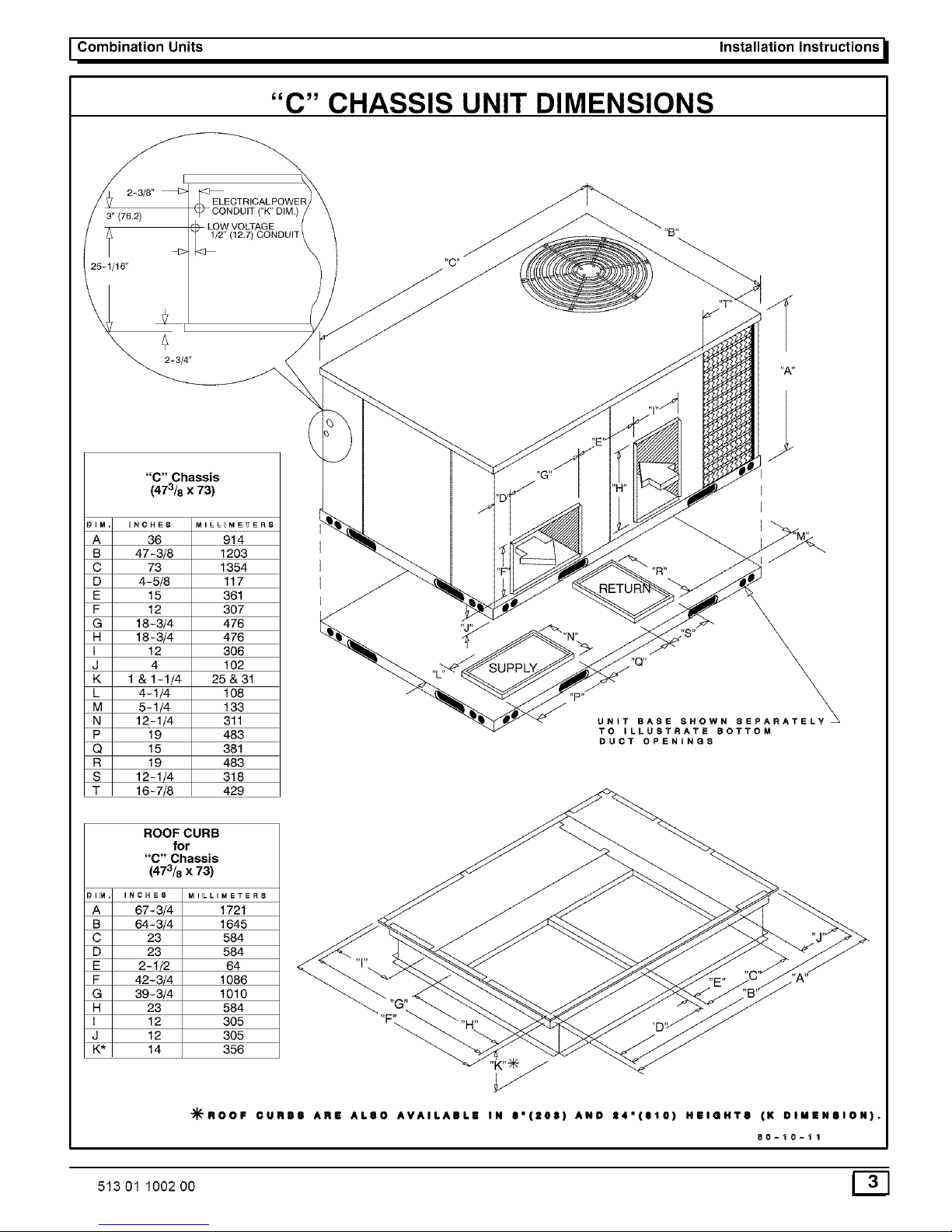

"C" CHASSIS UNIT DIMENSIONS

2-3/8"

3" (76.2)

) LOW VOLTAGE

1/2" (12.7) CONDUIT

"C" Chassis

(473/8 x 73)

DIM= ONCH_8 MILLOMETERS

A 36 914

B 47-3/8 1203

C 73 1354

D 4-5/8 t17

E 15 36t

F 12 307

G 18- 3/4 476

H 18- 3/4 476

I 12 306

J 4 102

K 1&1-1/4 25&31

L 4-1/4 108

M 5-1/4 133

N 12-1/4 311

P 19 483

Q 15 38t

R 19 483

S 12-1/4 318

T 16 - 7/8 429

ROOF CURB

for

"C" Chassis

(473/8 x 73)

DIM. INCH'8 MILLIMETER8

A 67-3/4 172t

B 64-3/4 1645

C 23 584

D 23 584

E 2-t/2 64

F 42-3/4 1086

G 39-3/4 1010

H 23 584

I 12 305

J 12 305

K* 14 356

"C"

UNIT BASE SHOWN SEPARAT

TO ILLUSTRATE BOTTOM

DUCT OPENINGS

_)_ROOF OURB8 ARE AL80 AVAILABLE IN I'(105) AND E4"(elo) HEIGHT8 (K DIMEN81ON).

80-10-11

513 01 1002 00

Page 4

_ Installation Instructions

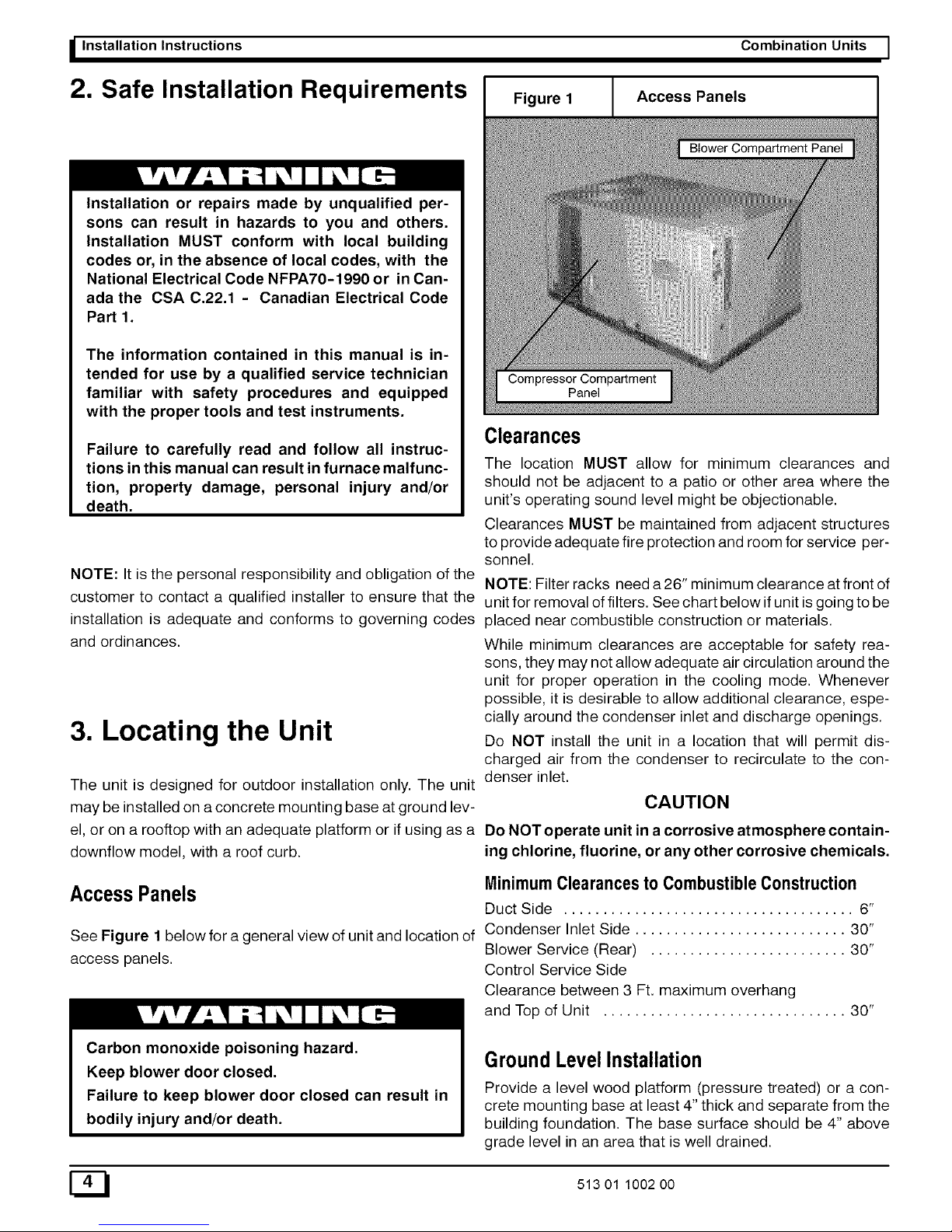

2. Safe Installation Requirements

Installation or repairs made by unqualified per-

sons can result in hazards to you and others.

Installation MUST conform with local building

codes or, in the absence of local codes, with the

National Electrical Code NFPA70-1990 or in Can-

ada the CSA C.22.1 - Canadian Electrical Code

Part 1.

The information contained in this manual is in-

tended for use by a qualified service technician

familiar with safety procedures and equipped

with the proper tools and test instruments.

Failure to carefully read and follow all instruc-

tions inthis manual can result in furnace malfunc-

tion, property damage, personal injury and/or

death.

NOTE: It is the personal responsibility and obligation of the

customer to contact a qualified installer to ensure that the

installation is adequate and conforms to governing codes

and ordinances.

3. Locating the Unit

The unit is designed for outdoor installation only. The unit

may be installed on a concrete mounting base at ground lev-

el, or on a rooftop with an adequate platform or if using as a

downflow model, with a roof curb.

AccessPanels

See Figure 1 below for a general view of unit and location of

access panels.

Figure 1

Clearances

Combination Units I

Access Panels

The location MUST allow for minimum clearances and

should not be adjacent to a patio or other area where the

unit's operating sound level might be objectionable.

Clearances MUST be maintained from adjacent structures

to provide adequate fire protection and room for service per-

sonnel.

NOTE: Filter racks need a 26" minimum clearance at front of

unit for removal offilters. See chart below if unit isgoing to be

placed near combustible construction or materials.

