Page 1

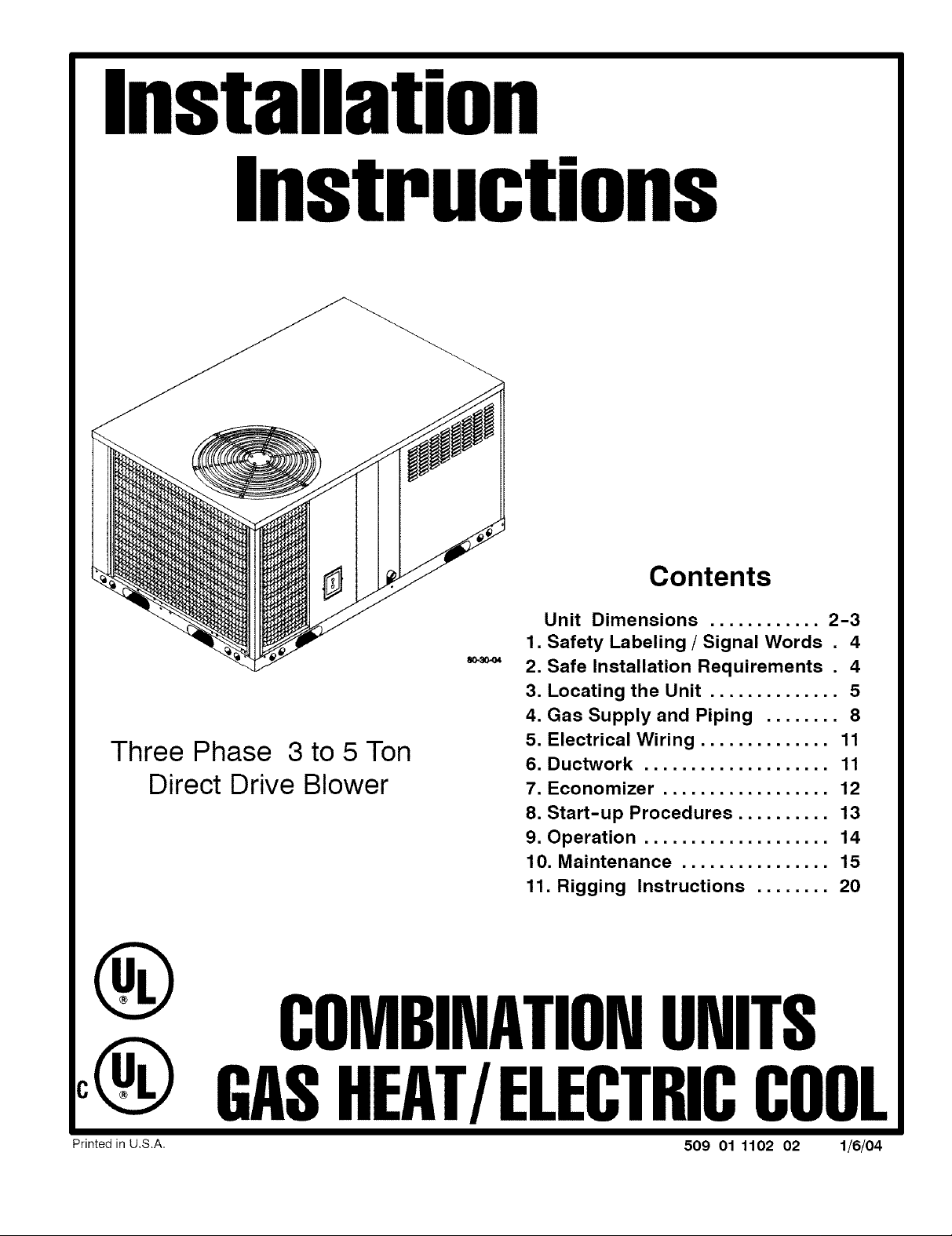

Installation

Instructions

Three Phase 3 to 5 Ton

Direct Drive Blower

COMBINATIONUNITS

Contents

Unit Dimensions ............ 2-3

1. Safety Labeling / Signal Words . 4

2. Safe Installation Requirements . 4

3. Locating the Unit .............. 5

4. Gas Supply and Piping ........ 8

5. Electrical Wiring .............. 11

6. Ductwork .................... 11

7. Economizer .................. 12

8. Start-up Procedures .......... 13

9. Operation .................... 14

10. Maintenance ................ 15

11. Rigging Instructions ........ 20

GASHEAT/ELECTRICCOOL

Printed in U,S.A. 509 01 1102 02 1/6/04

Page 2

_ Installation Instructions Combination Units I

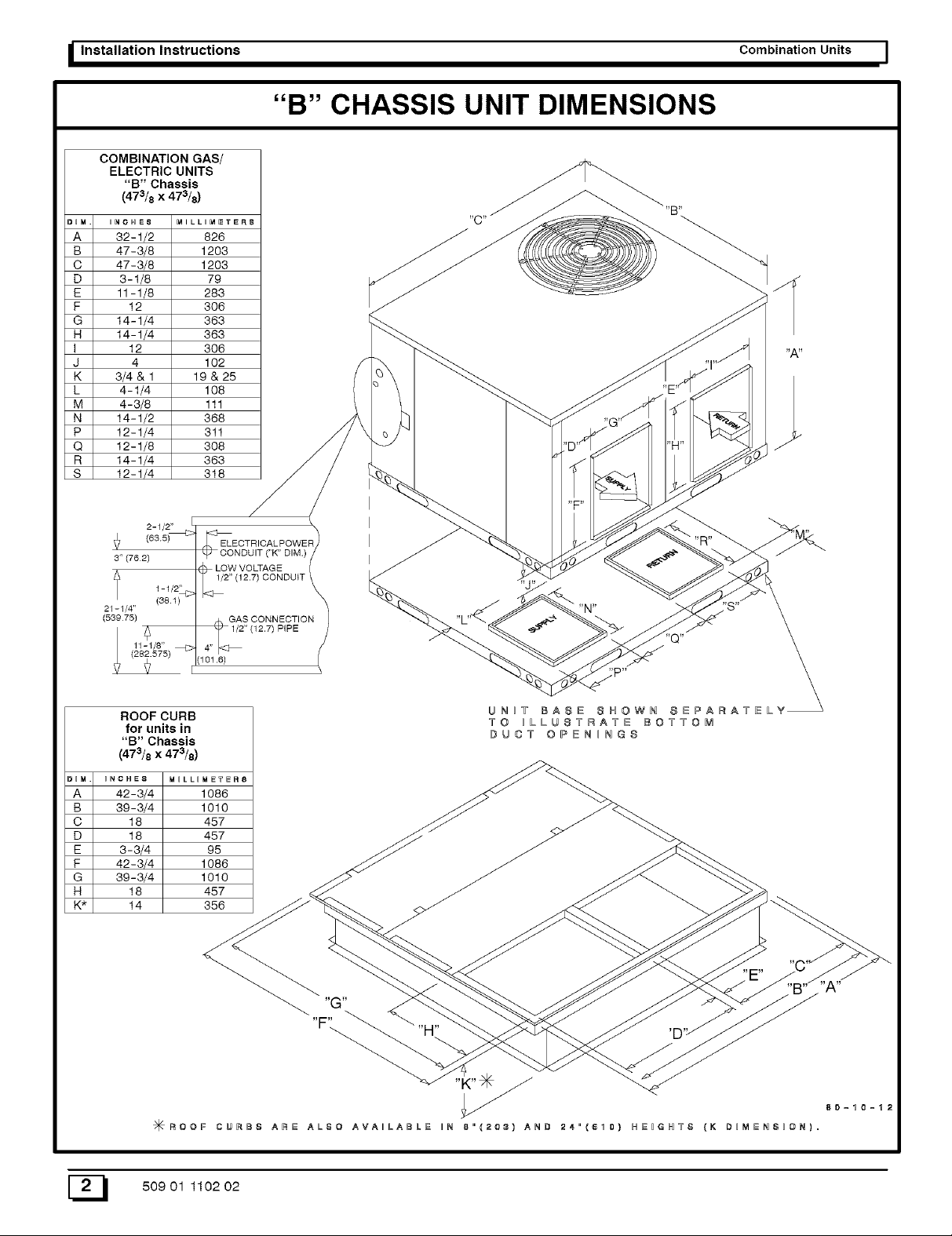

"B" CHASSIS UNIT DIMENSIONS

COMBINATION GAS/

ELECTRIC UNITS

"B" Chassis / A

(473/8 X 473/8)

,,o,Es M,UL,M_E,8 "C."--____"E"B"

A

82-i/2 828 / _ __'-._

B

47-3/8 I 1203 _ _ _ _((_(_(_(_-._)_)_)_) ))))})// _. _.

C

47-3/8 I 1208 _ _ _._____________________/////_ _t

D

3-1/8 I 79 _ / __/ _. _

E

11-1/8 I 283 _ _ /_

F

G

H

I

J

K

L

M

N

P

Q

R

S

12 I 306 _" _/

14-1/4 I 363 _ //

14-1/4I 363 _ _

12 I 306 "_ _ /t "A"

4 102 'T'/"

3/4&1 19&25 #_ _ _ _._'l"_j

4-1/4I lO8 (_ _ _ .i'E'_'_

12-1/8 308 / / _ 'D'_" _ "H" -"J / /

14-1/4 363 / / _ // _0_

12_1 4I 318

2-i/2" :_ I

(635) ELECTRICAL POWER

:, _ co.o_,T_"_"o,_.) _ _<.</_J _ _..'-._>_ / "

_7o_ , _ --.._--._.__ .__ ..>___

1-1/2" J

I _>_

(53975) _""_ "L''_ _ _ _.. /_ \

I i L_ 1/2"<12#)PIPE / _ _ _ "_'_'_" /._,,_,/_ \

ROOF CURB PA RATg LY

forunitsin TO BLLU8YRAYE BOY=TOM

"B"Chassis # U CT 0 P E N BN G S

(473/8 x 473/8)

BNCHE8 MBLLBMETER8

A

42-3/4 1086

B

39-3/4 1010 // /_....