While minimum clearances are acceptable for safety rea-

sons, they may not allow adequate air circulation around the

unit for proper operation in the cooling mode. Whenever

possible, it is desirable to allow additional clearance, espe-

cially around the condenser inlet and discharge openings.

Do NOT install the unit in a location that will permit dis-

charged air from the condenser to recirculate to the con-

denser inlet.

CAUTION

Do NOT operate unit in a corrosive atmosphere contain-

ing chlorine, fluorine, or any other corrosive chemicals.

MinimumClearances to CombustibleConstruction

Duct Side ..................................... 6"

Condenser Inlet Side ........................... 30"

Blower Service (Rear) ......................... 30"

Control Service Side

Clearance between 3 Ft. maximum overhang

and Top of Unit ............................... 30"

Carbon monoxide poisoning hazard.

Keep blower door closed.

Failure to keep blower door closed can result in

bodily injury and/or death.

Ground LevelInstallation

Provide a level wood platform (pressure treated) or a con-

crete mounting base at least 4" thick and separate from the

building foundation. The base surface should be 4" above

grade level in an area that is well drained.

E_ 513 01 1002 O0

Page 5

I Combination Units

CAUTION

Unit will NOT operate properly unless it is installed level

front to rear and side to side.

RooftopInstallation

The existing roof structure MUST be adequate to support the

weight of the unit or the roof MUST be reinforced. Check the

weight of the unit in relation to the roof structure and local

building codes or ordinances and reinforce if necessary.

The unit MUST besituated to provide safe access for servic-

ing. Support for the unit MUST be level and may consist of a

platform or a combination of platform and roof beams or

curb. The platform may be constructed of combustible mate-

rial (wood only), or covered with Class A, B or C roof cover-

ing.

Hoisting

The unit should be hoisted with two lifting slings. Attach the

slings to rigging shackles that have been hooked through

holes in the base rail.

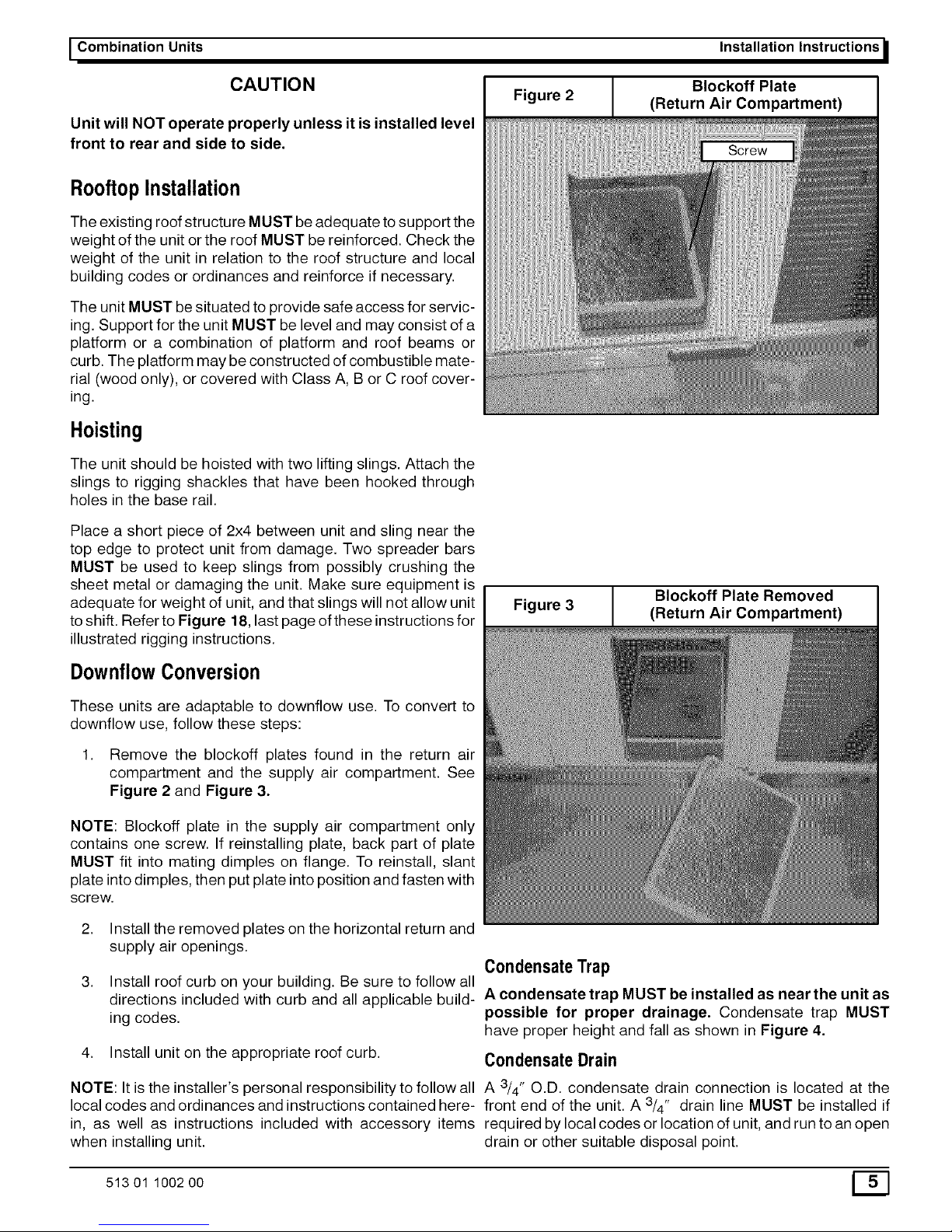

Figure 2

Installation Instructions

Blockoff Plate

(Return Air Compartment)

Screw

Place a short piece of 2x4 between unit and sling near the

top edge to protect unit from damage. Two spreader bars

MUST be used to keep slings from possibly crushing the

sheet metal or damaging the unit. Make sure equipment is

adequate for weight of unit, and that slings will not allow unit

to shift. Refer to Figure 18, last page of these instructions for

illustrated rigging instructions.

DownflowConversion

I Figure 3

Blockoff Plate Removed

(Return Air Compartment)

These units are adaptable to downflow use. To convert to

downflow use, follow these steps:

1. Remove the blockoff plates found in the return air

compartment and the supply air compartment. See

Figure 2 and Figure 3.

NOTE: Blockoff plate in the supply air compartment only

contains one screw. If reinstalling plate, back part of plate

MUST fit into mating dimples on flange. To reinstall, slant

plate into dimples, then put plate into position and fasten with

screw.

2. Install the removed plates on the horizontal return and

supply air openings.

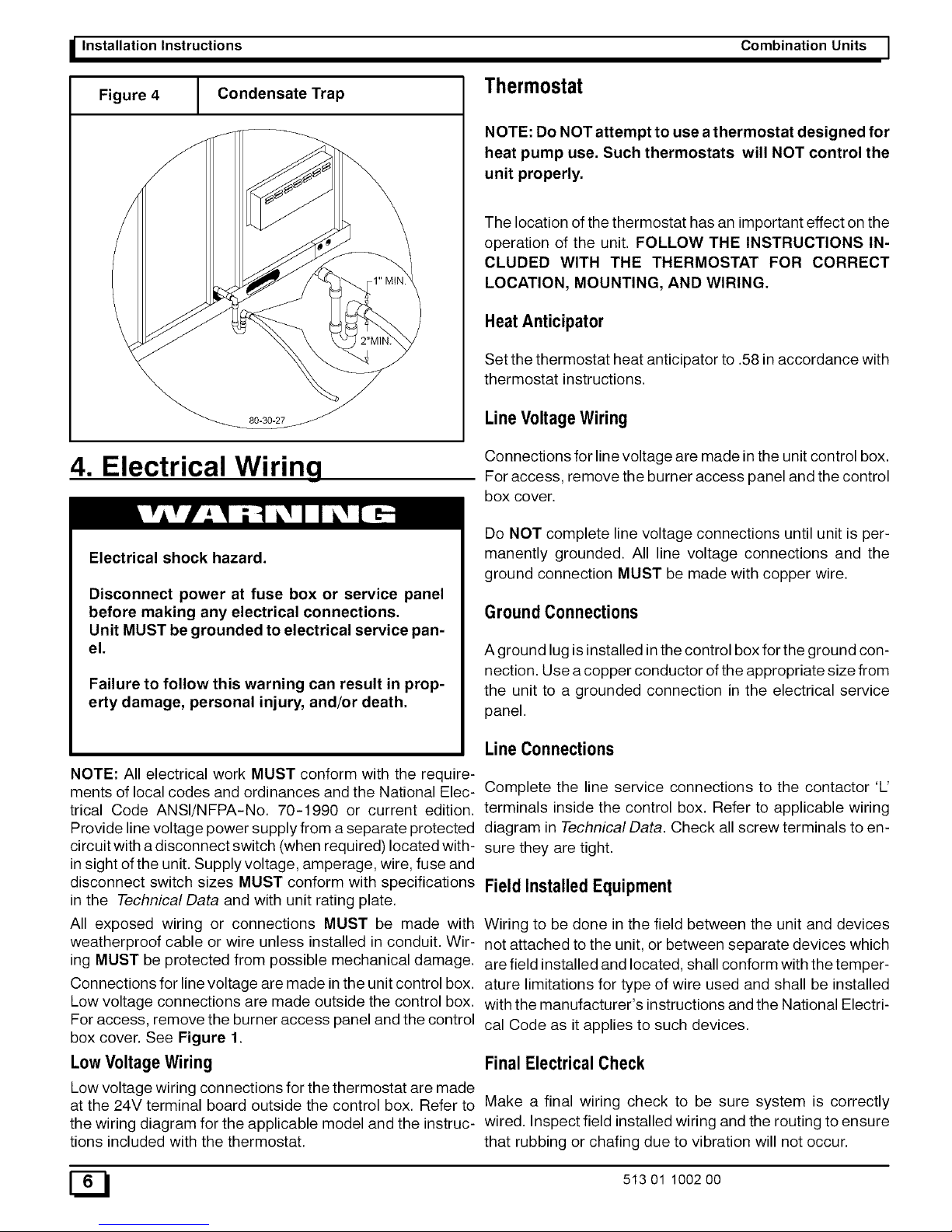

CondensateTrap

3. Install roof curb on your building. Be sure to follow all

directions included with curb and all applicable build- A condensate trap MUST be installed as near the unit as

ing codes, possible for proper drainage. Condensate trap MUST

have proper height and fall as shown in Figure 4.