C

D

E

F

G

H

K*

18 457 // _ _

18 457 //- /v

3-3/4 95 // / .././'_2..._

42-3/4 1086 _ / // _

3913/4 10;O _ _ __ "-._'_

/q_ROOF CURB8 gNg ALSO AVAILANLE IN 8"{2Q3) AND 24"{610) HN_GHT8 {K D_MNNS_@N}=

E_ 50901 110202

Page 3

I Combination Units Installation Instructions

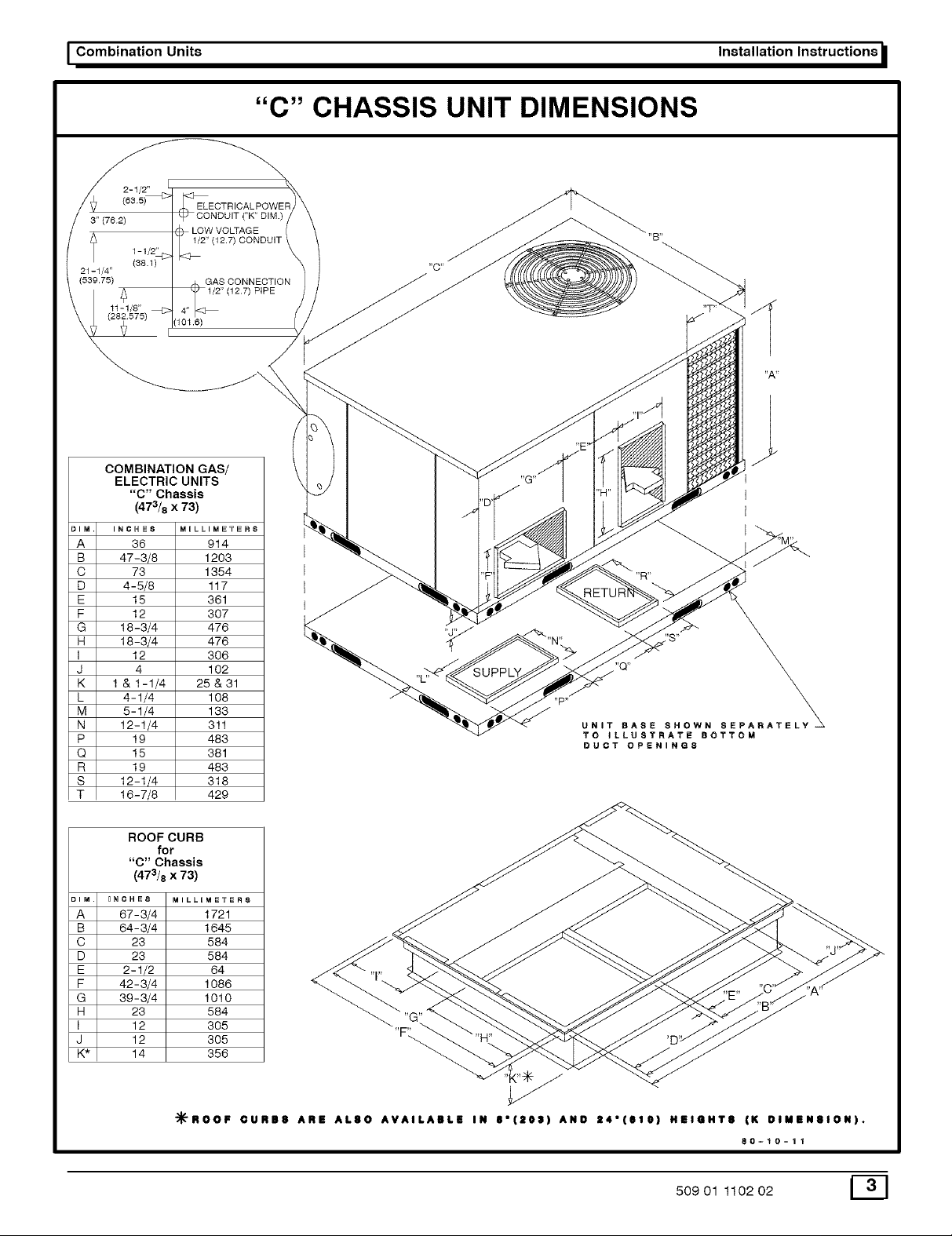

"C" CHASSIS UNIT DIMENSIONS

2-1/2"

3" (762) ("K" DIM.)

1- 1/2"

21-1/4"

(539.75) GAS CONNECTION

11-1/8"

COMBINATION GAS/

ELECTRIC UNITS

LOW VOLTAGE

1/2" (12.7) CONDUIT

(101.6)

"C" Chassis

(473/8 x 73)

_IM. INCHES M_LLIM_T_RS

A 36 914

B 47-3/8 1203

C 73 1354

D 4-5/8 117

E 15 361

F 12 307

G 18-3/4 476

H 18-3/4 476

] 12 306

J 4 102

K 1 &1-1/4 25&31

L 4-1/4 108

M 5-1/4 133

N 12-1/4 311

P 19 483

Q 15 381

R 19 483

S 12-1/4 318

T 16-7/8 429

"C"

"G"

"R"

,,p,,

UNIT BASE SHOWN SEPARAT

TO ILLUSTRATE BOTTOM

DUCT OPENINGS

ROOF CURB

for

"C" Chassis

(473/8 x 73)

DIM. _NCHE8 MILLIMETER8

A 67-3/4 1721

B 64- 3/4 1645

C 23 584

D 23 584

E 2-1/2 64

F 42-3/4 1086

G 39 - 3/4 1010

H 23 584

I 12 305

J 12 305

K* 14 356

_ROOF OURB8 ARE AL80 AVAILABLE IN 8"(208) AND Z4"(610) HEIGHT8 (K DIMENSION).

"F\

80-t0-11

50901 110202 E_]

Page 4

I Installation Instructions Combination Units I

1. Safety Labeling and Signal Words

Danger, Warning and Caution

The signal words DANGER, WARNING and CAUTION are used

to identify levels of hazard seriousness. The signal word DAN-

GER is only used on product labels to signify an immediate haz-

ard. The signal words WARNING and CAUTION will be used on

product labels and throughout this manual and other manuals that

may apply to the product.

Signal Words

DANGER - immediate hazards which WILL result in severe per-

sonal injury or death.

WARNING - Hazards or unsafe practices which COULD result in

severe personal injury or death.

2. Safe Installation Requirements

Installation or repairs made by unqualified persons can

result in hazards to you and others. Installation MUST

conform with local building codes or, in the absence of

local codes, with the ANSI Z223.1-1990 National Fuel

Gas Code and the National Electrical Code

NFPA70-1990 or in Canada the National Standard CAN/

CGA B149.1 and CSA C.22.1 - Canadian Electrical

Code Part 1.

CAUTION - Hazards or unsafe practices which COULD result in

minor personal injury or product or property damage.

Signal Words in Manuals

The signal word WARNING is used throughout this manual in the

following manner:

The signal word CAUTION is used throughout this manual in the

following manner:

CAUTION

NOTE: It is the personal responsibility and obligation of the cus-

tomer to contact a qualified installer to ensure that the installation

is adequate and conforms to governing codes and ordinances.

CAUTION

It is recommended that a qualified service technician check

the heat exchanger integrity every two (2) years, after the first

four (4) years of operation.

Check Pre-existing Common Vent From Old

Furnace

The information contained in this manual is intended

for use by a qualified service technician familiar with

safety procedures and equipped with the proper tools

and test instruments.

Failure to carefully read and follow all instructions in

this manual can result in furnace malfunction, property

damage, personal injury and/or death.

• Installation MUST conform to the most current version of

the following standards or a superseding standard.

In the USA:

•. ANSI Z223.1-1990 National Fue! Gas Code

• National Electrical Code NFPA70-1990

In Canada:

• National Standard CAN/CGA B149.1

• CSA C.22.1 - Canadian Electrical Code Part 1.

• Do NOT use this furnace as a construction heater.

• Use only the type of gas approved for this furnace (see rat-

ing plate).

• Do NOT use open flame to test for gas leak.

• Seal supply and return air ducts.

If the installation of the combination unit involves removing an ex-

isting furnace from a common vent with other appliances, the

venting system will probably be too large for the remaining ap-

pliances and they will not vent properly. The venting system

MUST be checked according to the following procedure.

NOTE: The following steps shall be followed with each appliance

remaining connected tothe common venting system placed in op-

eration, while the other appliances remaining connected to the

common venting system are not in operation.

1. Seal any unused openings in the common venting system.

Visually inspect the venting system for proper size and hor-

izontal pitch to ensure there is no blockage or restriction,

leakage, corrosion or other deficiencies which could cause

an unsafe condition.

insofar as is practical, close all doors and windows and all

doors between the space in which the appliances remain-

ing connected to the common venting system are located

and other spaces of the building

Turn on clothes dryers and any appliance not connected to

the common venting system. Turn on any exhaust fans,

such as range hoods and bathroom exhausts, so they will

operate at maximum speed. Do NOT operate a summer

exhaust fan. Close fireplace dampers.

Follow the lighting instructions, Place the appliance being

inspected in operation. Adjust thermostat so appliance wil!

operate continuously.

Test for spillage at the draft hood relief opening after 5 min-

utes of main burner operation. Use the flame of a match or

E_I 50901 110202

Page 5

I Combination Units

Installation Instructions

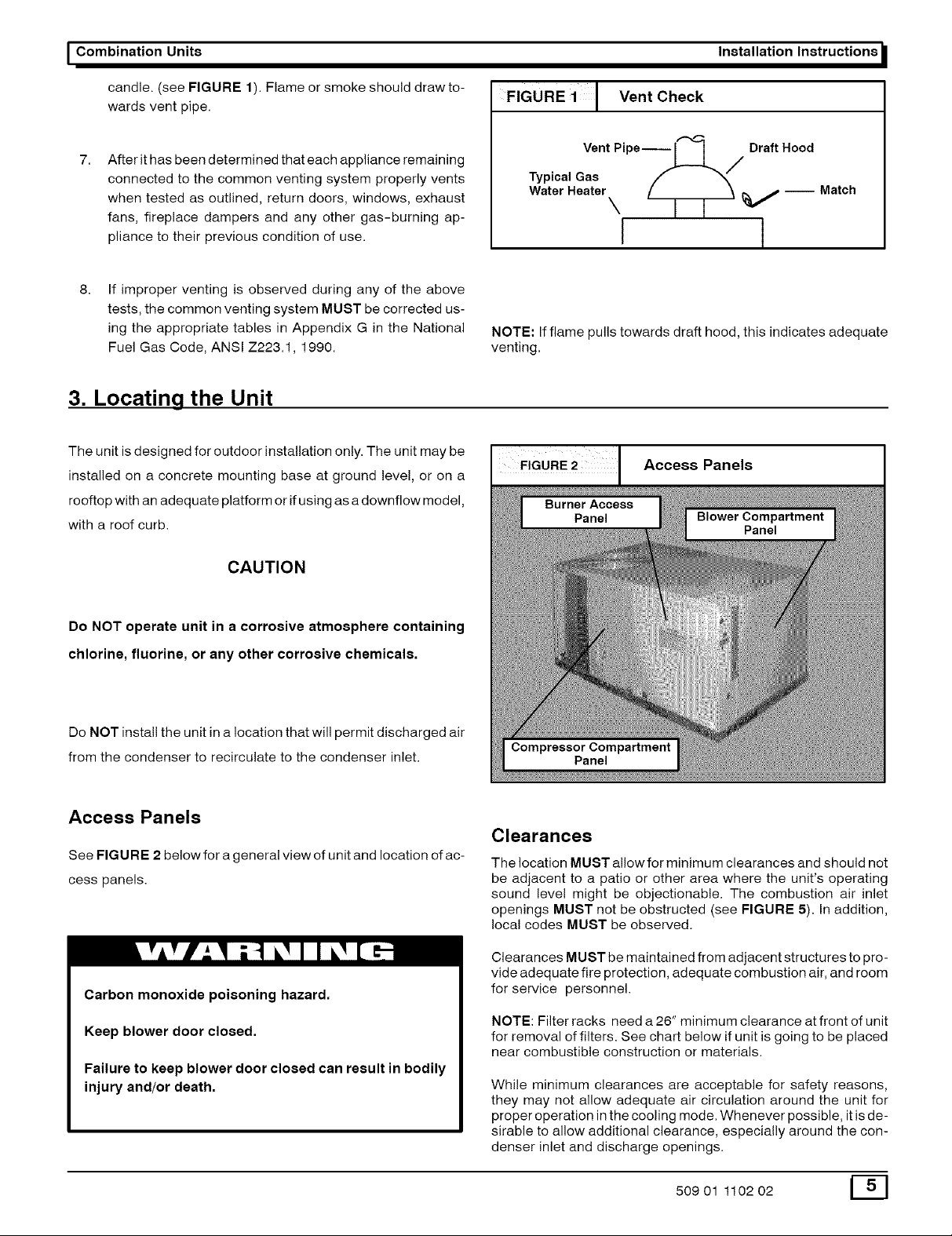

candle. (see FIGURE 1). Flame or smoke should drawto-

wards vent pipe.

After it has been determined that each appliance remaining

connected to the common venting system properly vents

when tested as outlined, return doors, windows, exhaust

fans, fireplace dampers and any other gas-burning ap-

pliance to their previous condition of use.

If improper venting is observed during any of the above

tests, the common venting system MUST be corrected us-

ing the appropriate tables in Appendix G in the National

Fuel Gas Code, ANSI Z223.1, 1990.

3. Locating the Unit

The unit is designed for outdoor installation only. The unit may be

installed on a concrete mounting base at ground level, or on a

rooftop with an adequate platform or if using as a downflow model,

with a roof curb.

FIGURE 1 Vent Check

Vent Pipe--___ Draft Hood

Typical Gas _/

WaterHeaterx [ I I _ v--Match

I j

NOTE: If flame pulls towards draft hood, this indicates adequate

venting.

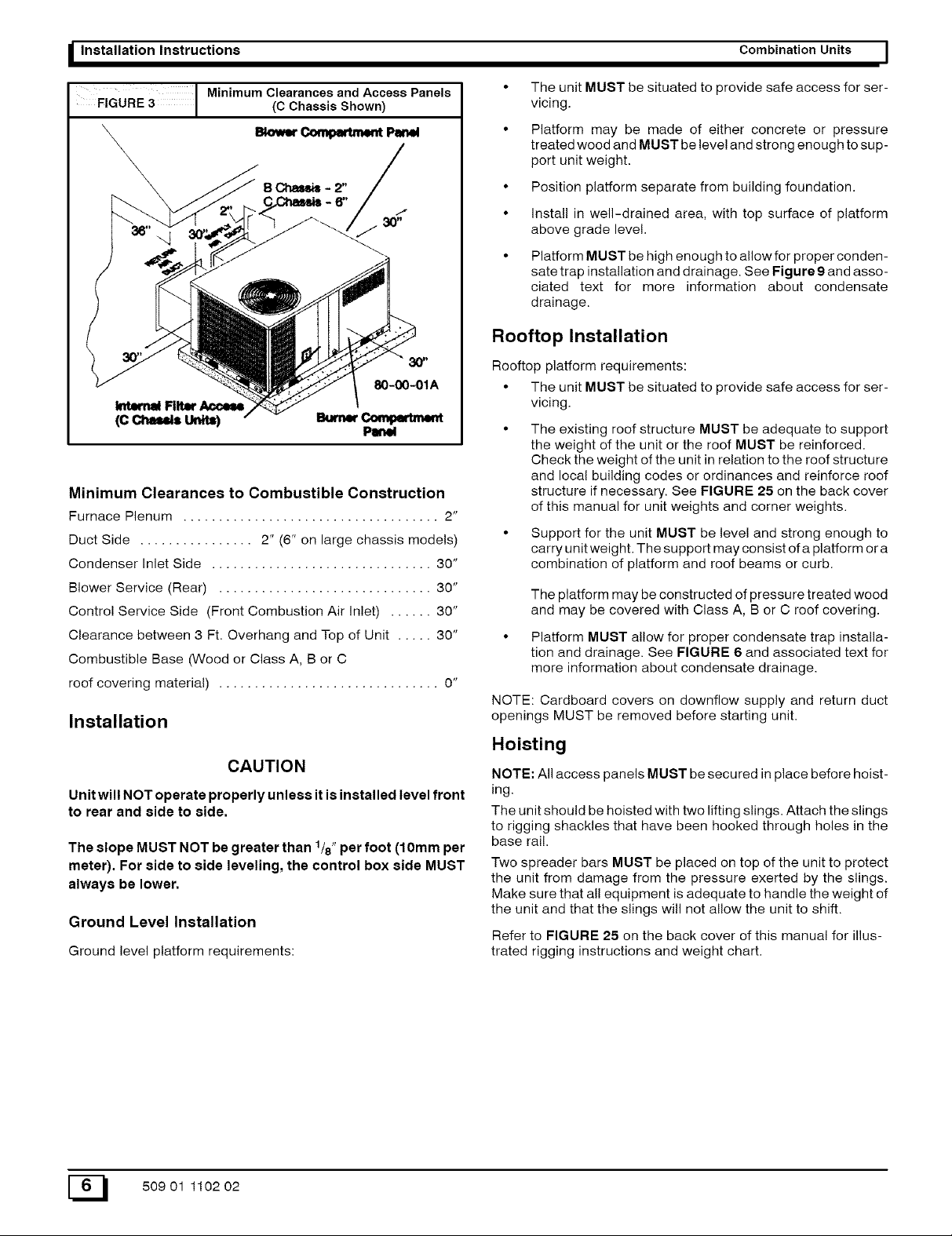

I FIGURE 2

Access Panels

CAUTION

Do NOT operate unit in a corrosive atmosphere containing

chlorine, fluorine, or any other corrosive chemicals.

Do NOT install the unit in a location that will permit discharged air

from the condenser to recirculate to the condenser inlet.

Access Panels

See FIGU RE 2 below for a general view of unit and location of ac-

cess panels.

Carbon monoxide poisoning hazard.

Keep blower door closed.

Failure to keep blower door closed can result in bodily

injury and/or death.

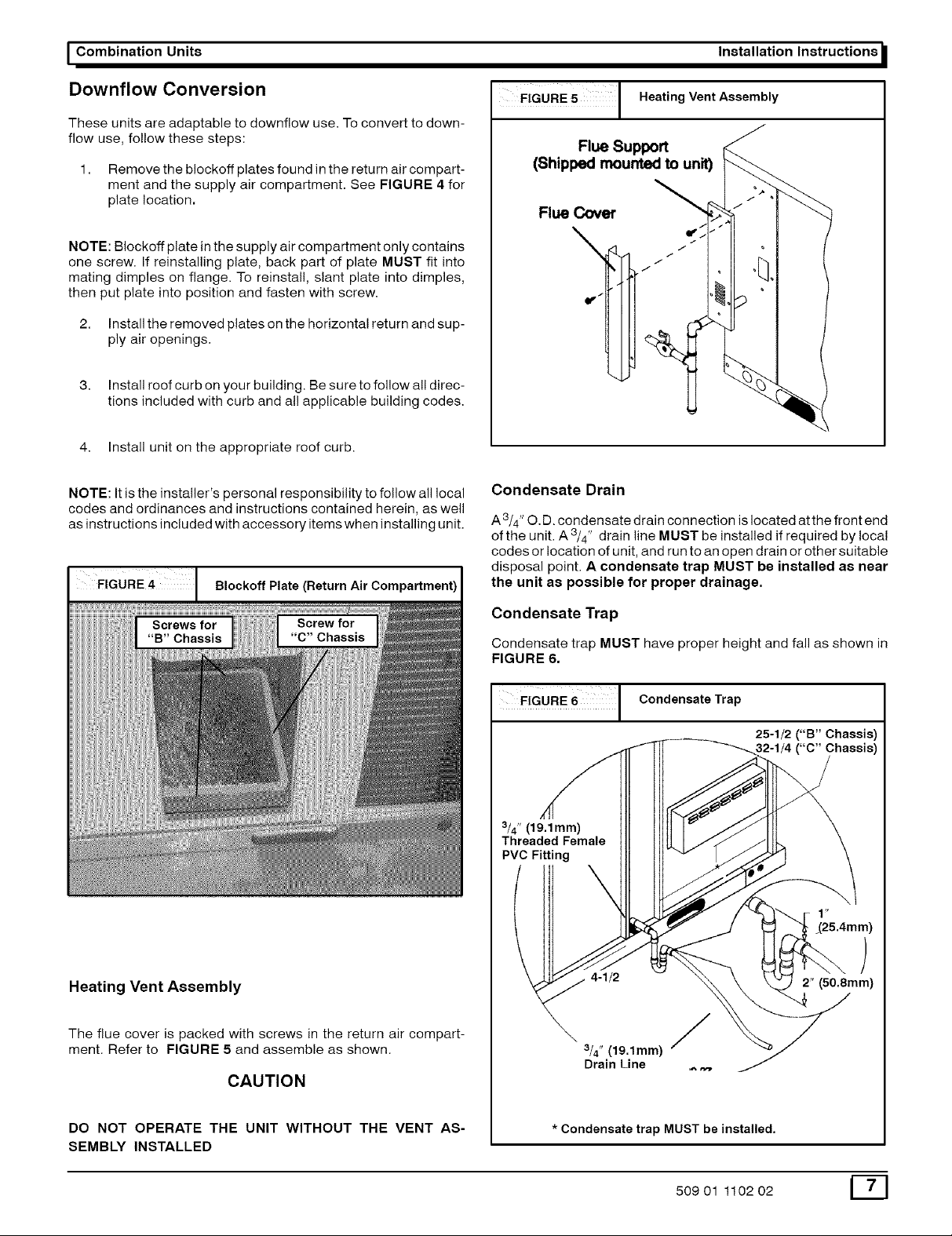

Clearances

The location MUST allow for minimum clearances and should not

be adjacent to a patio or other area where the unit's operating

sound level might be objectionable. The combustion air inlet

openings MUST not be obstructed (see FIGURE 5). In addition,

local codes MUST be observed.

Clearances MUST be maintained from adjacent structures to pro-

vide adequate fire protection, adequate combustion air, and room

for service personnel.

NOTE: Filter racks need a 26" minimum clearance at front of unit

for removal offilters. See chart below if unit is going to be placed

near combustible construction or materials.

While minimum clearances are acceptable for safety reasons,

they may not allow adequate air circulation around the unit for

proper operation in the cooling mode. Whenever possible, it is de-

sirable to allow additional clearance, especially around the con-

denser inlet and discharge openings.

50901 110202 E_]

Page 6

I Installation Instructions Combination Units I

The unit MUST be situated to provide safe access for ser-

FIGURE 3 (C Chassis Shown)

Minimum Clearances and Access Panels

sk>_r _ Pmww

Bcm.+,m,:

/+++++za_'

vicing.

Platform may be made of either concrete or pressure

treated wood and MUST be level and strong enough to sup-

port unit weight.