4. Install unit on the appropriate roof curb. Condensate Drain

NOTE: It is the installer's personal responsibility to follow all A 3/4" O.D. condensate drain connection is located at the

local codes and ordinances and instructions contained here- front end of the unit. A 3/4" drain line MUST be installed if

in, as well as instructions included with accessory items required by local codes or location of unit, and run to an open

when installing unit. drain or other suitable disposal point.

513 01 1002 00 E_]

Page 6

I Installation Instructions

Figure 4 Condensate Trap

80-30-27

Thermostat

Combination Units I

NOTE: Do NOT attempt to use a thermostat designed for

heat pump use. Such thermostats will NOT control the

unit properly.

The location of the thermostat has an important effect on the

operation of the unit. FOLLOW THE INSTRUCTIONS IN-

CLUDED WITH THE THERMOSTAT FOR CORRECT

LOCATION, MOUNTING, AND WIRING.

HeatAnticipator

Set the thermostat heat anticipator to .58 in accordance with

thermostat instructions.

LineVoltageWiring

4. Electrical Wiring

Connections for line voltage are made in the unit control box.

For access, remove the burner access panel and the control

box cover.

Electrical shock hazard.

Disconnect power at fuse box or service panel

before making any electrical connections.

Unit MUST be grounded to electrical service pan-

el.

Failure to follow this warning can result in prop-

erty damage, personal injury, and/or death.

NOTE: All electrical work MUST conform with the require-

ments of local codes and ordinances and the National Elec-

trical Code ANSI/NFPA-No. 70-1990 or current edition.

Provide line voltage power supply from a separate protected

circuit with a disconnect switch (when required) located with-

in sight of the unit. Supply voltage, amperage, wire, fuse and

disconnect switch sizes MUST conform with specifications

in the Technical Data and with unit rating plate.

All exposed wiring or connections MUST be made with

weatherproof cable or wire unless installed in conduit. Wir-

ing MUST be protected from possible mechanical damage.

Connections for line voltage are made inthe unit control box.

Low voltage connections are made outside the control box.

For access, remove the burner access panel and the control

box cover. See Figure 1.

LowVoltage Wiring

Low voltage wiring connections for the thermostat are made

at the 24V terminal board outside the control box. Refer to

the wiring diagram for the applicable model and the instruc-

tions included with the thermostat.

Do NOT complete line voltage connections until unit is per-

manently grounded. All line voltage connections and the

ground connection MUST be made with copper wire.

GroundConnections

A ground lug is installed in the control box for the ground con-

nection. Use a copper conductor of the appropriate size from

the unit to a grounded connection in the electrical service

panel.

Line Connections

Complete the line service connections to the contactor 'L'

terminals inside the control box. Refer to applicable wiring

diagram in Technical Data. Check all screw terminals to en-

sure they are tight.

FieldInstalled Equipment

Wiring to be done in the field between the unit and devices

not attached to the unit, or between separate devices which

are field installed and located, shall conform with the temper-

ature limitations for type of wire used and shall be installed

with the manufacturer's instructions and the National Electri-

cal Code as it applies to such devices.

FinalElectrical Check

Make a final wiring check to be sure system is correctly

wired. Inspect field installed wiring and the routing to ensure

that rubbing or chafing due to vibration will not occur.

E_ 513 01 1002 00

Page 7

I Combination Units Installation Instructions

5. Air Distribution System

Ductwork

NOTE: The total heat loss from the structure as expressed in

total Btu/hr(Kw) MUST be calculated by manufacturer's

method or in accordance with "A.S.H.R.A.E. Guide" or

"Manual N - Load Calculations" published by the Air Condi-

tioning Contractors ofAmerica or in Canada H.R.A.I. "Manu-

al N". The total heat loss calculated should be equal to or

less than the unit heating capacity, output based on D.O.E.

test procedures, steady state efficiency times input.

Ductwork, supply registers, and return air grilles MUST be

designed and sized to handle the greater of the units heating

or cooling airvolume requirements. If the unit isconnected to

an existing system, the ductwork MUST be checked to make

sure it is adequate. Extra runs or larger duct sizes may have

to be installed. Use only non-combustible type insula-

tion on supply plenum or supply ductwork within 6

feet(2m) of unit,

Maximum recommended velocity in supply trunk ducts is

1000 feet (305m) per minute and 800 feet (244m) per minute

in return trunk ducts. Velocity in branches should not exceed

800 feet (244m) per minute supply and 600 feet (183m) per

minute in the return.

Ductwork installed outdoors should have a minimum of 2"

(50.8mm) of fiberglass insulation and a weatherproof vapor

barrier. It should also be protected against damage. Caulk

and flashing, or other means adequate to provide a perma-

nent weather seal should be used.

Ductwork installed in attics or other areas exposed to out-

side temperatures should be installed with a minimum of 2"

(50.8mm) fiberglass insulation and have an indoor type va-

por barrier.

The use of flexible, non-combustible connectors between

main trunk ducts and supply and return air plenums is rec-

ommended to minimize vibration transmission.

NOTE: Connect supply and return air plenums to unit in a

manner that will allow the top of the unit to be removed with-

out removing plenums. Plenums MUST be individually

sealed to unit casing.

Filters

CAUTION

Do NOT operate the unit without all filters in place.

All air MUST pass through a filter before entering the unit.

Electronic air cleaner, optional filter racks, or other accessi-

ble filter arrangements MUST be installed in the return air

ductwork.

NOTE: Ifthe unit has an economizer or any other type of out-

door air damper, disposable filters MUST be used in the in-

ternal filter racks.

For replacement filter sizes and instructions, see Air Filters.

Circulating Blower

DeterminingPulleyTurns

1. From the system design, determine the external static

pressure (ESP) for the supply ducts, return ducts and

registers, diffusers, grilles, dampers, heaters and spe-

cial filters (if any).

2. If unit isto be set up in cooling mode, add .08" W.C. (20

Pa) for wet coil operation to the total ESP determined

in Step 1.

3. From the system design, determine the desired airflow

in CFM (L/s).

4. To determine the pulley turns necessary to obtain the

desired CFM (L/s), go to the Circulating Blower Perfor-

mance Data graph for the unit.

513 01 1002 00 [_]

Page 8

_ Installation Instructions Combination Units I

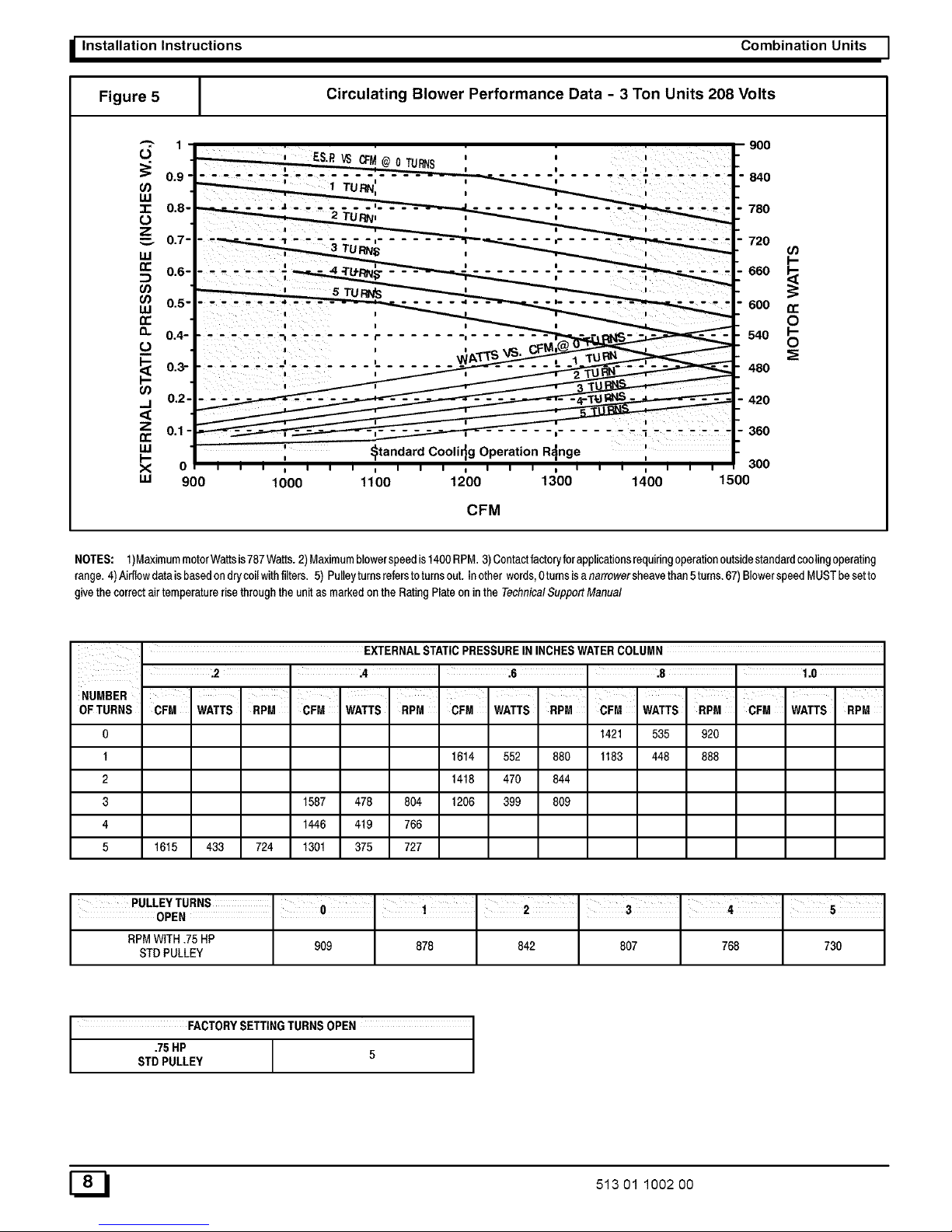

Figure 5 Circulating Blower Performance Data - 3 Ton Units 208 Volts

1100 1200 1300 1400

CFM

780

720

U)

1--

660

600 rr"

0

540 I--

0

=E

48O

420

360

300

1500

NOTES: 1)MaximummotorWattsis787Watts.2)Maximumblowerspeedist400RPM. 3)__ntactfact_ryf_rapp_icati_nsrequiring_perati_n_utsidesta_dardco__ing_perating

range.4)Airflowdata is basedondrycoilwithfilters. 5) Puneyturnsreferstoturnsout.Inother words,0turnsisa narrowersheavethan5turns.67)BlowerspeedMUSTbesetto

givethe correctair temperaturerise throughtheunit as markedonthe RatingPlateon inthe TechnicalSupportManual

EXTERNALSTATICPRESSUREIN INCHESWATERCOLUMN

. :2 -:4 -:6 -:8 - 1.0

NUMBER = I I , I _ I I I , I I

OFTURNS CFM WATTS RPM CFM WATTS RPM CFM WATTS RPM CFM WATTS RPM CFM WATTS RPM

0

t

2

3

4

5 1615 433 724

1587 478 804

1446 419 766

1301 375 727

1614 552 880

1418 470 844

1206 399 809

1421 535 920

t183 448 888

RPMWtTH.75 HP 909 878

STD PULLEY

842 807 768 730

I FACTORYSETTINGTURNSOPEN

.75HP

STD PULLEY 5

E_ 513 01 1002 O0

Page 9

I Combination Units Installation Instructions

Figure 6 Circulating Blower Performance Data - 3 Ton Units 230 / 460 Volts

d 1

0.9

o3

LU

•"r" 0.8-

O

Z

0.7-

U.I

n" 0.6-

:3

O3

O3 0.5-

ILl

n-

I:1. 0.4-

0.3-

_j 0.2-

<_

Z 0.1-

n"

LLI

LU

; ES.P,VSO:i @o TU_S

9OO

900

840

780

720

O3

8°o

600 n-

O

54O I-

0

48O

420

360

, Standard Cooling Operation Range ,

I I I I I

, , , , , , , , , , , , , , , , , , 300

tooo tt'oo 12'oo 13oo 14oo tsoo

CFM

NOTES: 1)MaximummotorWattsis808Watts.2)Maximumblowerspeedist400RPM. 3)__ntactfact_ryf_rapp_icati_nsrequiring_perati_n_utsidesta_dardco__ing_perating

range.4)Airflowdata isbasedondry coilwithfilters. 5) Puneyturnsreferstoturnsout. Inother words,0turns isa narrowersheavethan5turns.67)BlowerspeedMUSTbesetto

givethe correctair temperaturerisethroughthe unit as markedon the RatingPlateon inthe TechnicalSupportManual

EXTERNALSTATICPRESSUREIN INCHESWATERCOLUMN

, :2 -:4 -:6 -:8 - 1.0

NUMBER I I I , I = I I I , I I

OFTURNS CFM WATTS RPM CFM WATTS RPM CFM WATTS RPM CFM WATTS RPM CFM WATTS RPM

0

t

2

3

4

5 1604 467 727

1599 520 807

1455 467 769

1316 418 730

1420

1623 594 885 1264

1453 52t 848

1222 442 811

1032 393 772

575 925

509 891

RPMWtTH.75 HP 915 883

STD PULLEY

846 8O9

771

732

I FACTORYSETTINGTURNSOPEN

.75HP

STD PULLEY 5

513 01 1002 O0 E_]

Page 10

_ Installation Instructions Combination Units I

Figure 7 Circulating Blower Performance Data - 4 Ton Units 208 Volts

NOTES:

1.

2.

3.

4.

5.

6.

7.

0

w

:£

o

==

uJ

t_

uJ

.J

z

w

X

w

l

&9

&8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

I

o _

1200 1300 1400

CHART

I

1500 1600 t700 t800 1900

CFM

t000

930

860

790

72O

650

580

510

440

370

300

2OOO

F-

0

F.-

0

Maximum motor Watts is 928 Watts.

Airflow based on dry coil, horizontal flow, with filters.

For downflow SCFM, use a .15 static drop.

Pulley turns refer to turns out. I.E. 0 turns is a narrower sheave than 5 turns.

For applications requiring operation in shaded areas, contact the factory.

Maximum blower wheel speed is 1400 RPM.

The blower speed MUST be set to give the correct air temperature rise through the unit as marked on the Rating Plate or

Technical Support Manual.

TABLE

NO.

OF

TURNS

0

1

2

3

4

5

EXTERNAL STATIC PRESSURE IN INCHES W.C.

.2 .4 .6 .8 1.0

WIlL WIlL WIlL WIlL

W RPM CFM RPM CFM W RPM RPM CFM W

1851 750 952 960

1691 645 913 920

867 1513 546 871

822

777

CFM W CFM W

1567 649

1359 548

1778 620

1631 530

1716 518 774 1460 461

1587 456 725

TURNS/RPM CONVERSION TABLE

PULLEY TURNS 0 1 2 3 4 5

OPEN

RPM WITH.75 HP 950 910 870 825 780 730

STD PULLEY

WHL

RPM

W=Wa_s

UNIT FACTORY SETTING TURNS OPEN

PGB048D .75 HP STD PULLEY ...... 3.5

PGB048F .75 HP STD PULLEY ....... 2

[_ 513 01 1002 00

Page 11

I Combination Units Installation InstructionsI

Figure 8 Circulating Blower Performance Data - 4 Ton Units 230/460/575 Volts

O

NOTES:

1.

2.

3.

4.

5.

6.

7.

09

W

0

==

uJ

t_

09

09

uJ

o=

09

.J

z

w

X

w

f

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

f200

CHART

_F M Standard Cooling Operating Range

I URN _,,,_,_.

_ 4 TU ...... _: ...............

I I

I I

71 T : - i b_S

I

1000

930

86O

79O

72O

650

580

510

440

370

300

1300 1400 1500 1600 1700 1800 1900 2000

CFM

09

I==

t_

0

0

5;

Maximum motor Watts is 962 Watts.

Airflow based on dry coil, horizontal flow, with filters.

For downflow SCFM, use a .15 static drop.

Pulley turns refer to turns out. I.E. 0 turns is a narrower sheave than 5 turns.

For applications requiring operation in shaded areas, contact the factory.

Maximum blower wheel speed is 1400 RPM.

The blower speed MUST be set to give the correct air temperature rise through the unit as marked on the Rating Plate or

Technical Support Manual.

TABLE

NO.

OF

TURNS

O

1

2

3

4

5

EXTERNAL STATIC PRESSURE IN INCHES W.C.

.2 .4 .6 .8 1.0

WIlL WIlL WIlL WIlL

W RPM CFM RPM CFM W RPM RPM CFM W

1873 800 959 965

1706 698 919 925

870 1512 600 874

825 1317 519 829

778

CFM W CFM W

1588 708

1381 609

1788 673

1646 593

1727 574 776 1469 520

1593 522 728

TURNS/RPM CONVERSION TABLE

PULLEY TURNS 0 1 2 3 4 5

OPEN

RPM WITH.75 HP 960 920 875 825 780 730

STD PULLEY

WHL

RPM

W=Wa_s

UNIT FACTORY SETTING TURNS OPEN

PGB048D .75 HP STD PULLEY ...... 3.5

PGB048F .75 HP STD PULLEY ....... 2

513 01 1002 O0

Page 12

_ Installation Instructions Combination Units I

Figure 9 Circulating Blower Performance Data - 5 Ton Units 208 Volts

CHART

_gOperating Range

t400

1290

t180

t070

0

740 F.

0

630

520

410

300

1500 t600 1700 1800 t900 2000 2100 2200 2300 2400 2500

CFM

NOTES:

1. Maximum motor Watts is 1486 Watts.

2. Airflow based on dry coil, horizontal flow, with filters.

3. For downflow SCFM, use a .15 static drop.

4. Pulley turns refer to turns out. I.E. 0 turns is a narrower sheave than 5 turns.

5. For applications requiring operation in shaded areas, contact the factory.

6. Maximum blower wheel speed is 1400 RPM.

7. The blower speed MUST be set to give the correct air temperature rise through the unit as marked on the Rating Plate or

Technical Support Manual.

TABLE

NO.

OF

TURNS

0

1

2

3

4

5

EXTERNAL STATIC PRESSURE IN INCHES W.C.

.2 .4 .6 .8 1.0

WIlL WIlL WIlL WIlL WIlL

CFM W RPM CFM W RPM CFM W RPM CFM W RPM CFM W RPM

2240 1302 1153 2087 1213 1163 1914 1118 1174

2192 1196 1127 2028 1109 1137 1846 1017 1145

2199 1064 1074 2032 987 1082 1834 903 1089

2255 1018 1025 2098 945 1031 1916 868 1037

2132 875 982 1962 811 986 1761 742 991

1992 732 938 1814 671 942

TURNS/RPM CONVERSION TABLE

PULLEY TURNS 0 1 2 3 4 5

OPEN

RPM WITH 1 HP 1145 1120 1080 1035 990 945

STD PULLEY

W = Watts

FACTORY SETTING TURNS OPEN

1 HP STD PULLEY ........ 2.5 I

[_ 513 01 1002 00

Page 13

I Combination Units Installation Instructions

Figure 10 Circulating Blower Performance Data - 5 Ton Units 230/460/575 Volts

0.9

LL!

0 0.8

g

w 0.7

0.6

0.5

0,,

0.4

0.3

.J 0.2

Z

0.1

LJJ

p-

X 0

uJ

I I

--------r--

CHART

Standard Cooling Operating Range

t500

1400

t300

L t200

p.

L 1100 P

L 1000

0

L900 S

L800

L 700

600

500

1500 t600 1700 1800 t900 2000 2100 2200 2300 2400 2500

CFM

NOTES:

1. Maximum motor Watts is 1454 Watts.

2. Airflow based on dry coil, horizontal flow, with filters.

3. For downflow SCFM, use a .15 static drop.

4. Pulley turns refer to turns out. I.E. 0 turns is a narrower sheave than 5 turns.

5. For applications requiring operation in shaded areas, contact the factory.

6. Maximum blower wheel speed is 1400 RPM.

7. The blower speed MUST be set to give the correct air temperature rise through the unit as marked on the Rating Plate or

Technical Support Manual.