Position platform separate from building foundation.

Install in well-drained area, with top surface of platform

above grade level.

Platform MUST be high enough to allow for proper conden-

sate trap installation and drainage. See Figure 9 and asso-

ciated text for more information about condensate

drainage.

Rooftop Installation

30"

80-00-01A

Minimum Clearances to Combustible Construction

Furnace Plenum .................................... 2"

Duct Side ................ 2" (6" on large chassis models)

Condenser Inlet Side ............................... 30"

Blower Service (Rear) .............................. 30"

Control Service Side (Front Combustion Air Inlet) ...... 30"

Clearance between 3 Ft. Overhang and Top of Unit ..... 30"

Combustible Base (Wood or Class A, B or C

roof covering material) ............................... 0"

Installation

Rooftop platform requirements:

• The unit MUST be situated to provide safe access for ser-

vicing.

The existing roof structure MUST be adequate to support

the weight of the unit or the roof MUST be reinforced.

Check the weight of the unit in relation to the roof structure

and local building codes or ordinances and reinforce roof

structure ifnecessary. See FIGURE 25 on the back cover

of this manual for unit weights and corner weights.

• Support for the unit MUST be level and strong enough to

carry unit weight. The support may consist ofa platform or a

combination of platform and roof beams or curb.

The platform may be constructed of pressure treated wood

and may be covered with Class A, B or C roof covering.

• Platform MUST allow for proper condensate trap installa-

tion and drainage. See FIGURE 6 and associated text for

more information about condensate drainage.

NOTE: Cardboard covers on downflow supply and return duct

openings MUST be removed before starting unit.

Hoisting

CAUTION

Unit will NOT operate properly unless it is installed level front

to rear and side to side.

The slope MUST NOT be greater than 1/8" per foot (10mm per

meter). For side to side leveling, the control box side MUST

always be lower.

Ground Level Installation

Ground level platform requirements:

NOTE: All access panels MUST be secured in place before hoist-

ing.

The unit should be hoisted with two lifting slings. Attach the slings

to rigging shackles that have been hooked through holes in the

base rail.

Two spreader bars MUST be placed on top of the unit to protect

the unit from damage from the pressure exerted by the slings.

Make sure that all equipment is adequate to handle the weight of

the unit and that the slings will not allow the unit to shift.

Refer to FIGURE 25 on the back cover of this manual for illus-

trated rigging instructions and weight chart.

E_ 50901 110202

Page 7

I Combination Units Installation Instructions

Downflow Conversion

FIGURE 5 J Heating Vent Assembly

These units are adaptable to downflow use. To convert to down-

flow use, follow these steps:

1. Remove the blockoff plates found in the return air compart-

ment and the supply air compartment. See FIGURE 4 for

plate location.

NOTE: Blockoff plate in the supply air compartment only contains

one screw. If reinstalling plate, back part of plate MUST fit into

mating dimples on flange. To reinstall, slant plate into dimples,

then put plate into position and fasten with screw.

2. Install the removed plates on the horizontal return and sup-

ply air openings.

3. Install roof curb on your building. Be sure to follow all direc-

tions included with curb and all applicable building codes.

4. Install unit on the appropriate roof curb.

Flue Support

(Shipped moume(:lto unit)

Flue Cover

/

NOTE: It is the installer's personal responsibility to follow all local

codes and ordinances and instructions contained herein, as well

as instructions included with accessory items when installing unit.

Blockoff Plate (Return Air Compartment)

Condensate Drain

A3/4" O.D. condensate drain connection is located at the front end

of the unit. A 3/4" drain line MUST be installed if required by local

codes or location of unit, and run to an open drain or other suitable

disposal point. A condensate trap MUST be installed as near

the unit as possible for proper drainage.

Condensate Trap

Condensate trap MUST have proper height and fall as shown in

FIGURE 6,

FIGURE 6 ] Condensate Trap

25-1/2 ("B" Chassis)

("C" Chassis)

3/4" (19.1mm)

Threaded Female

PVC Fitting

_(25.4mm)

Heating Vent Assembly

The flue cover is packed with screws in the return air compart-

ment. Refer to FIGURE 5 and assemble as shown.

CAUTION

DO NOT OPERATE THE UNIT WITHOUT THE VENT AS-

SEMBLY INSTALLED

4-1/2

\

3/4" (19.1mm) '

Drain Line

* Condensate trap MUST be installed.

50901 110202 [_]

)

2" (50.8mm)

Page 8

I Installation Instructions

4. Gas Supply and Piping

Combination Units I

Because there are many types of liquefied petroleum (LP) gases,

the term LP as used in this manual refers to propane gas. If you

intend to use any type of LP gas, proper precautions MUST be

used in the handling, piping, and use ofsuch gas. NOTE: In Cana-

da, LP installations MUST be performed by licensed LP installers.

The Rating Plate located on the side panel on the unit contains the

model number, type of gas and gas input rating, and other impor-

tant information.

Fire and/or explosion hazard.

Make certain the unit is equipped to operate on the type

of gas available. Models designated as natural gas are

to be used with natural gas only. Models designated for

use with liquefied petroleum (LP) gas are shipped with

orifices sized for commercially pure propane gas. They

MUST not be used with butane or a mixture of butane

and propane unless properly sized orifices are installed

by a licensed LP installer.

Failure to follow this warning can result in property

damage, personal injury, and/or death.

Gas Pressures

1. Do NOT allow minimum gas supply pressure to fall below

the minimums. Doing so will decrease input to furnace. Re-

fer to FIGURE 7 for gas supply pressures.

2. Gas input MUST NOT exceed rated input shown on rating

plate.

3. Do NOT allow pressures to exceed the maximum limits as

listed in FIGURE 7.

NOTE: If gas supply pressures are not correct, contact your gas

supplier.

Gas Pressures

Natural Gas LP Gas

Minimum

Inlet 4.5"W.C. (1120 Pa) 11" W.C. (2740 Pa)

Pressure

Recom.

Inlet 7" W.C. (1740 Pa) 11" W.C. (2740 Pa)

Pressure

Maximum

Inlet 13"W.0. (3230 Pa) 13"W.C. (3230 Pa)

Pressure

Manifold 3.5" W.C. (870 Pa) 10" W.C. (2490 Pa)

Pressure

Manifold Pressures

Manifold pressures are covered in the startup procedure section.

Refer to Chapter 8, Start-Up Procedures on Page 13.

Gas Piping

The gas supply line MUST be of adequate size to handle the Btu/

hr requirements and length of the run for the unit being installed.

Determine the minimum pipe size for natural gas from the table in

Figure 8 & Figure 9. Base the length of the run from the gas meter

or source to the unit.

Gas Pipe Size

Btu ratings of all other gas appliances MUST be considered for

sizing of main gas line. Check gas line to installation for com-

pliance with local codes or, in the absence of local codes, with the

National Fuel Gas Code ANSI Z223.1-1990 and in Canada the

National Standard CAN/CGA B149.1 current editions.

FIGURE 8 GasPipeSize, LengthandBtu/hr Capacityfor Sched-

PipeLength Btu/hr (in thousands)

(Includes

Fittings) 3/4" 1" 11/4" 11/2" 2"

20' 190 350 730 1,100 2,100

40' 130 245 500 760 1,450

60' 105 195 400 610 1,150

PipeLength Btu/hr(inthousands)

(Includes

Fittings) 1/2" 3/4" 1" 11/4" 11/2"

20' 189 393 732 1,496 2,299

40' 129 267 504 1,039 1,559

60' 103 217 409 834 1,275

FIGURE 9

PipeLength kW**

(Includes

Fittings) 3/4" 1" 11/4" 11/2" 2"

6.1m 56 103 214 322 615

12.2m 38 72 147 223 425

18.3m 31 57 117 179 337

PipeLength kW**

(includes

Fittings) 1/2" 3/4" 1" 11/4" 11/2"

6.1m 55 115 215 438 574

12.2m 38 78 148 305 457

18.3m 30 64 120 244 374

**kW (Kilowatts) is the metric equivalent of Btu/hr.

FIGURE 10 Orifice Sizes

Gas Type Specific Gravity Btu/ft 3 (kJ/L) Pilot Orifice Sizes

Natural 0.6 1000 .018#

Propane 1.53 2500 .012#

#Adjust pilot flame as needed

ule40Iron Pipe(English)

NATURAL GAS

LP GAS

GasPipeSize, LengthandBtu/hr Capacityfor Sched-

ule40Iron Pipe(English)

NATURAL GAS

LP GAS

E_I 50901 110202

Page 9

I Combination Unite

Installation Instructions

TABLE 1: Equivalent Orifice Sizes at High Altitudes

(Includes 4% input reduction for each 1,000 ft.

Natural GasManifoldOrifice SizeRequiredbyElevation

BTU 0'- 2000' 4500'

INPUT 2000' 4000' 5000' 6000' 7000' 8000' 9000' 10000'

40.000to 44 45 46 47 47 48 48 49

60,00

90,000to 43 44 45 45 46 47 47 48

150,000

LPGas ManifoldOrifice Size Required by Elevation

BTU 0'- 2000' 4500'

INPUT 2000' 4000' 5000' 6000' 7000' 8000' 9000' 10000'

40.000to 55 56 56 56 56 56 56 57

60,000

90,000to 54 55 55 55 55 56 56 56

150,000

* 2-1/2 & 3 Ton with 3 burners.

** 3-1/2 & 4 ton with 4 burners.

Orifices

Orifice Sizes

Orifice sizes MUST be matched to the heating value of the gas

(see FIGURE 10 and Table 1). Check with your gas supplier and

the National Fuel Gas Code ANSI Z223.1 -1 990 and in Canada

the National Standard CAN/CGA B149.1; current edition.

NOTE: An LP Conversion Kit, which contains pilot and burner ori-

fices, a two-stage LP gas valve and an instruction manual, MUST

be used for conversion to LP gas.

NOTE: For elevations above 2000 feet (610 meters), the Btu input

rating MUST be reduced by 4% for each 1000 feet (305 meters)

above sea level, unless the gas supplier s Btu/ft content has al-

ready been adjusted for altitude. See Table I for the proper orifice

sizes.

Changing Orifices

, 3

6. Disconnect the pilot tubing from the gas valve.

7. Remove the four screws holding the manifold to the man-

ifold brackets.

8. Carefully remove the manifold with the gas valve attached.

9. Remove the orifices from the manifold with a 7/16" box end

or socket wrench.

10. Check to be sure that the size of each orifice is correct for

the Btu input desired.

FIGURE ii I Manifold/Orifice Measurement

Measure 11/16"

__ .11Ak _ of orifice to back

_,,,,",_J edg I of manifold

11.

install the correct orifices. Gauge the size of the orifices

(27mm) from face

with a new twist drill bit of the correct size.

Make sure that the orifices go in straight so that they form a

right angle (90 °) to the manifold pipe.

Tighten the orifices so that there is a 11/16" (27mm) dis-

tance between the faces of the orifices to the back of the

manifold pipe.

Measure the distance with a set of calipers, if you do not

have a calipers, you can use an adjustable wrench and

measure between the face of the jaws.