TABLE

NO.

OF

TURNS

0

1

2

3

4

5

EXTERNAL STATIC PRESSURE IN INCHES W.C.

.2 .4 .6 .8 1.0

WIlL WIlL WIlL WIlL WIlL

CFM W RPM CFM W RPM CFM W RPM CFM W RPM CFM W RPM

2312 1282 1179 2149 1195 1186 1974 1105 1193

2211 1192 1147 2037 1106 1153 1837 1017 1158

2248 1097 1087 2077 1021 1091 1879 940 1096

2256 1019 1037 2096 950 1042 1912 880 1046

2161 905 990 1991 843 993 1788 777 996

2029 771 944 1848 712 946

TURNS/RPM CONVERSION TABLE

PULLEY TURNS 0 1 2 3 4 5

OPEN

RPM WITH 1 HP 1175 1145 1090 1045 1000 950

STD PULLEY

W = Watts

I

FACTORY SETTING TURNS OPEN I

I

1 HP STD PULLEY ........ 2.5

513 01 1002 O0 _f_

Page 14

I Installation Instructions Combination Units I

I Standard Cooling Operating Range I

1700

1600

1500

1400

r_

1300

i119oo

O

'1000

9OO

800

7OO

2100 2300 2500 2700 2900 3100

CFM

NOTES: 1)MaximummotorWattsis1538Watts.2) Maximumblowerspeedis 1400RPM.3)Contactfactoryforapplicationsrequiringoperationoutsidestandardcoolingoperat-

ingrange.4)Airflowdataisbasedondrycoilwithfilters. 5) Pulleyturnsreferstoturnsout. Inother words,0turnsisa narrowersheavethan5turns. 6)BlowerspeedMUSTbesetto

givethe correctair temperaturerise throughtheunit as markedonthe RatingPlateon inthe TechnicalSupportManual

EXTERNALSTATICPRESSUREININCHESWATERCOLUMN

.2 .4 .6 .8 1.0

NUMBER

OFTURNS CFM WATTS RPM CFM WATTS RPM CFM WATTS RPM CFM WATTS RPM CFM WATTS RPM

0 2820 1538 1239 2682 1460 1242 2534 1380 1246 2372 1298 1249

t 2707 1361 1198 2558 1283 1200 2399 1207 1203 2231 1133 1205

2 2584 1213 1154 2429 1145 1156 2262 1077 1158

3 2441 1081 1108 2278 1011 t110

4 2348 976 1061

5 221t 863 1014

NOTE: For enteringairflow correctionfactorsand voltagecorrectionfactorsfor coolingand heating,see page7.

WilloperateatratedESPineitherhorizontalordownflowductposition.

PULLEYTURNS

OPEN O

RPMWITH 2 HP

STD PULLEY 1245

1

1202

2 3

1t57 1111

4

1064

5

1017

I

FACTORYSETTINGTURNSOPEN

2HP

STD PULLEY 2

[_ 513 01 1002 O0

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

Page 15

I Combination Units Installation Instructions

1 i 1700

[Standard CoolingOperatingRange]

(1) 0.9 1600

W

r.) 0.8 1500

Z

ILl 0.7 1400 (/)

I--

"-_ 0.6 1300

€.0

uJ O.5 1200 Pr

Pr

o. 0

0.4 1100 I-

_ 0

0.3 1000

2100 2300 2500 2700 2900

9OO

8OO

7OO

3100

CFM

NOTES: 1)MaximummotorWattsis1582Watts.2) Maximumblowerspeedis 1400RPM.3)Contactfactoryforapplicationsrequiringoperationoutsidestandardcoolingoperat-

ingrange.4)Airflowdataisbasedondrycoilwithfilters. 5) Pulleyturnsreferstoturnsout. Inother words,0turnsisa narrowersheavethan5turns. 6)BlowerspeedMUSTbesetto

givethe correctair temperaturerise throughtheunit as markedonthe RatingPlateon inthe TechnicalSupportManual

.2

EXTERNALSTATICPRESSUREININCHESWATERCOLUMN

.4 .6 .8

NUMBER

OFTURNS CFM WATTS RPM CFM WATTS RPM CFM WATTS RPM CFM WATTS RPM

0 2733 1505 1250 2588 1428 1253 2430 t346 1255

t 2730 1404 1205 2583 1327 1207 2422 1248 1209 2250 1t72 1211

2 2609 1263 1159 2450 1191 1161 2281 1121 1163

3 2464 1122 11t2 2300 1055 1114

4 2373 1013 1065 2199 953 1067

5 2239 910 1017

NOTE: Foren_ring airflow corre_ionfactors and voltagecorre_ionfacto_ _rcooling and heating,see page7.

Winoper_e _ r_ed ESPin eitherhorizontalordownflow du_ position.

1.0

CFM WATTS RPM

2251 1255 1258

PULLEYTURNS

O

OPEN

RPMWITH 2 HP

1255

STD PULLEY

1

1210

2

1165

3

1115

4

1070

5

1020

I

FACTORYSETTINGTURNSOPEN

2HP

STD PULLEY 2

513 01 1002 00

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

Page 16

_ Installation Instructions

-.:t=m-,]--t=,A==:! = =.],,=,Jill

230, 460 VOLT

1.4

Combination Units I

2200

0.8

o_

uJ

n,

n

_ 0.6

I--

I--

o_

,_ 0.4

iii

1.2

0.2

_,,,_,,_s _'_'_''_'_" _

|

o i

1600 1800

|

i

i

2000

2000

1800

O9

I--

1 600 j-

n"

1400 0

0

:E

1200

IOO0

I I I I I 800

2200 2400 2600 2800 3000 3200

AIRFLOW (SCFM) DRY COIL WITH FILTER

NOTES:1)MaximummotorWattsis 2158Wattsat208V,and2246Wattsat230-460V.2) Maximumblowerspeedis1400RPM.3)Contact

factoryforapplicationsrequiringoperationoutsidestandardcoolingoperatingrange.4)Airflowdataisbasedondrycoilwithfilters. 5) Pulley

turnsreferstoturnsout. Inotherwords,0turnsisanarrowersheavethan5turns.6)BlowerspeedMUSTbesettogivethecorrectairtempera-

turerisethroughtheunitas markedonthe RatingPlate.7)Add0.05 in. ESPfor 208volt operation.

EXTERNALSTATICPRESSUREININCHESWATERCOLUMN

TURNS .2 A .6 .8 1.0 1.2

VOLT OPEN CFM WATT RPM CFM WATT RPM CFM WATT RPM CFM WATT RPM CFM WATT RPM CFM WATT RPM

S

O 2996 2246 1345 2654 2077 1355

1 3095 2107 1295 2885 1992 t297 2571 1825 1300 2473 1775 1305

230/ 2 3041 1890 t240 2802 1772 1242 2578 1649 t245 2241 1487 1253 2091 1403 1255

460 3 3127 t850 1180 2812 1667 1t90 2599 1564 1192 2333 1436 1t95 1978 1281 1196 1873 1188 1200

4 2993 t590 1126 2752 1492 1t33 2478 1376 1136 2228 1228 1t40 1895 1096 1142 1754 1043 1145

5 2826 t355 1075 2574 1232 t080 2339 1161 1082 2097 1056 t085 1750 923 1088 1647 873 1090

tVOL,,OE PO'L *,U..SOP .0t, 2' 3 , ,

230- 460 RPMWITH2 HPSTD PULLEY t344 1299 1245 1191 1136 t082

*FactorySettingTurnsOpen

[_ 513 01 1002 O0

Page 17

I Combination Units Installation Instructions

6. Adjustable Belt Drive Blower

Personal injury hazard.

Use extreme care during the following proce-

dures and obey Safety Information.

Failure to do so may result in personal injury.

I

The following safety rules MUST always be followed when

working near belt drive.

Always Turn The Power Off

Turn the power to the unit OFF before you begin work-

ing on it.

Always Wear Protective Clothing

NEVER wear loose or bulky clothes, such as neckties,

exposed shirttails, loose sleeves, or lab coats around

belt drives. Wear gloves while inspecting sheaves to

avoid nicks, burrs, or sharply worn pulley edges.

The blower speed is changed by adjusting the variable

speed pulley mounted on the blower motor.

Ifthe blower speed needed is different than the speed of the

blower as shipped, follow the steps below to change the I

blower speed. Before changing the blower speed, read the

I

above safety rules first.

5. Turn electric power OFF.

6. Remove the side blower access panel (see Figure 1

on Page 4)

10. Loosen set screw(s) on the outer half of the adjustable

pulley.

The unit has one of two different types of adjustable

pulleys (see Figure 12 and Figure 13).

Figure 12 Adjustable Pulley (Keyway Type)

This keyway pulley has a removable key and two keyways cut through

the threads of the pulley hub. The keyways limit this type of pulley to

half turn adjustments.

Adjustable Pulley (Threaded Keys)Figure 13

Figure 11 I Motor Mount Assembly

Adjustable

Pulley

Motor Mount

Bolts (4)

__ Adjustment

Bolt

1054584

7.

8.

Loosen the four motor mount bolts.

Turn the motor adjustment bolt counterclockwise until

the belt is slack enough to come off easily (see

Figure 11).

9. Remove the belt. Do NOT pry off belt.

This type of pulley has non-removable threaded keys that ride on the

threads of the pulley shaft. This allows a full 360 °range of adjustment.

11. Remove key if unit has a keyway type pulley.

12. To set the blower for a desired CFM (L/s), first turn the

outer half of the adjustable pulley clockwise until it

meets the inner half of the pulley.

13. Turn the outer half of the adjustable pulley counter-

clockwise the correct number of turns to obtain the de-

sired CFM (L/s).

NOTE: To increase the blower speed, turn the outer half of

the adjustable pulley clockwise. To decrease the blower

513 01 1002 00 Ff_

Page 18

_ Installation Instructions

speed, turn the outer half of the adjustable pulley counter-

clockwise.