12. Reassemble in reverse order.

Electrical shock, fire and/or explosion hazard.

Shut off electric power at unit disconnect or ser-

vice panel and shut off gas at manual shut off

valve before beginning the following procedure.

Changing orifices requires a qualified service

technician.

Failure to follow this warning can result in prop-

erty damage, personal injury, and/or death.

1. Shut OFF gas at manual shut off valve.

2. Shut OFF electric power at unit disconnect or service pan-

el.

3. Remove the burner access pane!.

4. Disconnect the gas line from the gas valve.

5. Disconnect the wires from the gas valve.

Piping at Unit

Connections

NOTE: Refer to FIGU RE 13 for the general layout at the furnace.

The rules listed apply to natural and LP gas pipe installations.

1. If installation is for LP gas, have LP gas installer use TWO-

STAGE REGULATION and make all connections from

storage tank to unit.

2. Use black iron or steel pipe and fittings or other pipe ap-

proved by local code.

NOTE: If a flexible gas connector is used, it MUST be acceptable

to local authority. Connector MUST NOT be used inside the fur-

nace or be secured or supported bythe furnace or ductwork. Con-

nectors MUST comply with one of the following standards or a

superseding standard:

• ANSI Z21.24a-1983, Metal Connectors for

Gas Appliances.

• ANSI Z21.45b-1983, Flexible Connectors of

Other Than All-Metal Construction for Gas

Appliances.

50901 110202 E_]

Page 10

I Installation Instructions Combination Units I

Leak Check

1. Gas pressure MUST NOT exceed 1/2 PSIG (3450 Pa).

Fire and/or explosion hazard.

Gas connector MUST be properly installed and can NOT be

used inside the furnace.

Failure to do so can result in property damage, bodily inju-

ry or death.

3. Use pipe joint compound on external (male) threads ONLY.

Joint compound MUST be resistant to any chemical action

of LP gases (FIGURE 12).

4. Use ground joint unions and install a drip leg no less than 3

inches (76 mm) long to trap dirt and moisture before it can

enter gas valve.

5. Use a flat jawed wrench on gas valve when making con-

nections to prevent gas valve from turning. Do NOT use a

pipe wrench on the gas valve body.

CAUTION

Overtightening assembly may cause damage to the gas

valve and/or wiring and may misalign the burners.

6. Provide a 1/8 inch (3mm) National Pipe Thread (NPT) plug

for test gauge connection immediately upstream of the gas

supply connection to the furnace.

FIGURE i2 J Proper Piping Practice

Control

Use moderate

amount of compound

Checking gas piping above 1/2 PSIG (3450 Pa) requires

the gas valve and manual shutoff valve to be disconnected

during testing.

2. When checking gas piping to furnace, shut OFF manual

shutoff valve to furnace.

3. Test all pipes for leaks.

Fire and/or explosion hazard.

Never exceed specified pressures. Higher pressures

may damage the gas valve. Such damage may result in

overfiring and possible heat exchanger failure.

Do NOT use a match or open flame to test for leaks.

Failure to follow this warning can result in property

damage, personal injury, and/or death.

4.

Apply soap suds (or a liquid detergent) to each joint.

Bubbles forming indicate a leak.

5.

Make sure pilot tube and burner orifices are checked for

leakage.

6.

Correct even the smallest leak at once.

FIGURE !3 1 Piping at Unit for Natural Gas

Leave 2 end

Thread pipe right length

7. Install a manual shutoffvalve and tighten all joints securely.

threads bare

LP Connection Requirements

1. Have a licensed LP gas dealer make all connections at

storage tank and check all connections from tank to fur-

nace.

If copper tubing is used, it MUST comply with limitation set

in National Fuel Gas Code or in Canada the National Stan-

dard CAN/CGA B149.1; current edition..

3. Two-stage regulation of LP gas is required.

E_ 50901 110202

Page 11

I Combination Units Installation Instructions

5. Electrical Wiring

The location of the thermostat has an important effect on the op-

eration of the unit. FOLLOW THE INSTRUCTIONS INCLUDED

WITH THE THERMOSTAT FOR CORRECT LOCATION,

Electrical shock hazard.

MOUNTING, AND WIRING.

Disconnect power at fuse box or service panel before

making any electrical connections.

Unit MUST be grounded to electrical service panel.

Failure to follow this warning can result in property

damage, personal injury, and/or death.

NOTE: All electrical work MUST conform with the requirements of

local codes and ordinances and the National Electrical Code

ANSI/NFPA-No. 70-1990 or current edition. Provide line voltage

power supply from a separate protected circuit with a disconnect

switch (when required) located within sight of the unit. Supplyvolt-

age, amperage, wire, fuse and disconnect switch sizes MUST

conform with specifications in the Technical Support Manual and

with unit rating plate.

All exposed wiring or connections MUST be made with weather-

proof cable or wire unless installed in conduit. Wiring MUST be

protected from possible mechanical damage.

Connections for line voltage are made in the unit control box. Low

voltage connections are made outside the control box. For ac-

cess, remove the burner access panel and the control box cover.

See FIGURE 2.

Low Voltage Wiring

Low voltage wiring connections for the thermostat are made atthe

24Vterminal board outside the control box. Refer to the wiring dia-

gram for the applicable model and the instructions included with

the thermostat.

Thermostat

NOTE: Do NOT attempt to use a thermostat designed for

electric heat or heat pump use. Such thermostats will NOT

control the unit properly,

Heat Anticipator

Set the thermostat heat anticipator to. 58 in accordance with ther-

mostat instructions.

Line Voltage Wiring

Connections for line voltage are made in the unit control box. For

access, remove the burner access panel and the control box cov-

er.

Do NOT complete line voltage connections until unit is perma-

nently grounded. All line voltage connections and the ground con-

nection MUST be made with copper wire.

Ground Connections

A ground lug is installed in the control box for the ground connec-

tion. Use a copper conductor of the appropriate size from the unit

to a grounded connection in the electrical service panel.

Line Connections

Complete the line service connections to the contactor 'L' termi-

nals inside the control box. Refer to applicable wiring diagram in

Technical Support Manual. Check all screw terminals to ensure

they are tight.

Field Installed Equipment

Wiring to be done in the field between the unit and devices not at-

tached to the unit, or between separate devices which are field

installed and located, shall conform with the temperature limita-

tions for type T wire and shall be installed with the manufacturer's

instructions applicable to such devices.

Final Electrical Check

Make a final wiring check to be sure system is correctly wired. In-

spect field installed wiring and the routing to ensure that rubbing or

chafing due to vibration will not occur.

6. Ductwork

Maximum recommended velocity in trunk ducts is 1000 feet per

minute. Velocity in branches should not exceed 800 feet per min-

ute.

NOTE: Ductwork sizing affects temperature rise and cooling tem-

perature differential. Be sure to properly size ductwork to the ca-

pacity and airflow characteristics of your unit. Failure to do so can

affect limit controls, compressors, motors, and other components

and will lead to premature failure of components. This will also

adversely affect day to day unit performance. Refer to rating plate

and Temperature Rise Check section in this manual.

Ductwork Insulation

Ductwork installed outdoors should have a minimum of 2" Fiberg-

las insulation and a weatherproof vapor barrier. It should be pro-

tected against damage. Caulking and flashings, or other means

adequate to provide a permanent weather seal, should be used.

Ductwork installed in attics or other areas exposed to outside tem-

peratures should be installed with a minimum of 2" Fiberglas in-

sulation and have an indoor type vapor barrier.

Ductwork Connections

The use of flexible, non-combustible connectors between main

trunk ducts and supply and return air plenums is recommended to

minimize vibration transmission.

NOTE: Connect supply and return air plenums to unit in a manner

that will allow the top of the unit to be removed without removing

plenums. Plenums MUST be individually sealed to unit casing

with ducts terminating inside structure.

50901 110202

Page 12

_ Installation Instructions Combination Units I

Filters

All return air, including economizer air and outside damper air,

MUST pass through a filter before entering the evaporator. An

electronic air cleaner or other accessible filter arrangement

MUST be installed in the return air ductwork. This can ONLY be

done when the internal filters are removed and NO outdoor air ac-

7. Economizer

The purpose of an economizer is to:

• Provide cool outside air to the conditioned space during the

cooling cycle to minimize the use of the compressors.

• Bring outside air into the conditioned space to meet mini-

mum fresh air requirements whenever the circulation blow-

er is running.

Downflow Economizer

cessories are used. Mimimum recommended filter areas are

based on a velocity of 300 ft/min for disposable filters and 500 ft/

min for high velocity filters (washable).

CAUTION

DO NOT OPERATE THE UNIT WITHOUT A FILTER.

The economizer is controlled by a logic module which field con-

nects to the unit controls through a plug harness. The logic mod-

ule also controls the compressor staging based on the thermostat

input.

The minimum opening position of the fresh air dampers is field

settable. It is set on the logic module of modulating economizers

or on the actuator motor of three-position economizers.

The enthalpy sensor is factory installed on the fresh air dampers

of the economizer. The enthalpy change-over point is adjustable

on the logic module.

I

A discharge air sensor is field installed in the blower inlet. The dis-

charge air sensor keeps the discharge air above 56°F (13.3°C).

A positive pressure is created when the fresh air dampers open

and the return dampers close. This pressure must be vented or

the air will not circulate properly. This is the function of the baro-

metric relief dampers. A positive pressure forces the passive ex-

haust dampers to swing open.

The fresh air dampers open to the minimum position for outside air

whenever the circulation blower is ON.

When the thermostat is in the FAN AUTO position, the fresh air

dampers will close completely whenever heating or cooling is not

called for.

When the thermostat is in the FAN ON position:

1. The fresh air dampers will open to the minimum position for

fresh air.

Theory of Operation

The economizer has two sets of dampers that are mechanically

linked together. The fresh air dampers regulate the intake of out-

side air and the return air dampers regulate the flow of return air

(see FIGURE 14). When the fresh air dampers modulate open,

the linkage causes the return air dampers to modulate closed.

If Using a 2-Stage Thermostat

2. On a call for cooling, if the economizer outdoor air sensor

determines that the outside air is cool enough (and in the

case of an enthalpy sensor, dry enough), the fresh air

dampers will modulate open and the return air dampers wil!

modulate closed.

If the conditioned space is not being maintained at the se-

lected temperature, the thermostat will make Y2 and call for

second stage cooling by energizing the economizer logic

module at low voltage terminal board terminal Y4. This en-

ergizes the Y1 anti-cycle delay and contactor which ener-

gizes the condenser fan and compressor for cooling to

assist the economizer.

If Using a Single- Stage Thermostat

When using a single stage thermostat, all steps as outlined above

will be followed with the exception of the following:

The compressor will only be energized when the outside air

reaches a temperature above the preset limit of the economizer.

When ambient conditions are not suitable for economizer opera-

tion, ONLY the compressor will run, and the economizer will NOT

be energized.

E_ 50901 110202

Page 13

I Combination Units Installation Instructions

8. Start-up Procedures

FIGURE 15 Manifold Pressure Settings

Fire and/or explosion hazard.

Do NOT attempt to light the pilot or burner with a match

or flame of any kind.

Failure to follow this warning can result in property

damage, personal injury, and/or death.

Check Before Starting

Check that the blower motor speed terminal block isset for

the correct heating and cooling speeds. Refer to the unit

wiring diagram and tech sheet label and/or Technicallnfor-

mation Manual.

2. Check to see that clean, properly sized air filters are

installed.

3. Replace all service access panels.

Reverse Rotation (Scroll

Compressors Only)

Three phase scroll compressor equipped units CAN run in re-

verse if improperly wired. If the compressor makes an unusually

loud noise, or if high and low side pressures are nearly identical,

this indicates reverse rotation. To correct, reverse any two wires

at line voltage connections ONLY. Do NOT rewire any circuits in-

side the unit to attempt correction of reverse rotation.

Manifold Gas Pressure Adjustment

NOTE: Make adjustment to manifold pressure with burners oper-

ating.

Gas Type Manifold Pressure

Natural 3.5 Inches Water Column (870 Pa)

Propane 10 Inches Water Column (2490 Pa)

2. Turn gas ON and remove adjustment screw cover on gas

valve. Turn counterclockwise to decrease pressure and

clockwise to increase.

NOTE: Adjustment screw cover MUST be placed on gas valve

before reading manifold pressure and operating furnace.

3. Set pressure to value shown in FIGURE 15,_+0.07kPa (0.3

inches) water column. Pressure is also listed on furnace

rating plate. In NO case should final manifold pressure vary

more than _+0.07kPa (0.3 inches) water column.

Circulating Air Blower

Check the unit's operation asoutlined inthe following instructions.

If any unusual sparking, odors or unusual noises are encoun-

tered, shut off electric power immediately. Recheck for wiring er-

rors, or obstructions in or near blower motors.

NOTE: If spark wire is removed or replaced, always be certain to

remount wire on support bracket standoff.

1. Set thermostat Heat-Cool selector to OFF.

2. Set thermostat fan switch to AUTO.

3. Turn electric power ON. Nothing should start running.

4. Turn manual gas valve ON.

5. Turn gas control valve ON.

6. Set thermostat fan switch to ON. After 30 seconds, the cir-

culating air blower should come ON.

7. Reset thermostat fan switch to AUTO. After 30 seconds,

the circulating air blower should go OFF. Nothing should be

running.

Fire or explosion hazard.

Turn OFF gas at shut off before connecting U-tube ma-

nometer.

Do NOT adjust manifold pressure more than -+0.3 inches

water column to obtain rated input.

Failure to properly set input pressure can result in proper-

ty damage, personal injury and/or death.

1. With gas OFF, Connect U-Tube manometer to tapped

opening on gas valve. Use manometer with a 0 to 12 inches

water column range.

Heating

1. Adjust thermostat setting above room temperature and set

thermostat selector to HEAT. The combustion air blower

should come ON.

2. The ignitor should begin to glow and pilot flame should light.

NOTE: On a call for heat the ignitor and pilot valve will remain en-

ergized until a flame is detected by the flame sensor. It may take

several minutes to purge the air out of the gas lines at initial start-

up of the unit.

3. Once the flame sensor detects that a flame is present, the

hot surface ignitor will de-energize and the main burners

wil! light from the pilot.

4. 30 seconds after the burners light, the circulating blower

shuld begin to run.

50901 110202 _[]

Page 14

S Installation Instructions Combination Units I

Temperature Rise Check

NOTE: Air temperature rise is the temperature difference be-

tween supply and return air. With aproperly designed distribution

system, the proper amount of temperature rise will normally be

obtained when the unit is operating at rated input with the recom-

mended blower speed.

2. The temperature rise must be within the specifica-

tions marked on the unit rating plate.

To check the temperature rise through the unit, place

thermometers in the supply and return air ducts as

close to the unit as possible,

Open ALL registers and duct dampers. Operate unit AT

LEAST 15 minutes before taking readings.

Ifthe correct amount of temperature rise is not obtained when op-

erating on the recommended blower speed, it may be necessary

to change the blower speed. A faster blower speed will decrease

the temperature rise. A slower blower speed wil! increase the tem-

perature rise.

NOTE: The blower speed MUST be set to give the correct air tem-

perature rise through the furnace as marked on the rating plate.

3, After 15 minutes of operation check the limit control

function by blocking the return air grille(s),

After several minutes the main burners and pilot should go

OFF The circulating air blower should continue to run.

Remove air restrictions. Pilot and main burners should

relight after a cool down period of a few minutes.

NOTE: The maximum outlet air setting for all models is 175°F.

4. Adjust the thermostat setting below room tempera-

ture.

Pilot and main burners and combustion air blower should

go OFF

The circulating air blower should continue to run for 60,

100, 140 or 180 seconds. This time is adjustable.

5. Set thermostat Heat-Cool selector to OFE

Cooling

1. Turn electric power OFF

2. Set thermostat Heat-Cool select to COOL.

3.

Adjust thermostat setting to below room temperature.

4.

Turn power ON, for approximately one minute, then OFF

During power application check the following:

a. Contactor - Contacts Closing

b. Compressor - ON

c. Condenser fan motor - ON

d. Circulating Air Blower - ON after a 30

second delay

Turn power OFF, check the following:

a. Contactor contacts opening.

b. Compressor - OFF

c. Condenser fan motor - OFF

d. Circulating blower - OFF after a 30 second

delay.

9. Operation

Electrical shock hazard.

Turn off electric power supply at disconnect switch or

service panel before removing any access or service

panel from unit.

Failure to follow this warning can result in property

damage, personal injury, and/or death.

Controls and Features

Cooling Time Delay Relay (Not All Models)

A cooling time delay relay is used on the evaporator blower motor

to increase efficiency (SEER). On a call for cooling, the blower

motor starting is delayed for 30 seconds. Also, after the thermo-

stat is satisfied, the blower motor continues to run for 30 seconds

after the condenser fan motor and compressor have shut off.

Scroll Anti-cycle Timer (Not All Models)

Single phase scroll compressor equipped units are equipped with

an anti-cycle device which delays start of the compressor in the

event of a power interruption. This feature is to allow pressure

equalization throughout the system and to prevent possible re-

verse rotation of the scroll compressor. Three phase units do not

require this device.

High and Low Pressure Switches (Not All Models)

High and low pressure switches are provided on these units which

will shut down the system when high pressures exceed 420 psi

and low system pressures fall below 27 psi. The switches auto-

matically reset after afault. They are accessed through the com-

pressor compartment access panel.

Fan Cycle Pressure Switch Port (optional)

If your unit will be operated in low ambient conditions (below 40 °

F) and you elect to install a low ambient fan cycle control, you can

find the low ambient pressure port located on the discharge line

just inside the compressor compartment panel opening.

Freeze Protection Thermostat (Not All Models)

The freeze protection thermostat is located on the evaporator coil

bends on the burner side ofthe unit. It is designed to shut down the

cooling circuit if the evaporator coil temperaturefalls below 35 ° R

Filter Drier

A liquid line filter drier is located inside the compressor compart-

ment access panel opening. Be certain to replace filter driers with

the correct size and type as found in the Technical Data Sheets

available from your dealer.

E_I 50901 110202

Page 15

I Combination Units

Installation Instructions

Economizer Plug

A pre-wired economizer plug is located just inside the return air

opening. See Page 12 for more information about the economiz-

er.

Starting the Unit After Shutdown

Heating

1. Set thermostat to OFF.

2. Remove burner compartment access panel. Locate gas

control valve knob (NO TAG), and turn to OFF. Wait 5 min-

utes.

3. Turn gas control knob to ON. (Honeywell valve must be de-

pressed to turn). Replace burner compartment access

panel. Turn manual gas valve to supply pipe ON.

4. Turn electric power ON.

5. Set thermostat to HEAT and to desired temperature. Unit

will come on and operate automatically under control of the

thermostat, Never attempt to light the pilot manually.

may run continuously for several hours or longer on the initial run

because of residual heat and moisture in the house. This is nor-

mal for any air conditioning system.

CAUTION

Do not operate on cooling when outdoor temperature is be-

low 40°F. This is necessary to prevent possible damage to

the compressor.

Turning The Unit Off

1. Set the thermostat switch and OFF fan switch to AUTO. To

restart, set to HEAT or COOL and temperature desired.

2. To shut the unit down completely, turn electric power OFF

Turn manual gas valve off.

CAUTION

To prevent heat exchanger damage, wait at least 2 minutes

after blower stops before shutting off power to unit.

NOTE: If the furnace overheats or fails to shut off, turn OFF the

manual gas valve for the furnace then wait at least 2 minutes be-

fore turning off electric power.

Fire and/or explosion hazard

Do not operate the unit on heating (except during ser-

vice checks) unless all access panels are securely fas-

tened in place. Abnormal and possibly hazardous

burner operation could result.

Failure to follow this warning can result in property

damage, personal injury, and/or death.

Cooling

Set thermostat to desired temperature and set system switch to

COOL. The unit will come on and operate automatically under

control of the thermostat. Close all doors and windows. The unit

10. Maintenance

Monthly Maintenance and Inspection

Checks

Air Filters

CAUTION

Do NOT operate without air filters.

Thermostat Fan Switch Operation

With the selector switch in the ON position the circulating air blow-

er will run continuously (after the 30 second delay) at the speed

used for cooling. In the AUTO position the blower will only be on

during each heating or cooling cycle.

CAUTION

Some units use a lower blower speed for cooling than for

heating. Do NOT position selector switch to ON for continu-

ous operation during heating cycle if the cooling blower

speed is lower than the heating speed. Blower speeds for

each model are listed on the units Tech Label.

Adjusting Room Temperatures

If the temperature in individual rooms is not as desired, balance

the system by adjusting the dampers in the branch ducts. Adjust a

little at atime and wait a day after each change to judge the effect.

Once the dampers are adjusted for normal weather conditions, it

is best to leave them that way. Compensate for temporary weath-

er changes by adjusting the thermostat setting.

Inspect filters at least monthly and replace or clean as required.

Washable filters may be cleaned by soaking in mild detergent and

rinsing with cold water. Replace filters with the arrows on the side

pointing in the direction of air flow. Dirty filters are the most com-

mon cause of inadequate heating or cooling performance, and of

compressor failures.

50901 110202

Page 16

I Installation Instructions

Combination Units I

Refer to FIGURE 19 to illustrate location of filter racks and filter

access panel. Filters should be removed and replaced through

this access panel.

Heating Season Checks (Monthly)

Pilot Flame

FIGURE i 6 Pilot Assembly

Refrigeration Access Ports

This unit is equipped with refrigeration access ports mounted on

the side of the unit. Refer to FIGURE 18 for identification of ports.

Typical Access Ports

While the main burner is on, the flame should envelop the upper

part of the flame sensor, as shown in FIGURE 16.

Main Burner Flame

Flames should be stable and solid blue, (dust may cause orange

tips or they may have wisps of yellow, but they MUST not have

solid yellow tips). They should extend directly into the heat ex-

changer tubes and the turbulators should glow orange (after

about five minutes of operation). Main burner flame should be in-

spected monthly.