14. Replace key if unit has keyway type pulley.

15. Tighten set screw(s).

16. Put on belt.

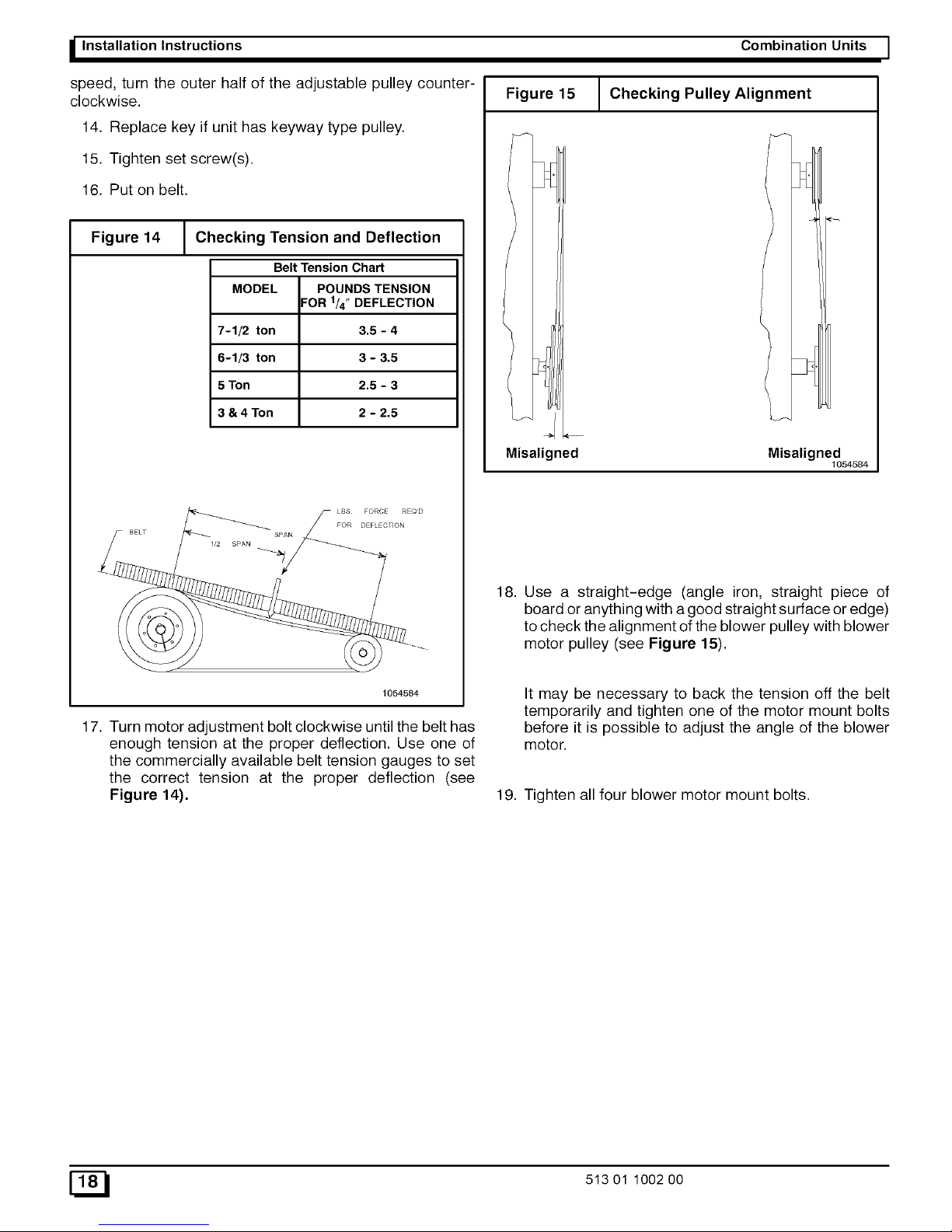

Figure 14 Checking Tension and Deflection

Belt Tension Chart

MODEL POUNDS TENSION

FOR 1/4" DEFLECTION

7-1/2 ton 3.5 - 4

6-1/3 ton 3 - 3.5

5 Ton 2.5 - 3

3 & 4 Ton 2 - 2.5

1054584

17. Turn motor adjustment bolt clockwise until the belt has

enough tension at the proper deflection. Use one of

the commercially available belt tension gauges to set

the correct tension at the proper deflection (see

Figure 14).

Figure 15

Combination Units

I Checking Pulley Alignment

Misaligned Misaligned

1054584

18. Use a straight-edge (angle iron, straight piece of

board or anything with a good straight surface or edge)

to check the alignment of the blower pulley with blower

motor pulley (see Figure 15).

It may be necessary to back the tension off the belt

temporarily and tighten one of the motor mount bolts

before it is possible to adjust the angle of the blower

motor.

19. Tighten all four blower motor mount bolts.

[_ 513 01 1002 O0

Page 19

I Combination Units Installation InstructionsI

7. Economizer

The purpose of an economizer is to: economizers or on the actuator motor of three-position

economizers.

• Provide cool outside air to the conditioned space dur-

ing the cooling cycle to minimize the use of the com-

pressors.

• Bring outside air into the conditioned space to meet

minimum fresh air requirements whenever the circula-

tion blower is running.

Figure 16 Downflow Economizer 1

Theoryof Operation

The economizer has two sets of dampers that are mechani-

cally linked together. The fresh air dampers regulate the in-

take of outside air and the return air dampers regulate the

flow of return air (see Figure 16). When the fresh air damp-

ers modulate open, the linkage causes the return air damp-

ers to modulate closed.

The economizer is controlled by a logic module which field

connects to the unit controls through a plug harness. The

logic module also controls the compressor staging based on

the thermostat input.

The minimum opening position of the fresh air dampers is

field adjustable. It is set on the logic module of modulating

The enthalpy sensor is factory installed on the fresh air

dampers of the economizer. The enthalpy change-over

point is adjustable on the logic module.

A discharge air sensor is field installed in the blower inlet.

The discharge air sensor keeps the discharge air above

56°F (13.3°O).

A positive pressure is created when the fresh air dampers

open and the return dampers close. This pressure must be

vented or the air will not circulate properly. This is the func-

tion of the barometric relief damper. A positive pressure

forces thebarometric relief damper to swing open.

The fresh air dampers open to the minimum position for out-

side air whenever the circulation blower is ON.

When the thermostat is in the FAN AUTO position, the fresh

air dampers will close completely whenever heating or cool-

ing is not called for.

If Using a2- StageThermostat

On a call for cooling, ifthe economizer outdoor air sensor de-

termines that the outside air is cool enough (and in the case

of an enthalpy sensor, dry enough), the fresh air dampers

will modulate open and the return air dampers will modulate

closed.

If the conditioned space is not being maintained at the se-

lected temperature, the thermostat will make Y2 and call for

second stage cooling by energizing the economizer logic

module at the low voltage terminal board. This energizes Y1

and contactor which energizes the condenser fan and com-

pressor for cooling to assist the economizer.

NOTE FOR 6-1/3 UNITS ONLY: Contactor C2 cannot be

energized to operate compressor 2 while the economizer is

still energized since Circuit 1 is activating the economizer

and Circuit 2 is activating compressor 1.

If the thermostat is still calling for cooling and the outside air

warms to above the setting for economizer operation:

A. The economizer dampers will close to the minimum

position for outside air and remain there.

B. Contactor Cl will remain energized and compressor 1

will continue to run.

C. Conctactor C2 will close and compressor 2 will start.

If Using a Single- Stage Thermostat

When using a single stage thermostat, all steps as outlined

above will be followed with the exception of the following:

The compressor will only be energized when the outside air

reaches a temperature above the preset limit of the econo-

mizer. When ambient conditions are NOT suitable for econo-

mizer operation, ONLY the compressor will run, and the

economizer will NOT be energized.

513 01 1002 00 _f_

Page 20

I Installation Instructions Combination Units I

8. Start-up Procedure

tion and be damaged. It is therefore necessary to check for

proper rotation.

CAUTION

Electrical shock, fire and/or explosion hazard.

Use extreme care during all of the following

checks and procedures.

Make sure Electric Power and is turned OFF as

instructed in appropriate steps.

Failure to follow this warning can result in prop-

erty damage, personal injury, and/or death.

Check the unit's operation as outlined in the following

instructions.

Blower and Phasing Check

1. Shut OFF electric power at unit disconnect.

2. Check to see that clean, properly sized air filters are

installed.

3. Check to see that everything inside the unit is clear and

ready to operate safely. Ensure that there are no ob-

jects in, on or around the motor, belt or blower wheel.

Do NOT operate the unit with the compressor(s) run-

ning until proper blower rotation has been confirmed by

running the following test.

7. Set thermostat fan switch to ON. The circulating air

blower should come ON.

.

Shut OFF electric power at unit disconnect and visual-

ly observe the direction of the blower rotation as it

slows down. Do NOT put hands or any other object in,

on or around the belt, motor or blower wheel. If blower

wheel rotation is the same as the directional arrow on

the blower housing, proceed to the next step.

CAUTION

If blower rotation is incorrect, shut electric power OFF at

unit disconnect and reverse any two supply wires at

field connections ONLY. Do NOT reverse the blower

and/or compressor leads or rewire any internal wiring.

After rewiring is done, repeat blower rotation check to

ensure that blower rotation is now correct.

9. If blower rotation iscorrect, reset thermostat fan switch

to AUTO.The circulating air blower should go OFF.

Nothing should be running.

10. Shut OFF electric power at unit disconnect.

4. Set thermostat Heat-Cool selector to OFF.

5. Set thermostat fan switch to AUTO.

Moving parts hazard.

Do NOT put hands or any other object in, on or

around the motor, belt or blower wheel. Ensure

that there are no objects in, on or around the mo-

tor, belt or blower wheel before turning electric

power on.

Failure to follow this warning can result in prop-

erty damage, personal injury, and/or death.

,

Turn ON electric power. Nothing should start running.

If any unusual arcing, odors or noises are encoun-

tered, shut OFF electric power immediately and check

for wiring errors.

NOTE: The circulation blower motor and compressor(s) are

three phase and are factory synchronized for proper rota-

tion. Even if the circulation blower motor comes on and air

seems to be circulating, it is possible that the blower motor

rotation isincorrect due to improperphasmg. The scroll com-

pressor(s) (if equipped) will run backwards under this condi-

Cooling Checks

The compressors have afive minute anti-cycle delay that is

activated whenever the compressors turn off. For instance, if

the unit is manually shut off when the compressors are run-

ning and the unit is turned back ontwo minutes later, it will be

an additional three minutes before the compressors will re-

start.

CAUTION

Do NOT operate the unit with the compressor(s) run-

ning until proper blower rotation has been confirmed

during the Blower and Phasing Check in the previous

section. If the phasing is incorrect, the scroll compres-

sor(s) (if equipped) will run backwards and they will be

damaged.

1. Be sure that electric power is OFF.

2. To check cooling Stage 1, place jumper wires across

low voltage terminal board terminals R to G, R to Y1.

3. Turn electric power ON. Check to see that the follow-

ing occurs:

a. Compressor 1 - ON

b. Condenser fan motor(s) - ON

c. Circulation air blower - ON with correct rotation

and adequate airflow from ductwork.

[_ 513 01 1002 00

Page 21

I Combination Units

4. Shut OFF electric power at unit disconnect.

5. To check cooling Stage 2, remove jumper wires from

Y1 and place it on Y2.

NOTE: Allow 5 minutes between Steps 4 and 6.

.

Turn ON electric power. Check to see that the following

occu rs:

a. Compressors 1 & 2 - ON

b. Condenser fan motor(s) - ON

c. Circulation air blower - ON

NOTE: IfY2 only is jumpered, condenser fans will not come

on.

7. Shut OFF electric power at unit disconnect. Begin tim-

ing the five minutes for the anti-cycle delay.

8. Remove jumpers from low voltage terminal board.

9. Set Thermostat to COOL and temperature to call for

Cooling.

10. Turn ON electric power. At the end of the five minute

anti-cycle delay, the unit should start and run.

11. Shut OFF electric power at unit disconnect.

12. Replace all service access panels.

9. Operation And Maintenance

Electrical shock hazard.

Turn off electric power supply at disconnect

switch or service panel before removing any ac-

cess or service panel from unit.

Failure to follow this warning can result in prop-

erty damage, personal injury, and/or death.

Installation Instructions

Turning Off the Unit

Heating

1. Set thermostat selector to OFF and fan switch to

AUTO.

2. If electric heat is running at time of shut-down, wait 2.5

minutes then shut OFF electric power supply at dis-

connect switch or service panel. (No wait is necessary

ifelectric heat was not running within 2.5 minutes prior

to shut-down.)

Cooling

1. Set thermostat selector to OFF and fan switch to

AUTO.

2. To shut the unit down completely, shut OFF electric

power supply at disconnect switch or service panel.

Starting the Unit After Shutdown

Heating

1. Set the thermostat to OFF.

4. Turn ON electric power.

5. Set thermostat to desired temperature and set selec-

tor to HEAT. Unit will come on and operate automati-

cally under control of the thermostat.

Cooling

CAUTION

To prevent possible damage to the compressor(s), do

NOT operate on cooling when outdoor temperature is

below 35°F (2°C).

NOTE: An optional low ambient kit is available that allows

the unit to operate at temperatures down to 0°F (-18°C).

1. Turn ON electric power.

2. Set thermostat to desired temperature and set system

switch to COOL. The unit will come on and operate au-

tomatically under control of the thermostat.

Close all doors and windows. The unit may run contin-

uously for several hours or longer on the initial run be-

cause of residual heat and moisture in the building.

This is normal for any air conditioning system.

Thermostat Fan Switch Operation

The circulating air blower will run continuously with the fan

selector switch in the ON position. When the fan selector

switch is in the AUTO position, the blower will run during

each heating or cooling cycle.

513 01 1002 00 r_

Page 22

_ Installation Instructions

Adjusting Room Temperatures

If the temperature in individual rooms is not as desired, bal-

ance the system by adjusting the dampers in the branch

ducts (see Figure 16). Adjust a little at a time and wait a day

after each change to judge the effect. Once the dampers are

adjusted for normal weather conditions, it is best to leave

them that way. Compensate for temporary weather changes

by adjusting the thermostat setting.

Figure 17 Typical Branch Duct Dampers

Monthly Maintenance and Inspection

Checks

Air Filters (Factory Installed)

CAUTION

Do NOT operate unit without all air filters installed in the

unit.

Dirty filters are the most common cause of compressor fail-

ures and inadequate heating and cooling performance.

Combination Units I

1. Remove filter access panel.

2. Remove the bottom filters.

.

The front of the center rail is attached to the unit by a

keyhole/screw connection. Unhook the front of the

center rail, swing it down approximately four inches

(100mm), and hook the keyhole on the screw pro-

vided.

4. Remove the bottom filters.

5. Replace bottom filters, center rail, and top filters.

6. Replace filter access panel.

Cooling Season Checks (Monthly)

Condenser Coil

Keep the condenser inlet and outlet area clean and free of

leaves, grass clippings and other debris. Grass should be

kept short in front of the condenser inlet. Shrubbery MUST

be trimmed back so it is no closer than 30 inches (762 mm) to

condenser coil.

Condensate Drain

Check for condensate drainage. Clean as required.

Annual Maintenance and Inspection

Electrical Shock, Fire and Explosion Hazards.

Turn off electric power supply at disconnect

switch or service panel before removing any ac-

cess or service panel from unit.

Failure to follow this warning can result in prop-

erty damage, personal injury, and/or death.

Inspect filters at least monthly and replace or clean as re- The annual inspection should include cleaning as required

quired, to ensure efficient operation of the unit.

Washable filters may be cleaned by soaking in mild deter- NOTE: All bearings are sealed and no lubrication is re-

gent and rinsing with cold water. Install filters so that the ar- quired.

rows on the side point in the direction of air flow.

Filter racks are accessible through the filter access panel. Circulating Air Blower

Disposable Replacement Filters

To replace disposable filters:

Visually inspect the blower wheel for accumulations of dirt or

lint. Clean the compartment and the blower wheel. If accu-

mulation is excessive on blower wheel or does not remove

easily, it will be necessary to remove the blower assembly.

[_ 513 01 1002 00

Page 23

60

0

8

o

o

o

@

RIGGINGINSTRUCTIONS

A WARNING

FAILURE TO FOLLOW THESE INSTRUCTIONS

CAN RESULT IN PROPERTY DAMAOE,

E_ODILY INJURY OR DEATH_

ALL PANELS MUST BE IN PLACE WHEN RIGGING AND LIFTING.

HOOK RIGGING SHACKLES THROUGH HOLES IN BASE RAIL, AS SHOWN IN DETAIL A.

USE SPREADER BARS, WHEN RIGGING, TO PREVENT UNIT DAMAGE.

BE SURE RIGGING AND SHACKLES ARE SUFFICIENT TO HANDLE WEIGHT LISTED BELOW.

SPREADER BARS

DETAIL A

HEIGHT

WIDTH

Unit Size (ton)

3

3-1/2

4

5

6-1/3

7-1/2

Weight (Ibs)

560

570

590

630

710

715

"1'1

m,

c

t,..

o

m,

o

m

(3

o

3

C

m,

¢e

o

2

t_

m

Page 24

INTERNATIONAL COMFORT PRODUCTS

LIMITED WARRANTY CERTIFICATE

For Cooling & Heating Products

SAVE THIS CERTIFICATE. It gives you specific legal rights, and you may also have other rights which may vary from state to state and

province to province.

If your unit needs servicing, contact a qualified dealer or qualified service technician of your choice. When requesting service, please have the model

and serial number from each unit in your heating and/or cooling system readily available. If your dealer needs assistance, the distributor is available to

provide support and we, in turn, support its efforts.

Fill in the installation date and model and serial numbers of the unit inthe space provided below and retain this Limited Warranty for your files.

GENERAL TERMS

Subject to the conditions and limitations stated herein, during the term of this Limited Warranty, we will provide a replacement for any functional

component part (as defined below) of your unit found to be defective in materials or workmanship. The term ofthis Limited Warranty is five years from

installation on Residential Products and one year from installation on Commercial Products. Except as otherwise stated in the "Additional Terms"

section, this Limited Warranty covers only the original purchaser and subsequent transferees, and only while the unit remains at the site of the original

installation (except for mobile home installations), and onty if the unit is installed inside the continental United States, Puerto Rico, Alaska, Hawaii or

Canada. In addition, the Limited Warranty applies only if the unit is installed and operated inaccordance with the printed instructions accompanying the

unit, and in compliance with alt applicable installation and building codes and good trade practices. As used in this Limited Warranty, "installation"

means the original installation of the unit.

TH ERE ARE EXCEPTIONS to this Limited Warranty as described on the reverse side of this page. All replacement parts will be warranted for the

unused portion of the warranty coverage period on the unit. The partto be replaced must be returned by the dealer to a distributor that sells products for

International Comfort Products, in exchange for the replacement part. In lieu of providing a replacement part, we may, at our sole option, refund to you

an amount equal tothe distributor's component purchase price from us,or provide to you acredit equal to that amount to be applied toward the purchase

of any new unit that we distribute. Ifa credit for a new unit is given in tieu of a replacement part, the rating plate from the unit being replaced must be

submitted on a warranty claim, and you r dealer must make the unit being replaced available to our distributor for disposition. As acondition towarranty

coverage, the unit must receive yearly maintenance, as described in the owner's manual, by a dealer. Satisfactory proof of yearly service by adealer

may be required.

"Functional component parts" include only the following: blower motor, unit-mounted sensors & timers, condenser motor, evaporator coil, condenser

coil, condenser fan, capacitor, transformer, single-phase strip heat elements, expansion device, reversing valve, solenoid valve, service valve,

electronic and electro-mechanical control board, ignitor, ignition module, draft inducer assembly, burner pilot, gas valve, limit control, pressure switch,

relays and contactors, blower wheel, interlock switch, crosslighter, pilot shield, gas & oil burners, oil pump assembly, accumulators and factory installed

driers and strainers.

This Limited Warranty DOES NOT COVER any labor, material, refractory chambers, oii nozzles, refrigerant, refrigerant inspection and refrigerant

reclaiming, freight and/or handling charges associated with any repair or replacement and such charges will be your responsibility.