FIGURE Normal Flame

Flame should be

Turbulator willglow

stable and solid blue.

orange when hot.

I FIGURE i9 Access to Built-In Filters

(Except "B" Chassic)

Vent Assembly

Burn hazard.

Flue cover may be hott Allow adequate time for flue

cover to cool.

E_ 50901 110202

Failure to follow this warning can result in property

damage or personal injury.

Using a light and mirror (as required) inspect the inside of the vent

hood and the inlet air opening in the burner compartment. Look for

Page 17

I Combination Units Installation Instructions

soot and severe rust or corrosion and any obstructions due to

leaves, spider webs, etc. Clean as required.

Cooling Season Checks (Monthly)

Condenser Coil

Keep the condenser inlet and outlet area clean and free of leaves,

grass clippings or other debris. Grass should be kept short in front

of the condenser inlet. Shrubbery MUST be trimmed back so it is

no closer than 30 inches to unit.

Condensate Drain

Check for condensate drainage. Clean as required.

NOTE: When unit is operating incooling mode under high humid-

ity ambient conditions, condensate can form in the burner

compartment and may drip from front of the compartment. This

condition is NOT harmful to unit.

Annual Maintenance and Inspection

Electrical shock hazard.

Turn off electric power supply at disconnect switch or

service panel before removing any access or service

panel from unit.

Failure to follow this warning can result in property

damage, personal injury, and/or death.

2. Remove the four screws securing the blower motor hous-

ing. If unit has a support bracket, remove the two screws

securing the bracket.

3. Remove the two red wires attached to the limit switch.

4. Slide entire housing toward you. This will allow easier ac-

cess to the speed tap block, motor, and wires.

5. After access, replace all wires, screws, and connections.

Motor removal and replacement

The blower motor may be replaced while accessing it using meth-

od 1.To replace motor, reach behind blower housing and locate

blower wheel set nut. Loosen set nut, all wires from motor, and

four pins on mounting cradle. Pull motor towards you. To replace

motor, reverse this procedure.

Method 2

This method is required to replace or repair blower wheel, blower

housing, or any unreachable components behind blower assem-

bly.

1. Repeat steps 1 through 4 in method 1.

2.

Remove all screws around rim of unit top, (except screws

which are inaccessible because of proximity to structure).

3.

Raise unit top at corner of unit closest to blower at least 2"

and place a sturdy brace at least 2" thick between top and

unit corner. See FIGURE 20. A 2X4 piece of wood is ideal

for this.

4. Disconnect al!wires from housing and slide housing out of

unit. Reverse this process to reinstall.

FIGuRE 20 ProppedBI°werAcceSSwith2x4Sh°wing Lid

The annual inspection should include lubrication and cleaning as

required to ensure efficient operation of the unit. To simplify ac-

cess, remove all access panels and the top from the unit if pos-

sible.

Condenser Fan Motor

Oil the condenser fan motor after five years of operation and every

five years thereafter.

Use SAE 10W30 motor oil. To oil, remove the hole plugs from the

motor end bells and add several drops (approximately 1/2 tea-

spoonful) of oil with a squeeze type, flexible tube oiler. Replace

hole plugs after oiling. Do not over oil.

Clean the surrounding area and the condenser and evaporator

coils. Use caution to avoid damage to coi! fins.

Blower Motor Access

Refer to NO TAG for a view of blower motor and compartment.

Method 1

This method allows you to work on the motor and housing while

still in the unit. The blower motor can be replaced with this method,

but some may prefer to work on the housing assembly separately.

Ifthis is your preference, use method 2.

1. Remove the blower access panel

Speed Taps

After determing necessary CFM and speed tap data on from tech

data label on the unit or in the Technicallnformation Manualfollow

the steps below to change speeds.

1. Refer to FIGURE 21 below and locate the speed tap block

on blower motor.

The yellow lead MUST always be connected to the speed

tap block atthe common quick connect terminal. The termi-

nal is identified as COM. Also, this is the only lead which is

3/16" wide. All other quick connects are /4' wide.

1 ,

50901 110202 [_[]

Page 18

_ Installation Instructions Combination Units I

3. If it has been determined that cooling and heating speeds lated male terminal on the black cooling lead. Then place

are needed on the same speed tap, remove the red heating the insulated black female quick connect to the required

lead from the speed tap block and connect it to the insu- speed tap.

FIGURE 2i Blower Motor Speed Taps (3-Speed and ,-Speed Motors)

BE SURE TO CHECK BLOWER MOTOR

I

SPEED DATA ON UNITS TECH LABEL I

Circulating Air Blower

Visually inspect the blower wheel for accumulations of dirt or lint.

Clean the compartment and the blower wheel. If accumulation is

excessive on blower wheel, or does not easily remove, it will be

necessary to remove the blower assembly.

Oil the blower motor by adding 1/2 teaspoonful (lcc) of SAE

10W30 to each motor bearing. The blower motor should be oiled

after five years of operation and every five years thereafter.

/ \\\

/ 4-SPEEDMOTOR

YELLOW

BLACK

RED

\\_\\\\

CAUTION

Do not use 3 in I oil, penetrating oil, WD40 or similar oils to oil

motor bearings.

Burners / Heat Exchangers / Flue Gas Passages

To inspect the burners, heat exchanger and interior flue gas pas-

sages, use a light and small mirror on an extension handle.

Check the exterior of the heat exchanger and the interior flue gas

passages for any evidence of deterioration due to corrosion,

cracking or other causes. If signs of scaling or sooting exist, re-

move the burners and clean the heat exchanger, as required.

50901 110202

Page 19

I Combination Units

Installation Instructions

Inspection And Cleaning Of Burner

Assembly/Heat Exchangers/Flue Gas

Passages

For Qualified Service Technician Only

See FIGURE 24 for identification of parts.

1. Disconnect electrical power to unit.

2. Turn OFF gas at manual shut off valve.

3. Remove burner access panel.

4. Remove the vent assembly flue cover.

5. Disconnect gas pipe at union.

6. Disconnect wires from gas valve, note connections.

Access to Burners

Burners, Valve, and Burner Box

Removed

7. Remove screws that secure the flame shield and remove

gas control valve, manifold and burners as an assembly.

8. Remove collector box, injector plate, and restrictor plate,

including gaskets. See FIGURE 23.

9. Hold the burner assembly vertically and lightly tap it against

a wood block. Clean also with a stiff brush.Severe cases of

lint clogging may require washing the burners in hot water.

10.

Remove turbulators and clean with small brush. Reinspect

after cleaning and replace turbulators if defective.

11.

Clean flue gas passages by using small brushes and avac-

uum cleaner. It may be necessary to fabricate handle ex-

tensions for the brushes to reach the areas that require

cleaning. Reinspect after cleaning and replace the heat ex-

changer if defective.

12.

Reinstall parts and gaskets in reverse order. On

spark to pilot models check the spark gap. 1/8inch is

required between the igniter and pilot hood.

EiGURE 24 Burner Assembly Removed

Gas Valve

13. Turn gas on and check for leaks.

14.

Install all access panels, turn power on and check for

normal operation.

50901 110202 [_

Page 20

o"1

o

_o

o

o

o

A WARNING

RIGGINGINSTRUCIONS

FAILURE TO FOLLOW THESE INSTRUCTIONS

CAN RESULT IN PROPERTY DAMAGE,

BODILY INJURY OR DEATH.

ALL PANELS MUST I}E IN PI ACE WHEN RGGING AND LFTNO.

HOOK RIGGNG SHACKLES TqROUGH HOLES N BASE RAL, AS SHOWN N DETAIL A.

USE SSREADER BARS, WHEN RGGNG, TO PREVENT UNI:: DAMAGE.

C

rtl

m.

m.

_t

o

Q

Q o

i•

Q

m

I--

am

0

t_

c

BE SUR" RIGGNG AND SHACKL S ARE SUFFCIENT TO HANDLE WEGHT LS::ED BELOW

CAB NET

B

C

LENGTH _/ WIDTH

COOL NO

ENGTq

CAPAC TY

RANGE

1.5 55 TONS

5 6.5 TONS

N MM

4S.OO 1219

75.00 185£

HEIGHT

WI/}] H

N MM

48,00 1219

48,00 1219

BARS

DET AlL A

HEGH]

N MM

35.00 838

3650 927

MAX. WEIGH I

LB KG

450 204

700 518

0

o

3

o

C

o)

Page 21

INTERNATIONAL COMFORT PRODUCTS

LIMITED WARRANTY CERTIFICATE

For Cooling & Heating Products

SAVE THIS CERTIFICATE. It gives you specific legal rights, and you may also have other rights which may vary from state to state and

province to province,

Ifyour unit needs servicing, contact aqualified dealer or qualified service agency of your choice. When requesting service, please have the modet and

serial number from each unit in your heating and/or cooling system readily available. If your dealer needs assistance, the distributor is available to

provide support and we, in turn, support its efforts.

Fill in the installation date and model and serial numbers of the unit inthe space provided below and retain this Limited Warranty for your files.

GENERAL TERMS

Subject to the conditions and limitations stated herein, during the term of this Limited Warranty, we will provide a replacement for any functional

component part (as defined below) of your unit that fails due to defect in materials or workmanship. The term ofthis Limited Warranty is five years from

installation on Residential Products and one year from installation on Commercial Products or applications. Except as otherwise stated in the

"Additional Terms" section, this Limited Warranty covers only the original purchaser and subsequent transferees, and onty while the unit remains atthe

site of the original installation (except for mobile home installations), and only if the unit is installed inside the continental United States, Puerto Rico,

Alaska, Hawaii or Canada. In addition, the Limited Warranty applies only ifthe unit is installed and operated in accordance with the printed instructions

accompanying the unit, and in compliance with all applicable installation and building codes and good trade practices. As used inthis Limited Warranty,

"installation" means the original installation of the unit.

TH ERE ARE EXCEPTIONS to this Limited Warranty as described on the reverse side of this page. All replacement parts will be warranted for the

unused portion of the warranty coverage period on the unit. The part to be replaced must be returned by the dealer to a distributor that sells products for

International Comfort Products, in exchange for the replacement part. In lieu of providing areplacement part, we may, at our sole option, refund to you

an amount equal tothe distributor's component purchase price from us, or provide to you acredit equal to that amount to be applied toward the purchase

of any new unit that we distribute. If a credit for a new unit is given in tieu of a replacement part, the rating plate from the unit being replaced must be

submitted on a warranty claim, and you r dealer must make the unit being replaced available to ou r distributor for disposition. As acondition to warranty

coverage, the unit must receive yearly maintenance, as described in the owner's manual, by a dealer. Satisfactory proof of yearly service by adealer

may be required.

"Functional component parts" include only the following: blower motor, unit-mounted sensors & timers, condenser motor, evaporator coil, condenser

coil, condenser fan, capacitor, transformer, single-phase strip heat elements, expansion device, reversing valve, solenoid valve, service valve,

electronic and electro-mechanical control board, ignitor, ignition module, draft inducer assembly, burner pilot, gas valve, limit control, pressure switch,

relays and contactors, blower wheel, interlock switch, crosslighter, pilot shield, gas & oil burners, oil pump assembly, accumulators and factory installed

driers and strainers.