Toestablish the installation date for any purpose under this Limited Warranty, you must retain the original records that can establish the installation date

ofyour unit. Ifyou donot providesuchdocumentsthe start dateoftheterm ofthis LimitedWarrantywillbe based uponthedate ofunit manufacture, ptus

thirty (30) days. In establishing that the required yearly service has occurred, you must furnish proof of yearly service by a qualified service technician.

This Limited Warranty does not cover: (a) failure or damages caused by accident, abuse, negligence, misuse, riot, fire, flood, or Acts of God (b)

damages caused by operating the unit where there is a corrosive atmosphere containing chlorine, fluorine, or any other damaging chemicals (other

than those found in a normal residential environment) (c) damages caused by an unauthorized alteration or repair of the unit affecting its stability or

performance (d) damages caused by improper matching or application of the unit or the unit's components (e) damages caused by failing to provide

proper maintenance and service to the unit in accordance with this Limited Warranty Certificate and the printed instructions originally provided with the

unit (f) any expenses incurred for erecting, disconnecting, or dismantling the unit (g) parts or supplies used in connection with service or maintenance,

such as refrigerant, refractory chambers, oil nozzles, filters, or belts (h) damage, repairs, inoperation or inefficiency resulting from faulty installation or

application (i) electricity or fuel costs or any increase in electricity or fuel cost whatsoever including additional or unusual use of supplemental electric

heat (j) units which have not had the required yearly maintenance described elsewhere in this limited warranty.

In no event shall we be liable for any incidental, consequential, or special damages or expenses in connection with any use or failure of this unit.

We have not made. do not make. and hereby disclaim any implied condition or implied warranty of fitness for a particular use or purpose, and

anv implied condition or implied warrantv of merchantabilitv, to the fu Ilest extent allowed bv law. We make no express or implied warranties

except as stated in this Limited Warrantv certificate.

No one is authorized to change this Limited Warranty or to create for us any other obligation or liability in connection with this unit. Any implied

warranties shall last for the term of the expressed warranty contained herein. Some states and provinces do not allow the exclusion or limitation of

incidental orconsequential damages or do not allow limitations onhow long an implied warranty or condition lasts, so the above limitations or exclusions

may not apply to you. The provisions of this Limited Warranty are in addition to and not amodification of or subtraction from any statutory warranties and

other rights and remedies provided by law.

Please refer to reverse side of this page for additional terms.

Model No.

Serial No. Date Installed

Effective on units installed After July 1, 2002,

USA: International Comfort Products Corporation (USA) • 650 Hell-Quaker Avenue *P.O. Box 128 • Lewisburg, Tennessee 37091 • (931-270-4100)

CANADA: International Comfort Products division of UTC Canada Corporation • 6060 Burnside Court, Unit 1, Mississauga, Ontario L5T 2T5

(905-795-8113).

Manufacturers of Airquest, Arcoaire, Clare, Comfortmaker, Dettson, Hell, Keeprite, Lincoln, Tempstar and other quality brand name private label

products.

Part No. 401 06 1010 18 (Orig. 8/9/2002)

Page 25

ADDITIONAL TERMS FOR RESIDENTIAL APPLICATIONS ONLY

The Additional Terms for the components listed below are in addition to, and subject to, the General Terms on the reverse side of this page.

Warranty coverage is limited to parts that fail due to defect in materials or workmanship during the specified term.

CENTRAL GAS & OIL FURNACE HEAT EXCHANGERS*

Gas Model Series: C9MPV. HgMPV. TgMPV. CgMPT. H9MPT. T9MPT. C9MPD. HgMPD. TgMPD: Limited Lifetime Warranty on heat exchangers. If

a heat exchanger on one of these furnaces fails due to defect in the part, we will provide a replacement part or, at our option, credit toward the purchase

of a new furnace manufactured by us. This additional Limited Warranty runs only to the original purchaser, and tasts only for as tong as the originat

purchaser tives in the home where the furnace is initially installed.** Itis not transferable to any subsequent owner. Ifthe furnace was not installed inthe

home owned by the original purchaser, if the original purchaser setls the home to a subsequent owner, or if proof of originat purchase cannot be

provided, then the limited warranty is only for 20 years from the date of original installation.

Gas Model Series: GDL. GNL. TNE. TDE. NTC7. NDC7. NTP6. NDP6. TDE. NTV6. VNE: A replacement heat exchanger will be provided for any

heat exchanger that fails in one of these furnaces due to defect for 25 years from the originat date of installation.

Gas Model Series: NTC6. GNE. GDE. NDN6. NTG3. NDN3. FBF. NBF. NDF. NTN3. NTN6. NNE. N9MPI. N9MP2. FUH: A replacement heat

exchanger witt be provided for any heat exchanger that faits in one of these furnaces due to defect for 20 years from original date of installation.

Oil Model Series: OLR(105, 160, 182), OCF, OLE OUF, NOLE NOUF, OLB, OHB, ODH, FLO, MBO, LBO, NOMF: Limited Lifetime Warranty on

heat exchangers. Ifa heatexchangerononeofthesefurnacesfailsduetodefectinthepart, wewitl provide a replacement part or, at our option, credit

toward the purchase of a new furnace manufactured by us. This additional Limited Warranty runs only to the original purchaser, and tasts only for as

long as the original purchaser lives in the home where the furnace is initially installed.** It is not transferable to any subsequent owner. If the furnace

was not installed in the home of the original purchaser, if the original purchaser sells the home to a subsequent owner, or if proof of original purchase

cannot be provided, then the limited warranty is only for 20 years from the date of original installation.

Oil Fired Floor Furnace: NFO: A replacement heat exchanger witl be provided for any heat exchanger that faits due to defect for 10 years from

installation with the following limitation: during the sixth through tenth year, any credit toward your purchase of a component or toward the purchase of

any new unit wilI be in an amount equal to the distributor's purchase price reduced by 20 percent for each year after the fifth year.

ADDITIONAL TERMS FOR OIL FURNACE APPLICATIONS ONLY

1) OIL BURNERS - A replacement for 5 years from date of original installation for Oil Burner Parts.

2) OPTIONAL ACCESSORIES AND FUNCTIONAL PARTS: A replacement for 5 years from date of original installation. (Refractory and

oil nozzles not included)

GAS/ELECTRIC PACKAGED UNITS HEAT EXCHANGERS

Model series: PGAD. PGAA. PGMD. PGME. PGF. GPFM. PGC. GPCM: A replacement for 10 years from original date of installation.

COMPRESSORS:*

1) Premium Model Units: HAC0. HAC2. HAC4. CAC0. CAC2. CAC4. KAC0. TCA0. TCA2. TCA4. HHP0. HHP2. HHP4. CliP0. CliP2. CliP4.

TCH0. TCH2. TCH4. PGME. PYMC. PHAD. PGAD. PA95. PAPC. PAK. APK: Tothe original purchaser a replacement for 10 years from original date

of installation, only if the unit is installed with factory matched coils, except air conditioner condensing units with a nominal SEER of 10 may be matched

with evaporator coils of the same nominal tonnage regardless of manufacturer and in accordance to factory recommendations. This limited 10-year

warranty is not transferable to any subsequent owner. HOWEVER, if the unit was not installed in the home owned by the original purchaser, if the

purchaser sells the home to a subsequent owner, or if proof of original purchase cannot be provided, then the limited warranty is only for 5years from the

original date of installation.**

2) All Other Models: Air Conditioners. Heat PumPs. & Combination Gas/Electric Units: NAC0. NAC2. NHP0. NHP2. AO. A2. HO. H2. PGF.

PGC, GPFM, GPCM, PAE APFM, PHE HPFM, PGAA, PGMD, PA55, PH55, PAPA, PYPA: A replacement for 5 years from date of original

installation, onty if: (a) air conditioner condensing units with SEER rating in the range of 10 to 11 SEER are matched with evaporator coils of the same

nominal tonnage regardless of manufacturer and in accordance to factory recommendations, or (b) heat pump condensing units are used with factory

matched coils, unless written approval to do otherwise is obtained from manufacturer.

ADDITIONAL TERMS FOR COMMERCIAL APPLICATIONS ONLY

For purposes of this warranty a commercial application is one in which: the product has over 5 tons nominal cooling capacity, or is designed

for operation with 3 phase electrical power, or is installed in a commercial establishment such as a beauty or hair salon, hospital, school,

restaurant, church, hotel etc..

3-Phase Models: PGF, GPFM, GPF, PGAD, PGME, PGB, PGMG, PGMF, PGS, PGE, APE, PAE, PAB, PAMD, PAS, PAl=,APFM, APF, PHB, PHE,

PYMD, HPB, PHS, CAC, ACC, CAE, ACE, CHC, HCC, CHE, HCE:

The additional Terms of the components listed below are in addition to and subject to the General Terms on the reverse side of this page.

1) GAS FIRED HEAT EXCHANGERS (ALL MODELS):* A replacement for 10 years from date of originat installation.

2) COMPRESSORS (ALL MODELS):* A replacement for 5 years from date of original installation.

3) OPTIONAL ACCESSORIES AND FUNCTIONAL COMPONENT PARTS (ALL MODELS):*

A replacement for 1 year from date of original installation.

4) COMMERCIAL OIL MODELS: OLR210, OLR350, OTF210, AMT3, AMT4, AMP3: Ten(10) Year Limited Warranty on heat exchangers.

*To receive advantage of your limited warranty, you must provide proof of yearly service by a qualified service technician.

**To receive advantage of your warranty, you must retain the original records that can establish the installation date and proof of purchase of the unit.

MINI SPLITS:

Summary - Mini Splits Warranted for one (1) year on all replacement parts.

Additional terms for Mini Splits:

The additional Terms of the components listed below are in addition to, and subject to, the General Terms on the reverse side of this page.

1) Compressors (All Models): A replacement compressor wili be provided for atIcompressors that faii due to defect for 5 years from date of original

installation.

2) Optional Accessories and Functional Components Parts (All Models):

A replacement part will be provided for alt parts that fail due to defect for one (1) year from date of original installation.

Failu re to maintain the equipment through annual maintenance bya qualified service technician shall void the warranty. Proof of service wili berequired

with ati warranty claims. Proof of purchase and installation date must be submitted with ali claims.

Loading...

Loading...