This Limited Warranty DOES NOT COVER any labor, material, refractory chambers, oit nozzles, refrigerant, refrigerant inspection and refrigerant

reclaiming, freight and/or handling charges associated with any repair or replacement and such charges will be your responsibility.

Toestablish the installation date for any purpose under this Limited Warranty, you must retain the original records that can establish the installation date

ofyour unit. Ifyou donot providesuchdocumentsthe start dateoftheterm ofthis LimitedWarrantywillbe based uponthedate ofunit manufacture, ptus

thirty (30) days. In establishing that the required yearly service has occurred, you must furnish proof of yearly service by a qualified service agency.

This Limited Warranty does not cover: (a) failure or damages caused by accident, abuse, negligence, misuse, riot, fire, flood, or Acts of God (b)

damages caused by operating the unit where there is a corrosive atmosphere containing chlorine, fluorine, or any other damaging chemicals (other

than those found in a normal residential environment) (c) damages caused by an unauthorized alteration or repair of the unit affecting its stability or

performance (d) damages caused by improper matching or application of the unit or the unit's components (e) damages caused by failing to provide

proper maintenance and service to the unit in accordance with this Limited Warranty Certificate and the printed instructions originally provided with the

unit (f) any expenses incurred for erecting, disconnecting, or dismantling the unit (g)parts or supplies used in connection with service or maintenance,

such as refrigerant, refractory chambers, oit nozzles, filters, or belts (h) damage, repairs, inoperation or inefficiency resulting from faulty installation or

application (i) electricity or fuel costs or any increase in electricity or fuel cost whatsoever including additional or unusual use of supplemental electric

heat (j) units which have not had the required yearly maintenance described elsewhere in this limited warranty.

In no event shall we be liable for any incidental, consequential, or special damages or expenses in connection with any use or failure of this unit.

WE HAVE NOT MADE, DO NOT MAKE, AND HEREBY DISCLAIM ANY IMPLIED CONDITION OR IMPLIED

WARRANTY OF FITNESS FOR A PARTICULAR USE OR PURPOSE, AND ANY IMPLIED CONDITION OR

IMPLIED WARRANTY OF MERCHANTABILITY, TO THE FULLEST EXTENT ALLOWED BY LAW. WE MAKE

NO EXPRESS OR IMPLIED WARRANTIES EXCEPT AS STATED IN THIS LIMITED WARRANTY CERTIFICATE.

No one is authorized to change this Limited Warranty or to create for us any other obligation or liability in connection with this unit. Any implied

warranties that are not disctaimable shall last only for the term of the express warranty contained herein. Some states and provinces do not allow the

exclusion or limitation of incidental or consequential damages or do not allow limitations on how long an implied warranty or condition lasts, so the above

limitations or exclusions may not apply to you. The provisions ofthis Limited Warranty are in addition to and not a modification of or subtraction from any

statutory warranties and other rights and remedies provided by law.

Please refer to reverse side of this page for additional terms.

Model No.

Serial No. Date Installed

USA: International Comfort Products, LLC ° 650 Hell-Quaker Avenue ° P.O. Box 128 • Lewisburg, Tennessee 37091 ° (931-270-4100)

CANADA: International Comfort Products division of UTC Canada Corporation • 6060 Burnside Court, Unit 1, Mississauga, Ontario L5T 2T5

(905-795-8113).

Manufacturers of Airquest, Arcoaire, Clare, Comfortmaker, Dettson, Hell, Keeprite, Lincoln, Tempstar and other quality brand name private label

products.

Part No. 401 06 1010 24 (Orig. 11/xx/2003)

Page 22

ADDITIONAL TERMS FOR RESIDENTIAL APPLICATIONS ONLY

The Additional Terms for the components listed below are in addition to, and subject to, the General Terms on the reverse side of this page.

Warranty coverage is limited to parts that fail due to defect in lnaterials or workmanship during the specified term.

CENTRAL GAS & OIL FURNACE HEAT EXCHANGERS*

Gas Model Series: C9MPV, HgMPV, TgMPV, CgMPT, H9MPT_TgMPT, C9MPD, H9MPD, TgMP: Limited Lifetime Warranty on heat exchangers. If a

heat exchanger on one of these furnaces fails due to defect inthe part, we witl provide a replacement part or, at our option, credit toward the purchase of

a new furnace manufactured by us. This additional Limited Warranty runs only to the original purchaser, and lasts only for as long as the originat

purchaser tives in the home where the furnace is initially installed .** Itis not transferable to any subsequent owner. Ifthe furnace was not installed in the

home owned by the original purchaser, if the original purchaser setls the home to a subsequent owner, or if proof of originat purchase cannot be

provided, then the limited warranty is only for 20 years from the date of originat installation.

Gas Model Series: T8MPV. H8MPV. C8MPV. T8MPT. H8MPT. C8MPT: A replacement heat exchanger wilI be provided for any heat exchanger that

fails in one of these furnaces due to defect for 25 years from the original date of installation.

Gas Model Series: T8MPN. H8MPN. C8MPN. T8MPL H8MPL. C8MPL. T8DNL. H8DNL C8DNL N8MPN. N8MPL NgMPI. N9MP2: A

replacement heat exchanger will be provided for any heat exchanger that fails in one of these furnaces due to defect for 20 years from original date of

installation.

Oil Model Series: OLR(105. 160. 182L OCF. OLF. OUE NOLF. NOUF. OLB. OHB. ODH. FLU. MBO. LBO. NOMF: Limited Lifetime Warranty on

heat exchangers. Ifa heatexchangerononeofthesefumacesfailsduetodefectinthepart, wewitl provide a replacement part or, at our option, credit

toward the purchase of a new furnace manufactured by us. This additional Limited Warranty runs only to the original purchaser, and tests only for as

Iong as the original purchaser lives in the home where the furnace is initially installed.** It is not transferable to any subsequent owner. If the furnace

was not installed in the home of the original purchaser, if the original purchaser selts the home to a subsequent owner, or if proof of original purchase

cannot be provided, then the limited warranty is only for 20 years from the date of original installation.

Oil Fired Floor Furnace: NFO: A replacement heat exchanger witl be provided for any heat exchanger that faits due to defect for 10 years from

installation with the following timitatiom during the sixth through tenth year, any credit toward your purchase of a component ortoward the purchase of

any new unit wilI be in an amount equal to the distributor's purchase price reduced by 20 percent for each year after the fifth year.

ADDITIONAL TERMS FOR OIL FURNACE APPLICATIONS ONLY

1) OIL BURNERS - A replacement for 5 years from date of original installation for Oil Burner Parts,

2) OPTIONAL ACCESSORIES AND FUNCTIONAL PARTS: A replacement for 5 years from date of original installation. (Refractory and

oil nozzles not included)

GAS/ELECTRIC PACKAGED UNITS HEAT EXCHANGERS

Model series: PGAD, PGAA, PGMD, PGME, PGE GPFM, PGC, GPCM: A replacement for 10 years from original date of installation.

COMPRESSORS:*

1) Premium Model Units: HAC0. HAC2. HAC4. CAC0. CAC2. CAC4. KAC0. TCA0. TCA2. TCA4. HHP0. HHP2. HHP4. CliP0. CliP2. CliP4.

TCH0. TCH2. TCH4.HXA2.TXA2.CXA2.HXA4.TXA4.CXA4. PGME. PYMC. PHAD. PGAD. PA95. PAPC. PAK. APK: To the original purchaser a

replacement for 10 years from original date of installation, only if the unit isinstalled with factory matched coiis, except air conditioner condensing units

with a nominal SEER of 10 may be matched with evaporator coils of the same nominal tonnage regardless of manufacturer and in accordance to factory

recommendations. This limited 10-year warranty is not transferable to any subsequent owner. HOWEVER, ifthe unit was not installed in the home

owned by the original purchaser, if the purchaser sells the home to a subsequent owner, or if proof of original purchase cannot be provided, then the

limited warranty is onty for 5 years from the original date of installation.**

2) All Other Models: Air Conditioners. Heat Pumps. & Combination Gas/Electric Units: NAC0. NAC2. NHP0. NHP2. AO. A2. Ha. H2. PGF.

PGC. GPFM. GPCM. PAF. APFM. PHF. HPFM. PGAA. PGMD. PA55. PH55. PAPA. PYPA. PGS. GPSM: A replacement for 5 years from date of

original installation, only if: (a) air conditioner condensing units with SEER rating in the range of 10 to 11 SEER are matched with evaporator coits of the

same nominal tonnage regardless of manufacturer and in accordance to factory recommendations, or (b) heat pump condensing units are used with

factory matched coils, unless written approval to do otherwise is obtained from manufacturer.

ADDITIONAL TERMS FOR COMMERCIAL PRODUCT OR APPLICATIONS ONLY

For purposes of this warranty a commercial product or application is one in which: the product has over 5 tons nominal cooling capacity, or

is designed for operation with 3 phase electrical power, or isinstalled in a commercial establishment such as abeauty or hair salon, hospital,

school, restaurant, church, hotel etc..

3-Phase Models: PGF, GPFM, GPF, PGAD, PGME, PGB, PGMG, PGMF, PGS, GPSM, PGE, APE, PAE, PAB, PAMD, PAS, PAL=,APFM, APF,

PHB, PHE, PYMD, HPB, PHS, CAC, ACC, CAE, ACE, CHC, HCC, CHE, HCE, CHB, YA:

The additional Terms of the components listed below are in addition to and subject to the General Terms on the reverse side of this page.

1) GAS FIRED HEAT EXCHANGERS (ALL MODELS, except PGS, GPSM 3to 5 Ton):* A replacement for 10 years from date of original installation.

a) NOTE: PGS, GPSM 3 to 5 Ton Models:* A replacement for 15 years from date of original installation.

2) COMPRESSORS (ALL MODELS):* A replacement for 5 years from date of original installation.

3) OPTIONAL ACCESSORIES AND FUNCTIONAL COMPONENT PARTS (ALL MODELS):*

A replacement for 1 year from date of original installation.

4) COMMERCIAL OIL MODELS: OLR210, OLR350, OTF210, AMT3, AMT4, AMP3: Ten(10) Year Limited Warranty on heat exchangers.

*To receive advantage of your limited warranty, you must provide proof of yearly service by a qualified service agency.

**To receive advantage of your warranty, you must retain the original records that can establish the installation date and proof of purchase of the unit.

MINI SPLITS:

Summary - Mini Splits Warranted for one (1) year on all replacement parts.

Additional terms for Mini Splits:

The additional Terms of the components listed below are in addition to, and subject to, the General Terms on the reverse side of this page.

1) Compressors (All Models): A replacement compressor wili be provided for atI compressors that faiI due to defect for 5 years from date of original

installation.

2) Optional Accessories and Functional Components Parts (All Models):

A replacement part will be provided for alI parts that fail due to defect for one (1) year from date of original installation.

Failure to maintain the equipment through annual maintenance by a qualified service agency shall void the warranty. Proof of service will be required

with ati warranty claims. Proof of purchase and installation date must be submitted with ali claims.

Loading...

Loading...